Page 1

Oil-Fired Water Boilers

Boiler Manual

Contents Page

1 Prepare boiler location ........................................................2

2 Prepare boiler ..................................................................... 5

3 Connect breeching .............................................................6

4 Connect water piping ..........................................................7

5 Connect tankless heater piping.........................................10

6 Connect wiring..................................................................11

7 Connect oil piping .............................................................14

8 Start-up ............................................................................15

9 Checkout procedure .........................................................16

10 Appendix ..........................................................................17

11 Service and maintenance ................................................. 1 8

12 Replacement parts ........................................................... 22

13 Dimensions ......................................................................26

14 Ratings .............................................................................27

Hazard definitions

Hazards that will cause severe personal injury,

death or substantial property damage.

Hazards that can cause severe personal injury,

death or substantial property damage.

INSTALLER — Read all instructions before

installing. Read page 2 first. Follow all instructions

in proper order to prevent personal injury or death.

• Consider piping and installation when determining

boiler location.

• Any claims for damage or shortage in shipment

must be filed immediately against the transportation

company by the consignee.

This manual must only be used by a qualified heating installer/service technician. Boiler and burner must be installed

and serviced only by a qualified heating installer/service technician. Failure to comply could result in se vere personal injury ,

death or substantial property damage.

When calling or writing about the boiler— Please have: • boiler model number from the boiler rating label and • CP number

from the boiler jacket. You ma y list the CP number in the space provided on the “Installation and service certificate” found on

page 16.

Hazards that will or can cause minor personal injury

or property damage.

Special instructions on installation, operation or

maintenance that are important but not related to

personal injury or property damage .

USER — Please read the following. Failure to

comply could result in severe personal injury , death

or substantial property damage.

• This manual is for use only by your qualified

heating installer/service technician.

• Please see the User’s Inf ormation Manual for your

reference.

• Have the boiler serviced by a qualified service

technician, at least annually .

Part Number 672 01 1005 00

Page 2

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

1 Prepare boiler locationRead this first!

Failure to adhere to the guidelines below can

result in severe personal injury, death or

substantial property damage.

When servicing boiler —

1. To avoid electric shock, disconnect electrical supply

before performing maintenance.

2. To avoid severe burns, allow boiler to cool before

performing maintenance.

Boiler operation —

3. Do not bloc k flow of combustion or v entilation air to boiler.

4. Should overheating occur, do not turn off or disconnect

electrical supply to circulator. Instead, shut off the oil

supply at a location external to the appliance, if possible.

5. Do not use this boiler if any part has been under water.

Immediately call a qualified service technician to inspect

the boiler and to replace any part of the control system

and any burner control that has been under water .

Boiler water —

6. DO NOT use petroleum-based cleaning or sealing

compounds in boiler system. Water seal deterioration will

occur, causing leakage between boiler sections, circulator

flanges, diaphragm tanks or other system components.

This can result in substantial property damage.

7. DO NOT use "homemade cures" or "boiler patent

medicines". Serious damage to boiler , personnel and/or

property may result.

8. Continual fresh makeup water will reduce boiler life. Mineral

buildup in sections reduces heat transfer , ov erheats cast

iron, and causes section failure. Addition of oxygen and

other gases can cause internal corrosion. Leaks in boiler

or piping must be repaired at once to prevent makeup

water .

9. Do not add cold water to hot boiler. Thermal shock can

cause sections to crack.

Glycol — potential fire hazard —

All glycol is flammable when exposed to high temperatures. If

glycol is allowed to accumulate in or around the boiler or any

other potential ignition source, a fire can dev elop. In order to

prevent potential se vere personal injury , death or substantial

property damage from fire and/or structural damage:

• Never store glycol of any kind near the boiler or any

potential ignition source.

• Monitor and inspect the system and boiler regularly for

leakage. Repair any leaks immediately to prevent possible

accumulation of glycol.

• Never use automotive antifreeze or ethylene glycol in the

system. Using these glycols can lead to hazardous

leakage of glycol in the boiler system.

Codes & checklist

Installations must follow these codes:

• Local, state, provincial, and national codes, laws, regulations

and ordinances.

• NFP A-31, Installation of Oil-Burning Equipment.

• Standard for Controls and Safety Devices for Automatically

Fired Boilers, ANSI/ASME CSD-1, when required.

• National Electrical Code.

• For Canada only: B149.1 or B149.2 Installation Code, CSA

C22.1 Canadian Electrical Code Part 1 and any local codes.

Certification

The OWB and OWT boilers, burners and controls

met safe lighting and other performance criteria when

boiler underwent tests specified in CSA B140.0 and

B140.7.1.

Before locating the boiler:

❏ Check for nearby connection to:

• System water piping

• V enting connections (page 6)

• Combustion and ventilation air provisions (page 4)

• Oil supply piping (page 14 and burner manual)

• Electrical power

❏ Check area around boiler. Remov e any combustible materials,

gasoline and other flammable liquids.

Failure to keep boiler area clear and free of

combustible materials, gasoline and other flammable

liquids and vapors can result in severe personal

injury, death or substantial property damage.

❏ Boiler must be installed so that burner and control system

components are protected from dripping or spraying water or

rain during operation or service.

❏ If new boiler will replace existing boiler, chec k f or and correct

system problems, such as:

1. System leaks causing oxygen corrosion or section cracks

from hard water deposits.

2. Incorrectly-sized expansion tank.

3. Lack of antifreeze (when required) in boiler water causing

system and boiler to freeze and leak.

2 Part Number 672 01 1005 00

Page 3

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

1 Prepare boiler location

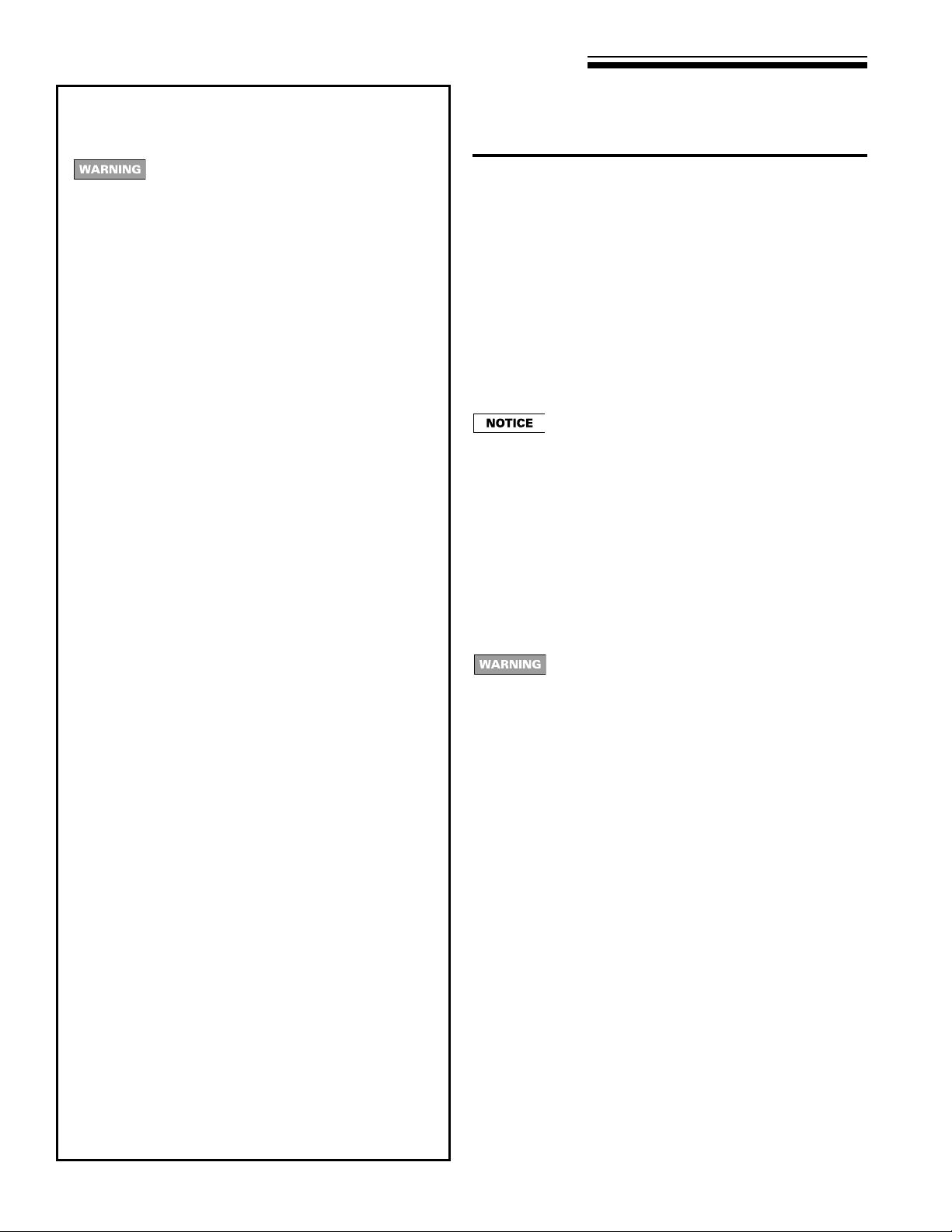

Clearances Flooring and foundation

Minimum clearance to combustible materials

1. Minimum clearances from vent pipe to combustible material (see

Figure 1, vent clearances indicated with “*”):

• Type “L” double wall vent — 6 inches minimum

• Singlewall vent — 18 inches minimum

Flue pipe clearances must take precedence over

jacket clearances (listed below).

Service clearances

1. Recommended service clearances (see Figure 1):

• Front and top — 24 inches

• Left side, back and right side — 6 inches

• Right side for burner door swing radius — 12 inches

2. Special close clearances (alcove, closet, under counters, etc.)

– see “Appendix,” page 17.

Figure 1 Minimum clearances

Flooring

The OWB and OWT boilers are approved for installation on

combustible flooring, but must never be installed on carpeting.

Do not install boiler on carpeting even if foundation is

used. Fire can result, causing se vere personal injury ,

death or substantial property damage.

Foundation

1. Provide a solid brick or minimum 2-inch thick concrete

foundation pad if any of the following is true:

• floor can become flooded.

• the boiler mounting area is not level.

2. See T ab le 1 for minimum f oundation dimensions.

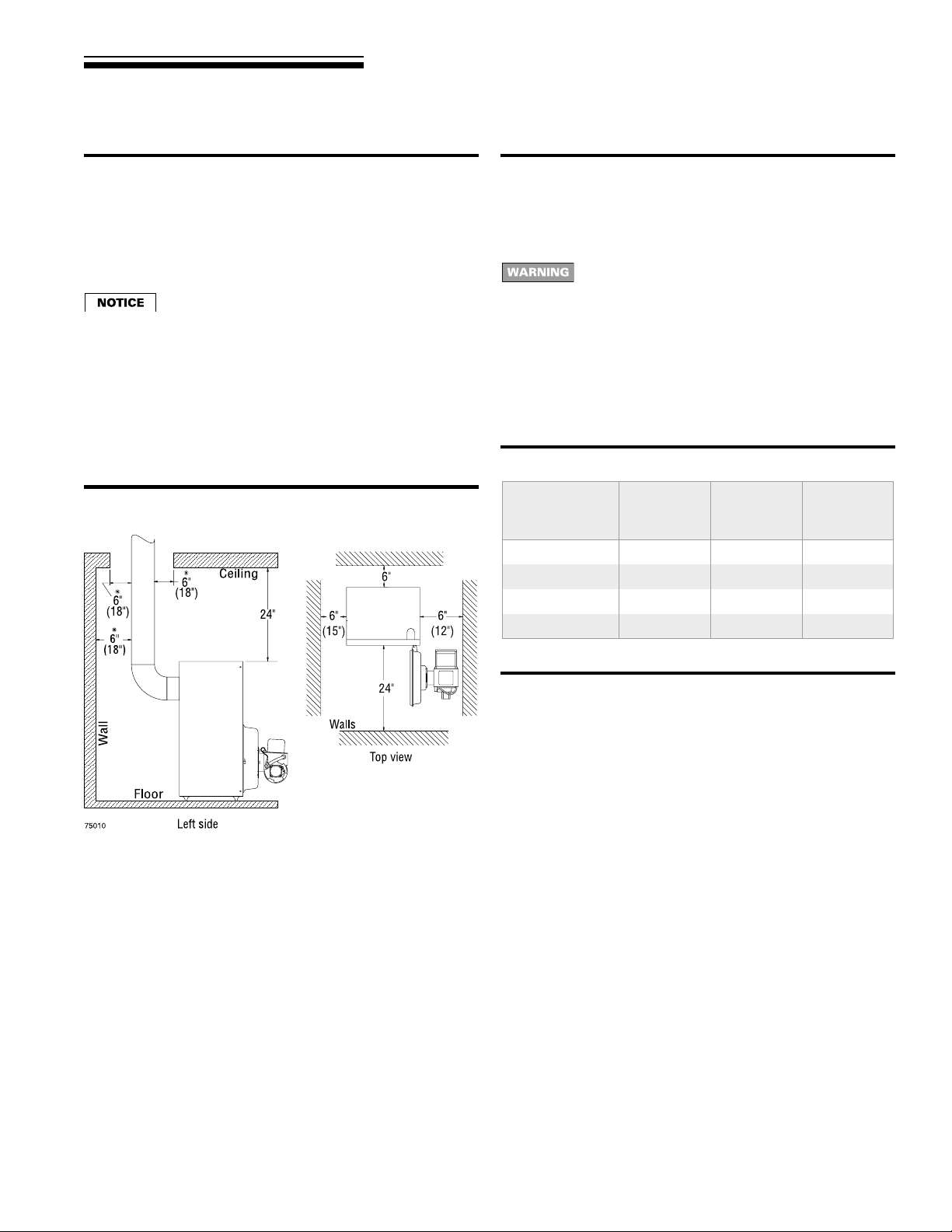

Table 1 Minimum foundation size

Boiler

model

number

OWB/OWT3 17 22 2

OWB/OWT4 17 22 2

OWB/OWT5 20 22 2

OWB/OWT6 23 22 2

Length

inches

Width

inches

Minimum

height

inches

Residential garage installations

T ake the f ollowing special precautions when installing the boiler in

a residential garage. If the boiler is located in a residential garage:

• Mount the boiler a minimum of 18 inches above the floor of the

garage to ensure the burner and ignition devices will be no less

than 18 inches above the floor .

• Locate or protect the boiler so it cannot be damaged by a moving

vehicle.

3Part Number 672 01 1005 00

Page 4

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

1 Prepare boiler location continued

Air contaminationAir for combustion and ventilation

Adequate combustion and ventilation air:

• Assures proper combustion.

• Reduces risk of severe personal injury or death from

possible flue gas leakage and carbon monoxide

emissions.

• Do not install exhaust fan in boiler room.

Consider building construction

Older buildings with single-pane windows, minimal weather-stripping

and no vapor barrier often provide enough natural infiltration and

ventilation without dedicated openings.

New construction or remodeled buildings are most often built tighter .

Windows and doors are weather-stripped, vapor barriers are used

and openings in walls are caulked. As a result, such tight

construction is unlikely to allow proper natural air infiltration and

ventilation.

Follow state, provincial or local codes when sizing adequate

combustion and ventilation air openings. In absence of codes, use

the following guidelines when boiler is in a confined room (defined

by NFPA 31 as less than 7200 cubic feet per 1 GPH input of all

appliances in area. A room 8 ft. high x 30.0 ft. x 30.0 ft. is 7200 cu.

ft.).

Provide two permanent openings:

One within 12 inches of ceiling, one within 12 inches of floor. Minimum

height or length dimension of each rectangular opening should be

at least 3 inches.

When inside air is used:

Each opening must freely connect with areas having adequate

infiltration from outside. Each opening should be at least 140 sq. in.

per 1 GPH input (1 sq. in. per 1000 Btu input) of all fuel-burning

appliances plus requirements for any equipment that can pull air

from room (including clothes dryer and fireplace).

When outside air is used:

Connect each opening directly or by ducts to the outdoors or to

crawl or attic space that freely connects with outdoors. Size per

below:

• Through outside wall or vertical ducts — at least 35 sq. in. per

1 GPH input (1 sq. in. per 4000 Btu input) of all fuel burning

appliances plus requirements for any equipment that can pull

air from room (including clothes dryer and fireplace).

• Through horizontal ducts — at least 70 sq. in. per 1 GPH boiler

input (1 sq. in. per 2000 Btu input) of all fuel-burning appliances

plus requirements for any equipment that can pull air from room

(including clothes dryer and fireplace).

• Where ducts are used, they should have same cross-sectional

area as free area of openings to which they connect.

Compensate for louver, grille or screen blockage when

calculating free air openings. Refer to their manufacturer’s

instructions for details. If unknown, use:

• Wood louvers , which provide 20-25% free air.

• Metal louvers or grilles, which provide 60-75% free air .

Lock louvers in open position or interlock with equipment to

prove open before boiler operation.

Please review the following information on potential combustion air

contamination problems.

See Tab le 2 for products and areas which may cause contaminated

combustion air .

T o prev ent potential of severe personal injury or death,

check for products or areas listed below before

installing boiler. If any of these contaminants are found:

• remove contaminants permanently .

— OR —

• isolate boiler and provide outside combustion air. See

national, provincial or local codes for further

information.

Table 2 Corrosive contaminants and likely locations

Products to avoid

Spray cans containing chloro/fluorocarbons

Permanent wave solutions

Chlorinated waxes/cleaners

Chlorine-based swimming pool chemicals

Calcium chloride used for thawing

Sodium chloride used for water softening

Refrigerant leaks

Paint or varnish removers

Hydrochloric acid/muriatic acid

Cements and glues

Antistatic fabric softeners used in clothes dryers

Chlorine-type bleaches, detergents, and cleaning solvents found in

household laundry rooms

Adhesives used to fasten building products and other similar products

Areas likely to have contaminants

Dry cleaning/laundry areas and establishments

Swimming pools

Metal fabrication plants

Beauty shops

Refrigeration repair shops

Photo processing plants

Auto body shops

Plastic manufacturing plants

Furniture refinishing areas and establishments

New building construction

Remodeling areas

Garages with workshops

4 Part Number 672 01 1005 00

Page 5

2 Prepare boiler

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

Place boiler

The boiler contains ceramic fiber and fiberglass

materials. Use care when handling these materials

per instructions on page 21 of this manual. F ailure to

comply could result in severe personal injury .

1. Remov e circulator carton strapped to pallet.

Circulator will be damaged if not removed before boiler

is lifted from pallet.

2. Remove boiler from pallet.

Do not drop boiler or bump jacket or burner on floor

or pallet. Damage to boiler or burner can result.

Smaller sized boilers may be top heavy . Use caution

when handling to avoid minor personal injury or

property damage.

3. Check level. Shim legs if needed.

4. Open burner mounting door. V erify that chamber ceramic liner

is securely in place on target wall, chamber floor and burner

door. V erify door seal is intact and in place. Close and securely

bolt the door.

6. Visually check:

a. Flue collector hood seal.

b . Burner mounting door seal.

Obtain gas-tight seal to prevent possible flue gas

leakage and carbon monoxide emissions, which can

lead to severe personal injury or death.

Hydrostatic pressure test

1. Install air vent in air vent tapping on top of boiler (see Figure 20,

page 26, for location).

3. Plug supply and return tappings.

4. Drain valve is factory-installed.

5. Fill boiler. V ent all air. Pressure test boiler at 1 ½ times w orking

pressure.

Do not leave boiler unattended. Cold water fill can

expand and damage cast iron, resulting in severe

personal injury, death or substantial property damage.

6. Verify that boiler maintains pressure for at least 10 minutes.

Visually check for leaks if gauge pressure drops.

7. Drain boiler. Repair leaks if f ound.

Using petroleum-based compounds to repair leaks

can damage system components, resulting in

property damage.

8. Retest boiler after repairing leaks.

9. Remove air vent and plugs.

5Part Number 672 01 1005 00

Page 6

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

3 Connect breeching

General venting requirements

Failure to follo w all instructions can result in flue gas

spillage and carbon monoxide emissions, causing

severe personal injury or death.

Inspect existing chimney before installing boiler.

Insufficient draft can cause flue gas leakage and

carbon monoxide emissions. Failure to clean or

replace perforated pipe or tile lining and/or patch

mortar and joints can cause severe personal injury

or death.

• The OWB and OWT boilers are designed to operate with an

over-fire draft of -0.01" to -0.02" w.c. Proper draft f or these oil

boilers may be achieved using either a conventional chimney

(natural draft) or a power vent (sidewall) system that has been

properly designed for use with oil-fired equipment. Pow er vent

manufacturer’s instructions must be f ollowed.

• Use vent material approved by local codes for oil-fired burners.

In their absence, refer to:

• NFP A 31, Installation of Oil-Burning Equipment.

• NFP A 211, Standard f or Chimneys, Fireplaces , Vents and

Solid Fuel Burning Appliances.

• In Canada, refer to CSA B139, Installation Code for Oil-

Burning Equipment.

• NFPA 211 requires chimney to be lined before connected

to boiler.

• To prevent downdrafts, extend chimney at least 3 feet above

highest point where it passes through roof and 2 feet higher

than any portion of building within 10 feet. Increase chimney

cross-sectional area and height at least 4% per 1,000 feet above

sea level.

• Provide minimum clearances from vent (flue) pipe to combustible

material:

• Type “L” double wall vent — 6 inches minimum

• Singlewall vent — 18 inches minimum

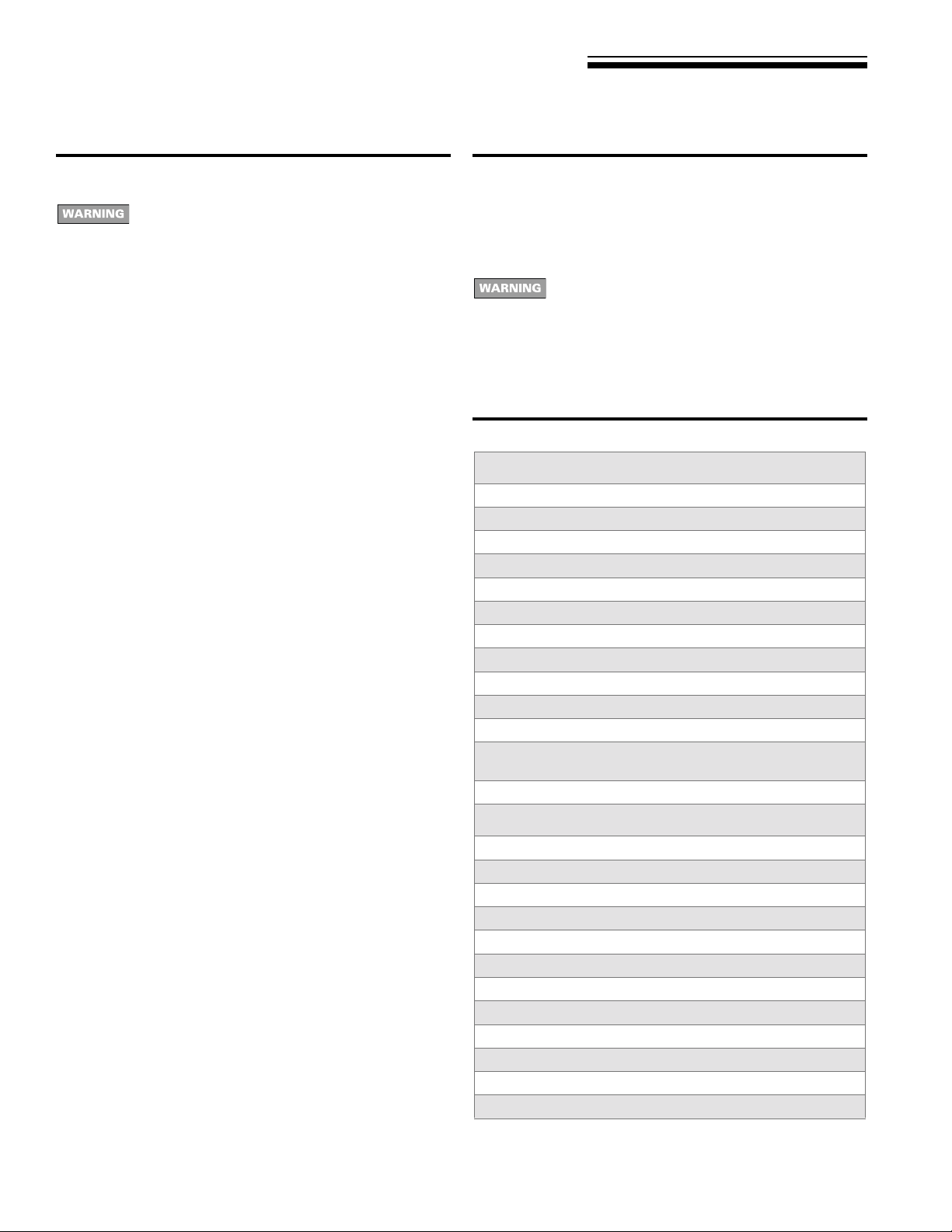

• Minimum chimney sizes should be used. See Table 3.

Oversized chimneys, outside masonry chimneys

and/or derated inputs can result in condensation in

chimney.

Connect breeching

Long horizontal breechings, excessive number of

tees and elbows, or other obstructions restricting

combustion gas flow can result in possibility of

condensation, flue gas leakage and carbon monoxide

emissions, which can lead to severe personal injury

or death.

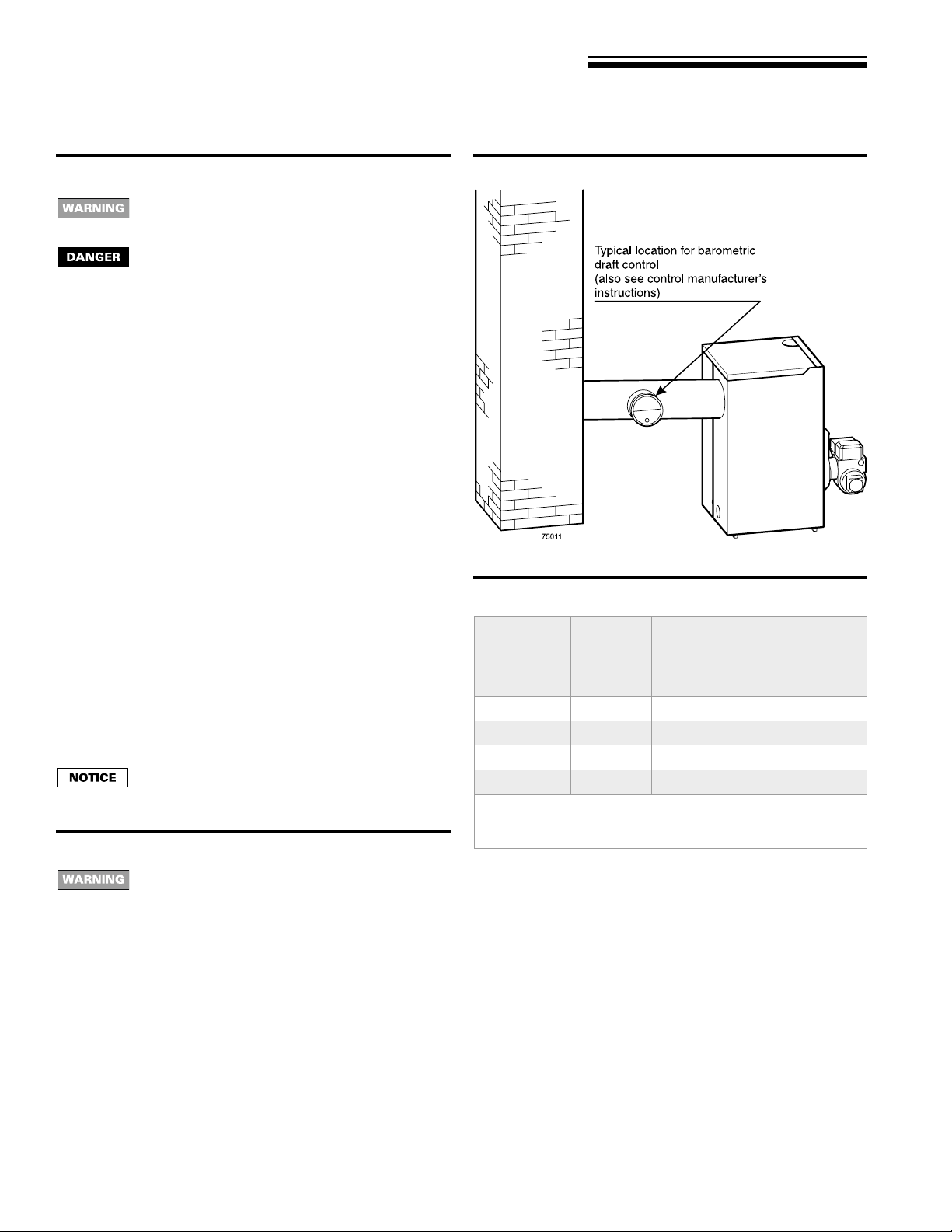

1. See Figure 2.

2. Connect full-sized breeching when possible. See Table 3.

3. Connection must be made above bottom of chimney to avoid

blockage. Breeching must not enter chimney far enough to

Figure 2 Chimney and breeching connections

Table 3 Chimney and breeching minimum sizes

Boiler

model

number

OWB/OWT3 5" 8" x 8" 6" 15'

OWB/OWT4 6" 8" x 8" 6" 15'

OWB/OWT5 6" 8" x 8" 7" 15'

OWB/OWT6 7" 8" x 8" 7" 15'

Notes:

1. Flue collar on boiler is7" diameter

2. 6 ¾"x6¾"insideliner

cause obstruction. Use thimble or slip joint where breeching

enters chimney to allow removal for cleaning.

4. When burner and boiler are properly installed, draft overfire will

be approximately -0.01" to -0.02" W .C . Install barometric control

in breeching, per control manufacturer's instructions, when

excess draft needs to be relieved or to comply with applicable

codes and regulations. Use draft gauge to adjust proper opening.

5. An induced draft fan for the chimney may be necessary if:

• Excessive resistance to flow of combustion gases can be

expected.

• Cross-sectional area of chimney is smaller than minimum

recommended.

• Chimney height is less than recommended.

• Seal all vent joints. Interlock burner with fan operation.

Minimum

breeching

diameter

Note 1

Minimum I=B=R

chimney size

Rectangle

Note 2

Round

Minimum

chimney

height

6 Part Number 672 01 1005 00

Page 7

OWB & OWT

4 Connect water piping

Oil-Fired Water Boilers – Boiler Manual

General

If installation is to comply with ASME or Canadian requirements,

an additional high temperature limit is needed. Install control in supply

piping between boiler and isolation valve. Set second control to

minimum 20 °F above setpoint of first control. Maximum allowable

setpoint is 240 °F. See page 11 for wiring.

A low water cutoff device is required when boiler is installed above

radiation level or by cer tain state or local codes or insurance

companies. Use low water cutoff designed for water installations.

Electrode probe-type is recommended. Purchase and install in tee

in supply piping above boiler .

Use backflow check valve in cold water supply if required by local

codes.

Near -boiler piping

See Figure 3 (diaphragm-type or bladder-type expansion tank) or

Figure 4 (closed-type expansion tank) on page 8, and Table 4, for

near-boiler and single-zone systems designed for return water at

least 130 °F. See Figure 6 or 7, page 9 for low return temperature

applications.

See this page for multiple-zone piping.

See page 8 for boilers used with refrigeration systems.

Relief valve

Install relief valve v ertically in ¾" tapping on rear of boiler using ¾"

nipple and elbow supplied in bag with valve. See the tag attached to

the relief valve f or manufacturer’s instructions.

To avoid water damage or scalding due to valve

operation, discharge line must be connected to relief

valve outlet and run to a safe place of disposal.

T erminate the discharge line to eliminate possibility

of severe burns should the valve discharge.

• Discharge line must be as short as possible and be

the same size as the valve discharge connection

throughout its entire length.

• Discharge line must pitch downward from the valve

and terminate at least 6" above the floor drain where

any discharge will be clearly visible.

• The discharge line shall terminate plain, not threaded,

with a material serviceable for temperatures of 375 °F

or greater.

• Do not pipe the discharge to any place where freezing

could occur.

• No shutoff valve shall be installed between the relief

valve and boiler , or in the discharge line. Do not plug

or place any obstruction in the discharge line.

• Failure to comply with the above guidelines could

result in failure of the relief valve to operate, resulting

in possibility of severe personal injury, death or

substantial property damage.

• Test the operation of the valve after filling and

pressurizing system by lifting the lever. Make sure

the valve discharges freely. If the valve f ails to operate

correctly , replace it with a new relief v alv e.

Near -boiler piping continued

Table 4 Water pipe size (based on 20 °F rise)

Boiler

model

number

OWB/OWT3 1 ¼" 1 ¼"

OWB/OWT4 1 ¼" 1 ¼"

OWB/OWT5 1 ½" 1 ½"

OWB/OWT6 1 ½" 1 ½"

All piping sizes based on 20 °F temperaturerise through boiler.

Circulator

The circulator is shipped loose (wiring pre-attached to boiler) to

allow you to locate it either in the return or supply piping, as desired.

See page 8 for a typical installation. Pipe the expansion tank to the

suction side of the circulator whenever possible. Install an air

separator in the supply piping. Connect the expansion tank to the

air separator only if the separator is on the suction side of the

circulator. Always install the system fill connection at the same point

as the expansion tank connection to the system. Figures 3 and 4,

on page 8, show typical near-boiler piping connections.

Expansion tank

Diaphragm- or bladder-type expansion tank — Figur e 3,

page 8

1. Ensure expansion tank size will handle boiler and system water

volume and temperature. T ank m ust be located in boiler return

piping as close to boiler as possible, bef ore inlet side of circulator.

See tank manufacturer’s instructions for details.

2. Install an automatic air vent as shown.

Closed-type expansion tank — Figure 4, page 8

1. Ensure expansion tank size will handle boiler and system water

volume and temperature. See tank manuf acturer’s instructions

for details.

2. Connect tank to ½" NPT tapping located behind supply outlet,

using ½" NPT piping. Pitch any horizontal piping up towards

tank 1 inch per 5 feet of piping.

Undersized expansion tanks cause system water to

be lost from relief valve and makeup water to be

added through fill valve. Eventual section failure can

result.

Water piping — multiple zone systems

Install system piping using either circulator zoning or zone valve

zoning. Install expansion tank on suction side of system pump.

Always connect fill line only at the expansion tank — never at

another point in the system.

To

system

From

system

7Part Number 672 01 1005 00

Page 8

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

4 Connect water piping continued

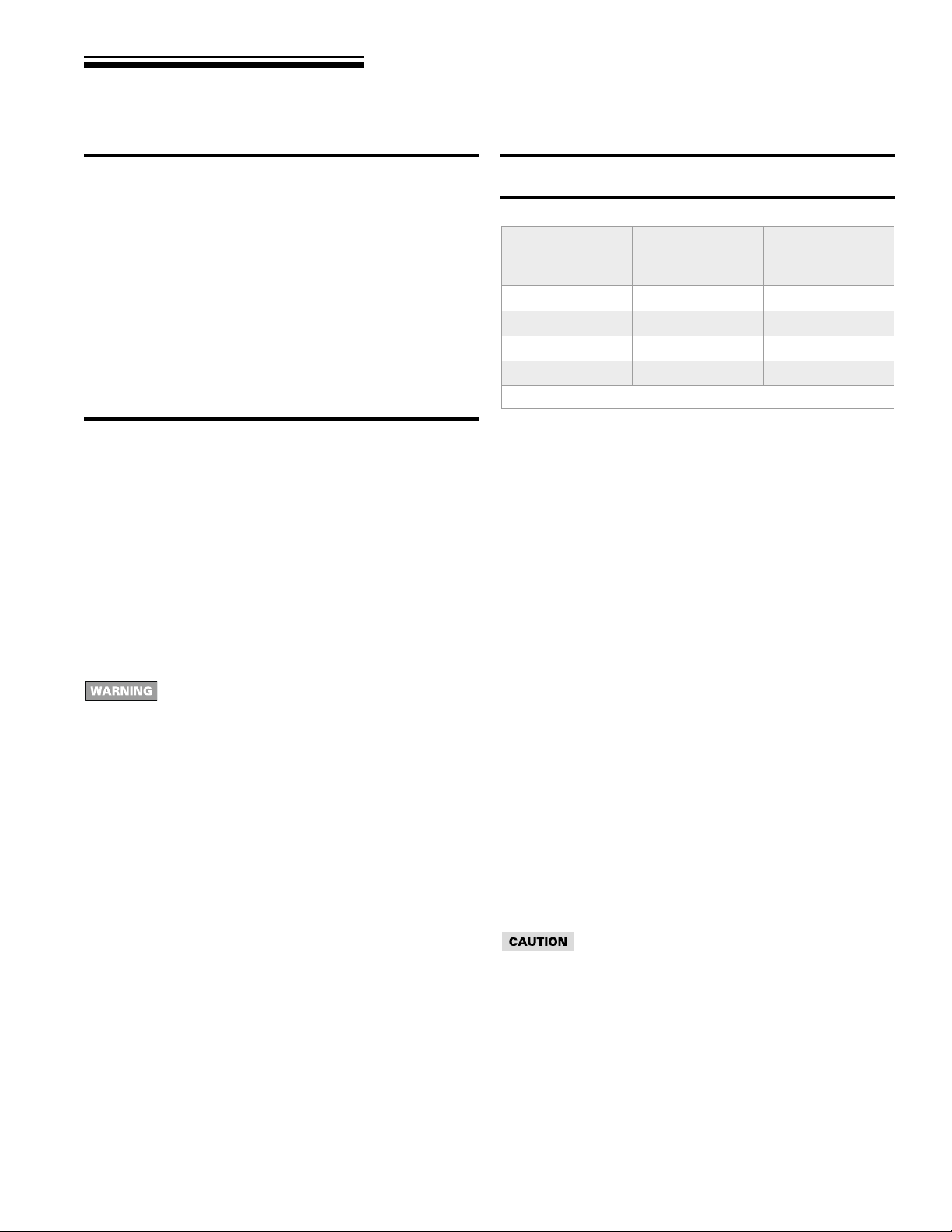

Figure 3 Diaphragm- or bladder-type expansion tank:

Piping to single-zone system using

diaphragm-type or bladder-type expansion

tank. See Table 4, page 7, for piping sizes.

Figure 4 Closed-type expansion tank: Piping to

single-zone system using closed-type

expansion tank. See Table 4, page 7, for

piping sizes.

Use Figure 3 or Figure 4 only for systems designed

for return water at least 130 °F. For systems with low

return water temperature possible, such as

converted gravity systems and radiant heating

systems, install by-pass piping (see page 9) to protect

boiler against condensation. Failure to prevent low

return water temperature to the boiler could cause

corrosion of the boiler sections or burners, resulting

in severe personal injury, death or substantial

property damage.

If system includes radiant heating circuits, provide

piping and controls to regulate the temperature

supplying the radiant circuits. Failure to comply could

result in substantial property damage.

Install boiler so that chilled medium is piped in parallel

with heating boiler. Use appropriate valves to pre vent

chilled medium from entering boiler. Consult I=B=R

Installation and Piping Guides.

If boiler is connected to heating coils located in air

handling units where they can be exposed to

refrigerated air, use flow control valves or other

automatic means to prevent gravity circulation during

cooling cycle. Circulation of cold water through the

boiler could result in damage to the heat exchanger ,

causing possible severe personal injury, death or

substantial property damage.

Water piping — refrigeration systems

Prevent chilled water from entering boiler

Install boiler so that chilled medium is piped in parallel with the

heating boiler. Use appropriate valves to prevent chilled medium

from entering boiler. See Figure 5 for typical installation of balancing

valve and check valve.

Figure 5 Piping refrigeration systems

8 Part Number 672 01 1005 00

Page 9

OWB & OWT

4 Connect water piping continued

Near -boiler piping continued

Oil-Fired Water Boilers – Boiler Manual

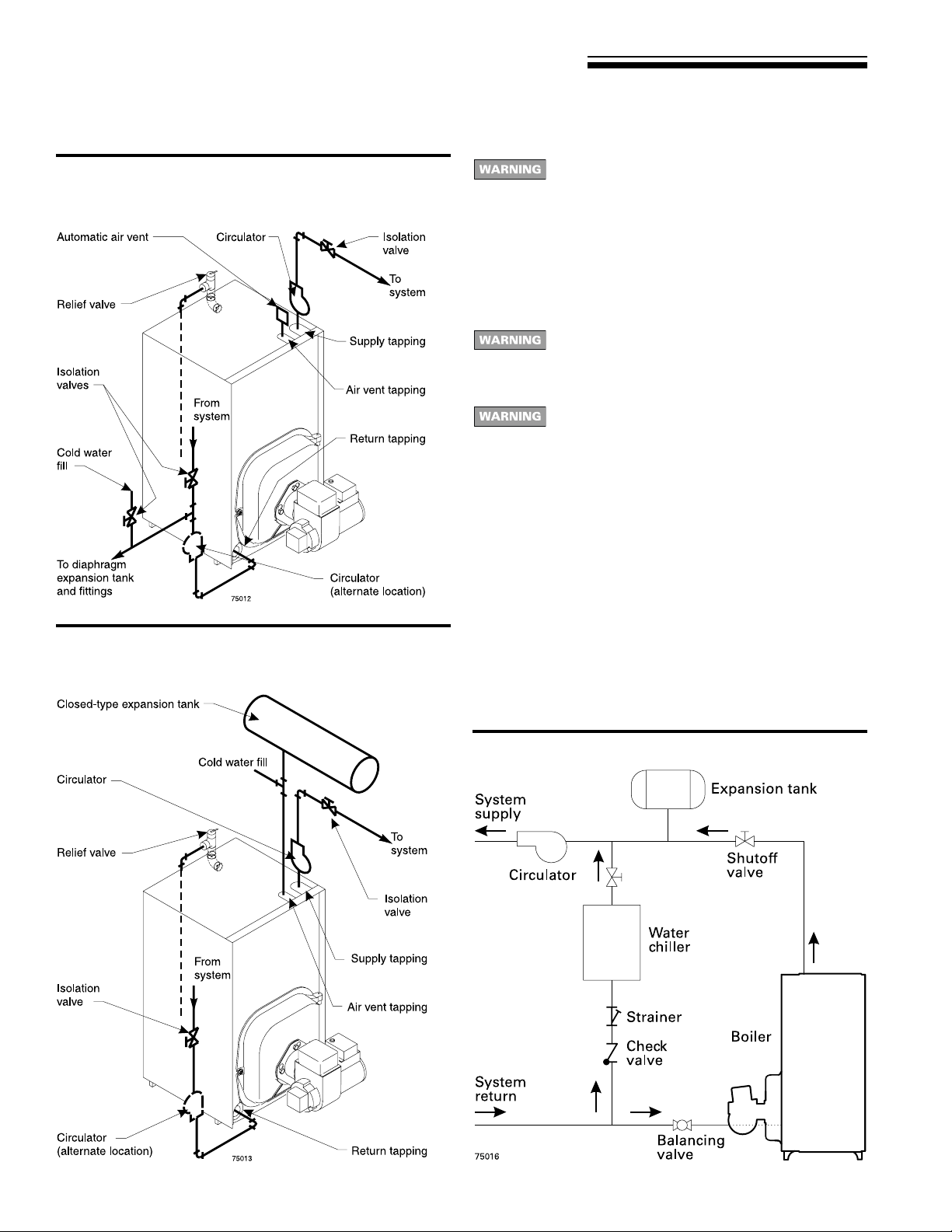

Figure 6 System bypass piping in boiler loop with

separate system circulator, using primary/

secondary piping.

Figure 7 Boiler bypass piping — use only for high

water content systems —DO NOT use for

radiant panel systems.

System bypass method

1. Apply bypass piping of Figure 6 to high water content systems,

radiant panel systems or any system that is likely to operate

with low return water temperature for extended periods.

2. The bypass arrangement shown protects the boiler from damage

caused by condensate corrosion due to low return water

temperature and protects low temperature systems from too

high a supply temperature.

3. Adjust the bypass valves as indicated below .

Adjust Bypass valves 1 and 2 as follows:

1. Start with valve 2 fully closed, valv e 1 fully open.

2. Slowly open valve 2 while closing valve 1. Adjust the valves

until the boiler pressure/temperature gauge reads 160 °F or

higher. As you open the valves, pause long enough to allow

temperatures to level off. It takes a while for the boiler water

temperature to rise as the flow changes.

3. Bypass valve 2 allows hot boiler outlet water to blend with colder

return water, raising the supply temper ature to the boiler. Bypass

valve 1 balances the pressure drop through valve 2.

4. The purpose of this piping is to raise the return water temperature

to the boiler enough to prevent condensation of flue gases.

Install all components specified above and adjust valv es as described to prev ent low temper ature in the boiler . Fa ilure to

prevent low water temperature in the boiler could cause corrosion of the boiler sections or burners, resulting in severe

personal injury, death or substantial property damage.

Boiler bypass method

1. Apply bypass piping of Figure 7 to high water content systems,

such as converted gravity systems.

2. The bypass arrangement shown protects the boiler from damage

caused by condensate corrosion due to low return water

temperature. This method does not pro vide protection from high

temperature water being supplied to the system.

3. DO NOT apply this piping to radiant panel systems.

4. Adjust the bypass valves as indicated below .

Adjust Bypass valves 1 and 2 as follows:

1. Start with valve 1 fully closed, valv e 2 fully open.

2. Slowly open valve 1 while closing valve 2. Adjust the valves

until the boiler pressure/temperature gauge reads approximately

60 °F higher than the system temperature gauge. As you open

the valves, pause long enough to allow temperatures to level

off. It takes a while for the boiler water temperature to rise as

the flow changes.

3. Bypass valve 1 controls system flow rate. Bypass valve 2

controls flow through the boiler.

4. The purpose of this piping is to cause a high enough temperature

rise in the boiler that the average temperature will be warm

enough to prevent condensation of flue gases.

9Part Number 672 01 1005 00

Page 10

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

5 Connect tankless heater piping (OWT boilers only)

Hot water can scald!

• Consumer Product Safety Commission and some

states recommend domestic hot water temperature

of 130 °F or less.

• When installing an automatic mixing valve, selection

and installation must comply with valve man ufacturer’s

recommendations and instructions.

• Water heated to a temperature suitable for clothes

washing, dish washing and other sanitizing needs

will scald and cause injury.

• Children and elderly , infirm or physically handicapped

persons are more likely to be injured by hot water.

Never leave them unattended in or near a bathtub,

shower or sink. Never allow small children to use a

hot water faucet or draw their own bath. If anyone

using hot water in the building fits this description, or

if state laws or local codes require certain water

temperatures at hot water faucets, take special

precautions:

• Install automatic mixing valve set according to those

standards.

• Use lowest practical temperature setting.

• Check water temperature immediately after first

heating cycle and after any adjustment.

Studies have indicated that dangerous bacteria can

form in potable water distribution systems if certain

minimum water temperatures are not maintained.

Contact local health department for more information.

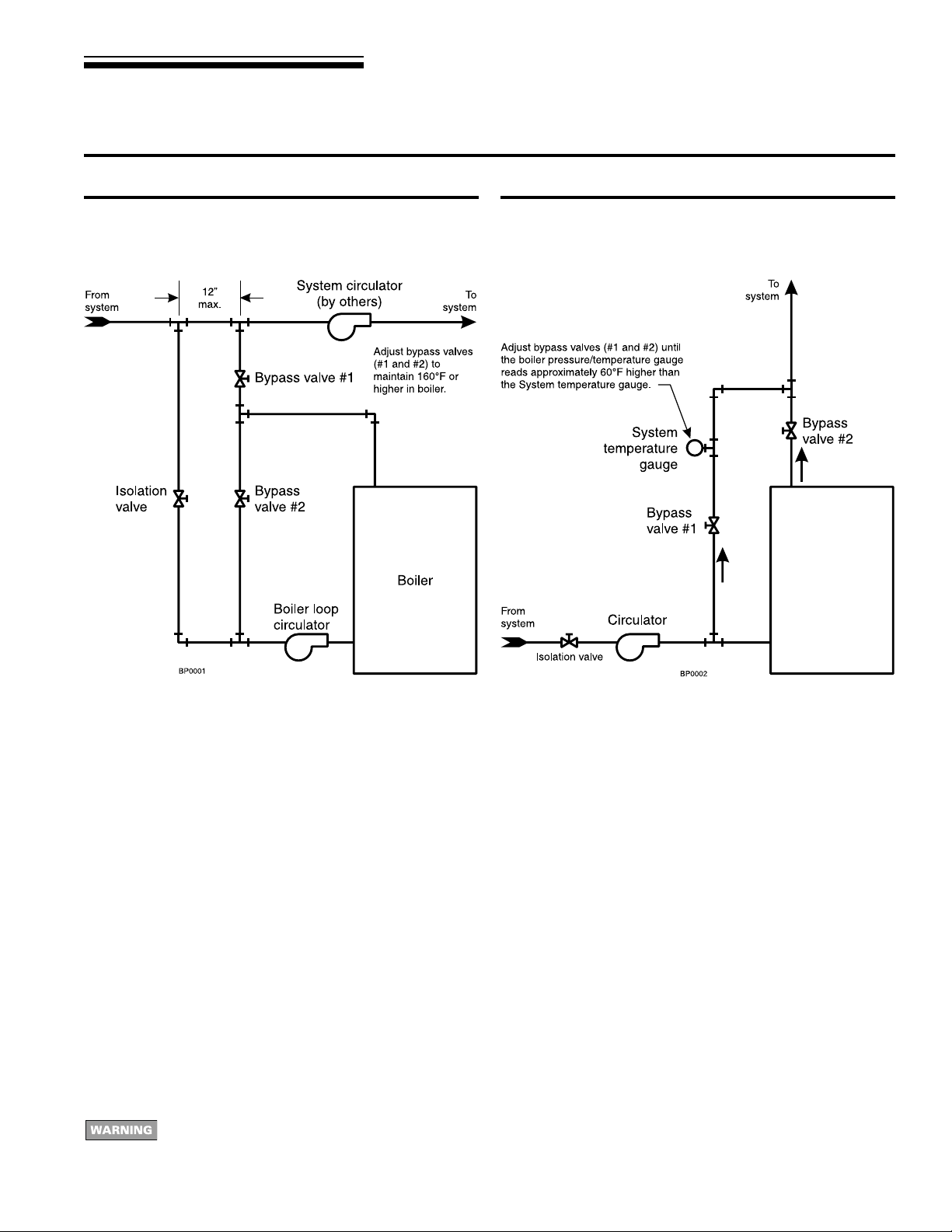

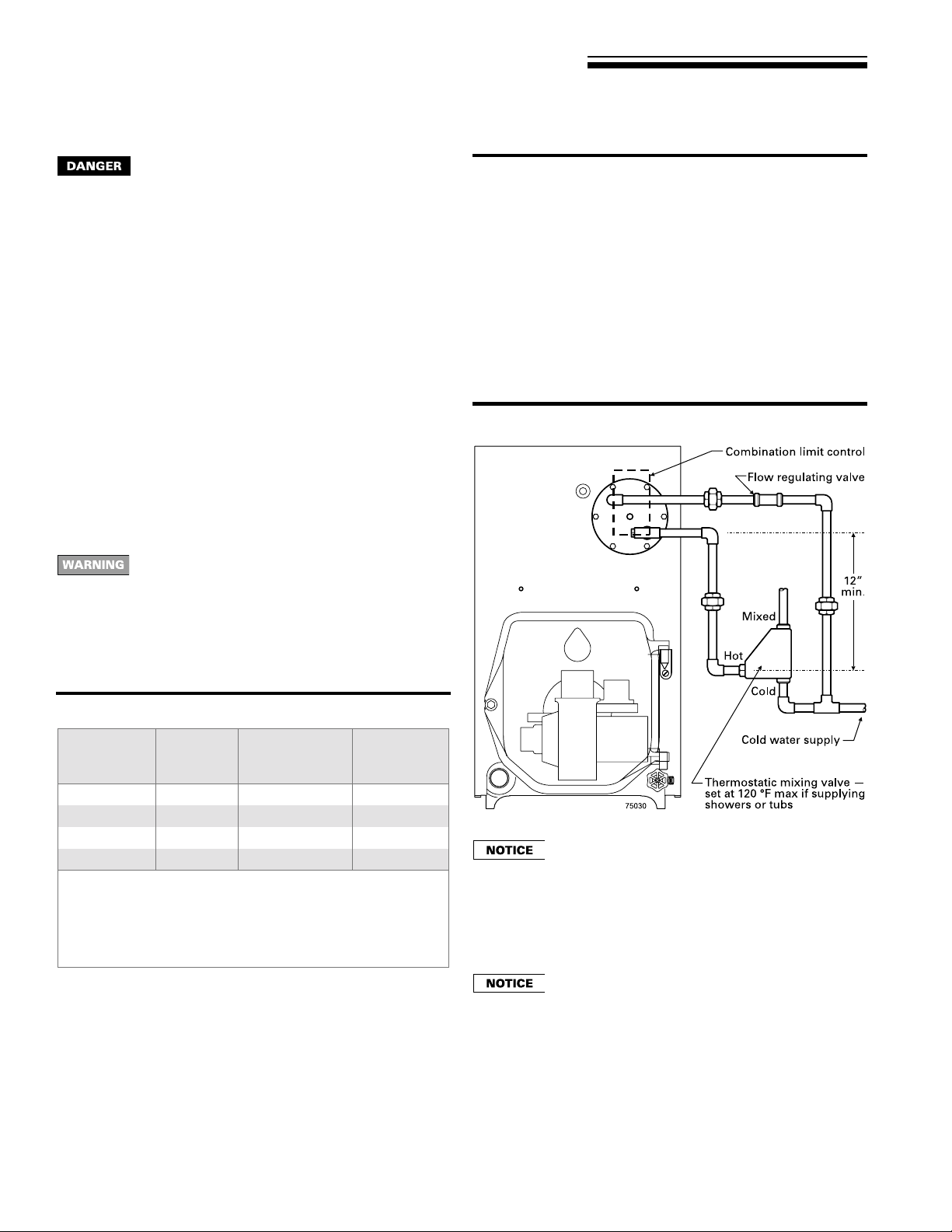

Pipe tankless heater

1. Size piping no smaller than tankless heater inlet and outlet.

2. Following controls (furnished by others) must be installed:

a. Automatic mixing valve. See Figure 8. (Read DANGER

statement at left.)

b. Flow regulating valve (see Figure 8). Size according to

intermittent draw of tankless heater. See Table 5. Follow

valve man ufacturer’s instructions to install.

3. Additional anti-scald devices may be installed at each hot water

faucet, bath and shower outlet.

4. In hard water areas, soften cold domestic supply water to

heaters to prevent lime buildup .

Figure 8 Piping connections to tankless heater, typical

Table 5 Tankless heater ratings

Boiler

model

number

OWB/OWT-3 WT-11 3.00

OWB/OWT-4 WT-14 3.75

OWB/OWT-5 WT-14 4.00

OWB/OWT-6 WT-14 4.25

Note 1: Gallons of water per minute heated from 50˚F to 140˚F with

200˚F boiler water temperature.

Note 2: Gallons of water per minute heated from 40˚F to 140˚F with

200˚F boiler water temperature.

Tested in accordance with I=W=H Testing and Rating Standard for

Indirect Tankless Water Heaters Tested with Boilers.

Heater

number

Intermittent

draw ratings

(GPM)

(note 1)

(note 2)

(note 2)

(note 2)

Inlet and

outlet

tapping sizes

¾"

¾"

¾"

¾"

These single wall heat exchangers comply with

National Standard Plumbing Code provided that:

• Boiler water (including additives) is practically

nontoxic, having toxicity rating or class of 1, as listed

in Clinical Toxicology of Commercial Products.

• Boiler water pressure is limited to maximum 30 psig

by approved water relief valve.

Tankless heater ratings are based on 200°F boiler

water temperature. To get rated output, set tankless

heater control to 200°F. Control can be adjusted to

meet system hot water requirements.

10 Part Number 672 01 1005 00

Page 11

6 Connect wiring

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

Electric shock hazard. Can cause severe personal

injury or death if power source, including service

switch on boiler , is not disconnected before installing

or servicing.

Installations must follow these codes:

• National Electrical Code, ANSI/NFP A 70, latest edition and an y

additional national, state or local codes.

• In Canada, CSA C22.1 Canadian Electrical Code Part One and

any local codes.

• Wiring must be N.E.C. Class 1. If original wire as supplied with

boiler must be replaced, type 105 °C wire or equivalent must

be used. Supply wiring to boiler and additional control wiring

must be 14 gauge or heavier.

• Provide electrical ground at boiler as required by codes.

Thermostat wiring

• Install thermostat on inside wall away from influences of drafts,

hot or cold water pipes, lighting fixtures, television, sun rays or

fireplaces.

• Follow instructions with thermostat. If it has a heat anticipator,

set heat anticipator in thermostat to match power requirements

of equipment connected to it. Boiler wiring diagrams give setting

for standard equipment.

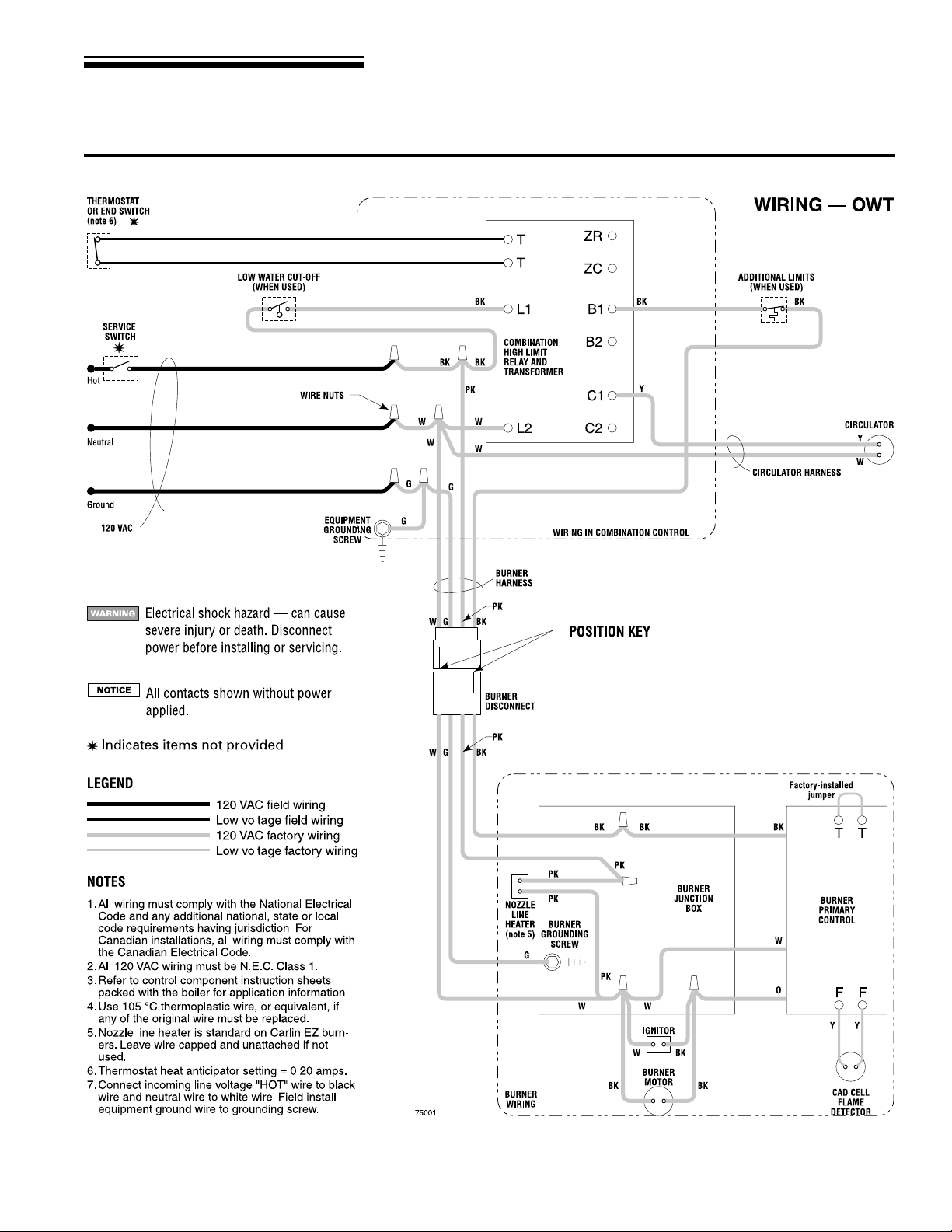

Figure 9 Electrical components and harnesses

Burner wiring

• Burner harness incorporates a disconnect plug, providing a

convenient way to disconnect wiring when burner mounting door

is opened. See Figure 9.

Wiring entrance

• The limit control enclosure houses electrical connections for all

boiler components.

• Boilers have harnesses furnished. See Figure 10, page 12,

(OWB boilers) or Figure 11, page 13, (OWT boilers) for factory

and field wiring information.

• All field-installed high voltage wiring must be sheathed in metal

conduit.

• Connect incoming line voltage wires as shown in Figure 10 or

Figure 11. Field-install equipment ground wire to green wire with

wire nut.

• Some local codes may require an emergency shut-off switch

installed at a location away from boiler . Follo w local codes.

11Part Number 672 01 1005 00

Page 12

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

6 Connect wiring continued

Figure 10 Wiring diagram — OWB boilers

12 Part Number 672 01 1005 00

Page 13

OWB & OWT

6 Connect wiring continued

Figure 11 Wiring diagram — OWT boilers

Oil-Fired Water Boilers – Boiler Manual

13Part Number 672 01 1005 00

Page 14

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

7 Connect oil piping

General oil piping requirements

• Location and installation of oil tanks, oil piping and burners must

follow:

• NFPA 31, Standard for the Installation of Oil-Burning

Equipment.

• In Canada, CSA B139, Installation of Oil-Burning Equipment.

• Local codes and regulations.

• Information provided with burner and fuel pump.

• If any part of fuel oil tank is above level of burner , an anti-siphon

device must be used to prevent flow of oil in case of oil line

break.

• Support oil lines as required by codes.

• Make tank connections with swing joints or copper tubing to

prevent breaking in case the tank settles. Make swing joints so

they will tighten as tank settles. Non-hardening pipe joint

compounds should be used on all threads.

Do not use Teflon tape as an oil pipe sealant. It can

cause valves to fail, creating hazards. Use only flare

fittings. Do not use compression fittings. Failure to

comply could result in severe personal injury, death

or substantial property damage from oil leakage and/

or fire hazard.

• Underground pipe must be run in a casing to prevent oil leaking

into ground or under floor. Check local codes f or information.

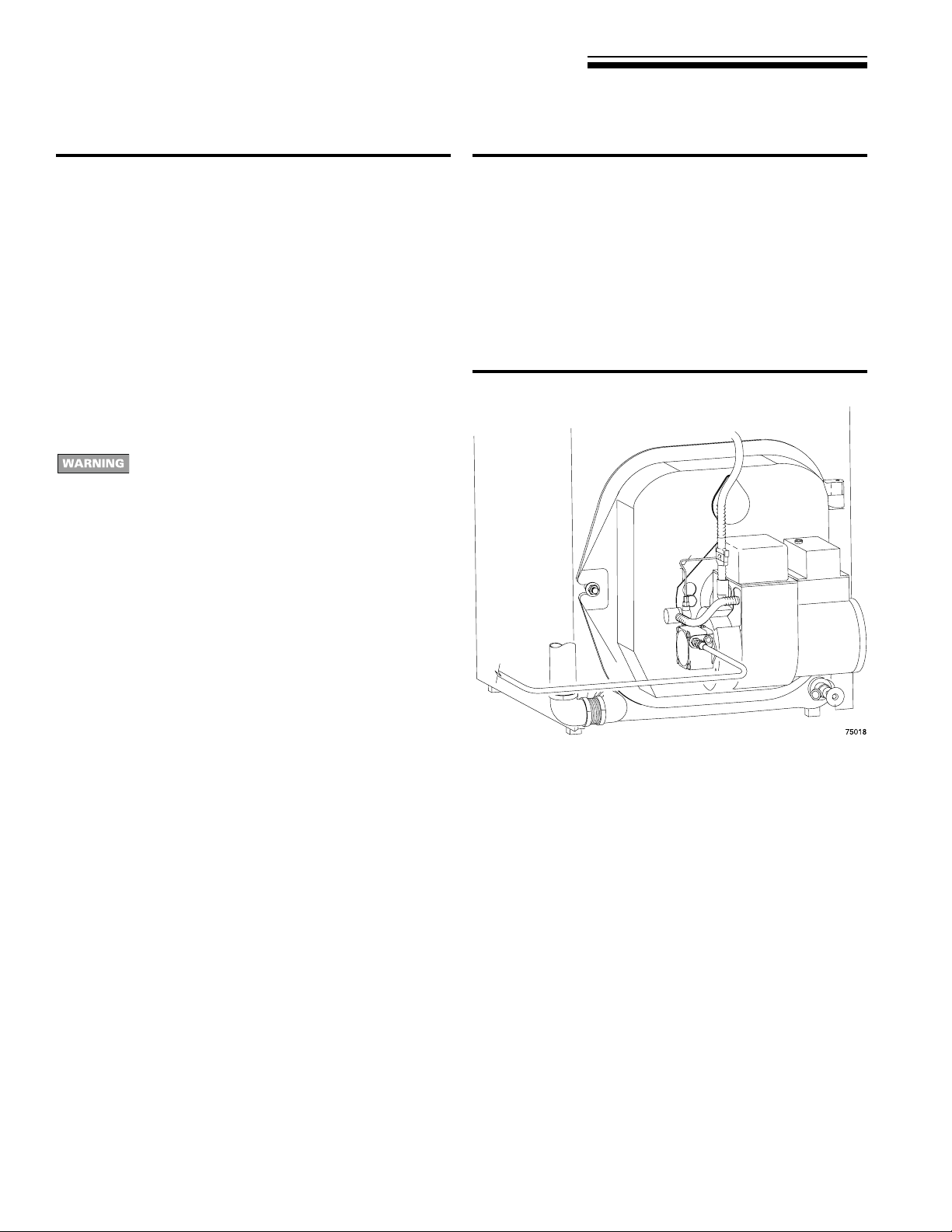

Oil piping connection at burner

• See Figure 12 for typical oil connection at burner, allo wing burner

mounting door to swing open completely for servicing.

• Connect oil line to burner using flare fitting (Figure 12).

• See local codes for appropriate arrangement and piping of filter,

control valves, etc. connecting to oil tank.

• Refer to burner manual for oil sytem requirements. Verify that

suction lift does not exceed stated limit. Where lift e xceeds limit

for a one-pipe system, use a two-pipe system as directed in

burner manual.

Figure 12 Oil piping connection to burner , typical

14 Part Number 672 01 1005 00

Page 15

8 Start-up

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

Follow information below to prevent severe personal

injury, death or substantial property damage:

• Do not use gasoline crankcase drainings or any oil

containing gasoline. See burner manual for proper

fuel oil.

• Do not attempt to start burner when excess oil has

accumulated, when unit is full of vapor or when

combustion chamber is very hot.

• Do not start burner unless collector hood, breeching

and burner mounting door are secured in place.

• Never b urn garbage or paper in the boiler.

• Never leave combustible material around it.

Fill the system

1. Close manual and automatic air vents and boiler drain cock.

2. Fill to correct system pressure. Correct pressure will vary with

each installation. Normal cold water fill pressure for residential

systems is 12 psig. Boiler water pH 7.0 to 8.5 is recommended.

Failure to maintain recommended pH le vel can cause

section failure and leaks.

3. Open automatic air vent one turn.

4. Open other vents.

a. Starting on the lowest floor, open air vents one at a time

until water squirts out. Close vent.

b . Repeat with remaining vents.

5. Refill to correct pressure.

Tips for water systems

• Check boiler and system piping for leaks. Continual makeup

water will reduce boiler life. Minerals can build up in sections,

reducing heat transfer and causing cast iron to overheat,

resulting in section failure.

Failure to maintain recommended pH and repair leaks

can cause section iron corrosion, leading to section

failure and leaks. Do not use petroleum-based sealing

or stop-leak compounds in boiler system. Damage

to system components can result.

• For pH conditions outside 7.0 to 8.5 range or unusually hard

water areas (above 7 grains hardness), consult local water

treatment company .

• When using antifreeze:

Do not use automotive, ethylene glycol, undiluted

or petroleum-based antifreeze. Severe personal

injury, death or substantial property damage can

result.

• Use antifreeze especially made for hydronic systems. Inhibited

propylene glycol is recommended.

• 50% solution provides protection to about -30 °F. Do not exceed

50% mixture.

• Local codes may require backflow preventer or actual

disconnect from city water supply.

• Determine quantity according to system water content. Boiler

water content is listed on back cover of manual. Percent of

solution will affect sizing of heat distribution units, circulator

and expansion tank.

• Follow antifreeze man ufacturer’s instructions.

Place in operation

1. Verify boiler is filled with water.

2. Open burner mounting door and verify rear target wall, floor

and burner door insulations are in proper position and condition.

3. V erify burner mounting door is closed tightly and burner wiring

harness is connected securely.

4. Factory burner adjustment and settings may not be suitable

for specific job conditions. Refer to burner manual for burner

start-up, adjustment and checkout procedures.

5. Refer to burner manual for start-up. Allow boiler to heat to

design temperature. Then adjust b urner for correct combustion,

using combustion test equipment. Adjust burner for:

Draft: –0.01 to –0.02 inches water column draft in boiler

combustion chamber.

: between 11% and 12%, with 0 smoke.

CO

2

Make final burner adjustments using combustion

test equipment to assure proper operation. Do not

fire boiler without water. Sections will overheat,

damaging boiler and resulting in substantial property

damage.

6. Vent air from system. Repeat steps 4 and 5 under “Fill the

system”. Air in system can interfere with water circulation and

cause improper heat distribution.

7. Check boiler and system piping for leaks. See “Tips for water

systems” on this page.

8. Inspect breeching and venting for proper operation.

For additional information, refer to instructions packed with boiler or burner:

• Burner Manual

• Component literature

15Part Number 672 01 1005 00

Page 16

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

9 Checkout procedure

Check off steps as completed

❑ 1. Boiler and heat distribution units filled with water?

❑ 2. Automatic air vent, if used, opened one full turn?

❑ 3. Air purged from system? Piping checked for leaks?

❑ 4. Air purged from oil piping? Piping checked for leaks?

❑ 5. Burner door closed, sealed and nut tight? Burner harness

securely plugged in?

Obtain gas-tight seal to prevent possible flue gas

leakage and carbon monoxide emissions, leading to

severe personal injury or death.

❑ 6. Proper draft and burner flame? Final adjustment made

with combustion test equipment?

❑ 7. T est limit control: While burner is operating, move indicator

on limit control below actual boiler water temperature.

Burner should go off while circulator continues to operate.

Raise setting on limit control above water temperature and

burner should reignite.

❑ 8. Test additional field-installed controls: If boiler has a lo w

water cutoff, additional high limit or other controls, test for

operation as outlined by manuf acturer. Burner should be

operating and should go off when controls are tested. When

controls are restored, burner should reignite.

❑ 9. Limit control set to system temperature requirements

(maximum 220 °F)?

❑ 10. For multiple zones, flow adjusted to distribute heat in all

zones?

❑ 11. Thermostat heat anticipator setting (if available) set

properly? Refer to “Connect wiring, ” page 11.

❑ 12. Boiler cycled with thermostat? Raise to highest setting

and verify boiler goes through normal start-up cycle. Lower

to lowest setting and verify boiler goes off.

❑ 13. Observed several operating cycles for proper operation?

❑ 14. Set room thermostat(s) to desired room temperature?

❑ 15. Completed “Installation and service certificate” below?

❑ 16. Reviewed User’s Information Manual with owner or

maintenance person and instructed person to keep for

future reference?

❑ 17. Returned all instructions provided with boiler to its envelope

and placed with boiler for future reference?

Installation and service certificate

Boiler model _______________________________________________________________ Series ____________

CP number _______________________________________ Date installed _________________________________

o Installation instructions have been followed.

Measured Btuh input ____________

Installer _______________________ ______________________________ ____________________________

(company) (address) (phone)

16 Part Number 672 01 1005 00

o Checkout sequence has been performed.

o Above information is certified to be correct.

o Information received and left with owner/maintenance person.

_____________________________________

(installer’s signature)

Page 17

10 Appendix

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

Close clearance installation

To provide close clearances as described on this

page, obtain Williamson-Thermoflo Close Clearance

Kit and and install as described below. F ailure to use

kit or install as described can result in a fire hazard,

causing severe personal injury , death or substantial

property damage.

Substitute these instructions for corresponding material in manual.

All other procedures and practices must remain the same.

Recommended service and minimum clearances shown on page

3 should be used where possible.

Where closer clearances are required:

• Top of boiler – If less than 24" available, provide removable

surface to allow for cleaning boiler flueways.

• Right or left side – Minimum 2 inches.

• Front – Minimum 2 inches from burner.

• Type “L” doub lewall flue (vent) pipe to comb ustible surface – as

listed in Table below and Figures 13, 14 and 15.

Flue pipe clearances must take precedence over

jacket clearances.

1. Install boiler using clearances described above.

2. Install barometric control 18 to 20 inches from boiler in

breeching.

3. Attach manual reset temperature switch near upper surface of

enclosed area. See Figure 13.

4. Wire switch in series with thermostat. See Figure 13.

5. Provide two combustion/ventilation openings when installing in

confined space. Size opening 140 sq. in. (1000 Btu) per 1 GPH

input. Locate openings near top and bottom of enclosed space.

Figure 14 Minimum vent clearances

Figure 15 Protection required for close clearance

Figure 13 Manual reset temperature switch wiring and

location

Protection required for clearance less than 6" from

doublewall vent pipe (Note 1)

Dimension A

When desired minimum

clearance from Type “L”

doublewall vent pipe to

combustible surface is:

3"

2"

3"

Notes:

1. All clearances measured from outer surface of equipment to combustible

surface, not to the protection used.

2. Apply to combustible surface unless otherwise noted. Cover all surfaces as

specified in Table above and Figure 14. Thicknesses are minimum.

3. Factory-fabricated board made of non-combustible materials, normally

fibers, having thermal conductivity in range of one (Btu-inch)/(hr/sq. ft/˚F)

or less.

4. Mineral wool batts (blanket or board), having minimum density of

3

and a minimum melting point of 1500 ˚F.

8 lb/ft

Use the following protection

(Note 2):

½" thick insulation board (Note 3) over

one-inch glass fiber of mineral wool batts

(Note 4)

24 gauge sheet metal with

one-inch ventilated air space

½" thick insulation board (Note 3) with

one-inch ventilated air space

17Part Number 672 01 1005 00

Page 18

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

11 Service and maintenance

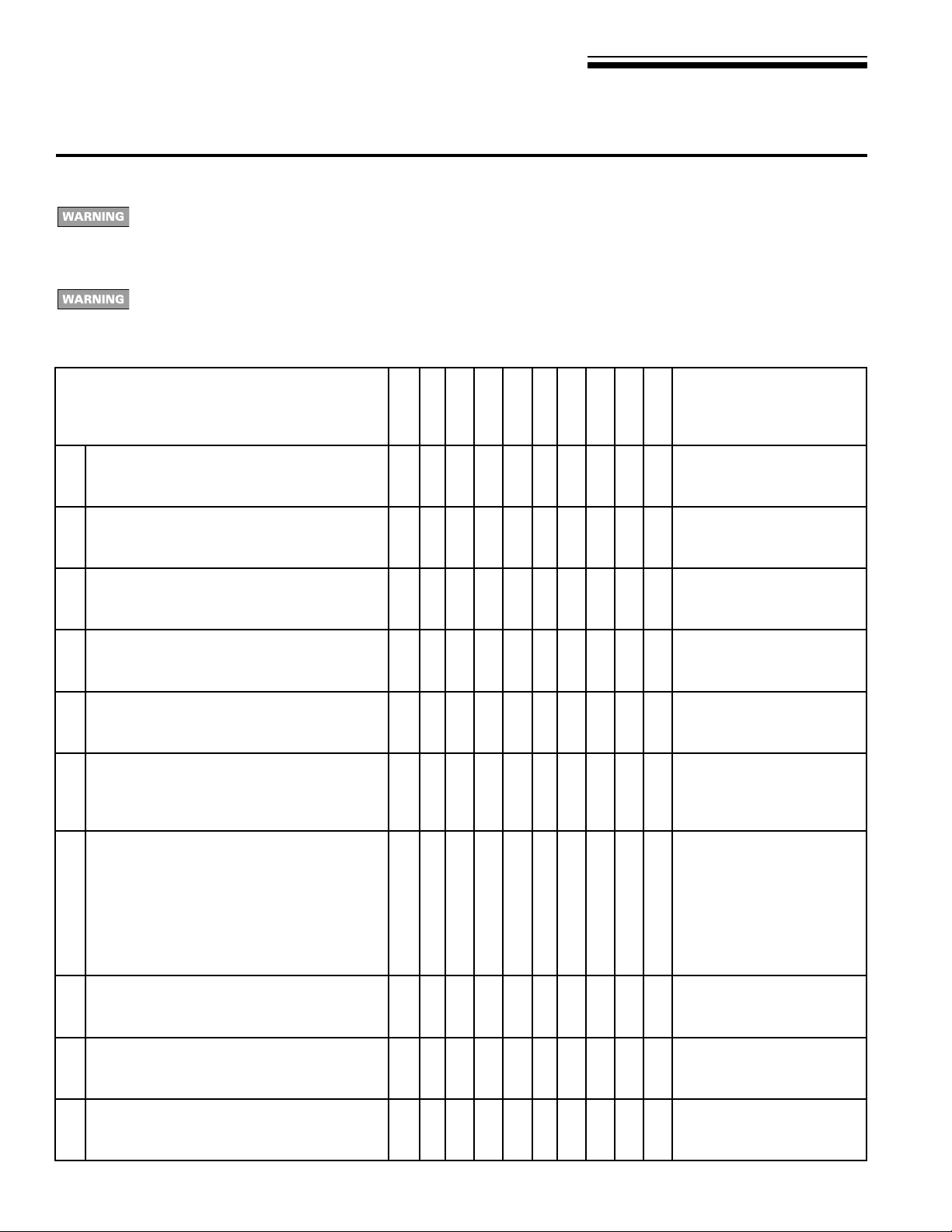

Annual service and start-up

Follow the “Service and maintenance” procedures given throughout this manual and in component literature shipped with

the boiler. Failure to perf orm the service and maintenance could result in damage to the boiler or system. F ailure to follow the

directions in this manual and component literature could result in severe personal injury, death or substantial property

damage.

The boiler should be inspected and started annually, at the beginning of the heating season, only by a qualified service

technician. In addition, the maintenance and care of the boiler designated in the tab le below , and explained on the following

pages must be performed to assure maximum boiler efficiency and reliability . F ailure to service and maintain the boiler and

system could result in equipment failure.

D

D

D

A

A

A

tsilkcehcllacecivreslaunnA

)wolebdetsilredroniwollof(

T

T

T

E

E

E

D

D

D

D

D

D

D

A

A

A

A

A

A

A

T

T

T

T

T

T

T

E

E

E

E

E

E

E stnemmoC

1

.sdiuqil

2

3

.yrassecen

4

5

.02egap

6

.).sbl.tf52-02oteuqrot

7

.elzzonegnahc-

.telnirianaelc-

.91egapeeS.syaweulfreliobnaelC

.sgnittesedortcelenoitingikcehc-

.leehwdnagnisuohrewolbnaelc-

.yleerfsnrutleehwrewolberusekam-

.deriuqerfirotomrenrublio-

elbitsubmocmorfeerfsiaerareliobtahtkcehC

dnasropavelbammalfrehtodnaenilosag,slairetam

otnoitcurtsboynaevomerdnarofkcehC

.reliobotwolfrianoitalitnevdnanoitsubmoc

roftnevroyenmihcdnagnihceerbkcehC

saecalperroriapeR.cte,egamad,snoitcurtsbo

eeS.rotalucricdnaevlavfeilernoecivresmrofreP

firiaperdnaskaelrofgnipipdnareliobkcehC

.etalpretaehsselknattaskaelrofkcehC.dnuof

TWOrof(dnuoferaskaelfiylnostunnethgiT

:dnalaunamrenrubeeS.renrubtsujdadnatcepsnI

.reniartsdnaretlifleufegnahcronaelc-

8

9

.tnempiuqetsetnoitsubmoc

.02egapeeS

01

.02

.retawhtiwdellifsirelioberusekaM

htiwsgnittesnoitsubmocyfirevdnatinutratS

egapeeS.reliobnoslortnocllafonoitarepoyfireV

18 Part Number 672 01 1005 00

Page 19

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

11 Service and maintenance continued

Cleaning boiler flueways

The boiler contains ceramic fiber and fiberglass

materials. Use care when handling these materials

per instructions on page 21 of this manual. F ailure to

comply could result in severe personal injury .

Make sure all electrical connections to boiler are

turned off and wait until boiler is warm, not hot, before

cleaning. F ailure to do so will result in severe personal

injury, death or substantial property damage.

1. Remove jacket top panel.

2. Remove flue collector hood, saving hardware for reassemb ly .

3. Shut off oil valves. Arrange drip pans under the areas of oil

piping that will be disconnected. Disconnect oil line at burner so

that you can swing open the door completely.

4. Line combustion chamber floor with newspaper to catch any

soot that will be loosened in the cleaning process.

5. Starting at the top of the boiler, use a wire flue brush to thoroughly

clean between all pins at all angles. Be careful not to damage

side walls of rear refractory .

6. Move to the bottom of the flueways and clean up between the

sections to reach pins left uncleaned in step #5.

7. Once the flueways are cleaned, carefully remove the paper

from the floor of the combustion chamber. Fold the paper to

capture the refuse, seal in a plastic bag, and dispose.

8. Verify sealing rope around flue area is intact. Visually check

condition and position of insulation in combustion chamber floor,

and the refractories at the rear of boiler and in the burner

mounting door. Replace any parts as necessary .

9. Close bur ner mounting door and tighten nut securely. Place

flue collector hood on top of boiler. Secure with hardware from

step #2. Maintain a gas-tight seal to avoid possible flue gas

leakage and carbon monoxide emissions, which can lead to

severe personal injury or death.

10. Check breeching for sooting and clean if necessary. Install

jacket top panel and breeching.

11. Reconnect oil line and all electrical connections.

Figure 16 Cleaning boiler flueways — Thoroughly clean

flueways between all pins at all angles. Start

on top of boiler, finish from the bottom.

Wear a NIOSH -certified dust respirator (N95) while

cleaning the boiler, per WARNING on page 21. Failure

to comply could result in severe personal injury.

19Part Number 672 01 1005 00

Page 20

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

11 Service and maintenance continued

Fill the system:

1. Close manual and automatic air vents and drain cock.

2. Fill to correct system pressure. Correct pressure will vary with

each installation. Normal cold water fill pressure for residential

systems is 12 psig. Boiler water pH 7.0 to 8.5 is recommended.

Failure to maintain recommended pH le vel can cause

section failure and leaks, resulting in potential of

severe personal injury , death or substantial property

damage.

3. Open automatic air vent (if installed) one turn.

4. Starting on the lowest floor, open manual air v ents one at a time

until water squirts out. Close vent. Repeat with remaining v ents.

5. Refill to correct pressure.

T o place boiler in operation:

Follow information below to prevent severe personal

injury, death or substantial property damage:

• Do not use crankcase drainings or any oil containing

gasoline. See burner manual for proper fuel oil.

• Do not attempt to start burner when excess oil has

accumulated in combustion chamber, when unit is

full of vapor, or when combustion chamber is very

hot.

• Do not start burner unless collector hood, breeching

and burner mounting door are secured in place. Never

burn garbage or paper in the boiler.

• Never leav e combustible material around boiler .

1. Verify boiler is filled with water.

2. Open burner door and verify rear target wall,floor and burner

door insulations are in proper condition and position.

3. Verify burner mounting door is closed and bolted tightly and

burner plug is connected.

4. Refer to burner manual for burner start-up, adjustment and

checkout procedures. F actory burner adjustment and settings

may not be suitable for specific job conditions.

Make final burner adjustments using combustion test

equipment to assure proper operation. Do not fire

boiler without water. Sections will ov erheat, damaging

boiler and resulting in substantial property damage.

5. Check boiler and system piping for leaks.

6. Inspect breeching and venting for proper operation.

Annual service

Boiler relief valve

1. Inspect the relief valve and lift the lever to verify flow as in the

following warnings, excerpted from a relief valve manuf acturer’s

warning label. Before operating any relief valve, ensure that it is

piped with its discharge in a safe area to avoid severe scald

potential. Read manual Section 4, page 7, before proceeding

further.

Safety relief valv es should be reinspected A T LEAST

ONCE EVERY THREE YEARS, by a licensed plumbing contractor or authorized inspection agency, to

ensure that the product has not been affected by

corrosive water conditions and to ensure that the

valve and discharge line have not been altered or

tampered with illegally. Certain naturally occurring

conditions may corrode the valve or its components

over time, rendering the valve inoperative. Such conditions are not detectable unless the valve and its

components are physically removed and inspected.

This inspection must only be conducted by a plumbing contractor or authorized inspection agency — not

by the owner . F ailure to reinspect the boiler relief valv e

as directed could result in unsafe pressure buildup ,

which can result in severe personal injury, death or

substantial property damage.

2. After following the above warning directions, if the relief valve

weeps or will not seat properly , replace the relief valve . Ensure

that the reason for relief valve weeping is the valve and not

over-pressurization of the system due to expansion tank

waterlogging or undersizing.

Following installation, the valve lever must be

operated AT LEAST ONCE A YEAR to ensure that

waterways are clear. Certain naturally occurring

mineral deposits may adhere to the valve, rendering

it inoperative. When manually operating the lever,

water will discharge and precautions must be taken

to avoid contact with hot water and to avoid water

damage. Before operating le ver , check to see that a

discharge line is connected to this valve directing the

flow of hot water from the valve to a proper place of

disposal otherwise severe personal injury may result.

If no water flows, valve is inoperative. Shut down

boiler until a new relief valve has been installed.

Oiled-bearing circulators

1. The circulator shipped with the OWB and OWT boilers are

water-lubricated. No oiling is required.

2. Check other circulators in the system. Oil any circulators

requiring oil, following circulator manufacturer’s instructions.

Over-oiling will damage the circulator .

Oiled-bearing burner motors

1. The burner may need to be lubricated if motor is equipped with

oiling cups. Apply a few drops only of SAE 20 detergent oil

(never use household oils). Do not attempt to “fill up” the oil cup.

Over-oiling can damage the motor .

Verify component operation

1. Perform the checkout sequence on page 16 to verify system

and components are operating correctly .

20 Part Number 672 01 1005 00

Page 21

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

11 Service and maintenance

continued

Handling ceramic fiber and fiberglass materials

REMOVAL OF COMBUSTION CHAMBER LINING OR BASE PANELS

The combustion chamber lining or base insulation panels in this product contain ceramic fiber materials. Ceramic

fibers can be converted to cristobalite in very high temperature applications. The International Agency for Research

on Cancer (IARC) has concluded, "Crystalline silica inhaled in the form of quartz or cristobalite from occupational

sources is carcinogenic to humans (Group 1).":

■ Avoid breathing dust and contact with skin and e yes.

• Use NIOSH certified dust respirator (N95). This type of respirator is based on the OSHA requirements f or

cristobalite at the time this document was written. Other types of respirators may be needed depending on

the job site conditions. Current NIOSH recommendations can be found on the NIOSH web site at http://

www.cdc.gov/niosh/homepage.html. NIOSH approved respirators, man ufacturers, and phone numbers are

also listed on this web site.

• Wear long-sleeved, loose fitting clothing, gloves, and eye protection.

■ Apply enough water to the combustion chamber lining or base insulation to prevent airborne dust.

■ Remove combustion chamber lining or base insulation from the boiler and place it in a plastic bag for disposal.

■ Wash potentially contaminated clothes separately from other clothing. Rinse clothes washer thoroughly .

NIOSH stated First Aid.

■ Eye: Irrigate immediately

■ Breathing: F resh air.

REMOVAL OF FIBERGLASS WOOL — OR —

INSTALLATION OF FIBERGLASS WOOL, COMBUSTION CHAMBER LINING OR BASE

PANELS:

This product contains fiberglass jacket insulation and ceramic fiber materials in combustion chamber lining or base

panels in gas fired products. Airborne fibers from these materials have been listed by the State of California as a

possible cause of cancer through inhalation.

■ Avoid breathing dust and contact with skin and e yes.

• Use NIOSH certified dust respirator (N95). This type of respirator is based on the OSHA requirements f or

fiberglass wool at the time this document was written. Other types of respirators may be needed depending

on the job site conditions. Current NIOSH recommendations can be found on the NIOSH web site at http://

www.cdc.gov/niosh/homepage.html. NIOSH approv ed respirators, manuf acturers, and phone numbers are

also listed on this web site.

• Wear long-sleeved, loose fitting clothing, gloves, and eye protection.

■ Operations such as sawing, blowing, tear out, and spraying may generate airborne fiber concentration requiring

additional protection.

■ Wash potentially contaminated clothes separately from other clothing. Rinse clothes washer thoroughly .

NIOSH stated First Aid.

■ Eye: Irrigate immediately

■ Breathing: F resh air.

21Part Number 672 01 1005 00

Page 22

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

12 Replacement parts

Figure 17 Boiler section assembly, refractories, collector hood and burner door assembly

22 Part Number 672 01 1005 00

Page 23

OWB & OWT

12 Replacement parts continued

Table 6 Parts list for Figure 17

Oil-Fired Water Boilers – Boiler Manual

Figure

number

Description Boilermodel

number

A Front section, number 7112 All 316722013WT

B Front section with tanklessheater opening, number 7113 All 316722005WT

C Intermediate section, number7115 All 316722017WT

D Back section, number 7117 All 316722021WT

E Section replacement kit, front or back section

(for 1 joint, includes seals, rope, adhesive and collector hood hardware)

Section replacement kit, intermediate section

(for 2 joints, includes seals, rope and adhesive)

Section assemblycomplete OWB3 326700020WT

F Collector hood kit

(includes rope and hardware for installation)

G Tie rod½ x10¾" OWB/OWT3 560234491WT

Tie rod ½ x14" OWB/OWT4 560234470WT

Tie rod ½ x17" OWB/OWT5 560234472WT

Tie rod ½ x20" OWB/OWT6 560234534WT

H Combustion chamber kit

(rear and front refractory, door refractory blanket andwater glass)

Burner mounting door assembly

(door, observation port, rope, insulation and pins)

J Burner mounting door, number 7171 All 330054305WT

K Door hinge, number 7054 All 330054300WT

L Door refractory All 592400028WT

M Door refractory blanket All 591222115WT

N Observation port shutter All 460039867WT

P Door seal rope 5’ All 59073-105WT

3

Q

/8" Glass rope for collectorhood (7’ forlargest size hood) All 590735109WT

R Heater cover plate carton (cover plate, gasket, studs and nuts) All 386700360WT

S Tankless heater kit (heater, gasket,studs and nuts)

OWT3 (heater model WT-11)

OWT4 through OWT6 (heater model WT-14)

Flue brush, 123D All 591706214WT

All 386700852WT

All 386700851WT

OWB4 326700021WT

OWB5 326700022WT

OWB6 326700023WT

OWT3 326700010WT

OWT4 326700011WT

OWT5 326700012WT

OWT6 326700013WT

OWB/OWT3 386700841WT

OWB/OWT4 386700842WT

OWB/OWT5 386700843WT

OWB/OWT6 386700844WT

All 386700836WT

All 343500546WT

OWT3

OWT4, 5 & 6

International Comfort Products

part number

590921599WT

590921612WT

23Part Number 672 01 1005 00

Page 24

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

12 Replacement parts continued

Figure 18 Jacket parts and replacement instructions

The boiler contains ceramic fiber and fiberglass

materials. Use care when handling these materials

per instructions on page 21 of this manual. F ailure to

comply could result in severe personal injury .

Before installing jacket:

1. Do not remove any knockouts.

2. Make sure all unused tappings are plugged.

3. These parts may be on boiler:

• Supply piping

• Return piping

• Drain valve

• Air vent or expansion tank piping

4. These parts must be off boiler:

• Breeching connection

• Pressure/temperature gauge and limit control

• Water relief valv e and piping

5. Remove burner mounting door by removing locking nut and

lifting door off hinge. Do not remove hinge.

Item

number

Descr i pti on Boiler

1 Jacket panel, front

without heateropening

with heater opening

2 Jacketpanel, leftside and

back

3 Jacket panel, top OWB/OWT3

4 Jacket panel, right side

and back

model

number

OWB (All)

OWT (All)

OWB/OWT3

OWB/OWT4

OWB/OWT5

OWB/OWT6

OWB/OWT4

OWB/OWT5

OWB/OWT6

OWB/OWT3

OWB/OWT4

OWB/OWT5

OWB/OWT6

Int ernational

Comfort

Products

partnumber

426722001WT

426722003WT

426722025WT

426722027WT

426722029WT

426722031WT

426722007WT

426722009WT

426722011WT

426722013WT

426722035WT

426722037WT

426722039WT

426722041WT

To install jacket:

1. Install jacket front panel to front section, making sure burner

door hinge lugs extend through holes in lower jacket leg. Secure

with two 3/8" x 1/2" black machine screws.

2. Right and left side pieces are shipped as straight pieces. Before

installing, bend about 90° at perforation as shown, to form sides

and back panels.

a. Secure side panels to front panel with four sheet metal

screws.

b. To secure bac k panels, using two 1/4" x 1/2" self-tapping

screws:

1) Start upper screw in boiler section. Do not tighten.

2) Slip keyhole opening in back panels behind scre w .

3) Install lower screw and tighten both screws.

c. Install top panel and secure with two sheet metal screws.

3. Reinstall burner mounting door and secure locking nut on stud,

making sure door is secured gas-tight.

Gas-tight seal must be obtained to prevent possible

flue gas leakage and carbon monoxide emissions,

leading to severe personal injury or death.

Jacket hardware kit All 386700845WT

24 Part Number 672 01 1005 00

Page 25

OWB & OWT

12 Replacement parts continued

Figure 19 Trim and controls

Oil-Fired Water Boilers – Boiler Manual

Item

number

not shown Circulator hardware kit, includes:

not shown Burner wiring harness International Comfort Products 591391911WT

not shown Burner plug International Comfort Products 643900020WT

not shown Balanced draft damper (barometric) Effikal ESOC-7 510512267WT

Description Manufacturer Manufacturer’s

1 Pressure relief valve, ASME, 30 PSIG, ¾" male inlet Watts M330 511546920WT

2 Combination high limit/circulator relay control (OWB)

Combination high limit/low limit/circulator relay control

(OWT)

3 Combination pressure-temperature gauge ENFM 4104 510218099WT

4 Circulator (Fittings shown are shipped loose with boiler.) Taco 007 511405113WT

5 Circulator gasket, universal(2 per boiler) International Comfort Products

2 flanges,4 nuts, 4 screws, 1 nipple, 1 ell —

1¼"NPT— OWB/OWT3 & OWB/OWT4

1½"NPT— OWB/OWT5 & OWB/OWT6

6 Circulator wiring harness International Comfort Products 591391910WT

7 Drain valve, ¾" Conbraco

Honeywell

Honeywell

International Comfort Products

Hammond Valve

Matco-Norca

Watts

part num ber

L8148A1157

L8124A1155

31-606-01

710

205F04

BD-2C

Internat ional

Comfort

Products

partnumber

510311030WT

510311040WT

590317535WT

381354526WT

381354531WT

511210423WT

511246392WT

511246392WT

511246392WT

25Part Number 672 01 1005 00

Page 26

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

13 Dimensions

Figure 20 Dimensional drawing — ALL DIMENSIONS IN INCHES

Boiler

model

number

Supply

tapping

(inches NPT)

Return

tapping

(inches NPT)

“B”

Combustion chamber

dept h (inches)

“D”

Jacket depth

(inches)

OWB/OWT3 1½ 1½ 10 ½ 13 ¾

OWB/OWT4 1½ 1½ 135/

OWB/OWT5 1½ 1½ 167/

OWB/OWT6 1½ 1½ 20 231/

8

8

167/

20

8

8

26 Part Number 672 01 1005 00

Page 27

14 Ratings

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

DOE

Boiler

model

number

Note 1 Note 3 Notes 2 & 4 Note 5 Note 6 Note 7

I=B=R

burner

capacity

GPH

DOE

heating

capacity

MBH

Net I=B=R

ratings

MBH

Water

sq. feet

DOE

seasonal

efficiency

%AFUE

Round

flue

outlet

size

inches

Minimu m I=B=R

Chimney

Rectangle

inches

Round

inches

Height

feet

Boiler

water

content

gallons

Draft loss

through

boiler

inches W.C.

OWB/OWT3075 0.75 90 78 84.3 7 8x8 6 15 11.0 .000

OWB/OWT3100 1.00 116 101 82.2 7 8x8 6 15 14.9 .000

OWB/OWT4110 1.10 129 112 82.5 7 8x8 6 15 13.4 .010

OWB/OWT4125 1.25 145 126 81.7 7 8x8 6 15 13.4 .010

OWB/OWT5135 1.35 159 138 82.8 7 8x8 7 15 15.9 .010

OWB/OWT5150 1.50 174 151 81.3 7 8x8 7 15 15.9 .010

OWB/OWT5165 1.65 191 166 81.2 7 8x8 7 15 15.9 .010

OWB/OWT6175 1.75 203 177 80.8 7 8x8 7 15 18.4 .000

Notes

1. See information at right for model number suffixes.

2. MBH refers to thousands of Btu per hour.

3. Base on 140,000 Btu per gallon.

4. Based on standard test procedures prescr ibed by the United States Department of

Energy , with combustion conditions of 13% CO

5. Net I=B=R ratings are based on net installed radiation of sufficient quantity for the

requirements of the building and nothing need be added for normal piping and pickup.

Ratings are based on a piping and pickup allowance of 1.15. An additional allowance

should be made for unusual piping and pickup loads.

6. See page 6 for minim um breeching diameter.

7. Listed draft losses are for factory-shipped settings.

and –0.02" W .C. draft.

2

Install OWB and OWT boilers f or residential radiant panel systems, converted

gravity heating systems or other low water temperature applications per

instructions in this manual to avoid damage due to condensation.

OWB and OWT boilers are CSA design certified for installation on combustib le

flooring.

OWB and OWT boilers are ASME rated for 50 psig working pressure.

27Part Number 672 01 1005 00

Page 28

OWB & OWT

Oil-Fired Water Boilers – Boiler Manual

28 Part Number 672 01 1005 00

Loading...

Loading...