ICP OMF112K14A, OMV112K14A Installation Instructions And Homeowner's Manual

MODEL:

OMF112K14A

OMV112K14A

DNS-1225A

US C

MULTIPOSITION

OIL FIRED FURNACE

INSTALLER / SERVICE TECHNICIAN:

USE THE INFORMATION IN THIS MANUAL FOR THE

INSTALLATION / SERVICING OF THE FURNACE AND KEEP

THE DOCUMENT NEAR THE UNIT FOR FUTURE

REFERENCE.

HOMEOWNER:

PLEASE KEEP THIS MANUAL NEAR THE FURNACE FOR

FUTURE REFERENCE.

Printed on 100% recycled paper 2009-12-07 X40165 Rev. B

Attention:

Do not tamper with the unit or its

controls. Call a qualified service

technician.

Manufactured by:

UTC Canada Corporation

ICP Division

445 014101 00

445 01 4101 00

TABLE OF CONTENTS

1 SAFETY REGULATIONS ..................................................................................3

1.1 SAFETY LABELING AND WARNING SIGNS .............................................................................................3

1.2 IMPORTANT INFORMATION.....................................................................................................................3

1.3 DETECTION SYSTEMS.............................................................................................................................3

1.4 DANGER OF FREEZING............................................................................................................................3

2 INSTALLATION ................................................................................................. 4

2.1 POSITIONING THE FURNACE ..................................................................................................................4

2.2 CONFIGURATIONS (FIGURES 1 & 2) ..........................................................................................................4

2.3 ELECTRICAL SYSTEM (FIGURES 3 & 4).....................................................................................................5

2.4 INSTALLATION OF THE THERMOSTAT ...................................................................................................5

2.5 INSTALLATION OF THE BURNER.............................................................................................................6

2.6 VENTING ...................................................................................................................................................6

2.7 BLOCKED VENT SHUT-OFF DEVICE (BVSO) FOR CHIMNEY VENTING.................................................7

2.8 COMBUSTION AIR SUPPLY AND VENTILATION......................................................................................7

2.9 OIL TANK...................................................................................................................................................8

2.10 DUCTING...................................................................................................................................................8

2.11 SUPPLY AIR ADJUSTMENTS (4 SPEED MOTORS).................................................................................8

2.12 SUPPLY AIR ADJUSTMENTS (ECM VARIABLE SPEED MOTORS).........................................................9

2.13 INSTALLATION OF ACCESSORIES..........................................................................................................9

3 OPERATION .................................................................................................... 10

3.1 START-UP................................................................................................................................................10

3.2 OPERATING SEQUENCE OIL HEATING MODE .....................................................................................10

3.3 CHECKS AND ADJUSTMENTS...............................................................................................................10

4 MAINTENANCE...............................................................................................12

4.1 CLEANING THE HEAT EXCHANGER......................................................................................................12

4.2 CLEANING THE BLOCKED VENT SHUT-OFF DEVICE (BVSO)..............................................................12

4.4 REPLACING THE NOZZLE......................................................................................................................12

4.5 REPLACING THE OIL FILTER .................................................................................................................12

4.6 REPLACING THE AIR FILTER.................................................................................................................12

5 FURNACE INFORMATION.............................................................................. 13

TABLE 1 - TECHNICAL SPECIFICATIONS................................................................................................................. 14

TABLE 2 - AIR FLOW, UNITS WITH ½ HP ECM MOTEUR ......................................................................................... 15

TABLE 3 - AIR FLOW, UNITS WITH ½ HP PSC MOTEUR.......................................................................................... 16

TABLE 4 - MINIMUM CLEARANCES FROM COMBUSTIBLE MATÉRIAL................................................................... 16

FIGURE 5 - DIMENSIONS..............................................................................................................................................17

FIGURE 6 - WIRING DIAGRAM, DD, 4 SPEED PSC MOTOR....................................................................................... 18

FIGURE 7 - WIRING DIAGRAM, DD, VARIABLE SPEED ECM MOTEUR.................................................................... 19

EXPLODED VIEWS OF COMPONENTS AND PARTS LISTS................................................................................20 to 23

TABLES AND FIGURES

2

445 01 4101 00

1 SAFETY REGULATIONS

1.1 SAFETY LABELING AND

WARNING SIGNS

The words DANGER, WARNING AND CAUTION are used

to identify the levels of seriousness of certain hazards. It is

important that you understand their meaning. You will

notice these words in the manual as follows:

DANGER

Immediate hazards that WILL result in death, serious

bodily injury and/or property damage.

WARNING

Hazards or unsafe practices that CAN result in death,

bodily injury and/or property damage.

CAUTION

Hazards or unsafe practices that CAN result in bodily injury

and/or property damage.

1.2 IMPORTANT INFORMATION

WARNING

Non-observance of the safety regulations outlined in

this manual will potentially lead to consequences

resulting in death, serious bodily injury and/or

property damage.

a) It is the homeowner’s responsibility to engage a

qualified technician for the installation and

subsequent servicing of this furnace;

b) Do not use this furnace if any part of it w as under

water. Call a qualified service technician

immediately to assess the damage and to replace

all critical parts that were in contact with water;

c) Do not store gasoline or any other flammable

substances, such as paper, carton, etc. near the

furnace;

d) This furnace is designed for use with #1 or #2

heating oil only. The use of gasoline, motor oil or

any other oil containing gasoline is prohibited;

e) Never block or otherwise obstruct the filter and/or

return air openings;

f) Ask the technician installing your furnace to show

and explain to you the following items:

i) The main disconnect switch;

ii) The shut-off valve on the oil tank;

iii) The oil filter and how to change it (once a

year);

iv) The air filter and how to change it (check

monthly and clean or replace if necessary.)

g) Before calling for service, be sure to have the

information page of your manual close by in order

to be able to provide the contractor with the

required information, such as the model and

serial numbers of the furnace.

WARNING

Installations and repairs performed by unqualified

persons can result in hazards to them and to others.

Installations must conform to local codes or, in the

absence of same, to codes of the country having

jurisdiction.

The information contained in this manual is intended

for use by a qualified technician, familiar with safety

procedures and who is equipped with the proper tools

and test instruments.

Failure to carefully read and follow all instructions in

this manual can result in death, bodily injury and/or

property damage.

1.3 DETECTION SYSTEMS

It is recommended that carbon monoxide detectors be

installed wherever oil or gas fired heaters are used.

Carbon monoxide can cause bodily harm or death. For

this reason, agency approved carbon monoxide detectors

should be installed in your residence and properly

maintained to warn of dangerously high carbon monoxide

levels.

There are several sources of possible smoke and flames

in a residence. Smoke and flames can cause bodily harm

or death. For this reason, agency approved smoke

detectors should be installed in your residence and

properly maintained, to warn early on, of a potentially

dangerous fire. Also, the house should be equipped with

approved and properly maintained fire extinguishers.

Your unit is equipped with safety devices that can prevent

it from functioning when anomalies are detected such as a

blocked venting system.

1.4 DANGER OF FREEZING

If your furnace is shut down during the cold weather

season, water pipes may freeze, burst and cause serious

water damage. Turn off the water supply and bleed the

pipes.

If the heater is left unattended during the cold weather

season, take the following precautions:

a. Close the main water valve in the house and purge

the pipes if possible. Open all the faucets in the

house;

b. Ask someone to frequently check the house during

the cold weather season to make sure that there is

sufficient heat to prevent the pipes from freezing. Tell

this person to call an emergency number if required.

CAUTION

3

445 01 4101 00

2 INSTALLATION

This furnace is a true multi-position unit, in that it will

function in an upflow, downflow or horizontal configuration

to the left or the right. Only a few modifications are

required during installation to change from one position to

another. The unit is shipped in the upflow configuration

and instructions as to how to change to the other

positions are included in this manual.

The unit is shipped with a burner and its controls. It

requires a 115VAC power supply to the control panel and

thermostat hook-up as shown on the wiring diagram, one

or more oil line connections, suitable ductwork and

connection to a properly sized vent.

All local and national code requirements governing the

installation of oil burning equipment, wiring and the flue

connection MUST be followed. Some of the codes that

may apply are:

CSA B139: Installation code for oil burning

equipment.

ANSI/NFPA 31: Installation of oil burning equipment.

ANSI/NFPA 90B: Warm air heating and air conditioning

systems.

ANSI/NFPA 211: Chimneys, Fireplaces, Vents and solid

fuel burning appliances.

ANSI/NFPA 70: National Electrical Code.

CSA C22.1 or CSA C22.10:

Canadian Electrical Code.

Only the latest issues of these codes may be used.

2.1 POSITIONING THE FURNACE

WARNING

Fire and explosion hazard.

The furnace must be installed in a level position, never

where it will slope toward the front.

Do not store or use gasoline or any other flammable

substances near the furnace.

Non-observance of these instructions will potentially

result in death, bodily injury and/or property damage.

CAUTION

This furnace is not watertight and is not designed for

outdoor installation. It must be installed in such a manner

as to protect its electrical components from water.

Outdoor installation will lead to a hazardous electrical

condition and to premature failure of the equipment.

The minimum clearances from combustible material

for each of the positions are specified in Table 4.

If the furnace is installed in a basement or on a dirt floor,

in a crawl space for example, it is recommended to install

the unit on a cement base 2.5 cm to 5.0 cm (1" to 2")

thick.

DNS-1227A

The unit must be installed in an area where the ambient

and return air temperatures are above 15°C (60°F). In

addition, the furnace should be installed as closely as

possible to the vent, so that the connections are direct

and kept to a minimum. The heater should also be

located close to the centre of the air distribution system.

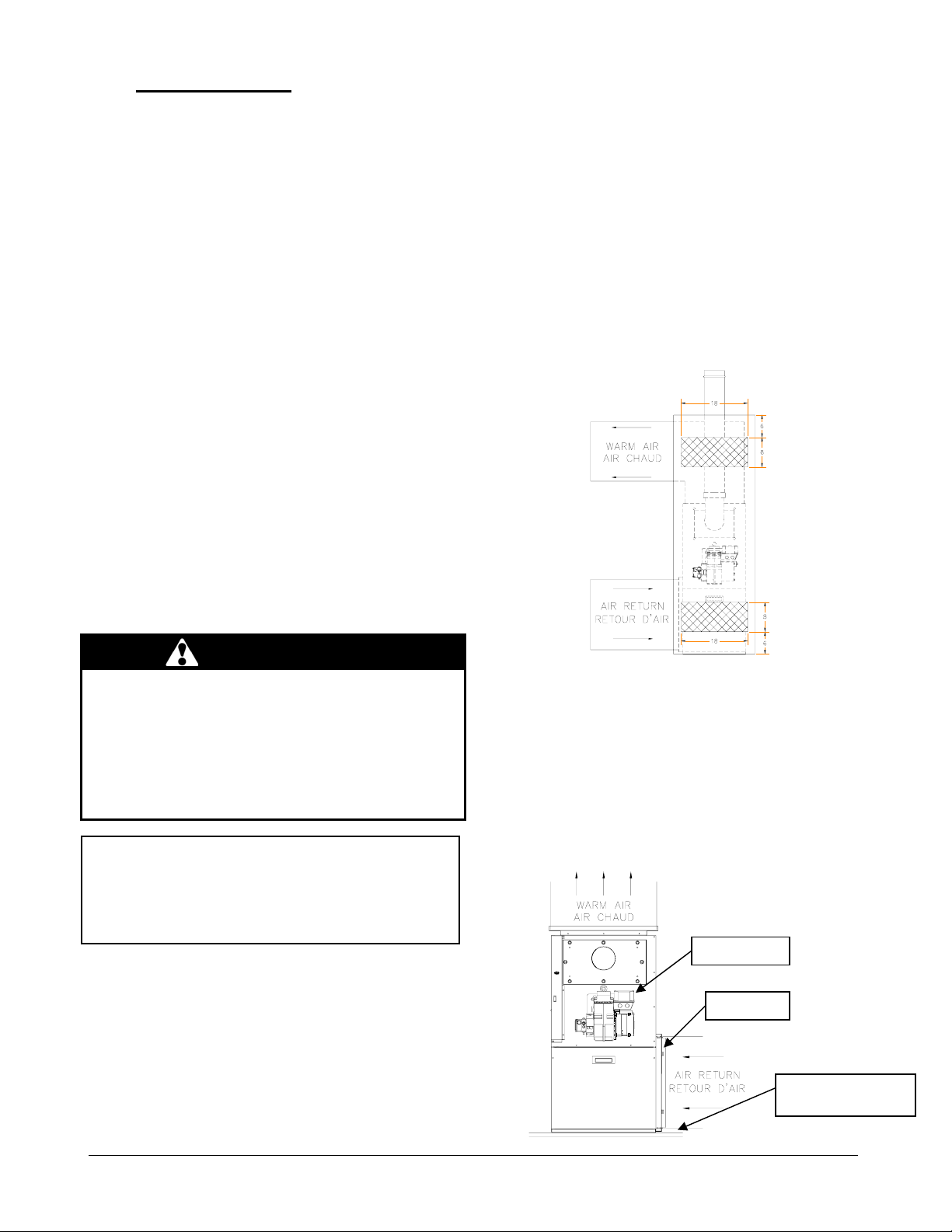

2.1.1

Installation in an enclosure

The unit can be installed in an enclosure such as a

closet. However, 2 ventilation openings are required for

combustion air. The openings should be located in front

of the furnace approximately 15 cm (6") above the floor

and 15 cm (6") below the ceiling. Figure 1 indicates the

minimum dimensions required and the location of the

openings.

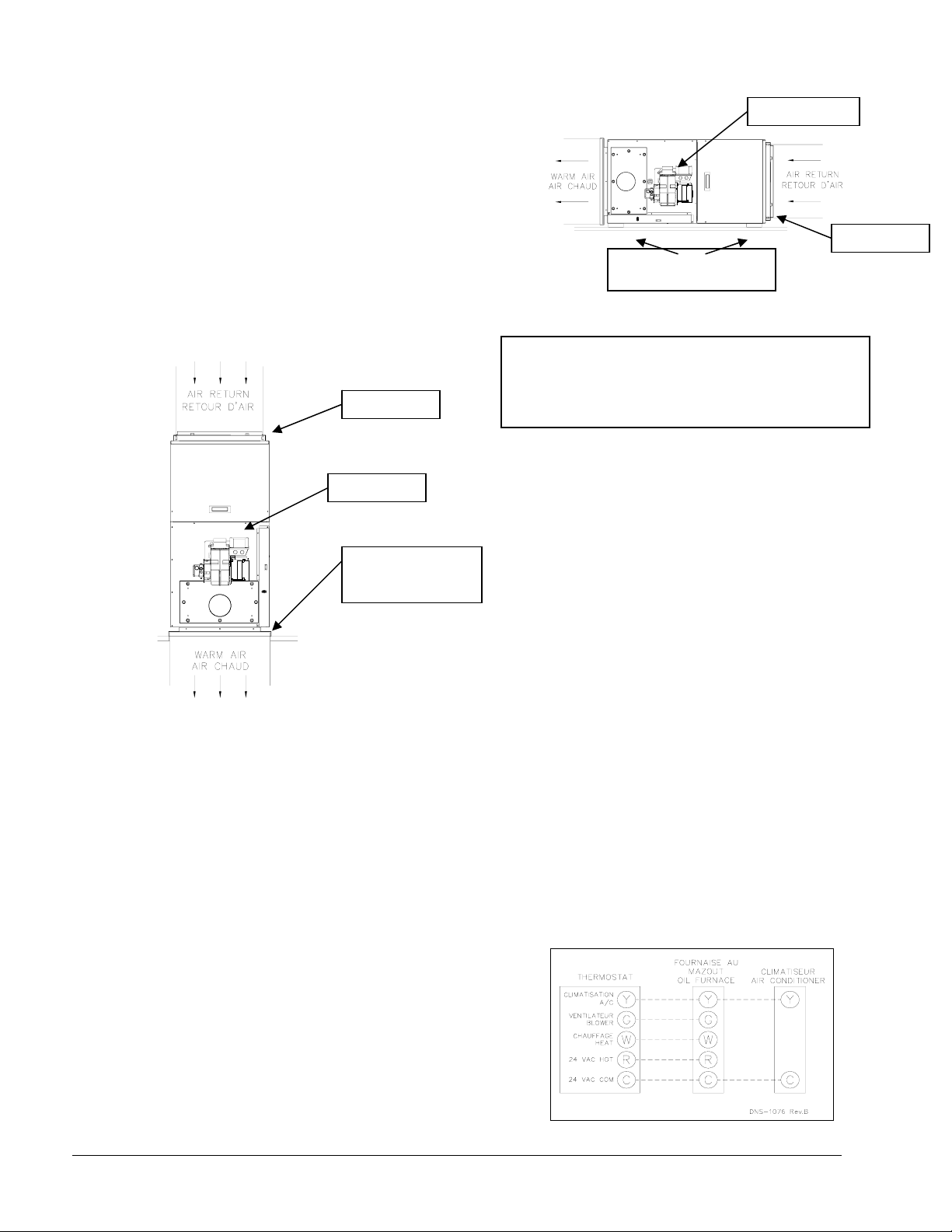

Figure 1

Location and dimensions of

ventilation air openings in a closet door

2.2 CONFIGURATIONS

2.2.1 Upflow Installation

The return air opening may be located on either side of

the furnace. Care should be taken not to damage the

wires inside, while cutting the opening. Install the filter

rack supplied with the unit according to the instructions

provided with it. It is also recommended to install the

blower door before handling or moving the unit. Refer to

Figure 2 for additional details.

Figure 2

Burner position

Filter 20X24

Combustible or noncombustible floor

4

445 01 4101 00

2.2.2 Downflow Installation

When the furnace is installed in the downflow position on a

combustible floor, the clearances from combustibles must

be adhered to. The downflow base DFB-103 or

KLASB0901DET can be used to ensure these clearances.

Refer to Figure 3 and the installation instructions provided

with the base.

The burner must always be installed in the same manner,

regardless of the discharge position of the furnace. Refer

to Figure 3 for additional details.

Figure 3

2.2.3 Horizontal Installation

When the furnace is installed in the horizontal position,

either suspended or on a combustible floor with a choice of

right or left discharge, the clearances from combustible

material must be adhered to. If the unit is installed on a

combustible floor, the horizontal floor base HFB-101 or

KLASB0701DET can be used to ensure these clearances.

Refer to the instructions supplied with the base.

The burner must always be installed in the same manner,

regardless of the discharge position of the furnace. Refer

to Figure 4 for additional details.

Burner position

Filter 20 x 24

Downflow base is

required for

combustible floor

DNS-1227A

Horizontal floor base required

for combustible floor

Burner position

Filter 20 x 24

DNS-1227A

2.3 ELECTRICAL SYSTEM

CAUTION

The exterior of the unit must have an uninterrupted

ground to minimize the risk of bodily harm, if ever an

electrical problem develops. A green ground screw is

supplied with the control box for that purpose.

The appliance must be installed in accordance with the

current ANSI/NFPA 70 National Electrical Code, CSA

C22.1 Canadian Electrical Code Part 1 and/or local

codes.

The control system depends on the correct polarity of

the power supply. Connect “HOT” wire (H) and

“NEUTRAL” wire (N) as shown in Figures 6 and 7, p. 18

and 19.

A separate line voltage supply should be used, with

fused disconnect switch or circuit breaker, between the

main power panel and the unit.

Only copper wire may be used for the 115V circuit on

this unit. If wires need to be changed, the replacements

must have the same temperature resistance as the

originals.

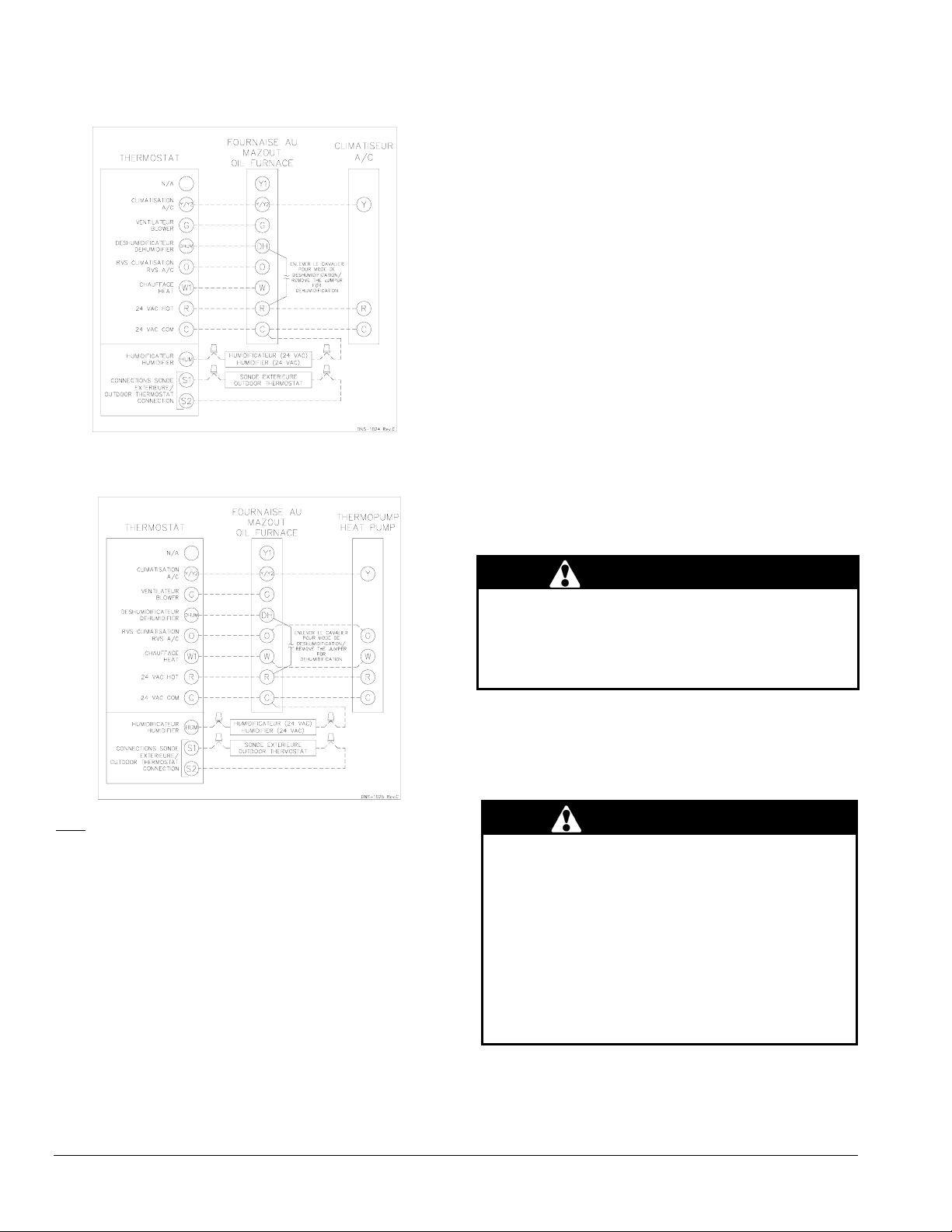

2.4 INSTALLATION OF THE

THERMOSTAT

A thermostat must be installed to control the

temperature of the area to be heated. Follow the

instructions supplied with the thermostat. Also refer to

the wiring diagrams provided with the heating/air

conditioning unit. The connections must be made as

indicated on the following diagrams and the wiring

diagrams, p. 18 and 19.

Thermostat Wiring

Heating and Air Conditioning

Figure 4

with 4-speed motor

5

445 01 4101 00

Thermostat Wiring

Heating and Air Conditioning

with ECM variable speed motor

Thermostat Wiring

Heating and Air Conditioning/Heat pump

with ECM variable speed motor

Note: On units with 2 stage cooling or heat pump, terminal Y1

must be used. When Y1 on the electronic control receives a 24

VAC signal, the air flow is reduced by 20%. Do not use

terminal Y1 with a single stage cooling or heat pump.

2.5 INSTALLATION OF THE BURNER

Refer to the burner manufacturer’s instructions. Also, the

burner must be installed always in the same way

independently of the furnace orientation.

1. Position the mounting gasket between the mounting

flange and the burner mounting plate. Align the holes in

the burner mounting plate with the studs on the mounting

flange and bolt securely in place.

2. Remove the burner drawer assembly or the air tube

assembly;

3. Install the nozzle (refer to Technical Specifications, p.14);

4. Check the electrode settings;

5. Make the electrical connections;

6. Complete oil line connections.

2.5.1 Nozzles

The burner comes equipped with an appropriate nozzle.

However, if another size or a replacement nozzle is

required, use the manufacturer’s recommended spray

angle and type a shown in Table 1 and based on a pump

pressure of 100 psi.

Always select nozzle sizes by working back from the

desired flow rate at operating pressure and not the nozzle

marking.

2.5.2 Air and Turbulator Settings

Before starting the burner for the first time, adjust the air

and turbulator settings to those listed in this manual. Once

the burner becomes operational, final adjustments will be

required. Refer to section 3 of this manual.

2.5.3 Post purge delay adjustment

The post purge delay on the oil-fired burners is factory set

to zero second. This delay is applicable for all installations

with chimney venting. For heating units installed with side

wall venting and a burner equipped with this feature, the

post purge delay must be set to 15 seconds. Refer to the

burner control instruction manual and markings for proper

adjustment of the post purge delay.

2.6 VENTING

WARNING

Poisonous carbon monoxide gas, fire and explosion

hazard.

Read and follow all instructions in this section.

Failure to properly vent this furnace can result in in

death, bodily injury and/or property damage.

To ensure the safe and proper functioning of an oil

furnace, it must always be connected to a flue with

sufficient draft or to an approved side-wall venting system.

In addition, it is strongly recommended to perform a

complete inspection of all the existing venting systems.

WARNING

Poisonous carbon monoxide gas hazard.

Never install a hand operated damper in the vent pipe.

However, any Underwriters Laboratories listed,

electrically operated automatic type vent damper may

be installed if desired. Be sure to follow the

instructions provided with vent damper. Also, read

and follow all instructions in this section of the

manual.

Failure to properly vent this furnace or other

appliances can result in death, bodily injury and/or

property damage.

6

445 01 4101 00

2.6.1 Masonry chimney

This furnace can be vented into an existing masonry chimney.

However, the unit must not be vented into a chimney into

which a solid fuel burning furnace is already being vented.

Before venting this furnace into a chimney, its condition must

be checked and repairs made, if necessary. Also, the chimney

lining and dimensions must conform to local and national

codes.

2.6.2 Factory Built Chimneys

Oil fired furnaces are approved for use with “L” type vents. The

unit may also be used with an approved chimney of proper

dimensions and temperature ratings as specified in the

installation code. Refer to chimney manufacturer’s instructions

for proper installation.

2.6.3 Draft Regulator

This unit may be installed with or without a draft regulator.

However, it is recommended that a draft regulator be installed

in cases where the draft is either high or variable due to

external conditions. Follow the instructions provided with the

regulator.

2.6.4 Side-wall Venting

The heating unit is approved for side-wall venting. This system

is comprised of a model VTK-098 / KLAVT0101DET side-wall

venter and a 4” insulated vent pipe, model IFV098 /

KLAFVxx01DET. Refer to the installation instructions provided

with the venting system.

2.7 BLOCKED VENT SHUT-OFF DEVICE

(BVSO) FOR CHIMNEY VENTING

CAUTION

It is imperative that this device be installed by a qualified service

technician.

A positive pressure venting system (Sealed Combustion System

or Direct Vent) MUST NOT use the BVSO. Follow the

instructions supplied with the venting system.

This device is designed to detect the insufficient evacuation of

combustion gases in the event of a vent blockage. In such a

case the thermal switch will shut down the oil burner. The

device will then need to be re-armed MANUALLY.

Refer to the detailed instructions and wiring diagrams supplied

with the BVSO for the installation and wiring procedures. The

length of wires supplied with the unit is such that the safety

device must be installed between the flue outlet of the

appliance and the draft regulator, as indicated in the

instructions.

It is also essential that the BVSO be maintained annually. For

more details refer to the instructions supplied with the device

itself, as well as Section 3. of this Manual.

2.7.1 BVSO Performance Test

The purpose of the following test is to check that the electrical

outlet on the furnace, designated to the BVSO, is functional.

7

1. Start up the burner;

2. Remove the three-pole plug from the BVSO outlet on

the furnace;

3. The burner must shut-off immediately, while the

blower continues to run to the end of the cool-down

cycle.

If the test is not in line with the above, call a QUALIFIED

SERVICE TECHNICIAN.

2.8 COMBUSTION AIR SUPPLY

VENTILATION

AND

WARNING

Poisonous carbon monoxide gas hazard.

Comply with NFPA 31 (U.S.) and CSA B139 (Canada)

standards for the installation of Oil Burning

Equipment and applicable provisions of local building

codes to provide combustion and ventilation air.

Failure to provide adequate combustion and

ventilation air can result in death, bodily injury and/or

property damage.

Oil furnaces must have an adequate supply of combustion

air. It is common practice to assume that older homes

have sufficient infiltration to accommodate the combustion

air requirement for the furnace. However, home

improvements such as new windows, doors, and weather

stripping have drastically reduced the volume of air

infiltration into the home.

Refer to oil furnace installation codes relative to

combustion and ventilation air requirements. Consult

Section 2.2 in this manual, specifically for units installed in

an enclosed space.

Home air exhausters are common. Bathroom and kitchen

fans, power vented clothes dryers and water heaters all

tend to create a negative pressure condition in the home.

Should this occur the chimney becomes less and less

effective and can easily downdraft. In certain cases,

mechanically supplied air, by way of a blower, interlocked

with the unit, is necessary. It is the installer’s responsibility

to check that.

2.8.1 Contaminated Combustion Air

Installations in certain areas or types of structures will

increase the exposure to chemicals or halogens that may

harm the furnace. These conditions will require that only

outside air be used for combustion.

The following areas or types of structures may contain or

be exposed to certain substances, potentially requiring

outside air for combustion:

a. Commercial buildings;

b. Buildings with indoor pools;

c. Furnaces installed near chemical storage areas.

Exposure to the following substances:

a. Permanent wave chemicals for hair;

b. Chlorinated waxes and cleaners;

c. Chlorine based swimming pool chemicals;

d. Water softening chemicals;

e. De-icing salts or chemicals;

f. Carbon tetrachloride;

Loading...

Loading...