ICP N8MSL0451408A1, N8MSL0451412A1, N8MSL0701408A1, N8MSL0701412A1, N8MSL0701716A1 Installation Guide

...Page 1

These instructions must be read and understood completely before attempting installation.

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and NOTE Signal Words in Manuals

The signal words DANGER, WARNING, CAUTION, and NOTE The signal word WARNING is used throughout this manual inthe

are used to identify levels of hazard seriousness. The signal word following manner:

DANGER isonly used on product labels to signify an immediate

hazard. The signal words WARNING, CAUTION, and NOTE will

be used on product labels and throughout this manual and other The signal word CAUTION is used throughout this manual in the

manual that may apply to the product, following manner:

DANGER - Immediate hazards which will result in severe person-

at injury or death.

WARNING - Hazards or unsafe practices which could result in

severe personal injury or death.

CAUTION - Hazards or unsafe practices which may result in or product labels.

minor personal injury or product or property damage.

NOTE - Used to highlight suggestions which wilt result in en- z_ Safety-alert symbol

hanced installation, reliability, or operation. When you see this symbol on the unit and in instructions or manu-

TABLE OF CONTENTS

DIMENSIONS ............................................... 3

SAFETY CONSIDERATIONS .................................. 3

INTRODUCTION ............................................ 4

CODES AND STANDARDS ................................... 5

SAFETY ................................................ 5

GENERAL INSTALLATION ................................ 5

COMBUSTION AND VENTILATION AIR ..................... 5

DUCT SYSTEMS ........................................ 5

ACOUSTICAL LINING AND FIBROUS GLASS DUCT ......... 5

GAS PIPING AND GAS PIPE PRESSURE TESTING .......... 5

ELECTRICAL CONNECTIONS ............................ 5

VENTING .............................................. 5

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS ........... 5

LOCATION ................................................. 6

AIR FOR COMBUSTION AND VENTILATION .................... 7

INSTALLATION .............................................. 10

UPFLOW INSTALLATION ................................. 10

DOWNFLOW INSTALLATION ............................. 11

FILTER ARRANGEMENT ................................. 12

AIR DUCTS ............................................. 13

AIR DELIVERY - CFM .................................... 14

ELECTRICAL CONNECTIONS ............................ 20

115-V WIRING .......................................... 20

J-BOX RELOCATION .................................... 20

ELECTRICAL CONNECTION TO J-BOX .................... 20

ELECTRICAL DATA ...................................... 21

24-V WIRING ........................................... 22

ACCESSORIES ......................................... 22

VENTING .................................................. 23

GENERAL VENTING REQUIREMENTS ..................... 23

MASONRY CHIMNEY REQUIREMENTS .................... 24

APPLIANCE APPLICATION REQUIREMENTS ............... 26

ADDITIONAL VENTING REQUIREMENTS .................. 26

SIDEWALL VENTING .................................... 27

START-UP, ADJUSTMENT, AND SAFETY CHECK ............... 30

GENERAL .............................................. 30

START-UP PROCEDURES ............................... 30

ADJUSTMENTS ......................................... 31

SPEED SELECTION ..................................... 32

CHECK SAFETY CONTROLS ............................. 33

CHECKLIST ............................................ 34

ORIFICE SIZE AND MANIFOLD PRESSURE ................ 35

SERVICE AND MAINTENANCE PROCEDURES ................. 39

CARE AND MAINTENANCE ................................... 39

SEQUENCE OF OPERATION ................................. 43

WIRING DIAGRAM .......................................... 44

TROUBLESHOOTING GUIDE ................................. 45

Signal Words on Product Labeling

Signal words are used in combination with colors and/or pictures

als, be alert to the potential for personal injury.

Use of the AHRI Certified TM Mark indicates

a manufacturer's participation in the program.

For verification of certification for individual

IS09001

PERSONAL INJURY, AND/OR PROPERTY

DAMAGE HAZARD

Failure to carefully read and follow this warning could

result in equipment malfunction, property damage,

3ersonal injury and/or death.

Installation or repairs made by unqualified persons

could result in equipment malfunction, property

damage, personal injury and/or death.

The information contained in this manual is intended for

use by a qualified service technician familiar with safety

3rocedures and equipped with proper tools and test

instruments.

Installation must conform with local building codes and

with the Natural Fuel Gas Code (NFCG) NFPA

54/ANSI Z223.1, and National standards of Canada

CAN/CSA-B149.1 and .2 Natural Gas and Propane

Installation Codes.

INSTALLER: Affixthese instructions on or adjacent tothe furnace.

CONSUMER: Retain these instructions for future reference.

products, go to www.ahridirectory.org .

Portionsofthe text and tables are reprintedfrom NFPA54/ANSI Z223.t -20096), with permission of National FireProtectionAssociation, Quincy, MA02269 and American Gas Association,Washing-

ton, DC 20001. This reprinted material is not the complete and official position of the NFPAor ANSI, onthe referencedsubiect, which is represented only by the standard in itsentirety,

PrintedinU.S.A. 441 01 1402 02 May. 2012

Page 2

I-- 5 16/16

| [150.7]

/ r- s1/2

i ;,;o.tt'1:'

27W4

FO'LT]

331/4 J

NR FLOW

• d

@ @

L..._ L..._ L..._ L..._

L..._ L..._ L..._ L..._

L..._ L..._ L..._ L..._

L..._ L..._ L..._ L..._

L..._ L..._ L..._ L..._

L..._ L..._ L..._ L..._

L..._ L..._ L..._ L..._

L..._ L..._ L..._ L..._

L..._ L..._ L..._ L..._

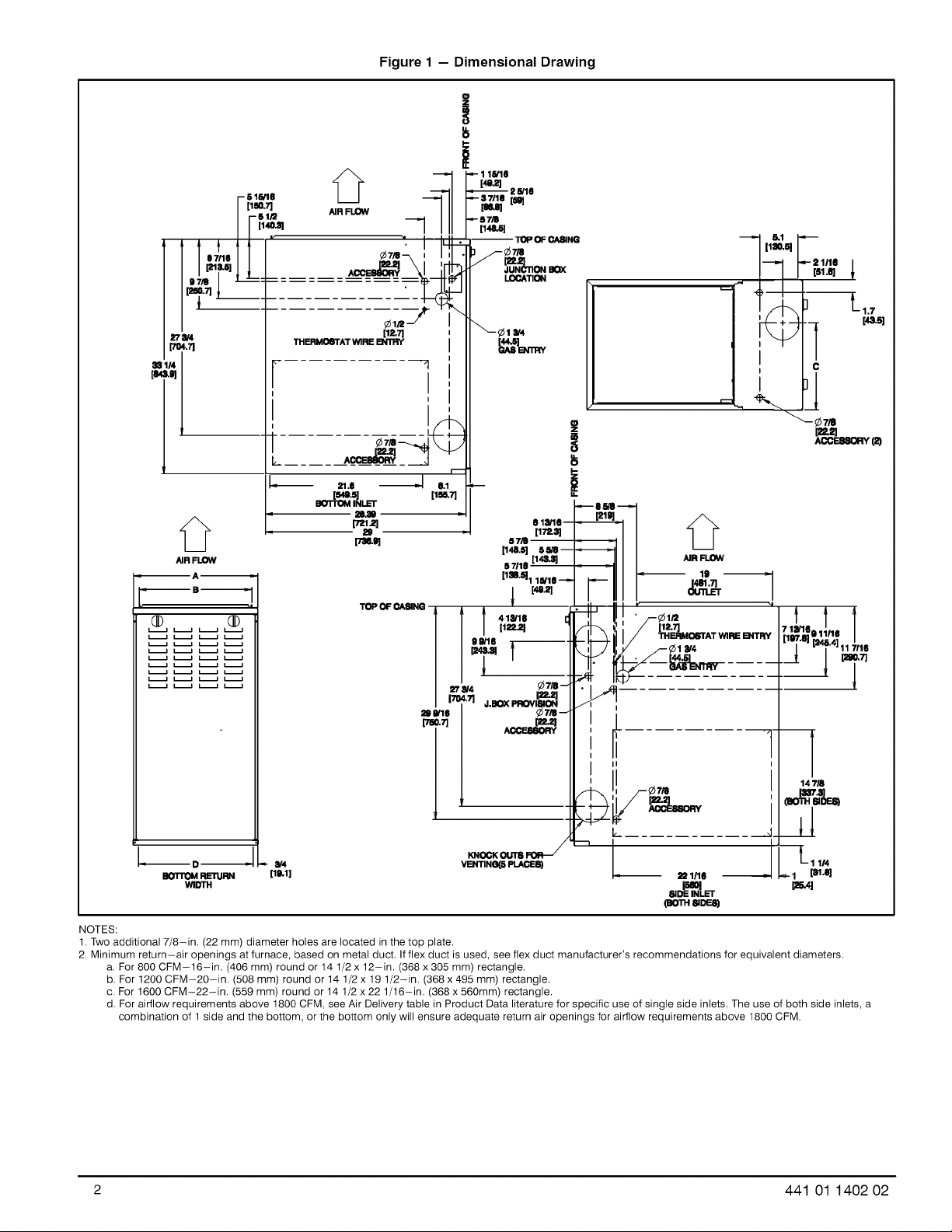

Figure 1 - Dimensional Drawing

¢ 7/8"-_ t

¢1/2-_--_ b

THERMOS'rATWIRE

F 7

, I

pC.71

I I'

I ¢7_

21.6 6.1

BO_[S40.5] ps6.7]

INLET

28,39

['r_1.2]

29

['ne.o]

TOPOF_kSING I l l 41a/16

o

z

b

118/16

Ll_ll

_57_

p4t_l

"r_ I_ CAImNG

LOCATION

I

P

6 1_V16--

p7e.Sl

ST_

[148.S] Sa_S--

57110 [14,t.Sl

[lS'IH1 llVffl _

_ p,o.21

/ / /s[,=.=l

/ i" J.BOXPROVISION

I-

_88/8

[els]-7"1 A

' 111 : ¢,=

"l I ¢1_/4

s] _22 1/le

I [51.O] 1

___. [,t_s]

c

_7/8

[=21=]

ACC_

t 1

[.vz.oj m_4] l

1

1

t, .......... __4

--D_ _ _V4

BOTrOM RE11JRN [11kl]

WIDTH

NOTES:

1. Two additional 7/8-in. (22 mm) diameter holes are located in the top plate.

2. Minimum return-air openings at furnace, based on metal duct. If flex duct is used, see flex duct manufacturer's recommendations for equivalent diameters.

a. For 800 CFM-16-in. (406 mm) round or 14 1/2 x 12-in. (368 x 305 mm) rectangle.

b. For 1200 CFM-20-in. (508 mm) round or 14 1/2 x 19 1/2-in. (368 x 495 mm) rectangle.

c. For 1600 CFM-22-in. (559 mm) round or 14 1/2 x 22 1/16-in. (368 x 560mm) rectangle.

d. For airflow requirements above 1800 CFM, see Air Delivery table in Product Data literature for specific use of single side inlets. The use of both side inlets, a

combination of 1 side and the bottom, or the bottom only will ensure adequate return air openings for airflow requirements above 1800 CFM.

2 441 01 1402 02

VEHTIHG(SPLACE8)

[r_

81DEINLET

(BOTHSlDF.m

147/8

la_.a]

I

(nOTH=,DES)

I

_A

L11/4

1 [Sl._]

[=r_]

Page 3

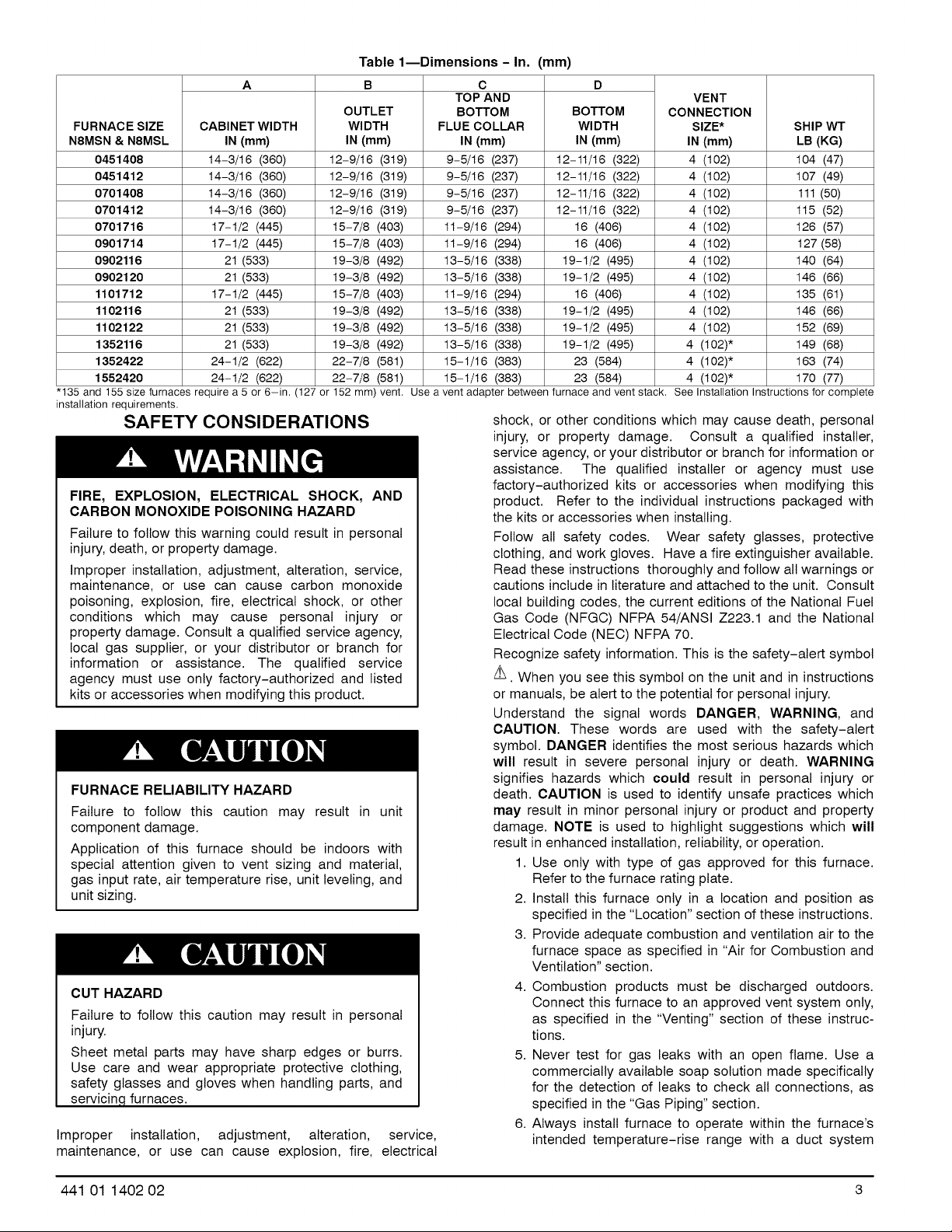

Table 1--Dimensions - In. (mm)

A

OUTLET

FURNACE SIZE

N8MSN & N8MSL

0451408

0451412

0701408

0701412

0701716

0901714

0902116

0902120

1101712

1102116

1102122

1352116

1352422

1552420

"135 and 155 size furnaces require a 5 or 6-in. (127 or 152 ram) vent.

installation requirements.

CABINET WIDTH

IN (mm)

14-3/16 (360)

14-3/16 (360)

14-3/16 (360)

14-3/16 (360)

17-1/2 (445)

17-1/2 (445)

21 (533)

21 (533)

17-1/2 (445)

21 (533)

21 (533)

21 (533)

24-1/2 (622)

24-1/2 (622) 22-7/8 (581)

WIDTH

IN (mm)

12-9/16 (319)

12-9/16 (319)

12-9/16 (319)

12-9/16 (319)

15-7/8 (403)

15-7/8 (403)

19-3/8 (492)

19-3/8 (492)

15-7/8 (403)

19-3/8 (492)

19-3/8 (492)

19-3/8 (492)

22-7/8 (581)

Use a vent adapter between furnace and vent stack. See Installation Instructions for complete

SAFETY CONSIDERATIONS

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

injury, death, or property damage.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide

poisoning, explosion, fire, electrical shock, or other

conditions which may cause personal injury or

property damage. Consult a qualified service agency,

local gas supplier, or your distributor or branch for

information or assistance. The qualified service

agency must use only factory-authorized and listed

kits or accessories when modifying this product.

FURNACE RELIABILITY HAZARD

Failure to follow this caution may result in unit

component damage.

Application of this furnace should be indoors with

special attention given to vent sizing and material,

gas input rate, air temperature rise, unit leveling, and

unit sizing.

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs.

Use care and wear appropriate protective clothing,

safety glasses and gloves when handling parts, and

servicin,q furnaces.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

C

TOP AND

BOTTOM

FLUE COLLAR

IN (mm)

9-5/16 (237)

9-5/16 (237)

9-5/16 (237)

9-5/16 (237)

11-9/16 (294)

11-9/16 (294)

13-5/16 (338)

13-5/16 (338)

11-9/16 (294)

13-5/16 (338)

13-5/16 (338)

13-5/16 (338)

15-1/16 (383)

15-1/16 (383) 23 (584) 4 (102)* 170 (77)

BOTTOM

WIDTH

IN (mm)

12-11/16 (322)

12-11/16 (322)

12-11/16 (322)

12-11/16 (322)

16 (406)

16 (406)

19-1/2 (495)

19-1/2 (495)

16 (406)

19-1/2 (495)

19-1/2 (495)

19-1/2 (495)

23 (584)

VENT

CONNECTION

SIZE*

IN (mm)

4 (102)

4 (102)

4 (102)

4 (102)

4 (102)

4 (102)

4 (102)

4 (102)

4 (102)

4 (102)

4 (102)

4 (102)*

4 (102)*

SHIP WT

LB(KG)

104 (47)

107 (49)

111(50)

115 (52)

126 (57)

127 (58)

140 (64)

146 (66)

135 (61)

146 (66)

152 (69)

149 (68)

163 (74)

shock, or other conditions which may cause death, personal

injury, or property damage. Consult a qualified installer,

service agency, or your distributor or branch for information or

assistance. The qualified installer or agency must use

factory-authorized kits or accessories when modifying this

product. Refer to the individual instructions packaged with

the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective

clothing, and work gloves. Have a fire extinguisher available.

Read these instructions thoroughly and follow all warnings or

cautions include in literature and attached to the unit. Consult

local building codes, the current editions of the National Fuel

Gas Code (NFGC) NFPA 54/ANSI Z223.1 and the National

Electrical Code (NEC) NFPA 70.

Recognize safety information. This is the safety-alert symbol

/_. When you see this symbol on the unit and in instructions

or manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety-alert

symbol. DANGER identifies the most serious hazards which

will result in severe personal injury or death. WARNING

signifies hazards which could result in personal injury or

death. CAUTION is used to identify unsafe practices which

may result in minor personal injury or product and property

damage. NOTE is used to highlight suggestions which will

result in enhanced installation, reliability, or operation.

1. Use only with type of gas approved for this furnace.

Refer to the furnace rating plate.

2. Install this furnace only in a location and position as

specified in the "Location" section of these instructions.

3. Provide adequate combustion and ventilation air to the

furnace space as specified in "Air for Combustion and

Ventilation" section.

4. Combustion products must be discharged outdoors.

Connect this furnace to an approved vent system only,

as specified in the "Venting" section of these instruc-

tions.

5. Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically

for the detection of leaks to check all connections, as

specified in the "Gas Piping" section.

6. Always install furnace to operate within the furnace's

intended temperature-rise range with a duct system

441 01 1402 02 3

Page 4

whichhasanexternalstaticpressurewithintheallow-

ablerange,asspecifiedinthe"Start-Up,Adjustments,

andSafetyCheck"section.Seefurnaceratingplate.

7.Whenafurnaceisinstalledsothatsupplyductscarry

aircirculatedbythefurnacetoareasoutsidethespace

containingthefurnace,thereturnairshallalsobe

handledbyduct(s)sealedtothefurnacecasingand

terminatingoutsidethespacecontainingthefurnace.

See"AirDucts"section.

8.Agas-firedfurnaceforinstallationinaresidentialgar-

agemustbeinstalledasspecifiedinthewarningboxin

the"Location"section.

9.Thefurnacemaybe usedfor constructionheat

providedthatthefurnaceinstallationandoperation

complieswiththefirstCAUTIONintheLOCATIONsec-

tionoftheseinstructions.

10.TheseMultipoiseGas-FiredFurnacesare CSA

(formerlyA.G.A.andC.G.A.)design-certifiedforuse

withnaturalandpropanegases(seefurnacerating

plate)andforinstallationinalcoves,attics,basements,

closets,utilityrooms,crawlspaces,andgarages.The

furnaceisfactory-shippedforusewithnaturalgas.A

CSA(A.G.A.andC.G.A.)listedaccessorygasconver-

sionkitisrequiredtoconvertfurnaceforusewithpro-

panegas.

11.SeeFigure1 forrequiredclearancesto combustible

construction.

12.Maintaina1-in.(25mm)clearancefromcombustible

materialstosupplyairductworkfora distanceof36in.

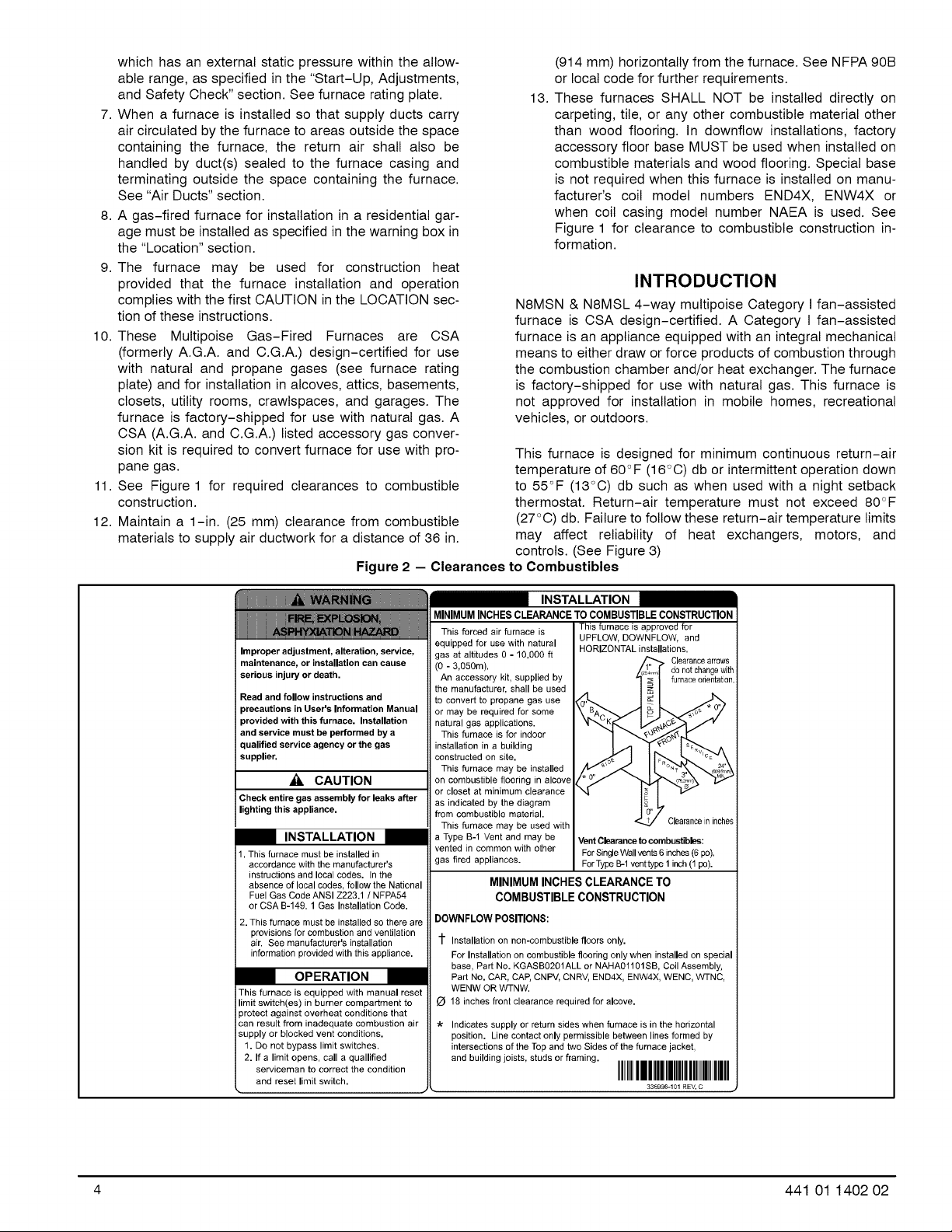

Figure 2 - Clearances to Combustibles

(914mm)horizontallyfromthefurnace.SeeNFPA90B

orlocalcodeforfurtherrequirements.

13.ThesefurnacesSHALLNOTbeinstalleddirectlyon

carpeting,tile,oranyothercombustiblematerialother

thanwoodflooring.In downflowinstallations,factory

accessoryfloorbaseMUSTbeusedwheninstalledon

combustiblematerialsandwoodflooring.Specialbase

isnotrequiredwhenthisfurnaceisinstalledonmanu-

facturer'scoilmodelnumbersEND4X,ENW4Xor

whencoilcasingmodelnumberNAEAis used.See

Figure1forclearancetocombustibleconstructionin-

formation.

INTRODUCTION

N8MSN & N8MSL 4-way multipoise Category I fan-assisted

furnace is CSA design-certified. A Category I fan-assisted

furnace is an appliance equipped with an integral mechanical

means to either draw or force products of combustion through

the combustion chamber and/or heat exchanger. The furnace

is factory-shipped for use with natural gas. This furnace is

not approved for installation in mobile homes, recreational

vehicles, or outdoors.

This furnace is designed for minimum continuous return-air

temperature of 60°F (16°0) db or intermittent operation down

to 55_'F (13°0) db such as when used with a night setback

thermostat. Return-air temperature must not exceed 80°F

(27°0) db. Failure to follow these return-air temperature limits

may affect reliability of heat exchangers, motors, and

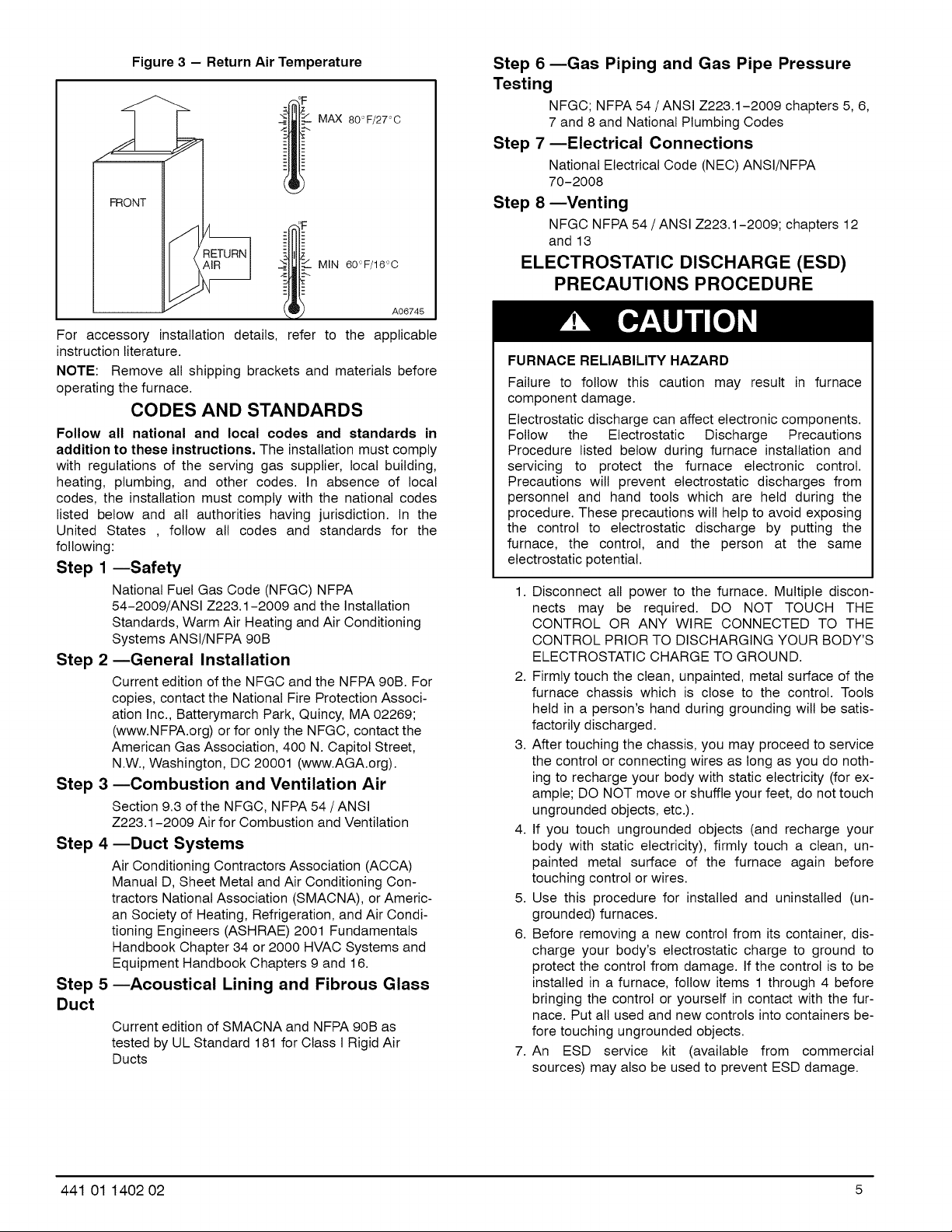

controls. (See Figure 3)

Improper adjustment, alteration, service,

maintenance, or installation can cause

serious injury or death,

Read and follow instructions and

arecautions in User's Information Manual

erovided with this furnace. Installation

and service must be performed by a

qualified service agency or the gas

supplier,

_IL CAUTION

Check entire gas assembly for leaks after

lighting this appliance.

I INSTALLATION I

1. This furnace must be installed in

accordance with the manufacturer's

instructions and local codes. In the

absence of local codes, follow the National

Fuel Gas Code ANSI Z223.1 / NFPA54

or CSA B-149.1 Gas Installation Code.

2. This furnace must be installed so there are

previsions for combustion and ventilation

air. See manufacturer's installation

information provided with this appliance.

I OPERATION I

This furnace is equipped with manual reset

limit switch(es) in burner compartment to

protect against overheat conditions that

can result from inadequate combustion air

supply or blocked vent conditions.

1. Do not bypass limit switches.

2. If a limit opens, call a quallified

serviceman to correct the condition

and reset limit switch.

MINIMUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

This forced air furnace is This furnace is approved for

equipped for use with natural HORIZONTAL installations,

gas at altitudes 0 - 10,000 ft

(0 - 3,050m), Clearancearrows

An accessory kit, supplied by furnaceorientation

the manufacturer, shall be used

to convert to propane gas use

or may be required for some

natural gas applications.

This furnace is for indoor

installation in a building

constructed on site.

This furnace may be installed

on combustible flooring in alcove

or closet at minimum clearance

as indicated by the diagram

from combustible material.

This furnace may be used with Clearancein inches

a Type B-1 Vent and may be VentOlearancetocombustibles:

vented in common with other For Single Wall vents 6 inches (6 po).

gas fired appliances. For Type B-1vent type 1 inch (1 po).

DOWNFLOW POSITIONS:

1" Installation on non-combustible floors only.

For Installation on combustible flooring only when installed on special

base, Part No. KGASB0201ALL or NAHAO1101SB, Coil Assembly,

Part No. CAR, CAP, CNPV, CNRV, END4X, ENW4X, WENC, WTNC,

WENW OR WTNW.

18 inches front clearance required for alcove.

* Indicates supply or return sides when furnace is in the horizontal

position. Line contact only permissible between lines formed by

intersections of the Top and two Sides of the furnace jacket,

and building joists, studs or framing.

I INSTALLATION I

UPFLOW, DOWNFLOW, and

do not change with

MINIMUM INCHES CLEARANCE TO

COMBUSTIBLE CONSTRUCTION

IIIIIIIIIHMIMHI

336996-101 REV. C

4 441 01 1402 02

Page 5

Figure 3 - Return Air Temperature

MAX 8OoF/27 oO

FRONT

"< :/ MIN 60°F/16°C

A06745

For accessory installation details, refer to the applicable

instruction literature.

NOTE: Remove all shipping brackets and materials before

operating the furnace.

CODES AND STANDARDS

Follow all national and local codes and standards in

addition to these instructions. The installation must comply

with regulations of the serving gas supplier, local building,

heating, plumbing, and other codes. In absence of local

codes, the installation must comply with the national codes

listed below and all authorities having jurisdiction. In the

United States , follow all codes and standards for the

following:

Step 1 --Safety

National Fuel Gas Code (NFGC) NFPA

54-2009/ANSI Z223.1-2009 and the Installation

Standards, Warm Air Heating and Air Conditioning

Systems ANSl/NFPA 90B

Step 2--General Installation

Current edition of the NFGC and the NFPA 90B. For

copies, contact the National Fire Protection Associ-

ation Inc., Batterymarch Park, Quincy, MA 02269;

(www.NFPA.org) or for only the NFGC, contact the

American Gas Association, 400 N. Capitol Street,

N.W., Washington, DO 20001 (www.AGA.org).

Step 3 --Combustion and Ventilation Air

Section 9.3 of the NFGC, NFPA 54/ANSI

Z223.1-2009 Air for Combustion and Ventilation

Step 4--Duct Systems

Air Conditioning Contractors Association (ACCA)

Manual D, Sheet Metal and Air Conditioning Con-

tractors National Association (SMACNA), or Americ-

an Society of Heating, Refrigeration, and Air Condi-

tioning Engineers (ASHRAE) 2001 Fundamentals

Handbook Chapter 34 or 2000 HVAC Systems and

Equipment Handbook Chapters 9 and 16.

--Acoustical Lining and Fibrous GlassStep 5

Duct

Current edition of SMACNA and NFPA 90B as

tested by UL Standard 181 for Class I Rigid Air

Ducts

Step 6--Gas Piping and Gas Pipe Pressure

Testing

NFGC; NFPA 54 /ANSI Z223.1-2009 chapters 5, 6,

7 and 8 and National Plumbing Codes

Step 7--Electrical Connections

National Electrical Code (NEC) ANSI/NFPA

70-2008

Step 8--Venting

NFGC NFPA 54/ANSI Z223.1-2009; chapters 12

and 13

ELECTROSTATIC DISCHARGE (ESD)

PRECAUTIONS PROCEDURE

FURNACE RELIABILITY HAZARD

Failure to follow this caution may result in furnace

component damage.

Electrostatic discharge can affect electronic components.

Follow the Electrostatic Discharge Precautions

Procedure listed below during furnace installation and

servicing to protect the furnace electronic control.

Precautions will prevent electrostatic discharges from

personnel and hand tools which are held during the

procedure. These precautions will help to avoid exposing

the control to electrostatic discharge by putting the

furnace, the control, and the person at the same

electrostatic potential.

1. Disconnect all power to the furnace. Multiple discon-

nects may be required. DO NOT TOUCH THE

CONTROL OR ANY WIRE CONNECTED TO THE

CONTROL PRIOR TO DISCHARGING YOUR BODY'S

ELECTROSTATIC CHARGE TO GROUND.

2. Firmly touch the clean, unpainted, metal surface of the

furnace chassis which is close to the control. Tools

held in a person's hand during grounding wilt be satis-

factorily discharged.

3. After touching the chassis, you may proceed to service

the control or connecting wires as long as you do noth-

ing to recharge your body with static electricity (for ex-

ample; DO NOT move or shuffle your feet, do not touch

ungrounded objects, etc.).

4. If you touch ungrounded objects (and recharge your

body with static electricity), firmly touch a clean, un-

painted metal surface of the furnace again before

touching control or wires.

5. Use this procedure for installed and uninstatled (un-

grounded) furnaces.

6. Before removing a new control from its container, dis-

charge your body's electrostatic charge to ground to

protect the control from damage. If the control is to be

installed in a furnace, follow items 1 through 4 before

bringing the control or yourself in contact with the fur-

nace. Put all used and new controls into containers be-

fore touching ungrounded objects.

7. An ESD service kit (available from commercial

sources) may also be used to prevent ESD damage.

441 01 1402 02 5

Page 6

LOCATION

CARBON MONOXIDE POISONING AND UNIT

DAMAGE HAZARD

Failure to follow this warning could result in personal

injury or death, and unit component damage.

Corrosive or contaminated air may cause failure of parts

containing flue gas, which could leak into the living

space. Air for combustion must not be contaminated by

halogen compounds, which include fluoride, chloride,

bromide, and iodide. These elements can corrode heat

exchangers and shorten furnace life. Air contaminants

are found in aerosol sprays, detergents, bleaches,

cleaning solvents, salts, air fresheners, and other

household products. Do not install furnace in a corrosive

or contaminated atmosphere. Make sure all combustion

and circulating air requirements are met, in addition to

all local codes and ordinances.

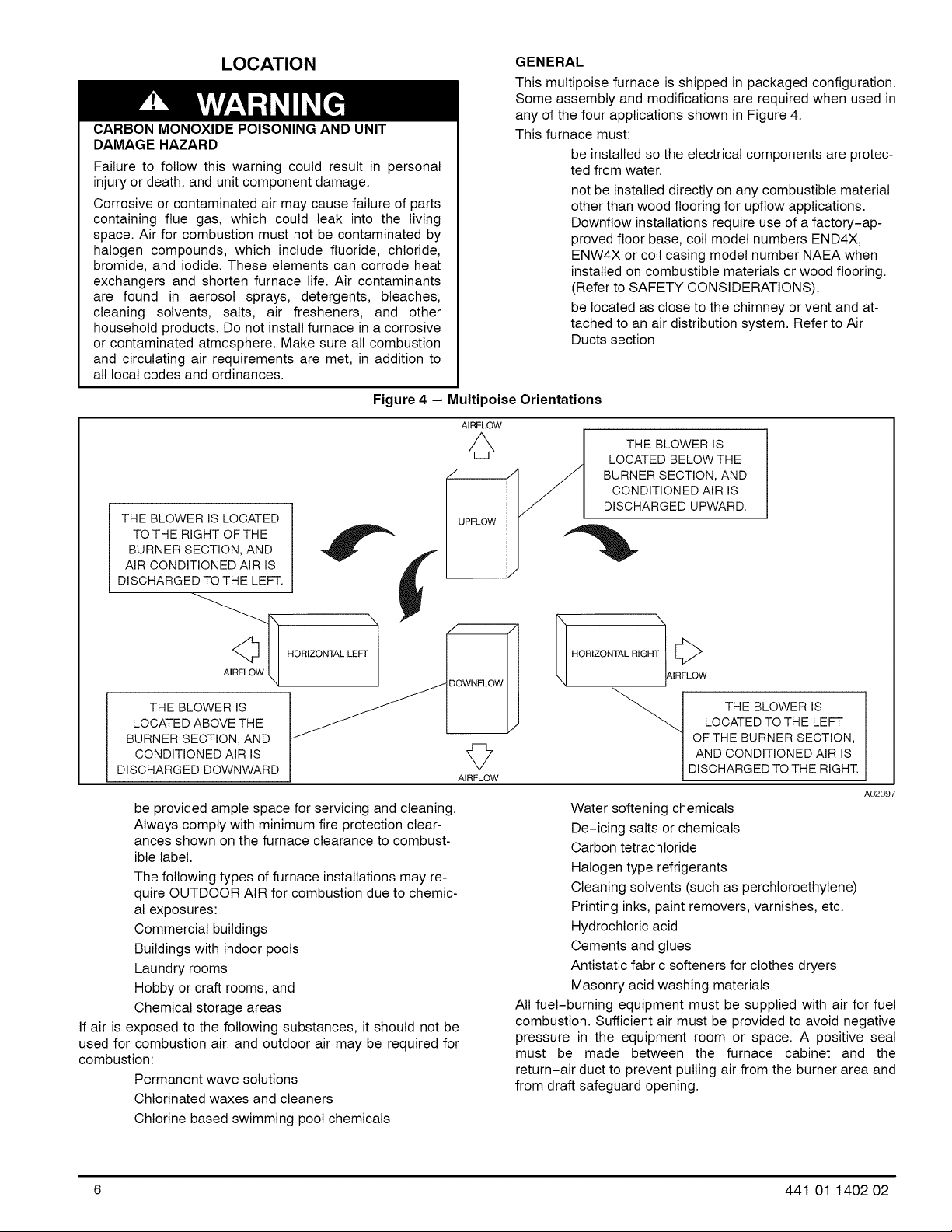

Figure 4 - Multipoise Orientations

THE BLOWER IS LOCATED

TOTHE RIGHT OFTHE

BURNERSECTION, AND

AiR CONDITIONED AIR IS

DISCHARGEDTO THE LEFT.

GENERAL

This multipoise furnace is shipped in packaged configuration.

Some assembly and modifications are required when used in

any of the four applications shown in Figure 4.

This furnace must:

be installed so the electrical components are protec-

ted from water.

not be installed directly on any combustible material

other than wood flooring for upflow applications.

Downflow installations require use of a factory-ap-

proved floor base, coil model numbers END4X,

ENW4X or coil casing model number NAEA when

installed on combustible materials or wood flooring.

(Refer to SAFETY CONSIDERATIONS).

be located as close to the chimney or vent and at-

tached to an air distribution system. Refer to Air

Ducts section.

AIRFLOW

THE BLOWER IS

LOCATED BELOWTHE

BURNERSECTION, AND

CONDITIONED AIR IS

DISCHARGED UPWARD.

LOCATEDABOVETHE

BURNER SECTION, AND

THE BLOWER IS '_7

CONDITIONEDAIR IS

DISCHARGED DOWNWARD

be provided ample space for servicing and cleaning.

Always comply with minimum fire protection clear-

ances shown on the furnace clearance to combust-

ible label.

The following types of furnace installations may re-

quire OUTDOOR AIR for combustion due to chemic-

al exposures:

Commercial buildings

Buildings with indoor pools

Laundry rooms

Hobby or craft rooms, and

Chemical storage areas

If air is exposed to the following substances, it should not be

used for combustion air, and outdoor air may be required for

combustion:

Permanent wave solutions

Chlorinated waxes and cleaners

Chlorine based swimming pool chemicals

AIRFLOW

_ HORIZONTAL RIGH_AIRF L_C w

THE BLOWER IS

LOCATED TO THE LEFT

OF THE BURNER SECTION,

AND CONDiTiONED AIR IS

DISCHARGED TO THE RIGHT.

A02097

Water softening chemicals

De-icing salts or chemicals

Carbon tetrachloride

Halogen type refrigerants

Cleaning solvents (such as perchloroethylene)

Printing inks, paint removers, varnishes, etc.

Hydrochloric acid

Cements and glues

Antistatic fabric softeners for clothes dryers

Masonry acid washing materials

All fuel-burning equipment must be supplied with air for fuel

combustion. Sufficient air must be provided to avoid negative

pressure in the equipment room or space. A positive seal

must be made between the furnace cabinet and the

return-air duct to prevent pulling air from the burner area and

from draft safeguard opening.

6 441 01 1402 02

Page 7

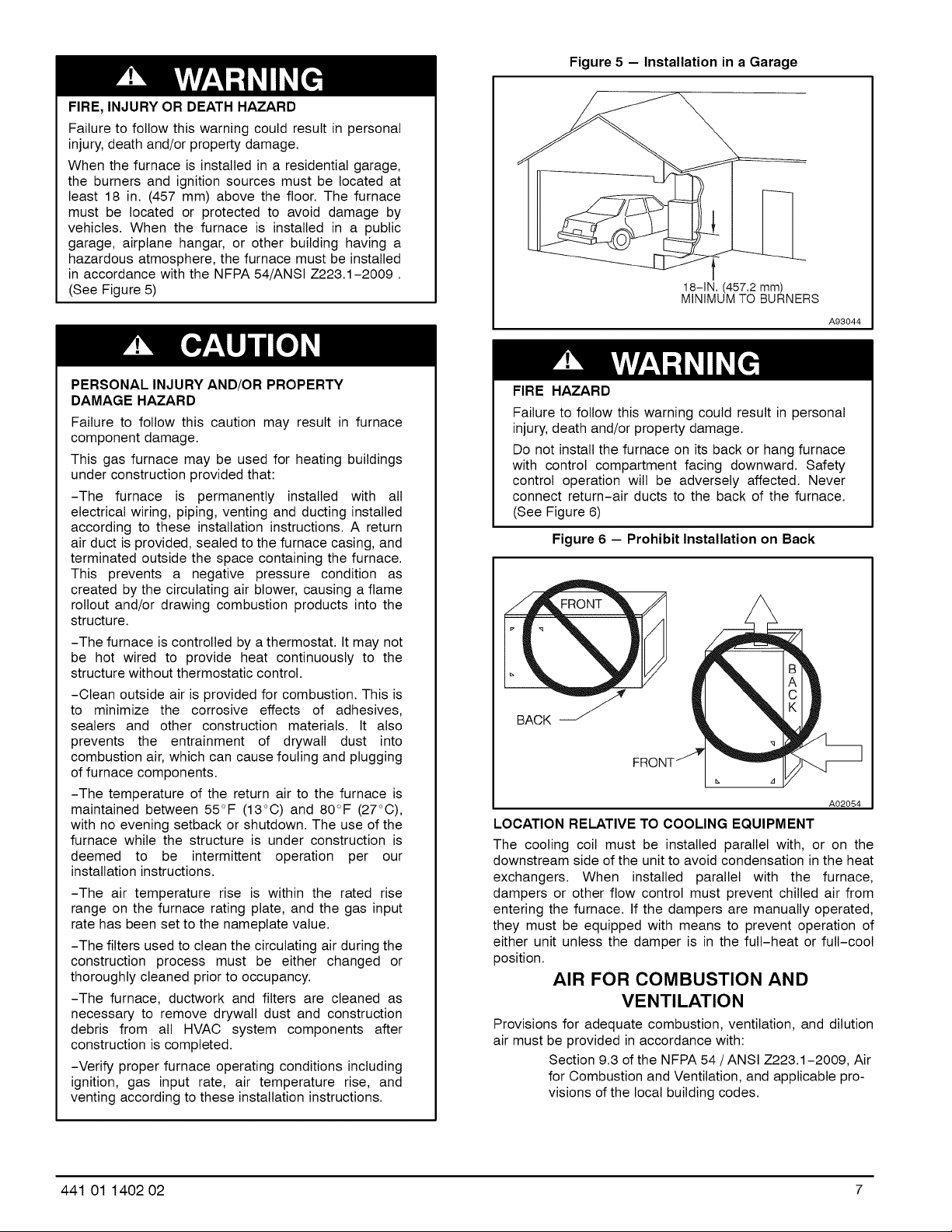

FIRE, INJURY OR DEATH HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

When the furnace is installed in a residential garage,

the burners and ignition sources must be located at

least 18 in. (457 mm) above the floor. The furnace

must be located or protected to avoid damage by

vehicles. When the furnace is installed in a public

garage, airplane hangar, or other building having a

hazardous atmosphere, the furnace must be installed

in accordance with the NFPA 54/ANSI Z223.1-2009.

(See Figure 5)

Figure 5 - Installation in a Garage

18-1N. (457.2 mm)

MINIMUM TO BURNERS

A93044

PERSONAL INJURY AND/OR PROPERTY

DAMAGE HAZARD

Failure to follow this caution may result in furnace

component damage.

This gas furnace may be used for heating buildings

under construction provided that:

-The furnace is permanently installed with all

electrical wiring, piping, venting and ducting installed

according to these installation instructions. A return

air duct is provided, sealed to the furnace casing, and

terminated outside the space containing the furnace.

This prevents a negative pressure condition as

created by the circulating air blower, causing a flame

rollout and/or drawing combustion products into the

structure.

-The furnace is controlled by a thermostat. It may not

be hot wired to provide heat continuously to the

structure without thermostatic control.

-Clean outside air is provided for combustion. This is

to minimize the corrosive effects of adhesives,

sealers and other construction materials. It also

prevents the entrainment of drywall dust into

combustion air, which can cause fouling and plugging

of furnace components.

-The temperature of the return air to the furnace is

maintained between 55°F (13°C) and 80°F (27°C),

with no evening setback or shutdown. The use of the

furnace while the structure is under construction is

deemed to be intermittent operation per our

installation instructions.

-The air temperature rise is within the rated rise

range on the furnace rating plate, and the gas input

rate has been set to the nameplate value.

-The filters used to clean the circulating air during the

construction process must be either changed or

thoroughly cleaned prior to occupancy.

-The furnace, ductwork and filters are cleaned as

necessary to remove drywall dust and construction

debris from all HVAC system components after

construction is completed.

-Verify proper furnace operating conditions including

ignition, gas input rate, air temperature rise, and

venting according to these installation instructions.

FIRE HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Do not install the furnace on its back or hang furnace

with control compartment facing downward. Safety

control operation will be adversely affected. Never

connect return-air ducts to the back of the furnace.

(See Figure 6)

Figure 6 - Prohibit Installation on Back

BACK

A02054

LOCATION RELATIVE TO COOLING EQUIPMENT

The cooling coil must be installed parallel with, or on the

downstream side of the unit to avoid condensation in the heat

exchangers. When installed parallel with the furnace,

dampers or other flow control must prevent chilled air from

entering the furnace. If the dampers are manually operated,

they must be equipped with means to prevent operation of

either unit unless the damper is in the full-heat or full-cool

position.

AIR FOR COMBUSTION AND

VENTILATION

Provisions for adequate combustion, ventilation, and dilution

air must be provided in accordance with:

Section 9.3 of the NFPA 54/ANSI Z223.1-2009, Air

for Combustion and Ventilation, and applicable pro-

visions of the local building codes.

441 01 1402 O2 7

Page 8

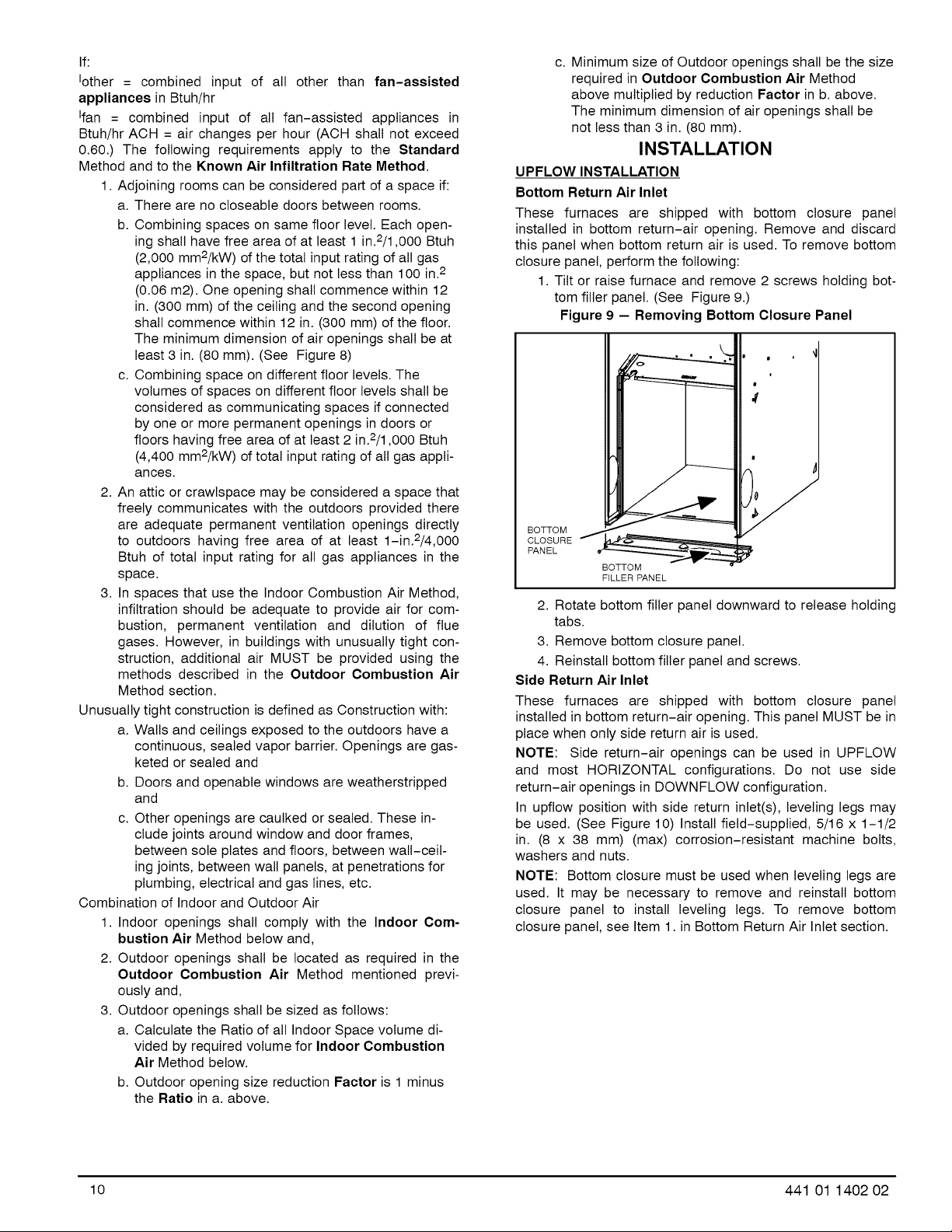

2. Figure 7 illustrates how to provide TWO OUTDOOR

OPENINGS, one inlet and one outlet combustion and

ventilation air opening, to the outdoors.

FURNACE CORROSION HAZARD

Failure to follow this caution may result in furnace

damage.

Air for combustion must not be contaminated by

halogen compounds, which include fluoride, chloride,

bromide, and iodide. These elements can corrode

heat exchangers and shorten furnace life. Air

contaminants are found in aerosol sprays,

detergents, bleaches, cleaning solvents, salts, air

fresheners, and other household products.

a. One opening MUST commence within 12 in. (300

mm) of the ceiling and the second opening MUST

commence within 12 in. (300 mm) of the floor.

b. Size openings and ducts per Figure 7 and Table 2.

c. TWO HORIZONTAL DUCTS require 1 sq./in, of free

area per 2,000 Btuh (1,100 mm2/kW) of combined

input for all gas appliances in the space per

Figure 7 and Table 2.

d. TWO OPENINGS OR VERTICAL DUCTS require 1

sq./in, of free area per 4,000 Btuh (550 mm2/kW)

for combined input of all gas appliances in the

space per Figure 7 and Table 2.

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

injury or death.

The operation of exhaust fans, kitchen ventilation

fans, clothes dryers, attic exhaust fans or fireplaces

could create a NEGATIVE PRESSURE CONDITION

at the furnace. Make-up air MUST be provided for the

ventilation devices, in addition to that required by the

furnace. Refer to Carbon Monoxide Poisoning Hazard

warning in venting section of these instructions to

determine if an adequate amount of make-up air is

available.

3. ONE OUTDOOR OPENING requires:

a. 1 square inch of free area per 3,000 Btuh (734

mm2/kW) for combined input of all gas appliances

in the space per Table 2 and

b. Not less than the sum of the areas of all vent con-

nectors in the space.

The opening shall commence within 12 in. (300 mm) of the

ceiling. Appliances in the space shall have clearances of at

least 1 in. (25 mm) from the sides and back and 6 in. (150

mm) from the front. The opening shall directly communicate

with the outdoors or shall communicate through a vertical or

horizontal duct to the outdoors or spaces (crawl or attic) that

freely communicate with the outdoors.

The requirements for combustion and ventilation air depend

upon whether or not the furnace is located in a space having

a volume of at least 50 cu/ft, per 1,000 Btuh input rating for all

gas appliances installed in the space.

Spaces having less than 50 cu/ft, per 1,000 Btuh

Indoor Combustion Air NFPA & AGA

Standard and Known-Air-Infiltration Rate Methods

Indoor air is permitted for combustion, ventilation, and

dilution, if the Standard or Known-Air-Infiltration Method

is used.

require the OUTDOOR COMBUSTION AIR

METHOD.

Spaces having at least 50 cu/ft, per 1,000 Btuh may

use the INDOOR COMBUSTION AIR, STANDARD

or KNOWN AIR INFILTRATION METHOD.

Outdoor Combustion Air Method

1. Provide the space with sufficient air for proper combus-

tion, ventilation, and dilution of flue gases using per-

manent horizontal or vertical duct(s) or opening(s) dir-

ectly communicating with the outdoors or spaces that

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in death

and/or personal injury.

Many homes require air to be supplied from outdoors

for furnace combustion, ventilation, and dilution of flue

gases. The furnace combustion air supply must be

provided in accordance with this instruction manual.

freely communicate with the outdoors.

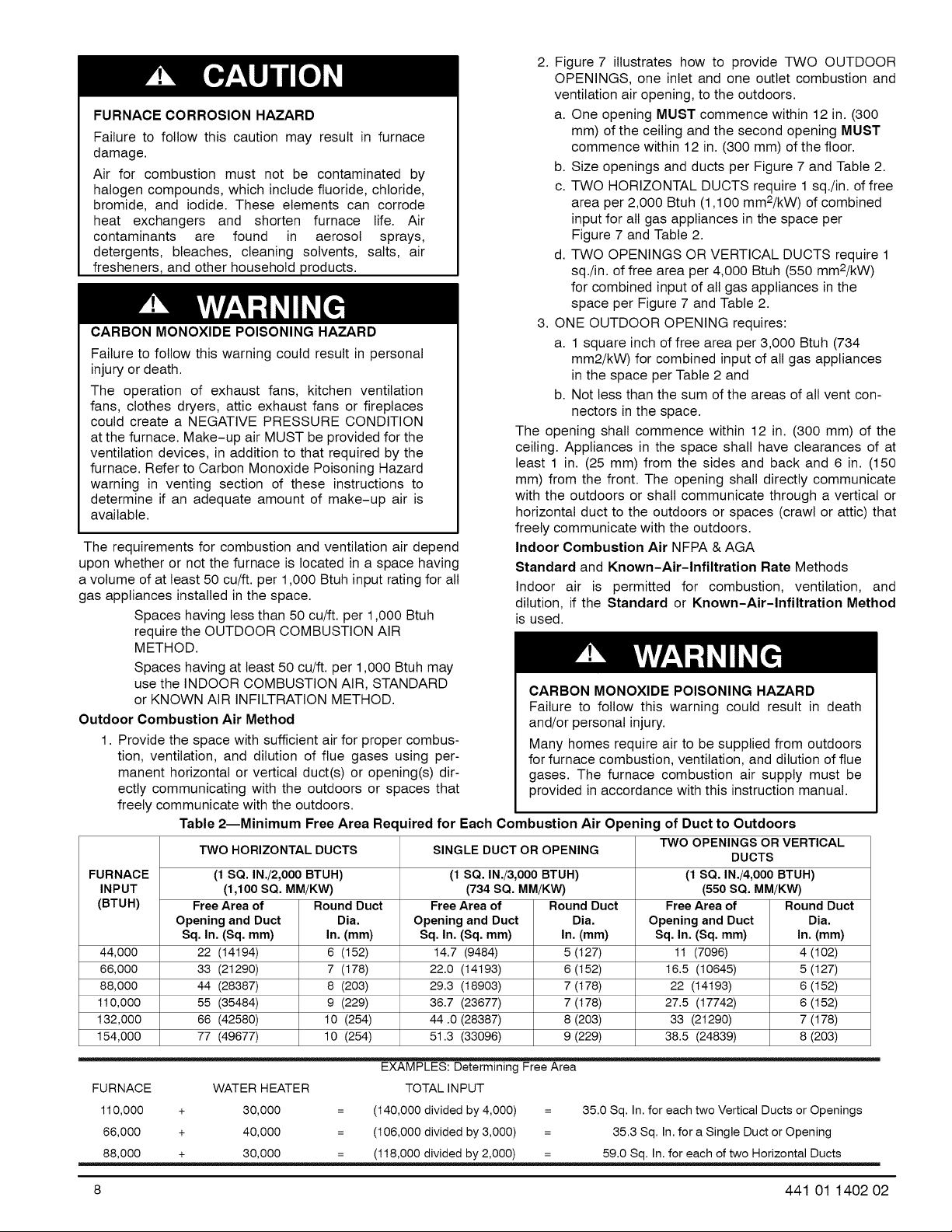

Table 2--Minimum Free Area Re(

TWO HORIZONTAL DUCTS SINGLE DUCT OR OPENING

FURNACE (1 SQ. IN./2,000 BTUH) (1 SQ. IN./3,000 BTUH)

INPUT (1,100 SQ. MM/KW) (734 SQ. MM/KW)

(BTUH) Free Area of Round Duct Free Area of Round Duct Free Area of Round Duct

Opening and Duct Dia. Opening and Duct Dia. Opening and Duct Dia.

Sq. In. (Sq. mm) In. (mm) Sq. In. (Sq. mm) In. (mm) Sq. In. (Sq. mm) In. (mm)

44,000 22 (14194) 6 (152) 14.7 (9484) 5 (127) 11 (7096) 4 (102)

66,000 33 (21290) 7 (178) 22.0 (14193) 6 (152) 16.5 (10645) 5 (127)

88,000 44 (28387) 8 (203) 29.3 (18903) 7 (178) 22 (14193) 6 (152)

110,000 55 (35484) 9 (229) 36.7 (23677) 7 (178) 27.5 (17742) 6 (152)

132,000 66 (42580) 10 (254) 44.0 (28387) 8 (203) 33 (21290) 7 (178)

154,000 77 (49677) 10 (254) 51.3 (33096) 9 (229) 38.5 (24839) 8 (203)

uired for Each Combustion Air Opening of Duct to Outdoors

TWO OPENINGS OR VERTICAL

DUCTS

(1 SQ. IN./4,000 BTUH)

(550 SQ. MM/KW)

EXAMPLES: Determining Free Area

FURNACE WATER HEATER TOTAL INPUT

110,000 + 30,000 (140,000 divided by 4,000) = 35.0 Sq. In. for each two Vertical Ducts or Openings

66,000 + 40,000 (106,000 divided by 3,000) = 35.3 Sq. In.for a Single Duct or Opening

88,000 + 30,000 (118,000 divided by 2,000) = 59.0 Sq. In. for each of two Horizontal Ducts

8 441 01 1402 02

Page 9

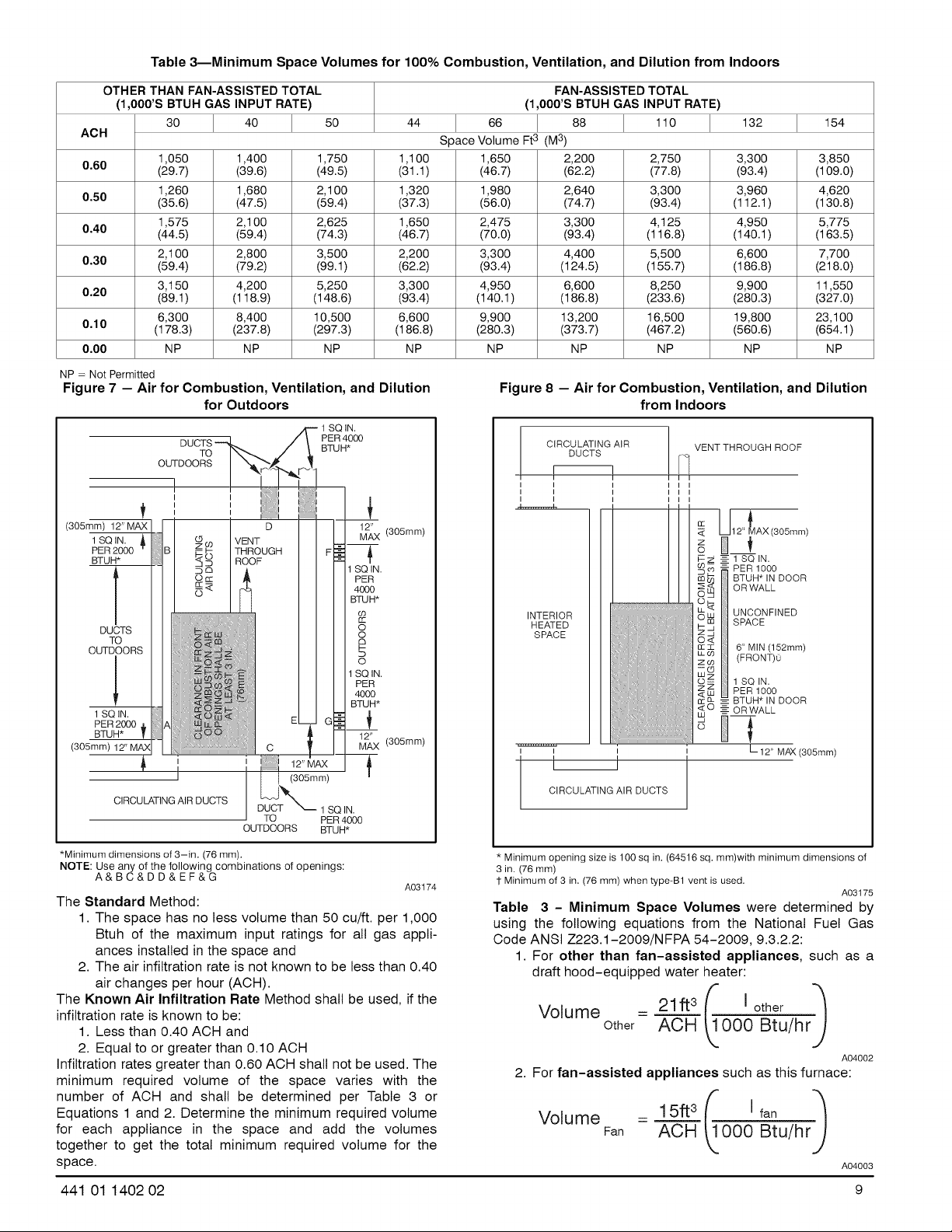

Table 3--Minimum Space Volumes for 100% Combustion, Ventilation, and Dilution from Indoors

OTHER THAN FAN-ASSISTED TOTAL FAN-ASSISTED TOTAL

(1,000'S BTUH GAS INPUT RATE) (1,000'S BTUH GAS INPUT RATE)

30 40 50 44 66 88 110 132 154

ACH Space Volume Ft3 (M3)

0.60 (29.7) (39.6) (49.5) (31.1) (46.7) (62.2) (77.8) (93.4) (109.0)

0.50 (35.6) (47.5) (59.4) (37.3) (56.0) (74.7) (93.4) (112.1 ) (130.8)

0.40 (44.5) (59.4) (74.3) (46.7) (70.0) (93.4) (116.8) (140.1 ) (163.5)

0.30 (59.4) (79.2) (99.1) (62.2) (93.4) (124.5) (155.7) (186.8) (218.0)

0.20 (89.1) (118.9) (148.6) (93.4) (140.1 ) (186.8) (233.6) (280.3) (327.0)

0.10 (178.3) (237.8) (297.3) (186.8) (280.3) (373.7) (467.2) (560.6) (654.1)

0.00 NP NP NP NP NP NP NP NP NP

NP = Not Permitted

Figure 7 -- Air for Combustion, Ventilation, and Dilution

1,050 1,400 1,750 1,100 1,650 2,200 2,750 3,300 3,850

1,260 1,680 2,100 1,320 1,980 2,640 3,300 3,960 4,620

1,575 2,100 2,625 1,650 2,475 3,300 4,125 4,950 5,775

2,100 2,800 3,500 2,200 3,300 4,400 5,500 6,600 7,700

3,150 4,200 5,250 3,300 4,950 6,600 8,250 9,900 11,550

6,300 8,400 10,500 6,600 9,900 13,200 16,500 19,800 23,100

Figure 8 - Air for Combustion, Ventilation, and Dilution

OUTDOORS

for Outdoors

TO

SQ IN.

PER 4000

BTUH*

from Indoors

VENT THROUGH ROOF

(305mm) 12" MAX

1 SQ IN.

PER 2000

BTUH*

DUCTS

TO

OUTDOORS

1 SQ IN.

PER 2000

BTUH*

(305mm)

(305mm)

CIRCULATING AIR DUCTS

TO PER 4000

OUTDOORS BTUH*

*Minimum dimensions of 3-in. (76 mm).

NOTE: Use any ofthe following combinations of openings:

A&BC&DD&EF&G

1 SQ IN.

12_X (305mm)

1 SQ IN.

PER

4000

BTUH*

O3

rr

O

O

a

F-

O

1 SQ IN.

PER

4000

BTUH*

12" (305mm)

MAX

The Standard Method:

1. The space has no less volume than 50 cu/ft, per 1,000

Btuh of the maximum input ratings for all gas appli-

ances installed in the space and

2. The air infiltration rate is not known to be less than 0.40

air changes per hour (ACH).

A03174

I I

INTERIOR

HEATED

SPACE

CIRCULATING AIR DUCTS

Minimum opening size is 100 sq in. (64516 sq. mm)with minimum dimensions of

in. (76 ram)

Minimum of 3 in. (76 mm) when type-B1 vent is used.

Table 3 - Minimum Space Volumes were determined by

using the following equations from the National Fuel Gas

Code ANSI 7223.1-2009/NFPA 54-2009, 9.3.2.2:

1. For other than fan-assisted appliances, such as a

draft hood-equipped water heater:

I

12" AX(305mm)

z

O

2_ 1 SQ IN.

BTUH* IN DOOR

i PER 1000

OR WALL

UNCONFINED

W SPACE

-4,

_: 6" MIN (152mm)

co (FRONT)0

_z 1 SQ IN.

PER 1000

_ BTUH* IN DOOR

OR WALL

L 12"MAX(305ram)

The Known Air Infiltration Rate Method shall be used, if the

infiltration rate is known to be:

1. Less than 0.40 ACH and

Vo'" m e Other: A-A0_ _k,T000 "a_/h r"#

2. Equal to or greater than 0.10 ACH

Infiltration rates greater than 0.60 ACH shall not be used. The

minimum required volume of the space varies with the

2. For fan-assisted appliances such as this furnace:

number of ACH and shall be determined per Table 3 or

Equations 1 and 2. Determine the minimum required volume

for each appliance in the space and add the volumes

together to get the total minimum required volume for the

V°lumeFan = ACH _000 Btu/hrJ

15ft3 f[ ]fan ="_

space.

441 01 1402 02 9

A03t 75

A04002

A04003

Page 10

If:

Iother= combinedinputof all otherthanfan-assisted

appliancesinBtuh/hr

Ifan= combinedinputof all fan-assistedappliancesin

Btuh/hrACH=airchangesperhour(ACHshallnotexceed

0.60.)Thefollowingrequirementsapplyto theStandard

MethodandtotheKnownAirInfiltrationRateMethod.

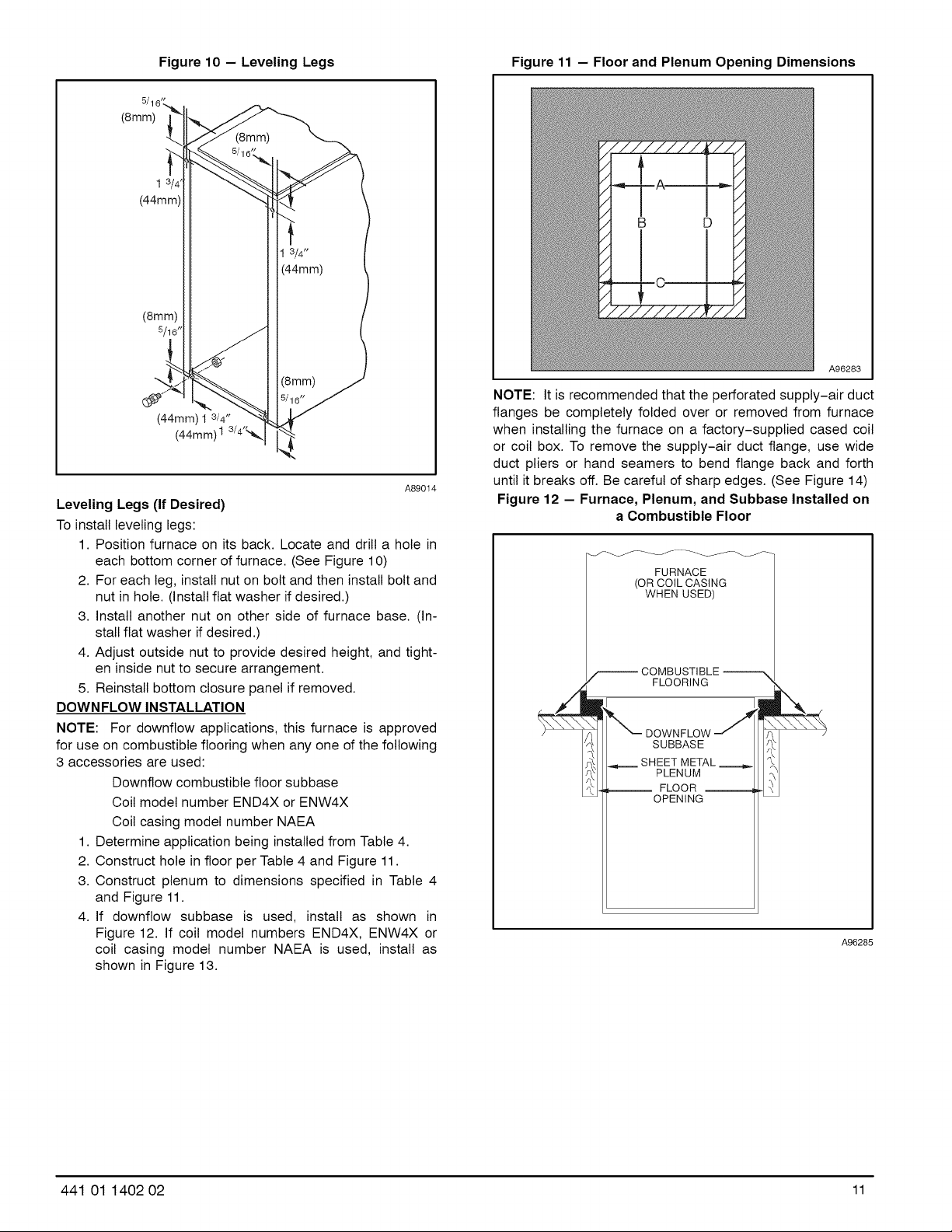

1.Adjoiningroomscanbeconsideredpartofaspaceif:

a.Therearenocloseabledoorsbetweenrooms.

b.Combiningspacesonsamefloorlevel.Eachopen-

ingshallhavefreeareaofatleast1in.2/1,000Btuh

(2,000mm2/kW)ofthetotalinputratingofallgas

appliancesinthespace,butnotlessthan100in.2

(0.06m2).Oneopeningshallcommencewithin12

in.(300mm)oftheceilingandthesecondopening

shallcommencewithin12in.(300mm)ofthefloor.

Theminimumdimensionofairopeningsshallbeat

least3in.(80mm).(SeeFigure8)

c.Combiningspaceondifferentfloorlevels.The

volumesofspacesondifferentfloorlevelsshallbe

consideredascommunicatingspacesifconnected

byoneormorepermanentopeningsindoorsor

floorshavingfreeareaofatleast2in.2/1,000Btuh

(4,400mm2/kW)oftotalinputratingofallgasappli-

ances.

2.Anatticorcrawlspacemaybeconsideredaspacethat

freelycommunicateswiththeoutdoorsprovidedthere

areadequatepermanentventilationopeningsdirectly

tooutdoorshavingfreeareaofat least1-in.2/4,000

Btuhoftotalinputratingforallgasappliancesinthe

space.

3.InspacesthatusetheIndoorCombustionAirMethod,

infiltrationshouldbeadequatetoprovideairforcom-

bustion,permanentventilationand dilutionof flue

gases.However,inbuildingswithunusuallytightcon-

struction,additionalairMUSTbeprovidedusingthe

methodsdescribedintheOutdoorCombustionAir

Methodsection.

UnusuallytightconstructionisdefinedasConstructionwith:

a.Wallsandceilingsexposedtotheoutdoorshavea

continuous,sealedvaporbarrier.Openingsaregas-

ketedorsealedand

b.Doorsandopenablewindowsareweatherstripped

and

c.Otheropeningsarecaulkedorsealed.Thesein-

cludejointsaroundwindowanddoorframes,

betweensoleplatesandfloors,betweenwall-ceil-

ingjoints,betweenwallpanels,atpenetrationsfor

plumbing,electricalandgaslines,etc.

CombinationofIndoorandOutdoorAir

1.IndooropeningsshallcomplywiththeIndoorCom-

bustionAirMethodbelowand,

2.Outdooropeningsshallbelocatedasrequiredinthe

OutdoorCombustionAir Methodmentionedprevi-

ouslyand,

3.Outdooropeningsshallbesizedasfollows:

a.CalculatetheRatioofallIndoorSpacevolumedi-

videdbyrequiredvolumeforIndoorCombustion

AirMethodbelow.

b.OutdooropeningsizereductionFactoris1minus

theRatioina.above.

c.MinimumsizeofOutdooropeningsshallbethesize

requiredinOutdoorCombustionAirMethod

abovemultipliedbyreductionFactorinb.above.

Theminimumdimensionofairopeningsshallbe

notlessthan3in.(80mm).

INSTALLATION

UPFLOW INSTALLATION

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel

installed in bottom return-air opening. Remove and discard

this panel when bottom return air is used. To remove bottom

closure panel, perform the following:

1. Tilt or raise furnace and remove 2 screws holding bot-

tom filler panel. (See Figure 9.)

Figure 9 -- Removing Bottom Closure Panel

I

I

#

I

BOTTOM

CLOSURE

PANEL

BOTTOM

FILLER PANEL

2. Rotate bottom filler panel downward to release holding

tabs.

3. Remove bottom closure panel.

4. Reinstall bottom filler panel and screws.

Side Return Air Inlet

These furnaces are shipped with bottom closure panel

installed in bottom return-air opening. This panel MUST be in

place when only side return air is used.

NOTE: Side return-air openings can be used in UPFLOW

and most HORIZONTAL configurations. Do not use side

return-air openings in DOWNFLOW configuration.

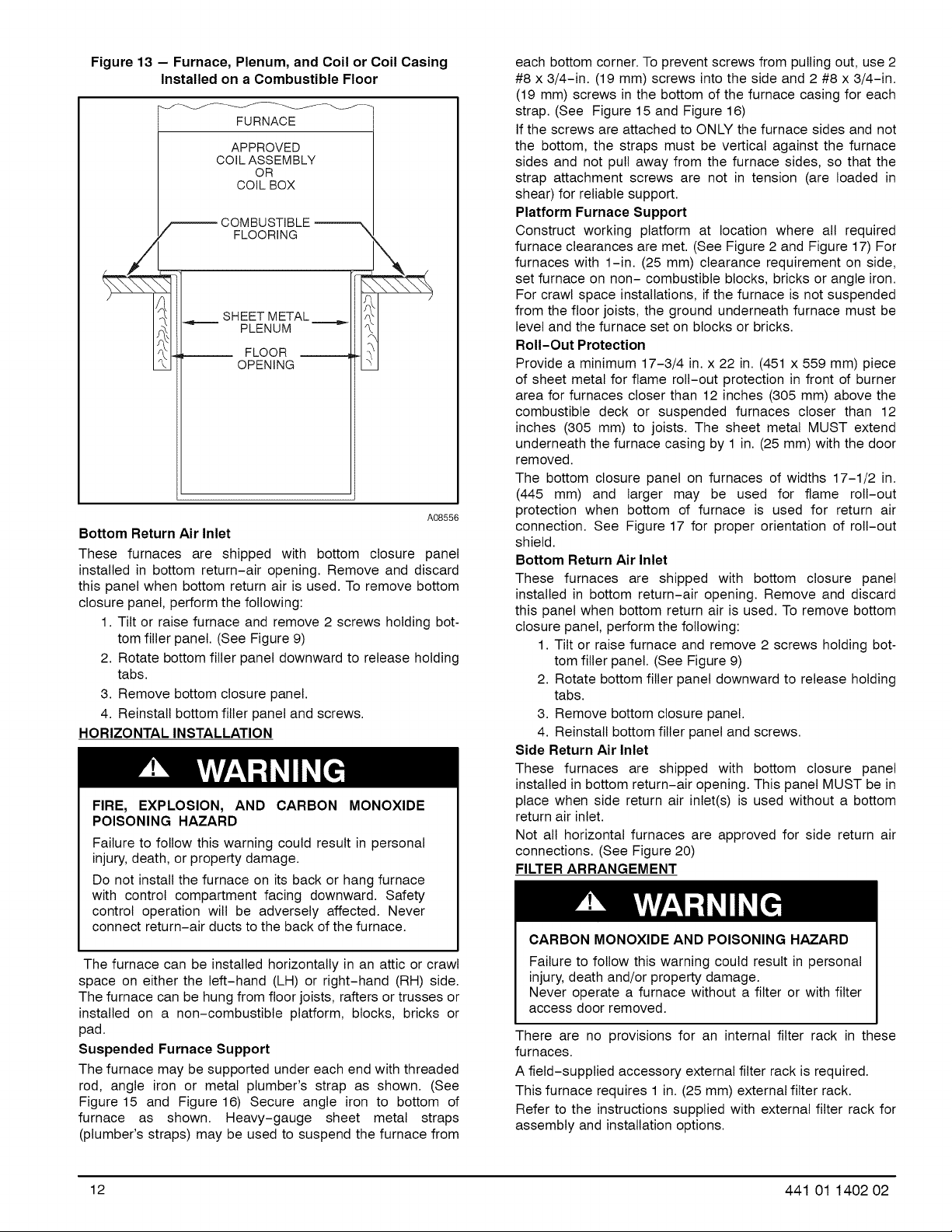

In upflow position with side return inlet(s), leveling legs may

be used. (See Figure 10) Install field-supplied, 5/16 x 1-1/2

in. (8 x 38 mm) (max) corrosion-resistant machine bolts,

washers and nuts.

NOTE: Bottom closure must be used when leveling legs are

used. It may be necessary to remove and reinstall bottom

closure panel to install leveling legs. To remove bottom

closure panel, see Item 1. in Bottom Return Air Inlet section.

P

10 441 01 1402 02

Page 11

Figure 10 - Leveling Legs Figure 11 - Floor and Plenum Opening Dimensions

(8mm)

I

(44mm)

1 3/4"

(44mm)

(8mm)

5/16 _

(8mm)

(44mm) 1 3/4"

(44mm) I 3/4'_.

A89014

Leveling Legs (If Desired)

To install leveling legs:

1. Position furnace on its back. Locate and drill a hole in

each bottom corner of furnace. (See Figure 10)

2. For each leg, install nut on bolt and then install bolt and

nut in hole. (Install flat washer if desired.)

3. Install another nut on other side of furnace base. (In-

stall flat washer if desired.)

4. Adjust outside nut to provide desired height, and tight-

en inside nut to secure arrangement.

5. Reinstall bottom closure panel if removed.

DOWNFLOW INSTALLATION

NOTE: For downflow applications, this furnace is approved

for use on combustible flooring when any one of the following

3 accessories are used:

Downflow combustible floor subbase

Coil model number END4X or ENW4X

Coil casing model number NAEA

1. Determine application being installed from Table 4.

2. Construct hole in floor per Table 4 and Figure 11.

3. Construct plenum to dimensions specified in Table 4

and Figure 11.

4. If downflow subbase is used, install as shown in

Figure 12. If coil model numbers END4X, ENW4X or

coil casing model number NAEA is used, install as

shown in Figure 13.

A96283

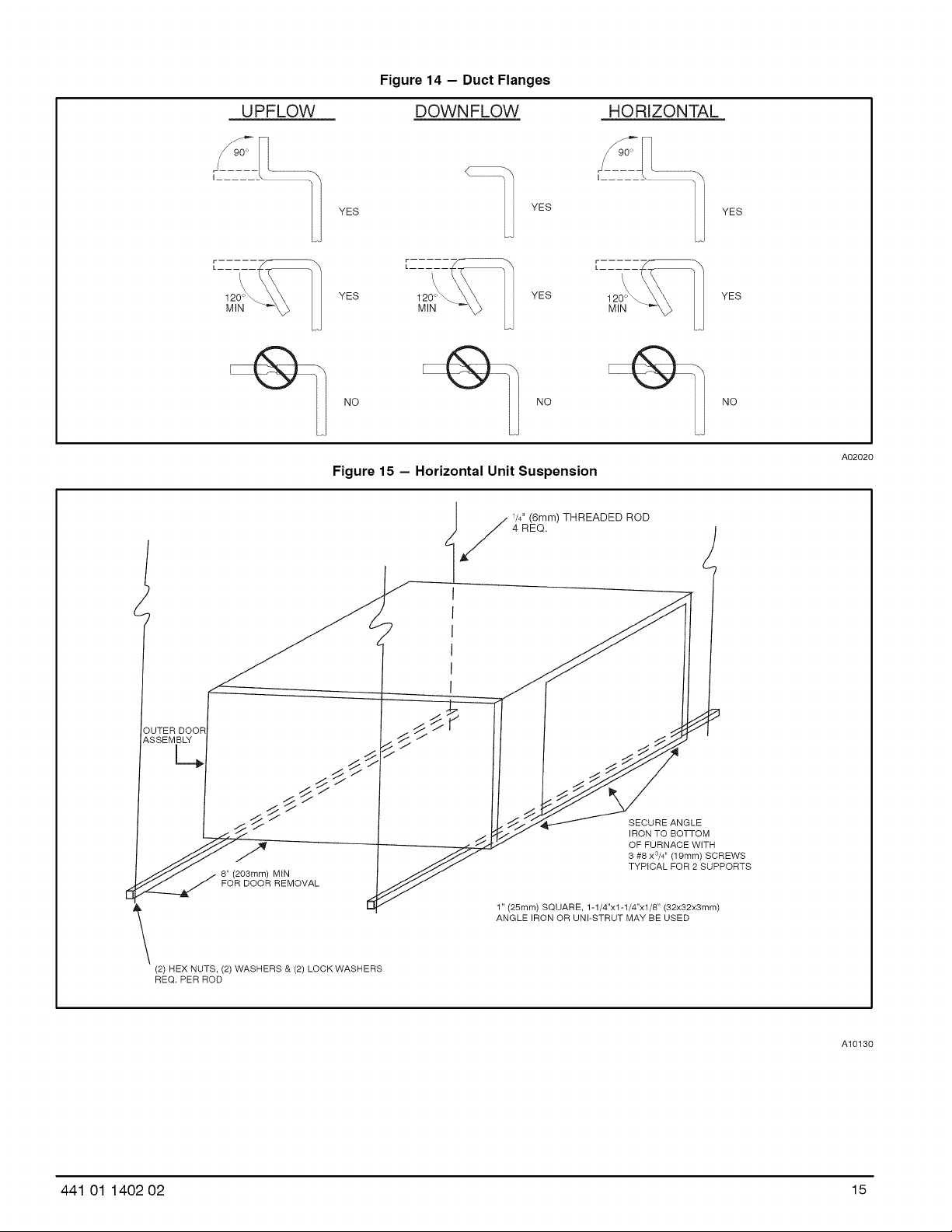

NOTE: It is recommended that the perforated supply-air duct

flanges be completely folded over or removed from furnace

when installing the furnace on a factory-supplied cased coil

or coil box. To remove the supply-air duct flange, use wide

duct pliers or hand seamers to bend flange back and forth

until it breaks off. Be careful of sharp edges. (See Figure 14)

Figure 12 - Furnace, Plenum, and Subbase Installed on

a Combustible Floor

FURNACE

(OR COIL CASING

WHEN USED)

COMBUSTIBLE

FLOORING

DOWNFLOW

SUBBASE

SHEET METAL

PLENUM

__ FLOOR __

OPENING

A96285

441 01 1402 02 11

Page 12

Figure 13 - Furnace, Plenum, and Coil or Coil Casing

Installed on a Combustible Floor

FURNACE

APPROVED

COIL ASSEMBLY

OR

COIL BOX

COMBUSTIBLE

FLOORING

\\\\_

_f,=====SHEET METAL =====.=_

I

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel

installed in bottom return-air opening. Remove and discard

this panel when bottom return air is used. To remove bottom

closure panel, perform the following:

1. Tilt or raise furnace and remove 2 screws holding bot-

tom filler panel. (See Figure 9)

2. Rotate bottom filler panel downward to release holding

tabs.

3. Remove bottom closure panel.

4. Reinstall bottom filler panel and screws.

HORIZONTAL INSTALLATION

FIRE, EXPLOSION, AND CARBON MONOXIDE

POISONING HAZARD

Failure to follow this warning could result in personal

injury, death, or property damage.

Do not install the furnace on its back or hang furnace

with control compartment facing downward. Safety

control operation will be adversely affected. Never

connect return-air ducts to the back of the furnace.

The furnace can be installed horizontally in an attic or crawl

space on either the left-hand (LH) or right-hand (RH) side.

The furnace can be hung from floor joists, rafters or trusses or

installed on a non-combustible platform, blocks, bricks or

pad.

Suspended Furnace Support

The furnace may be supported under each end with threaded

rod, angle iron or metal plumber's strap as shown. (See

Figure 15 and Figure 16) Secure angle iron to bottom of

furnace as shown. Heavy-gauge sheet metal straps

(plumber's straps) may be used to suspend the furnace from

PLENUM

FLOOR

OPENING

E

A08556

each bottom corner. To prevent screws from pulling out, use 2

#8 x 3/4-in. (19 mm) screws into the side and 2 #8 x 3/4-in.

(19 mm) screws in the bottom of the furnace casing for each

strap. (See Figure 15 and Figure 16)

If the screws are attached to ONLY the furnace sides and not

the bottom, the straps must be vertical against the furnace

sides and not pull away from the furnace sides, so that the

strap attachment screws are not in tension (are loaded in

shear) for reliable support.

Platform Furnace Support

Construct working platform at location where all required

furnace clearances are met. (See Figure 2 and Figure 17) For

furnaces with 1-in. (25 mm) clearance requirement on side,

set furnace on non- combustible blocks, bricks or angle iron.

For crawl space installations, if the furnace is not suspended

from the floor joists, the ground underneath furnace must be

level and the furnace set on blocks or bricks.

Roll-Out Protection

Provide a minimum 17-3/4 in. x 22 in. (451 x 559 mm) piece

of sheet metal for flame roll-out protection in front of burner

area for furnaces closer than 12 inches (305 mm) above the

combustible deck or suspended furnaces closer than 12

inches (305 mm) to joists. The sheet metal MUST extend

underneath the furnace casing by 1 in. (25 mm) with the door

removed.

The bottom closure panel on furnaces of widths 17-1/2 in.

(445 mm) and larger may be used for flame roll-out

protection when bottom of furnace is used for return air

connection. See Figure 17 for proper orientation of roll-out

shield.

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel

installed in bottom return-air opening. Remove and discard

this panel when bottom return air is used. To remove bottom

closure panel, perform the following:

1. Tilt or raise furnace and remove 2 screws holding bot-

tom filler panel. (See Figure 9)

2. Rotate bottom filler panel downward to release holding

tabs.

3. Remove bottom closure panel.

4. Reinstall bottom filler panel and screws.

Side Return Air Inlet

These furnaces are shipped with bottom closure panel

installed in bottom return-air opening. This panel MUST be in

place when side return air inlet(s) is used without a bottom

return air inlet.

Not all horizontal furnaces are approved for side return air

connections. (See Figure 20)

FILTER ARRANGEMENT

CARBON MONOXIDE AND POISONING HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Never operate a furnace without a filter or with filter

access door removed.

There are no provisions for an internal filter rack in these

furnaces.

A field-supplied accessory external filter rack is required.

This furnace requires 1 in. (25 mm) external filter rack.

Refer to the instructions supplied with external filter rack for

assembly and installation options.

12 441 01 1402 02

Page 13

Table 4_Opening Dimensions - In. (mm)

FURNACE

CASING

WIDTH

Upflow Applications on Combustible or Noncombustible Flooring 12-11/16 21-5/8 13-5/16 22-1/4

Downflow Applications on Noncombustible Flooring 12-9/16 19 13-3/16 19-5/8

14-3/16 (subbase not required) (319) (483) (335) (498)

(360) Downflow Applications on Combustible Flooring 11-13/16 19 13-7/16 20-5/8

Downflow Applications on Combustible Flooring with Coil END4X, 12-5/16 19 13-5/16 20

ENW4X or Coil Casing NAEA (subbase not required) (319) (483) (338) (508)

Upflow Applications on Combustible or Noncombustible Flooring 16 21-5/8 16-5/8 22-1/4

Downflow Applications on Noncombustible Flooring 15-7/8 19 16-1/2 19-5/8

17-1/2 (subbase not required) (403) (483) (419) (498)

(445) Downflow Applications on Combustible Flooring 15-1/8 19 16-3/4 20-5/8

Downflow Applications on Combustible Flooring with Coil END4X, 15-1/2 19 16-1/2 20

ENW4X or Coil Casing NAEA (subbase not required) (394) (483) (419) (508)

Upflow Applications on Combustible or Noncombustible Flooring 19-1/2 21-5/8 20-1/8 22-1/4

Downflow Applications on Noncombustible Flooring 19-3/8 19 20 19-5/8

21 (subbase not required) (492) (483) (508) (498)

(533) Downflow Applications on Combustible Flooring 18-5/8 19 20-1/4 20-5/8

Downflow Applications on Combustible Flooring with Coil END4X, 19 19 20 20

ENW4X or Coil Casing NAEA (subbase not required) (483) (483) (508) (508)

Upflow Applications on Combustible or Noncombustible Flooring 23 21- 1/8 23-5/8 22-1/4

Downflow Applications on Noncombustible Flooring 22- 7/8 19 23-1/2 19-5/8

24-1/2 (subbase not required) (581) (483) (597) (498)

(622) Downflow Applications on Combustible flooring 22-1/8 19 23-3/4 20-5/8

Downflow Applications on Combustible Flooring with Coil EN D4X, 22-1/2 19 23-1/2 20

ENW4X or Coil Casing NAEA (subbase not required) (572) (483) (597) (508)

APPLICATION

(subbase not required) (322) (549) (338) (565)

(subbase required) (284) (483) (34t) (600)

(subbase not required) (406) (549) (422) (565)

(subbase required) (384) (483) (425) (600)

(subbase not required) (495) (549) (511) (565)

(subbase required) (473) (483) (514) (600)

(subbase not required) (584) (537) (600) (565)

(subbase required) (562) (483) (603) (600)

PLENUM OPENING FLOOR OPENING

A B C D

AIR DUCTS

General Requirements

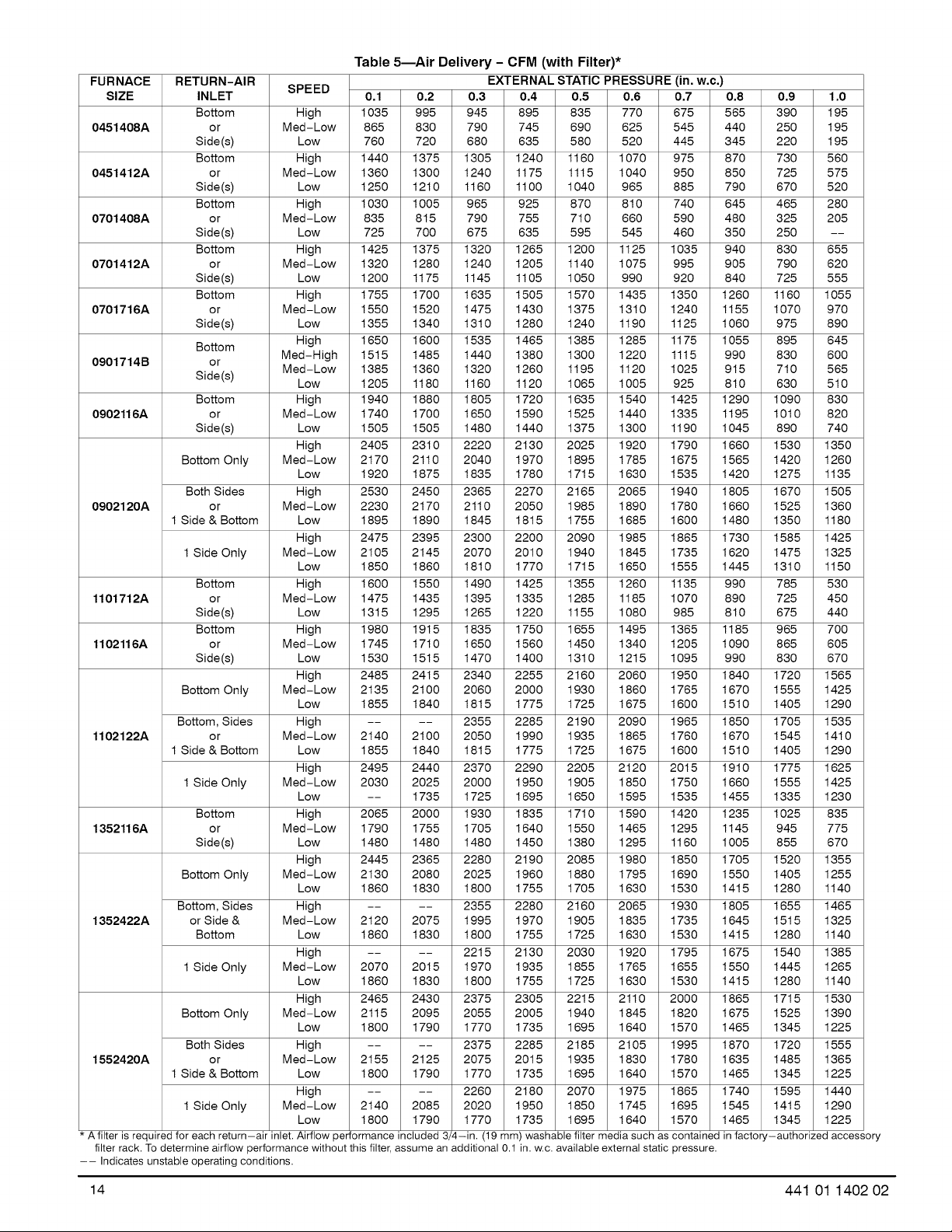

The duct system should be designed and sized according to

accepted national standards such as those published by: Air

Conditioning Contractors Association (ACCA), Sheet Metal

and Air Conditioning Contractors National Association

(SMACNA) or American Society of Heating, Refrigerating and

Air Conditioning Engineers (ASHRAE) or consult The Air

Systems Design Guidelines reference tables available from

your local distributor. The duct system should be sized to

handle the required system design CFM at the design

external static pressure. The furnace airflow rates are

provided in Table 5 - AIR DELIVERY-CFM (With Filter).

When a furnace is installed so that the supply ducts carry air

circulated by the furnace to areas outside the space

containing the furnace, the return air shall also be handled by

duct(s) sealed to the furnace casing and terminating outside

the space containing the furnace.

Secure ductwork with proper fasteners for type of ductwork

used. Seal supply- and return-duct connections to furnace

with code approved tape or duct sealer.

NOTE: Flexible connections should be used between

ductwork and furnace to prevent transmission of vibration.

Ductwork passing through unconditioned space should be

insulated and sealed to enhance system performance. When

air conditioning is used, a vapor barrier is recommended.

Maintain a 1-in. (25 mm) clearance from combustible

materials to supply air ductwork for a distance of 36 in. (914

mm) horizontally from the furnace. See NFPA 90B or local

code for further requirements.

Ductwork Acoustical Treatment

NOTE: Metal duct systems that do not have a 90 degree

elbow and 10 ft. (3 M) of main duct to the first branch take-off

may require internal acoustical lining. As an alternative,

fibrous ductwork may be used if constructed and installed in

accordance with the latest edition of SMACNA construction

standard on fibrous glass ducts. Both acoustical lining and

fibrous ductwork shall comply with NFPA 90B as tested by UL

Standard 181 for Class 1 Rigid air ducts.

Supply Air Connections

For a furnace not equipped with a cooling coil, the outlet duct

shall be provided with a removable access panel. This

opening shall be accessible when the furnace is installed and

shall be of such a size that the heat exchanger can be

viewed for possible openings using light assistance or a

probe can be inserted for sampling the air stream. The cover

attachment shall prevent leaks.

441 01 1402 02 13

Page 14

Table 5--Air Delivery - CFM (with Filter)*

FURNACE RETURN-AIR SPEED EXTERNAL STATIC PRESSURE (in, w,c,)

SIZE INLET 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1,0

0451408A or Med-Low 865 830 790 745 690 625 545 440 250 195

0451412A or Med-Low 1360 1300 1240 1175 1115 1040 950 850 725 575

0701408A or Med-Low 835 815 790 755 710 660 590 480 325 205

0701412A or M ed-Low 1320 1280 1240 1205 1140 1075 995 905 790 620

0701716A or Med-Low 1550 1520 1475 1430 1375 1310 1240 1155 1070 970

0901714B or Med-High 1515 1485 1440 1380 1300 1220 1115 990 830 600

0902116A or Med-Low 1740 1700 1650 1590 1525 1440 1335 1195 1010 820

0902120A or M ed-Low 2230 2170 2110 2050 1985 1890 1780 1660 1525 1360

1101712A or Med-Low 1475 1435 1395 1335 1285 1185 1070 890 725 450

1102116A or Med-Low 1745 1710 1650 1560 1450 1340 1205 1090 865 605

1102122A or Med-Low 2140 2100 2050 1990 1935 1865 1760 1670 1545 14t0

1352116A or Med-Low 1790 1755 1705 1640 1550 1465 1295 1145 945 775

1352422A or Side & Med-Low 2120 2075 1995 1970 1905 1835 1735 1645 1515 1325

1552420A or Med-Low 2155 2125 2075 2015 1935 1830 1780 1635 1485 1365

* A filter is required for each return-air inlet.Airflow performance included 3/_-in, (19mm) washable filter media such as contained infactory-authorized accessory

filter rack. Todetermine airflow performance without this filter,assume an additional 0.1 in. w.c. available external static pressure.

-- Indicates unstable operating conditions.

Bottom High 1035 995 945 895 835 770 675 565 390 195

Side(s) Low 760 720 680 635 580 520 445 345 220 195

Bottom High 1440 1375 1305 1240 1160 1070 975 870 730 560

Side(s) Low 1250 1210 1160 1100 1040 965 885 790 670 520

Bottom High 1030 1005 965 925 870 810 740 645 465 280

Side(s) Low 725 700 675 635 595 545 460 350 250 --

Bottom High 1425 1375 1320 1265 1200 1125 1035 940 830 655

Side (s) Low 1200 1175 1145 1105 1050 990 920 840 725 555

Bottom High 1755 1700 1635 1505 1570 1435 1350 1260 1160 1055

Side(s) Low 1355 1340 1310 1280 1240 1190 1125 1060 975 890

Bottom High 1650 1600 1535 1465 1385 1285 1175 1055 895 645

Side(s) Low 1205 1180 1160 1120 1065 1005 925 810 630 510

Bottom High 1940 1880 1805 1720 1635 1540 1425 1290 1090 830

Side(s) Low 1505 1505 1480 1440 1375 1300 1190 1045 890 740

Bottom Only M ed-Low 2170 2110 2040 1970 1895 1785 1675 1565 1420 1260

Both Sides High 2530 2450 2365 2270 2165 2065 1940 1805 1670 1505

1 Side & Bottom Low 1895 1890 1845 1815 1755 1685 1600 1480 1350 1180

1 Side Only Med-Low 2105 2145 2070 2010 1940 1845 1735 1620 1475 1325

Bottom High 1600 1550 1490 1425 1355 1260 1135 990 785 530

Side(s) Low 1315 1295 1265 1220 1155 1080 985 810 675 440

Bottom High 1980 1915 1835 1750 1655 1495 1365 1185 965 700

Side(s) Low 1530 1515 1470 1400 1310 1215 1095 990 830 670

Bottom Only Med-Low 2135 2100 2060 2000 1930 1860 1765 1670 1555 1425

Bottom, Sides High .... 2355 2285 2190 2090 1965 1850 1705 1535

1 Side & Bottom Low 1855 1840 1815 1775 1725 1675 1600 1510 1405 1290

1 Side Only M ed-Low 2030 2025 2000 1950 1905 1850 1750 1660 1555 1425

Bottom High 2065 2000 1930 1835 1710 1590 1420 1235 1025 835

Side (s) Low 1480 1480 1480 1450 1380 1295 1160 1005 855 670

Bottom Only M ed- Low 2130 2080 2025 1960 1880 1795 1690 1550 1405 1255

Bottom, Sides High .... 2355 2280 2160 2065 1930 1805 1655 1465

Bottom Low 1860 1830 1800 1755 1725 1630 1530 14t5 1280 1140

1 Side Only M ed-Low 2070 2015 1970 1935 1855 1765 1655 1550 1445 1265

Bottom Only M ed-Low 2115 2095 2055 2005 1940 1845 1820 1675 1525 1390

Both Sides High .... 2375 2285 2185 2105 1995 1870 1720 1555

1 Side & Bottom Low 1800 1790 1770 1735 1695 1640 1570 1465 1345 1225

1 Side Only Med-Low 2140 2085 2020 1950 1850 1745 1695 1545 14t5 1290

Med-Low 1385 1360 1320 1260 1195 1120 1025 915 710 565

High 2405 2310 2220 2130 2025 1920 1790 1660 1530 1350

Low 1920 1875 1835 1780 1715 1630 1535 1420 1275 1135

High 2475 2395 2300 2200 2090 1985 1865 1730 1585 1425

Low 1850 1860 1810 1770 1715 1650 1555 1445 1310 1150

High 2485 24t 5 2340 2255 2160 2060 1950 1840 1720 1565

Low 1855 1840 1815 1775 1725 1675 1600 1510 1405 1290

High 2495 2440 2370 2290 2205 2120 2015 1910 1775 1625

Low -- 1735 1725 1695 1650 1595 1535 1455 1335 1230

High 2445 2365 2280 2190 2085 1980 1850 1705 1520 1355

Low 1860 1830 1800 1755 1705 1630 1530 14t5 1280 1140

High .... 2215 2130 2030 1920 1795 1675 1540 1385

Low 1860 1830 1800 1755 1725 1630 1530 14t5 1280 1140

High 2465 2430 2375 2305 2215 2110 2000 1865 1715 1530

Low 1800 1790 1770 1735 1695 1640 1570 1465 1345 1225

High .... 2260 2180 2070 1975 1865 1740 1595 1440

Low 1800 1790 1770 1735 1695 1640 1570 1465 1345 1225

14 441 01 1402 02

Page 15

Figure 14 - Duct Flanges

UPFLOW

YES

/ t\ /\

120'_ YES 120°_ YES 120°_

MIN MIN MIN

NO NO NO

DOWNFLOW HORIZONTAL

I ......

YES

Figure 15 - Horizontal Unit Suspension

4 REQ,

/ /4" (6mm) THREADED ROD

YES

YES

A02020

/

OUTER DOOR

ASSEMBLY

c.

8" (203mm) MtN

FOR DOOR REMOVAL

(2) HEX NUTS, (2) WASHERS & (2) LOCK WASHERS

REQ. PER ROD

SECURE ANGLE

IRON TO BOTTOM

OF FURNACE WITH

3 #8 x3/4'' (19mm) SCREWS

TYPICAL FOR 2 SUPPORTS

1" (25ram) SQUARE, 1-1/4"x1-1/4"x1/8" (32x32x3mm)

ANGLE IRON OR UNI-STRUT MAY BE USED

A10130

441 01 1402 02 15

Page 16

Figure 16 - Horizontal Suspension with Straps

22 GAUGE GALVANIZED

STRAPS TYPICAL

FOR 4 STRAPS

/OPENING

AIR

OUTER DOOR

ASSEMBLY

[ //

7

J

J

J

J

J

J

J

J

J

J

Figure 17 - Typical Attic Installation

LINE CONTACT ONLY PERMISSIBLE BETWEEN

LINES FORMED BY INTERSECTIONS OF

THE TOP AND TWO SIDES OF THE FURNACE

JACKET AND BUILDING JOISTS,

STUDS, OR FRAMING.

I

ENTRY

METHOD 2

USE (4) #8 x 3/4 (19 mm) SHEET

METAL SCREWS FOR EACH

STRAR THE STRAPS

SHOULD BE VERTICAL

AGAINST THE FURNACE

FROM THE FURNACE

SIDES AND NOT PULL AWAY

SIDES.

BACK OF

FURNACE

METHOD 1

FOLD ALL STRAPS UNDER

FURNACE AND SECURE WTH

(4) #8 x 3/4 (t9 mm) SHEET METAL SCREWS

(2 SCREWS IN SiDE AND 2 SCREWS

iN BOTTOM).

TYPE-B

VENT

A10131

173/4" (451 mm)OVERALL

43/4" (121mm) UNDER DOOR

1" (25mm) UNDER FURNACE

EXTEND OUT 12" (305mm)

FROM FACE OF DOOR

i

30-IN. (762mm)

MIN WORK AREA *WHEN USED WITH

SINGLE WALL VENT

CONNECTIONS

EQUIPMENT MANUAL

SHUT-OFF GAS VALVE

SEDIMEN1

TRAP

UNWON

A10164

16 441 01 1402 02

Page 17

Figure 18 - Upflow Return Air Configurations and Restrictions

i ¸_

@

RETURN i

AIR

RETURN

AIR

UPFLOW RETURN AiR CONFiGURATiONS AND RESTRICTIONS

AIR _!_ RESTRICTIONS

RETURN T UPFL©W

RETURN AIR

AIR FLOW MODELS RETURN AIR RETURN AIR RETURN AIR RETURN AIR |

5 TONS AND YES YES YES YES |

GREATER *

ALL OTHER MODELS YES YES YES YES

• 2000 CFM AND GREATER AT .6 ESP HI COOLING SPEED

RETURN

AiR

CONNECTION 1 CONNECTION 2 CONNECTION 3 COMBINATIONS

ONLY ONLY ONLY OF 1,2, AND 3

Figure 19 - Downflow Return Air Configurations and Restrictions

_1_ RETURN

AIR

!

]

t

/

AIR

RETURN i

• NOTE: RESTRICTION SAME FOR

HORIZONAL LEFT

DOWNFLOWRETURNAJRCONRGURATIONSANDRESTRICq]ONS

AIR FLOW MODELS RETURN AIR RETURN AIR RETURN AIR RETURN AIR

5 TONS AND YES NO NO NO

GREATER *

ALL OTHER MODELS YES NO NO NO

• 2000 CFM AND GREATER AT .6 ESP HI COOLING SPEED

CONNECTION 1 CONNECTION 2 CONNECTION 3 COMBINATIONS

ONLY ONLY ONLY OF 1, 2, AND 3

Figure 20 - Horizontal Return Air Configurations and Restrictions

RETURN

........................(/ ........................

,@_ SIDERETURN AIR

_ NOTPERMI_ED FOR

066,060,-22-2O

AIR FLOWMODELS

AIR

II

II

II

II

I'\ /_lt_ _ SIDE RETURN AIR

, / _M NOT PERM _ED FOR

/" 066,060, _2_0

AIR FLOW MODELS

AaR RESTRICTIONS

i RETURN RETURNAIR

,r3_

_ HORIZONTAL RETURN AIR CONFIGURATIONS AND RESTRICTIONS

HORIZONAL

AiR FLOW MODELS RETURN AiR RETURN AIR RETURN AiR RETURN AiR

5 TONS AND YES NO NO NO

GREATER *

ALL OTHER MODELS YES YES YES YES

• 2000 CFM AND GREATER AT .6 ESP HI COOLING SPEED

CONNECTmON 1 CONNECTION 2 CONNECTmON 3 COMBJNATmONS

ONLY ONLY ONLY OF 1,2, AND 3

441 01 1402 02 17

Page 18

Upflow and Horizontal Furnaces

Connect supply-air duct to flanges on furnace supply-air

outlet. Bend flange upward to 90 ° with wide duct pliers. (See

Figure 14) The supply-air duct must be connected to ONLY

the furnace supply-outlet-air duct flanges or air conditioning

coil casing (when used). DO NOT cut main furnace casing

side to attach supply air duct, humidifier, or other accessories.

All accessories MUST be connected to duct external to

furnace main casing.

NOTE: For horizontal applications, the top-most flange may

be bent past 90 ° to allow the evaporator coil to hang on the

flange temporarily while the remaining attachment and

sealing of the coil are performed.

Downflow Furnaces

Connect supply-air duct to supply-air outlet on furnace. Bend

flange inward past 90 ° with wide duct pliers. (See Figure 14)

The supply-air duct must be connected to ONLY the furnace

supply-outlet or air conditioning coil casing (when used).

When installed on combustible material, supply-air duct must

be connected to ONLY the accessory subbase or a factory

approved air conditioning coil casing. DO NOT cut main

furnace casing to attach supply side air duct, humidifier, or

other accessories. All accessories MUST be connected to

duct external to furnace casing.

FIRE HAZARD

A failure to follow this warning could result in

personal injury, or death and/or property damage.

Never connect return-air ducts to the back of the

furnace. Follow instructions below.

Return Air Connections

Downflow Furnaces

The return-air duct must be connected to return-air opening

(bottom inlet) as shown in Figure 19. DO NOT cut into casing

sides (left or right). Side opening is permitted for only upflow

and most horizontal furnaces. (See Figure 19) Bypass

humidifier connections should be made at ductwork or coil

casing sides exterior to furnace.

Upflow and Horizontal Furnaces

The return-air duct must be connected to bottom, sides (left

or right), or a combination of bottom and side(s) of main

furnace casing as shown in Figure 18 and Figure 20. Bypass

humidifier may be attached into unused return air side of the

furnace casing. (See Figure 18 and Figure 20)

Not all horizontal furnaces are approved for side return air

connections. (See Figure 20)

GAS PIPING

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Never purge a gas line into a combustion chamber.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made

specifically for the detection of leaks to check all

connections.

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Use proper length of pipe to avoid stress on gas

control manifold and a gas leak.

Gas piping must be installed in accordance with national and

local codes. Refer to current edition of NFGC.

Installations must be made in accordance with all authorities

having jurisdiction. If possible, the gas supply line should be a

separate line running directly from meter to furnace.

NOTE: In the state of Massachusetts:

1. Gas supply connections MUST be performed by a li-

censed plumber or gas fitter.

2. When flexible connectors are used, the maximum

length shall not exceed 36 inches (915 mm).

3. When lever handle type manual equipment shutoff

valves are used, they shall be T-handle valves.

4. The use of copper tubing for gas piping is NOT ap-

proved by the state of Massachusetts.

Refer to Table 6 for recommended gas pipe sizing. Risers

must be used to connect to furnace and to meter. Support all

gas piping with appropriate straps, hangers, etc. Use a

minimum of 1 hanger every 6 ft. (1.8 M) Joint compound (pipe

dope) should be applied sparingly and only to male threads of

joints. Pipe dope must be resistant to the action of propane

gas.

Table 6--Maximum Capacity of Pipe

NOMINAL

IRON PIPE

SIZE

IN. (MM)

1/2 (12,7)

3/4 (19.0)

1(25.4)

1-1/4 (31.8)

1-1/2 (38.1)

* Cubic ft. of natural gas per hr for gas pressures of 0.5 psig (14-in. w.c,) or

less and a pressure drop of 0.5-in. w,c. (based on a 0.60 specific gravity

gas). Ref: Table 6 and ANSI Z223-2009/NFPA 54-2009.

INTERNAL LENGTH OF PIPE - FT (M)

DIA.

'N. (MM) 110/ 1620/ 1930/ 11401/ 115502/

0.622 (158) 175 120 97 82 73

0.824 (20.9) 360 250 200 170 151

1.049 (26.6) 680 465 375 320 285

1.380 (35.0) 1400 950 770 660 580

1.610 (40.9) 2100 1460 1180 990 900

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

If local codes allow the use of a flexible gas appliance

connector, always use a new listed connector. Do not

use a connector which has previously served another

gas appliance. Black iron pipe shall be installed at the

furnace gas control valve and extend a minimum of 2

in. (51 mm) outside the furnace.

18 441 01 1402 02

Page 19

FURNACE OVERHEAT HAZARD

Failure to follow this caution may result in unit

component damage.

Connect gas pipe to gas valve using a backup

wrench to avoid damaging gas controls and burner

misatiqnment.

An accessible manual equipment shutoff valve MUST be

installed external to furnace casing and within 6 ft. (1.8 M) of

furnace. A 1/8-in. (3 mm) NPT plugged tapping, accessible

for test gauge connection, MUST be installed immediately

upstream of gas supply connection to furnace and

downstream of manual equipment shutoff valve.

NOTE: The furnace gas valve inlet pressure tap connection

is suitable to use as test gauge connection providing test

pressure DOES NOT exceed maximum 0.5 psig (14-in. w.c.)

stated on gas control valve. (See Figure 41)

Figure 21 - Burner and Manifold

TOP VIEW OF BURNER AND MANIFOLD ASSEMBLY

Piping should be pressure and leak tested in accordance with

NFGC, local, and national plumbing and gas codes before

the furnace has been connected. After all connections have

been made, purge lines and check for leakage at furnace

prior to operating furnace.

If pressure exceeds 0.5 psig (14-in. w.c.), gas supply pipe

must be disconnected from furnace and capped before and

during supply pipe pressure test. If test pressure is equal to or

less than 0.5 psig (14-in. w.c.), turn off electric shutoff switch

located on furnace gas control valve and accessible manual

equipment shutoff valve before and during supply pipe

pressure test. After all connections have been made, purge

lines and check for leakage at furnace prior to operating

furnace.

Figure 23 - Relocating J-Box

FACTORY

INSTALLED

LOCATION

ALTERNATE

FIELD

LOCATION

2" (51 ram)Nipple

Street

t-Gas Valve

Figure 22 - Typical Gas Pipe Arrangement

GAS--

SUPPLY j'"_

MANUALJ II

SHUTOFF _ _

VALVE

(REQUIRED)_ "1_ }_

SEDIMENT-- /

TRAP /

UNION.-.J

Supply

A08551

Figure 24 - Field-Supplied Electrical Box on Furnace

Casing

O

A02035

Some installations require gas entry on right side of furnace

(as viewed in upflow.) (See Figure 21)

Install a sediment trap in riser leading to furnace as shown in

Figure 22. Connect a capped nipple into lower end of tee.

Capped nipple should extend below level of furnace gas

controls. Place a ground joint union between furnace gas

control valve and exterior manual equipment gas shutoff

valve. A 1/8-in. (3 mm) NPT plugged tapping, accessible for

test gauge connection, MUST be installed immediately

The gas supply pressure shall be within the maximum and

minimum inlet supply pressures marked on the rating plate

with the furnace burners ON and OFF.

upstream of gas supply connection to furnace and

downstream of manual equipment shutoff valve.

441 01 1402 02 19

Page 20

ELECTRICAL CONNECTIONS

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Blower access panel door switch opens 115-v power

to control. No component operation can occur. Do not

bypass or close switch with panel removed.

See Figure 26 for field wiring diagram showing typical field

115-v wiring. Check all factory and field electrical

connections for tightness.

ELECTRICAL SHOCK AND FIRE HAZARD

Failure to follow this warning could result in personal

injury, death, or property damage.

The cabinet MUST have an uninterrupted or

unbroken ground according to NEC ANSI/NFPA

70-2008 or local codes to minimize personal injury if

an electrical fault should occur. This may consist of

electrical wire, conduit approved for electrical ground

or a listed, grounded power cord (where permitted

by local code) when installed in accordance with

existing electrical codes. Refer to the power cord

manufacturer's ratings for proper wire gauge. Do not