Page 1

• Safety Rules

• Installation

• Ventilation Air

• Vent & Combustion Piping

• Gas Supply & Piping

• Wiring

• Ductwork Connections

• Start-Up

• Maintenance

q

Design Certified

Printed in U.S.A.

Manufactured by:

Inter-City Products Corporation (USA)

Lavergne, TN USA 37086

by AGA.

NUGMSeries

CondensingGasFurnace

LP1 1008854 3J8/94

Page 2

_ Condensing Gas Furnace Installation Instructions I

Table of Contents

1. Safety Labeling andSignalWords .............. 3

Danger, Warning and Caution .................. 3

Danger Label ............................... 3

Warning Label .............................. 3

Caution Label .............................. 3

2. Safe Installation Requirements ................ 4

3. Installation ................................ 6

Dual Certified Furnace ......................... 6

Location and Clearances ....................... 6

Installation Requirements ...................... 6

False Floor Closet Installation ................... 9

4. Combustion & Ventilation Air .................. 10

Venting and Combustion Air Check ............... 10

Air Openings and Connecting Ducts .............. 10

Confined Space Installation ..................... 10

Requirements ....................... . ...... 10

Unconfined Space Installation ................... 12

Unusually Tight Construction ................... 12

Ventilation Air ............................... 12

5. Vent and Combustion Air Piping ................ 13

Dual Certified Furnace ......................... 13

Contaminated Combustion Air ................... 13

Vent and Combustion Air Piping Guidelines ........ 13

Piping Insulation Guidelines ................... 14

Sizing Combustion Air and Vent Pipe ............. 14

Vent Termination Clearances .................. 16

Condensate Drain Trap and Neutralizer ........... 16

Connecting Furnace and Piping ................. 16

Vent Pipe Connection ........................ 17

Air Inlet Pipe Connection ...................... 17

Joining Pipe and Fittings ...................... 18

Connecting Vent Pipes and Termination ........... 18

Vertical Termination .......................... 18

Horizontal Termination ....................... 18

Using Extedor Risers ......................... 19

Optional Vent Screens ........................ 19

Vent Termination Shielding .................... 19

6. GasSupplyand Piping ....................... 20

Supply Pressure .............................. 20

General U.S. Derating Rules ................... 20

General Canadian Derating Rules ............... 20

Manifold Gas Pressure Adjustment ............... 20

High Altitude Air Pressure Switch ................ 21

Changing Orifices for High Altitude ............... 21

Natural Gas Input Rating Check ................. 21

Gas Piping Requirements ...................... 22

Connections ................................ 22

Additional LP Connection Requirements .......... 22

Final Check ................................. 23

Startup ..................................... 23

7. Electrical Wiring ............................ 24

Grounding .................................. 24

Polarizing ................................... 24

Labeling .................................... 24

Power Supply ................................ 24

Thermostat ................................. 24

Heat Anticipator ............................. 24

Optional Equipment .......................... 25

Humidifier/Electronic Air Cleaner ................ 25

Wiring for Air Conditioning ..................... 25

Fan Control ................................. 25

S. Ductwork and Filter ......................... 26

Installation .................................. 26

Connections ................................ 26

Sizing ..................................... 26

Insulation .................................. 26

Filters ..................................... 26

Filter Installation ............................. 27

Addition Of Air Conditioning .................... 27

9. Checks and Adjustments ...................... 2g

Main Burner Flame Check ..................... 29

Pilot Burner Flame Check ...................... 29

Limit Control Check .......................... 29

Fan Control Check ........................... 30

Temperature Rise Check ...................... 30

Continuous Fan Operation ..................... 31

Separate speed selections for Heat, Cool, and

Continuous Fan ............................. 31

Heating and Continuous BLower Speed the Same ... 31

10. Furnace Maintenance ....................... 32

Filters ..................................... 32

Replacement ............................... 32

Blower Motor ................................ 32

Furnace Inspection ........................... 32

Vent Pipe .................................. 32

Return Air Duct .............................. 32

Furnace Base ............................... 32

Furnace Intedor ............................. 33

Pilot Burners ................................ 33

Main Burners ............................... 33

Condensate Disposal ......................... 33

11. CleaningHeat Exchangers.................... 34

Primary Heat Exchanger ....................... 34

Accessing .................................. 34

Cleaning ................................... 34

Secondary Heat Exchanger .................... 34

Accessing .................................. 34

Extedor Cleaning ............................ 34

Accessing Intedor of Secondary Heat Exchanger ... 34

Interior Cleaning ............................. 34

Cleaning Burners ............................ 35

Reassembly ................................ 35

12. Glossary of Terms ........................... 36

13. Appendix of Helpful Information ............... 37

Canadian Codes ............................. 37

Applicable Natural Gas and Propane Codes ....... 37

Applicable Electrical Codes .................... 37

United States Codes .......................... 37

Applicable Natural Gas and Propane Codes ....... 37

Applicable Electrical Codes .................... 37

Page 3

I.Condensing Gas Furnace

1, SafetyLabelingandSi0nalWords

Installation Instructions I

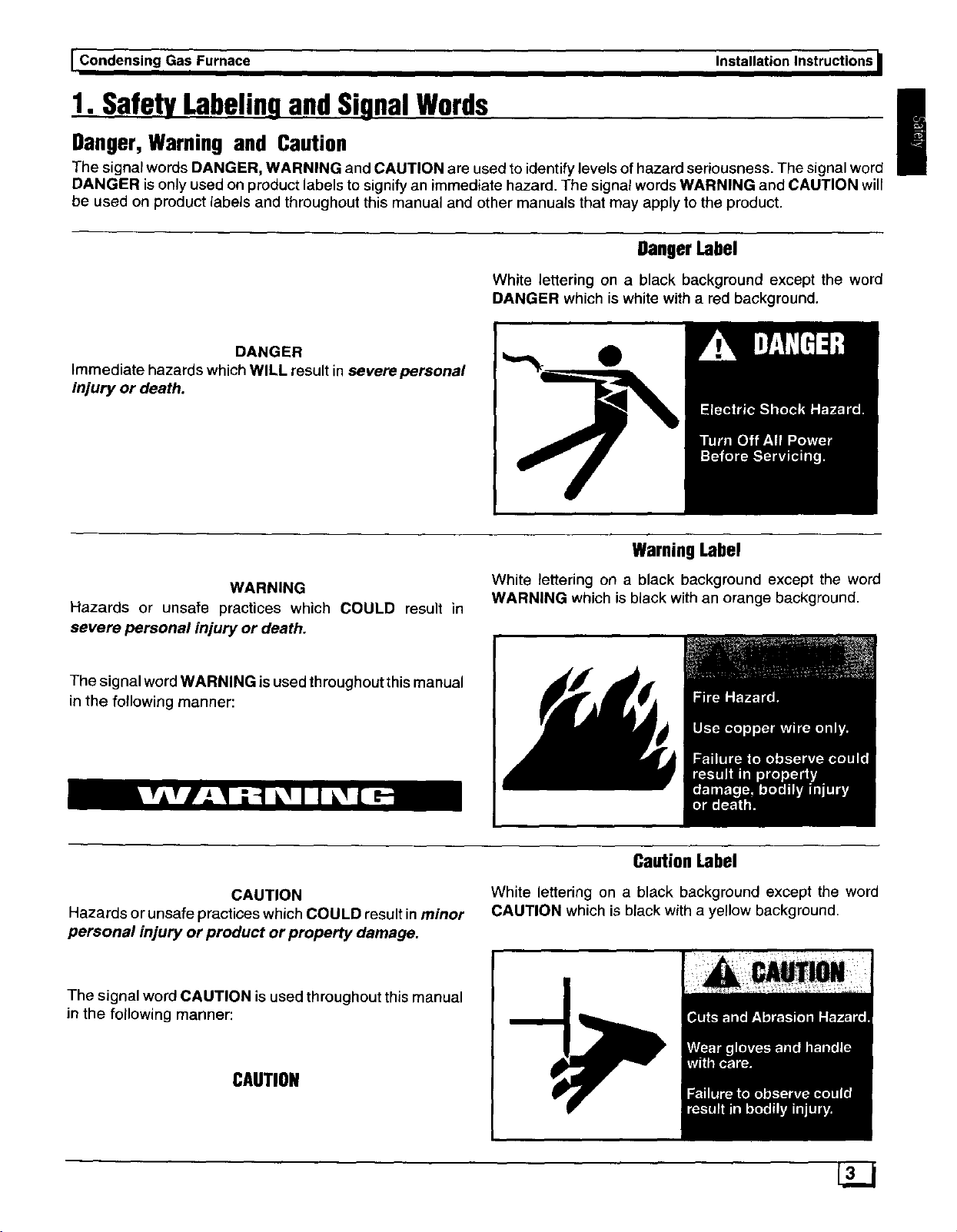

Danger,Warning and Caution

The signal words DANGER, WARNING and CAUTION are used to identify levels of hazard seriousness. The signal word

DANGER isonly used on product labels to signify an immediate hazard. The signal words WARNING and CAUTION will

be used on product labels and throughout this manual and other manuals that may apply to the product.

DangerLabel

White lettering on a black background except the word

DANGER which is white with a red background.

DANGER

Immediate hazards which WILL result in severe personal

injury or death.

WarningLabel

WARNING

Hazards or unsafe practices which COULD result in

severe personal injury or death.

White _ettering on a black background except the word

WARNING which is black with an orange background.

!

The signal word WARNING is used throughout this manual

in the following manner:

CAUTION

Hazards or unsafe practices which COULD result in minor

personal injury or product or property damage.

The signal word CAUTION is used throughout this manual

in the following manner:

CAUTION

CautionLabel

White lettering on a black background except the word

CAUTION which is black with a yellow background.

Page 4

_ Installation Instructions Condensin_l Gas Furnace I

2. SafeInstallationRequirements

Installation or repairs made by unqualified

persons can result in hazards to you and others.

Installation MUST conform with local codes or, in

the absence of local codes, with codes of the

country having jurisdiction. See Appendix.

The information contained in this manual is

intended for use by a qualified service technician

familiar with safety procedures and equipped

with the proper tools and test instruments.

Failure to carefully read and follow all instruc-

tions in this manual can result in furnace

malfunction, property damage, personal injury

and/or death.

NOTE: This furnace is design certified by the American

Gas Association and the Canadian Gas Association for in-

stallation in the United States and Canada. Refer to the ap-

propriate codes, along with this manual, for proper

installation.

• This furnace is NOT approved for installation in

mobile homes, trailers or recreation vehicles.

• Do NOT use this furnace as a construction heater.

• Use only the Type of gas approved for this furnace

(see Rating Plate on unit). Overfiring will result in

failure of heat exchanger and cause dangerous op-

eration.

• Ensure adequate combustion and ventilation air is

provided to the furnace.

• Seal supply and return air ducts.

• The vent system MUST be checked to determine that

it is the correct type and size.

• Install correct filter type and size.

• Unit MUST be installed so electrical components are

protected from direct contact with water.

NOTE; It is the personal responsibility and obligation of the

customer to contact a qualified installer to ensure that the

installation is adequate and conforms to governing codes

and ordinances.

Carbon Monoxide Poisoning Hazard.

This furnace can NOT be common vented or

connected to any type B, BW or L vent or vent

connector, nor to any portion of a factory-built or

masonry chimney. If this furnace is replacing a

previously common-vented furnace, it may be

necessary to resize the existing vent line and

chimney to prevent oversizing problems for the

other remaining appliance(s). See applicable

codes in appendix and Venting and Combustion

Air Check in Gas Vent Installation section. This

furnace MUST be vented to the outside.

Failure to properly vent this furnace or other

appliances can result in property damage,

personal injury and/or death.

• Do NOT use open flame to test for gas leak.

Page 5

I Condensing Gas Furnace

installation Instructions

START-UP CHECK SHEET

(Keep this page for future reference)

Dealer Name:

Address:

City, State(Province), Zip or Postal Code:

Phone:

Owner Name:

Address:

City, State(Province), Zip or Postal Code:

Model Number:

Serial Number:.

Type of Gas: Natural: [_1 LP: _1

Business Card Here

Manual Gas Shut-Off Upstream

of Furnace/Drip-Leg?

Drip-Leg Upstream of Gas Valve?

Condensate Drain Connected? YES _1 NO [_

Blower Speed Checked? YES CI NO [_1

All Electrical Connections Tight? YES _1 NO {_1

YES 1_1 NO [_1

YES {_1 NO _1

!

Blower Motor H.P.:

Supply Voltage:.

Limit Opens at...(°F) or(°C)__

Limit Closes at...(°F) or(°C).__

Which blower speed tap is used?

(Heating). (Cooling)

Temperature of Supply Air: (°F) or(°C).__

Temperature of Return Air: (°F)__. or(°C).__

Rise (Supply Temp - Return Temp): (°F) or(°C)__

Filter Type and Size:

Fan "Time ON" Setting:.

Fan 'q'ime OFF" Setting:

Gas Valve OK? YES CI NO[_I

Measured Line Pressure When Firing Unit:

Calculated Firing Rate:(See ChecksandAdjustmentsSec-

tion).

Measured Manifold Pressure:

Thermostat OK?

Subbase Level?

Anticipator Set?

Breaker On? YES [_1

Date of Installation:

Date of Start-Up:

YES O NO

YESI_I NOel

YES_I NO _1 Set At?:

NO _1

Dealer Comments:

Page 6

_ Installation Instructions Condensin_l Gas Furnace I

3. Installation

!

NOTE: Installation MUST conform with local building

codes and local plumbing and waste water codes, or inthe

absence of local codes, with codes of the country having

jurisdiction. See Appendix.

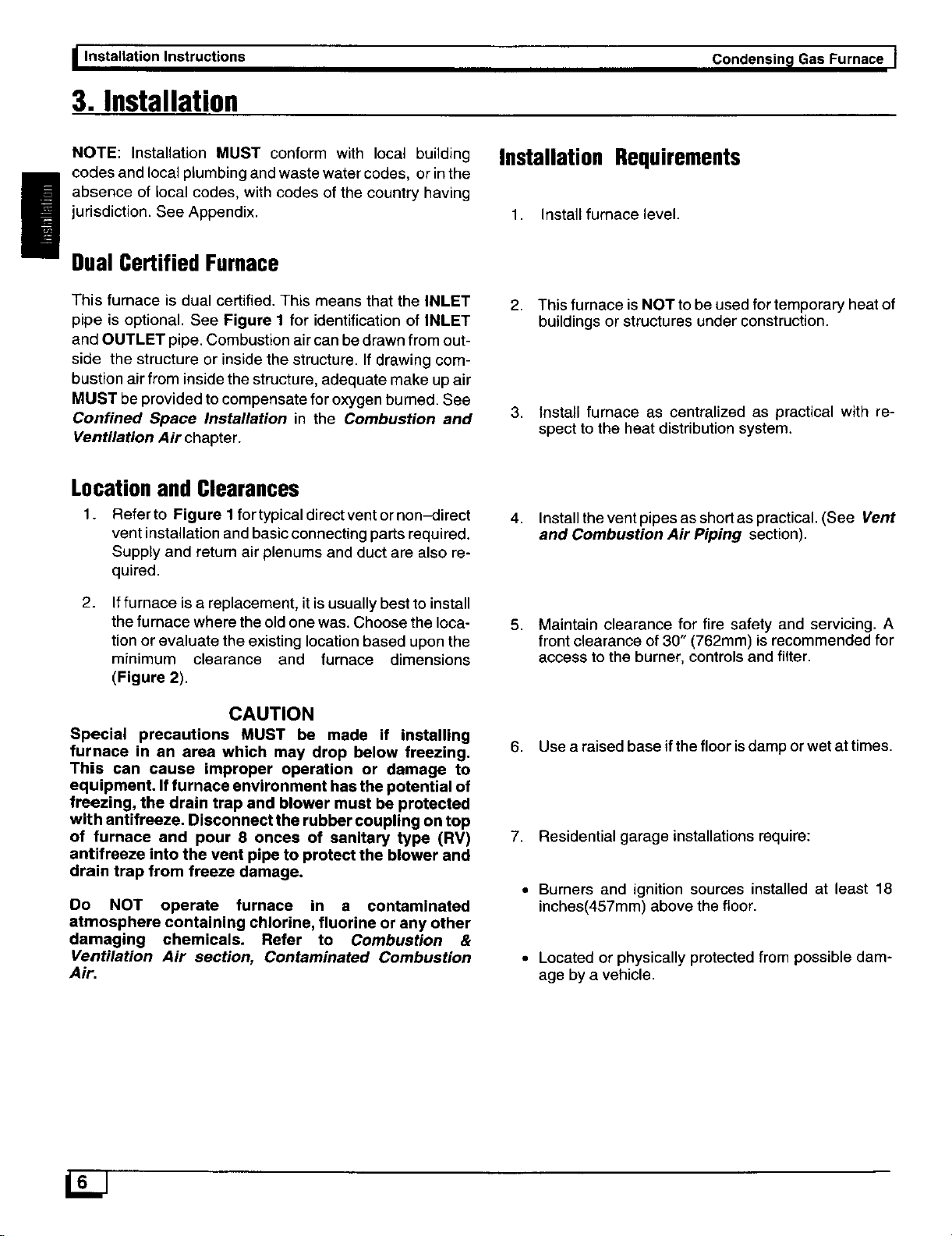

DualCertified Furnace

This furnace is dual certified. This means that the INLET

pipe is optional. See Figure "1for identification of INLET

and OUTLET pipe. Combustion air can be drawn from out-

side the structure or inside the structure. If drawing com-

bustion air from inside the structure, adequate make up air

MUST be provided to compensate for oxygen burned. See

Confined Space Installation in the Combustion and

Ventilation Air chapter.

LocationandClearances

1. Referto Figure 1 fortypicaldirectventornon_:lirect

vent installation and basicconnecting parts required.

Supply and return air plenums and duct are also re-

quired.

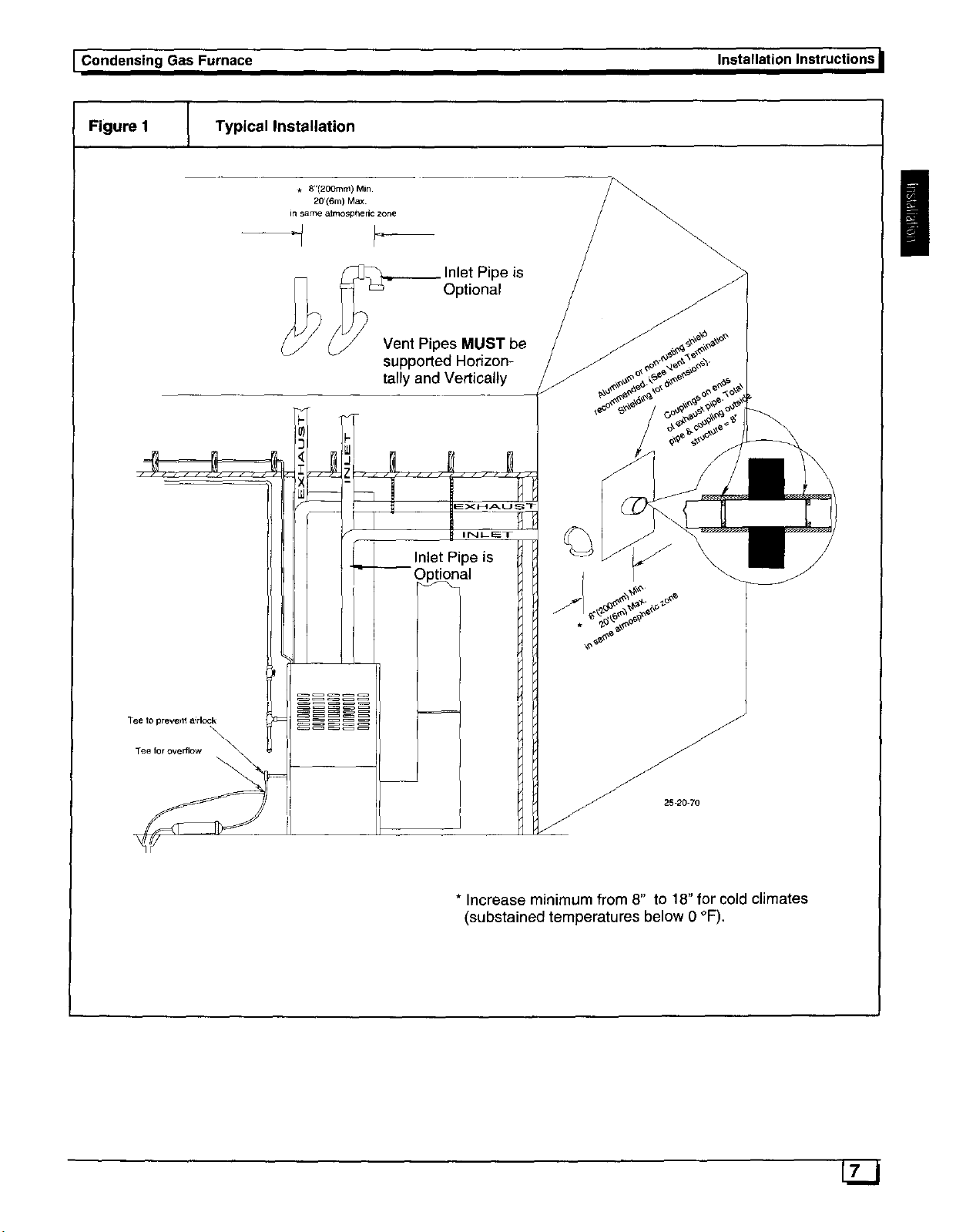

2.

If furnace is a replacement, it is usually best to install

the furnace where the old one was. Choose the loca-

tion or evaluate the existing location based upon the

minimum clearance and furnace dimensions

(Figure 2).

Installation Requirements

1. Install furnace level.

2. This furnace is NOT to be used for temporary heat of

buildings or structures under construction.

3. Install furnace as centralized as practical with re-

spect to the heat distribution system.

4. Install the vent pipes as short as practical. (See Vent

and Combustion Air Piping section).

5. Maintain clearance for fire safety and servicing. A

front clearance of 30" (762mm) is recommended for

access to the burner, controls and filter.

CAUTION

Special precautions MUST be made if installing

furnace in an area which may drop below freezing.

This can cause improper operation or damage to

equipment. If furnace environment has the potential of

freezing, the drain trap and blower must be protected

with antifreeze. Disconnect the rubber coupling on top

of furnace and pour 8 onces of sanitary type (RV)

antifreeze into the vent pipe to protect the blower and

drain trap from freeze damage.

Do NOT operate furnace in a contaminated

atmosphere containing chlorine, fluorine or any other

damaging chemicals. Refer to Combustion &

Ventilation Air section, Contaminated Combustion

Air,

6. Use a raised base if the floor is damp or wet at times.

7. Residential garage installationsrequire:

• Burners and ignition sources installed at least 18

inches(457mm) above the floor.

• Located or physically protected from possible dam-

age by a vehicle.

61ZJ

Page 7

I Condensing Gas Furnace Installation Instructions

Figure I Typical Installation

* 8"(200ram) Min.

20'(6m) Max.

in same atmospheric zone

--q

ipe is

Optional

Vent Pipes MUST be

supported Horizon-

tally and Vertically

!

Tee to prevellt a_rlc<tk

Tee for overflow

I NLE:T

Inlet Pipe is

\

* Increase minimum from 8" to 18" for cold climates

(substained temperatures below 0 °F),

7LZ.J

Page 8

_ Installation Instructions Condensin_lGas Furnace J

Figure 2 Dimensions and Clearances

|

I' 10 7_"

\

BACK

DRAIN

CONNECTION

Cabinet Clearances

TOP BOT RH LH BACK FRNT FLUE

1" 0 0 0 0" 3 0"

93/16.

A

L

U_IT

CAPACPTY

S00CO

7SCO0

_00.000

125CC_

_O

/CONWnSION

G,_S¢ON_ECTIO_S ORAIN CONNE¢ n_

AIG_T SIDE L_" SIO_ RdGH_SlOE

N I P N _, n s

t/2" i 2_-_B" :_,___- _.1_16. t _,_- 4._t_

i

ze 1_"=724

lt2-=$s

1o 7_.=_76

_.1F_=_7o

LEm" SlO_

S • V

7r_-_

c

nETURNApR

_)TTOM SIDE

J L I M

2_.tm. 23 IFZ" 22.1_2" I _ lrZ"

_LUE O,_TL_T

_" 2 _I_S" _.7_16_

231_'_7

14_'_'=375 2.V_.=S 4

2_._

Page 9

I Condensing Gas Furnace

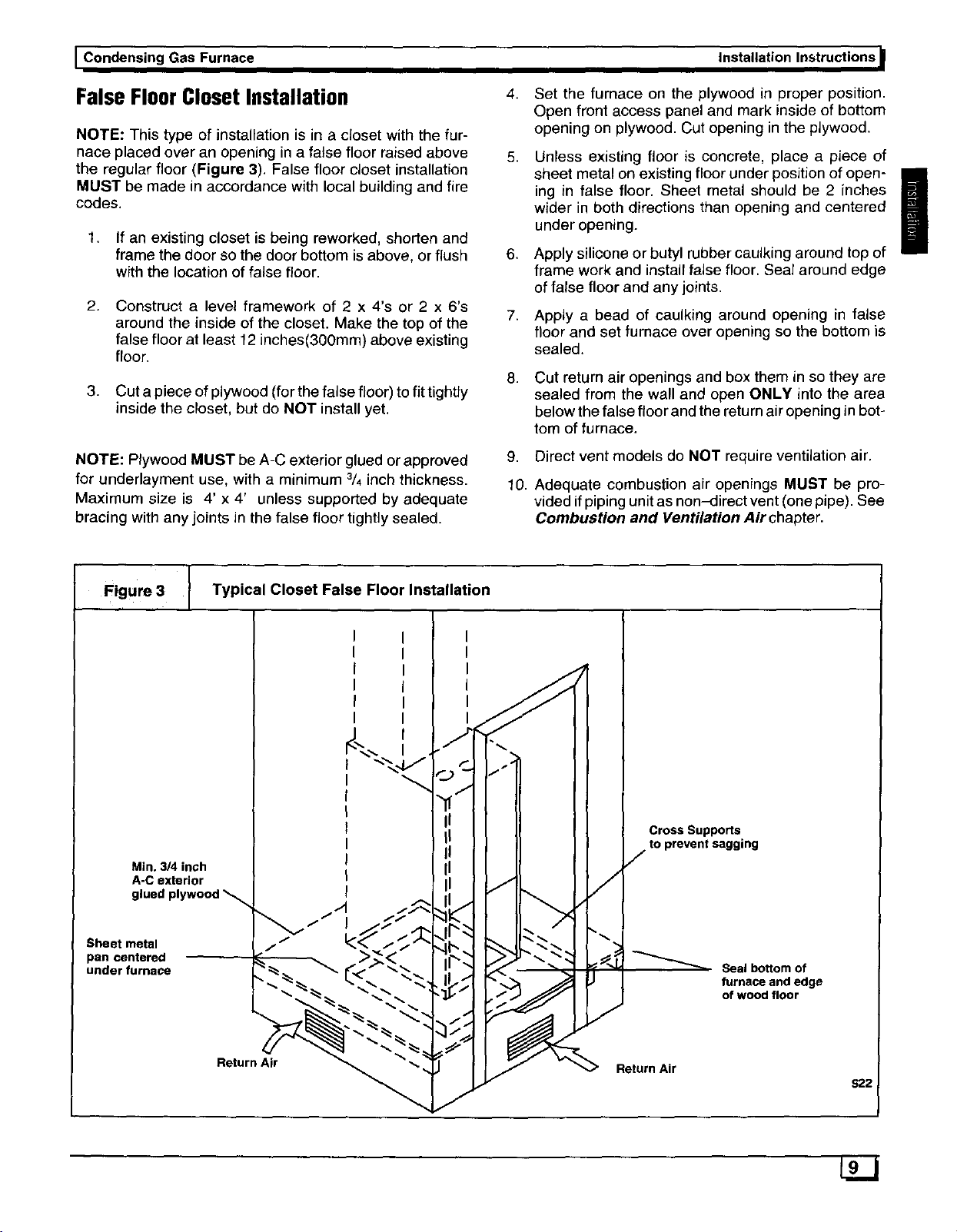

False FloorClosetInstallation

NOTE: This type of installation is in a closet with the fur-

nace placed over an opening in a false floor raised above

the regular floor (Figure 3). False floor closet installation

MUST be made in accordance with local building and fire

codes.

1. If an existing closet is being reworked, shorten and

frame the door so the door bottom is above, or flush

with the location of false floor.

2. Construct a level framework of 2 x 4's or 2 x 6's

around the inside of the closet. Make the top of the

false floor at least 12 inches(30Omm) above existing

floor.

3. Cut a piece of plywood (for the false floor) to fit tightly

inside the closet, but do NOT install yet.

NOTE: Plywood MUST be A-C exterior glued or approved

for underlayment use, with a minimum 3/4inch thickness.

Maximum size is 4' x 4' unless supported by adequate

bracing with any joints in the false floor tightly sealed.

Installation Instructions I

4.

Set the furnace on the plywood in proper position.

Open front access panel and mark inside of bottom

opening on plywood. Cut opening in the plywood.

5,

Unless existing floor is concrete, place a piece of

sheet metal on existing floor under position of open-

ing in false floor. Sheet metal should be 2 inches

wider in both directions than opening and centered

under opening.

6,

Apply silicone or butyl rubber caulking around top of

frame work and install false floor. Seal around edge

of false floor and any joints.

7,

Apply a bead of caulking around opening in false

floor and set furnace over opening so the bottom is

sealed.

8.

Cut return air openings and box them in so they are

sealed from the wall and open ONLY into the area

below the false floor and the return air opening in bot-

tom of furnace.

g,

Direct vent models de NOT require ventilation air.

10.

Adequate combustion air openings MUST be pro-

vided if piping unit as non-direct vent (one pipe). See

Combustion and Ventilation Air chapter.

|

Figure3 I Typical Closet False Floor Installation

Min. 3/4 inch

A-C exterior

glued plywood

Sheet metal

pan centered

under furnace

J

Cross Supports

to prevent sagging

Seal bottom of

furnace and edge

of wood floor

Return Air

Return Air

S22

Page 10

I Installation Instructions Condensin_lGas Furnace J

4. Combustion& VentilationAir

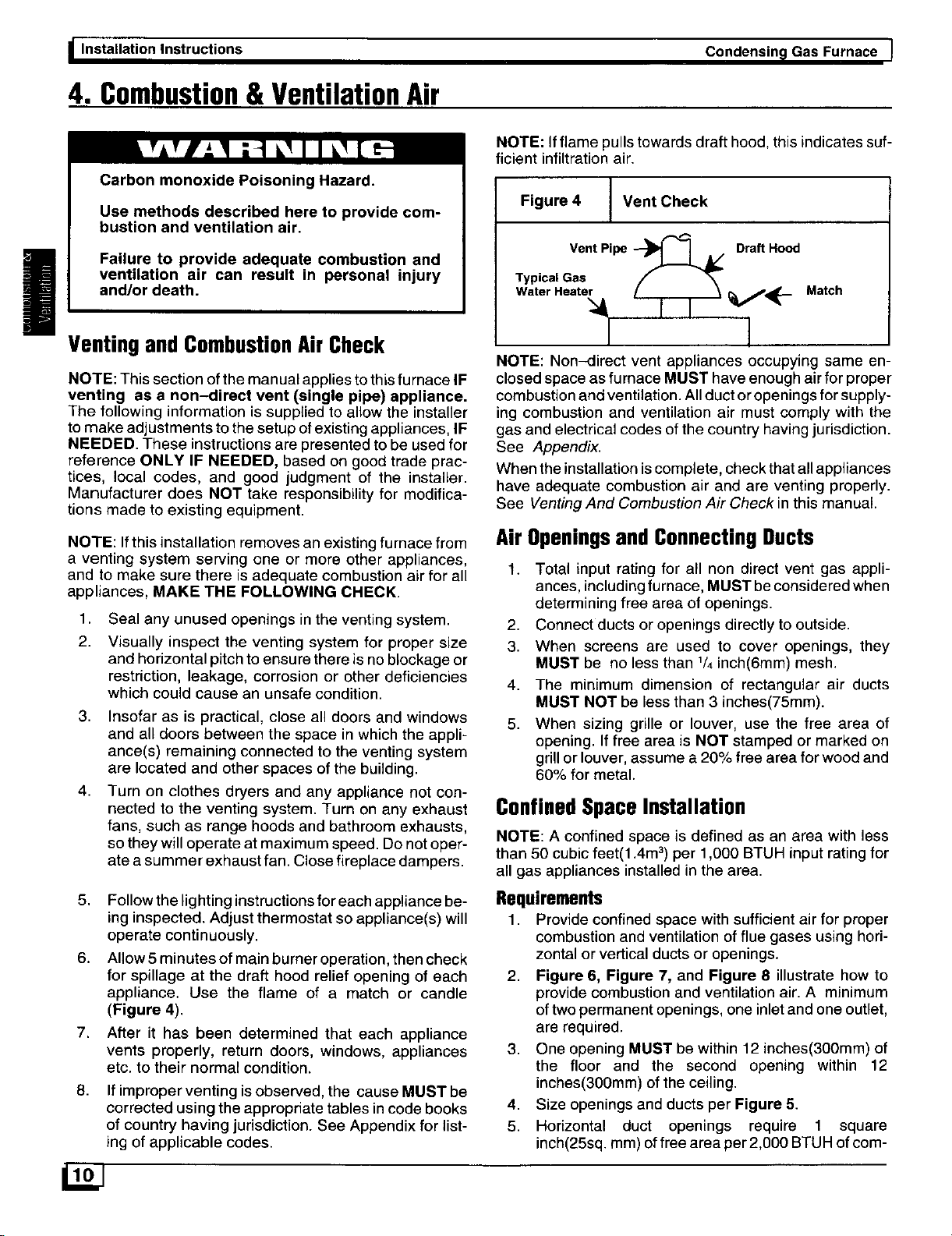

NOTE: Ifflame pulls towards draft hood, this indicates suf-

ficient infiltration air.

Carbon monoxide Poisoning Hazard.

Use methods described here to provide com-

bustion and ventilation air.

Figure 4 _ Vent Check

Failure to provide adequate combustion and

ventilation air can result in personal injury

and/or death.

!

VentingandCombustionAir Check

NOTE: This section ofthe manual applies to this furnace IF

venting as a non-direct vent (single pipe) appliance.

The following information is supp[iedto allow the installer

to make adjustments to the setup ofexisting appliances, IF

NEEDED. These instructions are presented to be used for

reference ONLY IF NEEDED, based on good trade prac-

tices, local codes, and good judgment of the installer.

Manufacturer does NOT take responsibility for modifica-

tions made to existing equipment.

NOTE: If this installation removes an existing furnace from

a venting system serving one or more other appliances,

and to make sure there is adequate combustion air for all

appliances, MAKE THE FOLLOWING CHECK.

1,

Seal any unused openings in the venting system.

2.

Visually inspect the venting system for proper size

and horizontal pitch to ensure there is no blockage or

restriction, leakage, corrosion or other deficiencies

which could cause an unsafe condition.

3. Insofar as is practical, close all doors and windows

and all doors between the space in which the appli-

ance(s) remaining connected to the venting system

are located and other spaces of the building.

4. Turn on clothes dryers and any appliance not con-

nected to the venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts,

so they will operate at maximum speed. Do not oper-

ate asummer exhaust fan. Close fireplace dampers.

Vent Pipe --_1 I A/ DraftHood

Typical Gas

Water Heate_l_l _ _,P_._ Match

NOTE: Non-direct vent appliances occupying same en-

closed space as furnace MUST have enough air for proper

combustion and ventilation. All duct or openings for supply-

ing combustion and ventilation air must comply with the

gas and electrical codes of the country having jurisdiction.

See Appendix.

When the installation is complete, check that all appliances

have adequate combustion air and are venting properly.

See Venting And Combustion Air Check in this manual.

Air Openingsand Connecting Ducts

1. Total input rating for all non direct vent gas appli-

ances, includingfurnace, MUST be considered when

determining free area of openings.

2. Connect ducts or openings directly to outside.

3. When screens are used to cover openings, they

MUST be no less than 1/4inch(6mm) mesh.

4. The minimum dimension of rectangular air ducts

MUST NOT be less than 3 inches(75mm).

5. When sizing grille or louver, use the free area of

opening. If free area is NOT stamped or marked on

grillor louver, assume a 20% free area for wood and

60% for metal.

ConfinedSpaceInstallation

NOTE: A confined space is defined as an area with less

than 50 cubic feet(1.4m 3)per 1,000 BTUH input rating for

all gas appliances installed in the area.

5. Follow the lighting instructions for each appliance be-

ing inspected. Adjust thermostat so appliance(s) will

operate continuously.

6. Allow 5 minutes of main burner operation, then check

for spillage at the draft hood relief opening of each

appliance. Use the flame of a match or candle

(Figure 4).

7,

After it has been determined that each appliance

vents properly, return doors, windows, appliances

etc. to their normal condition.

8.

If improper venting is observed, the cause MUST be

corrected using the appropriate tables in code books

of country having jurisdiction. See Appendix for list-

ing of applicable codes.

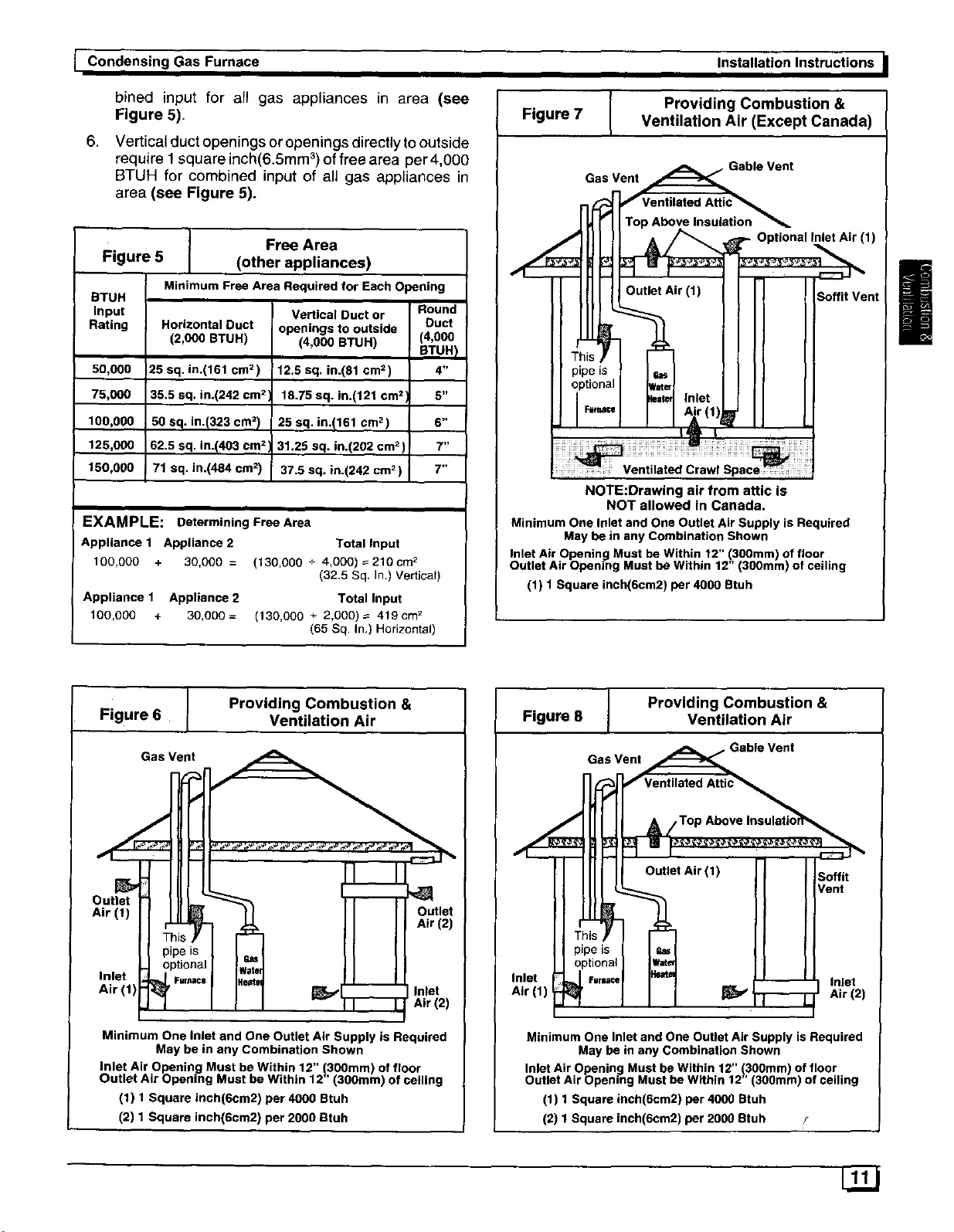

Requirements

1. Provide confined space with sufficient air for proper

combustion and ventilation of flue gases using hori-

zontal or vertical ducts or openings.

2. Figure 6, Figure 7, and Figure 8 illustrate how to

provide combustionand ventilation air. A minimum

of two permanent openings, one inletand one outlet,

are required.

3. One opening MUST be within 12 inches(300mm) of

the floor and the second opening within 12

inches(300mm) of the ceiling.

4. Size openings and ducts per Figure 5.

5. Horizontal duct openings require 1 square

inch(25sq, mm) offree area per 2,000 BTUH ofcorn-

Page 11

I Condensing Gas Furnace

Installation Instructions

bined input for all gas appliances in area (see

Figure 5).

,

Vertical duct openings or openings directly to outside

require I square inch(6.Smm 3)of free area per 4,000

BTUH for combined input of all gas appliances in

area (see Figure 5).

Free Area

Figure 5

STUH

Input

Rating

50,000

75,000

100,000

. 125,000

150,000

Minimum Free Area Required for Each Opening

Horizontal Duct

(2,000 BTUH)

25 sq. in.(161 cm 2)

35.5 aq. in.(242 cm 2

50 sq. in.(323 cm2I

62.5 sq. in.(403 cm z

71 sq. in.(484 cm 2)

(other appliances)

Vertical Duct or

openings to outside

(4,000 BTUH)

12.5 sq, in.(81 em2)

15.75 sq. in.(121 cm 2

25 sq. in.!161 cm 2)

31.25 sq. in.(202 cm2)

37.5 sq. in.(242 cm 2)

EXAMPLE: Determining Free Area

Appliance 1 Appliance 2 Total Input

100,000 + 30,000 = (130,000 + 4,000) 2210cm 2

Appliance 1 Appliance 2 Total Input

100,000 + 30,000= (130,000 + 2,000)= 4tgcm 2

(32.5 Sq. In.) Vertical)

(65 Sq. In.) Horizontal)

Round

Duct

(4,000

BTUH I

4"

5-

6 _

7"

7,,

Figure 7

Gas Vent

NOTE:Drawing air from attic is

NOT allowed in Canada.

Minimum One Inlet and One Outlet Air Supply is Required

May be in any Combination Shown

Inlet Air Opening Must be Within 12" (3O0mm) of floor

Outlet Air Opening Must be Within 12" (300mm) of ceiling

(1) 1 Square ineh(6cm2) per 4000 Btuh

Providing Combustion &

Ventilation Air (Except Canada)

Soffit Vent

(1)

!

I Providing Combustion &Figure 6 Ventilation Air

Gas Vent

f

Outlet

Air (1) Outlet

tn II liAr'2'

I Ilpels I I_-I II It

ptional

Air (1) _ilre_2)

Minimum One Inlet and One Outlet Air Supply is Required

Inlet Air Opening Must be Within 12" 130Omm) of floor

Outlet Air Opening Must be Within 12 (300ram) of ceiling

May be in any Combination Shown

(1) 1 Square inch(6cm2) per 4000 Btuh

(2) 1 Square inch(6cm2) per 2000 atuh

Figure 8 Ventilation Air

Minimum One Inlet and One Outlet Air Supply is Required

Inlet Air Opening Must be Within 12" 1,300mm) of floor

Outlet Air Opening Must be Within 12 (300ram) of ceiling

(1) 1 Square inch(6cm2) per 4000 Btuh

(2) 1 Square inch(6cm2) per 2000 Btuh r

I Providing Combustion &

Gas Vent _ Gable Vent

Ventilated Attic_

Top Above Insulatioif_

t Air (1) ! Soffit

I Vent

May be in any Combination Shown

Page 12

I Installation Instructions

Condensing]Gas Furnace I

!

Unconfined SpaceInstallation

Carbon Monoxide Poisoning Hazard.

Most homes will require additional air,

An unconfined space or homes with tight con-

struction may not have adequate air infiltration

for proper combustion and ventilation of flue

gases,

Failure to supply additional air by means of venti-

lation grilles or ducts could result in personal in-

jury and/or death•

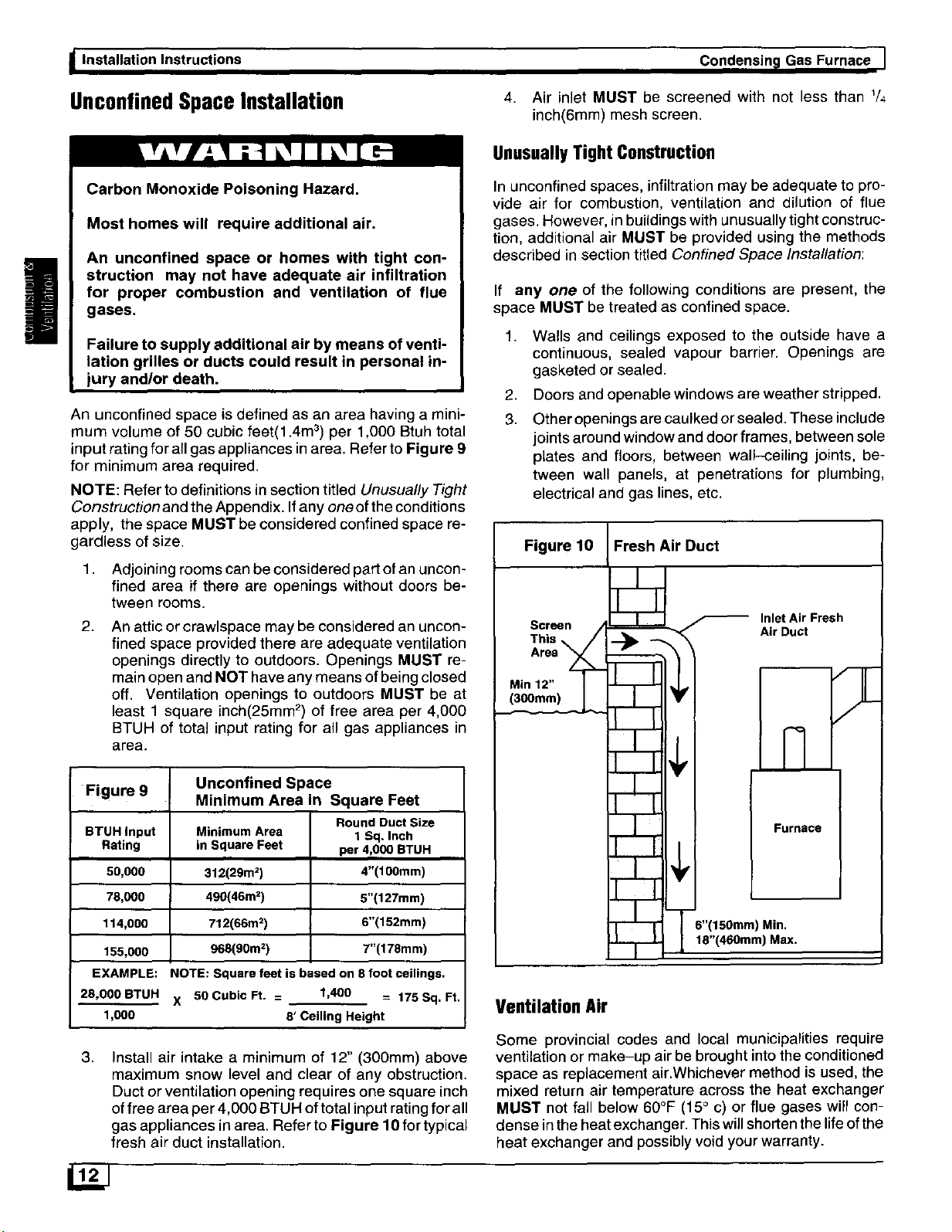

An unconfined space is defined as an area having a mini-

mum volume of 50 cubic feet(1.4m 3)per 1,000 Btuh total

input rating for all gas appliances in area. Refer to Figu re 9

for minimum area required.

NOTE: Refer to definitions in section titled Unusually Tight

Construction and the Appendix. If any one of the conditions

apply, the space MUST be considered confined space re-

gardless of size.

1. Adjoining rooms can be considered part of an uncon-

fined area if there are openings without doors be-

tween rooms.

2,

An attic or crawlspace may be considered an uncon-

fined space provided there are adequate ventilation

openings directly to outdoors. Openings MUST re-

main open and NOT have any means of being closed

off. Ventilation openings to outdoors MUST be at

least 1 square inch(25mm 2) of free area per 4,000

BTUH of total input rating for all gas appliances in

area.

4. Air inlet MUST be screened with not less than 1/4

inch(6mm) mesh screen.

UnusuallyTightConstruction

In unconfined spaces, infiltration may be adequate to pro-

vide air for combustion, ventilation and dilution of flue

gases. However, in buildings with unusually tight construc-

tion, additional air MUST be provided using the methods

described in section titled Confined Space Installation:

If any one of the following conditions are present, the

space MUST be treated as confined space.

1. Walls and ceilings exposed to the outside have a

continuous, sealed vapour barrier. Openings are

gasketed or sealed.

2. Doors and openable windows are weather stripped.

3,

Other openings are caulked or sealed. These include

joints around window and door frames, between sole

plates and floors, between wall-ceiling joints, be-

tween wall panels, at penetrations for plumbing,

electrical and gas lines, etc.

Figure 10

Screen /

Area

This _,_

Min 12" /

Fresh Air Duct

F Inlet Air Fresh

f

Air Duct

Figure 9 Unconfined Space

BTUH Input Minimum Area 1 Sq. Inch

Rating in Square Feet per 4,000 BTUH

50,000 312(29m 2) 4"(100ram)

78,000 490(46m 2) 5"(127mm)

114,000 712(66m _) 6"(152m m)

155,000 968(90m=) T'(178m m)

EXAMPLE: NOTE: Square feet is based on 8 foot ceilings,

28,000 BTUH X 50 Cubic Ft. = 1,400 -- 175 Sq. Ft.

1,000 8' Ceiling Height

3.

Install air intake a minimum of 12" (300mm) above

maximum snow level and clear of any obstruction.

Duct or ventilation opening requires one square inch

of free area per 4,000 BTUH of total input rating for all

gas appliances in area. Refer to Figure 10 for typical

fresh air duct installation.

Minimum Area in Square Feet

Round Duct Size

Furnace

6"(150mm) Min.

18"(460mm) Max.

Ventilation Air

Some provincial codes and local municipalities require

ventilation or make-up air be brought into the conditioned

space as replacement air.Whichever method is used, the

mixed return air temperature across the heat exchanger

MUST not fall below 60°F (15° c) or flue gases will con-

dense in the heat exchanger. This will shorten the life of the

heat exchanger and possibly void your warranty.

Page 13

Condensing Gas Furnace

5. VentandCombustionAirPiping

Carbon monoxide poisoning, fire and explosion

hazard.

Read and follow all instructions in this section

Failure to properly vent this furnace can result in

property damage, personal injury and/or death.

DualCertified Furnace

Installation Instructions,

• Carbon tetrachtoride.

• Halogen type refrigerants.

• Cleaning solvents (such as perchloroethylene).

• Printing inks, paint removers, varnishes, etc..

• Hydrochloric acid.

• Sulfuric Acid.

• Solvent cements and glues.

• Antistatic fabric softeners for clothes dryers.

• Masonry acid washing materials.

This furnace is certified as a category IV appliance and is

dual certified as a direct vent furnace using outside air for

combustion or it can use air from inside the structure for

combustion. The INLET air pipe is optional. If combustion

air comes from inside the structure, adequate make up air

MUST be provided to compensate for oxygen burned. See

Confined Space Installation in the Combustion and

Ventilation Air chapter. If combustion air is drawn from

outside the structure, it MUST be taken from the same at-

mospheric pressure zone as the vent pipe.

ContaminatedCombustionAir

Installations in certain areas or types of structures will in-

crease the exposure to chemicals or Halogens which may

harm the furnace.

The following areas or types of structures may contain

chemicals or Halogens. Inspect structure carefully to en-

sure listed chemicals or substances are NOT present.

• Commercial buildings.

• Buildings with indoorpools.

• Furnaces installed in laundry rooms.

• Furnaces installed in hobby or craft rooms.

• Furnaces installed near chemical storage areas.

Exposing the furnace to the following substances will dam-

age the furnace. Do NOT situate air inlet near any of the

following chemicals or their source.

CAUTION

Terminate the combustion air intake as far as possible

from any air conditioner, heat pump, swimming pool,

swimming pool pumping, chorlinator or filtration

units, or dryer vent.

• Permanent wave solutions for hair.

• Chlorinated waxes and cleaners.

• Chlorine based swimming pool chemicals.

• Water softening chemicals.

• De-icing salts or chemicals.

Vent andCombustionAirPipingGuidelines

!

NOTE: All vent piping MUST be installed in compliance

with local codes or ordinances, these instructions, good

trade practices, and codes of country having jurisdiction.

1. Determine the best routing and termination for the

vent pipe and air inlet pipe (when used) by referring

to all of the instructions and guidelines in Section 6.

2. Determine the size required for the vent pipe and air

inlet pipe (when used).

3. Looselyassemble allventing parts without adhesive

(pipe joint cement) for correct fit before final assem-

bly.

4. Use of vertical piping is preferred because there will

be some moisture in the flue gases that may con-

dense as it leaves the vent pipe (See Special Instruc-

tion For Horizontal Vents),

5. The vent MUST exit the furnace at the top left side.

6. The vertical vent pipe MUST be supported so that no

weight is allowed to rest on the combustion blower.

7. Exhaust vent piping diameter MUST NOT be re-

duced.

8. All piping from the furnace to termination MUST

slope upwards, away from furnace, a minimum of

U4" per foot of run (6mm per 300mm).

9. Use DWV type long radius elbows whenever possi-

ble, as they provide for the minimum slope on hori-

zontal runs and they provide less resistance in the

vent system. If DWV elbows cannot be used, use

two, 45 degree elbows when possible. On horizontal

runs the elbows can be slightly misaligned to provide

the correct slope.

10. All horizontal pipe runs MUST be supported at least

every five feet with metal pipe strapping. NO sags or

dips are permitted.

11. All vertical pipe runs MUST be supported every six

feet where accessible.

12. The maximum pipe length is40 total feet (12m) in the

inlet or outlet side of the system. Up to five, 90 de-

gree elbows can be used on the inlet orthe outlet,

(See Vent Tables).

13. The minimum pipe run length is 5 feet (1.5m).

14. Venting thr°ugh acrawl space is permitted °nly as di-

rected by your distributor or factory representative.

Page 14

Condensing Gas Furnace Installation Instructions

15.

The piping can be run in the same chase or adjacent

to supply or vent pipe for water supply or waste

plumbing. Itcan also be run in the same chase with a

vent from another 90+ furnace.

NOTE: In NO case can the piping be run in a chase

where temperatures can exceed 140° F. or where ra-

diated heat from adjacent surfaces would exceed

140° F.

16. If installing as a direct-vent appliance, the vent outlet

MUST be installed to terminate in the same atmos-

pheric pressure zone as the combustion air inlet.

17. The vent system can be installed in an existing un-

used chimney provided that:

Both the exhaust vent and air intake run the length of

the chimney.

No other gas fired appliance or fireplace is vented

into the chimney.

The top of the chimney MUST be sealed flush or

crowned up to seal against rain or melting snow so

ONLY the piping protrudes.

• The termination clearances shown in Figure 16 are

maintained.

Piping Insulation Guidelines

NOTE: In general, chimneys on an outside wall and attics

are exposed to cold conditions which can cause the vent

pipe to sweat from condensation. This can lead to moisture

damage to living spaces. It is highly recommended that pip-

ing in these cases be insulated to insure proper protection

from condensation damage.

Use 1/2" (50mm) wall, closed cell, neoprene insulation or

equivalent. If Fiberglas or equivalent insulation is used it

must have a vapor barrier. Use Rvalues of 7 up to 10 feet,

R-11 ifexposure exceeds 10 feet. If Fiberglas insulation is

used, exterior to the structure, the pipe MUST be boxed in

and sealed against moisture.

1. Insulate pipe when the exhaust vent passes through

an unconditioned space or raceway.

2. If situations require pipe to be run on the exterior wall

to reach a suitable termination point, it MUST be

properly insulated.

3. If it is necessary to insulate piping when an inactive

chimney is used as a chase, the top of the chimney

MUST be sealed flush or crowned up to seal against

rain or melting snow so ONLY the piping protrudes.

4. When the vent or combustion air pipe height above

the roof exceeds 30 inches(760mm), or if an exterior

vertical riser is used on a horizontal vent to get above

snow levels, the exterior portion MUST be insulated.

5. When combustion air inlet piping is installed above a

suspended ceiling, the pipe MUST be insulated with

moisture resistant insulation such as Armaflex or

other equivalent type of insulation.

6. Insulate combustion air inlet piping when run in

warm, humid spaces such as basements.

SizingCombustionAirandVentPipe

1. Single Pipelnstallation-lf installing as anon-direct

vent appliance, (single outlet pipe and no inlet pipe)

refer to Table 1. The table shows the maximum

number of elbows allowed with any given pipe di-

ameter and length of run.

2. Double Pipe Installation-If installing as a direct-

vent appliance, consult Table 2 to select the proper

diameter exhaust and combustion air piping. Ex-

haust and combustion air piping is sized for each fur-

nace Btuh size based on total lineal vent length (on

inlet or outlet side), and number of 90° elbows re-

quired.

3. Use of Elbows-Two 45 ° elbows can be substituted

for one 90° elbow. The elbow or elbows used for vent

termination outside the structure ARE counted, in-

cluding elbows needed to bring termination above

expected snow levels. When the vent system

length used is borderline with the next size com-

bination category, always use the next larger

size.

EXAMPLE: Refer to, 75,000 Btuh Furnace, Table 2.

• A vent system uses 25 feet of Inlet pipe and 24 feet

of Outlet pipe. Use the maximum length found in your

system, so 25 ft. is the lengthto use in these tables. The

25-30 column should be used.

• There are 4 elbows on the Outlet and 2 elbows on the

Inlet. Use the 4 elbows row because that is the maxi-

mum number of elbows on any one side (Inlet or Ex-

haust).

• In this example, combinations C or F are allowed.

Using the legend at the bottom of the table, combination

C is 3" Inlet with a 21/2" Exhaust. Combination F is a 3"

Inlet with a 3" Exhaust. Either combination is allowed to-

gether, but they can NOT be mixed. Inother words, part

of a C combination can NOT be used with part of an F

combination just because they are listed together in the

same block.

Page 15

J Condensing Gas Furnace Installation Instructions

Pipe Diameter Table

Table I Single Piping ONLY

50,000 & 75,000 Btuh Furnaces

Max No. Of

Elbows in One

Side3

UP TO 5 All combinations use "A" a 2" Exhaust

Max No. Of Feet of Pipe*

Elbows in One

Side _ 0-9 10-14 15-1 €. 20-24 25-29 30-3_ 35-40

1 A A A A A A B,C

2 A A A A A B,C B,C

3 A A A A B,C B,C B,C

4 A A A B,C B,C B,C B,C

5 A A B,C B,C B,C B,C B,C

Max No. Of Feet of Pipe*

Elbows in One

Side _ 0-9 10-14 15-19 20-24 25-2_ 30-3, 35-4(_

1 A A B,C B,C B,C B,C C

0-,1,0-t,lt5-,o120-2,125-,930- 3 0

100,000 Btuh Furnace

125 000 Btuh Furnace

Feet of Pipe*

Table 2 Pipe Diameter Table

50,000 Btuh Furnace

Max No. Of Feet of Pipe*

Side _ 0-9 10-14 15-19 20-24 25-29 30-3 35-4(

E,hows,oonsI I I I

UP TO 5 All combinations use "A" a 2" Exhaust

Max No. Of Feet of Pipe*

Elbows in One

Side _ 0-9 10-14 15-19 20-24 25-2c. 30-34 35-4C

1 A A A A D,B E,B E,B

2 A A A D,B E,B E,B C,F

3 A A D,B E,B E,B C,F C,F

4 A D,B E,B E,B C,F C,F C,F

5 D,B E,B E,B C,F C,F C,F C,F

Max No. Of Feet of Pipe*

Elbows in One

Side _ 0-9 10-14 15-19 20-24 25-20 30-34 35-4(1

1 A A A D,B E,B E,B C,F

and 2" Air Inlet Pipe

75,000 Btuh Furnace

100,000 Btuh Furnace

Dual Piping ONLY

!

2 A B,C B,C B,C B,C C C

3 B,C B,C B,C B,C C C C

4 R,C B,C B,C C C C C

5 B,C B,C C C C C C

Possible combination legend:

A = 2" Exhaust

B = 2_/z" Exhaust

C = 3" Exhaust

Elbows are DWV Long Radius Type for 2" and 3"vents.

Schedule 40 (sharp radius) for 2V2"

3 - Signifies the maximum number of elbows, includ-

ing the termination elbow(s), on any one part of the

system. Example: 4 elbows on the exhaust and 5 el-

bows on the inlet would use the chart showing 5 el-

bows, because 5 is the maximum number on any one

side,

* Feet of pipe is whichever pipe run is the longest,

either inlet oroutlet side,

2 A A D,B E,B E,F C,F C,F

3 A D,B E,B E,F C,F C,Fi C,F

4 D,B E,B E,F C,F C,F C,F C,F

5 E,B E,F C,F C,F C,F C,F C,F

125,000 Btuh Furnace

Max No. Of

Elbows in One

Side

UP TO 5

Possible combination legend:

A = 2" Inlet with a 2" Exhaust

B = 3" Inlet with a 2" Exhaust

C = 3" Inlet with a 2112" Exhaust

D = 2V2"Inlet with a 2" Exhaust

E = 2V2"Inlet with a 2V2"Exhaust

F = 3" Inlet with a 3" Exhaust

Elbows are DWV Long Radius Type for 2" and 3" vents.

Schedule 40 (sharp radius) for 2V="

0-,110-14115-t01 0- ,1 5- 0130- 5-49

All combinations use "F" a a- Ex-

haust and 3" Air Inlet Pipe

Feet of Pipe*

Page 16

Condensing Gas Furnace

Installation Instructions

Vent TerminationClearances

Carbon monoxide poisoning, fire and explosion

hazard.

Inlet and outlet pipes may NOT be vented

directly above each other.

Failure to properly vent this furnace can result in

property damage, personal injury and/or death.

1,

Determine termination locations based on clear-

ances specified in following steps and as shown in

Figure 11, Figure 14, Figure 15 and Figure 16.

The vent termination must be located at least 12

inches(300mm) above ground or normally expected

snow accumulation levels.

3. Do NOT terminate over public walkways. Avoid ar-

eas where condensate may cause problems such as

above planters, patios, or adjacent to windows where

steam may cause fogging.

4. The vent termination shall be located at least 4

feet(1220mm) horizontally from any electric meter,

gas meter, regulator, and any relief equipment.

These distances apply ONLY to U.S. installations.

5. The vent termination is to be located at least 3

feet(914mm) above any forced air inlet located within

10 feet(3m) ;and at least 10 feet(3m) from a combus-

tion air intake of another appliance, except another

direct vent furnace intake.

.

In Canada, the Canadian Fuel Gas Code takes

precedence over the preceding termination instruc-

tions. See Appendix.

Figure 11

I ent Termination Clearances

(United States Only)

See text for Canadian Requirements

/

CondensateDrainTrapand Neutralizer

This furnace removes both sensible and latent heat from

the combustion flue gases. Removal of latent heat results

in condensation of flue gas water vapor. This condensed

water vapor drains from the secondary heat exchanger,

through a built-in drain trap transition, and out of the unit.

Condensate piping or tubing can exit from the right side,

left side, or rear of the cabinet.

NOTE: The 90 ° compression fitting elbow(provided), re-

quires the drain line and overflow line are to be 1/2

inch(13mm) copper tube. CPVC. 5/8"(16mm) I.D. vinyl tub-

ing may be used outside the furnace cabinet to connect to

the drain line. Internal trap assembly provides the required

4 inches water column, so no additional trap is required.

1.

Do NOT put a loop in the drain piping. This would

cause an extra water column pressure in addition to

the pressure inside the built-in drain trap.

2,

Drains must terminate at an inside drain to prevent

freezing of condensate and possible property dam-

age.

3.

Consideration MUST be given to type of filter being

installed. 125,000 Btuh furnace require 2-16x25x1

filters(one on each side of furnace). This configura-

tion does NOT allow the condensate drain line to be

run out the side of furnace. If line MUST be run out

the side, an optional standoff filter rack with one

20x25x1 filter is needed. Install optional filter rack on

side of furnace opposite the side where condensate

drain line will exit.

4,

A condensate or sump pump MUST be used if local

codes require, or if no inside floor drain is available, if

pump is approved for use with acidic condensate, a

neutralizer cartridge is not needed. If using a neutral-

izer cartridge, it MUST be installed in the drain line in

a horizontal position ONLY.

NOTE: Recommended service time for replacing neutral-

izer cartridge is one year.

5. A condensate pump MUST have an auxiliary safety

switch to prevent operation of furnace and resulting

overlow of condensate in the event of pump failure.

The safety switch MUST be wired through the R cir-

cuit ONLY (low voltage) to provide operation in either

heating or cooling modes.

6. Install an overflow line if routing to floor drain or sump

pump. See Figure 1 for example of proper routing

and installation of overflow line.

Connecting Furnace and Piping

Carbon monoxide poisoning hazard.

Cement or mechanically seal all joints, fittings,

etc. to prevent leakage of flue gases.

Failure to properly seal vent piping can result in

personal injury and/or death.

1. Preassemble the exhaust and combustion air piping

from the furnace to the vent termination. Do NOT ce-

Page 17

I Condensing Gas Furnace Installation Instructions

ment any joints together until the preassembly proc-

ess is complete.

Vent Pipe Connection

1. Install the ABS supplied piece of vent pipe to the

combustion blower using RTV sealant ONLY. This

provides for future serviceability.

CAUTION

Do NOT cement pipe into combustion blower. When

inserting vent pipe into combustion blower, use a

bead of RTV sealant that is at least 3/8" (10mm) from

the edge of the pipe. Too much sealant can cause the

condensate drain to clog. See Figure 12.

2.

Install the flexible connector (provided) on the ABS

pipe from the combustion blower. This will be used to

connect to the rest of the vent system, See

Figure 13.

Air Inlet Pipe Connection

NOTE: Air Inlet Collar issized for 3" PVC pipe. If 2" (50mm)

or 2,,V2"(64mm) combustion air piping is used, a 3" (75m m)

to 2 (50mm) or 3 (75mm) to 21/2 (64mm) reducer fitting is

required.The reducing section can be before the 90° el-

bow in a horizontal section.

1. Install pipe section or pipe/reducer fitting (as re-

quired) to the inlet collar using RTV sealant ONLY to

provide for future serviceability.

NOTE: On single pipe installation, using combustion air

from inside the structure, it is recommended that a screen

be placed inside the Combustion Air Inlet. A 3" plastic

screen is available for this purpose. Itwill prevent small ob-

jects from falling into the combustion chamber. Use RTV

sealant ONLY to provide for future serviceability.

Figure 12 Proper Sealing Procedure for

Combustion Blower

ABS pipe (supplied)

MUST be used

SeaE to Combustion

blower with RTV

_ea]enl

I

Figure 13 ! Vent Trap and Furnace Connections

Flexible coupling and clamps

(supplied) are installed out-

side the cabinet.

ABS pipe (supplied) MUST be

installed between

tion blower and coupling.

RTV sealant used to join com-

bustion blower and ABS pipe

and Air Inlet Pipe to Combus-

tion Air Inlet.. See Figure 12.

Air Intake Pipe

(Direct-Vent Installation only)

Place a 3" Plastic Screen (Op-

tional) inside the Air Inlet Collar

when Combustion Air comes

from inside the structure.

Condensate compression

fitting can be turned to exit out

the left side, right side, or rear

of cabinet, If piping is exiting

out the right side of cabinet, it

is necessary to use an elbow to

run pipe In front of electronic

module. Cabinet entrance hole

is offset enough to allow ade-

quate clearance.

25-20-71

Page 18

I Condensing Gas Furnace

installation instructions

JoiningPipeand Fittings

Fire hazard.

Provide adequate ventilation and do NOT

assemble near heat source or open flame. Do NOT

smoke while using solvent cements and avoid

contact with skin or eyes.

Observe all cautions and warnings printed on

material containers to prevent possible personal

injury and/or death.

NOTE: All PVC, CPVC, ABS, and Cellular Core pipe fit-

!

tings, solvent cement, primers and procedures MUST con-

form to American National Standard Institute and

American Society for Testing and Materials (ANSI/ASTM)

standards. Schedule 40 is the ONLY approved wall thick-

ness.

• Pipe and Fittings-ASTM D1785, D2466, D2661,

D2665, F-891

• PVC Primer and Solvent Cement - ASTM D2564

• Procedure for Cementing Joints - Ref ASTM D2855

NOTE: In order to create a seal that allows future removal

of pipe, RTV sealant MUST be used on both the inlet and

the exhaust pipes where they join to the furnace. PVC,

CPVC, ABS, and Cellular Core pipe and cement may be

used on all other joints.

CAUTION

Do NOT use solvent cement that has become curdled,

lumpy or thickened and do NOT thin. Observe precau-

tions printed on containers. For applications below 32

degrees F., use only low temperature type solvent ce-

ment.

1. Cut pipe end square, remove ragged edges and

burrs. Chamfer end of pipe, then clean fitting, socket

and pipe joint of all dirt, grease, or moisture.

NOTE: Stir the solvent cement frequently while using. Use

a natural bristle brush or the dauber supplied with the ce-

ment. The proper brush size is one inch.

2_

After checking pipe and socket for proper fit, wipe

socket and pipe with cleaner-primer. Apply a liberal

coat of primer to inside surface of socket and outside

of pipe. Do NOT allow primer to dry before applying

cement.

3.

Apply a thin coat of cement evenly in the socket.

Quickly apply a heavy coat of cement to the pipe end

and insert pipe into fittings with a slight twisting

movement until it bottoms out.

NOTE: Cement MUST be fluid while inserting pipe. If NOT,

recoat pipe.

4. Hold the pipe in the fitting for 30 seconds to prevent

the tapered socket from pushing the pipe out of the

fitting.

5. Wipe all excess cement from the joint with a rag. Al-

low 15 minutes before handling. Cure time varies ac-

cording to fit, temperature and humidity.

ConnectingVent PipesandTermination

NOTE: Combustion air intake and vent MUST terminate in

the same atmospheric pressure zone. If installation is in a

cold climate (substained temperatures below 0°F), in-

crease the minimum distance between vent pipe and air in-

take from 8"to 18".

CAUTION

Maintain a minimum of 36 inches(Ira) between com-

bustion air inlet and clothes dryer vent. Terminate the

combustion air intake as far as possible from any air

conditioner, heat pump, swimming pool, swimming

pool pumping, chorlinator or filtration unit.

Carbon monoxide poisoning, fire and explosion

hazard.

Inlet and outlet pipes may NOT be vented

directly above each other.

Failure to properly vent this furnace can result in

property damage, personal injury and/or death.

1.

install all couplings, nipples and elbows using proper

procedures for Joining Pipe and Fittings and main-

tain spacing between vent and combustion air piping

as indicated in Figure 14 through Figure 16.

Vertical Termination

1. Figure 16 shows the proper installation and clear-

ances for vertical vent termination. The vertical roof

termination should be sealed with a plumbing roof

boot or equivalent flashing. The inlet of the intake

pipe and end of the exhaust vent must be terminated

no less than 12"(300mm) above the roof or snow ac-

cumulation level, and 12"(300mm) away from a verti-

cal wall or other protrusion.

2. If the vent system is installed in an existing chimney

make sure clearances shown in Figure 16 are main-

tained. Horizontal section before the termination el-

bow can be extended on the inlet air to provide

necessary clearance.

Horizontal Termination

1,

If installing as a direct-vent appliance, cut two holes.

21/2" (67mm) for 2" (50mm) pipe, 3"(75mm) for 2 _/2"

(67mm) pipe, or 31/2"(90mm) for 3"(75mm) pipe. Do

NOT make the holes oversized, or it will be neces-

sary to add a sheet metal or plywood plate on the out-

side with the correct size hole in it. If venting as a

single pipe appliance, cut only one hole.

Page 19

I Condensing Gas Furnace

Installation Instructions I

2. Check hole sizes by making sure it is smaller than the

couplings or elbows that will be installed on the out-

side. The couplings or elbows MUST prevent the

pipe from being pushed back through the wall.

3. Extend vent pipe and combustion air pipe through

the wall 3/4to 1"(19 to 25mm) and seal area between

pipe and wall.

4. install the couplings, nipple and termination elbows

as shown and maintain spacing between vent and

combustion air piping as indicated in Figure 14

through Figure 16.

UsingExteriorRisers

1. install elbows and pipe to form riser as shown in

Figure 15.

2. Secure vent pipe to wall with galvanized strap or

other rust resistant material to restrain pipe from

moving.

3. Insulate pipe with Armaflex or equivalent moisture

resistant closed cell foam insulationor Fiberglass in-

sulation ifboxed in and sealed against moisture.

Optional Vent Screens

To prevent unwanted pests or foreign material from enter-

ing terminated pipes, plastic vent screens are available in

2" and 3" sizes. Use of these screens is recommended ex-

cept in cold climate areas where ice is likely to form on

them. Glue the screen inside the termination elbow using

pipe cement. Screens should be inspected monthly for

blockage and cleaned yearly prior to startup.

Sidewall Termination

12 Inches or More Above

Snow Level or Grade Level

• 18" Minimum for cold climates

8"* _ (substainedbel°wO_F)

MIN

A metal shield is recommended 18" x 18"(457mm x

457mm) min. or 18"(457mm) min. diameter around the

vent termination at the exterior wall to protect the house ex-

terior materials from flue product or condensation (freez-

ing) damage.

Figure 15 Exterior Risers to Get Above

J Sidewall Termination with

Snow Level or Grade Level

18" Minimum for cold clirnate_

(substained below O°F)

I' MN

25-00-04F

Inlet is ]

optional

I

EXHAUST i

optionallnletis] !i/// _ _.Nj//

SNOW LEVEL

25_O,,35F

Vent Termination Shielding

Under certain wind conditions some building materials may

be affected by flue products expelled in close proximity to

unprotected surfaces. Sealing or shielding of the exposed

surfaces with a corrosion resistant material (such as alumi-

num sheeting) may be required to prevent staining or dete-

rioration. The protective material should be attached and

sealed (if necessary) to the building before attaching the

vent terminal.

FigMrei6 ;I Rooftop Termination

Inlet is

optional ]

A = f2" Above roof or snow accumulation level

B = 8" M_n., 2(_"Maximum, except in areas with extreme

cold temperatures (substamed below 0 F), then 18 Mw .

• o . =n

25-00-06

Page 20

Installation Instructions Condensing Gas Furnace ]

6. Gas

Fire and explosion hazard.

Natural Gas

Models designated for Natural Gas are to be used

with Natural Gas ONLY.

LP Gas

LP gas models have orifices sized for commer-

cially pure propane gas. Furnace MUST NOT be

used with butane or a mixture of butane unless

properly sized orifices are installed by a licensed

LP installer.

Failure to follow these instructions can result in

property damage, personal injury and/or death.

!

NOTE: The rating plate is stamped with the model number,

gas type and gas input rating. In addition, models manufac-

tured for sale in Canada have orifice size information

stamped on the rating plate.

General U.S. Derating Rules

1.

For operation with natural gas at altitudes 2,000 feet

and above, orifice change and/or manifold pressure

adjustment may be required to suit gas supplied.

Check with gas supplier. If orifice sizing is needed, it

should be based on reducing the input rating by 4

percent for each 1,000 feet above sea level. See

Figure18 and Figure 19 for required pressure

change and/or orifice change for high altitudes.

2.

For operation with LP gas, gas orifices MUST be

changed and manifold pressure MUST be

maintained as per Figure 17. Orifice sizes for

0-2000 ft. above sea level are #54. 2000-7000 ft.

above sea level, use #55. 7000-8000 ft. above sea

level, use #56 orifices. Orifices can be ordered

through your distributor.

General Canadian DeraUng Rules

3.

In Canada, to derate both Natural and LP gas, the in-

put MUST be decreased 10% for altitudes

2,000-4,500 ft. above sea level. The orifice MUST be

sized as shown on the rating plate, NOT as shown in

these instructions. Installations above 4,500 ft.

MUST consult provincial authorities.

SupplyPressure

Fire hazard.

Do NOT set input rating above that shown on

rating plate.

Failure to properly set input pressure can result in

property damage, personal injury and/or death.

1. Supply pressure can be checked using the

1/8"(3.2mm) NPT port on the supply side of the gas

valve.

2. Gas input to burners MUST NOT exceed the rated

input shown on rating plate.

3.

Do NOT allow minimum gas supply pressure to vary

downward. Doing so will decrease input to furnace.

Refer to Figure "17for normal gas supply and mani-

fold pressures.

Figure 17 Gas Pressures Below 2000 Ft.

Gas

Type

Natural 3.5 inches

LP 10 inches

Recommended Max.

7 inches 14 inches

11 inches 14 inches

With Propane gas, the rated input is obtained when the

BTU content is 2,500 BTU per cubic foot and manifold

pressure set at 10 inches W.C,

If Propane gas has a different BTU content, orifices MUST

be changed by licensed Propane installer.

Measured input can NOT exceed rated input.

Combustion Air Box Cover MUST be removed when ad*

justing manifold pressure.

Any major change in gas flow requires changing burner

orifice size.

Supply Pressure

Min.

4.5 inches

11 inches

Important Notes

Manifold

Pressure

Manifold Gas PressureAdjustment

NOTE: Gas suppty pressure MUST be within minimum and

maximum values listed on rating plate. Pressures are usu-

ally set by gas suppliers.

Make adjustment to manifoldpressure with burners oper-

ating and combustion air box cover removed.

Page 21

Condensing Gas Furnace

installation instructions

1. Remove combustion air box cover.

2. Connect U-Tube manometer to the tapped opening

on the outlet side of gas valve. Use manometer with a

O-12 inches water column range.

3. Turn gas ON, fire the furnace and remove adjust-

ment screw cover on gas valve.

4. Turn counterclockwise to decrease pressure and

clockwise to increase.

5. Set pressure to value shown in Figure 17. Refer to

Important Notes in Figure 17. Pressure is also

listed on furnace rating plate.

6. When pressure is set, replace adjustment screw

cover on gas valve.

7. Replace combustion air box cover.

NOTE: Adjustment screw cover MUST be replaced on gas

valve BEFORE reading manifold pressure and operating

furnace.

HighAltitudeAirPressureSwitch

Altitudes over 4,000 ft. require a different air pressure

switch than the one installed at the factory. Consult your

distributor for part number and availability. In Canada, pro-

vincial codes may govern installation of switch. Check with

governing authorities.

ChangingOrificesfor HighAltitude

5. Reinstall manifold and combustion air box cover. En-

sure burners de NOT bind on new orifices.

High Altitude Pressure Chart

Figure 18 2000-4999 ft. (Natural Gas)

Heat Value ;

Btu/Cu,Ft.

800

850

9O0

95O

1000

1050

1100

Figure 19

Heat Value'

Btu/Cu.Ft.

800

85O

900

950

1000

1050

1100

0-1999 2000-2999 3000-3999 4000_499. (

-I Shaded box requires orifice change to a #44.

No Shading indicates factory installed orifice and

manifold pressure change only.

J Shaded box requires odfice change to a #44.

No Shading indicates factory installed orifice and

manifold pressure change only.

Elevation Above Sea Level

3.5 3,5 3.5 3,5

3.5

3.5

3.5

3.5

3.2

2.9

3,5 3,5 3.2

3.2 3.2 2.9

3.1 2.8 2.6

2.8 2.5 2.3

2.5 2.3 3.5

2.3 3.5 3.3

High Altitude Pressure Chart

5000-7999 ft. (Natural Gas)

Elevation Above Sea Level

5000-6999

3.2

2,9

2.6

2.3

3.5

3.3

3.0

6000-6999 7000-7999

2.9 2.7

2.6 2.3

2,3 3.5

3.5 3.3

3.3 3.0

3.0 2.7

2.7 2.4

!

Electrical shock, fire or explosion hazard.

Turn OFF electric power (at disconnect) and gas

supply (at manual valve in gas line) when

installing orifices. Installation of orifices requires

a qualified service technician.

Failure to properly install orifices can result in

property damage, personal injury and/or death.

NOTE: Main burner orifices can be changed for high alti-

tudes.

1. Disconnect gas line from gas valve.

2,

Remove combustion box front cover and manifold

from furnace.

3.

Remove the orifices from the manifold and replace

them with properly sized orifices.

4.

Tighten orifices so there is 1_/_6" (27mm) from the

faces of the orifices to the back side of the manifold,

Figure 20.

Figure 20

Changing Orifices

Measure tlh6" (27ram)

from face of orifice to

the back side of the

manifold.

NaturalGasInputRatingCheck

NOTE: The gas meter can be used to measure input to fur-

nace. Rating is based on a natural gas BTU content of

1,000 BTU's per cubic meter. Check with gas supplier for

actual BTU content.

1. Make sure combustion air box cover is in place and

closed before performing the following steps.

Page 22

Installation Instructions Condensing Gas Furnace J

2.

Turn OFF gas supply to all appliances and start fur-

nace.

3.

Time how many seconds it takes the smallest dial on

the gas meter to make one complete revolution. Re-

fer to Example,

Example

Natural Gas No. of Seconds Time Per Cubic BTU Per

BTU Content Per Hour Meter in Seconds Hour

1,000 3,600 48 75,000

1,000 x 3,600 + 48 = 75,000 BTUH

NOTE: If meter uses a 2cubic foot dial, divide results (sec-

onds) by two.

4. Relight all appliances and ensure all pilots are oper-

ating.

GasPiping Requirements

!

1. Determine the minimum pipe size from the tables in

Figure 22 and Figure 23, basing the length of the

run from the main line, gas meter or source to the fur-

nace.

2.

Properly size gas pipe to handle combined appliance

load or run gas pipe directly from gas meter or LP gas

regulator.

3.

Install correct pipe size for run length and furnace rat-

ing.

4. Measure pipe length from gas meter or LP second

stage regulator.

Connections

NOTE: Refer toFigure 21 for the general layout at the fur-

nace. The rules listed apply to natural and LP gas pipe in-

stallations.

1. Use black iron or steel pipe and fittings or other pipe

approved by local code.

2.

Use ground joint unions and install a drip leg no less

than 3 inches long to trap dirt and moisture before it

can enter gas valve.

3.

Use two pipe wrenches when making connections to

prevent gas valve from turning.

4.

Install a manual shut-off valve and tighten all joints

securely.

Figure 21

Drip Leg and

Union, Union*

should be outside

the cabinet. Man-

ual shut-off valve

MUST be up-

stream of dripleg,

union, and fur-

nace.

LP Low

switch.

Optional

on some

models.

*Union may be installed inside the cabinet

when necessary because of clearances.

Typical Gas Piping

Air Intake Pipe

(Direct-Vent Use elbows to

Installation connect valve

only) to piping when

using right

side gas pipe

Additional LPConnectionRequirements

1. Have a licensed LP gas dealer make all connections

at storage tank and check all connections from tank

to furnace.

2. If copper tubing is used, it MUST comply with limita-

tion set in National Fuel Gas Code or CGA codes,

3. Two-stage regulation of LP gas is recommended.

Page 23

I Condensing Gas Furnace

Figure 22 Natural Gas Pipe Sizes/Capacity

Natural Gas Capacity

BTU Per Hour Input

(in Thousands)

Pipe Pipe Size I.D.

Length

(Feet) 3/6" 1/2" 3/4" 1" 11/4" 1112'

10 72 132 278 520 1,05C 1.600

20 49 92 190 350 730 1,100

30 40 73 152 285 590 890

40 34 63 130 245 500 760

Installation Instructions I

• ANSI Z21.24a-1983, Metal Connectors for Gas

Appliances

• ANSIZ21.45b-1983, FlexibleConnectorsofOther

Than All-Metal Construction for Gas Appliances.

2. Use pipe joint compound on external (male) threads

ONLY, Joint compound MUST be resistant to any

chemical action of LP gases (Figure 24),

/

Figure 24 / Proper Piping

&

Contro] Use Moderate Amount

Practice

of Compound

50 30 56 115 215 440 670

60 27 50 105 195 400 610

NOTE: Piping that is too small will prevent the proper

amount of gas from reaching the furnace.

Figure 23 LP Gas Pipe Sizes/Capacity

LP Gas Capacity

BTU Per Hour Input

(InThousands)

Pipe Copper Tubing O.D. Iron Pipe I,D.

Length

(Feet) 3/8" 1/2'1 518" 3141" 11211 3tt4" 1"

10 39 92 199 329 275 567 1,071

20 26 62 131 216 189 393 732

30 21 50 107 181 152 315 590

40 19 41 90 145 129 267 504

%

Leave 2 End

Thread Pipe Right Length

Final Check

1,

This furnace MUST be isolated from the gas supply

piping system by closing its individual manual shut-

off valve during any pressure testing of the gas sup-

ply system at pressures equal to or less than V2"

PSIG (3.5 kPa).

2. Test all pipes for leaks.

,

Gas pressure MUST NOT exceed 1/2"PSIG to gas

valve. Checking gas piping above _/2"PSIG requires

the furnace and manual shut-off valve to be discon-

nected during testing.

4. Apply soap suds (or a liquid detergent) to each joint.

Bubbles forming indicate a leak.

5. Correct even the smallest leak at once.

Threads Bare

!

50 -- 37 79 131 114 237 448

60 -- 35 72 121 103 217 409

NOTE: Copper tubing for gas supply MUST comply with limita-

tions in National Fuel Gas code, reference 2.6.3 Metallic Tub-

ing

NOTE: If a gas connector is used, it MUST be acceptable

to local authority. Connector may NOT be used inside the

furnace or be secured or supported by the furnace or

ductwork. Connectors MUST comply with one of the fol-

lowing standards or a superseding standard.

6. If orifices were changed, make sure they are

checked for leakage.

Startup

NOTE: Refer to Starting The Unit in the Users Informa-

tion Manual

CAUTION

If any sparks, odors or unusual noises occur, immedi-

ately shut OFF power to furnace. Check for wiring er-

rors or obstruction to blower.

Page 24

_ Installation Instructions Condensin_ Gas Furnace ]

7. ElectricalWiring

a

Electrical shock hazard.

Turn OFF electric power at fuse box or service

panel before making any electrical connections

and ensure a proper ground connection is made

before connecting line voltage.

Failure to do so can result in property damage,

personal injury and/or death.

Grounding

NOTE: The furnace MUST be electrically wired and

grounded in accordance with local codes or, inthe absence

of local codes, with the electrical codes of the country hav-

ing jurisdiction. Electronic controls and furnace will NOT

operate unless properly grounded. A ground lug wire is

provided for ground connection. Use an approved copper

connector from furnace to service panel or properly driven

ground rod. See Appendix.

I

5. Complete linevoltage connections insideconnection

box. See Figure 25.

Figure 25

115V 6OHz.

Electrical Connections

Air Intake Pipe

(Direct-Vent Installation only)

0

Polarizing

NOTE: To insure safe, reliable operation, unit MUST be

polarized. Proper polarity is shown in Figure 25. The white

wire is neutral and the black wire is hot.

Labeling

CAUTION

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dan-

gerous operation.

Power Supply

NOTE: Line voltage circuit is completely factory wired.

Make all line voltage connections inside furnace junction

box. ALL electrical work MUST conform with local codes,

ordinances and the national electrical code, NFPA

70-1990 or current edition.

1. Run #14 AWG hot and neutral wires from a 15 amp

circuit breaker. Ground wire gauge MUST meet or

exceed codes.

2. Do NOT connect furnace to existing lighting or other

circuit.

3,

Do NOT complete line voltage connections until fur-

nace is permanently grounded.

4.

Make all line voltage and ground connections with

copper wires.

_ THERMOSTAT

25 2O-72

Thermostat

NOTE: Thermostat location has an important effect on the

operation of the unit. Follow instructions included with ther-

mostat for correct mounting and wiring.

Heat Anticipator

• Set thermostat heat anticipator in accordance with

thermostat instructions and actual measured value.

To measure heat anticipator, do the following:

1,

Wrap 10 loops of single strand, insulated thermostat

wire around the prongs of an amp meter. Set the

scale on the amp meter to measure no more than 10

amps.

2.

Connect the uninsulated ends of this wire jumper

across terminals R and W on the subbase. (Multi-

stage thermostats use RH and W) Do NOT attach

thermostat to subbase.

3, Fire the thermostat for about one minute. Read the

amp meter. Divide the amp reading by 10 and set an-

ticipator to this number.

Page 25

Condensing Gas Furnace

Installation Instructions

4. Remove wires from subbase and attach thermostat

to subbase.

OptionalEquipment

NOTE: All wiring (except thermostat) from furnace to op-

tional equipment MUST conform to the temperature limita-

tions of local codes or, in the absence of local codes, with

the electrical codes of the country having jurisdiction. See

Appendix. Install wiring in accordance with manufacturer's

instructions.

Humidifier/ElectronicAirCleaner

The furnace is pre-wired for humidifier and/or electronic air

cleaner connection.

CAUTION

Do NOT exceed 115V/0.8 amp maximum currrent load

for both the EAC terminal and the HUM terminal com-

bined.

1,

For connection of a humidifier, break the designated

tabs ("HUM" and "N") on the electronic fan control

located in the circulating blower compartment

(Figure 26). This will expose the terminals required

for connection to the 115v power supply.

FanControl

The fan control is preset at the factory with a fixed blower

ON delay of 60 seconds in the heating mode. The blower

OFF timing is preset at 120 seconds. If desired, the fan

OFF delay can be reset to obtain the longest OFF time

while still maintaining comfort levels. See Figure 26 and

Figure 27.

I

Figure

"EAC" And "N" 7\

26 I Fan Timer Connections

i

Breakouts _

I

I

|

2. For connection of an electronic air cleaner, break the

designated tabs ("EAC" and "N") on the electronic

fan control located in the circulating blower compart-

ment (Figure 26). This will expose the terminals re-

quired for connection to the 115v power supply.

NOTE: The humidifier willbe powered when the combus-

tion blower is energized. The electronic air cleaner will be

powered anytime the thermostat calls. However, the elec-

tronic air cleaner is NOT energized during continuous fan

operation controlled by the electronic fan control.

Wiring for Air Conditioning

1. Replace heating only thermostat and cable with heat/

cooling thermostat and 4-wire thermostat cable if re-

quired.

2. Connect from W, G, R and Y on thermostat to W, G,

R and Yon furnace low voltage terminal board.

3. Connect wires from contactor on condensing unit to

Y and C on furnace low voltage terminal board.

4. Follow all instructions with condensing unit and

evaporator coil.

"_-Dip

Switch 10-11-44

Figure 27 Fan OFF Delay DIP switch Settings

1 2 1 2

60 Sec. 90 Sec.

1 2 1 2

NOTE: The furnace electronic fan control will change fan

speeds automatically as heat and cool are selected at the

thermostat.

120 Sec. t50 Sec.

Page 26

_ Installation instructions Condensing Gas Furnace I

8, Ductw0rk andFilter

Connections

NOTE: Return air can enter through either side, both sides,

Carbon monoxide poisoning hazard.

Do NOT draw return air from inside a closet or util-

ity room. Return air duct MUST be sealed to fur-

nace casing.

Failure to properly seal duct can result in personal

injury and/or death,

Installation