ICP NTP6/TNESeries, NDP6/TDESeries, NTP6050FB, TNE050B12, NTP6075GF Installation Instructions Manual

...Page 1

NTP6/TNESeries

Two-Stage Upflow/Horizontal

NDP6/TDESeries

Two-Stage Downflow

Non-condensing Furnace

SAFETY REQUIREMENTS

/X

Recognize safety information. This is the safety-alert symbol _. When you see this symbol on the furnace and in instructions

manuals be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, or CAUTION. These words are used with the safety-alert symbol. DANGER

identifies the most serious hazards, those that will result in severe personal injury or death. WARNING signifies a hazard that could

result in personal injury or death. CAUTION is used to identify unsafe practices that could result in minor personal injury or product and

property damage.

Installing and servicing heating equipment can be hazardous due to gas and electrical components. Only trained and qualified person-

nel should install, repair, or service heating equipment.

Untrained service personnel can perform basic maintenance functions such as cleaning and replacing air filters. All other operations

must be performed by trained service personnel. When working on heating equipment, observe precautions in the literature, on tags,

and on labels attached to or shipped with the unit and other safety precautions that may apply.

Follow all safety codes. In the United States, follow all safety codes including the current edition National Fuel Gas Code (NFGC) NFPA

No. 54/ANSIZ223.1. In Canada, refer tothe current edition ofthe National Standard Canada CAN/CGA-B149.1 - and .2-M91 Natural

Gas and Propane Installation Codes (NSCNGPIC). Wear safety glasses and work gloves. Have fire extinguisher available during start-

up and adjustment procedures and service calls.

These instructions cover minimum requirements and conform to existing national standards and safety codes. In some instances,

these instructions exceed certain local codes and ordinances, especially those that may not have kept up with changing residential

construction practices. We require these instructions as a minimum for a safe installation.

Design Certified

byAGA

Manufactured by:

International Comfort Products Corporation (USA)

Lewisburg, TN USA 37091

Table of Contents

1.Installation............................... 2

2.Combustion&VentilationAir ................. 5

3.GasVentInstallation ....................... 7

4.HorizontalVenting ......................... 8

5.GasSupplyandPiping ...................... 9

6.ElectricalWiring ........................

7. DuctworkandFilter(Upflow/Horizontal)......

8.DuctworkandFilter(Downflow).............

9.ChecksandAdjustments..................

10. FurnaceMaintenance...................

lt. SequenceofOperation& Diagncstic........

12

14

15

18

19

19

This furnace is not designed for use in mobile

homes, trailers or recreational vehicles. Such

use could result in death, bodily injury and/or

property damage.

Printed in U.S.A. LP1 6/4/99 441 01 2007 00

Page 2

1. Installation

Installation or repairs made by unqualified

persons can result in hazards to you and others.

Installation MUST conform with local codes or, in

the absence of local codes, with codes of all

governmental authorities having jurisdiction.

The information contained in this manual is

intended for use by a qualified service technician

who is experienced in such work, who is familiar

with all precautions and safety procedures

required in such work, and is equipped with the

proper tools and test instruments.

Failure to carefully read and follow all instruc-

tions in this manual can result in furnace

malfunction, death, personal injury and/or

property damage.

NOTE: This furnace is design certified by the American Gas

Association and the Canadian Gas Association for installation in

the United States and Canada. Refer to the appropriate codes,

along with this manual, for proper installation.

• This furnace is NOT approved for installation in mobile

homes, trailers or recreation vehicles.

• Do NOT use this furnace as a construction heater or to heat

a building that is under construction.

Use only the Type of gas approved for this furnace (see

Rating Plate on unit). Overfiring will result in failure of heat

exchanger and cause dangerous operation. (Furnace can

be converted to L.E gas with approved kit.)

• Do NOT use open flame to test for gas leak.

• Ensure adequate combustion and ventilation air is pro-

vided to the furnace.

• Seal supply and return air ducts.

A. The U.S. Consumer Product Safety Commission recom-

mends that users of gas-burning appliances install carbon

monoxide detectors. There can be various sources of car-

bon monoxide in a building or dwelling. The sources could

be gas-fired clothes dryers, gas cooking stoves, water

heaters, furnaces, gas-fired fireplaces, wood fireplaces,

and several other items. Carbon monoxide can cause seri-

ous bodily injury and/or death. Therefore, to help alert

people of potentially dangerous carbon monoxide levels,

you should have carbon monoxide detectors listed by a na-

tionally recognized agency (e.g. Underwriters Laborato-

ries or International Approval Services) installed and

maintained in the building or dwelling (see Note below).

B. There can be numerous sources of fire or smoke in a build-

ing or dwelling. Fire or smoke can cause serious bodily in-

jury, death, and/or property damage. Therefore, in order to

alert people of potentially dangerous fire or smoke, you

should have fire extinguisher and smoke detectors listed

by Underwriters Laboratories installed and maintained in

the building or dwelling (see Note below).

Note: The manufacturer of your furnace does not test any detec-

tors and makes no representations regarding any brand or

type of detector.

C. To ensure safe and efficient operation of your unit, you

should do the the following:

1. Thoroughly read this manual and labels on the unit.

This will help you understand how your unit operates and

the hazards involved with gas and electricity.

2. Do not use this unit if any part has been under water.

Immediately call a qualified service technician to inspect

the unit and to replace any part of the control system and

any gas control which has been under water.

3. Never obstruct the vent grilles, or any ducts that pro-

vide air to the unit. Air must be provided for proper com-

bustion and ventilation of flue gases.

Carbon monoxide or "CO" is a colorless and odorless gas

produced when fuel is not burned completely or when the

flame does not receive sufficient oxygen.

FreezingTemperaturesand Your Structure

• The vent system MUST be checked to determine that it is

the correct type and size.

• Install correct filter type and size.

• Unit MUST be installed so electrical components are pro-

tected from direct contact with water.

Freeze warning.

Turn off water system.

If your unit remains shut off during cold weather

the water pipes could freeze and burst, resulting

in serious water damage.

Safety Rules

Your unit is equipped with safety devices that may keep itfrom op-

erating if sensors detect abnormal conditions such as clogged ex-

haust flues.

Your unit is built to provide many years of safe and dependable

service providing it is properly installed and maintained. However,

abuse and/or improper use can shorten the life of the unit and

create hazards for you, the owner.

/SJ

Ifthe structure will be unattended during cold weather you should

take these precautions.

1. Turn off main supply water into the structure and drain the

water lines if possible. Open faucets in appropriate areas.

44101 200700

Page 3

Havesomeonecheckthestructurefrequentlyduringcold

weathertomakesureitiswarmenoughtopreventpipes

fromfreezing.Suggesttheycallaqualifiedserviceagency,

ifrequired.

Poison carbon monoxide gas hazard.

If this furnace is replacing a previously

common-vented furnace, it may be necessary to

resize the existing vent line and chimney to

prevent oversizing problems for the other

remaining appliances(s). See applicable codes

and Venting and Combustion Air Check in Gas

Vent Installation section.

Failure to properly vent this furnace or other

appliances can result in death, personal injury

and/or property damage.

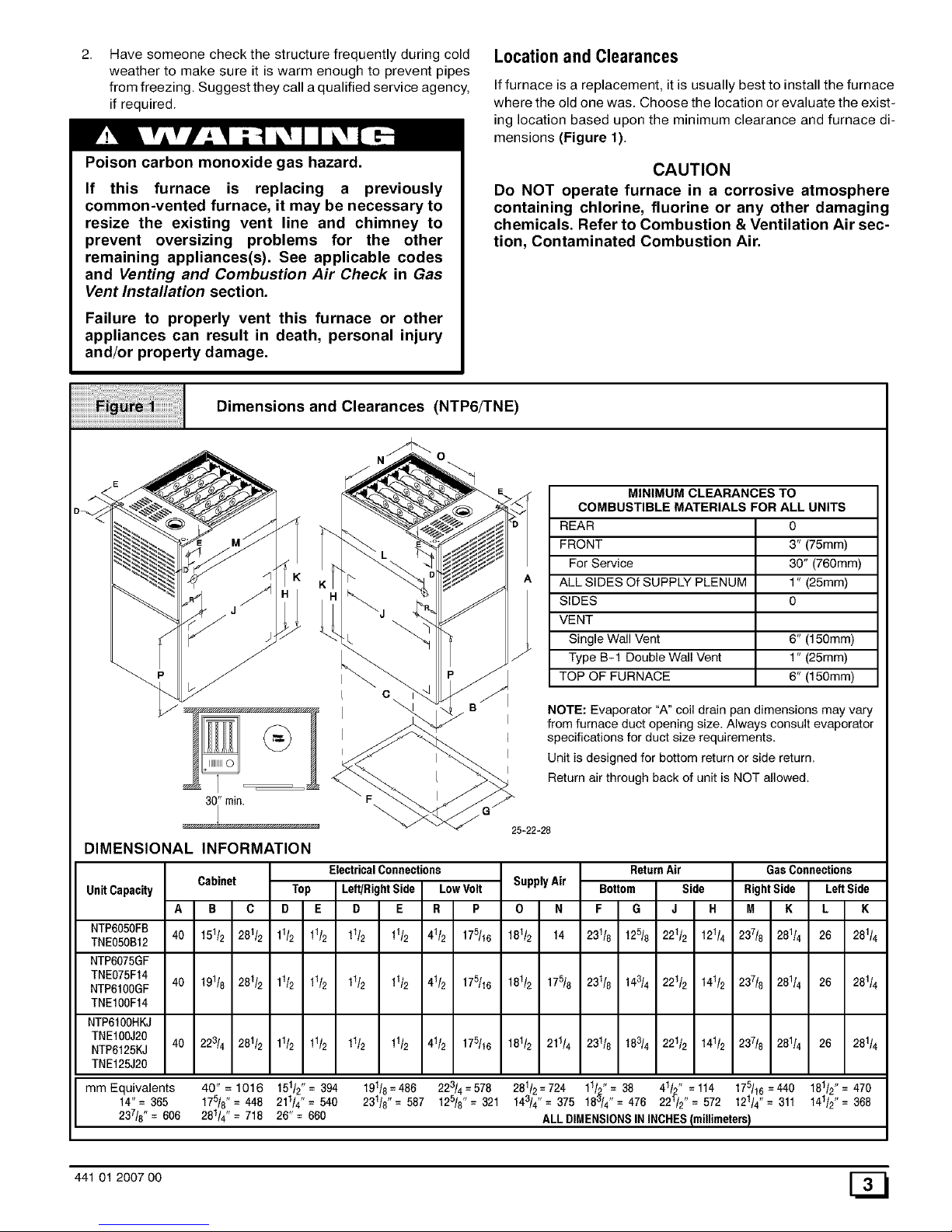

Locationand Clearances

Iffurnace is a replacement, it is usually best to install the furnace

where the old one was. Choose the location or evaluate the exist-

ing location based upon the minimum clearance and furnace di-

mensions (Figure 1).

CAUTION

Do NOT operate furnace in a corrosive atmosphere

containing chlorine, fluorine or any other damaging

chemicals. Refer to Combustion & Ventilation Air sec-

tion, Contaminated Combustion Air.

iiiiiiiiiiiiiiiiiiiiiiii_::i¸;;i¸I¸ii_!!!!!!!!!!!_!i!i;i¸ii¸ii;;;;;;;;;i;i¸iiiiii!i;iliii;!¸Iiiiiii;;;!

Dimensions and Clearances (NTP6/TNE)

" min. _

25-22-28

DIMENSIONAL INFORMATION

MINIMUM CLEARANCES TO

COMBUSTIBLE MATERIALS FOR ALL UNITS

REAR 0

FRONT 3" (75mm)

For Service 30" (760mm)

ALL SIDES Of SUPPLY PLENUM 1" (25mm)

SIDES 0

VENT

Single Wall Vent 6" (150mm)

Type B-1 Double Wall Vent 1" (25mm)

TOP OF FURNACE 6" (150mm)

NOTE: Evaporator "A" coil drain pan dimensions may vary

from furnace duct opening size. Always consult evaporator

specifications for duct size requirements.

Unit is designed for bottom return or side return.

Return air through back of unit is NOT allowed.

UnitCapacity

NTP6050FB

TNE050B12

NTP6075GF

TNE075F14

NTP6100GF

TNE100F14

NTP6100HKJ

TNE10OJ20

NTP6125KJ

TNE125J20

Cabinet

A B C

40 151/2 281/2

40 191/3 281/2

40 223/4 281/2

ElectricalConnections

Top Left/RightSide LowVolt

D E D E R P

11/2 11/2 11/2 11/2 41/2 175/16

11/2 11/2 11/2 11/2 41/2 175/16

11/2 11/2 11/2 11/2 41/2 175/16

Supp_Air

O N

181_ 14

17_8181t2

181/2 211/4

ReturnAir

Bottom Side

F G J H

231/8 t25/8 22112 121/4

231/8 t43/4 221/2 141/2

231/8 t83/4 22112 14112

GasConnections

RightSide LeftSide

M K L K

237/8 281/4 26 281/,

23718 281/4 26 2811,

23718 281/4 26 2811,

mm Equivalents 40"= 1016 151/2"= 394 191/8,_486 223/4=578 281/2_724 11/2"= 38 41/.2" =1t4 175/16=440 181/2"= 470

14"= 365 175/8"= 448 211/4"= 540 231/8 = 587 125/8"= 321 143/4 = 375 18_/4"= 476 22_/2"= 572 121/4 = 311 141/2"= 368

237/8" = 606 281/4" = 718 26" = 660 ALL DIMENSIONSININCHES(millimeters)

441 01 2007 O0 [_

Page 4

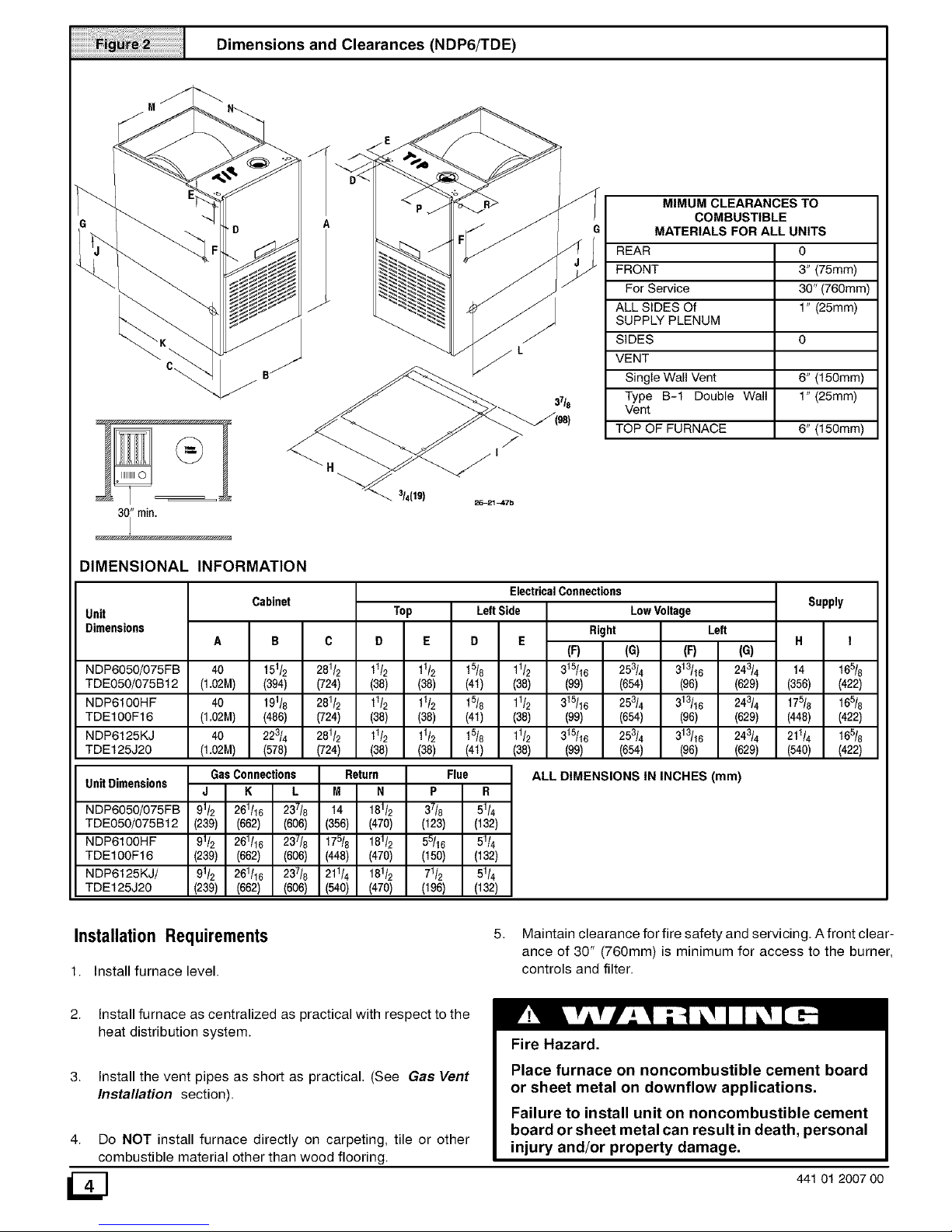

Dimensions and Clearances (NDP6/TDE)

IIIIIIIII©

_ _ : 3/4(19) _-21-47b

' min.

MIMUM CLEARANCES TO

COMBUSTIBLE

MATERIALS FOR ALL UNITS

REAR 0

FRONT 3" (75ram)

For Service 30" (760ram)

ALL SIDES Of I" (25ram)

SUPPLY PLENUM

SIDES 0

VENT

Single Wall Vent 6" (150mm)

Type B-1 Double Wall 1" (25mm)

Vent

TOP OF FURNACE 6" (150mm)

DIMENSIONAL INFORMATION

Unit

Dimensions

Cabinet

A D

ElectricalConnections

Top LeftSide

D E

C D

281/2 11/2

(724) (38)

28112 11/2

(724) (38)

281/2 11/2

(724) (38)

Return

U

14

(356)

17%

(448)

211/4

(540)

Left

Supply

LowVoltage

Right

(F) (G) (F)

316116 253/4 313116

(99) (654) (96)

316116 253/4 313116

(99) (654) (96)

316116 253/4 313116

(99) (654) (96)

H I

(G)

NDP6050/075FB 40 151/2 11/2 15/8 11/2 243/4 14 165/8

TDE050/075Bt2 (1.02M) (394) (38) (4t) (38) (629) (356) (422)

NDP6100HF 40 19118 1112 1518 11/2 243/4 175/8 16618

TDE100F16 (1.02M) (486) (38) (4t) (38) (629) (448) (422)

NDP6125KJ 40 22314 1112 1518 11/2 243/4 211/4 165/8

TDE125J20 (1.02M) (578) (38) (4t) (38) (629) (540) (422)

GasConnections Flue

Unit Dimensions

J K L N P R

NDP6050/075FB 91/2 261/16 237/8 181/2 37/8 51/4

TDE050/075Bt2 (239) (662) (606) (470) (123) (132)

NDP6100HF 91/2 261/16 23718 181/2 55116 51/4

TDE100F16 (239) (662) (606) (470) (150) (132)

NDP6125KJ/ 9112 261116 23718 181/2 71/2 51/4

TDE125J20 (239) (662) (606) (470) (196) (132)

ALL DIMENSIONS IN INCHES (mm)

Installation Requirements

1. Install furnace level.

5. Maintain clearance for fire safety and servicing. A front clear-

ance of 30" (760mm) is minimum for access to the burner,

controls and filter.

Install furnace as centralized as practical with respect to the

heat distribution system.

Install the vent pipes as short as practical. (See Gas Vent

Installation section).

Do NOT install furnace directly on carpeting, tile or other

combustible material other than wood flooring.

Fire Hazard.

Place furnace on noncombustible cement board

or sheet metal on downflow applications.

Failure to install unit on noncombustible cement

board or sheet metal can result in death, personal

injury and/or property damage.

441 01 2007 00

Page 5

6. Use a raised base if the floor is damp or wet at times.

Residential garage installations require:

• Burners and ignition sources installed at least 18" (457mm)

above the floor.

• Furnace must be located or physically protected from pos-

sible damage by a vehicle.

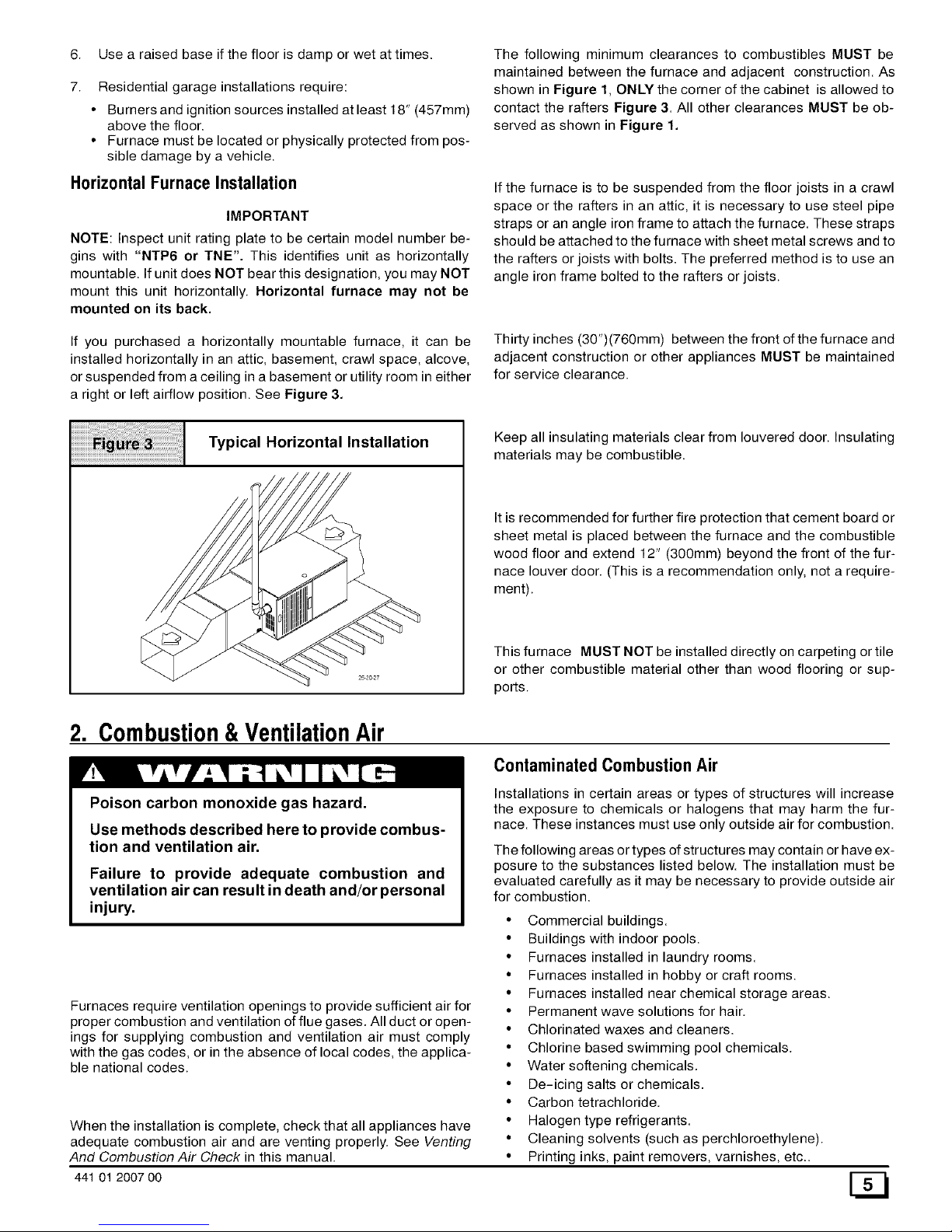

Horizontal FurnaceInstallation

IMPORTANT

NOTE: Inspect unit rating plate to be certain model number be-

gins with "NTP6 or TNE". This identifies unit as horizontally

mountable. If unit does NOT bear this designation, you may NOT

mount this unit horizontally. Horizontal furnace may not be

mounted on its back.

The following minimum clearances to combustibles MUST be

maintained between the furnace and adjacent construction. As

shown in Figure 1, ONLY the corner of the cabinet is allowed to

contact the rafters Figure 3. All other clearances MUST be ob-

served as shown in Figure 1.

If the furnace is to be suspended from the floor joists in a crawl

space or the rafters in an attic, it is necessary to use steel pipe

straps or an angle iron frame to attach the furnace. These straps

should be attached to the furnace with sheet metal screws and to

the rafters or joists with bolts. The preferred method is to use an

angle iron frame bolted to the rafters or joists.

If you purchased a horizontally mountable furnace, it can be

installed horizontally in an attic, basement, crawl space, alcove,

or suspended from a ceiling in a basement or utility room in either

a right or left airflow position. See Figure 3.

Thirty inches (30")(760mm) between the front of the furnace and

adjacent construction or other appliances MUST be maintained

for service clearance.

iiiiiiiiiiiiiiiiiiiiii_;i¸;I¸;I;I¸iiiiiiiiiiiii_;;;;;_!!!!!!!!!!!!!iiiil;!iii!i;Jili;i¸ii¸ii¸ii¸ii¸ii¸ii¸ii¸ii¸ii¸ii¸ii¸ii¸ii¸ii¸i¸i;i;i¸;

II II II

Typical Horizontal Installation

Keep all insulating materials clear from Iouvered door. Insulating

materials may be combustible.

It is recommended for further fire protection that cement board or

sheet metal is placed between the furnace and the combustible

wood floor and extend 12" (300mm) beyond the front of the fur-

nace louver door. (This is a recommendation only, not a require-

ment).

This furnace MUST NOT be installed directly on carpeting or tile

or other combustible material other than wood flooring or sup-

ports.

2. Combustion&VentilationAir

Contaminated Combustion Air

Poison carbon monoxide gas hazard.

Use methods described here to provide combus-

tion and ventilation air.

Failure to provide adequate combustion and

ventilation air can result in death and/or personal

injury.

Furnaces require ventilation openings to provide sufficient air for

proper combustion and ventilation of flue gases. All duct or open-

ings for supplying combustion and ventilation air must comply

with the gas codes, or in the absence of local codes, the applica-

ble national codes.

When the installation is complete, check that all appliances have

adequate combustion air and are venting properly. See Venting

And Combustion Air Check in this manual.

Installations in certain areas or types of structures will increase

the exposure to chemicals or halogens that may harm the fur-

nace. These instances must use only outside air for combustion.

The following areas or types of structures may contain or have ex-

posure to the substances listed below. The installation must be

evaluated carefully as it may be necessary to provide outside air

for combustion.

• Commercial buildings.

• Buildings with indoor pools.

• Furnaces installed in laundry rooms.

• Furnaces installed in hobby or craft rooms.

• Furnaces installed near chemical storage areas.

• Permanent wave solutions for hair.

• Chlorinated waxes and cleaners.

• Chlorine based swimming pool chemicals.

• Water softening chemicals.

• De-icing salts or chemicals.

• Carbon tetrachloride.

• Halogen type refrigerants.

• Cleaning solvents (such as perchloroethylene).

• Printing inks, paint removers, varnishes, etc..

441 01 2007 00 [_

Page 6

• Hydrochloric acid.

• Sulfuric Acid.

• Solvent cements and glues.

• Antistatic fabric softeners for clothes dryers.

• Masonry acid washing materials.

ConfinedSpace Installation

NOTE: A confined space is defined as an area with less than 50

cubic feet(1.4m 3) per 1,000 BTUH input rating for all gas ap-

pliances installed in the area.

Air Openings and Connecting Ducts

1. Total input rating for all gas appliances MUST be considered

when determining free area of openings.

2. Connect ducts or openings directly to outside.

3. When screens are used to cover openings, the openings

MUST be no smaller than 1/4" (6mm) mesh.

4. The minimum dimension of rectangular air ducts MUST NOT

be less than 3" (75mm).

5. When sizing grille or louver, use the free area of opening. If

free area is NOT stamped or marked on grill or louver, as-

sume a 20% free area for wood and 60% for metal.

Requirements

1. Provide confined space with sufficient air for proper combus-

tion and ventilation of flue gases using horizontal or vertical

ducts or openings.

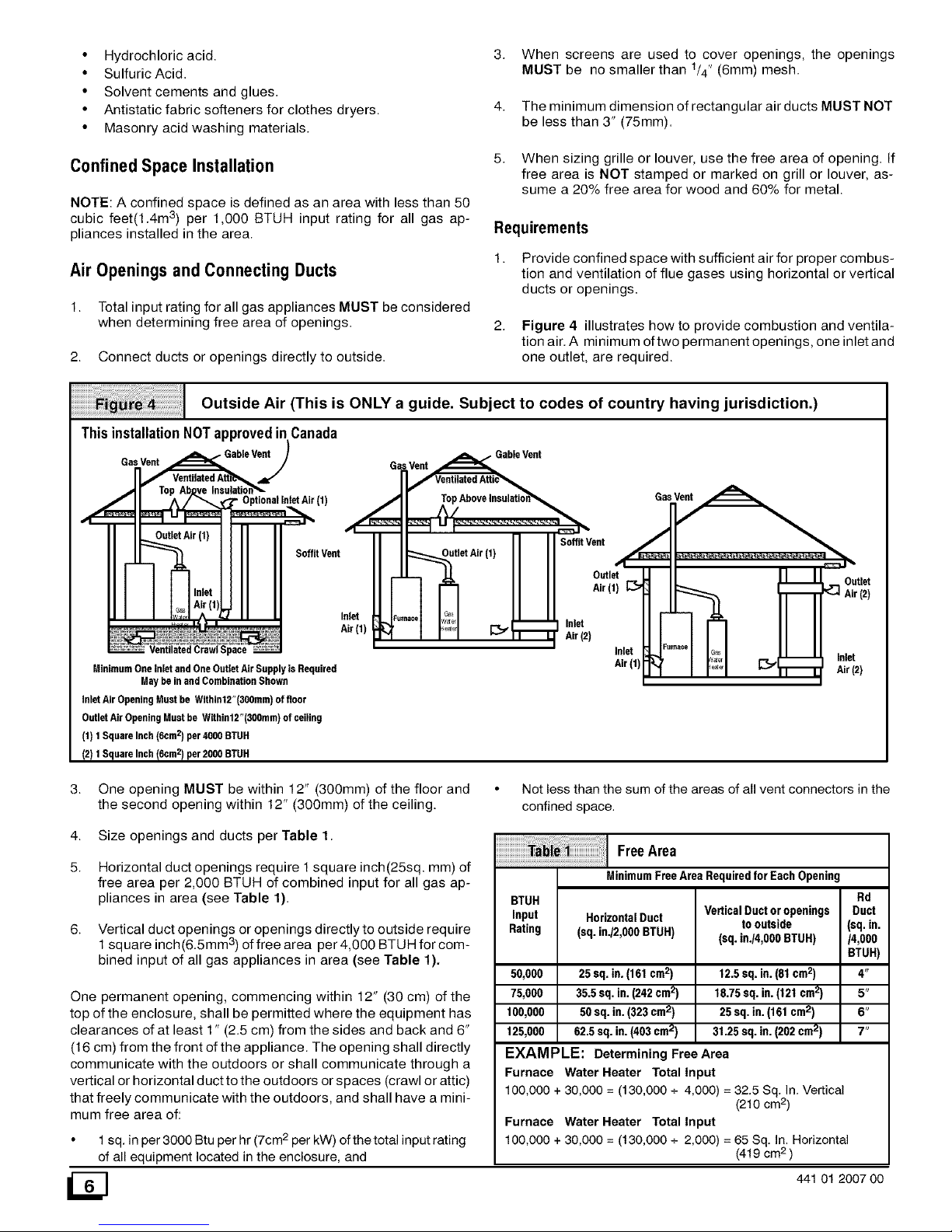

2. Figure 4 illustrates how to provide combustion and ventila-

tion air. A minimum oftwo permanent openings, one inlet and

one outlet, are required.

Outside Air (This is ONLY a guide. Subject to codes of country having jurisdiction.)

This installation NOT approved in Canada

_ L_ "Optional Inlet Air (1)

SoffitVent

fl

Inlet

Air (1)

MinimumOne Inlet and OneOutletAirSupply isRequired

May bein andCombinationShown

InletAir OpeningMustbe Withint2"(300mm)of floor

OutletAirOpeningMustbe Withint2"(300mm)of ceiling

(1) 1SquareInch(6cm2) per4000BTUH

(2) 1SquareInch(6cm2) per2000BTUH

I ' ' n Sot fflit ent

i1 ¢ etAir''ii L

I _ J-L II I Outlet

i N iii

.......I g%l r-_l"_" lulet

I_'l I I I _ _ Air(2)

Inlet

Air (t)

3. One opening MUST be within 12" (300mm) of the floor and • Not less than the sum of the areas of ai]vent connectors in the

the second opening within 12" (300mm) of the ceiling, confined space.

4.

5.

Size openings and ducts per Table 1.

Horizontal duct openings require 1 square inch(25sq, mm) of

free area per 2,000 BTUH of combined input for all gas ap-

pliances in area (see Table 1).

Vertical duct openings or openings directly to outside require

1square inch(6.5mm 3) of free area per 4,000 BTUH for com-

bined input of all gas appliances in area (see Table 1).

One permanent opening, commencing within 12" (30 cm) of the

top of the enclosure, shall be permitted where the equipment has

clearances of at least 1" (2.5 cm) from the sides and back and 6"

(16 cm) from the front of the appliance. The opening shall directly

communicate with the outdoors or shall communicate through a

vertical or horizontal duct to the outdoors or spaces (crawl or attic)

that freely communicate with the outdoors, and shall have a mini-

mum free area of:

• 1sq. in per 3000 Btu per hr (7cm 2per kW) ofthe total input rating

of all equipment located in the enclosure, and

/SJ

Free Area

MinimumFreeAreaRequiredforEachOpening

BTUH

Input HorizontalDuct

Rating (sq. in./2,000BTUH)

50,000 25sq. in. (161cm2)

75,000 35.5 sq. in.(242cm2)

100,000 50sq. in.(323cm2)

125,000 62.5sq. in.(403 cm2)

Rd

VerticalDuctor openings Duct

to outside (sq.in.

(sq. in./4,000BTUH) /4,000

BTUH)

12.5sq. in.(81cm2) 4"

18.75sq. in.(121cm2) 5"

25sq. in. (161cm2) 6"

31.25sq.in. (202cm2) 7"

EXAMPLE: Determining Free Area

Furnace Water Heater Total Input

100,000 + 30,000 = (t30,000 + 4,000) = 32.5 Sq. In. Vertical

(210 cm2)

Furnace Water Heater Total Input

100,000 + 30,000 = (t30,000 + 2,000) = 65 Sq. In. Horizontal

(419 cm2)

441 01 2007 00

Page 7

Unconfined Space Installation

Poison carbon monoxide gas hazard.

Most homes will require additional air.

An unconfined space or homes with tight

construction may not have adequate air infiltra-

tion for proper combustion and ventilation of

flue gases.

Failure to supply additional air by means of ven-

tilation grilles or ducts could result in death and/

or personal injury.

An unconfined space is defined as an area having a minimum vol-

ume of 50 cubic feet(1.4m 3)per 1,000 Btuh total input rating for all

gas appliances in area.

Adjoining rooms can be considered part of an unconfined area if

there are no doors between rooms.

An attic or crawl space may be considered an unconfined space

provided there are adequate ventilation openings directly to out-

doors. Openings MUST remain open and NOT have any means

of being closed off. Ventilation openings to outdoors MUST be at

least 1 square inch (25mm 2) of free area per 4,000 BTUH of total

input rating for all gas appliances in area.

In unconfined spaces, infiltration should be adequate to provide

air for combustion, ventilation and dilution of flue gases. However,

in buildings with unusually tight construction, additional air MUST

be provided using the methods described in section titled Con-

fined Space Installation:

Unusually tight construction is defined as: Construction with

1 Walls and ceilings exposed to the outside have a continuous,

sealed vapor barrier. Openings are gasketed or sealed and

2 Doors and openable windows are weather stripped and

Other openings are caulked or sealed. These include joints

around window and door frames, between sole plates and

floors, between wall-ceiling joints, between wall panels, at

penetrations for plumbing, electrical and gas lines, etc.

VentilationAir

Some provincial codes and local municipalities require ventilation

or make-up air be brought into the conditioned space as replace-

ment air. Whichever method is used, the mixed return air temper-

ature across the heat exchanger MUST not fall below 60°F (15 ° c)

or flue gases will condense in the heat exchanger. This will short-

en the life of the heat exchanger and possibly void your warranty.

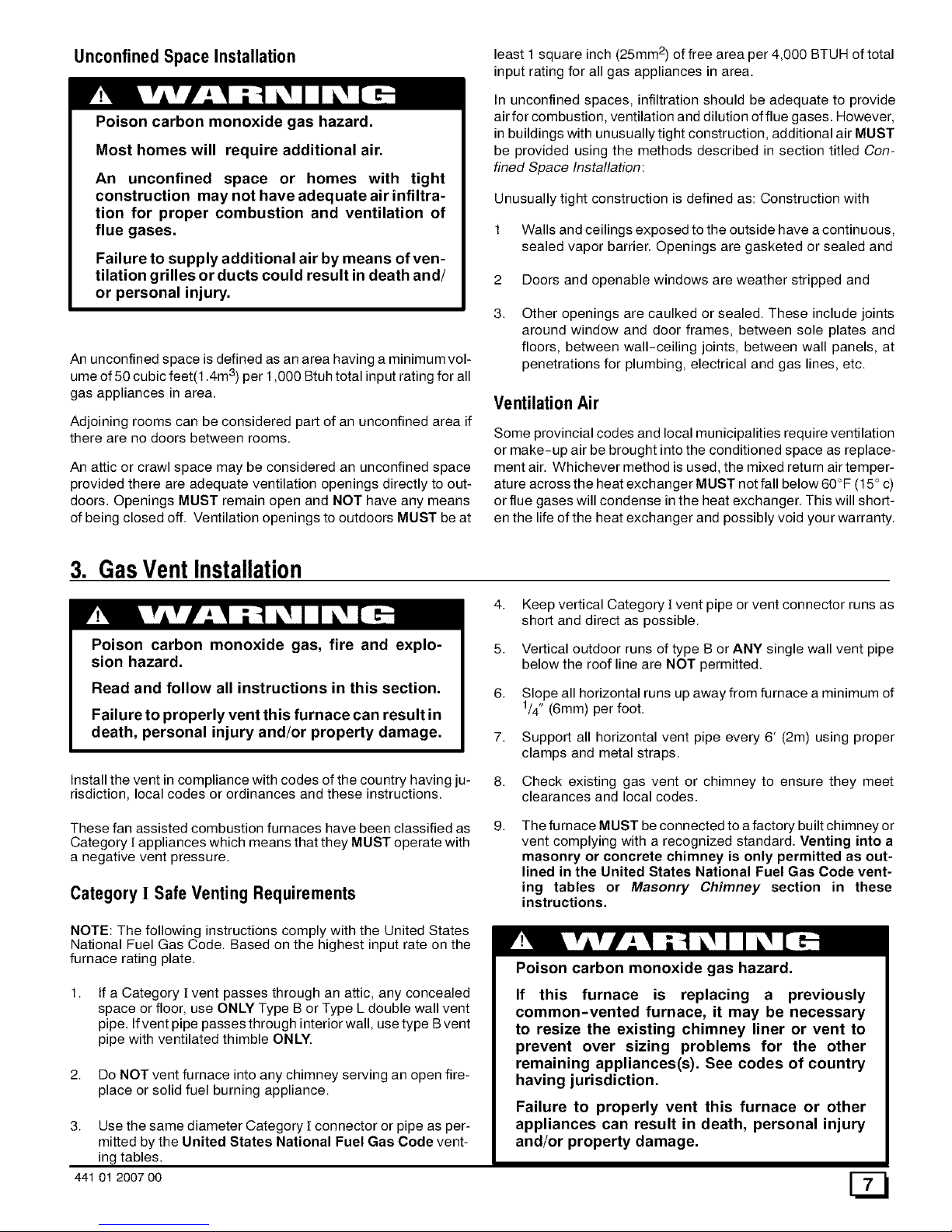

3. GasVent Installation

Poison carbon monoxide gas, fire and explo-

sion hazard.

4. Keep vertical Category [ vent pipe or vent connector runs as

short and direct as possible.

Read and follow all instructions in this section.

Failure to properly vent this furnace can result in

death, personal injury and/or property damage.

Install the vent in compliance with codes of the country having ju-

risdiction, local codes or ordinances and these instructions.

5.

6.

7.

8.

Vertical outdoor runs of type B or ANY single wall vent pipe

below the roof line are NOT permitted.

Slope all horizontal runs up away from furnace a minimum of

1/4" (6mm) per foot.

Support all horizontal vent pipe every 6' (2m) using proper

clamps and metal straps.

Check existing gas vent or chimney to ensure they meet

clearances and local codes.

These fan assisted combustion furnaces have been classified as

Category [ appliances which means that they MUST operate with

a negative vent pressure.

Category! Safe Venting Requirements

The furnace MUST be connected to a factory built chimney or

vent complying with a recognized standard. Venting into a

masonry or concrete chimney is only permitted as out-

lined in the United States National Fuel Gas Code vent-

ing tables or Masonry Chimney section in these

instructions.

NOTE: The following instructions comply with the United States

National Fuel Gas Code. Based on the highest input rate on the

furnace rating plate.

If a Category [ vent passes through an attic, any concealed

space or floor, use ONLY Type B or Type L double wall vent

pipe. If vent pipe passes through interior wall, use type B vent

pipe with ventilated thimble ONLY.

2. Do NOT vent furnace into any chimney serving an open fire-

place or solid fuel burning appliance.

3. Use the same diameter Category [ connector or pipe as per-

mitted by the United States National Fuel Gas Code vent-

ing tables.

44101 2007 00

Poison carbon monoxide gas hazard.

If this furnace is replacing a previously

common-vented furnace, it may be necessary

to resize the existing chimney liner or vent to

prevent over sizing problems for the other

remaining appliances(s). See codes of country

having jurisdiction.

Failure to properly vent this furnace or other

appliances can result in death, personal injury

and/or property damage.

EZ3

Page 8

Venting and CombustionAir Check

NOTE: Ifthis installation removes an existing furnace from a vent-

ing system serving one or more other appliances, and to make

sure there is adequate combustion air for all appliances, MAKE

THE FOLLOWING CHECK.

1. Seal any unused openings in the venting system.

Visually inspect the venting system for proper size and hori-

zontal pitch to ensure there is no blockage or restriction, leak-

age, corrosion or other deficiencies which could cause an

unsafe condition.

Insofar as is practical, close all doors and windows and all

doors between the space in which the appliance(s) remain-

ing connected to the venting system are located and other

spaces of the building.

Turn on clothes dryers and any appliance not connected to

the venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at maxi-

mum speed. Do not operate a summer exhaust fan. Close

fireplace dampers.

5. Follow the lighting instructions for each appliance being in-

spected. Adjust thermostat so appliance(s) will operate con-

tinuously.

6. Allow 5 minutes of main burner operation, then check for

spillage at the draft hood relief opening of each appliance.

Use the flame of a match or candle (Figure 5).

Vent Check

Vent Pipe "-_ I A/ Draft Hood

Typical Gas

Water Heater

! I

Match

7. After it has been determined that each appliance vents prop-

erly, return doors, windows, appliances etc. to their normal

condition.

8. If improper venting is observed, the cause MUST be cor-

rected.

NOTE: If flame pulls towards draft hood, this indicates sufficient

infiltration air.

Venting to Existing Masonry Chimney

NOTE: The tables and notes referred to below are found in the

most recent printing of the United States National Fuel Gas

Code venting tables.

Use the United States National Fuel Gas Code or NFGC Tables

to size the chimney or vent. Dedicated venting of one fan as-

sisted furnace into any masonry chimney is restricted.The

chimney must first be lined with either type B vent sized in accor-

dance with tables 1 or 2or a listed single wall, metal lining system,

sized in accordance with the vent tables.

Listed, corrugated metallic chimney liner systems in masonry

chimneys shall be sized by using United States National Fuel

Gas Code tables for dedicated venting and United States Na-

tional Fuel Gas Code tables for common venting with the maxi-

mum capacity reduced by 20% (0.80 X maximum capacity) and

the minimum capacity as shown in the applicable table. Corru-

gated metal vent systems installed with bends or offsets require

additional reduction of 10% of the vent capacity for each 90 ° el-

bow.

NOTE: Two(2) 45 ° elbows are equivalent to one (1 90° elbow.

Combined Venting into a Masonry Chimney

Venting into a masonry or concrete chimney is only per-

mitted as outlined in the United States National Fuel Gas

Code venting tables. Follow all safe venting requirements

4. HorizontalVenting

Category ! Furnaces With External Power Venters

Inorder to maintain a Category[ classification offan assisted fur-

naces when vented horizontally with sidewall termination, a pow-

er venter is REQUIRED to maintain a negative pressure in the

venting system. Please consult the Fields Controls Co. or Tjern-

lund Products, Inc. for power venters certified for use with our fur-

naces.

Vent Termination

Venting Through aNon-Combustible and Combustible

Wall

Consult External Power Venter manufacturer instructions.

CAUTION

It is the responsibility of the installer to properly termi-

nate the vent and provide adequate shielding, This is

essential in order to avoid water/ice damage to build-

ing, shrubs and walk-ways.

441 01 2007 00

Page 9

5. GasSupplyand Piping

Fire and explosion hazard.

Natural Gas

Models designated for Natural Gas areto be used

with Natural Gas ONLY.

Failure to follow these instructions can result in

death, personal injury and/or property damage.

7. Repeat steps 4 and 5 for low fire operation.

8. When the manifold pressures are properly set, replace the

adjustment screw covers on the gas valve.

9. Remove the jumper wires from the thermostat connections

on the fan board. Remove manometer and replace plug in

manifold.

10. Replace combustion air box cover.

11. Return fourth (4th) DIP switch to previous setting.

Natural Gas Input Rating Check

Gas Supply Requirements

• Use only the Type of gas approved for this furnace. See rat-

ing plate for approved gas type.

• Gas input must not exceed the rated input shown on the rat-

ing plate. Overfiring will result in failure of heat exchanger

and cause dangerous operation.

• Do not allow minimum supply pressure to vary downward.

Doing so will decrease input to furnace. Refer to Table 2 for

Gas supply and manifold pressures.

Gas Pressures

Gas Supply Pressure

Type

Recom- Max. Min.

mended

Natural 7" 14" 4.5"

(1.7 kPa) (3.5 kPa) (1.1 kPa)

Propane 11" 14" 11"

(2.7 kPa) (3.5 kPa) (2.7 kPa)

Manifold

Pressure

High Low

3.5" 1.7"

(0.9 (0.42

kPa) kPa)

10" 4.3"

(2.5 (1.07

kPa) kPa)

NOTE: The gas meter can be used to measure input to furnace.

Rating is based on a natural gas BTU content of 1,000 BTU's per

cubic meter. Check with gas supplier for actual BTU content.

1. Make sure combustion air box cover is in place and closed

before performing the following steps.

2. Turn OFF gas supply to all appliances and start furnace.

Use jumper wire on R to Wl and W2 for Hi fire.

3. Time how many seconds it takes the smallest dial on the

gas meter to make one complete revolution. Refer to Ex-

ample.

4. Repeat setps 2 and 3 with jumper wire on R to Wl for low

fire. NOTE: Fourth (4th) DIP switch must be in on position.

(See furnace wiring diagram). Return fourth (4th) DIP

switch to previous setting after check.

Example

NaturalGas No.ofSeconds TimePerCubic BTUPer

BTUContent PerHour FootinSeconds Hour

1,000 3,600 48 75,000

1,000 x 3,600 + 48 = 75,000 BTUH

NOTE: If meter uses a 2 cubic foot dial, divide results (seconds)

by two.

5. Relight all appliances and ensure all pilots are operating.

ManifoldGas Pressure Adjustments (Hi & Lo Fire)

NOTE: Gas supply pressure MUST be within minimum and maxi-

mum values listed on rating plate. Pressures are usually set by

gas suppliers.

Orifice Sizing

NOTE: Factory sized orifices for natural and LP gas are listed in

the furnace Technical Support manual.

Make adjustment to manifold pressure with burners operating

and combustion air box cover removed.

1. Remove combustion air box cover.

2. Connect manometer to the tapped opening on the outlet

side of gas valve or on the manifold pipe. Use a manometer

with a 0 to 12" minimum water column range.

3. TurngasON. Operatethe furnace on high fire by using a

jumper wire on the R to Wl & W2 thermostat connections

on the fan board.

4. Remove the adjustment cover on the gas valve. Turn ad-

justing screw counterclockwise to decrease the manifold

pressure and clockwise to increase. See Figure 27.

5. Set the manifold pressure to value shown in Table 2,

Table 3 or Table 4.

Operate the furnace on low fire by using a jumper wire on

the R to W1 thermostat connections on the fan board.

Note: The fourth (4th) DIP switch should be in the on posi-

tion to set the low fire manifold pressure. (See wiring di-

gram)

Ensure furnace is equipped with the correct main burner orifices.

Refer to Table 3 & Table 4 for correct orifice size for a given heat-

ing value and specific gravity for natural and propane gas.

OperationAbove 2000' Altitude

Fire, Explosion, Poison carbon monoxide gas haz-

ard.

This conversion shall be done by a qualified ser-

vice agency in accordance with the Manufactur-

er's instructions and all applicable codes and re-

quirements, or in the absence of local codes, the

applicable national codes.

Failure to follow these instructions exactly can re-

sult in death, personal injury and/or property dam-

age.

441 01 2007 00 [_

Page 10

These units may be used at full input rating when installed at alti-

tudes up to 2000L When installed above 2000', the high fire input

must be decreased 2% (natural) or 4% (LP) for each 1000' above

sea level. This may be accomplished by a simple adjustment of

manifold pressure or an orifice change, or a combination of a

pressure adjustment and an orifice change. The changes re-

quired depend on the installation altitude and the heating value of

the fuel. Table 3 & Table 4 show the proper furnace manifold

pressure and gas orifice size to achieve proper performance

based on elevation above sea level for both natural gas and pro-

pane.

To use the natural gas table, first consult your local gas utility for

the heating value of the gas supply. Select the heating value on

the vertical border and follow across the table until the appropriate

elevation for the installation is reached. The first value in the box

at the intersection of the heating value and elevation will be the

manifold pressure required. If a gas orifice change is also re-

quired, the box is shaded. The required orifice size is shown atthe

bottom of the table.

Sea Level

High Altitude Input Rate = Nameplate x (Multiplier)

Elevation

2000'-2999'

3000'-3999'

4000'-4999'

5000'-5999'

6000'-6999'

7000'-7999'

Input Rate

High Altitude Multiplier

Natural LP Gas

0.96 0.92

0.94 0.88

0.92 0.84

0.90 0.80

0.88 0.76

0.86 0.72

MANIFOLD PRESSURE AND ORIFICE SIZE FOR HIGH ALTITUDE APPLICATIONS

Table 3

HEATING VALUE

BTU/CU. FT.

800

850

900

950

1000

1050

1100

Orifice Size

Table 4

HEATINGVALUE

BTU/CU.F_

2500

Orifice Size

NATURAL GAS

0 to 1999

("wc)

Hi Lo

3.5 1.7

3.5 1.7

3.5 1.7

3.5 1.7

3.5 1.7

3.2 1.6

2.9 1.4

#42

2000 to

2999 (" wc)

Hi Lo

3.5 1.7

3.5 1.7

3.5 1.7

3.5 1.7

3.4 1.7

3.1 1.5

2.8 1.4

#42

MEAN ELEVATION FEET ABOVE SEA LEVEL

3000 to 4000 to 5000 to

3999 (" wc) 4999 (" wc) 5999 (" wc)

Hi Lo

3.5 1.7

3.5 1.7

3.5 1.7

3.5 1.7

3.2 1.5

2.9 1.4

2.6 1.3

#42

Hi Lo

3.5 1.7

3.5 1.7

3.5 1.7

3.3 1.6

3.0 1.5

2.7 1.3

2.5 1.2

#42

6000 to

6999 (" wc)

Hi Lo

3.5 1.7

3.5 1.7

3.5 1.7

3.2 1.6

2.9 1.4

2.6 1.3

2.4 1.2

#42

Hi Lo

3.5 1.7

3.5 1.7

3.5 1.7

3.5 1.7

3.3 1.6

3.0 1.5

2.7 1.3

#42

7000 to

8000 (" wc)

Hi Lo

3.5 1.7

3.5 1.7

3.4 1.7

3.1 1.5

2.8 1.4

2.5 1.2

2.3 1.1

#42

LPG or PROPANE

0 to 1999 2000 to

("wc) 2999 (" wc)

Hi I Lo Hi I Lo10.04.910.0 4.9

#54 #54

MEAN ELEVATION FEET ABOVE SEA LEVEL

3000 to 4000 to 5000 to

3999 (" wc) 4999 (" wc) 5999 (" wc)

Hi I Lo9.4 4.6

#54 #55 #55

6000 to

6999 (" wc)

7000 to

8000 (" wc)

#55 #55

NOTE: NATURAL GAS DATA BASED ON 0.60 SPECIFIC GRAVITY. PROPANE DATA BASED ON 1.53 SPECIFIC GRAVITY. FOR

FUELS WITH DIFFERENT SPECIFIC GRAVITY CONSULT THE LATEST EDITION OF THE NATIONAL FUEL GAS

CODE ANSI Z223.1 and CAN B149.

ChangingOrifices

After disconnecting power and gas supply to the furnace, re-

move the access door, exposing the burner compartment.

a. Remove the five (5) screws holding the burner box cover

to expose the manifold and burners. (Figure 6 or

Figure 7)

2.

3.

4.

Disconnect gas line and pilot tubing from gas valve so man-

ifold can be removed.

Disconnect wiring at gas valve. Be sure to note the proper

location of any and all electrical wiring disconnected.

Remove the four (4) screws holding the manifold and gas

valve to the manifold supports. Do not discard any screws.

See (Figure 6 or Figure 7).

Manifold (Upflow/Horizontal)

25-22-32

441 01 2007 00

Page 11

Manifold (Downflow)

25_22-38

iiiiiiiiiiiiiiiiii!i:i¸I¸I¸I¸I¸ili!!!!!!i;;;;;iiiiiiiiiiiii!!!!!!!i!!;; !ii¸iiil;

Bbow and

shortnlpple

25-22-3t

5.

6.

Carefully remove the manifold assembly.

Remove the orifices from the manifold and replace them with

proper sized orifices. See Figure 8.

Tighten orifices so there is 11/8"from the face of the orifice to

the back side of the manifold. See Figure 8.

Clearances

Measure11/8"(27mm) from face

oforifice to the back side of the

manifold.

3. Use black iron or steel pipe and fittings or other pipe ap-

proved by local code.

4. Use pipe thread compound which is resistant to natural and

LP gases.

5. Install a drip leg no less than 3" long to trap dirt and moisture

before it can enter gas valve.

6. Provide a 1/8" inch plug for test gauge connection immedi-

ately up stream of gas supply connection to furnace.

7. Use two pipe wrenches when making connections to prevent

gas valve from turning.

8. Flexible corrugated metal gas connector may NOT be used

inside the furnace or be secured or supported by the furnace

or ductwork.

9. Properly size gas pipe to handle combined appliance load or

run gas pipe directly from gas meter or LP gas regulator.

10. Install correct pipe size for run length and furnace rating.

11. Measure pipe length from gas meter or LP second stage reg-

ulator.

Reassemble all parts in reverse order as removed. Be sure to

engage the main burner orifices in the proper opening in the

burners.

After reassembling, turn gas on and check all joints for gas

leaks using a soapy solution. All leaks must be repaired im-

mediately.

Fire or explosion hazard.

Gas connector must be properly installed, cannot

go through the side of the furnace, and can not be

used inside the furnace,

Failure to properly install gas connector can

result in death, bodily injury and/or property

damage,

Additional LP Piping Requirements

Gas Piping Requirements

1.

Install gas piping in accordance with local codes, or in the ab-

sence of local codes, the applicable national codes.

Itis recommended that a manual shutoff valve be installed in

the gas supply line outside the unit. Locate valve as close to

the furnace as possible where it is readily accessible. Refer

to Figure 9.

• Have a licensed LP gas dealer make all connections at stor-

age tank and check all connections from tank to furnace.

• If copper tubing is used, it MUST comply with limitation set in

Local Codes, or in the absence of local codes, the gas codes

of the country having jurisdiction. See Appendix.

• Two-stage regulation of LP gas is recommended.

FinalCheck

• Test all pipe for leaks.

441 01 2007 00 [_

Page 12

• If orifices where changed, make sure they are checked for

leaks.

• During pressure testing of gas piping system, observe the

following:

a. Iftest pressure does not exceed 1/2" PSIG, isolate the fur-

nace by closing its individual manual shutoff valve.

b. Iftest pressure exceeds 1/2"PSIG, the furnace and its indi-

vidual shutoff valve must be disconnected from the gas sup-

ply system.

• To check for leaks apply soap suds or a liquid detergent to

each joint. Bubbles forming indicate a leak.

• Do not use an open flame to test for gas leaks. Fire or explo-

sion could occur.

• Correct even the smallest leak at once.

Fire or explosion hazard.

Liquid petroleum (LP) gas is heavier than air and

will settle and remain in low areas and open

depressions.

Thoroughly ventilate area and dissipate gas. Do

NOT use a match or open flame to test for leaks,

or attempt to start up furnace before thoroughly

ventilating area.

An open flame or spark can result in death,

personal injury and/or property damage.

6. ElectricalWiring

Power Supply Wiring

The furnace MUST be electrically wired and grounded in accor-

dance with local codes, or in the absence of local codes, the appli-

cable national codes.

Field wiring connections must be made inside the furnace con-

nection box. A suitable strain relief should be used at the point the

wires exit the furnace casing.

Copper conductors shall be used. Line voltage wires should be

sized for the input amps stated on the rating plate. Furnace must

be connected to its own separate circuit.

Thermostat

The 2-stage furnace control will operate with either a single stage

or a two stage heating thermostat and will provide 2-stage heat-

ing operation. For single stage thermostat installations, the Rand

W wires from the thermostat connect to the R and W1 connec-

tions on the furnace control. Note: The fourth (4th) DIP switch

should be in the off position for the furnace to operate properly

with a single stage thermostat. Failure to change DIP switch with

single stage thermostat will result in Low Fire operation ONLY.

(See wiring digram) During operation, the furnace will operate on

low fire for 12 minutes. If the heat request exists for more than 12

minutes, the furnace will automatically shift to the high fire mode

for the remaining duration of the heating cycle. For 2-stage ther-

mostatostat installations, the R, W1 and W2 wires from the ther-

mostat connect to the R, W1 and W2 connections on the furnace

control. During operation, the furnace will shift from low fire to high

fire as requested by the thermostat. The thermostat heat anticipa-

tor should be adjusted to a .10 setting for both types of thermo-

stats.

Thermostat location has an important effect on the operation of

the unit. Follow instructions included with thermostat for correct

mounting and wiring.

Low voltage connections to furnace must be made on terminal

board to fan control.

Optional Equipment

All wiring from furnace to optional equipment MUST conform to

local codes or, in the absence of local codes, the applicable na-

tional codes. Install wiring in accordance with manufacturer's

instructions.

Humidifier/Electronic Air Cleaner

The furnace is wired for 115 VAC humidifier and/or electronic air

cleaner connection.

CAUTION

Do NOT exceed 115V/0.8 amp. maximum current load

for both the EAC terminal and the HUM terminal com-

bined.

NOTE: The humidifier will be powered when the furnace is fired

and the circulating air blower comes on. The electronic air cleaner

will be powered anytime the thermostat calls for air movement.

However, the electronic air cleaner is NOT energized during con-

tinuous fan operation controlled by the electronic fan control.

_] 441 01 2007 00

Page 13

Figure 10 Electrical Connections

(Upflow/Horizontal)

NOTE:Control isground sensitive.

NOTE:Junction Box can be mounted to either the left or

rightside.

1ffiV. 60Hz.

:= z W

= Box

Gr_nd

[ LowVo_e

' TerminalBoard

i @

I

_ 8Ingle Stage

"_errnoet_t

i Terminal Board

I=

I I iI _

TwoStage i

25-22-54a

Figure 11 Electrical Connections

(Downflow)

11SV._Hz.

Gm=_nd

i LowVoltage

i Terminal Board

I I

_F

i Lowwr=ge

i TerminalBoard

I r

I I _w2

I I I

I I i

_Themlostat 1

25-22-60

Fan Control

The fan control is preset at the factory with an adjustable blower

ON delay of 30 seconds in the heating mode. The blower OFF tim-

ing is preset at 140 seconds. Ifdesired, the fan ON delay and OFF

delay can be reset to obtain the longest delay times while still

maintaining comfort levels. See "Furnace Wiring Diagram".

NOTE: It is recommended to achieve maximum efficiency that the

fan control be set to turn on at 30 seconds after the burners light.

Fan Timer Connections

Dip

Switch

See "Wiring

-Diagram"

for switch

settings

FUSE

25-22-44a

NOTE: For single stage thermostat operation the fourth (4th) DIP

switch must be in the off position. (See furnace wiring diagram

and Figure 12). Failure to change switch with single stage ther-

mostat will result in Lo fire operation ONLY.

441 01 2007 00 [_

Page 14

7. DuctworkandFilter(Upflow/Horizontal)on NTP6/TNE

Poison carbon monoxide gas hazard.

Do NOT draw return air from inside a closet or util-

ity room where furnace is located, Return air duct

MUST be sealed to furnace casing,

Failure to properly seal duct can result in death

and/or personal injury,

If separate evaporator and blower unit is used, install good

sealing dampers for air flow control. Chilled air going through

the furnace could cause condensation and shorten furnace

life. Dampers (purchased locally) can be either automatic or

manual. Manually operated dampers MUST be equipped

with a means to prevent furnace or air conditioning operation

unless damper is in the full heat or cool position.

DuctConnections

This furnace may be installed in only a bottom or side return ap-

plication. Return air through the back of the unit is NOT allowed.

Side connections can be made by cutting out the embossed area

shown in Figure 13.

Cutting Side Return Air Opening

Starting

Poison carbon monoxide gas hazard.

Cool air passing over heat exchanger can cause

condensate to form resulting in heat exchanger

failure.

This could result in death and/or personal injury,

Installation of locking-type dampers are recommended in all

branches, or in individual ducts to balance system's air flow.

Non-combustible, flexible duct connectors are recom-

mended for return and supply connections to furnace.

Ifair return grille is located close to the fan inlet, install at least

one, 90° air turn between fan and inlet grille to reduce noise.

Ductwork installed in attic, or exposed to outside tempera-

tures require 2" of insulation with outdoor type vapor barrier.

Ductwork installed in an indoor unconditioned space re-

quires a minimum of 1" of insulation with indoor type vapor

barrier.

Bottom returns can be made by removing the knockout panel in

the furnace base. Do NOT remove knock-out except for a bottom

return.

DuctDesign on NTP6/TNE

Design and install air distribution system to comply with Air Condi-

tioning Contractors of America manuals or other approved meth-

ods that conform to local codes and good trade practices.

When the furnace is located in an area near or adjacent to the liv-

ing area, the system should be carefully designed with returns to

minimize noise transmission through the return air grille. Any

blower moving a high volume of air will produce audible noise

which could be objectionable when the unit is located very close

to a living area. It is often advisable to route the return air ducts

under the floor or through the attic.

• Refer to furnace Technical Support Manual (Blower Data)

for air flow information.

• Size ductwork to handle air flow for heating and air condition-

ing.

Inspection Panel

A removable access panel should be provided in the outlet duct

when the furnace is installed without a cooling coil. This will allow

smoke or reflected light to be observable inside the casing to indi-

cate the presence of leaks in the heat exchanger. This access

cover shall be attached in such a manner as to prevent air leaks.

Filters

Afilter MUST be used. Filters may not be supplied with all models,

but can be purchased from your dealer.

The furnaces, with 1600 or less CFM rating, are supplied with a

16" x 25" high velocity filter and rack. On these models, the sup-

plied filter rack may be mounted internally for bottom return or ex-

ternally for side return.

The furnaces with greater than 1600 CFM requires that both left

and right side returns are used in side return applications. Two 16"

x 25" high velocity filters and racks are provided with furnace. Fil-

ter racks must be mounted externally. If return air must be on one

side only, an optional 20" x 25" filter standoff rack kits can be

used. (See Figure 17) For bottom return, an optional 20" x 25"

filter rack kit can be mounted internally.

DuctInstallation Requirements

• When furnace supply ducts carry air outside furnace area,

seal return air duct to furnace casing and terminate duct out-

side furnace space.

• When a refrigeration coil is used in conjunction with this unit,

it must be installed on the discharge side of the unit to avoid

condensation on the heat exchanger.

FiltersRackInstallation

Side Return

Center the filter rack on the side panel, flush with the bottom edge

of the furnace. Mark the fastening holes. Drill the fastening holes

in the side panel and fasten the filter rack in place with sheet metal

screws. See Figure 14 & Figure 16.

44101 200700

Page 15

CAUTION

If filters are only suitable for heating application, ad-

vise homeowner that filter size may need to be in-

creased if air conditioning is added.

Side Return Filter Rack

Filters Installed on Two Sides

Filtel Filter

Bottom Return

When installing a bottom mounted filter rack, slide the two side

filter clips to the back of the furnace BEFORE installing. This will

allow the rack to clear the front raised edge of the furnace. Insert

rack into side clips first and push rack back until it is fully engaged

into back clip. When rack is in place, slide clips back into place

midway on rack as shown in Figure 15.

Bottom Mounted Filter Rack

AW3192

Slide filter clips towards back before removing

Optional Duct Standoff

20 x 25 Optional

Filter Rack

j/""

8. DuctworkandFilter(Downflow}on NDP6/TDE

Subbasefor Combustible Floors - Furnace 0nly

The Subbase for Combustible Floors MUST be used when a

downflow furnace is set on combustible material even when the

furnace is installed on a coil box.

NOTE: Supply opening is 37/8" from the rear of the furnace.

Therefore maintain a 37/8" clearance from wall (where applica-

ble).

1. Cut the opening in the floor according to Table 5. The hole

in the floor must be cut to the dimensions listed in

Table 5since the base is equipped with locating tabs that

center the base over the opening.

The opening in the base is 11/4"(32mm ) shorter and 11/8"(29mm )

narrower than the recommended size of the opening in the floor.

This is done to maintain a 1" clearance between the floor and the

plenum.

2. Fabricate the plenum to the dimensions given in Table 5.

Note that the dimensions given are outside dimensions.

441 01 2007 O0 [_

Page 16

Table 5 Subbases for Combustible Floors Dimensions

Subbase for Com-

bustible Floors Part

Number

(Furnace Only)

NAHH001SB

NAHH002SB

NAHH003SB

Subbase for

Coil Box

NAHH004SB

NAHH005SB

NAHH006SB

Equivalents

in mm

14"

1511/16

195/16

2215/16

1511/16

195/16

2215/16

1511t16= 398

19_16=491

221_16 = 583

Outside Dimension

Base Spacer Side To Side

Subbase for Combustible

Floor Dimensions

J* K**

283/4 149/16

283/4 183/16

283/4 2t13/16

209/16 149/16

209/16 183/16

209/16 2t13/16

283/4 = 730 149/16= 370

209/16= 183/16= 462

522 2113116= 554

L

16

16

16

16 161_

16 161_

16 161_

16=406 161/4=412

Opening In Floor

M N

161/4 145/8

161/4 181/4

161/4 217/8

145/8

181/4

217/8

145/8= 37t

181/4=464

217/8=556

Opening ln

Base For Plenum

P R

15 131_

15 171_

15 193/4

15 131_

15 171_

15 193/4

131/2=343 I

15=381 17118=435

19_4= 502

Typical Plenum Di-

mensions

S T

t5 131_

t5 171/8

t5 19_4

t5 131_

t5 171/8

t5 19_4

131/2=343

t5=381 171/8=435

193/4=502

Set the base over the opening in the floor, centering the

opening in the base over the opening in the floor. Fasten the

base to the floor with screws or nails. See Figure 18 and

Figure 20.

Exploded View of Base for

Figure 18 Furnace ONLY

4. Drop the plenum through the opening in the base. The

flange of the plenum should rest on top of the combustible

floor base.

Subbasefor Combustible Floors- Downflow Coil Box

The Subbase for Combustible Floors MUST be used when a

downflow furnace, used with a downflow coil box, is set on

combustible flooring.

t.

Cut the opening in the floor according to Table 5. The hole

in the floor must be cut to the dimensions listed in Table 5

since the base is equipped with locating tabs that center the

base over the opening.

The duct opening in the base is 11/4"(32mm) shorter and 1

1/8"(29mm) narrower than the recommended size of the opening

in the floor. This is done to provide a 1" clearance between the

floor and the plenum.

2. Fabricate the plenum to the dimensions given in Table 5.

Note that the dimensions given are outside dimensions.

3.

Set the base over the opening in the floor, centering the

opening in the base over the opening in the floor. Fasten the

base to the floor with screws or nails. See Figure 19 and

Figure 20.

Figure 19 Exploded View of Base for

Downflow Cased Coil

25-21-46b

NOTE: Supply opening is 37/8 " from the rear of the furnace.

Therefore maintain a 37/8', clearance from wall (where applica-

ble).

4.

Drop the plenum through the opening in the base. The

flange ofthe plenum should rest ontop ofthe combustible

floor base.

44101 200700

Page 17

Thissubbaseforcombustiblefloorshasbeendesignedsothat

theheightofthesubbaseraisesthedownflowcoiloffthefloorto

alloweasyinstallationofthecondensatedrain.SeeFigure21.

Figure 20

Furnace

Subbase

Insulation

Setting the Base

Wood Floor

Figure 22 Filter Rack Installation

25-21-05C

Non-Combustible Floor:

Set the furnace over the opening in the floor. If necessary, grout

around the base to seal air leaks between the base and the floor.

Figure21 Condensate Line Raised by Base

25-20-52

Filters:

The filters supplied with the downflow furnace may be installed in

the return air plenum above the furnace. A filter rack is supplied

with each furnace. See Figure 22.

NOTE: The return air plenum MUST extend a sufficient height

above dimension "A" (Figure 22) to provide for the attachment of

a return air duct or grille above the filters.

1. Insert end of filter rack with 3/4" (19mm) flange into slot in

the back of the unit. See Figure 22.

2.

With filter rack pushed back, insert front end with 1/4"

(6mm) flange into position and push into front slot. with filter

rack pushed as far forward as it will go, bend 1/4"(6mm)

flange and 3/4"(19mm ) flange up 90 degrees. See

Figure 22.

NOTE: Plenum must be fitted as close to the return air flange of

the unit as possible to eliminate any air bypassing the filters.

3. Filters can only be installed through the right hand side of

the unit blower opening. Slide filter into unit until it is in posi-

tion to be pushed up and over into place on the left hand

side of unit. See Figure 23.

4. Slide remaining filter into unit and up into place on left hand

side of unit. See Figure 23.

Figure 23 Filter Installation

25-21-05d

441 01 2007 00 [_

Page 18

9. ChecksandAdjustments

Startup

NOTE: Refer to startup procedures in the Users Information

Manual.

CAUTION

If any sparks, odors or unusual noises occur, immedi-

ately shut OFF power to furnace. Check for wiring er-

rors or obstruction to blower.

Gas Supply Pressure

Gas supply pressure should be within minimum and maximum

values listed on rating plate. Pressures are usually set by gas sup-

pliers.

(See L.P. Kit instruction manual for furnaces converted to L.P.

gas)

Adjust Pilot Burner

The furnace has a pilot flame to light the main burner. The flame

should surround 3/8" to 1/2" of the flame rod. See Figure 24. To

adjust, remove cap from pilot adjusting screw on gas valve. Turn

screw counterclockwise to increase or clockwise to decrease

flame as required. Replace cap after adjusting screw.

Pilot Burner

/_ Flame Rod

Proper Flame _ /

Adjustment /_

_ / _"_ Hot Surface

/ _// / ,gniter

10-11-65

Main Burner Flame Check

Main Burner

Burner Face

10-10-78

TemperatureRise Check

The blower speed MUST be set to give the correct air temperatu re

rise through the furnace as marked on the rating plate. Tempera-

ture rise is the difference between supply and return air tempera-

tures.

To check temperature rise,use the following procedure:

1. Place thermometers in supply and return air registers as

close to furnace as possible, avoiding direct radiant heat

from heat exchangers.

2. Operate furnace on high fire for 10 minutes with all the reg-

isters and duct dampers open by using a jumper wire on R

to W1 and W2 thermostat connections on the fan board.

Note: The fourth (4th) DIP Switch should be in the on posi-

tion. (See furnace wiring diagram)

3. Take readings and compare with range specified on rating

plate.

4. Ifthe temperature rise is not in the correct range, the blower

speed must be changed. A higher blower speed will lower

the temperature rise. A lower blower speed will increase

the temperature rise.

5. Repeatsteps2thru4with the furnace operating on lowfire

for 10 minutes by using a jumper wire on the R to W1 ther-

mostat connections on the fan board.

6. Remove the jumper wire after the adjustments are com-

plete. Return fourth (4th) to previous setting.

Changing Blower Speed

Allow the furnace to run approximately 10 minutes then inspect

the main burner and pilot flames. See Figure 25.

Check for the following (Figure 25):

• Stable and blue flames. Dust may cause orange tips or

wisps of yellow, but flames MUST NOT have solid, yel-

low tips.

Electrical shock hazard.

Turn OFF power to furnace before changing speed

taps.

Failure to do so can result indeath and/or personal

injury.

• Flames extending directly from burner into heat ex-

changer.

• Flames do NOT touch sides of heat exchanger

Ifany problems with main burner flames are noted, it may be nec-

essary to adjust gas pressures, or check for drafts.

Since the manufacturer cannot establish the static pressure

that will be applied to the unit, it is the responsibility of the

installer dealer/contractor to select the proper speed taps for

the application when the unit is installed.

If it is necessary to change speeds, refer to steps below.

44101 200700

Page 19

1. Continuous Fan Operation

Refer to Furnace Wiring Diagram for location of the heating

and cooling speed taps located on the electronic fan control

as well as location of unused blower motor speed leads. Use

the chart (Table 6 )to determine the blower motor speed set-

tings.

Blower Speed Chart

Wire Color

Black

Orange*

Blue

Red

Motor Speed

High

Med-High

Medium

Low

* Med-High speed may not be provided on all models.

Change the heat or cool blower motor speed by removing the

motor lead from the "Heat" or "Cool" terminal and replace it

with the desired motor speed lead from the "MI" location.

Connect the wire previously removed from the "Heat" or

"Cool" terminal to the vacated "MI" terminal.

Ifthe same speed must be used for both heating and cooling,

remove the undesired motor speed lead from the "Heat" or

"Cool" terminal and connect that lead to the open terminal at

"M2" location or tape off. Attach a jumper between the "Heat"

and "Cool" terminals and the remaining motor speed lead.

Note: When using the same speed on motors with (4) speed

leads, it will be necessary to tape off the terminal of the motor

speed lead removed from the "Heat" or "Cool" terminal with

electrical tape since an open terminal will not be available at

the "M1 or M2" location.

A terminal is provided on the electronic fan control located in the

circulating blower compartment for operation of the continuous

fan option. This connection is intended for the low speed motor

tap, and has a lower contact rating (8 amps) than the heat and

cool taps. When the low speed blower lead is connected to this

terminal, this will provide low speed blower operation whenever

the other two speeds (Heat or Cool) are not energized.

Thoroughly check the system after modification to ensure the

proper operation of the circulating air blower in all modes of op-

eration.

Separate speed selections for Heat, Cool, and

Continuous Fan

Connect low speed lead from circulating motor to the "Cont" ter-

minal at the electronic fan control. The appropriate motor leads

should already be connected to the "Heat" and "Cool" terminals.

Heating and Continuous Blower Speed the Same

If it is necessary to operate the heating speed and continuous

blower speed using the same blower speed, connect a jumper be-

tween the "Heat" and "Cont" terminals on the electronic fan con-

trol.

Note: There should be only ONE motor lead going to the "Heat"

and "Cont" terminals.

10.FurnaceMaintenance

CAUTION

It is recommended that the furnace be inspected and

serviced on an annual basis (before the heating sea-

son) by a qualified service technician.

See "User's Information Manual".

11.Sequenceof Operation& Diagnostics

The following is the normal operating sequence for the 2-stage control system.

Cooling (Y) Request:

24 MAC signals applied to Y & G terminals of EFT (electronic fan timer) control.

• Cool motor speed energized after 5 second Cool Fan On Delay time.

Y & G signals removed from EFT.

• Cool motor speed de-energized after 60 second Cool Fan Off Delay time.

Cooling (Y) and dehumidification (Y2) requests: (Variable Speed ONLY)

• 24 VAC signals applied to Y, Y2 & G terminals of EFT (electronic fan timer) control.

• Same operation as the cooling (Y) request, except the cooling speed is reduced 20% to compensate for high humidity conditions during

cooling operation. The cooling speed returns to the normal setting after the Y2 signal is removed.

CirculatingFan (G) Request:

24 MAC signals applied to G terminals of EFT control.

• Low motor speed energized without delay.

G signal removed from EFT.

• Low motor speed de-energized without delay.

NOTE1) Furnaces with DC blower motors run a low circulating fan speed in response to G request.

44101 2007 00

Page 20

NOTE2)FurnaceswithPSCblowermotorsde-energizetheLowHeatfanspeedduringtheheatexchangerwarm-upperiodona

callforHeatingthatoccursduringaGrequest.

NOTE3)HeatingorCoolingrequestsreceivedduringaFanrequestcausethefanspeedtochangetotheappropriateheatorcool

speedaftertheselectedFanOnDelaytimeexpires.ThefanreturnstocirculatingspeedaftertheselectedFanOffDelaytimeexpires

followinglossoftheHeatingorCoolingrequest.

Heating (Wl) Request (singlestage thermostat operation, 4th DIP switch must be in off position) (see

furnace wiring diagram):

24 VAC signals applied to Wl terminal of EFT control.

• Inducer motor turns on at high speed.

• The high fire solenoid energizes.

• Following a 3 second prepurge delay, the pilot valve opens and the ignitor begins to warm up.

• After the pilot lights, the main burners energize and light (burners now at high fire rate).

• Timed from the opening of the main gas valve, the control will delay the selected Heat Fan On Delay time before switching the

inducer to low speed, de-energizing the high fire solenoid and the fan switches to Low Heat speed.

• Timed from initial application of the Heating request, if the Wl request is still present after the Low Fire Delay time expries

(12 minutes), the inducer switches to high speed, the high fire solenoid energizes and the fan switches to High Heat speed.

Wl signal removed from EFT.

• The gas valve de-energizes and the main burners go out.

• The inducer runs at its present speed for a 5 second postpurge period.

• The fan switches to (or stays at) Low Heat speed.

• Timed from the gas valve de-energizing, the Low Heat fan speed de-energizes after the selected Heat Fan Delay time expires.

NOTE4) If a new Heating request arrives while the control is waiting in the Heat Fan Off Delay time, the fan speed switches to High

Heat until the Heat Fan Off Delay expires or the Heat Fan On Delay expires for the new Heating request.

Heating Request(two stage thermostat operation, 4th DIP switch must be in on position)(see furnace

wiring diagram):

24 VAC signals applied to Wl terminal of EFT control.

• Same response as single stage thermostat operation described above except the control will not go to high fire, High Heat fan

speed unless a W2 signal is applied.

24 VAC signals applied to W1 and W2 terminals of EFT control.

• Same light-off routine as described for the signal stage thermostat operation except that at the end ofthe selected Heat Fan On Delay, the

inducer remains on high fire, the high fire solenoid remains energized and the High Heat fan speed energizes.

NOTE5) The EFT control responds without delayto the presence or loss of W2 (with W1 constant). W1 &W2 results in high inducer,

high fire and High Heat fan speed. W1 only results in low inducer, low fire and Low Heat fan speed.

Heating Requestwith Gas Supply Line Shut Off:

24 VAC signals applied to Wl terminal of EFT control.

• Inducer motor turns on at high speed.

• The high fire solenoid energizes.

• Following a 3 second prepurge delay, the pilot valve opens and the ignitor begins to warm up.

• The ignitor glows red-hot for 30 seconds, then turns off.

• The igniter stays off for 25 seconds, then begins to warm-up again.

• The igniter glows red-hot for 30 seconds, then turns off.

• The pilot valve closes 3 seconds after the igniter de-energizes.

• The inducer de-energizes 5 seconds after the pilot valve closes.

• The SmartValve proceeds to soft lockout and flashes error code 6.

• The control exits soft lockout after 5 minutes and begins another ignition sequence.

_] 441 01 2007 00

Page 21

Gas Valve Diagnostic Codes (See Figure 26)

Steady Flash = Normal Operation

2 Flashes = Low Pressure Switch Stuck Closed

3 Flashes = Low Pressure Switch Stuck Open or

Manual ON/OFF Switch in OFF Position or

(Aux. Limit Switch Open - Upflow ONLY)

4 Flashes = Limit Switch Open (Aux. Limit Switch Open - Downflow ONLY)

5 Flashes = Flame Sensed Out of Sequence

6 Flashes = Control in Soft Lockout (Automatic Restart or Retry Delay)

8 Flashes = High Pressure Switch Stuck Closed

9 Flashes = High Pressure Switch Stuck Open

Figure 26 I Typical Gas Valve Honeywell

Maniflod Pressure

(Hidden)

Diagnostic

Light

(on some

models)

On/Off

INLET

OUTLET

25-22-25a

/

27 | Gas Valve (Pressure Adjustment

Figure

I

locations)

Pressure adjustments

25-22-49a

441 01 2007 00 [_

Loading...

Loading...