ICP PAF324000K00A1, PAF330000K00A1, PAF336000K00A1, PAF342000K00A1, PAF348000K00A1 Installation Guide

...Page 1

Installation Instructions

PAF3 Series

PACKAGE AIR CONDITIONERS

TABLEOFCONTENTS

UNITDIMENSIONS ......................................... 2

SAFEINSTALLATIONREQUIREMENTS ......................... 3

LOCATINGTHE UNIT ....................................... 3

CLEARANCES ............................................ 3

INSTALLATION............................................ 3

GROUNDLEVELINSTALLATION .............................. 3

RooftopINSTALLATION..................................... 3

HOISTING................................................ 4

DOWNFLOWCONVERSION .................................. 4

CONDENSATEDRAIN....................................... 4

_ CLIS_IEDUS

ELECTRICALWIRING................................... 5

DUCTWORK.......................................... 6

FILTERS ............................................. 6

AIRFLOWADJUSTMENT ................................ 7

START-UPPROCEDURES ............................... 8

SequenceofOPERATION................................ 8

MAINTENANCE ....................................... 8

RIGGING ........................................... 11

WIRINGDIAGRAMS ................................ 12 - 13

Printed in U.S.A.

Key: PAF3

519 01 1201 O0 12-5-05

Page 2

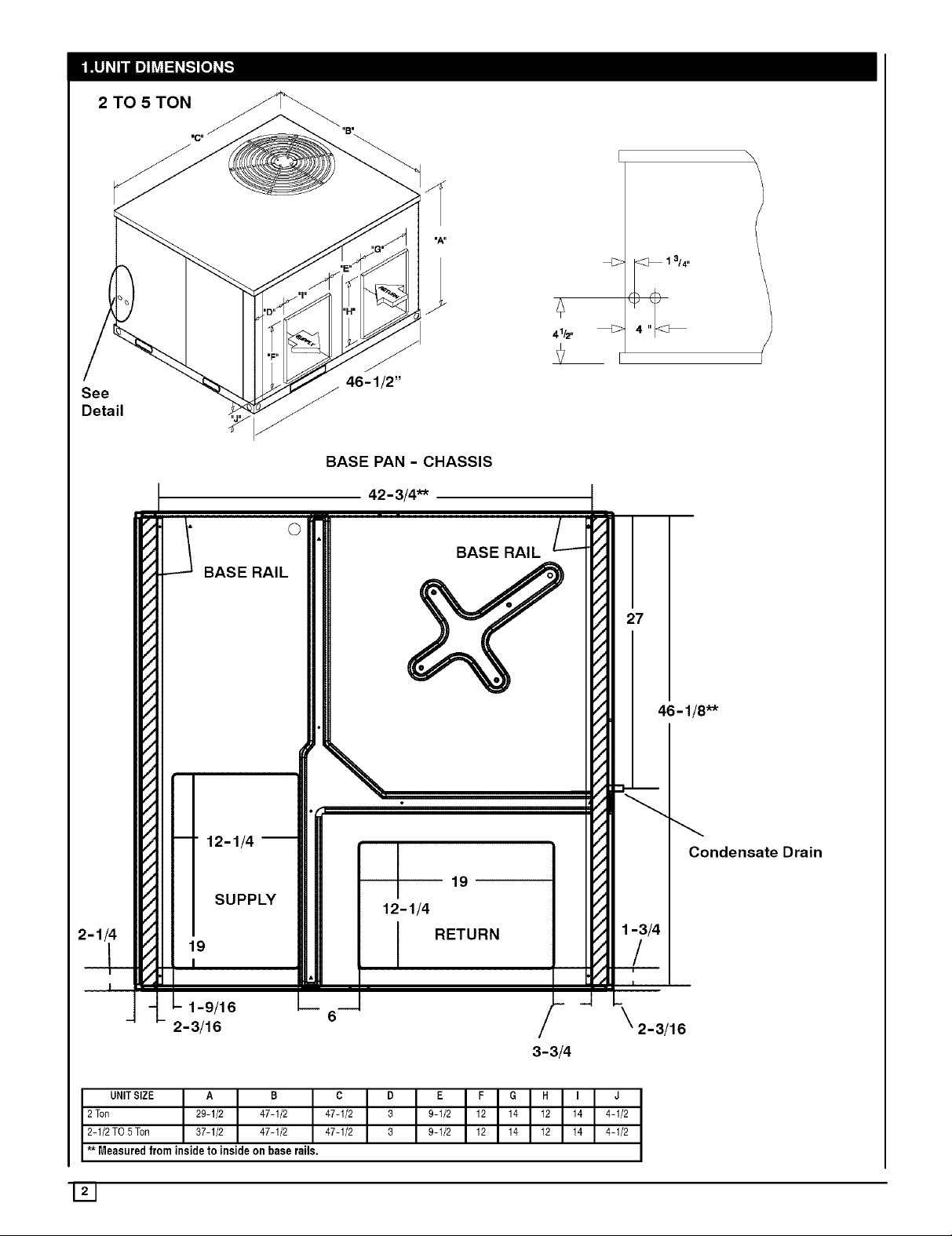

2 TO 5 TON

See

Detail

41/2"

BASE PAN - CHASSIS

42-3/4"*

BASE RAIL

27

46-1 !8"*

--" 12-1/4 i

Condensate Drain

19

SUPPLY 12-1/4

19

I

t

RETURN

1-9/16

2-3/16

3-3/4

1-3/4

/

I

2-3/16

UNITSIZE A B C D

2 Ton 29-1/2 47-1/2 47-1/2 3

2-1/2 TO 5Ton 37-1/2 47-1/2 47-1/2 3

** Measured from inside to inside on base rails.

E F G H I J

9-1/2 12 14 12 14 4-1/2

9-1/2 12 14 12 14 4-1/2

Page 3

2. SAFE INSTALLATION REQUIREMENTS

FIRE AND ELECTRICAL SHOCK HAZARD

Failure to carefully read and follow all instructions in this

manual could result in furnace malfunction, personal

injury, death and/or property damage.

Installation or repairs made by unqualified persons can

result in hazards to you and others. Installation MUST

conform with local building codes or, in the absence of

local codes, with the National Electrical Code

NFPA70-2005 or in Canada and CSA C.22.1 - Canadian

Electrical Code Part 1.

The information containedin this manual isintendedfor

use by a qualifiedservice technician familiar with safety

procedures and equipped withthe propertools and test

instruments.

• Seal supply and return air ducts.

• Check to see that filters are installed correctly and are

the proper type an size.

NOTE: Itis the personal responsibility and obligation of the

customer to contact a qualified installer to ensure that the

installation is adequate and conforms to governing codes

and ordinances.

3. LOCATING THE UNIT

ACCESS PANELS

See NO TAG for a general view of unit and location of

access panels.

CLEARANCES

The location MUST allow for minimum clearances and

should not be adjacent to a patio or other area where the

unit's operating sound level might be objectionable. The

combustion air inlet openings MUST not be obstructed (see

NO TAG). In addition, local codes MUST be observed.

NOTE: Units with available filter racks (3-1/2 to 5ton), need

a 26" minimum clearance at side of unit for removal of

filters. See Minimum Clearances below if unit is going to be

placed near combustible construction or materials.

While minimum clearances are acceptable for safety

reasons, they may not allow adequate air circulation around

the unit for proper operation inthe cooling mode. Whenever

possible, it is desirable to allow additional clearance,

especially around the condenser inlet and discharge

openings.

Do NOT install the unit in a location that will permit

discharged air from the condenser to recirculate to the

condenser inlet.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in shorten life

of unit components.

Do NOT operate unit in a corrosive atmosphere

containing chlorine, fluorine, or any other corrosive

chemicals.

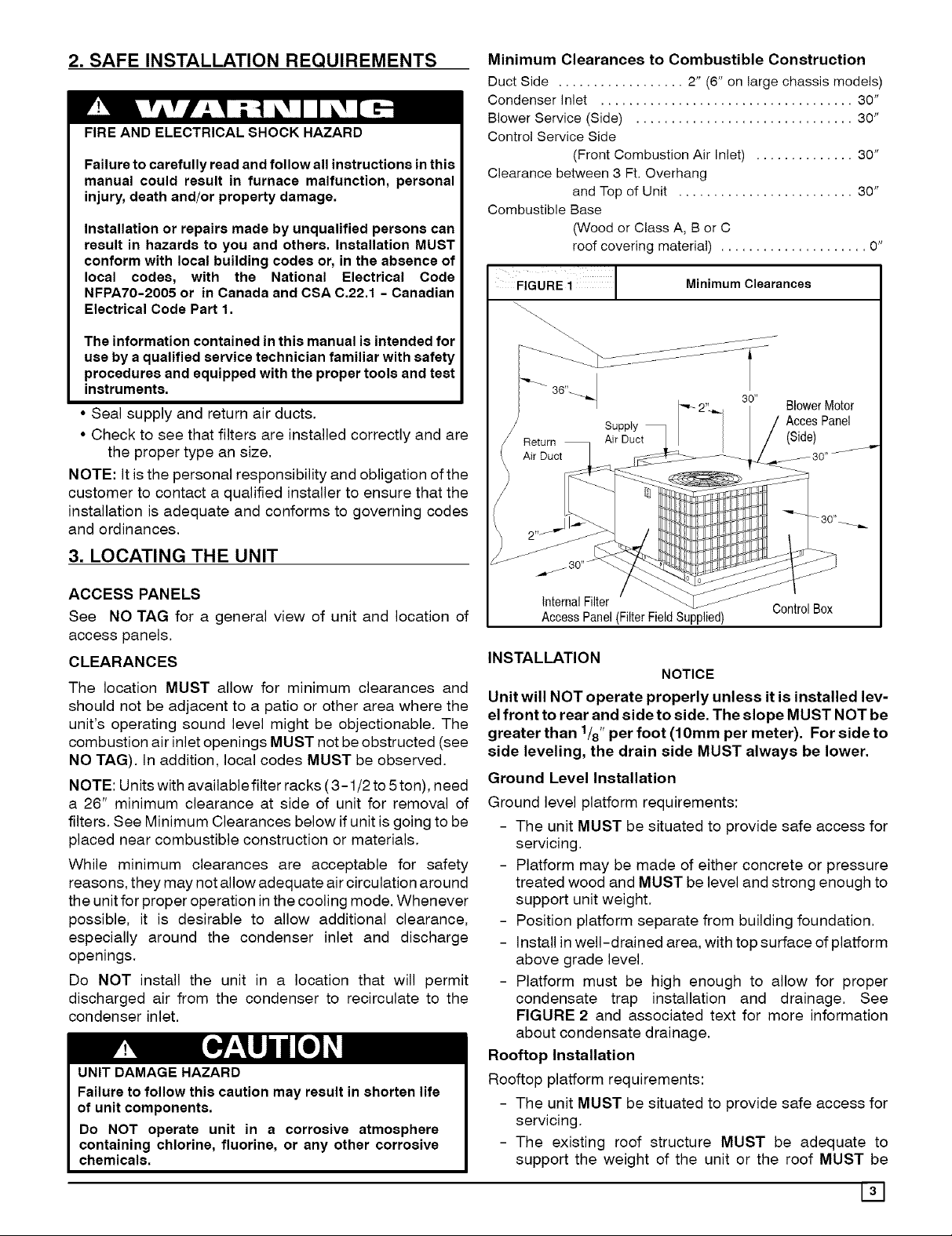

Minimum Clearances to Combustible Construction

Duct Side .................. 2" (6" on large chassis models)

Condenser Inlet .................................... 30"

Blower Service (Side) ............................... 30"

Control Service Side

(Front Combustion Air Inlet) .............. 30"

Clearance between 3 Ft. Overhang

and Top of Unit ......................... 30"

Combustible Base

(Wood or Class A, B or C

roof covering material) ..................... O"

FiGuRE i 1 Minimum Clearances

_ 36"_

3o" BlowerMotor

/ AeeesPanel

ASupPiYct I /(Side)

_ 30" _ _

InternalFilter

AccessPanel(FilterFieldSupplied)

INSTALLATION

NOTICE

Unit will NOT operate properly unless it is installed lev-

el front to rear and side to side. The slope MUST NOT be

greater than 1/8"per foot (10mm per meter). For side to

side leveling, the drain side MUST always be lower.

Ground Level Installation

Ground level platform requirements:

- The unit MUST be situated to provide safe access for

servicing.

- Platform may be made of either concrete or pressure

treated wood and MUST be level and strong enough to

support unit weight.

- Position platform separate from building foundation.

- Install in well-drained area, with top surface of platform

above grade level.

- Platform must be high enough to allow for proper

condensate trap installation and drainage. See

FIGURE 2 and associated text for more information

about condensate drainage.

Rooftop Installation

Rooftop platform requirements:

- The unit MUST be situated to provide safe access for

servicing.

- The existing roof structure MUST be adequate to

support the weight of the unit or the roof MUST be

Control Box

[]

Page 4

reinforced.

Check the weight of the unit in relation to the roof

structure and local building codes or ordinances and

reinforce roof structure if necessary.

- Support for the unit MUST be level and strong enough

to carry unit weight. The support may consist of a

platform or a combination of platform and roof beams or

curb.

HOISTING

NOTE: All access panels MUST be secured in place before

hoisting.

The unit should be hoisted with two lifting slings. Attach the

slings to rigging shackles that have been hooked through

holes in the base rail.

Two spreader bars MUST be placed on top of the unit to

protect the unit from damage from the pressure exerted by

the slings. Make sure that all equipment is adequate to

handle the weight ofthe unit and that the slings will not allow

the unit to shift.

Refer to Figure 8 for illustrated rigging instructions and

weight chart.

DOWNFLOW CONVERSION

NOTE: In downflow applications with roof curbs or jack

stands, the center rail under the unit must be removed. The

center rail is attached to the base rail with screws.

These units are adaptable to downflow use. To convert to

downflow use, follow these steps:

1. Remove the blockoff plates found in the return air

compartment and the supply air compartment.

NOTE: Blockoff plate in the supply air compartment only

contains one screw. If reinstalling plate, back part of plate

MUST fit into mating dimples on flange. To reinstall, slant

plate into dimples, then put plate into position and fasten

with screw.

2. Install the removed plates on the horizontal return and

supply air openings.

3. Install roof curb on the building. Be sure to follow all

directions included with curb and all applicable building

codes in your installation.

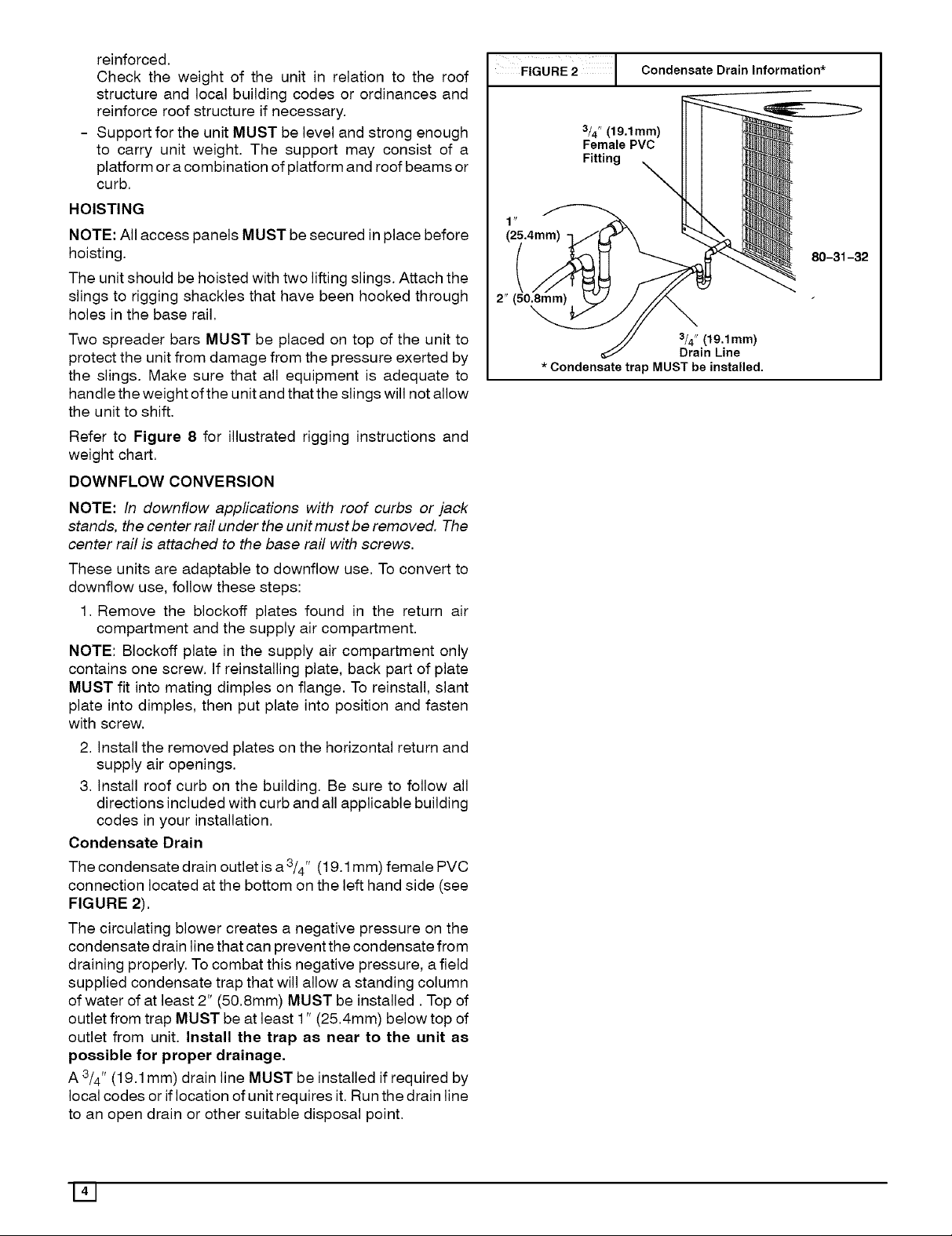

Condensate Drain

The condensate drain outlet is a 3/4" (19.1 mm) female PVC

connection located at the bottom on the left hand side (see

FIGURE 2).

The circulating blower creates a negative pressure on the

condensate drain line that can prevent the condensate from

draining properly. To combat this negative pressure, a field

supplied condensate trap that will allow a standing column

of water of at least 2" (50.8mm) MUST be installed. Top of

outlet from trap MUST be at least 1" (25.4mm) below top of

outlet from unit. Install the trap as near to the unit as

possible for proper drainage,

A 3/4" (19.1mm) drain line MUST be installed if required by

local codes or if location of unit requires it. Run the drain line

to an open drain or other suitable disposal point.

FIGURE 2 1 Condensate Drain Information*

3/4" (19.1mm)

Female PVC

Fitting _

(25.4mm)

(

2" (50.Smm)

3/4" (19,1mm)

Drain Line

* Condensate trap MUST be installed.

80-31-32

141

Page 5

4. ELECTRICAL WIRING

ELECTRICAL SHOCK HAZARD.

Failure to follow this warning could result in personal

injury, death and/or property damage.

The unit cabinet must have an uninterrupted,

unbroken electrical ground to minimize the possibility

of serious injury if an electrical fault should occur.

This ground may consist of an electrical wire

connected to the unit ground lug in the control

compartment, or conduit approved for electrical

ground when installed in accordance with National

Electric Code (NEC) NFPA 70, National Fuel Gas Code

NFPA 54-2005/ANSI Z223.1-2005 and local electrical

codes. In Canada, follow Canadian Electrical Code

CSA (Canadian Standards Association) C22.1 and

local electrical codes.

REDUCED EQUIPMENT LIFE HAZARD

Failure to follow these precautions could result in

damage to the unit being installed.

1)Make all electricalconnections inaccordance with

NationalElectriccode (NEC)NFPa70 andlocalelectrical

codes governing such wiring. In Canada, all electrical

connections must be inaccordance with CSA standard

C22.1, Canadian Electrical Code Part 1, and applicable

local codes. Refer to unit wiring diagram.

2) Use only copper conductor for connections

betweenfield-supplied electricaldisconnect switch and

unit. DO NOT USEALUMINUM WIRE.

3) Be sure that high-voltage power to unit is within

operating voltage range indicated on unit rating plate.

4) Donot damageinternalcomponentswhendrilling

through any panel to mount electrical hardware,

conduit, etc. Consult local power company for

correction of improper voltage and/orphase imbalance.

Disconnect Switch

The unit must have separate electrical service with a

field-supplied, waterproof, disconnect switch mounted at,

orwithin sight from, the unit. Refer tothe unit rating plate for

maximum fuse/circuit breaker size and minimum circuit

amps (ampacity) for wire sizing.

Ground Connections

Do NOT complete line voltage connections until unit is

permanently grounded. All line voltage connections and the

ground connection MUST be made with copper wire.

A ground lug is installed in the control box area for the

ground connection. Use a copper conductor of the

appropriate size from the unit to a grounded connection in

the electrical service panel or a properly driven and

electrically grounded ground rod. See warning above.

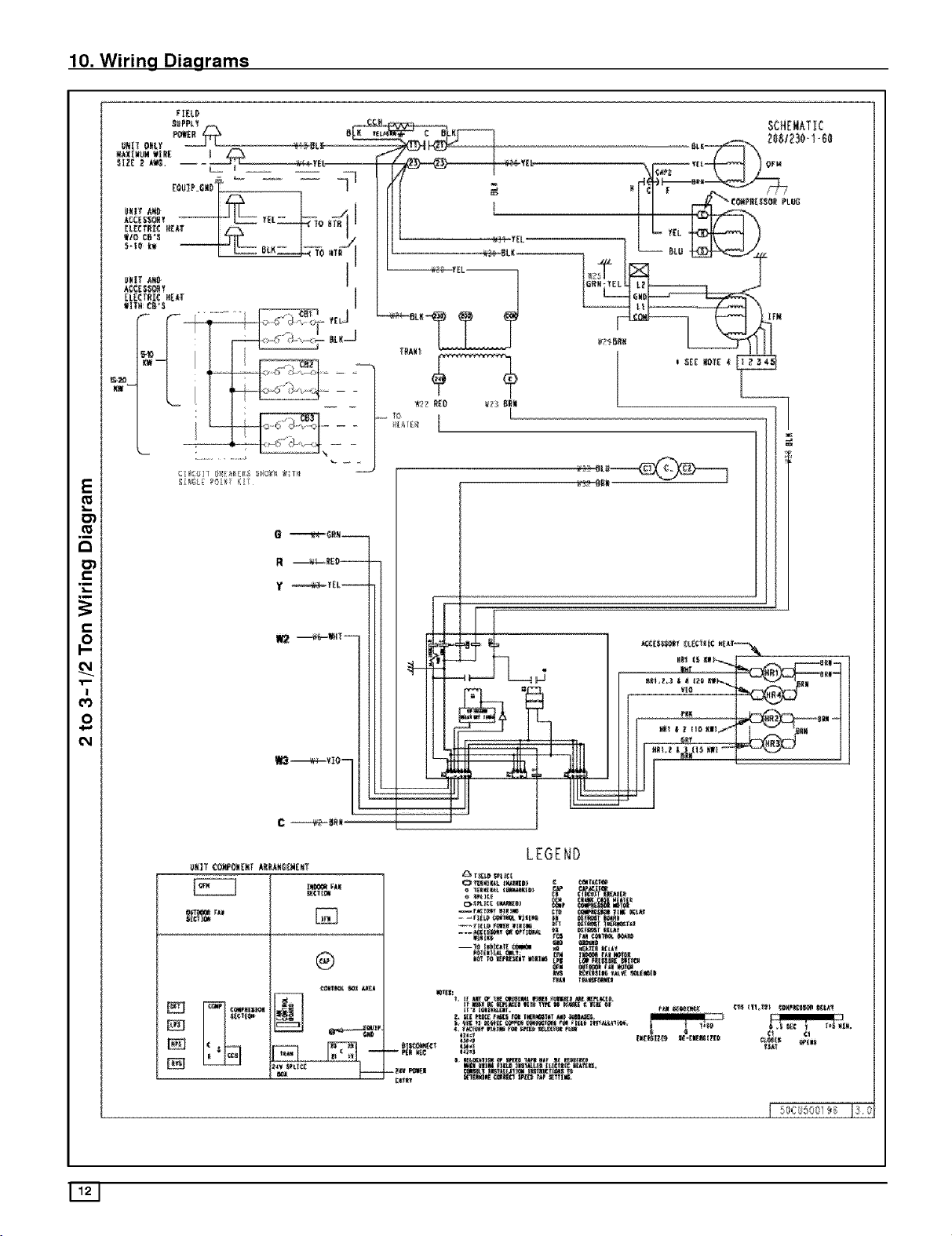

Line Voltage Wiring - (Wiring Diagrams page 12 & 13)

Connections for line voltage are made in the unit control box

area. Refer to wiring diagram located on the Burner Access

panel. For access, remove the burner access panel.

1. Run the high voltage (L1, L2) and ground leads into the

control box.

2. Connect ground lead to chassis ground connection.

3. Connect L1 to pressure lug connection 11 of the

compressor contactor.

4. Connect L2 to pressure lug connection 23 of the

compressor contactor.

Thermostat / Low Voltage Wiring

Location of the thermostat has an important effect on home

comfort. FOLLOW THE THERMOSTAT INSTRUCTION

MANUAL FOR CORRECT LOCATION, MOUNTING, AND

WIRING.

For 2 to 3-1/2 Ton Models Only:

A single stage thermostat is required for proper operation.

Thermostat must have the following terminals: "R', "W',

"Y", and "G'. Some electronic thermostats use low voltage

from the unit for power for temperature display and

programming. These electronic thermostats will have a'C"

terminal. The outdoor unit has color-coded wires for easy

connection. Using wire nuts, follow FIGURE 3 for proper

connections:

FIGURE 3 2 to 3-1/2 Ton Thermostat Connections

_!_ REO

\ J

K J i ',

Thermostat and subbase Unit Control Power

For 4 to 5 Ton Models Only:

A two-stage thermostat is required for proper operation.

Thermostat should have the following terminals: "R",

"W/W1 ", "Y1", "Y2", and "G'. Some electronic thermostats

use low voltage from the unit for power for temperature

display and programming. These electronic thermostats

will have a "C" terminal. The outdoor unit has color-coded

wires for easy connection. Using wire nuts, follow FIGURE

4 for proper connections:

FIGURE 4 4 to 5 Ton Thermostat Connections

©

Cv

©

Thermostat and subbase Unit Control Power

Page 6

THERMOSTAT HEAT ANTICIPATOR

Some thermostats have an adjustable heat anticipator. The

heat anticipator prevents temperature overshoot in heating

mode. If the heat doesn't turn off until the set point

temperature on the thermostat is exceeded, then the

anticipator setting is too low. If the heat turns off before the

thermostat reaches the set point temperature on the

thermostat, then the anticipator setting is too high. Follow

the thermostat instruction manual for proper adjustment of

the heat anticipator.

Final Electrical Check

1. Make a final wiring check to be sure system is correctly

wired. Inspect field installed wiring and the routing to

ensure that rubbing or chafing due to vibration will not

occur.

NOTE: Wiring MUST be installed so it is protected from

possible mechanical damage.

5. DUCTWORK

Ductwork Sizing

The maximum recommended velocity in trunk ducts is 1000

feet per minute. The maximum recommended velocity in

branch ducts is 800 feet per minute.

Ductwork sizing affects the discharge temperature, airflow

velocity, and efficiency of the system. Be sure to properly

size ductwork to the capacity of the unit and to the airflow

requirements of the conditioned space. Failure to properly

size ductwork can result in inadequate airflow and poor

efficiency. Undersized ductwork may result in tripped limit

controls and premature failure of compressors, motors and

other components.

Ductwork Insulation

Ductwork installed outdoors must have a minimum 2" thick

fiberglass "wrap" insulation and a weatherproof vapor

FIGURE 5 Filter Sizes

barrier installed around it. The insulation and vapor barrier

must be protected against potential damage. Caulking,

flashing, and other means of providing a permanent

weather seal must be used.

Ductwork Connections

The use of flexible, non-combustible connectors between

main trunk ducts and supply and return air plenums is

permitted. If flexible connectors are used, they should be

protected from potential mechanical damage such as

punctures and tears.

NOTE: When connecting the supply and return plenums to

the unit, make sure that the plenums are sealed against the

side casing of the unit and do not interfere with removal of

the top of the unit.

FILTERS

All return air MUST pass through a filter before entering the

unit. An electronic air cleaner, optional filter racks, or other

accessible filter arrangement must be installed in the return

air ductwork. Minimum recommended filter sizes are listed

in FIGURE 5 and are based on maximum face velocities of

300 ft/min for disposable filters and 500 ft/min for washable

(high velocity) filters. See FIGURE 5 for filter sizes.

REDUCED EQUIPMENT LIFE HAZARD

Failure to follow this caution may result in improper

unit operation.

Do not operate the unit without a filter,

PAF3 Filter sizes

Model

PAF324000K00A1

PAF330000K00A1

PAF336000K00A1

PAF342000K00A1

PAF348000K00A1

PAF354000K00A1

Disposable Filters

Nominal Size

(Qty x w x d)

1 x 20" x 20"

1 x 20" x 24"

2x 15"x20"

2x 18"x20"

2 x20"x20"

2 x20"x24"

Minimum Area

(sq inches)

384

480

576

672

768

900

Wasable Filters

Nominal Size

(Qty x w x d)

1 x 12" x 20"

1 x 15" x 20"

1 x 18" x 20"

1 x 20" x 20"

1 x 20" x 24"

1 x 24" x 24"

Minimum Area

(sq inches)

231

288

346

4O4

461

54O

Page 7

6. AIRFLOW ADJUSTMENT

CIRCULATING AIR BLOWER SPEEDS

BLOWERPERFORMANCEDATA

ModeINumber PAF324000KOOA1 PAF330000K00A1 PAF336000K00AI PAF342000K00AI PAF348000K00AI PAF354000KOOA1

SpeedTap 1 2 3 4 1 2 3 4 1 2 3 4 t 2 3 4 t 2 3 4 t 2 3 4

0.1 891 1136 986 1076 1286 1352 1162 1278 1529 1652 1138 1240 1505 1643 1154 1245 1750 1908 1348 1449 1998 2173

0.2 845 1098 949 1038 1225 1311 1118 1233 1484 1607 1087 1189 1467 1609 1084 1170 1696 1864 1274 1372 1943 2113

0.3 804 1056 908 997 1186 1274 1062 1191 1440 1574 1041 1145 1431 1577 1005 1110 1643 1819 1218 1318 1895 2067

AirDeliveryinCFM 0.4 758 1020 856 973 1158 1233 1014 1149 1402 1541 989 1104 1398 1541 940 1034 1592 1770 1151 1258 1850 2032

@Varying External 0.5 707 980 8t9 913 1129 1203 958 1108 1364 1501 940 1063 1363 1509 880 972 1547 1720 1085 1195 1800 2003

Static Pressure (in. 0.6 649 920 781 875 1085 1162 892 1060 1326 1462 865 1010 1324 1476 832 924 1497 1678 1032 1130 1750 1962

w.c.) 0.7 582 785 717 840 1044 1119 826 1005 1284 1426 806 952 1283 1439 780 875 1443 1632 989 1086 1705 1904

0.8 509 569 664 786 1004 1066 780 943 1238 1384 752 891 1234 1402 713 836 1400 1586 954 1048 1659 1822

0.9 318 612 717 948 989 735 892 1179 1338 694 828 1175 1352 663 773 1354 1538 904 1000 1602 1727

1 554 659 755 774 675 844 1123 1277 646 773 1120 1264 613 720 1302 1494 85I 946 1530 1603

Notes:

Air Defivery@listed external staticpressreare taken at 230Volts with Dry coil, no filter and approved heater

Forwet coit add .05 in. wc to Static Pressuremeasurement Note for 208Volts applications, reduceairflow by 15%

FIGURE 6

Blower Tap Connections

Blower Speed Tap Settings

Rated Airflow High Airflow

PAF324000K Speed Tap 1 Speed Tap 3

PAF330000K Speed Tap 2 Speed Tap 3

PAF336000K Speed Tap 2 Speed Tap 3

PAF342000K Speed Tap 3 Speed Tap 4

PAF348000K Speed Tap 3 (Hi); 2 (Lo) Speed Tap 4 (Hi); 3 (Lo)

PAF354000K Speed Tap 3 (Hi); 2 (Lo) Speed Tap 4 (Hi); 3 (Lo)

Verify that the proper blower speeds for heating and cooling

are selected on the blower motor by removing the blower

access panel and inspecting the blower motor, The motor

has 4 speeds numbered "1", "2", "3", and "4", The wires for

CONTINUOUS FAN OPERATION

Continuous fan speed operates at the cooling speed for 2

thru3-1/2 ton models and at the low stage cooling speed for

4 and 5 ton models.

the speed selection are as follows:

Red _ Heating

Black _ High Stage Cooling

Violet _ Low Stage Cooling (4 & 5 ton only)

Using the same speed for Heating and Cooling.

COOLING

1. Turn electric power OFF

2. Set thermostat Heat-Cool select to COOL.

3. Adjust thermostat setting to below room temperature.

4. Turn power ON, for approximately one minute, then

If the same speed is required for heating and high stage

cooling the following procedure must be used:

1. Set Red wire on proper speed selection on blower

motor.

2. Remove Black wire from "COOL" (2 - 3.5 Ton models)

or "HI" (4 - 5 Ton Models) on Blower Interface Board.

Tape end of Black lead using electrical tape.

3. Jumper the Red wire to both the "Heat" terminal and

either the "COOL" (2 - 3.5 Ton models) or'HI" (4 - 5Ton

Models) terminal on the Blower Interface Board.

If the same speed is required for heating and low stage

cooling (4 & 5 Ton models only), the following procedure

must be used:

OFF. During power application check the following:

a. Contactor - Contacts Closing

b. Compressor - ON

c. Condenser fan motor - ON

d. Circulating Air Blower - ON 0 second delay

5. Turn power OFE check the following:

a. Contactor contacts opening.

b. Compressor - OFF

c. Condenser fan motor - OFF

d. Circulating blower - OFF after a 60 second delay for

2 thru 3-1/2 ton models and a 90 second delay for 4

and 5 ton models.

1. Set Red wire on proper speed selection on blower

motor.

2. Remove Violet wire from "LO" on Blower Interface

Board. Tape end of Violet lead using electrical tape.

3. Jumper the Red wire to both the "Heat" terminal and the

"LO" terminal on the Blower Interface Board.

171

Page 8

7. START-UP PROCEDURES

CHECK BEFORE STARTING

1. Check that the blower motor speed terminal block is

running the correct heating and cooling speeds.

2. Check to see that clean, properly sized air filters are

installed.

3. Replace all service access panels.

Check the unit's operation as outlined in the following

instructions. If any unusual sparking, odors or unusual

noises are encountered, shut off electric power

immediately. Recheck for wiring errors, or obstructions in or

near blower motors.

1. Set thermostat Heat-Cool selector to OFE

2. Set thermostat fan switch to AUTO.

3. Turn electric power ON. Nothing should start running.

4. Set thermostat fan switch to ON,

5. Reset thermostat fan switch to AUTO,

8. Sequence of OPERATION

operation. When heating demand is met, W3 and W2

sequentially de-energize shutting the indoor fan and the

electric heater.

Heating Operation (048 - 054):

With a call for heating (W2), the auxiliary electric heater is

energized along with the Indoor blower. Ifthe demand is not

met, W3 is energized incase of staged heating. When

heating demand is satisfied, W3 and W2 sequentially

de-energize along with the indoor fan blower.

Continuous Fan:

With the continuous Indoor fan option selected on the

thermostat, G is continuously energized. Incase of 024 -

042 units, the selected airflow setting is provided. In the

case of 048 and 060 units, the system runs low stage (Y1)

airflow for continuous fan operation.

9. MAINTENANCE

MONTHLY MAINTENANCE AND INSPECTION

CHECKS

Air Filters

ELECTRICAL SHOCK HAZARD.

Failure to follow this warning could result in personal

injury, death and/or property damage.

Turn off electric power supply at disconnect switch or

service panel before removing any access or service

panel from unit.

Cooling Operation (024 - 042):

With a call for cooling (Y), the indoor fan energizes

immediately whereas the contactor energizes after a 5

minute time delay (incase of an initial start up) starting the

compressor and the outdoor fan motor. When the cooling

demand is met, (Y) de-energizes, shutting the compressor,

indoor fan and the outdoor fan.

Cooling Operation (048 - 054):

These units utilize a 2 stage indoor thermostat. With a first

stage call for cooling (Y1), the indoor fan (low stage)

energizes immediately whereas the contactor energizes

after a 5 minute time delay (incase of an initial start up)

starting the compressor (low stage) and the outdoor fan

motor. If the low stage operation cannot satisfy the cooling

demand, the second stage cooling (Y2) energizes

switching the compressor into high stage cooling through

energizing an internal solenoid valve inside the scroll

compressor and switching the indoor fan into high stage.

When second stage cooling is satisfied, Y2 de-energizes

switching the compressor and the indoor fan into low stage

cooling. When the low stage cooling demand is met, Y1

de-energizes shutting the compressor, indoor fan and the

outdoor fan.

Heating Operation (024 - 042):

With a call for heating (W2), the auxiliary or electric heat

energizes along with the Indoor blower. Incase of staged

heating, W3 is energized if the demand is not met. The

highest airflow selected is run while the electric heat is in

REDUCED EQUIPMENT LIFE HAZARD

Failure to follow this cautions may result in damage to

the unit being installed.

Do not operate the unit without a filter.

Inspect filters at least monthly and replace or clean as

required. Washable filters may be cleaned by soaking in

mild detergent and rinsing with cold water. Replace filters

with the arrows on the side pointing in the direction of air

flow. Dirty filters are the most common cause of inadequate

heating or cooling performance, and of compressor

failures.

COOLING SEASON CHECKS (MONTHLY)

Condenser Coil

Keep the condenser inlet and outlet area clean and free of

leaves, grass clippings or other debris. Grass should be

kept short in front of the condenser inlet. Shrubbery MUST

be trimmed back so it is no closer than 30 inches to unit.

Condensate Drain

Check for condensate drainage. Clean as required.

Page 9

ANNUAL MAINTENANCEANDINSPECTION

ELECTRICAL SHOCK HAZARD.

Failure to follow this warning could result in personal

injury, death and/or property damage.

Turn off electric power supply at disconnect switch or

service panel before removing any access or service

panel from unit.

The annual inspection should include cleaning as required

to ensure efficient operation of the unit. To simplify access,

remove all access panels and the top from the unit if

possible.

Condenser Fan Motor

Note: The condenser fan motor is permanently lubricated.

No further lubrication is required. Do not attempt to

lubricate the condenser fan motor.

Clean the surrounding area and the condenser and

evaporator coils. Use caution to avoid damage to coil fins.

BLOWER MOTOR ACCESS

1. Remove the blower access panel

2. Remove the three screws securing the blower motor

housing. If unit has a support bracket, remove the two

screws securing the bracket.

3. Remove the two red wires attached to the limit switch

and remove the limit switch.

Motor removal and replacement

This method is required to replace or repair blower wheel,

blower housing, or any unreachable components behind

blower assembly.

1. Remove all screws around rim of unit top, (except

screws which are inaccessible because of proximity to

structure).

2. Raise unit top at corner of unit closest to blower at least

2" and place a sturdy brace at least 2" thick between top

and unit corner. A 2X4 piece of wood is ideal for this.

3. Disconnect all wires from housing and slide housing out

of unit. Reverse this process to reinstall.

Circulating Air Blower

Visually inspect the blower wheel for accumulations of dirt

or lint. Clean the compartment and the blower wheel. If

accumulation is excessive on blower wheel, or does not

easily remove, it will be necessary to remove the blower

assembly.

Note: The blower motor is permanently lubricated. No

further lubrication is required. Do not attempt to lubricate

the blower motor.

191

Page 10

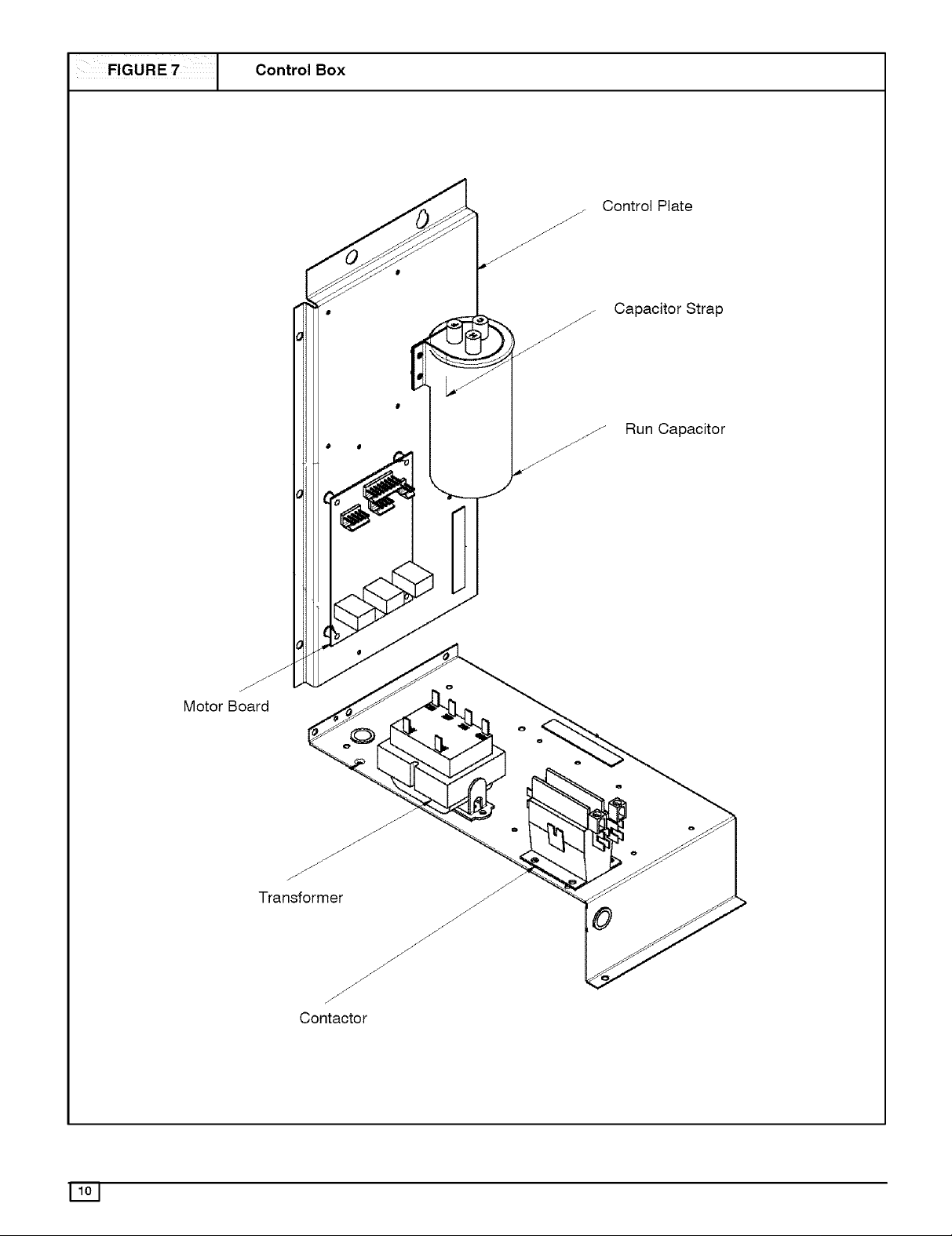

FIGURE 7

Control Box

Control Plate

Capacitor Strap

j-

.j/ Run Capacitor

Motor Board

Transformer

Page 11

R GG NG INSTRUCTIONS __

fAiLURETOfOLLOW-_-SE_.STRUC-r_O_S

//_ WA_\ NO CAN RESULT IN PROPERTY DAMAGE,

BoD,_,_u_R_oRDEAT_

.o

:D

C:

rn

QO

- ALL PANELS MUST BE IN PLACE WHEN RIGGING AND LIFTING.

- HOOK RIGGING SHACKLES THROUGH HOLES IN BASE RAIL, AS SHOWN IN DETAIL-A.

- USE SPREADER BARS, WHEN RIGGING, TO PREVENT UNIT DAMAGE.

- BE SURE RIGGING AND SHACKLES ARE SUFFICIENT TO HANDLE WEIGHT LISTED BELOW.

DETAIL-A

DER BARS

-¢

HEIGHT

_OR _

_J

LENGTH WIDTH

tQ

t_

f-

0

m.

o

:3

F

Max. Length Max. Width

Cabinet IN MM IN MM

2Ton 48 1219 48 1219

2-1/2 to 5 Ton 48 1219 48 1219

Max. Height

IN MM

30 762

38 965

Max. Weight

LB KG

300 137

400 182

Page 12

10. Wiring Diagrams

Fl_t 0

f_

,n

,m

C_l

cO

C_l

E

Ol

li

O_

ol

O'i

li

0

_ _I_! ¸ K_L

O _N_ 7

m

!

ii

II ? I :_.......

II | l ] II _,,,,,a,,,i__

!! !_ ; .... ]........ , .l{t%_ l{,l

UNIT CO_ON_NT _kNC_E_EXT

I i

®

Ill lll,ltt _lil_l_ll_ Illtl

Ifllll

{ 5_}6 589i_8 !3 0

Page 13

[I[L_

SCHEN_ATIC

2081230-140

E

r-

"r"

r-

t_

O

BL_

+

m2

Y2

_'I II},_I_ KII_ _B_ -II¸_

C _BkN

LEGEND

BNIT {OHPC_4[NT k_L!_6_WE_T

®

_L

EXCEPT

Loading...

Loading...