Page 1

INSTALLATION INSTRUCTIONS

For Long Vent Pressure Switch Kits

This kit is designed to replace the standard pressure switch on the N9MP1100F14A2,

N9MP1100J20A2, N9MP2075B12A2, N9MP2100F14A2, N9MP2100J20A2, _9MPD100J14A2

and _9MPD100J20A2 with a dual pressure switch for long vent installations.

Denotes Brand (T, H or C)

Please read these instructions completely before attempting installation.

Examine Kit to determine that the following parts are present:

Ifany parts are missing, immediately contact your parts supplier.

Kit Model No Use with Furnace Model No

NAHA001 LV01 N9MP1075B12A2

(Standard) N9MP1100F14A2

Description

Pressure Switch

Hose, Blower 10"

Hose, Transition 21"

Wire Asy.

Instructions

NAHAOO2LV01

(Standard)

Description

Pressure Switch

Hose, Blower 10"

Hose, Transition 21"

Wire Asy.

Instructions

NAHAOO3LV01

(Hi-Altitude)

Description

Pressure Switch

Hose, Blower 10"

Hose, Transition 21"

Wire Asy.

Instructions

N9MP2075B12A2

N9MP2100F14A2

Parts List

Part No. Qty,

1013518 1

1009238 1

1009238 1

1013814 1

441 06 1033 01 1

N9MP1100J20A2

N9MP2100J20A2

_9MPD100J 14A2

_9MPD100J20A2

Parts List

Part No. Qty,

10135185 1

1009238 1

1009238 1

1013814 1

441 06 1033 01 1

N9MP1075B12A2

N9MP1100F14A2

N9MP1100J20A2

N9MP2075B12A2

N9MP2100F14A2

N9MP2100J20A2

_9MPD100J 14A2

_9MPD100J20A2

Parts List

Part No. Qty,

10135165 1

1009238 1

1009238 1

1013814 1

441 06 1033 01 1

FIRE, EXPLOSION, CARBON MONOXIDE

POISONING HAZARD.

This conversion kit shall be installed by a qualified

service technician in accordance with the

Manufacturer's instructions and all applicable

codes and requirements of the authority having

jurisdiction. The qualified service agency

performing this work assumes responsibility for

the proper conversion of this furnace with this kit.

Failure to follow these instructions exactly can

result in death, personal injury and/or property

damage.

ELECTRIC SHOCK HAZARD/FIRE AND/OR

EXPLOSION HAZARD.

Turn OFF gas supply at manual gas valve before

turning OFF electric power supply and starting

installations.

Turn OFF electric power supply at disconnect

switch or service panel before starting

installations.

Failure to follow this warning can result in death,

personal injury, property damage, and/or

equipment damage.

Disassembly

1. After turning off the electrical power supply to the furnace,

remove the burner compartment access door to the fur-

Race.

2. Remove the two (2) blue wires from the 1/4" terminals on

the pressure switch.

3. Remove the 5/16" OD rubber hose from the pressure tap

on the plastic transition box that connects to the pressure

switch.

4. Remove the two (2) screws that fasten the pressure switch

to the front of the blower partition and remove the switch

from the furnace.

441 06 1033 01 (06/2004)

Page 2

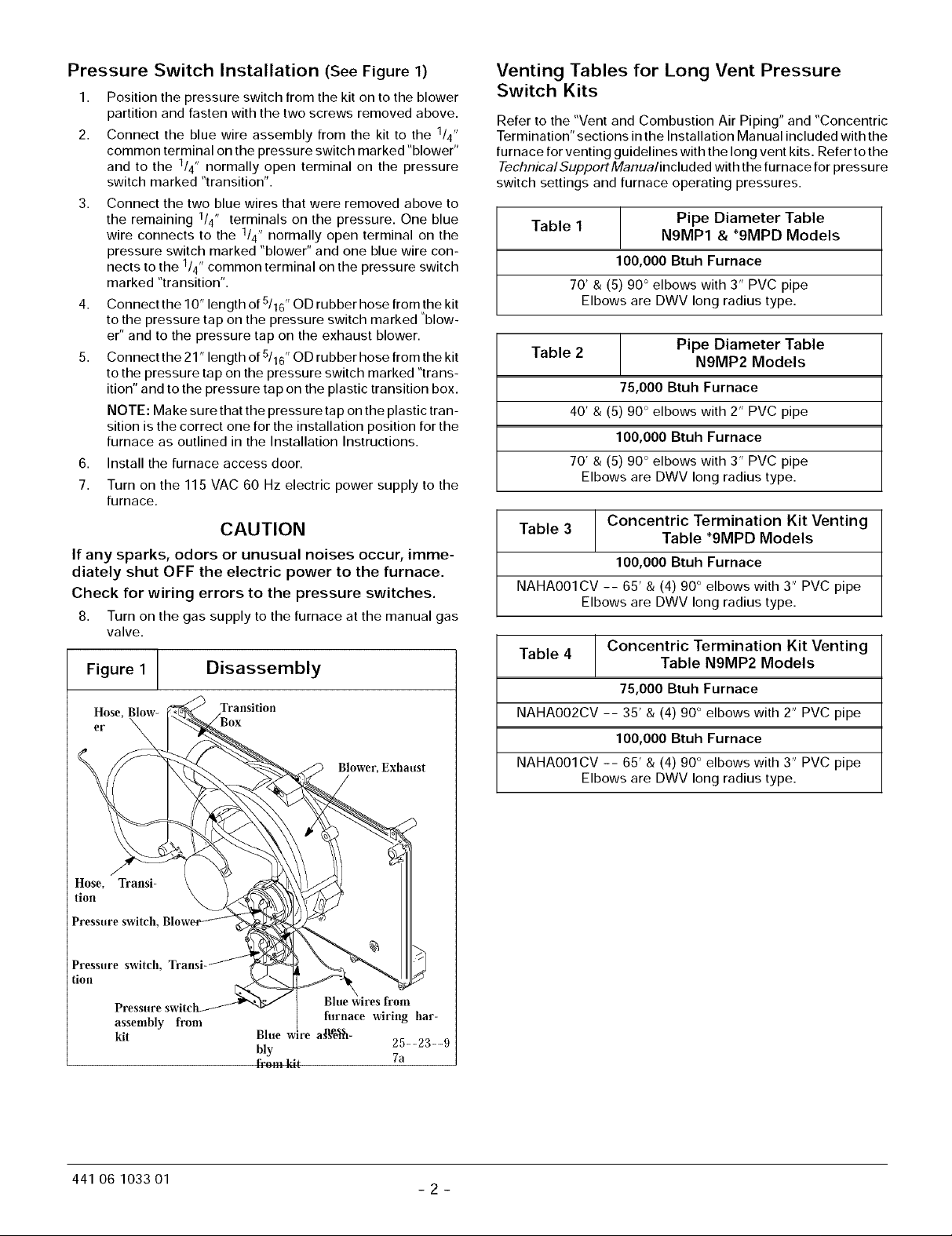

Pressure Switch Installation (See Figure 1)

1. Position the pressure switch from the kit on to the blower

partition and fasten with the two screws removed above.

2. Connect the blue wire assembly from the kit to the 1/4"

common terminal on the pressure switch marked "blower"

and to the 1/4" normally open terminal on the pressure

switch marked "transition".

3. Connect the two blue wires that were removed above to

the remaining 1/4" terminals on the pressure. One blue

wire connects to the 1/4" normally open terminal on the

pressure switch marked "blower" and one blue wire con-

nects to the 1/4" common terminal on the pressure switch

marked "transition".

4. Connectthe10"lengthofS/16"ODrubberhosefromthekit

to the pressure tap on the pressure switch marked "blow-

er" and to the pressure tap on the exhaust blower.

5. Connectthe21"lengthofS/16"ODrubberhosefromthekit

to the pressure tap on the pressure switch marked "trans-

ition" and to the pressure tap on the plastic transition box.

NOTE: Make sure that the pressure tap on the plastic tran-

sition is the correct one for the installation position for the

furnace as outlined in the Installation Instructions.

6. Install the furnace access door.

7. Turn on the 115 VAC 60 Hz electric power supply to the

furnace.

CAUTION

If any sparks, odors or unusual noises occur, imme-

diately shut OFF the electric power to the furnace.

Check for wiring errors to the pressure switches.

8. Turn on the gas supply to the furnace at the manual gas

valve.

Figure 1 ] Disassembly

Hose, Transition

er

Blower, Exhaust

Venting Tables for Long Vent Pressure

Switch Kits

Refer to the "Vent and Combustion Air Piping" and "Concentric

Termination" sections in the Installation Manual included with the

furnace for venting guidelines with the long vent kits. Refer to the

Technical Support Manualincluded with the furnace for pressure

switch settings and furnace operating pressures.

Table 1 Pipe Diameter Table

70' & (5) 90 ° elbows with 3" PVC pipe

Elbows are DWV long radius type.

Table 2 Pipe Diameter Table

40' & (5) 90 ° elbows with 2" PVC pipe

70' & (5) 90 ° elbows with 3" PVC pipe

Elbows are DWV long radius type.

Table 3

Concentric Termination Kit Venting

NAHA001CV -- 65' & (4) 90° elbows with 3" PVC pipe

Elbows are DWV long radius type.

Table 4

Concentric Termination Kit Venting

NAHA002CV -- 35' & (4) 90° elbows with 2" PVC pipe

NAHA001CV -- 65' & (4) 90° elbows with 3" PVC pipe

Elbows are DWV long radius type.

N9MP1 & *91VlPD Models

100,000 Btuh Furnace

N9MP2 Models

75,000 Btuh Furnace

100,000 Btuh Furnace

Table *9MPD Models

100,000 Btuh Furnace

Table N9MP2 Models

75,000 Btuh Furnace

100,000 Btuh Furnace

Hose, Transi-

tion

Pressure switch,

Pressure switch,

tion

froln

assembly from

kit

Blue

bly

from ldt

filrnace wiring har-

a_Fe_-

25::23::9

7a

441 06 1033 01 2

Loading...

Loading...