Page 1

Installation Instructions

I DIRECT DRIVE BLOWER

PA95/PAPC

PA55/PAPA SERI ES

SINGLEPACKAGEAIRCONDITIONERS

ELECTRICCOOL/

ELECTRICHEAT(OPTIONAL)c

TABLEOFCONTENTS

1. Safety Labeling and Signal Words .......................... 2

Danger,Warningand Caution .................................... 2

2. Safe Installation Requirements ....................... 2

3. Locating The Unit .................................. 2

Clearances ............................................... 2

Dimensions................................................... 2

MinimumClearancesto CombustibleConstruction..................... 3

Installation ................................................... 3

InstallingDuctCollars ........................................ 3

CondensateDrain ............................................. 4

4. Electrical Wiring .................................... 4

Ground Connections........................................... 4

LineVoltageWiring ............................................. 4

Unit Disconnect ............................................... 4

Converting230V Unitsto 208V .................................... 4

LowVoltageWiring ............................................ 4

ThermostatConnections......................................... 5

FieldInstalledEquipment ........................................ 5

5. Electric Heat Installation ............................. 6

GeneralInformation ................................ 6

AdjustingTherrnostatAnticipator ................................. 6

UmitControls .............................................. 6

TimeDelayOperation ................................... 6

Staging .................................................. 6

InstallHeater ................................................. 6

HeaterWiring ........................................... 6

Grounding ................................................ 6

InstallingWiring .......................................... 7

Unit DisconnectBreaker ......................................... 8

RainShield Installation ......................................... 8

6. Air Distribution System .............................. 9

Ductwork .................................................... 9

DuctworkInsulation ............................................ 9

DuctwotkConnections.......................................... 9

Fi_ers .............................. 9

7. Start-up Procedures ............................... 10

FinalElectricalCheck ................ 10

CirculaUngAirBlower .......................................... 10

Determining8_owerSpeed.......... 10

Steed Taos ............................ 10

Cooling andAuxiliary Electric Strip Heat ............................ tO

CheckBeforeStarting ...................... 10

CirculatingAir Blower ..................... 11

Cooling ................................................... 11

AuxiliaryHeating ......................... 11

TemperatureRiseCheck ..................... 11

SequenceofOperation ......................................... tt

CoolingMode:Energized(R,G,Yt_ De-energized_N/At................ 11

8. Operation .......................................... 11

Scroll Acti- Cycle Timer(WhereApplicable}.......................... 11

TurningTheUnit Off ....................... 12

ThermostatFan SwitchOperation ................................. 12

AdjustingRoomTemperatures ...... 12

13. Maintenance .................................. 12

MonthlyMaintenanceandInspectionChecks ........................ 12

Air Filters ................................................ 12

CoolingSeasonChecks(Monthly)................................. 12

CondenserCoil ........................................... 12

CondensateDrain............................................ 12

AnnualMaintenanceand Inspection ............................... 12

Condense"FanMotor ......................................... 12

CirculatingAir Blower ......................................... 12

Printed in U.S.A. 426 011001 02

2/20/96

Page 2

1. Safetv Labelinq and Siflnal Words

Danger,Warningand Caution

ThesignalwordsDANGER,WARNINGandCAUTIONareusedtoidentifylevelsofhaz-

ard seriousness.The signalword DANGERis onlyusedon productlabelsto signifyan

immediatehazard.The signalwords WARNINGandCAUTIONwill beused on product

labelsandthroughoutthis manualand othermanualsthat mayapplyto the product.

2. Safe Installation Requirem ents

CAUTION

Do NOToperate unit in a corrosive atmosphere containing chlorine,

fluorine, or any other corrosive chemicals.

Installation or repairs made by unqualified persons can result

in hazards to you and others. Installation MUST conform with

local building codes or, in the absence of local codes, with the

National Electrical Code NFPA70-1990 or current edition.

The information contained in this manual is intended for use

by a qualified service technician familiar with safety proce-

dures and equipped with the proper tools and test instru-

ments.

Failure to carefully read and follow all instructions in this

manual can result in unit malfunction, property damage, per-

sonal injury and/or death.

• Seal supply and return air ducts.

• Check to see that filters are installed correctly and are the proper

type and size.

NOTE:It isthepersonalresponsibilityandobligationofthecustomertocontactaqualified

installerto ensurethat theinstallationisadequateand conformsto governingcodesand

ordinances.

3. Locatinq & Installinq The Unit

The unitis designedfor outdoorinstallationonly.Placetheunit ona platformat ground

level. The unitmay be installedon a concreteslab of 48" (1219mm)x 48" (1219mm)

dimensions. Cement blocks on a 3" sand footing willalso work. The slab or blocks

SHOULDNOT bein contactwith any partofthe structure. Checklocalcodescovering

zoning,noise, platforms,etc..

Ifpracticalavoid locatingnexttofreshair intakes,ventorbedroomwindows. Noisemay

carryintotheopeningsand disturbpeopleinside.

Avoid installationsunderroof overhangswithoutguttering. Waterdrainingfromthe roof

ontotheunitcould produceexcessivenoise,andmaycauseicetobuildupon coil orfan.

Placementoftheunitshouldbe inawelldrainedareaortheunit MUSTbesupportedhigh

enoughso runoffwillnotenterthe unit.

Do not locate unitwhereheat, lint orexhaustfumeswill bedischargedon unit (asfrom

dryervents.)

Clearances

Minimum clearances,as specified in FIGURE1, MUSTbe maintainedfrom adjacent

structuresto provideadequateaircirculationand roomfor service personnel.

While minimumclearancesare acceptablefor safetyreasons,theymay not allowade-

quateaircirculationaroundtheunitforproperoperation.Wheneverpossible,itisdesirable

toallow additionalclearance,especiallyaroundthe condenserinletand dischargeopen-

ings.

Do NOTinstallthe unitin arecessedorconfinedareathat will permitdischargedairfrom

thecondensertorecirculatetothe condenserinlet.

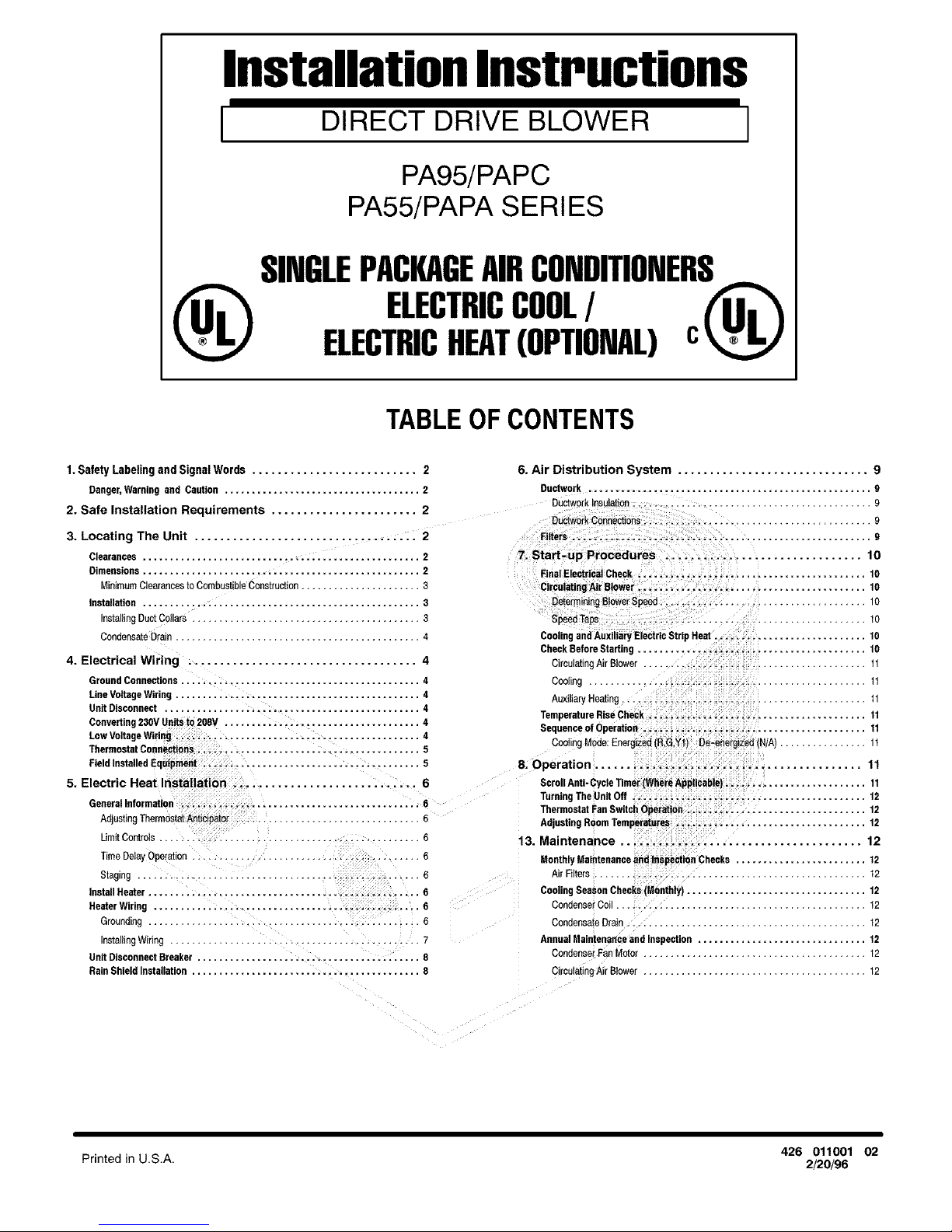

Dimensions

NOTE: DUCT COLLARS ATTACHED TO SUPPLY AND RETURN MUST BE REVERSED AT INSTALLATION. SEE INSTRUCTIONS ON PAGE 3.

ALL DIMENSIONS IN iNCHES ROUND SHAPED FLANGE WiLL

ACCOMMODATE 12" DIA.

SUPPLY DUCT

t

26.5

COIL

ACCESS

PANEL

ROUND FLANGE

WILL

ACCOMMODATE

14_ DIA.

RETURN DUCT

T m

10

\ 41

CONDENSATE DRAIN

CONECTION

* ELECTRICAL ACCESS FOR LINE VOLTAGE POWER SUPPLY-ONE FOR UNIT, ONE FOR HEATER

** FOR LOW VOLTAGE WIRING

DIA HOLE**

_/4 DIA.*

_/4 DIA.*

3/4

Page 3

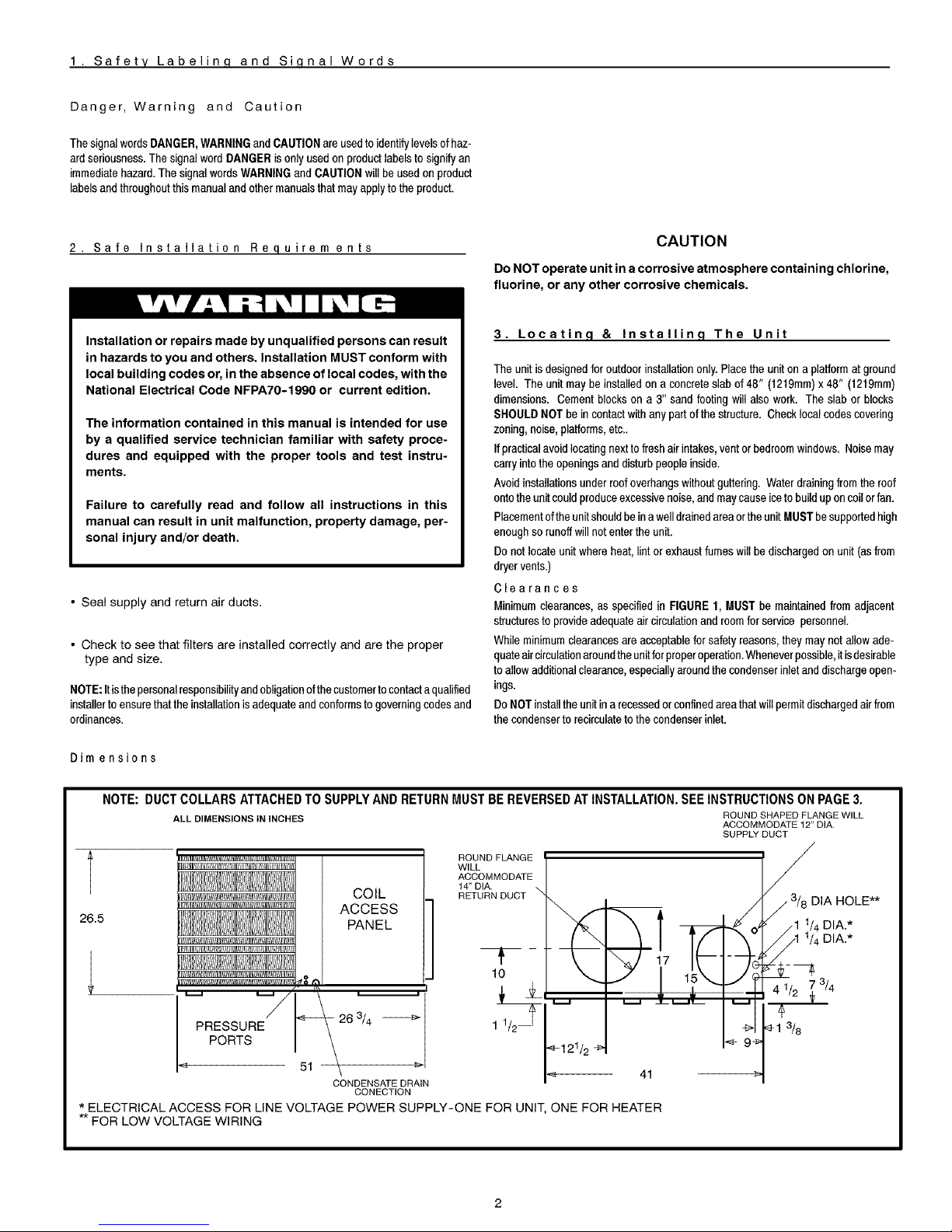

Minimum Clearances to Combustible Construction

SERVICE ACCESS CLEARANCES

Blower Access Panel Side .......................... 30" (762mm)

Electrical Access Panel Side ........................ 30" (762mm)

OPERATIONAL CLEARANCES

Combustible Base

(Wood or Class A, B or C

roof covering material) ......................... 0"

Supply and Return Air Ducts ................................. 0"

Duct Connection Side

Clearance between Overhang

and Top of Unit ..................... 48" (1219mm)

Clearance around Condenser Coil area to wall or shrubs ........ 10"

I

FIGURE 1

I Minimum Clearances and Access Panels

I

Overhang

Evaporator 48" Minimum Overhang Clearance

Access Panel

f 10"around

condenser

coil area

6" Blower/Electrical

Access Panel

Cover Plate

Installation

CAUTION

The unit must be installed as level as possible, with a maximau

slope no greater than 1/8" per foot (10mm per meter). For side to side

leveling, the condensate drain side of the unit MUST always be lower

to provide proper drainage.

The unit MUST be situated in such away as to provide safe access

for servicing.

The platform may be made of either concrete or pressure treated

wood and MUST be level and strong enough to support the unit's

weight.

Position platform separate from the building's foundation.

install in a well-drained area, with the top surface of the platform

high enough above grade level to allow installation of a conden-

sate drain trap. See FIGURE4

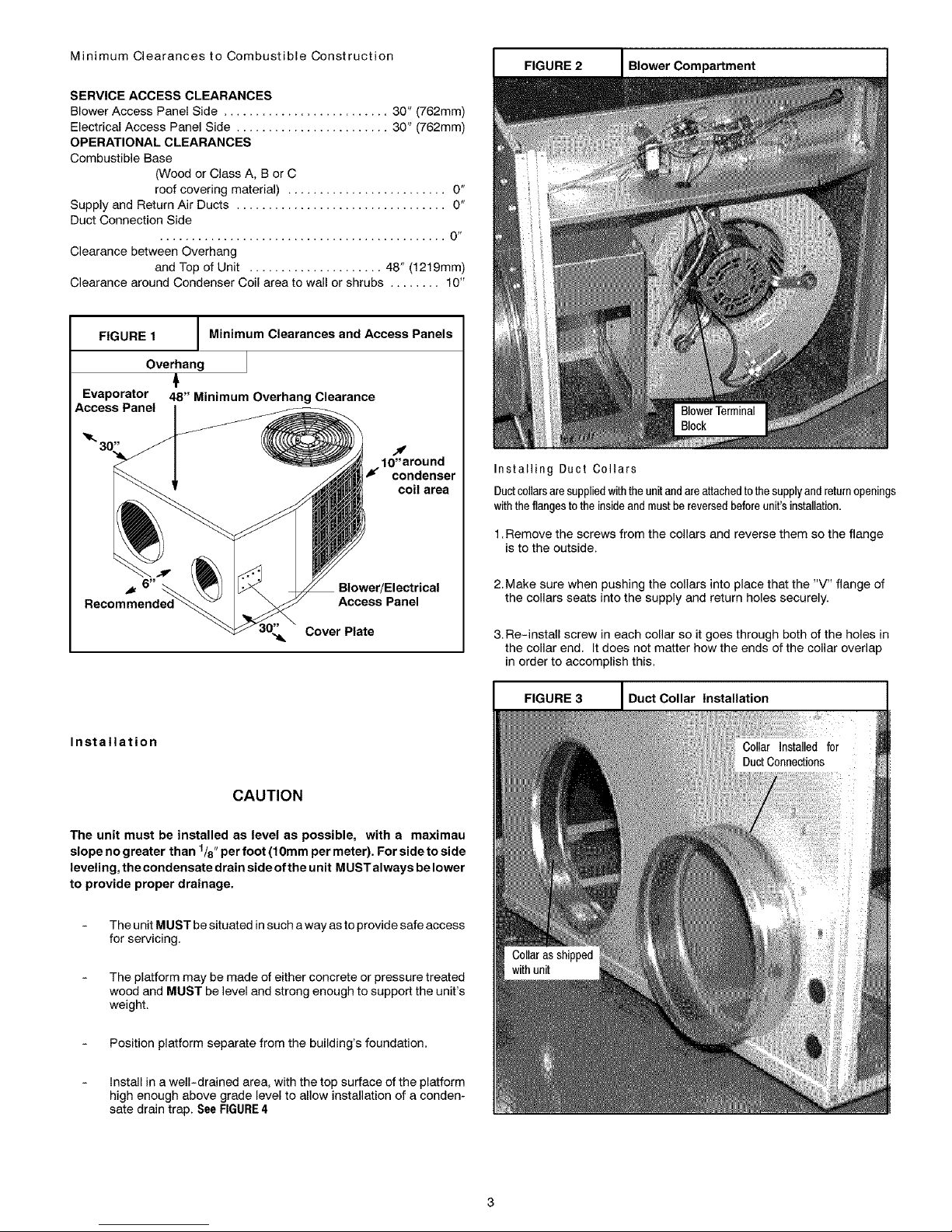

FIGURE 2 Blower Compartment

Installing Duct Collars

Ductcollarsaresuppliedwiththe unitand areattachedtothesupplyandreturnopenings

withthe flanges to theinsideand mustbe reversedbeforeunit'sinstallation.

1.Remove the screws from the collars and reverse them so the flange

isto the outside.

2. Make sure when pushing the collars into place that the "V" flange of

the collars seats into the supply and return holes securely.

3. Re-install screw in each collar so it goes through both of the holes in

the collar end. It does not matter how the ends of the collar overlap

in order to accomplish this.

FIGURE 3 I Duct Collar Installation I

Page 4

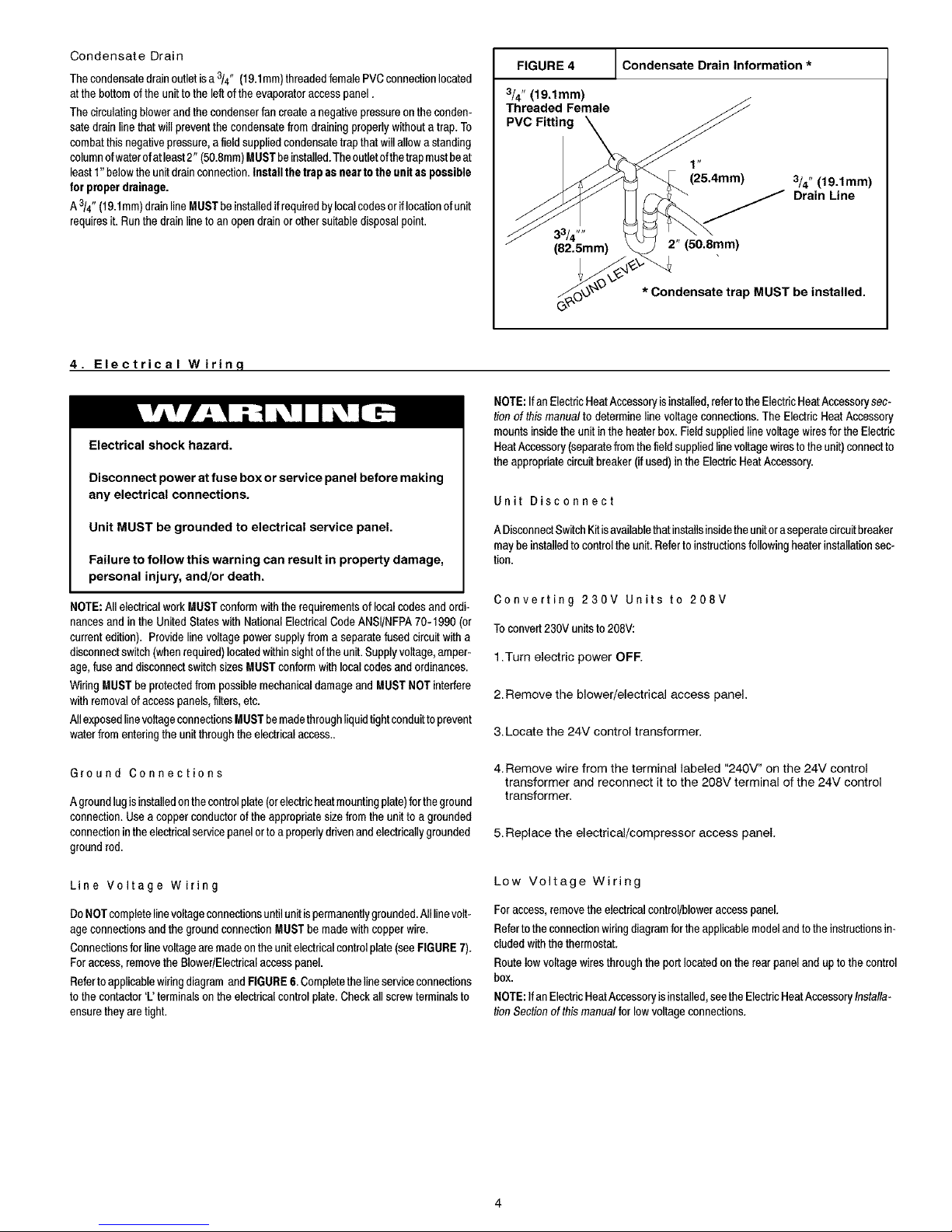

CondensateDrain

Thecondensatedrainoutletisa 314" (19.1mm)threadedfemalePVCconnectionlocated

atthe bottom of theunittothe leftof theevaporatoraccesspanel.

Thecirculatingblowerandthe condenserfancreatea negativepressureonthe conden-

satedrain linethat will preventthe condensatefromdrainingproperlywithouta trap.To

combatthisnegativepressure,afield suppliedcondensatetrapthat willallow astanding

columnofwaterofat least2" (50.8mm)MUSTbeinstalled.Theoutletofthetrapmustbeat

least1"belowthe unitdrainconnection.Install thetrapas nearto theunit aspossible

for properdrainage.

A3/4" (19.1mm)drainline MUSTbe installedifrequiredbylocalcodesor iflocationof unit

requiresit. Runthe drainlineto an open drainor othersuitabledisposalpoint.

FIGURE 4

3/4" (19.1mm)

Threaded Female

PVC Fitting

Condensate Drain Information *

1"

(25.4mm)

3/4" (19.1mm)

Drain Line

33/4 ""

(82.5mm) 2" (50.8mm)

_,_kv * Condensate trap MUST be installed.

4. Electrical Wirinq

Electrical shock hazard.

Disconnect power at fuse box or service panel before making

any electrical connections.

Unit MUST be grounded to electrical service panel.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

NOTE:All electricalworkMUST conformwiththerequirementsof localcodesandordi-

nancesand in the UnitedStates with NationalElectricalCodeANSI/NFPA70-1990 (or

currentedition). Provide linevoltagepowersupplyfrom aseparatefused circuitwitha

disconnectswitch(whenrequired)locatedwithinsight ofthe unit.Supplyvoltage,amper-

age,fuseanddisconnectswitchsizesMUST conformwithlocalcodes and ordinances.

WiringMUSTbe protectedfrompossiblemechanicaldamageandMUSTNOT interfere

with removalofaccesspanels,filters,etc.

AllexposedlinevoltageconnectionsMUSTbemadethroughliquidtightconduittoprevent

waterfromenteringthe unitthroughthe electricalaccess..

Ground Connections

Agroundlugisinstalledonthecontrolplate(orelectricheatmountingplate)fortheground

connection.Use acopperconductorofthe appropriatesizefromthe unitto a grounded

connectionintheelectricalservicepanelortoa properlydrivenandelectricallygrounded

groundrod.

Line Voltage Wiring

DoNOTcompletelinevoltageconnectionsuntilunitispermanentlygrounded.Alllinevolt-

ageconnectionsandthegroundconnectionMUSTbemade withcopper wire.

Connectionsfor linevoltagearemadeon the unitelectricalcontrolplate(seeFIGURE7).

For access,removethe Blower/Electricalaccesspanel.

Refertoapplicablewiringdiagram andFIGURE6. Completetheline serviceconnections

tothe contactor'L' terminalson theelectricalcontrolplate.Check allscrewterminalsto

ensuretheyare tight.

NOTE:If an ElectricHeatAccessoryisinstalled,refertotheElectricHeatAccessorysec-

tion of thismanual to determinelinevoltage connections.The ElectricHeat Accessory

mountsinsidethe unitin the heater box.FieldsuppliedlinevoltagewiresfortheElectric

HeatAccessory(separatefromthe fieldsuppliedlinevoltagewirestothe unit)connectto

theappropriatecircuitbreaker (ifused)in the ElectricHeatAccessory.

Unit Disconnect

ADisconnectSwitchKitisavailablethatinstallsinsidetheunitoraseperatecircuitbreaker

maybeinstalledtocontrolthe unit.Refertoinstructionsfollowingheaterinstallationsec*

tion.

Converting 230V Units to 208V

Toconvert230V unitsto 208V:

1.Turn electric power OFF.

2. Remove the blower/electrical access panel.

3. Locate the 24V control transformer.

4. Remove wire from the terminal labeled "240V" on the 24V control

transformer and reconnect it to the 208V terminal of the 24V control

transformer.

5. Replace the electrical/compressor access panel.

Low Voltage Wiring

For access,removethe electricalcontrol/bloweraccesspanel.

Refertothe connectionwiringdiagramfortheapplicablemodelandtothe instructionsin-

cludedwith the thermostat.

Routelowvoltagewiresthroughthe port locatedon the rearpaneland upto thecontrol

box.

NOTE:If an ElectricHeatAccessoryisinstalled,seetheElectricHeatAccessoryInstalla-

tion Sectionof thismanualfor lowvoltage connections.

Page 5

ThermostatConnections

Thelocationofthethermostathasanimportanteffectontheoperationofthe unit.Seethe

thermostatinstructionsfor properconnection. See FIGURE5for LowVoltageWireHar-

nessConnections

Field Installed Equipment

Wiringtobedoneinthefieldbetweentheunitandotherdevices,or betweenseparatede-

viceswhicharefieldinstalledandlocated,MUSTNOTexceedthetemperaturelimitations

fortypeT wireandMUSTbeinstalledaccordingtothemanufacturer'sinstructionsforthe

devices.

J Electronic Thermostat Low Voltage Wiring

FIGURE 5 Harness Connection Diagram

Typical Thermostat Subbase

[,q [?] [R,]

I I I I I

I I I I I

, = = , (when used)

I I I I I

i i , , [W'h

[Blue] [Green] [Red] [Yellow] ite]

Com Fan 24V Comp Elect.

(when Cool Heat

used) Acces.

Unit Low Voltage Wiring Harness.

FIGURE 6 J Typical Connections at Unit

"F_'I

I

II

II

aCT I '

I I

I I

I

I

USE CO PPER CONDUCTORS ONLY

208/Z30V 60HZ 7PH

I

I

I

I

I

] • I

J

F _ 3 1

'1 K_ I I\ I

' -_ I I 'l'' I_

I BL I J GND L__ R__/_R

I

L=BL

THERMOSTAT

OONNEOTION£

FIGURE 7 J Control Box Configuration

Blower

Relay or

Sequencer

Transformer

\

Anti-Cycle Time

(If Used)

Capacitor

Ground lug,

Contactor

Component Wire

Opening

Control Box

Line Volt Wire Entrance

Low Volt

Page 6

5. Electric Heat Installation

General Information

Adjusting Thermostat Anticipator

Set theheat anticipatorofthe thermostattothe propervalue.See instructionsprovided

with thethermostatbeforemakingthis adjustment.

ModelNumber AnticipatorSettin_l

AMMK05AHBIA .18

AMM F,U/API_tA ,;Jb

.._IVl IVli% I U,_,I'ID/P_ .,.lt_

^_AHV4c^t _ntA ,_

A_A_I _OI'_AWRIA _A

Limit Controls

Thelimitcontrolsaremountedonthefaceoftheheaterandarewiredintothesupplywires

toeachelement. If thereis notenoughair flowthroughthe heater,the limitwillopenand

breakthe powercircuit. The limitwillresetwhenthe electricaccessorycoolsdown.

Time Delay Operation

TheheaterelementsareswitchedON andOFFthroughoneormore controlswhichoper-

atethroughthe lowvoltagethermostatcircuit.

Thesecontrolsconsistofa numberoftimedelaysdependingon thespecificheatermodel.

Anelectricheataccessoryhas1,2or 3of thesecontrols.Thefirsttimedelayis activated

whenthethermostatcontactsclose.Approximately1to 20secondslatertheindoorblower

andthefirst heaterbankareenergized.Approximately70secondsafterthe first heater

bankisenergizedtheremainingtime delaysand heaterbanks areenergized.

Staging

Some electric utilities require staging on electric heaters larger than 6 kilo-

watts. Therefore, the heater elements are turned on in 5 or 10 kW incre-

ments under control of the sequencers.

Ifstaging based on heat loss or demand is required, the use of accessory

outdoor thermostats is recommended. The heat sequencer wiring isde-

signed to be staged by breaking the 24V "Common" Leg (normally brown

or gray). Outdoor thermostats available through your wholesale supplier

allow the control of two or four stages of electrical heat.

Some indoor electronic thermostats may provide for multiple stages of

electric heat. When this type thermostat isused, it may be necessary to

break the 24V "Hot" leg of the sequencer (as fed from the "W' circuit at the

thermostat). This will require field modification of the control wiring and

should only be done by an experienced controls technician or electrician.

Install Heater

1. Shut OFF electric power at unit disconnect switch or service panel.

2. Remove the blower access panel from unit.

NOTE: Installation of field wiring and conduit for heaters to the

unit prior to installing the heater will simplify wiring of heaters.

3. From inside the blower compartment, remove the six screws on the

heater cover plate and save the screws. Discard the heater cover

plate.

The screws will be used later to mount the electric heat accessory

and its cover.

4. Remove the cardboard wrapper from the heater's elements.

5. Insert the heater into the heater/blower box. Exercise caution to

prevent damage to heater elements.

6.Secure heater to heater/blower box with four of the six screws re-

moved in Step 3.

FIGURE 8 Typical Electric Heat Accessory

Breaker- Style Heater rle

FIGURE 9 Installing The Electric Heat Accessory

Heater Wiring

Grounding

Permanentlygroundtheelectricheataccessoryinaccordancewithlocalcodesandordi-

nancesandinthe UnitedStateswithNationalElectricalCodeANSIINFPA70-1990orcur-

rent edition. Usea copper conductor of the appropriate size from the electric heat

accessorytothe groundlug on thecircuitbreakerpanelas shownin FIGURE10.

Installing Wiring

Whenanelectricheataccessoryis installed,twoseparatefield powersuppliesMUSTbe

provided- one or more forthe electricheat accessoryandone for the unit.

1.Shut OFF electric power at unit disconnect or service panel.

Page 7

2.Installtheappropriatefieldsuppliedconduitfittingintotheheater

knockoutlocatedin the rear panel of the unit. The knockout is sized

11/4" in diameter.

NOTE: Check FIGURE 11 for heater/speed combinations that are

unacceptable.

3.Connect field installed copper ground wire(s) to the ground lug(s) on

the heater mounting plate. On models with more than one circuit, a

separate copper ground wire MUST be connected to a separate

ground lug for each circuit.

4. Route the field supplied line voltage wires for the heater to the line

side of the electric heat accessory's circuit breaker(s) or high voltage

wiring harness. Leave approximately 8" of excess wire so the break-

er or wiring harness may be moved to service. Make line voltage

connections to L3-L6 as appropriate. NOTE: If heaters without

breakers are used, route field wires to inside of unit and attach to

heater wires tagged L3-L6 as appropriate using supplied wire nuts.

5.Connect the black wire with terminal from the heater wire harness to

the loose black wire at the unit blower or appropriate speed tap if

lower speed is desired in electric heat mode.

FIGURE 10 1

6 Connect the red wire with terminal in the heater wire harness to the

loose red wire from the unit sequencer.

7.Connect the white wire from the heater wire harness to the white wire

from the thermostat at the field supplied low volt wire harness in the

control box.

8.Connect the grey and brown wires from the heater wire harness to

the blue wire from the unit 24V common. NOTE: If outdoor thermo-

stats are used for staging electric heat, connect the grey and brown

wires according to the thermostat instructions. See "Staging" in

Electrical Wiring Section of this Manual.

After completing installation of the heater, install the breaker rain shield on

the blower access panel according to the following instructions on page 8.

Ifusing a pigtail style heater, proceed to Start-Up Procedures for Auxiliary

Electric Strip Heat on page 10.

Typical Wiring Installation ( Breaker Style Heater Shown-Pigtail style also available)

Access hole for

low voltage

wires

Unit Line Volt-

age Wires

Knockout for unit

field supplied line

voltage wires

Ground

Lug

Heater

Ground Lug

Unit blower heat-

ing speed tap

leads

FIGURE 11 Accessory Electric Heater Electrical Data

MaximumOverourrent

HEATER Nominal Heating Supply Heater MininumCircuit ProtectiveDevice

MODEL UsedWith SupplyVoltage KW Rating BTUH CircuitNo. Amps Ampacity (Amps)

AMMK05AHA 2-5 TON 240-1-60 4.8 t6,382 L3_L4 20.0 25.0 30

AMMK05AHB 208-1-60 3.6 t2,287 L3- L4 17.3 21.6 25

AMMK07AHA 2-5 TON 240-1-60 7.5 25,598 L3-L4 3t.2 39.1 45

AMMK07AHB 208-1-60 5.6 19,113 L3-L4 26.9 33.6 40

AMMK10AHA 2-5 TON 240-1-60 9.6 32,765 L3- L4 40.0 50.0 60

AMMK10AHB 208-1-60 7.2 24,574 L5- L6 34.6 43.3 50

L3- L4 40.0 50.0 60

AMMK15AHB 21/2-5 TON 240-1-60 14.4 49,t47 L5- L6 20.0 25.0 30

L3- L4 34.6 43.3 50

208-1-60 10.8 36,860 L5- L6 17.3 21.6 25

L3- L4 40.0 50.0 60

AMMK20AHB 21/2-5 TON 240-1-60 19.2 65,530 L5 - L6 40.0 50.0 60

L3- L4 34.6 43.3 50

208-1-60 14.4 49,t47 L5- L6 34.6 43.3 50

Page 8

FIGURE 12 Accessory Electric Heater Heating Data

*TemperatureRise °F @ CFM

Heater

Model

AMMK05AHA

AMMK05AHB

AMMK07AHA

AMMK07AHB

AMMK10AHA

AMMK10AHB

AMMK15AHB*

AMMK20AHB**

UseWith

NC: 2-5 TON

NC: 2-5 TON

NC: 2-5 TON

21/2-5 TON

21/2-5 TON

SupplyVoltage KWHating

240-1-60 4.8

208-1-60 3.6

240-1-60 7.5

208-1-60 5.6

240-1-60 9.6

208-1-60 7.2

240-1-60 14.4

208-1-60 10.6

240-1-60 19.2

208-1-60 14.4

TotalHeating

BTUH 600 800

16,832 25.3 t9.0

12,287 19.0 t4.2

25,596 39.5 29.6

19,113 29.5 22.t

32,765 50.6 37.9

24,574 37.9 28.4

49,147 --- 56.9

36.860 56.9 42.7

65,530 ......

49,147 --- 56.9

1000 1200 1400 1600 1800 2000 2200

15.2 12.6 10.6 9.5 8.4 7.6 ---

11.4 9.5 8.1 7.1 6.3 5.7 ---

23.7 19.8 16.9 14.8 13.2 11.9 10.8

17.7 14.7 12.6 11.1 9.8 8.8 8.0

30.3 25.3 21.7 19.0 16.9 15.2 13.8

22.8 19.0 16.3 14.2 12.6 11.4 10.3

45.5 37.9 32.5 28.4 25.3 22.8 20.7

34.1 28.4 24.4 2t.3 19.0 17.1 15.5

- - - 50.6 43.3 37.9 33.7 30.3 27.6

45.5 37.9 32.5 28.4 25.3 22.8 20.7

* 15KWHEATERNOTTO BE OPERATEDON LOWTAP FOR2 1/2TONNC AND HP.

** 20KWHEATERNOTTOBE OPERATEDONLOWORMEDIUMLOWTAP FOR 3AND3 1/2 NC AND HP.

Unit Disconnect Breaker

FIGURE 13 l Installing Circuit Breaker

SpringClipReleaseTab

Rain Shield Installation

FIGURE 14 I Installing The Rain Shield

1

CLOSED CELL FOAM PAD

1/8" THICK 3 3/8' X 71/16"

IN SIZE, ADHESIVE BACKED.

INSIDE

CIRCUIT BREAKER COVER.

BREAKER

HEATER PLUGS

RAIN SHIELD

1.Removeallscrewsfromthecoverplateon Blower/ElectricalAccessPanel.

Ifa seperateunitdisconnectbreaker/switchisrequireditcan beinstalledinsidetheunitin 2. InstalladhesivebackedgasketonBlower/ElectricalAccessPanel.

theheateraccessoryorasa singleinstallationbyusingthe DisconnectSwitchKit.Asep

eratepowersupplycircuitmustbeprovidedforthe unit. 3. Installlowerframe ofrainshield with4 screws.

1.Toinstallthecircuitbreakerorswitch,insertthebottomfoot of thebreaker intolower

mountingholeon the heaterpanelwiththebreakerat aslightangleout fromthe 4. Installrain shieldhingedcoverwith4 screws.

panel.

2.Pushbreakerin towardspanelandlift up slightlyso breakerfits intothetopmount-

ingholeand snaps (locks)inposition.

Breakershavea lockingspringcliptoholdtheminposition.Toremovebreakerliftupon

thereleasetab on top ofthebreakerand pullout anddownslightly.

FIGURE 15 Accessory Electric Heater Heating Data

5. Installcircuitbreakerfiller plates(2eachper unusedbreakerslot.)

6. Re-installBlower/ElectricalAccess Panel.

NOTE: VERIFYALLAPPROPRIATESEALSAREiNPLACE.SEE FIGURE14.

Breaker Amps Part Number Application

25 1082008 PA9524, PA5524, PAPA24, PAPC24

30 1082009 PA9530, PA5530, PAPA30, PAPC30

35 1082010 PA5536, PAPA36

40 1082011 PA9536, PAPC36

45 1082012 PA9542, PAPC42

50 1082013 PA5542, PA5548, PAPA42, PAPA48

60 1082014 PA9548, PAPC48

60 Switch 1082042 Fits AII- Disconnect Switch Only (No Over Current Protection)

AMMO01 DSA DISCONNECT SWITCH KIT (includes 60A switch & rain shield) BREAKER FOR UNIT ONLY.

FOR "NO HEAT" or PIGTAIL STYLE HEATER APPLICATION ONLY.

Page 9

6. Air Distribution System

Forairflowdata(blowerperformancedata,blowerspeedtapsettings,etc.)seetheTechni-

calData Sheetattachedto theunit..

Ductwork

Ductwork Insulation

Itisrecommendedthatductworkinstalledoutdoorshaveaminimumof2" (51mm)offiber-

glassinsulationandbecoveredby aweatherproofvapor barrierthat isprotectedagainst

damage.Caulkingandflashings,or othermeansadequatetoprovideapermanentweath-

er seal,must beused.

Itisrecemmendedthatductworkinstalledinatticsorotherareasexposedtooutdoortem-

peratureshaveaminimumof2" (51ram)fiberglassinsulationandhaveanindoortypeva-

por barrier.

Ductwork Connections

Theuseof flexible,non-combustibleconnectorsbetweenmaintrunk ductsand supply

andreturnair plenumsis recommendedto minimizevibrationtransmission.

NOTE: Connectsupplyandreturnairplenumsto unitin amannerthatwill allowthe topof

theunittobe removedwithoutremovingplenums.PlenumsMUSTbeindividuallysealed

to unitcasing.DuctsMUSTbe terminatedinsidestructure.

Filters

Allreturnair MUSTpassthroughafieldsuppliedfilterbefore enteringtheunit.Ifused,an

electronicair cleanerMUST be installed in the return air ductwork. Minimum recom-

mendedfilter areasare listed in FIGURE16 and arebased on a velocityof 300 ftfmin

(12m/s) for disposablefiltersand500ff/min(2.54m/s)forwashablehighvelocityfilters.

CAUTION

NOTE:The total heatgain ofthestructuretobe conditionedas expressedintotal Btuihr

shouldbe calculatedby manufacturer'smethodor in accordancewith"A.S.H.R.A.E

Guide"or"ManualJ - LoadCalculations"publishedbytheAir ConditioningContractorsof

America.Thetotal heatgaincalculatedshouldbeequaltoor lessthanthecoolingcapac-

ityoutput basedon D.O.E.test procedures,steadystate efficiencytimes input.

Ductwork,supplyregisters,andreturnair grillesMUST bedesignedandsizedto handle

theunit's coolingairvolume requirements,tftheunitis connectedtoan existingsystem,

theductworkMUSTbecheckedto makesureitisadequate.Extrarunsorlargerductsizes

mayhaveto beinstalled.

Maximumrecemmendedvelocityintrunkductsis1000feetperminute(5.08m/s).Velocity

in branchesshouldnot exceed800feet perminute(4.06m/s).Refertothe TechnicaIData

Labelontheunit forunit air volumerequirementsandsystemsizing recommendations.

NOTE:Ductworksizing affectstemperatureriseand coolingtemperaturedifferential.Be

sureto properlysizeductworkto thecapacityandairflowcharacteristicsofyour unit.Fail-

uretodoso canaffectlimitcontrols,compressors,motors,andothercomponentsandwill

leadto prematurefailure of components. Thiswillalsoadverselyaffectday to dayunit

performance.

FlexibleDuctKitsareavailablefromyoursuppliertoeffectpropersizingandinstallationto

MobileHomesandother standardconstruction..

Refertounitratingplatefor properElectricHeatAccessorysizingandsee the Tempera-

tureRiseChecksectionintheElectricHeatAccessorylnstallaUonSectionofthismanuaL Do NOT operate the unit without all filters in place.

FIGURE 16 Recommended Filter Sizes

NOTE: Somefiltersare markedwithanarrowto indicatethe properdirectionofairflowthroughthefilter. The airflow directionwillbetowardstheblowermotor.Makesurefilter i

installedcorrectly.

2

21/2

3

31/2

4

5

Nominal Tons

Air Conditioning

Nominal Air Flow

Cubic Feet

per Minute

700-900

900-1100

t100-1300

1300-1500

1500-1700

1900-2100

Recommended Filter Sizes

Sq. In. Surface Arep/Nominal Size

Disposable Filters

400 or 20 x 25

487 or 20 x 30

576 or 14 x 25 (2Req.)

665 or 16 x 25 (2Req.)

753 or 20 x 25 (2 Rea.'_

960 or 20 x 30 (2 Req.'l

Cleanable Filters

246 or 15 x 20

30t or 14x25

356 or 16 x 25

411 or 20 x25

466 or 20 x 25

575 or 24 x 25

Page 10

7. Start-up Procedures

Electrical shock hazard.

Use extreme care during all of the following checks and pro-

cedures.

Make sure electric power is turned OFF as instructed in ap-

propriate steps.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

Final Electrical Check

Makeafinal wiringchecktobesuresystemiscorrectlywired.Inspectfieldinstalledwiring

andtheroutingtoensurethatrubbingorchafingdue tovibrationwillnot occur.

NOTE:Wiring MUSTbe installedsoit is protectedfrompossiblemechanicaldamage.

Circulating Air Blower

DeterminingBlowerSpeed

1.Turn electric power OFF.

2. From the system design, determine the total external static pressure

(ESP) for the supply ducts, return ducts and registers, diffusers,

grilles, dampers, heaters and filters.

3.To your system ESP determined in Step 2, add 0.05 In. W.C. for a

wet coil.

4. From the system design, determine the desired cooling airflow in

cubic feet per minute (CFM).

5. Locate the unit's Blower Performance Data table on the tech data

label for the unit's voltage. (The tech data sheet is attached to the

evaporator access panel on the unit.) From the table, determine the

speed tap required to achieve the desired airflow.

&See next section, Speed Taps, to set the blower motor speed termi-

nal block (speed taps) to the cooling speed determined in the pre-

vious steps.

I

FIGURE 18 I Blower Motor

Speed Taps

I

BIow'er Speed Tap Block

Auxiliary E_ectric Heat B

Wire (if used)

connects here

BE SURE TO CHECK BLOWER MOTOR SPEED DATA ON THE

UNITS TECHNICAL DATA LABEL LOCATED ON THE UNIT.

NOTE: Electric heater blower wire may be attached to any "Appropriate"

speed tap See FIGURE 11 notes. The yellow lead MUST always be con-

nected to the speed tap block at the common quick connect terminal. The

terminal is identified as COM.

Refer to FIGURE 18 and the appropriate unit wiring diagram included in

this manual. Wire the black wire to the required speed tap terminal to

achieve required airflow determined in Step 5.

Cooling and Auxiliary Electric Strip Heat

On Air Conditioning units with electric heat, the heat strip may be operated

on a lower blower speed than cooling (Refer to Heater Chart FIG URE 11)

See FIGURE 15 for connection location.

Check Before Starting

SpeedTaps

AfterdeterminingtherequiredCFMandspeedtap datafromthetechdatasheet, followthe

stepsbelowtochangespeedsif necessary.

FIGURE 17 [ Blower Speed Tap Settings

10 SEER 2 TON MED

10 SEER 21/2 TON MED

10 SEER 3 TON LOW

10 SEER 31/2 TON MED HI

10 SEER 4 TON LOW

10 SEER 5 TON HI

12 SEER 2 TON MED

12 SEER 21/2 TON MED

12 SEER 3 TON LOW

12 SEER 31/2 TON MED HI

12 SEER 4 TON LOW

1. Check that the blower motor speed terminal block is set to the prop-

er cooling speed. Refer to the unit wiring diagram and the various

airflow tables in this manual.

2. Check to see that clean, properly sized field supplied air filters are

installed in the return air duct.

3. Inspect the inside of the unit to be sure that all wires are in place and

all tools, etc. are removed.

4. Replace all service access panels.

Checktheunit'soperationasoutlinedinthe followinginstructions.Ifanyunusualsparking,

odorsornoisesareencountered,shutOFFelectricpowerimmediately.Recheckforwiring

errors,orobstructionsin ornearblower motors.

CirculatingAir Blower

1.Be sure electric power is OFF.

2.Set thermostat Heat-Cool selector to OFF.

10

Page 11

3.SetthermostatfanswitchtoAUTO.

4.TurnelectricpowerON.Nothingshouldstartrunning.

5.SetthermostatfanswitchtoON.Thecirculatingairblowershould

comeONaftera30seconddelay.

Atemperaturerisegreaterthan60°F(33.3°C)isnotrecommended.(Thisappliestoelec-

tricheatonly).

1.To check the temperature rise through the unit, place thermometers

in the supply and return air ducts as close to the unit as possible.

2.Open ALL registers and duct dampers.

6. Reset thermostat fan switch to AUTO. The circulating air blower

should go OFF after a 30 second delay. Nothing should be running.

Cooling

1. Be sure that electric power is OFF.

2. Set thermostat Heat-Cool select to COOL.

3. Adjust thermostat setting to below room temperature.

4. Turn electric power ON. During power application check the follow-

ing:

a. Contactor- Contactsclosing

b. Compressor- ON

c. Condenserfanmotor - ON

d. Circulatingair blower- ON (afterdelay)

5.Switch the thermostat to OFF, check the following:

a. Contactorcontactsopening.

b. Compressor- OFF

c. Condenserfanmotor - OFF

d. Circulatingblower - OFF(afterdelay)

6.Turn electric power OFF

AuxiliaryHeating

NOTE: Repeat circulatingairblower procedureaboveif AuxiliaryElectricHeatis being

installedafterunit hasbeen installedand checkedout.

3.Set thermostat Heat-Cool selector to HEAT.

4.Set the thermostat temperature setting as high as it will go.

5.Turn electric power ON.

6.Operate unit AT LEAST 5 minutes, then check temperature rise.

NOTE: The maximum outlet air temperature for all models is 200°F

(93.35C). Maximum temperature rise for electric heat is 60°F (33.35C)

7.Set thermostat to normal temperature setting.

8.Turn electric power OFF.

9 Change blower speed tap if 60°F (33.3°C)TemperatureRisewasexceeded

andrepeat.

10.Be sure to seal all holes in ducts if any were created during this

process.

Sequence of Operation

CoolingMode: Energized(R,G,YI) De-energized(N/A)

(a) When high and low voltage is initially applied to unit:

(f)On a call for cooling ......... :

The compressor and condenser fan will energize. The evaporator

blower motor will have a delay on and will energize after 30 seconds.

Temperature Rise Check

Temperaturerise is the differencebetweenthe supplyand returnairtemperatures.The

temperatureriseshouldbe-+2°F (1.1°C)of the temperatureriseshownin FIGURE12.

NOTE:The temperaturerisecan beadjustedby changingthe heatingspeed tapat the

unit'sblowerterminalblock.Referto the unit'sInstallationInstructionsfor airflowinforma-

tion.

(2)When the cooling setpoint has been satisfied ......... :

The compressor and condenser fan will de-energize immediately.

The evaporator blower motor will have a delay off and will de-ener-

gize after 30 seconds.

if temperature rise is excessive, verify proper airflow through the unit. if

temperature rise is inadequate, check for proper electrical supply to the

heater and verify correct airflow.

8. Operation

Electrical shock hazard.

Turn OFF electric power supply at disconnect switch or ser-

vice panel before removing any access or service panel from

unit.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

izespressurethroughoutthe systemand preventspossiblereverserotationof thescroll

compressor.

CAUTION

Do NOT operate unit on cooling when the outdoor temperature is be-

low 60°F. This is necessary to prevent possible damage to the com-

pressor.

TurningThe Unit Off

Scroll Anti-Cycle Timer (Where Applicable)

Single phaseunitswithscrollcompressorscan be equipped withan anti-cycle device

whichdelaysthe start ofthe compressorinthe eventof a powerinterruption.Thisequal-

1.Set the thermostat selector switch to OFF and set the fan switch to

AUTO. To restart, set thermostat selector switch to COOL or HEAT

and set thermostat to temperature desired.

2.To shut the unit down completely, turn electric high voltage power

OFF

tl

Page 12

Thermostat Fan Switch Operation

Withthe thermostatfan switchinthe ONposition,thecirculatingair blowerwillruncontinu-

ouslyatthe speed usedfor cooling.

Withthethermostatfanswitchinthe AUTOposition,thecirculatingairblowerwillonlyrun

duringeach cooling or heatingcycle.

9. Maintenance

Adjusting RoomTemperatures

Ifthe temperaturein individualroomsisnot as desired,balancethe systembyadjusting

thedampetsinthe branchducts.Adjusta littleatatimeandwaitadayaftereachchangeto

judgetheeffect.Oncethedampersareadjustedfornormalweatherconditions,it is bestto

leavethem that way.Compensatefortemporaryweatherchanges byadjustingthether-

mostatsetting.

Monthly Maintenance and Inspection Checks

CondenserFanMotor

Air Filters

CAUTION

Do NOT operate unit without air filters.

Inspectfiltersat leastmonthlyand replaceorclean as required.Washablefiltersmaybe

cleanedby soakingin mild detergentandrinsingwithcold water.Replacefilters withthe

arrowson thesidepointingin the directionof air flow.Dirtyfilters arethe mostcommon

causeofinadequateheatingor coolingperformance,andof compressorfailures.

Cooling Season Checks (Monthly)

CondenserCoil

Keepthe condenserinletandoutletarea cleanandfree ofleaves,grassclippingsorother

debris.Grassshouldbekeptshortinfrontof the condenserairinlet.ShrubberyMUSTbe

trimmedbackso it is no closer than 30 inches (762mm)to unit panels and 10 inches

(254mm)to coil inlet.

Thecondenserandevaporatorcoilsshouldbe cleanedbyusinga non-acidtypecleaner

toavoidremovingpaintorothertypeofcoatingon thecoi!. Alwaysturnoffelectricalpower

tothe unit duringserviceand maintenance.

CondensateDrain

Periodiccleaningofthecondensatedrain&trap mayberequired.Inspectdrainageofcon-

densateafteratleast 15minutesof continuousoperationin coolingmode duringhumid

conditions.

CAUTION

Do NOT use 3in I oil, penetrating oil, WD40 or similar oilsto oil motor

bearings.

Motors used in this product are considered permanently lubricated for up

to 5 years. Ifoil ports are provided on the motor, oilthe cendenserfanmotorand

evaporatorblowermotorafterfiveyearsof operationand everyfiveyearsthereafter.

UseSAE 10W30motoroil.Tooil,removethe holeplugsfromthemotor endbellsand add

severaldropsofoilwitha squeezetype,flexibletubeoiler.Replaceholeplugsafteroiling.

Do NOTover oil.

Cleanthesurroundingareaand the condenserandevaporatorcoils.Usecautiontoavoid

damagetocoil fins. Usea non-acidtype ofcleanerONLY.

CirculatingAir Blower

Toaccessorremovethe blowermotorusethe followingsteps.

1.Turn electric power OFF

2. Remove the blower access panel.

3. Unplug the wires connected to the speed tap block if necessary, not-

ing the location of each wire for re-installation.

4.Slide entire housing toward you.

Annual Maintenance and Inspection

Electrical shock hazard.

Turn OFF electric power supply at disconnect switch or service

panel before removing any access or service panel from unit.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

The annualinspectionMUST includelubricationandcleaningas requiredtoensureeffi-

cientoperationof the unit.To simplifyaccess,removeallaccesspanels.

&Visually inspect the blower wheel for accumulations of dirt or lint.

Clean the compartment and the blower wheel. If accumulation is

excessive on blower wheel, or does not easily remove, it may be

necessary to remove and disassemble the blower assembly for prop-

er cleaning.

&Oil blower motor if needed.

CAUTION

Do NOT use 3in I oil, penetrating oil, WD40 or similar oilsto oil motor

bearings.

Oiltheblowermotorbyadding severaldropsof SAE10W30to eachmotor bearing.The

blowermotor shouldbe oiledafterfiveyearsof operationandeveryfive yearsthereafter.

7.When finished, reassemble in reverse order.

12

Loading...

Loading...