Page 1

MULTI POSITION

SINGLE STAGE

GAS FURNACES

N9MP1, N9MP2 & *9MPD

This manual supports condensing gas furnaces manufactured in 2001

Manufactured by:

ã 2001 International Comfort Products Corporation (USA)

“A1 & A2”

Part Number

440 08 2001 02

4/2002

Page 2

N9MP1 -- Indoor combustion air (1 pipe only)

N9MP2 -- Direct Vent ONLY (2 pipe only)

*9MPD -- Dual Certified Venting (1 or 2 pipes)

* Denotes Brand (T, C or H)

Page 3

Single Stage Multi Position Furnace

Service Manual

TABLE OF CONTENTS

1. INTRODUCTION 2............................................................

2. UNIT IDENTIFICATION 2.....................................................

3. FURNACE THEORY OF OPERATION 3........................................

4. ELECTRICAL SUPPLY 4......................................................

5. INTERLOCK SWITCH 5......................................................

6. GAS SUPPLY 5..............................................................

7. BURNERS 7................................................................

8. L.P. PRESSURE SWITCH 7...................................................

9. HIGH ALTITUDE OPERATION 7...............................................

10. CHECKING TEMPERATURE RISE 8..........................................

11. ROOM THERMOSTATS 8....................................................

12. CONTROL WIRING 9.......................................................

13. TWINNING KITS 10..........................................................

14. LIMIT SWITCHES 10.........................................................

15. PRESSURE SWITCHES 12...................................................

16. VENT/COMBUSTION AIR PIPING 14..........................................

17. STANDARD VENT TERMINATION 14..........................................

18. CONCENTRIC VENT TERMINATION 16........................................

19. EXHAUST BLOWER 17......................................................

20. CONDENSATE DRAIN TRAP 17...............................................

21. HONEYWELL ST9160B FAN TIMER/FURNACE CONTROL 18....................

22. ST9160B TESTING SEQUENCE 19............................................

23. ST9160B -- UNIQUE CONTROL FUNCTIONS/RESPONSES 19...................

24. HONEYWELL SV9541M GAS VALVE/IGNITION SYSTEM 20.....................

25. HONEYWELL SV9541M SYSTEM OPERATION 20..............................

26. CHECKING FLAME CURRENT 21.............................................

27. CAPACITORS 22............................................................

28. BLOWER ASSEMBLY 22.....................................................

29. BLOWER ROTATION 23......................................................

30. HEAT EXCHANGER REMOVAL/REPLACEMENT 44.............................

SV9541M “SMART VALVE” -- Sequence of Operation 45.............................

SV9541M “SMART VALVE” -- Trouble shooting 47...................................

SV9541M “SMART VALVE” -- Electrical Variation 49.................................

WIRING DIAGRAM 50...........................................................

TECHNICAL SERVICE DATA (N9MP1 or 2) 52......................................

TECHNICAL SERVICE DATA (*9MPD/A1) 54......................................

TECHNICAL SERVICE DATA (*9MPD/A2) 55......................................

BLOWER PERFORMANCE DATA (N9MP1 or 2 & *9MPD) 56.........................

APPENDIX OF HELPFUL INFORMATION 57.......................................

Page 4

Service

Manual

1. INTRODUCTION

This service manual is designed to be used in conjunction

with the installation manual and/or technical support manual

provided with each furnace.

These furnaces represent the very latest in high efficiency

gas furnace technology. Consequently, they incorporate the

use of certain controls that contain highly sophisticated electronic components which are not user serviceable. there-

fore, it is essential that only competent, qualified, service

personnel attempt to install, service, or maintain this product.

This Service manual was written to assist the professional

HVAC service technician to quickly and accurately diagnose

and repair any malfunction of this product.

This service manual covers our new multi--position furnaces,

both Direct Vent (2 pipe Only), Indoor combustion (1 pipe

Only) and Dual Certified (1 or 2 pipe) models. The overall operation of all of these models is essentially the same.

This manual, therefore, will deal with all subjects in a general

nature (I.E. all text will pertain to all models) unless that subject is unique to a particular model or family, in which case

it will be so indicated.

Single Stage Multi Position Furnace

!

The information contained in this manual is

intended for use by a qualified service technician

who is familiar with the safety procedures required

in installation and repair and who is equipped with

the proper tools and test instruments.

Installation or repairs made by the unqualified

persons can result in hazards subjecting the

unqualified person making suchrepairs to the risk of

injury or electrical shock which can be serious, or

even fatal not only to them, but also to persons being

served by the equipment.

If you install or perform service on equipment, you

must assume responsibility for any bodily injury or

property damage which may result to you or others.

We will not be responsible for any injury or property

damage arising from improper installation, service

and/or service procedures.

2. UNIT IDENTIFICATION

The unit’s rating plate contains important information for the

service technician. It also lists the complete Model Manufacturing and Serial Numbers.

These complete numbers are required to obtain correct re-

MODEL NUMBER IDENTIFICATION GUIDE

placement parts (example, in certain model families a unit

having a MARKET REVISION of “C” is likely to be equipped

with one or more different components.

* 9 MP D 075 B 12 A 1

Brand Identifier Engineering Rev.

T=Tempstar Denotes minor changes

C = Comfortmaker Marketing Digit

H=Heil Denotes minor change

A = Arcoaire

X = Evaluation Cooling Airflow

Brand Identifier 08 = 800 CFM

8 = Non--Condensing, 80+% Gas Furnace 12 = 1200 CFM

9 = Condensing, 90+% Gas Furnace 14 = 1400 CFM

Installation Configuration 16 = 1600 CFM

UP = Upflow DN = Downflow UH = Upflow/Horizontal 20 = 2000 CFM

HZ = Horizontal DH = Downflow/Horizontal

MP = Multiposition, Upflow/Downflow/Horizontal Cabinet Width

Major Design Feature B = 15.5² Wide

1 = One (Single) Pipe N = Single Stage F = 19.1² Wide

2=TwoPipe P=PVCVent J = 22.8² Wide

D = 1 or 2 Pipe T = Two Stage L = 24.5² Wide

L = Low NOx V = Variable Speed Input (Nominal MBTUH)

440 08 2001 02

2

Page 5

Single Stage Multi Position Furnace

Service

Manual

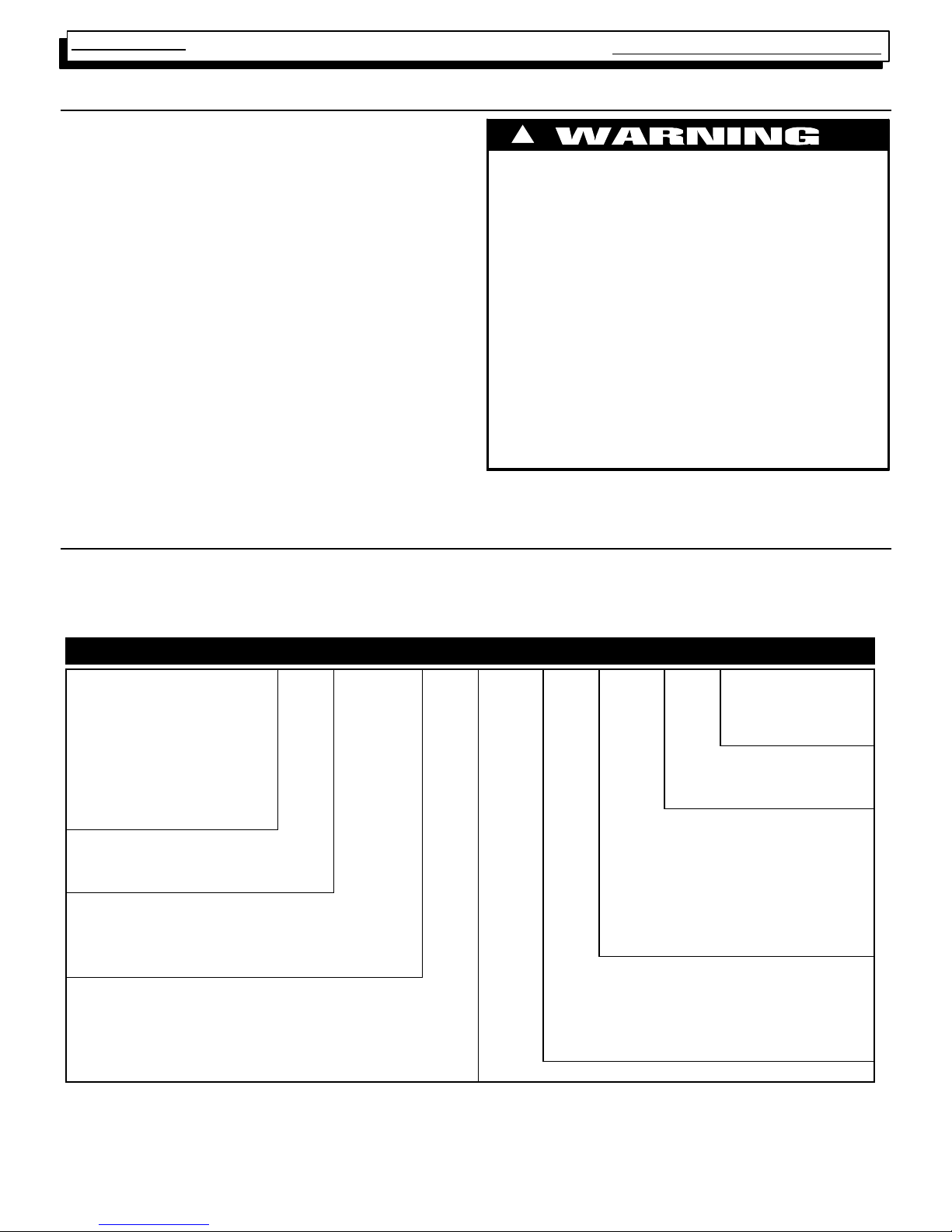

Figure 1

Gas Valve/Ignition Module

Component Locations for Four Position Furnaces

Furnace Vent Pipe

Manual Gas Valve

Vent Drain Fitting

Diagnostic Light

Combustion Air

5

Blower

/8² OD Vent Pipe

Drain Hose

3

/4² OD Transition Box

Drain Hose

Door Interlock Switch

Fan/Delay Control

Vent Pipe

Grommet

Rating Plate

Air Intake Pipe

(Dual Certified or Direct

Vent Model)

Primary Heat Exchanger

Secondary Heat Exchanger

Pressure Switch

Plastic Transition Box

Circulating Air Blower

dwg 25--23--29a

3. FURNACE THEORY OF OPERATION

The high efficiencies and lower profile (compared to previous

series) of this furnace have been obtained using design techniques not typical of traditional furnace designs. A brief description of these new design techniques and the purpose

they serve follows.

1. Reducing the height of the furnace while maintaining

the high efficiency of pervious models required maintaining the surface area of the heat exchanger and yet

minimizing the overall size.

The design required to achieve these results is the “SERPENTINE” design, wherein the flue gasses must follow a

serpent shaped passage through the heat exchanger via

convection.

This “Serpentine” path is resistive to normal convective flow,

and requires that a partial vacuum be created at the outlet

of the heat exchanger to maintain the flow of flue products

through the heat exchanger.

2. The serpentine heat exchanger design does not lend

itself well to the ribbon type, or slotted port type burner

found in more traditional design furnaces for the following reasons:

A. The secondary combustion airflows at right angles

to the burner flame, making it likely to “pull” the flame

off a ribbon or slotted port type burner.

B. The flame “height” of a ribbon or slotted port type

burner would make it difficult (if not impossible) to

prevent impingement of the flame on the heat exchanger surfaces whole maintaining the low profile

heat exchanger.

For these reasons, an “INSHOT” type burner is used in this

series. The inshot burner (also called a “jet” burner) fires a

flame straight out its end. This burner is designed to fire into

a tube style heat exchanger, making it an ideal application in

the tube--like passages of the serpentine heat exchanger.

3. In order to extract the maximum amount of heat possible from the flue gasses, a secondary heat exchanger (condenser) is connected to the outlet of the primary

heat exchanger. This condenser removes additional

heat from the flue gasses, causing their temperature to

drop below dew point. This results in the forming of

condensation (water) which then must be routed to a

drain.

4. The placement of the secondary heat exchanger at the

outlet of the primary heat exchanger creates additional

resistance to the flow of gasses.

5. To overcome the resistance to convective flow of the

Primary and Secondary heat exchangers requires the

use of an Induced Draft Combustion Blower Assembly.

3

440 08 2001 02

Page 6

Service

Manual

Single Stage Multi Position Furnace

6. The Combustion Blower Assembly is mounted on the

outlet side of the Secondary heat exchanger, This

blower creates a partial vacuum (negative pressure)

within the heat exchangers drawing the flue products

out of the furnace.

4. ELECTRICAL SUPPLY

!

Electrical shock hazard.

Turn OFF electric power at fuse box or service panel

before making any electrical connections and ensure a proper ground connection is made before

connecting line voltage.

Failure to do so can result in death, personal injury

and/or property damage.

SUPPLY CIRCUIT

The furnace cannot be expected to operate correctly unless

it is properly connected (wired) to an adequately sized (15

amp.) single branch circuit.

SUPPLY VOLTAGE

Supply voltage to the furnace should be a nominal 115 volts.

It MUST be between 97 volts and 132 volts. Supply voltage

to the furnace should be checked WITH THE FURNACE IN

OPERATION. Voltage readings outside the specified range

can be expected to cause operating problems. Their cause

MUST be investigated and corrected.

ELECTRICAL GROUND

Grounding of the electrical supply to ALL FURNACES IS

REQUIRED for safety reasons.

CHECKING GROUNDING AND POLARITY

7. A pressure switch (Air Proving Switch) is used as a

safety device that prevents the ignition system from firing the furnace until it senses that a proper draft has

been established through the furnace.

Polarity may be verified as follows:

1. Turn the power supply “ON”.

2. Using a Vo lt m e t e r check for voltage between the Hot

(Black) and Neutral (White) wire of supply circuit.

POLARITY

CORRECT POLARITY of the line voltage supply to all furnaces is also required for safety reasons.

3. Reading should be Line (Supply) Voltage.

4. Check for Voltage between the Neutral (White) wire

and Ground wire of the supply circuit.

5. Reading should be zero Volts. (if line voltage is read,

polarity is reversed)

6. A zero Volt reading indicates there is no voltage potential on Neutral wire.

7. Double check by checking for voltage between the Hot

(Black) wire and Ground wire of the supply circuit.

8. Reading should be Line (supply) Vo lt a g e.(ifzero

volts is read, there is no ground, or polarity is reversed.)

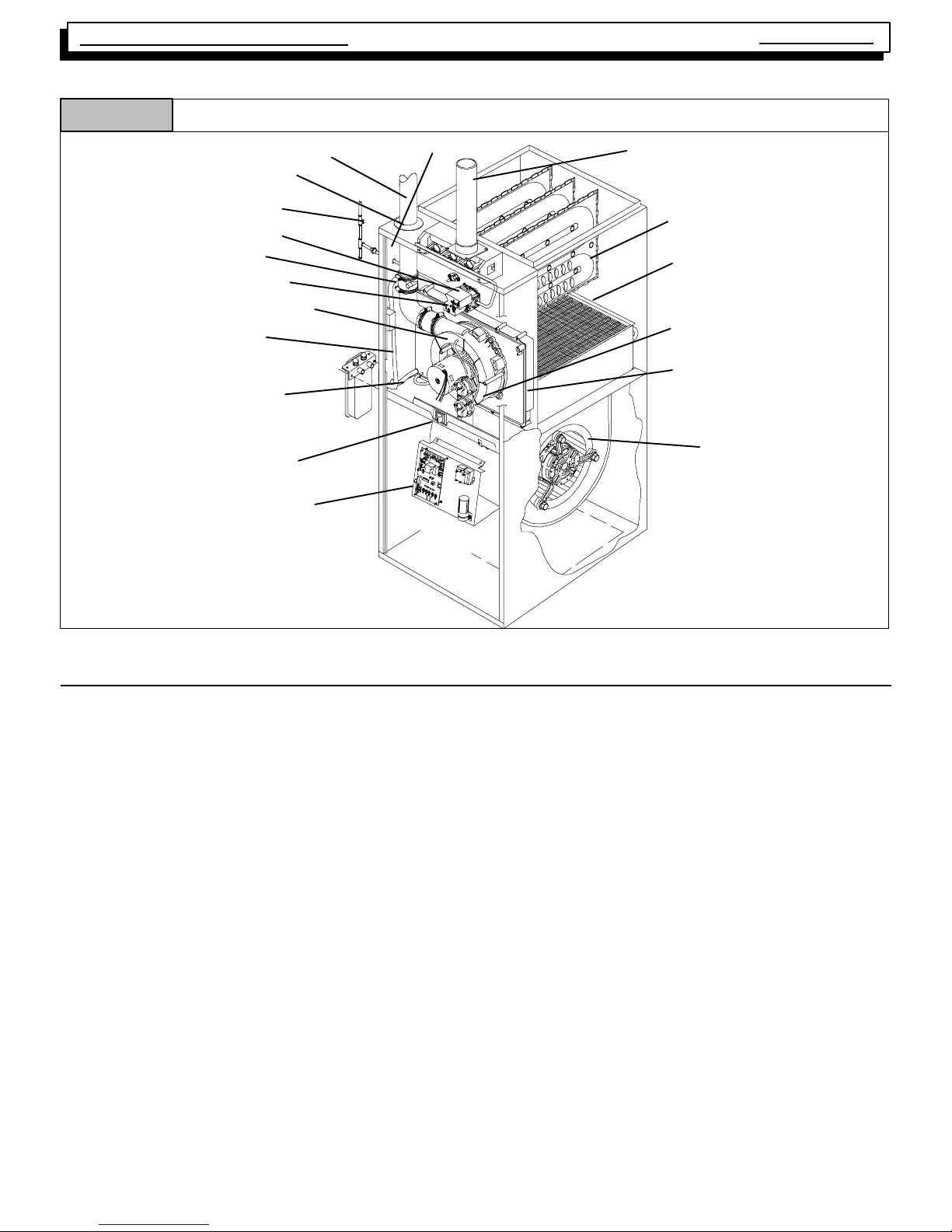

Figure 2

NOTE: Junction Box can

be mounted to either the

left or right side.

Electrical Connections

Grounding may be verified as follows:

1. Turn the power supply “OFF”.

2. Using an Ohmmeter check for continuity between the

Neutral (white) wire and Ground wire (green) of the

supply circuit.

3. With the Ohmmeter set on the R x 1 scale, the reading

should be zero Ohms.

4. A zero Ohm reading indicates that the neutral is

grounded back to the main panel.

5. An alternate check would be to check for continuity

from the Neutral to a cold water pipe, (Pipe must be

metal, and must have a continuous, uninterrupted connection to ground) or to a continuous, uninterrupted

connection to ground) or to a driven ground rod.

6. Any readings other than zero Ohms would indicate a

poor ground, or no ground.

440 08 2001 02

25--23--42

4

Page 7

Single Stage Multi Position Furnace

5. INTERLOCK SWITCH

The blower compartment door of all models is equipped with

an interlock switch. This switch is “Normally Open” (closes

when the door is on the furnace) and interrupts furnace operation when the door is open. This interlock switch is a safety device, and SHOULD NEVER BE BY--PASSED.

Since this is a single pole switch, (breaking only one side of

the line) proper line voltage is essential to insure that furnace

components are not “HOT” when switch is open. (See

Checking Grounding and Polarity)

6. GAS SUPPLY

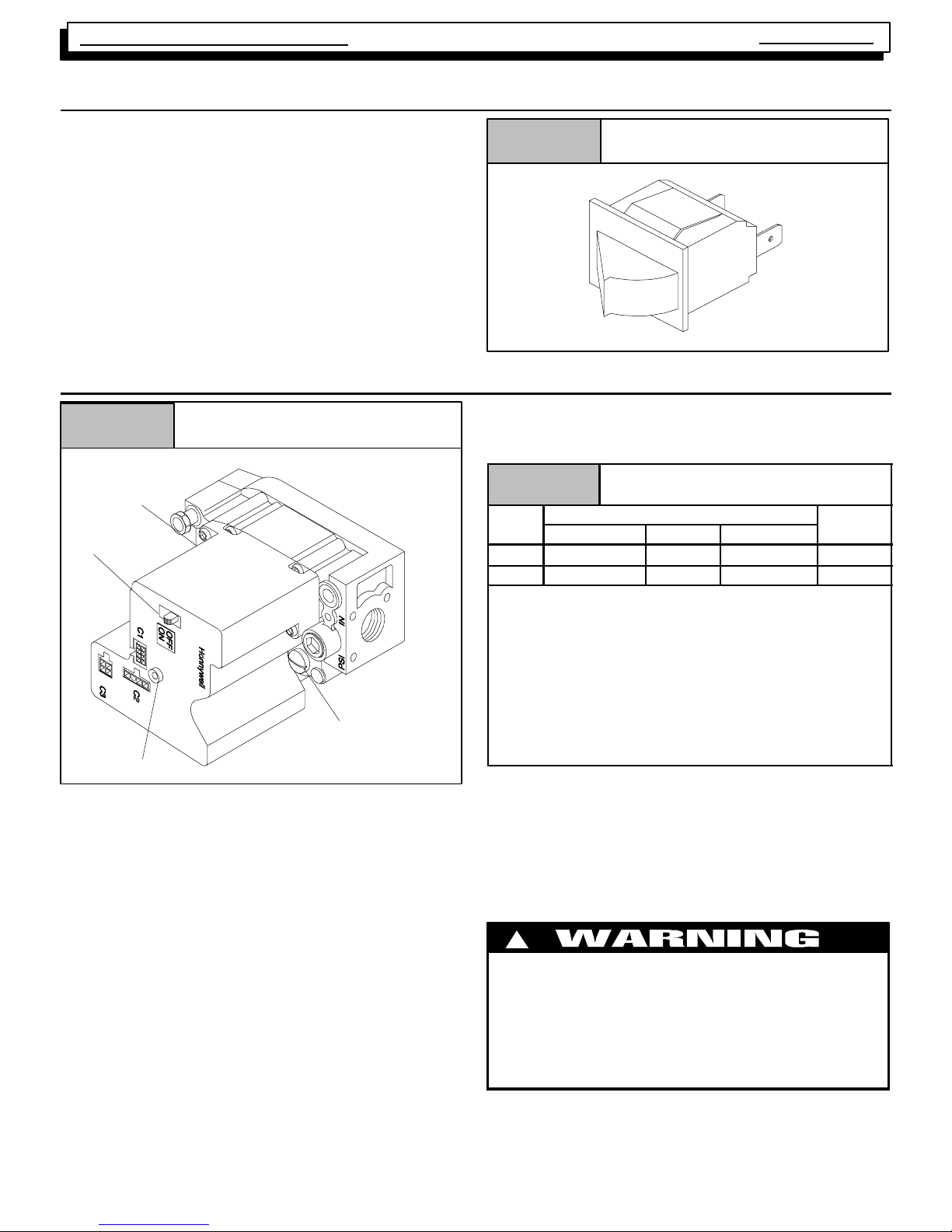

Typ ical Gas Valve HoneywellFigure 4

Pilot Pressure

Adjustment (Hid-

den)

On\Off

Switch

Diagnostic Light

An adequately sized gas supply to the furnace is required for

proper operation. Gas piping which is undersized will not

provide sufficient capacity for proper operation. Piping

should be sized in accordance with accepted industry standards.

NATURAL GAS

OUTLET

Manifold Pressure

Adjustment

dwg 25--23--31a

INLET

Manual

10--12--96

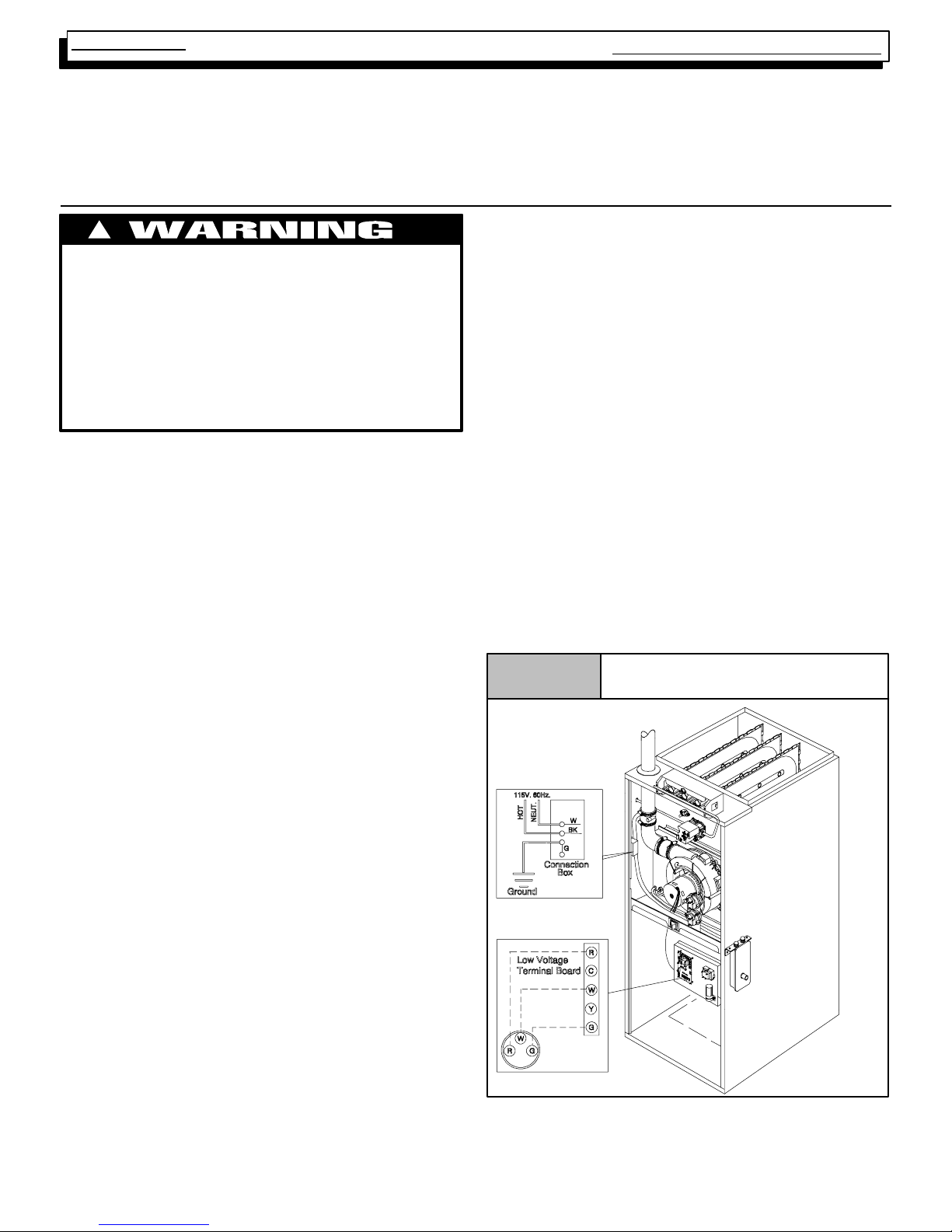

Figure 3

Service

Typical Interlock Switch

the inlet pressure MUST be a minimum of 11² W.C. If this

cannot be obtained, problems are indicated in either the regulator or pipe sizing.

Table 1 Gas Pressures Below 2000¢¢¢¢

Gas

Type

Natural 7² 14² 4.5² 3.5²

· With Propane gas, the rated input is obtained when the

· If Propane gas has a different BTU content, orifices

· Measured input can NOT exceed rated input.

· Any majorchange in gas flow requires changing burner

Recommended Max. Min.

LP 11² 14² 11² 10²

BTU content is 2,500 BTU per cubic foot and manifold

pressure set at 10²²²² W.C.

MUST be changed by licensed Propane installer.

orifice size.

Supply Pressure

Important Note:

Manifold

Pressure

CHECKING INPUT (FIRING) RATE

Once it has been determined that the gas supply is correct

to the furnace, it is necessary to check the input (firing) rate,

This can be done in two (2) ways. First by checking and adjusting (as necessary) the manifold (Outlet) pressure. The

second way is to “Clock” the gas meter.

Inlet (Supply) pressure to the furnace should be checked (at

the gas valve) with ALL OTHER GAS FIRED APPLIANCES

OPERATING. Inlet (Supply) pressure to the furnace under

these conditions MUST be a minimum of 4.5² W.C. (Water

Column). If the inlet pressure is less, it may be an indication

of undersized piping or regulator problems.

L.P. GAS

Inlet (Supply) pressure to the furnace should be checked in

the same manner as for Natural Gas, however with L.P. Gas,

!

Fire or explosion hazard.

Turn OFF gas at shut off before connecting

manometer.

Failure to turn OFF gas at shut off before

connecting manometer can result in death,

personal injury and/or property damage.

5

440 08 2001 02

Page 8

Service

H

Manual

Single Stage Multi Position Furnace

Figure 5

Pressure Connections

Typical "U" Tube

Manometer

MANIFOLD PRESSURE AND ORIFICE SIZE FOR HIGH ALTITUDE APPLICATIONS

Gas Pressure Testing Devices

3

2

1

0

1

2

3

0

INCHES OF WATER

510

MAGNEHELIC

MAX. PRESSURE 15 PSIG

15

1. Connect a manometer or Magnehelic gauge (0-- 12²

W.C. range) to the pressure tap on the “OUTLET” side

of the gas valve.

2. Turn gas “ON”, fire the furnace, and remove adjustment cover (screw--cap).

3. Turn adjustment screw clockwise (IN) to INCREASE

pressure, and counterclockwise (OUT) to DECREASE

pressure.

4. At altitudes BELOW 2,000¢¢¢¢ set manifold pressure to

3.5² W.C. for Natural Gas, and 10² W.C. for L.P. Gas.

5. For Natural Gas units ABOVE 2,000¢¢¢¢, set manifold

pressure according to TABLE 2.

6. For L.P. Gas units ABOVE 2,000¢¢¢¢, insure that orifice

size has been changed (per “National Fuel Gas Code”

-- Appendix “F”) if gas supply has not already been de-rated for altitude by the gas supplier .

7. For ALL UNITS ABOVE 8,000¢, contact the factory for

SPECIFIC de--rating information.

CHECKING MANIFOLD PRESSURE

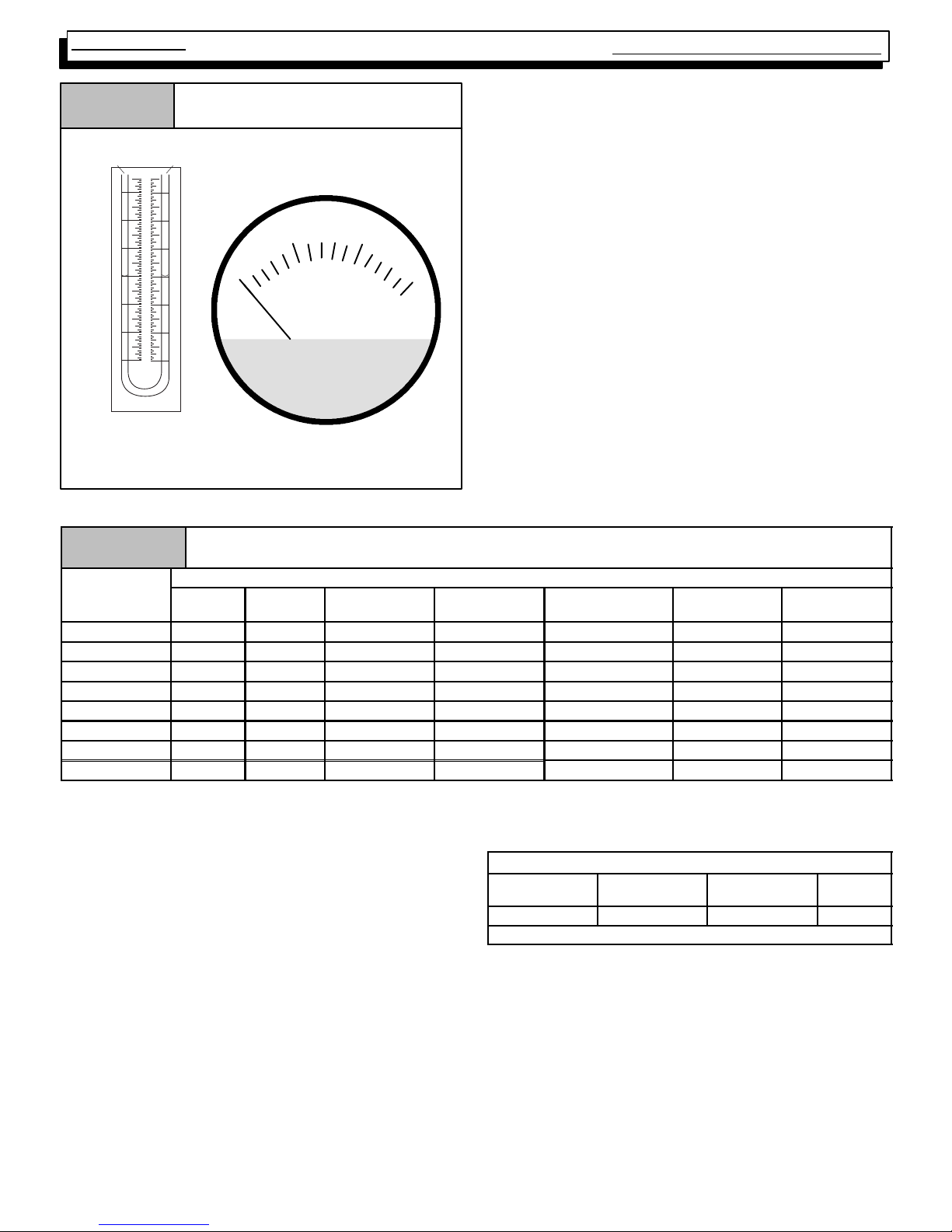

Table 2 NATURAL GAS

eatValue

Btu/Cu.Ft.

800 3.5 3.5 3.5 3.5 3.5 3.5 3.5

850 3.5 3.5 3.5 3.5 3.5 3.5 3.5

900 3.5 3.5 3.5 3.5 3.5 3.5 3.4

950 3.5 3.5 3.5 3.5 3.3 3.2 3.1

1000 3.5 3.4 3.3 3.2 3.0 2.9 2.8

1050 3.2 3.1 3.0 2.9 2.7 2.6 2.5

1100 2.9 2.8 2.7 2.6 2.5 2.4 2.3

Orifice Size #42 #42 #42 #42 #42 #42 #42

0--1999

(²²²²××××wc)

2000--2999

(²²²²××××wc)

3000--3999

(²²²²××××wc)

“CLOCKING” GAS METER (NATURAL GAS)

1. Check with gas supplier to obtain ACTUAL BTU content of gas.

2. Turn “OFF” gas supply to ALL other gas appliances.

3. Time how many seconds it takes the smallest (normally 1 cfh) dial on the gas meter to make one complete

revolution.

Elevation Above Sea Level

4000--4999

(²²²²××××wc)

5000--5999

(²²²²××××wc)

6000--6999

(²²²²××××wc)

4. Calculate input rate by using ACTUAL BTU content of

gas in formula shown in example.

Example

Natural Gas

BTU Content

1,000 3,600 48 75,000

No. of Seconds

Per Hour

1,000 x 3,600 ¸ 48 = 75,000 BTUH

Time Per Cubic

Foot in Seconds

7000--7999

(²²²²××××wc)

BTU Per

Hour

440 08 2001 02

6

Page 9

Single Stage Multi Position Furnace

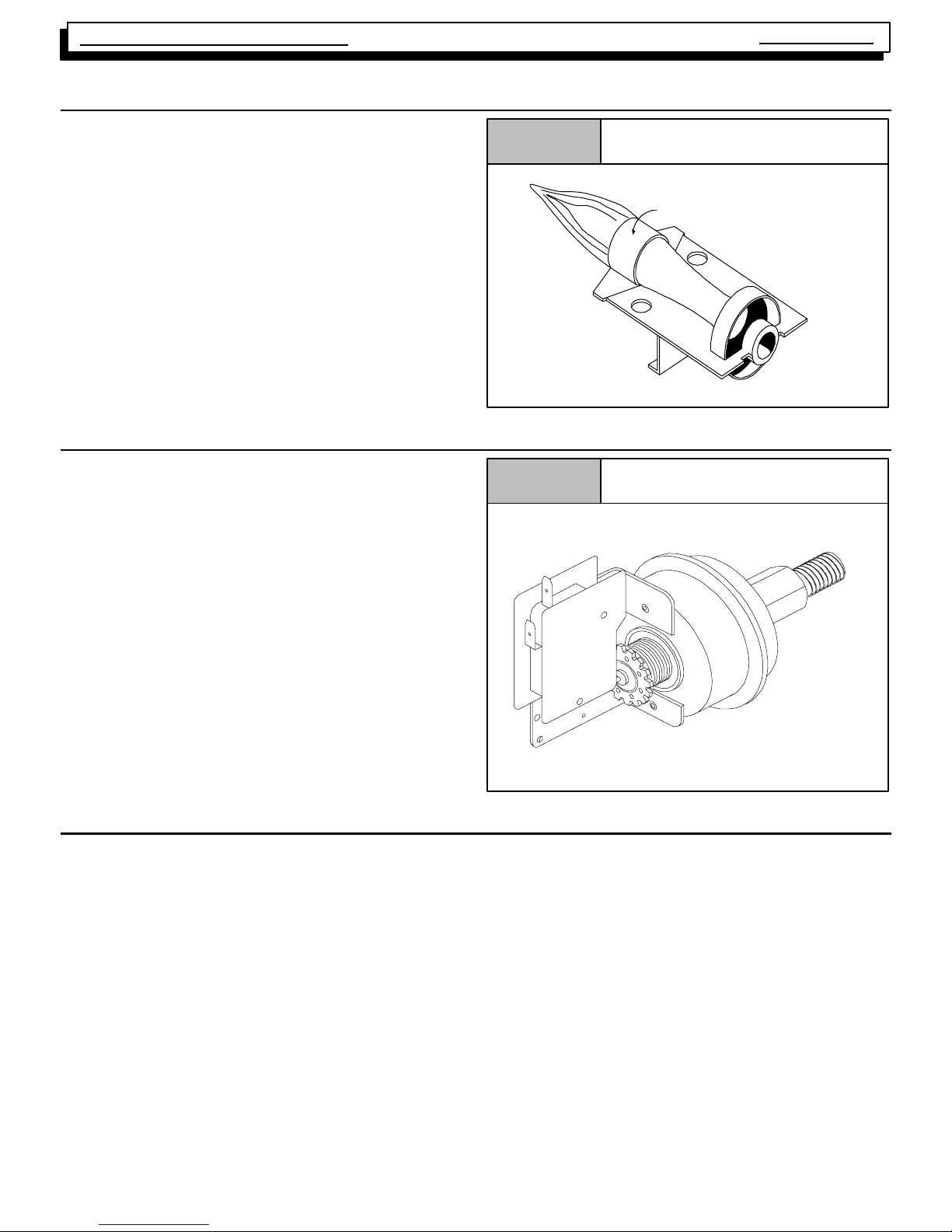

7. BURNERS

Burners used in this series of furnace are of the “INSHOT”

type. Their operation can be compared to that of a torch in

that they produce a hard, sharp, somewhat noisy flame.

Noise should not be an issue, however, because of the

closed compartment design. In order to insure that the burners are operating properly, and at their design noise level,

proper adjustment of the gas (manifold) pressure is essential. See page 6 for further information on manifold pressure

adjustments.

The burners used in this series ARE NOT EQUIPPED WITH

AIR SHUTTERS, as none are required. Proper operation

(flame characteristics) is obtained by insuring that the orifice

size, and manifold pressure are correct for the fuel being

used and the altitude of the installation.

8. L.P. PRESSURE SWITCH

Models converted to operate on L.P. Gas will be installed

with an L.P. Pressure Switch. If so equipped, the switch will

be located in the gas supply line (in a “Tee” fitting), just ahead

of the gas valve.

Figure 6

Figure 7

Service

Main Burner

Burner Face

Typical L.P . Pressure Switch

Manual

10--10--78

The purpose of this switch is to prevent furnace operating under low line (Supply) pressure conditions. Operating under

low line pressure conditions, can create problems such as incomplete combustion, flashback, sooting, etc.

The switch is a “Normally Open” pressure operated switch

that is wired in series with the furnace (vent) pressure switch.

The L.P. Pressure Switch closes when line (Supply) pressure is 8.0² W.C. or higher. the L.P. Pressure Switch Opens

if line pressure falls below 6.0²

power to the gas valve.

On some models, it is located (electrically) between the Furnace (vent) pressure switch and the gas Valve.

+

0.6² W.C. interrupting

9. HIGH ALTITUDE OPERATION

These furnaces are designed to operate in the majority of the

country without modifications. At altitudes over 2,000¢ above

sea level, however, certain measures need to be taken to insure continued, safe reliable operation. For example, units

must be de--rated for altitude (by adjusting manifold pressure and/or changing orifice size) based upon the type of fuel

(I.E. Natural Gas or L.P. gas), Btu content of the gas, and

installed altitude.

ALL UNITS must have a high altitude pressure switch

installed at altitudes above 4,000¢ above sea level.

When servicing a unit installed at altitudes above 2,000¢ insure that it has been properly modified to operate at that altitude. See the sections on Gas pressure (Page *), and pressure switches (Page **) to obtain specific information for you

particular installation altitude.

7

440 08 2001 02

Page 10

Service

Manual

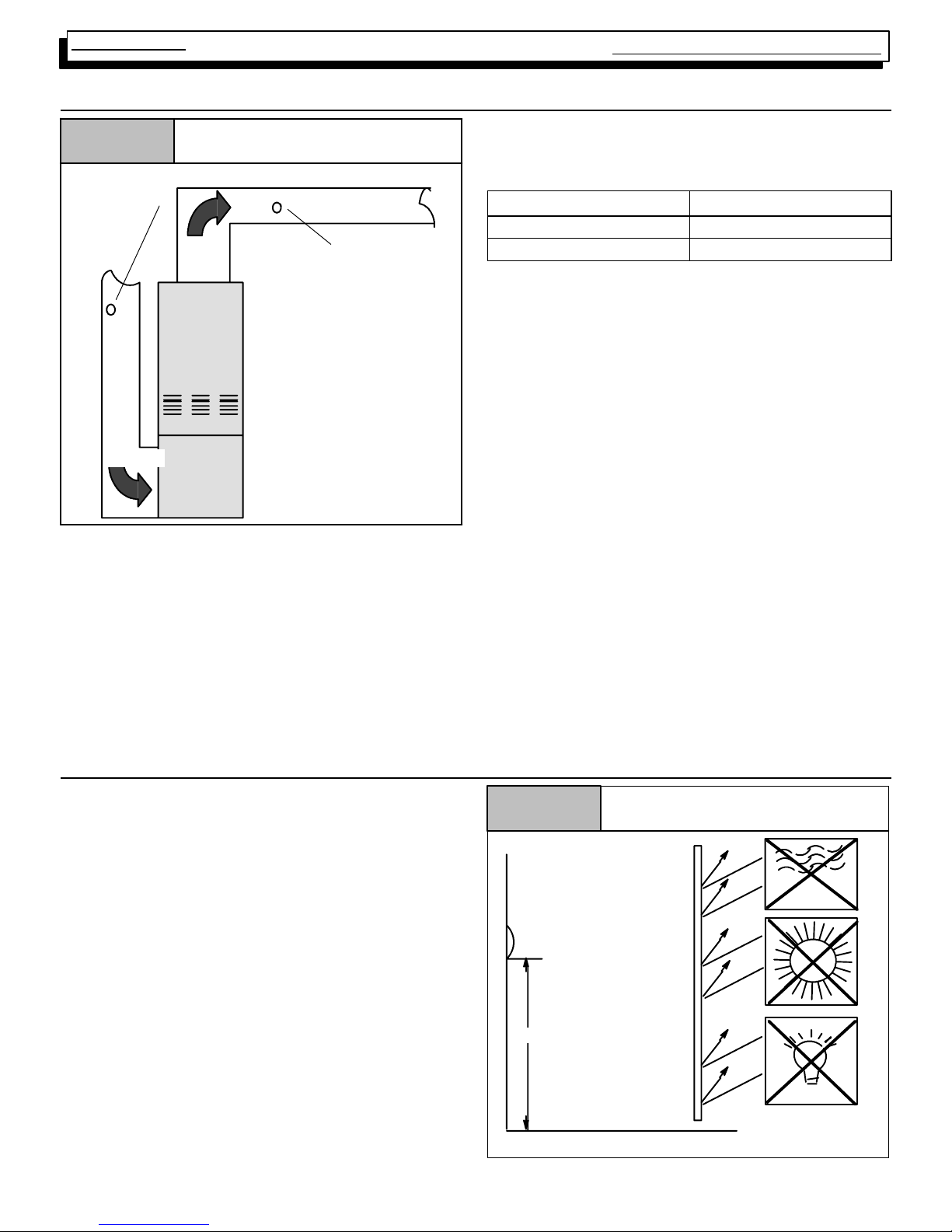

10. CHECKING TEMPERATURE RISE

Single Stage Multi Position Furnace

Figure 8

Thermometer:

Return Air Temp.

Return

Air Flow

Checking Temperature Rise

Supply

Air Flow

Thermometer;

Supply Air Temp.

The furnace is designed to operate within a certain specified

range of temperature rise.

Operating the furnace outside the specified range may result

in lower efficiency and/or comfort levels, as well as premature combustion component failures.

Simply stated, the temperature rise through the furnace is

the difference in temperature between the return air, and the

supply air.

NOTE: BEFORE CHECKING TEMPERATURE RISE BE

CERTAIN THAT MANIFOLD PRESSURE IS PROPERLY

ADJUSTED.

ALLOWABLE TEMPERATURE RISE ALL

MODELS

Model

50 Mbtu 35°F--65°F

75, 100 & 125 Mbtu 40°F--70°F

Operate the furnace for 15 minutes before taking temperature readings. Subtract the return air temperature from the

supply air temperature. The result is the temperature rise.

Compare with the allowable rise listed for the model (size)

you are checking.

Temperature Rise can be checked by placing a thermometer

in the return air duct within 6¢ of furnace. Place a second thermometer in the supply duct at lease two (2) ft. away from the

furnace. (This will prevent any false readings caused by radiation from the furnace heat exchanger) Make sure that the

FILTER IS CLEAN and that ALL REGISTERS AND/OR

DAMPERS ARE OPEN.

If the rise is not within the specified range, it will be necessary

to change the heating blower speed. If the rise is too high,

it will be necessary to increase the blower speed. If the

rise is too low, it will be necessary to reduce the blower

speed.

Example:

Supply T emp. 170

Return Temp. 70°

Temperature Rise 100° =

Too High

Solution: Increase Blower Speed

Range

°

11. ROOM THERMOSTATS

Room thermostats are available from several different

manufactures in a wide variety of styles. They range from the

very simple and inexpensive Bi--metallic type to the complex.

They are simply a switch (or series of switches) designed to

turn equipment (or components) “ON” or “OFF” at the desired conditions.

An improperly operating, or poorly located room thermostat

can be the source of perceived equipment problems. A careful check of the thermostat and wiring must be made then to

insure that it is not the source of problems.

440 08 2001 02

8

Figure 9

THERMOSTAT

5 ft.

Thermostat Location

DRAFTS

SUN

SHIELD

LIGHT

Page 11

Single Stage Multi Position Furnace

Service

Manual

LOCATION

The thermostat should not be mounted where it may be affected by drafts, discharge air from registers (hot or cold), or

heat radiated from the sun of appliances. Never install in alcoves, bathrooms or bedrooms.

The thermostat should be located about 5 ft. above the floor

in an area of average temperature, with good air circulation.

Normally, an area in close proximity to the return air grille is

the best choice.

Mercury bulb type thermostats MUST be level to control temperature accurately to the desired set--point. Electronic digital type thermostats SHOULD be level for aesthetics.

HEAT ANTICIPATORS

Heat anticipators are small resistance heaters built into most

electric--mechanical thermostats. Their purpose is to prevent wide swings in room temperature during furnace operation.

In order to accomplish this, the heat output from the anticipator must be the same regardless of the current flowing

through it. Consequently, most thermostats have an adjustment to compensate for varying current draw in the thermostat circuit.

The proper setting of heat anticipators then is important to

insure proper temperature control and customer satisfaction.

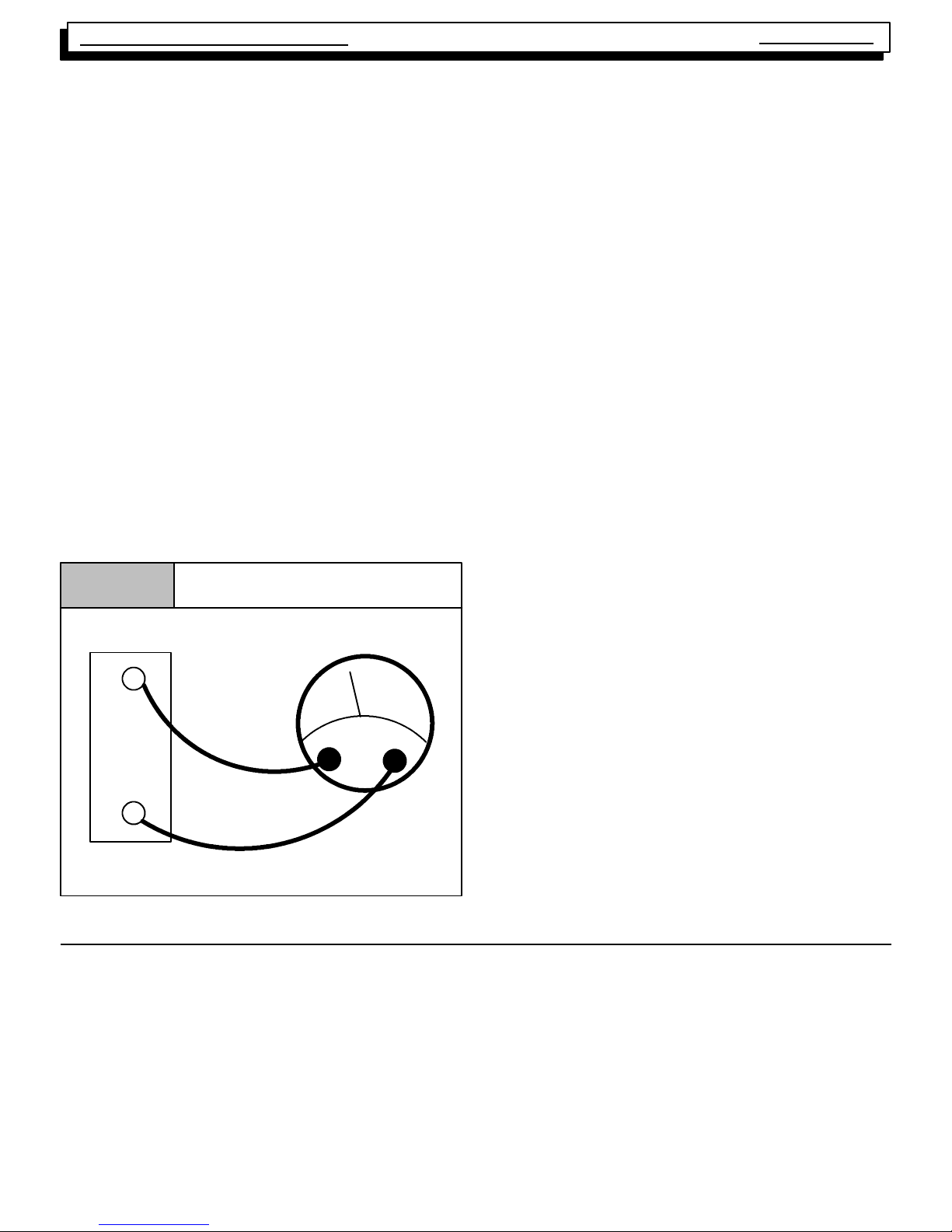

Figure 10

Measuring Current Draw

The best method to obtain the required setting for the heat

anticipator, is to measure the actual current draw in the control circuit (“W”) using a low range (0--2.0 Amps) Ammeter.

(See Figure 10) After measuring the current draw, simply

set the heat anticipator to match that value.

If a low range ammeter is not available, a “Clamp--on” type

meter may be used as follows:

1. Wrap EXACTLY ten (10) turns of wire around the jaws

of a clamp--on type ammeter.

2. Connect one end of the wire to the “W” terminal of the

thermostat sub--base, and the other to the “R” terminal.

3. Turn power on, and wait approximately 1 minute, then

read meter.

4. Divide meter reading by 10 to obtain correct anticipator

setting.

If an ammeter is not available, a setting of 0.30 amps may

be used for models equipped with the HONEYWELL

SV9541M Gas Valve/Ignition Control. They should, however, provide satisfactory operation in most cases.

Electronic thermostats do not use a resistance type anticipator. These thermostats use a microprocessor (computer)

that determines a cycle rate based on a program loaded into

it at the factory.

These cycle rates are normally field adjustable for different

types to equipment. The method of adjustment, however,

varies from one thermostat manufacturer to another. Check

with the thermostat manufacturer to find out the proper way

of adjusting the cycle rate.

W

Amps

R

Subbase

Ammeter

12. CONTROL WIRING

Control wiring is an important part of the total equipment

installation, since it provides the vital communications link

between the thermostat, and the equipment malfunctions.

Control wiring that is either too long, undersized, or improperly connected (be it simply loose, or on the wrong terminal)

can in fact be the source of many equipment problems.

ALWAYS check to make sure that the control wiring is connected to the proper terminal(s) of the equipment and thermostat you are using. Remember, also, that the thermostat

terminals are not always identified alike by different thermostat manufacturers. Connections MUST be clean and tight

to insure trouble--free operation.

For years, installers have run a wire from the “Y” terminal of

the room thermostat and connected it directly to the contact

on coil of a condensing unit. (not making any connection to

the furnace with this wiring. Then, run the low voltage “Common” wire from the condensing unit back to the “C” terminal

of the furnace.

With the HONEYWELL ST9160B electronic Fan Timer/Furnace Control, the “Y” terminal of the furnace does in fact

serve a particular purpose. Failure to connect it will result in

certain improper operation as follows:

9

440 08 2001 02

Page 12

Service

Manual

Single Stage Multi Position Furnace

The COOLING fan speed is energized via the “Y” terminal.

Failure to connect the thermostat “Y” terminal to the “Y” terminal on the control will result in the failure to energize the

13. TWINNING KITS

Some installations may require a Heating capacity or Airflow

capabilities greater than a single furnace of this series can

provide.. When this is necessary, furnaces may be installed

in a “Twinned” configuration.

The T winning Kit allows the two (2) furnaces to be controlled

by the same room thermostat. When Twinned, the circulating (conditioned air) blowers of BOTH furnaces will operate

14. LIMIT SWITCHES

Two (2) different kinds of limit switches are used on this series of furnaces. They are the main limit and roll out limit

switches. The main limit, and roll limit switches are used on

all models.

NOTE: All limit switch es are safety devices and other

than for testing purposes, should never be jumped out!

Limit switches are “normally closed” electrical switches, designed to open when their predetermined “limit setting” has

been reached.

It should also be remembered, that when a limit switch

opens, it more than likely is not due to a bad switch! The

cause of the opening limit must be found and corrected, before the furnace can resume proper operation.

COOLING speed on a call for cooling from the thermostat.

(The HEATING speed will be energized instead via the “G”

terminal)

simultaneously.

Models equipped with a HONEYWELL ST9160B series Fan

Timer/Furnace Control may be twinned using a model

NAHA003WK01 twinning kit.

To assist troubleshooting efforts of “Twinned” installations,

“TYPICAL” control wiring diagrams are provided on pages **

through **.

Maximum allowable outlet air temperature. While the main

limit is open, combustion blower, and/or the circulating blower will be energized continuously. This control is an “Automatic” reset control, which will reset itself when the temperature sensed drops to a safe level.

If furnace (burner) cycles on this limit switch, (I.E. switch

opens and closes during furnace operation) it is more than

likely due to a high temperature rise through the furnace.

(See checking temperature on page 8 of this manual)

High temperature rise can be caused by either OVER

FIRING (high manifold pressure. incorrect orifices, etc.) or

LOW AIR FLOW (dirty filter, blower speed too low, excessive

static in duct system, etc.)

!

Fire hazard.

Limit controls are factory preset and MUST NOT be

adjusted. Use ONLY manufacturer’s authorized

replacement parts.

Failure to do so can result in death, personal injury

and/or property damage.

The specific functions of the two (2) limit switches used in

this series of furnaces are as follows:

MAIN LIMIT SWITCH

A “Normally Closed” switch located on the front partition of

the furnace. It monitors supply air temperature, and interrupts furnace (burner) operation when a supply air temperature is sensed which would result in the furnace exceeding

Figure 11

Typical Limit Switch

440 08 2001 02

10

Page 13

Single Stage Multi Position Furnace

Service

Manual

To verify this, the cut--out (opening) point of the switch should

be checked (using a thermocouple type thermometer connected to the face of the switch) as follows:

1. Operate furnace for several minutes.

2. Block return air grille(s) to furnace.

3. Observe temperature at which switch opens (burner

operation ceases).

4. Remove blockage from return grille(s).

5. Observe temperature at which switch closes (burner

operation resumes).

6. Compare readings with the limit setting listed in the

appropriate chart for the model you are servicing.

If switch is opening within the specified range, then it is simply doing its job, and the cause of the over--temperature must

be determined and corrected.

If, however , the switch is found to be opening prematurely,

then it should be replaced. When replacing ANY limit switch,

use ONLY a switch of EXACTLY the same temperature setting. Use of a different temperature limit switch can create a

dangerous situation. Some of the main limit switches used

in this series are SIMILAR IN APPEARANCE. DIFFERENT

TEMPERATURE SETTINGS, HOWEVER, ARE USED for

different models. Be certain you have the correct control for

the model you are servicing.

ROLL OUT LIMIT

A “Normally Closed” switch (wired in series with the Main

Limit switch) mounted on the burner box.

This switch may be of the manual type, depending upon the

particular model and/or family. Different temperature

(OPENING) settings are also used on different models.

When replacing this switch, be absolutely certain the correct

one is used.

The roll out switch monitors the temperature inside the burner box, and interrupts furnace (burner) operation when its

temperature indicates flame roll out has occurred.

If the roll out switch has opened, the cause must be determined. Some possible reasons for flame roll out include a restricted primary or secondary heat exchanger or over fired

furnace.

MANUAL RESET SWITCH MODELS

Furnace models which are equipped with a Honeywell

ST9160 Fan timer/furnace control use a manual reset roll out

switch. Once the roll out switch has opened, burner operation will be prevented until the roll out switch is “Manually Reset” by pressing the red button located on the switch. While

the roll out switch is open, (Depending upon the particular

model) the combustion blower and/or circulating blower will

be energized continuously.

AUXILIARY LIMIT SWITCHES

All models are equipped with one (1) additional (AUXILIARY)

limit switch mounted on the blower deck. Its purpose is to

monitor return air temperature, and interrupt burner operation when a temperature is sensed which could result in the

filter surface(s) exceeding allowable temperatures. Depending upon the particular model, the combustion blower, and/or

circulating blower may be energized continuously while the

auxiliary limit switch remains open.

This control is an “Automatic” reset control which will reset

itself when the temperature drops to a safe level. See the

Tech. Service Data Sheet for the model you are servicing, to

obtain its specific auxiliary limit switch setting.

Figure 12

Typical Roll Out Limit Switch

CAUTION

NEVER use an automatic reset roll out switch to replace

a manual reset type roll out switch.

Doing so may cause potentially unsafe and/or intermittent operation.

11

440 08 2001 02

Page 14

Service

²

W.C

1

8+0.1

0

W.C

Manual

15. PRESSURE SWITCHES

Single Stage Multi Position Furnace

Transition Pressure Switch

This switch is designed to monitor a blockage of the condensate drain line. It uses a single tap (port) “Normally Open”

pressure switch (wired in series with the furnace air proving

(pressure) switch. The switch “Closes” at a (negative) pressure setting for the switch associated with that particular

model furnace (See unit specitications).

Under normal operating conditions, sufficient pressure is developed by the exhaust (combustion) blower to close the

switch, and permit the burner to operate. As the condensate

drain begins to back--up, however, the pressure begins to reduce. When the pressure drops sufficiently, burner operation

will be prevented until the condition is corrected.

Blower Pressure Switch

An air proving switch (pressure switch) is used on all models

to insure that a draft has been established through the heat

exchanger before allowing burner operation.

To insure continued SAFE, RELIABLE, operation, NEVER

SUBSTITUTE a pressure switch with one that is similar in

appearance. ONLY FACTORY PROVIDED or

AUTHORIZED SUBSTITUTES ARE ACCEPTABLE.

All models installed at altitudes of 4,000¢ above sea level or

higher require replacing the standard pressure switch with a

high altitude pressure switch. The different pressure switch

settings allow continued SAFE, RELIABLE, high altitude

operation.

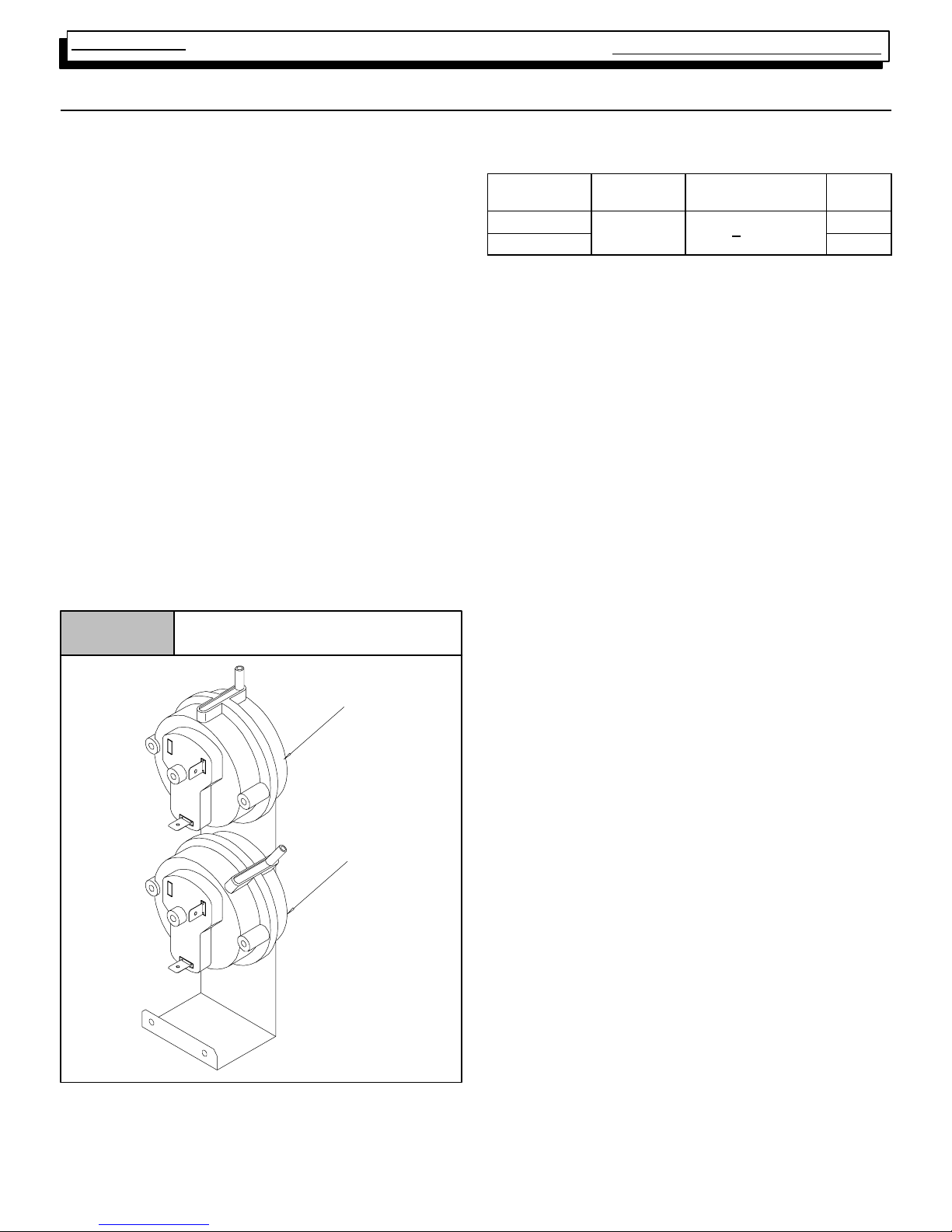

Figure 13

Pressure Switches

Blower

Transition

HIGH ALTITUDE PRESSURE SWITCHES - ALL

MODELS

--1.40

Max.

Close

²

Open Part #

--

--1.

.

²

--

.

Model

Upflow

Downflow

CHECK CURRENT TECHNICAL SUPPORT MANUAL

FOR PART NOS.

Under normal operating conditions, sufficient negative pressure will be created to close the pressure switch, and keep

it closed to keep furnace operating. Under abnormal conditions, however, such as a restricted vent pipe, or a leak in one

of the heat exchangers, sufficient negative pressure will not

be created. This will result in the switch failing to close or failing to remain closed during furnace operation.

When servicing a unit whose pressure switch will not close,

or remain closed during operation, the operating pressure of

that furnace should be checked and compared to

approximate operating pressures listed in Tab le 3 and the

switch setting(s) listed above for the model family you are

servicing.

It is important to remember, that greater negative pressures

are created by the furnace when “HOT” (I.E. upon initial

start--up) than when “COLD” (I.E. after furnaces has been in

operation for a few minutes). Because of this, furnace pressure should ONLY be checked when “HOT” to insure accurate readings.

Tab l e 3 lists approximate operating pressures for Direct

Vent (I.E. Two Pipe) installations of models in this series.

They were obtained in a test lab, under controlled conditions

using two (2) specific vent lengths. They are included in this

manual to provide you with a “Barometer” to gauge our pressures against. The pressures you obtain in the field will differ

slightly from these figures based upon vent length, gas pressure, operating temperature, etc.

Major discrepancies in pressures, will normally cause

problems with pressure switch operation. These Major discrepancies should be investigated as follows:

25--23--72

440 08 2001 02

12

Page 15

Single Stage Multi Position Furnace

0Mb

M

b

100Mb

1

25M

b

Tab l e 3 APPROXIMATE OPERATING PRESSURES (²²²² OF W.C.)

Model Vent Length @Blower @ Transition

5

75

tu

tu

tu

tu

Short -- (5¢ No. Elbows) --1.80 --2.60

Long -- (40¢ +590° Elbows) --1.30 --2.30

Short -- (5¢ No. Elbows) --1.80 --2.60

Long -- (40¢ +590° Elbows) --1.30 --2.30

Short -- (5¢ No. Elbows) --1.80 --2.60

Long -- (40¢ +590° Elbows) --1.70 --2.50

Short -- (5¢ No. Elbows) --1.80 --2.60

Long -- (40¢ +590° Elbows) --1.70 --2.50

Service

Manual

Lower (Lesser) Negative Pressures

Lower than normal negative pressures measured at the

Combustion Blower may be caused by:

1. Restriction on the Outlet side of the combustion blower. (I.E. Blocked Flue, Vent too long, Heat Exchanger

leak, etc.)

2. Leak (lack of restriction) on the Inlet side of the combustion blower.

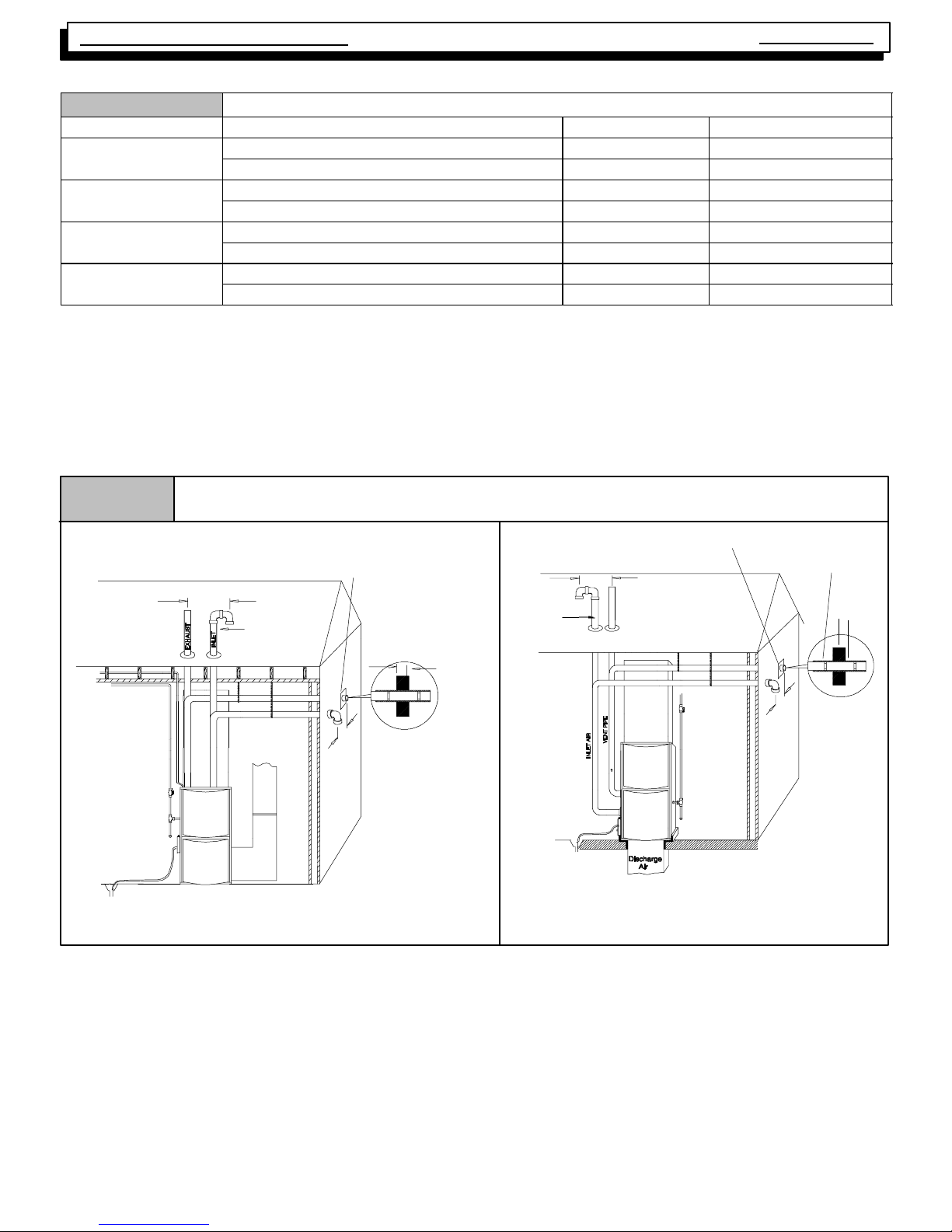

Figure 14

UPFLOW

*8²²²² Min.

20¢¢¢¢ Max.

in same

atmospheric zone

Vent Pipes MUST be

supported Horizontal-

ly and Vertically

Typical Vent/Combustion Air Piping Installation

Aluminum or non--rusting shield recommended.

(See Vent Termination Shielding for dimensions).

Inlet Pipe

(not used

on

Single Pipe

models)

DISCHARGE AIR

Coupling on ends of exhaust pipe. Total pipe &

coupling outside structure = 8²²²²

*8²²²² Min.

20¢¢¢¢ Max.

in same atmospheric zone

Higher (Greater) Negative Pressures

Higher than normal negative pressures measured at the

Combustion Blower may be caused by:

1. Restriction on the Inlet side of the combustion blower.

(I.E. Plugged Heat Exchanger, air inlet orifice too

small)

DOWNFLOW

Inlet Pipe

(not used on

Single Pipe

models)

Vent Pipes MUST

be supported

Horizontally and

Vertically

See Vent Termination Shielding

in Vent Section.

*8²²²² Min.

20¢¢¢¢ Max.

in same

atmospheric

zone

Coupling on inside

and outside of wall to

restrain vent pipe

8² Min.

*8²²²² Min.

20¢¢¢¢ Max.

in same

atmospheric zone

* Increase minimum from 8²

0 °°°° F).

² to 18²²²² for cold climates (sustained temperatures below

²²

25--23--33

13

* Increase minimum from 8²²²² to 18²²²² for cold climates (sustained temperatures

below 0°°°°F).

25--23--33a

440 08 2001 02

Page 16

Service

Manual

16. VENT/COMBUSTION AIR PIPING

Single Stage Multi Position Furnace

Vent and combustion air piping are an extremely important

part of the total furnace installation. Improperly installed or

inadequately sized vent and/or combustion air piping can be

the source of many perceived furnace problems.

For example, most problems associated with pressure

switch operation can normally be traced to short comings in

the vent and/or combustion air piping. Anytime these type

problems arise, a thorough inspection of the vent and/or

combustion air piping should be conducted.

ALL MODELS require a vent (exhaust) pipe to carry flue

17. STANDARD VENT TERMINATION

Vent/Combustion Air Piping Charts

Dual Certified Models ONLY - Non- Direct Vent

Installation

Single Piping Chart

Tab l e 4

50,000 & 75,000 Btuh Furnaces

40¢ & (5) 90° elbows with 2² PVC pipe or

70¢ & (5) 90° elbows with 3² PVC pipe or

70¢ & (5) 90° elbows with 3² PVC pipe

40¢ & (5) 90° elbows with 3² PVC pipe

Elbows are DWVLong Radius Type for 2² and

3² vents.

If more than five elbows are required,reduce the length of both

the inlet and exhaust pipes 5¢ for each additional elbow used.

NOTE: It is allowable to use larger diameter pipe and fitting than

shown in the tables but not smaller diameters than shown.

All Series (Models) - Direct Vent Installation

Tab l e 5

50,000 & 75,000 Btuh Furnaces

40¢ & (5) 90° elbows with 2² PVC pipe or

70¢ & (5) 90° elbows with 3² PVC pipe or

70¢ & (5) 90° elbows with 3² PVC pipe

40¢ & (5) 90° elbows with 3² PVC pipe

Elbows are DWVLong Radius Type for 2² and

3

² ven ts.

Pipe Diameter Table

Single Piping ONLY

100,000 Btuh Furnace

125,000 Btuh Furnace

Dual Piping Chart

Pipe Diameter Table

Dual Piping ONLY

100,000 Btuh Furnace

125,000 Btuh Furnace

products to the outside of the structure.

Direct VENT (ONLY) models require a combustion air inlet

to bring in all air for combustion from outside the structure.

DUAL CERTIFIED models require a combustion air inlet

pipe to bring in all air for combustion from outside the structure only when installed as a Direct Vent Furnace (I.E. Two

Pipe Installation)

Consult the appropriate Venting tables and/or piping chart

for the model (series) you are servicing.

If more than five elbows are required,reduce the length of both

the inlet and exhaust pipes 5¢ (1.5m) for each additional elbow

used.

* Feet of pipe is whichever pipe run is the longest, eitherinlet or

outlet side.

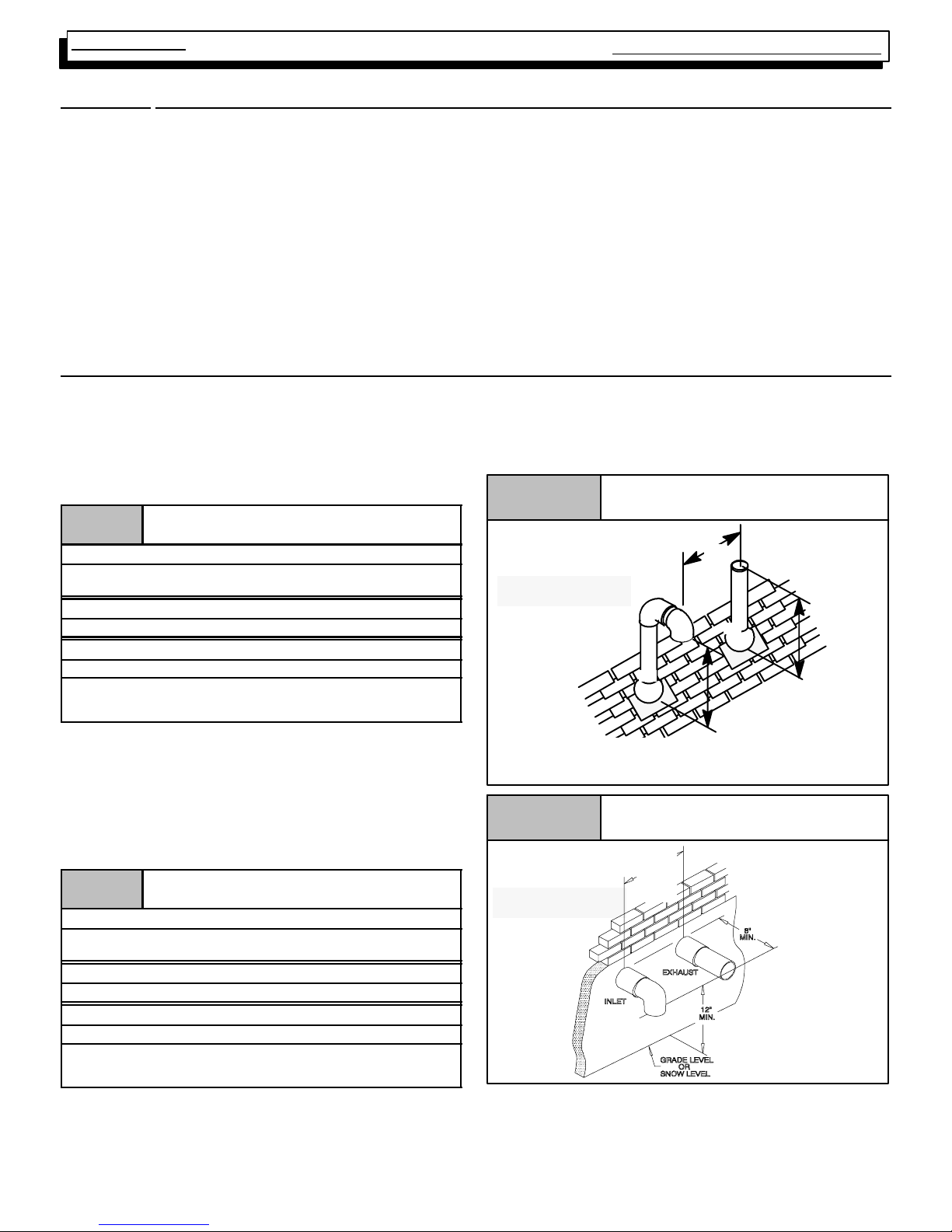

Figure 15

Inlet is optional on

Dual Certified models

A=12² Above roof or snow accumulation level

B=8² Min., 20¢ Maximum, except in areas with extreme cold

temperatures (sustained below 0°F), the 18² Min.

Figure 16

Inlet is optional on

Dual Certified models

Standard Termination

Rooftop Termination

B

A

A

25--00--06

Sidewall Termination12² or More

Above Snow Level or Grade Level

8²²²² *

MIN.

20’

MAX

*18² Minimum for cold climates

(substained below 0° F)

25--00--05F

440 08 2001 02

14

Page 17

Single Stage Multi Position Furnace

Service

Manual

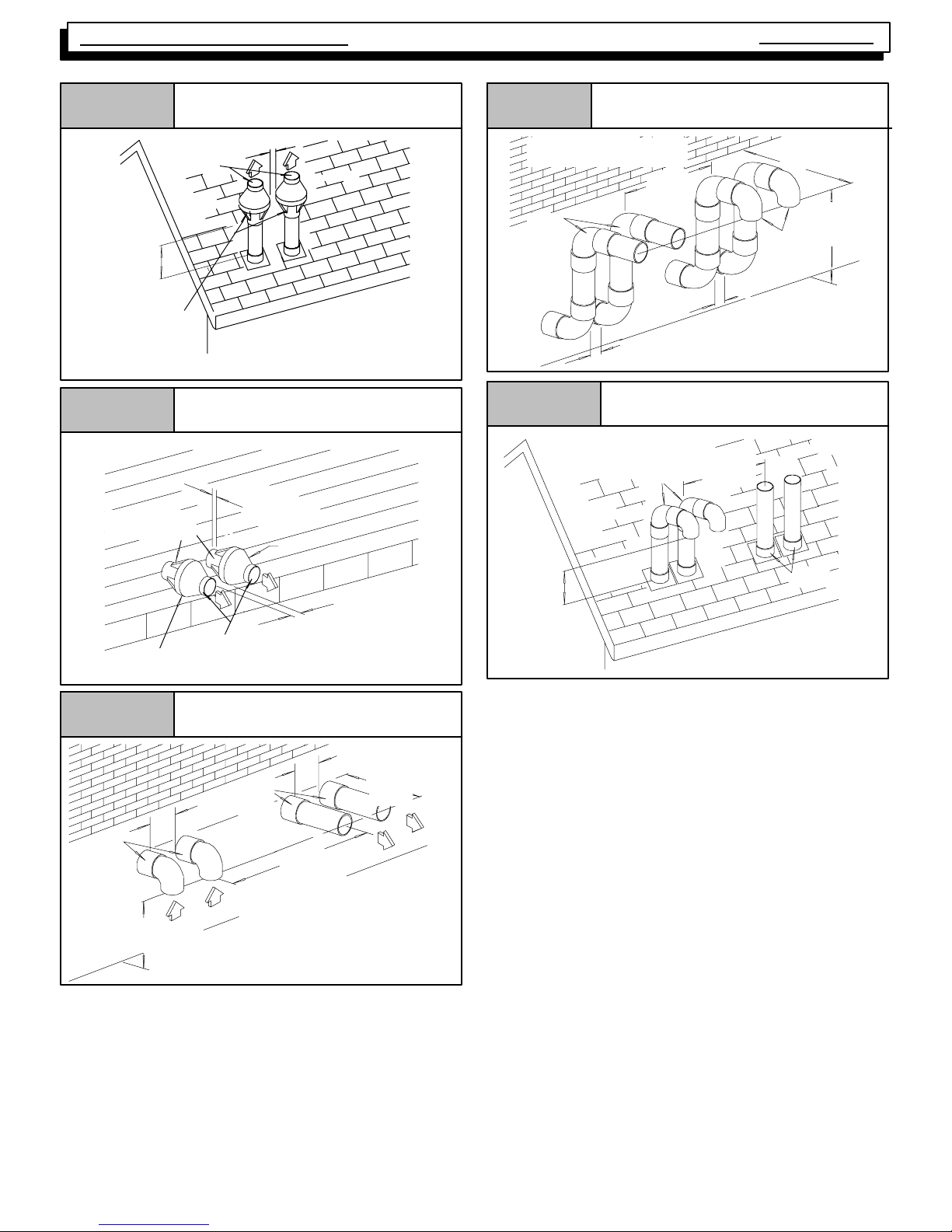

Figure 17

12²²²² Min.

Grade or

Snow Level

Dimension “A” is touching or 2² maximum separation.

Figure 18

Combustion

Concentric Vent and Combustion-

Air Roof Termination

Exhaust

Combustion

Air

Concentric Vent and Combustion-Air Sidewall Termination

Air

“A”

1²²²² Maximum

(TYP.)

Ven t

Figure 20

18²²²² Min. for Cold Climates

(Sustained Below 0°°°° F)

Exhaust

Figure 21

18²²²² Min. for Cold Climates

(Sustained Below 0°°°° F)

Sidewall Inlet Vent and Exhaust--Air

Termination with Exterior Risers

8²²²²

Inlet

Min.

12²²²² Min.

Grade or

Snow Level

8²²²² Min.

20¢¢¢¢ Max.

“A”

“A”

Dimension “A” is touching or 2² maximum separation.

Rooftop Inlet Vent and Exhaust--Air

Termination

Inlet

8²²²² Min.

20¢¢¢¢ Max.

Dimension “A” is touching or 2² maximum separation.

Figure 19

Inlet

12²²²² Min. Grade

or Snow Level

“A”

Ven t

Exhaust

25-- 22- -02d

Sidewall Inlet Vent and Exhaust--Air

Termination

“A”

Ex-

haust

“A”

8²²²² Min.

20¢¢¢¢ Max.

18²²²² Min. for

Cold Climates

(Sustained Below 0°°°° F)

Dimension “A” is touching or 2² maximum separation.

8²²²²

Min.

12²²²² Min.

Grade or

Snow Level

Exhaust

25-- 22- -43

15

440 08 2001 02

Page 18

Service

Manual

Single Stage Multi Position Furnace

Figure 22

FRONT VIEW

Recommended Alternate Installation for Sustained Cold Weather

(--0°°°° F & below)

OVERHANG

12²²²² MIN.

EXHAUST

90°°°°

INLET

12² MIN. Ground

Level

OR Snow Level

SIDE VIEW

12²

25--23--73

Same Joist

Space

18. CONCENTRIC VENT TERMINATION

Vent/Combustion Air Piping Charts

Concentric Termination Kit NAHA001CV

Tab l e 6

NAHA002CV -- 35¢ & (4) 90° elbows with 2² PVC pipe

NAHA001CV -- 65¢ & (4) 90° elbows with 3² PVC pipe

NAHA001CV -- 65¢ & (4) 90° elbows with 3² PVC pipe

NAHA001CV -- 35¢ & (4) 90° elbows with 3² PVC pipe

1. Do not include the field supplied 45° elbow in the total

elbow count.

2. If more than four elbows are required, reduce the length of

both the inlet and the exhaust pipes five feet for each

additional elbow used.

3. Elbows are DWV long radius type for 2² and 3² vents.

& NAHA002VC Venting Table Dual Piping

ONLY

50,000 & 75,000 Btuh Furnaces

100,000 Btuh Furnace

125,000 Btuh Furnace

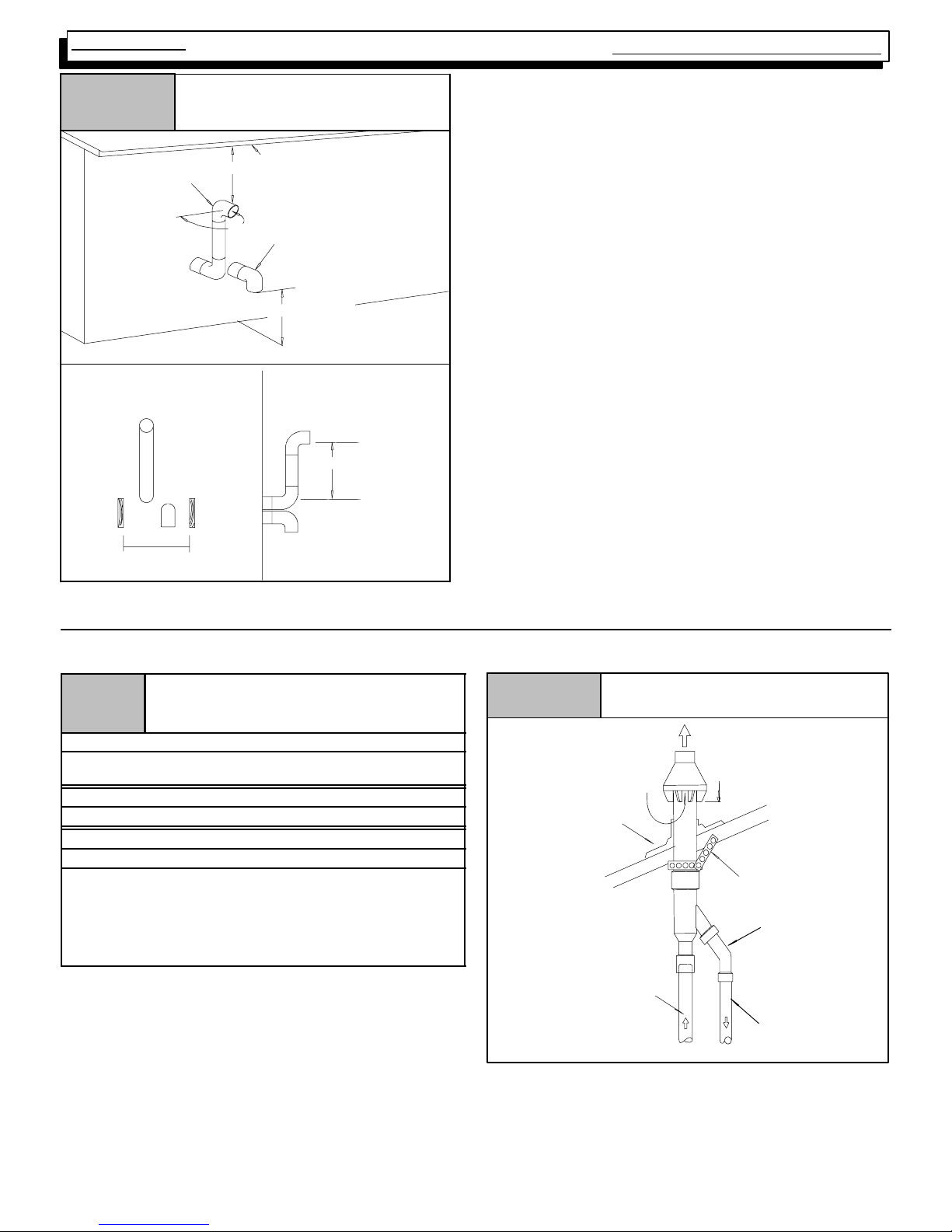

Figure 23

Roof Boot/

Flashing

(Field Supplied)

Concentric Vent Roof Installation

Vent

Combustion

Air

Vent

Maintain 12² min. clearance

above highest anticipated

snow level. Max. of 24² above

roof.

Support

(Field Supplied)

45° Elbow

(Field Supplied)

440 08 2001 02

Note:

Support must be field installed to secure termination kit to structure.

16

Combustion Air

25--22--02

Page 19

Single Stage Multi Position Furnace

Service

Manual

Figure 24

3² x2² Bushings or

1

3² x2

/2² Bushings

If 3² vent not used

(Field supplied)

Vent

Combustion

Air

Note:

Securing strap must be field installed to prevent movement of termination kit

in side wall.

Concentric Vent Sidewall

Attachment

Strap

(Field Supplied)

45° Elbow

(Field Supplied)

Combustion

Air

Vent

Flush to

1² max.

25--22--02

19. EXHAUST BLOWER

Figure 25

Rubber Coupling

&Clamps

Exhaust Blower

Vent Pipe

(Top Panel Exit)

11²²²² Section PVC pipe

Vent Fitting

90°°°° Street

Elbow

Vent Pipe

(Side Panel EXit)

DRAIN SIDE VIEW

Rotate downward

20°°°° to 30°°°°

&Clamps

Combustion

Blower

25--23--35

20. CONDENSATE DRAIN TRAP

The removal of additional heat from the flue products which

takes place in the secondary heat exchanger (condenser)

causes them to drop below their dew point resulting in condensation. This condensation (water) then must be drained

from the furnace, and routed to a remote drain, or condensate pump.

The combustion blower creates a negative pressure in excess of 2² W.C. while operating. Without a condensate drain

trap of sufficient depth, condensate would be held in the furnace, (because of this negative pressure), and not be able

to drain. Figure 26 shows the transition assembly, which is

mounted between the combustion blower and the front partition.

The condensate drain trap supplied with the furnace MUST

be used. The drain line between the condensate drain trap

and the drain location must be constructed of

3

/4² PVC or

CPVC pipe.

In standard Upflow, Counterflow and/or horizontal

installations, the external drain trap provides sufficient

depth (4²) to insure proper drainage of condensate from the

furnace. Additional traps are NOT required, and should NOT

be used. The use of additional traps will PREVENT proper

drainage of condensate from the furnace. Care should be

taken with the routing of the condensate drain hose, to eliminate all dips or sagging tubing which can create another trap,

and cause drainage problems.

17

440 08 2001 02

Page 20

Service

Manual

Single Stage Multi Position Furnace

Figure 26 (Transition Assembly)

25--23--62

NOTE: The vent fitting MUST be installed with the airflow marking

arrow pointed toward the vent pipe, with the drain stub at a 20°

downward slope.(See Figure 27)

Floats and/or condensate sensors are NOT used in the drain

trap. If the drain line becomes clogged, the condensate level

will rise higher in the external trap. When the level rises sufficiently, the furnace will begin to “Cycle” (On and Off) on the

pressure switch. If the condensate level rises high enough

in the trap, the pressure switch may not close at all, and water may be heard “Paddling” inside the combustion blower.

Figure 27

Vent Drain

Connection

Condensate Drain Trap

Vent Pipe

(Side panel exit)

Drain Line

NEW

Vent Drain

(hidden)

Transition

Box Drain

OLD

25--23--63

21. HONEYWELL ST9160B Series FAN TIMER/FURNACE CONTROL

The Honeywell ST9160B Electronic Fan Timer/Furnace

Control contains NO USER SERVICEABLE COMPONENTS. It is, as its name implies, a fan timer and a furnace control of sorts. In addition to controlling the fan operation for heating, it also takes the place of the blower relay, the

combustion air relay and/or the system relay.

The ST9160B is used in models equipped with the SV9541M

GAS VALVE/IGNITION CONT ROL. It provides the power

source to begin the ignition sequence through a monitored

safety circuit. It also serves as a low voltage terminal strip.

Accessory terminals for connecting a Humidifier and/or

Electronic Air cleaner are also provided, as well as a Continuous fan terminal which allows for continuous fan operation

at a speed other than either the heating or cooling speed.

The control provides a fixed (non--adjustable) 60 second

“ON” and 60 second “OFF” delay for the circulating blower

in COOLING and a 30 second “ON” delay for the circulating

blower in HEATING.

The ST9160B control also provides an adjustable HEATING

“OFF” delay for the circulating blower which can be field adjusted to 60, 100, 140, or 180 seconds.

Figure 28

FUSE

Honeywell ST9160B

Dip

Switch

25--23--63

440 08 2001 02

18

Page 21

Single Stage Multi Position Furnace

Service

Manual

Figure 29

Heating “OFF” Delay DIP switch

Setting

COOL ON DELAY: 6 SEC.

COOL OFF DELAY: 60 SEC.

HEAT ON DELAY: 30 SEC.

25--23--47

22. ST9160B TESTING SEQUENCE

If furnace successfully passes this testing sequence, it can

be assumed that there are no problems with the ST9160B

FAN TIMER/FURNACE CONTROL. If it does not, however,

it does not necessarily mean that there are problems with the

control. Any malfunctions should be thoroughly investigated

before replacing and components.

CHECKING COOLING FUNCTIONS

1. JUMPER “Y” & “G” TO “R”

2. CHECK COOLING FAN DELAY “ON”

3. CHECK COOLING SPEED FAN OPERATION

4. REMOVE JUMPER

5. CHECK COOLING FAN “OFF” DELAY

Setting “OFF” and “ON”

Setting the ST9160B Heating Fan “OFF” Delay is accomplished by the positioning of “DIP” switches. The label on the

back of the furnace door indicates how to position these

switches to obtain the desired setting. (See Figure 29)

The ST9160B Heating “OFF” delay can be set to (60. 100,

140, or 180). The control was shipped out in the 140 position.

This may be satisfactory for some installations, but not for

others.

The Heating “ON” delay is fixed at 30 seconds is not ad -

justable.

The “OFF” delay should be set as long as possible without

creating “COLD AIR” complaints at the end of the cycle.

Troubleshooting

The operation of the HONEYWELL ST9160B series FAN

TIMER/FURNACE CONTROL (as well as the operation of

the furnace in general) can be verified in a few minutes by

using two (2) jumper wires (to jumper terminals of the low

voltage terminal strip) and the “TEST SEQUENCE” below.

CHECKING HEA TING FUNCTIONS

1. JUMPER “W” TO “R”

2. CHECK COMBUSTION BLOWER START--UP

3. CHECK IGNITION SYSTEM ACTIVATION

4. WHEN MAIN BURNER LIGHTS, CHECK HEATING

FAN “ON” DELAY

5. CHECK HEATING SPEED FAN OPERATION

6. REMOVE JUMPER

7. CHECK POST PURGE DELAY

8. CHECK HEATING FAN “OFF” DELAY

23. ST9160B - UNIQUE CONTROL FUNCTIONS/RESPONSES

There are some unique responses from these controls that

differ from what one would normally expect, and may be

somewhat confusing. (See Figure 28) Specifically, these

are as follows:

Energizing the “G” terminal of this control will cause the blower to run on the HEA TING speed. (With most other furnaces,

the blower relay is energized via the “G” terminal normally

causing the blower to run on the cooling speed.)

Energizing the “G” & “Y” terminals (together) will cause the

blower to run on the COOLING speed. It is important that you

take note of this, since control wiring improperly connected

can cause perceived as well as real equipment problems.

For example, in the past, the “Y” terminal in nearly all furnaces was simply a binding post. There was no electrical

connection between this terminal and the rest of the furnace.

Consequently, many installers would not use this terminal to

connect the “Y” signal from the thermostat, but would run it

directly from the thermostat to the condensing unit, the run

the “Common” signal back to the furnace “C” terminal.

This method of wiring will result in improper operation from

this control. The control MUST receive a “Y” signal in order

for it to energize the “COOL” terminal, bringing on the blower

in the cooling speed. If it is wired as above, the condensing

unit will come on, but the blower will run on the HEATING

speed.

“NO TERMINALS” ENERGIZED (on low voltage terminal

strip) -- If a speed tap wire has been connected to the

“CONT.” (continuous) terminal, (operational terminal provided on the ST9160B series controls) the blower will run on

this speed. Maximum allowable connected load for this terminal is 8.0 FLA.

19

440 08 2001 02

Page 22

Service

Manual

Single Stage Multi Position Furnace

The “CONTINUOUS” terminal of the ST9160B control is energized ONLY when there is NO OTHER CALL FOR OP-

ERATION of any kind. If there is a call for HEAT, COOL, or

thermostat sub--base to “FAN ON”, (energizing the “G”terminal) which causes the blower to run on the “HEATING”

speed.

“FAN ON”, this terminal is DE--ENERGIZED. The purpose

of this terminal is to provide a means of air circulation during

“OFF CYCLES” at a different speed than either heating or

cooling. The use of this terminal is operational, and there

will be no speed tap wires connected to this terminal

when the furnace is shipped.

“CONTINUOUS” fan should not be confused with “FAN ON”

which is obtained by switching the fan selector switch on the

The ST9160B Electronic Air Cleaner terminal (EAC)IS

ONLY energized in conjunction with the HEATING and

COOLING speed terminals. The maximum allowable con -

nected load to the HUM terminal is 0.8 (eight tenths)

Amp.*

*The combined connected loads of the EAC and HUM terminals cannot exceed a total of 0.8 (eight tenths) amp.

24. HONEYWELL SV9541M GAS VALVE/IGNITION CONTROL

The system consists basically of only two (2) components.

The Ignition System Control and the Pilot Hardware. The operate on Two (2) 24 volt power circuits received from the

ST9160B Fan Timer/Furnace Control. One is the power supply to the ignitor, the second is to activate the ignition sequence.

The Ignition System Control manages the ignition sequence,

and the flow of gas to the pilot and main burners. It is in essence a combination Gas Valve and Ignition control.

It contains sophisticated electronic components (internally)

and has NO USER SERVICEABLE COMPONENTS.

Should a problem be verified internally within the device, IT

IS NOT REPAIRABLE, and must be replaced.

The Pilot Hardware includes the pilot burner, the hot surface

element that lights the pilot burner, the flame rod that senses

pilot flame, and the cable that attaches to the system control.

The hot surface element is made of tough break resistant ceramic composite material. It operates on 24 Volts A.C. The

Igniter/Flame Rod assembly can be replaced independently

from the pilot burner assembly.

The system operation is quite simple, and forgiving (I.E. nuisance lockouts are eliminated)

Figure 30

Pilot Burner/Sensor

Honeywell ST9541M Ignition System

Ignition/Sensor

Gas Valve/Ignition Control

dwg 25-- 23--31a

25. HONEYWELL SV9541M SYSTEM OPERATION

Connecting the furnace to the line voltage supply with the

blower door interlock switch closed provides 24 volts to power the system. (This is accomplished by the connections

from terminals [pins] #4 & #2 from the ST9160B fan timer to

terminals #1 & #3 of the SV9541M gas valve.)

When the thermostat calls for heat, (the combustion blower

starts, causing the pressure switch to close completing the

circuit to the ignition system control) there will be approximately a two (2) second delay, while the ignition system control runs a self check.

Part of the self check is to see if a flame signal is detected.

If a flame signal is detected upon a call for heat (and naturally

there shouldn’t be), the ignition system control will energize

the electronic fan timer output (causing the conditioned air

blower to start after the fixed 60 second “ON” delay) and will

keep the valve and ignitor to circuit off.

Assuming that no flame signal is detected upon the call for

heat, (Normal operation), the ignition system control will

power the ignitor circuit (24 volts) causing the ignitor to heat

up.

440 08 2001 02

If the ignitor circuit is not proven (I.E. the ignitor is missing,

broken, or the connections are loose) their will be no response from the ignition system control. (Lockout)

Once the ignitor circuit has been proven, and the ignitor begins to heat up, the pilot valve will be energized allowing gas

to flow to the pilot burner.

With the ignitor now hot, and gas flowing to the pilot , the pilot

should light, and the sensor should sense flame.

If no flame is sensed, (I.E. no gas, pilot not lit, flame not enveloping sensor, etc.) the ignitor will stay on, and the pilot

valve will remain open until it does sense flame, or until the

call for heat is satisfied. THE SYSTEM WILL NOT LOCK

OUT under this condition.

Assuming that the pilot does light, and flame is sensed, (normal operation) the ignition system control will turn the ignitor

off, while energizing the main valve. This will allow the pilot

to light the main burner. It will also energize the electronic fan

timer output (causing the conditioned air blower to start after

the fixed 60 second “ON” delay).

20

Page 23

Single Stage Multi Position Furnace

Service

Manual

If a flame outage (I.E. loss of gas supply, blown out, etc.)

should occur during a run cycle (Main burner operation), the

ignition system immediately de--energize the main valve and

re--power the ignitor circuit placing the system back in to the

“Trial For Ignition” mode.

As previously, it will remain in this “Trial For Ignition” mode

(Ignitor powered and pilot valve open) either until the pilot

lights and flame is sensed, or until the call for heat ends.

The SV9541M system is not sensitive to furnace grounding

or line voltage polarity. Accordingly, you cannot experience

a lockout due to those reasons.

Assuming that the main burner did not experience any problems during the run cycle (normal operation) it would continue to operate as long as the call for heat remained.

Once the call for heat ended, the ignition system control

26. CHECKING FLAME CURRENT

The Honeywell SV9541Q Ignition system used in this furnace

series proves (verifies) flame via the Flame Rectification

method.

Flame Rectification is a process of converting Alternating

Current (A.C.) into Direct Current (D.C.) During the ignition

sequence, an alternating current (A.C.) Voltage is applied to

the Flame probe.

When the burner lights the flame conducts an electrical current between the flame probe and the burner ground. Due to

would immediately close the main and pilot valves, and de-energize the electronic fan timer output.

De--energizing the electronic fan timer output causes the

“OFF” delay timing to begin, and when the pre--selected time

(90, 100, 140, or 180 seconds) expires, the blower will turn

off.

TROUBLESHOOTING

Malfunctions of the HONEYWELL SV9541M “Smart Pilot”

system may be easily diagnosed using a voltmeter and a

spare igniter/flame rod assembly.

The igniter itself can also be checked using an Ohmmeter.

Resistance of a “Good” igniter should be 10 Ohms or less.

See trouble shooting flow chart and the sequence of operation flow chart on pages 36 and 37 of this manual for additional information on the operation and troubleshooting of this

system.

the difference in size between the flame probe and the burner ground area this current flows mostly in one direction. This

creates a pulsating Direct Current that flows back to the ignition control proving flame.

This flame current (D.C. Microamps) may be checked (while

flame is present) using a D.C. Flame Sensor kit is available

from outside vendors.

27. CAPACITORS

Figure 31

Checking Capacitor

Microfarads

5 mp

100 m¦

10 m¦

+

1000

m¦

10000 m¦

Capacitors are used for both the circulating (conditioned air)

blower motor and the exhaust (combustion) blower. Before

replacing one of these motors (assumed to be bad) the condition of its capacitor should be verified, since it, and not the

motor, may be the source of the problem.

Before checking any capacitor, the supply power to the unit

should be turned “OFF”. The capacitor should then be discharged (through a resistor) before testing. A 20,000 Ohm

2 Watt resistor can be used for this purpose.

The condition of the capacitor should then be verified with a

capacitor analyzer (one that indicated the capacitor’s value

in microfarads) rather than with an Ohmmeter. The reason

for this, is that an Ohmmeter test can only indicate if a capacitor is “OPEN’, or “SHORTED”, it cannot verify if its value (microfarads) is within an acceptable range.

Capacitor should test to within 10% of its rated value. Capacitors testing outside this range should be replaced. A weak

capacitor can be the cause of a motor failing to start.

21

440 08 2001 02

Page 24

Service

s

PofW

a

c

e

Manual

28. BLOWER ASSEMBLY

Single Stage Multi Position Furnace

All models use a multi--speed, permanent split capacitor motor, direct--drive, blower assembly. Different size (HP) motors and/or different diameter blower wheels are used in

each model to obtain the required air flow. The entire blower

assembly slides out on rails for servicing after removing the

two screws at the front.

SELECTING BLOWER SPEEDS

The wide variety of applications and installations of furnaces

throughout the country makes it impossible to “Factory Select” blower speeds that will provide proper operation for all

installations. This means then, that the blower speeds for

both heating and cooling must be “Field Selected” for each

particular installation to insure proper operation. is to prevent

wide swings in room temperature during furnace operation.

The criteria for selecting the proper blower speeds IS NOT

“High for Cooling, Low for Heating”. Although that may be

how it works out SOMETIMES, it can (in many cases) be exactly the opposite. (I.E. a Lower speed for Cooling, and a

Higher speed for Heating)

The PROPER CRITERIA FOR SELECTING BLOWER

SPEEDS is as follows:

HEATING

A blower speed must be selected that will provide proper

temperature rise through the furnace. (See “checking temperature rise” found elsewhere in this manual), The required

CFM for a particular temperature rise can also be calculated

using the following formula:

Output BTU

Temp. Rise X 1.08 = CFM

EXAMPLE: using a 75 Mbtu furnace of this series with an

output of 67,500 Btuh and a desired temperature rise of 50°

F (range of 40--70° F allowable) and a measured external

static pressure of 0.2² W.C. with a dry coil.

67,500

50 X 1.08 54 = 1250 CFM

Checking the blower performance data for this model, (see

Figure 36) indicates that @ 0.2² W.C. E.S.P. medium--high

speed will deliver 1249 CFM. Accordingly, medium speed

should be used in this example for the HEATING speed.

or 67,500

ample. The external static pressure is measured and found

to be 0.4² W.C.

400 CFM (nominal) per TON required

400x2=800CFMrequired

Checking the blower performance data (see Figure 36) for

this model indicates that @ 0.4² W.C. ESP low speed will deliver 788 CFM. Accordingly, low speed should be used in this

example for the COOLING speed.

Tab l e 7

Blower Performance Data

75,0000 BTUH

Air Delivery in Cubic Feet per Minute (CFM)

sure

Pres

atic

lSt

erna

Ext

(Furnace Rated @ 0.5² W.C. ESP)

TAP LOW MEDLMED H HIGH

.10 778 984 1263 1576

.20 786 1003 1249 1532

.C.

.30 790 1003 1244 1489

.40 788 1001 1215 1432

hes

In

.50 781 982 1186 1371

.60 765 962 1146 1308

.70 743 923 1094 1229

SAMPLE ONLY

CHANGING BLOWER SPEED

The procedure for changing blower speeds (if needed) is

shoun in Table 8.

!

Electrical shock hazard.

Turn OFF power to furnace before changing speed

taps.

Failure to do so can result in death and/or personal

injury.

COOLING

A blower speed must be selected that will provide proper air

flow (Nominal 400 CFM per ton) for the size (capacity) air

conditioning coil being used at the external static pressure

of the Duct system (installation). This requires CHECKING

THE EXTERNAL STATIC PRESSURE, then consulting the

BLOWER PERFORMANCE DATA to determine the required speed tap.

EXAMPLE: A 24,000 BTU (2 TON) air conditioning system,

using the same 75,000 BTU furnace as in the previous ex-

440 08 2001 02

Tab l e 8 Blower Speed Chart

Wire Color Motor Speed

Black High

Orange* Med--High

Blue Medium

Red Low

*Med--High speed may not be provided on all models.

22

Page 25

Single Stage Multi Position Furnace

Service

Manual

Figure 32

FUSE

Honeywell ST9160B

29. BLOWER ROTATION

Cool

Dip

Switch

Heat

M2

M1

25--23--63

HONEYWELL ST9160B

HEATING SPEED

Should it be necessary to change blower speeds to obtain

proper temperature rise, simply take the appropriate speed

tap wire, and plug it on to the terminal marked “HEAT”.

COOLING SPEED

When the proper speed has been determined, simply plug

it on to the terminal of the control marked “COOL”.

“UNUSED” TERMINALS

There are two (2) terminals (marked “UNUSED MOTOR

LEADS” on the Honeywell ST9160B which has no internal

connection to the control. Their purpose is to provide a place

to connect. “UNUSED” speed tap wires to keep them out of

the way and prevent them from shorting out against the furnace casing, or each other.

· The startup of a furnace will involve a cycle or two of the furnace to properly prime the condensate trap with water. Until

the trap is fully primed, some condensate will be pulled into

the combustion blower. The furnace may cycle on the pressure switch connected to the plastic transition box due to condensate buildup. After the trap is primed, the condensate will

start draining from the furnace. The combustion blower will

clear out any remaining condensate in the blower housing

through the vent fitting downstream of the blower. Note that

the condensate trap can also be primed by pouring water into

the vent drain side of the trap. Remove the small plastic cap

and clamps from the unused drain stub on the vent drain side

of the condensate trap. Connect a section of the

with a funnel to the drain stub and pour eight (8) ounces of water into the trap. Remove the hose and replace the plasticcap

and clamp. This will prime both the vent and the transition

sides of the trap.

· The startup of a furnace will have “milky or oily”. looking condensate coming from the furnace. This is residual drawing

lube in the secondary heat exchanger that is being washed

out by the condensate. The condensate will clear up as the

5

/8² OD hose

furnace operates. Poisonous carbon monoxide gas hazard.

· The use of a vent tee at the outlet of the condensate trap is not

required if the condensate drain line from the trap to the open

drain is properly sloped (

not trap the drain line in any otherlocation than at the condensate trap.

· The combustion blowers and blower gaskets are different on

some of the furnace models. There are two part numbers of

the combustion blower for the 2--stage furnace models. (See

the Tech. Manual for the correct part number for the furnace.)

Besides the part number difference, the 50M, 75M and 100M

BTUH models use the shaded pole motor version with the

7

1

/8² diameter back plate with a raised lip. The blower gasket

is approximately 2

the recessed opening in the transition. The 125M BTUH models use the PSC motor version with the 2² diameter back plate

with no lip. The blower gasket is approximately 3

diameter and is positioned on the flat surface of the transition.

A mismatch of blower backplated and/or gaskets can cause

the furnace to cycle on the pressure switch or to not operate.

This could be misread as a condensate drainage problem.

3

1

/4² per foot downward slope). Do

/4² outside diameterand is positioned into

1

/4² outside

23

440 08 2001 02

Page 26

Service

Manual

Single Stage Multi Position Furnace

Figure 33

Supply Air

Vent Pipe Grommet

Vent Fitting & Clamps

GasPipeGrommet

Rubber Coupling

&Clamps

Plastic Caps

Condensate Tr ap

& Gasket

(Left or Right Side)

Drain Line

Upflow Installation s (Dual Certified *9MPD(A1) Models)

LEFT Side Venting

Combustion Air

Vent Pipe

90°°°° Elbow

5

/8²²²² Hose &

Clamps

Combustion

Blower

Exhaust

Rubber

Plug

3

/4²²²² Hose

&Clamps

Inlet

Combustion

Blower

Mounting

Screws (4)

25- 23- 53

Pipe (optional)

Air Intake

Coupling

Plastic Caps

Pressure Switch

Hose, Blower

Pressure Switch

Hose, Transition

Pressure Switch,

Blower

Transition

Box

Return

Air

Pressure Switch,

Transition

DRAIN SIDE VIEW

Ven t D rai n

Rotate

downward

20° to 30°

RIGHT Side Venting

Supply Air

Inlet

Rigid Plastic

Rubber

Hose

Rubber

Hose

Drain Tube

clamp

clamp

Rigid

Plastic

Drain

Tube

Exhaust

Return

Air

Upflow Installations - (Dual Certified *9MPD) (See Figure 33)

Mount the condensate drain trap in a vertical position to either the

left or right side of the furnace using the two screws and gasket that

are provided. If needed, remove the hole plugs from the furnace

side panel and relocate to the open set ofholes in the opposite side

panel. Drill two

7

/64² diameter holes in the casing using the conden-

sate trap as the template.

Ensure that the vent fittingand the 90° elbow is securely attached to

the combustion blower using the rubber coupling and clamps.

Plug the rightdrain stub of the vent fitting with the rubber plug. Use a

blunt pointed screwdriver to push the plug into the stub.

For left side venting, remove vent fitting assembly from combustion

blower. Remove 90° elbow and rubber tubingfrom the vent fitting by

loosening the clamp on the vent fitting. Securely attachvent fittingto

combustion blower.