Page 1

80+

SingleStage

NTG3/FBF& NTC6/GNE

NTN3/NBF& NTN6/NNE

NDN3/NDF& NDN6/GDE

SAFETY REQUIREMENTS

/X

Recognize safety information. This isthe safety-alert symbol/.v X. When you see this symbol on the furnace and in instructions manuals be

alert to the potential for personal injury.

UnderstandthesignalwordsDANGER, WARNING, orOAUTION. Thesewordsareusedwiththesafety-alertsymbol. DANGERidentifiesthe

most serious hazards, those that will result in severe personal injury or death. WARNINGsignifiesahazardthatoouldresultinpersonalinjury

or death. CAUTION is used to identify unsafe practices that could result in minor personal injury or product and property damage.

Installing and servicing heating equipment can be hazardous due to gas and electrical components. Only trained and qualified personnel

should install, repair, or service heating equipment.

Untrained service personnel can perform basic maintenance functions such as cleaning and replacing air filters. All other operations must be

performed by trained service personnel. When working on heating equipment, observe precautions in the literature, on tags, and on labels

attached to or shipped with the unit and other safety precautions that may apply.

Follow all safety codes. In the United States, follow all safety codes including the current edition National Fuel Gas Code (NFGC) NFPA No.

54/ANSIZ223.1. In Canada, refer to the current edition of the National Standard Canada CAN/CGA-B149.1- and .2-M91 Natural Gas and

Propane Installation Codes (NSCNGPIC). Wear safety glasses and work gloves. Have fire extinguisher available during start-up and adjust-

ment procedures and service calls.

These instructions cover minimum requirements and conform to existing national standards and safety codes. In some instances, these

instructions exceed certain local codes and ordinances, especially those that may not have kept up with changing residential construction

practices. We require these instructions as a minimum for a safe installation.

Manufactured by:

International Comfort Products Corporation (USA)

Lewieburg, TN USA 37091

Contents

1.SafeInstallationRequirements................ 3

2.Installation............................... 4

3.Combustion&VentilationAir ................. 7

4.GasVentInstallation ....................... 9

5.HorizontalVenting ......................... 10

6.MasonryChimneyVentingwithOptionalKit ...... 11

7.GasSupplyandPiping...................... 12

8.ElectricalWiring ......................... 15

9. DuctworkandFilter (Upflow/Horizontal)...... 16

10. Ductworkand Filter (Downflow)............ 17

11. ChecksandAdjustments ................. 19

12. FurnaceMaintenance.................... 21

13. TechSupportand Parts .................. 22

Fire or Explosion hazard.

This furnace is not designed for use in mobile

homes, trailers or recreational vehicles.

Such use could result in death, bodily injury

and/or property damage.

Printed in U.S.A. LP1 3/4/2002 441 01 2603 02

Page 2

START-UP CHECK SHEET

(Keep this page for future reference)

Dealer Name:

Address:

City, State(Province), Zip or Postal Code:

Business Card Here

Phone:

Owner Name:

Address:

City, State(Province), Zip or Postal Code:

Model Number:

Serial Number:

Natural: [_1 LP: [_1

Type of Gas:

Blower Motor H,P,:

Supply Voltage:.

Limit Opens at...(°F)__.or(°C)

Limit Closes at...(°F) or(°C)

Which blower speed tap is used?

(Heating) (Cooling).

Temperature of Supply Air: (°F) or(°C)

Temperature of Return Air: (°F)___or(°C)

Rise (Supply Temp,-Return Temp,): (°F) or(°C).__

Filter Type and Size:

Fan "Time ON" Setting:

Fan "Time OFF" Setting:

Manual Gas Shut-Off Upstream

of Furnace!Drip-Leg? YES [_1 NO [_1

Dealer Comments:

Drip-Leg Upstream of Gas Valve?

Condensate Drain Connected? YES [_

Condensate Drain Trapped? YES [_

YES _1 NO _1

Noel

NO_1

Horizontal Condensate Switch Installed? YES [_ NO [_

Blower Speed Checked? YES [_ NO [_

All Electrical Connections Tight? YES [_ NO [_

Gas Valve OK? YES [_ NO [_

Measured Line Pressure When Firing Unit:

Calculated Firing Rate:(See Checks and Adjustments Sec-

tion),

Measured Manifold Pressure:

Thermostat OK? YES [_1

Subbase Level? YES [_1

Anticipator Set? YES [_1

Breaker On? YES [_1

Date of Installation:

Date of Start- Up:

NOel

NO_1

NO _1 Set At?:

Noel

I_] 441012603 02

Page 3

1. Safe Installation Requirements

Installation or repairs made by unqualified persons can

result in hazards to you and others. Installation MUST

conform with local codes or, in the absence of local

codes, with codes of all governmental authorities

having jurisdiction.

The information contained in this manual is intended for

use by a qualified service technician who is experienced

in such work, who is familiar with all precautions and

safety procedures required in such work, and is

equipped with the proper tools and test instruments.

Failure to carefully read and follow all instructions in this

manual can result in furnace malfunction, death,

personal injury and/or property damage.

NOTE: This furnace is design certified by the American Gas

Association and the Canadian Gas Association for installation in

the United States and Canada. Refer to the appropriate codes,

along with this manual, for proper installation.

• This furnace is NOT approved for installation in mobile

homes, trailers or recreation vehicles.

• Do NOT use this furnace as aconstruction heater or to heat

a building that is under construction.

Use only the Type of gas approved for this furnace (see

Rating Plate on unit). Overfiring will result in failure of heat

exchanger and cause dangerous operation, (Furnace can

be converted to LR gas with approved kit.)

• Do NOT use open flame to test for gas leak.

• Ensure adequate combustion and ventilation air is provided

to the furnace.

a.

There can be numerous sources of fire or smoke in a building

or dwelling. Fire or smoke can cause serious bodily injury,

death, and/or property damage. Therefore, in order to alert

people of potentially dangerous fire or smoke, you should

have fire extinguisher and smoke detectors listed by Under-

writers Laboratories installed and maintained in the building

or dwelling (see Note below).

Note: The manufacturer of your furnace does not test any detec-

tors and makes no representations regarding any brand or

type of detector.

C. To ensure safe and efficient operation ofyour unit, you should

do the the following:

1. Thoroughly read this manual and labels on the unit. This

will help you understand how your unit operates and the haz-

ards involved with gas and electricity.

Do not use this unit if any part has been under water. Im-

mediately call a qualified service technician to inspect the

unit and to replace any part of the control system and any gas

control which has been under water.

3. Never obstruct the vent grilles, or any ducts that provide

air to the unit. Air must be provided for proper combustion

and ventilation of flue gases.

Carbon monoxide or "CO" is a colorless and odorless gas

produced when fuel is not burned completely or when the

flame does not receive sufficient oxygen.

• Seal supply and return air ducts.

• The vent system MUST be checked to determine that it is

the correct type and size.

FreezingTemperaturesandYour Structure

• Install correct filter type and size.

• Unit MUST be installed so electrical components are pro-

tected from direct contact with water.

• It is the suggestion of the manufacturer to install fire and

carbon monoxide detectors.

Safety Rules

Your unit is built to provide many years of safe and dependable

service providing it is properly installed and maintained. However,

abuse and/or improper use can shorten the life of the unit and

create hazards for you, the owner.

The U.S. Consumer Product Safety Commission recom-

mends that users of gas-burning appliances install carbon

monoxide detectors. There can be various sources of carbon

monoxide in a building or dwelling. The sources could be

gas-fired clothes dryers, gas cooking stoves, water heaters,

furnaces, gas-fired fireplaces, wood fireplaces, and several

other items. Carbon monoxide can cause serious bodily inju-

ry and/or death. Therefore, to help alert people of potentially

dangerous carbon monoxide levels, you should have carbon

monoxide detectors listed by a nationally recognized agency

(e.g. Underwriters Laboratories or International Approval

Services) installed and maintained in the building or dwelling

(see Note below).

A.

44101 260302

Freeze warning.

Turn off water system.

If your unit remains shut off during cold weather the

water pipes could freeze and burst, resulting in serious

water damage.

Your unit is equipped with safety devices that may keep it from op-

erating if sensors detect abnormal conditions such as clogged ex-

haust flues.

If the structure will be unattended during cold weather you should

take these precautions.

1. Turn off main supply water into the structure and drain the

water lines if possible. Open faucets in appropriate areas.

Have someone check the structure frequently during cold

weather to make sure it is warm enough to prevent pipes

from freezing. Suggest they call a qualified service agency, if

required.

Page 4

2. Installation

Poison carbon monoxide gas hazard.

Ifthis furnace is replacing a previously common-vented

furnace, it may be necessary to resize the existing vent

line and chimney to prevent oversizing problems for the

other remaining appliances(s). See applicable codes

and Venting and Combustion Air Check in Gas Vent

Installation section.

Failu reto properly vent this furnace or other appliances

can result in death, personal injury and/or property

damage.

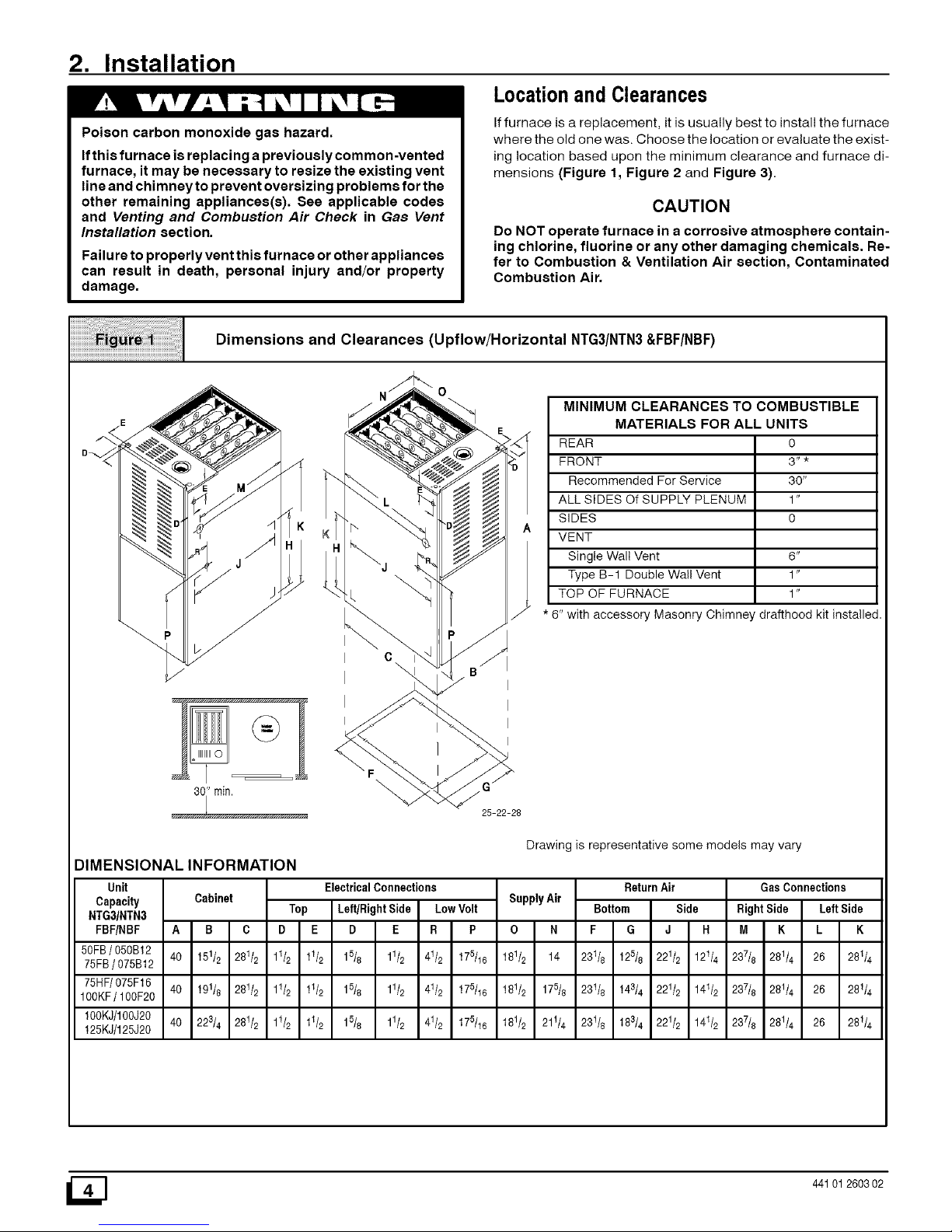

Locationand Clearances

If furnace is a replacement, it is usually best to install the furnace

where the old one was. Choose the location or evaluate the exist-

ing location based upon the minimum clearance and furnace di-

mensions (Figure 1, Figure 2 and Figure 3).

CAUTION

Do NOT operate furnace in a corrosive atmosphere contain-

ing chlorine, fluorine or any other damaging chemicals. Re-

fer to Combustion & Ventilation Air section, Contaminated

Combustion Air.

Dimensions and Clearances (Upflow/Horizontal NTG3/NTN3&FBF/NBF)

" rain.

25-22-28

MINIMUM CLEARANCES TO COMBUSTIBLE

MATERIALS FOR ALL UNITS

REAR 0

FRONT 3" *

Recommended For Service 30"

ALL SIDES Of SUPPLY PLENUM 1"

SIDES 0

VENT

Single Wall Vent 6"

Type B-1 Double Wall Vent 1"

TOP OF FURNACE 1"

* 6" with accessory Masonry Chimney drafthood kit installed

Drawing is representative some models may vary

DIMENSIONAL INFORMATION

Unit

Capacity

NTG31NTN3

FBF/NBF A

50FB/ 050B12 40

75FB/ 075B12

75HF/075F16 40

100KF/ 100F20

100KJ/100J20 40

125KJ/125J20

Cabinet

B C

151/2 281/2

191/8 281/2

223/4 281/2

ElectricalConnections

Top Left/RightSide LowVolt

D E D E R P

11/2 11/2 15/8 11/2 41/2 175/16

11/2 11/2 15/8 11/2 41/2 175/16

11/2 11/2 15/8 11/2 41/2 175/16

SupplyAir

O N

181/2 14

181/2 175/8

181/2 211/4

Return Air

Bottom Side

F G J R

231/8 125/8 221/2 121/4

23t/8 143/4 221/2 141/2

231/8 183/4 221/2 141/2

GasConnections

Right Side Left Side

M K L K

237/8 281/4 26 28t/4

237/8 281/4 26 28t/4

237/8 281/4 26 281/4

441012603 02

Page 5

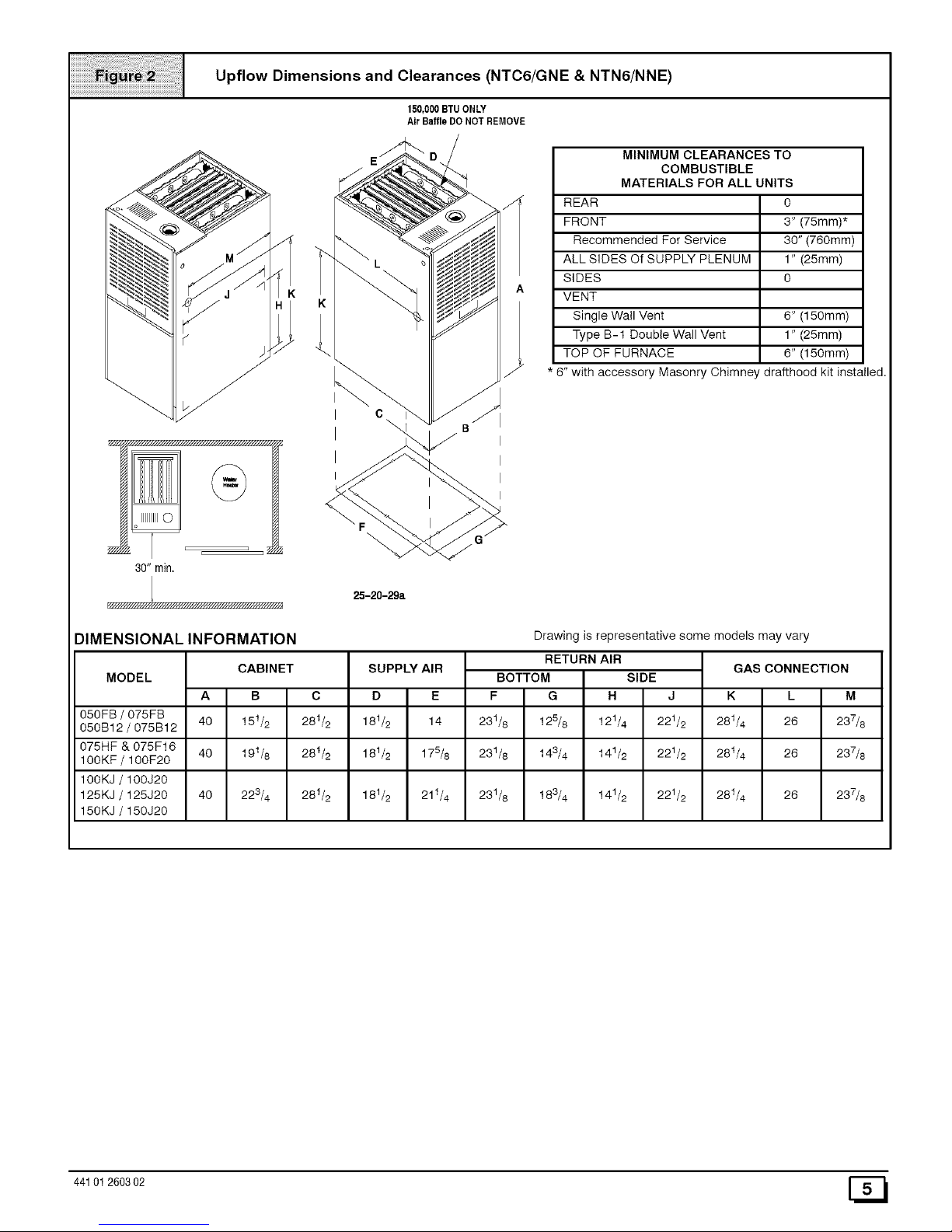

Upflow Dimensions and Clearances (NTC6/GNE & NTN6/NNE)

150,000BTUONLY

Air BaffleDO NOT REMOVE

30" min.

K

K

o

25-20-29a

MINIMUM CLEARANCES TO

COMBUSTIBLE

MATERIALS FOR ALL UNITS

REAR 0

FRONT 3" (75mm)*

Recommended For Service 30" (760mm)

ALL SIDES Of SUPPLY PLENUM 1" (25mm)

SIDES O

VENT

Single Wall Vent 6" (150mm)

Type B-1 Double Wall Vent 1" (25mm)

TOP OF FURNACE 6" (150mm)

* 8" with accessory Masonry Chimney drafthood kit installed.

I

I

I

I

DIMENSIONAL INFORMATION

MODEL

Drawing is representative some models may vary

GAS CONNECTIONCABINET

A I B C

I

40 I 151/2 281/2

40 I 191/8 28t/2

I

40 I 223/4 28t/2

SUPPLY AIR

D I E

181/2 I 14

181/2 I 178/8

RETURN AIR

BOTTOM SIDE

F IG I. IJ

231/8 125/8 I 121/4 221/2

231/8 143/4 I 141/2 221/2

231/8 183/4 141/2 221/2

K I L M

I

050FB / 075FB 281/4 I 26 237/8

050B12 / 075B12

075HF & 075F16 28t/4 I 26 237/8

100KF / 10OF2O

100KJ / 100J2O

125KJ / 125J20 181/2 I 21t/4 28t/4 I 26 237/8

150KJ / 15OJ2O

44101 260302 [_

Page 6

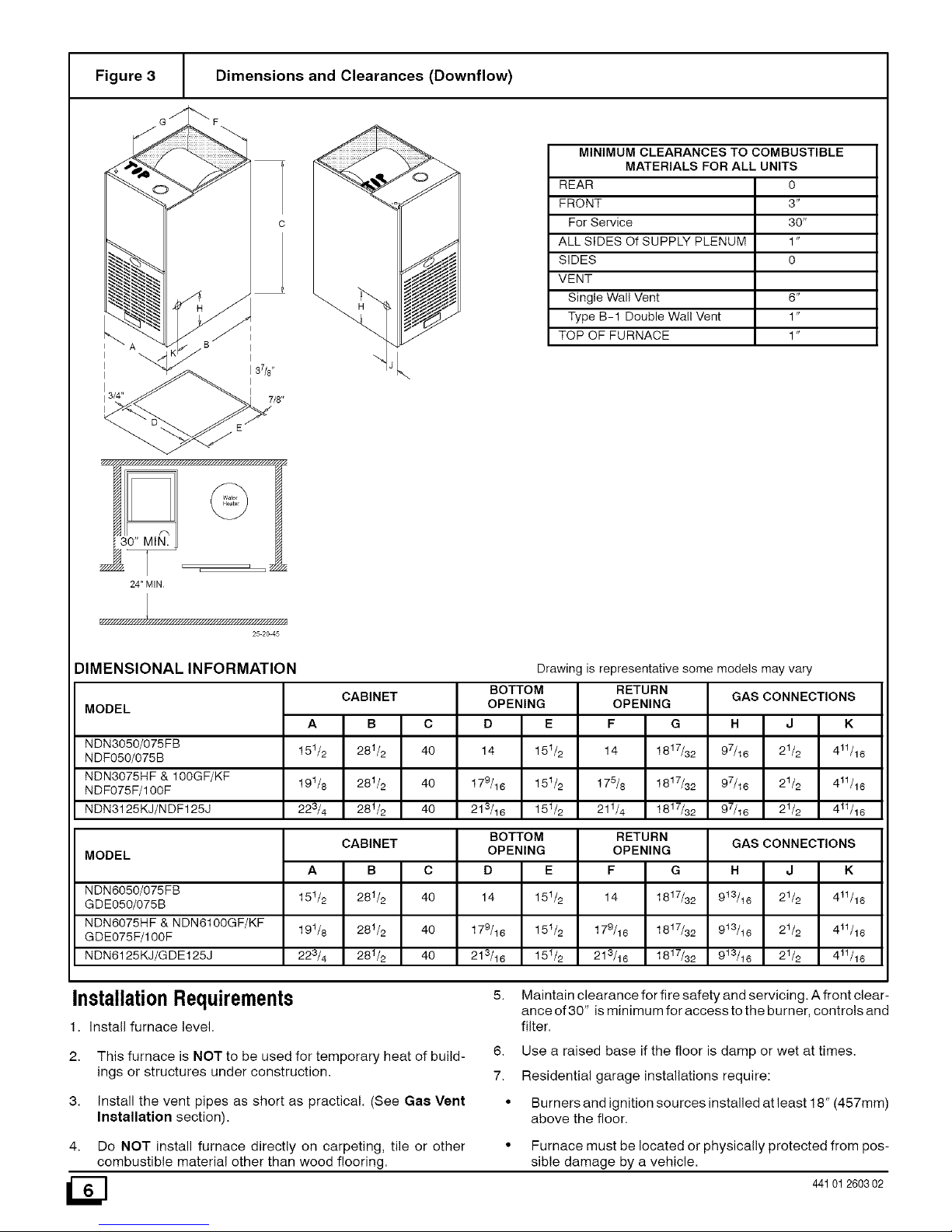

Figure 3 Dimensions and Clearances (Downflow)

I _A ",Jj B I

I3/4" 7/8"

/_ y////////////////////////.'////////////////////////h ,_

MINIMUM CLEARANCES TO COMBUSTIBLE

MATERIALS FOR ALL UNITS

REAR 0

FRONT 3"

For Service 30"

ALL SIDES Of SUPPLY PLENUM 1"

SIDES O

VENT

Single Wall Vent 6"

Type B-1 Double Wall Vent 1"

TOP OF FURNACE 1"

f_

130" MIN.

_, ._ _

24" MIN

25 2O 45

DIMENSIONAL INFORMATION

MODEL

NDN3050/075FB

NDF050/075B

NDN3075HF & 100GF/KF

NDF075F/100F

NDN3125KJ/N DF125J

MODEL

NDN6050/075FB

GDE050/075B

NDN6075HF & NDN6100GF/KF

GDE075F/100F

NDN6125KJ/GDE125J

CABINET

A B C

151/2 281/2 40

191/8 281/2 40

223/4 28t/2 40

BOTTOM

OPENING

F G

14 1817/32

175/8 1817/32

211/4 1817/32

Drawing is representative some models may vary

RETURN

GAS CONNECTIONS

H J K

97/16 21/2 411/16

97/16 21/2 411/16

97/16 21/2 411/16

OPENING

D E

14 151/2

179/16 151/2

213/16 151/2

CABINET

A B C

15t/2 281/2 40

19t/8 281/2 40

223/4 28t/2 40

BOTTOM RETURN

OPENING

F G

14 1817/32

179/16 1817/32

213/16 1817/32

OPENING

D E

14 15t/2

179/16 15 t/2

213/16 151/2

GAS CONNECTIONS

H J K

9t3/t6 21/2 4tl/16

9t3/t6 21/2 4tl/16

913/16 21/2 411/16

InstallationRequirements

1. Install furnace level.

5. Maintain clearance for fire safety and servicing. A front clear-

ance of 30" is minimum for access to the burner, controls and

filter.

2.

3.

This furnace is NOT to be used for temporary heat of build-

ings or structures under construction.

Install the vent pipes as short as practical. (See Gae Vent

Installation section).

6. Use a raised base if the floor is damp or wet at times.

7. Residential garage installations require:

• Burners and ignition sources installed at least 18" (457mm)

above the floor.

4. Do NOT install furnace directly on carpeting, tile or other

combustible material other than wood flooring.

• Furnace must be located or physically protected from pos-

sible damage by a vehicle.

441012603 02

Page 7

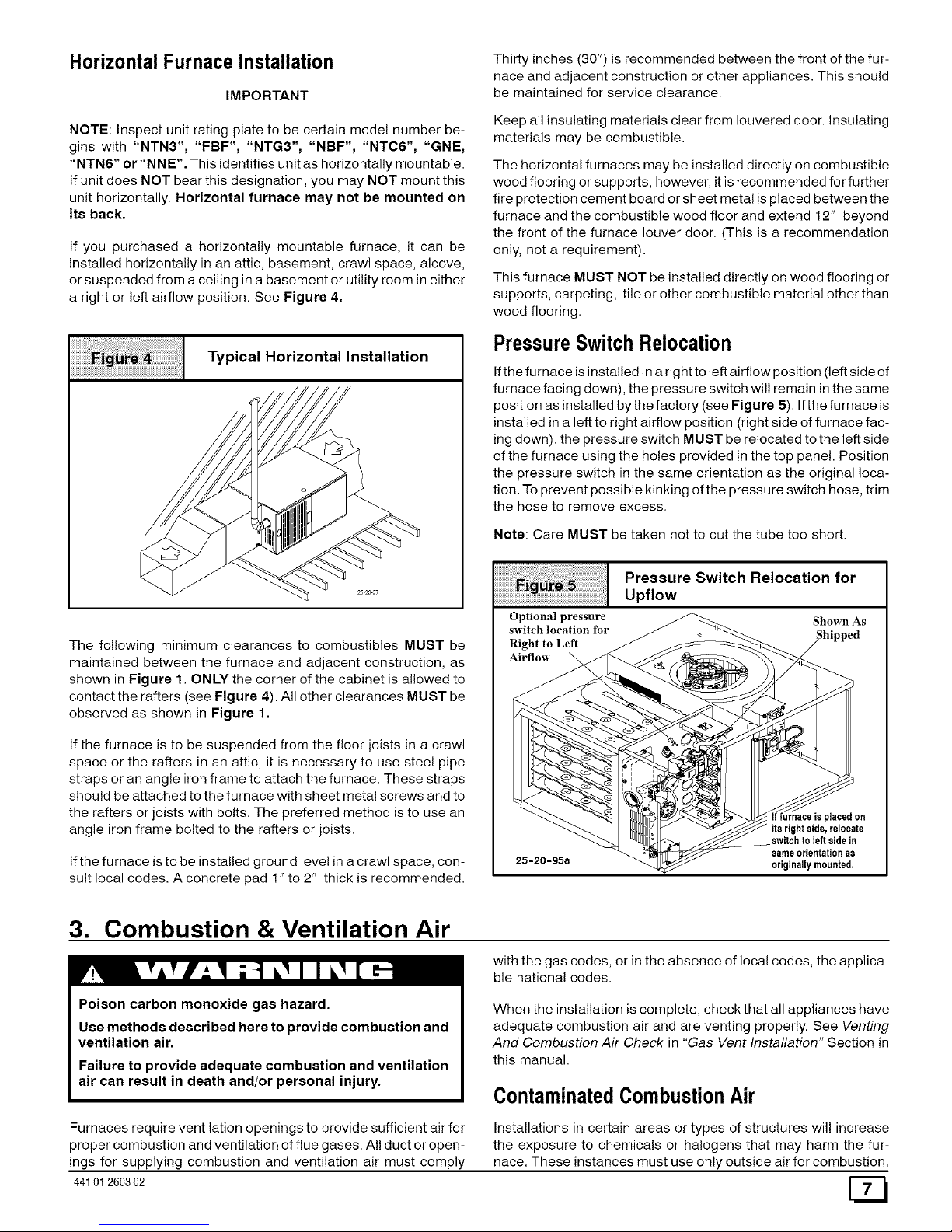

HorizontalFurnaceInstallation

IMPORTANT

NOTE: Inspect unit rating plate to be certain model number be-

gins with "NTN3", "FBF', "NTG3", "NBF", "NTC6", "GNE,

"NTN6" or"NNE". This identifies unit as horizontally mountable.

If unit does NOT bear this designation, you may NOT mount this

unit horizontally. Horizontal furnace may not be mounted on

its back.

If you purchased a horizontally mountable furnace, it can be

installed horizontally in an attic, basement, crawl space, alcove,

or suspended from a ceiling ina basement or utility room in either

a right or left airflow position. See Figure 4.

iiiiiiiii%;:i¸iiiiiiiii!ii;i;i]]i]]i]]iiii;i]]]]ii;i;fill!;;!!i!i!i!i!i!i!i!ill;;;;;;;;;;;;;;;;;;;;;!

ii ii ii ii ii ii ii il ii ii ii ii ii i

Typical Horizontal Installation

The following minimum clearances to combustibles MUST be

maintained between the furnace and adjacent construction, as

shown in Figure 1. ONLY the corner of the cabinet is allowed to

contact the rafters (see Figure 4). All other clearances MUST be

observed as shown in Figure 1.

If the furnace is to be suspended from the floor joists in a crawl

space or the rafters in an attic, it is necessary to use steel pipe

straps or an angle iron frame to attach the furnace. These straps

should be attached to the furnace with sheet metal screws and to

the rafters or joists with bolts. The preferred method is to use an

angle iron frame bolted to the rafters or joists.

If the furnace is to be installed ground level in a crawl space, con-

sult local codes. A concrete pad 1" to 2" thick is recommended.

Thirty inches (30") is recommended between the front of the fur-

nace and adjacent construction or other appliances. This should

be maintained for service clearance.

Keep all insulating materials clear from Iouvered door. Insulating

materials may be combustible.

The horizontal furnaces may be installed directly on combustible

wood flooring or supports, however, it is recommended for further

fire protection cement board or sheet metal is placed between the

furnace and the combustible wood floor and extend 12" beyond

the front of the furnace louver door. (This is a recommendation

only, not a requirement).

This furnace MUST NOT be installed directly on wood flooring or

supports, carpeting, tile or other combustible material other than

wood flooring.

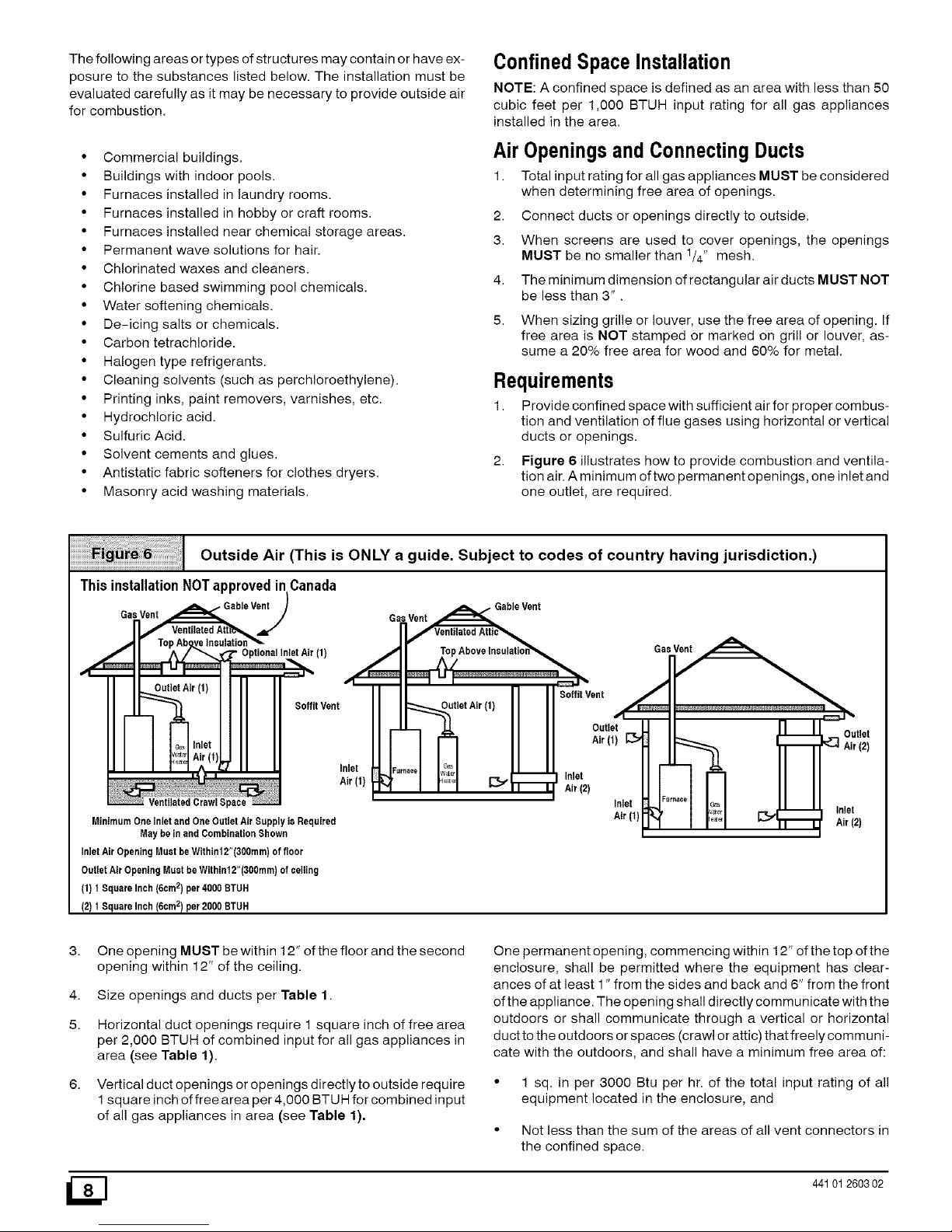

PressureSwitchRelocation

If the furnace is installed in a right to left airflow position (left side of

furnace facing down), the pressure switch wil! remain in the same

position as installed by the factory (see Figure 5). If the furnace is

installed in a left to right airflow position (right side of furnace fac-

ing down), the pressure switch MUST be relocated to the left side

of the furnace using the holes provided in the top panel. Position

the pressure switch in the same orientation as the original loca-

tion. To prevent possible kinking of the pressure switch hose, trim

the hose to remove excess.

Note: Care MUST be taken not to cut the tube too short.

iiiiiiiiiiiiiiiiiiiiiiiiiiiill¸iiiiiiiii_i%i;!iiiiiiiiiiiiii!;iiii;i;i;i;i;i;i;i;i;i;i;i;i;i;i;i;i;iiiil

iiiiiiiiiiiiiiiiiiiiiii ii i! ! ii J i ; ; i!i!i!i!i!i!i!i!i!i!i!i!i!i!i!i! !!!!i

Optional pressure

switch location for

Right to Left

Airflow

Pressure Switch Relocation for

Upflow

Shown As

25-20-95a

If furnace is placedon

itsrightside, relocate

switchto left sidein

sameorientationas

originallymounted,

3. Combustion & Ventilation Air

Poison carbon monoxide gas hazard.

Use methods described here to provide combustion and

ventilation air.

Failure to provide adequate combustion and ventilation

air can result in death and/or personal injury.

with the gas codes, or in the absence of local codes, the applica-

ble national codes.

When the installation is complete, check that all appliances have

adequate combustion air and are venting properly. See Venting

And Combustion Air Check in "Gas Vent Installation" Section in

this manual.

ContaminatedCombustionAir

Furnaces require ventilation openings to provide sufficient airfor

proper combustion and ventilation of flue gases. All duct or open-

ings for supplying combustion and ventilation air must comply

44101260302

Installations in certain areas or types of structures will increase

the exposure to chemicals or halogens that may harm the fur-

nace. These instances must use only outside air for combustion.

Page 8

Thefollowingareasortypesofstructuresmaycontainorhaveex-

posuretothesubstanceslistedbelow.Theinstallationmustbe

evaluatedcarefullyasitmaybenecessarytoprovideoutsideair

forcombustion.

• Commercialbuildings.

• Buildingswithindoorpools.

• Furnacesinstalledinlaundryrooms.

• Furnacesinstalledinhobbyorcraftrooms.

• Furnacesinstallednearchemicalstorageareas.

• Permanentwavesolutionsforhair.

• Chlorinatedwaxesandcleaners.

• Chlorinebasedswimmingpoolchemicals.

• Watersofteningchemicals.

• De-icingsaltsorchemicals.

• Carbontetrach!oride.

• Halogentyperefrigerants.

• Cleaningsolvents(suchasperchloroethylene).

• Printinginks,paintremovers,varnishes,etc.

• Hydrochloricacid.

• SulfuricAcid.

• Solventcementsandglues.

• Antistaticfabricsoftenersforclothesdryers.

• Masonryacidwashingmaterials.

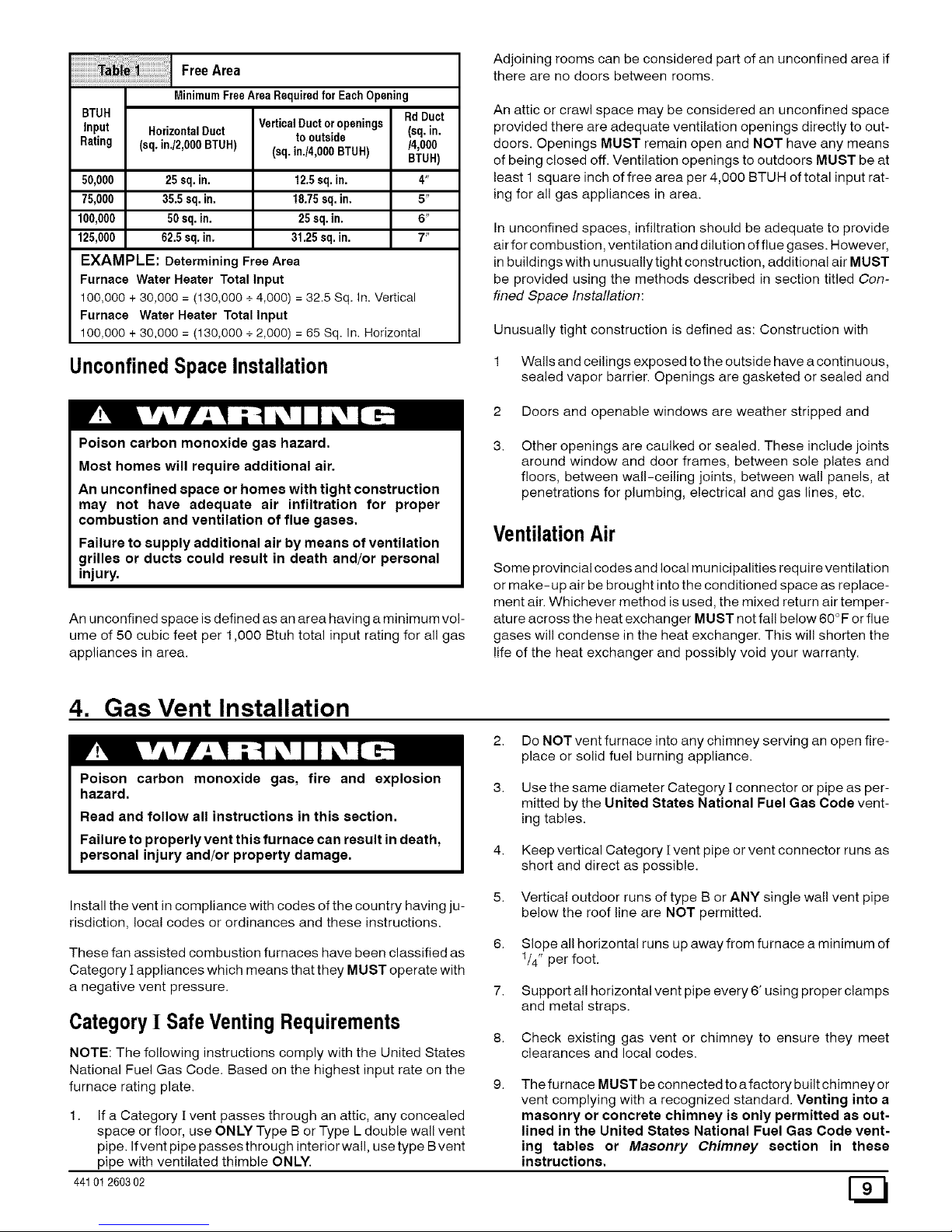

ConfinedSpace Installation

NOTE: A confined space is defined as an area with less than 50

cubic feet per 1,000 BTUH input rating for all gas appliances

installed in the area.

AirOpeningsandConnectingDucts

1. Total input rating for all gas appliances MUST be considered

when determining free area of openings.

2. Connect ducts or openings directly to outside.

3. When screens are used to cover openings, the openings

MUST be no smaller than 1/4" mesh.

4. The minimum dimension of rectangular air ducts MUST NOT

be less than 3".

5. When sizing grille or louver, use the free area of opening. If

free area is NOT stamped or marked on grill or louver, as-

sume a 20% free area for wood and 60% for metal.

Requirements

1. Provide confined space with sufficient air for proper combus-

tion and ventilation of flue gases using horizontal or vertical

ducts or openings.

2. Figure 6 illustrates how to provide combustion and ventila-

tion air. A minimum of two permanent openings, one inlet and

one outlet, are required.

Outside Air (This is ONLY a guide. Subject to codes of country having jurisdiction.)

ThisinstallationNOTapprovedinCanada

Gas Vent , Gable Vent Gsl.slVe_le Vent

(f)

/3

i iI I _ ITM

| l] Soffit Vent

soffitvent utletAi''f'II

I _ .LL II I Outlet

Inlet -_'"'"1 [::t;I Inlet

Air(f) d"l I I I _11 • Air(2)

VentilatedCrawlSpace Inlet

MinimumOneInletandOneOutletAirSupplyisRequired Air(1}

MaybeinendCombinationShown

InletAirOpeningMustbeWithinf2"(300mm)offloor

OutletAirOpeningMustbeWithin12"(300mm)ofceiling

(1)1SquareInch(6om2)per4000BTUH

(2)1SquareInch(6cm2)per2000BTUH

iFurn_oe

3a_

Outlet

_] Air(2)

Inlet

Air(2)

3.

4.

5.

6.

One opening MUST be within 12" of the floor and the second

opening within 12" of the ceiling.

Size openings and ducts per Table 1.

Horizontal duct openings require 1 square inch of free area

per 2,000 BTUH of combined input for all gas appliances in

area (see Table 1).

Vertical duct openings or openings directly to outside require

1 square inch of free area per 4,000 BTUH for combined input

of all gas appliances in area (see Table 1).

One permanent opening, commencing within 12" of the top of the

enclosure, shall be permitted where the equipment has clear-

ances of at least 1" from the sides and back and 6" from the front

of the appliance. The opening shall directly communicate with the

outdoors or shall communicate through a vertical or horizontal

duct to the outdoors or spaces (crawl or attic) that freely communi-

cate with the outdoors, and shall have a minimum free area of:

• 1 sq. in per 3000 Btu per hr. of the total input rating of all

equipment located in the enclosure, and

• Not less than the sum of the areas of all vent connectors in

the confined space.

_] 44101260302

Page 9

ilFreeAre0

MinimumFreeArea Requiredfor Each Opening

BTUH Rd Duct

VerticalDuctor openings (sq. in.

Input HorizontalDuct to outside

Rating (sq. in./2,OOOBTUH) (sq. in./4,0O0BTUH) /4,000

BTUR)

50,000 25 sq.in. 12.5sq.in. 4"

75,000 35.5 sq. in. 18.75sq. in. 5"

100,000 50sq. in. 25sq. in. 6"

125,000 62.5 sq. in. 31.25 sq.in. 7"

EXAMPLE: Determining Free Area

Furnace Water Heater Total Input

100,000 + 30,000 = (130,000 +4,000) = 32.5 Sq. in. Vertical

Furnace Water Heater Total Input

100,000 + 30,000 = (130,000 + 2,000) = 65 Sq. In. Horizontal

UnconfinedSpaceInstallation

Poison carbon monoxide gas hazard.

Most homes will require additional air.

An unconfined space or homes with tight construction

may not have adequate air infiltration for proper

combustion and ventilation of flue gases.

Failure to supply additional air by means of ventilation

grilles or ducts could result in death and/or personal

injury.

An unconfined space is defined as an area having a minimum vol-

ume of 50 cubic feet per 1,000 Btuh total input rating for all gas

appliances in area.

Adjoining rooms can be considered part of an unconfined area if

there are no doors between rooms.

An attic or crawl space may be considered an unconfined space

provided there are adequate ventilation openings directly to out-

doors. Openings MUST remain open and NOT have any means

of being closed off. Ventilation openings to outdoors MUST be at

least 1 square inch of free area per 4,000 BTUH of total input rat-

ing for all gas appliances in area.

In unconfined spaces, infiltration should be adequate to provide

air for combustion, ventilation and dilution of flue gases. However,

in buildings with unusually tight construction, additional air MUST

be provided using the methods described in section titled Con-

fined Space Installation:

Unusually tight construction is defined as: Construction with

1 Walls and ceilings exposed to the outside have a continuous,

sealed vapor barrier. Openings are gasketed or sealed and

2 Doors and openable windows are weather stripped and

Other openings are caulked or sealed. These include joints

around window and door frames, between sole plates and

floors, between wall-ceiling joints, between wall panels, at

penetrations for plumbing, electrical and gas lines, etc.

VentilationAir

Some provincial codes and local municipalities require ventilation

or make-up air be brought into the conditioned space as replace-

ment air. Whichever method is used, the mixed return air temper-

ature across the heat exchanger MUST not fall below 60 °F or flue

gases will condense in the heat exchanger. This will shorten the

life of the heat exchanger and possibly void your warranty.

4. Gas Vent Installation

Poison carbon monoxide gas, fire and explosion

hazard.

2. Do NOT vent furnace into any chimney serving an open fire-

place or solid fuel burning appliance.

Read and follow all instructions in this section.

Failure to properly vent this furnace can result in death,

personal injury and/or property damage.

Use the same diameter Category ][connector or pipe as per-

mitted by the United States National Fuel Gas Code vent-

ing tables.

Keep vertical Category [vent pipe or vent connector runs as

short and direct as possible.

Install the vent in compliance with codes of the country having ju-

risdiction, local codes or ordinances and these instructions.

These fan assisted combustion furnaces have been classified as

Category ][ appliances which means that they MUST operate with

a negative vent pressure.

Category! SafeVentingRequirements

NOTE: The following instructions comply with the United States

National Fuel Gas Code. Based on the highest input rate on the

furnace rating plate.

1. If a Category [ vent passes through an attic, any concealed

space or floor, use ONLY Type B or Type L double wall vent

pipe. If vent pipe passes through interior wall, use type Bvent

pipe with ventilated thimble ONLY.

44101260302

5. Vertical outdoor runs of type B or ANY single wall vent pipe

below the roof line are NOT permitted.

6. Slope all horizontal runs up away from furnace a minimum of

1/4" per foot.

7. Support all horizontal vent pipe every 6' using proper clamps

and metal straps.

8. Check existing gas vent or chimney to ensure they meet

clearances and local codes.

The furnace MUST be connected to a factory built chimney or

vent complying with a recognized standard. Venting into a

masonry or concrete chimney is only permitted as out-

lined in the United States National Fuel Gas Code vent-

ing tables or Masonry Chimney section in these

instructions.

Page 10

Poison carbon monoxide gas hazard.

If this furnace is replacing a previously common-

vented furnace, it may be necessary to resize the

existing chimney liner or vent to prevent over sizing

problems for the other remaining appliances(s). See

codes of country having jurisdiction.

Failure to properly vent this furnace or other

appliances can result in property damage, personal

injury and/or death.

Ventingand CombustionAir Check

NOTE: Ifthis installation removes an existing furnace from a vent-

ing system serving one or more other appliances, and to make

sure there is adequate combustion air for all appliances, MAKE

THE FOLLOWING CHECK.

1. Seal any unused openings in the venting system.

2.

Visually inspect the venting system for proper size and hori-

zontal pitch to ensure there is no blockage or restriction, leak-

age, corrosion or other deficiencies which could cause an

unsafe condition.

8.

Insofar as is practical, close all doors and windows and all

doors between the space in which the appliance(s) remain-

ing connected to the venting system are located and other

spaces of the building.

4.

Turn on clothes dryers and any appliance not connected to

the venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at maxi-

mum speed. Do not operate a summer exhaust fan. Close

fireplace dampers.

5. Follow the lighting instructions for each appliance being in-

spected. Adjust thermostat so appliance(s) will operate con-

tinuously.

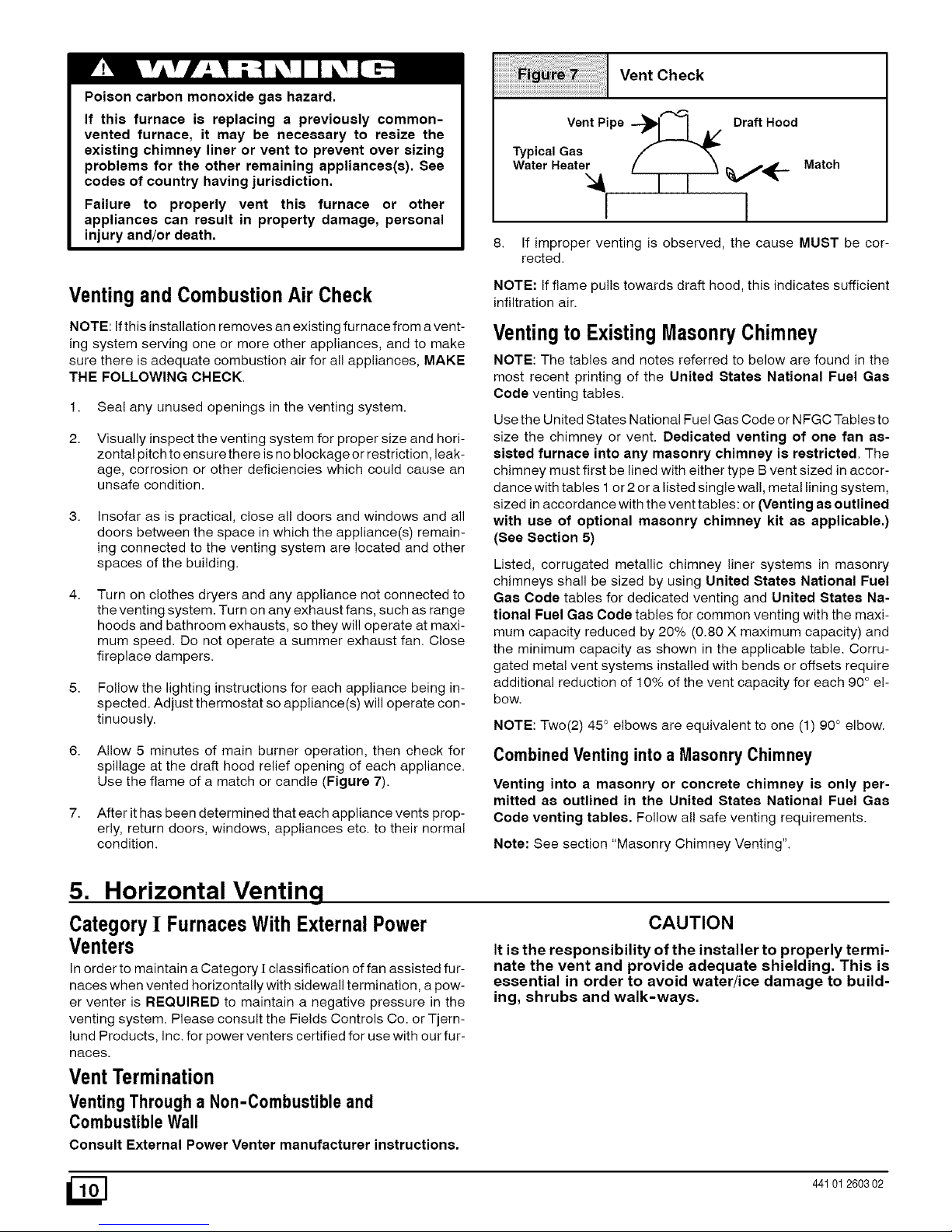

6. Allow 5 minutes of main burner operation, then check for

spillage at the draft hood relief opening of each appliance.

Use the flame of a match or candle (Figure 7).

7. After it has been determined that each appliance vents prop-

erly, return doors, windows, appliances etc. to their normal

condition.

Vent Check

Vent Pipe "_ I A/ Draft Hood

Typical Gas

Water Heater

I 1

Match

8. If improper venting is observed, the cause MUST be cor-

rected.

NOTE: If flame pulls towards draft hood, this indicates sufficient

infiltration air.

Ventingto Existing MasonryChimney

NOTE: The tables and notes referred to below are found in the

most recent printing of the United States National Fuel Gas

Code venting tables.

Use the United States National Fuel Gas Code or NFGC Tables to

size the chimney or vent. Dedicated venting of one fan as-

sisted furnace into any masonry chimney is restricted, The

chimney must first be lined with either type B vent sized in accor-

dance with tables 1 or 2 or a listed single wall, metal lining system,

sized in accordance with the vent tables: or (Venting as outlined

with use of optional masonry chimney kit as applicable.)

(See Section 5)

Listed, corrugated metallic chimney liner systems in masonry

chimneys shall be sized by using United States National Fuel

Gas Code tables for dedicated venting and United States Na-

tional Fuel Gas Code tables for common venting with the maxi-

mum capacity reduced by 20% (0.80 X maximum capacity) and

the minimum capacity as shown in the applicable table. Corru-

gated metal vent systems installed with bends or offsets require

additional reduction of 10% of the vent capacity for each 90 ° e!-

bow.

NOTE: Two(2) 45 ° elbows are equivalent to one (1) 90 ° elbow.

Combined Ventinginto a Masonry Chimney

Venting into a masonry or concrete chimney is only per-

mitted as outlined in the United States National Fuel Gas

Code venting tables. Follow all safe venting requirements.

Note: See section "Masonry Chimney Venting".

5. Horizontal Venting

CategoryI FurnacesWith ExternalPower

Venters

In order to maintain a Category ][classification of fan assisted fur-

naces when vented horizontally with sidewall termination, a pow-

er venter is REQUIRED to maintain a negative pressure in the

venting system. Please consult the Fields Controls Co. or Tjern-

lund Products, Inc. for power venters certified for use with our fur-

naces.

CAUTION

It is the responsibility of the installer to properly termi-

nate the vent and provide adequate shielding, This is

essential in order to avoid water/ice damage to build-

ing, shrubs and walk-ways.

VentTermination

Venting Through a Non-Combustible and

CombustibleWall

Consult External Power Venter manufacturer instructions.

441012603 02

Page 11

6. Masonry Chimney Venting with Optional Kit Upflow/Horizontal

(USA ONLY) Not recommended for Downflow Furnaces

ChimneyInspection

All masonry chimney construction must conform to Standard

ANSl/NFPA211 and to any state or local codes applicable. The

chimney must be in good condition and a complete investigation

must be conducted prior to installation. If the inspection reveals

damage or abnormal conditions, make necessary repairs or seek

expert help. See "The Chimney Inspection Chart". Measure area

of tile-liner and exact height of chimney.

Connector Type 6.

To reduce flue gas heat loss and the chance of condensate prob- 7.

lems, the vent connector must be double wall Type B vent.

Venting Restrictionsfor ChimneyTypes 8.

Interior Chimney - has no sides exposed to the outside below

the roofline. All installations can be single furnace or common 9.

vented with another draft hood equipped Category I appliance.

Exterior Chimney - has one or more sides exposed to the out-

side below the roof line. All installations must be common vented

only with another draft hood equipped Category I appliance.

I I

lines may cause severe property dama_le.

Optional Masonry Vent Kit 3.

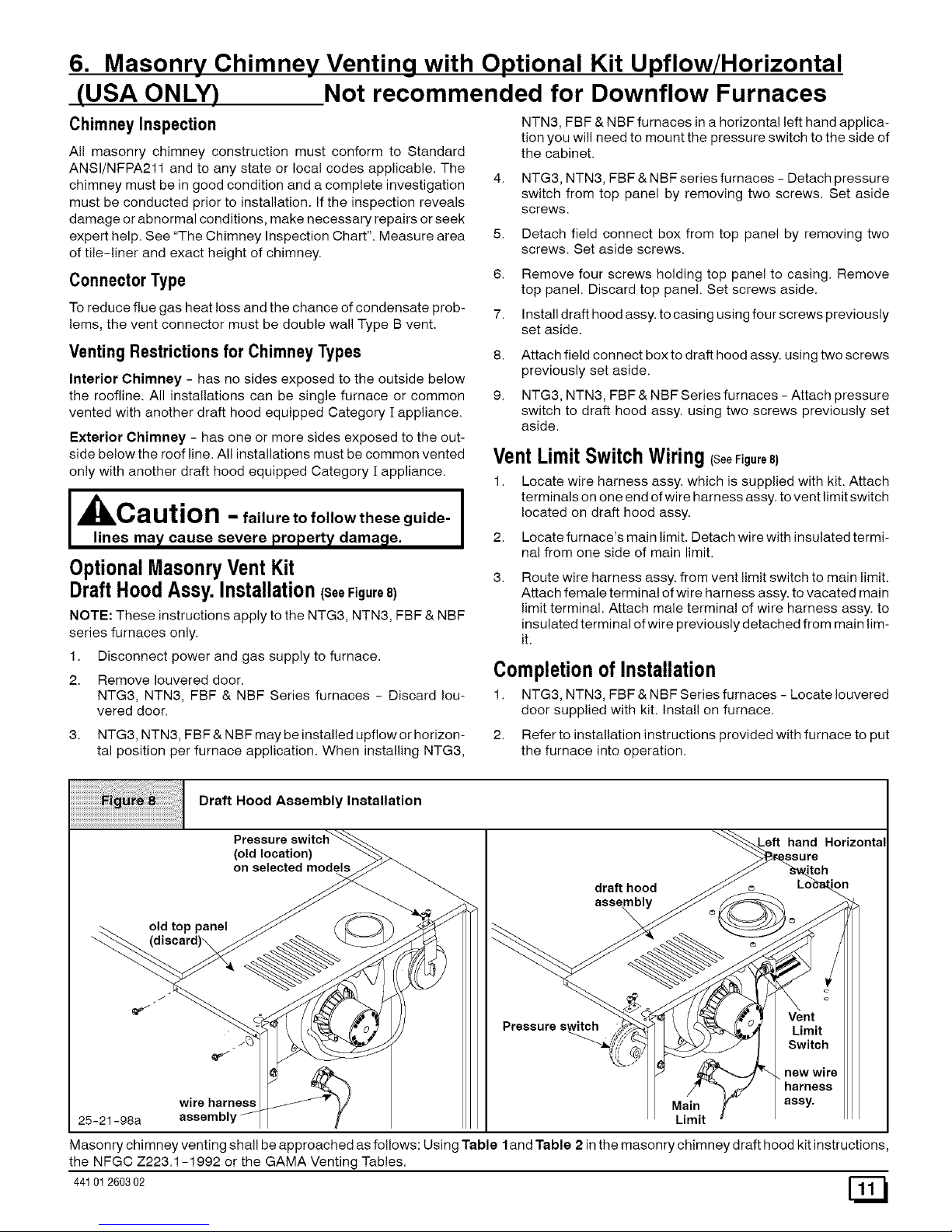

DraftHoodAssy. Installation(SeeFigure8)

NOTE: These instructions apply to the NTG3, NTN3, FBF & NBF

series furnaces only.

1. Disconnect power and gas supply to furnace.

2. Remove Iouvered door.

NTG3, NTN3, FBF & NBF Series furnaces - Discard Iou-

vered door.

NTN3, FBF & NBF furnaces in a horizontal left hand applica-

tion you will need to mount the pressure switch to the side of

the cabinet.

4. NTG3, NTN3, FBF & NBF series furnaces - Detach pressure

switch from top panel by removing two screws. Set aside

screws.

5. Detach field connect box from top panel by removing two

screws. Set aside screws.

Remove four screws holding top panel to casing. Remove

top panel. Discard top panel. Set screws aside.

Install draft hood assy. to casing using four screws previously

set aside.

Attach field connect box to draft hood assy. using two screws

previously set aside.

NTG3, NTN3, FBF & NBF Series furnaces - Attach pressure

switch to draft hood assy. using two screws previously set

aside.

VentLimit SwitchWiring(SeeFigure8)

1. Locate wire harness assy. which is supplied with kit. Attach

terminals on one end of wire harness assy. to vent limit switch

located on draft hood assy.

2. Locate furnace's main limit. Detach wire with insulated termi-

nal from one side of main limit.

Route wire harness assy. from vent limit switch to main limit.

Attach female terminal of wire harness assy. to vacated main

limit terminal. Attach male terminal of wire harness assy. to

insulated terminal of wire previously detached from main lim-

it.

Completionof Installation

1. NTG3, NTN3, FBF & NBF Series furnaces - Locate Iouvered

door supplied with kit. Install on furnace.

3. NTG3, NTN3, FBF & NBF may be installed upflow or horizon-

tal position per furnace application. When installing NTG3,

2. Refer to installation instructions provided with furnace to put

the furnace into operation.

Draft Hood Assembly Installation

Pressure switch_

(oO/dle_cation) "--.._>_

old top panel _ ( _C )) _ >

wire harness _J_%'_

25-21-98a assembly//-

ft hand Horizontal

_ch..

draft hood __ e__._ LOcain

""-_'_ _ _ _ f I_q/ /f_ ! Vent

Pressure s_ _ __...(l__ u_ Limit

/2 ,_"

/ . new wire

. ..;:ro:,:e

Main _" assy.

Limit

Masonry chimney venting shall be approached as follows: Using Table land Table 2 in the masonry chimney draft hood kit instructions,

the NFGC Z223.1-1992 or the GAMA Venting Tables.

44101 260302

Page 12

7. Gas Supply and Piping

Poison carbon monoxide gas, fire and explosion hazard.

Models designated for Natural Gas are to be used with

Natural Gas ON LY,unless properly converted to use with

LP gas.

Failure to follow these instructions can result in death,

personal injury and/or property damage.

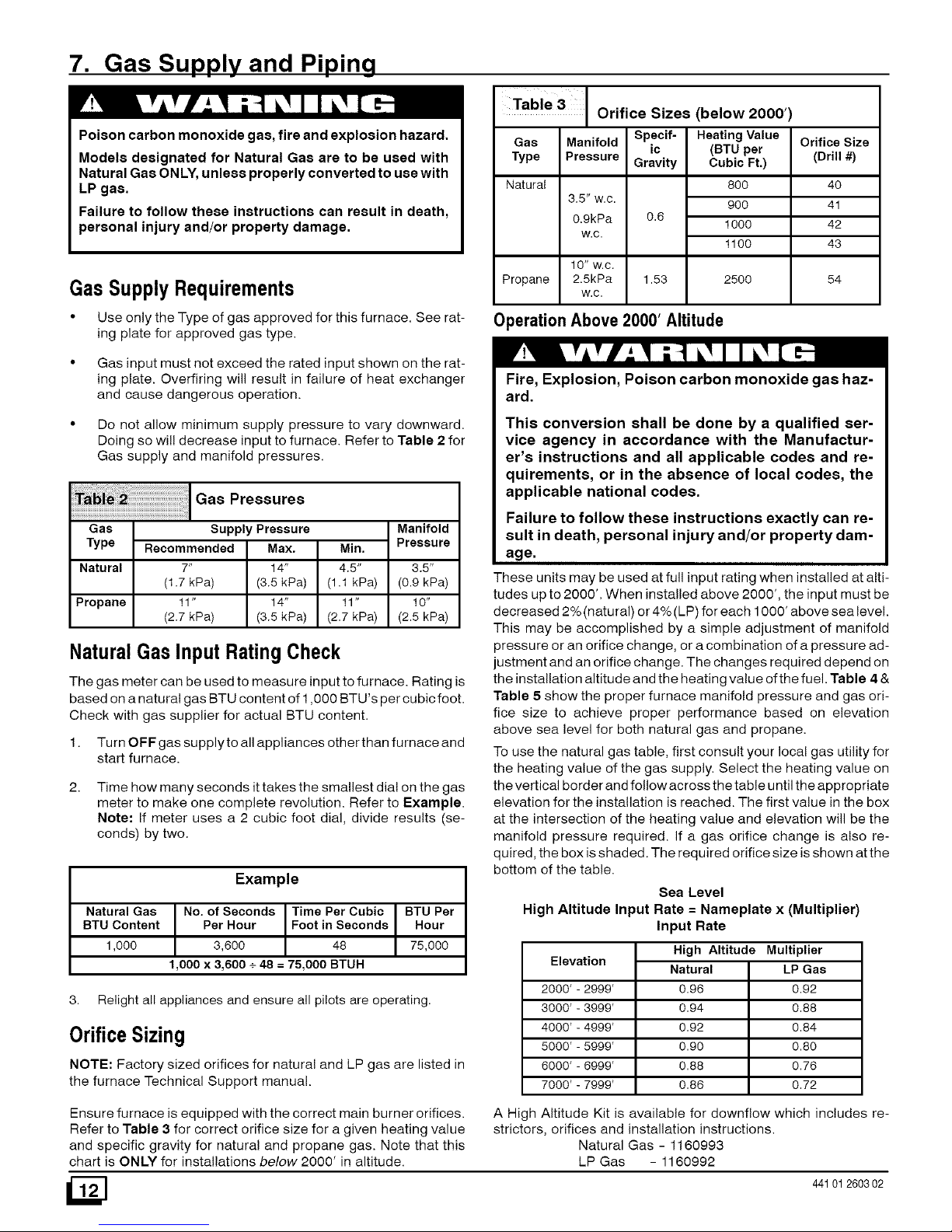

Table 3

Orifice Sizes (below 2000')

Gas Manifold Spacif- HeatingValue

ic (BTU par

Type Pressure Gravity Cubic Ft.)

Natural

Propane

GasSupplyRequirements

80O

3.5" w.c.

90O

0.9kPa 0.6

1000

w.c.

1100

10" w.c.

2.5kPa 1.53

w.c.

2500

Orifice Size

(Drill #)

4O

41

42

43

54

• Use only the Type of gas approved for this furnace. See rat-

ing plate for approved gas type.

OperationAbove 2000' Altitude

Gas input must not exceed the rated input shown on the rat-

ing plate. Overfiring will result in failure of heat exchanger

and cause dangerous operation.

Do not allow minimum supply pressure to vary downward.

Doing so will decrease input to furnace. Refer to Table 2 for

Gas supply and manifold pressures.

Pressures

Gas

Type

Natural

Manifold

Pressure

Supply Pressure

Recommended Max.

7" 14"

(1.7 kPa) (3.5 kPa)

11" 14"

(2.7 kPa) (3.5 kPa)

Min.

4.5" 3.5"

(1,1 kPa) (0.9 kPa)

Propane 11" 10"

(2.7 kPa) (2.5 kPa)

NaturalGas Input RatingCheck

The gas meter can be used to measure input to furnace. Rating is

based on a natural gas BTU content of 1,000 BTU's per cubic foot.

Check with gas supplier for actual BTU content.

1. Turn OFF gas supplyto all appliances otherthan furnace and

start furnace.

2.

Time how many seconds ittakes the smallest dial on the gas

meter to make one complete revolution. Refer to Example.

Note: If meter uses a 2 cubic foot dial, divide results (se-

conds) by two.

Example

Natural Gas No. of Seconds Time Per Cubic BTU Par

BTU Content Per Hour Foot in Seconds Hour

1,000 3,600 48 75,000

1,000 x 3,600 + 48 = 75,000 BTUH

3. Relight all appliances and ensure all pilots are operating.

OrificeSizing

NOTE: Factory sized orifices for natural and LP gas are listed in

the furnace Technical Support manual.

Fire, Explosion, Poison carbon monoxide gas haz-

ard.

This conversion shall be done by a qualified ser-

vice agency in accordance with the Manufactur-

er's instructions and all applicable codes and re-

quirements, or in the absence of local codes, the

applicable national codes.

Failure to follow these instructions exactly can re-

sult in death, personal injury and/or property dam-

age.

These units may be used at full input rating when installed at alti-

tudes up to 2000'. When installed above 2000', the input must be

decreased 2%(natural) or 4%(LP) for each 1000' above sea level.

This may be accomplished by a simple adjustment of manifold

pressure or an orifice change, or a combination of a pressure ad-

justment and an orifice change. The changes required depend on

the installation altitude and the heating value of the fuel. Table 4 &

Table 5 show the proper furnace manifold pressure and gas ori-

fice size to achieve proper performance based on elevation

above sea level for both natural gas and propane.

To use the natural gas table, first consult your local gas utility for

the heating value of the gas supply. Select the heating value on

the vertical border and follow across the table until the appropriate

elevation for the installation is reached. The first value in the box

at the intersection of the heating value and elevation will be the

manifold pressure required. If a gas orifice change is also re-

quired, the box is shaded. The required orifice size is shown atthe

bottom of the table.

Sea Level

High Altitude Input Rate -- Nameplate x (Multiplier)

Elevation

2000'-2999'

3000'-3999'

4000'-4999'

5000'-5999'

6000'-6999'

7000'-7999'

Input Rate

High Altitude Multiplier

Natural LP Gas

0.96 0.92

0.94 0.88

0.92 0.84

0.90 0.80

0.88 0.76

0.86 0.72

Ensure furnace is equipped with the correct main burner orifices.

Refer to Table 3 for correct orifice size for a given heating value

and specific gravity for natural and propane gas. Note that this

chart is ONLY for installations below 2000' in altitude.

/2N

A High Altitude Kit is available for downflow which includes re-

strictors, orifices and installation instructions.

Natural Gas - 1160993

LP Gas - 1160992

44101260302

Page 13

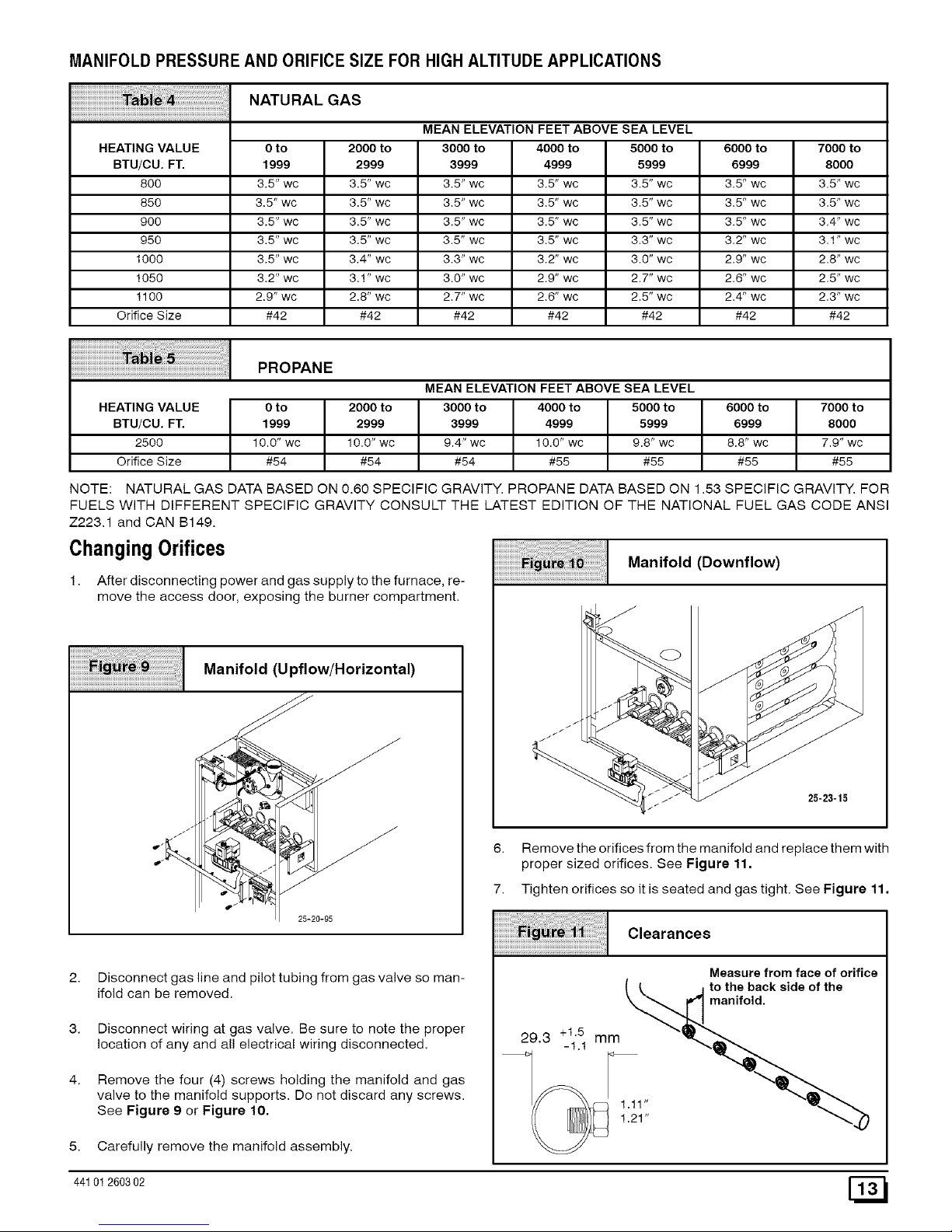

MANIFOLD PRESSUREAND ORIFICESIZE FOR HIGHALTITUDE APPLICATIONS

NATURAL GAS

MEAN ELEVATION FEET ABOVE SEA LEVEL

HEATING VALUE 0 to 2000 to 3000 to 4000 to 5000 to 6000 to 7000 to

BTU/CU. FT. 1999 2999 3999 4999 5999 6999 8000

800 3.5" wc 3.5" wc 3.5" wc 3.5" wc 3.5" wc 3.5" wc 3.5" wc

850 3.5" wc 3.5" wc 3.5" wc 3.5" wc 3.5" wc 3.5" wc 3.5" wc

900 3.5" wc 3.5" wc 3.5" wc 3.5" wc 3.5" wc 3.5" wc 3.4" wc

950 3.5" wc 3.5" wc 3.5" wc 3.5" wc 3.3" wc 3.2" wc 3.1" wc

1000 3.5" wc 3.4" wc 3.3" wc 3.2" wc 3.0" wc 2.9" wc 2.8" wc

1050 3.2" wc 3.1" wc 3.0" wc 2.9" wc 2.7" wc 2.6" wc 2.5" wc

1100 2.9" wc 2.8" wc 2.7" wc 2.6" wc 2.5" wc 2.4" wc 2.3" wc

Orifice Size #42 #42 #42 #42 #42 #42 #42

PROPANE

MEAN ELEVATION FEET ABOVE SEA LEVEL

HEATING VALUE 0 to 2000 to 3000 to 4000 to 5000 to 6000 to 7000 to

BTU/CU. FT. 1999 2999 3999 4999 5999 6999 8000

2500 10.0" wc 10.0" wc 9.4" wc 10.0" wc 9.8" wc 8.8" wc 7.9" wc

Orifice Size #54 #54 #54 #55 #55 #55 #55

NOTE: NATURAL GAS DATA BASED ON 0.60 SPECIFIC GRAVITY. PROPANE DATA BASED ON 1.53 SPECIFIC GRAVITY. FOR

FUELS WITH DIFFERENT SPECIFIC GRAVITY CONSULT THE LATEST EDITION OF THE NATIONAL FUEL GAS CODE ANSI

Z223.1 and CAN B149.

ChangingOrifices

1. After disconnecting power and gas supply to the furnace, re-

move the access door, exposing the burner compartment.

Manifold (Upflow/Horizontal)

jJ_

25-20-95

2.

3.

4.

Disconnect gas line and pilot tubing from gas valve so man-

ifold can be removed.

Disconnect wiring at gas valve. Be sure to note the proper

location of any and all electrical wiring disconnected.

Remove the four (4) screws holding the manifold and gas

valve to the manifold supports. Do not discard any screws.

See Figure 9 or Figure 10,

5. Carefully remove the manifold assembly.

Manifold (Downflow)

/

//

25-23-15

6. Remove the orifices from the manifold and replace them with

proper sized orifices. See Figure 11.

7. Tighten orifices so it is seated and gas tight. See Figure 11.

Clearances

Measure from face of orifice

( _ j to the back side of the

_anifold.

1.21"

44101 260302 [_

Page 14

8. Reassembleallpartsinreverseorderasremoved.Besureto

engagethemainburnerorificesintheproperopeninginthe

burners.

9. Afterreassembling,turngasonandcheckalljointsforgas

leaksusingasoapysolution.Allleaksmustberepairedim-

mediately.

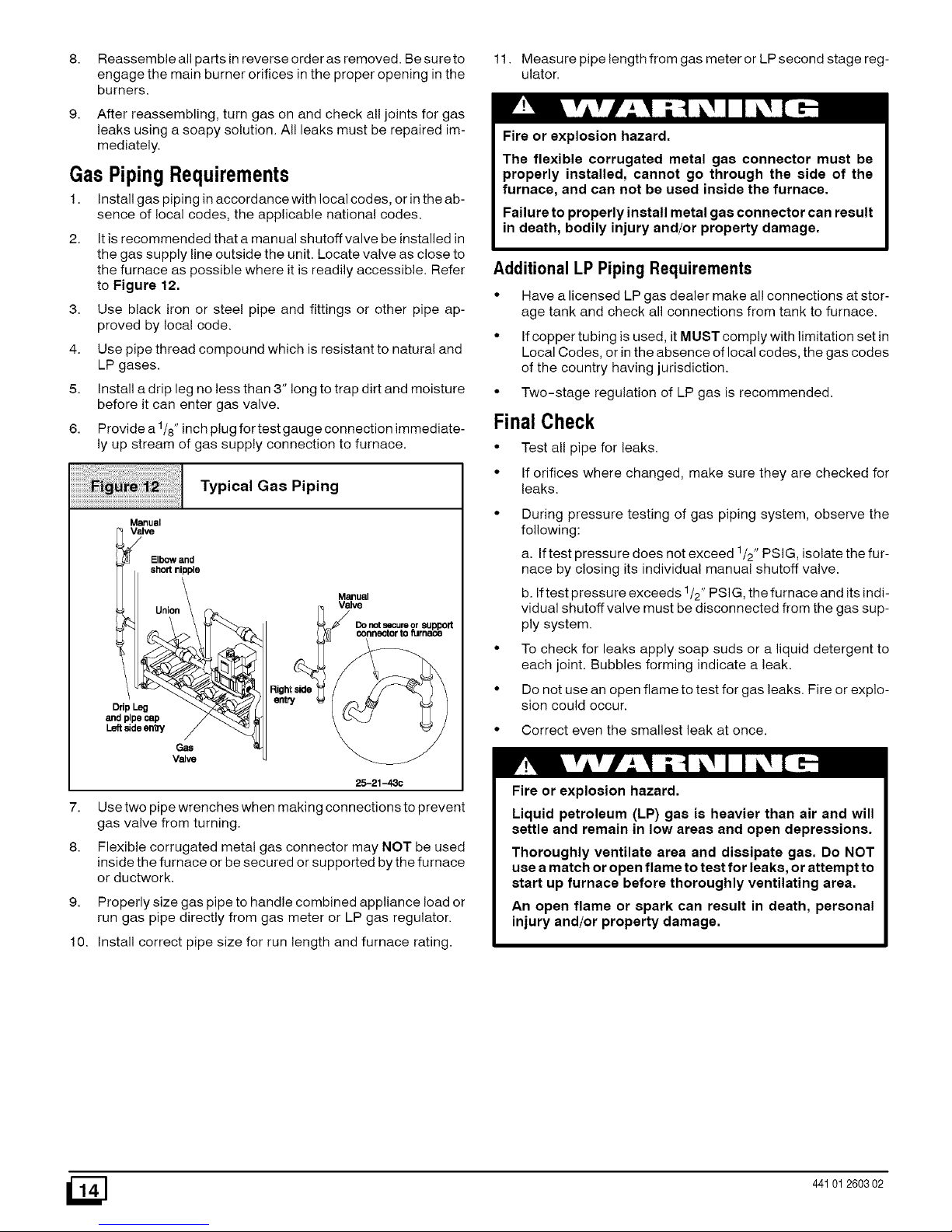

GasPipingRequirements

1. Install gas piping in accordance with local codes, or in the ab-

sence of local codes, the applicable national codes.

2.

3.

4.

5.

6.

It is recommended that a manual shutoff valve be installed in

the gas supply line outside the unit. Locate valve as close to

the furnace as possible where it is readily accessible. Refer

to Figure 12.

Use black iron or steel pipe and fittings or other pipe ap-

proved by local code.

Use pipe thread compound which is resistant to natural and

LP gases.

Install a drip leg no less than 3" long to trap dirt and moisture

before it can enter gas valve.

Provide a 1/8" inch plug for test gauge connection immediate-

ly up stream of gas supply connection to furnace.

Typical Gas Piping

Manual

V_lve

Elbow and

short nipple

Union _

and pipe cap / _

L_deen_ / _._

Gas

Valve

Manuel

Valve

25-21-43c

7.

8.

Use two pipe wrenches when making connections to prevent

gas valve from turning.

Flexible corrugated metal gas connector may NOT be used

inside the furnace or be secured or supported by the furnace

or ductwork.

9. Properly size gas pipe to handle combined appliance load or

run gas pipe directly from gas meter or LP gas regulator.

10. Install correct pipe size for run length and furnace rating.

11. Measure pipe length from gas meter or LP second stage reg-

ulator.

Fire or explosion hazard.

The flexible corrugated metal gas connector must be

properly installed, cannot go through the side of the

furnace, and can not be used inside the furnace.

Failure to properly install metal gas connector can result

in death, bodily injury and/or property damage.

Additional LP PipingRequirements

• Have a licensed LP gas dealer make all connections at stor-

age tank and check all connections from tank to furnace.

• If copper tubing is used, it MUST comply with limitation set in

Local Codes, or in the absence of local codes, the gas codes

of the country having jurisdiction.

• Two-stage regulation of LP gas is recommended.

FinalCheck

• Test all pipe for leaks.

• If orifices where changed, make sure they are checked for

leaks.

During pressure testing of gas piping system, observe the

following:

a. If test pressure does not exceed 1/2" PSIG, isolate the fur-

nace by closing its individual manual shutoff valve.

b. If test pressure exceeds 1/2" PSIG, the furnace and its indi-

vidual shutoff valve must be disconnected from the gas sup-

ply system.

To check for leaks apply soap suds or a liquid detergent to

each joint. Bubbles forming indicate a leak.

Do not use an open flame to test for gas leaks. Fire or explo-

sion could occur.

• Correct even the smallest leak at once.

Fire or explosion hazard.

Liquid petroleum (LP) gas is heavier than air and will

settle and remain in low areas and open depressions.

Thoroughly ventilate area and dissipate gas. Do NOT

use a match or open flame to test for leaks, or attempt to

start up furnace before thoroughly ventilating area.

An open flame or spark can result in death, personal

injury and/or property damage.

_] 441012603 02

Page 15

8. Electrical Wiring

Electrical shock hazard.

Turn OFF electrical power at fuse box or service panel

before making any electrical connections and ensure a

proper ground connection is made before connecting

line voltage.

Failure to do so can result in death, personal injury

and/or property damage.

PowerSupplyWiring

The furnace MUST be electrically wired and grounded in accor-

dance with local codes, or in the absence of local codes, the appli-

cable national codes.

Field wiring connections must be made inside the furnace con-

nection box. A suitable strain relief should be used at the point the

wires exit the furnace casing.

Copper conductors shall be used. Line voltage wires should be

sized for the input amps stated on the rating plate. Furnace must

be connected to its own separate circuit.

Thermostat

Thermostat location has an important effect on the operation of

the unit. Follow instructions included with thermostat for correct

mounting and wiring.

Low voltage connections to furnace must be made on terminal

board to fan control. (See Figure 13 or Figure 14)

If cooling is used, the Y from the thermostat must be connected to

the control board Y to energize cooling blower speed.*

Set thermostat heat anticipator in accordance with the Technical

Support Manual.

OptionalEquipment

All wiring from furnace to optional equipment MUST conform to

local codes or, in the absence of local codes, the applicable na-

tional codes. Install wiring in accordance with manufacturer's

instructions.

Humidifier/ElectronicAir Cleaner

The furnace is wired for humidifier and/or electronic air cleaner

connection.

CAUTION

Do NOT exceed 115V/0,8 amp, maximum current load

for both the EAC terminal and the HUM terminal com-

bined.

NOTE: The humidifier will be powered when the furnace is fired

and the circulating air blower comes on. The electronic air cleaner

will be powered anytime the thermostat calls for air movement.

However, the electronic air cleaner is NOT energized during con-

tinuous fan operation controlled by the electronic fan control.

Electrical Connections

(Upflow/Horizontal)

115V, 60Hz

NEUT.

Connection Box

Ground

Thermostat

i i

I i ! _ I

--q I I I

Low Voltage

Termina_Board

25-22-30

115V, 60Hz

NEUT.

Electrical Connections

(Downflow)

Ground

LowVoltage

TerminalBoard

25-21-05b

Control CenterFuse

The 24V circuit contains a 5-amp, automotive-type fuse located

on control center. (See Figure 15) Any electrical shorts of 24V

wiring during installation, service, or maintenance may cause

fuse to blow. If fuse replacement is required, use only a fuse of

identical size (5 amp.)

44101 260302 [_

Page 16

Fan Timer Connections

Fuse

25-22-68

9. Ductwork and Filter (Upflow/Horizontal)

Poison carbon monoxide gas hazard.

Do NOT draw return air from inside a closet or utility

room where furnace is located. Return air duct MUST

be sealed to furnace casing.

Failure to properly seal duct can result in death and/or

personal injury.

When the furnace is located in an area near or adjacent to the liv-

ing area, the system should be carefully designed with returns to

minimize noise transmission through the return air grille. Any

blower moving a high volume of air will produce audible noise

which could be objectionable when the unit is located very close

to a living area. It is often advisable to route the return air ducts

under the floor or through the attic.

• Refer to furnace Technical Support Manual (Blower Data)

for air flow information.

DuctConnections

This furnace may be installed in only a bottom or side return ap-

plication. Return air through the back of the unit is NOT allowed.

Side connections can be made by cutting out the embossed area

shown in Figure 16,

Cutting Side Return Air Opening

Starting

Hole

• Size ductwork to handle air flow for heating and air condition-

ing if used.

DuctInstallationRequirements

• When furnace supply ducts carry air outside furnace area,

seal return air duct to furnace casing and terminate duct out-

side furnace space.

• When a refrigeration coil is used in conjunction with this unit,

it must be installed on the discharge side of the unit to avoid

condensation on the heat exchanger.

If separate evaporator and blower unit is used, install good

sealing dampers for air flow control. Chilled air going through

the furnace could cause condensation and shorten furnace

life. Dampers (purchased locally) can be either automatic or

manual. Manually operated dampers MUST be equipped

with a means to prevent furnace or air conditioning operation

unless damper is in the full heat or coo! position.

Bottom returns can be made by removing the knockout panel in

the furnace base. Do NOT remove knock-out except for a bottom

return.

Duct Design

Design and install air distribution system to comply with Air Condi-

tioning Contractors of America manuals or other approved meth-

ods that conform to local codes and good trade practices.

Poison carbon monoxide gas hazard.

Cool air passing over heat exchanger can cause

condensate to form resulting in heat exchanger failure.

This could result in personal injury and/or death.

Installation of locking-type dampers are recommended in all

branches, or in individual ducts to balance system's air flow.

If air return grille is located close to the fan inlet, install at least

one, 90 ° air turn between fan and inlet grille to reduce noise.

441012603 02

Page 17

Ductwork installed in attic, or exposed to outside tempera-

tures requires a minimum of 2" of insulation with outdoor type

vapor barrier.

Ductwork installed in an indoor unconditioned space re-

quires a minimum of 1" of insulation with indoor type vapor

barrier.

Filters

A filter MUST be used:

Filters are not supplied with these furnaces, but can be purchased

from your dealer.

Use either filter type:

• Washable, high velocity filters are based on a maximum air

flow rating of 600 FPM.

• Disposable, Iowvelocity filters are based on a maximum air

flow of 300 FPM when used with filter grille.

• The furnaces, with 1600 or less CFM rating use a 16" x 25"

high velocity filter. On these models the filter may be

mounted internally for bottom return using factory kit or ex-

ternally for side return.

• The furnaces with greater than 1600 CFM requires that

both !eft and right side returns are used in side return ap-

plications. Two 16" x 25" high velocity filters and racks are

provided with furnace. Filter racks must be mounted exter-

nally. !f return air must be on one side only. an optional 20" x

25" filter standoff rack kits can be used. (See Figure 17)

For bottom return, an optional 20" x 25" filter rack kit can be

mounted internally.

10. Ductwork and Filter (Downflow)

Fire or explosion hazard.

Use sub-base for downflow installation on combustible

floors.

Failure to use sub-base on combustible floors can result

in death, bodily injury and/or property damage.

Sub-Bases for CombustibleFloors - Furnace Only

The Subbase for Combustible Floors MUST be used when a

downflow furnace is set on combustible material even when the

furnace is installed on a col! box (cased col!).

NOTE: The 20 x 25" standoff filter rack gives more filter area but

does not provide more air. To achieve 2000 CFM a bottom return

or 2 side returns are still needed.

NOTE: Disposable, low velocity filters may be replaced with

washable, high velocity filter providing they meet the minimum

size areas. Washable, high velocity filters can be replaced ONLY

with same type and size.

Figure 17

1

Optional Duct Standoff

20 x 25 Optional

Filter Rack

NOTE: Supply opening is 37/8" from the rear of the furnace.

Therefore maintain a 37/8" clearance from a wall behind the fur-

nace (where applicable).

Cut the opening in the floor according to Table 6. The hole in

the floor must be cut to the dimensions listed in Table 6 since

the base is equipped with locating tabs that center the base

over the opening.

The opening in the base is 1t/4" shorter and 1t/8" narrower than

the minimum required size of the opening in the floor. This is done

to maintain a 1" clearance between the floor and the plenum.

2. Fabricate the plenum to the dimensions given in Table 6.

Note that the dimensions given are outside dimensions.

Sub-bases for Combustible Floors Dimensions

H _

15tl/16

195/16

22t5/16

15tl/16

195/I6

22t5/16

sub-base for Com-

bustible Floors

Part Number

(Furnace Only)

NAHHOOlSB

NAHHOO2SB

NAHHOO3SB

sub-base for

Cased Coil

NAHHOO4SB

NAHHOO5SB

NAHHOOSSB

* Outside Dimension

sub-base for Combustible

Floor Dimensions

J* K**

283/4 149/16

283/4 183/16

283/4 2113/16

209/16 149/I6

209/16 183/I6

209/16 2113/16

Opening In Floor

L M N

16 161/4 145/8

16 161/4 181/4

16 161/4 217/8

16 161/4 145/8

16 161/4 181/4

16 161/4 217/8

Opening In

Base For Plenum

Typical Plenum

Dimensions

15

15

15

P R

15 13t/2

15 17t/8

15 193/4

15 13t/2

15 17t/8

15 193/4

15

15

15

131/2

171/8

193/4

131/2

171/8

193/4

** Base Spacer Side To Side

44101 260302

Page 18

3.

4.

Set the base overthe opening in the floor, centering the open-

ing in the base over the opening in the floor. Fasten the base

to the floor with screws or nails. See Figure 18 and

Figure 20.

Drop the plenum through the opening in the base. The flange

of the plenum should rest on top of the combustible floor

base.

Exploded View of Sub-Base

Figure 18 for Furnace ONLY

Sub-base for Combustible Floors- Downflow Coil

Box

The Subbase for Combustible Floors MUST be used when a

downflow furnace, used with a downflow coil box, is set on

combustible flooring.

NOTE: Supply opening is 37/8" from the rear of the furnace.

Therefore maintain a 37/8" clearance from wall (where applica-

ble).

Cut the opening in the floor according to Table 6. The hole in

the floor must be cut to the dimensions listed in Table 6 since

the base is equipped with locating tabs that center the base

over the opening.

The opening in the base is 11/4" shorter and 1 1/8" narrower than

the recommended size of the opening in the floor. This is done to

provide a 1" clearance between the floor and the plenum.

2.

3.

4.

Fabricate the plenum to the dimensions given in Table 6.

Note that the dimensions given are outside dimensions.

Set the base over the opening in the floor, centering the open-

ing in the base over the opening in the floor. Fasten the base

to the floor with screws or nails. See Figure 19 and

Figure 20.

Drop the plenum through the opening in the base. The flange

of the plenum should rest on top of the combustible floor

base.

Figure 19 Exploded View of Base for

Downflow Cased Coil

Setting the Base

Subbase

Insulation

25-21-46b

Wood Floor

25 20 46A

This subbase for combustible floors has been designed so that

the height of the sub-base raises the downflow coil off the floor to

allow easy installation of the condensate drain. See Figure 21.

Figure 21 Condensate Line Raised by Base

Filters:

25-20-52

The filter may be installed in the return air plenum above the fur-

nace. A filter rack is supplied with each furnace. See Figure 22 or

Figure 23.

NOTE: The return air plenum MUST extend a sufficient height

above dimensions "A" (Figure 23) to provide for the attachment

of a return air duct or grille above the filters.

1. Insert end of filter rack with 3/4" (19mm) flange into slot in the

back of the unit, See Figure 22.

_] 441012603 02

Page 19

2.

With filter rack pushed back, insert front end with 1/4" flange

into position and push into front slot. with filter rack pushed as

far forward as it will go, bend 1/4" flange and 3/4" flange up

90°. See Figure 22.

NOTE: Plenum must be fitted as close to the return air flange of

the unit as possible to eliminate any air bypassing the filters.

NOTE: If filters are installed in the plenum with the filter rack pro-

vided use two 16" x 18" high velocity filters. Otherwise consult fil-

ter section of the "User's Information Manual" for proper size.

Figure 22 Filter Rack Installation

25-21-05c

3. Filters can only be installed through the right hand side of the

unit blower opening. Slide filter into unit until it is in position to

be pushed up and over into place on the left hand side of unit.

See Figure 23.

4. Slide remaining filter into unit and up into place on left hand

side of unit. See Figure 23.

Figure 23 Filter Installation

25-21-05d

If there is insufficient plenum height for this type of installation, fil-

ters may be installed in any accessible location in the return air

system. In such a case, the filters should be of adequate size and

style as originally supplied with the furnace.

Filter Removal

1. Remove compartment door.

2. Reach up above right side of blower and lift dirty filters out of

rack at top of furnace.

3. Straighten up filters and pull straight down at side of blower.

Pull out through right door opening.

4. Vacuum clean or wash with warm water and dry thoroughly

before replacing.

11. Checks and Adjustments

Startup

NOTE: Refer to startup procedures in the Users Information

Manual.

CAUTION

If any sparks, odors or unusual noises occur, immedi-

ately shut OFF power to furnace. Check for wiring er-

rors or obstruction to blower.

Fire or explosion hazard.

Turn OFF gas at shut off before

manometer.

connecting

Failure to turn OFF gas at shut off before connecting

manometer can result in death and/or personal injury.

GasSupplyPressure

Gas supply pressure should be within minimum and maximum

values listed on rating plate. Pressures are usually set by gas sup-

pliers.

(See L.R Kit instruction manual for furnaces converted to L.R

gas)

ManifoldGas PressureAdjustment

NOTE: Make adjustment to manifold pressure with burners oper-

ating.

1. With gas OFF, Connect manometer to gas valve or maniflod

tap. Use manometer with a 0 to min. 12" water column range.

2. Turn gas ON and remove adjustment screw cover on gas

valve. Turn counterclockwise to decrease pressure and

clockwise to increase.

NOTE: Adjustment screw cover MUST be placed on gas valve

before reading manifold pressure and operating furnace.

3. For altitudes up to 2000', set pressure to value shown in

Table 2. For altitudes between 2000' to 8000', see Section

7. "Gas Supply and Piping" for correct pressure value.

44101 260302 [_

Page 20

AdjustPilot Burner

The furnace has a pilot flame to light the main burner. The flame

should surround 3/8" to 1/2" of the flame rod. See Figure 24. To

adjust, remove cap from pilot adjusting screw on gas valve. Turn

screw counterclockwise to increase or clockwise to decrease

flame as required. Replace cap after adjusting screw.

iiiiiiiiiiiiiiiiJ!;iiiiiiiiiil¸;i ;;;;;;;;;;!!ii ¸ ;;;;;

Proper flame

adjustment

Pilot Burner

3/8to 1/2"

Igniter-sensor

I 10-12-12c

ChangingBlowerSpeed

Electrical shock hazard.

Turn OFF power to furnace before changing speed taps.

Failure to do so can result in death, personal injury

and/or property damage.

NOTE: The speed taps that the manufacture sets from the factory

for this product are based on a nominal 400 CFM per ton cooling

and the basic mid range on the temperature rise for heating.

Since the manufacturer cannot establish the static pressure

that will be applied to the unit, it is the responsibility of the

installer deal er/contractor to select the proper speed taps for

the application when the unit is installed.

If it is necessary to change speeds, refer to steps below.

1. Refer to Furnace Wiring Diagram for location of the heating

and cooling speed taps located on the electronic fan control

as well as location of unused blower motor speed leads. Use

the chart (Table 7) to determine the blower motor speed set-

tings.

Main BurnerFlameCheck

Allow the furnace to run approximately 10 minutes then inspect

the main burner and pilot flames. See Figure 25.

Check for the fol!owing (Figure 25):

• Stable and blue flames. Dust may cause orange tips or

wisps of yellow, but flames MUST NOT have solid, yellow

tips.

• Flames extending directly from burner into heat exchanger.

• Flames do NOT touch sides of heat exchanger

If any problems with main burner flames are noted, it may be nec-

essary to adjust gas pressures, or check for drafts.

Main Burner

10-10-78

TemperatureRiseCheck

The blower speed MUST be set to give the correct air temperature

rise through the furnace as marked on the rating plate. Tempera-

ture rise is the difference between supply and return air tempera-

tures.

IN

Blower Speed Chart

Wire Color

Black

Orange*

Blue

Red

Motor Speed

High

Med-High

Medium

low

* Med-High speed may not be provided on all models.

Change the heat or cool blower motor speed by removing the

motor lead from the "Heat" or "Cool" terminal and replace it

with the desired motor speed lead from the "Unused Motor

Lead" location. Connect the wire previously removed from

the "Heat" or "Cool" terminal to the vacated "Unused Motor

Lead" terminal.

Ifthe same speed must be used for both heating and cooling,

remove the undesired motor speed lead from the "Heat" or

"Cooi"terminal and connect that lead to the open terminal at

"Unused Motor Lead" location ortape off. Attach a jumper

between the "Heat" and "Cool" terminals and the remaining

motor speed lead.

Note: When using the same speed on motors with (4) speed

leads, it will be necessary to tape off the terminal of the motor

speed lead removed from the "Heat" or "Cool" terminal with

electrical tape since an open terminal wi!! not be available at

the "Unused Motor Lead" location.

ContinuousFanOperation

A terminal is provided on the electronic fan control located in the

circulating blower compartment for operation of the continuous

fan option. This connection is intended for the low speed motor

tap, and has a lower contact rating (8 amps) than the heat and

cool taps. When the low speed blower lead is connected to this

terminal, this will provide low speed blower operation whenever

the other two speeds (Heat or Cool) are not energized.

Thoroughly check the system after modification to ensure the

proper operation of the circulating air blower in all modes of opera-

tion.

441012603 02

Page 21

Separatespeed selectionsfor Heat, Cool,and

Continuous Fan

Connect low speed lead from circulating motor to the "Cont" ter-

minal at the electronic fan control. The appropriate motor leads

should already be connected to the "Heat" and "Cool" terminals.

Heating and Continuous Blower Speed the Same

If it is necessary to operate the heating speed and continuous

blower speed using the same blower speed, connect a jumper be-

tween the "Neat" and "Cont" terminals on the electronic fan con-

trol.

Note: There should be only ONE motor lead going to the "Heat"

and "Cont" terminals.

12. Furnace Maintenance

CAUTION

It is recommended that the furnace be inspected and

serviced on an annual basis (before the heating sea-

son) by a qualified service technician.

See "User's Information Manual".

44101 260302 [_

Page 22

Save This Manual For Future Reference

Models

NTC6050FBG1

NTC6075FBG1

NTC6075HFG1

NTC6100GFG1

NTC6100KFG1

NTC6100KJG1

NTC6125KJG1

NTC6150KJG1

NTN6050FBG1

NTN6075FBG1

NTN6075HFG1

NTN6100KFG1

NTN6100KJG1

NTN6125KJG1

NDN6050FBG1

NDN6075FBG1

NDN6075HFG1

NDN6100GFG1

NDN6100KFG1

NDN6125KJG1

GNE050B12G1

GNE075B12G1

GNE075F16G1

GNE100F14G1

GNE100F20G1

GNE100J20G1

GNE125J20G1

GNE150J20G1

NNE050B12G1

NNE075B12G1

NNE075F16G1

NNE100F20G1

NNE100J20G1

NNE125J20G1

GDE050B12G1

GDE075B12G1

GDE075F16G1

GDE100F14G1

GDE100F20G1

GDE125J20G1

Models

NTN3050FBG1

NTN3075FBG1

NTN3075HFG1

NTN3100KFG1

NTN3100KJG1

NTN3100LJG1

NTN3125KJG1

NTN3125LJG1

NTG3050FBG1

NTG3075FBG1

NTG3075HFG1

NTG3100GFG1

NTG3100KFG1

NTG3100LJG1

NTG3125KJG1

NTG3125LJG1

NDN3050FBG1

NDN3075FBG1

NDN3075HFG1

NDN3100GFG1

NDN3100KFG1

NDN3125KJG1

NBF050B12G1

NBF075B12G1

NBF075F16G1

NBF100F20G1

NBF100J20G1

NBF100J22G1

NBF125J20G1

NBF125J22G1

FBF050B12G1

FBF075B12G1

FBF075F16G1

FBF100F14G1

FBF100F20G1

FBF100J22G1

FBF125J20G1

FBF125J22G1

NDF050B12G1

NDF075B12G1

NDF075F16G1

NDF100F14G1

NDF100F20G1

NDF125J20G1

Manufactured by:

International Comfort Products Corporation (USA)

Lewisburg, TN USA 37091

_] 44101 260302

Page 23

ManufacturersNumber(Mfr No-See RatingPlate)

ALL Models

Specifications

NTN305OFB/ NTN3075FB/ NTN3075HF/ NTN31OOKF/ NTN31OOKJ/ NTN31OOLJ/ NTN3125KJ/ NTN3125LJ/

NBFO5OB12 NBFO75B12 NBFO75F16 NBFIOOF20 NBFIOOJ20 NBFIOOJ22 NBF125J20 NBF125J22

NTG305OFB NTG3075FB NTG3075HF NTG31OOKF NTG31OOLJ/ NTG3125KJ/ NTG3125LJ/

/FBFO5OB12 /FBFO75B12 /FBFO75F16 /FBFIOOF20 FBFIOOJ22 FBF125J20 FBF125J22

General

Input(Btuh) 50,000 75,000 75,000 100,000 100,000 1O0,OO0 125,000 125,000

Output(Btuh) 40,000 59,000 59,000 79,000 79,000 79,000 99,000 99,000

Temp.Rise (F) 35-65 35-65 25-55 35-65 35-65 40-70 40-70 40-70

Electrical(Votts/Hz!FLA) 115/60/5.3 115/60/5.3 115/60/12.0 115/60/12.0 115/60/12.0 115/60/12.0 115/60/12.0 115/60/12.0

GasType Nat LP Nat LP Nat LP Nat LP Nat LP Nat LP Nat LP Nat LP

Transformer Size (VA) 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40

T'statHeat Anticipator .30 .30 .30 .30 .30 .30 .30 .30 .30 .30 .30 .30 .30 .30 .30 .30

Gas& Ignition

Std.MainOrifices(No/Size) 2/#42 2/#54 3/#42 3/#54 3/#42 3/#54 4/#42 4/#54 4/#42 4/#54 4/#42 4/#54 5/#42 5/#54 5/#42 5/#54

GasValve HoneywellVR 8204 8204 8204 8204 8204 8204 8204 8204 8204 8204 8204 8204 8204 8204 8204 8204

RegulationType SNAP SNAP SNAP SNAP SNAP SNAP SNAP SNAP SNAP SNAP SNAP SNAP SNAP SNAP SNAP SNAP

ManifoldPress.(Inch'sWC) 3.5 10.0 3.5 10.0 3.5 10.0 3.5 10.0 3.5 10.0 3.5 10.0 3.5 10.0 3.5 10.0

PilotOrificeSize .018 .011 .018 .011 .018 .011 .018 .011 .018 .011 .018 .011 .018 .011 .018 .011

IgnitionType/Series HW S8600 HW $8600 HW$8600 HW$8600 HW $8600 HW$8600 HW$8600 HW $8600

Lock-Out Time NA NA NA NA NA NA NA NA

Combustion

FlueOutlet Size (Inches) 3 3 3 3 3 3 3 3

Std.OutletTemp(F) <480 <480 <480 <480 <480 <480 <480 <480

Limits &Controls

ThermalSensor ('F) 300 300 300 300 300 300 300 300

LimitControlSetting(F) See PartsList SeeParts List See PartsList See PartsList See PartsList SeeParts List See PartsList See PartsList

Auxiliary Umit (F) 130 130 130 130 130 130 130 130

Std.PressureSw. (PartNo) 1010898 1010898 1010898 1010898 1010898 1010898 1010898 1010898

Press(Close) -0.81 -0.81 -0.81 -0.81 -0.81 -0.81 -0.81 -0.81

Press(Open) -0.65 -0.65 -0.65 -0.65 -0.65 -0.65 -0.65 -0.65

FanControl(Type) HWST9120 HWST9120 HW ST9120 HWST9120 HWST9120 HW ST9120 HWST9120 HW ST9120

FanControt On 30/60 30/60 30/60 30/60 30/60 30/60 30/60 30/60

(Timed-secs) Off 60,100,140,180 60,100,140,180 60,100,140,180 60,100,140,180 60,100,140,180 60,100,140,180 60,100,140,180 60,100,140,180

Blower Data

Type&Size 10-8 10-8 10-10 10-10 11-10 11-10 11-10 11-10

MotorAmps/Rpm 6.5/1050 6.5/1050 10.3/110O 11.9/900 11.9/900 11.9/900 11.9/900 11.9/900

MotorType/H.p. PSC/1/3 PSC/1/3 PSC/1/2 PSC/3/4 PSC/3/4 PSC/3/4 PSC/3/4 PSC/3/4

Cap.MfdiVolts 5/370 5/370 10/370 10/370 10/370 10/370 10/370 10/370

FilterType Washable Washable Washable Washable Washable Washable Washable Washable

FilterSize (") 14x25x1 14x25x1 16x25x1 16x25x1 16x25x1 16x25x1 16x25x1(2) 16x25x1

Min.CootCap. (Tons) 1.5 1.5 3 3 3 3 3 3

Max.0oot OaF (Tons) 3 3 4 5 5 5 5 5

GasConversionKits

Natto LP NAHFOO2LPor NAHLO02LP,*1160991

LPto Nat NAHF002NG,*1009510*

LPHighAltitude *1160992

*Mustbe orderedfromServiceParts

44101260302 THIS DATA IS SUBJECT TO CHANGE WITHOUT NOTICE [_]

Page 24

ManufacturersNumber(Mfr No-See RatingPlate)

ALL Models

Specifications

NDN305OFB/ NDN3075FB/ NDN3075HF/ NDN31OOGF/ NDN31OOKF/ NDN3125KJ/

NDFO5OB12 NDFO75B12 NDFO75F16 NDFIOOF14 NDFIOOF20 NDF125J20

General

Input(Btuh) 50,000 75,000 75,000 100,000 100,000 125,000

Output(Btuh) 40,000 61,000 61,000 81,000 81,000 102,000

Temp.Rise (F) 30-60 40-70 40-70 40-70 40-70 45-75

Electrical(Volts/liz!FLA) 115/60/5.3 115/60/5.3 115/60/12.0 115/60/7.5 115/60/12.0 115/60/12.0

GasType Nat LP Nat LP Nat LP Nat LP Nat LP Nat LP

Transformer Size (VA) 40 40 40 40 40 40 40 40 40 40 40 40

T'statHeat Anticipator .30 .30 .30 .30 .30 .30 .30 .30 .30 .30 .30 .30

Gas& Ignition

Std.MainOrifices(No/Size) 2/#42 2/#54 3/#42 3/#54 3/#42 3/#54 4/#42 4/#54 4/#42 4/#54 5/#42 5/#54

GasValve Honeywell SV9501 SV9501 SV9501 SV9501 SV9501 SV9501 SV9501 SV9501 SV9501 SV9501 SV9501 SV9501

RegulationType SNAP SNAP SNAP SNAP SNAP SNAP SNAP SNAP SNAP SNAP SNAP SNAP

ManifoldPress.(Inch'sWC) 3.5 10.0 3.5 10.0 3.5 10.0 3.5 10.0 3.5 10.0 3.5 10.0

PilotOrificeSize .018 .011 .018 .011 .018 .011 .018 .011 .018 .011 .018 .011

IgnitionType/Series HWHSP HWHSP HW HSP liW liSP liW HSP HW HSP

Lock-Out Time NA NA NA NA NA NA

Limits &Controls

ThermalSensor('F) 300 300 300 300 300 300

LimitControlSetting(F) See Parts Ust SeePartsList See Parts List See PartsList See PartsList SeeParts List