Page 1

il ii

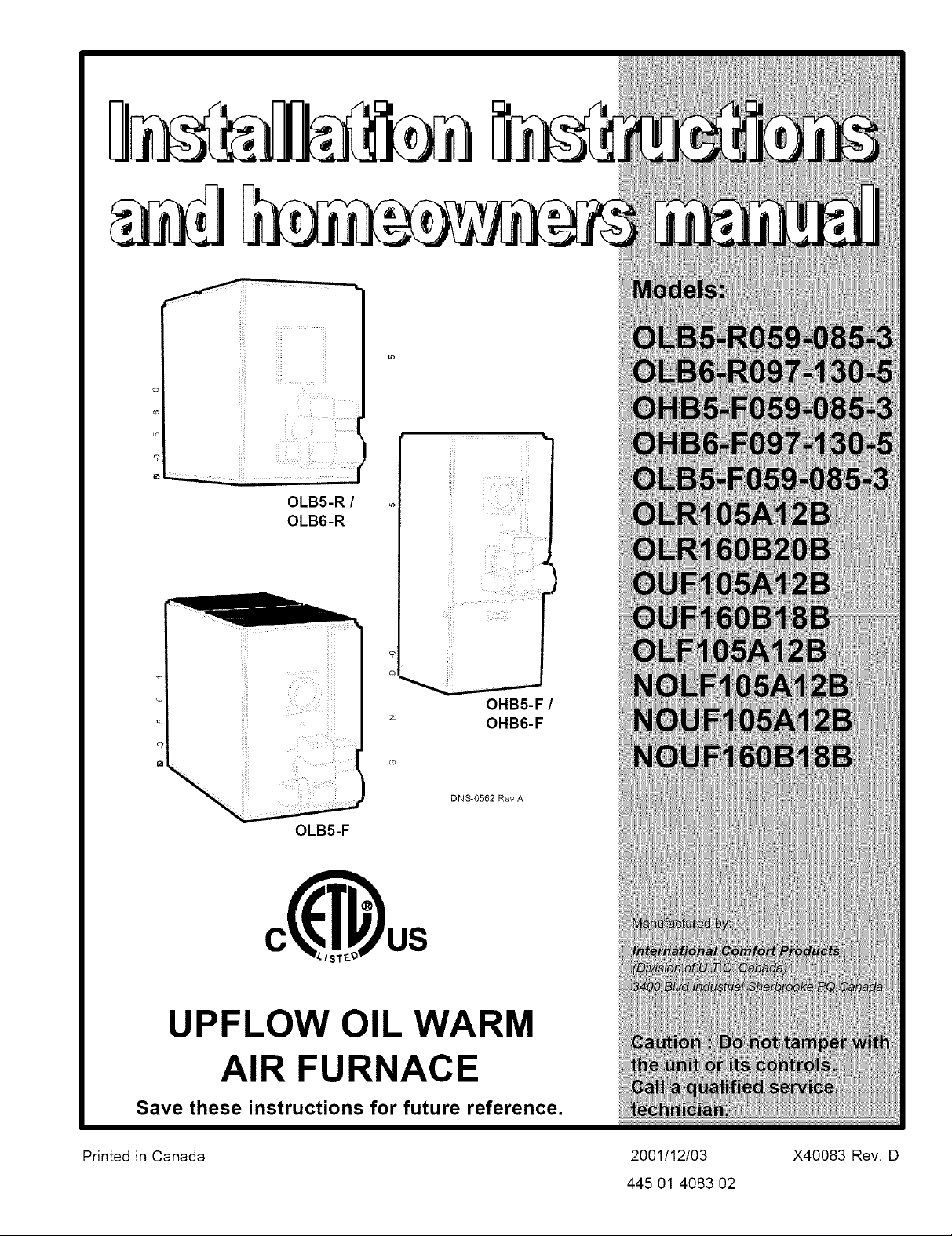

OLB5-R /

OLB6-R

OLB5-F

I

DNS_0562 Rev A

i_!ii

OHB5-F /

OHB6-F

UPFLOW OIL WARM

AIR FURNACE

Save these instructions for future reference.

Printed in Canada 2001/12/03

445 01 4083 02

X40083 Rev. D

Page 2

1)

INSTALLATION

SAFETY LABELLING AND SIGNAL WORDS

PART 1

2) SAFE INSTALLATION REQUIREMENTS

Installation or repairs made by unqualified persons

can result in hazards to you and others. Installation

MUST conform with codes or, in the absence of

local codes, with codes of the country having

jurisdiction.

The information contained in this manual is

intended for use by a qualified service technician

familiar with safety procedures and equipped with

the proper tools and test instruments.

Failure to carefully read and follow all instructions

in this manual can result in furnace malfunction,

property damage, personal injury and/or death.

1.1) Danger, Warning and Caution:

The signal words DANGER, WARNING and CAUTION are used to

identify levels of hazard seriousness. The signal word DANGER is

only used in product labels to signify an immediate hazard. The signal

words WARNING and CAUTION will be used on product labels and

throughout this manual and other manuals that may apply to the

product.

1.2) Signal Words:

DANGER - Immediate hazards which WILL result in death or serious

injury.

WARNING - Hazards or unsafe practices which COULD result in

death or injury.

CAUTION - Hazards or unsafe practices which COULD result in

personal injury or product or property damage.

1.3) Signal Words in Manuals:

The signal word WARNING is used throughout this manual in the

following manner:

The signal word CAUTION is used throughout this manual in the

following manner:

CAUTION

Fire hazard

The furnace must be installed in a level position,

never where it will slope to the front.

If the furnace were installed in that position, oil

could drain into the furnace vestibule and create a

fire hazard, instead of draining properly into the

combustion chamber.

NOTE: It is the personal responsibility and obligation of the customer

to contact a qualified installer to ensure that the installation is

adequate and conforms to governing codes and ordinances.

a. This furnace is NOT approved for installation in mobile homes,

trailers or recreation vehicles.

b. You must have a sufficient supply of fresh air for combustion and

ventilation to the area in which the furnace is located.

c. Do NOT use this furnace as a construction heater or to heat a

building that is under construction.

d. Use only the Type of fuel oil approved for this furnace (see

Rating Plate on unit). Overfiring will result in failure of heat

exchanger and cause dangerous operation.

e. Visually check all oil line joints for signs of wetness, which would

indicate a leak.

f. Connect furnace to a side-wall terminal or chimney.

g. The points in Part 2 "Operation" are vital to the proper and safe

operation of the heating system. Take the time to be sure they

are all done.

h. Follow the rules of the NFPA Pamphlet No.31 (for USA) and B-

139 (for Canada) or local codes for locating and installing the oil

storage tank.

i. Follow a regular service and maintenance schedule for efficient

and safe operation.

Page 3

j. Beforeservicing,allowfumacetocool.Alwaysshutoffelectricity

andfueltofurnacewhenservicing.Thiswillpreventelectrical

shockorburns.

k. Sealsupplyandreturnairducts.

I. TheventsystemMUSTbecheckedtodeterminethatitisthe

correcttypeandsize.

m. Installcorrectfiltertypeandsize.

n. UnitMUSTbeinstalledsoelectricalcomponentsareprotected

fromdirectcontactwithwater.

2.1) Safety Rules:

Your unit is built to provide many years of safe and dependable

service providing it is properly installed and maintained. However,

abuse and/or improper use can shorten the life of the unit and create

hazards for you, the owner.

a. The U.S. Consumer Product Safety Commission recommends

that users of oil-burning appliances install carbon monoxide

detectors. There can be various sources of carbon monoxide in

a building or dwelling. The sources could be gas-fired clothes

dryers, gas cooking stoves, water heaters, furnaces, gas-fired

fireplaces, wood fireplaces, and several other items. Carbon

monoxide can cause serious bodily injury and/or death.

Therefore, to help alert people of potentially dangerous carbon

monoxide levels, you should have carbon monoxide detectors

listed by a nationally recognised agency (e.g. Underwriters

Laboratories or Intemational Approval Services) installed and

maintained in the building or dwelling (see Note).

b. There can be numerous sources of fire or smoke in a building or

dwelling. Fire or smoke can cause serious bodily injury, death,

and/or property damage. Therefore, in order to alert people of

potentially dangerous fire or smoke, you should have fire and

smoke detectors listed by Underwriters Laboratories installed

and maintained in the building or dwelling (see Note below).

Freeze warning.

Turn off water system.

If your unit remains shut off during cold weather the

water pipes could freeze and burst, resulting in

serious water damage.

If the structure will be unattended during cold weather you should take

these precautions.

a.

Turn off main water supply into the structure and drain thewater

lines if possible. Open faucets in appropriate areas.

b.

Have someone check the structure frequently during cold

weather to make sure it is warm enough to prevent pipes from

freezing. Suggest they call a qualified service agency, if

required.

2.3) Installation regulation:

All local and national code requirements governing the installation of

oil burning equipment, wiring and flue connections MUST be followed.

Some of the codes that may be applicable are:

CSA B139 INSTALLATION CODE FOR OIL

NFPA31 INSTALLATION OF OIL BURNING

BURNING EQUIPMENT

EQUIPMENT

and makes no representations regarding any brand or type of

I NOTE: The manufacturer of your furnace does not test any detectors

detector.

Insure that the area around the combustion air intake

I CAUTION

terminal is free of snow, ice and debris.

The air pressure switch MUST be used when the

I CAUTION

furnace is vented by the side-wall.

CAUTION

Do not use any commercially available soot remover.

This furnace has fiber type refractory combustion

chamber. Normal servicing of this unit does not require

cleanings of the combustion chamber. Use extreme

care if for any reason you have to work in the area of

the combustion chamber,

2.2) Freezing Temperature and Your

Structure:

Your unit is equipped with safety devices that may keep it from

operating if sensors detect abnormal conditions such as clogged

exhaust flues.

ANSltNFPA 90B WARM AIR HEATING AND AIR

CONDITIONING SYSTEMS

ANSItNFPA 70 NATIONAL ELECTRICAL CODE

CSA C22.2 No3 CANADIAN ELECTRICAL CODE

Only the latest issues of the above codes should be used.

3) LOCATING THE FURNACE

CAUTION

Check carefully your furnace upon delivery for any

evidence of damage that may have occurred during

shipping and handling. Any claims for damages or lost

parts must be made with the Transport Company,

3.1) Location:

Locate the furnace as closely as possible to the chimney or vent

terminal, providing ample clearance to permit easy accessibility for

cleaning the inside of the furnace, the removal of filters, blower,

motors, controls and flue connections.

The OCF is certified for reduced clearances to combustibles, which

means it can be installed in an alcove, closet or crawl space by

obeying the clearances specified on the rating plate.

In the downflow position, the OCF is certified for use on combustible

floors only when the accessory No CFB-1 "Combustible Floor Base" is

used in the installation.

Page 4

Inthehorizontal(airleftorright)position,theOCFiscertifiedforuse

oncombustiblefloorsonlywhentheaccessoryNo.HFB-1'l-lorizor_al

Floor Base" is used in the installation.

In the horizontal (air left or right) position, the OCF can be suspended

using an angle iron frame with threaded rod hangers provided the

weight of the frame and furnace considered in the support

calculations.

For an attic installation, keep the building at least 12" away from any

opening in the furnace enclosure as some insulation can be

combusted.

However, do not install furnace directly on carpet or other combustible

material which can trapped air under the floor.

The furnace must be installed level for safe quiet operation.

CAUTION

Do NOT operate furnace in a corrosive atmosphere

containing chlorine, fluorine or any other damaging

chemicals. Refer to Part 1, section 5.2.

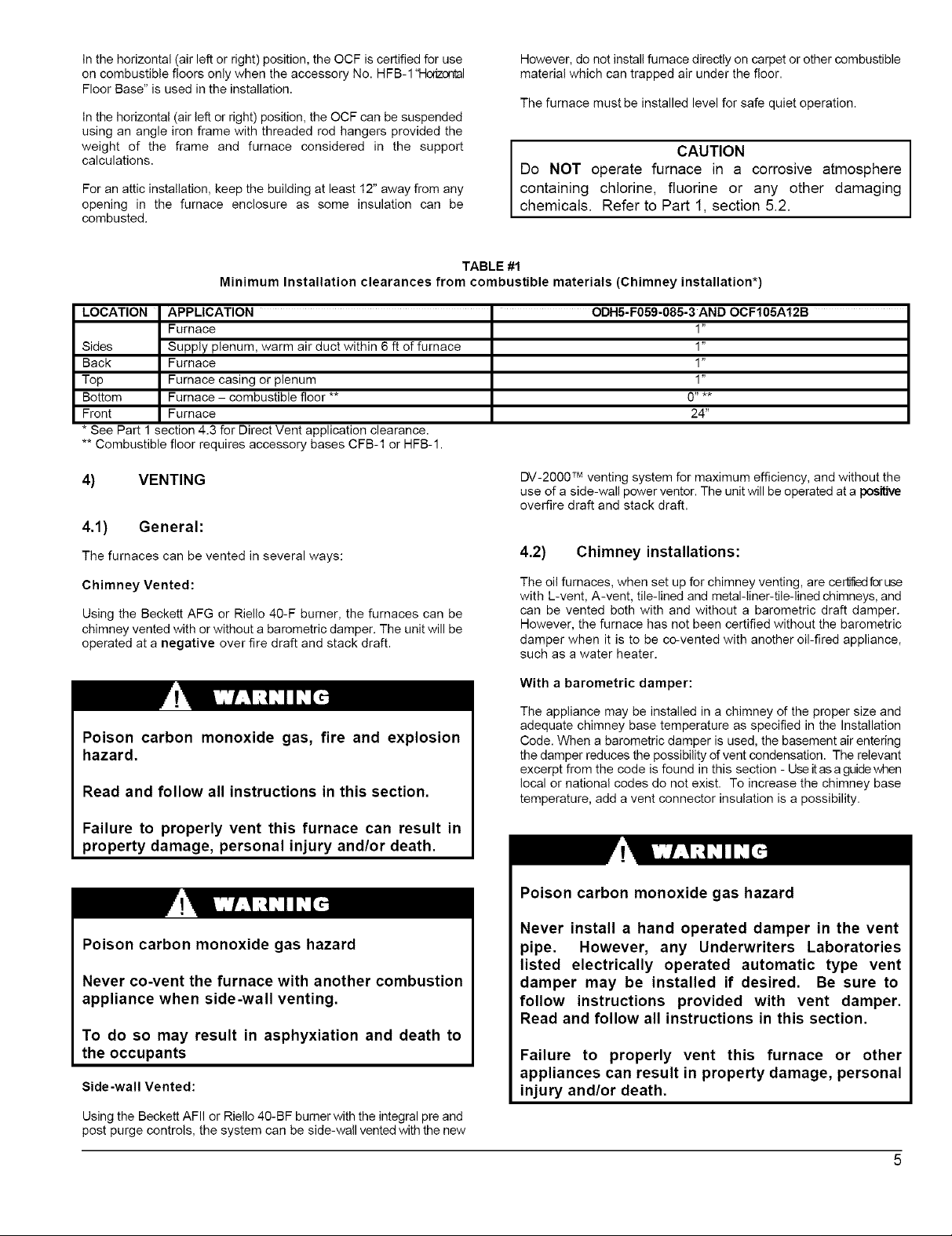

TABLE #1

Minimum Installation clearances from combustible materials (Chimney installation*)

LOCATION APPLICATION " ODH5-F059-085-3 AND OCF105A12B

Furnace 1"

Sides Supply plenum, warm air duct within 6 ft of furnace 1"

Back Furnace 1"

Top Fumace casing or plenum 1"

Bottom Fumace- combustible floor ** 0....

Front Furnace 24"

* See Part 1 section 4.3 for Direct Vent application clearance.

** Combustible floor requires accessory bases CFB-1 or HFB-1.

4) VENTING

4.1) General:

The furnaces can be vented in several ways:

Chimney Vented:

Using the Beckett AFG or Riello 40-F burner, the furnaces can be

chimney vented with or without a barometric damper. The unit will be

operated at a negative over fire draft and stack draft.

Poison carbon monoxide gas, fire and explosion

hazard.

Read and follow all instructions in this section.

Failure to properly vent this furnace can result in

property damage, personal injury and/or death.

Poison carbon monoxide gas hazard

Never co-vent the furnace with another combustion

appliance when side-wall venting.

To do so may result in asphyxiation and death to

the occupants

Side-wall Vented:

Using the Beckett AFII or Riello 4O-BF burner with the integral pre and

post purge controls, the system can be side-wall vented with the new

DV-2000 TM venting system for maximum efficiency, and without the

use of a side-wall power ventor. The unit will be operated at a positive

overfire draft and stack draft.

4.2) Chimney installations:

The oil furnaces, when set up for chimney venting, are cedilied for use

with L-vent, A-vent, tile-lined and metal-liner-tile-lined chimneys, and

can be vented both with and without a barometric draft damper.

However, the furnace has not been certified without the barometric

damper when it is to be co-vented with another oil-fired appliance,

such as a water heater.

With a barometric damper:

The appliance may be installed in a chimney of the proper size and

adequate chimney base temperature as specified in the Installation

Code. When a barometric damper is used, the basement air entering

the damper reduces the possibility of vent condensation. The relevant

excerpt from the code is found in this section - Use it as aguide _4qen

local or national codes do not exist. To increase the chimney base

temperature, add a vent connector insulation is a possibility.

Poison carbon monoxide gas hazard

Never install a hand operated damper in the vent

pipe. However, any Underwriters Laboratories

listed electrically operated automatic type vent

damper may be installed if desired. Be sure to

follow instructions provided with vent damper.

Read and follow all instructions in this section.

Failure to properly vent this furnace or other

appliances can result in property damage, personal

injury and/or death.

Page 5

Without a barometric damper:

Due to the lack of dilution air that would ordinarily be drawn into the

barometric damper, the dew point of the flue gasses is raised. To

offset the increased tendency for vent condensation, the chimney

must be lined. The liner must be insulated according to the insulating

procedure recommended by the manufacturer of the liner. Also, the

vent connector should be as short as possible and either be of double

wa!l construction, or be of single wall construction insulated with 1" of

insulation.

CAUTION

When the furnace (chimney installation) is co-vented

with other combustion appliances such as a water

heater, the allowable venting materials (i.e. L-Vent etc.)

for use with those appliances should also be

investigated.

I NOTES: Thermal resistance values for typical chimneys are asfollows:

R2 (2 ft 2 ,hr ,°F / Btu):

R3 (3 ft t ,hr ,°F / Btu):

R6 (6 ft 2 ,hr ,°F / Btu):

Applying the Table:

If a fumace with 0.60 USGPH nozzle is to be connected to a 20 ft. tall

clay-lined masonry chimney, the thermal resistance of this chimney

type is R2, which is less than R6. The actual firing rate at 156 psig is

1.25 x .60 = .75. Therefore this table shall apply as:

clay-lined masonry, A-vent

metal liner in clay-lined

Masonry

metal or clay-lined masonry

with R4.5 (4.5 ft2 *hr *°F / Btu)

insulation between liner and

masonry (e.g. 2 in. of

expanded mica or 1 3/8 in. of

high density glass fibreboard.)

Flue pipe sizing:

The following table is an except from the installation code and

indicates permitted flue sizes and minimum base temperatures for

circular flues in chimney with thermal resistance less than R6 (6 ftt*hr

*°F / Btu). Where a new appliance, burner, or chimney is installed,

chimney vent sizes and flue-gas temperatures (measured at the

chimney connector with the barometric damper shut, if applicable,

after 5 minutes of operation) shall comply with the table #2.

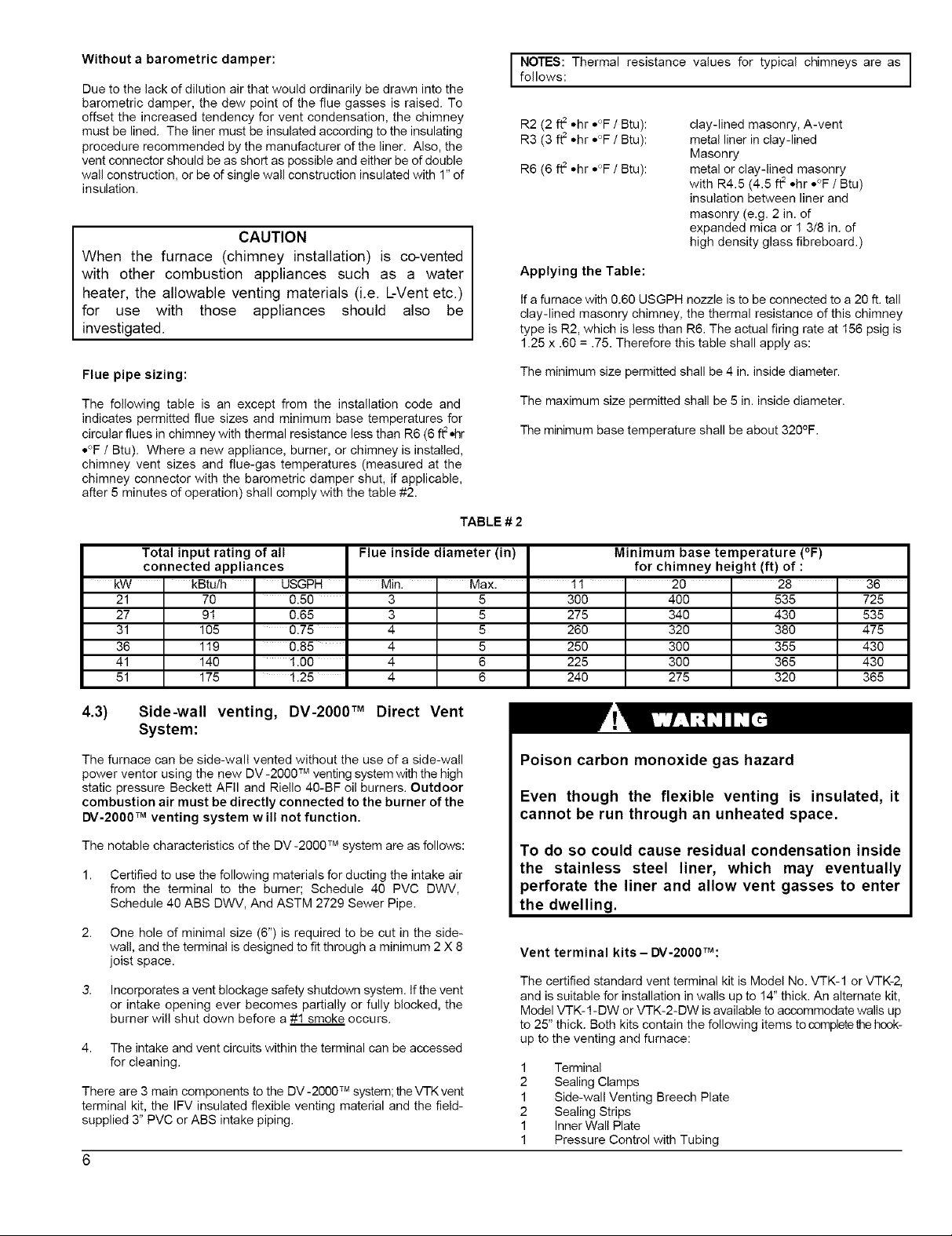

Total input rating of all

connected appliances

kW " kBtu/h

21 70

27 91

31 105

36 119

41 140

51 175

USGPH

0.50

0.65

0.75

0.85

1.00

1.25

Flue inside diameter(in) Minimum base temperature (°F)

Min. " Max. " 11 ' 20 " 28 " 36

3 5 300 400 535 725

3 5 275 340 430 535

4 5 260 320 380 475

4 5 250 300 355 430

4 6 225 300 365 430

4 6 240 275 320 365

4.3) Side-wall venting, DV-2000 TM Direct Vent

System:

The furnace can be side-wall vented without the use of a side-wall

power ventor using the new DV -2000 TM venting system with the high

static pressure Beckett AFII and Riello 40-BF oil burners. Outdoor

combustion air must be directly connected to the burner of the

DV-2000 TM venting system w ill not function.

The notable characteristics of the DV-2000 system are as follows:

Certified to use the following materials for ducting the intake air

from the terminal to the burner; Schedule 40 PVC DWV,

Schedule 40 ABS DWV, And ASTM 2729 Sewer Pipe.

2,

One hole of minimal size (6") is required to be cut in the side-

wall, and the terminal is designed to fit through a minimum 2 X 8

joist space.

3,

Incorporates a vent blockage safety shutdown system. Ifthe vent

or intake opening ever becomes partially or fully blocked, the

burner will shut down before a #1 smoke occurs.

4,

The intake and vent circuits within the terminal can be accessed

for cleaning.

There are 3 main components to the DV-2000 system; the VTK vent

terminal kit, the IFV insulated flexible venting material and the field-

supplied 3" PVC or ABS intake piping.

TM

TM

TABLE # 2

The minimum size permitted shall be 4 in. inside diameter.

The maximum size permitted shall be 5 in. inside diameter.

The minimum base temperature shall be about 320°F.

for chimney height(if)of:

Poison carbon monoxide gas hazard

Even though the flexible venting is insulated, it

cannot be run through an unheated space,

To do so could cause residual condensation inside

the stainless steel liner, which may eventually

perforate the liner and allow vent gasses to enter

the dwelling.

Vent terminal kits - DV-2000TM:

The certified standard vent terminal kit is Model No. VTK-1 or VTK-2,

and is suitable for installation in walls up to 14" thick. An altemate kit,

Model VTK-1-DW or VTK-2-DW is available to accommodate walls up

to 25" thick. Both kits contain the following items to complete the hook-

up to the venting and furnace:

1 Terminal

2 Sealing Clamps

1 Side-wall Venting Breech Plate

2 Sealing Strips

1 Inner Wall Plate

1 Pressure Control with Tubing

Page 6

2 InsulatedQuick-connectTerminals

3 StainlessSteelScrews

6 Selftappingstainlesssteelscrews

Insulatedflexible venting - DV-2000TM:

The certified venting materials come in 3 lengths, Model No. IFV3-15,

IFV3-23 and IFV3-30 (or IFV4-15, IFV4-23 and IFV4-30 for 160

models) are corresponding to 15', 23' and 30' continuous lengths of

vent. The vent construction is coaxial and incorporates a stainless

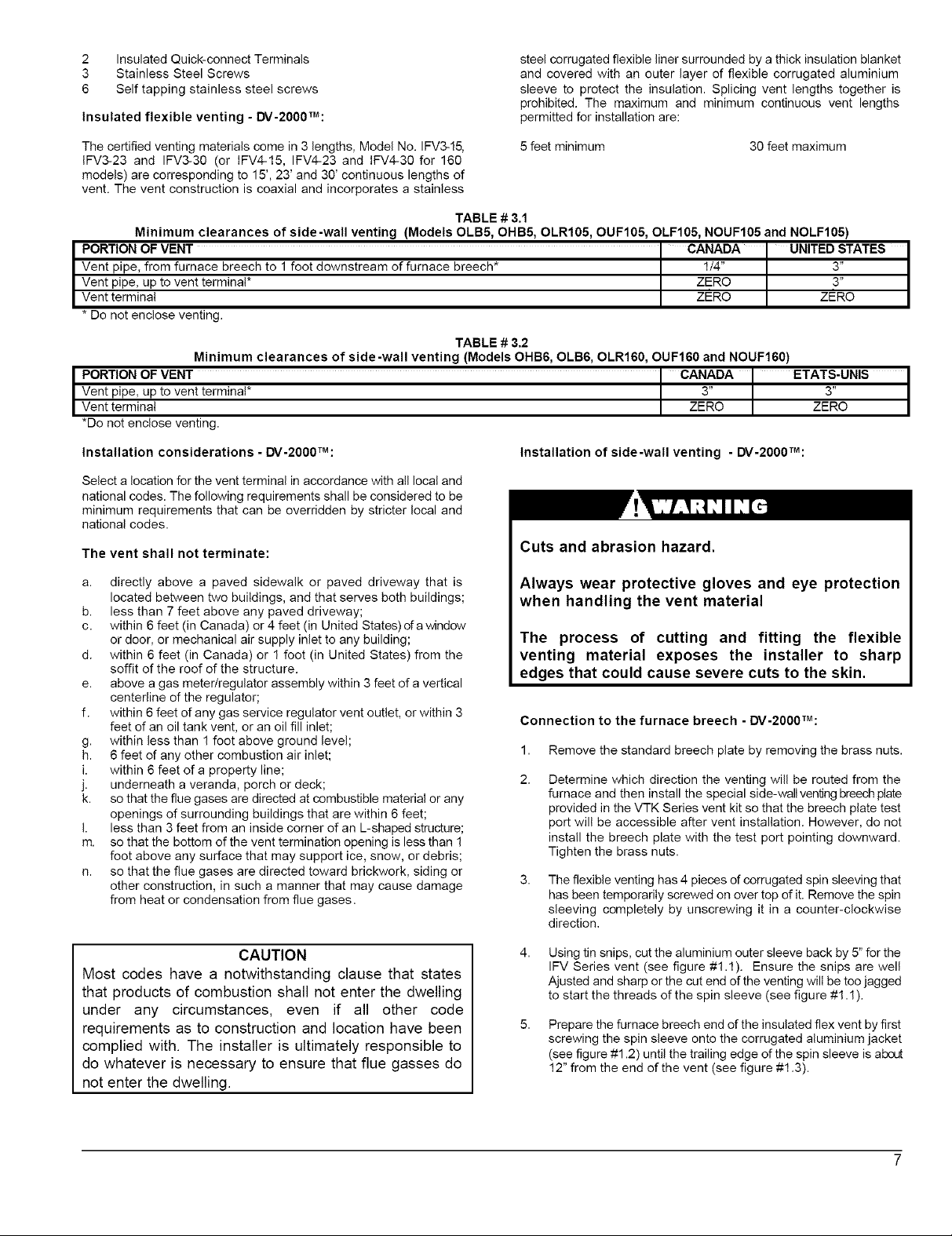

TABLE # 3.1

Minimum clearances of side-wall venting (Models OLB5, OHB5, OLR105, OUF105, OLF105, NOUF105 and NOLF105)

PORTION OF VENT CANADA UNITED STATES

Vent pipe, from furnace breech to 1 foot downstream of furnace breech* 1/4" 3"

Vent pipe, up to vent terminal* ZERO 3"

Vent terminal ZERO ZERO

* Do not enclose venting.

TABLE # 3.2

Minimum clearances of side-wall venting (Models OHB6, OLB6, OLR160, OUF160 and NOUF160)

Vent pipe, up to vent terminal* 3" 3"

I PORTION OF VENT CANADA ETATS-UNIS I

Vent terminal ZERO ZERO

*Do not enclose venting.

Installation considerations - DV'2000TM:

Select a location for the vent terminal in accordance with all local and

national codes. The following requirements shall be considered to be

minimum requirements that can be overridden by stricter local and

national codes.

The vent shall not terminate:

steel corrugated flexible liner surrounded by a thick insulation blanket

and covered with an outer layer of flexible corrugated aluminium

sleeve to protect the insulation. Splicing vent lengths together is

prohibited. The maximum and minimum continuous vent lengths

permitted for installation are:

5 feet minimum 30 feet maximum

Installation of side-wall venting - DV-2OOOTM:

Cuts and abrasion hazard.

a. directly above a paved sidewalk or paved driveway that is

located between two buildings, and that serves both buildings;

b. less than 7 feet above any paved driveway;

c. within 6 feet (in Canada) or 4 feet (in United States) of a window

or door, or mechanical air supply inlet to any building;

d. within 6 feet (in Canada) or 1 foot (in United States) from the

soffit of the roof of the structure.

e. above a gas meter/regulator assembly within 3 feet of a vertical

centerline of the regulator;

f. within 6 feet of any gas service regulator vent outlet, or within 3

feet of an oil tank vent, or an oil fill inlet;

g. within less than 1 foot above ground level;

h. 6 feet of any other combustion air inlet;

i. within 6 feet of a property line;

j. underneath a veranda, porch or deck;

k. so that the flue gases are directed at combustible material or any

openings of surrounding buildings that are within 6 feet;

I. less than 3 feet from an inside corner of an L-shaped structure;

m. so that the bottom of the vent termination opening is less than 1

foot above any surface that may support ice, snow, or debris;

n. so that the flue gases are directed toward brickwork, siding or

other construction, in such a manner that may cause damage

from heat or condensation from flue gases.

CAUTION

Most codes have a notwithstanding clause that states

that products of combustion shall not enter the dwelling

under any circumstances, even if all other code

requirements as to construction and location have been

complied with. The installer is ultimately responsible to

do whatever is necessary to ensure that flue gasses do

not enter the dwelling.

Always wear protective gloves and eye protection

when handling the vent material

The process of cutting and fitting the flexible

venting material exposes the installer to sharp

edges that could cause severe cuts to the skin.

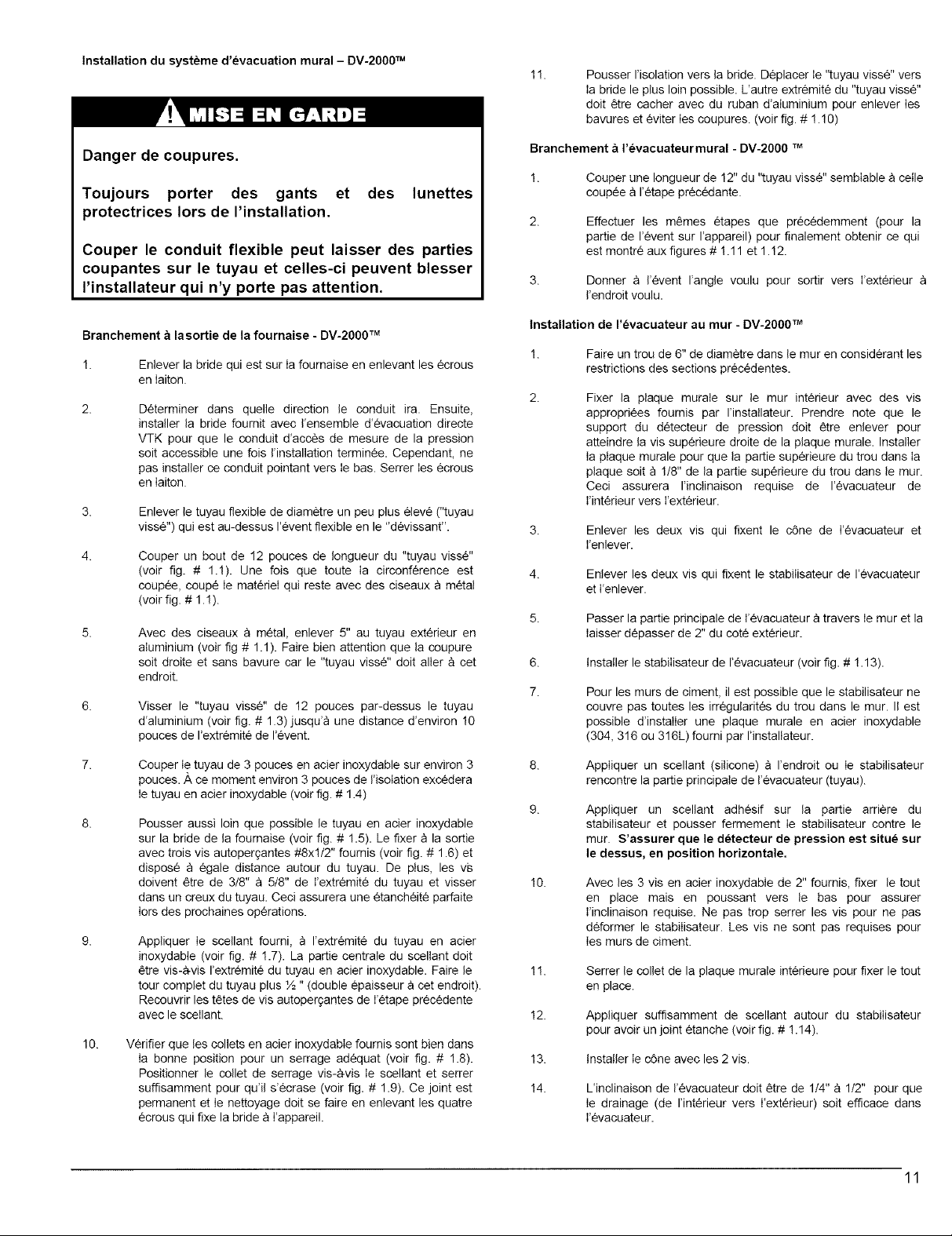

Connection to the furnace breech - DV'2000TM:

1. Remove the standard breech plate by removing the brass nuts.

2,

Determine which direction the venting will be routed from the

furnace and then install the special side-wall venting breech plate

provided in the VTK Series vent kit so that the breech plate test

port will be accessible after vent installation. However, do not

install the breech plate with the test port pointing downward.

Tighten the brass nuts.

3,

The flexible venting has 4 pieces of corrugated spin sleeving that

has been temporarily screwed on over top of it. Remove the spin

sleeving completely by unscrewing it in a counter-clockwise

direction.

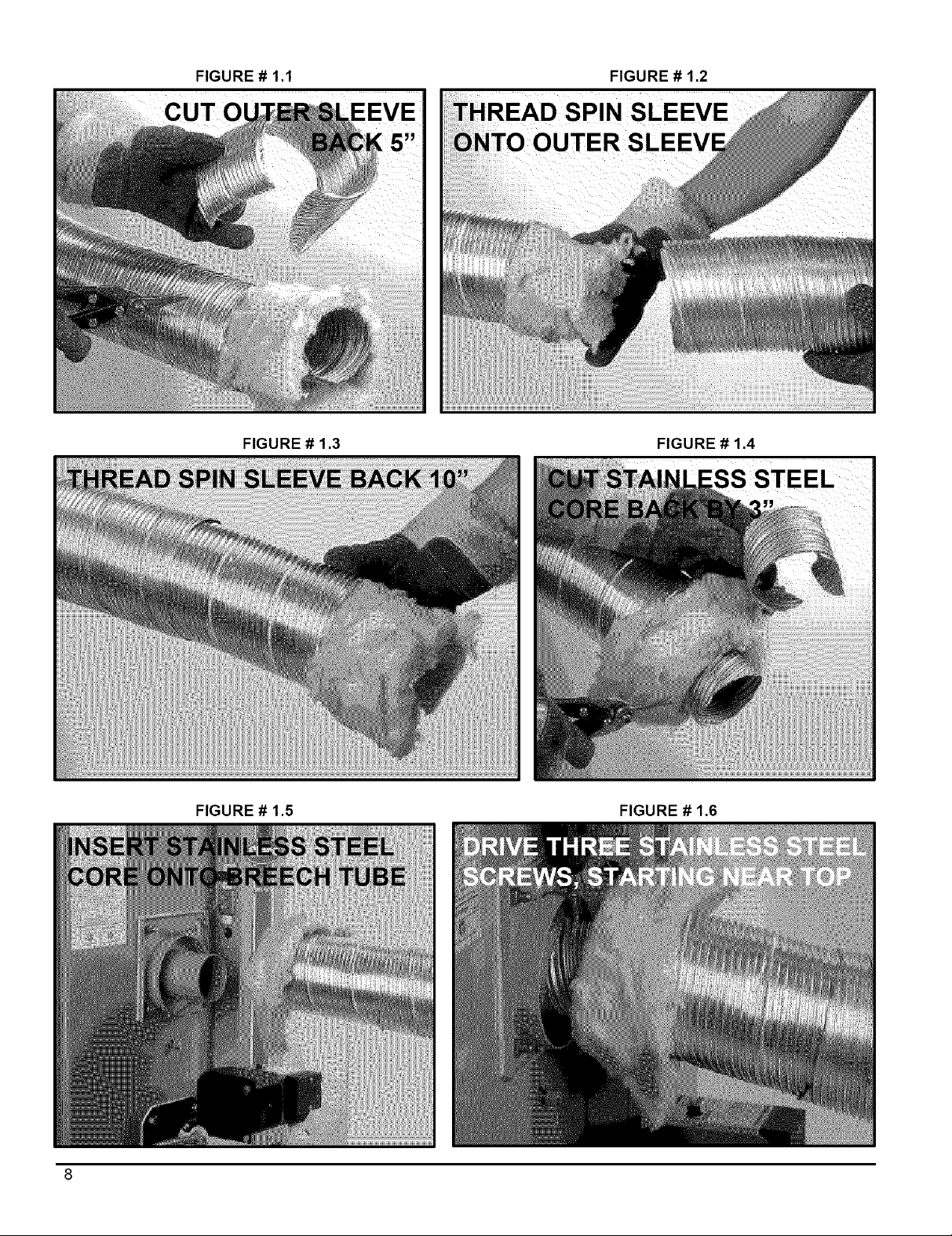

4,

Using tin snips, cut the aluminium outer sleeve back by 5" for the

IFV Series vent (see figure #1.1). Ensure the snips are well

Ajusted and sharp or the cut end of the venting will be too jagged

to start the threads of the spin sleeve (see figure #1.1).

5,

Prepare the furnace breech end of the insulated flex vent by first

screwing the spin sleeve onto the corrugated aluminium jacket

(see figure #1.2) until the trailing edge of the spin sleeve is about

12" from the end of the vent (see figure #1.3).

Page 7

FIGURE # 1.1

FIGURE # 1.2

EEVE

SLEEVE

ITER SI

FIGURE # 1.3 FIGURE # 1.4

FIGURE # 1.5 FIGURE # 1.6

Page 8

FIGURE# 1.7 FIGURE# 1.8

FIGURE# 1.9 FIGURE#1.10

FIGURE# 1.11

Page 9

FIGURE # 1.12

FIGURE # 1.13 FIGURE # 1.14

10

Page 10

6. Pull the insulation back to expose the corrugated stainless steel

core.

7. Cut the corrugated stainless steel core back by 3" for the IFV

Series vent. You should now have about 3" of insulation hanging

out past the stainless steel core (see figure #1.4).

8,

Push the stainless steel core onto the breech pipe as far as it will

go (see figure #1.5) and mechanically attach the vent to the

breech using three of the #8 X 1/2" self-drilling screws provided

with the VTK Series kit. The screws should be equally spaced

around the circumference of the stainless steel core, starting with

the first screw at top dead center. Start the drill point of the

screws in the valleys of the corrugations at 3/8"-5/8" back from

the end of the stainless steel core, so the screw heads can be

properly sealed in the forthcoming operations (see figure #1.6).

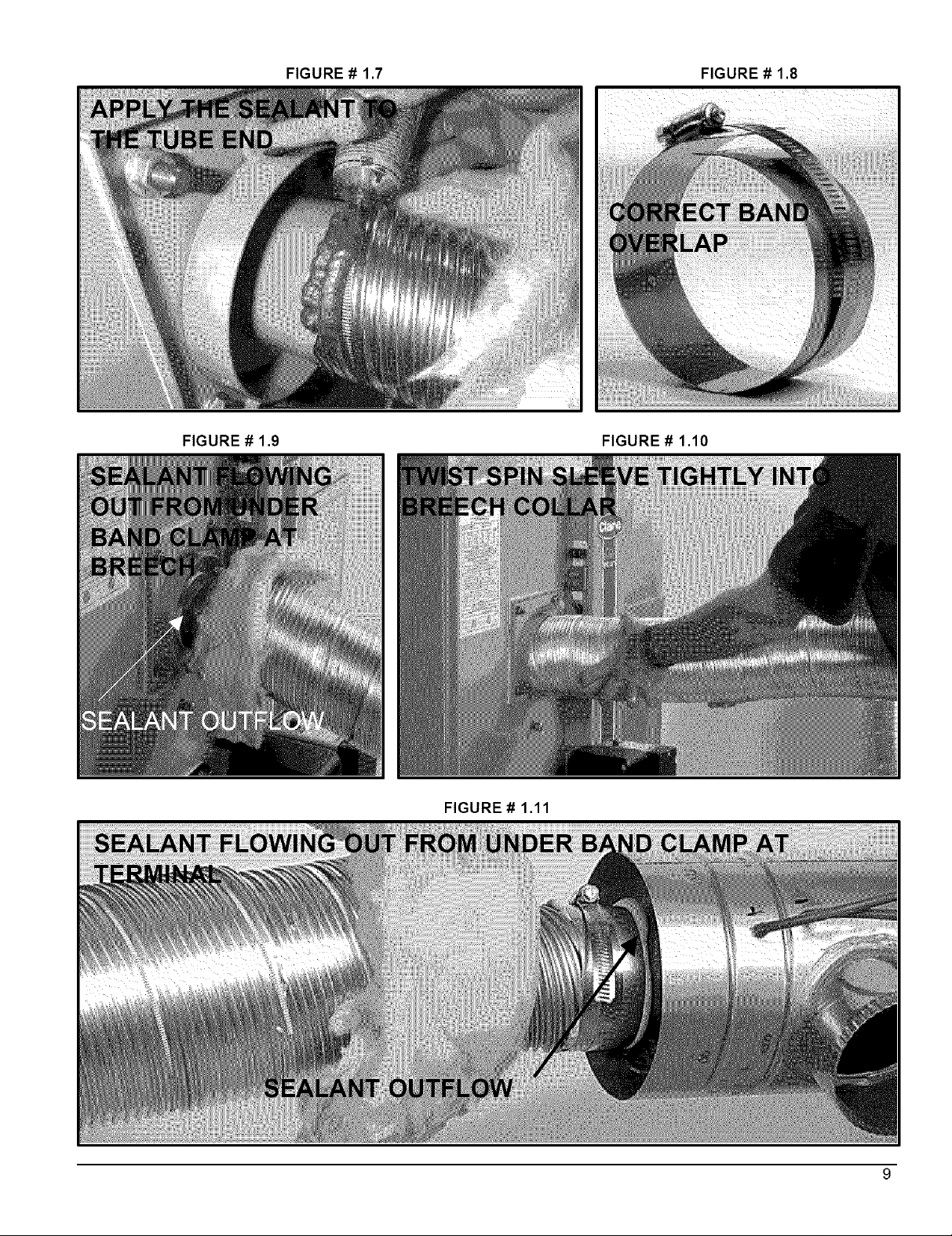

9,

With the stainless steel core now firmly attached to the breech,

tear off one green gum-sealing strip from the backing strip. Wrap

the seal strip around the joint, always keeping the centerline of

the seal strip over the line where the corrugated stainless steel

core makes the transition to the smooth outer surface of the

breech pipe. In other words, the seal strip must be centered over

the joint. After wrapping the seal strip around once, allow 1/2"

overlap and tear offthe residual length (see figure #1.7).

10. Break the residual length of seal strip in to 3 equal parts and stuff

them onto the screw heads of the stainless steel self-drilling

screws so that the screw heads are completely covered.

11. Two stainless steel band clamps are provided in the VTK Series

kits. Position one stainless steel band clamp over the gum seal

joint so that the edge of the clamp closest to the breech lines up

with the edge of the gum seal that is closest to the breech.

Ensure that the band will close with an action of one strip sliding

over the other - not under the gearhead of the draw clamp (see

figure #1.8). Tighten the band clamp with considerable torqueto

cause the gum sea! be squeezed into all crevices and to ooze

out of the end of the clamp closest to the breech (see figure

#1.9). The gum will eventually become rubbery.

12. The seal is permanent and should never need to be

disconnected as the breech plate can be removed for cleaning

and inspection using the 4-bolt joint.

13. Tuck the vent insulation into the breech collar.

14. Screw the spin sleeve tightly into the breech cellar for a finished

appearance. Wrap the other end of the spin sleeve with

aluminium tape to cover any metal burrs that may be present

(see figure #1.10).

15. Bend the venting into the desired radius coming offthe breech.

Connection to the vent terminal - DV-2000TM:

Prepare the terminal end of the insulated flex vent by first

screwing the spin sleeve onto the corrugated aluminium jacket

until the trailing edge of the spin sleeve is about 19" from the end

of the vent.

2. Using sharp tin snips, cut the aluminium outer sleeve back by 5"

for the IFV Series vent

3. Pull the insulation back to expose the corrugated stainless steel

core.

4. Cat the corrugated stainless steel core back by 3" for the IFV

Series vent. You should now have about 3" of insulation hanging

out past the stainless steel core.

5,

Push the stainless steel core onto the pipe on the back of the

terminal as far as it will go and mechanically attach the vent to

the terminal using three of the #8 X 1/2" self-drilling screws

provided with the VTK Series kit. The screws should be equally

spaced around the circumference of the stainless steel core,

starting with the first screw at top dead center. Start the drill point

of the screws in the valleys of the corrugations at 3/8"-5/8"back

from the end of the stainless steel core.

8,

With the stainless steel core now firmly attached to the terminal,

tear off the other green gut_sealing strip from the backing strip.

Wrap the sea! strip around the joint, always keeping the

centerline of the seal strip over the line where the corrugated

stainless steel core makes the transition to the smooth outer

surface of the terminal pipe. After wrapping the seal strip around

once, allow 1/2" overlap and tear off the residual length.

7. Break the residual length of seal strip in to 3 equal parts and stuff

them onto the screw heads of the stainless steel self-drilling

screw s so that the screw heads are completely covered.

8.

Position the other stainless steel band clamp over the gum seal

joint so that the edge of the clamp closest to the terminal lines up

with the edge of the gum sea! that is closest to the terminal.

Tighten the band clamp with considerable torque to cause the

gum seal be squeezed into all crevices and to ooze out of the

end of the clamp closest to the terminal (see figure #1.11 ).

9.

The seal is permanent and should never need to be

disconnected as the end of the terminal can be opened for

cleaning and inspection by removing the screened end-cone

assembly. Tuck the vent insulation into the recess in the terminal

body.

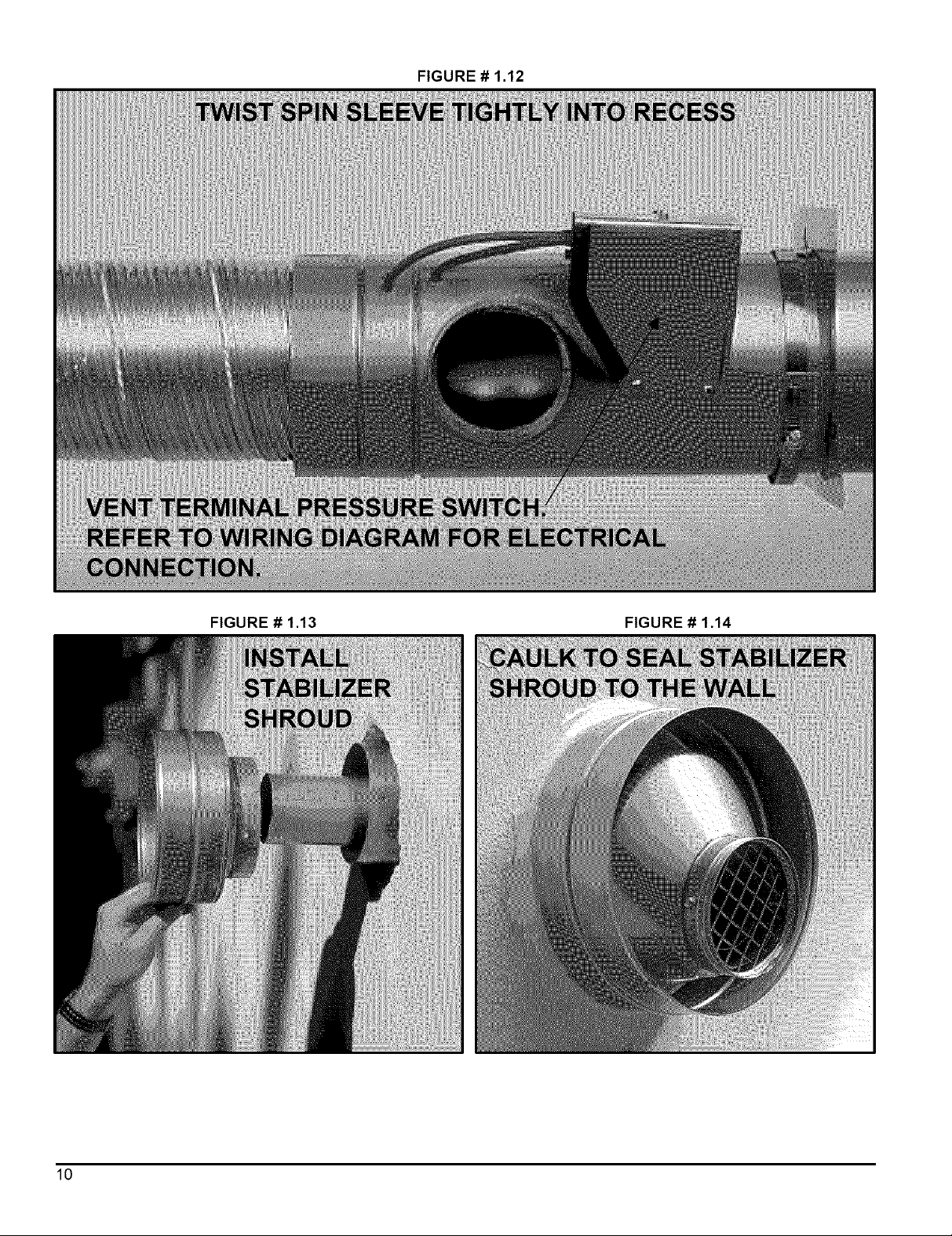

10.

Screw the spin sleeve tightly into the recess for a finished

appearance. Wrap the other end of he spin sleeve with

aluminium tape to cover any metal burrs that may be present

(see figure #1.12).

1I. Bend the venting into the desired radius coming off the terminal.

Installing terminal in the wail - DV'2000TM:

1. Cut a 6" hole in the side-wall in accordance with the location

considerations outlined in the previous section.

2.

Fasten the wall plate to the inside-wall using 4 field-provided

fasteners appropriate for the material behind the wall plate.

Depending on the angle of access, the pressure control bracket

may need to be removed to access the top right wall plate screw

hole. For concrete and block, Tapcon TM screws or equivalent are

recommended. Install the wall plate so that the top of the hole in

the wall plate is positioned 1/8" lower than the top of the 6" hole

in the wall. This will accommodate the proper downward slope of

the terminal, in the direction from the inside to the outside.

3. Remove the 2 screws fastening the end cone in place and

remove the cone.

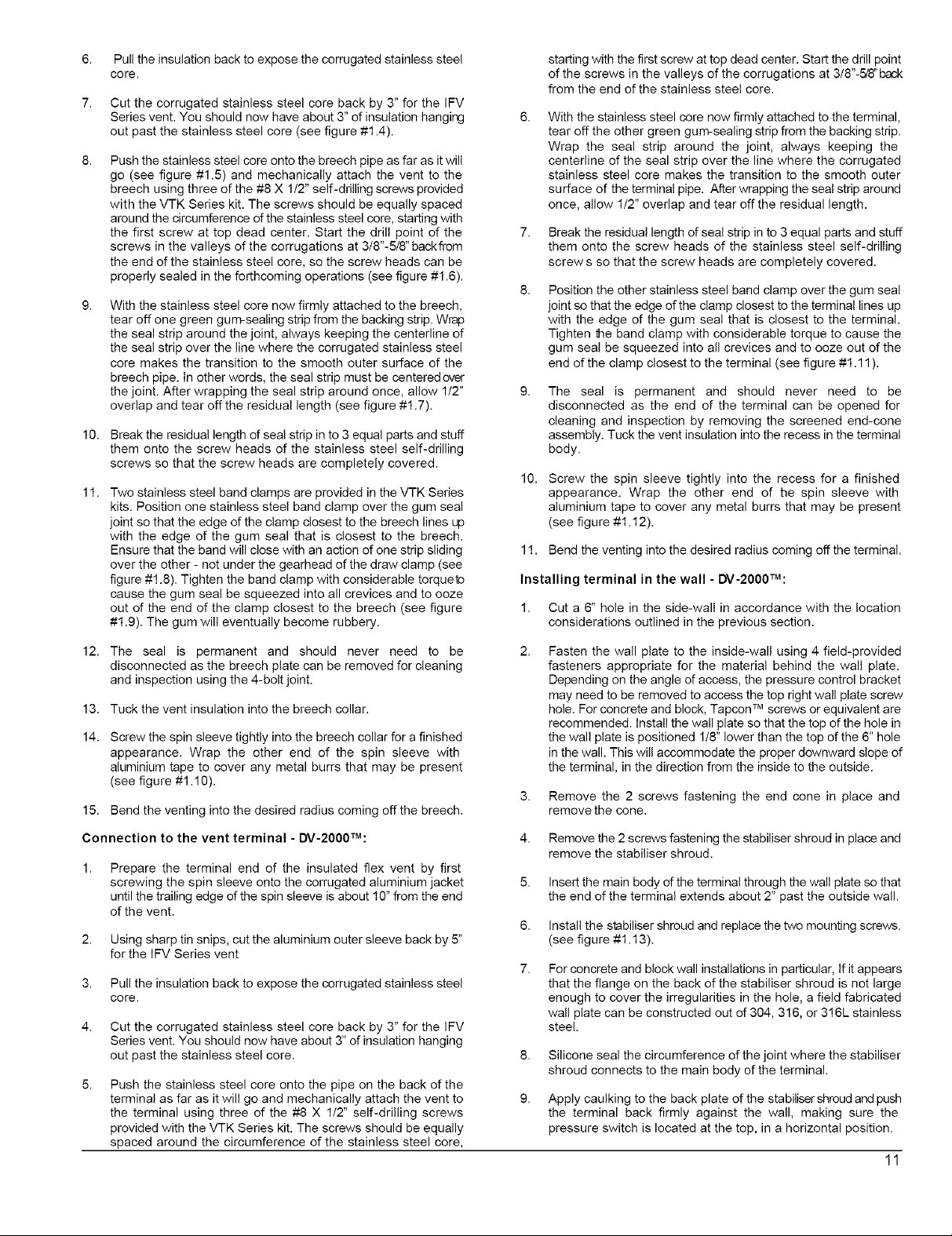

4. Remove the 2 screws fastening the stabiliser shroud in place and

remove the stabiliser shroud.

5. Insert the main body of the terminal through the wall plate so that

the end of the terminal extends about 2" past the outside wall.

6. Install the stabiliser shroud and replace the two mounting screws.

(see figure #1.13).

7,

For concrete and block wall installations in particular, If it appears

that the flange on the back of the stabiliser shroud is not large

enough to cover the irregularities in the hole, a field fabricated

wall plate can be constructed out of 304,316, or 316L stainless

steel.

8. Silicone seal the circumference of the joint where the stabiliser

shroud connects to the main body of the terminal.

9. Apply caulking to the back plate of the stabiliser shroud and push

the terminal back firmly against the wall, making sure the

pressure switch is located at the top, in a horizontal position.

11

Page 11

10. While pushing down gently on the top of the stabiliser shroud,

install the 3 stainless steel 2" screws provided with the kit to

secure the back of the shroud to the wall. Do not overtighten the

screws or it will distort the stabiliser shroud. The screws will not

be necessary in a concrete or block wall as the mortar can

provide positive positioning.

These instances will require that only outside air for combustion.

The following areas or types of structures may contain or have

exposure to the substances listed below. The installation must be

evaluated carefully as it may be necessary to provide outside air for

combustion.

11. Tighten the clamp on the wall plate to secure the terminal in

position.

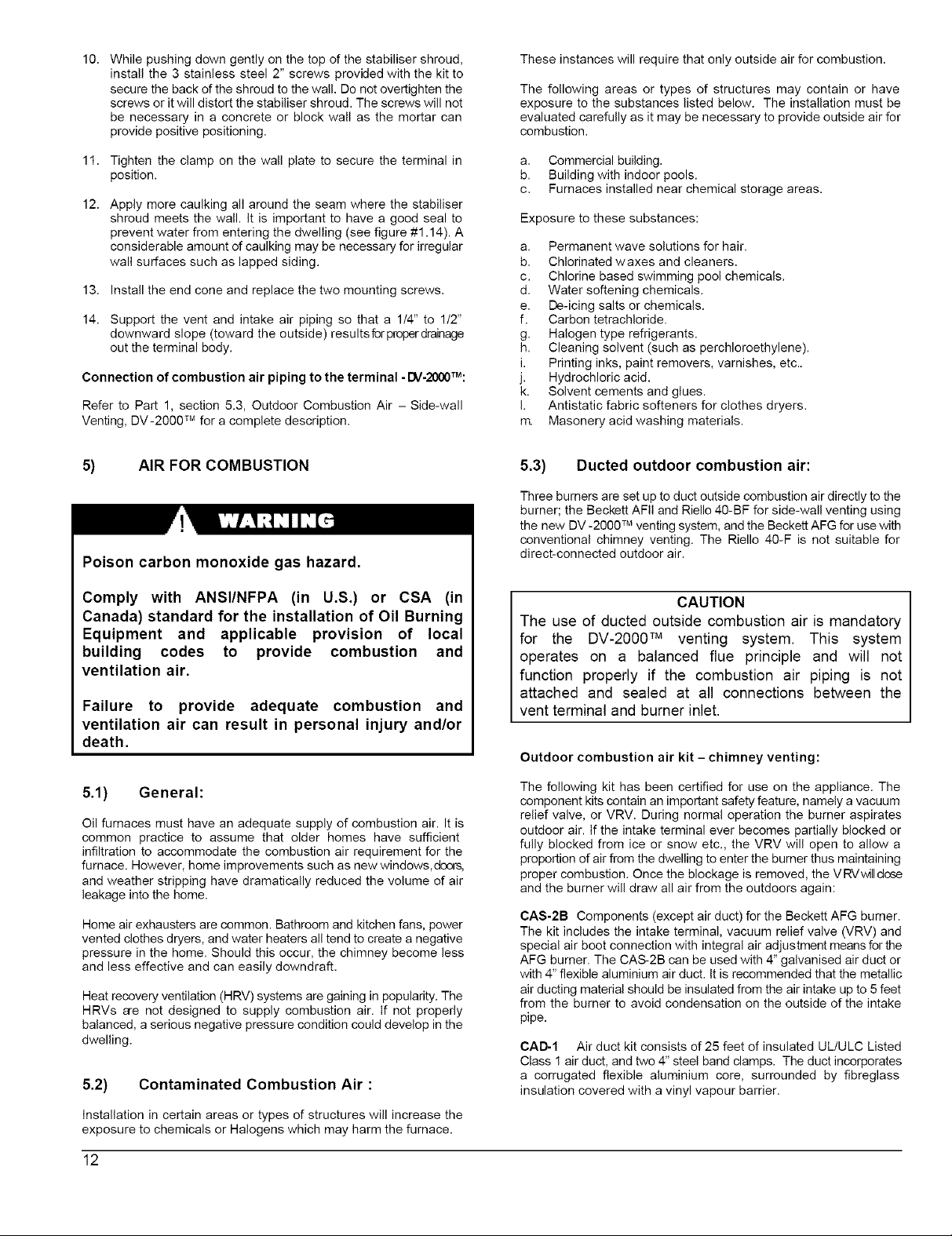

12. Apply more caulking all around the seam where the stabiliser

shroud meets the wall. It is important to have a good seal to

prevent water from entering the dwelling (see figure #1.14). A

considerable amount of caulking may be necessary for irregular

wall surfaces such as lapped siding.

13. Install the end cone and replace the two mounting screws.

14. Support the vent and intake air piping so that a 114" to 1/2"

downward slope (toward the outside) resultsforproperdrainage

out the terminal body.

Connection of combustion air piping to the terminal - DV-2000TM:

Refer to Part 1, section 5.3, Outdoor Combustion Air - Side-wall

Venting, DV-2000 TM for a complete description.

5) AIR FOR COMBUSTION

Poison carbon monoxide gas hazard.

Comply with ANSI/NFPA (in U.S.) or CSA (in

Canada) standard for the installation of Oil Burning

Equipment and applicable provision of local

building codes to provide combustion and

ventilation air.

Failure to provide adequate combustion and

ventilation air can result in personal injury and/or

death.

a. Commercial building.

b. Building with indoor pools.

c. Furnaces installed near chemical storage areas.

Exposure to these substances:

a. Permanent wave solutions for hair.

b. Chlorinated waxes and cleaners.

c. Chlorine based swimming pool chemicals.

d. Water softening chemicals.

e. De-icing salts or chemicals.

f. Carbon tetrachloride.

g. Halogen type refrigerants.

h. Cleaning solvent (such as perchloroethylene).

i. Printing inks, paint removers, varnishes, etc..

j. Hydrochloric acid.

k. Solvent cements and glues.

I. Antistatic fabric softeners for clothes dryers.

m Masonery acid washing materials.

5.3) Ducted outdoor combustion air:

Three burners are set up to duct outside combustion air directly to the

burner; the Beckett AFII and Riello 40-BF for side-wall venting using

the new DV -2000 TM venting system, and the Beckett AFG for use with

conventional chimney venting. The Riello 40-F is not suitable for

direct-connected outdoor air.

CAUTION

The use of ducted outside combustion air is mandatory

for the DV-2000 TM venting system. This system

operates on a balanced flue principle and will not

function properly if the combustion air piping is not

attached and sealed at all connections between the

vent terminal and burner inlet.

Outdoor combustion air kit - chimney venting:

5.1) General:

Oil furnaces must have an adequate supply of combustion air. It is

common practice to assume that older homes have sufficient

infiltration to accommodate the combustion air requirement for the

furnace. However, home improvements such as new windows,dcors,

and weather stripping have dramatically reduced the volume of air

leakage into the home.

Home air exhausters are common. Bathroom and kitchen fans, power

vented clothes dryers, and water heaters all tend to create a negative

pressure in the home. Should this occur, the chimney become less

and less effective and can easily downdraft.

Heat recovery ventilation (HRV) systems are gaining in popularity. The

HRVs are not designed to supply combustion air. If not properly

balanced, a serious negative pressure condition could develop in the

dwelling.

5.2) Contaminated Combustion Air :

Installation in certain areas or types of structures will increase the

exposure to chemicals or Halogens which may harm the furnace.

12

The following kit has been certified for use on the appliance. The

component kits contain an important safety feature, namely a vacuum

relief valve, or VRV. During normal operation the burner aspirates

outdoor air. If the intake terminal ever becomes partially blocked or

fully blocked from ice or snow etc., the VRV will open to allow a

proportion of air from the dwelling to enter the burner thus maintaining

proper combustion. Once the blockage is removed, the V RVwill dose

and the burner will draw all air from the outdoors again:

CAS-2B Components (except air duct) for the Beckett AFG burner.

The kit includes the intake terminal, vacuum relief valve (VRV) and

special air boot connection with integral air adjustment means for the

AFG burner. The CAS-2B can be used with 4" galvanised air duct or

with 4" flexible aluminium air duct. It is recommended that the metallic

air ducting material should be insulated from the air intake up to 5 feet

from the burner to avoid condensation on the outside of the intake

pipe.

CAD-1 Air duct kit consists of 25 feet of insulated UL/ULC Listed

Class 1 air duct, and two 4" steel band clamps. The duct incorporates

a corrugated flexible aluminium core, surrounded by fibreglass

insulation covered with a vinyl vapour barrier.

Page 12

CAUTION

The CAS-2B does not turn the furnace installation into a

direct vent system. Therefore the building structure

must provide for adequate combustion air to be

delivered at the vacuum relief valve. The burner will

need to draw combustion air from the VRV's

surroundings if the intake ever becomes blocked.

Therefore non-direct vent installation codes must be

followed.

Comprehensive installation instructions are provided with the kit.

Outdoor combustion air - side-wall venting, DV-2000TM:

The new DV-2000 TM venting system is a sealed system and

completely isolates the furnace from the interior of the building. The

burner is totally unaffected by any pressure fluctuations within the

building which makes it ideal for tight home constructions.

The DV-2000 TMventing system requires additional parts, which are

not included with the kit. These additional parts must be constructed of

3" Schedule 40 PVC, PVOSWV, SDR-26,SDR-21, Septic Sewer

Pipe, or ABS plastic pipe, fittings and sealant. Also, installation

procedures, piping and fittings must conform to the following ANSI

/ASTM standards:

PVC ASTM D- 1785

SDR26, SDR21 ASTM D-2241

Septic Sewer Pipe ASTM D-2729

PVC-DWV ASTM D-2665

PVC Primer and

Solvent Cement ASTM D-2564

ABS Pipe and Fittings ASTM D-2235

Procedure for

Cementing Joints ASTM D-2855

Additional parts required (not included in VTK kit):

a. 3" elbow fitting as required

b. 3" plastic pipe

c. 3" 90°elbow, female-female(for terminal)

d. 3" female to 2" female reducer (Riello 40-BF burner only)

e. 2" 90°elbow, street type, female-male (Riello 40-BF bumer only)

f. 3" female-female PVC or ABS coupling (not sewer pipe) (Beckett

AFII burner only)

g. transition bushings to go from PVC or ABS to ASTM D2729

Septic Sewer Pipe (if applicable).

If PVC fittings are mixed with ABS fittings, use a solvent cement that is

approved for bonding the two plastics.

Intake pipe length - DV-2000TM:

The DV-2000 TMventing system has been certified for 120 equivalent

feet of 3" intake pipe. Count a 90°elbow as 10 equivalent feet and a

45°elbow as 5 equivalent feet in the calculation.

For Example:

1

2

3

2

1

1

5' Length = 5 equivalent feet

10' Lengths = 20 equivalent feet

90°elbows = 30 equivalent feet

45°elbows = 10 equivalent feet

90°elbow (terminal) = 10 equivalent feet

90°elbow (Riello Burner) = 10 equivalent feet

Total = 85 equivalent feet,

which is less than 120 feet, which is

acceptable.

Intake pipe installation - DV-2000TM:

Obtain the necessary additional parts, to complete the installation, and

start by piping at the burner. If the optional vestibule has been

installed, remove the appropriate knockouts in the side panels of the

vestibule. The lower 5" knockout inthe right hand panel is used for the

Beckett AFII bumer. The higher 5" knockouts on the right and left-

hand panels are for right or left connection to the Riello 40-BFbumer.

Beckett AFII burner:

Remove the burner intake cover by removing the 3 screws securing it

in place. Discard the cover and screws. Apply silicone liberally around

the end of a 3" coupling and fully insert the silicone end onto the

burner opening. Fasten securely with 3 self-tapping sheet metal

screws.

Riello 40-BF burner:

Fully insert the female end of the 2" 90 ° street elbow into the

combustion air fitting on top of the burner. Fasten securely with 3 self-

tapping sheet metal screws. Cement the 2" end of the 3" female to 2"

female reducer onto the male end of the 2" 90° street elbow. If these

parts are not easily obtained, use a 3" 90 ° street elbow with the male

end fitted over the combustion air fitting. The fitting will have to be

silicone sealed as the fit is a bit loose. Fasten securely with 3 self-

tapping sheet metal screws

Terminal connection:

Insert the 3" 90 ° female-female elbow onto the stainless steel air

intake fitting located on the right side of the vent terminal (viewing from

the rear). Fasten securely with 3 self-tapping sheet metal screws.

Intermediate piping:

Pipe as required between the terminal and the burner. Ensure that the

3" piping is routed and supported in accordance with local and national

codes. Obey minimum furnace clearances to combustibles when

routing any sections of 3" piping in the vicinity of the furnace. IfSeptic

Sewer Pipe is to be used, install transition bushings at the 3" female

ends of the fittings at the burner and at the terminal. Transition

bushings are readily available and are required because 3" PVC and

ABS pipes have a typical outside diameter of 3.5", whereas Septic

Sewer Pipe has a typical outside diameter of 3.25".

6) OIL TANKS AND LINES

Check your local codes for the installation of the tank and accessories.

At the beginning of each heating season or each year, verify the 11-

complete oil distribution system for oil leak.

A manual shut-off valve and an oil filter shall follow sequence from

tank to burner. Be sure that the oil line is clean before connecting to

the bumer. The oil line should be protected to eliminate any possible

damage. Installations having the fuel oil tank below the burner level

must employ a two pipe fuel supply system with an appropriate fuel

pump (more than 8' lift use 2 stage pump and more than 16' an

auxiliary pump).

Follow the pump instructions to determine the size of tubing you need

in relation of the lift, or the horizontal distance.

7) BURNER INSTALLATION

Mounting the burner:

a,

The warm air furnace burner mounting plate has a four bolts

configuration.

b.

Position the mounting gasket between the mounting flange and

the appliance burner mounting plate. Line up the holes in the

mounting flange with the studs on the appliance mounting plate

and securely bolt in place.

13

Page 13

After the burner is mounted:

Fuel supply system:

a. Remove drawer assembly or air tube combination

b. Install nozzle (see specifications)

c. Confirm electrode settings

d. Make the electrical connections

e. Complete oil line connections

Do not turn on the burner until you have checked the

I CAUTION

polarity

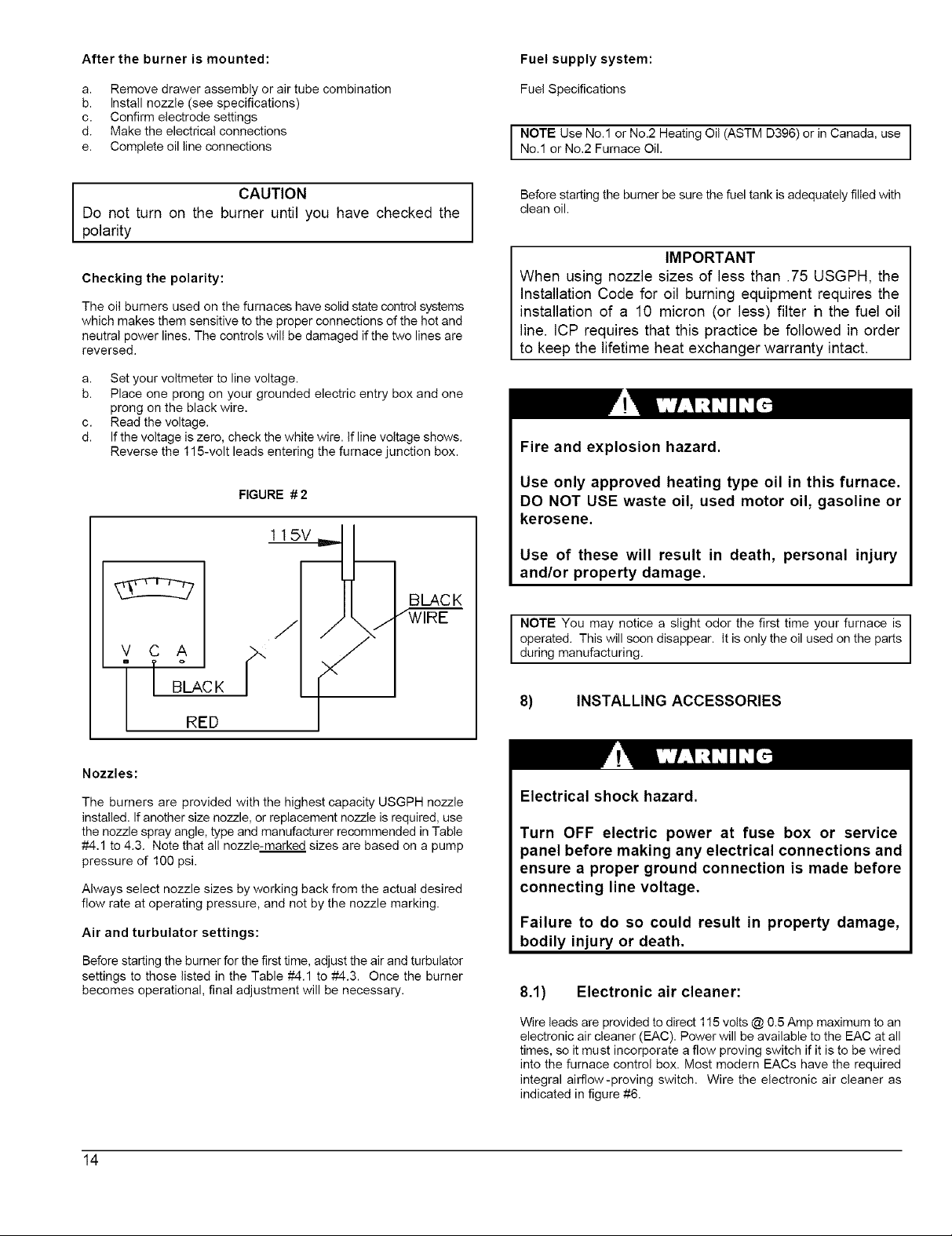

Checking the polarity:

The oil burners used on the furnaces have solid state control systems

which makes them sensitive to the proper connections of the hot and

neutral power lines. The controls will be damaged if the two lines are

reversed.

a. Set your voltmeter to line voltage.

b. Place one prong on your grounded electric entry box and one

prong on the black wire.

c. Read the voltage.

d. If the voltage is zero, check the white wire. If line voltage shows.

Reverse the 115-volt leads entering the furnace junction box.

FIGURE # 2

1 15V

BLAC K

Fuel Specifications

No.1 or No.2 Furnace Oil.

I NOTE Use No.1 or No.2 Heating Oil (ASTM D396) or in Canada, use

Before starting the burner be sure the fuel tank is adequately filled with

clean oil.

IMPORTANT

When using nozzle sizes of less than .75 USGPH, the

Installation Code for oil burning equipment requires the

installation of a 10 micron (or less) filter h the fuel oil

line. ICP requires that this practice be followed in order

to keep the lifetime heat exchanger warranty intact.

Fire and explosion hazard.

Use only approved heating type oil in this furnace.

DO NOT USE waste oil, used motor oil, gasoline or

kerosene.

Use of these will result in death, personal injury

and/or property damage.

NOTE You may notice a slight odor the first time your furnace is

operated. This will soon disappear. It is only the oil used on the parts

during manufacturing.

vcA

" m °

BLAC K

RED

Nozzles:

The burners are provided with the highest capacity USGPH nozzle

installed. If another size nozzle, or replacement nozzle is required, use

the nozzle spray angle, type and manufacturer recommended in Table

#-4.1 to 4.3. Note that all nozzle-marked sizes are based on a pump

pressure of 100 psi.

Always select nozzle sizes by working back from the actual desired

flow rate at operating pressure, and not by the nozzle marking.

Air and turbulator settings:

Before starting the burner for the first time, adjust the air and turbulator

settings to those listed in the Table #-4.1 to #4.3. Once the burner

becomes operational, final adjustment will be necessary.

8) INSTALLING ACCESSORIES

Electrical shock hazard.

Turn OFF electric power at fuse box or service

panel before making any electrical connections and

ensure a proper ground connection is made before

connecting line voltage.

Failure to do so could result in property damage,

bodily injury or death.

8.1) Electronic air cleaner:

Wire leads are provided to direct 115 volts @ 0.5 Amp maximum to an

electronic air cleaner (EAC). Power will be available to the EAC at all

times, so it must incorporate a flow proving switch if it is to be wired

into the furnace control box. Most modern EACs have the required

integral airflow-proving switch. Wire the electronic air cleaner as

indicated in figure #6.

14

Page 14

8.2) Humidifier:

Terminals are provided to direct 115 volts @ 1.0 Amp maximum to the

transformer powering the humidifier. The humidifier will be energised

anytime the blower is operating on the "Heating Speed". Wire the 115-

volt power as indicated in figure #6.

I CAUTION

Dampers (purchased locally) MUST be automatic.

8.3) Air conditioning:

An air conditioning coil may be installed on the supply air side only.

Also, notwithstanding the evaporator coil manufacturer's instructions,

a minimum of 6 inches clearance must be allowed between the bottom

of the coil drain pan, and the top of the heat exchanger. Wire the

thermostat and condensing unit contactor as indicated in figure #6.

8.4) Ductwork and Filter:

Installation:

Design and install air distribution system to comply with Air

Conditioning Contractors of America manuals or other approved

methods that conform to local codes and good trade practices.

When furnace supply ducts carry air outside furnace area, seal return

air duct to furnace casing and terminate duct outside furnace space.

Install air conditioning cooling coil (evaporator)on down.steam side (in

the supply air plenum) or furnace.

If separate evaporator and blower unit is used, install good sealing

dampers for air flow control. Cold air from the evaporator coil going

through the furnace could cause condensation and shorten furnace

life.

Poison carbon monoxide gas hazard.

Do NOT draw return air from inside a closet or

utility room. Return air duct MUST be sealed to

furnace casing.

Failure to properly seal duct can result in death,

personal injury and/or property damage.

Poison carbon monoxide gas hazard.

Install evaporator coil on the supply side of the

furnace ducting.

Evaporator coil installed in return side ducting can

cause condensation to f_rm inside heat exchanger

resulting in heat exchanger failure. This could

result in death, personal injury and/or property

damage.

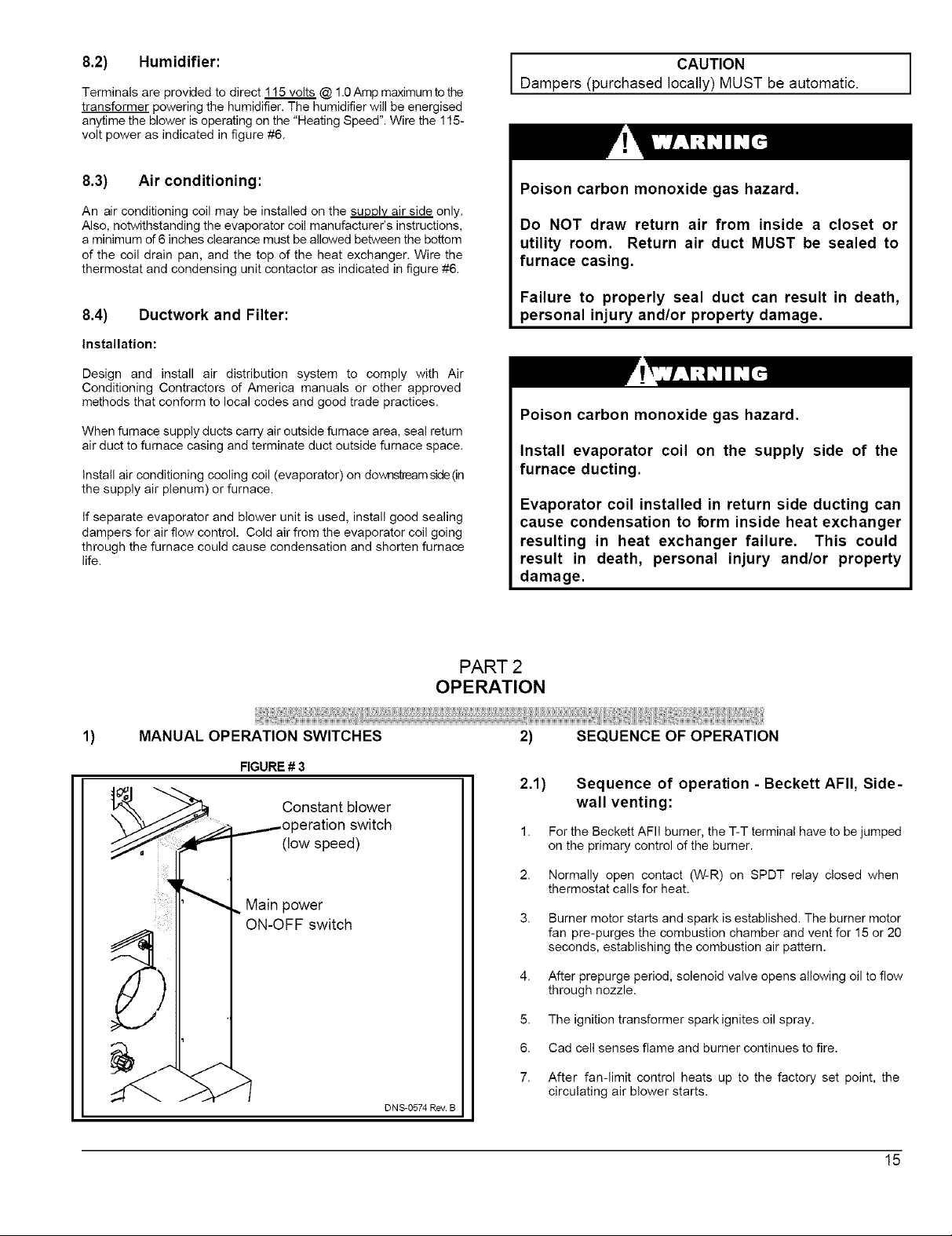

1)

MANUAL OPERATION SWITCHES

FIGURE # 3

Constant blower

3eration switch

(low speed)

Main power

ON-OFF switch

OPERATION

DNS-0574 Rev. B

PART 2

2) SEQUENCE OF OPERATION

2.1) Sequence of operation - Beckett AFII, Side-

wall venting:

1. For the Beckett AFII burner, the T-T terminal have to be jumped

on the primary control of the burner.

2. Normally open contact (W-R) on SPDT relay closed when

thermostat calls for heat.

3. Burner motor starts and spark is established. The burner motor

fan pre-purges the combustion chamber and vent for 15 or 20

seconds, establishing the combustion air pattern.

4. After prepurge period, solenoid valve opens allowing oil to flow

through nozzle.

5. The ignition transformer spark ignites oil spray.

6. Cad cell senses flame and burner continues to fire.

7. After fan-limit control heats up to the factory set point, the

circulating air blower starts.

15

Page 15

8. The circulating air blower, burner motor and ignition transformer

remains on until the thermostat is satisfied. Also, the solenoid

valve remains open.

9. Thermostat is satisfied.

10. SPDT relay contacts open, solenoid valve closes, burner fan

motor post-purges the combustion chamber and vent for a pre-

set time (30 sec. to 4 min.). The ignition transformer also

continues to spark for this time period.

11. During the post-purge cycle, the fan-limit control cools down to

the factory set point of 90 degrees Fahrenheit, and the circulating

air blower turns off.

2.2) Sequence of operation - Riello 40-BF, Side-

wall Venting:

1. Normally open contact (W-R) on SPDT relay closed when

thermostat calls for heat.

2.

Burner motor starts. The burner motor fan pre-purges the

combustion chamber and vents for 10 seconds, establishing the

combustion air pattern. During this time the solenoid valve

holding coil pressure will be approximately 100 psig.

3. After prepurge period, solenoid valve opens, allowing oil to flow

through nozzle. At the same time, the burner motor's ignition coil

produces spark.

holding coil pressure will be approximately 100 psig. Solenoid

valve opens, allowing oil to flow through nozzle. At the same

time, the burner motor's ignition coil produces spark.

4,

Spark ignites oil droplets.

5.

Cad cell senses flame and burner continues to fire. Ignition

transformer ceases sparking (Riello R40-F).

6.

After fan-limit control heats up to the factory set point, the

circulating air blower starts.

7.

The circulating air blower and burner motor remain on until the

thermostat is satisfied (AFG). The ignition transformer continues

to spark (AFG). The solenoid valve remains open (R40-F).

8.

Thermostat is satisfied.

9.

SPDT relay contacts open, solenoid valve closes (R40-F), burner

fan motor shuts down. The ignition transformer ceases sparking

(AFG).

10.

The fan-limit control BI-metal cools down to the factory set point

of 90 degrees Fahrenheit, and the circulating air blower turns off.

2.4) Sequence of operation - DV-2000 TM Venting

system:

Normal operation:

4. The ignition transformer spark ignites oil spray.

5. Cad cell senses flame and burner continues to fire. Ignition

transformer ceases sparking.

6. After fan-limit control heats up to the factory set point, the

circulating air blower starts.

7. The circulating air blower and burner motor remain on until the

thermostat is satisfied. Also, the solenoid valve remains open.

8. Thermostat is satisfied.

9. Relay contacts open, solenoid valve closes, and then the burner

fan motor post-purges the combustion chamber and vent for a

pre-set time (5" breech model only) (0 min. to 6 min.).

10. During the post-purge cycle, the fan-limit control BI-metal cools

down to the factory set point of 90 degrees Fahrenheit, and the

circulating air blower turns off.

NOTE: With burner relay contact open, the Riello 40-BF will post- I

purge when 115 volt power is applied to the burner.

2.3) Sequence of operation - Beckett AFG and

Riello 40-F, chimney:

1. For the AFG burner, the T-T terminal have to be jumped on the

primary control of the burner.

1. Before a call for heat the contacts of the pressure switch are

closed.

2,

When the room thermostat calls for heat the normally open

contact W-R close and the burner blower starts and creates

suction in the intake piping circuit and a pressure in the vent

piping circuit.

3,

The differential pressure setpoint of the pressure switch is not

exceeded and the thermostat circuit remains closed until the call

for heat has ended.

Abnormal operation:

Start-up:

1. When the room thermostat calls for heat the normally open

contact W-R close and the burner blower starts and creates

suction in the intake piping circuit and a pressure in the vent

piping circuit.

2.

If there is a blockage in the intake or vent openings to cause a

pressure differential beyond the set point of the pressure switch,

1

then the thermostat circuit is opened and the burner will go into a

2 minute post-purge and then shut down.

3,

After the post-purge, once the burner blower shuts down, the

pressure switch contacts will re-dose. Ifthe callfor heat remains,

the burner will re-start. If the blockage still exists, the thermostat

is again opened, and the burner post- purges again. The post-

purge function thus becomes an inherent anti-short cycling

device.

2. Normally open contact (W-R) on SPDT relay closed when

thermostat calls for heat.

3,

AFG Burner: The motor starts and spark is established. The

pump pressure builds and the poppet valve opens admitting fuel

to the nozzle. Pressure builds and poppet valve opens, allowing

oil to flow through nozzle.

40F: Burner motor starts. The burner motor fan pre-purgesthe

combustion chamber and vent for 10 seconds, establishing the

combustion air pattern. During this time the solenoid valve

16

4,

The unit will essentially go into a continuous re-cycling post-

purge mode with no heat being supplied to the dwelling, which

will prompt a call for service to the equipment.

5,

During the re-cycling post-purges, if the blockage of the terminal

is removed, the burner will immediately fire up at the end of the

current post purge cycle.

Page 16

During operation:

If the terminal vent or intake openings become blocked to the point

where the set point of the pressure switch is exceeded, during a firing

cycle, the burner flame will shut down and the burner wiii go into the

indefinite recycling post-purge mode as described above, until the

blockage is removed.

3) CHECKS AND ADJUSTMENTS

3.1) General:

During initial start-up and subsequent yearly maintenance calls, the

furnace must be thoroughly tested.

Open the oil bleed port screw and start the burner. Allow the oil to

flush into a portable container for at least 10 seconds. Slowly close the

bleed screw - the oil should flow absolutely free of white streaks or

bubbles to indicate that no air is being drawn into the suction side of

the oil piping and pump. Tighten the bleed screw and the burner will

fire. Adjust the oil pressure as indicated in Table #-4.1 to #4.3.

IMPORTANT

The burner must be put in operation for at least 10

minutes before any test readings are taken. For new

installations, set up the burner to the settings (see table

#4.1 to 4.3), before firing. These are rough adjustments

but they will ensure that the burner will start and run

smoke-free in advance of the fine adjustments being

made.

3.2) Restart if Burner Should Stop:

1. Set thermostat lower than the room temperature.

2. Press the reset button on the burner primary control (relay).

3. With side-wall venting and Riello burner, set thermostat higher

than the room temperature for 10 seconds and set lower than

room temperature. This will start pre purge cycle. Repeat twice.

4. Set thermostat higher than the room temperature.

5. If the burner motor does not start or ignition fails, turn off the

disconnect switch and CALL YOUR SERVICEMAN

3.4) Perform the smoke / CO2 test:

1. For chimney installations, pierce a test hole in the smoke pipe

near the furnace breech. For side-wall vented installations,

remove the threaded cap from the extended test pipe that is

welded into 4-bolt breech plate. Insert the smoke test instrument

probe into the open hole.

2. Starting with a zero smoke reading, gradually reduce the burner

air setting until just a trace (#1 on Bacharach Scale) of smoke

results.

3. Take a CO2 sample at the same test location w here the smoke

sample was taken. Note the CO2 reading associated with the #1

smoke condition.

4. For chimney vented installations, adjust the burner air setting to

obtain a CO2 reading 1% lower than the reading associated with

the #1 smoke.

5. For side-wall vented installations, adjust the burner air setting to

obtain a CO2 reading 1.5% lower than the reading associated

with the #1 smoke.

6.

This method of adjusting the CO2 will allow adequate excess air

to ensure that the burner will burn clean for the entire heating

season, and will ensure proper calibration of the DV-2000 TM

blocked intake/vent safety shutdown system used in side-wall

venting applications.

3.5) Perform the supply air temperature rise test:

1. Operate the burner for at least 10 minutes.

2. Measure the temperature of the air in the return air plenum.

3.

Measure the temperature of the air in the largest trunk coming off

the supply air plenum, just "out of the line of sight" of the radiation

coming off the heat exchanger; 12" away from the plenum on the

main take-off usually satisfies this objective.

4. The temperature rise is calculated by subtracting the return air

temperature from the supply air temperature.

5.

If the temperature rise exceeds the temperature specified in table

#4.1 to #4.3, change to the next higher blower speed tap until the

temperature rise falls to at this temperature or below. If the

excessive temperature rise cannot be reduced by increasing fan

speed, investigate for ductwork restriction(s), dirty or improper air

filter, or overfiring caused by excessive pump pressure, or

inproper nozzle sizing.

Do not attempt to start the burner when excess oil has

accumulated, when the furnace is full of vapour, or

I CAUTION

when the combustion chamber is very hot.

3.3) Combustion chamber curing:

Some moisture and binders remain in the ceramic combustion

chambers after fabrication. It is important to clear the chamber of

these residues before testing. If you smoke test before curing, the

instrument may become damaged. To cure the chamber, run the unit

for 3 consecutive cycles, with 3 minutes of elapsed time in between

each cycle. Each burn cycle should be 3 minutes duration. The

exhaust will have a pungent odor and produce a white cloud ofsteam.

3.6) Vent temperature test:

1. Place a thermometer in the test hole located in the breech pipe.

2. The vent temperature should be between 400 and 575°F. If

not, check for improper air temperature rise, pump pressure,

nozzle size, or for a badly sooted heat exchanger.

17

Page 17

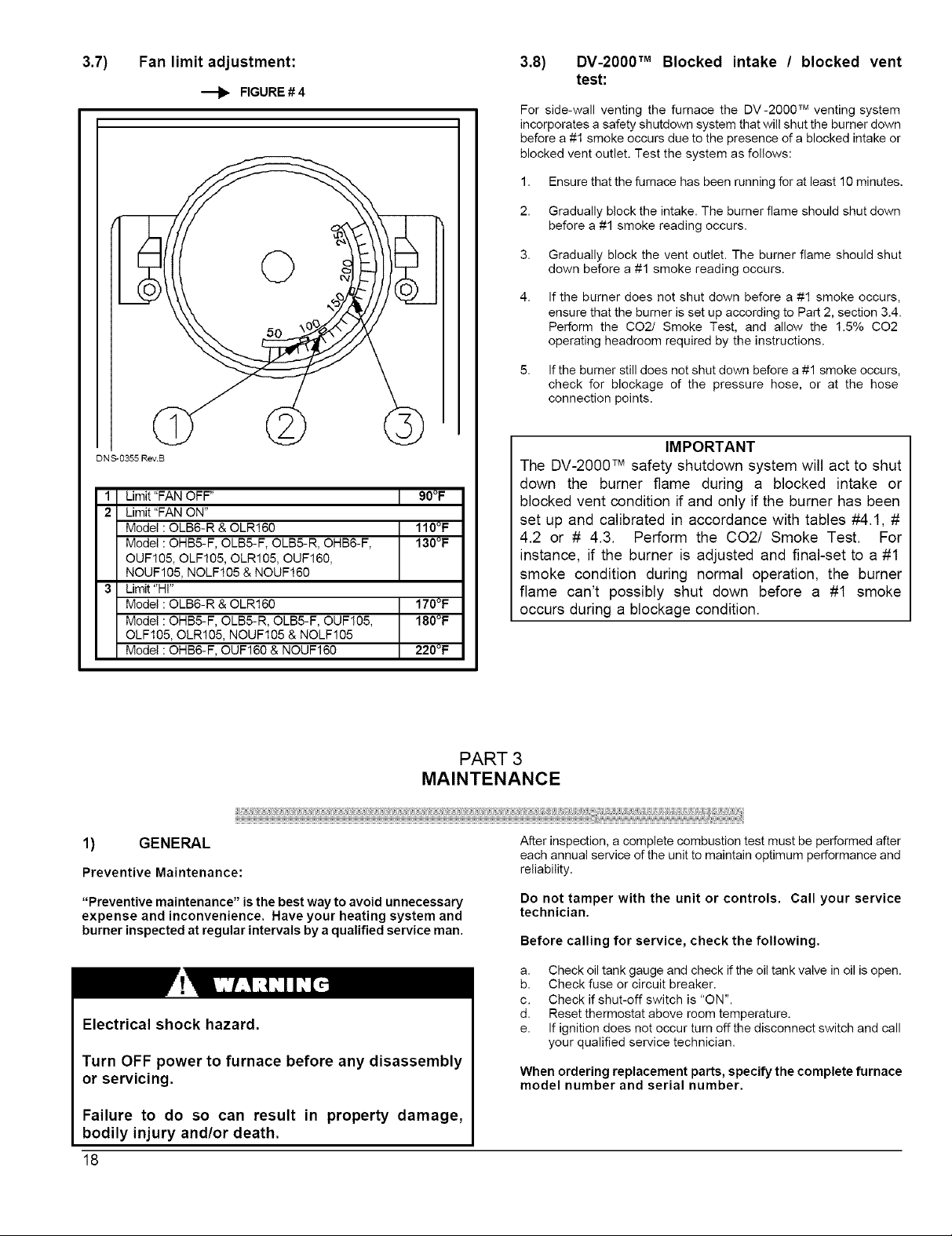

3.7) Fan limit adjustment:

FIGURE#4

3.8) DV-2000 TM Blocked intake / blocked vent

test:

For side-wall venting the furnace the DV-2000 TM venting system

incorporates a safety shutdown system that will shut the burner down

before a #1 smoke occurs due to the presence of a blocked intake or

blocked vent outlet. Test the system as follows:

1. Ensure that the furnace has been running for at least 10 minutes.

2. Gradually block the intake. The burner flame should shut down

before a #1 smoke reading occurs.

3. Gradually block the vent outlet. The burner flame should shut

down before a #1 smoke reading occurs.

4,

If the burner does not shut down before a #1 smoke occurs,

ensure that the burner is set up according to Part 2, section 3.4.

Perform the CO2/ Smoke Test, and allow the 1.5% CO2

operating headroom required by the instructions.

5. If the burner still does not shut down before a #1 smoke occurs,

check for blockage of the pressure hose, or at the hose

connection points.

DN S_0355 eev.S

1 Limit "FAN OFF" I 90°F

2 Limit "FAN ON"

Model: OLB6-R & OLR160 110°F

Model: OHB5-F, OLB5-F, OLB5-R, OHB6-F, 130°F

OUF105, OLF105, OLR105, OUF160,

NOUF105, NOLF105 & NOUF160

3 Limit "HI"

Model: OLB6-R & OLR160 170°F

Model: OHB5-F, OLB5-R, OLB5-F, OUF105, 180°F

OLF105, OLR105, NOUF105 & NOLF105

Model: OHB6-F, OUF160 & NOUF160 220°F

I

MAINTENANCE

1) GENERAL

Preventive Maintenance:

"Preventive maintenance" is the best way to avoid unnecessary

expense and inconvenience. Have your heating system and

burner inspected at regular intervals by a qualified service man.

PART 3

IMPORTANT

The DV-2000 TM safety shutdown system will act to shut

down the burner flame during a blocked intake or

blocked vent condition if and only if the burner has been

set up and calibrated in accordance with tables #4.1, #

4.2 or # 4.3. Perform the CO2/ Smoke Test. For

instance, if the burner is adjusted and final-set to a #1

smoke condition during normal operation, the burner

flame can't possibly shut down before a #1 smoke

occurs during a blockage condition.

After inspection, a complete combustion test must be performed after

each annual service of the unit to maintain optimum performance and

reliability.

Do not tamper with the unit or controls. Call your service

technician.

Before calling for service, check the following.

Electrical shock hazard.

Turn OFF power to furnace before any disassembly

or servicing.

Failure to do so can result in property damage,

bodily injury and/or death.

18

a. Check oil tank gauge and check if the oil tank valve in oil is open.

b. Check fuse or circuit breaker.

c. Check if shut-off switch is "ON".

d. Reset thermostat above room temperature.

e. If ignition does not occur turn off the disconnect switch and call

your qualified service technician.

When ordering replacement parts, specify the complete furnace

model number and serial number.

Page 18

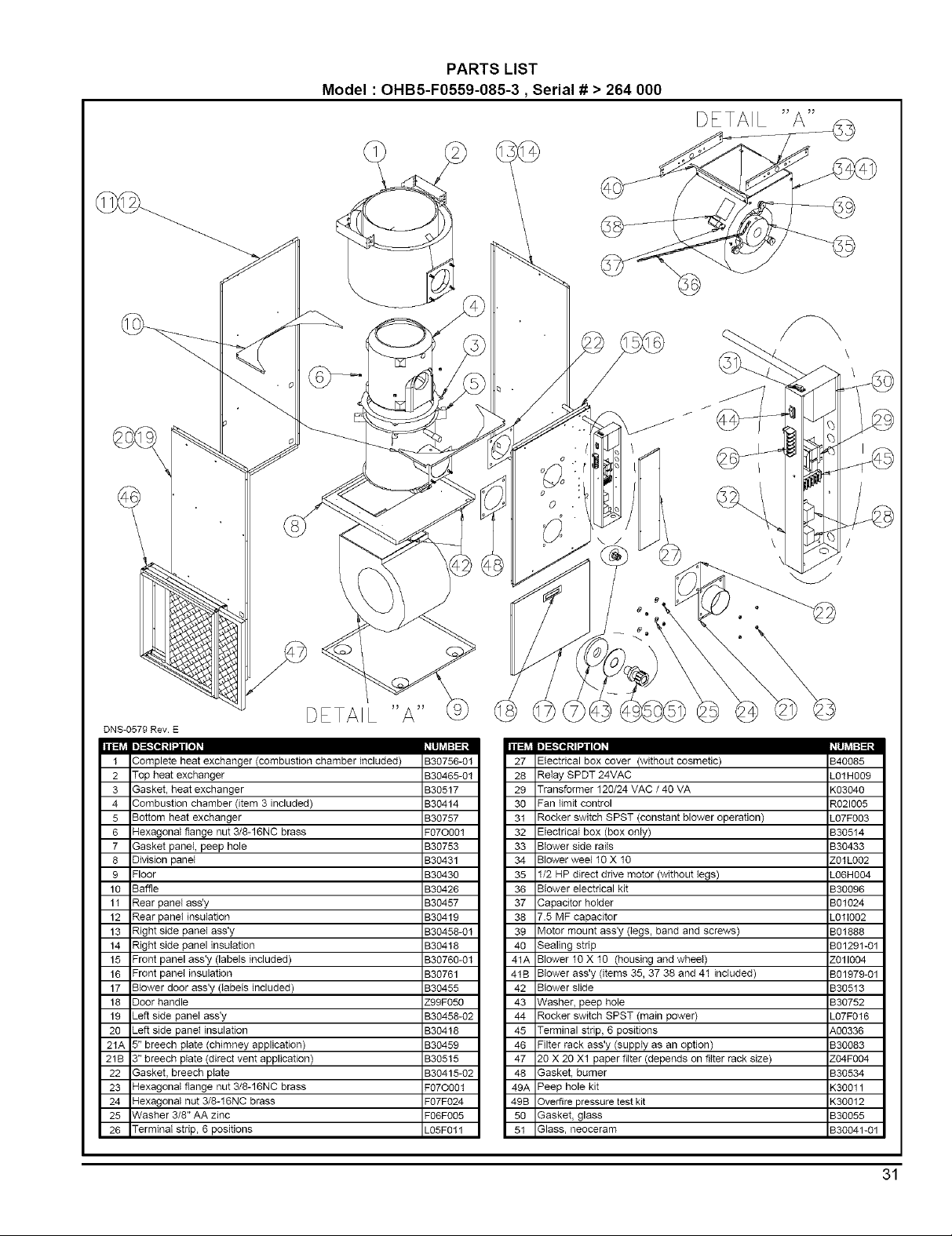

1.1) Heat exchanger:

The entire heat exchanger should be inspected annually for scot

accumulation. If the burner is operating normally there should very

little soot accumulation. If the heat exchanger requires scale removal,

use a wire brush first to loosen the scale and then vacuum the soot

and scale that has fallen into the secondary heat exchanger (radiator)

section. You will find that a 36" long flexible hose attachment will be

helpful to reach into the back of the radiator; a piece of 1/2" flexible

gas connector, or a piece of 1/2" liquid-tight vinyl jacket metallic

electrical conduit works well as a makeshift device.

Cleaning the heat exchanger:

Remove the 4-bolt flange from the front of the furnace to reveal the

clean-out port and check for soot deposits. If there is very little soot in

the radiator section visible from the clean-out port, you will not need to

clean it. However, if you notice scaling in the radiator, you should

remove the scale.

The wrap-around radiator can now be cleaned entirely from the front

inspection port. Also the new furnace has external clean_utpods so

the soot does not fall into the fan compartment during the cleaning

operation.

Do not vacuum the ceramic chambers--they are easily

I IMPORTANT

damaged.

CAUTION

If you observe the red warning light on the burner, push

once ONLY to try and restart. If the burner will not start,

phone your authorised service agent. Do not press the

button again.

Self-aligning firepot:

The appliance primary heat exchanger is comprised of an upper and

lower half. The lower half is essentially a "can" that houses a self-

aligning firepot, the firepot will fit into the bottom half in one orientation

only.

Removing the firepot:

The firepot is seldom replaced, but when it must be replaced one must

simply :

1. Remove the burner.

2. Remove the bumer limit control.

3. Remove the breech plate.

4. Remove the front panel.

5. Remove the brass nuts on the stainless steel heat exchanger

studs.

Soot will have collected in the first sections of the heat exchangers

only if the burner was started after the combustion chamber was

flooded with fuel oil, or if the burner has been operating in a severely

fouled condition.

1.2) Refractory fire pot:

Remove the burner and check the fire pot.

IMPORTANT

Use extreme care if cleaning of the pot is required. After

firing, the pot becomes very fragile. Do not use any

commercially available soot remover. This furnace has

a fiber type refractory combustion chamber. Normal

servicing of this unit does not require cleaning of the

combustion chamber.

If the pot is damaged, it must be replaced. A damaged pot could lead

to premature heat exchanger failure. Cracking of the fire pot is normal,

however, replace the pot if the cracks have propagated more than 2/3

the way through the wall thickness. The average wallthickness of the

firepot is 3/4".

Flooding of the fire pot:

Flooding can occur when the oil primary control has been reset a

number of times in a no-heat situation. Each time oil is fired into the

pot and does not ignite, it is absorbed in the pot. Even if the burner is

removed and the pot is felt for wetness, it is difficult to assess the

degree of oil absorption by the pot.

There is only one way to properly service a flooded fire pot, and that is

to change it.

6. Pry the bottom heat exchanger halves apart using the designated

prying tabs.

7. Remove the bottom heat exchanger half from the furnace cavity

through the front of the furnace.

8. Pull the firepot up and out of the bottom heat exchanger half.

9. Pull the old sealing gasket down off the flange of the upper heat

exchanger half.

10. Scrape off any residual gasket material off the heat exchanger

mating flanges.

Replacing the firepot:

1. Align the slot in the front face of the firepot with the burner tube

sleeve and gently lower the firepot into the bottom heat

exchanger half.

2. Holding the firepot near the perimeter, gently push the firepot all

the way into the bottom heat exchanger half until it seats.

3. Completely wet the gasket with water using a spray pump bottle,

position the tabs over the studs, and push the gasket upward

against the sealing flange of the upper heat exchanger half.

4. Install the brass nuts on the studs by engaging only 2 or 3

threads.

5.

Position the bottom heat exchanger half underneath the upper

heat exchanger half and rotate the bottom half so that the slots in

the bolting tabs engage the stainless steel studs. There is no

further need to hold onto the bottom half as it will now be

suspended on the stud nuts.

6. Push upward on the can and thread the nuts finger-'right asfar as

possible.

7,

Intermittently tighten the stud nuts with a wrench in a sequence

that will pu!l the heat exchanger halves together evenly. Tighten

all nuts to 90 inch-lbs Torque once and then alternately re4_qten

all nuts again to lOg inch-lbs THE RE-TIGHTENING

SEQUENCE IS ABSOLUTELY NECESSARY TO ENSURE A

TIGHT JOINT,

19

Page 19

8,

Re-assemble the front panel, breech plate, limit control and

burner in opposite sequence to their removal.

9.

Follow the instructions for starting the burner for the first time to

cure the firepot and perform combustion checks.

1.6) Air filters:

Air filters are the disposable types. The disposable filters should be

replaced on at least an annual basis. Dusty conditions, presence of

animal hair etc. may demand much more frequent filter changes. Dirty

filters will impact furnace efficiency and increase oil consumption.

1.3) Drawer assembly:

Remove the drawer assembly. Clean all foreign matter from the

retention head and electrodes. If a Beckett AFG burner has been

installed, the burner will have to be removed to check the retention

head and to check for proper "Z" dimension with the Beckett "T" gauge

supplied with every burner. Check for any sign of oil boiling out of the

nozzle and caulking - the solenoid valve could be leaking (if

applicable).

1.4) Nozzle:

Replace the nozzle with the one specified in table #-4.1to #4.3.

1.5) Oil filter:

Tank filter:

The tank filter should be replaced as required.

Secondary filter:

The lg micron (or less) filter cartridges should be replaced annually.

INFORMATION

1.7) Motor lubrication:

Do not lubricate the oil burner motor or the direct drive blower motor

as they are permanently lubricated.

1.8) CAS-2B combustion air kit (chimney

venting):

If used, check the CAS-2B combustion air kit for proper operation.

Check to see that the inlet screen is not plugged. Block the air inlet

completely and ensure that a zero smoke reading results. If a zero

smoke reading is not obtained, set up the burner as indicated in table

#4.1, #4.2 or#4.3.

Gradually block off the intake. The CO2 should increase by a

maximum of 0.5 percentage points at the fully blocked condition. If

not, check that the VRV gate is pivoting freely and that the pivot rod is

in a horizontal position. Also, check that the counterweight has been

properly adjusted in accordance with the CAS-2B installation

instructions.

PART 4

Model:

Date of installation of the furnace :

Service telephones - day :

Dealer's name and address :

RESULT OF START-UP TEST

Nozzle:

Burner adjustments : Primary air

Fine air

Draw Assembly

CO 2 : %

Gross stack temperature:

Ambiant temperature:

Chimney draft:

Overfire draft :

Test made by :

Smoke scale :

Serial number:

Night :

Pressure :

Ibpsi

(Bacharach)

o F

o F

"C.E

" C.E.

2O

Page 20

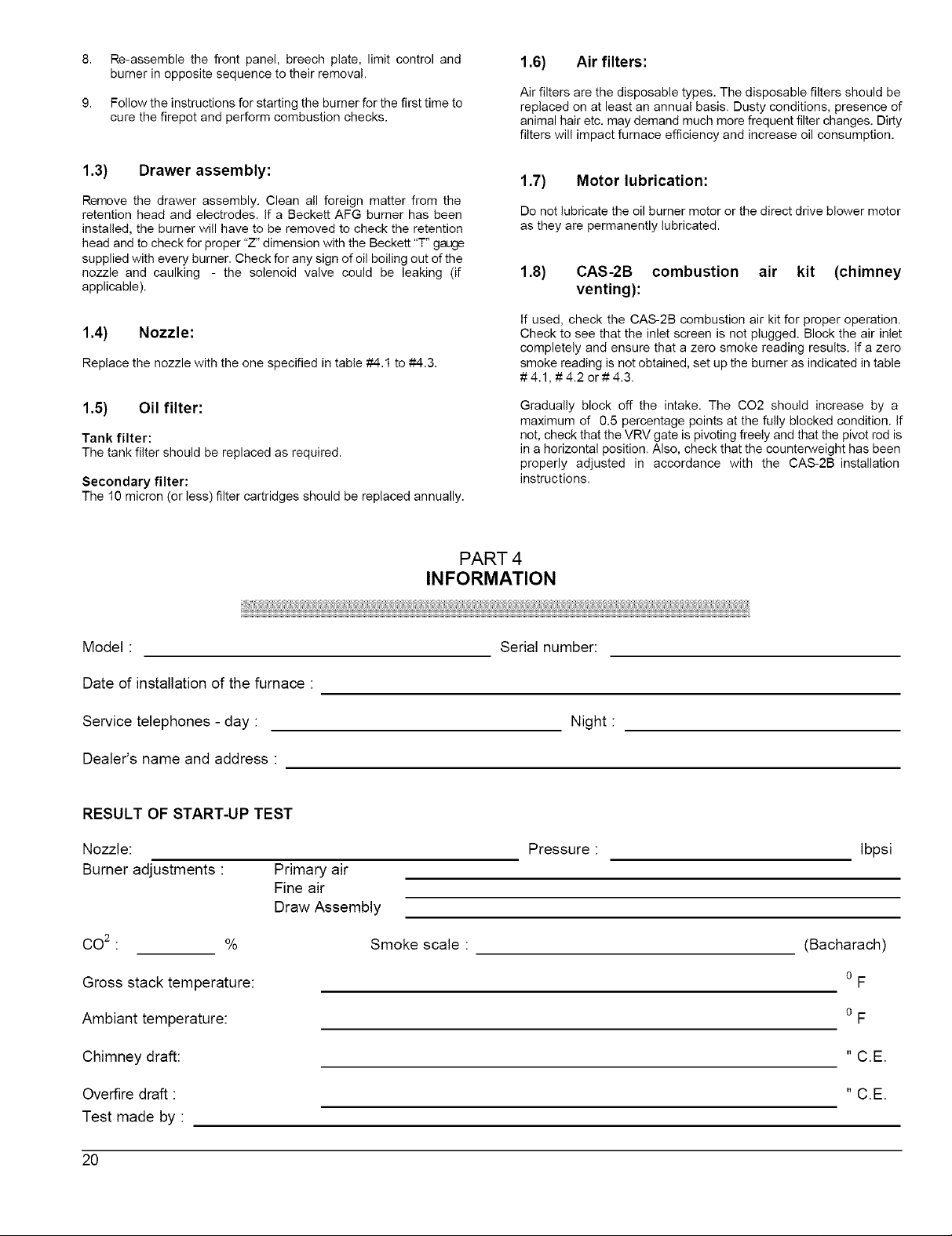

V]odei :OLB & OLR

F_J_TINGAND PERFORMANCE

--iring rate

_ump pressure (PSIG)

nput (BTU/h)

4eating capacity, chimney installation (BTU/h)

4eating capacity, side-w atl installation (BTUih)

V]inimum - maximum temperature rise

Stack draft, (Chimney), (Side-w all)

Dverfire pressure (chimney), (Side-w atl)

BECKETT BURNER, CHIM NEY INSTALLATION

_ow firing rate baffle

Static disc, model

klozzle (Delavan)

.Combustion air adjustment (shutter / band)

I_IELLO BURNER, CHIM NEY INSTALLATION

klozzle (Delavan)

.Combustion air adjustment (turbulator / damper)

BECKETT BURNER, SIDE-WALL INSTALLATION

klozzle (Detavan)

.Combustion air adjustment (screw / dial) or (dial only)

_IELLO BURNER, SIDE-WALL INSTALLATION

klozzle (Delavan)

.Combustion air adjustment (turbulator / damper)

ELECTRICAL SYSTEM

Jolts - Hertz - Phase

Dperating voltage range

Rated voltage Amp

Vlinimum ampacity for wiring sizing

Vlax. fuse size (Amps)

Sontrot transformer

Ext. control power available, cooling and accessories

BLOWER DATA

3Iow er speed at 0.5" W.C. static pressure

3Iow er speed at 0.25" W.C. static pressure

Vlaximum cooling, speed

Vlaximum cooling, tons @ 0.5" W.C.

Vlotor (HP) / number d speeds

3Iow er wheeI size (in.)

--liter quantity and size

TABLE # 4.1

Technical specifications

OLB5-R & OLR105A!2B

.50

100

70,000

59,200

59,400

(-0,035 to -0,06) (+0,04 to +0,16)

(0,00 to +0,035)t+0,10 to +0,25)

AFG-F0 Itube msersion 5 1/8")

Yes Yes No

2 3/4 #3382 2 3/4 #3383 2 3/4 #3383

0.50-70A 0.50-70A 0.60-70B

4.5/0 8/0 7.5/0

40-F3 Itube insersion 5 3/16" t

.63 .75

156 156

88,200 105,000

73,000 87,800

73,200 88,200

52- 75 Degr. F

.72

145

100,800

84,200

05o-8oAO6O-80A

o/3 o/4

AFII-85 Itube insersion 4 15/16")

0.50-60W 0.50-60W 0.60-60W

3/1.5 3/3 3/4.5

40-BF3 IK7Rtltube ,nsersion 5 3/16")

o.5o-8ow 0.60-8ow

0/6 _ 0/7.5

115-60-1 115-60-1

104- 132 104- 132

12,2 15.7

13.7 18.!

15 20

40 Va 40 Va

30 Va 30Va

MED-LO HIGH HIGH

LOW MED-HI MED-HI

LOW HIGH HIGH

1.5 3 5

MED-HI HIGH

MED-HI MED-HI

MED-LO MED-HI

2 2.5

1/3 HP / 4 speeds

10 X 10

(!)20 X20

OLB6-R & OLR160B20B

0.85

130

119,000

99,000

97,000

(-0.035 to -0.06) (+0.04 to +0.22)

(-0100 to +0.04)(+0.10 to +0.25)

AFG-F3, tube insersion 6 518")

No No No

2 3/4 #3383 2 3/4 #3383 2 3/4 #3383

0.75-70B 0.85-70B 1.00-70B

5/0 6.5/0 10/0

40-F5 Itube insersion 6 5/8" t

0.75-70B 0.85-70B 1.00-70B

1/2 1/2.5 1/3

AFII-150 'tube insersion 6 518")

0.75-70B 0.85-70B 1.00-70B

2.75 4.25 6.75

40-BF5/tube insersion 6 5/8" t

0.75-70B 0.85-70B 1.00-70B

1/3 1/4 2/4.5

MENLO ME.HI

MENLO ME.HI

MENLO ME.HI

3.5 4

0.97 1.14

130 130

135,800 159,600

111,000 129,000

110,000 127,000

50-80 Degr.F

3_ HP/4speeds

12 X 10

t2) 16 X 24

TABLE # 5.1

Air delevery - CFM with air filter

OLB5-R & OLR105A12B OLB6-R & OLR160B20B

EXTERNAL STATIC PRESSURE WITH AIR FILTER EXTERNAL STATIC PRESSURE WITH AIR FILTER

SPEED 0.25 0.5 0.25 0.5

LOW 850 700 1100 1020

MED-LO 940 750 1360 1350

MED-HI 1090 1000 1625 1540

HIGH 1390 1300 2100 1850

21

Page 21

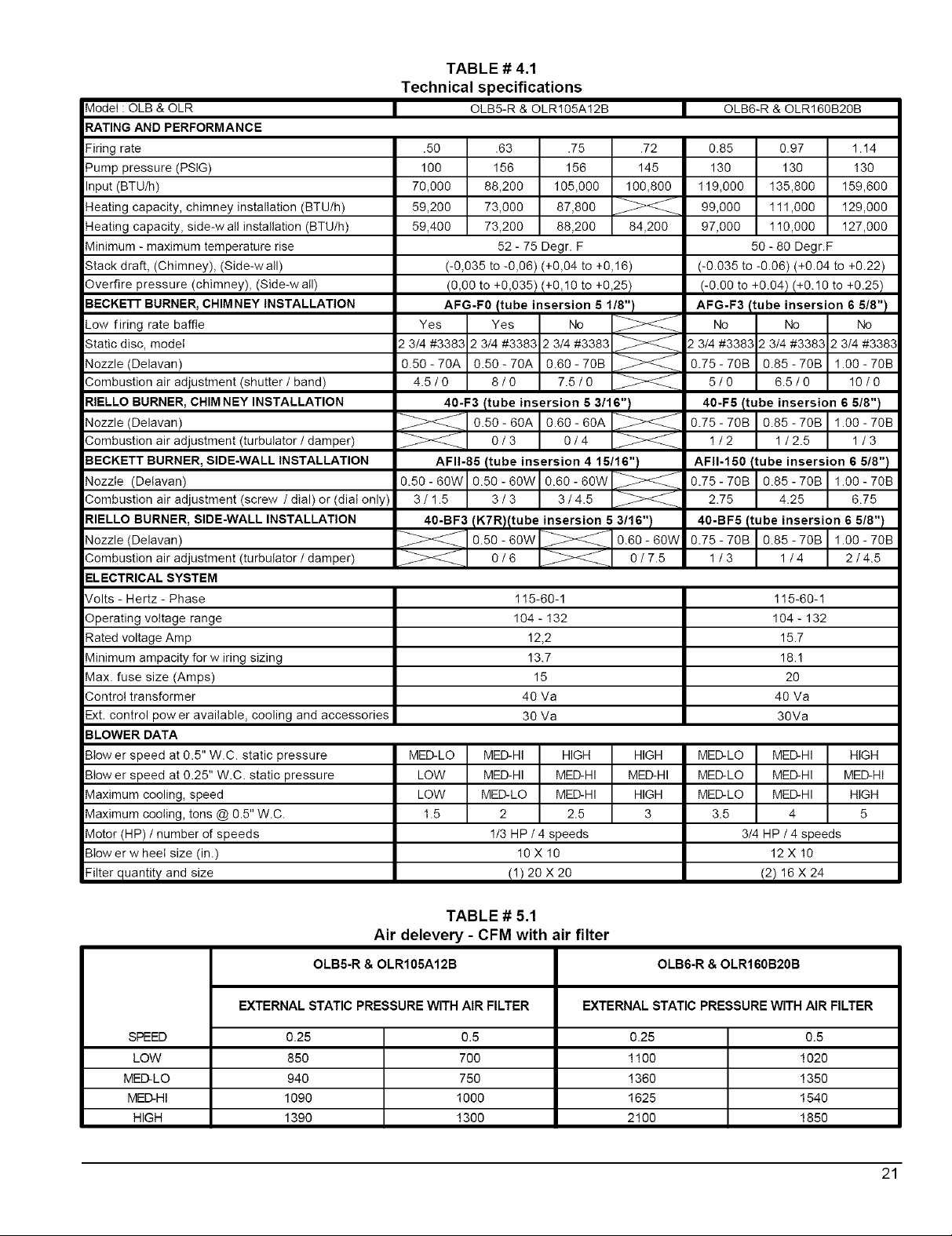

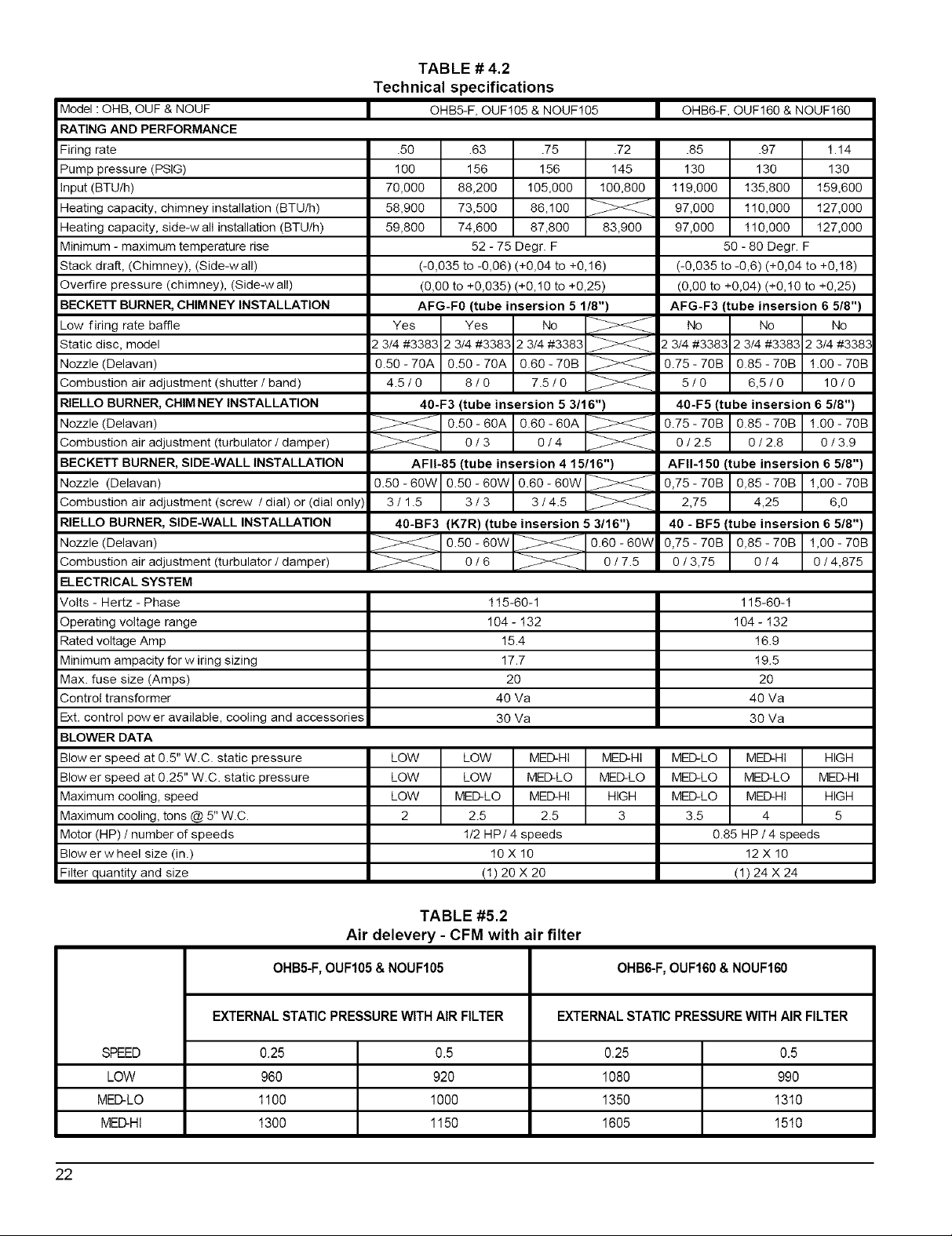

Model : OHB, OUF & NOUF

RATING AND PERFORMANCE

Firing rate

Pump pressure (PSIG)

Input (BTU/h)

Heating capacity, chimney installation (BTU/h)

Heating capacity, side-w all installation (BTU/h)

Minimum - maximum temperature rise

Stack draft, (Chimney), (Side-wall)

Overfire pressure (chimney), (Side-w all)

BECKEFF BURNER, CHIMNEY INSTALLATION

Low firing rate baffle

Static disc, model

Nozzle (Delavan)

Combustion air adjustment (shutter / band)

RIELLO BURNER, CHIM NEY INSTALLATION

Nozzle (Delavan)

Combustion air adjustment (turbulator / damper)

BECKETT BURNER, SIDE-WALL INSTALLATION

Nozzle (Delavan)

Combustion air adjustment (screw / dial) or (dial only)

RIELLO BURNER, SIDE-WALL INSTALLATION

Nozzle (Delavan)

Combustion air adjustment (turbulator / damper)

ELECTRICAL SYSTEM

Volts - Hertz - Phase

Operating voltage range

Rated voltage Amp

Minimum ampacity for w iring sizing

Max. fuse size (Amps)

Control transformer

Ext. control power available, cooling and accessories

BLOWER DATA

Blower speed at 0.5" W.C. static pressure

Blower speed at 0.25" W.C. static pressure

Maximum cooling, speed

Maximum cooling, tons @ 5" W.C.

Motor (HP) / number of speeds

Blow er w heel size (in.)

Filter quantity and size

TABLE # 4.2

Technical specifications

OHB5-F,OUF105 & NOUF105

.5O

100

70,000

58,900

59,800

(-0,035 to -0,06) (+0,04 to +0,18)

(0,00 to +0,035 (+0,10 to +0,25)

AFG-F0 (tube insersion 5 1/8")

Yes Yes No

2 3/4 #3363 2 3/4 #3363 2 3/4 #3363

0.50-70A 0.50-70A 0.80-70B

4.5/0 8/0 7.5/0

40-F3 (tube insersion 5 3/16")

.63 .75

156 156

88,200 105,000

73,500 86,100

74,600 87,800

52- 75 Degr. F

.72

145

100,800

83,900

o.5o-60A0.60-60A

0/3 0/4

AFII-85 (tube insersion 4 15116")

0.50 - 6OW 0.50 - 6OW 0.60 - 6OW

3/1.5 3/3 3/4.5