Page 1

These instructions must be read and understood completely before attempting installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock,

or other conditions which may cause death, personal injury, or

property damage. Consult a qualified installer, service agency, or

your distributor or branch for information or assistance. The

qualified installer or agency must use factory-authorized kits or

accessories when modifying this product. Refer to the individual

instructions packaged with the kits or accessories when

installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit. Consult local building codes,

the current editions of the National Electrical Code (NEC) NFPA-

70.

TABLE OF CONTENTS

General Information/Installation .......................................... 2

Installation ............................................................................. 2

Vertical/Horizontal Installation ............................................. 3

Ductwork Connection ............................................................ 4

Filter Installation .................................................................... 4

Electrical Connection ............................................................. 4

Blower Performance .............................................................. 8

Sequence of Operation ........................................................ 10

Wiring Diagram .................................................................... 11

Replacement Parts .............................................................. 12

In Canada refer to the current editions of the Canadian Electrical

Code CSA C22.1 Recognize safety information.

This is the safety-alert symbol Z_. When you see this symbol on

the unit and in instructions or manuals, be alert to the potential

for personal injury. Understand these signal words; DANGER,

WARNING, and CAUTION. These words are used with the

safety-alert symbol. DANGER identifies the most serious

hazards which will result in severe personal injury or death.

WARNING signifies hazards which could result in personal

injury or death. CAUTION is used to identify unsafe practices

which may result in minor personal injury or product and property

damage. NOTE is used to highlight suggestions which will result

in enhanced installation, reliability or operation.

ELECTRICALSHOCK HAZARD

Failure to turn off electric power could result in

personal injury or death.

Before installing or servicing system, turn off main

power to the system. There may be more than one

disconnect switch, including accessory heater(s}.

April 2012 Specifications subject to change without notice. X40159 Rev.C

Page 2

Figure i Nominal Installation Dimensions and Clearances-in(ram)

12-7/16" (316/- MF08

15-3/4" (400)- MF12

19-1/4" (489)- MF16

22-3/4" (578)- MF20

Low Voltage

Entrance

14-3/16" (360/- MFO8

17.112" (445/- MF12

21" (533/- MF16

24-1/2" (622/- MF20

314" (19)

Line Voltage | 24" (610)- MFO8 & MF12

Entrance l 25" (635)- MF16 & MF20

GENERAL INFORMATION

DEATH, PERSONAL INJURY, AND/OR PROPERTY DAMAGE

HAZARD

Failure to carefully read and follow this warning could result

in equipment malfunction, property damage, personal injury

and/or death.

The information contained in this manual is intended for use

by a qualified service technician familiar with safety

procedures and equipped with the proper tools and test

instruments.

Installation must conform with local building codes and with

the National Electrical Code NFPA70 current edition.

INTRODUCTION

The MF modular blower cabinet uses a 208/230V PSC blower motor,

with an electronic fan control board. The MF may be used for cooling

or heat pump applications either with or without electric heat.

Installations without electric heat require a NO HEAT KIT

(EHIA00KN10). The cabinet can be installed in an upflow, downflow

or horizontal position. Refer to Figure 3 and 4.

LOCATION

Select the best position which suits the installation site conditions.

The location should provide adequate structural support, space in

the front of the unit for service access, clearance for return air and

supply duct connections, space for refrigerant piping connections

and condensate drain line connections. If heaters are being installed,

CLEARANCES

NO HEATERS

All Sides...0"

From Supply Duct_.0"

Recommended Service From Front_.20"(508 mm)

(Service for blower, filter if installed)

WITH HEATERS

All Sides...O"

From First Three Feet of Supply Duct

to Combustibles...1" (25ram)

From Duct after Three Feet...0"

Recommended Service From Front...20" (508mm)

(Service for blower, heaters if installed)

Fire Hazard

Failure to follow this warning could result in

personal injury, death, and/or property damage.

When heaters are installed maintain clearances

from combustible materials as specified on unit

rating plate. Do not use plastic lined or combustible

flexible ducting within 36" (914 mm) of the supply

end of the modular unit.

make sure adequate clearance is maintained from supply ductwork;

See Clearances and Warning in Figure 1.

If the unit is located in an area of high humidity, nuisance sweating of

casing may occur. On these installations a wrap of 2" (51mm)

fiberglass insulation with a vapor barrier should be used.

HEATER PACKAGES

Factory approved, field installed, UL listed heater packages are

available from the equipment supplier. See unit rating plate for a list

of factory approved heaters (electric heat accessory models EHIA

only). Heaters that are not factory approved could cause damage

which would not be covered under the equipment warranty.

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing and gloves when

handling parts.

INSTALLATION

The unit is ready to install in any position without modifications.

Refer to the coil instructions for information on drain pan

configurations etc. Make sure coil is set up properly for desired

position of blower cabinet.

Coil must be secured to blower cabinet with the three tabs that are

part of the blower cabinet base. Bend the tabs out from the bottom

so they fit over the coil cabinet.

Position coil cabinet in relation to the blower so they will be correct

for desired application.

2 Specifications subject to change without notice. X40159 Rev.C

Page 3

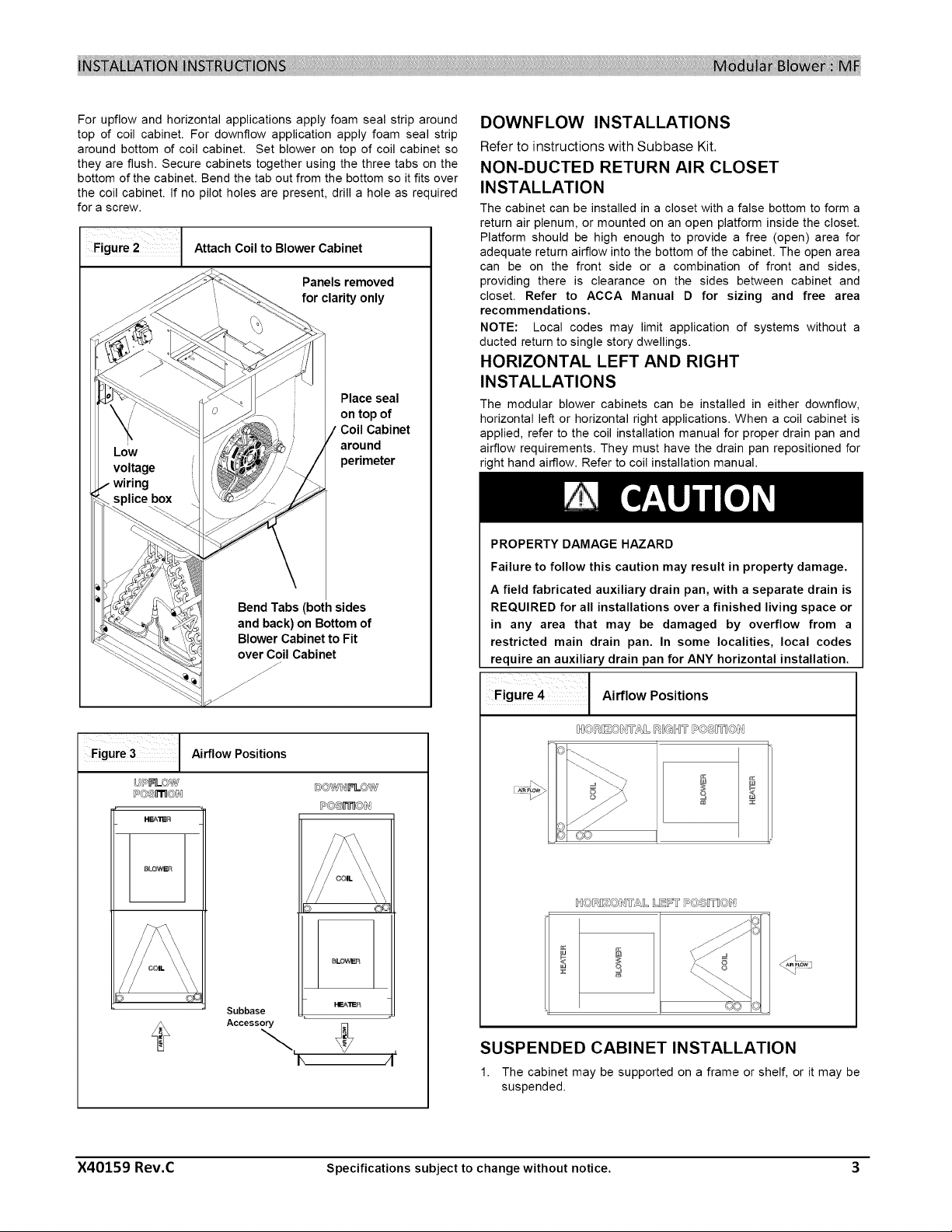

For upflow and horizontal applications apply foam seal strip around

top of coil cabinet. For downflow application apply foam seal strip

around bottom of coil cabinet. Set blower on top of coil cabinet so

they are flush. Secure cabinets together using the three tabs on the

bottom of the cabinet. Bend the tab out from the bottom so it fits over

the coil cabinet. If no pilot holes are present, drill a hole as required

for a screw.

Figuie 2

AttachCoil to BlowerCabinet

Panelsremoved

for clarity only

Placeseal

on topof

CoilCabinet

around

perimeter

DOWNFLOW INSTALLATIONS

Refer to instructions with Subbase Kit.

NON-DUCTED RETURN AIR CLOSET

INSTALLATION

The cabinet can be installed in a closet with a false bottom to form a

return air plenum, or mounted on an open platform inside the closet.

Platform should be high enough to provide a free (open) area for

adequate return airflow into the bottom of the cabinet. The open area

can be on the front side or a combination of front and sides,

providing there is clearance on the sides between cabinet and

closet. Refer to ACCA Manual D for sizing and free area

recommendations.

NOTE: Local codes may limit application of systems without a

ducted return to single story dwellings.

HORIZONTAL LEFT AND RIGHT

INSTALLATIONS

The modular blower cabinets can be installed in either downflow,

horizontal left or horizontal right applications. When a coil cabinet is

applied, refer to the coil installation manual for proper drain pan and

airflow requirements. They must have the drain pan repositioned for

right hand airflow. Refer to coil installation manual.

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property damage.

A field fabricated auxiliary drain pan, with a separate drain is

REQUIRED for all installations over a finished living space or

in any area that may be damaged by overflow from a

restricted main drain pan. In some localities, local codes

require an auxiliary drain pan for ANY horizontal installation.

Airflow Positions

J

Subbase

Accessory

F-

I'EA"I_J_

4

Figure4 J Airflow Positions

i

t

4

SUSPENDED CABINET INSTALLATION

1. The cabinet may be supported on a frame or shelf, or it may be

suspended.

I

X40159 Rev.C Specifications subject to change without notice. 3

Page 4

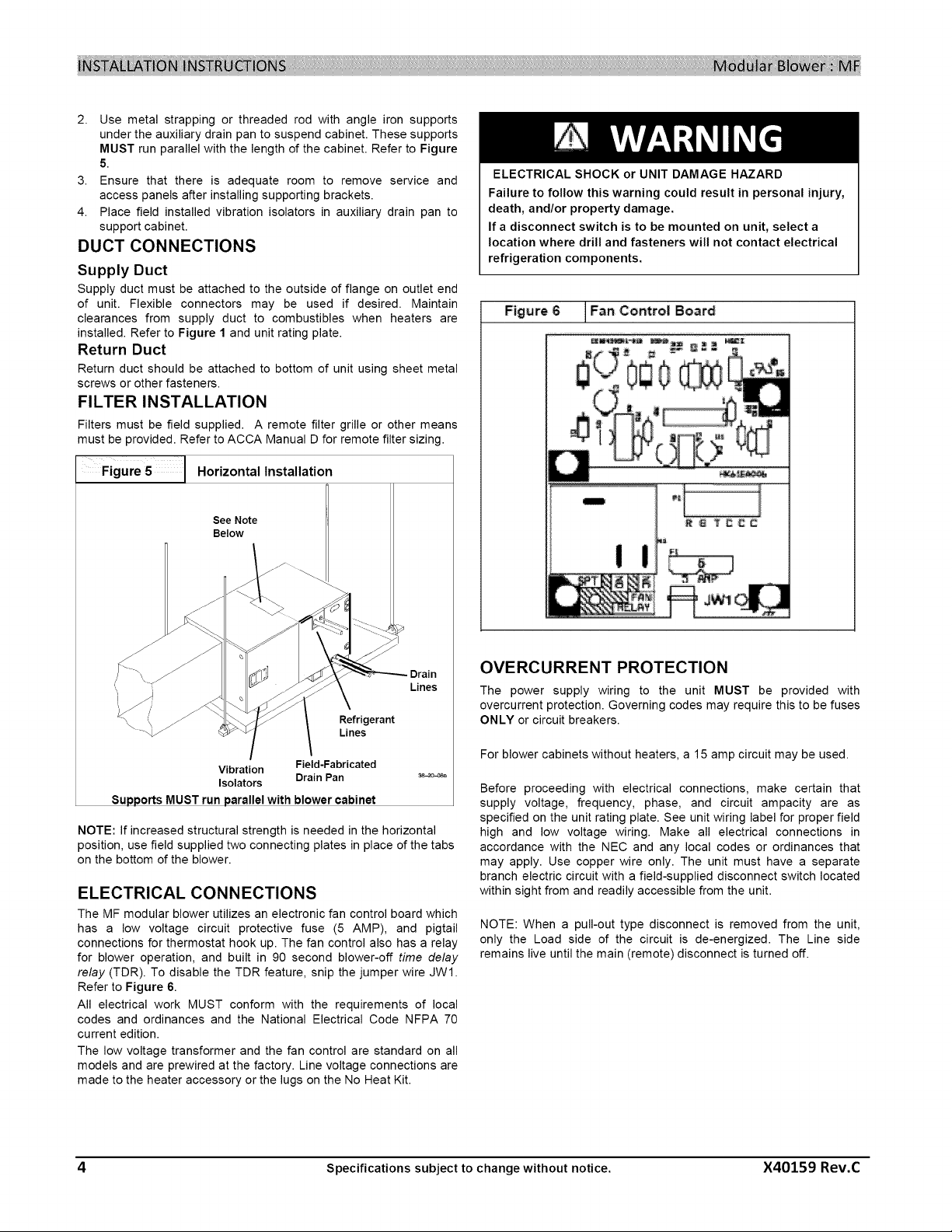

2. Usemetalstrappingorthreadedrodwithangleironsupports

undertheauxiliarydrainpantosuspendcabinet.Thesesupports

MUST run parallel with the length of the cabinet. Refer to Figure

5.

3. Ensure that there is adequate room to remove service and

access panels after installing supporting brackets.

4. Place field installed vibration isolators in auxiliary drain pan to

support cabinet.

DUCT CONNECTIONS

Supply Duct

Supply duct must be attached to the outside of flange on outlet end

of unit. Flexible connectors may be used if desired. Maintain

clearances from supply duct to combustibles when heaters are

installed. Refer to Figure 1 and unit rating plate.

Return Duct

Return duct should be attached to bottom of unit using sheet metal

screws or other fasteners.

FILTER INSTALLATION

Filters must be field supplied. A remote filter grille or other means

must be provided. Refer to ACCA Manual D for remote filter sizing.

Figure 5 Horizontal Installation

see Note

Below

ELECTRICAL SHOCK or UNIT DAMAGE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

If a disconnect switch is to be mounted on unit, select a

location where drill and fasteners will not contact electrical

refrigeration components.

Figure 6

Fan Control Board

, rnT

_ '\ / _ _ Refrigerant

....._ _\'_ \Lines

Vibration Field-Fabricated

Isolators

Supports MUST run parallel with blower cabinet

NOTE: If increased structural strength is needed in the horizontal

position, use field supplied two connecting plates in place of the tabs

on the bottom of the blower.

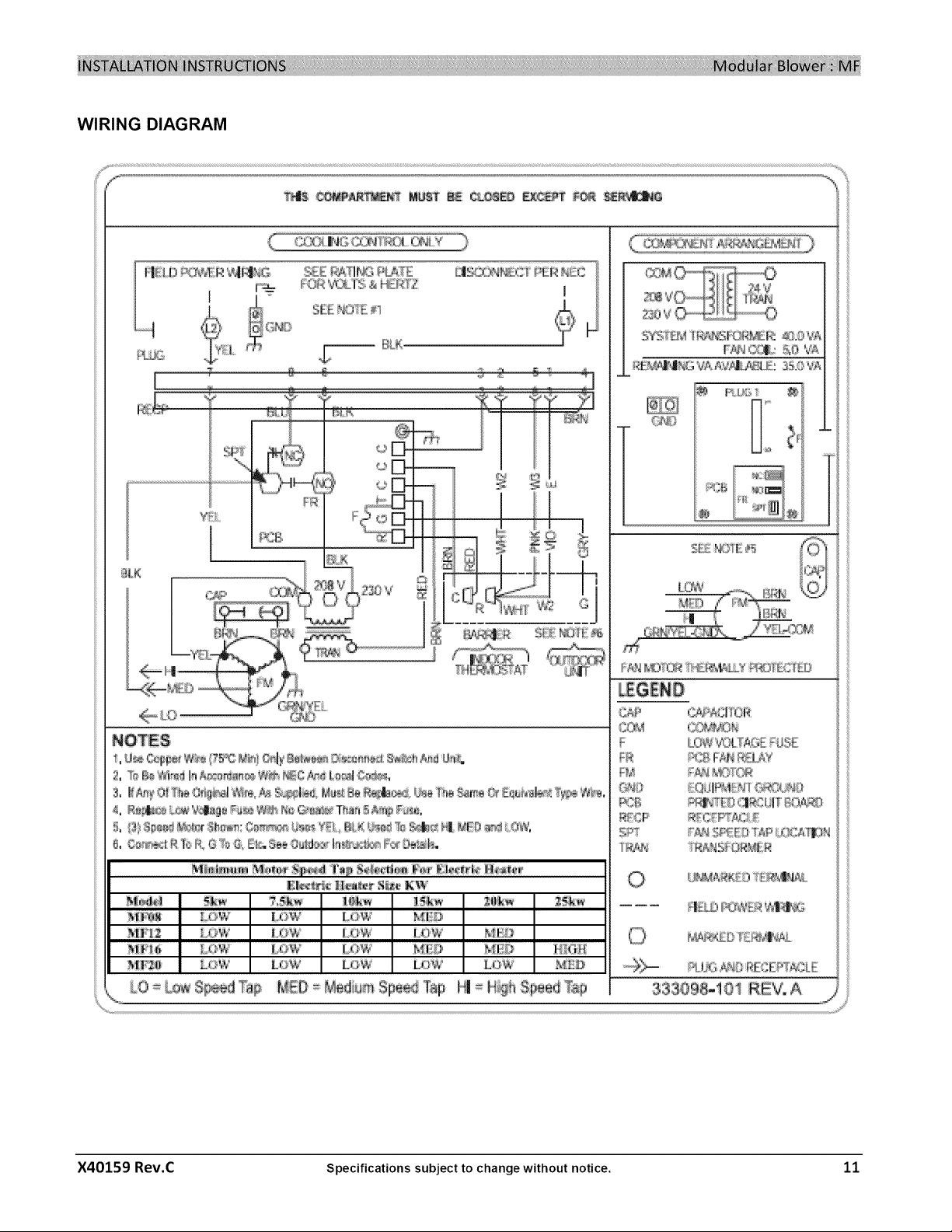

ELECTRICAL CONNECTIONS

The MF modular blower utilizes an electronic fan control board which

has a low voltage circuit protective fuse (5 AMP), and pigtail

connections for thermostat hook up. The fan control also has a relay

for blower operation, and built in 90 second blower-off time delay

relay (TDR). To disable the TDR feature, snip the jumper wire JWI.

Refer to Figure 6.

All electrical work MUST conform with the requirements of local

codes and ordinances and the National Electrical Code NFPA 70

current edition.

The low voltage transformer and the fan control are standard on all

models and are prewired at the factory. Line voltage connections are

made to the heater accessory or the lugs on the No Heat Kit.

DrainPan _-_-_

OVERCURRENTPROTECTION

The power supply wiring to the unit MUST be provided with

overcurrent protection. Governing codes may require this to be fuses

ONLY or circuit breakers.

For blower cabinets without heaters, a 15 amp circuit may be used.

Before proceeding with electrical connections, make certain that

supply voltage, frequency, phase, and circuit ampacity are as

specified on the unit rating plate. See unit wiring label for proper field

high and low voltage wiring. Make all electrical connections in

accordance with the NEC and any local codes or ordinances that

may apply. Use copper wire only. The unit must have a separate

branch electric circuit with a field-supplied disconnect switch located

within sight from and readily accessible from the unit.

NOTE: When a pull-out type disconnect is removed from the unit,

only the Load side of the circuit is de-energized. The Line side

remains live until the main (remote) disconnect is turned off.

4 Specifications subject to change without notice. X40159 Rev.C

Page 5

Low Voltage Control Connections

ELECTRICAL SHOCK or UNIT DAMAGE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Turn OFF electric power at fuse box or service panel before

making any electrical connections and ensure a proper

ground connection is made before connecting line voltage.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Turn OFF the main (remote) disconnect device before

working on incoming (field) wiring. Incoming (field) wiring on

the line side of the disconnect found in the modular blower

unit remains live, even when the pull-out is removed. Service

and maintenance to incoming (field) wiring cannot be

performed until the main disconnect switch (remote to the

unit) is turned off.

MF units installed without electric heat require the use of a factory-

authorized No Heat Kit (accessory part number EHIA00KN 10). This

kit provides the electrical connections necessary to supply the unit

with 208/230V power when electric heat is not present.

For units without electric heat:

1. Locate adapter and filler plates with screws inside package. If

necessary, adjust plates to allow for installation of No Heat Kit

required inside cabinet. Refer to Figure 7,

2. Secure No Heat Kit accessory with four (4) screws.

3. Connect the 9-pin plug from No Heat Kit wiring into the

receptacle that attaches to fan control board.

4. Connect ground wire to unit ground lug.

5. Connect 208/230V power lead from field disconnect to No Heat

Kit.

For units with electric heat, see Electric

Heater Installation

Instructions and blower airflow requirements.

Wire low-voltage in accordance with wiring label on the blower (also

refer to Figures 8 - 12. Use 18 AWG color-coded, insulated (35_C

minimum) wire to make the low-voltage connections between:

thermostat, indoor equipment, and outdoor equipment. If thermostat

is located more than 100 feet (31m) from the unit (as measured

along the low voltage wire), use 16 AWG color-coded, insulated

(35_C minimum) wire. All wiring must be NEC Class 1 and must be

separated from incoming power leads. Refer to outdoor unit wiring

instructions for additional wiring recommendations.

Field supplied low-voltage wiring should be field connected inside

control splice box area (secure with wire nuts), and strain relief

bushing or rubber grommet to seal cabinet opening.

Figure7 J Electrical Controls

LowVoltage

Connections

\,

FillerPlate

Adapter Plate

\

No Heat Kit _\

Ground

Connection

Control Splice Box

NOTE: Transformer is factory-wired for 230V operation. For 208V

applications the transformer must be rewired to the 208V tap. Refer

to unit wiring label.

GROUNDING CONNECTION

Use a copper conductor(s) from the ground lug on the No Heat Kit

or ground lugs on the electric heater to a grounded connection in

the electric service panel or a properly installed grounding rod.

X40159 Rev.C Specifications subject to change without notice. 5

Page 6

Table1

Supply Circuit

Volts Phase

Hertz

Supply

Circuit

No.

H.P.

Max. MCA Max

Motor Branch Over-

Amps Circuit current

AMP

Protectio

n Devise

(Amps)

Recommended

Supply Wire Ground Wire

75°C copper

# of

Min Max. Ft.(m) # of Min

Wires

Size Length Wires Size

MF08* 208

23O

MF12* 208

23O

MF16* 208

23O

MF20* 208

230

'guii

THERMOSTAT

E3-

D

60 Single 1/3 2.5

60 Single 1/2 2.9 3.6 15

60 Single 1/2 2.9 3.6 15

60 Single 3/4 6.0 7.5 15

Wiring Layout Air Conditioning Unit

(Cooling Only)

RED

GRY

W2

W3

R

G

E

C

AIRCOND.

3.1 15

THERMOSTAT

[_ L vlo

Fq

14 105 (32) 1 14

14 105 (32) 1 14

14 105 (32) 1 14

14 90 (27)

Wiring Layout Heat Pump Unit (Cooling

and Single-Stage Heat with No Outdoor

Thermostat)

R

G

C

W2

W3

E

1 14

HEATPUMP

(CONTROL)

z;_ R

_- w 2

_-o

ITt---

Wiring Layout Air Conditioning Unit

(Cooling and Single-Stage Heat)

THERMOSTAT

_, GRY G

6 Specifications subject to change without notice. X40159 Rev.C

m

RED R

W3

E

AIRCOND.

Page 7

Wiring Layout Heat Pump Unit (Cooling and

Two-Stage Heat with One Outdoor

Thermostat)

THERMOSTAT

m

D-

J3-

D-

E3-

m

R

G

c

W2

[-q

W3- ODTS

Fq

E

E]-

D-

- .-t.igure 1z I Wiring Layout Heat Pump Unit (Cooling and

THERMOSTAT

m

D-

%

Fq

Two-Stage Heat with Two Outdoor

1

_WHT

VlO

PINK

Thermostats)

m

R

G

C

W2

E

w3.....2.__

o Lw2

ODTS

HEATPUMP

(CONTROL)

R

c

w2

o

z;:5._

Y

HEAT PUMP

(CONTROL)

4Q_ R

L __c

£___y

CHANGING MOTOR SPEED

To change the blower speed, disconnect the black wire at the

blower motor terminal block and reconnect at the desired blower

speed tap (refer to Table 4).

HEATER STAGING

The modular controls are factory circuited for single-stage electric

heat operation. Refer to Table 2 for available heaters and Table 3

for unit airflow based without a coil, filter, or electric heat applied.

When two-stage electric heat is desired (refer to Table 2 - Heat

Strip Staging), separate out the pink W3 wire from W2 & E

connections. Refer to Table 2-2 and wiring diagram Figure 11. W3

can be separated and controlled by the indoor wall thermostat (if

multi-stage capable), or by an outdoor thermostat (ODTS). Refer to

ODTS kit instruction for proper wiring.

When three-stage electric heat is desired, cut the W2 wire nut off

and discard. Strip W2, W3, and E. Refer to Table 2-3, and wiring

diagram Figures 12. Connect according to the thermostat kit

instructions or ODTS kit instructions for proper wiring.

Table 2 Heat Strip Staging

2-1 2-2

Single-Stage Two-Stage

Operation Capable

(no staging - all

electric heat

Single- EHIA05KB / KN EHIA15KB

Phase EHIA07KB / KN EHIA20KB

EHIA10KB / KN EHIA25KB

EHIA15KB

EHIA20KB

EHIA25KB

Three- EHIA10HB EHIA10HB

Phase EHIA15HB EHIA15HB

EHIA20HB EHIA20HB

EHIA25HB EHIA25HB

KB is single-phase with circuit breaker

KN is single-phase with terminal block (no-breaker)

HB is three-phase with circuit breaker

Table 3 Minimum Motor Speed Tap Selection For

Electric Heater

Electric Heater SIZE kW

Model 5 kW 7.5 kW 10 kW 15 kW 20 kW 25 kW

MF08 LOW LOW LOW MED ....

MF12 LOW LOW LOW LOW MED --

MF16 LOW LOW LOW MED MED HIGH

MF20 LOW LOW LOW LOW LOW MED

LOW = low speed tap selection

MED = medium speed tap selection

HIGH - high speed tap selection

2-3

Three-Stage

Capable

(with ODTS

only)

EHIA25KB10

EHIA20HB

EHIA25HB

AIR FLOW CHECK

For proper system operation, the air flow through the indoor coil

should be between 350 and 450 cfm per ton of cooling capacity.

The air flow through the unit can be determined by measuring the

external static pressure to the unit and selecting the motor speed

tap that will most closely provide the required air flow.

1. Set up to measure external static pressure at the supply and

return duct connections. Refer to Figure 13.

2. Drill holes in the ducts for pressure taps, pilot tubes, or other

accurate pressure sensing devices.

3. Connect these taps to a level inclined manometer or draft

gauge.

4. Ensure the coil and filter are clean, and all the registers are

open.

5. Determine the external static pressure with the blower

operating.

X40159 Rev.C Specifications subject to change without notice. 7

Page 8

TEMPERATURE RISE CHECK

Refer to the Air Flow Data, Table 4, to find the speed setting

that will most closely provide the required air flow for the

system.

7.

Refer to Motor Speeds and Airflow in these instructions if the

speed is to be changed.

8.

Recheck the external static pressure with the new setting, and

confirm speed switch selection.

StaticPressoroCheck

Temperature rise is the difference between the supply and return air

temperatures.

NOTE: The temperature rise can be adjusted by changing the

heating speed tap at the unit's blower terminal block. Refer to the

unit's Installation Instructions for airflow information.

A temperature rise greater than 60°F (33,3°C) is not

recommended.

1. To check the temperature rise through the unit, place

thermometers in the supply and return air ducts as close to the

unit as possible,avoiding direct radiant heat from the heater

elements.

2. Open ALL registers and duct dampers.

3. Set thermostat Heat-Cool selector to HEAT.

4. Set the thermostat temperature setting as high as it will go.

5. Turn electric power ON.

6. Operate unit AT LEAST 5 minutes, then check temperature

rise.

NOTE: The maximum outlet air temperature for all models is 200°F

(93.3°C).

7. Set thermostat to normal temperature setting.

8. Be sure to seal all holes in ducts if any were created during this

process.

Airflow Based on no coil, no filter, no electric heat. Deduct heater static shown in heater static table.

Deduct coil static, See Coil Specification Sheet. Deduct .20 in wc (50 Pa) for Downflow Subbase Kit.

Table 4 Airflow is blower only, no coil attached

SPEED VOLTS 0.20 0.30 0.40 0.50 0.60 0.70 0.80

Low

Med

High 208v 1317 1305 1286 1255 1220 1170 1008

SPEED VOLTS 0.20 0.30 0.40 0.50 0.60 0.70 0.80

Low 230v 973 975 979 979 973 955 931

Med 230v 1284 1295 1301 1305 1302 1280 1246

High 230v 1663 1670 1671 1655 1631 1585 1519

SPEED VOLTS 0.20 0.30 0.40 0.50 0.60 0.70 0.80

Low 230v 1020 1015 1009 1002 991 975 950

Med 230v 1379 1385 1386 1379 1364 1343 1309

High 230v 1776 1782 1783 1765 1736 1698 1643

SPEED VOLTS 0.20 0.30 0.40 0.50

Low 230v 1492 1495 1492 1475

Med 230v 1969 1955 1935 1890

High 230v 2696 2600 2492 2350

* THE MAXIMUM EXTERNAL STATIC PRESSURE IS 0.8" W.C., WITHOUT COOLING

FOR MAXIMUM STATIC PRESSURE.

MF08 In wc

230v 1029 1020 1007 985 960 915 862

208v 872 860 845 825 797 765 721

230v 1286 1270 1254 1220 1180 1125 1058

208v 1113 1105 1091 1070 1042 1000 947

230v 1500 1470 1432 1380 1315 1250 1168

MF012 In wc

208v 811 815 816 810 797 780 749

208v 1084 1084 1084 1090 1089 1065 1030

208v 1383 1385 1390 1390 1383 1365 1328

MF16 In wc

208v 858 845 830 815 801 780 749

208v 1156 1154 1149 1144 1134 1120 1098

208v 1496 1496 1496 1495 1495 1470 1433

MF20 In wc

208v 1246 1245 1238 1225

208v 1641 1640 1633 1615

208v 2417 2355 2287 2200

COIL.

0.60 0.70 0.80

1451 1395 1308

1203 1175 1125

1818 1700 1570

1584 1510 1406

2192 2020 1844

2092 1940 1774

DEDUCT STATIC PRESSURE OF COIL

8 Specifications subject to change without notice. X40159 Rev.C

Page 9

I Table 5 - ELECTRIC HEATHER STATIC PRESSURE DROP I

EHIA EHIA EHIA EHIA EHIA EHIA

Single-Phase

CFM 05 07 10 15 20 25

In wc

600 0.01 0.01 0.01 - - -

700 0.01 0.01 0.01 - - -

800 0.01 0.01 0.01 0.01 - -

900 0.01 0.01 0.01 0.01 - -

1000 0.01 0.01 0.01 0.01 0.02 -

1100 0.01 0.01 0.01 0.02 0.02 -

1200 0.01 0.01 0.01 0.02 0.02 -

1300 0.01 0.02 0.02 0.02 0.02 -

1400 0.01 0.02 0.02 0.02 0.03 0.03

1500 0.01 0.02 0.02 0.02 0.03 0.04

1600 0.01 0.02 0.02 0.03 0.03 0.04

1700 0.01 0.02 0.02 0.03 0.03 0.04

1800 0.01 0.02 0.02 0.03 0.04 0.04

1900 0.01 0.02 0.02 0.03 0.04 0.05

2000 0.01 0.02 0.02 0.03 0.04 0.05

CFM N/A N/A 10 15 20 25

600 __ 0.01 - - -

700 __ 0.01 - - -

8oo__ OOl OOl - -

900 __ OOl OOl - -

lOOO__ OOl OOl 002 -

1100__ 001 002 002 -

1200__ 001 002 002 -

1300__ 002 002 002 -

1400__ 002 002 003 003

1500__ 002 002 003 004

1600 __ 0.02 0.03 0.03 0.04

1700 __ 0.02 0.03 0.03 0.04

1800__ 002 003 004 004

1900__ 002 003 004 005

2000__ 002 003 004 005

Three-Phase

EHIA EHIA EHIA EHIA

In wc

ACCESSORIES

ELECTRIC AIR CLEANER

The Electronic Air Cleaner may be connected to MF as shown in

Figure 14. This method requires a field supplied transformer. See

Electronic Air Cleaner literature for kit requirements.

Figure 14 Cleaner to Modular Blower

Wiring Layout of Electronic Air

CONTROL BOARD

FANR:ELA¥ I R G T C C C

/

Figure 15 Wiring Layout of Humidifier to Modu-

THERMOSTAT

lar Blower with Electric He_t

MODU_ BLOWER

3ONTROL}

°iiI" li!!ll

W_RE

NUT

_ ................. _M

CONVERSION KIT ,..,>.,.,,L._.,J

BLOwERTOTRANSFORMER I I I I

MOTOR

SPT N©NC ii

""°°°'"24VAC

i i l OOM

TO EAC

FROM I_YOLEX

PLUG AND

_P_oNSFORMER

(IN UNIT)

%.....

HUMIDIFIER

Connect humidifier and humidistat to modular blower unit as shown

in Figures 15 and 16.

X40159 Rev.C Specifications subject to change without notice. 9

Page 10

Figure 16 Wiring Layout of Humidifier to Heat

_DULAR BLOWER HEATPUMP

(3ONTR_ L) (CONTROL}

Pump

F-_,_, _PR R

[] ............ _Ry G

r-q..... c ...............c

D I o

SEQUENCE OF OPERATION

A. CONTINUOUS FAN

Thermostat closes R to G. G energizes fan relay on FAN

CONTROL BOARD which completes the high voltage circuit to

indoor blower motor. When G is de-energized, there is a built in 90

second blower-off time delay relay (TDR). To disable the TDR

feature, snip the jumper wire JW1.

B. COOLING MODE

Air Conditioner Only:

Thermostat energizes R to G and Y. G energizes fan relay on fan

control board which completes high-voltage circuit to indoor blower

motor. Y energizes the 24 low-voltage contactor in condensing unit.

When call is satisfied, Y drops out and there is a 90 second blower

TDR before fan relay opens.

Heat Pump:

Same as above - except thermostat will also energize O for

reversing valve operation in cooling mode. O will typically remain

energized by the thermostat (after cooling call is satisfied), or until

the mode is changed to heating.

C. HEAT PUMP

Coolinq Mode:

Thermostat energizes R to G, Y and O. G energizes indoor an relay

on fan control board which completes high-voltage circuit to indoor

blower motor. Y energizes the outdoor 24V low-voltage circuit in

heat pump to energize compressor. O energizes reversing valve in

cooling mode and typically remains energized until the mode is

changed to heating. When thermostat cooling call is satisfied. Y

drops out. O remains energized, and there is a 90 second TDR

before indoor fan relay opens.

Heatinq Mode:

Thermostat energizes R to G and Y only (no O signal in heating). G

energizes indoor fan relay on fan control board which completes

high-voltage circuit to indoor blower motor. Y energizes the outdoor

24V low-voltage circuit in heat pump to energize compressor. The

reversing valve is not energized in heating unless a defrost cycle

should occur. When call is satisfied, Y drops out and there is a 90

second TDR before indoor fan relay opens.

D. HEAT PUMP HEATING WITH AUXILIARY

ELECTRIC HEAT

Coolinq Mode:

Same operation as above in Heat Pump Cooling Mode.

Heatinq Mode:

Same operation as above in Heat Pump Heating Mode with the

addition of W. Thermostat energizes R to G, Y, and W. W energizes

electric heat relay(s) which completes circuit to heater element(s).

When W is de-energized, electric heat relay(s) open, turning off

heater elements. The White wire in pigtail connects W2, W3, and E

together. This may be separated for heater staging when available,

see electric heat kit for more information.

E. ELECTRIC HEAT OR EMERGENCY HEAT MODE

Thermostat closes R to W. W energizes electric heat relay(s) which

completes circuit to heater elements(s). Blower motor is energized

through N.C. (normally closed) contacts on fan relay. When W is

de-energized, electric heat relay(s) opens.

CARE AND MAINTENANCE

The system should be regularly inspected by a qualified service

technician. Consult the servicing dealer for recommended

frequency. Between visits, the only consumer service

recommended or required is air filter maintenance and condensate

drain operation.

AIR FILTER

Inspect air filters at least monthly and replace or clean as required.

Disposable type filters should be replaced. Reusable type filters

may be cleaned by soaking in mild detergent and rinsing with cold

water. The frequency of cleaning depends upon the hours of

operation and the local atmospheric conditions. Install filters with

the arrows on the side pointing in the direction of air flow. Clean

filters keep unit efficiency high.

LUBRICATION

The bearings of the blower motor are permanently lubricated.

CONDENSATE DRAINS

During the cooling season check the condensate drain lines to be

sure that condensate is flowing from the primary drain but not from

the secondary drain. If condensate ever flows from the secondary

drain, the unit should be promptly shut off and the condensate pan

and drains cleaned to insure a free flowing primary drain.

10 Specifications subject to change without notice. X40159 Rev.C

Page 11

WIRING DIAGRAM

X40159 Rev.C Specifications subject to change without notice. 11

Page 12

REPLACEMENT PARTS

ITEM CURRENT

NO. PART# DESCRIPTION

1 B60077-13BLOWERDOORASS'Y

B60077-14

B60077-15

B60077-16

2 B60029 PLATEHEATERADAPTER

3 B60048 PLATEHEATERFILLER

4 B60106 WIRECHANNEL

5 B60107 DECKBLOWERRAILRIGHT/LEFT

6 B60093 FRONTBLOWERDECK

B60094

B60095

B60096

7 B60101 SIDEBLOWERDECK

B60102

B60103

B60104

8 B60097 REARBLOWERDECK

B60098

B60099

B60100

9 B60076-01PANELTOPASS'Y

B60076-02

B60076-03

B60076-04

10 B60089-02LEFTSIDEWRAPPER

B60090-02

11 B60087-01BACKWRAPPER

B60087-02

B60088-01

B60088-02

12 B60089-01RtGHTSIDEWRAPPER

B60090-01

Z_'_

1

1111

2222

1

2

1

1

11

1

11

1

1

1 1 1

11

1

1

2

2

1

1

1

1

11

1

1

11

NO. PART# DESCRPTION _; _; _; _;

13 ETo0106..015R/_CEBO'R'CMFRONT 1

ETo0106..0"2 1

1

1

2

1

1

1

ETo0106..0_ 1

14 B601C8 =JOA4BRRAILRG-fTtLB='I" 1 1 1 1

15 t301888-01VOTCRM3._NTASSY_A',DLEG8) 1 1 1

1301888-02 1

16 E018£0..0_VDTCRASSY(WTHMOTCRM3LNTS) 1/3-P-3_od 1

13018£0-05 1/2-P - 3_ 1

E018£0..07 1/2-P - 3S_ 1

B318_-_ 3/4bP- _ 1

17 2D11Q27 B._OhB_HDLSINGWITHV_-BB_ lC0-7R 1

2D11Q28 100-8: 1

2DIlCL_9 100-_ 1 1

18 B01024 Sz_c_CITCRSLPFURT 1 1 1 1

19 L0110C6 Sz_c_CITCR 370V10iVF 1 1 1

L011005 370V15 _ 1

23 ETo0109-015RA34£TCTLiVITG 1

ETo0109..0"2 1

ETo0109-0_ 1 1

21 R99G010 =ANCCN'[R3_BCARD 1 1 1 1

22 B60C67 _IREHAR'.E_ 1 1 1 1

23 LO1FO12"rPAkER3qMB_33_230-24v,40VA 1 1 1 1

International Comfort Products, LLC

Lewisburg, TN 37091 USA

55'55

0 0 0 0

0 0 0 0

1

12 Specifications subject to change without notice. X40159 Rev.C

Loading...

Loading...