ICP C8MPT050B12A1, C8MPT075F14A1, C8MPT100F14A1, C8MPT100J20A1, C8MPT125J20A1 Installation Guide

...Page 1

INSTALLATION INSTRUCTIONS

For Natural Gas to Propane and High Altitude Conversion Kit No: 1011789

This kit is designed to convert the NTP6, TNE, NDP6, TDE, NTPM, TNK, NCPM, TCK, NTVM,

VNK, *9MPV, *9MPT, *8MPV and *8MPT Series Furnaces equipped with Honeywell SV9540

Series gas valves and Honeywell Q3450 igniters from Natural Gas to Propane Gas.

* Denotes Brand (T, H or C)

This conversion kit shall be installed by aqualified service agency.

Please read these instructions completely before attempting

installation. Consult gas supplier and tables in National Fuel Gas

Code NFPA 54/ANSI Z223.1,1992 or latest edition. InCanada, the

National Standard CAN/CGA B149-1 and B149-2.

Parts List

Description Part# Qty

Burner Orifice #54 1011376 5

Pilot Orifice, LP (0.011) 1009136 1

Honeywell Cony. Kit #396021 1011828 1

Switch, Low Pressure 1008801 1

Fitting Asy. 1009775 1

Inlet Fitting 1147904 1

Wire Asy. 1009516 1

Label, Field Conversion 1009678 1

Label, LP Conversion 1011832 1

Label, Derate 2505235 1

Instructions 44106101507 1

Parts for High Altitude Conversion

Burner Orifice #55 (2000' - 7000')

Burner Orifice #56 (7000' - 8000')

Orifices required, but not included in kits.

1011354 as required

1011355 as required

This conversion kit shall be installed by a

qualified service technician in accordance with the

Manufacturer's instructions and all applicable

codes and requirements of the authority having

jurisdiction. The qualified service agency

performing this work assumes responsibility for

the proper conversion of this furnace with this kit.

Failure to follow these instructions exactly can

result in death, personal injury and/or property

damage.

AVERTISSMENT

Cet ensemble de conversion ne doit etre installe

que par le representant d'un organisme qualifie et

conformement aux instructions du fabricant et

tous les codes et exigences applicables de

I'autorite competente. L'organisme qualifie

quieffectue les travaux est responsable de la

conversion correcte de ce generateur d'air chaud

I'aide de cet ensemble. Quiconque ne respecte

pas a la lettre les instructions darts le present

manuel risque de declencher un incendie ou une

explosion entrainant des dommages materiels,

des lesions corporelles ou la perte de vies

humaines.

General Information

This kit is for conversion of furnaces equipped with Honeywell

SV9540 Series 2-stage gas valves certified for use with Natural

Gas (and so marked) to units functionally the same as the certified

furnace for use with Propane Gas. Before the furnace can be

operated with LP Gas, the LP low pressure must be installed (90+

models ONLY). A gas valve conversion kit must be installed and

main burner orifices and pilot burner orifice must be replaced with

orifices in this kit or with properly sized orifices for high altitude

ordered separately.

The orifices provided in this kit are stamped to indicate the size

(twist drill number) and are sized for commercially pure propane

gas ONLY. Do NOT use them with butane or a mixture of butane

and propane gas, or at elevations above 2000'. The parts list

specifies the size orifices supplied in the kit. Compare the size

marking on the orifices with the sizes as listed in the parts list.

Make sure you have the correct main burner orifices.

Extreme care is used to assure that this kit contains the proper

orifices. Oversized orifices could result in hazardous

conditions, especially if the venting is inadequate. For that

reason, we recommend that the installer check the size of the

orifice with a new twist drill of the correct size. This procedure

assures that the orifices provided are the correct size.

D Shut off gas supply to furnace at manual shut-off valve

before starting installation.

D Disconnect electric power supply to the furnace before

starting installation.

D Check for gas leaks after installation of kit and before

attempting to start furnace.

D Locate the LP Gas Conversion Label next to the furnace

rating plate.

D Fill out and attach the Field Conversion Label to the front

exterior of the furnace.

Gas Pressure

D Refer to the furnace rating plate for the approved gas input

ratings.

D Gas input to burners MUST NOT exceed the rated input

shown on rating plate.

D Do NOT allow minimum gas supply pressure to vary

downward. Doing so will decrease input to furnace. Refer

to Table 1 for gas supply and manifold pressures.

441 06 1015 07 (10/2003)

Page 2

Table 1 Gas Pressures

Gas Pressure

Type Recommended Max. Min. Hi Fire Lo Fire

Nat. 7" 14" 4.5" 3.5" 1.7"

LP 11" 14" 11" 10" 4.9"

• With Propane gas, the rated input is obtained when the

BTU content is 2,500 BTU per cubic foot and manifold

pressure set at 10 inches W.C.

• If Propane gas has a different BTU content, orifices

MUST be changed by licensed Propane installer.

• Measured input can NOT exceed rated input.

• Combustion Air Box Cover MUST be removed when ad-

justing manifold pressure.

• Any major change in gas flow requires changing burner

orifice size.

Supply Pressure Manifold

(1.7kPa) (3.5kPa) (1.1kPa) (0.9kPa) (0.5kPa)

(2.7kPa) (3.5kPa) (2.7kPa) (2.5kPa) (1.3kPa)

Important Notes

Installation

Electric shock hazard/Fire and/or explosion

hazard.

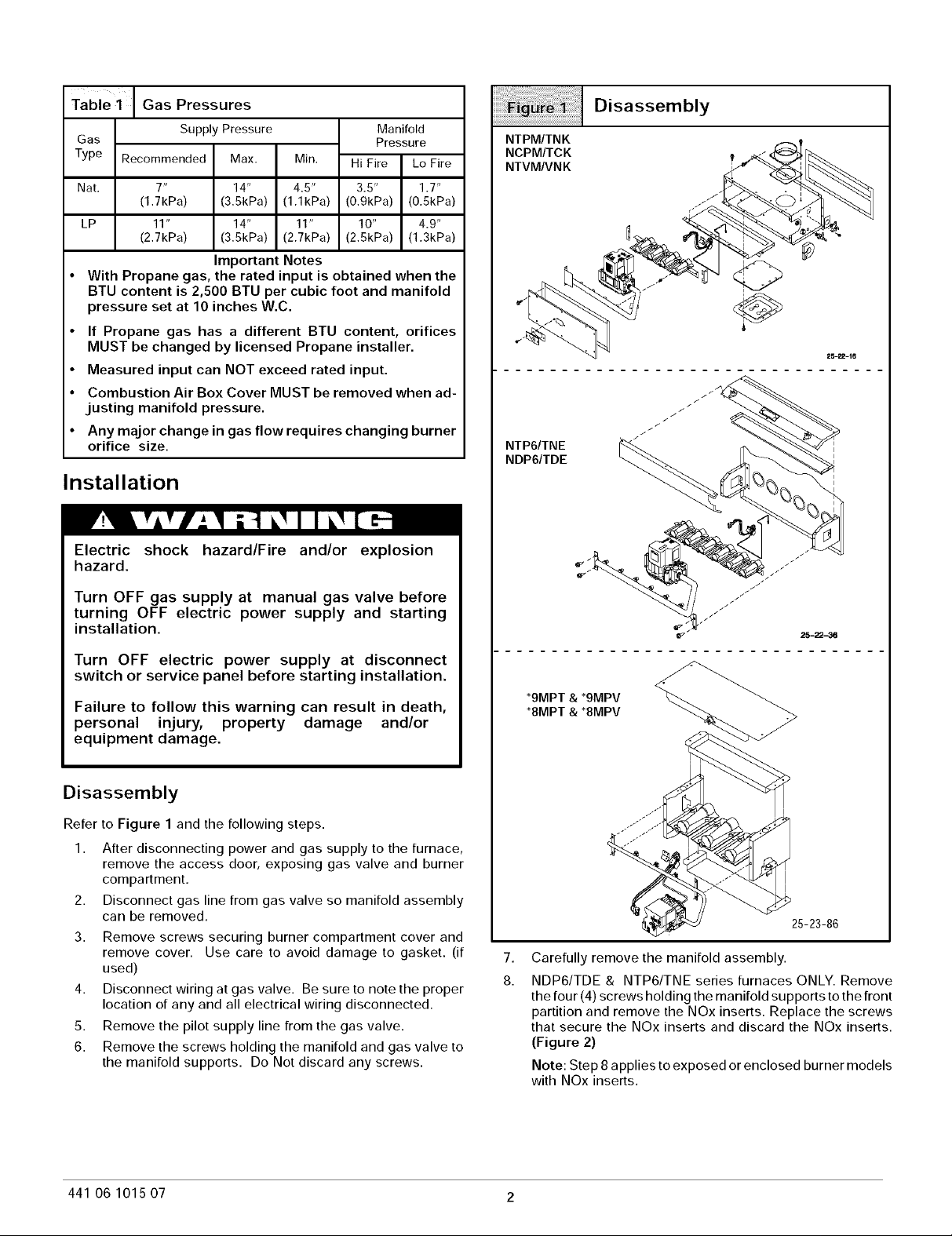

Disassembly

NTPM/TNK

NCPM/TCK

NTVM/VNK

NTP6/TNE

NDP6/TDE

Turn OFF gas supply at manual gas valve before

turning OFF electric power supply and starting

installation.

Turn OFF electric power supply at disconnect

switch or service panel before starting installation.

Failure to follow this warning can result in death,

personal injury, property damage and/or

equipment damage.

Disassembly

Refer to Figure 1 and the following steps.

1. After disconnecting power and gas supply to the furnace,

remove the access door, exposing gas valve and burner

compartment.

2. Disconnect gas line from gas valve so manifold assembly

can be removed.

3. Remove screws securing burner compartment cover and

remove cover. Use care to avoid damage to gasket. (if

used)

4. Disconnect wiring at gas valve. Be sure to note the proper

location of any and all electrical wiring disconnected.

5. Remove the pilot supply line from the gas valve.

6. Remove the screws holding the manifold and gas valve to

the manifold supports. Do Not discard any screws.

_" 25-22-36

*9MPT & *9MPV

*8MPT & *8MPV

25-23-86

7.

Carefully remove the manifold assembly.

8.

NDP6/TDE & NTP6/TNE series furnaces ONLY. Remove

the four (4) screws holding the manifold supports to the front

partition and remove the NOx inserts. Replace the screws

that secure the NOx inserts and discard the NOx inserts.

(Figure 2)

Note: Step 8 applies to exposed or enclosed burner models

with NOx inserts.

441 06 1015 07 2

Page 3

High Altitude Installation

CarbonMonoxidehazard.

NOxinsertsfor usewith NaturalGasunits

ONLY.If LPGasisrequired,NOxinsertsmust

beremoved.

Failureto followthis warningcan result in

property damage,personal injury and/or

death.

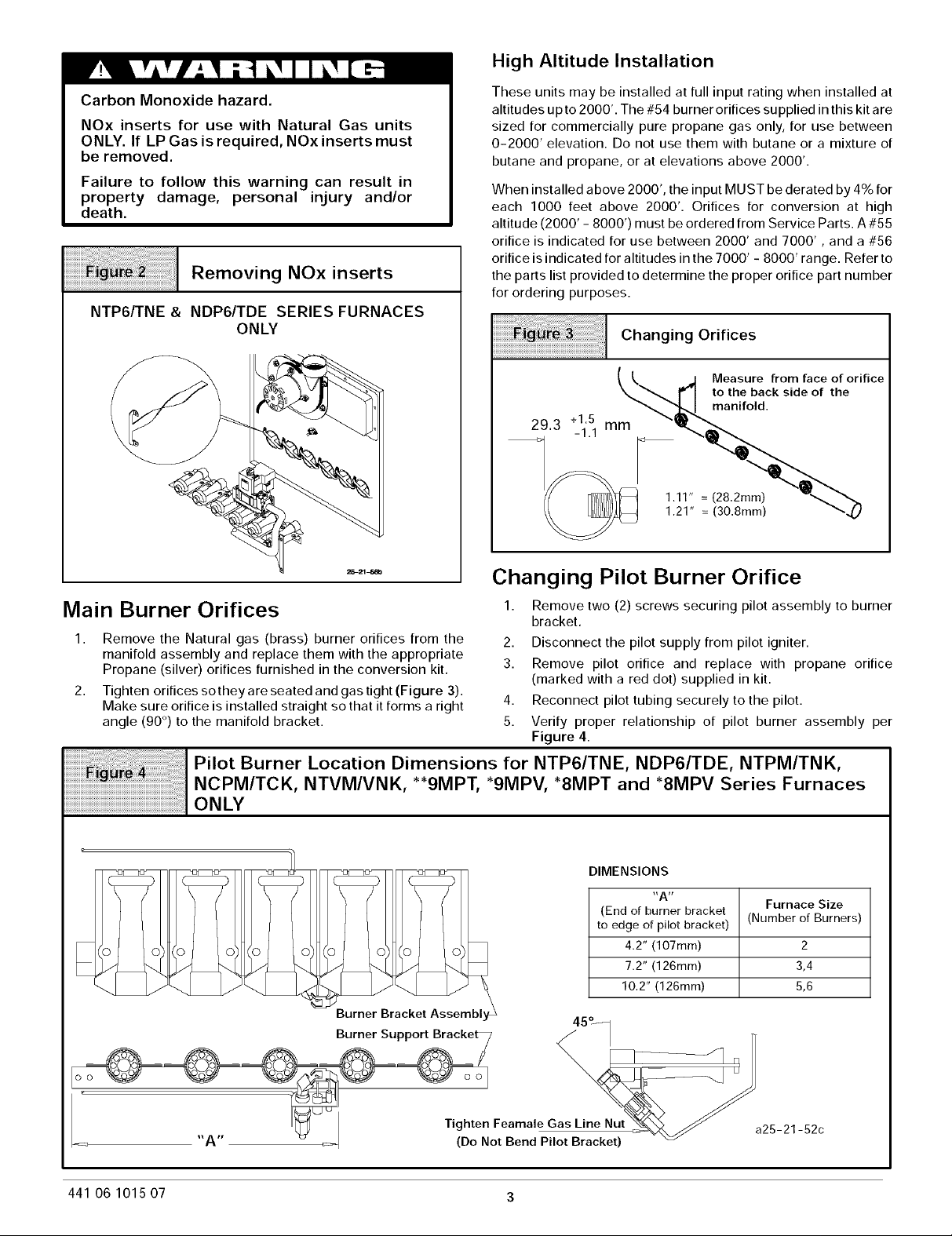

Removing NOx inserts

NTP6/TNE & NDP6/TDE SERIES FURNACES

ONLY

These units may be installed at full input rating when installed at

altitudes up to 2000'. The #54 burner orifices supplied in this kit are

sized for commercially pure propane gas only, for use between

0-2000' elevation. Do not use them with butane or a mixture of

butane and propane, or at elevations above 2000'.

When installed above 2000', the input MUST be derated by 4% for

each 1000 feet above 2000'. Orifices for conversion at high

altitude (2000' - 8000') must be ordered from Service Parts. A #55

orifice is indicated for use between 2000' and 7000', and a #56

orifice is indicated for altitudes in the 7000' - 8000' range. Refer to

the parts list provided to determine the proper orifice part number

for ordering purposes.

iiiiiiiiiiiiiiiiiiiiiiiiiii!iiiii_ii_!il! !!i!ii!ii!i!_iliiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii!i!i!i!iiChanging Orifices

(I J Measure from face of orifice

___ _ to the back side of the

_£-,,d manifold.

293+_11.!1mm

Changing Pilot Burner Orifice

Main Burner Orifices

Remove the Natural gas (brass) burner orifices from the

1. 2. Disconnect the pilot supply from pilot igniter.

manifold assembly and replace them with the appropriate

Propane (silver) orifices furnished in the conversion kit.

Tighten orifices so they are seated and gas tight (Figure 3).

2. 4. Reconnect pilot tubing securely to the pilot.

Make sure orifice is installed straight so that it forms a right

angle (90 °) to the manifold bracket.

_i!_ l i l Pil°t Burner L°cati°n Dimensi°ns f°r Nzp61zNE' NDp61zDE' NzpMIzNK'

NCPM/TCK, NTVM/VNK, "*9MPT, *9MPV, "8MPT and *8MPV Series Furnaces

ONLY

\ /

_ _ _ 4.2"(107mm)

Burner Bracket Assembly _

Burner Support Bracke _ |

1. Remove two (2) screws securing pilot assembly to burner

bracket.

3. Remove pilot orifice and replace with propane orifice

(marked with a red dot) supplied in kit.

5. Verify proper relationship of pilot burner assembly per

Figure 4.

DIMENSIONS

,,Art

(End of burner bracket

to edge of pilot bracket)

7.2" (126mm)

10.2" (126mm)

45°_1

Furnace Size

(Number of Burners)

2

3,4

5,6

Feamale Gas Lin_e_Nut

A _ (Do.... N"^ " _ ot Bend Pilot Bracket)

441 06 1015 07 3

a25-21-52c

Page 4

Changing Pilot Orifice

Orifice with

Red Dot

25-22-17

Gas Valve Conversion

Conversion of Honeywell SV9540 & SV9541 Gas Valves using

Natural Gas Conversion Kit #396021.

1. Remove the two screws securing the Hi/Lo regulator cover

to the valve. (See Figure 6 & Figure 7)

Typical Honeywell Gas Valve

Outlet Pressure Tap Inlet Pressure Tap .Connect

on manifold.Connect manometer & check inlet

manometer & check pr, ure. (11" wc

outlet pressure recommended)

per Table 1.

Regulatol

Cover

Screws

INLET

High Fire/Low Fire

Adjusting screws

2. Remove the existing regulator spring plunger (white color)

from the regulator housing.

3. Insert the replacement spring plunger (black color)

contained in this kit into regulator housing with the spring

end down.

Typical Honeywell

Regulator Assembly

LP Natural

Gas Gas

BLACK WHITE

25-22-56

4. Replace the Hi/Lo regulator cover and secure with the two

screws.

5. Attach the Caution Label contained in the kit to the Gas

Valve where it can be readily seen.

LP Low Pressure Switch (Required for 90+

and recommended for 80+)

1. Install the inlet fitting adapter #1147904 to the inlet of the gas

valve using the O-ring and the four screws provided with the

kit. Tighten securely.

2. Using pipe joint compound that is resistant to LP gas,

tighten the fitting assembly into the inlet side of the gas

valve. (Figure 8). Position fitting assembly as shown.

3. Screw the LP pressure switch into the bushing. Use pipe

dope on connection. Tighten securely.

Note: Do not block inlet port of pressure switch with pipe dope.

Switch will not operate if inlet port is blocked.

4. Remove one blue wire from the low fire pressure switch.

Connect this wire to the male insulated blue wire in the wire

harness provided.(See Figure 8).

5. Connect the other blue wire in the harness to the open

termination on the Low Fire pressure switch.

6. Connect the other end of the wire harness to the two

terminals on the LP switch.

Note: LP switch is factory set to open if LP gas supply pressure

falls below 6" w.c.

441 06 1015 07 4

Page 5

Typical Gas Piping and Adding LP Low Pressure Switch (Required for 90+ and

recommended for 80+)

Low Fire

Switch

Switch

goes here

High Fire

Pressure

Switch

Typical left

side gas

pipe entry.

Shutoff valve

Fire

Lr%Wssure_

Switch _

Wires from kP Low \

Pressure Switch

BL

BL J \_'

Disconnect blue wire from wire harness going

Disconnect Splice

BL

\

BL--

to low fire pressure switch and connect to wire

harness splice on the blue wire going to the LP

low pressure switch, Refer to step 4 - 6.

25-22-53

25-24-27a-1

441 06 1015 07 5

Page 6

Reassembly

Reassemble all parts in reverse order as removed except leave

the burner compartment cover off (90+ONLY) until after the

manifold pressure has been adjusted. Attach LP Conversion Label

to the front exterior of the furnace,

D Manifold Assembly - Be sure to engage the main burner

orifices in the proper openings in the burners.

D Testing for leaks - After reassembly, turn the gas on and

check all joints for gas leaks using a soapy solution. All

leaks must be repaired immediately.

Start-up and Check-out

1. Remove the plug from the Inlet Pressure Tap on gas valve

and install a manometer. (See Figure 5)

2. Openmanualgaslinevalvetounit. Checkforgasleaksand

correct as necessary. Check supply pressure, 11" WC

recommended, (11" WC minimum, 14" maximum). If not

within these limitations DO NOT OPERATE

FURNACE, contact gas supplier.

3. Close manual gas line valve to unit, remove manometer and

replace inlet pressure tap plug.

Manifold Gas Pressure Adjustments (Hi &

Lo Fire)

NOTE: Gas supply pressure MUST be within minimum and

maximum values listed on rating plate. Pressures are usually set

by gas suppliers.

Make adjustment to manifold pressure with burners operating and

combustion air box cover removed.

1. Remove combustion air box cover. (90+ ONLY)

2. Connect U-Tube manometer to the tapped opening on the

outlet side of gas valve on the manifold pipe. Use a

manometer with a 0 to 12" minimum water column range.

3. Turn gas ON. Operate the furnace on high fire by using a

jumper wire on the R to Wl & W2 thermostat connections on

the fan board.

4. Remove the adjustment screw covers on the gas valve.

Turn counterclockwise to decrease the manifold pressure

and clockwise to increase.

5. Set the manifold pressure to value shown in Table 1.

6. Operate the furnace on low fire by using a jumper wire on

the R to Wl thermostat connections on the fan board.

Note: The fourth (4th) DIP switch should be in the on

position to set the low fire manifold pressure. (See wiring

diagram)

7. Repeat steps 4 and 5 for low fire operation.

8. When the manifold pressures are properly set, replace the

adjustment screw covers on the gas valve. Remove

manometer and replace plug.

9. Remove the jumper wires from the thermostat connections

on the fan board.

10. Return fourth (4th) DIP switch to correct setting.

11. Start the main burners and check pressure tap plug for gas

leaks.

12. With gas valve on, observe furnace through two or more

complete cycles to be sure all controls are operating.

13. With furnace operating, observe pilot connections for gas

leaks. Turn gas off and tighten connections if required.

14. Check and adjust pilot flame if necessary. Flame should

envelope 3/8' to 1/2' of end of igniter sensor. To adjust;

remove pilot adjustment cap on gas valve and adjust, then

replace cap. (See Figure 10)

Main Burner

,_ Burner Face

14. Turn gas valve to OFF. Remove the pressure gauge and

replace the pressure tap plug and pressure regulator cap

screw.

15. Replace burner compartment cover.

Burner Orifice Ring

10-11-92

Checking Input Rate

Checking Burner Input Using A Meter. To check the BTU input

rate, the test hand on the meter should be timed for at least one

revolution and the input determined from this timing. Refer to

Section 8, Table XIII of the National Fuel Gas Code for converting

test hand readings to cubic feet per hour.

Example

Propane Gas Time Per

BTU Content Cubic Foot in

2,500 120

Seconds

Cubic Feet BTU Per

Per Hour Hour

30 75,000

Example:

2500 BTU/ft 3 x 30 ft3/hr = 75,000 BTU/hour

Checking Burner Input Not Using a Meter. The fixed orifice size

for each burner may be used to determine the burner input in

accordance with Table F-2 of the National Fuel Gas code for

liquefied petroleum gas. Excerpt of Table F-2 is listed below.

Table F - Excerpt

Orifice # # 53 # 54 # 55

BTUH/hr at

Sea Level 28,769 24,630 21,939

For Altitudes above 5,000 feet, refer to Section, High Altitude

Installation.

Main Burner Flame Check

Check for the following:

D Stable and blue flames

D Flames extending directly from burner into heat

exchanger.

D Flames DO NOT touch sides of heat exchanger.

NOTE: Dust may cause orange tips or wisps of yellow, but flames

MUST NOT have solid, yellow tips.

441 06 1015 07 6

Page 7

Pilot Burner Flame Check

Pilot flame should envelope end of the igniter sensor 3/8" to 1/2".

Pilot Burner

High Alitude Derate Label

The derate label supplied with the orifice kit must be completed

and affixed to the furnace near the rating plate. Fill in the manifold

pressure, orifice size and revised input rate. The revised input rate

is determined in the following manner:

Proper Flame

i

Adjustment

Altitude Vs Rating Multiplier Chart

Sensor Tip

Hot Surface

Igniter

10-11-65

Sea Level - 8000' (Natural Gas)

Heat Value

Btu/Cu.Ft.

2,500

0-1999 2000-2999 3000-3999 4000-4999

1 .92 .88 .84

Elevation Above Sea Level

Verify System Operation

Upon completion of all conversion procedures, perform the

following steps to verify the system operation.

1. Turn the thermostat to its lowest temperature setting or to

OFF if equipped with a System Select Switch.

2. Turn the gas valve control knob to ON.

Refer to the parts list provided to determine the proper orifice part

numbers for ordering purposes.

High Altitude Input Rate = Nameplate Input x (Multiplier)

Example:

For a furnace with a input of 100,000 BTU/hr installed at an altitude

of 5280', the revised high altitude input is:

High Altitude Input Rate = 100,000 x 0.80 = 80,000 BTU/hr.

5000-5999

.80

3. Reinstall all access panels.

4. Turn ON all electrical power to the unit.

5. Set the thermostat to the desired temperature and the

System Select Switch to HEAT.

6. Upon call for H EAT from the thermostat, the Ignitor will ignite

the pilot flame. Upon ignition of pilot flame, the main valve

will open, providing gas for ignition of the main burners.

6000-6999

.76

7000-8000

.72

441 06 1015 07 7

Loading...

Loading...