ICP PDX424040K00A1, PDX424040K01A1, PDX430060K00A1, PDX430060K01A1, PDX436080K00A1 Installation Guide

...Page 1

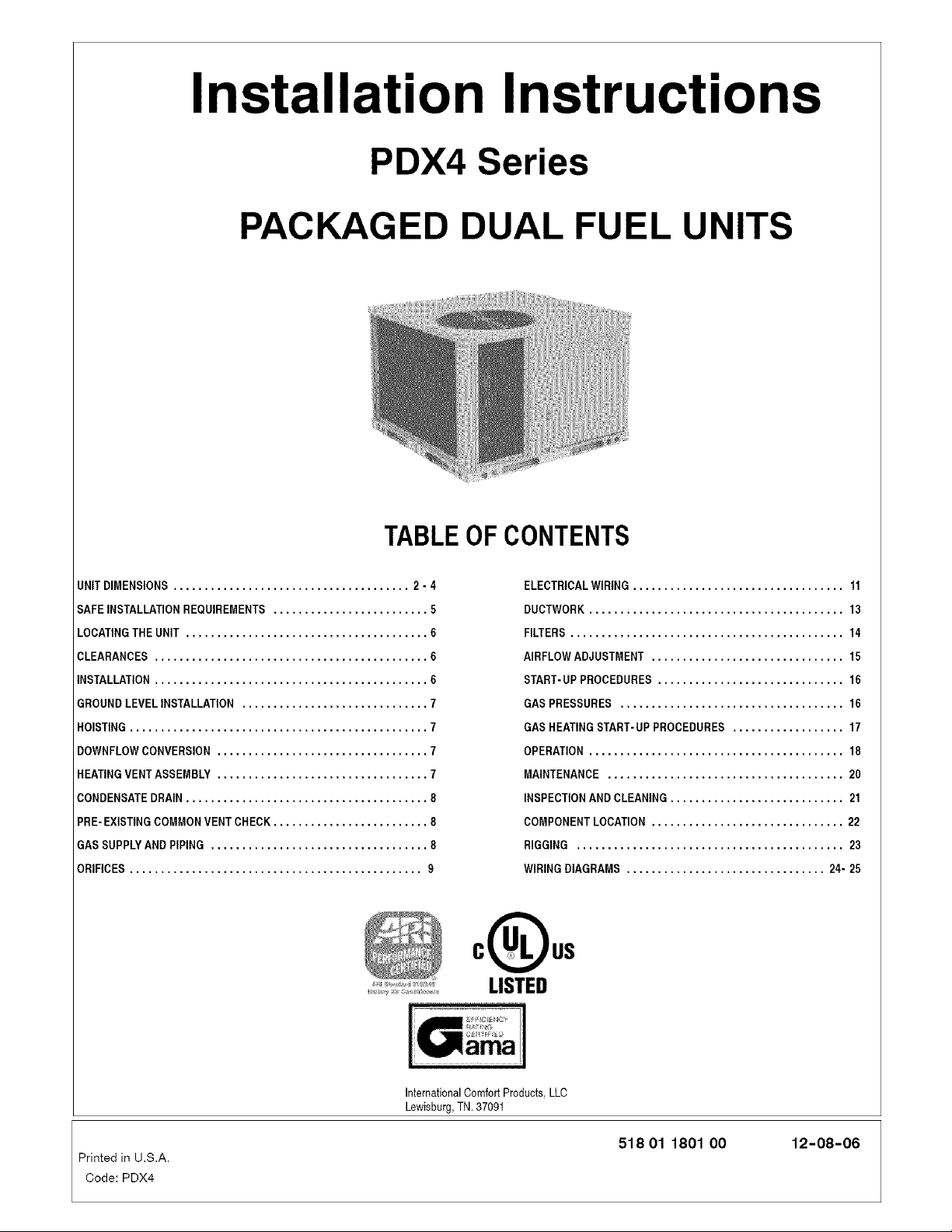

Installation Instructions

PDX4 Series

PACKAGED DUAL FUEL UNITS

TABLEOFCONTENTS

UNITDIMENSIONS ...................................... 2 - 4

SAFEINSTALLATIONREQUIREMENTS ......................... 5

LOCATINGTHE UNIT ....................................... 6

CLEARANCES ............................................ 6

INSTALLATION............................................ 6

GROUNDLEVELINSTALLATION .............................. 7

HOISTING................................................ 7

DOWNFLOWCONVERSION .................................. 7

HEATINGVENTASSEMBLY.................................. 7

CONDENSATEDRAIN....................................... 8

PRE-EXISTINGCOMMONVENTCHECK......................... 8

GASSUPPLYAND PIPING ................................... 8

ORIFICES............................................... 9

ELECTRICALWIRtNG.................................. 11

DUCTWORK ......................................... 13

FILTERS ............................................ 14

AIRFLOWADJUSTMENT ............................... 15

START-UPPROCEDURES .............................. 16

GAS PRESSURES .................................... 16

GAS HEATINGSTART-UPPROCEDURES .................. 17

OPERATION......................................... 18

MAINTENANCE ...................................... 20

INSPECTIONANDCLEANING............................ 21

COMPONENTLOCATION............................... 22

RIGGING ........................................... 23

WIRINGDIAGRAMS ................................ 24- 25

CQUS

LISTED

Printed in U.S.A.

Code: PDX4

InternationalComfortProducts,LLC

Lewisburg,TN. 37091

518 01 1801 00 12-08-06

Page 2

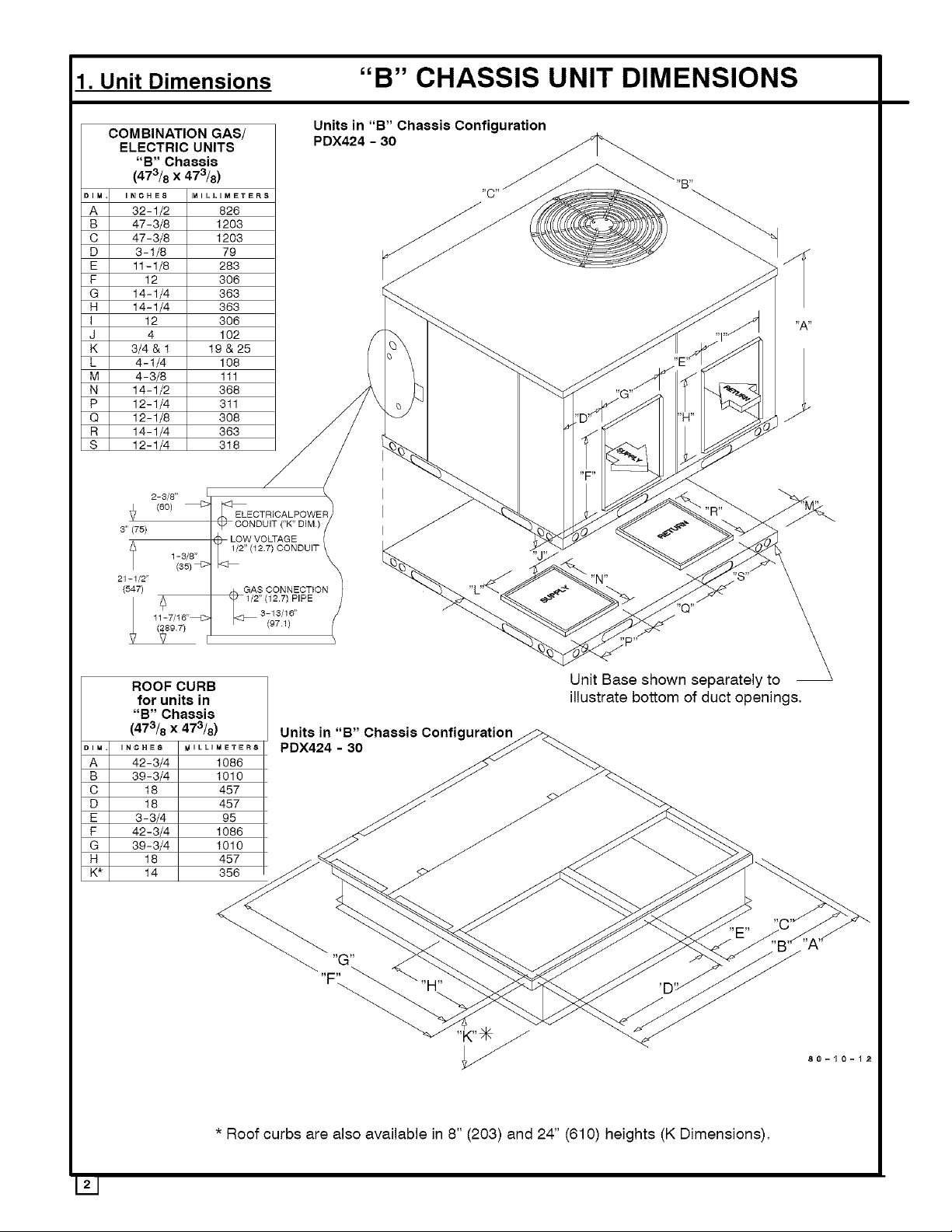

1. Unit Dimensions "B" CHASSIS UNIT DIMENSIONS

COMBINATION GAS/

ELECTRIC UNITS

"B" Chassis z A

DIM.

A

32-1/2 826 _ _ _ _,_,_-_"_._"_.

B

47-3/8I 1203 _ _ f(_d((_'_%_ _

C

47-3/8 I 1203 J J _ _N_.._.___._/ _. "_

D

3-1/8 I 79 _" _ _"___ _ ./i"

E

11-1/8 283 _ _

F

G

H

I

J

K

L

M

N

P

Q

R

S

12 I 308 _

14-1/4 I 363 L_ _

14-1/4 I 363 _ _

12 I 308 "_ _ _ 'w'

4 102 "1''j

3,4 I19 28

4-1/4I lO8 [ _ _ _ "E'_

4-3/8 111 .._ _ __ ....._-_ < .

14-1/2 I 368 _ ["1 _"""_/_ ...../ f "_

12-1/4 I 311 y/ _, _ )-d .... ,._ |,L--4 _ ,_

12-1/8 308 j / _ "D" _ "H" _"-_/

14-1/4 363 / / *" _ _"

12-1/4 I 318 _" / _. I _>_. _

Units in "B" Chassis Configuration

PDX424 - 30

I "F"

f 1-3/8" _ _NDUIT k _ _ _ S_'_-_

A ,. I '2"3'1123]16,PIP E

ROOF CURB Unit Base shown separately to

for units in illustrate bottom of duct openings,

"B" Chassis

(473/8 x 473/8) Units in "B" Chassis Configuration_

DIM.

,NC,E_ M......... 8 PDX424 - 30 _ _.

A

42-3/4 1086 .,._v

B

39-3/4 1010 J_ _

C

D

E

F

G

H

K*

18 457 _ _ _

18 457 _ j

3-3/4 98 _ _ _.....-_

42-3/4 1086 _ J _ _._

39-3/4 1010 _ _ J_ _ _.

18 457 __ _<'_ _- _- _ /'-_l

_ ..... __ _ _._ _,,B:_ A

* Roof curbs are also available in 8" (203) and 24" (610) heights (K Dimensions).

Page 3

2-3/8"

3i (75) 1-3/8"

25-1/16"

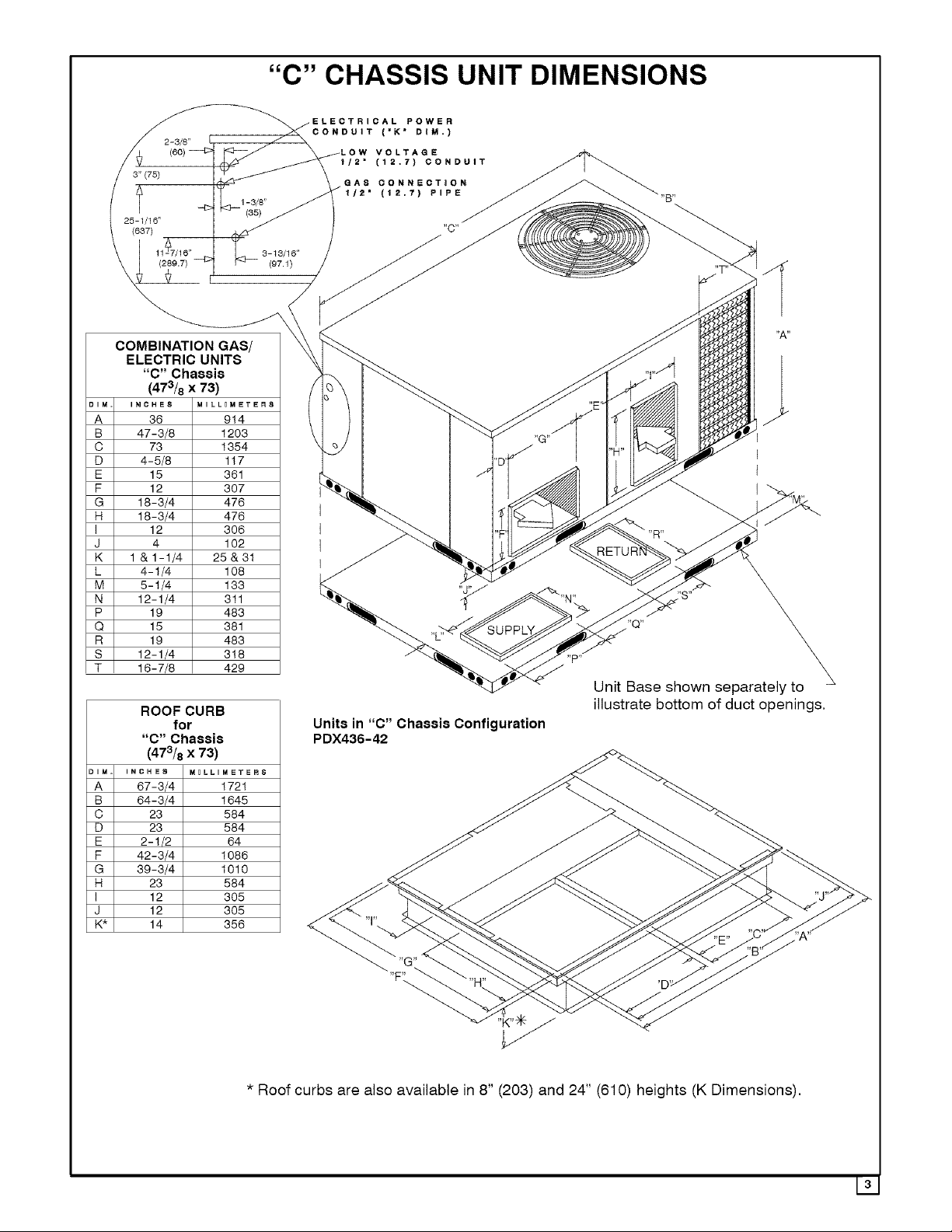

COMBINATION GAS/

ELECTRIC UNITS

"C" Chassis

(473/8 x 73)

DIN INCHE8 _41LLOMEYER8

A 36 914

B 47-3/8 1203

C 73 1354

D 4-5/8 117

E 15 361

F 12 307

G 18-3/4 476

H 18-3/4 476

I 12 306

J 4 102

K 1 &1-1/4 25&31

L 4-1/4 108

M 5-1/4 133

N 12-1/4 311

P 19 483

Q 15 381

R 19 483

S 12-1/4 318

T 16-7/8 429

ROOF CURB

for

"C" Chassis

(473/8 x 73)

IM INCHES MgLLIM_T_RS

A 67-3/4 1721

B 64-3/4 1645

C 23 584

D 23 584

E 2-1/2 64

F 42-3/4 1086

G 39-3/4 1010

H 23 584

I 12 305

J 12 305

K* 14 356

"C" CHASSIS UNIT DIMENSIONS

ECTRICAL POWER

CONDUIT ('l(" DIM.)

W VOLTAGE

1/2" (12.7) CONDUIT

GAS CONNECTION

1/2" (12.7) PIPE

(97.1)

3-13/16"

,,p,,

Unit Base shown separately to

illustrate bottom of duct openings,

Units in "C" Chassis Configuration

PDX436-42

"F'L

* Roof curbs are also available in 8" (203) and 24" (610) heights (K Dimensions),

13

Page 4

3" (75)

l 1-3/8"

31-1/16"

(789 4)

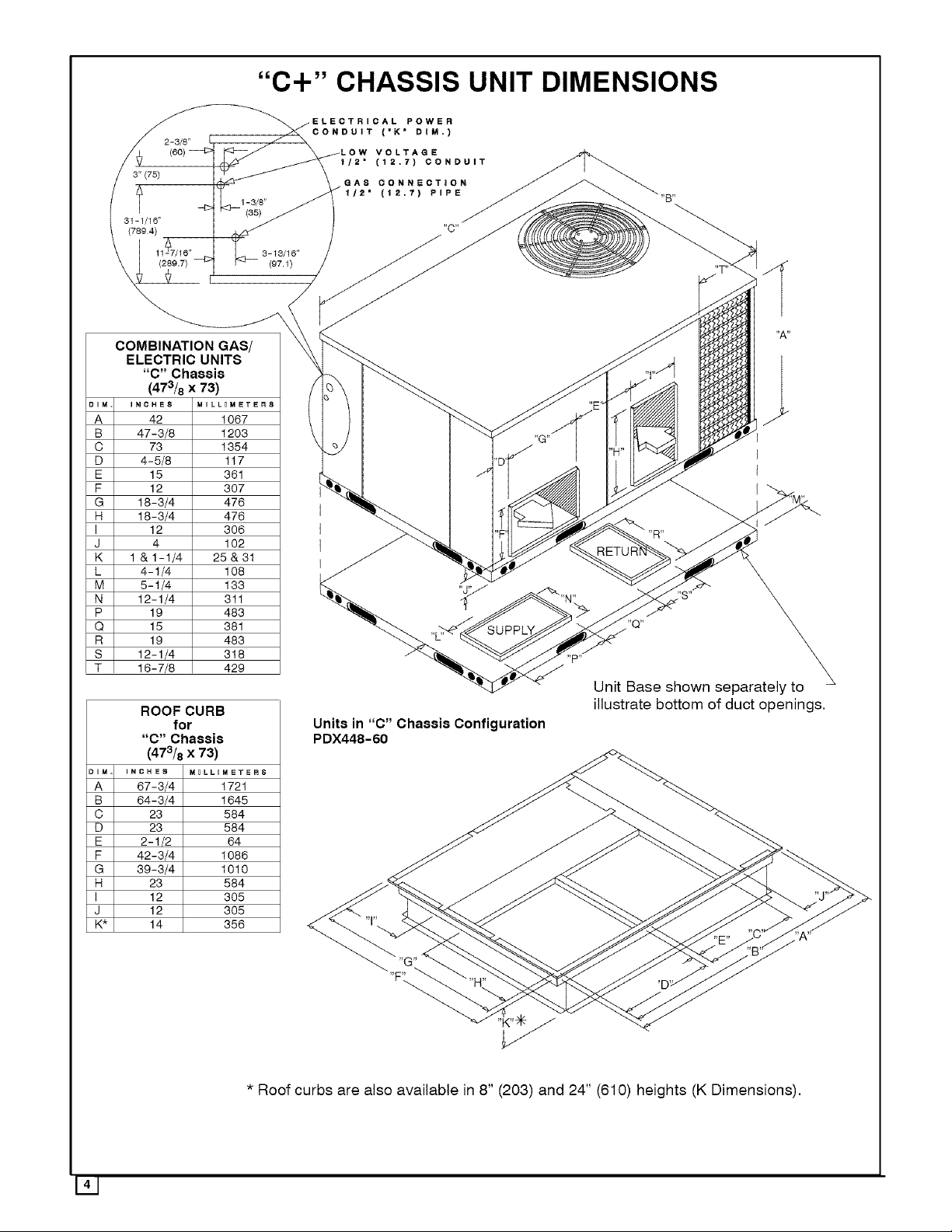

"C+" CHASSIS UNIT DIMENSIONS

ECTRICAL POWER

CONDUIT ('K" DIM.)

W VOLTAGE

_/2" (12.7) CONDUIT

GAS CONNECTION

1/2" (12.7) PIPE

"C"

1 (2_79,7) 3-13/16"

COMBINATION GAS/

ELECTRIC UNITS

"C" Chassis

(473/8 x 73)

DIM

INOHE8 MILL_MEYER8

A

B

C

D

E

F

G

H

I

J

K

L

M

N

P

Q

R

S

T

42 1067

47-3/8 1203

73 1354

4-5/8 117

15 361

12 307

18-3/4 476

18-3/4 476

12 306

4 102

1 &1-1/4 25&31

4-1/4 108

5-1/4 133

12-1/4 311

19 483

15 381

19 483

12-1/4 318

16-7/8 429

ROOF CURB

for

"C" Chassis

(473/8 x 73)

IM INCHES MOLLIM_T_RS

A 67-3/4 1721

B 64-3/4 1645

C 23 584

D 23 584

E 2-1/2 64

F 42-3/4 1086

G 39-3/4 1010

H 23 584

I 12 305

J 12 305

K* 14 356

(97.1)

,,p,,

Unit Base shown separately to

illustrate bottom of duct openings,

Units in "C" Chassis Configuration

PDX448-60

141

"F'L

* Roof curbs are also available in 8" (203) and 24" (610) heights (K Dimensions),

Page 5

2. SAFE INSTALLATION REQUIREMENTS

Installation and servicing of air-conditioning equipment can

be hazardous due to system pressure and electrical

components. Only trained and qualified personnel should

install, repair, or service air-conditioning equipment.

Untrained personnel can perform basic maintenance

functions of cleaning coils and filters. All other operations

should be performed by trained service personnel. When

working on air-conditioning equipment, observe

precautions inthe literature, tags, and labels attached to the

unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for unbrazing operations.

Have fire extinguisher available for all brazing operations.

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND

CARBON MONOXIDE POISON HAZARD

Improper installation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide

poisoning, fire, or an explosion which could result in

personal injury or unit damage. Consult a qualified

installer, service agency, or gas supplier for information

or assistance. The qualified installer or agency must use

only factory-authorized kits or accessories when

modifying this product.

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND

CARBON MONOXIDE POISON HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Before performing service or maintenance operations

on unit, turn off gas supply to unit. Then turn off unit main

power switch and install lockout tag.

Recogniz_ safety information. This is the safety-alert

symbol/.rk. When you see this symbol in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. These words are used with the

safety-alert symbol. DANGER identifies the most serious

hazards which will result in serious injury or death.

WARNING signifies a hazard which could result in serious

injury or death. CAUTION is used to identify unsafe

practices which may result in minor personal injury or

product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation,

reliability, or operation.

These instructions cover minimum requirements and

conform to existing national standards and safety codes. In

some instances, these instructions exceed certain local

codes and ordinances, especially those that may not have

kept up with changing residential construction practices.

We require these instructions as a minimum for a safe

installation.

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND CARBON

MONOXIDE POISON HAZARD

Failure to carefully readand follow all instructions in this

manual could result in furnace malfunction, property

damage, personal injury and/or death.

Installation or repairs made by unqualified persons can

result in hazards to you and others. Installation MUST

conform with local building codes or, in the absence of

local codes, with the National Fuel Gas Code NFPA

54-2005/ANSI Z223.1-2005 and the National Electrical

Code NFPA70-2005 or in Canada the National Standard

CAN/CGA B149-1 and CSA C.22.1 - Canadian Electrical

Code Part 1.

The information contained in this manual is intended for

use by a qualified service technician familiar with safety

orocedures and equipped with the proper tools and test

instruments.

SAFETY CONSIDERATIONS

• Use only with type of gas approved for this unit. Refer to

unit rating plate.

• Install this unit only in a location and position as specified

in section 3 of this manual.

• Never test for gas leaks with an open flame. Use a com-

mercially available soap solution made specifically for the

detection of leaks to check all connections, as specified in

section 5.

•Always install unit to operate within the unit's intended

temperature-rise range with a duct system, which has an

external static pressure within the allowable range, as

specified in section 9. Refer to unit rating plate for the al-

lowable external static pressures.

•All connecting ductwork to the unit (supply and return)

must be sealed to the unit casing as specified in section 7.

• Do NOT use this furnace as a construction heater.

•Check to see that filters are installed correctly and are the

proper type an size.

NOTE: Itis the personal responsibility and obligation of the

customer to contact a qualified installer to ensure that the

installation is adequate and conforms to governing codes

and ordinances.

UNIT SAFETY

Failureto follow this caution may reduceunit reliability.

It is recommended that a qualified service technician

check the heat exchanger integrity everytwo (2)years,

after the first four (4) years of operation.

INTRODUCTION

The PDX4 unit is a fully self-contained, combination

Category Igas heating/electric heat pump unit designed for

outdoor installation (See pages 2 to 4 for unit dimensions).

All unit sizes have return and discharge openings for both

horizontal and downflow configurations, and are

factory-shipped with all downflow duct openings covered.

Page 6

Unitsmaybeinstalledeitherona rooftop,cementslab,or

directlyonthegroundiflocalcodespermit.

Modelswitha'l" inthetwelfthpositionofthemodelnumber

are dedicatedLowNOxunitsdesignedfor California

installations.Theemissionsofthesemodelsdonotexceed

40nanogramsofnitrogenoxideemissionsperjouleofheat

outputasshippedfromthefactory,andmustbeinstalledin

CaliforniaAirQualityManagementDistrictsor anyother

regionsinNorthAmericawherea LowNOxruleexists.

3. LOCATING THE UNIT

ACCESS PANELS

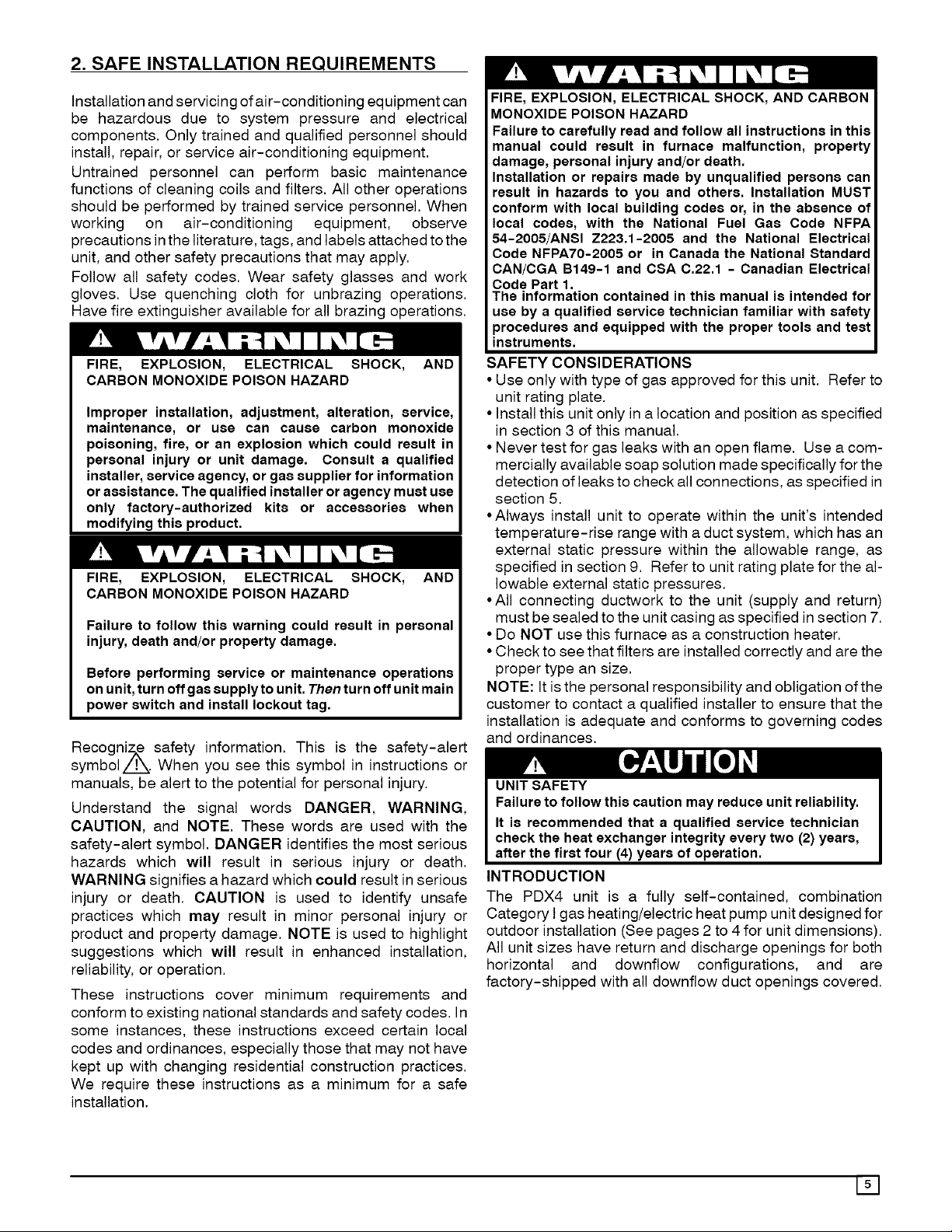

See Figure 1 for a general view of unit and location of

access panels.

CARBON MONOXIDE POISONING HAZARD.

Failure to follow this warning could result in personal

injury and/or death.

Keep blower door closed.

CLEARANCES

The location MUST allow for minimum clearances and

should not be adjacent to a patio or other area where the

unit's operating sound level might be objectionable. The

combustion air inlet openings MUST not be obstructed (see

Figure 1). In addition, local codes MUST be observed.

NOTE: Units with available filter racks (3-1/2 to 5ton), need

a 26" minimum clearance at side of unit for removal of

filters. See chart below if unit is going to be placed near

combustible construction or materials.

While minimum clearances are acceptable for safety

reasons, they may not allow adequate air circulation around

the unit for proper operation inthe cooling mode. Whenever

possible, it is desirable to allow additional clearance,

especially around the condenser inlet and discharge

openings.

Do NOT install the unit in a location that will permit

discharged air from the condenser to recirculate to the

condenser inlet.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in shorten life

of unit components.

Do NOT operate unit in a corrosive atmosphere

containing chlorine, fluorine, or any other corrosive

chemicals.

Minimum Clearances to Combustible Construction

Furnace Plenum ..................................... 2"

Duct Side ........................................... 2"

Condenser Inlet .................................... 30"

Blower Service (Side) ............................... 30"

Control Service Side

(Front Combustion Air Inlet) .............. 30"

Clearance between 3 Ft. Overhang

and Top of Unit ......................... 30"

Combustible Base

(Wood or Class A, B or C

roof covering material) ..................... 0"

FIGURE 1

I Minimum Clearances and Access Panels

B Chassis Shown)

\

80-00-01

Internat Filter Access

from Burner Compartment Side

26" (C Chassis Units)

INSTALLATION

NOTICE

Unit will NOT operate properly unless it is installed

level front to rear and side to side. The slope MUST NOT

be greater than 1/8"per foot (10mm per meter). For side

to side leveling, the drain side MUST always be lower.

Ground Level Installation

Ground level platform requirements:

- The unit MUST be situated to provide safe access for

servicing.

- Platform may be made of either concrete or pressure

treated wood and MUST be level and strong enough to

support unit weight.

- Position platform separate from building foundation.

- Install in well-drained area, with top surface of platform

above grade level.

- Platform must be high enough to allow for proper

condensate trap installation and drainage. See

FIGURE 4 and associated text for more information

about condensate drainage.

Rooftop Installation

Rooftop platform requirements:

- The unit MUST be situated to provide safe access for

servicing.

- The existing roof structure MUST be adequate to

support the weight of the unit or the roof MUST be

reinforced.

Check the weight of the unit in relation to the roof

structure and local building codes or ordinances and

reinforce roof structure if necessary. See the last page

of this manual for unit weights.

- Support for the unit MUST be level and strong enough

to carry unit weight. The support may consist of a

platform or acombination of platform and roof beams or

curb.

- See Hoisting section for hoisting instructions.

HOISTING

Burner Compartment

Panel

161

Page 7

NOTE: All access panels MUST be secured inplace before

hoisting.

The unit should be hoisted with two lifting slings. Attach the

slings to rigging shackles that have been hooked through

holes in the base rail,

Two spreader bars MUST be placed on top of the unit to

protect the unit from damage from the pressure exerted by

the slings. Make sure that all equipment is adequate to

handle the weight ofthe unit and that the slings will not allow

the unit to shift,

Refer to Figure 20 on the back cover of this manual for

illustrated rigging instructions and weight chart,

DOWNFLOW CONVERSION

NOTE: In downflow applications with roof curbs or jack

stands, the center rail under the unit must be removed. The

center rail is attached to the base rail with screws.

These units are adaptable to downflow use, To convert to

downflow use, follow these steps:

1, Remove the blockoff plates found in the return air

compartment and the supply air compartment.

NOTE: Blockoff plate in the supply air compartment only

contains one screw. If reinstalling plate, back part of plate

MUST fit into mating dimples on flange. To reinstall, slant

plate into dimples, then put plate into position and fasten

with screw,

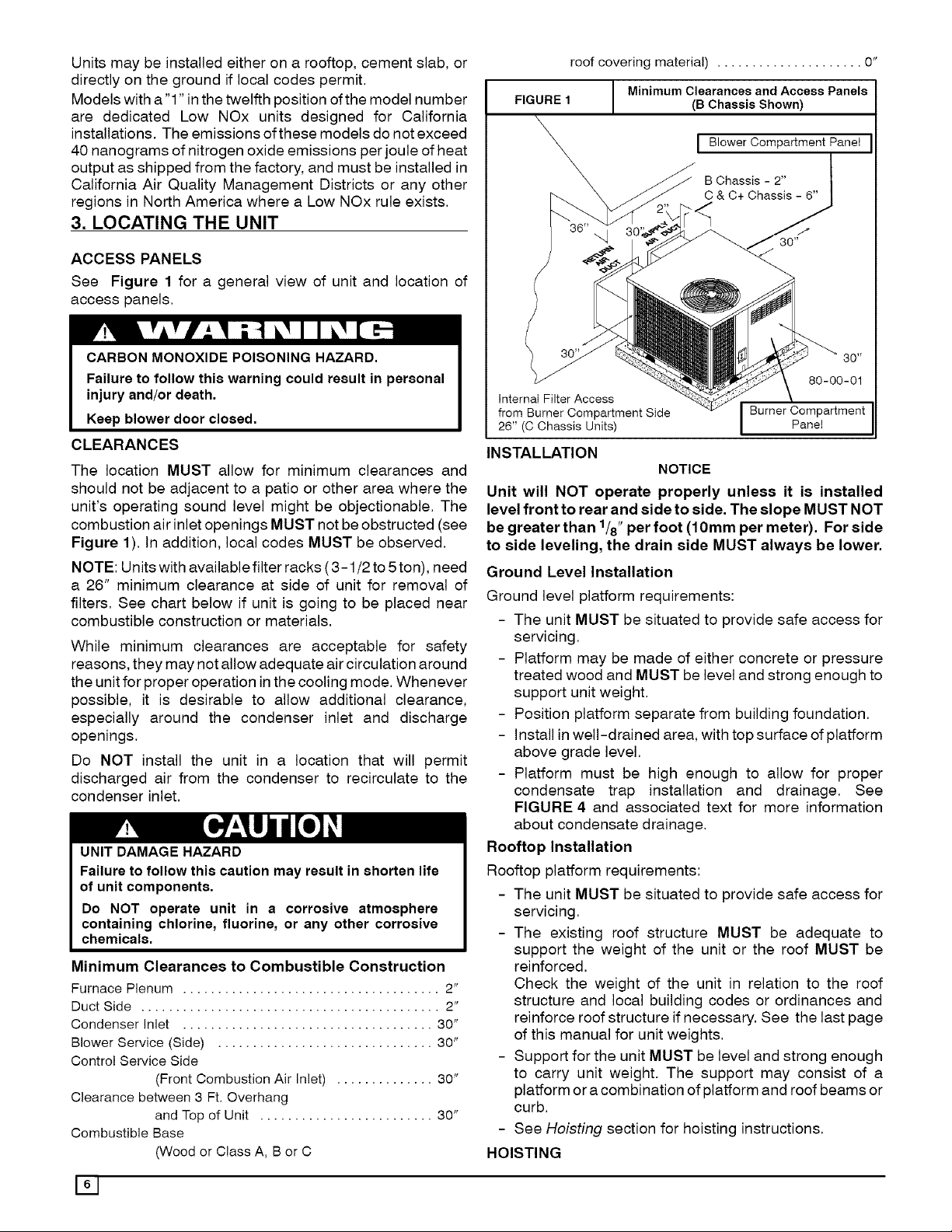

I FIGURE 2 I Heating vent Assembly I

Screwsfor

"B" Chassis

(473/8 x 473/8)

/

FIGURE 3 1 Heating Vent Assembly

Flue Support

(Shipped mounted to unit

Flue Cover

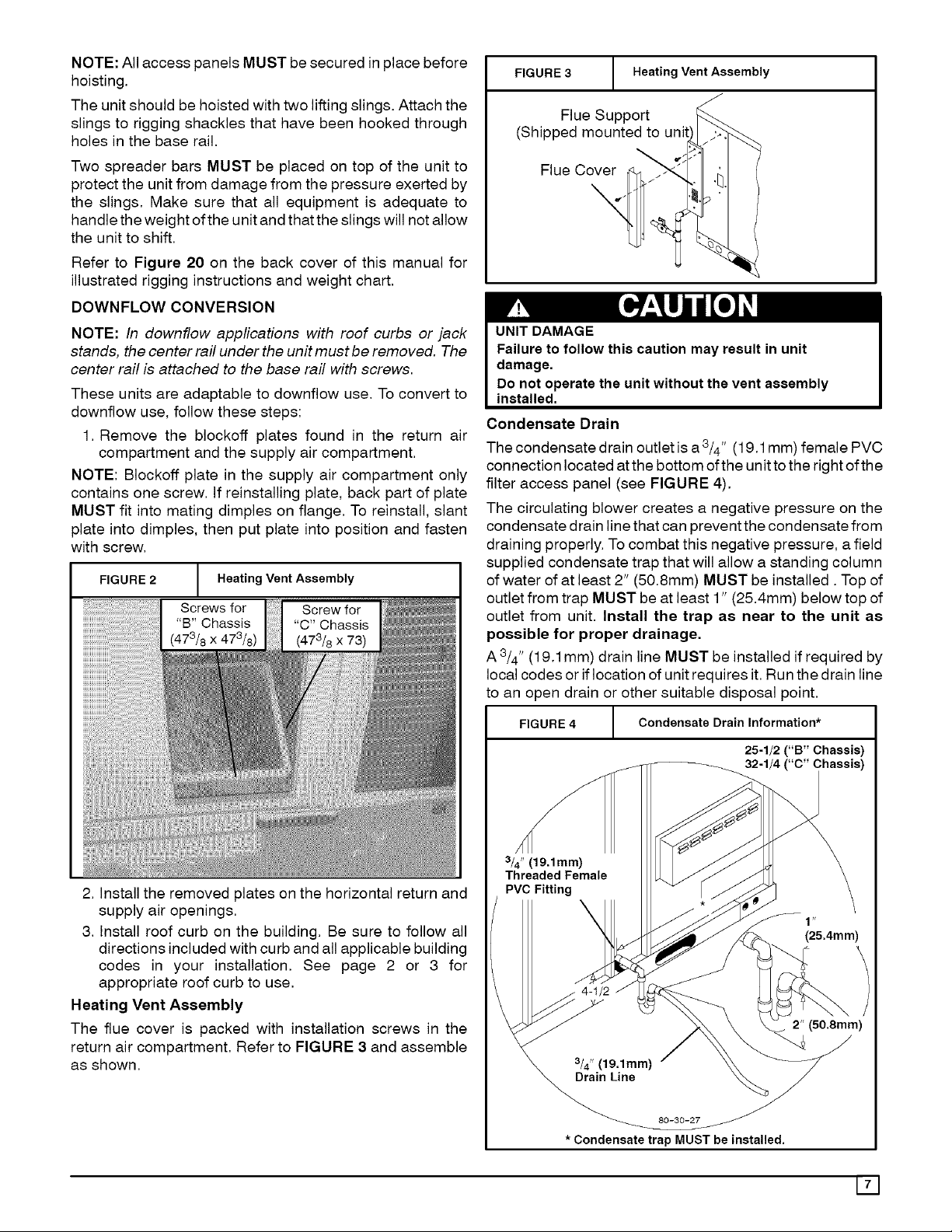

Condensate Drain

The condensate drain outlet is a 3/4" (19.1mm) female PVC

connection located atthe bottom of the unit tothe right of the

filter access panel (see FIGURE 4).

The circulating blower creates a negative pressure on the

condensate drain line that can prevent the condensate from

draining properly. To combat this negative pressure, afield

supplied condensate trap that will allow a standing column

of water of at least 2" (50.8mm) MUST be installed. Top of

outlet from trap MUST be at least 1" (25.4mm) below top of

outlet from unit. Install the trap as near to the unit as

possible for proper drainage,

A 3/4" (19.1 mm) drain line MUST be installed if required by

local codes or if location of unit requires it. Run the drain line

to an open drain or other suitable disposal point,

2. Install the removed plates on the horizontal return and

supply air openings.

3, Install roof curb on the building. Be sure to follow all

directions included with curb and all applicable building

codes in your installation. See page 2 or 3 for

appropriate roof curb to use.

Heating Vent Assembly

The flue cover is packed with installation screws in the

return air compartment, Refer to FIGURE 3 and assemble

as shown,

FIGURE 4

3/4" (19.1mm)

Threaded Female

* Condensate trap MUST be installed.

/ Condensate Drain Information*

25-1/2 ("B" Chassis)

32-1/4 ("C" Chassis)

(25.4mm)

2" (50.8mm)

171

Page 8

4. PRE-EXISTING COMMON VENT CHECK

If the installation of this new combination gas heat/electric

cool unit involves removing an existing gas-fired furnace

from a common vent system with other gas-fired

appliances (gas-fired hot water heater, etc.), the existing

vent system must be checked and inspected by a qualified

technician. The qualified technician can determine if the

existing vent system will properly vent the flue products of

the remaining gas-fired appliances. In many cases, the

existing vent system may be oversized for the remaining

appliances.

5. GAS SUPPLY AND PIPING

NOTE: Because there are many types of liquified petroleum

(propane (LP)) gases, the term propane (LP) as used inthis

manual refers to propane gas. Ifyou intend to use any type

of propane (LP) gas, proper precautions MUST be used in

the handling, piping, and use of such gas. NOTE: In

Canada, installations MUST be performed by licensed

propane (LP) installers.

The UL rating plate located on the side panel on the unit

contains the model number, type of gas, gas input rating,

and other important information.

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Makecertainthe unitisequippedtooperateonthetype of

gasavailable.Models designatedasnatural gas areto be

used with natural gas only. Models designated for use

with liquefied petroleum (propane (LP)) gas are shipped

with orifices sized for commercially pure propane gas.

They MUST not be used with butane or a mixture of

butane and propane unless properly sized orifices are

installed by a licensed propane (LP) installer.

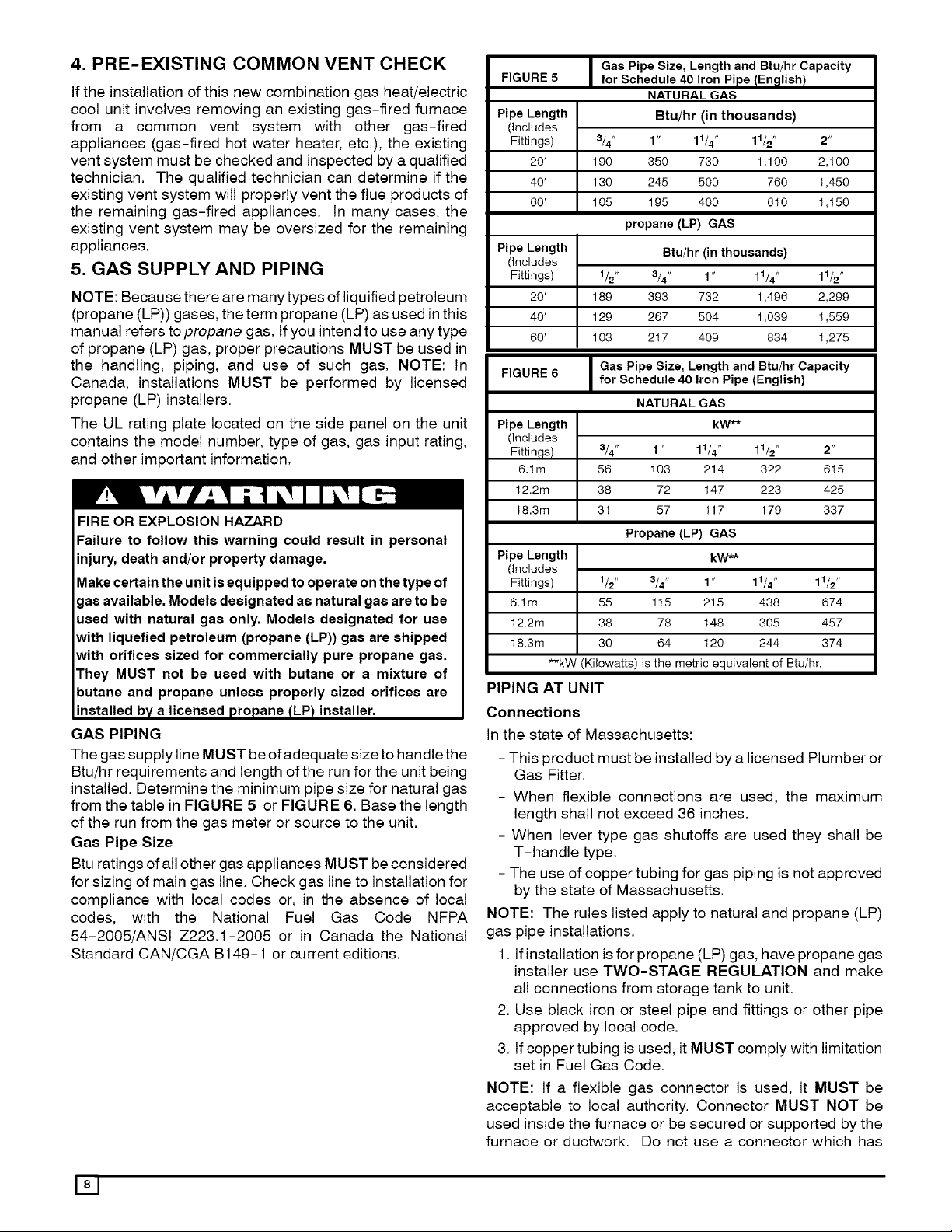

GAS PIPING

The gas supply line MUST be of adequate size to handle the

Btu!hr requirements and length of the run for the unit being

installed. Determine the minimum pipe size for natural gas

from the table in FIGURE 5 or FIGURE 6. Base the length

of the run from the gas meter or source to the unit.

Gas Pipe Size

Btu ratings of all other gas appliances MUST beconsidered

for sizing of main gas line. Check gas line to installation for

compliance with local codes or, in the absence of local

codes, with the National Fuel Gas Code NFPA

54-2005/ANSI Z223.1-2005 or in Canada the National

Standard CAN/CGA B149-1 or current editions.

FIGURE 5 for Schedule 40 Iron Pipe tEn_llish/

Pipe Length Btu/hr (in thousands)

(includes

Fittings) 3/4" 1 " 11/4" 11/2" 2"

20' 190 350 730 1,100 2,100

40' 130 245 500 760 1,450

60' 105 195 400 610 1,150

Pipe Length Btu/hr (in thousands)

(includes

Fittings) 1/2" 3/4" 1" 11/4" 11/2"

20' 189 393 732 1,496 2,299

40' 129 267 504 1,039 1,559

60' 103 217 409 834 1,275

FIGURE 6 for Schedule 40 Iron Pipe (English)

Pipe Length kW**

(includes

Fittinqs) 3/4" 1 " 11/4" 11/2" 2"

6.1m 56 103 214 322 615

12.2m 38 72 147 223 425

18.3m 31 57 117 179 337

Pipe Length kW**

(includes

Fittings) 1/2" 3/4" 1" 11/4" 11/2"

6.1m 55 115 215 438 674

12.2m 38 78 148 305 457

18.3m 30 64 120 244 374

I Gas Pipe Size, Length and Btu/hr Capacity

NATURAL GAS

propane (LP) GAS

I Gas Pipe Size, Length and Btu/hr Capacity

NATURAL GAS

Propane (LP) GAS

**kW (Kilowatts) is the metric equivalent of Btu/hr.

PIPING AT UNIT

Connections

In the state of Massachusetts:

- This product must be installed by a licensed Plumber or

Gas Fitter.

- When flexible connections are used, the maximum

length shall not exceed 36 inches.

- When lever type gas shutoffs are used they shall be

T-handle type.

- The use of copper tubing for gas piping is not approved

by the state of Massachusetts.

NOTE: The rules listed apply to natural and propane (LP)

gas pipe installations.

1. Ifinstallation is for propane (LP) gas, have propane gas

installer use TWO-STAGE REGULATION and make

all connections from storage tank to unit.

2. Use black iron or steel pipe and fittings or other pipe

approved by local code.

3. tf copper tubing is used, it MUST comply with limitation

set in Fuel Gas Code.

NOTE: If a flexible gas connector is used, it MUST be

acceptable to local authority. Connector MUST NOT be

used inside the furnace or be secured or supported by the

furnace or ductwork. Do not use a connector which has

181

Page 9

previously serviced another gas appliance. Always use a LEAK CHECK/PRESSURE TESTING OF GAS SUPPLY

new listed connector. PIPING

FIRE OR EXPLOSION HAZARD

Failure to do so could result in personal injury, death

and/or property damage.

Gas connector MUSTbeproperlyinstalledand can NOT

be usedinside thefurnace.

4. Use pipe joint compound on external (male) threads

ONLY. Joint compound MUST be resistant to any

chemical action of propane (LP) gases. Do NOT put

pipe compound on last 2 threads of pipe.

5. Use ground joint unions and install a drip leg no less

than 3 inches (76 mm) long to trap dirt and moisture

before it can enter gas valve.

UNIT OPERATION AND COMPONENT DAMAGE HAZARD

Failure to follow this caution may result in misaligned

burners, flame rollout and or unit damage.

Overtightening assembly may cause damage to the gas

valve and/or wirin_land may misali_lnthe burners.

6. Use a wrench on gas valve when making connections

to prevent gas valve from turning. Do NOT use a pipe

wrench on the gas valve body.

7. Provide a t/8 inch (3mm) National Pipe Thread (NPT)

plug for test gauge connection immediately upstream of

the gas supply connection to the furnace if none is

supplied with the gas valve of unit.

8. Install a manual shutoff valve and tighten all joints

securely.

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings could result in per-

sonal injury, death or property damage.

Never test for gas leaks with an open flame. Use a com-

mercially available soap solution made specifically for

the detection of leaks to check all connections. A fire or

explosion may result causing property damage, person-

al injury or loss of life.

The unit and its equipment shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of .5 psi (3.5kPa).

The unit must be isolated from the gas supply piping system

by closing the equipment shut off valve during any pressure

testing of the gas supply piping system at test pressures

equal to or less than .5 psi (3.5 kPa).

ORIFICES

Orifice Sizes

Orifice sizes MUST be matched to the heating value of the

gas (see TABLE 1 & 2). Check with your gas supplier and

the National Fuel Gas Code ANSI Z223.1.

NOTE: A Propane (LP) Conversion Kit MUST be used for

conversion to propane (LP) gas.

NOTE: For elevations above 2000 feet (610 meters), the

Btu input rating MUST be reduced by 4% for each 1000 feet

(305 meters) above sea level, unless the gas supplier's

Btu/ft3 content has already been adjusted for altitude.

Check Table 1 & 2 for the proper orifice sizes.

191

Page 10

Table I NATURAL GAS MANIFOLD PRESSURE ("w c )

0 to 2001 to 300I to 4001 to 500I to 6001 to 700I to 6001 to 9001 to

HEATING 2000 3000 4000 5000 6000 7000 8000 9000 10000

VALUE at

ALTITUDE Odfic_ MnfldPress Orlfic_ MnfldPress Odfic_ MnfldPress Odfic_ MnfldPress Oriflc_ MnfldPress Orifice MnfldPress 9dflc_ MnfldPress Dr4fice MnfidPress 3dfice MnfldPress

BTU/CU. FT No Hi Lo No Hi Lo No Hi Lo No Hi Lo No Hi Lo No Hi Lo No. Hi Lo No Hi Lo No. Hi Lo

700 47 37 18 48 36 1.8 49 36 18

725 46 36 1.7 47 35 17 48 34 1.7 49 34 17

750 46 33 1.6 46 37 18 49 37 1.8 50 37 18

775 46 36 1 6 47 35 1.7 48 35 17 49 35 1.7 50 35 17

600 45 37 1.8 46 34 17 47 33 1.6 46 33 16 49 33 1.6 50 33 16

625 46 37 1.8 47 36 16 48 36 1.7 49 36 18 50 36 1.8 51 37 18

850 45 37 18 46 34 1.7 47 34 17 48 34 1.6 49 34 17 50 34 1.7 51 35 17

675 46 37 18 47 37 1.8 46 37 16 49 37 1.8 49 32 16 50 32 1.6 51 33 16

900 46 35 17 47 35 1.7 46 35 17 4g 35 1.7 50 36 18 5I 37 1.8 51 3I 15

925 43 3.4 17 45 36 18 46 33 16 48 37 1.8 46 33 16 49 33 1.6 50 34 17 5I 35 1.7 52 36 18

950 44 3.7 18 46 36 18 47 36 17 48 36 1.7 49 36 18 50 37 1.6 50 32 16 5I 33 1.6 52 34 17

975 44 3.5 17 46 34 17 47 34 17 48 34 1.7 49 35 17 50 35 1.7 51 36 18 5I 31 1.5 52 33 16

1000 44 3.3 16 47 37 I8 46 37 18 48 32 1.6 49 33 16 50 34 1.6 51 34 17 52 37 1.8 52 3I 15

1050 45 3.6 18 47 33 I6 46 3.3 16 49 34 I7 50 35 17

II00 46 3.5 17 48 34 I7 49 3.6 17 50 37 I8

Note: The orifice sizes inthe chad above derate the input rate at 4% per 1000 feet above sea level for altitudes exceeding 2000 feet above sea level

If converting from propane (LP) gas to Natural Gas, use kit number 1175405 for altitudes up to 2000 feet above sea level

If converting from propane (LP) gas to Natural Gas, use kit number 1175405 and altitudes exceeding 2000 feet above sea level, use kit number 1I 75405 with field-supplied orifices

Natural gas data Jsbased on .6 specific gravity

For fuels with different specific gravity, consuk the National Fuel Gas Code NFPA 54-2605/ANSI Z223.1 - 2005 or

National Standard of Canada, Natural Gas and Propane Installation Code CSA B149.1-05

Table 2

HI-AIIN(5

VALUE at

ALTITUDE Oto 2000 2001to3000 3001to4000 7001to8000 8001to9000 9001to10000

MEAN ELEVATION FEET ABOVE SEA LEVEL

PROPANE (LP) GAS MANIFOLD PRESSURE ("w.c.)

MEAN ELEVATION FEET ABOVE SEA LEVEL

4001to5000 5001to6000 600tto7000

2500 10.0 5.5 10.0 5.0 11.0 6.0 11.0 5.7 10.7 5.2 10.0 5.0 11.0 5.9 10.6 5.2 10.0 5.0

Orifice Size # 55 # 55 # 56 #56 #56 # 56 # 57 #57 #57

KitNumber 1175406

Note:The orificesizes in thechart above deratethe inputrate at 4% per 1000feet abovesea level foraltitudesexceeding 2000feet abovesea level.

Propane(LP) gasdatais basedon f.52 specificgravity.

For fuelswith differentspecificgravity, consultthe NationalFuel GasCodeNFPA54-2005/ANSIZ223.1- 2005 or

NationalStandardof Canada,Natural Gas andPropane InstallationCodeCSA B149.f-05.

Changing Orifices

3. Disconnect the wires from the gas valve, sparker, and

flame sensor.

4. Remove the four screws holding the manifold to the

manifold brackets.

ELECTRICAL SHOCK, FIRE AND/OR EXPLOSION

HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

5. Carefully remove the manifold with the gas valve

attached.

6. If unit has v-shaped NOx baffles installed in the firing

tubes, they must be removed when coverting to

propane (LP). Some baffles may be attached by

Shut off electric power at unit disconnect or service

panel and shut off gas at manual shut off valve before

beginning the following procedure.

Changing orifices requires a qualified service

technician.

1. Shut OFF gas at manual shut off valve.

2. Shut OFF electric power at unit disconnect or service

panel. If unit is still running, allow 3 minutes after gas

screws. Replace screws after removing NOx baffles

(figure 7).

CARBON MONOXIDE HAZARD.

Failure to follow this warning could result in per-

sonal injury death and/or property damage.

NOx baffles for use with Natural Gas units ONLY. If

propane (LP) Gas is required, NOx inserts must be

YAml_v_t'{

shut off before turning off power.

Page 11

FIGURE 7 i Removing NOx Baffles

or

25-22-46a

7. Remove the orifices from the manifold with a 7/t6" box

end or socket wrench.

8. Check to be sure that the size of each orifice is correct

for the Btu input desired.

6. ELECTRICAL WIRING

ELECTRICAL SHOCK HAZARD.

Failure to follow this warning could result in personal

injury, death, and/or property damage.

The unit cabinet must have an uninterrupted,

unbroken electrical ground to minimize the possibility

of serious injury if an electrical fault should occur.

This ground may consist of an electrical wire

connected to the unit ground lug in the control

compartment, or conduit approved for electrical

ground when installed in accordance with National

Electric Code (NEC) NFPA 70, National Fuel Gas Code

NFPA 54-2005/ANSI Z223.1-2005 and local electrical

codes. In Canada, follow Canadian Electrical Code

CSA (Canadian Standards Association) C22.1 and

local electrical codes.

REDUCED EQUIPMENT LIFE HAZARD

FIGURE 8 Manifold/Orifice Measurement

_lpi°l_e°rifiee

9. Install the correct orifices. Gauge the size ofthe orifices

with a new twist drill bit of the correct size.

Make sure that the orifices go in straight so that they

form a right angle (90 °) to the manifold pipe.

Tighten the orifices so that there is a 13/16" distance

between the faces of the orifices to the back of the

manifold pipe.

Measure the distance with a set of calipers. Ifyou do not

have a calipers, you can use an adjustable wrench and

measure between the face of the jaws.

1O.Reassemble in reverse order.

Failure to follow these cautions could result in damage

to the unit being installed.

1) Make all electrical connections in accordance with

National Electric code (NEC) NFPa 70, National Fuel Gas

Code NFPA 54-2005/ANSI Z223.1-2005 and local

electrical codes governing such wiring. In Canada, all

electrical connections must be in accordance with CSA

standard C22.1, Canadian Electrical Code Part 1, and

applicable local codes. Refer to unit wiring diagram.

2) Use only copper conductor for connections between

field-supplied electrical disconnect switch and unit. DO

NOT USE ALUMINUM WIRE.

3) Be sure that high-voltage power to unit is within

operating voltage range indicated on unit rating plate.

4) Do not damage internal components when drilling

through any panel to mount electrical hardware,

conduit, etc. Consult local power company for

correction of improper voltage and/or phase imbalance.

For access, remove the burner access panel. See Figure

for access panel location. Wiring MUST be protected from

possible mechanical damage.

Disconnect Switch

The unit must have separate electrical service with a

field-supplied, waterproof, disconnect switch mounted at,

orwithin sight from, the unit. Refer tothe unit rating plate for

maximum fuse/circuit breaker size and minimum circuit

amps (ampacity) for wire sizing.

Ground Connections

Do NOT complete line voltage connections until unit is

permanently grounded. All line voltage connections and the

ground connection MUST be made with copper wire.

A ground lug is installed in the control box area for the

ground connection. Use a copper conductor of the

appropriate size from the unit to a grounded connection in

the electrical service panel or a properly driven and

electrically grounded ground rod. See warning above.

Page 12

LineVoltageWiring

Connectionsforlinevoltagearemadeintheunitcontrolbox

area.RefertowiringdiagramlocatedontheBurnerAccess

panel.Foraccess,removetheburneraccesspanel.

1.Runthehighvoltage(L1,L2)andgroundleadsintothe

controlbox.

2.Connectgroundleadtochassisgroundconnection.

3.ConnectL1 to pressurelugconnection11 of the

compressorcontactor.

4.ConnectL2 to pressurelug connection23 of the

compressorcontactor.

Thermostat/ Low Voltage Wiring

Location of the thermostat has an important effect on home

comfort. FOLLOW THE THERMOSTAT INSTRUCTION

MANUAL FOR CORRECT LOCATION, MOUNTING, AND

WIRING.

A two-stage thermostat is required for proper operation.

Thermostat must have the following terminals: "R",

"W/W1 ", "Y1", "Y2", and "G'. Some electronic thermostats

use low voltage from the unit for power for temperature

display and programming. These electronic thermostats

will have a "C" terminal. The outdoor unit has color-coded

wires for easy connection. Using wire nuts, follow figure 9

for proper connections:

PLEASE NOTE: While a high stage heat pigtail is provided

('W2", BLK), the approved thermostat will not respond to

this connection. Make sure that dip switch 3 on the ignition

control board is in the "OFF" position. The ignition control

board is inthe control box assembly, and the wiring diagram

label will show the correct dip switch position. With dip

switch 3 inthe "OFF" position, gas heating will always be on

low stage for the first 10 minutes. If after 10 minutes of

continuous low stage gas heat operation the thermostat is

still not satisfied, the ignition control will step up to high

stage gas heat for the remainder of the thermostat call.

FIGURE 9 I Thermostat Connections

I

is the presence of 24V to the violet-colored pigtail.

Approved thermostats that have the "DH" terminal are

available through your distributor

THERMOSTAT HEAT ANTICIPATOR

Some thermostats have an adjustable heat anticipator. The

heat anticipator prevents temperature overshoot in heating

mode. If the heat doesn't turn off until the set point

temperature on the thermostat is exceeded, then the

anticipator setting is too low. If the heat turns off before the

thermostat reaches the set point temperature on the

thermostat, then the anticipator setting is too high. Follow

the thermostat instruction manual for proper adjustment of

the heat anticipator.

Final Electrical Check

1. Make afinal wiring check to be sure system is correctly

wired. Inspect field installed wiring and the routing to

ensure that rubbing or chafing due to vibration will not

occur.

NOTE: Wiring MUST be installed so it is protected from

possible mechanical damage.

BALANCE POINT TEMPERATURES

The dual fuel models require a dual fuel thermostat for

proper operation. A dual fuel thermostat allows a balance

point temperature to be programmed into the thermostat

and has an outdoor temperature sensor that must be

installed outside. Follow the thermostat installation

instructions for proper location of outdoor sensor. The dual

fuel unit operates either in heat pump mode or gas heat

mode, but NEVER both modes at the same time.

There are 2 different balance point temperatures to

consider when programming the thermostat: Economic

and Load.

Economic Balance Point Temperature

The economic balance point temperature is the outdoor

temperature where the utility cost of running in heat pump

mode is the same as running in gas heat mode. If the

outdoor temperature is above the economic balance point

temperature, then the heat pump mode will be less costly. If

the outdoor temperature is below the economic balance

point temperature, then the gas heat mode will be less

costly. The economic balance point temperature is affected

by electrical utility cost, gas utility cost, and model size.

Knowing the utility cost of electricity and gas, the economic

balance point temperature can be determined using Figure

10.

Thermostat and subbase

The violet-colored pigtail connects to the dehumidification

feature of this unit. The dehumidification feature reduces

cooling airflow by 20% to increase latent heat removal when

the humidity is high. The reduced airflow occurs when there

Unit ControJ Power

Figure 10 - Economic Balance Point Temperature Chart

Economic Balance Point Temperature (°F)

Cost PDX424 PDX430 PDX436 PDX442 PDX448 PDX460

Ratio* 040 060 080 080 100 100

0.075 0 0 2 0 1 2

0.100 20 19 20 20 18 18

0.125 42 32 34 34 31 29

0.1375 50 40 38 38 40 38

0.150 57 48 43 42 46 44

* CostRatioisthe electricalcost,in$ perkilowatt-hour,dividedbythegas

cost,in$ per therm.

Page 13

Example: A PDX442080 is installed in a residence where

the electrical utility cost is 9 cents per kilowatt-hour and the

gas cost is 90 cents per therm. Proceed as follows:

1. $.09/$.90 = .1

2. Using Figure 10, a PDX342080 with a .1 cost ratio =>

Economic Balance Point Temperature = 20°F

Some utilities have asliding cost based onconsumption. In

this case, take the total bill and divide by the total

consumption to determine the average utility cost.

Some natural gas suppliers sell gas by every 100 cubic feet

(CCF) of gas. For an approximate gas cost per therm,

multiply CCF by 97. Example: A price of $.01 per CCF is

approximately equivalent to $.97 per therm.

Note: The 97 multiplier is based on a typical heating

value of 1030 Btu per cubic foot of natural gas. For a

more accurate cost, contact your gas supplier to obtain

the Btu content of natural gas in your area. Divide

100,000 by the actual Btu content per cubic foot to obtain

the correct multiplier.

If the economic balance point is chosen, keep in mind that

utility rates fluctuate substantially over time. Review

monthly utility bills and re-calculate economic balance

)oints as necessary.

11 I Load Balance Point

Figure Temperature

m

I

Load Balance Point Temperature

The load balance point temperature is the outdoor

temperature at which the load may be met using either heat

pump mode or gas heat mode. Ifthe outdoor temperature is

above the load balance point temperature, the demand for

heat may be met using the heat pump mode. If the outdoor

temperature is below the load balance point temperature,

the gas heat mode is required to meet the building load.

To find the load balance point temperature, a load

calculation must be performed on the building. The load

calculation must be performed at 3 different outdoor

temperatures and graphed on Figure 11. Plot the three

load calculations at their appropriate outdoor temperatures

and draw a smooth line through the 3 points. NOTE: The

line connecting the 3 points may not be a straight line.

Locate where the building load line intersects the

appropriate model capacity line. This is the load balance

point temperature.

No matter what the balance point temperature is set at, the

unit will automatically switch to gas heat if the heat pump is

not able to meet the demand of the house. Calculating the

load balance point temperature and programming itinto the

thermostat will minimize temperature fluctuations in the

house.

Load Balance Point Temperature

10 20 30 40 50 60

Outdoor Air Temperature (F)

7. DUCTWORK

Ductwork Sizing

The maximum recommended velocity in trunk ducts is 1000

feet per minute. The maximum recommended velocity in

branch ducts is 800 feet per minute.

Ductwork sizing affects the discharge temperature, airflow

velocity, and efficiency of the system. Be sure to properly

size ductwork to the capacity of the unit and to the airflow

requirements of the conditioned space. Failure to properly

size ductwork can result in inadequate airflow and poor

efficiency. Undersized ductwork may result in tripped limit

controls and premature failure of compressors, motors and

other components.

Ductwork Insulation

Ductwork installed outdoors must have a minimum 2" thick

fiberglass "wrap" insulation and a weatherproof vapor

barrier installed around it. The insulation and vapor barrier

must be protected against potential damage. Caulking,

flashing, and other means of providing a permanent

weather seal must be used.

Ductwork Connections

The use of flexible, non-combustible connectors between

main trunk ducts and supply and return air plenums is

permitted. If flexible connectors are used, they should be

protected from potential mechanical damage such as

punctures and tears.

NOTE: When connecting the supply and return plenums to

the unit, make sure that the plenums are sealed against the

Page 14

sidecasingoftheunitanddonotinterferewithremovalof

thetopoftheunit.

FILTERS

AllreturnairMUSTpassthroughafilterbeforeenteringthe

unit.Anelectronicaircleaner,optionalfilterracks,orother

accessiblefilterarrangementmustbeinstalledinthereturn

airductwork.Minimumrecommendedfiltersizesarelisted

REDUCED EQUIPMENT LIFE HAZARD

Failure to follow this caution may result in improper

unit operation,

Do not operate the unit without a filter.

inFIGURE12andarebasedonmaximumfacevelocitiesof

300ft/minfordisposablefiltersand600ft/minforwashable

(highvelocity)filters.Seefigure10forfiltersizes.

Figure 12 Filter Sizes

Disposable Filters

Model

PDX424040

PDX430060

PDX436080

PDX442080

PDX448100

PDX460100

1 Washable filter size is based on an allowable face velocity of 600 ft/min. Refer to

filter manufacturer's specifications for allowable face velocity and required filter area.

Nominal Size Area(sq.

(qty x w x d) inches)

1 x 20" x 20" 384

1 x 20" x 24" 480

2 x 15" x 20" 576

2 x 18" x 20" 672

2 x 20" x 20" 768

2 x 20" x 24" 960

Minimum

Washable Filters'

NomlnaI Size

(w x d)

(inches)

1 x 10" x 20"

1 x 12" x 20"

1 x 15" x 20"

1 x 18" x 20"

1x20"x20"

1x20"x24"

Minimum

Area (sq.

inches)

192

240

288

336

384

48O

D2J

Page 15

8. AIRFLOW ADJUSTMENT

Figure 13

Model Tons

PDX424040 2

PDX430050 25

PDX436080 3

PDX442080 35

PDX448100 4

PDX460100 5

NOTES:

* Factory-shipped speed

NA = Not Allowed for Heating Speed

Cooling

Airflow Adjustment

COOLING

HighStage

High Stage Heating

CFM Heating Rise (°F)

Low Stage

Ext. Static Pressure (in we)

.1" ~ .7"

904 33

791 37

578 44

554 52

904 49

791 56

589 54

554 NA

1288 48

1164 53

1034 59

904 NA

1379 45

1288 48

1198 51

1113 55

1785 43

1719 45

1653 46

1588 48

1797 43

1732 44

1669 46

1605 48

Heating Rise

Range(°F)

25-55

25-55

25-55

25-55

25-55

25-55

HEAT PUMP - Comfort Mode

Low Stage Heating

Ext. Static Pressure (in wc)

.1" ~ .7"

Heating Rise (°F)

25

30

35

42

39

44

51

NA

38

42

47

NA

35

38

41

44

34

35

36

38

34

35

36

38

Model

PDX424040

PDX430060

PDX436080

PDX442080

PDX448100

PDX460100

Normal Dehumidy

Mode(CFM Mode(CFM)

800 640

875 700

1200 960

1400 1120

1600 1280

1750 1400

Dehumidify

Mode (CFM)

448

518

682

784

883

1036

HighStage LowStage

700 490

875 650

1050 746

1225 853

1450 998

1575 1170

L!2J

Page 16

CIRCULATING AIR BLOWER SPEEDS

ELECTRICAL SHOCK HAZARD.

Failure to follow this warning could result in personal

injury, death and/or property damage.

Turn off electric power supply at disconnect switch or

service panel before removing access or service panels

from unit.

GAS HEATING

Available heating speeds are listed in Figure 13. The

heating speeds may be selected by adjusting dipswitches 3

and 4 on the motor interface board. The motor interface

board may be found in the control box assembly. Refer to

wiring diagram on inside of the access panel for dip switch

settings. Please note that the setting of dipswitches 3 and 4

affects both the low stage gas heating speed and the high

stage gas heating speed.

COOLING

Cooling speeds are listed in Figure 13. In dehumidification

mode, cooling airflow is reduced to 80% of nominal.

CONTINUOUS FAN OPERATION

CHECK BEFORE STARTING

1. Check that the blower motor speed terminal block is

running the correct heating and cooling speeds.

2. Check to see that clean, properly sized air filters are

installed.

3, Replace all service access panels,

FIREOR EXPLOSIONHAZARD.

Failuretofollow this warning could resultin personalinjury

and/ordeath.

TurnOFFgasatshutoffbeforeconnectingU-tubemanometer.

Figure 14 J_ Honeywell Gas Valve

Regulator

Adjustment

/

©

For energy efficiency, continuous fan speed is 40% of the

high stage cooling speed,

COOLING

1. Turn electric power OFF

2. Set thermostat Heat-Cool select to COOL.

3. Adjust thermostat setting to below room temperature.

4. Turn power ON, for approximately one minute, then

OFF. During power application check the following:

a. Contactor - Contacts Closing

b. Compressor - ON

c. Condenser fan motor - ON

d. Circulating Air Blower - ON, Adustable delay ON of 0

or 30 seconds.

5. Turn power OFE check the following:

a. Contactor contacts opening.

b. Compressor - OFF

c. Condenser fan motor - OFF

d. Circulating blower - OFF, Adustable delay OFF of 0

or 90 seconds.

9. START-UP PROCEDURES

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Do NOT attempt to light the burner with a match or

flame of any kind.

tntlet Pressure

Tap 1/8 NPT

Outlet Pressure

Tap 1/8 NPT

GASPRESSURES

1. Do NOT allow gas supply pressure to fall below the

listed minimums. Doing so will decrease input to

furnace. Refer to Figure 15 for gas supply pressures.

2. Gas input MUST NOT exceed rated input shown on

rating plate.

3. Do NOT allow pressures to exceed the maximum limits

as listed in Figure 15.

Figure 15 Gas Pressures

Natural Gas Propane (LP) Gas

Minimum 4.5 in wc (1120 Pa) 11 in wc (2740 Pa)

Inlet

Recommended 7 in wc (1740 Pa) 11 in wc (2740 Pa)

Inlet

Maximum 13 in wc. (3230 Pa) 13 in wc (3230 Pa)

Inlet

Manifold Pressure Adjustment

Manifold pressures are listed in Tables 1 and 2. Check

manifold pressures using the following procedure.

1. With gas OFF, connect U-Tube manometer to outlet

pressure tap on gas valve (see figure 14). Use a

manometer with a 0" to 12" water column range.

Page 17

2.Turn gas ON. Temporarilyset balancepoint

temperaturewarmenoughto lockout heatpump

operation.Changethermostatto HEATmodeand

adjusttemperaturesetpointtoatleast7degreesabove

roomtemperature.Makesurethatthethird(3rd)dip

switchontheignitionboardissetintheOFFposition

(Seewiringdiagram).Wait10minutesforunittoswitch

tohighstagegasheat.

3.Removethemanifoldpressureadjustmentscrewcover

ongasvalve.Turnhighstageadjustingscrew,marked

"HI", counterclockwiseto decreasethe manifold

pressureandclockwiseto increasepressure.See

figure14.

4.Setmanifoldpressureto valueshowninTable1 or

Table2. Replaceadjustmentscrewcover and

re-checkmanifoldpressure.

5.Turnthermostatmodeto OFF.Changethermostatto

HEATmodeand adjusttemperatureset point 5

degreesaboveroomtemperature.

NOTE:Fromthetimethethermostatissettogasheat,you

have10minutestocompletelowstagegasadjustments.

After10minutes,thethermostatwillshifttohighstagegas

heat.

6.Removethemanifoldpressureadjustmentscrewcover

ongasvalve.Turnlowstageadjustingscrew,marked

"LO', counterclockwiseto decreasethe manifold

pressureandclockwiseto increasepressure.See

figure14.

7.Setmanifoldpressureto valueshowninTable1or

Table2. Replaceadjustmentscrewcover and

re-checkmanifoldpressure.

8.Turn thermostat "OFF". Remove manometer

connectionfromtheoutletpressuretapofgasvalve

andreplacepluginoutletpressuretap.Seefigure14.

9.Returnthermostatto customer'sdesiredsettings

(balancepoint temperature,mode, and desired

temperature)afterfinalcheckout.

FIRE AND/OR EXPLOSION HAZARD

Failure to follow this warning could result in per-

sonal injury, death and/or property damage.

Do NOT adjust manifold pressure more than + 0.3

inches water column to obtain rated input.

GAS HEATING START-UP PROCEDURE

1. Temporarily set balance point warm enough to lock out

heat pump. Adjust thermostat setting above room

temperature and set thermostat selector to HEAT. The

combustion air blower will energize on high speed.

2. The combustion air blower will run on high speed for 15

seconds to purge the combustion chamber.

3. After the 15 second purge, the combustion air blower

will remain on. The sparker will turn on to ignite the gas

at the same time the gas valve is energized on low

stage. Make sure the gas valve is in the "ON" position

(Refer to Figure 14 and the instruction label located on

the inside of the burner access panel.

4. The sparker will remain energized for 7 seconds or until

a flame is detected by the flame sensor. It may take

several ignition attempts to purge the air out of the gas

line at the initial start-up of the unit.

5. Once flame is proven, the ignition control will switch the

combustion air blower to low speed. The unit will run in

low stage gas heat for 10 minute or until the thermostat

is satisfied, whichever is shorter. Ifthe thermostat is not

satisfied after 10 minutes, the unit will go to second

stage gas heat and run until the thermostat is satisfied.

6.30 seconds after the burners light, the circulating air

blower will begin to run.

7. After checking start up, return balance point

temperature to desired setting.

FIRE AND/OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Do NOT attempt to light the burner with a match or

flame of any kind,

GAS HEATING INPUT RATE CHECK

The gas input tothe unit isdetermined by measuring the gas

flow at the meter. Measuring gas flow at the meter is

recommended for natural gas units. To measure the

heating input, perform the following steps for both low and

high stage:

1. Turn off all other gas appliances that use the same

meter.

Check the unit's operation as outlined in the following

instructions, tf any unusual sparking, odors or unusual

noises are encountered, shut off electric power

immediately. Recheck for wiring errors, or obstructions in or

near blower motors.

1. Set thermostat Heat-Cool selector to OFF.

2. Set thermostat fan switch to AUTO.

3. Turn electric power ON. Nothing should start running.

4. Turn manual gas valve ON.

5. Turn gas control valve ON.

6. Set thermostat fan switch to ON.

7. Reset thermostat fan switch to AUTO,

2. Turn off gas supply to unit and attach manifold

pressure manometer as instructed in the "Manifold

Pressure Adjustment" section. Turn gas ON.

3,

Temporarily set balance point temperature warm

enough to lock out heat pump operation. Change

thermostat to HEAT mode and adjust temperature set

point to at least 7 degrees above room temperature to

set unit to high stage. Wait 10 minutes for unit to

switch to high stage. Make sure that the third (3rd) dip

switch on the ignition board is set in the OFF position

(See wiring diagram).

4. Record the number of seconds for the gas meter dial

to make 1 revolution.

1171

Page 18

5, Divide number of seconds in step 4 into 3600 (number

of seconds in 1 hour).

6. Multiply result of step 5 by the number of cubic feet

shown for one revolution of the meter dial to obtain the

cubic feet of gas flow per hour.

7,

Multiply result of step 6 by Btu heating value of gas to

obtain total measured input in Btu/hr. Compare this

with the unit rating plate and make any adjustments

as needed according to the "Manifold Pressure

Adjustments" section. Consult with local gas supplier

if the heating value of gas is not known.

NOTE: From the time the thermostat is set to gas heat, you

have 10 minutes to complete low stage gas adjustments.

After 10 minutes, the thermostat will shift to high stage gas

heat.

8. Turn thermostat mode to OFF. Reset the thermostat

by changing mode back to HEAT and adjust

temperature set point to 5 degrees above room

temperature to set unit to low stage.

9. Repeat steps 4 thru 7 for low stage.

be necessary to change the blower speed. A faster blower

speed will decrease the temperature rise. A slower blower

speed will increase the temperature rise.

NOTE: The blower speed MUST be set to give the correct

air temperature rise through the furnace as marked on the

rating plate. See Figure 13 for more information.

2. After 15 minutes of operation check the limit control

function by blocking the

return air grille(s).

After several minutes the main burners and pilot should

go OFE The circulating air blower should continue to

run.

Remove air restrictions. Pilot and main burners should

relight after a cool down period of a few minutes.

3,

Adjust the thermostat setting below room temperature.

Main burners and combustion air blower should go

OFF.

The circulating air blower should continue to run for 60,

100, 140 or 180 seconds. This time is adjustable. See

Figure 16 for more information.

4. Set thermostat Heat-Cool selector to OFF.

FAN CONTROL CHECK

10. Return thermostat to customer's desired settings

(balance point temperature, mode, and desired

temperature) after final checkout.

11. Relight all appliances and ensure all pilots are

operating.

Example: Assume that the size of the meter dial is 1 cu. ft.,

one revolution takes 44 seconds, and the heating value of

the gas is 1020 Btu/ft3. Proceed as follows:

1.38 sec. To complete 1 revolution

2. 3600/38 = 94.7

3.94.7 x 1 = 94.7

4.94.7 x 1020 = 96,632 Btu/hr

For this example, the nameplate input is 100,000 Btu!hr, so

only a minor change in manifold pressure is required. In no

case should the final manifold pressure vary more than

+- .3 in wc from the values in Tables 1 and 2.

GAS HEATING TEMPERATURE RISE CHECK

NOTE: Air temperature rise is the temperature difference

between supply and return air. With a properly designed

distribution system, the proper amount of temperature rise

will normally be obtained when the unit is operating at rated

input with the recommended blower speed.

Figure 16 Fan Delay DIP Switch Settings

80 J :_¢/

(;t ,[/ L_,l

J

The Fan Control has adjustable settings for the circulating

air blower to delay it "ON" and "OFF".

1. The Fan Control has afixed "ON" delay of 30 seconds,

and a field adjustable "OFF" delay of 60, 100, 140 and

180 seconds. The "OFF" delay is factory set at 140

seconds.

Refer to Figure 16 for proper DIP switch settings.

2. Operate the furnace and ensure that the blower turns

ON and OFF at the appropriate time to provide the

desired comfort level.

10. OPERATION

ELECTRICAL SHOCK HAZARD.

1. The temperature rise must be within the specifica-

tions marked on the unit rating plate for each stage of

gas heat.

To check the temperature rise through the unit, place

thermometers in the supply and return air ducts as

close to the unit as possible.

Open ALL registers and duct dampers. Operate unit

AT LEAST 15 minutes before taking readings.

If the correct amount of temperature rise is not obtained

when operating on the recommended blower speed, it may

b2J

Failure to follow this warning could result in personal

injury or death.

Turn off electric power supply at disconnect switch or

service panel before removing any access or service

panel from unit.

TROUBLE SHOOTING

Models are factory equipped with the Comfort AlertTM

Diagnostics device (refer to Figure 17) in the control box.

Comfort AlertTM Diagnostics device provides compressor

staging from low to high and high to low capacity. Comfort

Page 19

AlertTM Diagnostics device provides around-the-clock

monitoring for common electrical problems, compressor

defects, and broad system faults.

If trouble is detected, an alert code is displayed with a

flashing LED indicator. Alert codes are listed in Figure 17.

The device is factory wired and requires no modification.

Low voltage lead wires are provided in the control box for

connection to thermostat wires (use wire nuts). The

Comfort Alert TM Diagnostics device must be powered to

properly stage compressor to high capacity. Energizing the

Y (Y1) terminal operates the compressor in low stage. Both

the Y (Y1) and Y2 terminals must be energized for

Figure 17 Comfort Alert TM Diagnostics

high?stage operation. The Comfort Alert TM Diagnostics

device device operates by monitoring the compressor

power leads and the thermostat demand signals Y (Y1) and

Y2 terminals. It draws constant 24 VAC power at the Rand

Cterminals. When the compressor is operating inlow stage

(Y or Y1), the 24v DC compressor solenoid coil is

de?energized. When the compressor is operating in high

stage 0( or Yland Y2), the 24v DC solenoid coil is

energized. The 24v

DC plug that is connected to the compressor does NOT

have an internal rectifier. DO NOT INSTALL A PLUG WITH

INTERNAL RECTIFIER.

/is/_S

COMBUSTION/INDOOR FAN CONTROL

All functions of the combustion and indoor blower are

controlled by the ignition control board and interface board.

On a call for gas heat:

The ignition control energizes the combustion blower on

high speed. Once the combustion air proving switch closes,

the ignition sequence begins. The ignition control will sense

when the main (low stage) operator of gas valve has been

energized thereby firing the burners and starting the "delay

on" timing sequence of the indoor blower. The unit will then

run in low stage gas heat or until the thermostat is satisfied,

whichever isshorter. If the thermostat is not satisfied ater 10

minutes, the unit will go to second stage gas heat and run

until the thermostat is satisfied.

NOTE: Ifthe control senses that one of the safety limits has

opened, the combustion and indoor fans will operate until

the limit resets.

On a call for cooling:

The fan interface control board starts the indoor blower on

;12;/&]l

._8 9£a,L_. :i>:!:_!]pfs:£_!f,i_:_:_.........

" _

37_S41 201 R[VA

full speed immediately or after a 30 second delay

(field-selectable). Once the thermostat is satisfied, the fan

control will operate the blower for 0or 90 additional seconds

(field-selectable).

Defrost Mode

On a call for defrost:

When the defrost sensor closes in the heating mode, there

isa 30, 60, 90 or 120 minute delay before the defrost mode

begins. This delay is selected by the position of the

dipswitches on the defrost board. Defrost interval timing

can be configured by selection switch 1 and 2 on the

dipswitch per the following table.

Switch 1 Switch 2 Time

ON OFF 30 Minutes

OFF ON 60 Minutes

OFF OFF 90 Minutes

ON ON 120 Minutes

NOTES:

L2J

Page 20

1.The backup defrost terminate time is fixed at 10

minutes.

2. The compressor recycle delay timer is 5 minutes.

3. The power interrupt response is minimum 17 msec. to

maximum 35 msec.

4. Quite shift compressor recycle delay is 30 seconds.

In normal defrost mode, the following sequence will occur

after the set delay:

1. Condenser fan off.

2. Reversing valve energized to cooling and auxiliary gas

heat (W1) is energized.

3. After defrost sensor opens or a maximum of 10

minutes; the condenser fan is energized (after 20

seconds) and the reversing valve is de-energized to

the heat mode. The call for heating is completed bythe

auxiliary gas heat. ON the next call for heat, the heat

pump will be used for heat, provided the outdoor

temperature is above the balance point.

4. Should the system indoor thermostat be satisfied

during the defrost cycle, the control will de-energize the

reversing valve and auxiliary heat outputs and "hold"

the defrost timer until the next call for heat, at which time

the defrost cycle will be completed.

Service testing: the pins marked "speed up" when

momentarilyshorted together (for 5 seconds) and released,

will defeat the 5 minutes recycle delay timer and allow the

compressor contactor to be immediately energized, thus

forcing a defrost cycle. Termination of this forced mode will

be by the defrost thermostat or the 10 minute backup timer,

provided the defrost thermostat was closed when the

defrost was "forces." If the defrost thermostat was not

closed, at the time of the "forced defrost," the defrost mode

will remain for 30 seconds and then terminate.

11. MAINTENANCE

MONTHLY MAINTENANCE AND INSPECTION

CHECKS

Air Filters

HEATING SEASON CHECKS (MONTHLY)

Main Burner Flame

Flames should be stable and solid blue, (dust may cause

orange tips or they may have wisps of yellow, but they

MUST not have solid yellow tips). They should extend

directly into the heat exchanger tubes and the turbulators

should glow orange (after about five minutes of operation).

Main burner flame should be inspected monthly.

Figure 18 1

Normal Flame

Turbulator will glow stable and solid

orange when hot. blue.

t Flame should be

Using a light and mirror (as required) inspect the inside of

the vent hood and the inlet air opening in the burner

compartment. Look for soot and severe rust or corrosion

and any obstructions due to leaves, spiderwebs, etc. Clean

as required.

COOLING SEASON CHECKS (MONTHLY)

Condenser Coil

Keep the condenser inlet and outlet area clean and free of

leaves, grass clippings or other debris. Grass should be

kept short in front of the condenser inlet. Shrubbery MUST

be trimmed back so it is no closer than 30 inches to unit.

Condensate Drain

Check for condensate drainage. Clean as required.

ANNUAL MAINTENANCE AND INSPECTION

REDUCED EQUIPMENT LIFE HAZARD

Failure to follow this cautions may result in damage to

the unit being installed.

Do not operate the unit without a filter.

Inspect filters at least monthly and replace or clean as

required. Washable filters may be cleaned by soaking in

mild detergent and rinsing with cold water. Replace filters

with the arrows on the side pointing in the direction of air

flow. Dirty filters are the most common cause of inadequate

heating or cooling performance, and of compressor

failures.

ELECTRICAL SHOCK HAZARD.

Failure to follow this warning could result in personal

injury, and/or death.

Turn off electric power supply at disconnect switch or

service panel before removing any access or service

panel from unit.

The annual inspection should include cleaning as required

to ensure efficient operation of the unit. To simplify access,

remove all access panels and the top from the unit if

possible.

Page 21

Condenser Fan Motor

Note: The condenser fan motor is permanently lubricated.

No further lubrication is required. Do not attempt to

lubricate the condenser fan motor.

VENT ASSEMBLY

BURN HAZARD.

Failure to follow this caution may result in personal

injury.

Flue cover may be hot! Allow adequate time for flue

cover to cool.

Clean the surrounding area and the condenser and

evaporator coils. Use caution to avoid damage to coil fins.

BLOWER MOTOR ACCESS

Refer to Figure 16 for a view of blower motor and

compartment.

1. Remove the blower access panel

2. Remove the three screws securing the blower motor

housing. If unit has a support bracket, remove the two

screws securing the bracket.

3. Remove the two red wires attached to the limit switch.

Motor removal and replacement

This method is required to replace or repair blower wheel,

blower housing, or any unreachable components behind

blower assembly.

1. Remove all screws around rim of unit top, (except

screws which are inaccessible because of proximity to

structure).

2. Raise unit top at corner of unit closest to blower at least

2" and place asturdy brace at least 2" thick between top

and unit corner. A 2X4 piece of wood is ideal for this.

3. Disconnect all wires from housing and slide housing out

of unit. Reverse this process to reinstall.

Circulating Air Blower

Visually inspect the blower wheel for accumulations of dirt

or lint. Clean the compartment and the blower wheel. If

accumulation is excessive on blower wheel, or does not

easily remove, it will be necessary to remove the blower

assembly.

Note: The blower motor is permanently lubricated. No

further lubrication is required. Do not attempt to lubricate

the blower motor.

Burners / Heat Exchangers / Flue Gas Passages

To inspect the burners, heat exchanger and interior flue gas

passages, use a light and small mirror on an extension

handle.

Check the exterior of the heat exchanger and the interior

flue gas passages for any evidence of deterioration due to

corrosion, cracking or other causes. If signs of scaling or

sooting exist, remove the burners and clean the heat

exchanger, as required.

INSPECTION AND CLEANING OF BURNER

ASSEMBLY/HEAT EXCHANGERS/FLUE GAS

PASSAGES

For Qualified Service Technician Only

See Figure 19 for identification of parts.

1. Disconnect electrical power to unit.

2. Turn OFF gas at manual shut off valve.

3. Remove burner access panel.

4. Remove the vent assembly flue pipe.

5. Disconnect gas pipe at union.

6. Disconnect wires from gas valve, note connections.

7. Remove screws that secure the flame shield and

remove gas control valve, manifold and burners as an

assembly.

8. Remove collector box, injector plate, and restrictor

plate, including gaskets.

9. Hold the burner assembly vertically and lightly tap it

against a wood block. Clean also with a stiff brush.

Severe cases of lint clogging may require washing the

burners in hot water.

10. Clean flue gas passages by using small brushes and a

vacuum cleaner. It may be necessary to fabricate

handle extensions for the brushes to reach the areas

that require cleaning. Reinspect after cleaning and

replace the heat exchanger if defective.

11. Reinstall parts and gaskets in reverse order. On direct

spark models check the spark gap. 1/8inch is required

between the sparker electrodes.

12. Turn gas on and check for leaks.

13. Install all access panels, turn power on and check for

normal operation.

REFRIGERANT CIRCUIT

For Qualified Service Technician Only

Annually inspect all refrigerant tubing connections and the

unit base for oil accumulations. Detecting oil generally

indicates a refrigerant leak.

FIRE AND EXPLOSION HAZARD.

Failure to follow this warning could result in personal

injury, death and/or property damage.

System under pressure. Relieve pressure and recover

all refrigerant before system repair or final unit

disposal to avoid serious injury or death. Use all

service ports and open all flow control devices,

including solenoid valves.

If oil is detected or if low cooling performance is suspected,

leak-test all refrigerant tubing using an electronic leak

detector, halide torch, or liquid-soap solution,

1211

Page 22

Figure 19 Component Locations

El /!l •

I Remote Sparker Unit I

i

....

.... [

_ IGasValveI

I Flame Sensor I

I Re,,eutSwitch]

1221

0

Selector Leads

I IFM and Speed I

I Primary LimitSwitch I

Page 23

12. Rigging Instructions

Figure 20

CO

o

o

z

0

F_

Rigging Instructions

1

z

0

Z_ c_ co

P--_ <::_ ___

L-LJ

_-- L..._ L._ co ._ _:

z --J

w _

xi

iI. ''

F--

___1

@=:7>-- _._

z

0

z

0

0

222) _

__z_

i t i i

xi

._iz:

Page 24

USE COPPER CONDUCTORS ONlY

FIELD SUPPLY IB_ Y_

_os/2soVAC "_j_l, -160HZ, /PN !I_ _BK m \,

y OFM

I

CONTACPS

o

/ ....................BR

FURNAC CON}RO BOARD

CRANKCASE BEATER

M,/vv,

J

.........................................................................................................o

DE ROST BOARD

ET_

P3

C R

B_

COMFORT A ERT BOARD

HP81 LPS

24 _ 30 S]ZE

0

Y

UN1TS ONL_

NA_UALRESEI

-R

IRANS

>

N

Pl

Y2

L2

CO_IBUSTi ONAN

PRIMARY IINIT

7f7

GAS VALVE Sl:'Ak_E_

G/_

............................. _i_:f_[ _[_ FTfi: gi_ii_ ..........................

SEE INSTALLAT!iON INSTRUCTIONS FOR PROPER HEATING AND CO0[ING CONNECTIONS FOR YOUR UNIT INDOOR FAN MOTOR PLUGS "Oo NoI O[s(onnecI Under Load"

--LINE VOLIAGE FACIORY COLOR CODE 8LAC_ B_ GREEN G WHITE W SOL = SOIENOID HPS = HIGN PRESSURESWITCN

LOW VOLTAGEFIELD BLUE BL ORANGE 0 YF!LOW Y CAP : CAPACITOR LPS : LOWPRESSURESWITCN

LOW VOLIAGE fACTORY

_LIRR VOI/AGE[]EII) PRI :: PRIMARY DPT :D[FROST

INTERNAl C]RCUII GRAY GY VIOLET V SEC : SECONDARY CON1: CONFINUOUS

BOARD WIRING P!NN P GRN & TEL G/Y _N : DEHUMIDIFIER • : WIRE SPLICE

BROWN BR RED R iEN : INDOORFAN MOTOR CAB : COM_ORTALERT BOARD

6/T

ROLLOUTLiMlr

PRESSURESW[TCN

R

2b-

COMP: COMPRESSOR O_N : OUTDOORFAN_()TOR

CB : CIRCUIT BREAKER LLS : LIQUID LINE SOLENO!t

8CB : FURNACECONTROLBOARD LGPS : lOW GAS PRESSURESWIICN

P7

L_

IFM

Page 25

All Models Wiring Diagram

L/\}[}/R W/I:R}N{} DIAG/i/\M

L1

11( )

USE COPPERCONDUCTORSONLY G/'Y

BK FIE [) SUPP Y ....|

208/250 VAC, 60 PZ, P/!

CONTACTS

81 CRANKCASE HEATER 23 CONTACTS

CAP t_ --

S @C2_d2_E_ _R @ ¢A8

!

2

LOW

VOL]AGE

IERM]NAT[ON

RQ

0 0

_'_

w20

B_

D}MO

DC

MOTOR

R

0

TB2,00 _

Y

Tt2, Y/ 0

..................BY........

W

f_s©

6

BK

O

I1

P23 ,,,_

RVS C

,y_

,12

112

}COM,FCB

BR

P22

TAP

SELECT

INTERFACE

BOARD

P1 !O,FCB

CAB

v20 .....

LO

cO

_R

FCB, 24

COMIFCB

P7

}ANG:IR _!EC1RICAI SIIOCK IIAZA/I) D]SCONNEC1 /OW_:R }I Ol::/{ SEI::/V!C]NG 50CY501710 5 2

Loading...

Loading...