ICP PAPA48GA1, PAPA42GA1, PAPA42GA, PAPA36GA1, PAPA36GA Owner’s Manual

...

Installation Instructions

I DIRECT DRIVE BLOWER

Three Phase

PA55/PAPA SERI ES

SINGLEPACKAGEAIRCONDITIONERS

ELECTRICHEAT(OPTIONAL)c

ELECTRIC / @

TABLEOFCONTENTS

1,SafetyLabelingand Signal Words .......................... 2

Danger, Warning and Caution ................................... 2

2. Safe Installation Requirements ..................... 2

3. Locating The Unit .................................. 2

Clearances ................................................... 2

Dimensions ................................................... 2

Minimum Clearances to ComLJstibte Construction 3

Installation ................................................... 3

Installing Duct Collars .. 3

_'ondensate Drain ,1

4. Electrical Wiring .................................. 4

Ground Connections ........................................... 4

Line Voltage Wiring ............................................ 4

Unit Disconnect ............................................... 4

Converting 230M tJnils to 208V ................................... 4

Low Voltage Wiring ........................................... 4

Thermostat Connections ........................................ 5

Field Installed Equipment ........................................ 5

5. Electric Heat Installation ............................. 6

General Information .......................................... 6

Adjustinc Thermostat Anticipator ....... 6

Limit Controls ....... 6

Operation ........ 6

Install Heater ................................................. 6

Heater Wiring ................................................. 6

Grounding ..................... 6

Installing Wrong 6

Unit Disconnect Breaker ......................................... 8

Rain Shield Installation ........................................ 8

6. Air Distribution System .............................. 8

Ductwork .................................................... 8

DuctworkInsulation.. ..... 8

DactwerkConnections........ 8

Filters ........................................................ 8

7. Start-up Procedul'es ................................ 9

Final Electrical Check ........................................... 9

Circulating Air Blower ......................................... 9

DeterminingEower Speed ......... g

BDeedTai3s.................. 9

Cooling and AuxiliaryElectric StripHeat ............................ 9

CheckBefore Starting .......................................... 9

CirculatingAir Blower ......... 10

Cooling ..................................... 10

Auxiliary _ea[mg......................... 10

Temperature Rise Check ..... i,,. ................................ 10

SequenceofOperation , .................................... 10

CoolingMode:Energizan RGY'_) De_ene_gized(NA ............... 10

8. Operation ............................................ 11

ScrollAnti-Cycle Timer {Wh_reApplicai:31e}......................... 11

Turning The UnitOff ............................................... 11

ThermostatFanSwitch Operation...,, ........................... 11

AdjustingRoomTemperatures .... .., ........................... 11

13, Maintenance ...................................... 11

MonthlyMaintenanceandInspection Checks ....................... 11

Air Fitters . 11

Cooling Season Checks (Monthly} ................................ 11

CondenserCo ..... 11

CondensateDrain... 11

AnnualMaintenanceand inspection .............................. 1t

CondenserFan Motor 11

CircaiatingAir Blower 12

Printed in U.S.A. 426 O11OO5 CO

1o/15/Ol

1. Safety Labeling and Signal Words

Danger, Warning and Caution

The signal words DANGER, WARNING and CAUTION are used

to identify levels of hazard seriousness. The signal word DAN-

GER is only used on product labels to signify an immediate haz-

ard. The signal words WARNING and CAUTION will be used on

product labels and throughout this manual and other manuals that

may apply to the product.

2. Safe Installation Requirements

Installation or repairs made by unqualified persons can result

in hazards to you and others. Installation MUST conform with

local building codes or, in the absence of local codes, with the

National Electrical Code NFPA70-1990 or current edition.

The information contained in this manual is intended for use

by a qualified service technician familiar with safety proce-

dures and equipped with the proper tools and test instru-

ments.

Failure to carefully read and follow all instructions in this

manual can result in unit malfunction, property damage, per-

sonal injury and/or death.

• Seal supply and return air ducts.

• Check to see that filters are installed correctly and are the

proper type and size.

NOTE: It is the personal responsibility and obligation of the cus-

tomer to contact aqualified installer to ensure that the installation

is adequate and conforms to governing codes and ordinances.

CAUTION

Do NOT operate unit in a corrosive atmosphere containing

chlorine, fluorine, or any other corrosive chemicals.

3. Locating & Installing The Unit

The unit is designed for outdoor installation only. Place the unit on

a platform at ground level. The unit may be installed on a concrete

slab of 48" (1219mm) x 48" (1219mm) dimensions. Cement

blocks on a 3" sand footing will also work. The slab or blocks

SHOULD NOT be in contact with any part of the structure. Check

local codes covering zoning, noise, platforms, etc..

If practical avoid locating next to fresh air intakes, vent or bed-

room windows. Noise may carry into the openings and disturb

people inside.

Avoid installations under roof overhangs without guttering. Water

draining from the roof onto the unit could produce excessive

noise, and may cause ice to build up on coil or fan.

Placement of the unit should be in a well drained area or the unit

MUST be supported high enough so runoff will not enter the unit.

Do not locate unit where heat, lint or exhaust fumes wil! be dis-

charged on unit (as from dryer vents.)

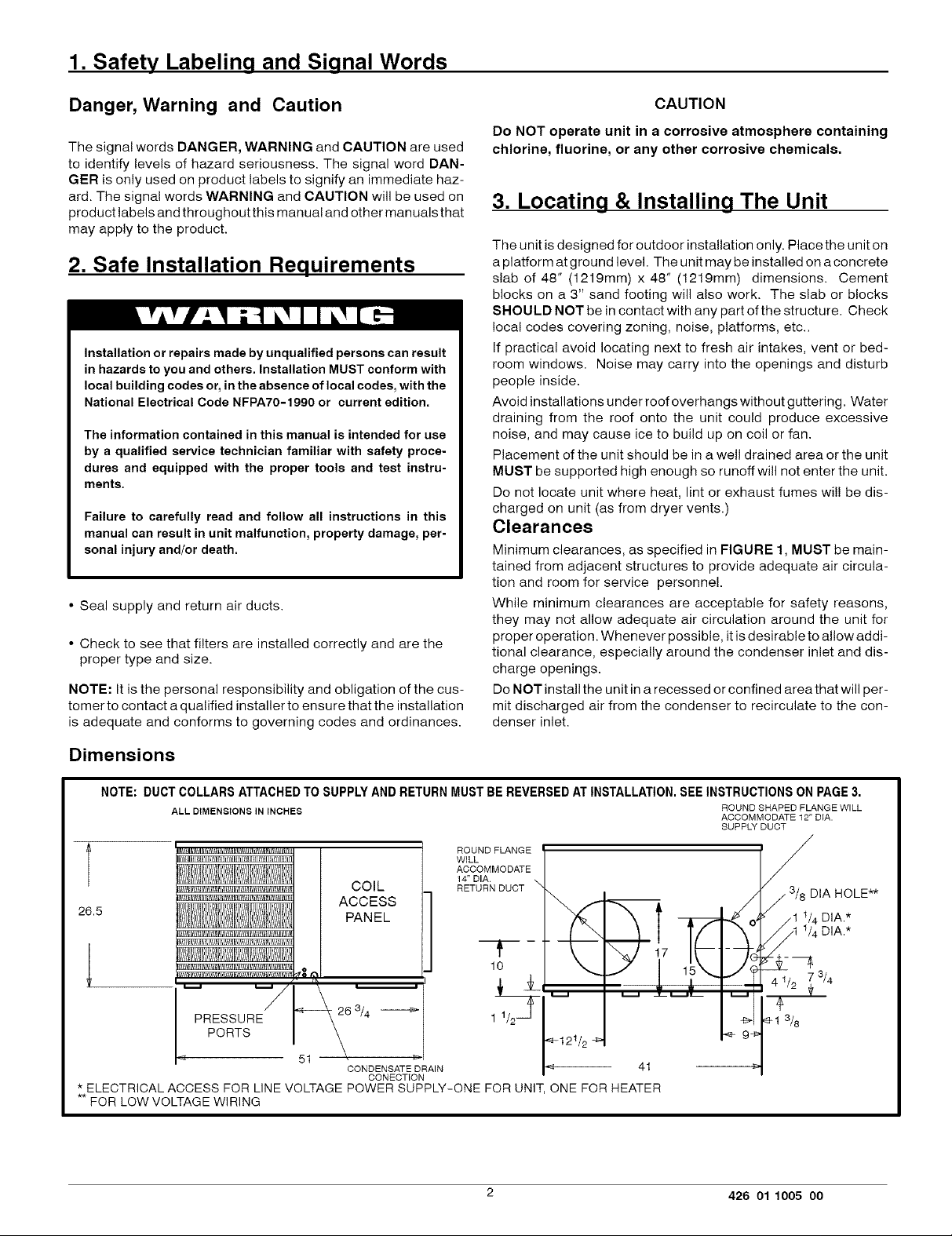

Clearances

Minimum clearances, as specified in FIGURE 1, MUST be main-

tained from adjacent structures to provide adequate air circula-

tion and room for service personnel.

While minimum clearances are acceptable for safety reasons,

they may not allow adequate air circulation around the unit for

proper operation. Whenever possible, it is desirable to allow addi-

tional clearance, especially around the condenser inlet and dis-

charge openings.

Do NOT install the unit in a recessed or confined area that will per-

mit discharged air from the condenser to recirculate to the con-

denser inlet.

Dimensions

NOTE: DUCT COLLARS ATTACHED TO SUPPLY AND RETURN MUST BE REVERSED AT INSTALLATION. SEE INSTRUCTIONS ON PAGE 3.

ALL DIMENSIONS IN INCHES ROUND SHAPED FLANGE WILL

T

IIIl_ll_1_LI1_1_l]_l_ll_m I_1_11m]11_1111_111 WILL

IlllHlllliltllliHla#ltlillllti/i_ll_Jlltll_iltlialtlla RETURN DUCT DIA HOLE**

26.5

_llllllllllll[llllll_ftlllllt_illlllJlllltlllit#lll_ll_

PRpEoSSUsRE_/_ 263/4 _ 1

<_ 61 \

* ELECTRICAL ACCESS FOR LINE VOLTAGE POWER SUPPLY-ONE FOR UNIT, ONE FOR HEATER

** FOR LOW VOLTAGE WIRING

COIL

ACCESS

PANEL

CONDENSATE DRAIN 41

CONECTION

ROUND FLANGE r /

ACCOMMODATE14D,A

10

2 426 01 1005 00

ACCOMMODATE 12" DtA.

SUPPLY DUCT

3/4

Minimum Clearances to Combustible Construction ......

SERVICE ACCESS CLEARANCES

Blower Access Pane! Side ................... 30" (762mm)

Electrical Access Panel Side ................. 30" (762mm)

OPERATIONAL CLEARANCES

Combustible Base

(Wood or Class A, B or C

roof covering material) .................... 0"

Supply and Return Air Ducts ........................... 0"

Duct Connection Side

....................................... 0 _

Clearance between Overhang

and Top of Unit ............... 48" (1219mm)

Clearance around Condenser Coil area to wall or shrubs . 10"

FIGURE i Minimum Clearances and Access Panels

Overhang

Evaporator 48" Minimum Overhang Clearance

Access Panel

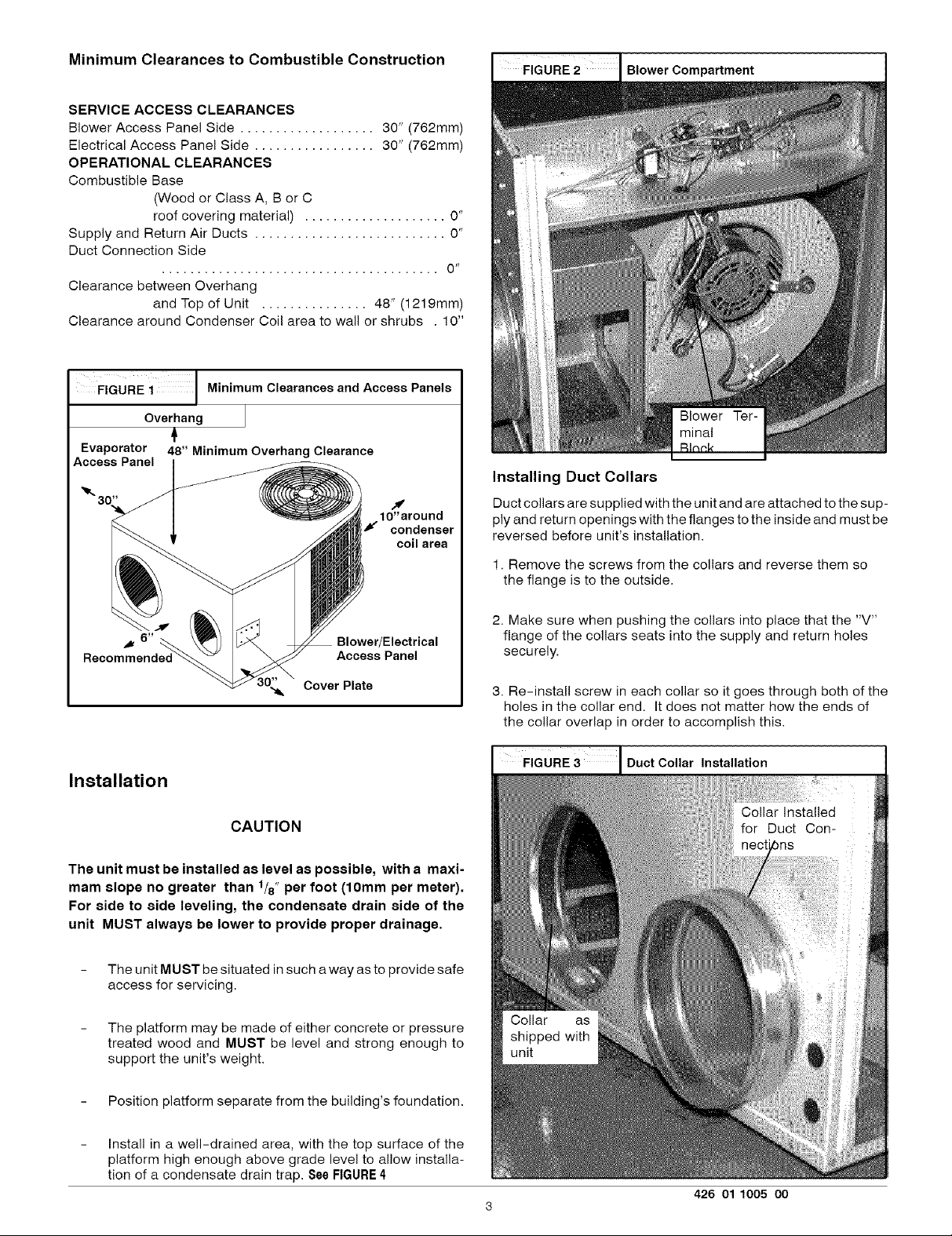

Installing Duct Collars

J

lO"around

f condenser

coilarea

Duct collars are supplied with the unit and are attached to the sup-

ply and return openings with the flanges to the inside and must be

reversed before unit's installation.

1. Remove the screws from the collars and reverse them so

the flange is to the outside.

6 _

,,_ Cover Plate

Blower/Electrical

Access Panel

Installation

CAUTION

The unit must be installed as level as possible, with a maxi-

mam slope no greater than 1/8" per foot (lOmm per meter).

For side to side leveling, the condensate drain side of the

unit MUST always be lower to provide proper drainage.

The unit MUST be situated in such a way as to provide safe

access for servicing.

The platform may be made of either concrete or pressure

treated wood and MUST be level and strong enough to

support the unit's weight.

2. Make sure when pushing the collars into place that the "V"

flange of the collars seats into the supply and return holes

securely.

3. Re-install screw in each collar so it goes through both of the

holes in the collar end. It does not matter how the ends of

the collar overlap in order to accomplish this.

FIGURE 3 I Duct Collar Installation

Position platform separate from the building's foundation.

Install in a well-drained area, with the top surface of the

platform high enough above grade level to allow installa-

tion of a condensate drain trap. See FIGURE 4

3

426 01 1005 O0

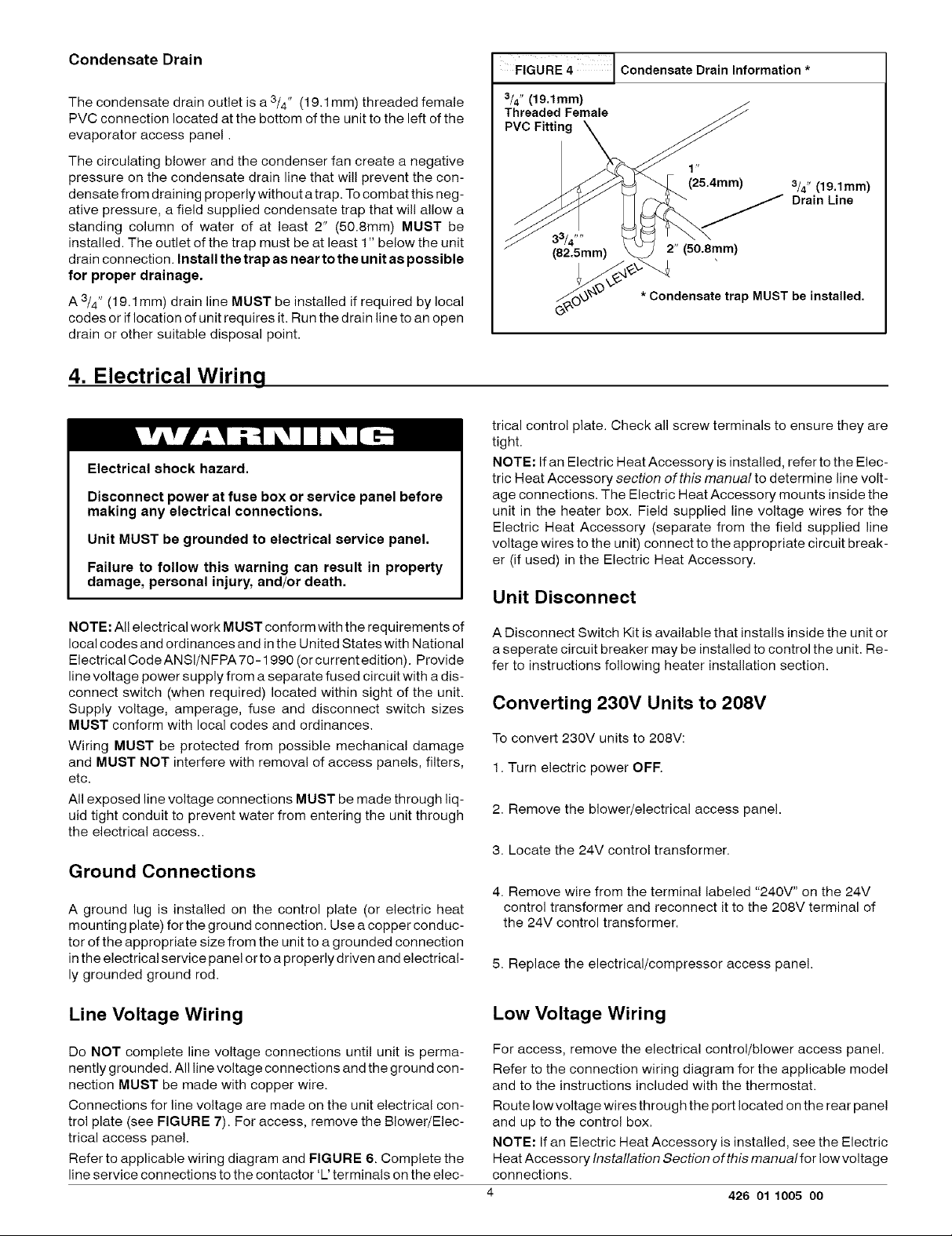

Condensate Drain

The condensate drain outlet is a 3/4" (19.1 mm) threaded female

PVC connection located at the bottom of the unit to the left of the

evaporator access panel.

The circulating blower and the condenser fan create a negative

pressure on the condensate drain line that will prevent the con-

densate from draining properly without a trap. To combat this neg-

ative pressure, a field supplied condensate trap that will allow a

standing column of water of at least 2" (50.8mm) MUST be

installed. The outlet of the trap must be at least 1" below the unit

drain connection. Install the trap as near to the unit as possible

for proper drainage.

A 3/4" (19.1 mm) drain line MUST be installed if required by local

codes or iflocation of unit requires it. Run the drain line to an open

drain or other suitable disposal point.

4. Electrical Wiring

Electrical shock hazard.

Disconnect power at fuse box or service panel before

making any electrical connections.

Unit MUST be grounded to electrical service panel.

Failure to follow this warning can result in property

damage, personal injury, and/or death.

FIGURE 4 J Condensate Drain Information*

3/4" (19.1mm)

Threaded Female

PVC Fitting

(25.4mm)

33/4 t_ .

(82.5mm)

trical control plate. Check all screw terminals to ensure they are

tight.

NOTE: If an Electric Heat Accessory is installed, refer to the Elec-

tric Heat Accessory section of this manual to determine line volt-

age connections. The Electric Heat Accessory mounts inside the

unit in the heater box. Field supplied line voltage wires for the

Electric Heat Accessory (separate from the field supplied line

voltage wires to the unit) connect to the appropriate circuit break-

er (if used) in the Electric Heat Accessory.

2" (50.8mm)

* Condensate trap MUST be installed.

3/4" (19.1mm)

Drain Line

Unit Disconnect

NOTE: All electrical work MUST conform with the requirements of

local codes and ordinances and in the United States with National

Electrical Code ANSI/NFPA 70-1990 (or current edition). Provide

line voltage power supply from a separate fused circuit with a dis-

connect switch (when required) located within sight of the unit.

Supply voltage, amperage, fuse and disconnect switch sizes

MUST conform with local codes and ordinances.

Wiring MUST be protected from possible mechanical damage

and MUST NOT interfere with removal of access panels, filters,

etc.

All exposed line voltage connections MUST be made through liq-

uid tight conduit to prevent water from entering the unit through

the electrical access..

Ground Connections

A ground lug is installed on the control plate (or electric heat

mounting plate) for the ground connection. Use a copper conduc-

tor of the appropriate size from the unit to a grounded connection

in the electrical service panel or to a properly driven and electrical-

ly grounded ground rod.

Line Voltage Wiring

Do NOT complete line voltage connections until unit is perma-

nently grounded. All line voltage connections and the ground con-

nection MUST be made with copper wire.

Connections for line voltage are made on the unit electrical con-

trol plate (see FIGURE 7). For access, remove the Blower/Elec-

trical access panel.

Refer to applicable wiring diagram and FIGURE 6. Complete the

line service connections to the contactor 'L' terminals on the elec-

A Disconnect Switch Kit is available that installs inside the unit or

a seperate circuit breaker may be installed to control the unit. Re-

fer to instructions following heater installation section.

Converting 230V Units to 208V

To convert 230V units to 208V:

1. Turn electric power OFE

2. Remove the blower/electrical access panel.

3. Locate the 24V control transformer.

4. Remove wire from the terminal labeled "240V" on the 24V

control transformer and reconnect it to the 208V terminal of

the 24V control transformer.

5. Replace the electrical/compressor access panel.

Low Voltage Wiring

For access, remove the electrical control/blower access panel.

Refer to the connection wiring diagram for the applicable model

and to the instructions included with the thermostat.

Route low voltage wires through the port located on the rear panel

and up to the control box.

NOTE: If an Electric Heat Accessory is installed, see the Electric

Heat Accessory Installation Section of this manual for low voltage

connections.

4 426 01 1005 00

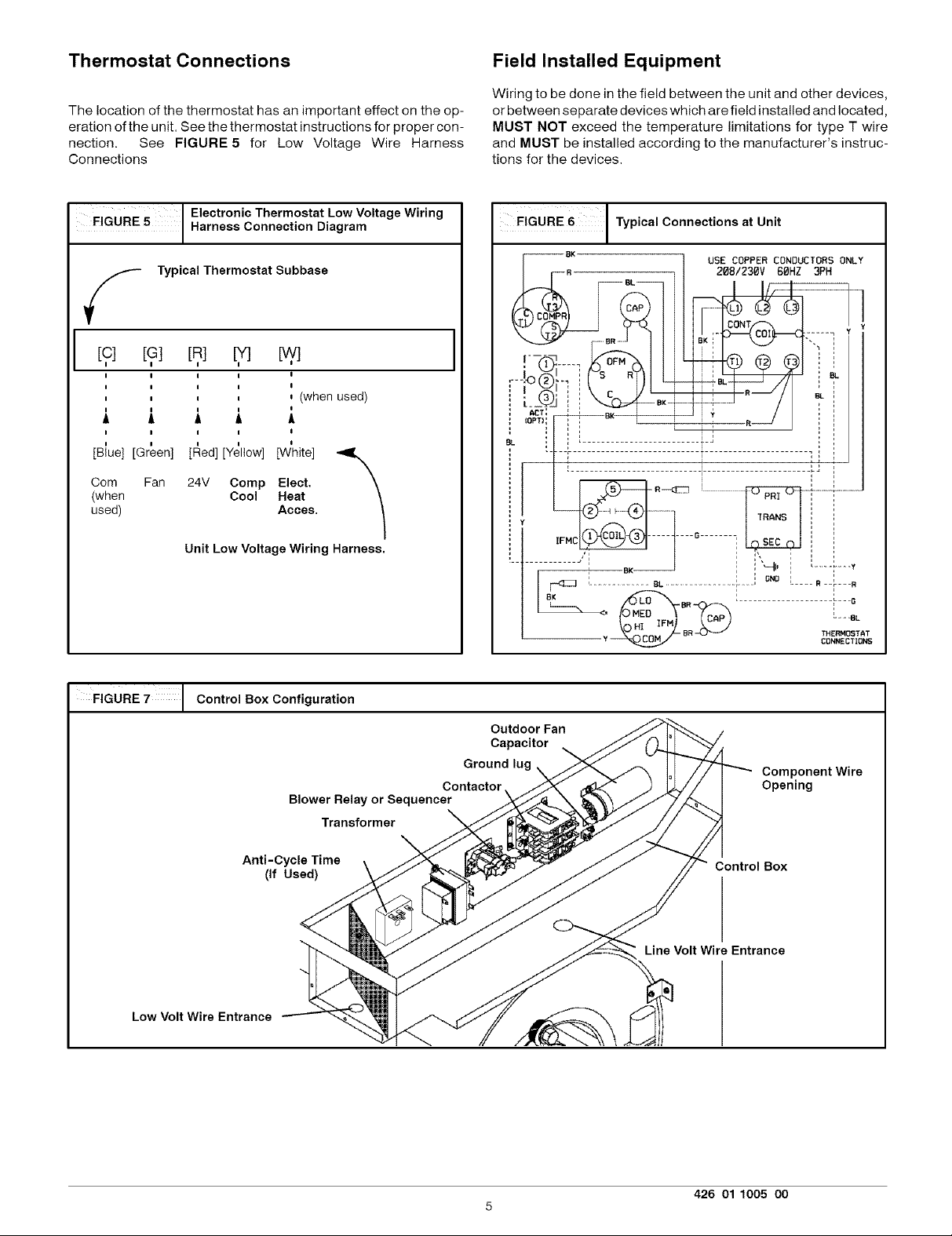

Thermostat Connections

The location of the thermostat has an important effect on the op-

eration ofthe unit. See the thermostat instructions for proper con-

nection. See FIGURE 5 for Low Voltage Wire Harness

Connections

Field Installed Equipment

Wiring to be done in the field between the unit and other devices,

or between separate devices which are field installed and located,

MUST NOT exceed the temperature limitations for type T wire

and MUST be installed according to the manufacturer's instruc-

tions for the devices.

FIGURE 5 I HarnessElectr°niCconnectionTherm°statDiagramL°WVoltage Wi ring

Typical Thermostat Subbase

[c] [?] [R,] _ _,]

I I I I I

I I I I I

_ _ _ _ (when used)

I I I I /

i i i i A

I I I I I

Corn Fan 24V Comp Elect.

(when Cool Heat

used) Acces.

[Blue] [Green] [F_ed][Yellow] [White] _[

Unit Low Voltage Wiring Harness.

I

FIGURE 6 I Typical Connections at Unit

USE COPPER CONDUCTORS ONLY

2g8/23gV 60HZ 3PH

FIGURE 7 Control Box Configuration

Outdoor Fan f._ '_-_ t

copao,tor\ _0-:__"_

Bl°wer Relay °r Sequence L __2_"_///_

Transformer%___ ___/__/_

Anti-Cycle Time J_.X_ _ I_:_"_:;_ j_f /'_" Control Box

_owvo,twireEntrance_ _.__ __i_i

c;: o;en,

Volt Wire Entrance

Wire

5

426 01 1005 O0

Loading...

Loading...