Page 1

MULTIPOSITION

HIGH-BOY

OIL-FIRED MODELS:

FURNACE

OMF112K14A

OMV112K14A

INSTALLER / SERVICE TECHNICIAN:

USE THE INFORMATION IN THIS MANUAL FOR THE INSTALLATION AND SERVICING OF THE FURNACE AND

KEEP THE DOCUMENT NEAR THE UNIT FOR FUTURE

REFERENCE.

HOMEOWNER: Manufactured by: Dettson Industries Inc.

PLEASE KEEP THIS MANUAL NEAR THE FURNACE FOR

FUTURE REFERENCE.

Printed in Canada on 100% recycled paper 2017-08-31 X40165 Rev.M

Attention:

Do not tamper with the unit or its controls.

Call a qualified service technician.

Sherbrooke, Qc, Canada

www.dettson.com

Page 2

Table of content

1 SAFETY 2

1.1 SAFETY LABELING AND WARNING SIGNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 IMPORTANT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 DETECTION SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 DANGER OF FREEZING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 INSTALLATION 3

2.1 POSITIONING THE FURNACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 Installation in an enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.1 Upflow installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.2 Downflow Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.3 Horizontal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 INSTALLATION OF THE THERMOSTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 INSTALLATION OF THE BURNER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5.1 Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5.2 Air and Turbulator Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5.3 Post purge delay adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6 VENTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6.1 Masonry chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6.2 Factory-built chimneys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6.3 Draft regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6.4 Side wall venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7 BLOCKED VENT SHUT-OFF DEVICE (BVSO) FOR CHIMNEY VENTING . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7.1 BVSO Functional Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.8 COMBUSTION AIR SUPPLY AND VENTILATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.8.1 Contaminated Combustion Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.8.2 Burner with Outdoor Combustion Air Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.9 DUCTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.9.1 Air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.10 SUPPLY AIR ADJUSTMENTS (4 SPEED MOTORS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.11 SUPPLY AIR ADJUSTMENTS (ECM VARIABLE SPEED MOTORS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.12 INSTALLATION OF ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.12.1 Humidifier (HUM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.12.2 Electronic Air Cleaner (EAC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.12.3 Air Conditioner (or Heat Pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.12.4 Emergency Heating Mode - variable speed Motor (ECM) . . . . . . . . . . . . . . . . . . . . . . . 11

3 OPERATION 11

1

Page 3

3.1 START-UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 OPERATING SEQUENCE OIL HEATING MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 CHECKS AND ADJUSTMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.1 Purging the oil line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.2 Pressure adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.3 Combustion Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.4 Draft Regulator adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.5 Overfire pressure test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.6 Vent Temperature Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.7 Supply Air Temperature Rise Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.8 Limit control check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.9 Restart after Burner Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 MAINTENANCE 13

4.1 CLEANING THE HEAT EXCHANGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 CLEANING THE BLOCKED VENT SHUT-OFF DEVICE (BVSO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 CLEANING THE BURNER HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4 REPLACING THE NOZZLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5 REPLACING THE OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.6 CHANGING THE AIR FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 FURNACE INFORMATION 15

6 TECHNICAL SPECIFICATIONS 16

List of figures

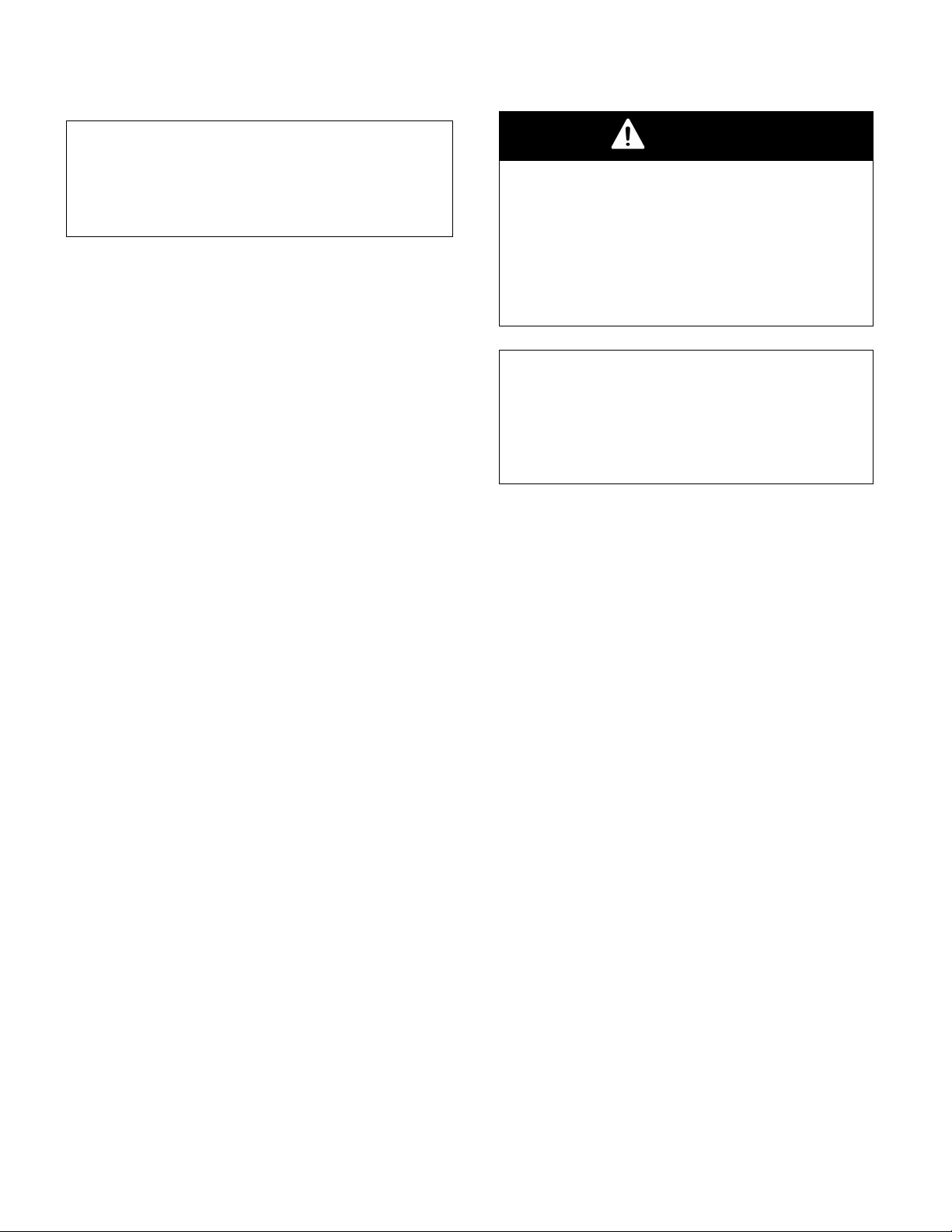

Figure 1: Location and dimensions of ventilation air openings in a closet door . . . . . . . . . . . . . . . . . 4

Figure 2: Upflow Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

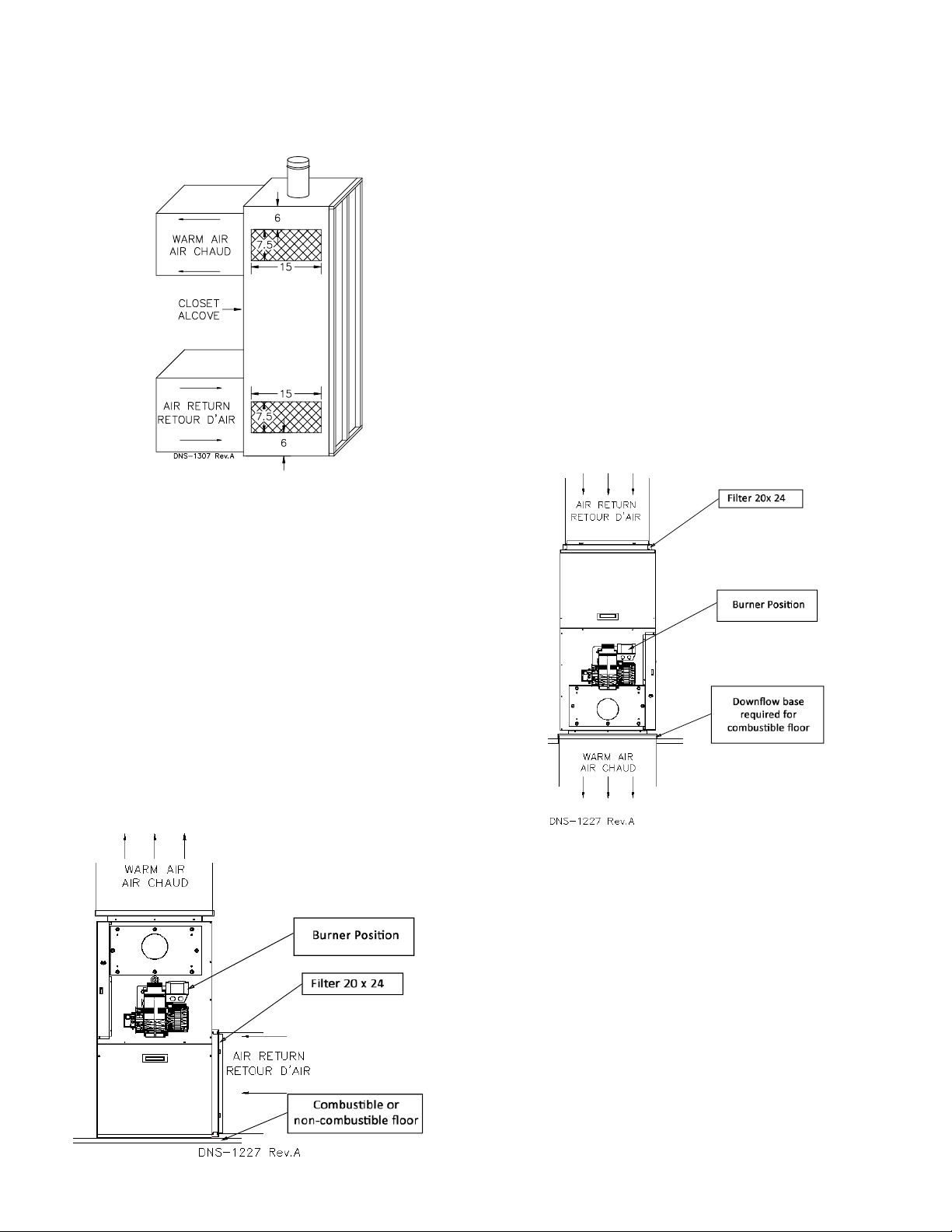

Figure 3: Downflow Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 4: Horizontal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

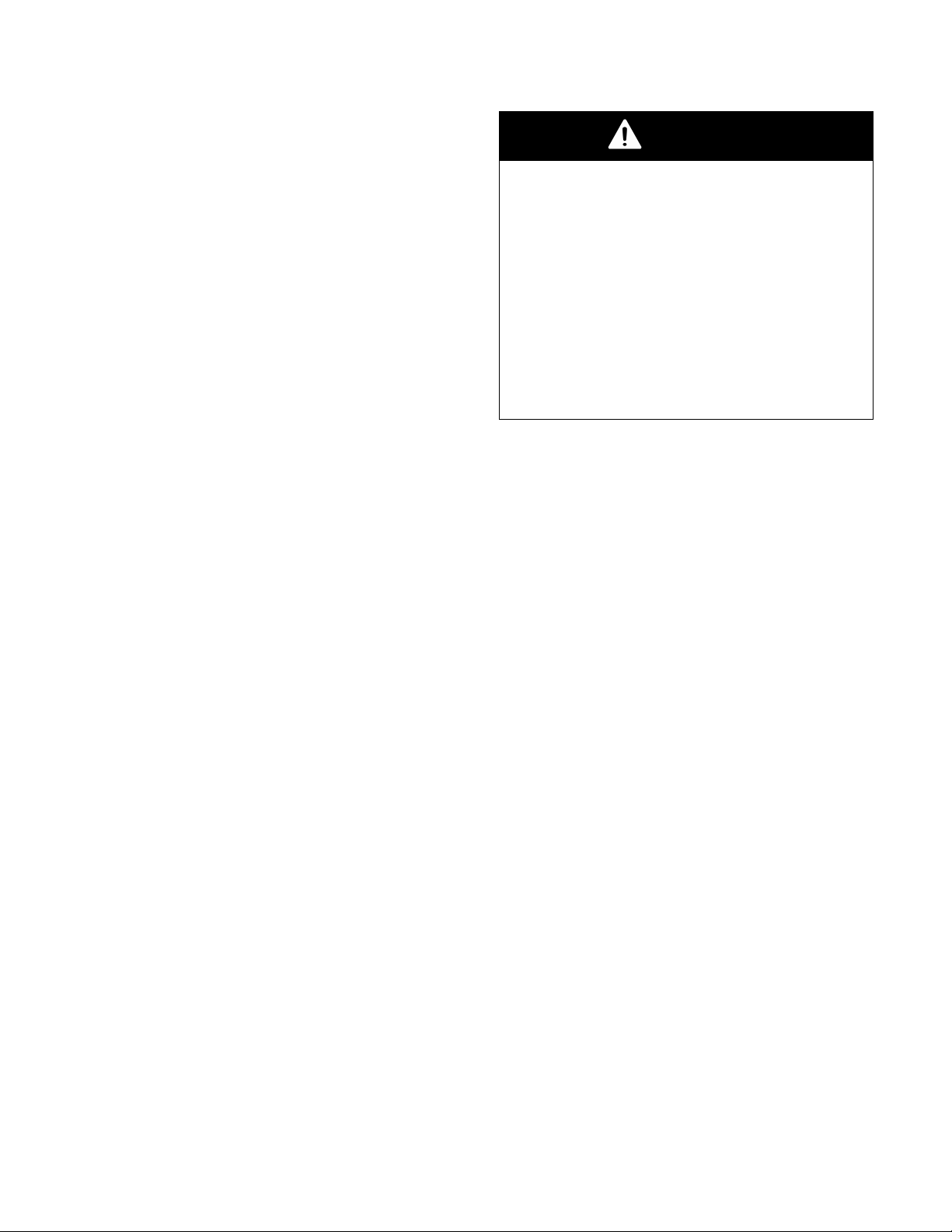

Figure 5: Heating & Air Conditioning with 4-speed motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

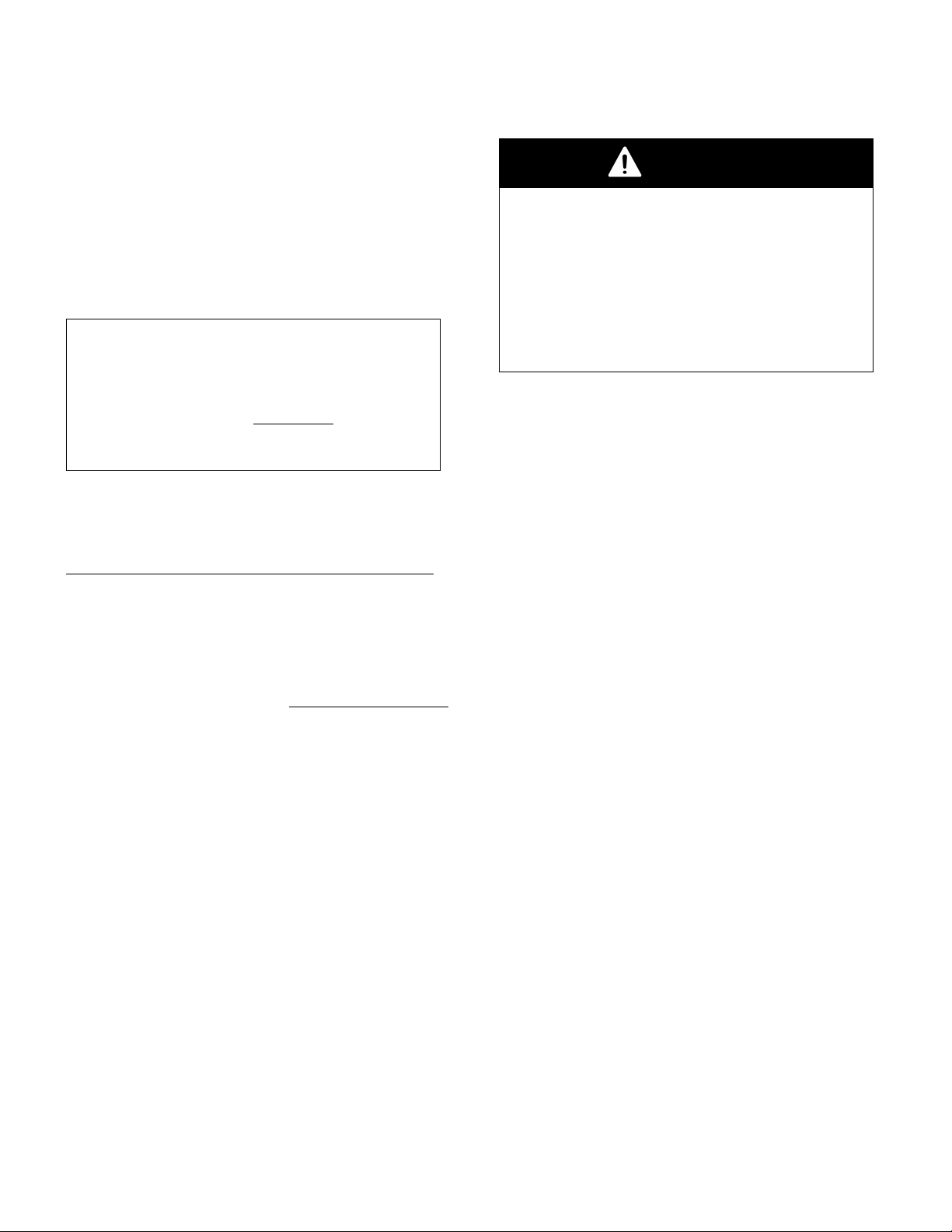

Figure 6: Thermostat wiring, heating and air conditioning with ECM variable speed motor . . . . . . . . . . 5

Figure 7: Thermostat wiring, heating and air conditioning/heat pump with ECM variable speed motor . . . . 5

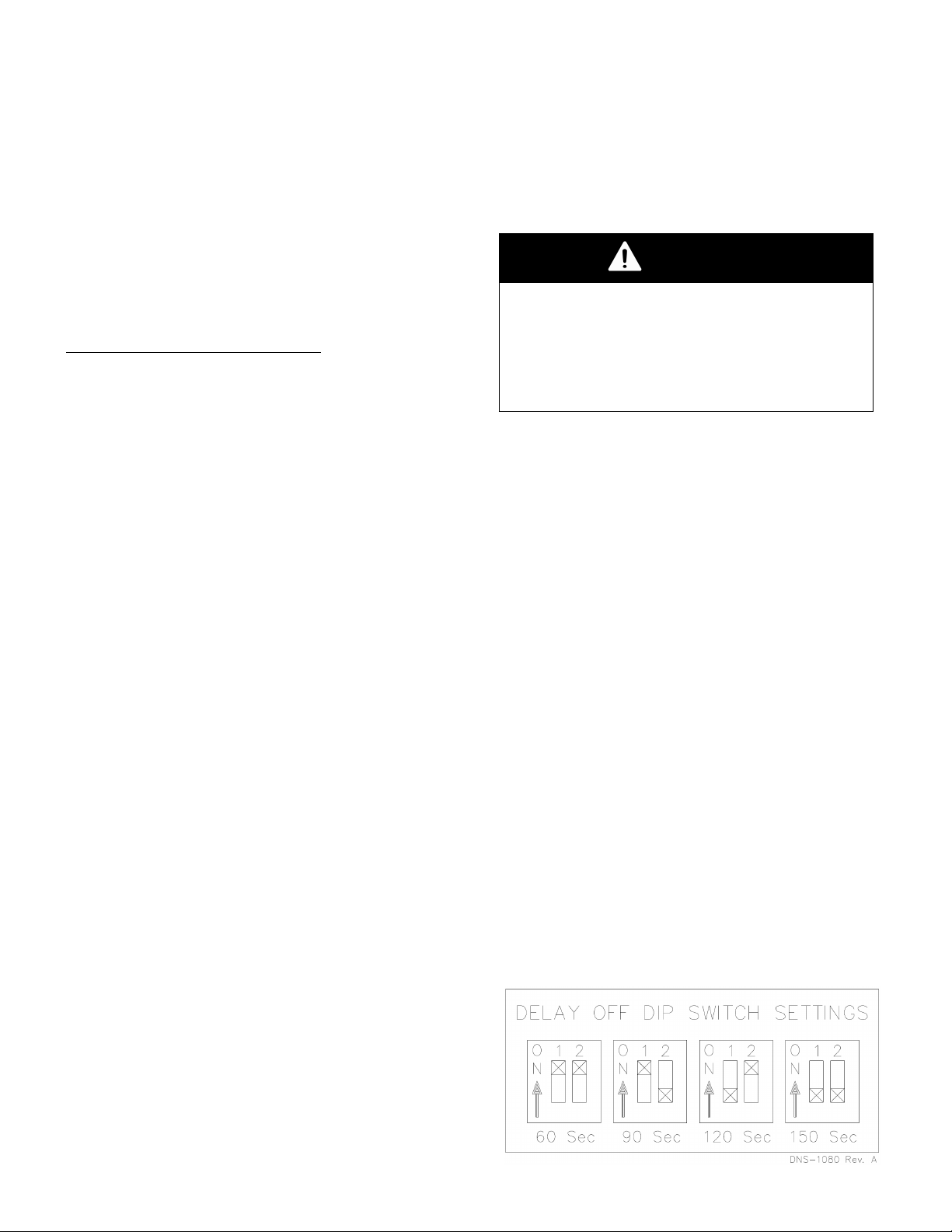

Figure 8: Blower “OFF” delay - Board #ST9103A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

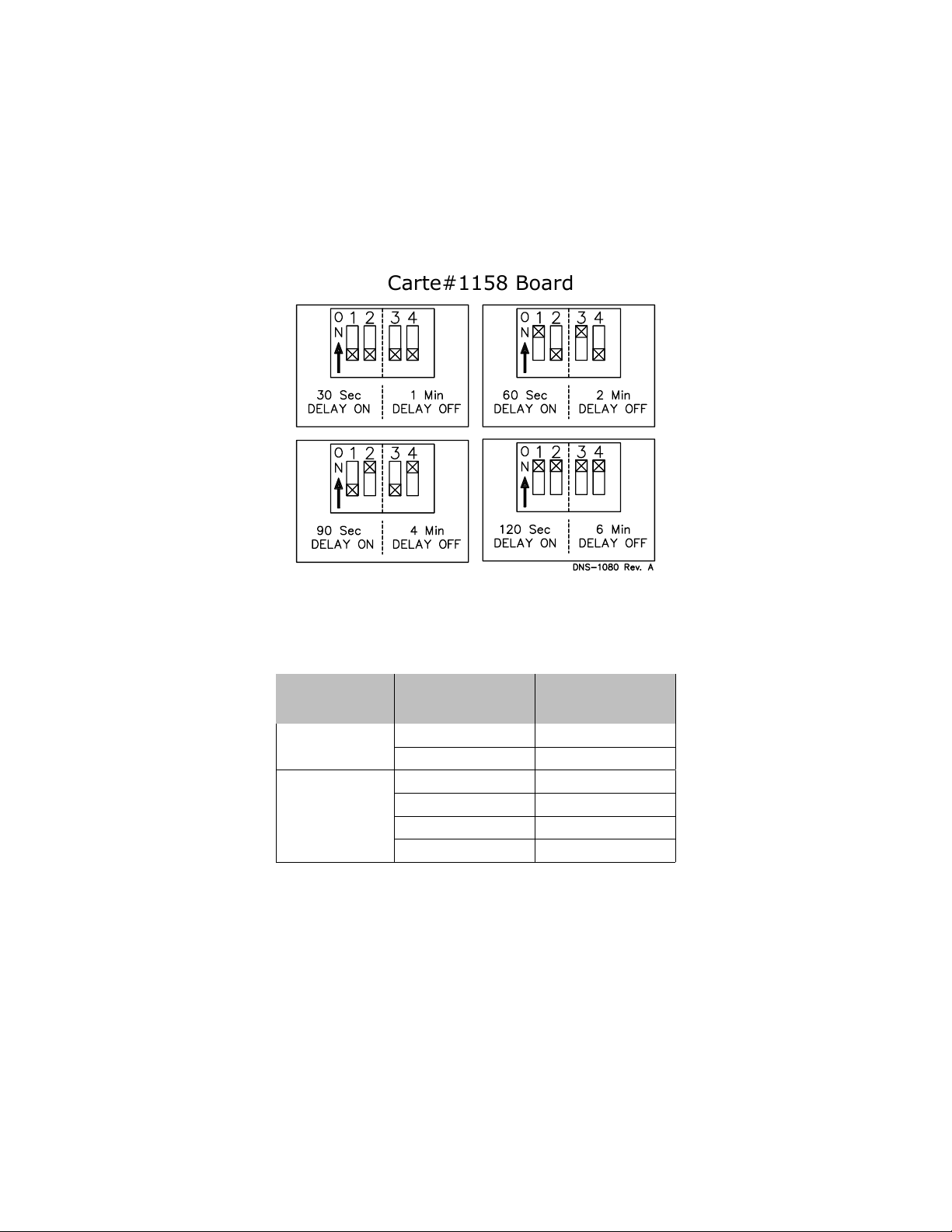

Figure 9: Blower Start/Stop Delays - Board#1158 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 10: Furnace Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 11: Wiring diagram 4-speed motor (PSC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 12: Wiring diagram variable speed motor (ECM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 13: Parts list with 4-speed motor (PSC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 14: Parts list with variable speed motor (ECM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2

Page 4

List of tables

Table 1: Blower speed adjustments, 4-speed motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 2: Airflow adjustments heating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 3: Airflow adjustments air conditioning mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 4: Airflow adjustments heating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 5: Delay adjustments heating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 6: Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 7: Airflow data, models with 1/2HP ECM motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 8: Airflow data model with 1/2 HP 4-speed motor (PSC) . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 9: Minimum clearances from combustible materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 10: Parts list with 4-speed moto (PSC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 11: Parts list with 4-speed moto (PSC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 12: Accessoires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3

Page 5

1 SAFETY

1.1 SAFETY LABELING AND WARNING SIGNS

The words DANGER, WARNING and CAUTION are

used to identify the levels of seriousness of certain hazards. It is important that you understand their meaning.

You will notice these words in the manual as follows:

a) It is the homeowner’s responsibility to engage a

qualified technician for the installation and subsequent servicing of this furnace;

b) Do not use this furnace if any part of it was under

water. Call a qualified service technician immediately to assess the damage and to replace all critical parts that were in contact with water;

c) Do not store gasoline or any other flammable sub-

stances, such as paper or carton, near the furnace;

d) Do not stack items or boxing within the required

clearances to combustible materials specified in Table 9;

DANGER

Immediate hazards which WILL result in death or

serious bodily and/or material damage.

WARNING

Hazards or unsafe practices which CAN result in

death or serious bodily and /or material damage.

CAUTION

Hazards or unsafe practices which CAN result in mi-

nor bodily and /or material damage.

1.2 IMPORTANT INFORMATION

WARNING

Non-observance of the safety regulations outlined in this manual will potentially lead to consequences resulting in death, serious bodily injury

and/or property damage.

WARNING

Installation and repairs performed by unqualified

persons can result in hazards to them and to others. Installations must conform to local codes or,

in the absence of such codes, to codes of the

country having jurisdiction.

The information contained in this manual is intended for use by a qualified technician, familiar

with safety procedures and who is equipped with

the proper tools and test instruments.

Failure to carefully read and follow all instructions

in this manual can result in death, bodily injury

and/or property damage.

e) This furnace is designed for use with #1 or #2 heat-

ing oil only. The use of gasoline, motor oil or any

other oil containing gasoline is prohibited;

f) Never block or otherwise obstruct the filter and/or

return air openings;

g) Ask the technician installing your furnace to show

and explain to you the following items:

i. The main disconnect switch or circuit breaker;

ii. The shutt off valve on the oil tank

iii. The oil filter and how to change it (it must be

changed once a year);

iv. The air filter and how to change it (check

monthly and clean or replace if necessary);

h) Before calling for service, be sure to have the in-

formation of section 5 of your manual close by in

order to be able to provide the contractor with the

required information, such as the model and serial

numbers of the furnace.

1.3 DETECTION SYSTEMS

It is recommended that carbon monoxide detectors be

installed wherever oil or gas fired heaters are used. Carbon monoxide can cause bodily harm or death. For this

reason, agency approved carbon monoxide detectors

should be installed in your residence and properly maintained to warn of dangerously high carbon monoxide

levels.

There are several sources of possible smoke and flames

in a residence. Smoke and flames can cause bodily harm

or death. For this reason, agency approved smoke detectors should be installed in your residence and properly

maintained, to warn early on, of a potentially dangerous

fire. Also, the house should be equipped with approved

and properly maintained fire extinguishers.

Your unit is equipped with safety devices that can prevent

it from functioning when anomalies are detected such as

a blocked venting system.

4

Page 6

1.4 DANGER OF FREEZING

2.1 POSITIONING THE FURNACE

CAUTION

If your furnace is shut down during the cold weather

season, water pipes may freeze, burst and cause serious water damage. Turn off the water supply and

bleed the pipes.

If the heater is left unattended during the cold weather

season, take the following precautions:

a) Close the main water valve in the house and purge

the pipes if possible. Open all the faucets in the

house;

b) Ask someone to frequently check the house during

the cold weather season to make sure that there is

sufficient heat to prevent the pipes from freezing.

Tell this person to call an emergency number if required.

2 INSTALLATION

This furnace is a true multi-position unit, in that it will

function in an upflow, downflow or horizontal configuration to the left or the right. Only a few modifications are

required during installation to change from one position

to another. The unit is shipped in the upflow configuration and instructions as to how to change to the other

positions are included in this manual.

The unit is shipped with a burner and its controls. It requires a 115VAC power supply to the control panel and

thermostat hook-up as shown on the wiring diagram, one

or more oil line connections, suitable ductwork and connection to a properly sized vent.

All local and national code requirements governing the

installation of oil burning equipment, wiring and the flue

connection MUST be followed. Some of the codes that

may apply are:

CSA B139: Installation code for oil burning equip-

ment;

ANSI/NFPA 31: Installation of oil burning equipment;

ANSI/NFPA 90B: Warm air heating and air conditioning

systems;

ANSI/NFPA 211: Chimneys, Fireplaces, Vents and

solid fuel burning appliances;

ANSI/NFPA 70: National Electrical Code;

CSA C22.1 : Canadian Electrical Code;

or CSA C22.10

Only the latest issues of these codes shall be used.

WARNING

FI RE AND EXPL OSI ON HA ZAR D

The furnace must be installed in a level position,

never where it will slope toward the front.

Do not store or use gasoline or any other

flammable substances near the furnace.

Non-observance of these instructions will potentially result in death, bodily injury and/or property

damage.

CAUTION

This furnace is not watertight and is not designed for

outdoor installation. It must be installed in such a manner as to protect its electrical components from water.

Outdoor installation will lead to a hazardous electrical

condition and to premature failure of the equipment.

The minimum clearances from combustible material

for each of the positions are specified in Table 9.

If the furnace is installed in a basement or on a dirt floor,

in a crawl space for example, it is recommended to install

the unit on a cement base 2.5 cm to 5.0 cm (1" to 2")

thick.

The unit must be installed in an area where the ambient

and return air temperatures are above 15°C (60°F). In

addition, the furnace should be installed as closely as

possible to the vent, so that the connections are direct

and kept to a minimum. The heater should also be located close to the centre of the air distribution system.

2.1.1 Installation in an enclosure

The unit can be installed in an enclosure such as a closet.

However, two ventilation openings are required for combustion air. The openings should be located in front of the

furnace approximately 15 cm (6") above the floor and 15

cm (6") below the ceiling. Figure 1 indicates the minimum

dimensions required and the location of the openings.

5

Page 7

Figure 1 – Location and dimensions of ventilation air

openings in a closet door

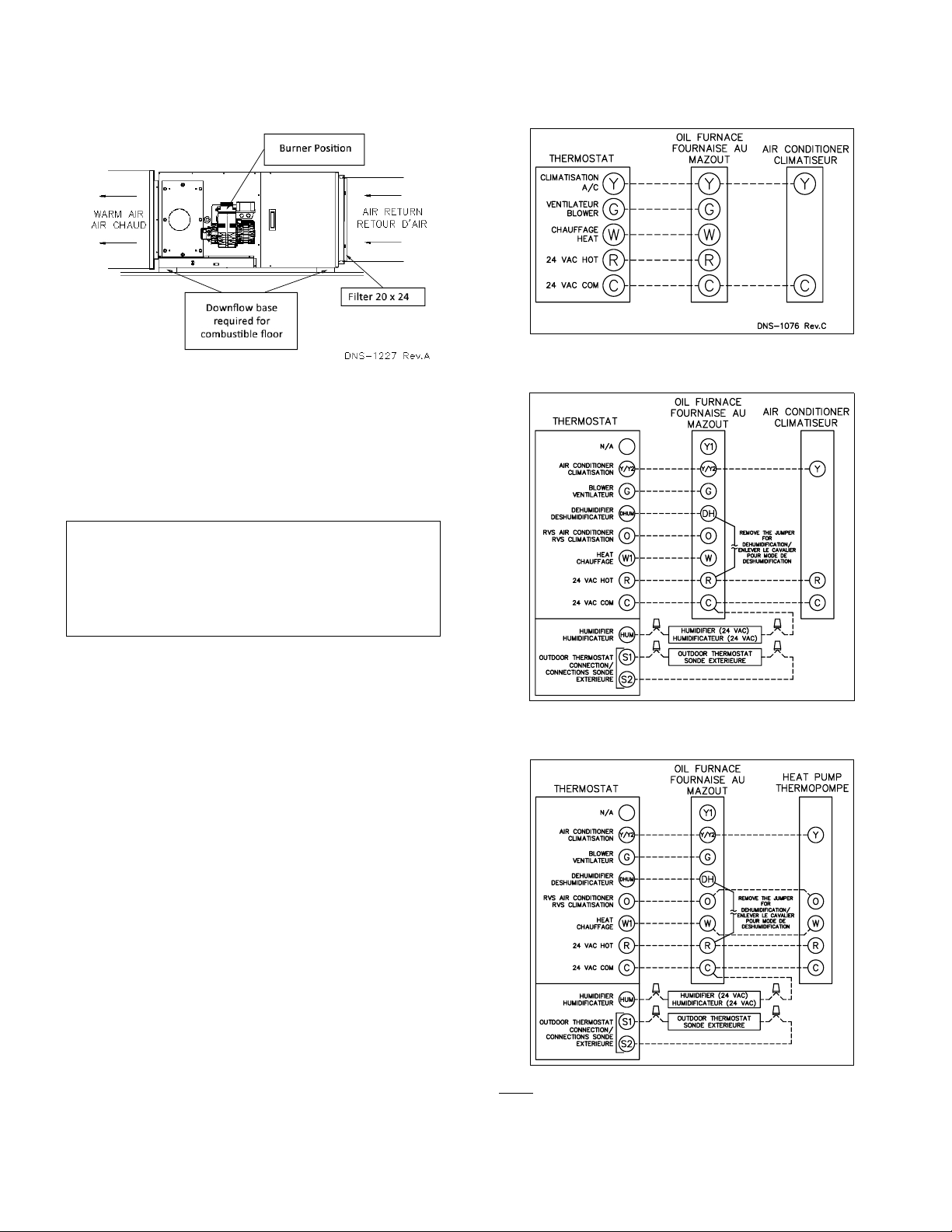

2.2.2 Downflow Installation

When the furnace is installed in the downflow position on

a combustible floor, the clearances from combustibles

must be adhered to. The downflow base DFB-102 or

KLASB0801DET can be used to ensure these clearances. Refer to Figure 3 and the installation instructions

provided with the base.

In cases where the return air enters through the floor,

the floor return base FRB-101 or KLARB0101DET must

be used.

The burner must always be installed in the same manner,

regardless of the discharge position of the furnace. Refer

to Figure 3 for additional details.

The protection plate (B03789) must be installed on

the plastic cover of the Beckett NX burner to protect

it from vent. ONLY the AMP098 in downflow position

requires the protection plate provided with the unit.

Figure 3 – Downflow Installation

2.2 CONFIGURATIONS

2.2.1 Upflow installation

The return air opening may be located on either side of

the furnace. Care should be taken not to damage the

wires inside, while cutting the opening. Install the filter

rack supplied with the unit according to the instructions

provided with it. It is also recommended to install the

blower door before handling or moving the unit. Refer to

Figure 2 for additional details.

Figure 2 – Upflow Installation

2.2.3 Horizontal Installation

When the furnace is installed in the horizontal position,

either suspended or on a combustible floor with a

choice of right or left discharge, the clearances from

combustible material must be adhered to. If the unit is

installed on a combustible floor, the horizontal floor base

HFB-101 or KLASB0701DET can be used to ensure

these clearances. Refer to the instructions supplied with

the base.

In cases where the return air enters through the floor,

the floor return base FRB-101 or KLARB0101DET can

be installed as per the supplied instructions.

The burner must always be installed in the same manner,

regardless of the discharge position of the furnace. Refer

to Figure 4 for additional details.

6

Page 8

Figure 4 – Horizontal Installation

2.3 ELECTRICAL SYSTEM

Figure 5 – Heating & Air Conditioning with 4-speed

motor

Figure 6 – Thermostat wiring, heating and air conditioning with ECM variable speed motor

CAUTION

The exterior of the unit must have an uninterrupted

ground to minimize the risk of bodily harm, if ever an

electrical problem develops. A green ground screw is

supplied with the control box for that purpose.

The appliance must be installed in accordance with the

current ANSI/NFPA 70 National Electrical Code, CSA

C22.1 Canadian Electrical Code Part 1 and/or local

codes.

The control system depends on the correct polarity of the

power supply. Connect “HOT” wire (H) and “NEUTRAL”

wire (N) as shown in figures 11 and 12.

A separate line voltage supply should be used, with fused

disconnect switch or circuit breaker, between the main

power panel and the unit.

Only copper wire may be used for the 115V circuit on this

unit. If wires need to be changed, the replacements must

have the same temperature resistance as the originals.

2.4 INSTALLATION OF THE

Figure 7 – Thermostat wiring, heating and air conditioning/heat pump with ECM variable speed motor

THERMOSTAT

A thermostat must be installed to control the temperature

of the area to be heated. Follow the instructions supplied

with the thermostat. Also refer to the wiring diagrams

provided with the heating/air conditioning unit. The connections must be made as indicated on the following diagrams and the wiring diagrams, Figure 11 and Figure

12.

Note: On units with 2-stage cooling or heat pump,

terminal Y1 must be used. When Y1 on the electronic

control receives a 24 VAC signal, the airflow is reduced by 20%. Do not use termninal Y1 with a single

stage cooling or heat pump.

7

Page 9

2.5 INSTALLATION OF THE

BURNER

2.6 VENTING

Refer to the burner manufacturer’s instructions. Also,

the burner must be installed always in the same way

independently of the furnace orientation.

1. Position the mounting gasket between the mounting flange and the burner mounting plate. Align the

holes in the burner mounting plate with the studs

on the mounting flange and bolt securely in place.

2. Remove the burner drawer assembly or the air tube

assembly;

3. Install the nozzle (refer to Technical Specifications

in Table 6);

4. Check the electrode settings;

5. Make the electrical connections;

6. Complete oil line connections.

2.5.1 Nozzles

WARNING

PO ISONO US CARBO N M ONOX IDE GAS, FIR E A ND EX-

PL OSION HA ZARD.

Read and follow all instructions in this section.

Never install a hand operated damper in the vent

pipe. However, any Underwriters Laboratories

listed, electrically operated automatic type vent

damper may be installed if desired. Be sure to

follow the instructions provided with vent damper.

Also, read and follow all instructions in this section of the manual.

Failure to properly vent this furnace or other appliances can result in death, bodily injury and/or

property damage.

To ensure the safe and proper functioning of an oil

furnace, it must always be connected to a flue with sufficient draft or to an approved side-wall venting system.

In addition, it is strongly recommended to perform a

complete inspection of all the existing venting systems.

2.6.1 Masonry chimney

The burner comes equipped with an appropriate nozzle.

However, if another size or a replacement nozzle is

required, use the manufacturer’s recommended spray

angle and type as shown in Table 6 and based on a

pump pressure of 100 psi.

Always select nozzle sizes by working back from the

desired flow rate at operating pressure and not the

nozzle marking.

2.5.2 Air and Turbulator Settings

Before starting the burner for the first time, adjust the

air and turbulator settings to those listed in this manual

(Table 6). Once the burner becomes operational, final

adjustments will be required. Refer to the section 3 of

this manual.

2.5.3 Post purge delay adjustment

The post purge delay on the oil-fired burners is factory

set to zero second. This delay is applicable for all installations with chimney venting. For heating units installed

with side wall venting and a burner equipped with this feature, the post purge delay must be set to 15 seconds. No

delay is required for Riello burners. Refer to the burner

control instruction manual and markings for proper adjustment of the post purge delay.

This furnace can be vented into an existing masonry

chimney. However, the unit must not be vented into a

chimney into which a solid fuel burning furnace is already

being vented.

Before venting this furnace into a chimney, its condition

must be checked and repairs made, if necessary. Also,

the chimney lining and dimensions must conform to local

and national codes.

2.6.2 Factory-built chimneys

Oil fired furnaces are approved for use with “L” type

vents. The unit may also be used with an approved

chimney of proper dimensions and temperature ratings

as specified in the installation code. Refer to chimney

manufacturer’s instructions for proper installation.

2.6.3 Draft regulator

It is recommended that a draft regulator be installed in

cases where the draft is either high or variable due to

external conditions. Follow the instructions provided with

the regulator.

2.6.4 Side wall venting

The heating unit is approved for side-wall venting.

This system includes model VTK-54 / VTK-098 /

8

Page 10

KLAVT0101DET side-wall venter and a 4” insulated vent

pipe, model IFV-410 / IFV098-10 / KLAFV0101DET, IFV420 / IFV098-20 / KLAFV0201DET. Refer to the installation instructions provided with the venting system.

2.7 BLOCKED VENT SHUT-OFF DEVICE (BVSO) FOR CHIMNEY VENTING

CAUTION

It is imperative that this device be installed by a qualified service technician.

A positive pressure venting system (Sealed Combustion System or Direct Vent) MUST NOT use the BVSO.

Follow the instructions supplied with the venting system.

This device is designed to detect the insufficient evacuation of combustion gases in the

event of a vent blockage. In such a case the

thermal switch will shut down the oil burner.

The device will then need to be re-armed MANUALLY.

Refer to the detailed instructions and wiring diagrams

supplied with the BVSO for the installation and wiring

procedures. The length of wires supplied with the unit

is such that the safety device must be installed between

the flue outlet of the appliance and the draft regulator, as

indicated in the instructions.

It is also essential that the BVSO be maintained annually.

For more details refer to the instructions supplied with

the device itself, as well as in section 4 of this Manual.

2.8 COMBUSTION AIR SUPPLY AND VENTILATION

WARNING

PO ISONO US CAR BO N MONOX IDE GA S HAZARD.

Comply with NFPA 31 (U.S.) and CSA B139

(Canada) standards for the installation of Oil Burning Equipment and applicable provisions of local

building codes to provide combustion and ventilation air.

Failure to provide adequate combustion and ventilation air can result in death, bodily injury and/or

property damage.

Oil furnaces must have an adequate supply of combustion air. It is common practice to assume that older

homes have sufficient infiltration to accommodate the

combustion air requirement for the furnace. However,

home improvements such as new windows, doors, and

weather stripping have drastically reduced the volume of

air infiltration into the home.

Refer to oil furnace installation codes relative to combustion and ventilation air requirements. Consult Section

2.1.1 in this manual, specifically for units installed in an

enclosed space.

Home air exhausters are common. Bathroom and

kitchen fans, power vented clothes dryers and water

heaters all tend to create a negative pressure condition in

the home. Should this occur the chimney becomes less

and less effective and can easily downdraft. In certain

cases, mechanically supplied air, by way of a blower, interlocked with the unit, is necessary. It is the installer’s

responsibility to check that.

2.7.1 BVSO Functional Test

The purpose of the following test is only to check that the

electrical outlet on the furnace, designated to the BVSO,

is functional only.

1. Start up the burner;

2. Remove the three-pole plug from the BVSO outlet

on the furnace;

3. The burner must shut-off immediately, while the

blower continues to run to the end of the cool-down

cycle.

If the test is not in line with the above, call a QUALIFIED

SERVICE TECHNICIAN.

9

Page 11

2.8.1 Contaminated Combustion Air

Installations in certain areas or types of structures will increase the exposure to chemicals or halogens that may

harm the furnace. These conditions will require that only

outside air be used for combustion.

The following areas or types of structures may contain or

be exposed to certain substances, potentially requiring

outside air for combustion:

1. Commercial buildings;

2. Buildings with indoor pools;

3. Furnaces installed near chemical storage areas.

Exposure to the following substances:

a) Permanent wave chemicals for hair;

b) Chlorinated waxes and cleaners;

requires a two stage pump and a rise greater than 4.9 m

(16’) an auxiliary pump. Follow the pump instructions to

determine the size of pipe needed in relation to the rise

or to the horizontal distance.

2.9 DUCTING

WARNING

PO ISONO US CAR BO N MONOX IDE GA S HAZARD.

DO NOT draw return air from inside a closet or utility room. Return air MUST be sealed to the furnace

casing.

Failure to properly seal ducts can result in death,

bodily injury and/or property damage.

c) Chlorine based swimming pool chemicals;

d) Water softening chemicals;

e) De-icing salts or chemicals;

f) Carbon Tetrachloride;

g) Halogen type refrigerants;

h) Cleaning solvents (such as perchloroethylene);

i) Printing inks, paint removers, varnishes, etc. ;

j) Hydrochloric acid;

k) Solvent based glue;

l) Antistatic fabric softeners for clothes dryers;

m) Acid based masonry cleaning materials.

2.8.2 Burner with Outdoor Combustion Air Kit

Some burners are designed to function with combustion

air taken directly from the outside. Follow the instructions

provided with the burner, the fresh-air supply kit or the

side-wall venting kit.

Check your local codes for the installation of the oil tank

and accessories.

At the beginning of each heating season or once a year,

check the complete oil distribution system for leaks.

Ensure that the tank is full of clean oil. Use No.1 or No.2

Heating Oil (ASTM D396 U.S.) or in Canada, use No.1

or No.2 Furnace Oil.

A manual shut-off valve and an oil filter shall be installed

in sequence from tank to burner. Be sure that the oil

line is clean before connecting to the burner. The oil line

should be protected to eliminate any possible damage.

Installations where the oil tank is below the burner level

must employ a two-pipe fuel supply system with an

appropriate fuel pump. A rise of 2.4 m (8’) and more

The ducting must be designed and installed according to

approved methods, local and national codes as well as

good trade practices.

When ducting supplies air to a space other than where

the furnace is located, the return air must be sealed

and also be directed to the space other than where the

furnace is located.

2.9.1 Air filter

A properly sized air filter must be installed on the return

air side of the unit. Refer to the Technical Specifications

in Table 6, for the correct dimensions. Also refer to Section 2.2 and the instructions supplied with the filter.

2.10 SUPPLY AIR ADJUSTMENTS (4 SPEED MOTORS)

On units equipped with 4-speed blower motors, the

supply air must be adjusted based on heating/air conditioning output and the static pressure of the duct

system. For the desired air flow refer to Table 1 as well

as the table 8 based on static pressure in the Technical

Specifications section of this manual.

Figure 8 – Blower “OFF” delay - Board #ST9103A

10

Page 12

To effect the adjustment, the RED (for heating) and

Carte#1158 Board

BLUE (for cooling and heat pump) wires can be changed

on the motor. Also, refer to the position of the wires on

the electronic board of the unit and consult the wiring

diagrams. If the heating and air conditioning speeds are

the same, the RED wire must be moved to “UNUSED

LEADS” on the electronic board and the jumper provided

with the BLUE wire must be used between the “HEAT”

Figure 9 – Blower Start/Stop Delays - Board#1158

and “COOL” terminals.

The blower start/stop delays can be adjusted by positioning the DIP switches on the electronic board as

shown in the following figures. For upflow installation,

the recommended blower ON delay is 60 seconds and

blower OFF delay 2 minutes.

Table 1 – Blower speed adjustments, 4-speed motor

FURNACE

APPLICATION

HEATING

A/C

HEATING OR A/C

OUTPUT

0.68 USGPH MED-LOW

0.80 USGPH MED-HIGH

2.0 TONS LOW

2.5 TONS MED-LOW

3.0 TONS MED-HIGH

3.5 TONS HIGH

RECOMMENDED

BLOWER SPEED

11

Page 13

2.11 SUPPLY AIR ADJUSTMENTS (ECM VARIABLE SPEED MOTORS)

On units equipped with ECM variable speed blower motors, the air supply must be adjusted based on heating/air

conditioning output. The start/stop delays of the blower

must also be adjusted by positioning the DIP switches on

the electronic board.

Refer to the following tables, airflow tables and the wiring

diagram in this manual for the proper settings:

Table 2 – Airflow adjustments heating mode

SW1-HEAT

DIP Switch Positions

1 2 POSITION

OFF OFF A

ON OFF B

OFF ON C*

ON ON D*

*Alternate adjustments for both input rate (refer to air

flow tables)

Table 4 – Airflow adjustments heating mode

SW3-ADJ (Adjustment)

DIP Switch Positions

1 2 POSITION

OFF OFF A

ON OFF B

OFF ON C

ON ON D

CFM HT G. CFM A/G.

% Increase % Increase

or decrease or decrease

0% 0%

10% 10%

-10% -10%

N/A 0%

INPUT

USGPH

0.63

0.80

0.68

0.80

Table 3 – Airflow adjustments air conditioning

mode

SW2-COOL

DIP Switch Positions

1 2 POSITION

OFF OFF A

ON OFF B

OFF ON C

ON ON D

Table 5 – Delay adjustments heating mode

SW4-Delay

DIP Switch Positions

1 2 POSITION

OFF OFF A

ON OFF B

OFF ON C

ON ON D

INPUT

USGPH

3.5

3.0

2.5

2.0

INPUT

USGPH

0.68

0.80

ALL

ALL

2.12 INSTALLATION OF ACCESSORIES

WARNING

EL ECTRI CAL SHOC K HAZA RD.

Turn OFF electrical power at the fuse box or service panel before making any electrical connections and ensure a proper ground connection is

made before connecting line voltage.

Failure to do so can result in death or bodily injury.

2.12.1 Humidifier (HUM)

The electronic board supplies 120 VAC for a humidifier

on the HUM terminal. It supplies 120 VAC electric power

when the burner is in operation.

A 24 VAC signal can also be supplied from the W and

C terminals on the blower electronic board to activate a

switching relay.

Also refer to the instructions supplied with the accessory.

2.12.2 Electronic Air Cleaner (EAC)

The EAC terminal on the electronic board supplies 120

VAC when the blower is operating in the heating or air

conditioning mode. This signal can be used to activate an

electronic air cleaner that is not equipped with an air flow

switch. If the cleaner is equipped with an air flow switch,

the S terminal on the PSC electronic board or one of the

120 VAC terminals on the ECM electronic board can be

used to provide a constant supply of 120 VAC.

Also refer to the instructions supplied with the accessory.

12

Page 14

2.12.3 Air Conditioner (or Heat Pump)

An air conditioning coil may be installed on the supply air

side ONLY.

Before starting up the unit, be sure to check that

the following items are in compliance:

1) The electrical installation, the oil supply system, the

venting system, combustion air supply and ventilation;

WARNING

PO ISONO US CAR BO N MONOX IDE GA S HAZARD.

Install the evaporator coil on the supply side of the

furnace ducting ONLY.

An evaporator coil installed on the return air side

of the ducting can cause condensation to form

inside the heat exchanger, resulting in heat exchanger failure. This in turn, can result in death,

bodily injury and/or property damage.

A clearance of 15 cm (6") is required between the bottom

of the coil drain pan and the top of the heat exchanger.

If a heat pump is installed, a “dual-energy” thermostat,

or other control is required, in order to prevent the simultaneous operation of the furnace and the heat pump. It

also prevents a direct transition from heating by way of

the heat pump to heating with oil. Refer to the thermostat instructions or those of another control used for the

proper wiring.

If a coil blower compartment is used, install air tight, motorized and automatic air dampers. Cold air coming from

the coil and passing across the furnace can cause condensation and shorten the life of the heat exchanger.

2) The blower access door is in place and the blower

rail locking screws are well tightened;

3) The Blocked Vent Shut-Off (BVSO) is installed according to instructions (for chimney venting);

4) The oil supply valve is open;

5) The burner ‘’Reset” button is well pushed in or rearmed;

6) The preliminary air adjustments on the burner comply with the technical specifications in this manual;

7) The blower speed adjustments for heating and air

conditioning are appropriate and according to the

specifications in this manual;

8) The blower start/stop delays are satisfactory;

9) The thermostat of the room is in the heating mode

and is set higher than the ambient temperature.

To start the unit, turn the main electrical switch on.

3.2 OPERATING SEQUENCE OIL

2.12.4 Emergency Heating Mode - variable speed Motor (ECM)

If the ECM blower motor is defect and that no spare are

available right away, you can temporarily replace it with a

conventional fractional PSC blower motor. Connect neutral wire to neutral terminal on the control panel of the

machine and the hot line to the EAC terminal. This one

is working as long as heating or cooling is requested, and

the blower will work until a new ECM motor is installed.

CAUTION

We recommend to use this mode only for a short period of time since it affects the efficiency of the unit and

the user comfort..

3 OPERATION

3.1 START-UP

CAUTION

DO NOT START THE BURNER UNLESS THE

BLOWER ACCESS DOOR IS SECURED IN PLACE.

HEATING MODE

1) The W-R contact closes;

2) The burner motor starts up to pre-purge the combustion chamber for a period of 10 to 15 seconds.

During that time a spark is established on the electrodes;

3) The solenoid valve opens and a flame is established. Shortly after, the electrodes cease to spark;

4) Then the blower runs up to full speed. The delay

depends on the adjustments that were made on the

electronic board, which controls the blower motor.

Refer to Sections 2.10 and 2.11 above as well as to

the airflow tables 7 and 8 for more details.

5) When the call for heat is satisfied, the solenoid

valve closes, the flame goes out and the burner motor stops (after post purge delay, if applicable).

6) The blower stops shortly after the burner. The delay depends on the adjustments that were made on

the electronic board that controls the blower. Refer

to Sections 2.10 and 2.11 above as well as to the

airflow table 7 and 8 for more details.

Note: A detailed operating sequence of the oil burner is

outlined in the instructions provided with the burner.

13

Page 15

3.3 CHECKS AND ADJUSTMENTS

3.3.1 Purging the oil line

Open the bleed port screw and start the burner. Allow

the oil to drain into a container for at least 10 seconds.

The oil should flow absolutely free of white streaks or

air bubbles to indicate that no air is being drawn into the

suction side of the oil piping and pump. Slowly close and

tighten the bleed screw. Once closed, the flame will light

up.

3.3.2 Pressure adjustment

The oil pressure must be adjusted according to the Technical Specifications of this manual. An adjustment screw

and a connection for a pressure gauge are located on

the oil pump for that purpose. Also refer to the burner

instruction manual.

5. the burner air setting to obtain a CO2 reading 1.5%

lower (or a O2 reading 2.0% higher) than the reading associated with the “trace” of smoke. Example:

12.3% of CO2 or 4.5% of O2;

6. This method of adjusting the burner will result

in clean combustion (Bacharach smoke scale between 0 and a trace) and ensure the proper functioning of the system. The optimum CO2 level is

around 12% to 13% (or 3.5% to 5.0% of O2).

3.3.4 Draft Regulator adjustment

On chimney installations only, a barometric draft regulator (supplied with the furnace) must be installed, in order

to ensure proper draft through the furnace. The barometric damper must be mounted with the hinge pins in

a horizontal position and the face of the damper vertical

for proper functioning (see instructions included with the

damper.) After the furnace has been firing for at least

five minutes, the draft regulator should be set to between

-0.025" and -0.060" W.C.

3.3.3 Combustion Check

IMPORTANT

The heat exchanger metal surfaces may have oil and

the baffle insulation also contains binders. These

products will burn or evaporate when the unit operates for the first time. Because of this, the smoke

reading may be inexact during the first minutes of

operation. Therefore, the unit must operate during

at least 60 minutes before taking any readings to adjust the combustion quality. Let the unit cool down before making any adjustments.

IMPORTANT

The combustion check verification MUST be performed after the nozzle replacement or the burner

cleaning. After these manipulations, the combustion

parameters are necessarily modified. Refer also to the

burner instruction manual.

1. Drill a test hole in the flue pipe, approximately 18

inches from the furnace breech. Insert the smoke

test probe into the hole. For installation using a

sidewall venting, use the orifice provided on the

breech plate;

2. From a cold start, let the unit operate for about 5

minutes;

3.3.5 Overfire pressure test

The overfire draft that is taken through the observation

port, located above the burner, is a measurement necessary to determine if there is a blockage in the heat exchanger or the flue pipe. Refer to the Technical Specifications in this manual for overfire pressure values. A high

pressure condition may be caused by excessive combustion air, due to the air band being too wide open, or a

lack of flue draft (chimney effect) or some other blockage, such as soot in the secondary section of the heat

exchanger or the use of an oversize nozzle input or high

pressure pump.

3.3.6 Vent Temperature Test

1. After having adjusted the burner combustion, insert

a thermometer into the test hole in the breech pipe;

2. The total vent temperature should be between 204

and 302°C (400 and 575°F). If not, check for improper air temperature rise, pump pressure, nozzle

size or a badly sooted heat exchanger.

CAUTION

Low flue gas temperature increases the risk of condensation. Adjust the total temperature at or higher

then 204°C (400°F) in order for the heat exchanger

warranty to remain in force.

3. Set the burner air setting until you have between 0

and 1 on the Bacharach Scale (or a “trace”);

4. Take a CO2 sample at the same test location where

the #1 smoke reading was taken and make note of

it. Example: 13.8% of CO2 or 2.5% of O2;

3.3.7 Supply Air Temperature Rise Test

1. Operate the burner for at least 10 minutes;

2. Measure the air temperature in the return air

plenum;

14

Page 16

3. Measure the air temperature in the largest trunk

coming off the supply air plenum, just outside the

range of radiant heat from the heat exchanger. 0.3

m (12") from the plenum of the main take-off is usually sufficient;

4 MAINTENANCE

4. The temperature rise is calculated by subtracting

the return air temperature from the supply air temperature;

5. If the temperature rise is lower or exceeds the temperature specified in Table 6, change to the next

lower or higher blower speed tap, until the temperature rise falls to the target. If the excessive temperature rise cannot be increased or reduced by

changing fan speed, investigate for ductwork obstructions, dirty or improper air filter, improper firing

caused by improper pump pressure or nozzle sizing.

3.3.8 Limit control check

After operating the furnace for at least 15 minutes, restrict the return air supply by blocking the filters or the

return air register and allow the furnace to shut off on

High Limit. The burner will shut off but the blower will

continue to run.

Remove the obstruction and the burner should restart

after a few minutes. The time required for the restart also

depends on the adjustment of the blower “OFF” delay.

WARNING

EL ECTRI CAL SHOC K HAZA RD.

Turn OFF power and fuel to the furnace before any

disassembly or servicing.

Failure to do so can result in death, bodily injury

and/or property damage.

Preventive maintenance is the best way to avoid unnecessary expense and inconvenience. Have your heating

system and burner inspected by a qualified service technician at regular intervals and after extended periods of

shutdown.

To maintain the reliability and optimal performance of the

furnace, have a complete combustion check done after

the annual maintenance call. Do not attempt to repair the

furnace or its controls. Call a qualified service technician.

ALWAYS KEEP THE OIL SUPPLY VALVE SHUT OFF IF

THE BURNER IS SHUT DOWN FOR AN EXTENDED

PERIOD OF TIME.

Before calling for repair service check the following

points:

1. Check the oil tank gauge and make sure that the

valve is open;

2. Check fuses and the circuit breaker;

3.3.9 Restart after Burner Failure

1. Set the thermostat lower than room temperature;

2. Press the reset button on the burner primary control

(relay);

3. Set the thermostat higher than room temperature;

4. If the burner motor does not start or ignition fails,

turn off the disconnect switch and CALL A QUALIFIED SERVICE TECHNICIAN.

CAUTION

Do not attempt to start the burner when excess oil

has accumulated, when the furnace is full of vapour or

when the combustion chamber is hot.

3. Check if the main disconnect switch is ON ;

4. Set the thermostat above room temperature;

5. If ignition does not occur, turn off the disconnect

switch and call a qualified service technician.

When ordering replacement parts, please specify the

complete furnace model number and serial number.

4.1 CLEANING THE HEAT EXCHANGER

It is not generally necessary to clean the heat exchanger

or flue pipe every year, but it is advisable to have the

oil burner service technician check the unit before each

heating season to determine whether the cleaning or replacement of parts is necessary.

If a cleaning is necessary, the following steps should be

performed:

1. Turn OFF all utilities upstream from the furnace;

15

Page 17

2. Disconnect the flue pipe;

3. Remove the flue collar panel located at the front of

the furnace;

4. Remove the heat exchanger baffles;

5. Disconnect the oil line and remove the oil burner;

6. Clean the secondary tubes and the primary cylinder with a stiff brush and a vacuum cleaner;

7. Before re-assembling the unit, the heat exchanger

and combustion chamber should be inspected to

determine if replacement is required;

8. After the cleaning, replace the heat exchanger baffles, flue collar plate and oil burner;

9. Readjust the burner for proper operation.

4.2 CLEANING THE BLOCKED

6. Clean and remove any build-up or obstruction inside the heat transfer tube;

7. Re-mount, lock and fasten the control box with the

2 screws removed in step 4;

8. Re-attach the assembly cover with the screws removed in step 2;

9. Re-establish power to the unit.

4.3 CLEANING THE BURNER HEAD

Once a year, remove the retention head and electrodes

from the drawer assembly and remove all foreign matter,

if necessary. Also clean the extremity of the burner tube,

if necessary.

VENT SHUT-OFF DEVICE

(BVSO)

For continuous safe operation, the Blocked Vent Shut-off

device (BVSO) must be inspected and maintained annually by a qualified service technician.

1. Disconnect power to the appliance;

2. Remove the two screws holding on the BVSO assembly cover;

3. Remove the cover;

4. Remove the two screws holding the control box to

the heat transfer tube assembly. Sliding the control

box in the appropriate direction will unlock it from

the heat transfer tube assembly;

5. Carefully remove any build-up from the thermal

switch surface;

CAUTION

Do not dent or scratch the surface of the thermal

switch. If the thermal switch is damaged it MUST

be replaced.

4.4 REPLACING THE NOZZLE

Change the nozzle once a year with the one specified in

Table 6.

4.5 REPLACING THE OIL FILTER

Tank Filter

The tank filter should be changed as required. Follow the

manufacturer’s instructions.

Secondary Filter

The 10 micron, or finer, filter cartridge should be changed

annually. Follow the manufacturer’s instructions.

4.6 CHANGING THE AIR FILTER

Dirty filters have an impact on the efficiency of the furnace and increase fuel consumption.

Air filters should be changed at least once a year. Very

dusty conditions, the presence of animal hair and the like

will require more frequent changing or cleaning.

16

Page 18

5 FURNACE INFORMATION

Model: . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . Serial number: . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . .

Furnace installation date: . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . .

Service telephone # - Day: . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . Night: . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .

Dealer name and address: . . . . . . . . . . . . . . . . .. . . . . . . . . . . . .

. . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . .

START-UP RESULTS

Nozzle: . . . . . .. . Pressure: . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . lb/po2

Burner adjustments: Primary air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . .

Fine air . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . .

Drawer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . .

% CO2: . . . . . . . . Smoke scale: . . .. . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . (Bacharach)

Gross stack temperature: . . .. . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . °F

Ambient temperature: . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . °F

Chimney draft: . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . .” W.C.

Overfire draft: . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . .” W.C.

Test performed by: . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . .

17

Page 19

6 TECHNICAL SPECIFICATIONS

Table 6 – Technical specifications

112 Series, multi-position models UNITS WITH 1/2 HP 4-SP. MOTOR UNITS WITH 1/2 HP ECM MOTOR

RATING AND PERFORMANCE

Firing rate(USGPH)* 0.68 0.80 0.68 0.80

Input (BTU/h)* 95,200 112,000 95,200 112,000

Maximum Heating capacity, (BTU/h)* 81,000 94,000 81,000 94,000

Heating temperature rise (Degr. F)* 55 - 75 Degr. F 60 - 72 Degr. F

Flue draft with chimney (inch of w.c.) -0.06 to -0.025 -0.06 to -0.025

Overfire pressure with chimney (inch of w.c.) -0.035 to +0.025 -0.035 to +0.025

Flue pressure with direct vent (inch of w.c. - no wind) +0.03 to +0.15 +0.03 to +0.15

Overfire pressure with direct vent (inch of w.c. - no wind) +0.05 to +0.17 +0.05 to +0.17

BECKETT BURNER; AFG MODEL (Chimney) AFG70MQSS AFG70MQSS

Burner tube insertion length (inches) 1 3/4” 1 3/4”

Head type 2 Slots - L2 head 2 Slots - L2 head

Nozzle (Delavan)** 0.60 - 60W 0.65 - 60B 0.60 - 60W 0.65 - 60B

Pump pressure (PSIG)* 140 150 140 150

Head/Air setting 10/0 10/0 (Note 1) 10/0 10/0 (Note 1)

AFUE % (From CSA B212 standard and Canadian regulation)*** 86.3% 85.6% ‡ 86.3% ‡ 85.6%

AFUE % (From ASHRAE 103 standard and US regulation)*** 85.3% 85.4% ‡ 85.3% ‡ 85.4%

BECKETT BURNER; NX MODEL (Chimney or DV) NX56LQ NX56LQ

Burner tube insertion length (inches) 1 3/4” 1 3/4”

Head type 6 Slots - LQ head 6 Slots - LQ head

Nozzle (Delavan)** 0.60 - 60A 0.70 - 60A 0.60 - 60A 0.70 - 60A

Pump pressure (PSIG)* 130 130 130 130

Head/Air setting 3.5 2.5 3.5 2.5

AFUE % (From CSA B212 standard and Canadian regulation)*** 87.1% 86.6% ‡ 87.1% ‡ 86.6%

AFUE % (From ASHRAE 103 standard and US regulation)*** 85.8% 85.3% ‡ 85.8% ‡ 85.3%

RIELLO BURNER; 40-F3 MODEL (Chimney) F3 WITH AIR INLET DAMPER F5 WITH AIR INLET DAMPER

Burner tube insertion length (inches) 2 3/4” 2 3/4”

Nozzle (Delavan)** 0.60 - 70A 0.70 - 70A 0.60 - 70A 0.70 - 70A

Pump pressure (PSIG)* 130 130 130 130

Combustion air adjustment (turbulator/damper) 1 / 2.6 2 / 3.1 1 / 2.6 2 / 3.1

AFUE % (From CSA B212 standard and Canadian regulation*** 87.0% 86.8% ‡ 87.0% ‡ 86.8%

AFUE % (From ASHRAE 103 standard and US regulation)*** 85.8% 85.4% ‡ 85.8% ‡ 85.4%

...Continued

18

Page 20

Table 6 (Continued): Technical specifications(240V)

112 Series, multi-position models UNITS WITH 1/2 HP 4-SP. MOTOR UNITS WITH 1/2 HP ECM MOTOR

RIELLO BURNER; 40-BF5 MODEL (Direct vent DV) BF5 BF5

Burner tube insertion length (inches) 2 3/4” 2 3/4”

Nozzle (Delavan)** 0.60 - 70A 0.70 - 70A 0.60 - 70A 0.70 - 70A

Pump pressure (PSIG)* 130 130 130 130

Combustion air adjustment (turbulator/damper) 0 / 2.75 0 / 3.25 0 / 2.75 0 / 3.25

AFUE % (From CSA B212 standard and Canadian regulation)*** 86.7% 85.5% ‡ 86.7% ‡ 85.5%

AFUE % (From ASHRAE 103 standard and US regulation)*** 85.5% 85.3% ‡ 85.5% ‡ 85.3%

ELECTRICAL SYSTEM

Volts - Hertz - Phase 115 - 60 - 1 115 - 60 - 1

Rated current (Amps) 12.6 10.3

Minimum ampacity for wire sizing (Amps) 15.2 12.2

Max. fuse size (Amps) 20 15

Control transformer(VA) 40 40

External control power available: Heating (VA) 40 40

External control power available: Cooling (VA) 30 30

BLOWER DATA

Heating blower speed at 0.25" W.C. SP MED-LOW MED-HIGH

Heating blower speed at 0.50" W.C. SP MED-LOW MED-HIGH

Motor (HP) / number of speeds 1/2 HP / 4 speeds 1/2 HP / ECM

Blower size (diam. x width) 10” x 10” (tight housing) 10” x 10” (tight housing)

GENERAL INFORMATION

Overall dimensions (width x depth x height) 21 3/4” x 25 3/4” x 41 1/2” 21 3/4” x 25 3/4” x 41 1/2”

Supply air opening (width x depth) 17 3/4” x 18 3/4” 17 3/4” x 18 3/4”’

Return air opening (width x depth) 23” x 19” 23” x 19”

Filter size 24” x 20” x 1" 24” x 20” x 1"

Shipping weight Lbs/Kg 153 / 70 153 / 70

Air conditioning, maximum output (tons) at 0.5" W.C. SP 3.5 3.5

See the ECM air flow table

Note 1 : Without low firing baffle #3708

cline1-1 * INPUT AND OUTPUT ADJUSTMENT :

- Pump pressure can be adjusted to maintan proper firing rate

- Increase pump pressure if flue gases’ temperature is under 400°F

- Adjust the total flue gas temperature between 400°F and 575 °F (330°and 505°F net approx.)

- Adjust fan speed for air temperature rise to be in specified range

** Default installed nozzle in bold character.

*** AFUE value established after minimum 20 hours of operation.

19

‡=

Page 21

Table 7 – Airflow data, models with 1/2HP ECM motor

OIL HEATING MODE

24 VAC input (R) on W only

SW1- HEAT HEAT INPUT

DIP switch position (USGPH)

A (1=OFF, 2=OFF)

B (1=ON, 2=OFF)

C (1=OFF, 2=ON)*

D (1=ON, 2=ON)*

0,68 1160 1275 1045

0,80 1340 1475 1205

0,68 1000 1100 900

0,80 1160 1275 1045

CFM with SW3-ADJ

DIP switch position A

CFM with SW3-ADJ

DIP switch position B

CFM with SW3-ADJ

DIP switch position C

CONTINUOUS FAN

24 VAC input (R) on G only

SW2 - COOL DIP switch

position

A (1=OFF, 2=OFF)

B (1=ON, 2=OFF)

C (1=OFF, 2=ON)

D (1=ON, 2=ON)

A/C size (TON)

3.5 1050 1210 895

3.0 900 1035 765

3.5 750 865 640

3.0 600 690 510

CFM with SW3-ADJ

DIP switch position A

CFM with SW3-ADJ

DIP switch position B

CFM with SW3-ADJ

DIP switch position C

COOLING OR HEAT PUMP HEATING MODE

24 VAC input (R) to G, Y/Y2 and O (for cooling)

SW2 - COOL DIP switch

position

A (1=OFF, 2=OFF)

B (1=ON, 2=OFF)

C (1=OFF, 2=ON)

D (1=ON, 2=ON)

A/C size (TON)

3.5 1400 1400 1260

3.0 1200 1320 1080

2.5 1000 1100 900

2.0 800 880 720

CFM with SW3-ADJ

DIP switch position A

CFM with SW3-ADJ

DIP switch position B

CFM with SW3-ADJ

DIP switch position C

In cooling - Dehumidification mode, with no 24 VAC input to DH, the CFMs are reduced by 15%.

The CFMs shown are reduced by 20% if there is 24 VAC input to Y1 (first stage of the 2-stage cooling unit)

DELAY PROFILE FOR OIL HEATING MODE

SW4 - DELAY DIP switch

position

A (1=OFF, 2=OFF)

B (1=ON, 2=OFF)

C (1=OFF, 2=ON)

D (1=ON, 2=ON)

HEAT IN-

PUT(USGPH)

PreRun On-Delay

CFM Level - Time

ShortRun On-Delay

CFM Level - Time

Off-Delay CFM Level -

0.68 13% - 45 sec. 19% - 60 sec 38% - 3 min.

0.80 13% - 45 sec. 19% - 30 sec 38% - 3 min.

All 13% - 45 sec. 100% - 0 sec 100% - 2 min.

All 13% - 90 sec. 100% - 0 sec 100% - 2 min.

Time

PreRun and ShortRun are the periods of time when the blower strats at very low CFM to minimize the distribution of

cool air in the system and then runs up to normal speed.

Off Delay is the time required to cool down the heat exchanger with low CFMs, to minimize cool draft in the air distribution

system.

DELAY PROFILE FOR COOLING OR HEAT PUMP HEATING MODE

No adjustment required A/C size

PreRun On-delay

CFM Level - Time

ShortRun On-delay

CFM Level - Time

Off-Delay CFM level -

Time

- All NO DELAY NO DELAY 100% - 90 sec

*Alternate adjustment in oil-fired heating mode with higher temperature rise

20

Page 22

Table 8 – Airflow data model with 1/2 HP 4-speed motor (PSC)

BLOWER SPEED

0.2” (W.C.) 0.3” (W.C.) 0.4” (W.C.) 0.5” (W.C.) 0.6” (W.C.) 0.7” (W.C.)

HIGH 1550 1510 1460 1400 1320 1220

MED-HIGH 1320 1280 1240 1200 1160 1020

MED-LOW 1180 1150 1110 1080 1040 940

LOW 1070 1040 1010 980 910 840

EXTERNAL STATIC PRESSURE WITH AIR FILTER

Table 9 – Minimum clearances from combustible materials

LOCATION UPFLOW HORIZONTAL DOWNFLOW

SIDES

FURNACE

PLENUM AND WARM-AIR DUCT WITHIN 6ft. OF FURNACE

BOTTOM FURNACE

BACK FURNACE (OPPOSITE SIDE OF THE BURNER)

TOP

FLUE PIPE

PLENUM OR HORIZONTAL WARM-AIR DUCT WITHIN 6ft. OF FURNACE25.08cm (2”) 5.08cm (2”) 5.08cm (2”)

FURNACE

AROUND FLUE PIPE 22.86cm (9”) 22.86cm (9”) 22.86cm (9”)

FRONT FURNACE (BURNER SIDE)

1

These are horizontal dimensions

2

These are vertical dimensions

3

This dimension can be obtained by using Horizontal Flow Base #HFB-101 or #KLASB0701DET

4

This dimension can be obtained by using Downflow Base #DFB-104 or #KLASB1001DET

1

1

2

1

2

1

Figure 10 – Furnace Dimensions

2.54cm (1”) N/A 5.08cm (2”)

5.08cm (2”) 2.54cm (1”) 5.08cm (2”)

Ø 2.54cm (1”)35.08cm (2”)

7.62cm (3”) 7.62cm (3”) 7.62cm (3”)

N/A 5.08cm (2”) N/A

45.72cm (18”) 45.72cm (18”) 45.72cm (18”)

4

21

Page 23

Figure 11 – Wiring diagram 4-speed motor (PSC)

22

Page 24

Figure 12 – Wiring diagram variable speed motor (ECM)

23

Page 25

Figure 13 – Parts list with 4-speed motor (PSC)

24

Page 26

Table 10 – Parts list with 4-speed moto (PSC)

# Item Description Note

1 B03622 HEAT EXCHANGER Heat exchanger only

2 J06L002 SEAL STRIP, DIA 1/8 x 25’

3 B03652-01 FRONT PANEL ASSEMBLY Panel, insulation and labels included

4 B03667 FRONT PANEL INSULATION

5 B03637-01 BAFFLE, LATERAL

6 B03651-01 SIDE PANEL ASSEMBLY (RIGHT) Panel, insulation and baffle included

7 B03666 SIDE PANEL INSULATION

8 B03455-01 ELECTRICAL KIT, BVSO INT.

9 F06F015 WASHER, ZINC 1 7/16"

10 Z99F061 OBSERVATION PORT

11 R02R004 HIGH LIMIT 195-30F, 7"

12 B03453 ELECTRICAL KIT, TT

13 B03454 ELECTRICAL KIT, BURNER

14 B03639 WIRE CHANNEL (BVSO/SWITCH)

15 B03630-01 BAFFLE One baffle included

16 B03675 SMOKE OUTLET GASKET

17 B03662 RADIATOR BAFFLE Item # 16 included

18 F07O001 FLANGE NUT, HEXAGONAL 3/8-16NC BRASS

19 F07F011 HEX NUT 3/8-16NC ZINC

20 B01684 COVER, ELECTRICAL BOX

21 Z99F050 HANDLE , RECESSED BLACK

22 B03654-01 BLOWER DOOR ASSEMBLY Door and labels included

23 B03680-02 REPLACEMENT BLOWER ASSEMBLY Blower, motor included

24 Z06G001 BLOCKED VENT SHUT-OFF BVSO-225

25 B03118-01 ELECTRICAL KIT, BVSO EXT.

26 L07F003 ROCKER SWITCH, DPST

27 L04I013 STRAIN RELIEF BUSHING

28 L04J001 CABLE CLAMP, 9/16" WHITE

29 B03640 WIRE CHANNEL, INT.

30 B03636 BLOWER DIVIDER

31 B30513 BLOWER SLIDE One blower slide included

32 B03637-02 LATERAL BAFFLE

33 B03480-01 FILTER RACK KIT

34 B03635 FLOOR

35 B03651-02 SIDE PANEL ASSEMBLY (LEFT) Panel, insulation and baffle included

36 B03653 REAR PANEL ASSEMBLY Panel, insulation and baffles included

37 B03665 REAR PANEL INSULATION

38 B03638 REAR BAFFLE

39 B01682 SUPPORT, ELECTRONICS BOX

40 L01F009 TRANSFORMER, 120-24Volt, 40VA

41 B01683 ELECTRICAL BOX

42 R99G004 ELECTRONIC BOARD, UTEC 1158-110

43 L01I002 CAPACITOR 7,5 MF

44 B01024 CAPACITOR HOLDER

45 B03669 ELECTRICAL KIT, BOARD

46 B03668-01 ELECTRICAL KIT, BLOWER

47 B03720-04 BLOWER ASSEMBLY WITH LABEL Housing, wheel and label included

48 L06H004 MOTOR 1/2 HP 4V DD

49 B01888 MOTOR SUPPORT ASSEMBLY Legs, band & hardware included

50 R02R007 HIGH LIMIT 120-20F, 1.75”

51 B03641 BLOWER SLIDE One blower slide included

52 L01G009 CONTROL CARD FUSE - 3 AMPS

25

Page 27

Figure 14 – Parts list with variable speed motor (ECM)

26

Page 28

Table 11 – Parts list with 4-speed moto (PSC)

# Item Description Note

1 B03622 HEAT EXCHANGER Heat exchanger only

2 J06L002 SEAL STRIP, DIA 1/8 x 25’

3 B03652-01 FRONT PANEL ASSEMBLY (RIGHT) Panel, insulation and labels included

4 B03667 FRONT PANEL INSULATION

5 B03637-01 BAFFLE, LATERAL

6 B03651-01 SIDE PANEL ASSEMBLY Panel, insulation and baffle included

7 B03666 SIDE PANEL INSULATION

8 B03455-01 ELECTRICAL KIT, BVSO INT.

9 F06F015 WASHER, ZINC 1 7/16"

10 Z99F061 OBSERVATION PORT

11 R02R004 HIGH LIMIT 195-30F, 7"

12 B03453 ELECTRICAL KIT, TT

13 B03454 ELECTRICAL KIT, BURNER

14 B03642 WIRE CHANNEL (BVSO)

15 B03630-01 BAFFLE One baffle included

16 B03675 SMOKE OUTLET GASKET

17 B03662 RADIATOR BAFFLE Item # 16 included

18 F07O001 FLANGE NUT, HEXAGONAL 3/8-16NC BRASS

19 F07F011 HEX NUT 3/8-16NC ZINC

20 B01684 COVER, ELECTRICAL BOX

21 Z99F050 HANDLE , RECESSED BLACK

22 B03654-01 BLOWER DOOR ASSEMBLY Door and labels included

23 B03680-02 REPLACEMENT BLOWER ASSEMBLY Blower, motor included

24 Z06G001 BLOCKED VENT SHUT-OFF BVSO-225

25 B03118-01 ELECTRICAL KIT, BVSO EXT.

26 L04I013 STRAIN RELIEF BUSHING

27 L04J001 CABLE CLAMP, 9/16" WHITE

28 B03640 WIRE CHANNEL, INT.

29 B03636 BLOWER DIVIDER

30 B30513 BLOWER SLIDE One blower slide included

31 B03637-02 LATERAL BAFFLE

32 B03480-01 FILTER RACK KIT

33 B03635 FLOOR

34 B03651-02 SIDE PANEL ASSEMBLY (LEFT) Panel, insulation and baffle included

35 B03653 REAR PANEL ASSEMBLY Panel, insulation and baffles included

36 B03665 REAR PANEL INSULATION

37 B03638 REAR BAFFLE

38 B01682 SUPPORT, ELECTRONICS BOX

39 L01F009 TRANSFORMER, 120-24Volt, 40VA

40 B01683 ELECTRICAL BOX

41 R99G003 ELECTRONIC BOARD, UTEC 1168

42 B01888 MOTOR SUPPORT ASSEMBLY Legs, band and hardware included

43 B03669 ELECTRICAL KIT, BOARD

44 B03242 ELECTRONIC KIT, BLOWER

45 B03243 ELECTRICAL KIT, BLOWER

46 B03720-04 BLOWER ASSEMBLY WITH LABEL Housing, wheel and label only

47 B03811-07 MOTOR 1/2 HP ECM

48 N/A MOTOR MODULE ECM

49 R02R007 HIGH LIMIT 120-20F, 1.75”

50 B03641 BLOWER SLIDE One blower slide included

51 L01G009 CONTROL CARD FUSE - 3 AMPS

27

Page 29

Table 12 – Accessoires

Item Description Note

DFB-103

KLASB0901DET

HFB-101

KLASB0701DET

DOWNFLOW BASE B03464-02

HORIZONTAL FLOW BASE B00488-01

VTK-54

VTK-098

VENT TERMINAL KIT 4” For sealed combustion

KLAVT0101DET

IFV-420

IFV-098-20

4" INSULATED FLEX VENT 20ft For sealed combustion (B02551-10)

KLAFV0201DET

N01J055 BURNER BECKETT AFG (0,60-60W NOZZLE)

N01J052

KLABR0201BEC

N01F051

KLABR0301RLO

N01F052

KLABR0401RLO

BECKETT NX BURNER (0.60-60A NOZZLE)

RIELLO 40-F5 BURNER (0.60-70A NOZZLE)

RIELLO 40-BF5 BURNER (0.60-70A NOZZLE) For sealed combustion

B03789 PROTECTION PLATE BURNER NX For down flow instalation only

28

Page 30

FOURNAISE

AU MAZOUT

"HIGH-BOY" MODÈLES:

MULTIPOSITION

OMF112K14A

OMV112K14A

INSTALLATEUR/TECHNICIEN:

Utiliser les renseignements dans ce manuel pour

l’installation et l’entretien de l’appareil et garder le document près de l’unité pour références ultérieures.

PROPRIÉTAIRE: Fabriqué par: Les industries Dettson Inc.

SVP, veuillez garder ce manuel près de l’unité pour

références ultérieures.

Imprimé au Canada sur du papier 100% recyclé 2017-08-31 X40165 Rev.M

Attention:

Ne pas altérer votre unité ou ses con-

trôles. Appeler un technicien qualifié.

Sherbrooke, Qc, Canada

www.dettson.com

Page 31

Table des matières

1 SÉCURITÉ 2

1.1 SIGNALISATION DANGER, MISE EN GARDE ET AVERTISSEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 REMARQUES IMPORTANTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 SYSTÈMES DE PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 RISQUES DE GEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 INSTALLATION 3

2.1 EMPLACEMENT DE LA FOURNAISE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 Installation dans un espace clos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.1 Débit ascendant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.2 Débit descendant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.3 Débit horizontal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 RACCORDEMENT ÉLECTRIQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 INSTALLATION DU THERMOSTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 INSTALLATION DU BRÛLEUR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5.1 Gicleurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5.2 Réglage de l’air et du turbulateur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.3 Réglage du délai post purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6 ÉVACUATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6.1 Cheminée de maçonnerie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6.2 Cheminée fabriquées en usine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6.3 Régulateur de tirage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6.4 Évacuation directe murale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7 DISPOSITIF D’ARRÊT ANTI-REFOULEMENT (BVSO) POUR ÉVACUATION PAR CHEMINÉE. . . . . . . . . 8

2.7.1 Vérification du dispositif d’arrêt anti-refoulement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.8 ALIMENTATION EN AIR DE COMBUSTION ET VENTILATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.8.1 Air de combustion contaminé . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.8.2 Brûleur – Air de combustion extérieur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.9 SYSTÈME DE DISTRIBUTION D’AIR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.9.1 Filtre à air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.10 AJUSTEMENT DES DÉBITS D’AIR DE VENTILATION (MOTEUR 4 VITESSES) . . . . . . . . . . . . . . . . . . . 9

2.11 AJUSTEMENT DES DÉBITS D’AIR (MOTEUR À VITESSE VARIABLE ECM). . . . . . . . . . . . . . . . . . . . . . 11

2.12 INSTALLATION D’ÉQUIPEMENTS CONNEXES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.12.1 Humidificateur (HUM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.12.2 Filtre électronique (EAC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.12.3 Unité de climatisation (ou thermopompe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.12.4 Mode de chauffage d’urgence - Moteur à vitesse variable (ECM) . . . . . . . . . . . . . . . . . . . 12

3 OPÉRATION 12

1

Page 32

3.1 MISE EN MARCHE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 SÉQUENCE DE FONCTIONNEMENT EN MODE CHAUFFAGE AU MAZOUT . . . . . . . . . . . . . . . . . . . . . 12

3.3 VÉRIFICATIONS ET AJUSTEMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.1 Purge de la ligne de mazout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.2 Ajustement de la pression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.3 Vérification de la combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.4 Ajustement du régulateur de tirage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.5 Test de pression au dessus du feu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3.6 Test de la température de l’évent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3.7 Test de hausse de température . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3.8 Vérification des limiteurs de température . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3.9 Démarrage après défaillance du brûleur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 ENTRETIEN 14

4.1 NETTOYAGE DE L’ÉCHANGEUR DE CHALEUR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 NETTOYAGE DU DISPOSITIF D’ARRÊT ANTI-REFOULEMENT (BVSO). . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 NETTOYAGE DE LA TÊTE DU BRÛLEUR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4 REMPLACEMENT DU GICLEUR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5 REMPLACEMENT DU FILTRE À L’HUILE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.6 REMPLACEMENT DU FILTRE À AIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 FICHE TECHNIQUE DE L’APPAREIL 17

6 SPÉCIFICATIONS TECHNIQUES 18

Liste des figures

Figure 1: Dimensions & localisation, ouvertures de ventilation dans la porte du placard . . . . . . . . . . . . 4

Figure 2: Débit ascendant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3: Débit descendant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5