Page 1

• Safety Labeling & Rules

• Installation Requirements

• Location / Clearances

',× _ ,

• Air Distribution

• Wiring '_

• Ductwork Connections

• Economizer Accessory

• Start-Up

• Maintenance

• Hoisting / Rigging

MODELS

PAB240 RAMA20

513 01 14 01 01 7/1/97

LP1

Page 2

Table of Contents

1. Safety Labeling and Signal Words ........................... 2

Danger, Warning and Caution

...............................................................

Signal Words

...............................................................

Signal Words in Manuals ............................................. 2

Product Labeling ................................................... 2

Danger Label ...................................................... 2

Warning Label ..................................................... 2

Caution Label ...................................................... 2

2. Unit Dimensions ......................................... 3

3. Safe Installation Requirements ............................. 4

4. Location And Set-up ..................................... 5

Access Panels ...................................................... 5

Clearances ......................................................... 5

Minimum Clearances to Combustible and

non-Combustible Construction (Horizontal Flow) ................... 6

Minimum Clearances to Combustible and

non-Combustible Construction (Downflow) ........................ 6

Installation ........................................................ 7

Ground Level Installation ............................................ 7

Rooftop Installation ................................................. 7

Hoisting ........................................................... 7

Converting to Horizontal Operation ................................... 7

Condensate Drain .................................................. 7

5. Electrical Wiring ......................................... 9

Line Voltage Wiring ................................................. 9

Line Connections ................................................... 9

Converting 230V Units to 208V ....................................... 9

Field Installed Equipment ........................................... 10

Low Voltage Wiring ................................................. 10

Low Voltage Wiring With Economizer Option ........................... 10

Thermostat ........................................................ 10

Heat Anticipator ................................................... 10

Final Check ........................................................ 10

6. Air Distribution System ................................... 11

Ductwork .......................................................... 11

Ductwork Connections .............................................. 11

Filters ............................................................ 11

Circulating Blower ................................................. 11

Determining Blower Speed ........................................... 11

7. Adjustable Belt Drive Blower ............................... 14

8. Economizer Accessory ..................................... 16

Static Additions .................................................... 16

Page 3

Theory of Operation ................................................ 16

Sequence of Operation .............................................. 17

9. Start-up Procedure ...................................... 18

Blower and Phasing Check ........................................... 18

Cooling Checks ..................................................... 19

10. Operation And Maintenance Instructions ................... 20

Turning Off the Unit ................................................ 20

Heating ........................................................... 20

Cooling ........................................................... 20

Starting the Unit After Shutdown ..................................... 20

Heating ........................................................... 20

Cooling ........................................................... 20

Thermostat Fan Switch Operation ..................................... 20

Adjusting Room Temperatures ........................................ 20

Monthly Maintenance and Inspection Checks ........................... 21

Air Filters (Factory Installed) ......................................... 21

Disposable Replacement Filters ....................................... 21

Cooling Season Checks (Monthly) ..................................... 21

Condenser Coil ..................................................... 21

Condensate Drain .................................................. 21

Annual Maintenance and Inspection ................................... 21

Circulating Air Blower .............................................. 21

11. Rigging Instructions ..................................... 23

Page 4

I Single Package Air Conditioners Installation Instructions !

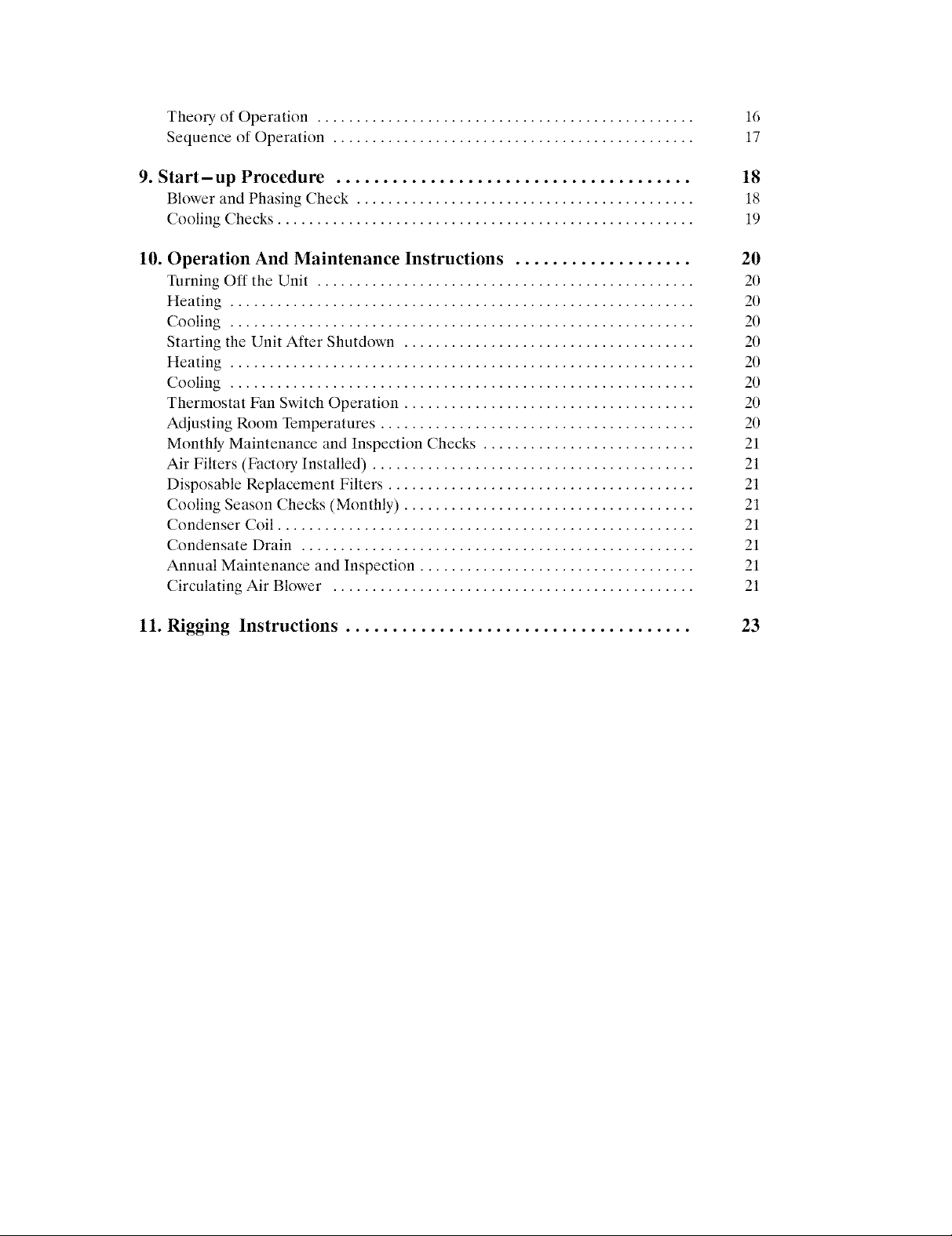

1. Safety Labeling and Signal Words

Danger, Warning and Caution

The signal wordsDANGER, WARNING and CAUTION are

used to identify levels of hazard seriousness. The signal

word DANGER is only used on product labels to signify an

immediate hazard. The signal words WARNING and

CAUTION will be used on product labels and throughout

this manual and other manuals that may apply to the

product.

Signal Words

DANGER - Immediate hazards which WILL result in

severe personal injury or death.

WARNING - Hazards or unsafe practices which COULD

result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which COULD

result in minor personal injury or product or property

damage.

Danger Label

White lettering on a black background except the word

DANGER which is white with a red background.

Warning Label

White lettering on a black background except the word

WARNING which is black with an orange background.

Signal Words in Manuals

The signal word WARNING is used throughout this manual

in the following manner:

The signal word CAUTION is used throughout this manual

in the following manner:

CAUTION

Product Labeling

Signal words are used in combination with colors and/or

pictures on product labels. Following are examples of

product labels with explanations of the colors used.

Caution Label

White lettering on a black background except the word

CAUTION which is black with a yellow background.

12J

Page 5

_ Installation Instructions Single Package Air Conditioners I

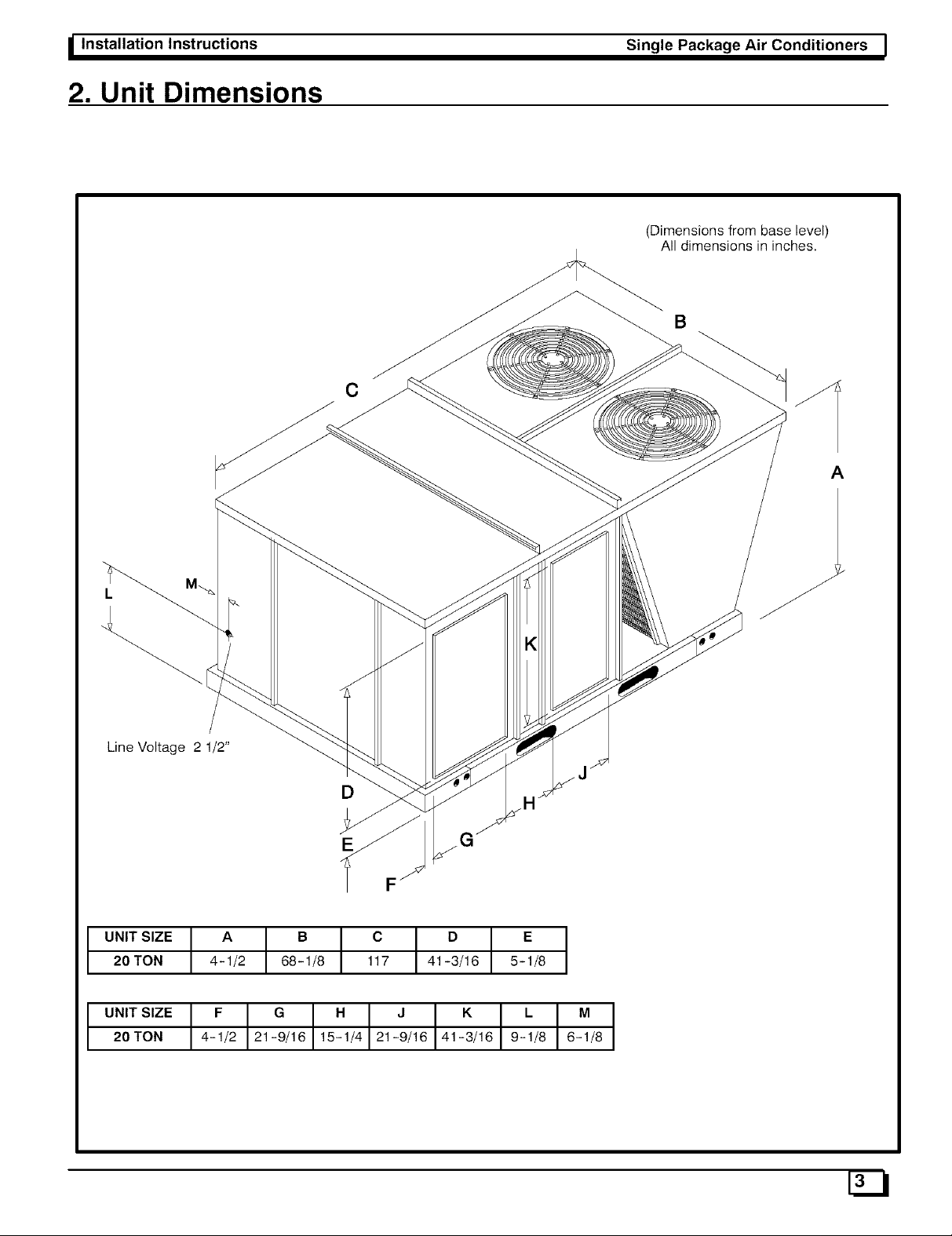

2. Unit Dimensions

(Dimensions from base level)

All dimensions in inches.

B

C

A

Line Voltage 2 1/2"

D

G

F

UNIT SIZE A B C / D E

20TON 4-1/2 68-1/8 117 T 41-3/16 5-1/8

U.,TS,Z.t_ o .

20 TON 21-9/16 21-9/16 41-3/16

Page 6

I Single Package Air Conditioners

3. Safe Installation Requirements

Installation or repairs made by unqualified

persons can result in hazards to you and others.

Installation must conform with local building

codes or, in the absence of local codes, with

National Electrical Code ANSI/NFPA 70-1990 or

current edition. In Canada the National Standard

CAN/CGA 1-B149.1 or current edition and CSA

C.22.1 - Canadian Electrical Code Part 1 or

current edition.

The information contained in this manual is

intended for use by aqualified service technician

familiar with safety procedures, equipped with

the proper tools and test instruments.

Failure to carefully read and follow all instruc-

tions in this manual can result in furnace

malfunction, property damage, personal injury

and/or death.

Installation Instructions

Installation MUST conform to the most current

version of the following standards or a superseding

standard.

In the United States:

• National Electrical Code ANSI/NFPA 70-1990

In Canada:

• CSA C.22.1 - Canadian Electrical Code Part 1.

Seal supply and return air ducts.

NOTE: It is the personal responsibility and obligation of the

customer to contact a qualified installer to ensure that the

installation is adequate and conforms to governing codes

and ordinances.

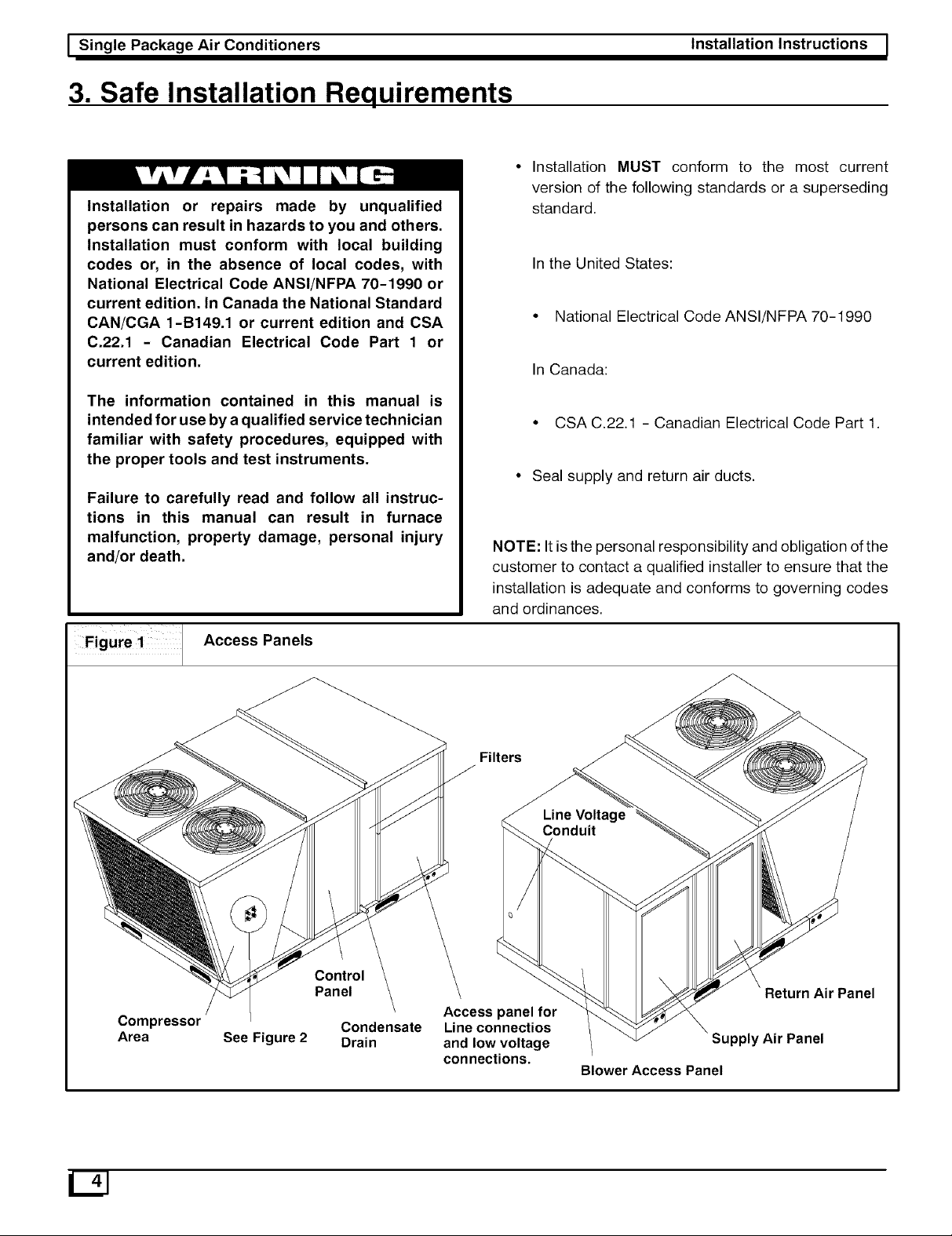

Figure ! 1 Access Panels

Control

Panel

Compressor Condensate

Area See Figure 2 Drain

Filters

Access panel for

Line connectios

and low voltage

connections.

Return Air Panel

Supply Air Panel

Blower Access Panel

Page 7

_ Installation Instructions Single Package Air Conditioners I

4. Location And Set-up

The unit is designed for outdoor installation ONLY. The unit

may be installed on a level concrete mounting base (or

other adequate platform) at ground level oron a flat rooftop

with an adequate platform. If using as a downflow model,

use a roof curb. Typical installations are shown in Figures

3 and 4.

Access Panels

CAUTION

Unit will NOT operate properly without all access

panels in place. Access panels are shown in Figure 1.

Unit MUST NOT be moved unless all access panels are

in place.

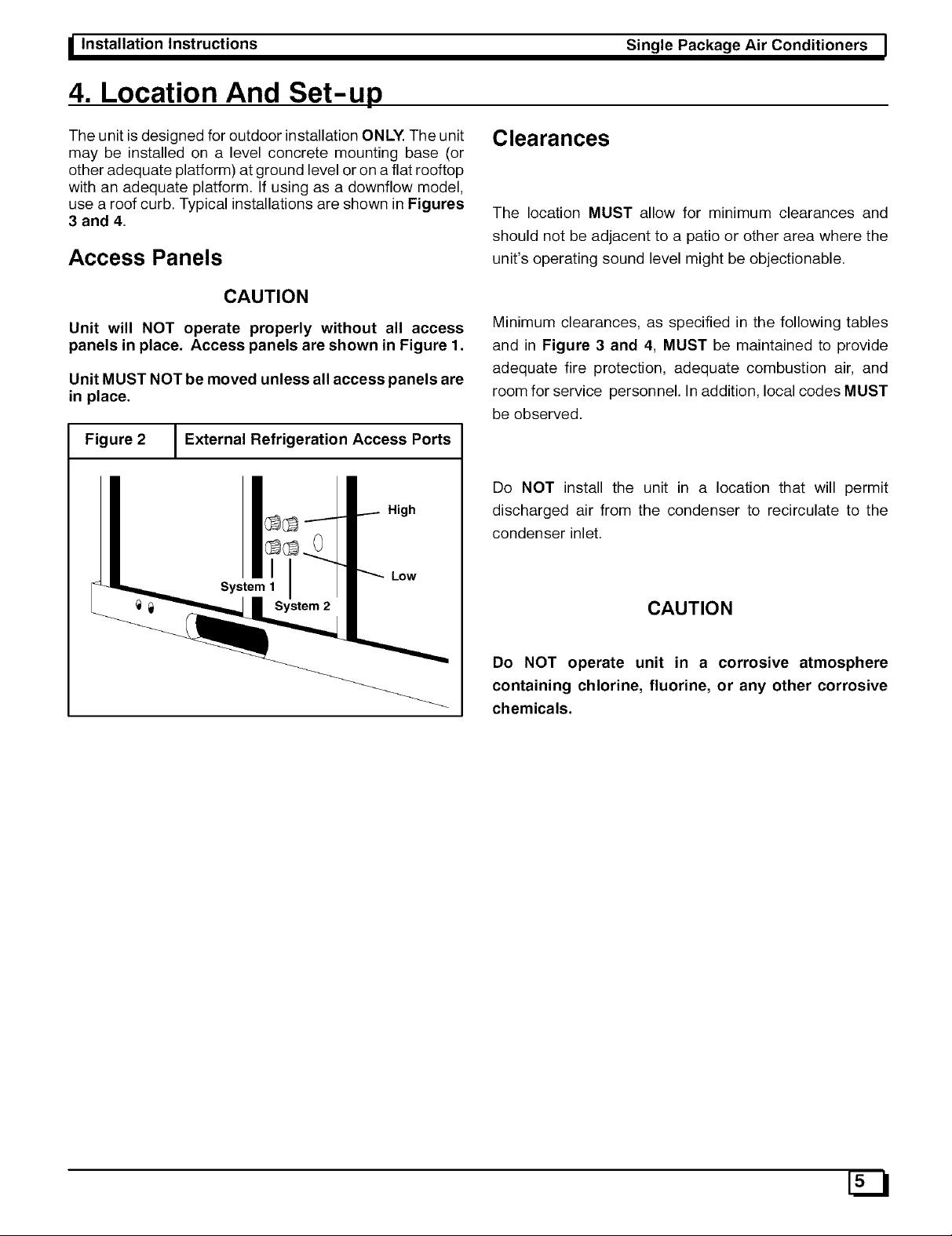

Figure 2 I External Refrigeration Access Ports

1

High

Low

System 1

_ System 2

Clearances

The location MUST allow for minimum clearances and

should not be adjacent to a patio or other area where the

unit's operating sound level might be objectionable.

Minimum clearances, as specified in the following tables

and in Figure 3 and 4, MUST be maintained to provide

adequate fire protection, adequate combustion air, and

room for service personnel. In addition, local codes MUST

be observed.

Do NOT install the unit in a location that will permit

discharged air from the condenser to recirculate to the

condenser inlet.

CAUTION

Do NOT operate unit in a corrosive atmosphere

containing chlorine, fluorine, or any other corrosive

chemicals.

Page 8

I Single Package Air Conditioners

Installation Instructions !

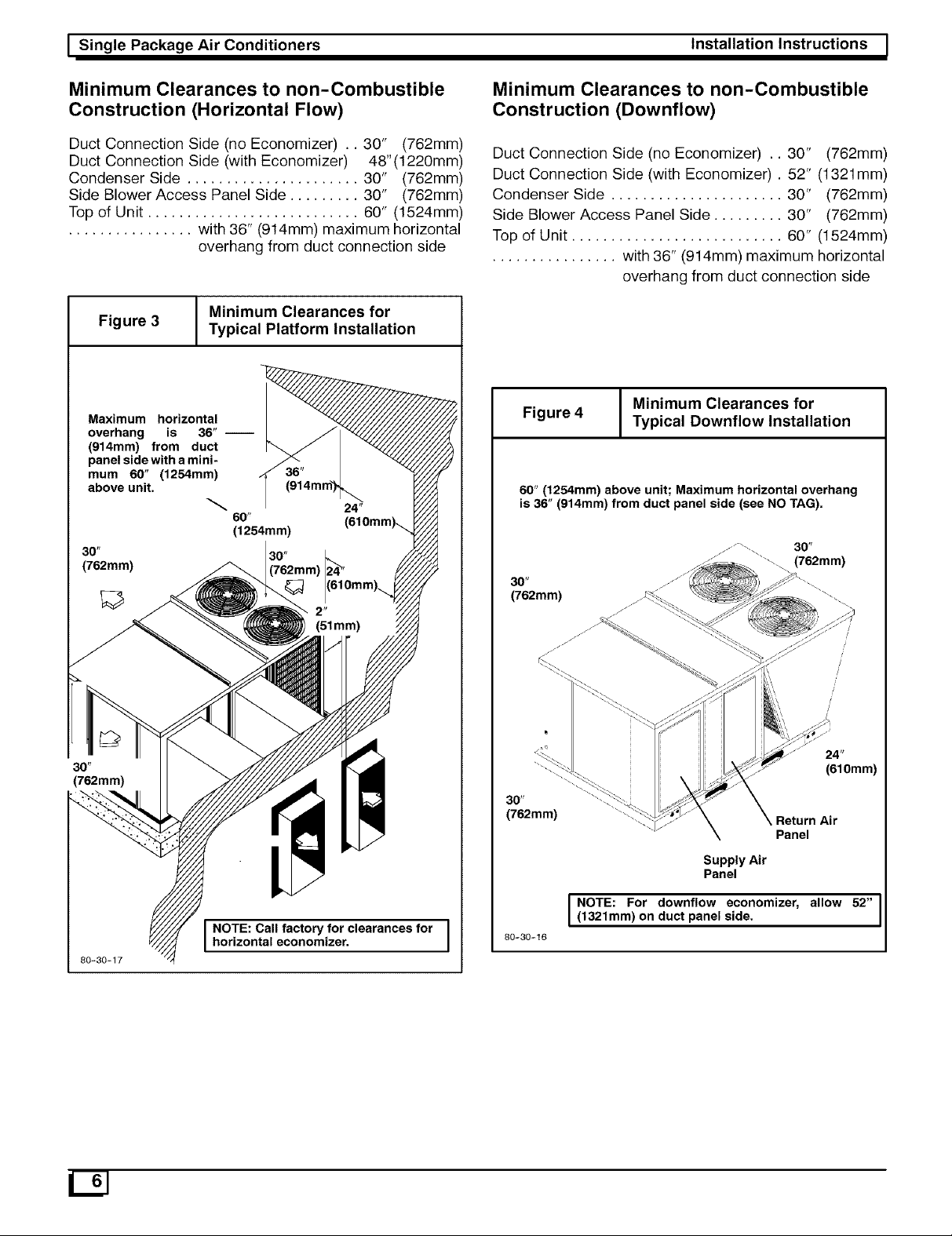

Minimum Clearances to non-Combustible

Construction (Horizontal Flow)

Duct Connection Side (no Economizer) .. 30" (762mm)

Duct Connection Side (with Economizer) 48"(1220mm)

Condenser Side ...................... 30" (762mm)

Side Blower Access Panel Side ......... 30" (762mm)

Top of Unit ........................... 60" (1524mm)

................ with 36" (914mm) maximum horizontal

overhang from duct connection side

Minimum Clearances for

Figure 3 Typical Platform Installation

Maximum horizontal

overhang is 36" i

(914mm) from duct

panel side with a mini-

mum 60" (1254mm)

above unit.

60"

Minimum Clearances to non-Combustible

Construction (Downflow)

Duct Connection Side (no Economizer) .. 30" (762mm)

Duct Connection Side (with Economizer) . 52" (1321mm)

Condenser Side ...................... 30" (762mm)

Side Blower Access Panel Side ......... 30" (762mm)

Top of Unit ........................... 60" (1524mm)

................ with 36" (914mm) maximum horizontal

overhang from duct connection side

Minimum Clearances for

Figure 4 Typical Downflow Installation

60" (1254mm) above unit; Maximum horizontal overhang

is 36" (914mm) from duct panel side (see NO TAG).

30 _

(762mm)

30 _

(762mm)

80-30-17

horizontal economizer.

I NOTE: Call factory for clearances for I

30"

(762mm)

30"

(762mm)

80-30-16

30 _

(762mm)

24"

(610mm)

Return Air

Panel

SupplyAir

Panel

I NOTE: For downflow economizer, allow 52"(1321mm) on duct panel side.

Page 9

_ Installation Instructions Single Package Air Conditioners I

Installation

CAUTION

Unit will NOT operate properly unless it is installed

level front to rear and side to side.

The slope MUST NOT be greater than 1/8" per foot

(10mm per meter). For side to side leveling, the control

box side MUST always be lower.

Ground Level Installation

Ground level platform requirements:

The unit MUST be situated to provide safe access for

servicing.

Platform may be made of either concrete or pressure

treated wood and MUST be level and strong enough

to support unit weight.

Position platform separate from building foundation.

Install in well-drained area, with top surface of

platform above grade level.

Platform MUST be high enough to allow for proper

condensate trap installation and drainage. See

Figure 5 and associated text for more information

about condensate drainage.

- See Hoisting section below for hoisting instructions.

NOTE: Cardboard covers on horizontal supply and

return duct openings MUST be removed before

starting unit.

Hoisting

NOTE: All access panels MUST be secured in place before

hoisting.

The unit should be hoisted with two lifting slings. Attach the

slings to rigging shackles that have been hooked through

holes in the base rail.

Two spreader bars MUST be placed on top of the unit to

protect the unit from damage from the pressure exerted by

the slings. Make sure that all equipment is adequate to

handle the weight of the unit and that the slings will not

allow the unit to shift.

Refer to the back cover of this manual for illustrated

rigging instructions and weight chart.

Converting to Horizontal Operation

These units are shipped ready for downflow operation but

are adaptable to horizontal use. To convert to horizontal

operation, follow these steps:

Rooftop Installation

Rooftop platform requirements:

The unit MUST be situated to provide safe access for

servicing.

The existing roof structure MUST be adequate to

support the weight of the unit or the roof MUST be

reinforced.

Check the weight of the unit in relation to the roof

structure and local building codes or ordinances and

reinforce roof structure if necessary. See the back

cover of this manual for unit weights and corner

weights.

Support for the unit MUST be level and strong

enough to carry unit weight. The support may consist

of a platform or a combination of platform and roof

beams or curb.

The platform may be constructed of pressure treated

wood and may be covered with Class A, B or C roof

covering.

Platform MUST allow for proper condensate trap

installation and drainage. See Figure 5 and

associated text for more information about

condensate drainage.

1.

Remove horizontal supply and return panels (see

Figure 1).

2.

Remove cardboard covers from downflow supply

and return openings.

.

Install horizontal supply and return panels on

downflow supply and return openings. Be sure

flanges are down and insulation side is up. Install

from inside of unit.

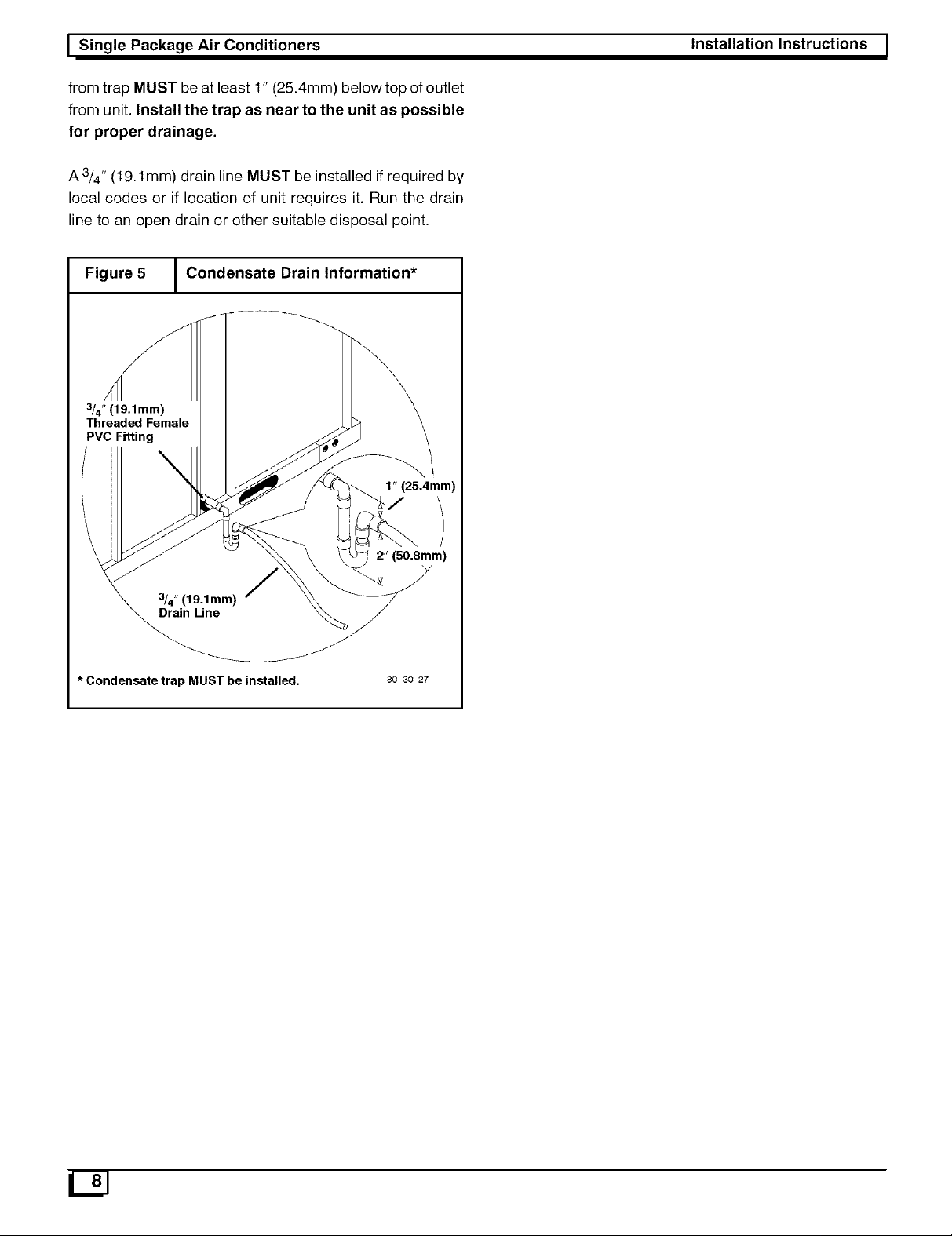

Condensate Drain

The condensate drain outlet is a 3/4" (19.1mm) threaded

female PVC connection located at the bottom of the unit to

the left of the electrical access panel (see Figure 5).

Condensate drain outlet MUST be held with wrench when

installing trap and drain line.

The circulating blower and the condenser fan create a

negative pressure on the condensate drain line that will

prevent the condensate from draining properly without a

trap. To combat this negative pressure, a field supplied

condensate trap that will allow a standing column of water

of at least 2" (50.8mm) MUST be installed. Top of outlet

Page 10

I Single Package Air Conditioners Installation Instructions !

from trap MUST be at least 1" (25.4mm) below top of outlet

from unit. Install the trap as near to the unit as possible

for proper drainage.

A3/4 " (19.1mm) drain line MUST be installed if required by

local codes or if location of unit requires it. Run the drain

line to an open drain or other suitable disposal point.

Figure 5 I Condensate Drain Information*

3/4" (19.1mm)

Threaded Female

PVC Fitting

1" (25.4mm)

/,

\

3/4"(19.1mm)

Drain Line

* Condensate trap MUST be installed.

2" (50.8mm)

8_3_27

Page 11

I Installation Instructions

5. Electrical Wiring

Electrical shock hazard.

Shut off electric power at unit disconnect or ser-

vice panel before making any electrical connec-

tions.

Unit MUST be grounded to electrical service pan-

el.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

NOTE: All electrical work MUST conform with the

requirements of local codes and ordinances and in the

United States the National Electrical Code

ANSI/NFPA70-1990 (or current edition) and in Canada

CSA C.22.1 - Canadian Electrical Code Part 1 (or current

edition). Provide line voltage power supply from a separate

protected circuit with a disconnect switch (when required)

located within sight of the unit. Supply voltage, amperage,

wire, fuse and disconnect switch sizes MUST conform with

specifications on the unit rating plate.

Single Package Air Conditioners I

Figure 6 J Control Box

Anti-Cycle

Anti-Cycle Timer 1

Timer 2 _,

Transformer

Transformer (460/575 Volt

(240v) Only)

Contactor

DSP

(Blower)

Contactor

Contactor C2

Contactor C1

Ground Lug

Wiring MUST be protected from possible mechanical

damage and MUST NOT interfere with removal of access

panels, filters, etc.

All exposed wiring or connections MUST be made with

weatherproof cable or wire unless installed in conduit.

Connections for line voltage are made in the lower blower

section section. Low voltage connections are made at the

terminal board in the blower section on the right hand side

(see Figure 7).

For access to high and low voltage connections, remove

the lower blower access panel. (see Figure 1).

Line Voltage Wiring

Line voltage wires enter the unit through the double

knockout on the end of the unit next to the blower. (see

Figure 7). Do NOT complete line voltage connections until

unit is permanently grounded. All line voltage connections

and the ground connection MUST be made with copper

wire.

fans)

Line Connections

Complete the line service connections to the terminal block

in the blower section. Refer to applicable wiring diagram.

Check all screw terminals to ensure they are tight.

Converting 230V Units to 208V

To convert 230V units to 208V:

1. Turn electric power OFF.

2. Remove control box access panel and open control

box. Locate the 24V control transformer.

.

Remove wires from the terminal labeled '240V' on

the 24V control transformer and reconnect them to

the 208V terminal of the 24V control transformer.

4.

Close control box and replace control box access

panel.

Page 12

I Single Package Air Conditioners

Installation Instructions

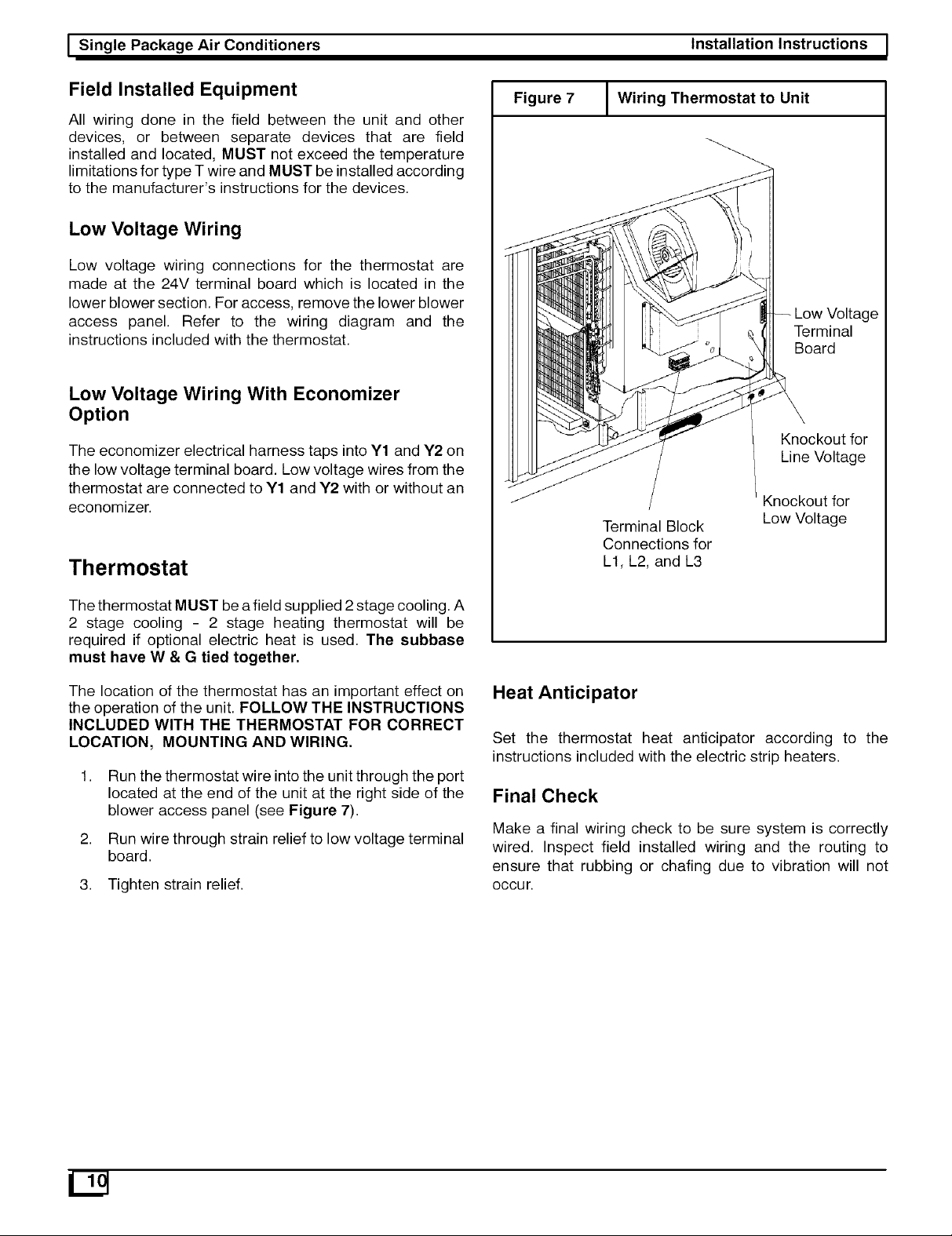

Field Installed Equipment

All wiring done in the field between the unit and other

devices, or between separate devices that are field

installed and located, MUST not exceed the temperature

limitations for type T wire and MUST be installed according

to the manufacturer's instructions for the devices.

Low Voltage Wiring

Low voltage wiring connections for the thermostat are

made at the 24V terminal board which is located in the

lower blower section. For access, remove the lower blower

access panel. Refer to the wiring diagram and the

instructions included with the thermostat.

Low Voltage Wiring With Economizer

Option

The economizer electrical harness taps into Y1 and Y2 on

the low voltage terminal board. Low voltage wires from the

thermostat are connected to Y1 and Y2 with or without an

economizer.

Thermostat

Figure 7

J Wiring Thermostat to Unit

Knockout for

Line Voltage

Knockout for

Terminal Block

Connections for

L1, L2, and L3

Low Voltage

Terminal

Board

The thermostat MUST be afield supplied 2stage cooling. A

2 stage cooling - 2 stage heating thermostat will be

required if optional electric heat is used. The subbase

must have W & G tied together.

The location of the thermostat has an important effect on

the operation of the unit. FOLLOW THE INSTRUCTIONS

INCLUDED WITH THE THERMOSTAT FOR CORRECT

LOCATION, MOUNTING AND WIRING,

1.

Run the thermostat wire into the unit through the port

located at the end of the unit at the right side of the

blower access panel (see Figure 7).

2.

Run wire through strain relief to low voltage terminal

board.

3. Tighten strain relief.

Heat Anticipator

Set the thermostat heat anticipator according to the

instructions included with the electric strip heaters.

Final Check

Make a final wiring check to be sure system is correctly

wired. Inspect field installed wiring and the routing to

ensure that rubbing or chafing due to vibration will not

Occur.

129

Page 13

_ Installation Instructions

6. Air Distribution System

Single Package Air Conditioners I

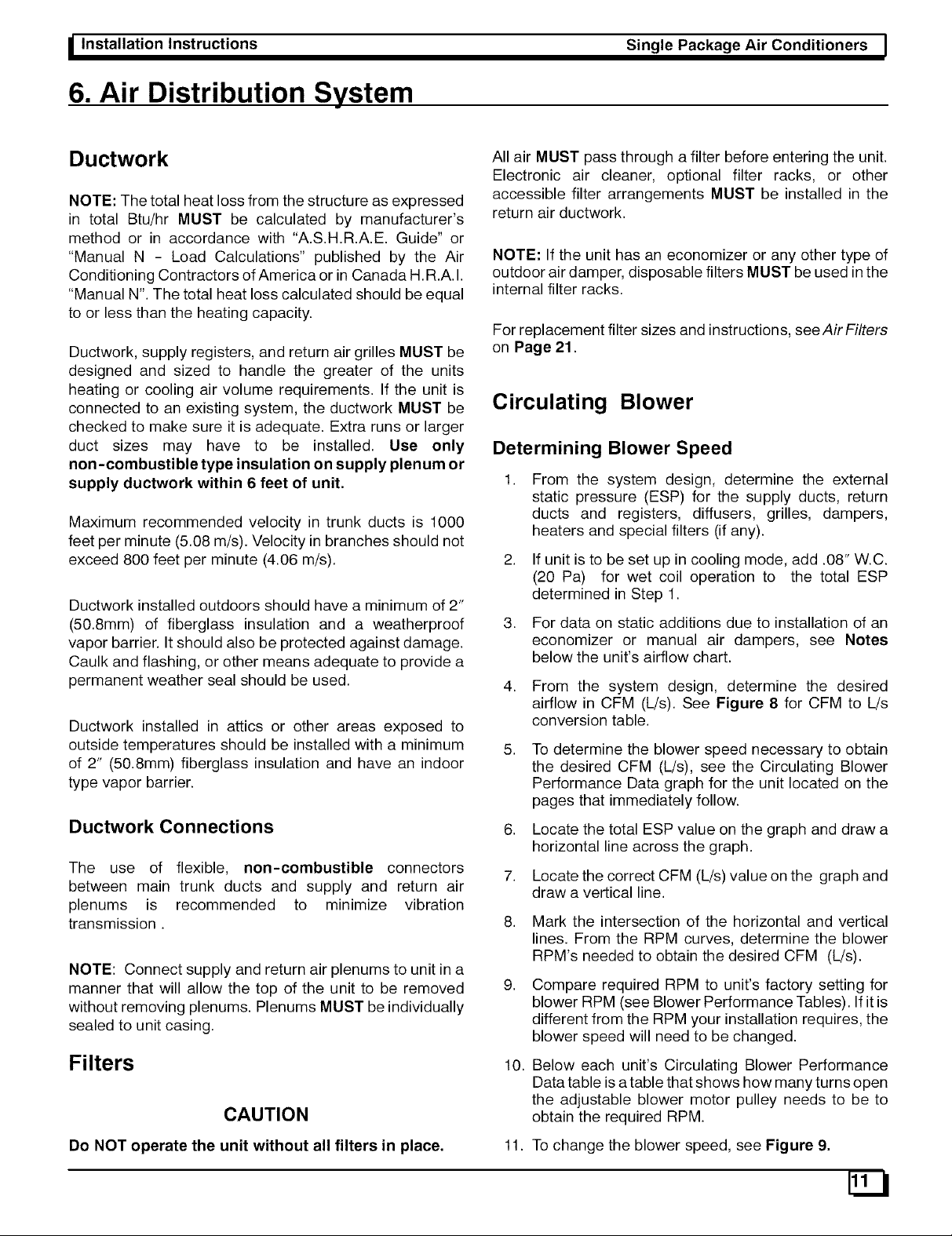

Ductwork

NOTE: The total heat loss from the structure as expressed

in total Btu/hr MUST be calculated by manufacturer's

method or in accordance with "A.S.H.R.A.E. Guide" or

"Manual N - Load Calculations" published by the Air

Conditioning Contractors of America or in Canada H.R.A.I.

"Manual N". The total heat loss calculated should be equal

to or less than the heating capacity.

Ductwork, supply registers, and return air grilles MUST be

designed and sized to handle the greater of the units

heating or cooling air volume requirements. If the unit is

connected to an existing system, the ductwork MUST be

checked to make sure it is adequate. Extra runs or larger

duct sizes may have to be installed. Use only

non-combustible type insulation on supply plenum or

supply ductwork within 6 feet of unit.

Maximum recommended velocity in trunk ducts is 1000

feet per minute (5.08 m/s). Velocity in branches should not

exceed 800 feet per minute (4.06 m/s).

Ductwork installed outdoors should have a minimum of 2"

(50.8mm) of fiberglass insulation and a weatherproof

vapor barrier. It should also be protected against damage.

Caulk and flashing, or other means adequate to provide a

permanent weather seal should be used.

Ductwork installed in attics or other areas exposed to

outside temperatures should be installed with a minimum

of 2" (50.8mm) fiberglass insulation and have an indoor

type vapor barrier.

Ductwork Connections

The use of flexible, non-combustible connectors

between main trunk ducts and supply and return air

plenums is recommended to minimize vibration

transmission.

NOTE: Connect supply and return air plenums to unit in a

manner that will allow the top of the unit to be removed

without removing plenums. Plenums MUST be individually

sealed to unit casing.

Filters

CAUTION

All air MUST pass through a filter before entering the unit.

Electronic air cleaner, optional filter racks, or other

accessible filter arrangements MUST be installed in the

return air ductwork.

NOTE: If the unit has an economizer or any other type of

outdoor air damper, disposable filters MUST be used inthe

internal filter racks.

For replacement filter sizes and instructions, see Air Filters

on Page 21.

Circulating Blower

Determining Blower Speed

1.

From the system design, determine the external

static pressure (ESP) for the supply ducts, return

ducts and registers, diffusers, grilles, dampers,

heaters and special filters (if any).

2. If unit is to be set up in cooling mode, add .08" W.C.

(20 Pa) for wet coil operation to the total ESP

determined in Step 1.

3. For data on static additions due to installation of an

economizer or manual air dampers, see Notes

below the unit's airflow chart.

4. From the system design, determine the desired

airflow in CFM (L/s). See Figure 8 for CFM to L/s

conversion table.

.

To determine the blower speed necessary to obtain

the desired CFM (L/s), see the Circulating Blower

Performance Data graph for the unit located on the

pages that immediately follow.

6. Locate the total ESP value on the graph and draw a

horizontal line across the graph.

7. Locate the correct CFM (L/s) value on the graph and

draw a vertical line.

8. Mark the intersection of the horizontal and vertical

lines. From the RPM curves, determine the blower

RPM's needed to obtain the desired CFM (L/s).

.

Compare required RPM to unit's factory setting for

blower RPM (see Blower Performance Tables). If it is

different from the RPM your installation requires, the

blower speed will need to be changed.

10.

Below each unit's Circulating Blower Performance

Data table is a table that shows how many turns open

the adjustable blower motor pulley needs to be to

obtain the required RPM.

Do NOT operate the unit without all filters in place.

11. To change the blower speed, see Figure 9.

Page 14

I Single Package Air Conditioners Installation Instructions !

Metric Conversions: Cubic Feet per Minute (CFM) to Liters per Second (L/s);

Figure 8 Inches of Water Column (In. W.C.) to Pascals (Pa)

CFM ' Lis

I

=

50, 24

1O0 : 47

150' 71

I

200, 94

250:118

300' 142

350:165

400:189

450, 212

I

5OO

, 236

55O

' 260

I

600

, 283

650

' 307

I

7OO

' 330

I

75O

, 354

8OO

' 378

I

85O

, 401

I

900

, 425

950

' 448

I

1000

, 472

I

1050

, 495

1100

' 519

I

1150

, 543

' 566

1200

I

1250

' 590

I

1300

, 613

1350

' 637

I

1400

, 661

I

1450

, 684

1500

' 708

I

1550

, 731

' 755

1600

I

1650

' 779

I

1700

, 802

1750

' 826

I

1800

' 849

I

1850

, 873

1900

' 897

I

1950

, 920

I

2000

, 944

2050

' 967

I

2100

, 991

2150

'1015

I

2200

' 1038

I

2250

,1062

2300

'1085

I

2350

' 1109

I

2400

, 1133

2450

'1156

I

2500

, 1180

I

I

CFM In. W.C2 Pa In. W.C2 Pa In. W.C2 Pa In.W.CJ Pa

2550

2600

2650

2700

2750

2800

2850

2900

2950

3000

3050

3100

3150

3200

3250

3300

3350

3400

3450

3500

3550

3600

3650

3700

3750

3800

3850

3900

3950

4000

4050

4100

4150

4200

4250

4300

4350

4400

4450

4500

4550

4600

4650

4700

4750

4800

4850

4900

4950

5000

' L/s

I

=

, 1203

'1227

I

' 1251

I

, 1274

'1298

I

, 1321

I

,1345

'1369

I

, 1392

I

, 1416

' 1439

I

,1463

'1486

I

' 1510

I

,1534

'1557

I

, 1581

I

,1604

'1628

I

, 1652

I

, 1675

' 1699

I

, 1722

' 1746

I

' 1770

I

,1793

'1817

I

,1840

I

,1864

'1888

I

, 1911

'1935

I

' 1958

I

,1982

'2006

I

' 2029

I

, 2053

'2076

I

, 2100

I

, 2124

'2147

I

, 2171

'2194

I

' 2218

I

, 2242

'2265

I

' 2289

I

, 2312

'2336

I

, 2360

I

I

CFM ' US

I

i

5050, 2383

5100:2407

5150' 2430

I

5200, 2454

5250:2477

5300' 2501

5350:2525

5400:2548

5450, 2572

5500:2595

5550:2619

5600, 2643

5650:2666

5700' 2690

I

5750, 2713

5800:2737

5850' 2761

5900:2784

5950:2808

6000, 2831

6050:2855

6100:2879

6150, 2902

6200:2926

6250' 2949

I

6300, 2973

6350:2997

6400,3020

6450:3044

6500:3067

6550, 3091

6600:3115

6650' 3138

I

6700,3162

6750:3185

6800' 3209

I

6850, 3233

6900:3256

6950, 3280

7000:3303

7050:3327

7100, 3350

7150:3374

7200' 3398

I

7250, 3421

7300:3445

7350' 3468

I

7400, 3492

7450:3516

7500, 3539

I

I

0.01 ,

0.02:

0.03 '

0.04 ,

o.o5:

0.06 ,

0.07:

0.08 '

0.09 ,

O.lO:

0.11 '

0.12 ,

0.13:

0.14 '

0.15 ,

0.16:

0.17 ,

o.18:

0.19 '

0.20 ,

0.21 ',

0.22 '

0.23 ,

0.24 :

0.25 '

0.26 ,

0.27',

0.28 ,

0.29 ',

0.30 '

0.31 ,

0.32 ',

0.33 '

0.34 ,

0.35:

0.36 '

0.37 ,

0.38 ',

0.39 ,

0.40:

0.41 ',

0.42 ,

0.43 ',

0.44 '

0.45 ,

0.46 :

0.47 '

0.48 ,

0.49;

0.50 ,

I

i

I

I

I

I

I

I

I

I

I

I

I

I

I

I

10

12

15

17

20

22

25

27

30

32

35

37

40

42

45

47

5O

52

55

57

60

62

65

67

70

72

75

77

80

82

85

87

90

92

95

97

100

102

105

107

110

112

115

117

120

122

125

I

0.51

0.52

0.53

0.54

0.55

0.56

0.57

0.58

0.59

0.60

0.61

0.62

0.63

0.64

0.65

0.66

0.67

0.68

0.69

0.70

0.71

0.72

0.73

0.74

0.75

0.76

0.77

0.78

0.79

0.80

0.81

0.82

0.83

0.84

0.85

0.86

0.87

0.88

0.89

0.90

0.91

0.92

0.93

0.94

0.95

0.96

0.97

0.98

0.99

1.00

i

, 127

' 130

I

' 132

I

, 135

' 137

I

, 139

I

, 142

' 144

I

, 147

I

, 149

' 152

I

, 154

' 157

I

' 159

I

, 162

' 164

I

, 167

I

, 169

' 172

I

, 174

I

, 177

' 179

I

, 182

' 184

I

' 187

I

, 189

' 192

I

, 194

I

, 197

' 199

I

, 202

' 204

I

' 207

I

, 209

' 212

I

' 214

I

, 217

' 219

I

, 222

I

, 224

' 227

I

, 229

' 232

I

' 234

I

, 237

' 239

I

' 242

I

, 244

' 247

I

, 249

I

I

2

5

7

1.01

1.02

1.03

1.04

1.05

1.06

1.07

1.08

1.09

1.10

1.11

1.12

1.13

1.14

1.15

1.16

1.17

1.18

1.19

1.20

1.21

1.22

1.23

1.24

1.25

1.26

1.27

1.28

1.29

1.30

1.31

1.32

1.33

1.34

1.35

1.36

1.37

1.38

1.39

1.40

1.41

1.42

1.43

1.44

1.45

1.46

1.47

1.48

1.49

1.50

I

i

, 251

' 254

I

' 257

I

, 259

' 262

I

, 264

I

, 267

' 269

I

, 271

I

, 274

' 276

I

, 279

' 281

I

' 284

I

, 286

' 289

I

, 291

I

, 294

' 296

I

, 299

I

, 301

' 304

I

, 306

' 309

I

' 311

I

, 314

' 316

I

, 319

I

, 321

' 324

I

, 326

I

, 329

' 331

I

, 334

' 336

I

' 339

I

, 341

' 344

I

, 346

I

, 349

' 351

I

, 354

I

, 356

' 359

I

, 361

' 364

I

' 366

I

, 369

' 371

I

, 374

I

I

1.51

1.52

1.53

1.54

1.55

1.56

1.57

1.58

1.59

1.60

1.61

1.62

1.63

1.64

1.65

1.66

1.67

1.68

1.69

1.70

1.71

1.72

1.73

1.74

1.75

1.76

1.77

1.78

1.79

1.80

1.81

1.82

1.83

1.84

1.85

1.86

1.87

1.88

1.89

1.90

1.91

1.92

1.93

1.94

1.95

1.96

1.97

1.98

1.99

2.00

I

i

, 376

' 379

I

' 381

I

, 384

' 386

I

' 389

I

, 391

' 394

I

, 396

I

, 399

' 401

I

, 404

' 406

I

' 408

I

, 411

' 413

I

, 416

I

, 418

' 421

I

, 423

I

, 426

' 428

I

, 431

' 433

I

' 436

I

, 438

' 441

I

, 443

I

, 446

' 448

I

, 451

' 453

I

' 456

I

, 458

' 461

I

' 463

I

, 466

' 468

I

, 471

I

, 473

' 476

I

, 478

' 481

I

' 483

I

, 486

' 488

I

' 491

I

, 493

' 496

I

, 498

I

I

In. W.C. _ Pa

I

i

2.01 , 501

2.02:503

2.03 ' 506

I

2.04, 508

2.05:511

2.06, 513

2.07:516

2.08:518

2.09, 521

2.10:523

2.11 ' 526

I

2.12 , 528

2.13:531

2.14 ' 533

I

2.15 , 536

2.16:538

2.17 , 541

2.18:543

2.19:545

2.20 , 548

2.21:550

2.22' 553

I

2.23, 555

2.24:558

2.25' 560

I

2.26, 563

2.27:565

2.28, 568

2.29 : 570

2.30 : 573

2.31 , 575

2.32 : 578

2.33' 580

I

2.34, 583

2.35:585

2.36' 588

I

2.37, 590

2.38:593

2.39, 595

2.40:598

2.41' 600

I

2.42, 603

2.43:605

2.44' 608

I

2.45, 610

2.46:613

2.47' 615

I

2.48, 618

2.49:620

2.50, 623

I

I

129

Page 15

_ Installation Instructions Single Package Air Conditioners I

Figure 9 Circulating 20 Ton Blower Performance Data

9500

9O00

1.75

1.5

8500

8O00

1.25

7500 _

i11

a.

_ o.75

u) 0.5 6000

X

uJ

0.25 5500

7000

6500 :S

O

o L 5000

I I

I i I 4500

6500 7000 7500 8000 8500

ESP Vs CFM _ AIRFLOW (SCFM) DRY COIL WITH FILTER _/Jsf;\T_:_V_ C_k _z_

NOTES: 1) Maximum motor Watts is 10,100 Watts. 2) Maximum blower wheel speed is 1800 RPM. 3) Contact factory for applications re-

quiring operation outside standard cooling operating range. 4) Airflow data based on dry coil with filters. For wet coil add 0.08 inches to

ESP. Downflow has the same ESP as horizontal flow. 5) Add 0.20 incles to ESP for horizontal economizer, downflow economizer, or manual

air dampers. 6) Pulley turns refers to turns out. In other words, 0 turns is a narrower sheave than 5 turns. 7) Blower speed MUST be set to

give the correct air tem _erature rise through the unit as marked on the Rating Plate.

EXTERNALSTATICPRESSUREIN INCHESWATERCOLUMN(PASCALS)

CFM .25(62) .50(124) .75(186)

RPM W RPM W RPM W

6750

7000 1220

7250 1190 5760 1220 5920 1260

7500 1220 6150 1255 6500 1300

7750 1250 6750 1280 6850 1360

8000 1280 7300 1380

8250 1400 8890 1420 9150 1432 9200 1455 9250 1470 9270 1480 9300 " "

8800 1420 8800 1433 8870 1455 8950 1470 9000 1480 9050 "

5800 1265 6250 t350 6650 1380 7200 1410 7400 1430 7600

6300 1290 6550 t390 7500 1410 7700 1425 7750 1480 8600

6950 1390 8010 1420 8250 1440 8400 1460 8650

8000 1420 8450 1450 8700 1460 9750 1475 8800 "

1.0(249) 1.25 (311) 1.50(373) 1.75(435) 2.0(497)

RPM W RPM W RPM W RPM W RPM W

1390 7100 1410 7300

_igh Static Data

NOTE: DO NOT EXCEED 25.3AMPSON BLOWER MOTOR ATANYPOINT.

PULLEYTURNSOPEN 0

FAN I STDPULLEY 1390 1340

RPM I HIGHSTATICPULLEY 1540 1495

AIRFLOW CORRECTION FACTORS - 20 TON

CFM - ACTUAL 5760 6480 7200 7920

TOTAL MBH 0,95 0,98 1,00 1,02

SENSIBLE MBH 0,90 0,95 1,00 1,05

POWER KW 0,98 0,99 1,00 1,01

864O

1,05

1,10

1,02

NOTES: 1) Multiply correction factor times gross

2 3 4

1295 1245 t195

1445 1390 1345

FACTORY SETTING TURNS OPEN

10 HP STD PULLEY 4

10 HP HIGH STATIC PULLEY See NOTE

NOTE: High static pulleys are field installed and MUST be

adjusted by the installing technician.

3erformance data. 2) Resulting sensible capacity cannot

exceed total capacity.

PART NUMBERS FOR APPROVED HIGH STATIC CONVERSIONS

Unit Motor Motor Pulley Blower Pulley Belt

20 Ton No Change 1082350(IVP65) No Change No Change

5

1140

1295

Page 16

I Single Package Air Conditioners Installation Instructions !

7. Adjustable Belt Drive Blower

.

Loosen the four motor mount bolts.

4.

Personal injury hazard,

Use extreme care during the following proce-

dures and obey Safety Information,

Failure to do so may result in personal injury.

Turn the motor adjustment bolt counterclockwise

until the belt is slack enough to come off easily (see

Figure 10).

.

Remove the belt. Do NOT attempt to pry off belt with

tools or fingers.

6.

Loosen set screw(s) on the outer half of the

adjustable pulley.

The following safety rules MUST always be followed when

working near belt drive.

Always Turn The Power Off

Turn electric power to the unit OFF before you begin

working on it.

Always Wear Protective Clothing

NEVER wear loose or bulky clothes, such as

neckties, exposed shirttails, loose sleeves, or lab

coats around belt drives. Wear gloves while

inspecting sheaves to avoid nicks, burrs, or sharply

worn pulley edges.

The blower speed is changed by adjusting the variable

speed pulley mounted on the blower motor.

If the blower speed needed is different than the speed of

the blower as shipped, follow the steps below to change the

blower speed. Before changing the blower speed, read the

above safety rules first.

The unit has one of two different types of adjustable

pulleys (see Figure tt or 12).

Figure 11 Adjustable Pulley (Keyway Type)

This keyway pulley has a removable key and two keyways cut through

the threads of the pulley hub. The keyways limit this type of pulley to

half turn adjustments.

1. Turn electric power OFF.

2. Remove the side blower access panel (see Figure

1).

Figure 10 I Motor Mount Assembly

Adjustable

Pulley

Motor Mount

Bolts (4)

__ Adjustment

Bolt

1054584

Figure 12 Adjustable Pulley (Threaded Keys)

This type of pulley has non-removable threaded keys that ride on the

threads of the pulley shaft. This allows a full 360 orange of adjustment.

7. Remove key if unit has a keyway type pulley.

Page 17

_ Installation Instructions Single Package Air Conditioners I

8. To set the blower for a desired CFM (L/s), first turn the

outer half of the adjustable pulley clockwise until it

meets the inner half of the pulley.

9. Turn the outer half of the adjustable pulley

counterclockwise the correct number of turns to

obtain the desired CFM (L/s).

NOTE: To increase the blower speed, turn the outer half of

the adjustable pulley clockwise. To decrease the blower

speed, turn the outer half of the adjustable pulley

counterclockwise.

10. Replace key if unit has keyway type pulley.

11. Tighten set screw(s).

12. Put on belt.

Figure 14

1/4,,

(6.4mm)*

I Checking Pulley Alignment

1/4"

(6.4mm)*

*Maximum Misalignment Allowed

Figure 13 I Checking Tension and Deflection

3 Lbs. (1.4kg) force

with a 3/8" (9.5mm)

deflection of the belt

from the straight-edge

1054584

13. Turn motor adjustment bolt clockwise until the belt

has enough tension at the proper deflection. Use one

of the commercially available belt tension gauges to

set the correct tension at the proper deflection (see

Figure 13).

14.

Use a straight-edge (angle iron, straight piece of

board or anything with a good straight surface or

edge) to check the alignment of the blower pulley with

blower motor pulley (see Figure 14).

It may be necessary to back the tension off the belt

temporarily and tighten one of the motor mount bolts

before it is possible to adjust the angle of the blower

motor.

15.

Tighten all four blower motor mount bolts.

16.

Ensure that all bolts, nuts and screws are tightened

and ensure that all tools, gloves, etc. are removed

from unit.

17.

Replace side blower access panel before Start-up.

18.

During Start-up, listen for any unusual noises or

vibrations.

19.

Shut down the unit after it runs for a while and check

the bearings and motor. If they feel hot, the belt

tension may be too tight, bearings may be misaligned

or not lubricated correctly, etc.

20.

It is a good ideato retension a new belt after a run-in

period of about 24 hours. A run-in period of overnight

or during a lunch break is better than no run-in period

at all.

Page 18

I Single Package Air Conditioners

8. Economizer Accessory

Installation Instructions !

The purpose of an economizer is to:

Provide cool outside air to the conditioned space

during the cooling cycle to minimize the use of the

compressors.

Bring outside air into the conditioned space to meet

minimum ventilation air requirements whenever the

circulation blower is running.

Figure 15 _ Downflow Economizer

Outdoor Air Dampers

Actuator Motor

Return Air

Dampers

Static Additions

Static numbers from the following table must be added to

the unit's total static if a horizontal economizer, vertical

economizer, or manual air damper is used.

20 ton ............... 0.20" W.C.

Theory of Operation

The economizer has two sets of dampers that are

mechanically linked together. The outdoor air dampers

regulate the intake of outside air and the return air dampers

regulate the flow of return air (see Figure 15). When the

outdoor air dampers modulate open, the linkage causes

the return air dampers to modulate closed.

The economizer is controlled by a logic module which field

connects to the unit controls through a harness plug. The

logic module also controls the compressor staging based

on the thermostat input.

The minimum opening position of the outdoor air dampers

is field adjustable. It is set on the logic module of

modulating economizers or on the actuator motor of

three-position economizers.

Log

Harness Plug

80-50-28

The enthalpy sensor is factory installed on the outdoor air

dampers. The enthalpy change-over point is adjustable on

the logic module.

A mixed air sensor is field installed inthe blower inlet. The

mixed air sensor keeps the mixed air above 56°F (13.3°C).

See the economizer installation instructions for the location

of the air sensor.

A positive pressure is created in the building when the

outdoor air dampers open and the return dampers close.

This pressure must be vented or the air will not circulate

properly. This is the function of the barometric relief

dampers. A positive pressure forces the passive exhaust

dampers to swing open.

The outdoor air dampers open to the minimum position for

outside air whenever the circulation blower is ON.

When the thermostat is in the FAN AUTO position, the

outdoor air dampers will close completely whenever

heating or cooling is not called for.

Page 19

_ Installation Instructions Single Package Air Conditioners I

5.

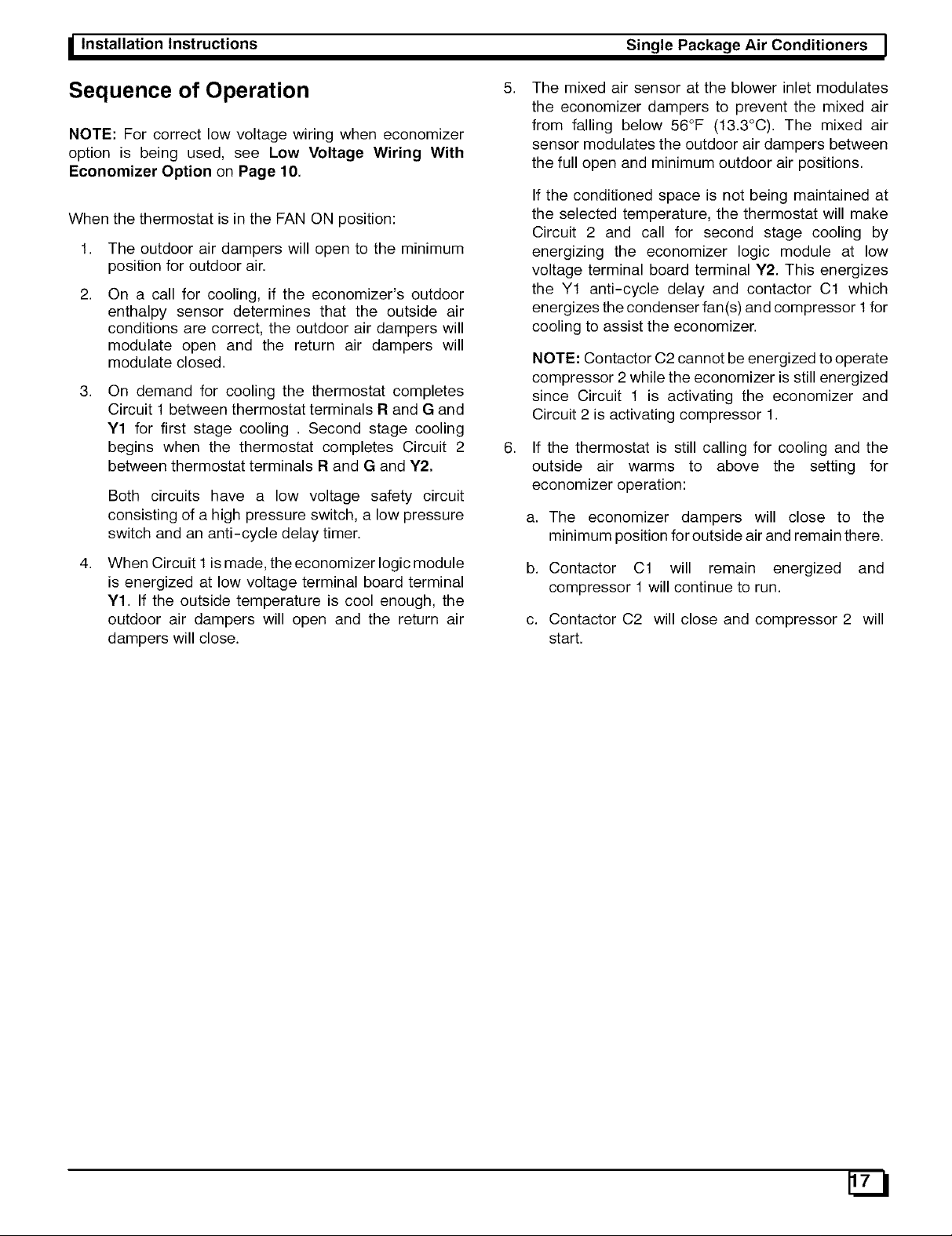

Sequence of Operation

The mixed air sensor at the blower inlet modulates

the economizer dampers to prevent the mixed air

NOTE: For correct low voltage wiring when economizer

option is being used, see Low Voltage Wiring With

Economizer Option on Page 10.

from falling below 56°F (13.3°C). The mixed air

sensor modulates the outdoor air dampers between

the full open and minimum outdoor air positions.

If the conditioned space is not being maintained at

When the thermostat is in the FAN ON position:

the selected temperature, the thermostat will make

Circuit 2 and call for second stage cooling by

1.

The outdoor air dampers will open to the minimum

position for outdoor air.

2.

On a call for cooling, if the economizer's outdoor

enthalpy sensor determines that the outside air

conditions are correct, the outdoor air dampers will

energizing the economizer logic module at low

voltage terminal board terminal Y2. This energizes

the Y1 anti-cycle delay and contactor Cl which

energizes the condenser fan(s) and compressor 1for

cooling to assist the economizer.

modulate open and the return air dampers will

modulate closed.

NOTE: Contactor C2 cannot be energized to operate

compressor 2 while the economizer is still energized

.

On demand for cooling the thermostat completes

Circuit 1 between thermostat terminals R and G and

since Circuit 1 is activating the economizer and

Circuit 2 is activating compressor 1.

Y1 for first stage cooling . Second stage cooling

begins when the thermostat completes Circuit 2

between thermostat terminals R and G and Y2.

.

If the thermostat is still calling for cooling and the

outside air warms to above the setting for

economizer operation:

Both circuits have a low voltage safety circuit

consisting of a high pressure switch, a low pressure

switch and an anti-cycle delay timer.

4.

When Circuit 1 is made, the economizer logic module

is energized at low voltage terminal board terminal

a. The economizer dampers will close to the

minimum position for outside air and remain there.

b. Contactor Cl will remain energized and

compressor 1 will continue to run.

Y1. If the outside temperature is cool enough, the

outdoor air dampers will open and the return air

dampers will close.

c. Contactor C2 will close and compressor 2 will

start.

Page 20

I Single Package Air Conditioners Installation Instructions !

9. Start-up Procedure

.

Turn ON electric power. Nothing should start running.

If any unusual arcing, odors or noises are

Electrical shock, fire and/or explosion hazard.

Use extreme care during all of the following

checks and procedures.

Make sure Electric Power and is turned OFF as

instructed in appropriate steps.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

NOTE: For correct low voltage wiring when economizer

option is being used, see Low Voltage Wiring With

Economizer Option on Page 10.

Check the unit's operation as outlined in the following

instructions.

Blower and Phasing Check

1. Shut OFF electric power at unit disconnect.

2. Check to see that clean, properly sized air filters are

installed.

.

Check to see that everything inside the unit is clear

and ready to operate safely. Ensure that there are no

objects in, on or around the motor, belt or blower

wheel.

4. Set thermostat Heat-Cool selector to OFF.

encountered, shut OFF electric power immediately

and check for wiring errors.

NOTE: The circulation blower motor and compressor(s)

are three phase and are factory synchronized for proper

rotation. Even if the circulation blower motor comes on and

air seems to be circulating, it is possible that the blower

motor rotation is incorrect due to improper phasing. The

scroll compressor(s) (if equipped) will run backwards

under this condition and be damaged. It is therefore

necessary to check for proper rotation.

CAUTION

Do NOT operate the unit with the compressor(s)

running until proper blower rotation has been

confirmed by running the following test.

7. Set thermostat fan switch to ON. The circulating air

blower should come ON.

.

Shut OFF electric power at unit disconnect and

visually observe the direction of the blower rotation

as it slows down. Do NOT put hands or any other

object in, on or around the belt, motor or blower

wheel. If blower wheel rotation is the same as the

directional arrow on the blower housing, proceed to

the next step.

5. Set thermostat fan switch to AUTO.

Moving parts hazard.

Do NOT put hands or any other object in, on or

around the motor, belt or blower wheel. Ensure

that there are no objects in, on or around the mo-

tor, belt or blower wheel before turning electric

power on.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

CAUTION

If blower rotation is incorrect, shut electric power OFF

at unit disconnect and reverse any two supply wires at

field connections ONLY. Do NOT reverse the blower

and/or compressor leads or rewire any internal wiring.

After rewiring is done, repeat blower rotation check to

ensure that blower rotation is now correct.

9. if blower rotation is correct, reset thermostat fan

switch to AUTO.The circulating air blower should go

OFF. Nothing should be running.

10. Shut OFF electric power at unit disconnect.

Page 21

_ Installation Instructions Single Package Air Conditioners I

Cooling Checks

The compressors have a five minute anti-cycle delay that

is activated whenever the compressors turn off. For

instance, if the unit is manually shut off when the

compressors are running and the unit is turned back ontwo

minutes later, it will be an additional three minutes before

the compressors will restart.

NOTE: For correct low voltage wiring when economizer

option is being used, see Low Voltage Wiring With

Economizer Option on page 10.

CAUTION

Do NOT operate the unit with the compressor(s)

running until proper blower rotation has been

confirmed during the Blower and Phasing Check in the

previous section. If the phasing is incorrect, the scroll

compressor(s) (if equipped) will run backwards and

they will be damaged.

1. Be sure that electric power is OFF.

2. To check cooling Stage 1, place jumper wires across

low voltage terminal board terminals R to G, R to Y1.

3. Turn electric power ON. Check to see that the

following occurs:

a. Compressor 1 - ON

b. Condenser fan motor(s) - ON

c. Circulation air blower - ON with correct rotation

and adequate airflow from ductwork.

4. Shut OFF electric power at unit disconnect.

5. To check cooling Stage 2, remove jumper wires from

Y1 and place it on Y2.

NOTE: Allow 5 minutes between Steps 4 and 6.

6. Turn ON electric power. Check to see that the

following occurs:

a. Compressors 1 & 2 - ON

b. Condenser fan motor(s) - ON

c. Circulation air blower - ON

NOTE: IfY2 only is jumpered, condenser fans will not come

on.

7.

Shut OFF electric power at unit disconnect. Begin

timing the five minutes for the anti-cycle delay.

8.

Remove jumpers from low voltage terminal board.

9.

Set Thermostat to COOL and temperature to call for

Cooling.

10.

Turn ON electric power. At the end of the five minute

anti-cycle delay, the unit should start and run.

11.

Shut OFF electric power at unit disconnect.

12.

Replace all service access panels.

Page 22

I Single Package Air Conditioners Installation Instructions !

10. Operation And Maintenance Instructions

NOTE: An optional low ambient kit is available that allows

the unit to operate at temperatures down to 0°F (-18°C).

Electrical shock hazard.

Turn off electric power supply at disconnect

switch or service panel before removing any ac-

cess or service panel from unit.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

1. Turn ON electric power.

2,

Set thermostat to desired temperature and set

system switch to COOL. The unit will come on and

operate automatically under control of the

thermostat.

Close all doors and windows. The unit may run

continuously for several hours or longer on the initial

run because of residual heat and moisture in the

building. This is normal for any air conditioning

system.

Turning Off the Unit

Heating

1. Set thermostat selector to OFF and fan switch to

AUTO.

2. If electric heat is running at time of shut-down, wait

2.5 minutes then shut OFF electric power supply at

disconnect switch or service panel. (No wait is

necessary if electric heat was not running within 2.5

minutes prior to shut-down.)

Cooling

1. Set thermostat selector to OFF and fan switch to

AUTO.

2. To shut the unit down completely, shut OFF electric

power supply at disconnect switch or service panel.

Starting the Unit After Shutdown

Heating

1.

Set the thermostat to OFF.

4.

Turn ON electric power.

5.

Set thermostat to desired temperature and set

selector to HEAT. Unit will come on and operate

automatically under control of the thermostat.

Thermostat Fan Switch Operation

The circulating air blower will run continuously with the fan

selector switch in the ON position. When the fan selector

switch is in the AUTO position, the blower will run during

each heating or cooling cycle.

Adjusting Room Temperatures

If the temperature in individual rooms is not as desired,

balance the system by adjusting the dampers in the branch

ducts (see Figu re 16). Adjust a little at a time and wait a day

after each change to judge the effect. Once the dampers

are adjusted for normal weather conditions, it is best to

leave them that way. Compensate for temporary weather

changes by adjusting the thermostat setting.

Figure 16 Typical Branch Duct Dampers

Cooling

CAUTION

To prevent possible damage to the compressor(s), do

NOT operate on cooling when outdoor temperature is

below 35°F (2°C).

Page 23

I InstallationInstructions

Single Package Air Conditioners I

Monthly Maintenance and Inspection

Checks

Air Filters (Factory Installed)

CAUTION

Do NOT operate unit without all air filters installed in

the unit.

Dirty filters are the most common cause of compressor

failures and inadequate heating and cooling performance.

Inspect filters at least monthly and replace or clean as

required.

Washable filters may be cleaned by soaking in mild

detergent and rinsing with cold water. Install filters so that

the arrows on the side point in the direction of air flow.

Filter racks are accessible through the filter access panel.

6. Replace filter access panel.

Cooling Season Checks (Monthly)

Condenser Coil

Keep the condenser inlet and outlet area clean and free of

leaves, grass clippings and other debris. Grass should be

kept short in front of the condenser inlet. Shrubbery MUST

be trimmed back so it is nocloser than 30 inches (762 mm)

to condenser coil.

Condensate Drain

Check for condensate drainage. Clean as required.

Annual Maintenance and Inspection

Electrical Shock, Fire and Explosion Hazards.

Turn off electric power supply at disconnect

switch or service panel before removing any ac-

cess or service panel from unit.

Disposable Replacement Filters

For 20 ton units: 4 filters 20" x 30" x 2"

To replace disposable filters:

1.

Remove filter access panel.

2.

Remove the bottom filters.

3.

The front of the center rail is attached to the unit by a

keyhole/screw connection. Unhook the front of the

center rail, swing it down approximately four inches

(100mm), and hook the keyhole on the screw

provided.

4.

Remove the bottom filters.

5.

Replace bottom filters, center rail, and top filters.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

The annual inspection should include cleaning as required

to ensure efficient operation of the unit.

NOTE: All bearings are sealed and no lubrication is

required.

Circulating Air Blower

Visually inspect the blower wheel for accumulations of dirt

or lint. Clean the compartment and the blower wheel. If

accumulation is excessive on blower wheel or does not

remove easily, it will be necessary to remove the blower

assembly.

Page 24

I Single Package Air Conditioners

11. Rigging Instructions

Installation Instructions

Figure 17

Rigging Instructions

iNSTRUCTiONSDESQULEVAGE

SI CETAVERTtSSEMENT N'EST PAS RESPECTE,

AVERTJ$SEMENT ,LPEUTENRESULTERDESDEG,_TSMATERIELS

DES DOMMAGES CORPORELS OU LA MORT.

=TOUSLES PANNEAUX DOIVENT ETRE EN PL,_CE AU MOMENT DU MONTCHARGE ET SOULEVAGE.

- ACCROCHEZ LES CHAJNES DE SOULEVAGE A TRAVERS LES TROUS DE LA BARRE DE BASE,

COMME LE MONTRE DETAIL-A.

- U,TILISEZ DES PLANCHES Dr ELARGISSEMENTAU MOMENT DU SOULEVAGE POUR EVITER DES DOMMAGES

A L'APPAREIL

- ASSUREZ QU,E LE ik4ONTECHARGE ET LES CHAiNES DE SOULEVAGE SONT SUFFISANT POUR MANOEUVRER

LES POIDS ENUMERER.

A

A_III_WAAI_____ RNING FAILURE TO FOLLOW THESE INSTRUCTIONS

CAN RESULT IN PROPERTY DAMAGE,

BODILY INJURY OR DEATH.

=ALL PANELS MUST BE IN PLACE WHEN RiGGiNG AND LiFTiNG.

- HOOK RiGGiNG SHACKLES THROUGH HOLES iN BASE RAIL, AS SHOWN iN DETAIL-A.

- USE SPREADER BARS, WHEN RIGGING, TO PREVENT UNIT DAMAGE.

- BE SURE RIGGING AND SHACKLES ARE SUFFiCiENT TO HANDLE WEIGHT LISTED.

CORNER WEIGHTS in LBS. (KG)

UNIT

20 TON

OPERATING WEIGHT A B C

1700 300 (136) 400 (182) 500 (227)

CORNER WEIGHTS

1071210

D

500 (227)

Loading...

Loading...