ICP PAPC42GA1, PAPC36GA1, PAPC30GA1, PAPC24GA1, PAPA48GA1 Owner’s Manual

...

Installation Instructions

I DIRECT DRIVE BLOWER

PA95/PAPC

PA55/PAPA SERI ES

SINGLEPACKAGEAIRCONDITIONERS

ELECTRICCOOL/

ELECTRICHEAT(OPTIONAL)c

TABLEOFCONTENTS

1. Safety Labeling and Signal Words .......................... 2

Danger,Warning and Caution .................................... 2

2. Safe Installation Requirements ....................... 2

3. Locating The Unit .................................. 2

Clearances ............................................... 2

Dimensions................................................... 2

MinimumClearancesto CombustibleConstruction..................... 3

Installation ................................................... 3

InstallingDuctCollars ........................................ 3

CondensateDrain ............................................. 4

4. Electrical Wiring .................................... 4

Ground Connections........................................... 4

LineVoltageWiring ............................................. 4

Unit Disconnect ............................................... 4

Converting230V Unitsto 208V .................................... 4

LowVoltageWiring ............................................ 4

ThermostatConnections......................................... 5

FieldInstalledEquipment ........................................ 5

5. Electric Heat Installation ............................. 6

GeneralInformation ................................ 6

AdjustingTherrnostatAnticipator ................................. 6

UmitControls .............................................. 6

TimeDelayOperation ................................... 6

Staging .................................................. 6

InstallHeater ................................................. 6

HeaterWiring ........................................... 6

Grounding ................................................ 6

InstallingWiring .......................................... 7

Unit DisconnectBreaker ......................................... 8

RainShield Installation ......................................... 8

6. Air Distribution System .............................. 9

Ductwork .................................................... 9

DuctworkInsulation ............................................ 9

DuctwotkConnections.......................................... 9

Fi_ers .............................. 9

7. Start-up Procedures ............................... 10

FinalElectricalCheck ................ 10

CirculaUngAirBlower .......................................... 10

Determining8_owerSpeed.......... 10

Steed Taos ............................ 10

Cooling andAuxiliary Electric Strip Heat ............................ tO

CheckBeforeStarting ...................... 10

CirculatingAir Blower ..................... 11

Cooling ................................................... 11

AuxiliaryHeating ......................... 11

TemperatureRiseCheck ..................... 11

SequenceofOperation ......................................... tt

CoolingMode:Energized(R,G,Yt_ De-energized_N/At................ 11

8. Operation .......................................... 11

Scroll Acti- Cycle Timer(Where Applicable}.......................... 11

TurningTheUnit Off ....................... 12

ThermostatFan SwitchOperation ................................. 12

AdjustingRoomTemperatures ...... 12

13. Maintenance .................................. 12

MonthlyMaintenanceandInspectionChecks ........................ 12

Air Filters ................................................ 12

CoolingSeasonChecks(Monthly)................................. 12

CondenserCoil ........................................... 12

CondensateDrain............................................ 12

AnnualMaintenance and Inspection ............................... 12

Condense"FanMotor ......................................... 12

CirculatingAir Blower ......................................... 12

Printed in U.S.A. 426 011001 02

2/20/96

1. Safetv Labelinq and Siflnal Words

Danger,Warningand Caution

ThesignalwordsDANGER,WARNINGandCAUTIONareusedtoidentifylevelsofhaz-

ard seriousness.The signalword DANGERis onlyusedon productlabelsto signify an

immediatehazard.The signalwords WARNINGandCAUTIONwill beused on product

labelsandthroughoutthis manualand othermanualsthat mayapplyto the product.

2. Safe Installation Requirem ents

Installation or repairs made by unqualified persons can result

in hazards to you and others. Installation MUST conform with

local building codes or, in the absence of local codes, with the

National Electrical Code NFPA70-1990 or current edition.

The information contained in this manual is intended for use

by a qualified service technician familiar with safety proce-

dures and equipped with the proper tools and test instru-

ments.

Failure to carefully read and follow all instructions in this

manual can result in unit malfunction, property damage, per-

sonal injury and/or death.

• Seal supply and return air ducts.

• Check to see that filters are installed correctly and are the proper

type and size.

NOTE:It isthepersonalresponsibilityandobligationofthecustomertocontactaqualified

installerto ensurethat theinstallationisadequateand conformsto governingcodesand

ordinances.

CAUTION

Do NOToperate unit in a corrosive atmosphere containing chlorine,

fluorine, or any other corrosive chemicals.

3. Locatinq & Installinq The Unit

The unitis designedfor outdoorinstallationonly.Placethe unit on a platformatground

level. The unitmay be installedon a concreteslabof 48" (1219mm)x 48" (1219mm)

dimensions. Cement blocks on a 3" sand footing willalso work. The slabor blocks

SHOULDNOT bein contactwith any partofthe structure. Checklocalcodescovering

zoning,noise, platforms,etc..

Ifpracticalavoid locatingnexttofreshair intakes,ventorbedroomwindows. Noisemay

carryintotheopeningsand disturbpeopleinside.

Avoid installationsunderroof overhangswithoutguttering. Waterdrainingfromthe roof

ontotheunitcould produceexcessivenoise,andmaycauseicetobuildupon coil orfan.

Placementoftheunitshouldbe ina welldrainedareaortheunit MUSTbesupportedhigh

enoughso runoffwillnotenter the unit.

Do not locate unitwhereheat, lint orexhaustfumeswill bedischargedon unit (asfrom

dryervents.)

Clearances

Minimum clearances,as specified in FIGURE1, MUSTbe maintainedfrom adjacent

structuresto provideadequateaircirculationand roomforservice personnel.

While minimumclearancesare acceptablefor safetyreasons,theymay not allowade-

quateaircirculationaroundtheunitforproperoperation.Wheneverpossible,itisdesirable

toallow additionalclearance,especiallyaroundthe condenserinletand dischargeopen-

ings.

Do NOTinstallthe unitin arecessedorconfinedareathat will permitdischargedairfrom

thecondensertorecirculatetothe condenserinlet.

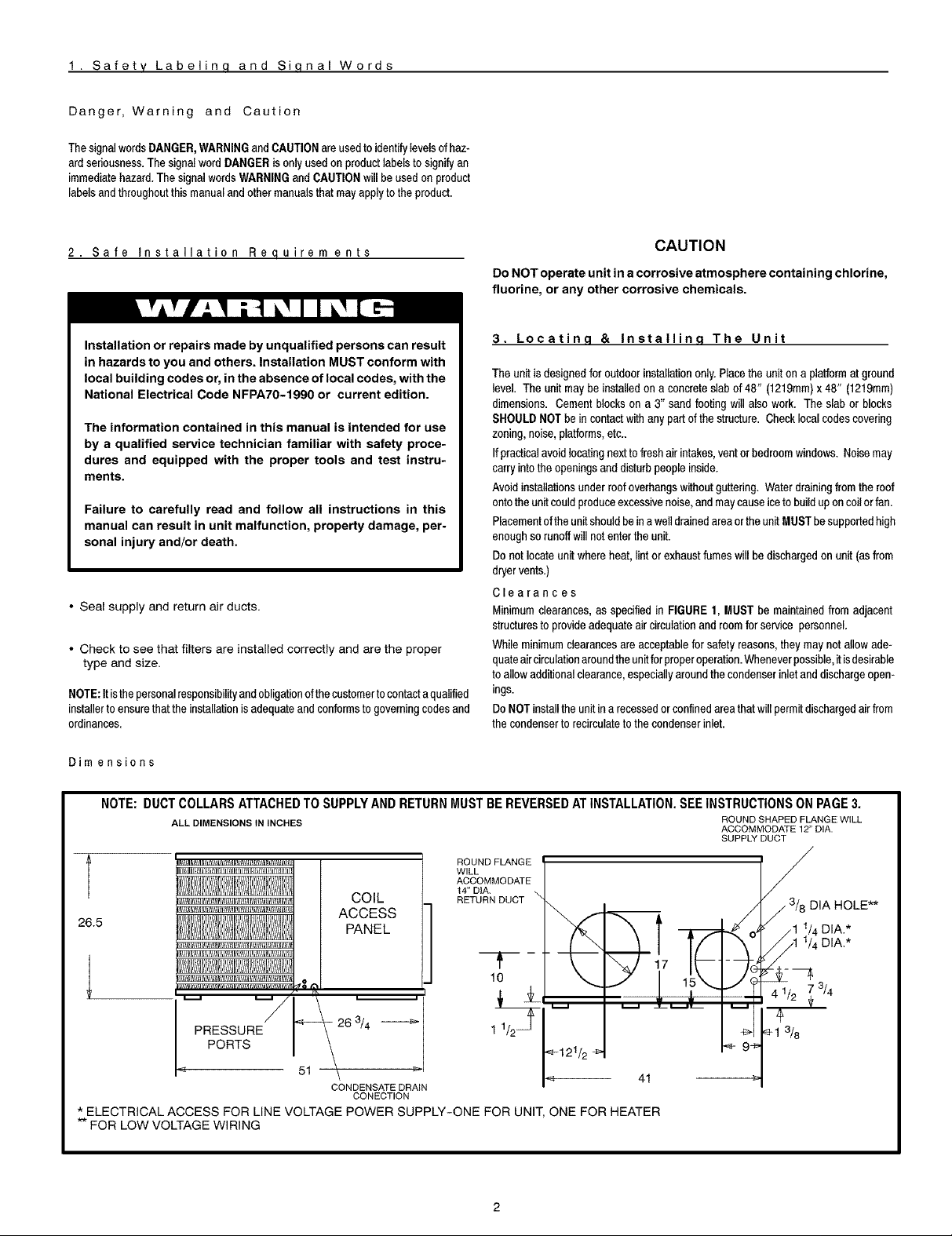

Dimensions

NOTE: DUCT COLLARS ATTACHED TO SUPPLY AND RETURN MUST BE REVERSED AT INSTALLATION. SEE INSTRUCTIONS ON PAGE 3.

ALL DIMENSIONS IN iNCHES ROUND SHAPED FLANGE WiLL

ROUND FLANGE

WILL

t

COIL

26.5

* ELECTRICAL ACCESS FOR LINE VOLTAGE POWER SUPPLY-ONE FOR UNIT, ONE FOR HEATER

** FOR LOW VOLTAGE WIRING

ACCESS

PANEL

\ 41

CONDENSATE DRAIN

CONECTION

ACCOMMODATE

14_ DIA.

RETURN DUCT

T m

10

ACCOMMODATE 12" DIA.

SUPPLY DUCT

DIA HOLE**

_/4 DIA.*

_/4 DIA.*

3/4

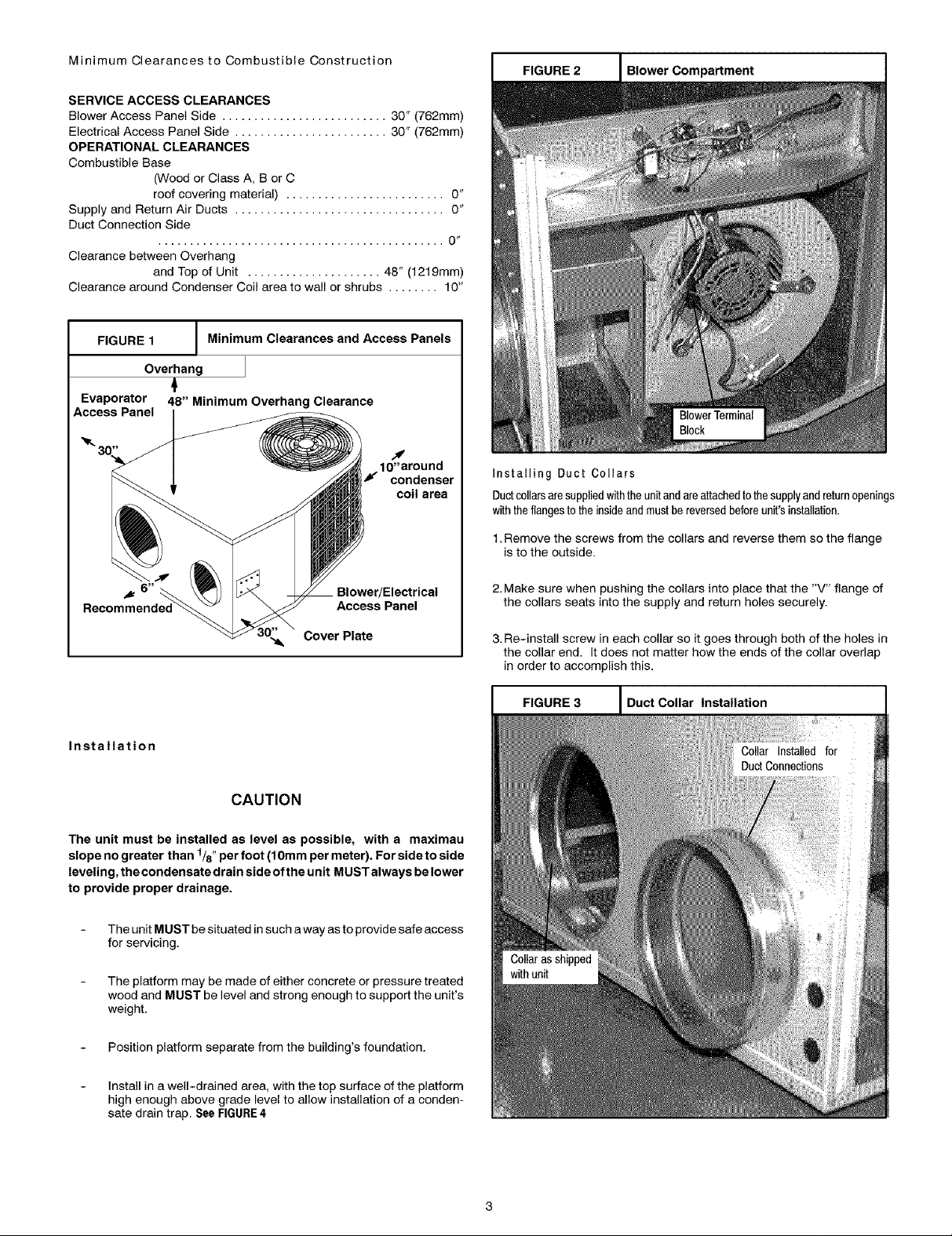

Minimum Clearances to Combustible Construction

SERVICE ACCESS CLEARANCES

Blower Access Panel Side .......................... 30" (762mm)

Electrical Access Panel Side ........................ 30" (762mm)

OPERATIONAL CLEARANCES

Combustible Base

(Wood or Class A, B or C

roof covering material) ......................... 0"

Supply and Return Air Ducts ................................. 0"

Duct Connection Side

Clearance between Overhang

and Top of Unit ..................... 48" (1219mm)

Clearance around Condenser Coil area to wall or shrubs ........ 10"

FIGURE 2 Blower Compartment

FIGURE 1

Overhang

Evaporator 48" Minimum Overhang Clearance

Access Panel

6" Blower/Electrical

Installation

I Minimum Clearances and Access Panels

I

Cover Plate

I

f 10"around

condenser

coil area

Access Panel

Installing Duct Collars

Ductcollarsaresuppliedwiththeunitand areattachedtothesupplyandreturnopenings

withthe flanges to theinsideand mustbe reversedbeforeunit'sinstallation.

1.Remove the screws from the collars and reverse them so the flange

isto the outside.

2. Make sure when pushing the collars into place that the "V" flange of

the collars seats into the supply and return holes securely.

3. Re-install screw in each collar so it goes through both of the holes in

the collar end. It does not matter how the ends of the collar overlap

in order to accomplish this.

FIGURE 3 I Duct Collar Installation I

CAUTION

The unit must be installed as level as possible, with a maximau

slope no greater than 1/8" per foot (10mm per meter). For side to side

leveling, the condensate drain side of the unit MUST always be lower

to provide proper drainage.

The unit MUST be situated in such a way as to provide safe access

for servicing.

The platform may be made of either concrete or pressure treated

wood and MUST be level and strong enough to support the unit's

weight.

Position platform separate from the building's foundation.

install in a well-drained area, with the top surface of the platform

high enough above grade level to allow installation of a conden-

sate drain trap. See FIGURE4

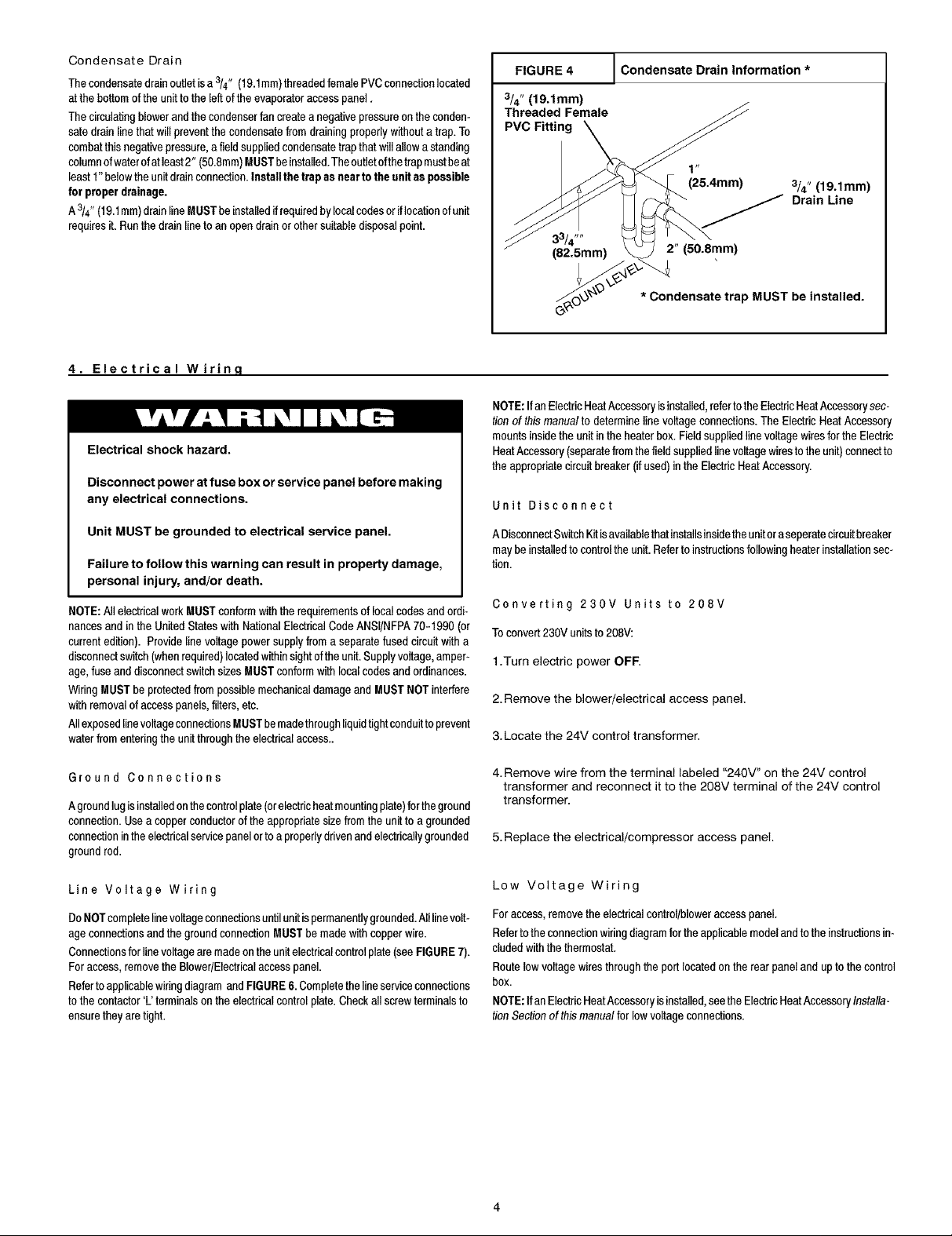

CondensateDrain

Thecondensatedrainoutletisa 314" (19.1mm)threadedfemalePVCconnectionlocated

atthe bottom of theunittothe leftof the evaporatoraccesspanel.

Thecirculatingblowerandthe condenserfancreatea negativepressureonthe conden-

satedrain linethat will preventthe condensatefromdrainingproperlywithouta trap. To

combatthisnegativepressure,afield suppliedcondensatetrapthat willallow astanding

columnofwaterof atleast2" (50.8mm)MUSTbeinstalled.Theoutletofthetrap mustbeat

least1"belowthe unitdrainconnection.Install the trapas nearto theunit as possible

for properdrainage.

A3/4" (19.1mm)drainline MUSTbe installedifrequiredbylocalcodesor iflocationof unit

requiresit. Runthe drainlineto an open drainor othersuitabledisposalpoint.

4. Electrical Wirinq

Electrical shock hazard.

Disconnect power at fuse box or service panel before making

any electrical connections.

FIGURE 4

3/4" (19.1mm)

Threaded Female

PVC Fitting

33/4 ""

(82.5mm) 2" (50.8mm)

_,_kv * Condensate trap MUST be installed.

NOTE:If an ElectricHeatAccessoryisinstalled,refertotheElectricHeatAccessorysec-

tion of thismanual to determinelinevoltage connections.The ElectricHeatAccessory

mountsinsidethe unitin the heaterbox.Fieldsuppliedlinevoltage wiresfor the Electric

HeatAccessory(separatefromthe fieldsuppliedlinevoltagewirestothe unit)connectto

theappropriatecircuitbreaker (ifused)in the ElectricHeatAccessory.

Unit Disconnect

Condensate Drain Information *

1"

(25.4mm)

3/4" (19.1mm)

Drain Line

Unit MUST be grounded to electrical service panel.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

NOTE:All electricalworkMUST conformwith therequirementsof localcodesandordi-

nancesand in the UnitedStates with NationalElectricalCodeANSI/NFPA70-1990 (or

currentedition). Provide linevoltagepowersupplyfrom aseparatefused circuitwitha

disconnectswitch(whenrequired)locatedwithinsight ofthe unit.Supplyvoltage,amper-

age,fuseanddisconnectswitchsizesMUST conformwithlocalcodes and ordinances.

WiringMUSTbe protectedfrompossiblemechanicaldamageand MUSTNOT interfere

with removalofaccesspanels,filters,etc.

AllexposedlinevoltageconnectionsMUSTbemadethroughliquidtightconduittoprevent

waterfromenteringthe unitthroughthe electricalaccess..

Ground Connections

Agroundlugisinstalledonthecontrolplate(orelectricheatmountingplate)for theground

connection.Use acopperconductorofthe appropriatesizefromthe unitto a grounded

connectionintheelectricalservicepanelortoa properlydrivenandelectricallygrounded

groundrod.

Line Voltage Wiring

DoNOTcompletelinevoltageconnectionsuntilunitispermanentlygrounded.Alllinevolt-

ageconnectionsand thegroundconnectionMUSTbemade withcopper wire.

Connectionsfor linevoltagearemadeonthe unitelectricalcontrolplate(seeFIGURE7).

For access,removethe Blower/Electricalaccesspanel.

Refertoapplicablewiringdiagram andFIGURE6. Completetheline serviceconnections

tothe contactor'L' terminalson the electricalcontrol plate.Checkall screwterminalsto

ensuretheyare tight.

ADisconnectSwitchKitisavailablethatinstallsinsidetheunitoraseperatecircuitbreaker

maybeinstalledtocontrolthe unit.Refertoinstructionsfollowingheaterinstallationsec*

tion.

Converting 230V Units to 208V

Toconvert230V unitsto 208V:

1.Turn electric power OFF.

2. Remove the blower/electrical access panel.

3. Locate the 24V control transformer.

4. Remove wire from the terminal labeled "240V" on the 24V control

transformer and reconnect it to the 208V terminal of the 24V control

transformer.

5. Replace the electrical/compressor access panel.

Low Voltage Wiring

For access,removethe electricalcontrol/bloweraccesspanel.

Refertothe connectionwiringdiagramfortheapplicablemodelandto the instructionsin-

cludedwith the thermostat.

Routelow voltagewiresthroughthe portlocatedon the rearpaneland upto thecontrol

box.

NOTE:If an ElectricHeatAccessoryisinstalled,seetheElectricHeatAccessoryInstalla-

tion Sectionof thismanualfor lowvoltage connections.

Loading...

Loading...