Page 1

OIL FIRED FURNACE

445 01 4024 05

DOWNFLOW or HORIZONTAL

Model:

OCF105A12C

D

N

S

-

0

58

8

R

ev

.

B

INSTALLER / SERVICE TECHNICIAN:

USE THE INFORMATION IN THIS MANUAL FOR THE

INSTALLATION / SERVICING OF THE UNIT AND KEEP

THE DOCUMENT NEAR THE FURNACE FOR FUTURE

REFERENCE.

HOMEOWNER:

PLEASE KEEP THIS MANUAL NEAR THE FURNACE

FOR FUTURE REFERENCE.

Printed in Canada

Printed on 100% recycled paper

Caution: Do not tamper with the

unit or its controls.

Call a qualified service technician.

Manufactured by:

UTC Canada Corporation

ICP DIVISION

3400 Industrial Boulevard

Sherbrooke, Quebec - Canada

J1L 1V8

2008/12/02 X40084 Rev. K

Page 2

PART 1

445 01 4024 05

INSTALLATION

SAFETY CONSIDERATIONS

INSTALLATION OF OIL FIRED HEATING UNITS

SHALL BE IN STRICT ACCORDANCE WITH THE

REGULATIONS OF THE AUTHORITIES HAVING

JURISDICTION. IN CANADA, CSA B139 AND IN THE

UNITED STATES, NFPA NO.31-1992 INSTALLATION

CODES FOR OIL BURNING EQUIPMENT APPLY.

DO NOT OPERATE FURNACE IN A CORROSIVE

ATMOSPHERE CONTAINING CHLORINE, FLUORINE

OR ANY OTHER DAMAGING CHEMICALS.

DO NOT STORE OR USE GASOLINE, OR OTHER

FLAMMABLE VAPOURS AND LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

1.1) SAFETY LABELLING AND WARNING SIGNS

DANGER, WARNING AND CAUTION

The words DANGER, WARNING and CAUTION are used to identify

the levels of seriousness of certain hazards. It is important that you

understand their meaning. You will notice these words in the manual

as follows:

DANGER

Immediate hazards which WILL result in death or

serious injury.

WARNING

Hazards or unsafe practices which CAN result

in death or injury.

CAUTION

Hazards or unsafe practices which CAN result in

personal injury or product or property damage.

1.2) SAFE INSTALLATION REQUIREMENTS

WARNING

Installation or repairs performed by unqualified

persons can result in hazards to them and others.

Installation MUST conform to local codes or, in the

absence of same, to codes of the country having

jurisdiction.

The information contained in this manual is

intended for use by a qualified service technician

familiar with safety procedures and equipped with

the proper tools and test instruments.

Failure to carefully read and follow all instructions

in this manual can result in personal injury and/o r

death, property damage, furnace malfunction.

WARNING

Fire hazard.

The furnace must be installed in a level position;

never where it will slope toward the front.

If the furnace is installed in that position, oil will

drain into the furnace vestibule and create a fire

hazard, instead of being directed into the

combustion chamber.

NOTE: It is the personal responsibility and obligation of the customer

to contact a qualified installer to ensure tha t the installation conforms

to governing local and/or national codes and ordinances.

a. This furnace is NOT approved for installation in mobile homes,

trailers or recreational vehicles;

b. Do NOT use this furnace as a construction he ater or to heat a

building under construction;

c. There must be a sufficient suppl y of fresh air for combustion as

well as ventilation in the area where the furnace is located;

d. Use only the type of fuel oil approved for this furnace (see Rating

Plate on unit). Overfiring will result in heat exchanger failure and

cause dangerous operat ing con di tio ns;

e. Visually check all oil line joints for signs of leakage;

f. Connect furnace to a side-wall terminal or chimney;

g. The points in Part 2 “Oper ation” are vital to the proper and safe

operation of the heating system. Tak e the time to ensure that all

steps were followed;

h. Follow the regulations of the ANSI / NFPA No.31 (USA) and

B-139 (Canada) or local codes for placing and installing the oil

storage tank;

i. Follow a regular service and maintenance schedule for efficient

and safe operation;

3

Page 3

445 01 4024 05

j. Before servicing, allow furnace to cool down. Always shut off

electricity and fuel to furnace when servicing. This will prevent

electrical shock or burns;

k. Seal supply and return air ducts;

l. The vent s ystem MUST be checked to determine that it is the

correct type and size;

m. Install correct filter ty pe and size;

n. Unit MUST be installed so that electrical components are

protected from direct contact with water.

1.2.1) Safety Rules

Your unit is built to provide many years of safe and dependable

service, provided it is properly installed and maintained. However,

abuse and/or improper use can s horten the life of the unit and create

hazards for you, the owner.

a. The U.S. Consumer Product Safety Commission recommends

that users of oil-burning appliances install carbon monoxide

detectors. There can be various sources of carbon monoxide in a

building or dwelling. The sources could be gas-fired clothes

dryers, gas cooking stoves, water heaters, furnaces, gas-fired

fireplaces, wood fireplaces, and several other items. Carbon

monoxide can cause serious bodily injury and/or death.

Therefore, to help alert people to pot entially dangerous carbon

monoxide levels, you should have carbon monoxide detectors

listed by a nationally recognised agency (ex. Underwriters

Laboratories or International Approval Services) installed and

maintained in the building or dwelling (see Note below).

b. There can be numerous sources of fire or smoke in a buil ding or

dwelling. Fire or smoke can cause serious bodily injury, death,

and/or property damage. Therefore, in order to alert people to

potentially dangerous fire or smoke conditions, you should have

Underwriters Laboratories listed fire and smoke detectors

installed and maintained in the building or dwelling (see Note

below).

NOTE: The manufacturer of your furnace does not test

detectors and makes no representations regarding any

brand or type of detector.

CAUTION

Ensure that the area around the combustion air intake

terminal is free of snow, ice and debris.

CAUTION

An air pressure switch MUST be used when the furnace

is side-wall vented.

CAUTION

Do not use any commercially available soot remover.

This furnace has a ceramic fibre type of combustion

chamber. Normal servicing of this unit does not require

the cleaning of same. Use extreme caution if for any

reason you have to work in the area of the combustion

chamber.

1.2.2) Freezing Temperatures and Your Structure

WARNING

Freezing temperature warning.

Turn off water supply.

If your heater remains shut off during cold weather,

the water pipes could freeze and burst, resulting in

serious water damage.

Your unit is equipped with safety devices that may keep it from

operating if sensors detect abnormal conditions such as clogged

exhaust flues.

If the structure is unattended durin g cold weather you sh ould take the

following precautions:

a. Tu rn off main water suppl y into the structure a nd drain the water

lines if possible. Open faucets in appropriate areas;

b. Have someone check the structure frequently during cold

weather to make sure it is warm enoug h to prevent pipes from

freezing. Contact a qualified service agency, if required.

1.2.3) Installation regulations

All local and national code requirements governing the installation of

oil burning equipment, wiring and flue connections MUST be follo wed.

Some of the codes that may be applicable are:

CSA B139 INSTALLATION CODE FOR OIL

BURNING EQUIPMENT

NFPA 31 INSTALLATION OF OIL B URN ING

EQUIPMENT

ANSI/NFPA 90B WARM AIR HEATING AND AIR

CONDITIONING SYSTEMS

ANSI/NFPA 70 NATIONAL ELECTRICAL CODE

CSA C22.1 CANADIAN ELECTRICAL CO DE

Only the latest issues of the above codes should be used.

1.3) POSITIONING THE FURNACE

CAUTION

Carefully check your furnace upon delivery for any

evidence of damage that may have occurred during

shipping and handling. Any claims for damages or lost

parts must be made with the Transport Company.

4

Page 4

Minimum Installation clearances from combustible materials (Chimney installation*)

445 01 4024 05

LOCATION APPLICATION OCF105 AND ODH53

Sides

Back Furnace 25.4 mm (1”)

Top Furnace casing or plenum 25.4 mm (1”) 0.6 m (24”)

Bottom Furnace – combustible floor ** 0” **

Front Furnace 0.6 m (24”)

* See Part 1 Section 4.3 for Direct Vent application clearances.

** Combustible floor requires accessory bases CFB-1 or HFB-1.

Furnace 25.4 mm (1”)

Supply plenum, warm air duct within 6 ft of furnace 25.4 mm (1”)

1.3.1) Location

Position the furnace as closely as possible to the chimney or vent

terminal, providing ample clearance to permit easy accessibility for

cleaning the inside of the furnace, the removal of filters, blower,

motors, controls and flue connections.

This furnace is approved for reduced clearances to combustibles.

Therefore, it may be installed in an alcove, closet, or crawl space.

Clearances indicated on the rating plate must be respected.

In the downflow position, this furnace is approved for installation on

combustible floors only when the accessory No C FB-1 "Combustible

Floor Base" is used.

In the horizontal position (air left or right), this furnace is approved for

installation on combustible floors only when the accessory No. HFB-1

"Horizontal Floor Base" is used.

In the horizontal position (air left or right), this furnace may be

suspended using an angle iron frame with threaded rod hangers.

Appropriate calculations, considering the weight of the furnace and the

frame must be made.

However, do not install furnac e dir ectly on carp et o r othe r c ombus tibl e

material, which can trap air under the floor.

The furnace must be installed level for safe and quiet operation.

CAUTION

Do NOT operate the furnace in a corrosive a tmosphere

containing chlorine, fluorine or any other damaging

chemicals. Refer to Part 1, section 5.2.

1.4) VENTING

1.4.1) General

The furnaces can be vented in several ways:

Chimney Vented

Using the Beckett AFG or Riello 40-F burner, the furnaces can be

chimney vented with or without a barometric damper. The unit will

operate at a negative overfire draft and flue dra ft.

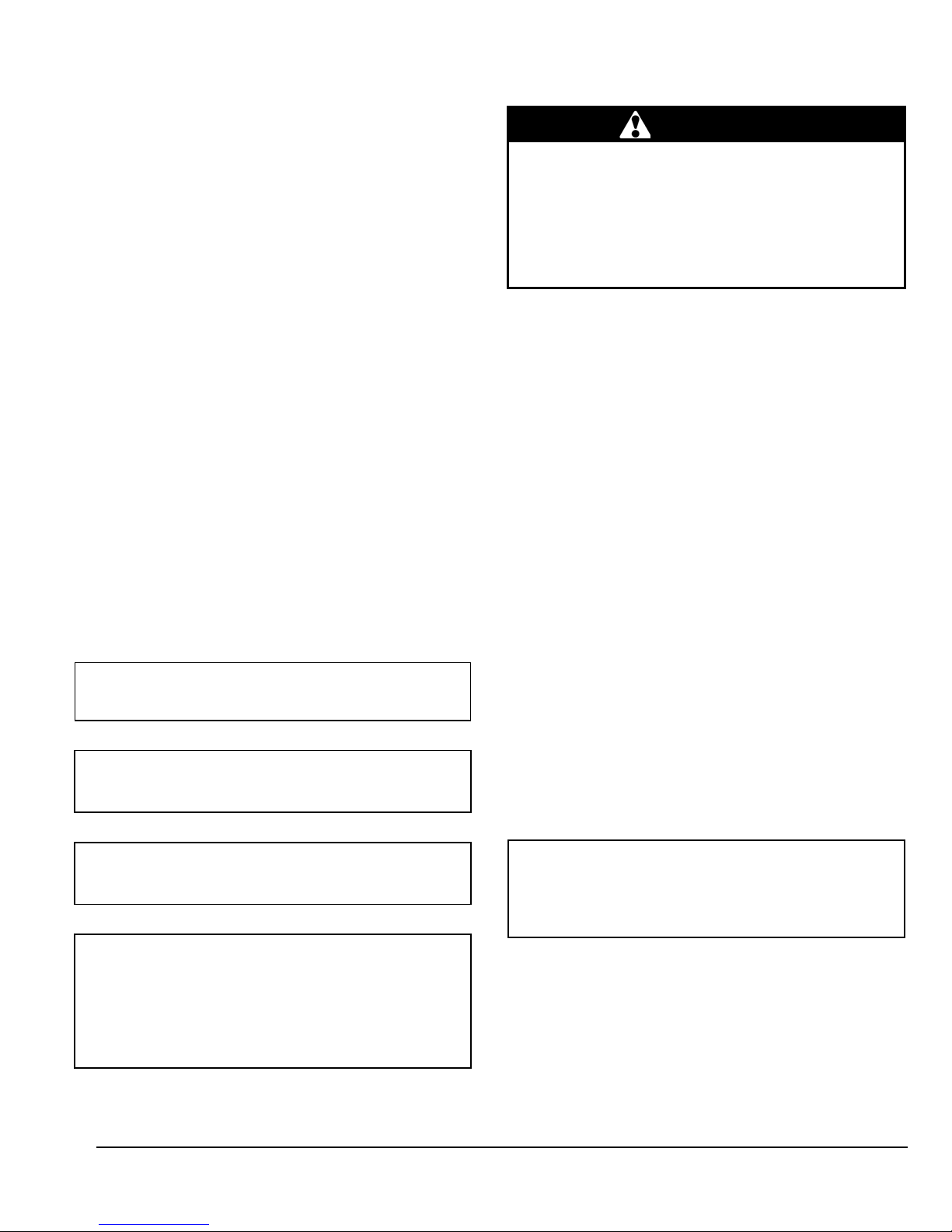

TABLE 1

RECOMMENDED ACCESS

FOR SERVICE

WARNING

Poisonous carbon monoxide gas, fire and

explosion hazard.

Read and follow all instructions in this section.

Failure to properly vent this furnace can cause

bodily injury or death, property damage.

Side-wall Vented

Using the Beckett AFII or Riello 40-BF burner with the integral preand post-purge controls, the system can be side-wall vented with the

new DV-2000™ venting system f or maximum efficiency and without

the use of a side-wall power vent. The unit will operate at a positive

overfire draft and flue draft.

WARNING

Poisonous carbon monoxide gas hazard.

Never vent this furnace together with another

combustion appliance when side-wall venting.

To do so may result in asphyxiation and death to

the occupants

1.4.2) Chimney installations

When set up for chimney venting, this furnace is certified for use with

an L-vent, A-vent, tile-lined and metal-lin er-tile lined chimn ey, and can

be vented both with and without a barometric draft damper. However,

this furnace is not approved for use without a barometric damper if it is

to be vented together with another oil-fired appli ance such as a water

heater.

With barometric damper

This furnace may be vented into a chimney of suitable size and

adequate chimney base temperatur e, as specified in the Installation

Code. When a barometric damper is used, the ba sement air entering

the damper reduces the possibility of vent condensation. The relevant

excerpt from the code is found in this section and can be used as a

guide where local or national codes do not exist. One option, to

increase the chimney base temperature, is to use vent connection

insulation.

5

Page 5

Without barometric damper

445 01 4024 05

Due to the lack of dilution air that would ordinarily be drawn into the

barometric damper, the dew point of the flue g ases is raise d. To offs et

the increased tendency for vent condensation , the chimney must be

lined. The liner must be insulated according to the insulating

procedure recommended by the manuf acturer of the liner. Also, the

vent connector should be as short as p ossible an d eithe r be of do uble

wall construction or of single wall construction with 25.4 mm (1") of

insulation.

WARNING

Poisonous carbon monoxide gas hazard.

Never install a hand operated damper in the vent

pipe. However, any Underwriters Laboratories listed

electrically operated automatic type vent damper

may be installed if desired. Be sure to follow

instructions provided with vent damper. Read and

follow all instructions in this section.

Failure to properly vent this furnace or other

appliances can result in personal injury and/or

death, property damage.

CAUTION

When the furnace (chimney installation) is vented

together with other combustion appliances such as a

water heater, the allowable venting materials (L-Vent,

etc.) for use with those appliances must be investigated.

Flue pipe sizing

The following table is an excerpt from the Installation Code and

indicates the permitted flue sizes and minimum base temperat ures for

circular flues in chimneys with thermal resistance of less than R6 (6 ft

•hr •°F / Btu). Where a new appliance, burner, or chimney is installed,

chimney vent sizes and maximum flue ga s te mp erat ur e s (me a sur ed at

the chimney connector with the barometric damper shut, after 5

minutes of operation) shall comply with Table 2.

Note: Thermal resistance values for typical chimneys

are as follows:

Total input rating of all

connected appliances

kW Btu/h USGPH Min. Max. 11' 20' 28' 36'

21 70,000 0.50 76.2 mm (3") 0.13 m (5") 149°C / 300°F 204°C / 400°F 279°C / 535°F 385°C / 725°F

27 91,000 0.65 76.2 mm (3") 0.13 m (5") 135°C / 275°F 171°C / 340°F 221°C / 430°F 279°C / 535°F

31 105,000 0.75 0.1 m (4") 0.13 m (5") 127°C / 260°F 160°C / 320°F 193°C / 380°F 246°C / 475°F

36 119,000 0.85 0.1 m (4") 0.13 m (5") 121°C / 250°F 149°C / 300°F 179°C / 355°F 221°C / 430°F

41 140,000 1.00 0.1 m (4") 0.15 m (6") 107°C / 225°F 149°C / 300°F 185°C / 365°F 221°C / 430°F

51 175,000 1.25 0.1 m (4") 0.15 m (6") 116°C / 240°F 135°C / 275°F 160°C / 320°F 185°C / 365°F

Flue inside diameter

2

TABLE 2

R2 (2 ft2 •hr •°F / Btu): Clay-lined masonry, A-vent

2

•hr •°F / Btu): Metal liner in clay-lined Masonry

R3 (3 ft

2

R6 (6 ft

•hr •°F / Btu): Metal or clay-lined masonry with R4.5 (4.5

Applying Table 2

If a furnace with a 0.60 USGPH nozzle is to be connected to a 20 foot

tall clay-lined masonry chimney, the thermal resistance of this type of

chimney is R2, (which is less than R6). The actual firing rate at 156

psig is 1.25 x .60 = .75. Therefore this table shall apply as follows:

The minimum size permitted shall be 101.6 mm (4") inside diameter;

The maximum size permitted shall be 127.0 mm (5") inside diameter;

The minimum base temperatur e sha ll be abou t 160°C (320°F).

2

• hr •°F / Btu) insulation between liner

ft

and masonry (e.g. 2" of expanded mica or 1

3/8" of high density glass fibreboard.)

1.4.3) Side-wall venting - DV-2000™

Direct Vent System

The furnace can be side-wall vented without the use of a side-wall

power vent, using the new DV-2 000™ venting system with the high

static pressure Beckett AFII and Riello 40-BF oil burners. Outdoor

combustion air must be directly conn ected to the burner or the

DV-2000™ venting system will not function.

The notable characteristics of the DV-2000™ system are as follows:

a) Certi fied to use the following materials for d ucting the intake air

from the terminal to the burner: Schedule 40 PVC DWV,

Schedule 40 ABS DWV, and ASTM 2729 sewer Pipe;

b) One hole of minimal size (152.4 mm

into the side-wall, and the terminal is designe d to fit through a

minimum 2 X 8 joist space;

c)

Incorporates a vent blockage safety shutdown system. If the vent

or intake opening ever becomes partially or fully blocked, the

burner will shut down before a #1 smoke

d) The intake and vent circuits within the te rminal can be accessed

for cleaning.

There are 3 main components to the DV-2000™ system: the VTK vent

terminal kit, the IFV insulated flexible venting material and the

field-supplied 3 inch PVC or ABS intake piping.

Minimum base temperature

for chimney height of:

ø

/ 6"ø) is required to be cut

condition occurs;

6

Page 6

DV-2000™ – Vent terminal kits

445 01 4024 05

The certified standard vent termi nal kit is Mod el No. VTK-1 for models

ODH5-F and OCF105A12B and is suitable for installation in walls up

to 0.3 m (14") thick. Both kits contain the following items to complete

the hook-up to the venting and furnace:

Qty Description

1 Terminal

2 Sealing clamps

1 Side-wall venting breach plate

2 Sealing strips

1 Inner wall plate

1 Pressure control with tubing

2 Insulated quick-connect terminals

3 Stainless steel screws

6 Self tapping stainless steel screws

Insulated flexible venting - DV-2000™

The certified venting materials come in 3 l engths, Model No. IFV 3-15,

IFV3-23 and IFV3-30 and correspond t o 4.6 m, 7.0 m, and 9 .1 m (15',

23' and 30') of continuous lengths of ve nt. The vent construction is

coaxial and incorporates a stainless steel corrugated flexible liner

surrounded by a thick blanket of insulation and covered with an o uter

layer of flexible corrugated aluminium sle eve to protect the insulation .

Splicing vent lengths together is prohibited. The minimum and

maximum continuous vent lengths permitted for installation are:

1.5 m (5') minimum 9.1 m (30') maximum

WARNING

Poisonous carbon monoxide gas hazard

Even though the flexible venting is insulated, it

must not be run through an unheated space.

To do so can cause residual condensation inside

the stainless steel liner, which may eventually

perforate the liner and allow vent gasses to enter

the dwelling. This can result in death, personal

injury and/or property damage.

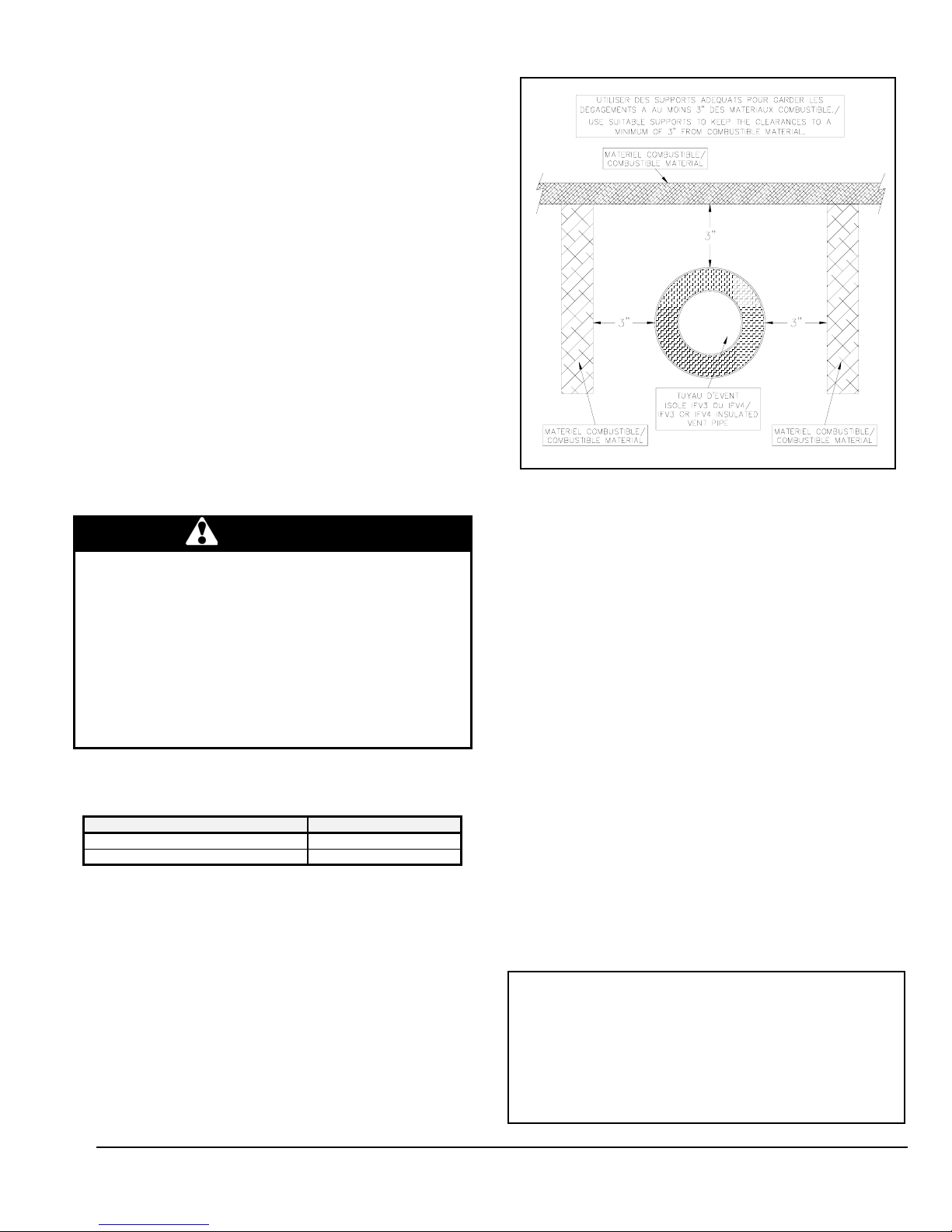

Side-wall venting clearances to combustibles

PORTION OF VENT CLEARANCES

Vent pipe, up to vent terminal* 76.2 mm (3”)

Vent terminal ZERO

*Do not enclose venting

Installation considerations - DV-2000

Select a location for the vent terminal i n accordance with all local and

national codes. The following requ irements shall be considered to be

minimum requirements that can be overridden by stricter local and

national codes.

TABLE 3

TM

-

DNS-0623 Rev. A

The vent shall not terminate

a. Directly above a paved sidewalk or paved driveway that is

located between two buildings, and that serves both buildings;

b. Less than 2.1 m (7') above any paved driveway;

c. Within 1.8 m (6') (in Canada ) of a windo w or door, or mech anical

air supply inlet to any building, including soffit openings;*

d. Within 1.8 m (6') (in Canada) from the soffit of the roof of the

structure;*

e. Above a gas meter/regulator assembly within 0.9 m (3') of a

vertical centreline of the regulator;

f. Within 1.8 m (6') of any gas service regulator vent outlet, or within

0.9 m (3') of an oil tank vent, or an oil fill inlet;

g. Within less than 0.3 m (1') above grade level;

h. Within 1.8 m (6') of any other combustion air inlet;

i. Within 1.8 m (6') of a property line;

j. Underneath a veranda, porch or deck;

k. So that the flue gases are directed at combustible material or any

openings of surrounding buildings that are within 1.8 m (6');

l. Less than 0.9 m (3') from an inside corner of an L-shaped

structure;

m. So that the bottom of the vent termination opening is less than

0.3 m (1') above any surface that may support ice, snow, or

debris;

n. So t hat the flue gases are directed toward brickwork , siding or

other construction, in such a manner that may cause damage

from heat or condensation from flue gases.

For installations in the U.S.A. refer to Sectio n 6.7.3.4 of t he NFPA

31.

FIGURE 1

CAUTION

Most codes have a notwithstanding clause that states

that products of combustion shall not enter the dwelling

under any circumstances, even if all other code

requirements as to construction and location have been

complied with. The installer is ultimately responsible to

do whatever is necessary to ensure that flue gasses do

not enter the dwelling.

7

Page 7

Side wall venting installation - DV-2000™

445 01 4024 05

WARNING

Cuts and abrasion hazard.

Always wear protective gloves and eye protection

when handling the vent material.

The process of cutting and fitting the flexible

venting material exposes the installer to sharp

edges that could cause severe cuts to the skin.

Connection to the furnace breach - DV-2000™

1. Remove the standard breach plate by removin g the brass nu ts;

2. Determine which direction the venting will be routed from the

furnace and then install the special side-wall venting breach plate

provided in the VTK Series vent kit so that the breach plate test

port will be accessible after vent installation. However, do not

install the breach plate with the test port pointing downward.

Tighten the brass nuts;

3. The flexible venting h as 4 pieces of corrugated spin sleeve that

has been temporarily screwed on over top of it . Remove t he spin

sleeve completely by unscrewing it in a counter-clockwise

direction;

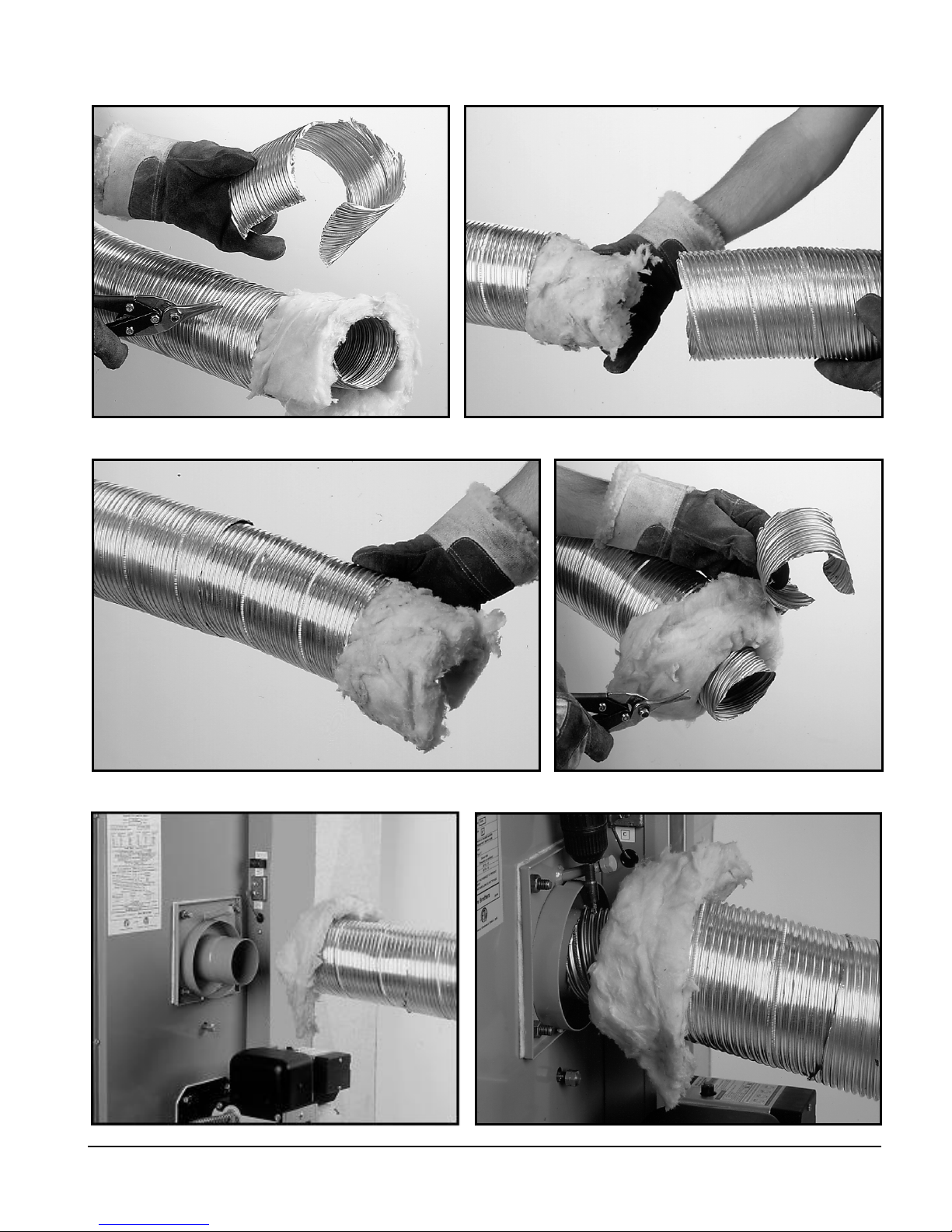

4. Using tin snips, cut t he aluminium outer sleeve back by 127.0

mm (5") on the IFV Series vent (see Figure 1.1). Ensure the

snips are well adjusted and sharp or th e cut end of the venting

will be too jagged to start the threads of the spin sleeve (see

Figure 1.1);

5. Prepare the furnace breach end of the i nsulated fle x vent by first

screwing the spin sleeve onto the corrugated aluminium jacke t

(see Figure 1.2) until the trailing edge of the s pin sleeve is about

0.3 m (12") from the end of the vent (see Figure 1.3);

6. Pull the insulatio n back to expose the corrugated s tainless steel

core;

7. Cut th e corrugated stainless steel core b ack by 76.2 mm (3") on

the IFV Series vent. You should now have about 76 .2 mm (3") o f

insulation hanging out past the stainless steel core (s ee Figure

1.4);

8. Push the stainless steel core ont o the b re ach pipe as far as it will

go (see Figure 1.5) and mechanically attach the vent to the

breach using three of the #8 X 1/2” self-drilling screws provided

with the VTK Series kit. The screws should be equally space d

around the circumference of the s tainl ess st eel c o r e, sta rtin g with

the first screw at top dead centre. Start the drill point of the

screws in the valleys of the corru gations at 9.5 mm –15.8 mm

(3/8”-5/8”) back from the end of the s tainless steel core, so the

screw heads can be properly sealed in the forthcoming

operations (see Figure 1.6);

9. With the stainless steel core no w firmly attached to the breach,

tear off one green gum-sealing str ip from the backing. Wrap the

seal strip around the joint, always keeping the centreline of the

seal strip over the line where the corrugate d stainless steel core

makes the transition to the smooth oute r surface of the breach

pipe. In other words, the seal strip must be ce nt re d over t he j oin t.

After wrapping the seal strip around once, allow 12.7 mm (1/2”)

overlap and tear off the residual length (see Figure 1.7);

10. Break the residual length of seal strip into 3 equal parts a nd stuf f

them onto the screw heads of the stainless steel self-drilling

screws so that the screw heads are completely covered;

11. Two stainless steel band clamps are provided in the VTK Series

kits. Position one stainless steel band clamp over the gum seal

joint so that the edge of the clamp closest to t he breach lines up

with the edge of the gum seal that is closest to the breach.

Ensure that the band will close with an action of one strip sliding

over the other - not under the gear hea d of the draw clamp (see

Figure 1.8). Tighten the band cla mp with considerable torque to

cause the gum seal to be squeezed i nto all crevice s and to ooze

out of the end of the clamp closest to the breach (see Figure 1.9).

The gum will eventually become rubbery;

12. The seal is permanent and should never need to be

disconnected as the breach plate can be r emoved for cleaning

and inspection using the 4-bolt joint;

13. Tuck the vent insulation into the breach collar;

14. Screw the spin sleeve tightly into the breach c ollar for a finished

appearance. Wrap the other end of the spin sleeve with

aluminium tape to cover any metal burrs that may be present

(see Figure 1.10);

15. Bend the venting into the desired radius coming off the breach.

Connection to the vent terminal - DV-2000™

1. Prepare the terminal end of the insulated flex vent by first

screwing the spin sleeve onto the corrugated aluminium jacke t

until the trailing edge of the spin sleeve is about 254.0 mm (10")

from the end of the vent;

2. Using sharp tin snips, c ut the aluminium outer sleeve back by

127.0 mm (5") on the IFV Series vent;

3. Pull the insulatio n back to expose the corrugated s tainless steel

core;

4. Cut th e corrugated stainless steel core b ack by 76.2 mm (3") on

the IFV Series vent. You should now have about 76 .2 mm (3") o f

insulation hanging out past the stainless st eel core ;

5. Push the stainless steel core onto the pipe on the back of the

terminal as far as it will go and mechanically attach the vent to

the terminal using three of the #8 X 1/2” self-drilling screws

provided with the VTK Series kit. The screws sho uld be equally

spaced around the circumference of the stainless steel core,

starting with the first screw at top dead centre. Start the d rill point

of the screws in the valleys of the corrugations at 9.5 mm-15.8

mm (3/8”-5/8”) back from the end of the stainless steel core;

6. With the s tainless steel core now firmly at tached to the terminal,

tear off the other green gum-sealing strip from the backing. Wrap

the seal strip around the joint, al ways keeping the centreline of

the seal strip over the line whe re the corrugated stainless steel

core makes the transition to the smooth outer surface of the

terminal pipe. After wrapping the seal strip around once, allow

12.7 mm (1/2”) overlap and tear off the residual length;

7. Break the residual length of se al strip in to 3 e qual parts and s tuff

them onto the screw heads of the stainless steel self-drilling

screws so that the screw heads are completely covered;

8. Position the o ther stainless steel band clam p over the gum seal

joint so that the edge of the clamp closest to the terminal lines up

with the edge of the gum seal that is closest to the terminal.

Tighten the band clamp with considerable t orque to cause the

gum seal to be squeezed into all crevices and to ooze out of the

end of the clamp closest to the terminal (see Figure 1.11);

9. The seal is permanent and should never need to be

disconnected as the end of the terminal can be opened for

cleaning and inspection by removing the screened end-cone

assembly. Tuck the vent insulation into the recess in the terminal

body;

10. Screw the spin sleeve tightly into the recess for a finished

appearance. Wrap the other end of the spin sleeve with

aluminium tape to cover any metal burrs that may be present

(see Figure 1.12);

11. Bend the venting into the desired radius coming off the terminal.

8

Page 8

THREAD SPIN SLEEVE

ONTO OUTER SLEEVE

CUT OUTER SLEEVE

BACK 5”

THREAD SPIN SLEEVE BACK 10” CUT STAINLESS STEEL

CORE BACK BY 3”

9

FIGURE 1.3 FIGURE 1.4

FIGURE 1.1 FIGURE 1.2

FIGURE 1.5 FIGURE 1.6

INSERT STAINLESS STEEL

CORE ONTO BREECH TUBE

DRIVE THREE STAINLESS STEEL

SCREWS, STARTING NEAR TOP

445 01 4024 05

Page 9

CORRECT BAND

OVERLAP

FIGURE 1.9 FIGURE 1.10

FIGURE 1.7 FIGURE 1.8

SEALANT FLOWING OUT FROM UNDER BAND CLAMP AT

TERMINAL

SEALANT OUTFLOW

FIGURE 1.11

1

0

APPLY THE

SEALANT TO THE

TUBE END

SEALANT OUTFLOW

SEALANT FLOWING

OUT FROM UNDER

BAND CLAMP AT

BREECH

TWIST SPIN SLEEVE TIGHTLY INTO

BREECH COLLAR

445 01 4024 05

Page 10

11

TWIST SPIN SLEEVE TIGHTLY INTO RECESS

INSTALL

STABILIZER

SHROUD

CAULK TO SEAL STABILIZER

SHROUD TO THE WALL

FIGURE 1.13 FIGURE 1.14

FIGURE 1.12

VENT TERMINAL PRESSURE SWITCH.

REFER TO WIRING DIAGRAM FOR ELECTRICAL

CONNECTION.

445 01 4024 05

Page 11

Installing terminal in the wall - DV-2000™

445 01 4024 05

1. Cut a 152.4 mm (6") hole in t he side-wall in accord ance with the

location considerations outlined in the previous section;

2. Fasten the wall plate to the inside-wall using 4 field-provided

fasteners appropriate for the material behind the wall plate.

Depending on the angle of access, the p ressure control bracket

may need to be removed to access the top righ t wall plate scre w

hole. For concrete and block, Tapcon™ scr ews or equivale nt are

recommended. Install the wall plate so that the top of the hole i n

the wall plate is positioned 3.2 mm (1/8”) lower than the top of the

152.4 mm (6") hole in the wall. This will accommodate the proper

downward slope of the terminal, in the direction from the inside to

the outside;

3. Remove the 2 screws fastening the end cone in place and

remove the cone;

4. Remove the 2 screws fastening the stabiliser shroud in plac e and

remove the stabiliser shroud;

5. Insert the main body of the ter min al th roug h t he wa ll plat e so t hat

the end of the terminal extends about 50.8 mm (2") past the

outside wall;

6. Install the stabiliser shroud and replace the two mounting screws.

(see Figure 1.13);

7. On concrete and block wall ins talla tions in particul ar, if it appea rs

that the flange at the back of the stabiliser shroud is not large

enough to cover the irregularities in the hole, a field fabricated

wall plate can be constructed of 304, 316, or 316L stainless steel;

8. Silicone seal the circumference of the joint where the stabiliser

shroud connects to the main body of the terminal;

9. Apply caulking to the back plate of the stabiliser shroud and push

the terminal back firmly against the wall;

10. While pushing down gently on the top of the stabiliser shroud,

install the three 2" stainless steel screws provided with the kit to

secure the back of the shroud to the wall. Do not overtighten the

screws or it will distort the stabiliser shroud. The screws will not

be necessary in a concrete or block wall as the mortar can

provide positive positioning;

11. Tighten the clamp on the wall plate to secure the terminal in

place;

12. Apply more caulking all around the seam where the stabiliser

shroud meets the wall. It is important to have a good seal to

prevent water from entering the dwelling (see Figure 1.14). A

considerable amount of caulking may be necessary for irregula r

wall surfaces such as lapped siding;

13. Install the end cone and replace the two mounting screws;

14. Support the vent and intake air piping so that a 6.4 mm to 12.7

mm (1/4” to 1/2”) downward slope (toward the outsi de ) results for

proper drainage out the terminal body.

Connection of combustion air piping to the terminal - DV-2000™

Refer to Part 1, section 5.3 (1.5.3), Outdo or Combustion Air – Sidewall Venting, DV-2000™ for a complete description.

1.5) AIR FOR COMBUSTION

WARNING

Poisonous carbon monoxide gas hazard.

Comply with NFPA standards for the installation of

Oil Burning Equipment and applicable provisions of

local building codes to provide combustion and

ventilation air.

Failure to provide adequate combustion and

ventilation air can result in personal injury and/or

death.

1.5.1) General

Oil furnaces must have an adequate supply of combustion air. It is

common practice to assume that older homes have sufficient

infiltration to accommodate the combustion air requirement for the

furnace. However, home improvements such as new windows, doors,

and weather stripping have drastically reduced the volume of air

infiltration into the home.

Home air exhausters are common. Bathroom a nd kitchen fans , power

vented clothes dryers, and water h eaters all tend to creat e a negative

pressure in the home. Should this occur, the chimne y becomes less

and less effective and can easily downdraft.

Heat Recovery Ventilation Systems (H RVs) are gaining in popularity.

HRVs are not designed to supply combustion air. If not properly

balanced, a serious negative pressure co ndition could develop in the

dwelling.

1.5.2) Contaminated Combustion Air

Installations in certain areas or types of structures will increase the

exposure to chemicals or Halogens which may harm the furnace.

These instances will require that only outside air be used for

combustion.

The following areas or types of structures may contain or be exposed

to certain substances, potentially requiring outside air for combustion:

a. Commercial buildings;

b. Buildings with indoor pools;

c. Furnace s insta lled ne ar ch emica l storag e ar eas.

Exposure to the following substances:

a. Permanent wave chemicals for hair;

b. Chlorinated waxes and cleaners;

c. Chlorine based swimming pool chemicals;

d. Water softening chemicals;

e. De-icing salts or chemicals;

f. Carbon tetrachloride;

g. Halogen type refriger ants;

h. Cleaning solvents (such as perchloroethylene);

i. Printing inks, paint removers, varnishes, etc.;

j. Hydrochloric acid;

k. Solvent based glue;

l. Antistatic fabric softeners for clothes dryers;

m. Acid based masonry cleaning materials.

1.5.3) Ducted outdoor combustion air

Three burners are set up to duct outside combus tion air direc tly to the

burner: the Beckett AFII and Riello 40 -BF for side-wall venting using

the new DV-2000™ venting system, and t he Becke tt AF G for us e wit h

conventional chimney venting. The Riello 40-F is not suitable for

direct-connected outdoor air.

CAUTION

The use of ducted outside combustion air is mandatory

for the DV-2000™ venting system. This system

operates on a balanced flue principle and will not

function properly if the combustion air piping is not

attached and sealed at all connections between the

vent terminal and burner inlet.

12

Page 12

Outdoor combustion air kits – chimn ey v enting

445 01 4024 05

The following kit has been certified f or use on this appliance. The kit

contains an important safety featu re, namel y a vacu um relief valve, or

VRV. During normal operation th e burner aspirates outdoor ai r. If the

intake terminal ever becomes partially blocked o r fully blocked from

ice or snow etc., the VRV will open to allow a proportion of air from the

dwelling to enter the burner thus maintaining proper combustion. Once

the blockage is removed, the VRV will close and the burner will draw

all air from the outdoors again.

CAS-2B Components (except air duct ) for the Beckett AFG burner:

The kit includes the intake terminal, vacuum relief valve (VRV) and

special air boot connection with integral air adjust ment means for the

AFG burner. The CAS-2B can be used with a 101.6 mm (4")

galvanized steel air duct or with a 101.6 mm (4") flexible alumini um ai r

duct. It is recommended that the metallic air ducting material be

insulated from the air intake up to 1.5 m (5') from the burner, to avoid

condensation on the outside of the intake pipe.

CAUTION

The CAS-2B does not turn the furnace installation into a

direct vent system. Therefore, the building structure

must provide for adequate combustion air to be

delivered to the Vacuum Relief Valve. The burner will

need to draw combustion air from the VRV’s

surroundings if the intake ever becomes blocked.

Therefore, non-direct vent installation codes must be

followed.

CAD-1 This air duct kit consists of 7.6 m (25') o f insulated UL/U LC

Listed Class 1 air duct and two 101.6 mm (4") steel band clamps . The

duct incorporates a corrugated flex ible aluminium c ore, su rrounded by

fibreglass insulation and a vinyl vapour barrier.

Comprehensive installation instructions are provided with the kit.

Outdoor combustion air – side-wall venting, DV-2000™

The new DV-2000™ venting system is a sealed system and

completely isolates the furnace from the inte rior of the building. The

burner is totally unaffected by any pressure fluctuations within the

building which makes it ideal for tight home construction.

The DV-2000 ™ venting system requires a dditional parts, which are

not included with the kit. These additional parts must be constructed of

3" Schedule 40 PVC, PVC-SWV, SDR-26, SDR-21, Septic Sewer

Pipe, or ABS plastic pipe, fittings and sealant. Also, installation

procedures, piping and fittings must conform to the following ANSI

/ASTM standards:

PVC ASTM D-1785

SDR26, SDR21 ASTM D-2241

Septic Sewer Pipe ASTM D-2729

PVC-DWV ASTM D-2665

PVC Primer and Solvent Cement ASTM D-2564

ABS Pipe and Fittings ASTM D-2235

Procedure for Cementing Joints ASTM D-2855

Additional parts required (not included in VTK kit)

a. 3" elbow fitting as required;

b. 3" plastic pipe;

c. 3" 90° elbow, female-female(for terminal);

d. 3" female to 2 inch female reducer (Riello 40-BF burner only);

e. 2" 90° elbow, street type, female-male (Riello 40-BF burner only);

f. 3" female-female PVC or ABS coupling (not sewer pipe) (Beckett

AFII burner only);

g. Transition bushings to go from PVC or ABS to ASTM D2729

Septic Sewer Pipe (if applicable).

If PVC fittings are mixed with ABS fittings, use solvent ceme nt that is

approved for bonding the two plastics.

Intake pipe length - DV-2000™

The DV-2000 ™ venting system has been certified for 37 equivalent m

(120 equivalent feet) of 3" intake pipe. Count a 90° elbow as 10

equivalent feet and a 45° elbow as 5 equivalent feet in the calculation.

For example:

1 1.5 m (5') length = 1.5 equivalent m (5 equiv. feet)

2 3.0 m (10') lengths = 6.0 equivalent m (20 equiv. feet)

3 90° elbows = 9.0 equivalent m (30 equiv. feet)

2 45° elbows = 3.0 equivalent m (10 equiv. feet)

1 90° elbow (terminal) = 3.0 equivalent m (10 equiv. feet)

1 90° elbow (Burner) = 3.0 equivalent m (10 equiv. feet)

Total = 25.5 equivalent m (85 equiva lent feet) ;

this is below the 37 equivalent meters (120 equiv. feet).

Intake pipe installation - DV-2000™

Obtain the necessary additional parts, to comple te t he inst allation , an d

start by piping at the burner. If the optional vestibule has been

installed, remove the appropriate knockouts in the side panels of the

vestibule. The lower 127.0 mm (5") knockout in t he righ t-hand p anel is

used for the Beckett AFII burner. The high er 127.0 mm ( 5") knockout s

on the right and left-hand pa nels are for righ t or left connectio n to the

Riello 40-BF burner.

Beckett AFII burner

Remove the burner intake cover by removing the 3 screws sec uring it

in place. Discard the cover and screws. Apply silicone liberally around

the end of a 3" coupling and fully insert the siliconed end into the

burner opening. Fasten securely with 3 self-tapping sheet metal

screws.

Riello 40-BF burner

Fully insert the female end of the 2" 90° street elbow into the

combustion air fitting on top of the burner. Faste n securely with 3 selftapping sheet metal screws. Cement the 2" end o f t he 3" fe mal e to th e

2" female reducer onto the male end of the 2" 90° street elbow. If

these parts are not easily obtained, use a 3" 90 ° street elbow with the

male end fitted over the combustion air fitting. The fitting will have to

be silicone sealed as the fit is a bit loose. Fasten securely with 3 selftapping sheet metal screws.

Terminal connection

Insert the 3" 90° female-female elbow onto the stainless steel air

intake fitting located on the right side of the vent terminal (viewe d from

the rear). Fasten securely with 3 self-tapping sheet metal screws.

Intermediate piping

Pipe as required between the term inal and t he burn er. Ens ure th at th e

3" piping is routed and supported in accordance with local and

national codes. Obey minimum furnace clearances to combustibles

when routing any section of 3" piping in the vicinity of the furnace. If

Septic Sewer Pipe is to be used, install transition bushings on the 3"

female ends of the fittings at the burner and at the terminal. Transition

bushings are readily available and are required because 3" PV C and

ABS pipes have a typical outside diameter of 3.5", whereas Septic

Sewer Pipe has a typical outside diameter of 3.25".

1.6) OIL TANKS AND LINES

Check your local codes for the installation of the tank and accessories.

A manual shut-off valve and an oil filter shall be installed in sequenc e

from tank to burner. Be sure that the oil line is clean before connecti ng

to the burner. The oil line should be protected to eliminate any

possible damage. Installations having the fuel oil tank below burner

level must employ a two pipe fuel supply system with an ap propriate

fuel pump. For more than a 2.4 m (8') rise use a 2 stage pump; for

more than a 4.9 m (1 6') rise, an auxiliary pu mp .

13

Page 13

445 01 4024 05

Follow the pump instructions to determine the size o f pipe yo u need i n

relation to the rise, or the horizontal distance.

At the beginning of each heating season or onc e a year, check the

complete oil distribution system for leaks.

1.7) BURNER INSTALLATION

Mounting the burner

1. The warm air furnace burner mounting plate has a 4-bolt

configuration;

2. Position the mounting gasket between the mounting flange and

the appliance burner mounting plate. Line up the holes in the

mounting flange with the studs on the appliance mounting plate

and securely bolt in place.

After the burner is mounted

1. Remove drawer assembly or air tube combination;

2. Install nozzle (see specifications);

3. Confirm electrode settings;

4. Make the electrical connections;

5. Complete oil line connections.

CAUTION

Do not turn on the burner until you have checked:

Checking the polarity

Oil burners used on furnaces have solid state co ntrol systems which

make them sensitive to the proper con nections of the hot and n eutral

power lines. The controls will be damaged if the 2 lines are reversed.

1. Set your voltmeter to line voltage;

2. Place one prong on your grounded electric entry box and one

prong on the black wire;

3. Read the voltage;

4. If the voltage is zero, check the white wire. If line voltage shows,

reverse the 115-volt leads entering the furnace junction box;

5. If you do not have a voltmeter, use a pilot light.

DNS-0864 Rev. A

Checking the nozzle

The burner is equipped with an appropriate nozzle. However, if

another size or a replacement nozzle is required, use the

manufacturer’s nozzle data concerning spray angle, as shown in

Table 4. Note that all nozzle sizes are based on a pump pressure of

100 PSI.

Always select nozzle sizes by working back from the actual desired

flow rate at operat in g pr e s sur e , and not by the nozzle ma r k in g.

FIGURE 2

Checking the air and turbulator settings

Before starting the burner for the first time, adjust the air and turbulator

settings to those listed in Table 4. Once the burner becomes

operational, final adjustments will be necessary.

Checking the fuel supply system

Fuel Specifications

NOTE: Use No.1 or No.2 Heating Oil (ASTM D396) or

in Canada, use No.1 or No.2 Furnace Oil.

Before starting the burner, be sure the fuel tank is filled with clean oil.

NOTE: You may notice a slight odor the first time your

furnace is operated. This will soon disappear. It is only

the oil used on certain parts during manufacturing.

WARNING

Fire and explosion hazard.

Use only approved heating type oil in this furnace.

DO NOT USE waste oil, used motor oil, gasoline or

kerosene.

Use of these will result in death, personal injury

and/or property damage.

IMPORTANT

When using nozzle sizes of less than .75 USGPH, the

Installation Code for oil burning equipment requires the

installation of a 10 (or less) micron filter in the fuel oil

line. ICP requires that this practice be followed in order

to keep the lifetime heat exchanger warranty intact.

1.8) BLOCKED VENT SHUT-OFF (BVSO)

For chimney venting

WARNING

It is imperative that this device be installed by a

qualified agency.

This device is designed to detect the insufficient evacuation of

combustion gases in the event of a ven t blockage. In suc h a case the

thermal switch will shut down the oil burner. The device will then need

to be re-armed MANUALLY.

Refer to the wiring diagrams and the detailed instructions supplied

with the BVSO for the installation and wiring procedures. The leng th of

wires supplied with the unit is such that the safety device must be

installed between the flue outlet of the appliance and the draft

regulator, as indicated in the instructions.

It is further imperative that the BVSO be maintained annually

more details refer to the instructions supplied with the device itself, as

well as Section 3. of this Manual.

. For

14

Page 14

445 01 4024 05

CAUTION

A positive pressure venting system (Sealed Combustion

System or Direct Vent) MUST NOT use the BVSO. Follow

the instructions supplied with the venting system.

1.9) INSTALLING ACCESSORIES

WARNING

Electrical shock hazard.

Turn OFF electric power at fuse box or service

panel before making any electrical connections and

ensure a proper ground connection is made before

connecting line voltage.

Failure to do so could result in bodily injury or

death, property damage.

1.9.1) Electronic air cleaner

Wire terminals are provided to direct 115 volts @ 0.5 Amp maximum

to an Electronic Air Cleaner (EAC). Power will be available to the EAC

at all times, so it must incorporate a flow proving switch if it is to be

wired into the furnace control box. Most modern EACs have the

required integral airflow proving switch. Wire the Electronic Air Cleaner

between terminals #5 and #2. Refer to wiring diagram, Figure 6.

1.9.2) Humidifier

The red wire from burner ca n be used to direct 1 15 volts

maximum to the transformer

will be energized anytime the burner is operating in the “Heating

Mode”. Refer to wiring diagram, Figure 6.

powering the humidifier. The humidifi er

1.9.3) Air conditioning

An air conditioning coil may be i nstalled on the supply air side only.

Also, notwithstanding the evaporator coil manuf acturer’s instructions,

a minimum of 6 inches clearance must be allowed between the bottom

of the coil drain pan and the top of the heat exchanger. Wire the

thermostat and condensing unit contactor as indicated in the wiring

diagram (Figure 6).

1.9.4) Ductwork and Filter

Installation

Design and install the air distribution system to comply with Air

Conditioning Contractors of America manuals or other approved

methods that conform to local and/or national codes and good trade

practices.

@ 1.0 Amp

CAUTION

When ducting supplies air to a space other than where

the furnace is located, the return-air ducts must be

sealed and also be directed to the space other than

where the furnace is located. Incorrect ductwork

termination and sealing will create a hazardous

condition which can lead to bodily harm.

Install air conditioning cooling coil (eva porator) on downstream side

from the supply air plenum of the fu rnace. If a separate evaporator

and blower unit is used, install appropriate sealing dampers for air flow

control. Cold air from the evaporator coil goi ng through the furnace

could cause condensation and shorten furnace life.

CAUTION

Dampers (purchased locally) MUST be automatic.

WARNING

Poisonous carbon monoxide gas hazard.

Do NOT draw return air from inside a closet or

utility room. Return air duct MUST be sealed to

furnace casing.

Failure to properly seal duct can result in death,

personal injury and/or property damage.

WARNING

Poisonous carbon monoxide gas hazard.

Install evaporator coil on the supply side of the

furnace ducting.

Evaporator coil installed in return side ducting can

cause condensation to form inside heat exchanger

resulting in heat exchanger failure. This could

result in death, personal injury and/or property

damage.

15

Page 15

PART 2

445 01 4024 05

OPERATION

2.1) MANUAL OPERATION SWITCHES

DNS-0604 Rev.B

2.2) SEQUENCE OF OPERATION

2.2.1) Sequence of operation - Beckett AFII

Side-wall venting

1. On the Beckett AFII burner, the T-T terminals have to be

jumpered on the primary control of the burner;

2. Normally open contact (W-R) on SPDT relay closed when

thermostat calls for heat;

3. Burner motor starts and spark is established. The burner motor

fan pre-purges the combustion cham ber and vent for 15 to 20

seconds, establishing the combustion air pattern;

4. After pre-pur ge period, solenoid valve opens, allowing oil to flow

through nozzle;

5. The ignition transformer spark ignites oil spray;

6. Cad cell senses flame and burner continues to fire;

7. After Fan-Limit Control heats up to the factory set point, the

circulating air blower starts;

8. The circulating ai r blower, burner motor and igniti on transformer

remain on until the thermostat is satisfied. Also, the solenoid

valve remains open;

Thermostat is sat isf ie d:

9. SPDT relay contacts open, solenoid valve closes, burner fan

motor post-purges the combustion cham ber and vent for a preset time of 15 seconds. The ignition transformer also continues to

spark for this time period;

10. During the post-purge cycle, the Fan-Li mit Control cools down to

the factory set point of 32°C (90°F) and the circulating ai r blowe r

turns off.

2.2.2) Sequence of operation - Riello 40-BF

Side-wall venting

1. Normally open contact (W-R) on SPDT relay closed when

thermostat calls for heat;

2. Burner motor starts. The burner motor fan pre-purges the

combustion chamber and vent for 10 seconds, e stablishing the

combustion air pattern. During this time the solenoid valve

holding coil pressure will be approximately 100 psig;

FIGURE 3

3. Afte r the pre-purge p eriod, the solenoi d valve opens, allowing oil

to flow through the nozzle. At the same time, th e burner motor

ignition coil produces spark;

4. The ignition transformer spark ignites the oil spray;

5. Cad cell senses flame and burner continues to fire. Ignition

transformer ceases sparking;

6. After Fan-Limit Control heats up to the factory set point, the

circulating air blower starts;

7. The circulating air blower an d burner motor remain on until the

thermostat is satisfied. Also, the solenoid valve remains open;

Thermostat is sat isf ie d:

8. Rel ay contacts open, solenoid valve closes and the burner fan

motor post-purges the combustion cham ber and vent for a preset time of up to 15 seconds (5 inch breach model only);

9. During the post-purge cycle, the Fan -Limit C ontrol BI-metal co ols

down to the factory set point of 3 2°C (90°F), and the circulati ng

air blower shuts down.

NOTE: With burner relay contact open, the Riello 40BF will post-purge when 115 volt power is applied to the

burner.

2.2.3) Sequence of operation - Beckett AFG and

Riello 40-F - Chimney venting

1. On the AFG burner, the T-T te rminals have to be jumpered on

the primary control of the burner;

2. Normall y open contact (W-R) relay closes when thermostat calls

for heat;

3. Burner motor starts. The burner motor fan pre-purges the

combustion chamber and vent for 10 to 15 seco nds, establis hing

the combustion air pattern. After the pre-purge period, the

solenoid valve opens, allowing oil to flow through nozzle. At the

same time, the burner motor ignition coil produces a spark;

4. Spark ignites oil droplets;

5. Cad cell senses flame and burner continues to fire. Ignition

transformer ceases sparking;

6. After Fan-Limit Control heats up to the factory set point, the

circulating air blower starts;

7. The circulating air blower an d burner motor remain on until the

thermostat is satisfied;

Thermostat is sat isf ie d:

8. Relay contacts open, solenoid valve closes, burner fan motor

shuts down and the ignition transformer ceases sparking.

2.2.4) Sequence of operation - DV-2000™

Venting system

Normal operation

1. Before a call for heat, the contacts of the pressure switch are

closed;

2. When the room thermostat calls for heat, the normally open

contact W-R closes, the burner blower starts and creates suc tion

in the intake piping circuit and pressure in the vent piping circuit;

3. The differential pressure set poi nt of the pressure switch is not

exceeded and the thermostat circ uit remains close d until the call

for heat has ended.

16

Page 16

445 01 4024 05

Abnormal operation

Start-up

1. When the room thermostat calls for heat, the normally open

contact W-R closes, the burner blower starts and creates suc tion

in the intake piping circuit and pressure in the vent piping circuit;

2. If there is a blockage in the intake or vent openings to c ause a

pressure differential beyond the set poin t of the pressure switch,

then the thermostat circuit is opened and the burner will go into a

15 seconds post-purge and then shut down;

3. Once the burner blower shuts down, after the post-purge, the

pressure switch contacts will re-close. If the call for heat remains,

the burner will re-start. If the blockage still exists, th e thermostat

is again opened, and the burner post- purges agai n. The postpurge function thus becomes an inherent anti-short cycling

device;

4. The unit will essentially go into a continuous re-cycling/postpurge mode with no heat being suppli ed to the dwelling, which

will prompt a service call;

5. If, d uring the re-cyclin g/post-purges, th e blockage of the termi nal

is removed, the burner will immediately fire up at the end of the

current post-purge cycle.

During operation

If the terminal vent or intake openings become blocked to th e point

where the set point of the pressure switch is e xceeded, duri ng a firing

cycle, the burner flame will shut down and the burner will go into the

indefinite recycling/post-purge mode as described above, until the

blockage is removed.

2.3) CHECKS AND ADJUSTMENTS

2.3.1) General

During initial start-up and subsequent yearly maintenance calls, the

furnace must be thoroughly tested.

Open the oil bleed port screw and start the burner. Allow the oil to

drain into a container for at least 10 seconds. Slo wly clos e and ti ghte n

the bleed screw. The oil should fl o w absol ut el y f ree of whi te s tr eaks o r

air bubbles to indicate that no air is being drawn into the suction side

of the oil piping and pump. Fire the burne r. Adjust the oil pressure as

indicated in Table 4.

IMPORTANT

The burner must be put in operation for at least 10

minutes before any test readings are taken. For new

installations, set up the burner to the settings in Table 4

before firing. These are rough adjustments but they will

ensure that the burner will start and run smoke-free in

advance of the fine adjustments being made.

2.3.2) Restart after burner failure

1. Set thermostat lower tha n the room temperatur e;

2. Press the reset button on the burner primary control (relay);

3. Set thermostat higher than the room temper at u re for 10 secon ds,

then set lower than room temperature. This will start the

pre-purge cycle. Repeat twice;

CAUTION

Do not attempt to start the burner when excess oil has

accumulated, when the furnace is full of vapour, or

when the combustion chamber is very hot. Always keep

the supply valve closed if the burner is shut down for an

extended period of time.

4. Set thermostat higher than the room temp er atur e;

5. If the burner motor does not start or ignition fails, turn off the

disconnect switch and CALL A QUALIFIED SERVICE

TECHNICIAN.

2.3.3) Combustion chamber curing

Some moisture and binders remain in the ceramic combustion

chamber after fabrication. It is important to clear the chamber of th is

residue before testing. If you smoke test befo re curing, t he instrumen t

may become damaged. To cure the chamber, run the unit for 3

consecutive cycles, with 3 minutes of elapsed time in b etween each

cycle. Each burn cycle should be 3 minutes long. The exhaust will

have a pungent odour and produce a white cloud of steam.

2.3.4) Smoke / CO2 test

1. On chimney installations, pierce a test hole in the smoke pipe 1 8

inches above the furnace breach. On side-wall vented

installations, remove the threaded cap from the extended test

pipe that is welded into the 4-bolt breach pla te. Insert the smoke

test instrument probe into the open hole;

2. From a cold start, let the unit operate during 5 to 10 minutes;

3. Set the burner air setting until just a trace of smoke results (#1 on

the Bacharach scale);

4. Take a CO

smoke reading was taken and make note of it. Exa mple: 13.8%

of CO

5. Adjust th e burner air setting to obtain a CO

(or a O

the #1 smoke. Example: 12.3% of CO

6. This method of adjusting the burner will result in clean

combustion and ensure the proper functioning of the system.

sample at the same test location where the #1

2

or 2.5% of O2;

2

reading 1.5% lower

reading 2.0% higher) than the reading associat ed with

2

2

or 4.5% of O2;

2

2.3.5) Perform the supply air temperature rise test

1. Operate the burner for at least 10 minutes;

2. Measure the temperature of the air in the return air plenum;

3. Measure the temperature of the air in the largest trunk coming off

the supply air plenum, just outside the range of radiant heat

coming off the heat exchanger; 0.3 m (12") away from the

plenum on the main take-off is usually sufficient;

4. The temperature rise is calculated by subtracting the return air

temperature from the su pply a ir tem pera ture ;

5. If the temperature rise exceeds the temperature specified in

Table 4, change to the next higher blower speed tap until the

temperature rise falls to this temperature or below. If the

excessive temperature rise cannot be reduced b y increasing fan

speed, investigate for ductwork restricti on (s), dirt y or im prop er ai r

filter, overfiring caused by excessive pump pressure, or improper

nozzle sizing.

2.3.6) Vent temperature test

1. Afte r 5 to 10 minutes of operation, place a thermometer in the

test hole located in the breach pipe;

2. Th e vent temperature should be between 204 and 302°C (400

and 575°F). If not, check for improper air temperature rise, pump

pressure, nozzle size, or for a badly sooted heat exchanger;

3. Check the minimum permitted temperature at the base of the

chimney. Refer to the installation code in order to avoid the risk

of condensation in the chimney .

17

Page 17

445 01 4024 05

2.3.7) Overfire pressure test procedure

1. To read the pressure, replace the glass with the washe r supplied

with the appliance;

2. After the test, put the glass back in place in the sight glass

assembly;

3. Verify that the pressure readi ng c orres ponds to th e one sp ecified

in Table 4. Also see Figure 3.1.

DNS-0703 Rev. A

FIGURE 3.1

2.3.8) Fan-Limit adjustment

Modification of the “FAN ON” and “ HI” limit settings on the Fan-Limit

can cause malfunctioning of the furnace and result in pre mature wear

of the heat exchanger.

CAUTION

Modification of the factory set limits will void the

warranty.

2.3.9) Limit control check

After operating the furnace for at least 15 minutes, restrict the return

air supply by blocking the filters or the return air register and allow the

furnace to shut off on High Limit. The burner will shut off but the

blower will continue to run.

Remove the obstruction and the burner shou ld resta rt af ter a f ew

minutes.

DNS-0355 Rev. B

FIGURE 4

90˚ F Limit ‘’FAN OFF’’ 1

130˚ F Limit ‘’FAN ON’’ 2

200˚ F Limit ‘’HI’’ 3

2.3.10) DV-2000™ Blocked intake / blocked vent

test

On side-wall vented furnaces, the DV-2000™ venting system

incorporates a safety shutdown system that will shut the burner down

before #1 smoke occurs due to the prese nce of a blocked intake or

blocked vent outlet. Test the system as follows:

1. Ensure that the furnace has been running for at least 10 minutes;

2. Gradually block the intake. The burner flame sho uld shut down

before a #1 smoke reading occurs;

3. Gradually block the vent outlet. The burner flame should shut

down before a #1 smoke reading occurs;

4. If the burner does not shut down before #1 smoke occurs, ensure

that the burner is set up accordi ng to Part 2, section 3.4 (2 .3.4).

Perform the CO

operating headroom required by the instructions;

5. If the burner still does not shut down before #1 s moke occurs,

check for a blockage in the pressure hose, or at the hose

connection points.

/ Smoke Test, and allow for the 1.5% CO2

2

IMPORTANT

The DV-2000™ safety shutdown system will shut down

the burner flame during a blocked intake or blocked

vent condition if and only if the burner has been set up

and calibrated in accordance with Part 2, section 3.4

(2.3.4). Perform the CO2 / Smoke Test. For instance, if

the burner is adjusted and final-set to a #1 smoke

condition during normal operation, the burner flame

cannot possibly shut down before #1 smoke occurs

during a blockage condition.

2.3.11) BVSO performance test

The purpose of the following tes t is to check that the electrical outle t

on the furnace, designated to the BVSO, is functional.

1. Start up the burner;

2. Remove the three-pole plug from the BVSO outlet on the

furnace;

3. The burner must shut-off immediately, while the blower continues

to run to the end of the cool-down cycle.

If the test is not in line with the above, call a QUALIFIED SE RVICE

TECHNICIAN.

18

Page 18

PART 3

445 01 4024 05

MAINTENANCE

3.1) GENERAL

Preventive Maintenance

“Preventive maintenance” is the best way to avoid unnecessary

expense and inconvenience. Have your heating system and

burner inspected at regular intervals by a qualified service

technician.

After inspection, a complete combustio n test must be performed a fter

each annual service of the unit to maintain optimum performance and

reliability.

Do not tamper with the unit or controls. Call a qualified service

technician.

Before calling for service, check the following:

1. Check oil tank gauge and check if the oil tank valve is open;

2. Check fuse or circuit breaker;

3. Check if shut-off switch is “ON”;

4. Reset thermostat above room te mper atur e;

5. If ignition does not occur, turn off the disconnect switch and call a

qualified service technician.

When ordering replacement parts, specify the complete furnace

model number and serial number.

WARNING

Electrical shock hazard.

Turn OFF power to furnace before any disassembly

or servicing.

Failure to do so can result in bodily injury and/or

death, property damage.

3.1.1) Heat exchanger

The entire heat exchanger should be inspected annually for soot

accumulation. If the burner is operating nor mally there should be v ery

little soot accumulation. If the heat excha nger requires scale re moval,

use a wire brush first, to loosen the scal e and then vacuum the soot

and scale that has fallen into the s econdary heat exchanger (radia tor)

section. You will find that a 0.9m (36”) long flexible hose attachment

will be helpful to reach into the back of the radiator; a piece of 12.7

mm (1/2”) flexible gas connector, or a piec e of 12.7 mm (1/2”) liquidtight vinyl jacket metallic electrical conduit works well as a makeshift

device.

Cleaning the heat exchang er

Remove the 4-bolt flange from the fr ont of the furnace to expose th e

clean-out port and check for soot deposits. If t here is very little soot in

the radiator section visible from the clean-out port, you will not need to

clean it. However, if you notice scaling in the radiator, you should

remove the scale.

The wrap-around radiator can now be cleaned entirely from the front

inspection port. Also, the furnace has external cle an-out ports so the

soot does not fall into the fan compartment during the cleaning

operation.

IMPORTANT

Do not vacuum the ceramic chambers—they are easily

damaged.

Soot will have collected in the first sections of the heat exchangers

only if the burner was started after the combustion chamber was

flooded with fuel oil, or if the bu rner has been oper ating in a severely

contaminated condition.

3.1.2) Refractory firepot

Remove the burner and check the firepot.

IMPORTANT

Use extreme care if cleaning of the pot is required. After

firing, the pot becomes very fragile. Do not use any

commercially available soot remover. This furnace has

a fibre type refractory combustion chamber. Normal

servicing of this unit does not require cleaning of the

combustion chamber.

If the pot is damaged, it must be replaced. A dama ged pot could lead

to premature heat exchanger failure. Cracking of the firepot is normal,

however, replace the pot only if the cracks have propagated more

than 2/3 the way through the wall thickness. The average wall

thickness of the firepot is 19.1 mm (3/4”).

Flooding of the firepot

Flooding can occur when the oil primary control has been reset a

number of times in a no-heat situatio n. Each time oil is fired into the

pot and does not ignite, it is absorbed into the pot. Even if the burner is

removed and the pot is felt for wetness, it is difficult to assess the

degree of oil absorption by the pot.

There is only one way to pr operly service a floo ded firepot , and th at is

to change it.

CAUTION

If you observe the red warning light on the burner, push

ONLY once to try and restart. If the burner will not start,

call a qualified service technician. Do NOT press the

button again.

Self-aligning firepot

The primary heat exchange r of the furnace is comprised of an upper

and lower half. The lower half is essentially a “can” that contains a

self-aligning firepot. The firepot fits into the bottom half in one directio n

only.

Removing the firepot

The firepot is seldom replaced, b ut when it has to be replaced one

must simply:

1. Remove the burner;

2. Remove the burner Limit Control;

3. Remove the breach plate;

4. Remove the front panel;

5. Remove the brass nuts on the stainless steel heat exchanger

studs;

19

Page 19

445 01 4024 05

6. Pry the bottom half of the heat exchanger apart by using the

designated prying tabs;

7. Remove th e bottom half of the heat e xchanger through the f ront

of the furnace;

8. Pull the firepot up and out of the bottom half of the heat

exchanger;

9. Remove th e old sealing gasket from the flan ge of the upper half

of the heat exchanger;

10. Scrape any residual gasket material off the matching flanges of

the heat exchanger.

Replacing the firepot

1. Align the slot at the f ront part of the firepot with the b urner tube

sleeve and gently lower the firepot into the bottom half of the heat

exchanger;

2. Holding the fire pot near the perimeter, gently pus h the firepot all

the way into the bottom half of the heat exchanger until it is

properly seated;

3. Thoroughly wet the gasket with water using a sp ray pum p bottle,

position the tabs over the studs, and push the gasket upward

against the sealing flange of the upper half of the heat

exchanger;

4. Install the brass nuts on the studs by engaging only 2 or 3

threads;

5. Position the bottom half of the heat exchanger underneath the

upper half and align the bottom half so that the slots in the bolting

tabs engage the stainless steel studs. T he re is n o f urth er ne ed to

hold onto the bottom half as it will now be suspended on the stud

nuts;

6. Push upward on the housing a nd thread the nuts finger-tight as

far as possible;

7. Intermittently tighten the brass nuts with a wrenc h in a sequence

that will pull the heat exchanger halves together evenly. Tighten

all nuts to 90 inch-lbs torque once and then alterna tely re-tighten

all nuts again to 100 inch-lb. THE RE-TIGHTENING SEQUENCE

IS ABSOLUTELY NECESSARY TO ENSURE A TIGHT JOINT;

8. Re-assemble the front panel, breach plate, Limit Control and

burner in reverse sequence to their removal;

9. Follow the ins tructions for starting the b urner for the first time to

cure the firepot and perform combustion checks. See Section

2.3.

3.1.3) Drawer assembly

Remove the drawer assembly. Clean all foreign matter from the

retention head and electrodes. If a Beckett AFG burner has been

installed, the burner will have to be removed to check the retention

head.

3.1.4) Nozzle

Replace the nozzle with the one specified in Table 4.

3.1.5) Oil filters

Tank filter

The tank filter should be replaced as required.

Secondary filter

The 10 (or less) micron filter cartridges should be replaced annually.

3.1.6) Air filters

Air filters are the disposable type. They s hould be replaced at least

once a year. Dusty conditions, presence of animal hair etc. may

require much more frequent filter changes. Dirty filters will impact

furnace efficiency and increase oil consumption.

3.1.7) Motor lubrication

Do NOT lubricate the oil burner motor or the direct driv e blowe r motor

as they are permanently lubricated.

3.1.8) CAS-2B combustion air kit (chimney

venting)

If used, check the CAS-2B combustion air kit for proper operation.

Check to see that the inlet screen is not plu gged. Block the air inlet

completely and ensure that a zero smoke reading res ults. If a zero

smoke reading is not obtained, s et up the burner as indicated in Part

2, section 3.

Gradually block off the intake. The CO

of 0.5 percentage points at the fully bl ocked condition. If not, check

that the VRV gate is pivoting freely and that the pivot rod is in a

horizontal position. Also, check that the counterweight has been

properly adjusted in accordance with CAS-2B installation instructions.

should increase to a maximum

2

3.1.9) Blocked Vent Shut-Off (BVSO) Cleaning

For continued safe operation, the Blocked Vent Shut-Off System

(BVSO) is required to be inspected and maintained annually by a

qualified agency.

1. Disconnect the power to the appliance.

2. Remove the two screws holding on the BVSO assembly cover.

3. Remove the cover.

4. Remove the two screws holding the thermal switch to the

assembly base.

6. Without removing the electrical wires, remov e the thermal s witch

and remove any build-up from the thermal switch surface.

CAUTION

Do not dent or scratch the surface of the t hermal

switch. If the thermal switch is damaged,

replacement is required.

6. Clear and remove any build-up or obstruction inside the heat

transfer tube.

7. Re-mount the thermal switch to the assembly base.

8. Re-attach the assembly cover with the screws removed in step 2.

9. Re-establish power to the appliance.

20

Page 20

445 01 4024 05

PART 4

INFORMATION

Model:

Installation date of the furnace:

Service telephone # - Day:

Dealer name and address:

START-UP TEST RESULTS

Nozzle:

Burner adjustments:

CO

% Smoke scale: (Bacharach)

:

2

Gross stack temperature:

Ambient temperature:

Chimney draft:

Overfire draft:

Test performed by:

Primary air

Fine air

Drawer Assembly

Serial number:

Night:

Pressure:

°F

°F

" W.C.

" W.C.

lbpsi

21

Page 21

TABLE 4

445 01 4024 05

Technical specifications

Model :

RATING AND PERFORM ANCE

Firing rate (USGPH) 0.50 0.63 0.75 0.72

Input (BT U/h) 70 000 88 200 105 000 100 800

Heating capacity, chimney installation (BTU/h) 58 000 72 500 85 200

Heating capacity, side-w all installation (BTU/h) 58 200 72 600 85 700 83 000

Minimum - maximum tem perature rise

Flue draft, (Chimney), (Side-w all)

Overfire pressure (chimney), (Side-w all)

BECKETT BURNER, CHIMNEY INSTALLATION