ICP GWA 052, GWA 070, GWA 140, GWA 105, GWA 175 User Manual

...

Part Number 670 01 1001 00

GWA

This manual must only be used by a qualified heating installer/service technician. Failure to comply could result in

severe personal injury , death or substantial property damage.

When calling or writing about the boiler— Please have: • boiler model number from the boiler rating label and • CP number

from the boiler jacket. You may list the CP number in the space provided on the “Installation and service certificate” found on

page 18.

Contents Page

1 Prepare boiler location ........................................................2

2 Prepare boiler .....................................................................6

3 Install water piping ............................................................ 10

4 Install gas piping ...............................................................13

5 Field wiring .......................................................................14

6 Start-up ............................................................................ 15

7 Checkout procedure......................................................... 1 8

8 Sequence of operation — standing pilot boilers.................19

9 Lighting instructions — GW A standing pilot boilers ........... 2 0

10 Service and maintenance ................................................. 2 2

11 Troubleshooting ................................................................27

12 Replacement parts ........................................................... 2 9

13 Dimensions ......................................................................34

14 Ratings .............................................................................35

Boiler Manual

Gas-Fired Water Boilers

Hazards that will or can cause minor personal injury

or property damage.

Special instructions on installation, operation or

maintenance that are important but not related to

personal injury or property damage.

INSTALLER — Read all instructions before

installing. Read page 2 first. Follow all instructions

in proper order to prevent personal injury or death.

• Consider piping and installation when determining

boiler location.

• Any claims for damage or shortage in shipment

must be filed immediately against the transportation

company by the consignee.

USER — Please read the following. Failure to

comply could result in severe personal injury , death

or substantial property damage.

• This manual is for use only by your qualified

heating installer/service technician.

• Please see the User’s Inf ormation Manual for your

reference.

• Have the boiler serviced by a qualified service

technician, at least annually .

Hazards that will cause severe personal injury,

death or substantial property damage.

Hazards that can cause severe personal injury,

death or substantial property damage.

Hazard definitions

GW A

Gas-Fired Water Boilers – Boiler Manual

3Part Number 670 01 1001 00

Service clearances

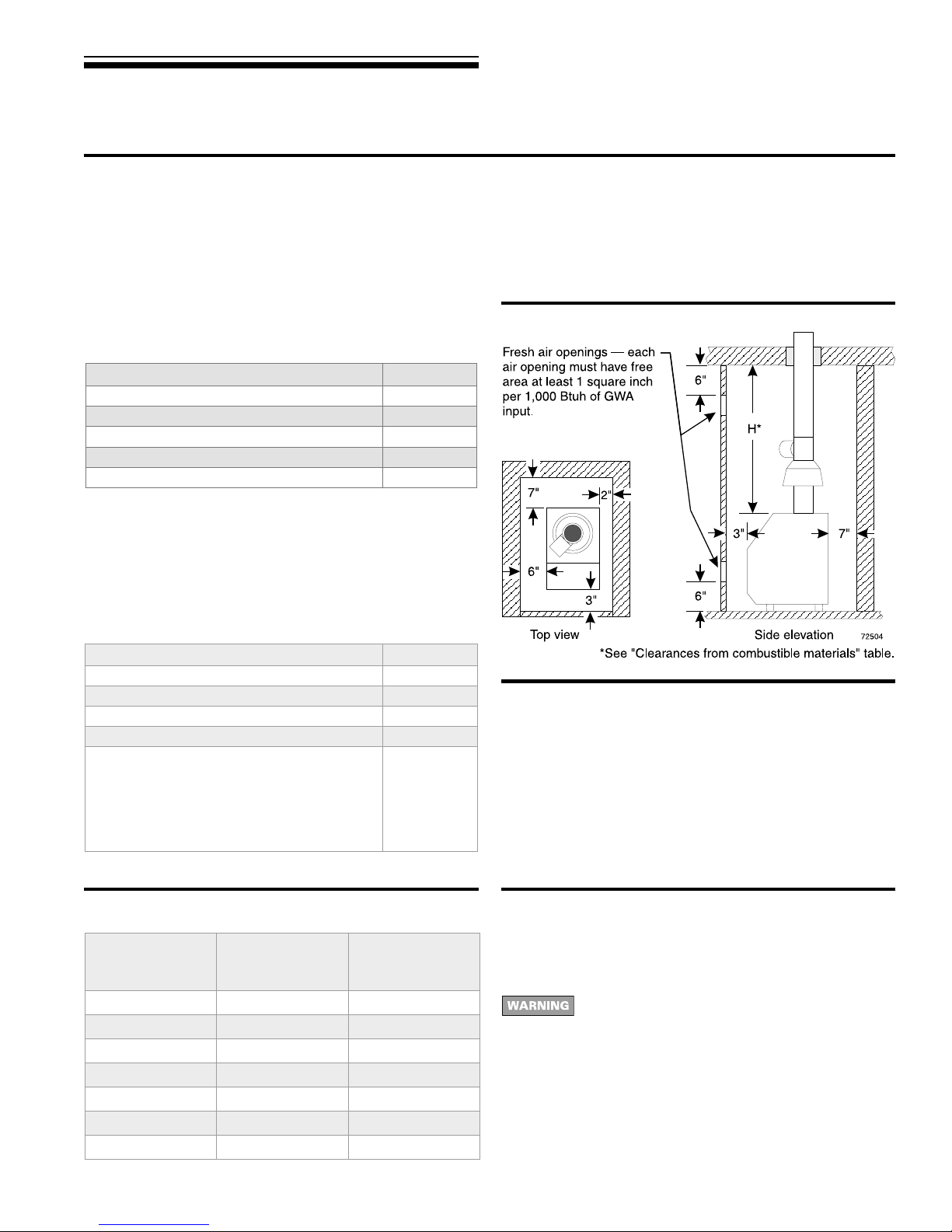

1. Provide minimum clearances for cleaning and servicing the

boiler and for access to controls and components as listed in

the table below:

2. Provide at least screwdriver clearance to jacket front panel

screws for removal of front panel for inspection and minor

service. If unable to provide at least screwdriver clearance,

install unions and shutoff valves in system so boiler can be

moved for servicing.

Figure 1 Minimum clearances

Clearances

Service clearances: Minimum

Top

(for cleaning flueways)

35"

Front

(for access to controls and components)

18"

Back 7"

Left side

(for cleaning and servicing)

24"

Right side 7"

Flooring and foundation

Flooring

The GWA boiler is approv ed for installation on combustib le flooring,

but must never be installed on carpeting.

Do not install boiler on carpeting even if foundation is

used. Fire can result, causing se vere personal injury ,

death or substantial property damage.

Foundation

1. Provide a solid brick or minimum 2-inch thick concrete

foundation pad if any of the following is true:

• floor can become flooded.

• the boiler mounting area is not level.

2. See T ab le 1 for minimum f oundation dimensions.

Residential garage installation

T ake the f ollowing special precautions when installing the boiler in

a residential garage. If the boiler is located in a residential garage,

per ANSI Z223.1, paragraph 5.1.9:

• Mount the boiler a minimum of 18 inches above the floor of the

garage to assure the burner and ignition devices will be no less

than 18 inches above the floor .

• Locate or protect the boiler so it cannot be damaged by a moving

vehicle.

Minimum clearance to combustible materials

1. Hot water pipes must be at least ½" from combustible material.

2. Single-wall vent pipe must be at least 6 inches from combustible

material.

3. Type B double-wall metal vent pipe — See v ent manufacturer’s

recommendation for clearances to combustible material.

Small space installations

1. When the boiler is located in a closet or small space, provide

clearances no less than those shown in Figure 1. The clearances

are required to any surface, whether combustible or noncombustible.

Table 1 Minimum foundation size

1 Prepare boiler location continued

Clearances from combustible materials: Minimum

Front (provide means of access) 3"

Back 7"

Left side (provide means ofaccess) 6"

Right side 2"

Top

GWA052 toGWA105

GWA140

GWA175

GWA210

GWA245

H

35"

35½"

38½"

39¾"

42½"

Boiler

model

Mini mu m

foundation

length

Mini mu m

foundation

width

GWA052 25" 12"

GWA070 25" 12"

GWA105 25" 15"

GWA140 25" 18"

GWA175 25" 21"

GWA210 25" 24"

GWA245 25" 27"

GW A

Gas-Fired Water Boilers – Boiler Manual

1 Prepare boiler location continued

Air contamination Air openings

Please review the following information on potential combustion air

contamination problems.

See Table 2 for products and areas which ma y cause contaminated

combustion air .

T o prev ent potential of severe personal injury or death,

check for products or areas listed below before

installing boiler. If any of these contaminants are found:

• Remove contaminants permanently .

— OR —

• Isolate boiler and provide outside combustion air . See

national, provincial or local codes for further

information.

Table 2 Corrosive contaminants and likely locations

Products to avoid

Spray cans containing chloro/fluorocarbons

Permanent wave solutions

Chlorinated waxes/cleaners

Chlorine-based swimming pool chemicals

Calcium chloride used for thawing

Sodium chloride used for water softening

Refrigerant leaks

Paint or varnish removers

Hydrochloric acid/muriatic acid

Cements and glues

Antistatic fabric softeners used in clothes dryers

Chlorine-type bleaches, detergents, and cleaning solvents found in

household laundry rooms

Adhesives used to fasten building products and other similar products

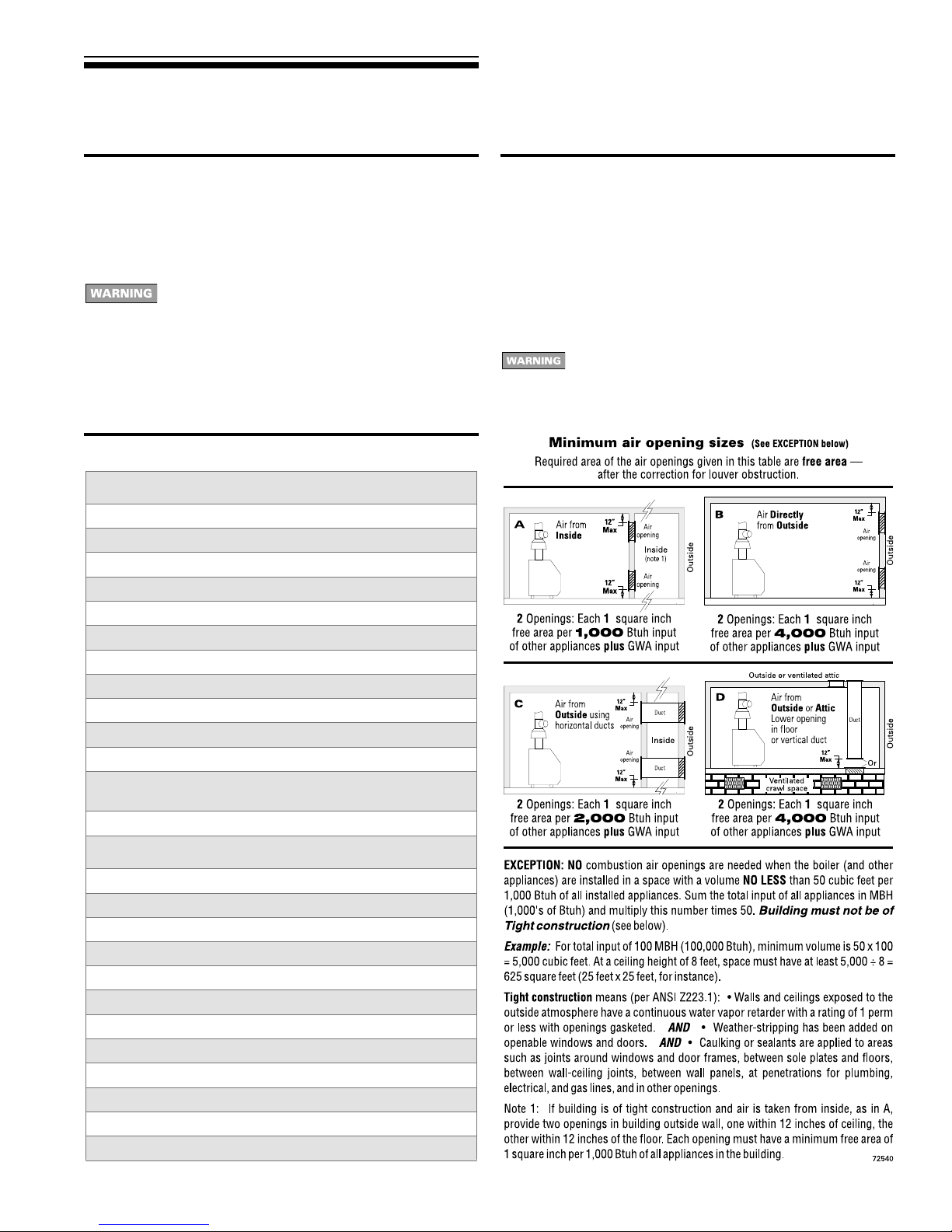

Combustion air and ventilation openings must comply with Section

5.3, “Air for Combustion and V entilation”, of National Fuel Gas Code

ANSI Z223.1–latest edition, or applicable local building codes.

Canadian installations must comply with B149.1 or B149.2

Installation Codes.

See table below for minimum combustion/ventilation air opening

sizes. Where openings are required, provide two (2) openings —

one within 12 inches of the ceiling, the other within 12 inches of the

floor, as shown in the tab le illustrations.

Provide adequate combustion and ventilation air to

assure proper combustion and reduce the risk of

severe personal injury , death or substantial property

damage caused by flue gas spillage and carbon

monoxide emissions.

Areas likely to have contaminants

Dry cleaning/laundry areas and establishments

Swimming pools

Metal fabrication plants

Beauty shops

Refrigeration repair shops

Photo processing plants

Auto body shops

Plastic manufacturing plants

Furniture refinishing areas and establishments

New building construction

Remodeling areas

Garages with workshops

5Part Number 670 01 1001 00

2 Prepare boiler continued

Pressure test

GW A

Gas-Fired Water Boilers – Boiler Manual

Perform h ydrostatic pressure test

Pressure test boiler before attaching water or gas piping or electrical

supply (except as noted below).

Prepare boiler for test

1. Remove the shipping nipple (from GWA supply tapping) and

remove the boiler relief valv e. Temporarily plug the relief valve

tapping with a ¾" NPT pipe plug.

2. Remove 1¼" nipple, reducing tee and drain valve from

accessory bag. Install in boiler return connection as shown on

in Figure 19, item 3, page 32. Install circulator on either the

return or supply .

3. Remove 1¼" nipple, 1¼" tee, bushing and pressure/temperature

gauge from accessory bag. Pipe to boiler supply connection as

shown in Figure 19, item 2, page 32. (Use pipe dope sparingly.)

4. Connect a hose to boiler drain valve, the other end connected

to a fresh water supply. Make sure hose can also be used to

drain boiler after test.

5. Connect a nipple and shutoff valve to system supply connection

on the 1¼" tee. This v alve will be used to bleed air during the fill.

(V alve and nipple are not included with boiler. )

6. Connect a nipple and shutoff valve to system return connection

(at circulator flange if circulator installed on return). This valv e

will be used to bleed air during the fill. (V alv e and nipple are not

included with boiler.)

7. Temporarily plug the air elimination tapping (next to supply

tapping).

Fill and pressure test

1. Open the shutoff valves you installed on supply and return

connections.

2. Slowly open boiler drain valve and fresh water supply to fill

boiler with water.

3. When water flows from shutoff valves, close boiler drain valve.

4. Close shutoff valves.

5. Slowly reopen boiler drain valve until test pressure of not more

than 45 psi is reached on the pressure/temperature gauge.

6. Test at no more than 45 psi f or no more than 10 minutes.

Do not leave boiler unattended. A cold water fill could

expand and cause excessive pressure, resulting in

severe personal injury , death or substantial property

damage.

7. Make sure constant gauge pressure has been maintained

throughout test. Check for leaks. Repair if found.

Leaks must be repaired at once. Failure to do so can

damage boiler, resulting in substantial property

damage.

Do not use petroleum-based cleaning or sealing

compounds in boiler system. Severe damage to boiler

will occur, resulting in substantial property damage.

Drain and remove fittings

1. Disconnect fill water hose from water source.

2. Drain boiler at drain valve or out hose, whichever provides best

access to drain. Remove hose after draining if used to drain

boiler.

3. Remove nipples, valves and plus unless they will remain for

use in the system piping.

4. Remove plug from relief valve tapping. See Section 3, page 10,

to replace relief valve.

7Part Number 670 01 1001 00

2 Prepare boiler continued

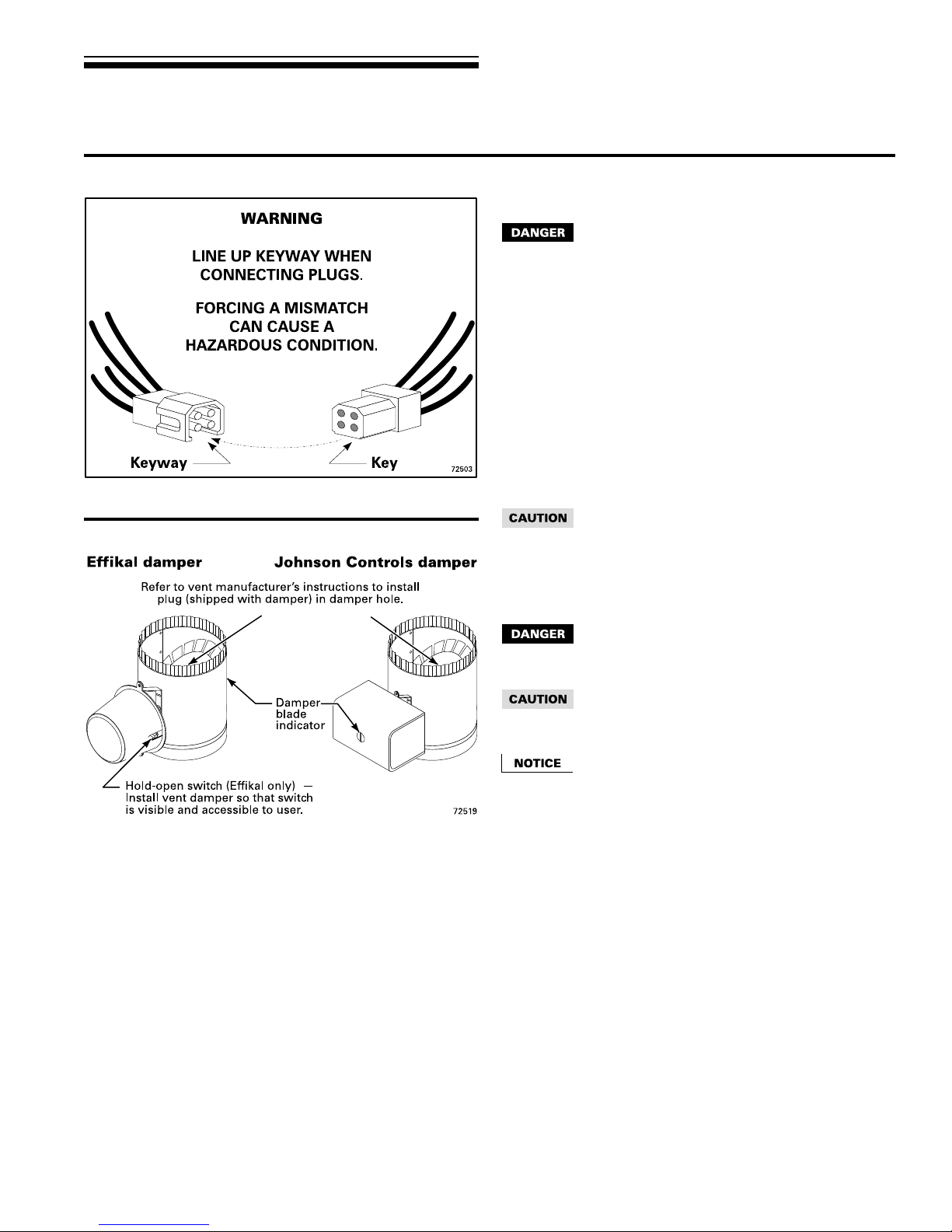

V ent damper continued

Figure 4 Vent damper assemblies

GW A

Gas-Fired Water Boilers – Boiler Manual

Damper installation

Do not modify draft hood or vent damper, or make

another connection between draft hood and vent

damper or boiler except as noted below . This will void

CSA certification and will not be covered by

Williamson-Thermoflo warranty. Any changes will

cause severe personal injury, death or substantial

property damage.

1. Install vent damper horizontally or vertically as shown in vent

damper manufacturer’s instructions. Vent damper must be

installed so that it serves only one boiler and so damper blade

indicator is visible to the user . See Figure 4.

2. Screws or rivets used to secure the vent damper to the draft

hood must not interfere with rotation of the damper blade.

3. Install damper harness between damper actuator and hole in

jacket left side panel. See Figure 3, page 8.

Use strain relief connectors and locknuts to secure both ends

of damper harness.

Keep wiring harness clear of all hot surfaces. Wire

insulation could be damaged, causing risk of electrical

short-circuit.

4. Read and apply the harness plug warning label (shown upperleft) so that it is visible after installation

5. Plug damper harness receptacle into damper harness plug.

Bypassing (jumpering) vent damper will cause flue

products such as carbon monoxide to escape into

the house. This will cause se vere personal injury or

death.

After boiler has operated once, if either end of harness

is disconnected, the system safety shutdown will

occur. The boiler will not operate until harness is

reconnected.

Effikal damper — Damper hold open switch must be

in Automatic Operation position for system to operate

properly .

9Part Number 670 01 1001 00

GW A

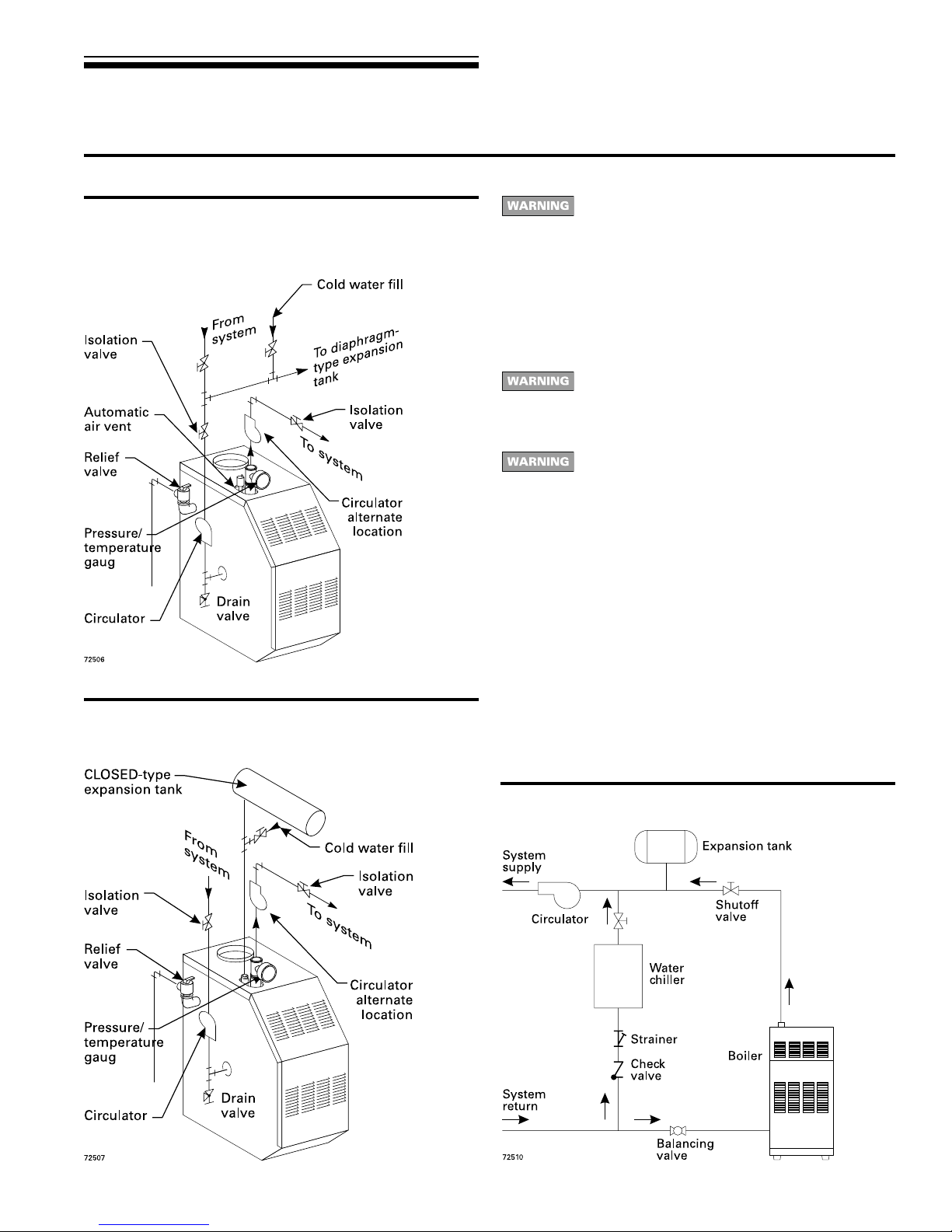

3 Install water piping continued

Near -boiler piping continued

Figure 5 Diaphragm- or bladder-type expansion tank:

Piping to single-zone system using

diaphragm-type or bladder-type expansion

tank. See Table 4 for piping sizes.

Gas-Fired Water Boilers – Boiler Manual

Use Figure 5 or Figure 6 only for systems designed

for return water at least 130 °F. F or systems with low

return water temperature possible, such as

converted gravity systems and radiant heating

systems, install bypass piping (see page 12) to

protect boiler against condensation. F ailure to prevent

low return water temperature to the boiler could cause

corrosion of the boiler sections or burners, resulting

in severe personal injury, death or substantial

property damage.

If system includes radiant heating circuits, provide

piping and controls to regulate the temperature

supplying the radiant circuits. Failure to comply could

result in substantial property damage.

Install boiler so that chilled medium is piped in parallel

with heating boiler (Figure 7). Use appropriate valves

to prevent chilled medium from entering boiler . Consult

I=B=R Installation and Piping Guides.

If boiler is connected to heating coils located in air

handling units where they can be exposed to

refrigerated air, use flow control valves or other

automatic means to prevent gravity circulation during

cooling cycle. Circulation of cold water through the

boiler could result in damage to the heat exchanger ,

causing possible severe personal injury, death or

substantial property damage.

Figure 6 Closed-type expansion tank: Piping to

single-zone system using closed-type

expansion tank. See Table 4 for piping sizes.

Water piping — refrigeration systems

Prevent chilled water from entering boiler

Install boiler so that chilled medium is piped in parallel with the

heating boiler. Use appropriate valves to prevent chilled medium

from entering boiler. See Figure 7 for typical installation of balancing

valve and check valve.

Figure 7 Piping refrigeration systems

11Part Number 670 01 1001 00

Loading...

Loading...