Page 1

This manual contains important information and should be made available to all personnel who operate and/or maintain this product.

Carefully read this manual before attempting to operate or perform maintenance on this equipment

Instructions for installation and operation english

www.i compressorpartners.com

.

Page 2

Page 3

Contents

1. SAFETY AND SYSTEM PRECAUTIONS ................................................................................................................................................... 3

1.1 Definition of the Safety Symbols............................................................................................................................................. 3

1.2 Operational Warnings ........................................................................................................................................................... 3

2. INSPECTION AND INSTALLATION ......................................................................................................................................................... 4

2.1 Incoming Inspection and Transportation .............................................................................................................................. 4

2.2 Design and Use of the Dryer ................................................................................................................................................. 4

2.3 Location and Installation ....................................................................................................................................................... 4

2.4 Filters Mounted with Bypass ................................................................................................................................................. 6

3. TECHNICAL SPECIFICATIONS AND GENERAL FUNCTION ...................................................................................................................... 7

3.1 Technical Data by Model Size ................................................................................................................................................ 7

3.2 Correction Factors ................................................................................................................................................................. 8

3.3 General Function ................................................................................................................................................................... 8

3.4 Flow Diagram ........................................................................................................................................................................ 9

3.5 Cycle Operation ................................................................................................................................................................... 10

4. PURGE VALVE ADJUSTMENT .............................................................................................................................................................. 11

5. START-UP ............................................................................................................................................................................................ 12

5.1 Verification Prior to Start-up ............................................................................................................................................... 12

5.2 Start-up Procedures ............................................................................................................................................................ 13

5.3 General Operation .............................................................................................................................................................. 14

6. ISOLATION AND SHUT DOWN PROCEDURES ..................................................................................................................................... 14

7. CONTROLLER INFORMATION AND OPERATION ................................................................................................................................ 15

7.1 Display Overview ................................................................................................................................................................. 15

7.2 Startup ................................................................................................................................................................................ 15

7.3 Controller Inputs ................................................................................................................................................................. 15

7.4 Contoller Outputs ................................................................................................................................................................ 16

7.5 Controller Settings .............................................................................................................................................................. 16

7.6 Service Rest Button ............................................................................................................................................................. 18

7.8 Power Requirements ........................................................................................................................................................... 18

8. MAINTENANCE AND SERVICE ............................................................................................................................................................. 19

8.1 Routine Maintenance ................................................................................................................................................................... 19

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 1

Page 4

8.2 Maintenance and Service Intervals .............................................................................................................................................. 20

8.3 Fuses ............................................................................................................................................................................................. 20

8.4 Desiccant Replacement ................................................................................................................................................................ 21

8.5 Inlet and Exhaust Valve Repair ..................................................................................................................................................... 21

9. TROUBLESHOOTING GUIDE ................................................................................................................................................................ 22

10. MAINTENANCE AND SPARE PARTS .................................................................................................................................................. 25

10.1 Required Maintenance Parts ...................................................................................................................................................... 25

10.2 Spare Parts ................................................................................................................................................................................. 27

11. DISMANTLING OF THE DRYER .......................................................................................................................................................... 28

12. ELECTRICAL WIRING DIAGRAM ........................................................................................................................................................ 29

13. GENERAL DESCRIPTION OF PARTS ................................................................................................................................................... 29

For technical product support please use website www.i compressorpartners.com

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 2

Page 5

Before attempting any

service, please read

the manual

General Warning:

Risk of damage or injury

Electrical Hazard:

Possibility of

electrocution

Warning:

Under pressure

Warning:

High temperature

Warning:

Non-breathable air

Warning:

Water cannot be used

to extinguish fire

Warning:

Do not operate if parts

are missing or have been

tampered with

Warning:

Machine level noise

may exceed 85 dBA

Warning:

Personal

protection

required

Warning:

All work to be

performed by qualified

personnel only

Operations that can be

performed by qualified

operators1

Compressed air inlet connection

Compressed air outlet connection

Connection point for condensate drain

WARNING: VESSELS UNDER PRESSURE

In most countries, states, cities and/or local municipalities the installation, operation and maintenance of

devices where pressure vessels are in use are subject to local boiler and pressure vessel regulations.

The end user is responsible for following all of the relevant laws, rules and regulations and ensuring that only

experienced and trained personnel install and/or operate the dryer.

In most countries, states, cities and/or local municipalities the installation may only be carried out by a

licensed installation company. Inspections must be carried out by a qualified and licensed third-party firm in

accordance with all applicable laws, rules and regulations for the region where the dryer is installed.

The pressure vessels used in this device are built according to the American Society of Mechanical Engineers

(ASME) standard Section 8, Division 1.

Compressed Air Warning:

Compressed air is a highly dangerous energy source.

Never work on the dryer while components are under pressure.

Never point the compressed air stream or the condensate drain outlet towards anybody.

The end user is responsible for the installation of the dryer as laid out in this manual. If proper commissioning steps are

not followed, the warranty will be void and dangerous situations involving injury or death and/or damages to the

machine could occur.

Only qualified personnel can use and service electrically powered devices. Before attempting any maintenance:

Ensure that no part of the machine is powered and is locked out of the electrical mains by following proper

“Lock-out, Tag-out” procedures and requirements.

Ensure that no part of the dryer is under pressure by isolating the dryer from the compressed air system.

Any change to the machine or to the standard operating parameters (see page 5), if not previously verified and

authorized by the manufacturer, in addition to creating a potentially dangerous situation, will void the warranty.

Don’t use water to extinguish fire on the dryer or in the surrounding area.

ARIA

AIR

LUFT

AIR

1. SAFETY AND SYSTEM PRECAUTIONS

1.1 Definition of the Safety Symbols

1 Only experienced and trained personnel familiar with all of the relevant laws, rules and regulations, capable to perform the needed activities and to

identify and avoid possible dangerous situations while handling, installing, using and servicing the machine.

1.2 Operational Warnings

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 3

Page 6

The packaging materials are recyclable. Each material must be properly disposed in a manner complying

with the rules and regulations of the local municipality government.

The purpose of the machine is the separation of water vapor that is present in compressed air. It is not

intended to separate oil or other contaminants that are present in compressed air.

The dried compressed air output from this dryer cannot be used for respiration purposes of any kind.

Serious consideration should be given when selecting the installation site for the dryer, as an improper

location could directly affect the proper operation of the dryer.

This unit is not suitable to be used in explosive atmospheres, where risk of fire could exist, in the presence

of gaseous or solid pollutants or in outdoor applications or areas exposed to the elements.

Do not use water to extinguish fire on the dryer or in the surrounding area.

Machine level noise could be higher than 85 dBA. Install the unit in a dedicated area where people are not

normally present. The installer and/or end user is responsible for the correct installation of the dryer in

order to prevent excessive noise exposure in the work environment. The installer and/or end user is

responsible to install proper safety signs at the installation site.

2. INSPECTION AND INSTALLATION

2.1 Incoming Inspection and Transportation

All dryers are tested and inspected at the factory prior to shipping. Thoroughly inspect and verify the integrity of the

packaging upon receipt and note any damage on the freight bill. Place the unit as close as possible to the installation

point before unpacking the contents and inspect for concealed damage. Freight claims are to be filed with the carrier

immediately and the manufacturer’s technical service department notified thereafter.

To move the packaged unit, we suggest the use of a suitable crane or forklift. We do not recommend moving the

unit by any hand operated or manual mechanism.

Handle with care. Heavy blows could cause irreparable damage.

Even when packaged, keep the machine protected from severe weather.

2.2 Design and Use of the Dryer

This dryer has been designed, manufactured and tested to be used only to separate the humidity normally contained in

compressed air, any other use is considered to be improper. The manufacturer is not responsible for any problems

arising from the improper use of this machine.

The end user, in any and all cases, is responsible for any resulting damages.

Moreover, the correct use of this machine requires the verification of certain installation conditions, in particular:

Voltage and frequency of the electrical power supplied

Pressure, temperature, flow rate and chemical composition of the incoming compressed air

Ambient temperatures

The dryer is supplied as tested and fully assembled. The only operation left for the end user is the connection to the plant

and adjustment of the purge rate in compliance with the instructions given in this manual. Factory settings are at

nominal conditions at 100 psig and the stated model flow rate (see page 5).

2.3 Location and Installation

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 4

Page 7

Technicians that service the machine must wear hearing and eye protection while servicing the dryer. Each

employee must select a proper personal protection device (PPD) hearing protector such as earmuffs, ear

canal caps or earplugs in order to prevent permanent hearing damage or loss.

Incorrect installation may void warranty.

1. Inlet piping including an isolation valve

2. Outlet piping including an isolation valve

3. Coalescing pre-filter and particulate post-filter

We recommend the dryer be installed with a 0.01 micron iPUR coalescing pre-filter at the inlet and a 1.0 micron

iPUR particulate post-filter at the outlet. It is recommended to install both 5.0 micron and

1.0 micron filters upstream of the dryer in order to maintain the operational lifespan of the inlet filter to the

dryer. In addition, we recommend the use of a iMAT zero air loss drain on the pre-filter and at all other

condensate collection points, especially those upstream of the dryer.

4. IMPORTANT! Bypass piping is necessary. Only bubble tight valves should be used.

5. Make the required electrical connections; please refer the type plate of your dryer. The end user is

responsible for providing short circuit protection for the dryer.

6. Points of access should be provided upstream and downstream of the dryer for periodic monitoring of

dew point, pressure and temperature prior to finalizing the installation. Taking periodic dew point

measurements just downstream of the dryer gives the best indication of whether the dryer is

performing optimally. We recommend using METPOINT® instrumentation to ensure accurate

measurements.

7. All piping must be adequately supported and at least of equal size to the dryer connections.

Minimum Installation Requirements:

Select a clean, dry room that is free of dust and protected from atmospheric disturbances.

The location must be smooth, horizontally level, able to bear the weight of the dryer and vibration free

Minimum ambient temperature of +40 °F

Maximum ambient temperature of +120 °F

Allow a clearance of at least 3’ on all sides of the dryer in order easily facilitate all maintenance needs

The dryer is not required to be anchored to the supporting surface

Coalescing pre-filter with drain must be installed

The location of an air receiver tank will vary depending on compressor type and application conditions

NOTE: All piping and electrical connections should be inspected prior to installation to ensure they have maintained

their integrity during shipping and locating the dryer.

First, make the initial connections as follows:

Locate the coalescing pre-filter as close to the dryer as possible while still maintaining sufficient space for routine

maintenance and service. Inlet air entering the dryer must pass through a coalescing pre-filter in order remove entrained

condensate and oil to prevent fouling of the desiccant and maintain standard operation. Any liquid condensate entering

the desiccant bed will lead to overloading of the dryer, poor dew point performance and rapid deterioration of the

desiccant material. Any oil entering the desiccant bed may permanently reduce the capacity of the desiccant material.

Desiccant dust traveling downstream of the dryer may cause contamination and/or accelerated wear to other

components and equipment. Therefore, a particulate post-filter should be provided to prevent desiccant dust from

traveling downstream. Activated alumina is considered a nuisance dust and proper precautions should be taken when

handling desiccant (refer to applicable MSDS sheet).

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 5

Page 8

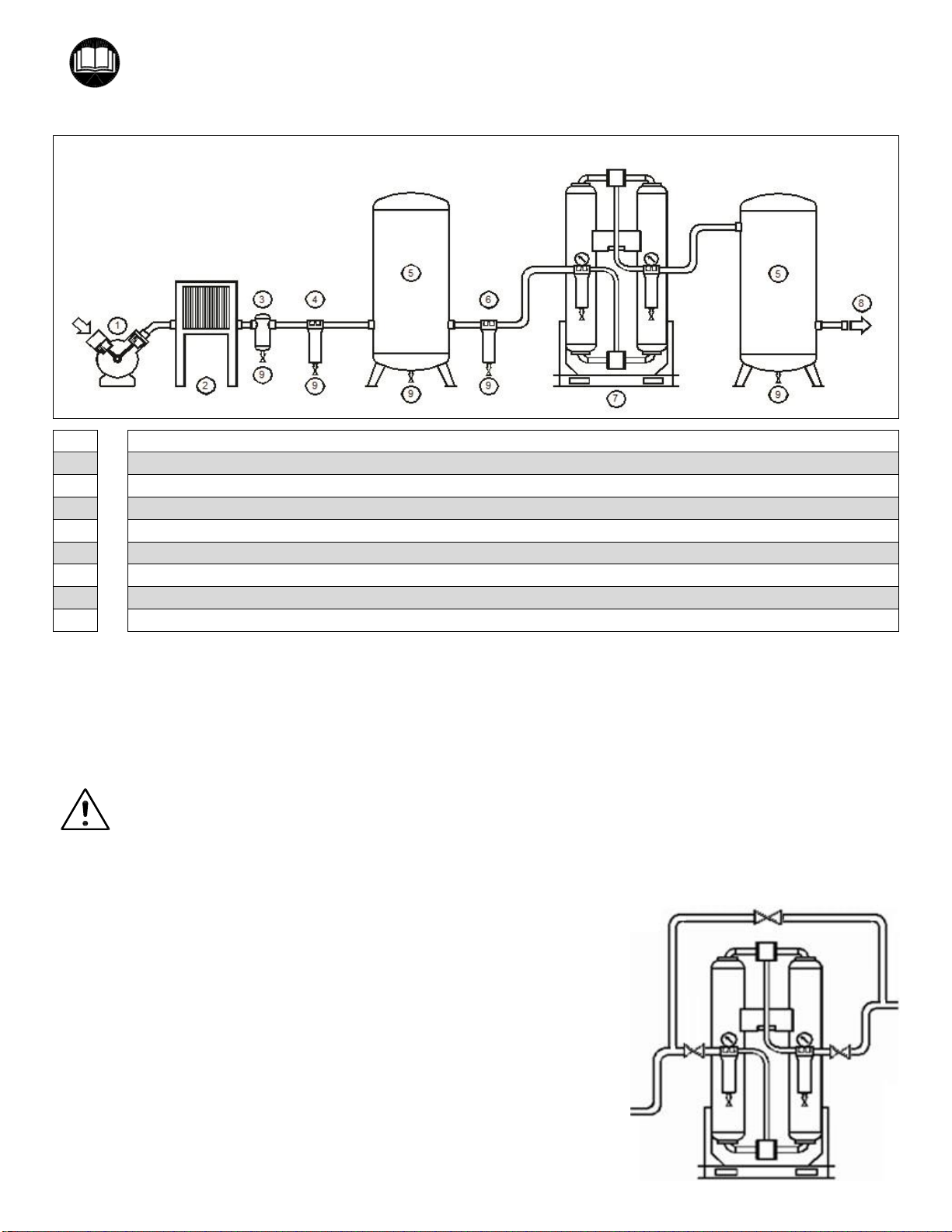

Before any attempt is made to operate the dryer, the operator must thoroughly read and understand this

installation and operation manual.

Optimal Installation Diagram

1 Air Compressor

2 After Cooler

3 iPUR Inline Water Separator

4 iPUR 5.0 Micron (Grade G) Filtration

5 Receiver Tank

6 iPUR 1.0 Micron (Grade F) Filtration

7 iDRY iDHLBe Desiccant Dryer with iPUR Pre and Post-filtration

8 Dry Air Outlet

9 Condensate Drainage Points for iMAT

We recommend the dryer be installed with a 0.01 micron iPUR coalescing pre-filter at the inlet and a 1

micron iPUR particulate post-filter at the outlet. It is recommended to install both 5 micron and 1 micron

filters upstream of the dryer in order to maintain the operational lifespan of the inlet filter.

Optimal installation is with moderately sized receivers at the inlet and outlet side of the dryer. This allows for the

additional free cooling and moisture collection and more consistent dryer inlet flow provided by an upstream receiver,

while providing the most reliable shop air supply due to the downstream receiver.

Under no circumstances should the peak demand air flow exceed the maximum rated air flow of the dryer.

2.4 Mounted Filters with Bypass

Mounted Filters with Bypass is an optional setup for the heatless regenerative

dryer. The three valve system bypass allows for the flow of air to be uniterupted

while servicing or completing preventative maintinance such as:

Exchange pre- and post- filters

Services exhaust sIlencers

Change desiccant

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 6

Page 9

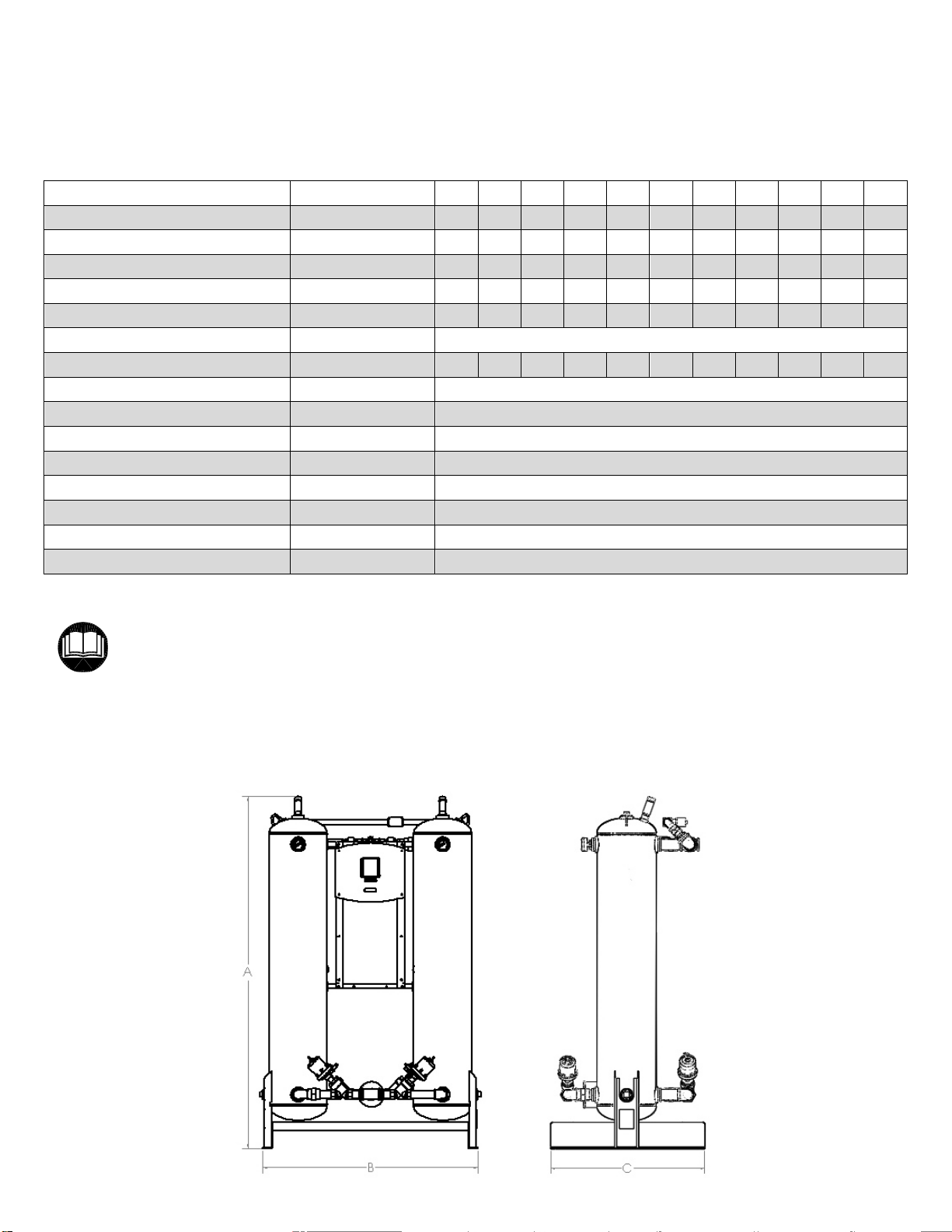

iDRY iDHLBe

Model Size

080

100

120

160

200

250

300

400

500

650

800

Flow Rate

scfm

80

100

120

160

200

250

300

400

500

650

800

Inlet / Outlet Connection

in. (NPT-F)

¾ 1 1

1 ¼

1 ¼

1 ½

1 ½ 2 2

2 ½

2 ½

Height (A)

in.

69

69

69

69

69

70

70

73

75

76

76

Width (B)

in.

31

34

34

39

39

45

45

51

54

62

63

Depth (C)

in.

22

24

24

27

27

32

32

36

38

41

44

Adsorbent Material

Activated Alumina

⅛”

Total per Dryer

Lbs.

95

150

150

230

230

340

340

480

625

795

940

Outlet Pressure Dew Point

°F

-40

Minimum Ambient Temperature

°F

40

Maximum Ambient Temperature

°F

120

Standard Inlet Air Temperature

°F

100

Maximum Inlet Air Temperature

°F

120

Minimum Air Pressure

psig

60

Standard Air Pressure

psig

100

Maximum Air Pressure

psig

150

Dryer ratings adhere to the following inlet conditions per ISO 7183, Table 2, Option A2:

Inlet Compressed Air Temperature 100 °F (38 °C)

Inlet Compressed Air Pressure 100 psig (7 bar)

Maximum Ambient Air Temperature 100 °F (38 °C)

Inlet Compressed Air Relative Humidity 100% (Saturated)

3. TECHNICAL SPECIFICATIONS AND GENERAL FUNCTION

3.1 Technical Data by Model Size

SCFM is defined as the volume of free air in cubic feet per minute measured at 14.7 psia (1.013 bar) at 68 °F (20 °C)

temperature with 0% relative humidity (0 WVP).

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 7

Page 10

Correction Factors

≤ 90°F

95°F

100°F

105°F

110°F

115°F

120°F

60 PSIG

0.89

0.76

0.65

0.59

0.49

0.44

0.38

70 PSIG

1.00

0.85

0.73

0.66

0.55

0.49

0.42

80 PSIG

1.00

0.96

0.82

0.74

0.62

0.55

0.48

90 PSIG

1.06

1.05

0.90

0.81

0.68

0.60

0.52

100 PSIG

1.10

1.10

1.00

0.90

0.76

0.67

0.58

110 PSIG

1.15

1.15

1.15

1.04

0.87

0.77

0.67

120 PSIG

1.20

1.20

1.20

1.08

0.91

0.80

0.70

130 PSIG

1.24

1.24

1.24

1.12

0.94

0.83

0.72

140 PSIG

1.28

1.28

1.28

1.15

0.97

0.86

0.74

150 PSIG

1.33

1.33

1.33

1.20

1.01

0.89

0.77

3.2 Correction Factors

Operating Pressure and Inlet Air Temperature

How to size the dryer capacity for actual conditions: How to select the dryer for actual conditions:

ADJUSTED CAPACITY =

Standard Flow Rate x Correction Factor System Flow Rate ÷ Correction Factor

Example: Example:

Dryer Model: iDRY iDHLBe 250 System Flow Rate: 300 scfm

Standard Flow Rate: 250 scfm Operating Conditions: 130 psig / 100 °F

Operating Conditions: 110 psig / 110 °F ADJUSTED CAPACITY = 300 scfm ÷ 1.24 = 242 scfm

ADJUSTED CAPACITY = 250 scfm x 0.87 = 218 scfm Select Dryer Model: iDRY iDHLBe 250

3.3 General Function

The iDRY iDHLBe heatless desiccant dyer series are fitted with two pressure vessels, positioned parallel to one another

and filled with adsorption material (⅛” activated alumina as standard). While the compressed air is dried in one tower,

the saturated desiccant is regenerated in the second. A minimal portion of the treated air is used for the regeneration

process and expelled along with the condensate, through the silencers.

The saturated inlet air is cycled through each of the two desiccant beds in an alternating sequence where one bed is online at full line pressure and flow, adsorbing the water vapor. This is the drying bed.

The other bed is then considered to be in an off-line state at atmospheric pressure and is being regenerated by a

depressurized portion of the dried, treated outlet air (purge air). This is the regenerating bed.

The purge air is routed from the dry outlet air through the purge flow control valve, desiccant bed, purge exhaust valve

and finally exhausted to atmosphere through silencers to finish the regeneration process. Purge air consumption is

generally the highest cost involved with operating a heatless adsorption dryer and is non-recoverable. Therefore, the air

system where the dryer is installed must account for this usage (approximately 15% of the inlet air flow).

Just before the freshly regenerated bed is brought to an on-line state to become the drying bed, it is slowly pressurized

from atmospheric pressure up to line pressure. This is the re-pressurization step that prevents desiccant bed fluidization

(bed lifting) and dusting. The desiccant beds will now switch functions where the fresh desiccant bed is now drying and

the saturated bed is now regenerating.

This cycle will continue automatically unless the dryer is shut down.

All desiccant dryers work using the principle of adsorption, which is the process by which water vapor is removed from

the compressed air being dried. All desiccant material types are adversely affected by oil, aerosols, dirt, rust, scale and

ADJUSTED CAPACITY =

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 8

Page 11

Number

Name

Number

Name

1

Inlet Valve (Normally Open)

7

Optional iMAT Zero Loss Drain

2

Purge Exhaust Valve (Normally Closed)

8

Solenoid Block

3

Exhaust Silencer

9

Pilot Air Filter and Regulator

4

Outlet Check Valves

10

Vessel Pressure Gauge

5

Pressure Relief Valve

13

Pre-filter with Float Drain

6

Purge Control Valve

14

Post-filter with Manual Drain

liquid water. If contaminated the desiccant material will lose its adsorption proprieties. Moreover during operation, the

desiccant releases solid particles (as fine powder) that are particularly abrasive and can be extremely damaging to

downstream components and users.

For this reason, it is highly recommended that the dryer is equipped with two high-efficiency iPUR filters:

0.01 micron filtration grade coalescing pre-filter with differential pressure gauge and either a float drain or iMAT

1.0 micron filtration grade particulate post-filter (differential gauge optional) and with a manual drain.

3.4 Flow Diagram

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 9

Page 12

The cycle time is factory set for operation at

100 psig inlet air pressure and 100 °F inlet air

temperature.

10 minutes for -40 °F (-40 °C)

IV-A = Inlet Valve, Vessel A

IV-B = Inlet Valve, Vessel B

PV-A = Purge Valve, Vessel A

PV-B = Purge Valve, Vessel B

3.5 Cycle Operation

Pressurization Sequence

After proper pressurization of the unit the dryer the operator may begin the start-up. During the start-up phase, both

purge exhaust valves PVA and PVB (5 and 6) are closed for a period of 70-seconds to help guarantee the complete

pressurization of the dryer.

Step 1-2 The purge exhaust valve PV-B (2) is powered open to depressurize vessel for regeneration.

Simultaneously the solenoid valve IV-B (1) is powered closed by the pneumatic tower selection. The

compressed air flow is directed to vessel A, where the desiccant material adsorbs the humidity down to

the target dew point. Through the purge control valve (6) a defined amount of dry air coming out from

tower A is expanded into vessel B. This dry air while crossing vessel B, dries the adsorbent material

dragging away the humidity through the PV-B valve (2) and exits the silencers (3). At the end of this stage

the adsorption material of vessel B is completely regenerated.

Step 3 The purge exhaust valve PV-B (2) is closed and then through the Purge Control Valve (6) vessel B is re-

pressurized to the working pressure. The sum of steps 1-2 + 3 equals a half cycle time.

Step 4-5 The purge exhaust valve PV-A (2) is powered open to depressurize vessel for regeneration.

Simultaneously the solenoid valve IV-B (1) is powered closed. The compressed air flow is directed to

vessel B, where the desiccant material adsorbs the humidity down to the target dew point. Through the

purge control valve (6) a defined amount of dry air coming out from tower A is expanded into vessel B.

This dry air while crossing vessel A, dries the adsorbent material dragging away the humidity through the

PV-A valve (2) and the silencers (3). At the end of this stage the adsorption material of vessel A is

completely regenerated.

Step 6 The purge exhaust valve PV-A (8) is closed and then through the Purge Control Valve (6) vessel A is re-

pressurized up to the working pressure. The sum of step 4-5 + 6 equals a half cycle time. At the end, the

cycle starts up again from step 1-2.

NOTE: The cycles are symmetrical therefore 1-2=4-5 and 3=6

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 10

Page 13

Rendered drawing of purge

flow control valve

Turn knob clockwise

(to the right) to close

Turn knob counter clockwise

(to the left) to open

Approximate Purge Valve Setting (number of turns to open)

Purge Flow

Rate [scfm]

Dryer Inlet Pressure

Dryer

80 psig

90 psig

100 psig

110 psig

115 psig

iDRY 80

16

3.5

3.2

3.1

2.9

2.9

iDRY 100

20

4.0

3.8

3.7

3.6

3.5

iDRY 120

24

5.5

5.3

5.0

4.8

4.5

iDRY 160

32

5.9

5.7

5.5

5.4

5.4

iDRY 200

40

6.5

5.6

5.2

4.8

4.7

iDRY 250

50

7.0

6.5

6.0

6.0

5.5

iDRY 300

60

8.0

7.5

7.1

6.9

6.8

iDRY 400

80

3.6

3.5

3.3

3.2

3.1

iDRY 500

100

4.5

4.4

4.2

4.1

4.0

iDRY 800

160

6.2

4.9

4.7

4.6

4.5

4. PURGE VALVE ADJUSTMENT

The purge flow control valve must be set to match the inlet pressure of the dryer. The valve must be opened to the

corresponding number of turns referenced in the table below.

Always base the pressure adjustment on the lowest operating pressure of the system

The initial setting from factory is for 100 psig operation

The procedure for adjusting the purge flow control valve is as follows:

The knob stem of the valve is numbered and a complete turn is considered turning the control knob 360° from number to

number. The number of turns expressed in the table below is based on the number of turns from the closed position.

1. Loosen the screw using a flathead screwdriver or allen-head

2. Turn the purge flow control valve clockwise until the stopping point – the valve is now closed

3. Turn the purge flow control valve counter clockwise until the setting for the desired operating pressure value is

reached – the valve is now open

4. Tighten the screw using a flathead screwdriver or allen-head

Purge Adjustment Table

Consult a factory representative for more information.

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 11

Page 14

Verify that the operating parameters match with the acceptable ranges indicated on the data plate of the

dryer (voltage, frequency, air pressure, air temperature, ambient temperature, etc.). This is not the same as

the ASME UW plate on the vessels and may be lower than what is stamped on the ASME UW plate.

The start-up must be performed by qualified personnel only. It is mandatory that the qualified person in

charge will verify safe operational conditions complying with the local safety and accident prevention

requirements.

The same qualified person will be responsible for the proper and safe operation of the dryer. Never operate

the dryer if all panels are not properly in place or if any componentry is missing or appears damaged.

Service to be performed by qualified personnel only. The end user is responsible to ensure that the dryer

will never be operated with pressure that exceeds the maximum pressure rating of the unit. Operating the

dryer at a pressure higher than the maximum rating could be dangerous for both the operator and the

machine.

The connection to the main power is to be carried out by qualified personnel, and the safety protocol must

comply with local rules and laws.

It is mandatory to ensure the connection to the ground terminal.

The condensate is discharged at the same pressure as the air entering the dryer. Never point the

condensate drain discharge towards anybody.

DO NOT DISPOSE OF CONDENSATE INTO THE ENVIRONMENT

The condensate collected in the dryer contains oil particles released into the air stream by the compressor.

Dispose of the condensate in a manner compliant with all local, state and Federal rules and regulations.

We highly recommend the installation of either a QWIK-PURE® or ÖWAMAT® oil-water separator at the

final collection point for all condensate discharge lines within the facility (i.e. from the main header).

5. START-UP

5.1 Verification Prior to Start-up

Before delivery, each dryer is submitted to accurate tests simulating real operating conditions. Nevertheless, the unit

could be damaged during transportation. Therefore, we suggest checking the integrity of the dryer upon arrival (see

page 4) and observing the dryer during the first hours of operation.

The inlet air temperature and air flow rate entering the dryer must be within the limits indicated on the data plate.

Installation precautions must be taken in order to limit the vibration that can occur during the operation of the dryer.

Therefore, we recommend using flexible connecting pipes that are able to insulate the dryer from possible vibrations

originating from the pipe line.

Before connecting the unit to the electric power, verify that the voltage and the frequency available on the mains

correspond to the data on the data plate of the dryer. In terms of voltage, a 5% tolerance is acceptable. The wire size

feeding the dryer must comply with the consumption of the dryer, while keeping into account also the ambient

temperature, the conditions of the main power junction box, the length of the wire, and the requirements enforced by

the National Electric Code.

Connect and properly fasten the condensate drain to a collection system or container. The outlet condensate hose

cannot be connected to pressurized systems.

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 12

Page 15

During the first start-up or start-up after a long period of inactivity or following maintenance, the technician

must comply with the instructions below. The start-up must be performed by qualified personnel only.

The employee that operates the machine must wear hearing and eye protection before operating the dryer.

Each employee must select a proper personal protection device (PPD) hearing protector such as earmuffs,

ear canal caps or earplugs in order to prevent permanent hearing damage or loss.

1. With the dryer bypassed and in isolation (see page 14)

2. SLOWLY open the inlet isolation valve allowing compressed air into the dryer. It is critical that the dryer

be pressurized slowly to prevent fluidization of the desiccant bed. Keep the outlet isolation valve closed

at this time.

3. SLOWLY open the outlet isolation valve. All valves are now in their open positions and compressed air is

flowing through both towers and downstream.

4. Close the dryer bypass valve. The bypass valve must be bubble tight to prevent any moisture from

contaminating the dry air outlet from the dryer.

5. Plug in the dryer and energize the electrical circuit – the dryer is now ON.

6. Verify that the controller is on.

7. Check all piping for compressed air leaks.

8. Test the condensate drain on the pre-filter.

9. After 1-minutes from start-up the adsorption tower B will be depressurized.

10. Wait for the dryer to make 10 full cycles (i.e. the depressurization from tower A to tower B).

11. The dryer will make the first 5 cycles short cycles, running at 50% run time without regard for dew point.

12. The pressure swing cycles occurs, every 5 minutes (outlet dew point of -40°F).

5.2 Start-up Procedures

Start-up Sequence

Please read and understand the entire manual before operating the dryer

Verify the factory settings

Verify the wiring diagrams that pertain to your unit and ensure the correct power supply is connected

Do not energize the circuit at this time

Verify that proper short circuit protection has been provided following all applicable codes and regulations

Verify that all the steps of in the previous chapters relating to installation have been observed

Verify that the connection to the compressed air system is correct

Verify that the condensate drain pipe is properly fastened and connected to a collection system or container

Remove any packaging and other material that might obstruct the area around the dryer

Before starting the dryer your compressor should be running, your compressed air system pressurized and the dryer

bypassed and not yet pressurized.

NOTE: During the first days in operation, the dew point cannot be guaranteed because the adsorption material can

contain humidity from storage. At the first start-up or start-up after a long inactivity period or following maintenance

shutdowns, we recommend operating the dryer at a reduced nominal flow of 50% during the first two days.

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 13

Page 16

Users operating the machine must wear hearing and eye protection. Each employee must select a proper

personal protection device (PPD) hearing protector such as earmuffs, ear canal caps or earplugs in order to

prevent permanent hearing damage or loss.

Isolation

1. Allow the dryer to reach its re-pressurization step and fully re-pressurize.

2. Once fully re-pressurized, remove power from the dryer.

3. Open the bypass valve.

4. Close the outlet isolation valve.

5. Close the inlet isolation valve.

Depressurization and Shut Down

1. Open the bypass valve.

2. Close the outlet isolation valve.

3. Close the inlet isolation valve.

4. Allow the dryer to continue to run. During the normal operating cycle both towers will blow down and

depressurize.

5. Disconnect the power to the dryer.

6. Open the manual ball valves on any filters with manual ball valves to allow full depressurization. Also,

leave manual ball valves on filter open during maintenance and service.

IMPORTANT! Always remove all pressure and disconnect all power before servicing the dryer.

To restart the dryer, follow the start-up procedure in Section 5. START-UP

5.3 General Operation

The dryer may require up to 48-hours of operation to reach normal operating outlet dew point. Therefore,

indicators and alarms do not need to be recognized during this time. Applications where a dew point lower than

-40 °F is needed, may require additional time to reach equilibrium.

The dryer will not perform without properly sized and installed pre-filtration, condensate drainage and correct

purge flow adjustment.

After the initial start-up some dusting may occur. This is normal and will diminish with time, although may

accelerate the first maintenance interval of the exhaust valves, exhaust silencers and post-filter element.

Exhaust valves and silencers may have to be cleaned due to dusting from shipping and the initial start-up, and

should be cleaned regularly to ensure proper operation. Post-filter elements should also be part of a regular

preventative maintenance schedule.

Never service the dryer or filters without first relieving pressure from the dryer.

A desiccant dryer should never be pressurized or depressurized suddenly. This will cause degradation and

dusting of the desiccant bed.

The dryer is designed for a maximum operating pressure of 150 psig as standard.

6. ISOLATION AND SHUT DOWN PROCEDURES

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 14

Page 17

7. CONTROLLER INFORMATION AND OPERATION

7.1 Display Overview

The LED illuminated PID controller interfaces between the dryer and the operator (shown above). The following pages

the detailed information about the controller’s settings and operation.

The controller has a total of nine LEDs to inform the operator its step in operation:

Two check valves indicating the direction of air flow out of the dryer

One purge valve indicator used during regeneration

Two LEDs are used to indicate the active dryer tower during operation

Four LEDs indicate purge exhaust valve and inlet valve PV- and IV-

The controller has two additional LEDs used to indicate power and service in the upper left corner of the display as shown

by the corresponding icons. During normal operation, the power LED is green and the service indicator LED is off.

7.2 Controller Startup

It is important to note that the controller is programed to run five times in succession for a short cycle. That is a 50%

shorter run times without consideration of the dew point input to bring the dryer to a defined state. After this startup

procedure the device is in normal operation mode.

During startup the compressor synchronization input is also active.

7.3 Controller Inputs

The controller and housing provide three M12 and two M16 glands on for its input / output connection lines. For input,

the connections are:

Power cable

Compressor-synchronization signal

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 15

Page 18

The input “compressor synchronization”, is meant to synchronize the

dryer with switching ON and OFF of the compressor. Hence, it

prevents a situation where the dryer continues to operate and use

rinsing air from the compressed air network though there is no supply

of compressed air. In case the voltage (120V AC-Input) drops at the

input, all valves are immediately closed.

After the compressor signal comes back online, the drying cycle is

continued from the same point, meaning that the last open valve also

opens again. Note two exceptions:

This is not valid if the remaining regeneration time is less than

30 seconds, in which case it immediately switches over to the

other drying column, which means the other valve is opened.

If the compressor is switched off for more than 24 hours, then

the device is started with five short full Nema cycles as though

the operating voltage has been interrupted (i.e. as after

RESET).

7.4 Controller Outputs

The controller outputs information two ways, one, to the controller

display, the other, to the dryer system through the housing glands:

Purge Exhaust Valve A

Purge Exhaust Valve B

The controller outputs the dryer’s operational step to the controller

display LED indicators. This indicates the activated valves and drying

tower. In addition, the power light and service indicator are displayed.

The controller outputs an electrical signal to the tower selector

solenoid valve and energizes the appropriate valves based on dryer’s

step of operation.

7.5 Controller Settings

The controller unit has a total of eight DIP switches with the following parameters:

Three DIP switches are used to set the tower regeneration time

Two DIP switches are used to set the pressure build-up time

One DIP switch used for future expansion

One DIP switch aligns the controller with the compressor sync

One DIP switch used for future expansion

Below is a picture of the DIP switch control interface:

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 16

Page 19

The controller’s eight DIP switches are detailed in the following section. These switches are adjustable but should only be

done so by a qualified person.

7.5.1 Regeneration Time (1, 2, 3)

The regeneration time is the time selected for steps 1-2 detailed in Section 3.5. The three DIP switches can be adjusted

to eight (8) selection times between 2.5 and 6 minutes in increments of 30-seconds as follows:

000 2.5 minutes

100 3.0 minutes

010 3.5 minutes

110 4.0 minutes (factory setting)

001 4.5 minutes

101 5.0 minutes

011 5.5 minutes

111 6.0 minutes

7.5.2 Re-Pressure Build-Up Time (4, 5)

The re-pressure build-up time is the time selected for step 3 in Section 3.5. The two DIP switches can be adjusted to four

(4) regeneration times between 60 and 120 seconds in 20-second increments as follows:

00 60 seconds (factory setting)

10 80 seconds

01 100 seconds

11 120 seconds

7.5.3 Expansion (6)

This DIP switch is not currently in use and should be set to OFF, ‘0’.

7.5.4 Compressor Sync (7)

The compressor sync to the controller is detailed in section 7.3. It can be set wither to an ‘ON’ or ‘OFF’ position.

0 OFF - compressor is synched

1 ON - compressor is NOT synched (factory setting)

7.5.6 Expansion (8)

This DIP switch is not currently in use and should be set to OFF, ‘0’.

7.5.7 Factory Default Settings

The factory default settings of the DIP switches are as follows:

Purge Air Time 4.0 minutes (1, 1, 0)

Re-Pressure Build-Up 60 seconds (0, 0)

Expansion OFF (0)

Compressor Sync ON (1)

Expansion OFF (0)

(1) (1) (0) (0) (0) (0) (1) (0)

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 17

Page 20

The optional iMAT on the pre-filter at the dryer inlet is supplied according to the power voltage indicated

in the order; verify its compatibility with the information given on the type plate.

7.6 Service Reset Button

The service indicator LED can be reset after maintenance or service is performed on the dryer by pressing

the RESET button located in the lower right corner of the controller.

After 360-days of the service indicator LED will flash amber indicating that service is due, and after 400days the LED will flash red indicating that service is overdue.

7.7 Power Requirements

The controller operates on 100-120VAC / 50-60Hz. The units are shipped with an installed standard US 120 volt cord for

convenience. Before starting up the machine it is necessary to have a qualified electrician review the electrical

requirements schematic and install to the National Electric Code. Please refer to Section 12.

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 18

Page 21

8. MAINTENANCE AND SERVICE

The service must be carried out only by a qualified technician.

Before any service is carried out, always verify that:

The power has been disconnected following proper Lock-out, Tag-out procedures

Depressurize the unit and ensure the unit is isolated from the compressed air system (see pg 14)

The personnel that service the machine must wear hearing and eye protection before operating the dryer.

Each employee must select a proper personal protection device (PPD) hearing protector such as earmuffs,

ear canal caps or earplugs in order to prevent permanent hearing damage or loss.

DAILY

Check that pre-filter condensate drain is working properly

Check the differential pressure of any installed pre and post filtration

Check that the tower switching operation takes place correctly at the set cycle times.

Check that the tower pressure gauge of the regenerating tower reads 0 psig while the drying tower

reads full line pressure

ANNUALLY

Replace the pre and post filter elements

Replace the exhaust silencers

Replace the pre-filter float drain or iMAT service unit

Check if the solenoid valves are working properly

Check if all screws of the electrical wiring are securely tightened

Verify operation of the dryer

EVERY 2-YEARS

In addition to the scheduled annual maintenance:

Install inlet and purge exhaust valve service kit

Verify operation of the dryer

EVERY 3-YEARS

In addition to the scheduled annual maintenance:

Replace the desiccant adsorption material in both towers

The estimated average lifespan of the adsorption material is 3-5 years when using 10-minute cycle

times or 3,000 operating hours per year. In all cases, the lifetime of desiccant material is heavily

dependent on the quality and temperature of the inlet air and ensuring that scheduled maintenance

is consistently carried out.

Verify operation of the dryer

8.1 Routine Maintenance

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 19

Page 22

The fuses can break if there are any problems with the dryer. In which case, only a certified technician

can replace the fuse, but only after solving the problem that caused the malfunction first. Refer to

Section 9, ‘TROUBLESHOOTING GUIDE’.

8.2 Maintenance and Service Intervals

Preventative maintenance of the pre- and post-filter element, and desiccant material is required.

The controller monitors the dryers operating hours and will activate the maintenance alarms after the following intervals:

360 Days: Amber Service Light

400 Days: Red Service Light

The dryer system should be check for items that require standard replacement and maintenance such as: the filter

elements, exhaust silencers, and desiccant material.

NOTE: The maintenance alarms (reminders) do not change the operation of the controller in any way.

8.3 Fuses

One safety fuse is fitted on the electronic board, in positions F1. The fuse protects all circuits the electronic board of the

BEKOMINI controller. The replacement fuse type is:

T1A type Radial lead fuse, PCB style

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 20

Page 23

8.4 Desiccant Replacement

CAUTION: Activated alumina desiccant dust is considered a nuisance dust. Proper precautions should be

taken prior to replacing the desiccant material in the dryer. Please refer to the Material Safety Data Sheet

(MSDS).

1. Isolate and shut down the dryer (see page 14).

2. Place a suitable container at the edge of each drain port on the bottom of the towers that are located on

the sides, facing outward.

3. Open the drain ports on the bottom of the towers and catch the desiccant in the containers.

4. Refill each tower with the recommended type, size and quantity of desiccant. Only use manufacturer

supplied desiccant, which is high quality, high capacity desiccant designed and sized for the dryers.

5. Carefully knock on the sides of the tower chambers while filling so that the desiccant will pack tightly.

Some settling may be required in order to fit the specified fill amount into the tower. Tank sizes may be

the same for multiple models, so do not be concerned if the tower is not entirely full.

6. Desiccant that has been contaminated with oil or other substances may require different disposal

methods and procedures than desiccant that is being replaced due to aging. Consult the appropriate

MSDS and follow all applicable laws and regulations regarding disposal.

1. Isolate and shut down the dryer (see page 14).

2. Make certain that there are no “pockets” of pressure contained by the various valves.

3. Open the bleed valve on the bottom of the control air filter housing.

4. Loosen the “one touch” pneumatic fitting (no tools required) that attaches the control air tubing to the

valve body. Carefully move the tubing aside and out of the way. We suggest

5. Disassemble the valve for cleaning or repair. Service kits are available for all valves (see page 30).

6. Reassemble the valve and ensure that all O-rings, gaskets and components have reassembled or

replaced accordingly.

8.5 Inlet and Exhaust Valve Repair

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 21

Page 24

9. TROUBLESHOOTING GUIDE

The troubleshooting and the eventual checks must be performed by qualified personnel only.

The technician that services the machine must wear hearing and eye protection while servicing the dryer.

Each employee must select a proper personal protection device (PPD) hearing protector such as earmuffs,

ear canal caps or earplugs in order to prevent permanent hearing damage or loss.

SYSTEM TROUBLE

POSSIBLE CAUSE

SUGGESTED ACTION

The service LED

on the

controller is

flashing amber or

red.

Service Reminder

Service Due

If the service LED indicator light is flashing amber this is an

indication that the dryer is approaching the annual

maintenance interval, and schedule maintenance should be

performed within the next 5-days. – 360 hours

If the service LED indicator light is flashing red then the dryer

is overdue for scheduled maintenance by approximately one

month, and should be serviced immediately to ensure

trouble free operation. – 400 hours

Dryer stopped

No power

Valve problem

No pilot control air

Solenoid valves

Controller

Compressor off

Check power and electric

Check the operation of inlet and purge exhaust valves

Ensure Control pilot air is delivering at 80 psi

Ensure DIN connectors are properly attached to solenoid

valves

See controller troubleshooting

Check if compressor Sync is commanding dryer off

All the inlet air is

discharged

through the

silencers

Faulty inlet valve

Faulty signal

Faulty Outlet valve

Pneumatic

The inlet valves are blocked – open and clean

The controller continuously supplies solenoid valve PVA

and/or PVB – check the electric wiring and if necessary

replace

Outlet Check valve(s) stuck open – serviceable only by

qualified technician

Ensure tube routing matches diagram

Liquid comes out

of the silencers

High dew point

Overloaded

Ensure operation sequence and purge setting

Check capacity versus operating conditions

Depressurization

No power

Flow control valve

No pilot control air

Exhaust Silencers

Check purge exhaust valve for normal operation

Ensure that the purge exhaust valve actuators is not closed

Ensure pilot air reading is 80 psi

Replace silencer filter elements if clogged

Repressurization

Purge Exhaust Valve

Purge line

Purge Valve

Inlet Valve

See purge Exhaust Valve troubleshooting

Purge setting or clog, full open purge valve to clean out and

then set according to table xx

See Purge valve troubleshooting

See Inlet Valve Failure troubleshooting

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 22

Page 25

High Dewpoint

(as checked by

external sensor)

Purge Valve

Exhaust Silencers

Desiccant

Purge Exhaust Valve

Low Pressure

High Flow

High Temperature

Inlet Valve

Power

Controller

Adjust and ensure correct setting based on table xx

Backpressure due to clog, install new mufflers

Media is fouled, replace new

See Purge Exhaust Valve troubleshooting

Increase to rated pressure

ensure air inlet flow does not exceed dryer capacity

ensure air inlet temperature does not exceed dryer capacity

See Inlet Valve troubleshooting

Ensure that the controller has correct voltage

See controller troubleshooting

High Pressure

Drop

Desiccant

Pre-filter

Post-filter

Capacity

Desiccant screens

Purge Exhaust valve

Replace fouled desiccant

Contaminated inlet pre-filter, replace

Contaminated outlet post- filter, replace

Overflow, ensure air inlet flow does not exceed dryer

capacity

Remove desiccant/screens and clean screens

See purge exhaust troubleshooting

Back pressure

Purge muffler fouled

Vessel screen

Restricted purge piping

Bad Purge Exhaust

Valve

Replace with new

Empty towers, remove screens and clean

Clean

See purge Exhaust Valve troubleshooting

COMPONENT

TROUBLE

POSSIBLE CAUSE

SUGGESTED ACTION

Purge control

Valve

Setting

Damaged

Dirty

ensure proper setting from table xx

replace valve

open full for clean out or dismantle and clean

Purge Exhaust

Valve

Worn seals

Pneumatic

Electrical

Restriction

Install service kit

check pilot valve, pilot air supply, pilot air filter, flow control

valve on actuator

Check power to solenoid valves

Backpressure – silencers or mufflers are clogged, install new

muffler elements

Inlet Valve

Worn seals

Pneumatic

Electrical

Restriction

Install service kit

check pilot valve, pilot air supply, pilot air filter, flow control

valve on actuator

Check power to solenoid valves

Backpressure – silencers or mufflers are clogged, install new

muffler elements

Outlet Check Valve

Restriction

Damaged Seal

SERVICEABLE ONLY BY QUALIFIED TECHNICIAN

Drain

Application

Electrical

Overloaded with water, check pre-filter and upstream bulk

water separator

Check electrical connections

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 23

Page 26

Contaminated

Drain

Clean drain and plumbing

Install service drain kit or replace entire unit

Pre-Filter

Application

Dirty element

Electrical

Differential pressure

gauge

Failure with upstream bulk water separator

Contaminated filter, replace element

Faulty electrical signal

Clean, check and or replace

Post-Filter

Dryer dusting

Dirty element

Electrical

Differential pressure

gauge

Ensure proper dryer sequence

Contaminated filter, replace element

Faulty electrical signal

Clean, check and or replace

Controller

Defective

No power supply

Loose connection

Replace controller

Ensure voltage supply

Check connections

Relief Valve

Over pressure

Leak

Over temperature

Check system pressure and correct

Replace valve

Ensure system temperature or fire has not occurred

Solenoid

Electrical

Pneumatic

Defective

Ensure connections and signal are adequate

Ensure pilot supply is good and valve is clean

Replace with new

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 24

Page 27

Interval

DESCRIPTION

Order No.

080

100

120

160

200

250

300

400

500

650

800

Annual

Pre-filter Element 0.01 μm

iELE-07S

iELE-07S-00

iELE-10S

iELE-10S-00

iELE-12S

iELE-12S-00

iELE-15S

iELE-15S-00

iELE-18S

iELE-18S-00

iELE-20S

iELE-20S-00

iELE-25S

iELE-25S-00

Post-filter Element 1.0 μm

iELE-07F

iELE-07F-00

iELE-10F

iELE-10F-00

iELE-12F

iELE-12F-00

iELE-15F

iELE-15F-00

iELE-18F

iELE-18F-00

iELE-20F

iELE-20F-00

iELE-25F

iELE-25F-00

Exhaust Silencer

¾” Exhaust Silencer

4020833

1” Exhaust Silencer

4020834

1¼” Exhaust Silencer

4026420

1½” Exhaust Silencer

4020835

2” Exhaust Silencer

4020836

Float Drain for iPUR (Standard)

FAD050 Float Drain

4025536

Service Unit for iPUR with iMAT (Optional)

iMAT 31 Service Unit

4028457-ICP

iMAT 32 Service Unit

4028458-ICP

- - - - - - - - - - -

2-years

Inlet Angle Body Valve / Actuator Only

¾” Inlet Valve / Actuator

4020801 /

4026892

1” Inlet Valve / Actuator

4020803 /

4026893

1¼” Inlet Valve / Actuator

4026417 /

4026894

1½” Inlet Valve / Actuator

4020805 /

4026895

2” Inlet Valve / Actuator

4020807 /

4026896

2½” Inlet Valve / Actuator

4020809 /

4026897

10. MAINTENANCE AND SPARE PARTS

We strongly recommend stocking the suggested spare parts to help enable you to promptly carry out any required

maintenance and/or replace any parts that may fail without having to wait for the parts to be delivered. If you need to

replace any other parts, please contact your local distributor or ICP Technical Service Department at

www.icompressorpartners.com for assistance.

10.1 Required Maintenance Parts

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 25

Page 28

Interval

DESCRIPTION

Order No.

080

100

120

160

200

250

300

400

500

650

800

2-years

Exhaust Angle Body Valve / Actuator Only

¾” Exhaust Valve / Actuator

4020800 /

4026887

1” Exhaust Valve / Actuator

4020802 /

4026888

1¼” Exhaust Valve / Actuator

4026416 /

4026889

1½” Exhaust Valve / Actuator

4020804 /

4026890

2” Exhaust Valve / Actuator

4020806 /

4026891

Service Seal Kit

¾” Service Seal Kit

4027898

- - - - - - - - - - -

1” Service Seal Kit

4027899

- - - - - - - - - - -

1¼” Service Seal Kit

4027900

- - - - - - - - - - -

1½” Service Seal Kit

4027901

- - - - - - - - - - -

2” Service Seal Kit

4027902

- - - - - - - - - - -

2½” Service Seal Kit

4027903

- - - - - - - - - - -

3-years

Desiccant Adsorption Material

⅛” Activated Alumina

(total weight in lbs. per dryer)

4027023

95

150

150

230

230

340

340

480

625

795

940

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 26

Page 29

10.2 Spare Parts

DESCRIPTION

Order No.

080

100

120

160

200

250

300

400

500

650

800

Inline Check Valve (Outlet)

¾” Outlet Poppet Check Valve

4020820

1” Outlet Poppet Check Valve

4020822

1¼” Outlet Poppet Check Valve

4026421

1½” Outlet Poppet Check Valve

4020821

2” Outlet Poppet Check Valve

4020823

2½” Outlet Poppet Check Valve

4020816

Pressure Relief Safety Valve

¼” Pressure Relief Safety Valve

4026666

½” Pressure Relief Safety Valve

4026667

¾” Pressure Relief Safety Valve

4026668

1” Pressure Relief Safety Valve

4026669

Purge Flow Control Valve

½” Purge Flow Control Valve

4020764

¾” Purge Flow Control Valve

4020765

1” Purge Flow Control Valve

4020766

Electronic Controller

MINI Electronic Controller / PLC

4026540

Solenoid Valve Assembly

Complete MAC Solenoid Valve Assembly

4024046

Tower Pressure Gauge

2½” 0-160 psig Pressure Gauge Economy

4026663

Gauge Clamp

4026665

FRL Combo Package

¼” 20-130 psig Filter Regulator Combo

4026419

Pilot Air Filter Element

Replacement Filter Element for FRL Combo

on request

Brass Cone Silencer

Replacement Brass Cone Silencer

4026418

On / Off Switch

Replacement On / Off Switch

4026722

Pressure Switch

Replacement Pressure Switch

on request

Tube Fitting Package

Replacement Tube Fitting Package

on request

Speed Control

Replacement Speed Control

4027427

Tower Screen

Replacement Tower Screen

on request

NOTE: When inquiring about any other part always indicate the data listed on the identification plate.

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 27

Page 30

Part

Material

Desiccant material

Activated alumina, Oil contaminated

Frame and supports

Carbon steel, Powder coated

Piping

Galvanized steel, Galvanized malleable iron, Brass, Aluminum

Towers and screens

Carbon steel, Stainless steel

Valves

Brass, Stainless steel, Bronze, Plastic

Filter housing

Aluminum, Epoxy paint

Filter cartridge

Filtering material, PVC, Oil

Solenoid valve

Bronze, Steel, Techno-polymer, PVC

Condensate Drain

PVC, Aluminum, Steel, Bronze

Silencers

Aluminum, Stainless steel

Safety Valves

Brass, Bronze

Gaskets and O-Ring

Graphite, Synthetic elastomer

Electric cables

Copper, PVC

Electric Parts

PVC, Copper, Bronze, Silicon

We recommend complying with the safety rules and regulations for the disposal of each type of material.

The adsorption material and the filter cartridge will contain droplets of lubrication oil. Do not dispose of

these materials in the environment. All local Governmental laws and regulations must be followed in

disposing of the above listed materials.

11. DISMANTLING OF THE DRYER

If the dryer is to be dismantled and disposed of then it must be split into groups of materials of construction.

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 28

Page 31

12. ELECTRICAL WIRING DIAGRAM

13. GENERAL DESCRIPTION OF PARTS

Desiccant – An adsorbent used for drying air or gases. The proper quantity, size and type are necessary.

Inlet Valve – Normally open air operated switching valves used to direct air flow through the towers.

Exhaust Valve – Normally closed air operated switching valves used to exhaust purge air, hold air in the on-line

tower and exhaust air from the tower ready to be regenerated.

Outlet and Check Valves – Valves that allow full flow in one direction and no flow in the opposite direction.

These valves are used in conjunction with the inlet and exhaust valves to control the desired flow of process air

through the dryer.

Safety Relief Valves – Valves on each tower to protect the vessels from overpressure situations. The setting is

indicated on each valve.

Purge Exhaust Silencer – Installed to reduce exhaust noise during purge and blow down for the protection all

personnel and to comply with OSHA standards. Silencers are non-mechanical, but must be maintained.

Purge Flow Control Valve – Valve that allows the adjustment and regulation of purge air flow used for the

regeneration process.

MINI Controller – Electronic controller that provides an interface between the operator and dryer, provides dryer

cycle status, operates the electric solenoid valves, provides indicator lights and alarm controls. All hard wired

connections, including the power connections during installation are made to this device.

Electric Solenoid – An electromechanical device used for controlling the flow of liquid or gas.

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A) 29

Page 32

Page 33

Subject to technical changes without prior notice; errors not excluded.

www.i compressorpartners.com

Independent Compressor Partners, LLC

P.O. Box 206

Jeffersonville, IN 47131

www.i compressorpartners.com

iDRY Series Heatless Regenerated Dryers: IOM10003-C (Rev. A)

Loading...

Loading...