ICP F9MXE0601714A1, G9MXE0401410A1, G9MXE0601714A1, G9MXE0801716A1, G9MXE1002116A1 Installation Guide

...

INSTALLATION INSTRUCTIONS

Two−Stage ECM Motor and Single−Stage

35” Tall, High Efficiency Condensing Gas Furnace

(F/G)9MXT, (F/G)9MXE

These instructions must be read and understood completely before attempting installation.

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and NOTE

The signal words DANGER, WARNING,

CAUTION, and NOTE are used to identify levels of

hazard seriousness. The signal word DANGER is

only used on product labels to signify an immediate

hazard. The signal words WARNING, CAUTION,

and NOTE will be used on product labels and

throughout this manual and other manual that may

apply to the product.

DANGER − Immediate hazards which will result in

severe personal injury or death.

WARNING − Hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION − Hazards or unsafe practices which

may result in minor personal injury or product or

property damage.

NOTE − Used to highlight suggestions which will

result in enhanced installation, reliability, or

operation.

Signal Words in Manuals

The signal word WARNING is used throughout

this manual in the following manner:

!

WARNING

The signal word CAUTION is used throughout

this manual in the following manner:

!

CAUTION

Signal Words on Product Labeling

Signal words are used in combination with

colors and/or pictures or product labels.

Safety−alert symbol

When you see this symbol on the unit and in

instructions or manuals, be alert to the

potential for personal injury.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS 3.......................

INTRODUCTION 4..................................

CODES AND STANDARDS 4.........................

ELECTROSTATIC DISCHARGE PRECAUTIONS 5......

DIMENSIONS 6....................................

LOCATION 7.......................................

LOCATION RELATIVE TO COOLING EQUIPMENT 9....

AIR FOR COMBUSTION AND VENTILATION 9.........

CONDENSATE TRAP 12.............................

INSTALLATION 20...................................

UPFLOW INSTALLATION 21..........................

DOWNFLOW INSTALLATION 22.......................

HORIZONTAL INSTALLATION 23......................

AIR DUCTS 29......................................

GAS PIPING 29......................................

ELECTRICAL CONNECTIONS 32......................

J−BOX INSTALLATION 34............................

VENTING 38........................................

SPECIAL VENTING REQUIREMENTS FOR

INSTALLATIONS IN CANADA 38......................

DIRECT VENT / 2−PIPE SYSTEM 44...................

VENTILATED COMBUSTION AIR 44...................

TERMINATION REQUIREMENTS FOR THE

PROVINCES OF ALBERTA AND SASKATCHEWAN 44..

Portions of the text and tables are reprinted from NFPA 54 /ANSI Z223.1, with permission of National Fire Protection Association, Quincy, MA 02269 and American Gas Association, Washington, DC 20001.

This reprinted material is not the complete and official position of the NFPA or ANSI, on the referenced subject, which is represented only by the standard in its entirety.

INSTALLING THE VENT TERMINATION 55.............

MAXIMUM EQUIVALENT VENT LENGTH 60............

MAXIMUM ALLOWABLE EXPOSED VENT LENGTHS 63.

Use of the AHRI Certified TM Mark indicates a

manufacturer’s participation in the program.

For verification of certification for individual

products, go to www.ahridirectory.org .

INSTALLER: Affix these instructions on or adjacent to the

furnace.

CONSUMER: Retain these instructions for future

reference.

Printed in U.S.A. 440 01 4005 04 9/15/2017

Required Notice for Massachusetts Installations

Important

The Commonwealth of Massachusetts requires compliance with regulation 248 CMR as follows:

5.08: Modifications to NFPA−54, Chapter 10

2) Revise 10.8.3 by adding the following additional requirements:

(a) For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential

purposes, including those owned or operated by the Commonwealth and where the side wall exhaust vent termination is less than seven (7) feet

above finished grade in the area of the venting, including but not limited to decks and porches, the following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side wall horizontal vented gas fueled equipment, the

installing plumber or gasfitter shall observe that a hard wired carbon monoxide detector with an alarm and battery back−up is installed on the floor

level where the gas equipment is to be installed. in addition, the installing plumber or gasfitter shall observe that a battery operated or hard wired

carbon monoxide detector with an alarm is installed on each additional level of the dwelling, building or structure served by the side wall

horizontal vented gas fueled equipment. It shall be the responsibility of the property owner to secure the services of qualified license professionals

for the installation of hard wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic, the hard wired carbon

monoxide detector with alarm and battery back−up may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision can not be met at the time of completion of installation, the owner shall have a period of

thirty (30) days to comply with the above requirement; provided, however, that during said thirty (30) day period, a battery operated carbon

monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in accordance with the above provisions shall

comply with NFPA 720 and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mounted to the exterior of the building at a minimum height of eight (8) feet

above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment. The sign shall

read, in print size no less than one−half (1/2) inch in size, “GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state of local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve the installation unless,

upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance with the provisions of 248 CMR

5.08(2)(a) 1 through 4.

(b) EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a) 1 through 4:

1. The equipment listed in Chapter 10 entitled “Equipment Not Required To Be Vented” in the most current edition of NFPA 54 as adopted by the

Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate from the dwelling, building or

structure used in whole or in part for residential purposes.

(c) MANUFACTURER REQUIREMENTS − GAS EQUIPMENT VENTING SYSTEM PROVIDED. When the manufacturer of Product Approved side wall

horizontally vented gas equipment provides a venting system design or venting system components with the equipment, the instructions provided by

the manufacturer for installation of the equipment and the venting system shall include:

1. Detailed instructions for the installation of the venting system design or the venting system components; and

2. A complete parts list for the venting system design or venting system.

(d) MANUFACTURER REQUIREMENTS − GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED. When the manufacturer of a Product Approved side

wall horizontally vented gas fueled equipment does not provide the parts for venting the flue gases, but identifies “special venting systems”, the

following requirements shall be satisfied by the manufacturer:

1. The referenced “special venting system” instructions shall be included with the appliance or equipment installation instructions; and

2. The “special venting systems” shall be Product Approved by the Board, and the instructions for that system shall include a parts list and detailed

installation instructions.

(e) A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment, all venting instructions, all parts lists

for venting instructions, and/or all venting design instructions shall remain with the appliance or equipment at the completion of the installation.

For questions regarding these requirements, please contact the Commonwealth of Massachusetts Board of State Examiners of Plumbers and Gas

Fitters, 239 Causeway Street, Boston, MA 02114. 617−727−9952

2 440 01 4005 05

Specifications are subject to change without notice.

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

Safety Considerations

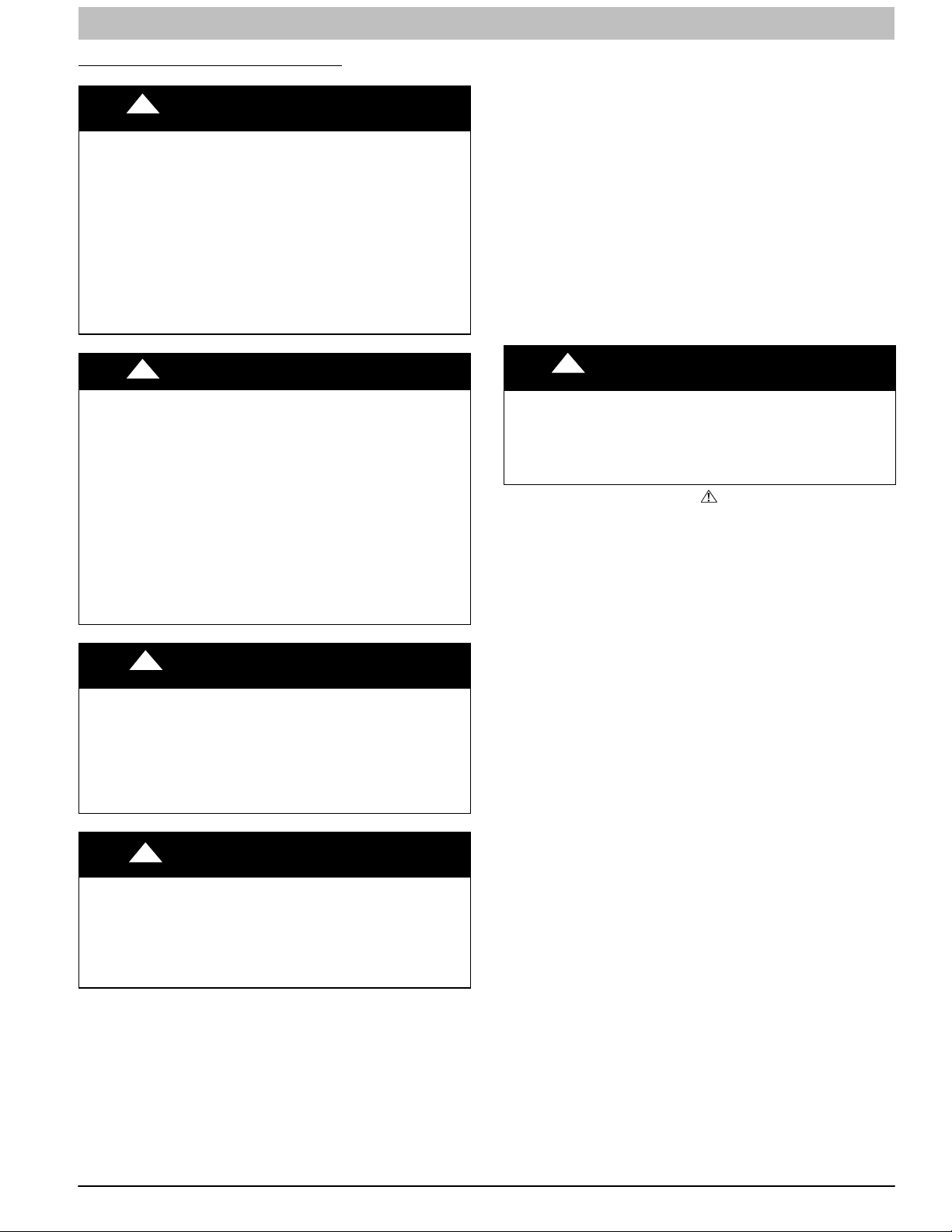

!

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND CARBON

MONOXIDE POISONING HAZARD

Failure to follow this warning could result in dangerous

operation, personal injury, death, or property damage.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide poisoning,

explosion, fire, electrical shock, or other conditions which

may cause personal injury or property damage. Consult a

qualified service agency, local gas supplier, or your distributor

or branch for information or assistance. The qualified service

agency must use only factory−authorized and listed kits or

accessories when modifying this product.

!

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND CARBON

MONOXIDE POISONING HAZARD

Failure to follow this warning could result in dangerous

operation, personal injury, death, or property damage.

Furnaces shall NOT be twinned (i.e. tandem or staged

operation) unless approved in factory technical specifications

literature for the furnace. A factory authorized, field−supplied

Twinning Kit MUST be used. Consult furnace pre−sale

literature for specific models approved for twinning and the

correct twinning kit. Twinned furnaces must be installed on

both a common supply AND a common return duct system

as shown in the Twinning Kit Installation Instructions. Only

two furnaces can be twinned on a common supply and return

duct system using a factory authorized twinning kit.

!

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, or property damage.

Solvents, cements, and primers are combustible. Keep away

from heat, sparks and open flame. Use only in well−ventilated

areas. Avoid breathing in vapor or allowing contact with skin

or eyes.

!

FURNACE RELIABILITY HAZARD

Failure to follow this caution may result in unit component

damage.

Application of this furnace should be indoors with special

attention given to vent sizing and material, gas input rate, air

temperature rise, unit leveling, and unit sizing.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock,

or other conditions which may cause personal injury or property

damage. Consult a qualified service agency, local gas supplier,

or your distributor or branch for information or assistance. The

qualified installer or agency must use only factory−authorized

and listed kits or accessories when modifying this product.

Refer to the individual instructions packaged with the kits or

accessories when installing.

Installing and servicing heating equipment can be hazardous

due to gas and electrical components. Only trained and

440 01 4005 05 3

WARNING

WARNING

WARNING

CAUTION

Specifications subject to change without notice.

qualified personnel should install, repair, or service

heating equipment. Untrained personnel can perform basic

maintenance functions such as cleaning and replacing air

filters. All other operations must be performed by trained

service personnel. When working on heating equipment,

observe precautions in literature, on tags, and on labels

attached to or shipped with furnace and other safety

precautions that may apply.

These instructions cover minimum requirements and conform

to existing national standards and safety codes. In some

instances, these instructions exceed certain local codes and

ordinances, especially those that may not have kept up with

changing residential construction practices. We require these

instructions as a minimum for a safe installation.

Follow all safety codes. Wear safety glasses, protective

clothing, and work gloves. Have a fire extinguisher available.

Read these instructions thoroughly and follow all warnings or

cautions included in literature and attached to the unit.

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing, safety glasses and

gloves when handling parts, and servicing furnaces.

This is the safety−alert symbol . When you see this symbol

on the furnace and in instructions or manuals, be alert to the

potential for personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety−alert symbol.

DANGER identifies the most serious hazards which will result

in severe personal injury or death. WARNING signifies a

hazard which could result in personal injury or death.

CAUTION is used to identify hazards which may result in minor

personal injury or product and property damage. NOTE and

NOTICE are used to highlight suggestions which will result in

enhanced installation, reliability, or operation.

!

!

1. Use only with type of gas approved for this furnace.

Refer to the furnace rating plate.

2. Install this furnace only in a location and position as

specified in the “Location” section of these instructions.

3. Provide adequate combustion and ventilation air to the

furnace space as specified in “Air for Combustion and

Ventilation” section.

4. Combustion products must be discharged outdoors.

Connect this furnace to an approved vent system only,

as specified in the “Venting” section of these

instructions.

5. Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically

for the detection of leaks to check all connections, as

specified in the “Gas Piping” section.

6. Always install furnace to operate within the furnace’s

intended temperature−rise range with a duct system

which has an external static pressure within the

allowable range, as specified in the “Start−Up,

Adjustments, and Safety Check” section. See furnace

rating plate.

7. When a furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space

containing the furnace, the return air shall also be

handled by duct(s) sealed to the furnace casing and

terminating outside the space containing the furnace.

See “Air Ducts” section.

8. A gas−fired furnace for installation in a residential

garage must be installed as specified in the warning box

in the “Location” section. (See Figure 4)

CAUTION

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

9. The furnace may be used for construction heat provided

that the furnace installation and operation complies with

the first CAUTION in the LOCATION section on page 8

of these instructions.

10. These Multipoise Gas−Fired Furnaces are CSA

design−certified for use with natural and propane gases

(see furnace rating plate) and for installation in alcoves,

attics, basements, closets, utility rooms, crawlspaces,

and garages. The furnace is factory−shipped for use

with natural gas. A CSA (A.G.A. and C.G.A.) listed

accessory gas conversion kit is required to convert

furnace for use with propane gas.

11. See Table 1 for required clearances to combustible

construction.

12. Maintain a 1−in. (25 mm) clearance from combustible

materials to supply air ductwork for a distance of 36−in.

(914 mm) horizontally from the furnace. See NFPA 90B

or local code for further requirements.

Table 1

POSITION

Minimum Clearances to

Combustible Materials for All Units

CLEARANCE

In(mm)

REAR 0

FRONT (Combustion air openings in

furnace and in structure)

1 (25)

Required for service *24 (610)

All Sides of Supply Plenum *1 (25)

Sides 0

Vent 0

Top of Furnace 1 (25)

* Consult local building codes

13. These furnaces SHALL NOT be installed directly on

carpeting, combustible tile, or any other combustible

material other than wood flooring. In downflow

installations, factory accessory floor base MUST be

used when installed on combustible materials and wood

flooring. Special base is not required when this furnace

is installed on manufacturer’s Coil Assembly or when

Coil Box is used. See Table 1 for clearance to

combustible construction information.

used. Refer to the furnace rating plate for conversion kit

information.

These furnaces are not approved for installation in recreational

vehicles or outdoors. Single-stage furnaces (40k through

120k) are approved for installation in manufactured

housing/mobile homes with manufacturer approved accessory.

Single Stage furnace is approved for installation in a mobile

home when a factory−supplied accessory mobile home

conversion kit is used. The conversion kit is required for use

with both natural and propane gas. The furnace must also be

installed on a factory−supplied accessory combustible floor

base or evaporator coil casing.

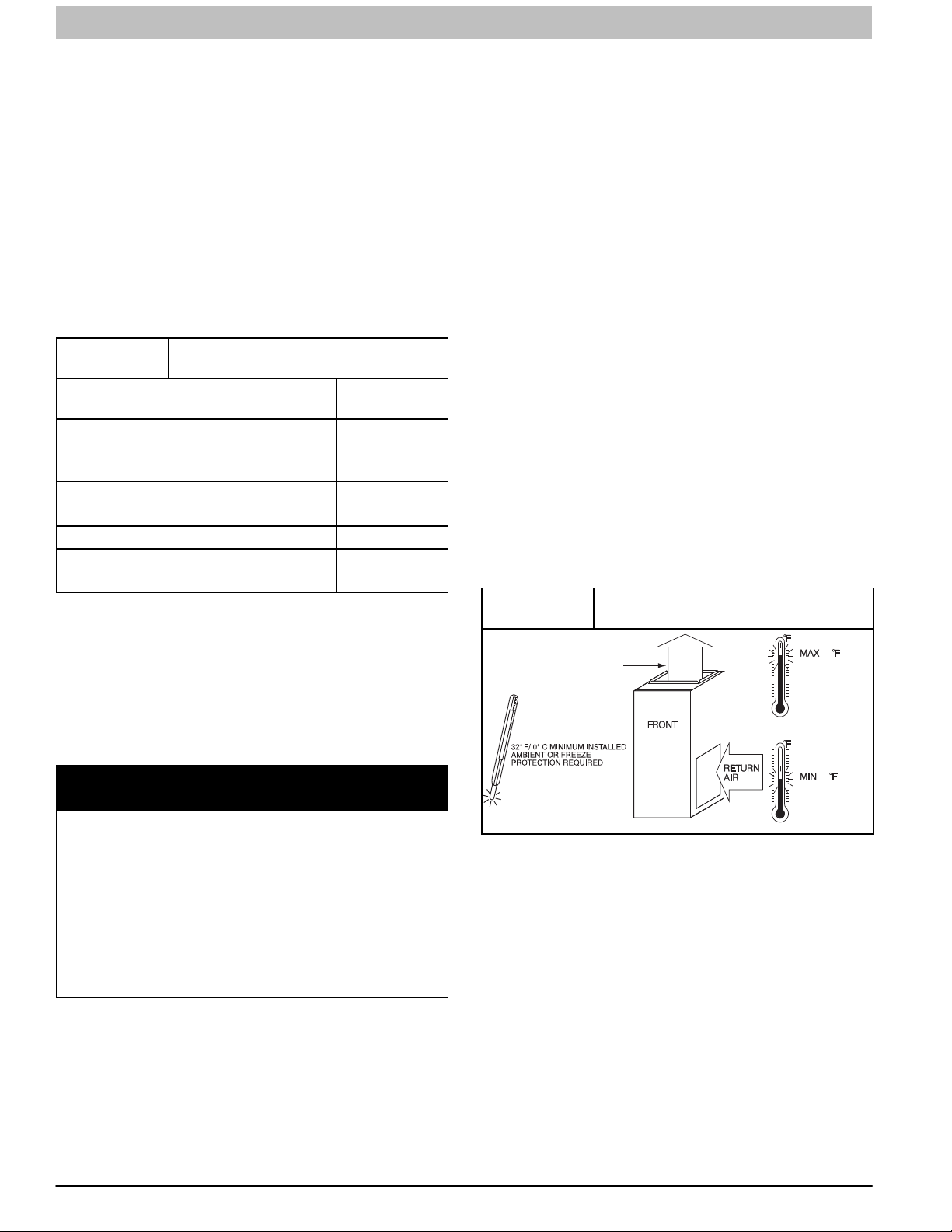

This furnace is designed for minimum continuous return−air

temperature of 60°F (15°C) db or intermittent operation down to

55°F (15°C) db such as when used with a night setback

thermostat. Return−air temperature must not exceed 80°F

(27°C) db. Failure to follow these return−air temperature limits

may affect reliability of heat exchangers, motors, and controls

(See Figure 1)

The furnace should be sized to provide 100 percent of the

design heating load requirement plus any margin that occurs

because of furnace model size capacity increments. None of

the furnace model sizes can be used if the heating load is

12,000 BTU or lower. Use Air Conditioning Contractors of

America (Manual J and S); American Society of Heating,

Refrigerating, and Air−Conditioning Engineers; or other

approved engineering method to calculate heating load

estimates and select the furnace. Excessive oversizing of the

furnace may cause the furnace and/or vent to fail prematurely,

customer discomfort and/or vent freezing.

Failure to follow these guidelines is considered faulty

installation and/or misapplication of the furnace; and resulting

failure, damage, or repairs may impact warranty coverage.

For accessory installation details, refer to the applicable

instruction literature.

NOTE: Remove all shipping materials, parts assemblies and

literature before operating the furnace.

Figure 1

Freeze Protection and Return Air

Temperature

80 / 27˚C

SUPPLY AIR

60

NOTICE

IMPORTANT INSTALLATION AND START−UP

PROCEDURES

Failure to follow this procedure may result in a nuisance

smoke or odor complaint.

The manifold pressure, gas rate by meter clocking,

temperature rise and operation must be checked after

installation. Minor smoke and odor may be present

temporarily after start−up from the manufacturing process.

Some occupants are more sensitive to this minor smoke

and odor. It is recommended that doors and windows be

open during the first heat cycle.

Introduction

The 4−way multipoise Category IV condensing furnace is CSA

design certified as: A direct vent (2−pipe) furnace of 40,000

BTUH through 140,000 BTUH models using outside air for

combustion. The 26,000 BTUH model can use the same

2−pipe venting system using outside air for combustion, but is

not considered direct vent. A non−direct vent (1−pipe) furnace

for all models using indoor air for combustion or from a well

ventilated attic or crawl space, where permitted by local code.

(See Figure 3) The furnace is factory−shipped for use with

natural gas. The furnace can be converted in the field for use

with propane gas when a factory−supplied conversion kit is

4 440 01 4005 05

Specifications subject to change without notice.

SEE PRODUCT DATA FOR

ACCESSORY CONDENSATE

TRAP HEATER AND CONDENSATE

DRAIN LINE PROTECTION.

Codes and Standards

Follow all national and local codes and standards in

addition to these instructions. The installation must comply

with regulations of the serving gas supplier, local building,

heating, plumbing, and other codes. In absence of local codes,

the installation must comply with the national codes listed

below and all authorities having jurisdiction.

In the United States and Canada, follow all codes and

standards for the following:

Safety

S US: Current edition of the National Fuel Gas Code

(NFGC) NFPA 54/ANSI Z223.1 and the Installation

Standards, Warm Air Heating and Air Conditioning

Systems ANSI/NFPA 90B

S A manufactured (Mobile) home installation must

conform with the Manufactured Home Construction

and Safety Standard, Title 24 CFR, Part 3280, or

when this standard is not applicable, the Standard for

Manufactured Home Installation (Manufactured Home

/ 16˚C

A150573

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

Sites, Communities, and Set-Ups),ANSI/NCS A225.1,

and/or CAN/CSA-Z240, MH Series Mobile Homes.

S CANADA: Current edition of the Standard of Canada,

Natural Gas and Propane Installation Code

(NSCNGPIC) CAN/CSA B149.1

General Installation

S US: Current edition of the NFGC and the NFPA 90B.

For copies, contact the National Fire Protection

Association Inc., Batterymarch Park, Quincy, MA

02269; or for only the NFGC contact the American

Gas Association, 400 N. Capitol, N.W., Washington

DC 20001

S CANADA: Current edition of the NSCNGPIC. For a

copy, contact Standard Sales, CSA International, 178

Rexdale Boulevard, Etobicoke (Toronto), Ontario,

M9W 1R3, Canada.

Combustion and Ventilation Air

S US: Current edition of Section 9.3 of the

NFPA54/ANSI Z223.1, Air for Combustion

and Ventilation

S CANADA: Current edition of Part 8 of the CAN/CSA

B149.1, Venting Systems and Air Supply for

Appliances

Duct Systems

S US and CANADA: Current edition of the Air

Conditioning Contractors Association (ACCA) Manual D,

Sheet Metal and Air Conditioning Contractors National

Association (SMACNA), or American Society of Heating,

Refrigeration, and Air Conditioning Engineers

(ASHRAE).

Acoustical Lining and Fibrous Glass

Duct

S US and CANADA: Current edition of the SMACNA,

NFPA 90B as tested by UL Standard 181 for Class I

Rigid Air Ducts

Gas Piping and Gas Pipe Pressure

Testing

S U.S.A.: Current edition of the NFPA 54/ANSI Z223.1,

NFGC; Chapters 5, 6, 7, and 8 and national plumbing

codes.

S CANADA: Current edition of the CAN/CSA−B149.1,

Parts 4, 5, 6 and 9.

In the state of Massachusetts:

S This product must be installed by a licensed plumber or

gas fitter.

S When flexible connectors are used, the maximum

length shall not exceed 36−in. (914 mm).

S When lever type gas shutoffs are used they shall be

T−handle type.

S The use of copper tubing for gas piping is not

approved by the state of Massachusetts.

Electrical Connections

S U.S.A.: Current edition of the National Electrical Code

(NEC) NFPA 70

S CANADA: Current edition of the Canadian Electrical

Code CSA C22.1

Condensate Drain Connection

US: Current edition of the National Standard Plumbing

Code

Canada: Current edition of the National Plumbing Code of

Canada

IMPORTANT: Gas furnaces manufactured on or after

May 1, 2017 are not permitted to be used in Canada for

heating of buildings or structures under construction.

Electrostatic Discharge (ESD)

Precautions Procedure

!

FURNACE RELIABILITY HAZARD

Failure to follow this caution may result in unit component

damage.

Electrostatic discharge can affect electronic components.

Take precautions during furnace installation and servicing to

protect the furnace electronic control. Precautions will prevent electrostatic discharges from personnel and hand tools

which are held during the procedure. These precautions will

help to avoid exposing the control to electrostatic discharge

by putting the furnace, the control, and the person at the

same electrostatic potential.

1. Disconnect all power to the furnace. Multiple

disconnects may be required. DO NOT TOUCH THE

CONTROL OR ANY WIRE CONNECTED TO THE

CONTROL PRIOR TO DISCHARGING YOUR BODY’S

ELECTROSTATIC CHARGE TO GROUND.

2. Firmly touch the clean, unpainted, metal surface of the

furnace chassis which is close to the control. Tools held

in a person’s hand during grounding will be satisfactorily

discharged.

3. After touching the chassis, you may proceed to service

the control or connecting wires as long as you do nothing

to recharge your body with static electricity (for example;

DO NOT move or shuffle your feet, do not touch

ungrounded objects, etc.).

4. If you touch ungrounded objects (and recharge your

body with static electricity), firmly touch a clean,

unpainted metal surface of the furnace again before

touching control or wires.

5. Use this procedure for installed and uninstalled

(ungrounded) furnaces.

6. Before removing a new control from its container,

discharge your body’s electrostatic charge to ground to

protect the control from damage. If the control is to be

installed in a furnace, follow items 1 through 4 before

bringing the control or yourself in contact with the

furnace. Put all used and new controls into containers

before touching ungrounded objects.

7. An ESD service kit (available from commercial sources)

may also be used to prevent ESD damage.

Accessories

See Specification Sheets for a list of accessories for this

product.

CAUTION

440 01 4005 05 5

Specifications subject to change without notice.

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

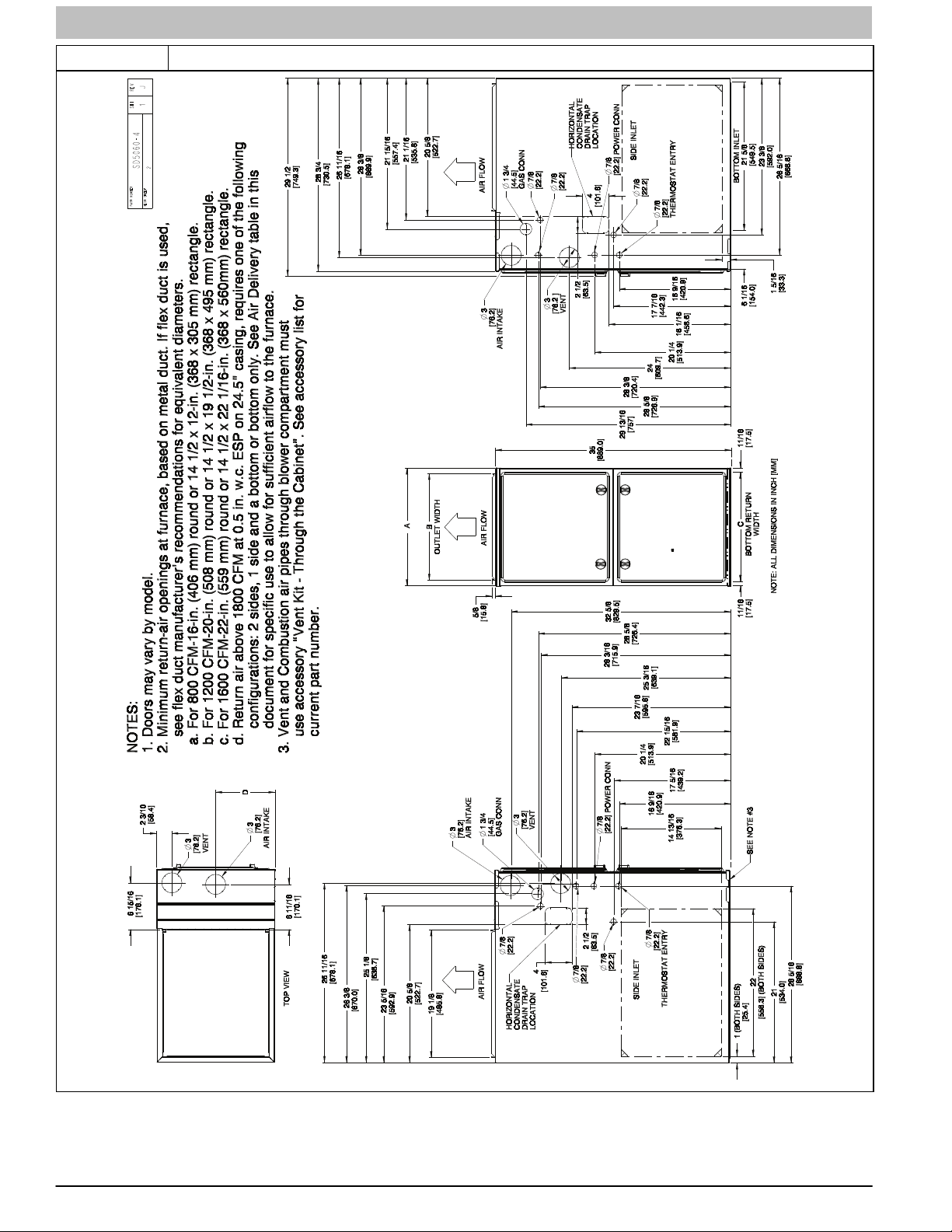

Figure 2 Dimensions

A180202

6 440 01 4005 05

Specifications subject to change without notice.

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

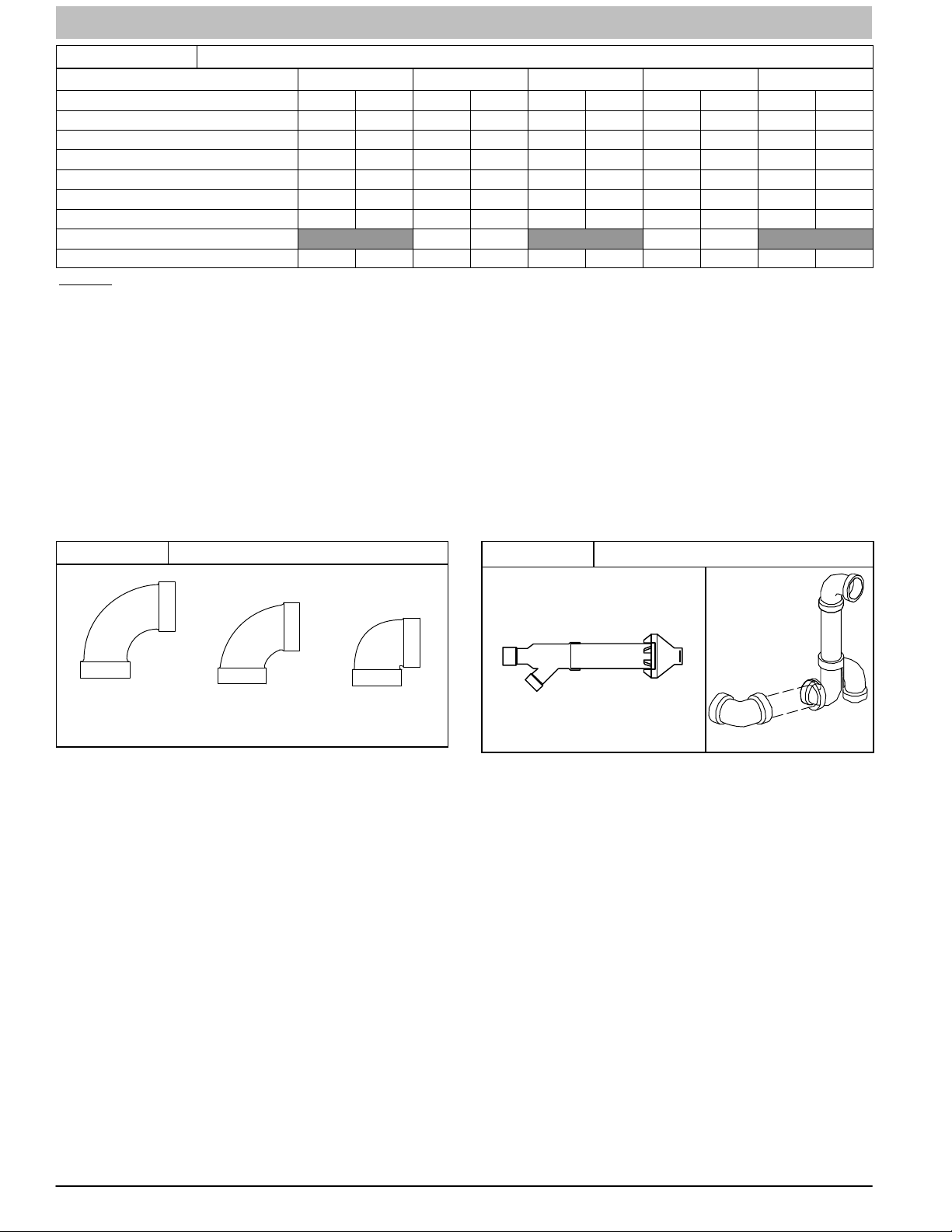

(F/G)9MXT

FURNACE SIZE

0401410 14−3/16 (361) 12−1/2 (319) 12−9/16 (322) 7−1/8 (181) 125 (56)

0401714 17−1/2 (445) 15−7/8 (403) 16 (406) 8−3/4 (222) 135 (61)

0601412 14−3/16 (361) 12−1/2 (319) 12−9/16 (322) 7−1/8 (181) 136 (62)

0601714 17−1/2 (445) 15−7/8 (403) 16 (406) 8−3/4 (222) 146 (66)

0801716 17−1/2 (445) 15−7/8 (403) 16 (406) 8−3/4 (222) 156 (70)

0802120 21 (533) 19−3/8 (492) 19−1/2 (495) 10−1/2 (267) 161 (73)

1002120 21 (533) 19−3/8 (492) 19−1/2 (495) 10−1/2 (267) 171 (77)

1202422 24−1/2 (622) 22−7/8 (581) 23 (584) 12−1/4 (311) 195 (88)

(F/G)9MXE

FURNACE SIZE

0261410 14−3/16 (361) 12−1/2 (319) 12−9/16 (322) 7−1/8 (181) 118 (54)

0401410 14−3/16 (361) 12−1/2 (319) 12−9/16 (322) 7−1/8 (181) 120 (54)

0401714 17−1/2 (445) 15−7/8 (403) 16 (406) 8−3/4 (222) 131 (59)

0601412 14−3/16 (361) 12−1/2 (319) 12−9/16 (322) 7−1/8 (181) 131 (59)

0601714 17−1/2 (445) 15−7/8 (403) 16 (406) 8−3/4 (222) 141 (63)

0801716 17−1/2 (445) 15−7/8 (403) 16 (406) 8−3/4 (222) 151 (68)

0802120 21 (533) 19−3/8 (492) 19−1/2 (495) 10−1/2 (267) 156 (71)

1002120 21 (533) 19−3/8 (492) 19−1/2 (495) 10−1/2 (267) 166 (75)

1202422 24−1/2 (622) 22−7/8 (581) 23 (584) 12−1/4 (311) 190 (85)

CABINET WIDTH OUTLET WIDTH

CABINET WIDTH OUTLET WIDTH

A B C D

BOTTOM

INLET WIDTH

A B C D

BOTTOM

INLET WIDTH

AIR INTAKE

AIR INTAKE

SHIP WT.

LB (KG)

SHIP WT.

LB (KG)

440 01 4005 05 7

Specifications subject to change without notice.

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

Location

!

PERSONAL INJURY AND/OR PROPERTY DAMAGE

HAZARD

Improper use or installation of this furnace may result in

premature furnace component failure. Unless otherwise

prohibited, this gas furnace may be used for heating

buildings under construction provided that:

−The furnace is permanently installed with all electrical

wiring, piping, venting and ducting installed according to

these installation instructions. A return air duct is

provided, sealed to the furnace casing, and terminated

outside the space containing the furnace. This prevents

a negative pressure condition as created by the

circulating air blower, causing a flame rollout and/or

drawing combustion products into the structure.

−The furnace is controlled by a thermostat. It may not be

“hot wired” to provide heat continuously to the structure

without thermostatic control.

−Clean outside air is provided for combustion. This is to

minimize the corrosive effects of adhesives, sealers and

other construction materials. It also prevents the

entrainment of drywall dust into combustion air, which

can cause fouling and plugging of furnace components.

−The temperature of the return air to the furnace is

maintained between 55°F (13°C) and 80°F (27°C), with

no evening setback or shutdown. The use of the furnace

while the structure is under construction is deemed to be

intermittent operation per our installation instructions.

−The air temperature rise is within the rated rise range on

the furnace rating plate, and the gas input rate has been

set to the nameplate value.

−The filters used to clean the circulating air during the

construction process must be either changed or

thoroughly cleaned prior to occupancy.

−The furnace, ductwork and filters are cleaned as

necessary to remove drywall dust and construction

debris from all HVAC system components after

construction is completed.

−Verify proper furnace operating conditions including

ignition, gas input rate, air temperature rise, and venting

according to these installation instructions.

General

These furnaces are shipped with materials to assist in proper

furnace installation. These materials are shipped in the main

blower compartment.

See Table 2 for loose parts bag contents.

This furnace must:

be installed so the electrical components are protected

from water.

not be installed directly on any combustible material other

than wood flooring (refer to SAFETY

CONSIDERATIONS).

CAUTION

be located close to the chimney or vent and attached to an

air distribution system. Refer to Air Ducts section.

be provided ample space for servicing and cleaning.

Always comply with minimum fire protection clearances

shown in Table 1 or on the furnace clearance to

combustible construction label.

Table 2

QUANTITY DESCRIPTION

1

1 Air Intake Pipe Flange

1 Vent Pipe Flange

2 Pipe Flange Gaskets

10 Sharp Tip Screws (Vent and Inlet Flanges)

1 Vent Pipe Coupling

2 Vent Pipe Coupling Clamps

1 Pressure Switch Tube

1 Rubber Drain Elbow

4 Drain Elbow Clamps

1 1/2”CPVC to 3/4” PVC Pipe Adapter

1 Gas Line Grommet

1 Gas Line Knockout Plug

1 Junction Box Cover

1 Junction Box Base

1 Green Ground Screw

3 Blunt Tip Screws (Junction Box)

1 Thermostat Wire Grommet

Provided separately in furnace

1 Drain Extension Tube − “Z” Pipe

NOTE: The 26K and 40K models are the only furnace that

receives the outlet restrictor in loose parts bag. See Maximum

Equivalent Vent Length Table for usage.

Loose Parts Bag Contents

Outlet Restrictor Plate − see NOTE

(Provided with 26K and 40K BTUH furnaces,

only)

!

WARNING

CARBON MONOXIDE POISONING / COMPONENT

DAMAGE HAZARD

Failure to follow this warning could result in personal injury or death and unit component damage.

Corrosive or contaminated air may cause failure of parts

containing flue gas, which could leak into the living

space. Air for combustion must not be contaminated by

halogen compounds, which include fluoride, chloride,

bromide, and iodide. These elements can corrode heat

exchangers and shorten furnace life. Air contaminants

are found in aerosol sprays, detergents, bleaches, cleaning solvents, salts, air fresheners, and other household

products. Do not install furnace in a corrosive or contaminated atmosphere. Make sure all combustion and circulating air requirements are met, in addition to all local

codes and ordinances.

8 440 01 4005 05

Specifications subject to change without notice.

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

The following types of furnace installations may require

OUTDOOR AIR for combustion due to chemical exposures:

Commercial buildings

Buildings with indoor pools

Laundry rooms

Hobby or craft rooms, and

Chemical storage areas

If air is exposed to the following substances, it should not be

used for combustion air, and outdoor air may be required for

combustion:

Permanent wave solutions

Chlorinated waxes and cleaners

Chlorine based swimming pool chemicals

Water softening chemicals

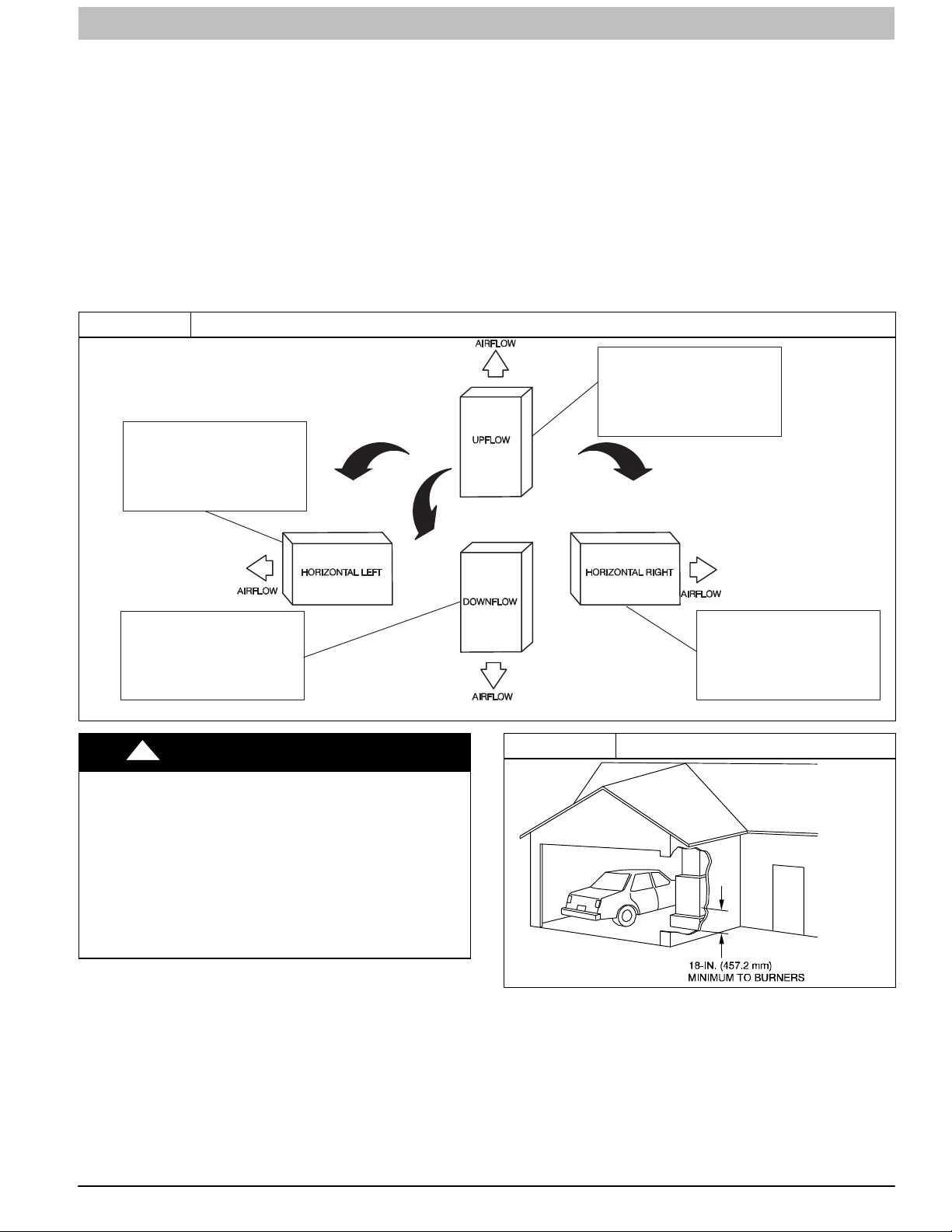

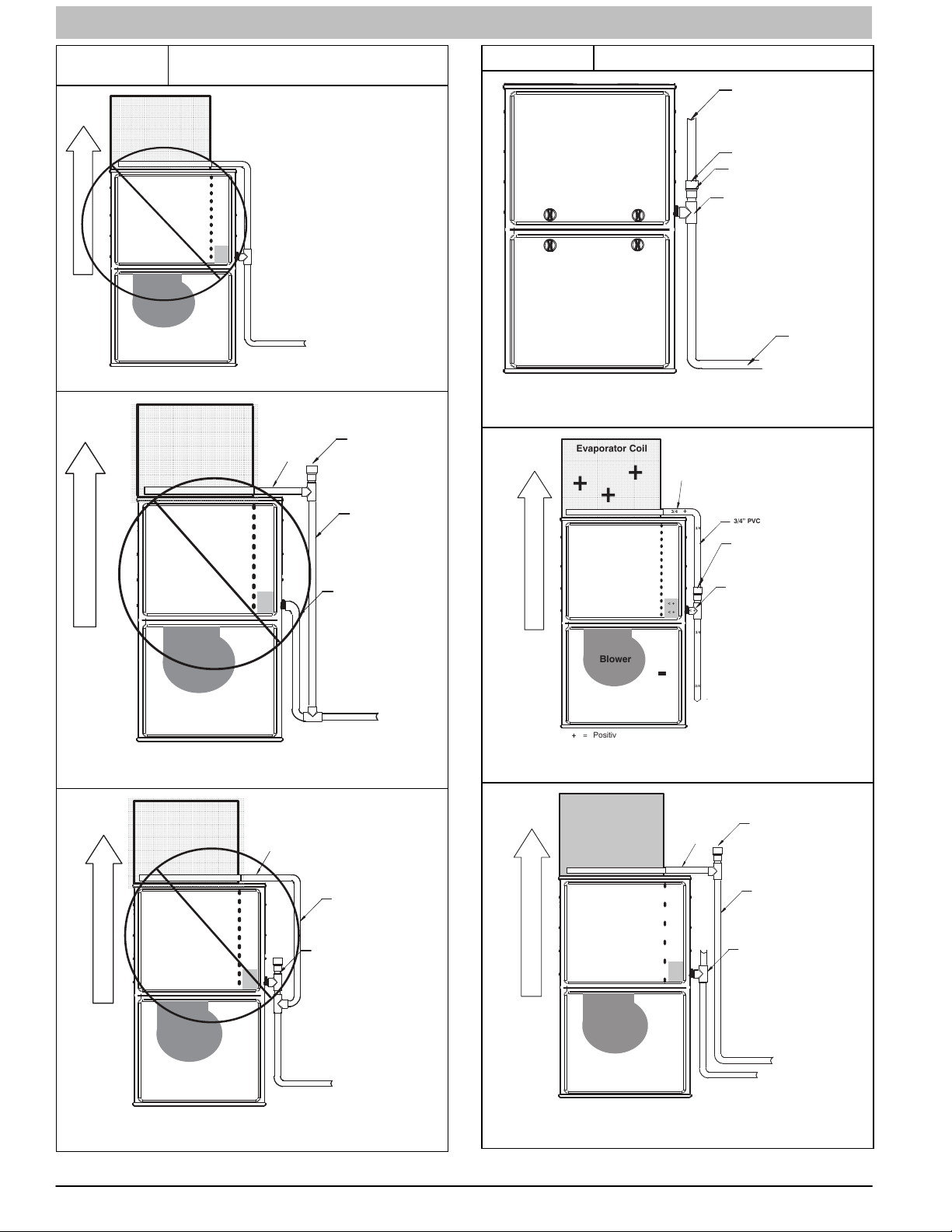

Figure 3 Multipoise Orientations

THE BLOWER IS LOCATED

TO THE RIGHT OF THE

BURNER SECTION, AND

CONDITIONED AIR IS

DISCHARGED TO THE LEFT.

De−icing salts or chemicals

Carbon tetrachloride

Halogen type refrigerants

Cleaning solvents (such as perchloroethylene)

Printing inks, paint removers, varnishes, etc.

Hydrochloric acid

Cements and glues

Antistatic fabric softeners for clothes dryers

Masonry acid washing materials

All fuel−burning equipment must be supplied with air for fuel

combustion. Sufficient air must be provided to avoid negative

pressure in the equipment room or space. A positive seal must

be made between the furnace cabinet and the return−air duct

to prevent pulling air from the burner area.

THE BLOWER IS

LOCATED BELOW THE

BURNER SECTION, AND

CONDITIONED AIR IS

DISCHARGED UPWARD.

THE BLOWER IS

LOCATED ABOVE THE

BURNER SECTION, AND

CONDITIONED AIR IS

DISCHARGED DOWNWARD.

!

WARNING

FIRE, INJURY OR DEATH HAZARD

Failure to follow this warning could result in personal injury,

death and/or property damage.

When the furnace is installed in a residential garage, the

burners and burner ignition devices must be located at least

18−in. (457 mm) above the floor. The furnace must be located

or protected to avoid damage by vehicles. When the furnace is

installed in a public garage, airplane hanger, or other building

having a hazardous atmosphere, the furnace must be installed

in accordance with the current edition of the NFPA 54/ANSI

Z223.1 or CAN/CSA B149.1. (See Figure 4)

THE BLOWER IS

LOCATED TO THE LEFT

OF THE BURNER SECTION,

AND CONDITIONED AIR IS

DISCHARGED TO THE RIGHT.

L12F010

Figure 4 Installation in a Garage

A93044

440 01 4005 05 9

Specifications subject to change without notice.

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

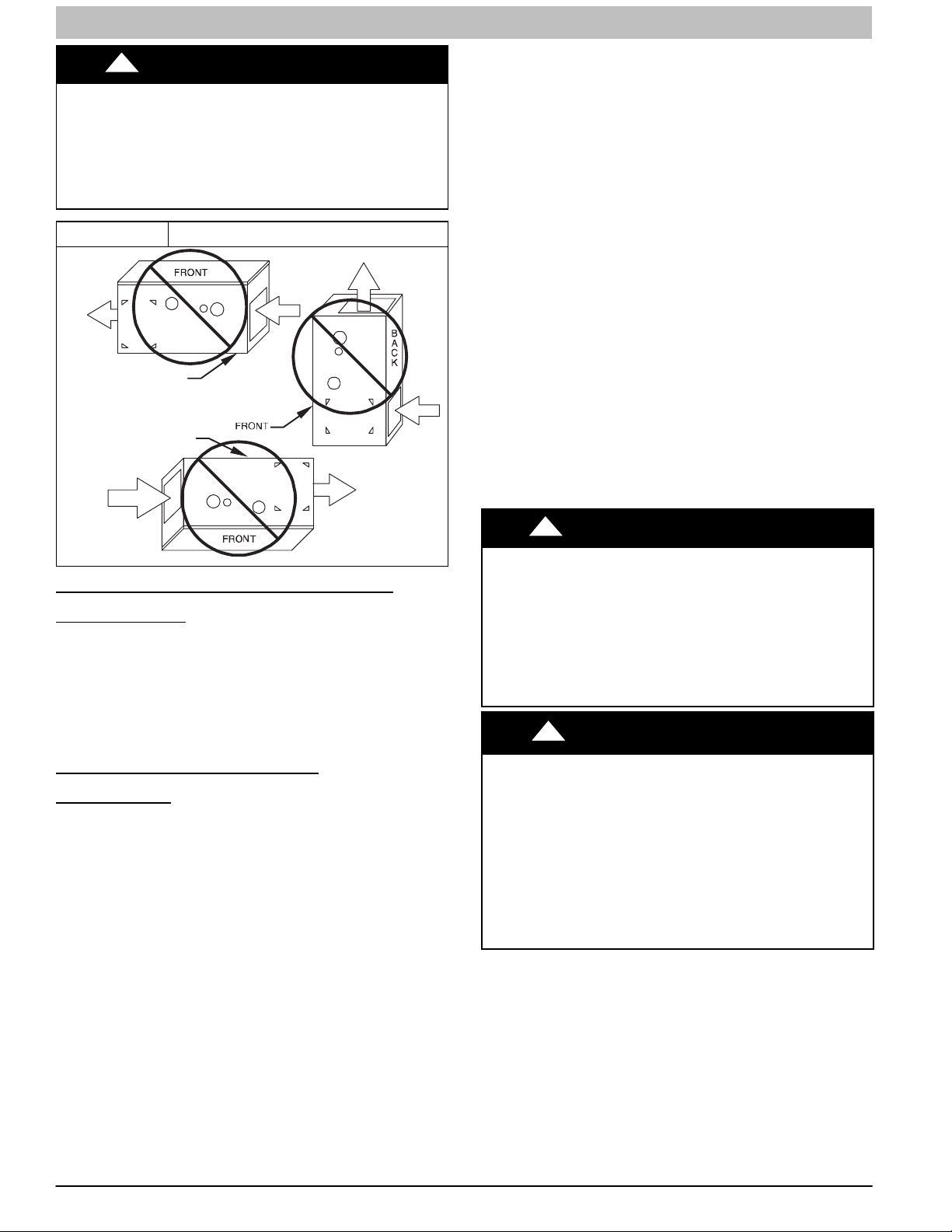

!

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death and/or property damage.

Do not install the furnace on its back or hang furnace with control compartment facing downward. Safety control operation will

be adversely affected. Never connect return−air ducts to the

back of the furnace. (See Figure 5)

WARNING

Figure 5 Prohibit Installations

BACK POSITIONED

DOWNWARD

BACK POSITIONED

UPWARD

AIR

RETURN

CUT IN

BACK

Ventilated Combustion Air Applications

When the furnace is installed using the ventilated combustion

air option, the attic or crawlspace must freely communicate with

the outdoor to provide sufficient air for combustion. The

combustion air pipe cannot be terminated in attics or

crawlspaces that use ventilation fans designed to operate

during the heating season. If ventilation fans are present in

these areas, the combustion air pipe must terminate outdoors

as a Direct Vent/ 2-Pipe system.

All air for combustion is piped directly to the furnace from a

space that is well ventilated with outdoor air (such as an attic,

crawlspace, or equipment closet) and the space is well isolated

from the living space or garage. In addition, other gas

appliances installed in the space with the furnace may require

outside air for combustion. Follow the guidelines below to

insure that the roof or crawlspace walls have sufficient free

area to provide sufficient air for combustion and ventilation for

the furnaces. The guidelines below can be used to insure that

other gas appliances have sufficient air for combustion.

Provisions for adequate combustion, ventilation, and dilution air

must be provided in accordance with:

U.S. Installations: Current edition of Section 9.3 of the

NFPA 54/ANSI Z223.1, Air for Combustion and Ventilation

and applicable provisions of the local building codes.

Canadian Installations: Current edition of Part 8 of

CAN/CSA−B149.1, Venting Systems and Air Supply for

Appliances and all authorities having jurisdiction.

L12F011

Location Relative to Cooling

Equipment

The cooling coil must be installed parallel with, or on the

downstream side of the unit to avoid condensation in the heat

exchangers. When installed parallel with the furnace, dampers

or other flow control must prevent chilled air from entering the

furnace. If the dampers are manually operated, they must be

equipped with means to prevent operation of either unit unless

the damper is in the full−heat or full−cool position.

Air for Combustion and

Ventilation

Introduction

Direct Vent (2−pipe) Applications

When the furnace is installed as a direct vent (2-pipe) furnace,

no special provisions for air for combustion are required.

However, other gas appliances installed in the space with the

furnace may require outside air for combustion. Follow the

guidelines below to insure that other gas appliances have

sufficient air for combustion.

Non−Direct Vent (1−pipe) Applications

When the furnace is installed as a non-direct vent (1-pipe)

furnace, it will be necessary to insure there is adequate air for

combustion. Other gas appliances installed with the furnace

may also require air for combustion and ventilation in addition

to the amount of combustion air and ventilation air required for

the furnace. Follow the guidelines below to insure that the

furnace and other gas appliances have sufficient air for

combustion.

!

FURNACE CORROSION HAZARD

Failure to follow this caution may result in furnace damage.

Air for combustion must not be contaminated by halogen

compounds, which include fluoride, chloride, bromide, and

iodide. These elements can corrode heat exchangers and

shorten furnace life. Air contaminants are found in aerosol

sprays, detergents, bleaches, cleaning solvents, salts, air

fresheners, and other household products.

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or

death.

The operation of exhaust fans, kitchen ventilation fans,

clothes dryers, attic exhaust fans or fireplaces could create a

NEGATIVE PRESSURE CONDITION at the furnace.

Make−up air MUST be provided for the ventilation devices, in

addition to that required by the furnace. Refer to the Carbon

Monoxide Poisoning Hazard warning in the venting section of

these instructions to determine if an adequate amount of

make−up air is available.

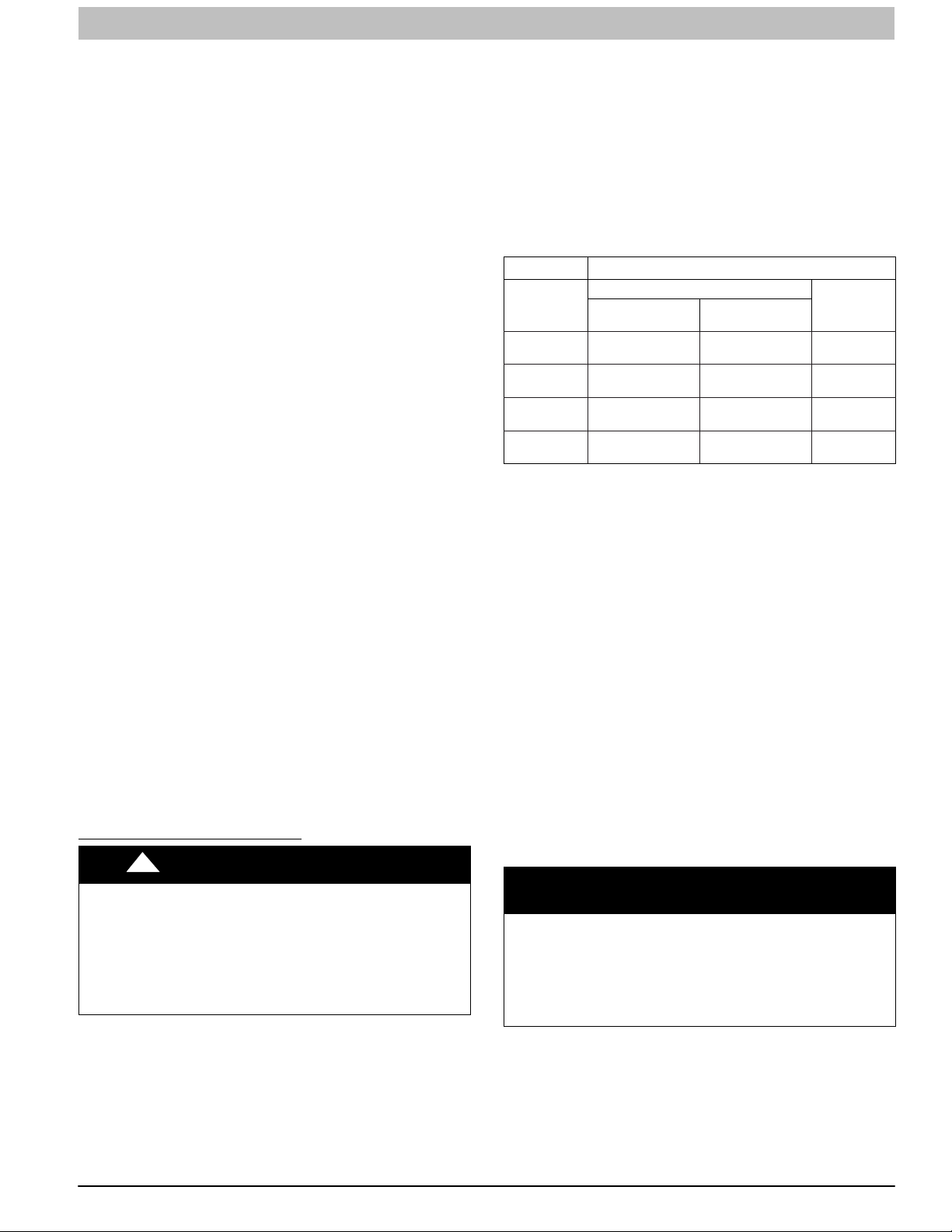

The requirements for combustion and ventilation air depend

upon whether or not the furnace is located in a space having a

volume of at least 50 cubic feet per 1,000 Btuh (4.8 cubic

meters per kW) input rating for all gas appliances installed in

the space.

Spaces having less than 50 cubic feet per 1,000 Btuh (4.8

cubic meters per kW) require the OUTDOOR

COMBUSTION AIR METHOD.

Spaces having at least 50 cubic feet per 1,000 Btuh (4.8

cubic meters per kW) may use the INDOOR

COMBUSTION AIR, STANDARD or KNOWN AIR

INFILTRATION METHOD.

CAUTION

WARNING

10 440 01 4005 05

Specifications subject to change without notice.

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

Outdoor Combustion Air Method

1. Provide the space with sufficient air for proper

combustion, ventilation, and dilution of flue gases using

permanent horizontal or vertical duct(s) or opening(s)

directly communicating with the outdoors or spaces that

freely communicate with the outdoors.

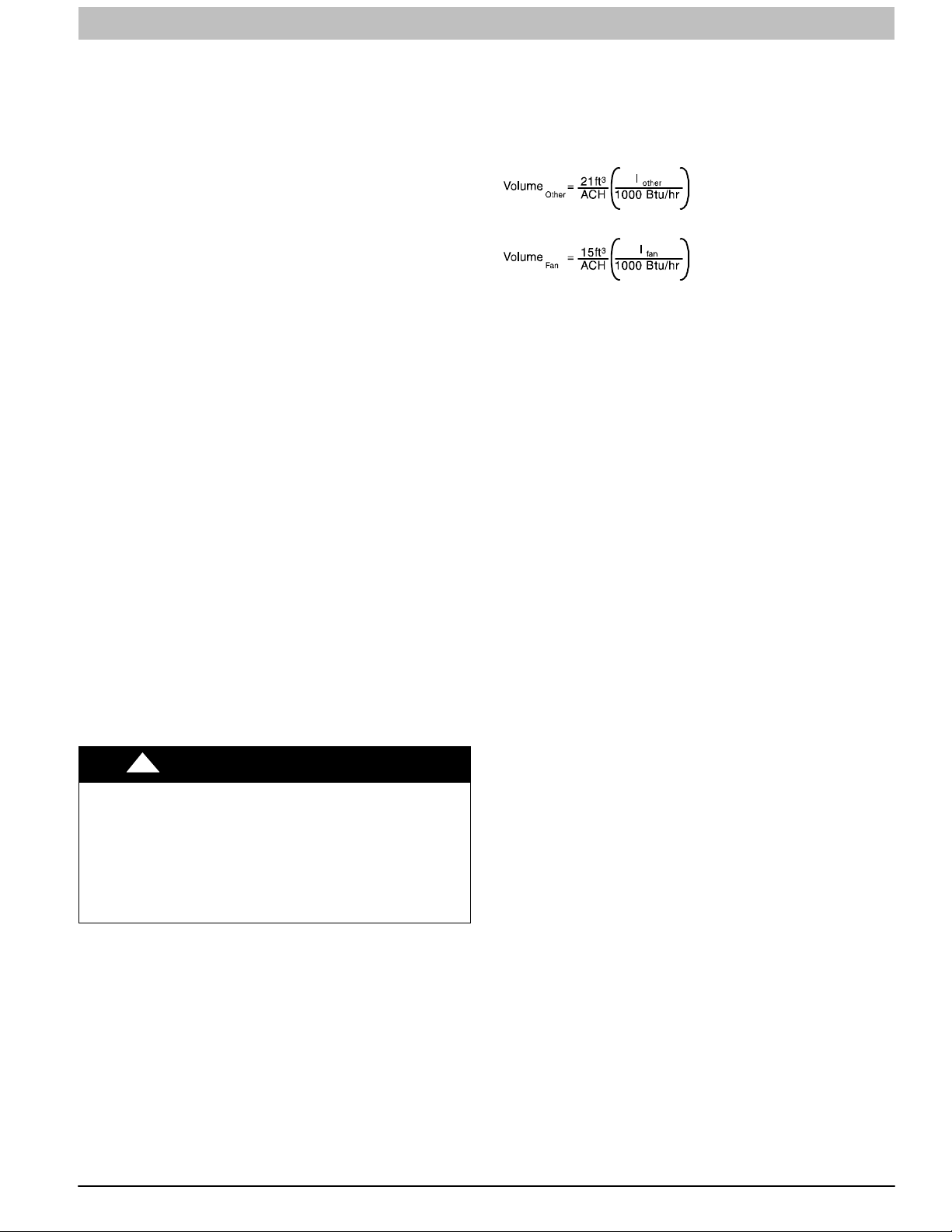

2. Figure 6 illustrates how to provide TWO OUTDOOR

OPENINGS, one inlet and one outlet combustion and

ventilation air openings to the outdoors.

appliance in the space and add the volumes together to get the

total minimum required volume for the space.

Table 4 − Minimum Space Volumes were determined by

using the following equations from the current edition of the

National Fuel Gas Code ANSI Z223.1/NFPA 54, 9.3.2.2:

1. For other than fan-assisted appliances, such as a

draft hood-equipped water heater

A04002

a. One opening MUST commence within 12-in.

(300 mm) of the ceiling and the second opening

MUST commence within 12-in. (300 mm) of the floor.

2. For fan-assisted appliances such as this furnace:

A04003

b. Size openings and ducts per Figure 6 and Table 3.

c. TWO HORIZONTAL DUCTS require 1 square inch

(25.4 square mm) of free area per 2,000 Btuh (1,100

2

mm

/kW) of combined input for all gas appliances in

the space per Figure 6 and Table 3.

d. TWO OPENINGS OR VERTICAL DUCTS require 1

square inch (25.4 square mm)of free area per 4,000

Btuh (550 mm

2

/kW) for combined input of all gas

appliances in the space per Figure 6 and Table 3.

3. ONE OUTDOOR OPENING requires:

a. 1 sq. in. (25.4 square mm)of free area per 3,000 Btuh

(734 mm

2

/kW) for combined input of all gas

appliances in the space per Table 3 and

b. Not less than the sum of the areas of all vent

connectors in the space.

The opening shall commence within 12-in. (300 mm) of the

ceiling. Appliances in the space shall have clearances of at

least 1-in. (25 mm) from the sides and back and 6-in. (150 mm)

from the front. The opening shall directly communicate with the

outdoors or shall communicate through a vertical or horizontal

duct to the outdoors or spaces (crawl or attic) that freely

communicate with the outdoors.

Indoor Combustion Air

NFPA & AGA

Standard and Known-Air-Infiltration Rate

Methods

Indoor combustion air is permitted for combustion, ventilation,

and dilution, if the Standard or Known-Air-Infiltration Rate

Method is used.

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or

death.

Many homes require air to be supplied from outdoors for

furnace combustion, ventilation, and dilution of flue gases.

The furnace combustion air supply must be provided in

accordance with this instruction manual.

WARNING

If:

I

other=combined input of all other than fan-assisted

appliances in Btuh/hr

fan=combined input of all fan-assisted appliances in Btuh/hr

I

ACH = air changes per hour (ACH shall not exceed 0.60.)

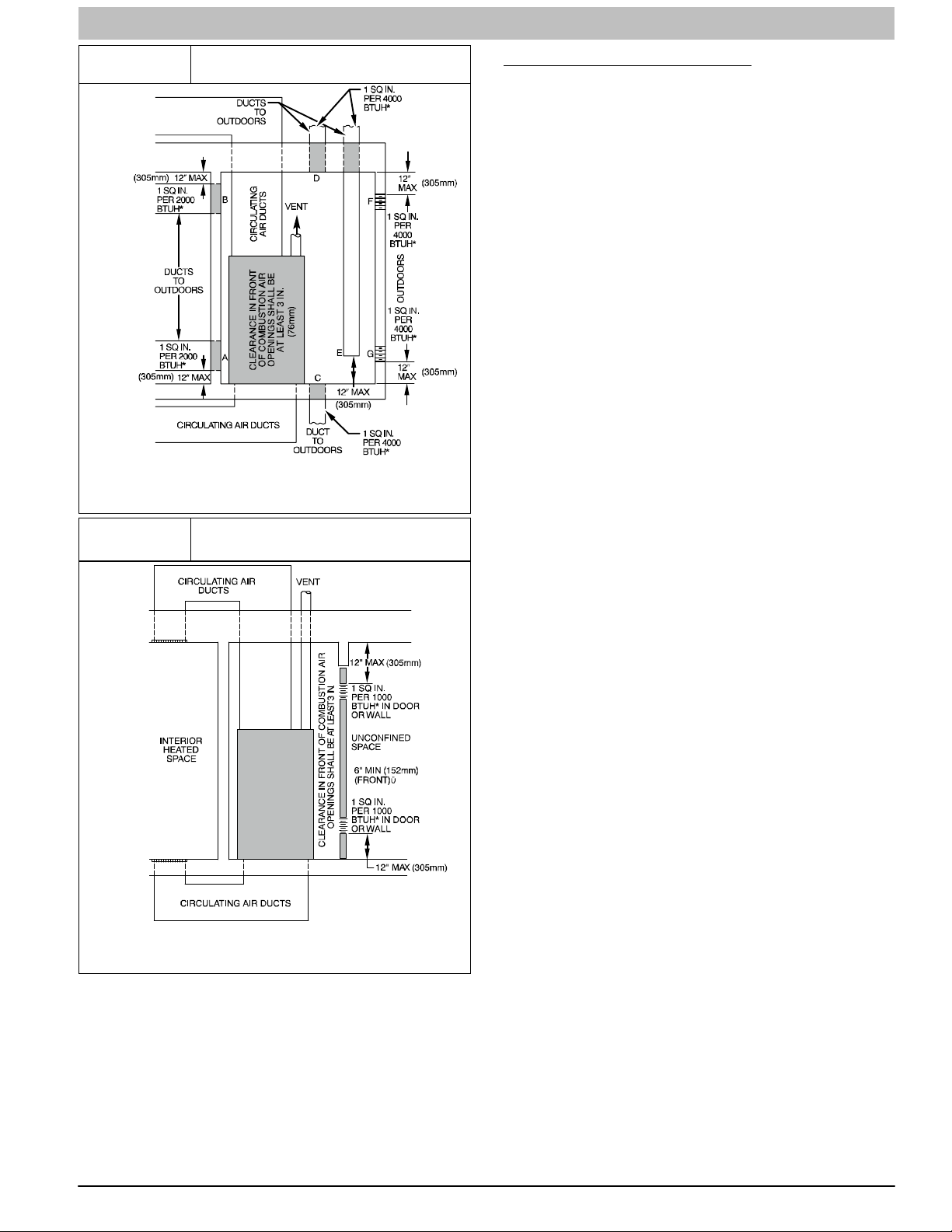

The following requirements apply to the Standard Method and

to the Known Air Infiltration Rate Method.

1. Adjoining rooms can be considered part of a space if:

a. There are no closable doors between rooms.

b. Combining spaces on same floor level. Each opening

shall have free area of at least 1-in.

(2,000 mm

2

/kW) of the total input rating of all gas

2

/1,000 Btuh

appliances in the space, but not less than 100-in.

(0.06 m2). One opening shall commence within 12−in.

(300 mm) of the ceiling and the second opening shall

commence within 12-in. (300 mm) of the floor. The

minimum dimension of air openings shall be at least

3-in. (80 mm). (See Figure 7)

c. Combining space on different floor levels. The

volumes of spaces on different floor levels shall be

considered as communicating spaces if connected by

one or more permanent openings in doors or floors

having free area of at least 2−in.

(4,400 mm

2

/kW) of total input rating of all

2

/1,000 Btuh

gas appliances.

2. An attic or crawlspace may be considered a space that

freely communicates with the outdoors provided there

are adequate permanent ventilation openings directly to

outdoors having free area of at least 1-in.

2

/4,000 Btuh of

total input rating for all gas appliances in the space.

3. In spaces that use the Indoor Combustion Air Method,

infiltration should be adequate to provide air for

combustion, permanent ventilation and dilution of flue

gases. However, in buildings with unusually tight

construction, additional air MUST be provided using

the methods described in the Outdoor Combustion Air

Method section.

4. Unusually tight construction is defined as Construction

with:

The Standard Method:

1. The space has no less volume than 50 cubic feet per

1,000 Btuh (4.8 cubic meters per kW) of the maximum

input ratings for all gas appliances installed in the space

and

2. The air infiltration rate is not known to be less than 0.40

air changes per hour (ACH).

The Known Air Infiltration Rate Method shall be used, if the

infiltration rate is known to be:

1. Less than 0.40 ACH and

a. Walls and ceilings exposed to the outdoors have a

continuous, sealed vapor barrier. Openings are

gasketed or sealed and

b. Doors and openable windows are weatherstripped

and

c. Other openings are caulked or sealed. These include

joints around window and door frames, between sole

plates and floors, between wall-ceiling joints, between

wall panels, at penetrations for plumbing, electrical

and gas lines, etc.

2. Equal to or greater than 0.10 ACH

Infiltration rates greater than 0.60 ACH shall not be used. The

minimum required volume of the space varies with the number

of ACH and shall be determined per Table 4 or Equations 1

and 2. Determine the minimum required volume for each

440 01 4005 05 11

Specifications subject to change without notice.

2

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

Combination of Indoor and Outdoor Air

1. Indoor openings shall comply with the Indoor

Combustion Air Method below and,

2. Outdoor openings shall be located as required in the

Outdoor Combustion Air Method mentioned previously

and,

3. Outdoor openings shall be sized as follows:

b. Outdoor opening size reduction Factor is one minus

the Ratio in a. above.

c. Minimum size of Outdoor openings shall be the size

required in Outdoor Combustion Air Method above

multiplied by reduction Factor in b. above. The

minimum dimension of air openings shall be not less

than 3-in. (80 mm).

a. Calculate the Ratio of all Indoor Space volume

divided by required volume for Indoor Combustion

Air Method.

Table 3 Minimum Free Area Required for Each Combustion Air Opening or Duct to Outdoors

TWO OPENINGS OR

VERTICAL DUCTS

(1 SQ. IN./4,000 BTUH)

(550 SQ. MM/KW)

Free Area of Open-

ing and Duct

Sq. In (mm)

FURNACE

INPUT

(BTUH)

TWO HORIZONTAL DUCTS

(1 SQ. IN./2,000 BTUH)

(1,100 SQ. MM/KW)

Free Area of

Opening and Duct

Sq. In (Sq. mm)

Round

In. (mm)

Duct

Dia

SINGLE DUCT OR OPENING

(1 SQ. IN./3,000 BTUH)

(734 SQ. MM/KW)

Free Area of Open-

ing and Duct

Sq. In (Sq. mm)

Round

Duct

In. (mm)

Dia

26,000 * 13 (8388) 4 (102) 9 (5807) 4 (102) 7 (4517) 3 (77)

40,000 * 20 (12904) 5 (127) 14 (8696) 5 (127) 10 (6452) 4 (102)

60,000 30 (19355) 6 (152) 20 (13043) 5 (127) 15 (9678) 5 (127)

80,000 40 (25807) 7 (178) 27 (17391) 6 (152) 20 (12904) 5 (127)

100,000 50 (32258) 8 (203) 34 (21739) 7 (178) 25 (16130) 6 (152)

120,000 60 (38709) 9 (229) 40 (26087) 7 (178) 30 (19355) 6 (152)

140,000 * 70 (45161) 10 (254) 47 (30435) 8 (203) 35 (22581) 7 (178)

Round Duct

In. (mm)

Dia.

* Not all families have these models.

EXAMPLE: Determining Free Area

FURNACE WATER HEATER TOTAL INPUT

100,000 + 30,000 = (130,000 divided by 4,000) = 32.5 Sq. In. for each two Vertical Ducts or Openings

60,000 + 40,000 = (100,000 divided by 3,000) = 33.3 Sq. In. for each Single Duct or Opening

80,000 + 30,000 = (110,000 divided by 2,000) = 55.0 Sq. In. for each two Horizontal Ducts

Table 4 Minimum Space Volumes for 100% Combustion, Ventilation and Dilution Air from Outdoors

OTHER THAN FAN‐ASSISTED TOTAL

(1,000'S BTUH GAS INPUT RATE)

ACH

0.60

0.50

0.40

0.30

0.20

0.10

0.00 NP NP NP NP NP NP NP NP NP NP

NP = Not Permitted

30 40 50 26 40 60 80 100 120 140

Space Volume Ft

1,050

(29.7)

1,260

(35.6)

1,575

(44.5)

2,100

(59.4)

3,150

(89.1)

6,300

(178.0)

1,400

(39.6)

1,680

(47.5)

2,100

(59.4)

2,800

(79.2)

4,200

(118.9)

8,400

(237.8)

1,750

(49.5)

2,100

(59.4)

2,625

(74.3)

3,500

(99.1)

5,250

(148.6)

10,500

(297.3)

910

(25.8)

1,092

(30.9)

1,365

(38.7)

1,820

(51.5)

2,730

(77.3)

5,460

(154.6)

1,400

(39.6)

1,680

(47.5)

2,100

(59.4)

2,800

(79.2)

4,200

(118.9)

8,400

(237.8)

FAN‐ASSISTED TOTAL

(1,000'S BTUH GAS INPUT RATE)

3

3

(M

)

1,500

(42.5)

1,800

(51.0)

2,250

(63.7)

3,000

(84.9)

4,500

(127.3)

9,000

(254.6)

2,000

(56.6)

2,400

(67.9)

3,000

(84.9)

4,000

(113.2)

6,000

(169.8)

12,000

(339.5)

2,500

(70.8)

3,000

(84.9)

3,750

(106.1)

5,000

(141.5)

7,500

(212.2)

15,000

(424.4)

3,000

(84.9)

3,600

(101.9)

4,500

(127.3)

6,000

(169.8)

9,000

(254.6)

18,000

(509.2)

3,500

(99.1)

4,200

(118.9)

5,250

(148.6)

7,000

(198.1)

10,500

(297.1)

21,000

(594.1)

12 440 01 4005 05

Specifications subject to change without notice.

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

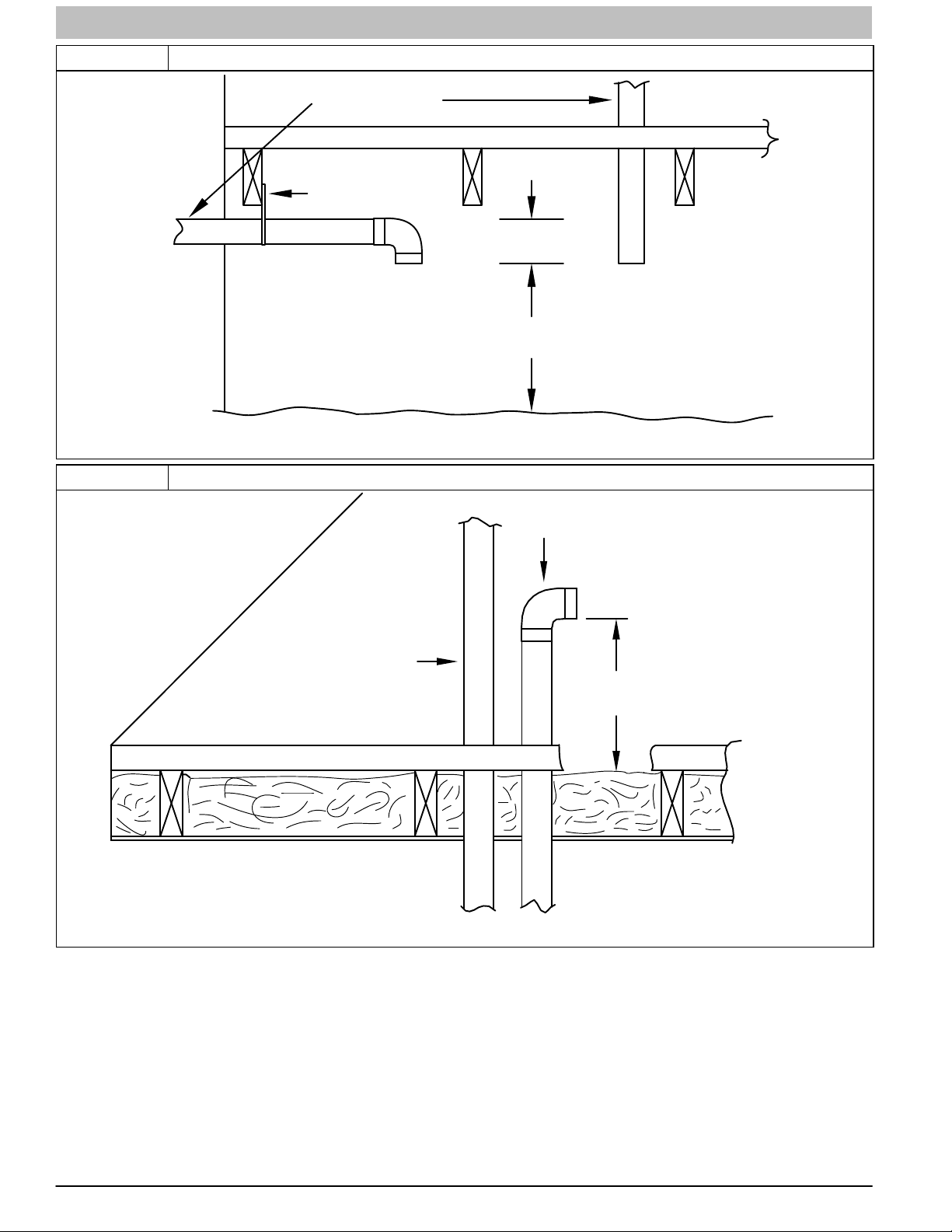

Figure 6

Figure 7

Air for Combustion, Ventilation,

and Dilution for Outdoors

*Minimum dimensions of 3‐in. (76mm)

NOTE: Use any of the following combinations of openings:

A & B, C & D, D & E, F & G

Air for Combustion, Ventilation,

and Dilution from Indoors

CONDENSATE TRAP

Condensate Trap − Upflow Orientation

When the furnace is installed in the upflow position, it is not

necessary to relocate the condensate trap or associated

tubing. Refer to Figure 8 for upflow condensate trap

information. Refer to Condensate Drain section for information

how to install the condensate drain.

Condensate Trap − Downflow

Orientation

When the furnace is installed in the downflow position, the

condensate trap will be initially located at the upper left corner

of the collector box, as received from the factory. See the top

image in Figure 9. When the furnace is installed in the

downflow orientation, the condensate trap must be relocated

for proper condensate drainage. See the bottom image in

Figure 9.

To Relocate the Condensate Trap:

S Orient the furnace in the downflow position.

S Figure 9 shows the condensate trap and tubing before and

after relocation. Refer to Figure 9 to begin the trap conversion.

S Refer to Condensate Drain section for information how to install

the condensate drain.

L12F012

* Minimum opening size is 100 sq in. (64516 sq. mm) with

minimum dimensions of 3‐in. (76mm)

{ Minimum of 3‐in. (76mm) when type‐B1 vent is used.

440 01 4005 05 13

L12F013

Specifications subject to change without notice.

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

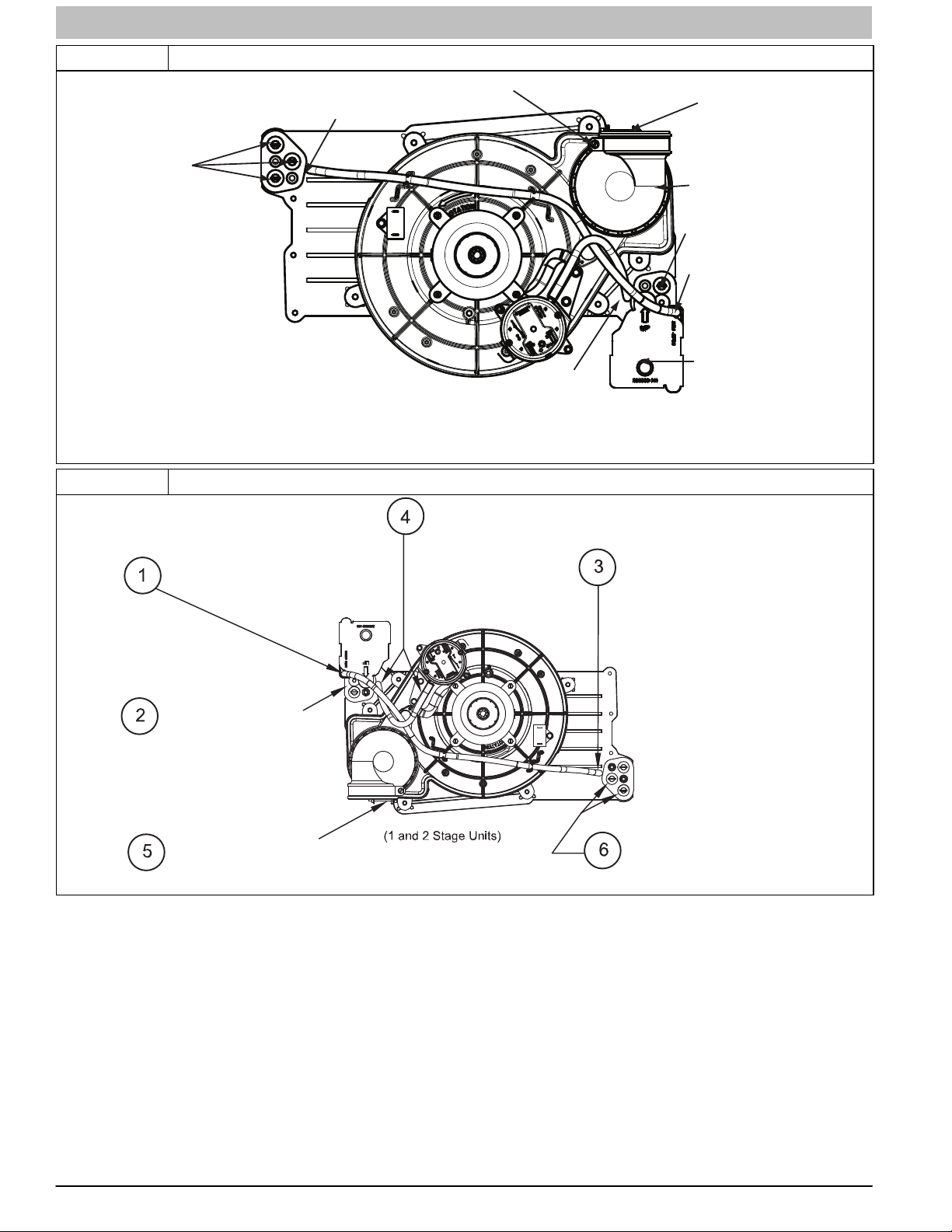

Figure 8 Upflow Trap Configuration

Vent Pipe Clamp

Condensate Trap

Relief Port

Collector Box

Plugs

Pressure Switch

Port

UPFLOW TRAP CONFIGURATION

1 & 2 Stage Units

Representative drawing only, some models may vary in appearance.

Vent Elbow Clamp

Vent Elbow

Collector Box

Plug

Condensate Trap

Relief Port

Condensate Trap

Outlet

A11307

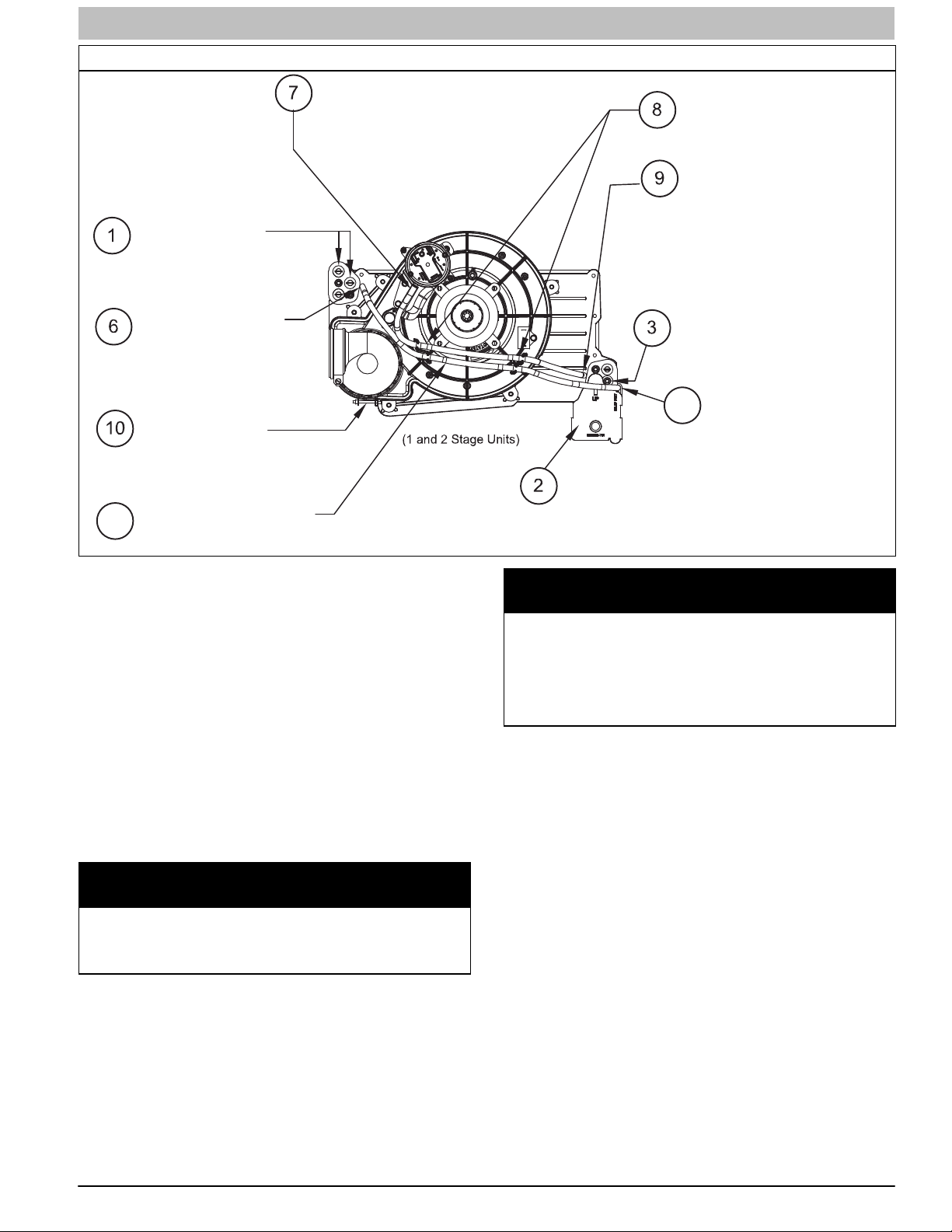

Figure 9 Unconverted Factory Configuration as viewed in the Downflow Orientation

Remove pressure switch tube from

front pressure switch and discard. A

new tube is shipped in the loose parts

Remove relief tube from relief

port on condensate trap.

Remove the screw

that secures the trap

to the collector box and

remove trap.

Loosen clamp on inlet

to vent elbow.

Representative drawing only, some models may vary in appearance.

bag.

Remove tube from relief port.

Remove middle and bottom

plugs. DO NOT DISCARD.

A11587LA

14 440 01 4005 05

Specifications subject to change without notice.

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

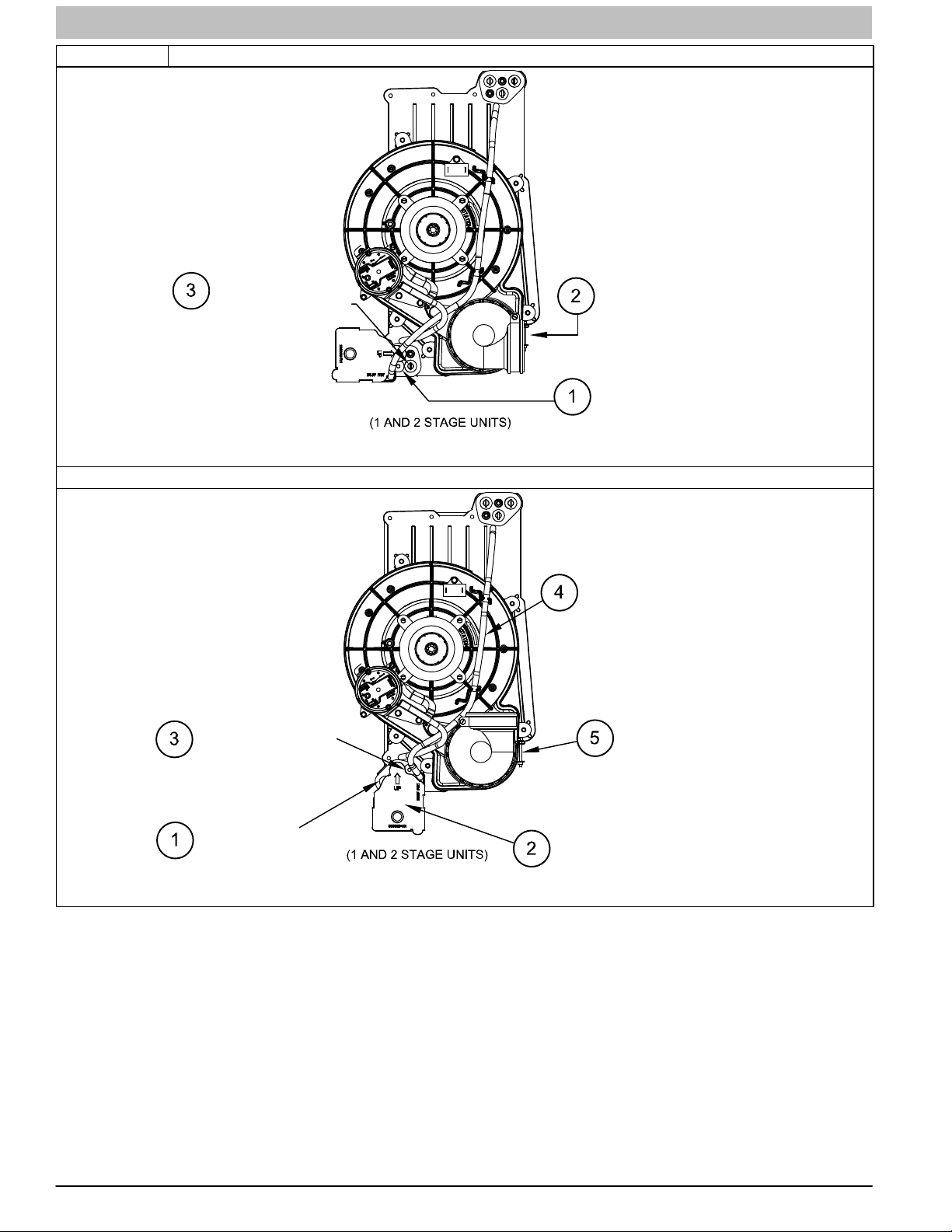

Downflow Trap Configuration

Connect the new pressure switch

tube from Loose Parts bag to

port on front pressure switch.

Install the two plugs

previously removed

on the open ports

of the collector box.

Route tube through inducer

stand−offs to adjust position

of the tube.

Trim excess tube.

Connect pressure switch

tube to port on collector

box.

Connect relief tube

to port on collector

box.

Rotate elbow to

desired position

and

tighten clamp to

15 lb.−in.

Slide tube in stand−offs

4

to adjust length.

Representative drawing only, some models may vary in appearance.

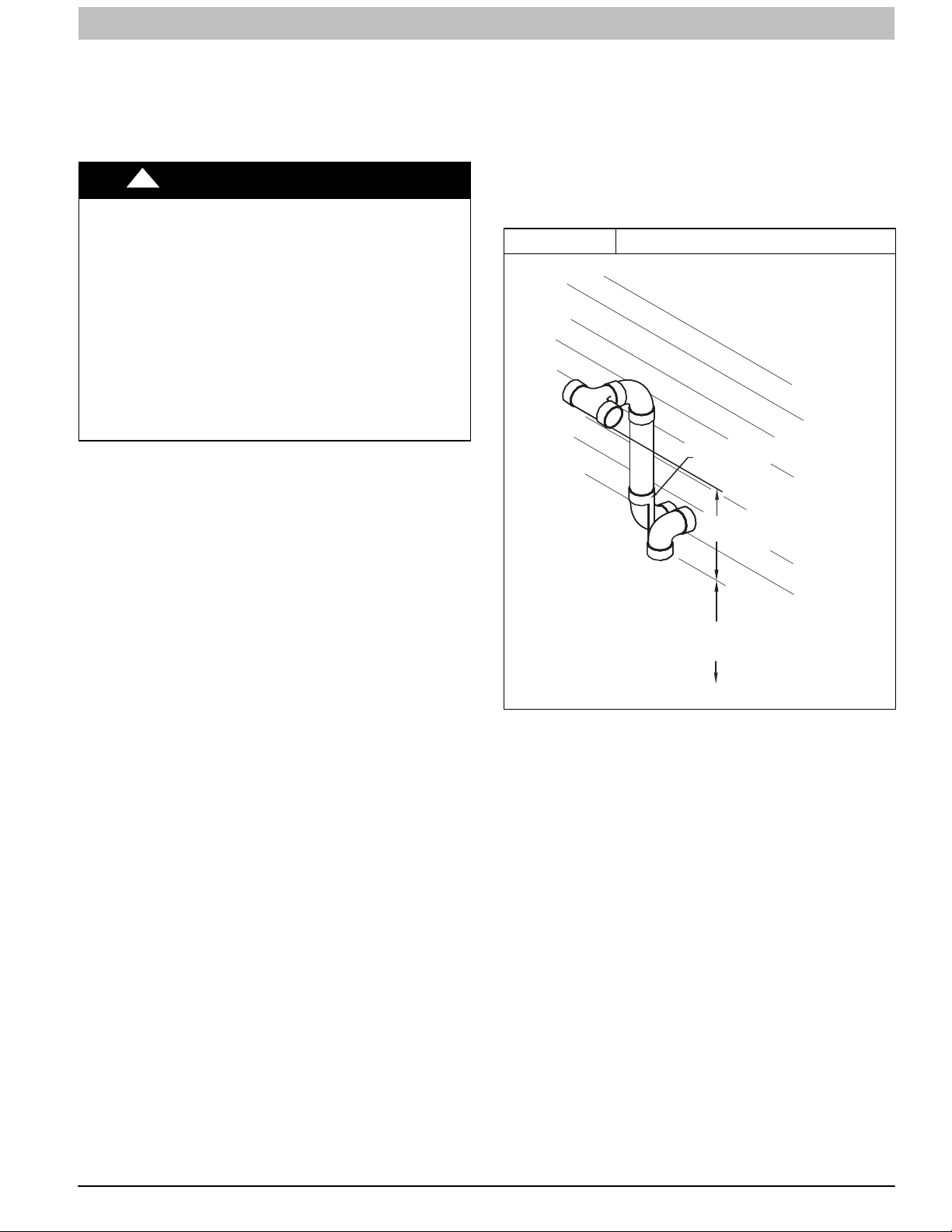

Condensate Trap − Horizontal

Orientation

When the furnace is installed in the horizontal right position, the

condensate trap will be initially located at the bottom of the

collector box, as received from the factory. See the top image in

Figure 10. When the furnace is installed in the horizontal left

position, the condensate trap will be initially located at the top of

the collector box, as received from the factory. See the top image

in Figure 11. In both cases the trap must be repositioned on the

collector box for proper condensate drainage. See bottom images

in Figure 10 and Figure 11.

A field−supplied, accessory Horizontal Installation Kit (trap

grommet) is required for all direct−vent horizontal installations

(only). The kit contains a rubber casing grommet designed to seal

between the furnace casing and the condensate trap. (See

Figure 16)

NOTICE

The field-supplied, accessory horizontal drain trap grommet

is ONLY REQUIRED FOR DIRECT VENT APPLICATIONS. It

is NOT required for applications using single-pipe or ventilated combustion air venting.

Attach condensate trap

with screw to collector box.

Connect relief tube to

5

relief port on condensate

trap.

Align condensate trap

over middle and bottom

ports of collector box.

A11587LB

NOTICE

The condensate trap extends below the side of the casing in

the horizontal position. A minimum of 2-in. (51 mm) of clearance is required between the casing side and the furnace

platform for the trap to extend out of the casing in the horizontal position. Allow at least 1/4-in. per foot (20mm per

meter) of slope down and away from the furnace in horizontal

sections of drain line.

To Relocate the Condensate Trap:

S Remove the knockout in the casing for the condensate trap.

S Install the grommet in the casing when required for direct−vent

horizontal applications.

S Orient the furnace in the desired position.

S Allow for 2 in. (51 mm) of clearance underneath the furnace for

the condensate trap and drain line.

S Figure 10 shows the condensate trap and tubing before and

after relocation in the horizontal right position.

S Figure 11 shows the condensate trap and tubing before and

after relocation in the horizontal left position.

S Refer to the appropriate figure to begin the trap conversion.

S Refer to Condensate Drain section for information how to install

the condensate drain.

440 01 4005 05 15

Specifications subject to change without notice.

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

Figure 10 Unconverted Factory Configuration as viewed in the Horizontal Right Orientation

Remove plug from

collector box.

DO NOT DISCARD.

Horizontal Right Trap Configuration (continued)

NOTE: Remove knockout in

casing before re−installing the

condensate trap.

Attach condensate

trap with screw to

collector box.

If alternate vent position

is required, loosen clamp

on inlet of vent elbow.

Remove the screw that secures

the trap to the collector box and

remove trap.

Representative drawing only, some models may vary in appearance.

Slide relief tube in stand−offs

to adjust length.

A11573LA

Vent elbow shown in alternate

orientation. Tighten clamp on

inlet to vent elbow 15 lb.−in.

Install plug on

open port of

collector box

Representative drawing only, some models may vary in appearance.

16 440 01 4005 05

Specifications subject to change without notice.

Align trap over middle and

right−hand port on collector box.

A11573LB

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

Figure 11 Unconverted Factory Configuration as viewed in the Horizontal Left Orientation

Remove the screw that secures the

condensate trap to the collector box

If alternate vent position

5

is required, loosen clamp

on vent elbow inlet.

Remove relief tube

from port on collector

box.

Representative drawing only, some models may vary in appearance.

and remove trap.

Remove relief tube from

relief port on condensate

trap.

Remove middle and right

6

plug from collector box.

DO NOT DISCARD.

Remove front pressure

switch tube and discard.

A new tube is shipped in

the Loose Parts bag.

A11574LA

Horizontal Left Trap Configuration (continued)

NOTE: Remove knockout in

casing before re−installing the

condensate trap.

Rotate elbow to

9

desired position

and torque clamp

on inlet 15 lb.−in.

Install two plugs previously

removed in open ports on

collector box.

Connect relief tube to port

on collector box.

Slide relief tube in

stand−offs to adjust

length.

Attach condensate

trap with screw to

collector box.

Align trap over middle

and right−hand port on

collector box.

Representative drawing only, some models may vary in appearance.

Connect the new pressure switch

7

tube from Loose Parts bag to port

on front pressure switch.

Route pressure switch tube

underneath relief tube and

8

connect to port on

collector box.

Connect relief tube to relief

port on condensate trap.

A11574LB

440 01 4005 05 17

Specifications subject to change without notice.

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

Condensate Drain Connection

!

FROZEN AND BURST WATER PIPE HAZARD

Failure to protect against the risk of freezing may result in

property damage.

Special precautions MUST be made if installing furnace in an

area which may drop below freezing. This can cause

improper operation or damage to equipment. If furnace

environment has the potential of freezing, the drain trap and

drain line must be protected. The use of accessory drain trap

heaters, electric heat tape and/or RV antifreeze is required

for these installations.

!

PROPERY DAMAGE HAZARD

Failure to follow this caution may result in burst water pipes

and/or property damage.

If a condensate pump is installed, a plugged condensate

drain or a failed pump may cause the furnace to shut down.

Do not leave the home unattended during freezing weather

without turning off water supply and draining water pipes or

otherwise protecting against the risk of frozen pipes.

DO NOT trap the drain line in any other location than at the

condensate drain trap supplied with the furnace. If possible, DO

NOT route the drain line where it may freeze. The drain line

must terminate at an inside drain to prevent freezing of the

condensate and possible property damage.

Special precautions MUST be made if installing furnace in an

area which may drop below 32°F (0°C). This can cause

improper operation or damage to the equipment. If the furnace

environment has the potential of freezing, the drain trap and

drain line must be protected. In areas where the temperature

may be below 32°F (0°C), a Condensate Freeze Protection kit

is required. The kit includes a condensate trap with heat pad

and replaces the factory−installed condensate trap. Refer to the

accessory section of the Specification Sheets for current kit

number. A self−regulating, shielded and waterproof heat tape

rated at 3 to 6 watt per foot (10 to 20 watt per meter) at 115 volt,

40° F (4° C) may be used to provide freeze protection of the

remaining condensate drain line. Wrap the drain trap and the

drain line with the heat tape and secure with appropriate plastic

ties. Follow the heat tape manufacturer’s recommendations.

Prime the trap before furnace operation.

The condensate drain line must be supported and/or secured

per local codes. Supports and clamps should be spaced to

prevent the drain line from sagging or being dislocated from the

furnace or termination point. In the absence of local codes,

consult current edition of the National Standard Plumbing

Code, in the US or current edition of the National Plumbing

Code of Canada in Canada.

CAUTION

CAUTION

c. All condensate piping is at least 1/2 in. PVC and

there is a relief tee at the top of condensate drain

piping as shown below:

NOTE: On narrower casings, it may be easier to remove the

condensate trap, connect the drain line components and

re-install the condensate trap. Read the steps thoroughly to

familiarize yourself with the required steps.

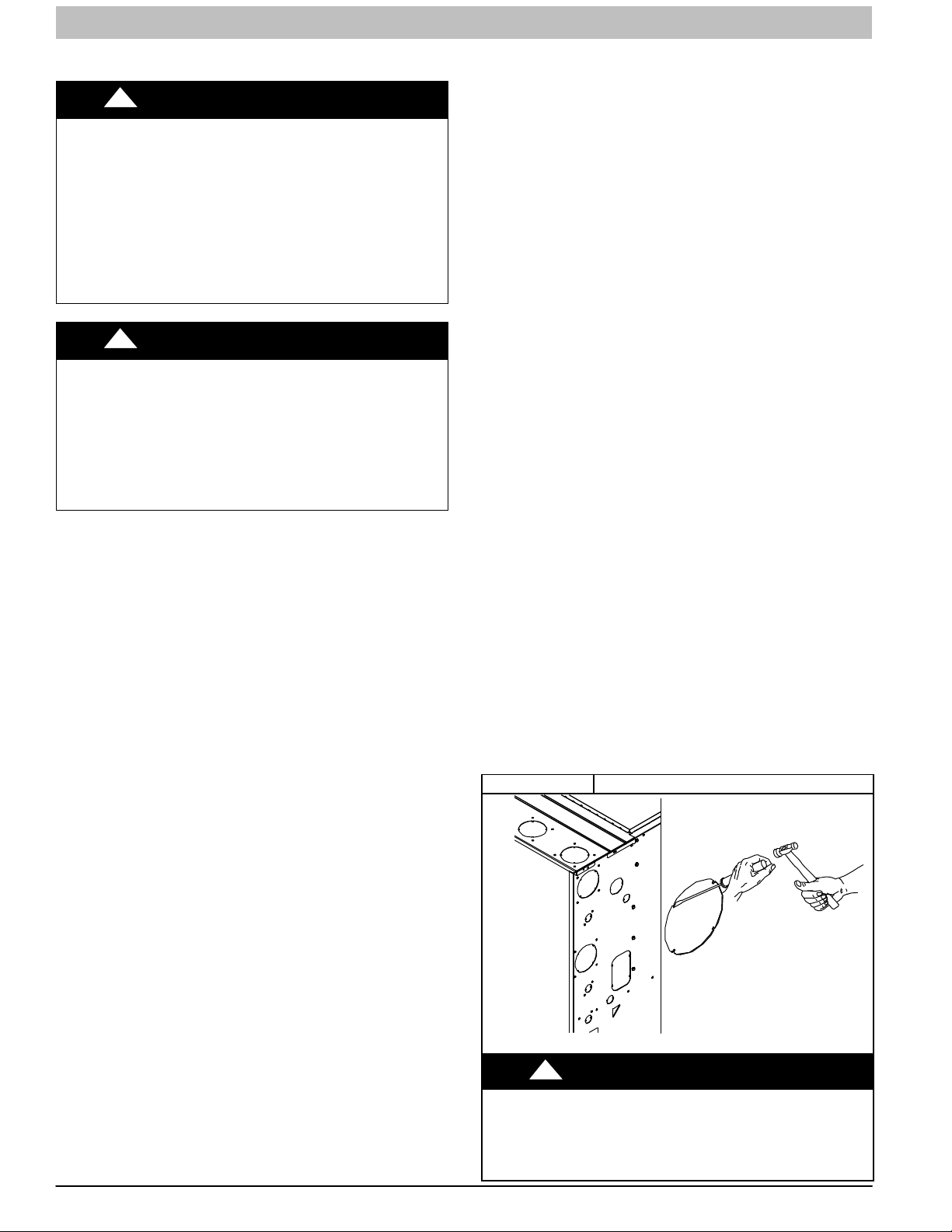

For Right Side Condensate Drain:

1. Remove the 7/8−in. knock−out from the right side of the

casing. (See Figure 12 for suggested knockout removal

technique.)

2. Remove the pre−formed rubber drain elbow and two

spring clamps from the loose parts bag.

3. Slide a spring clamp 1−in. (25 mm) down the plain end

(the end without the formed grommet) of the drain elbow.

4. From inside the casing, insert the formed grommet end

of the elbow through the 7/8−in. knockout in the casing.

5. Pull the grommet through the casing from the outside

until it is seated in the knockout

6. Attach the plain end of the drain elbow to the outlet stub

on the drain trap. Secure the drain elbow to the trap with

the spring clamp.

The remaining drain line can be constructed from field supplied

1/2−in. CPVC or 3/4−in. PVC pipe in compliance with local

building codes. A factory−supplied 1/2−in. CPVC to 3/4−in PVC

adapter is supplied in the loose parts bag for use as required.

7. Install the adapter or connect the 1/2−in. CPVC pipe by

sliding a spring clamp over the open end of the grommet

on the outside of the furnace casing.

8. Open the spring clamp and insert the long end of the

adapter of the 1/2−in. CPVC pipe into the outlet stub on

the drain elbow.

9. Connect additional condensate piping to a

code−approved drain, or to a condensate pump

approved for use with acidic furnace condensate and

compatible with mineral and vegetable oils, such as

canola oil.

Allow at least 1/4−in. per foot (20 mm per meter) of slope down

and away from the furnace in horizontal sections of drain line.

TIPS FROM CONTRACTORS: Contractors have found that

temporarily removing the inducer assembly in upflow

applications while performing the steps below, makes upflow

left−side drain connections easier.

Figure 12 Knockout Removal

Upflow/Downflow Orientation

In the Upflow or Downflow orientation, the condensate trap is

inside the furnace casing. The condensate drain must be

routed from the trap through the furnace casing. The

condensate drain can be routed through the left or right side of

the casing. (The left or right side is as you are viewing/facing

the furnace from the front.)

An indoor coil condensate drain or humidifier drain can be

connected to the external furnace condensate drain provided:

a. The drains are not hard piped together, and

b. There is an air gap at the point where the two drain

lines meet or

18 440 01 4005 05

Specifications subject to change without notice.

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing, safety glasses and

gloves when handling parts, and servicing furnaces.

!

CAUTION

L12F019

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

For Left Side Condensate Drain Connection:

1. For left side condensate drainage, the drain line is routed

from the condensate trap, behind the inducer (upflow) or

gas valve (downflow) and out through the left side of the

furnace casing. A pre-formed 1/2−in. CPVC “Z” pipe is

provided with the furnace. The “Z“ pipe is long enough to

extend across the casing for drain connections.

2. Locate the “Z” pipe. Remove the pre-formed drain elbow

and four spring clamps from the loose parts bag.

3. The “Z” pipe is connected to the condensate trap and the

outside of the furnace by modifying the formed rubber

drain elbow as shown in Figure 17.

4. Remove the formed grommet from the rubber drain

elbow by cutting the elbow along the vertical line located

about 1 3/8−in. (35 mm) away from the formed grommet.

See Figure 15. DO NOT DISCARD THE FORMED

GROMMET OR THE RUBBER ELBOW. Both of these

pieces will be used.

Assemble and route the drain line to the opposite side of the

furnace as detailed below:

5. Remove the knock−out from the left side of the casing.

(See Figure 12 for suggested knockout removal

technique.)

6. From the outside of the casing, insert the angled end of

the ”Z” pipe through drain hole in the left side of the

casing and behind the inducer or gas valve. Allow the ”Z”

pipe to temporarily rest on the blower shelf (upflow) or

burner box (downflow). (NOTE: When the inducer

housing has been removed to ease installation in upflow

applications, this step is not needed.)

7. After inserting the “Z” pipe through the casing, slide a

spring clamp over each end of the “Z” pipe.

8. From inside the casing, insert the short end of the formed

grommet cut from the rubber drain elbow through the

7/8−in. drain knockout in the casing.

9. Pull the grommet through the casing from the outside

until it is seated in the knockout.

10. Align the ”Z” pipe with the long end of the grommet inside

the furnace and insert slightly. The angled end of the

tube at the other side of the casing should be facing the

front of the furnace.

11. Slide a spring clamp over the end of the remaining

rubber drain elbow.

12. Attach the drain elbow to the angled end of ”Z” pipe and

the drain trap outlet stub. Adjust the length of ”Z” pipe

inserted into the grommet at the opposite side of the

furnace as necessary for proper fit and positioning. In

both upflow and downflow orientations, the ”Z” pipe

should NOT be resting on any sheet metal parts.

13. Secure the rubber elbow to the drain trap and the ”Z”

pipe with spring clamps.

14. Secure the grommet to the ”Z” pipe with the spring

clamp. The remaining drain line can be constructed from

field supplied 1/2−in. CPVC or 3/4−in. PVC pipe, in

compliance with local building codes. A factory−supplied

1/2−in. CPVC to 3/4−in. PVC adapter is supplied in the

loose parts bag for use as required.

15. Install the adapter or connect the 1/2−in. CPVC pipe by

sliding a spring clamp over the open end of the grommet

on the outside the furnace casing.

16. Open the spring clamp and insert the long end of the

adapter or the 1/2−in. CPVC pipe into the outlet stub on

the drain elbow.

17. Connect additional condensate piping to a

code−approved drain, or to a condensate pump

approved for use with acidic furnace condensate and

compatible with mineral and vegetable oils, such as

canola oil.

Allow at least 1/4-in. per foot (20 mm per meter) of slope down

and away from the furnace in horizontal sections of drain line.

NOTICE

The field-supplied, accessory horizontal drain trap grommet

is ONLY REQUIRED FOR DIRECT VENT APPLICATIONS. It

is NOT required for applications using single-pipe or ventilated combustion air venting.

TIPS FROM CONTRACTORS: When installing the furnace

horizontally, use the entire drain elbow (that is, do NOT cut as

shown in Figure 15) to connect the trap to the drain line. This

helps to prevent bumps and shocks to the drain line from

damaging the furnace drain trap. Avoid misalignment of the

drain pipe which may cause kinks in the elbow.

Horizontal Orientation

1. The condensate trap outlet extends 2−in. (51 mm) below

the furnace casing. Leave enough clearance between

the furnace and the furnace platform for the trap.

2. To allow for servicing the trap, the condensate drain

elbow in the loose parts bag can be used to make a

coupler to allow for future service of the condensate trap

and drain line.

3. Remove the knock−out for the condensate trap in the

side of the casing.

4. Install the drain trap grommet in the casing, if required for

direct−vent applications. If necessary, remove the trap,

install the grommet and re−install the trap.

5. Remove the pre−formed rubber drain elbow and two

spring clamps from the loose parts bag.

6. Connect the full or modified elbow and/or grommet to the

outlet of the condensate trap with one spring clamp.

Avoid misalignment of the drain pipe which may cause

kinks in the elbow or grommet.

7. The remaining drain line can be constructed from field

supplied 1/2−in. CPVC or 3/4−in. PVC pipe, in

compliance with local building codes. A factory−supplied

1/2−in. CPVC to 3/4−in. PVC adapter is supplied in the

loose parts bag for use as required.

8. Install the adapter or connect the 1/2−in. CPVC pipe by

sliding a spring clamp over the open end of the elbow or

grommet on the outside the furnace casing.

9. Open the spring clamp and insert the long end of the

adapter or the 1/2−in. CPVC pipe into the outlet stub on

the drain elbow.

10. Connect additional condensate piping to a

code−approved drain, or to a condensate pump

approved for use with acidic furnace condensate and

compatible with mineral and vegetable oils, such as

canola oil.

Allow at least 1/4-in. per foot (20 mm per meter) of slope down

and away from the furnace in horizontal sections of drain line.

440 01 4005 05 19

Specifications subject to change without notice.

INSTALLATION INSTRUCTIONS Gas Furnace: (F/G)9MXT, (F/G)9MXE

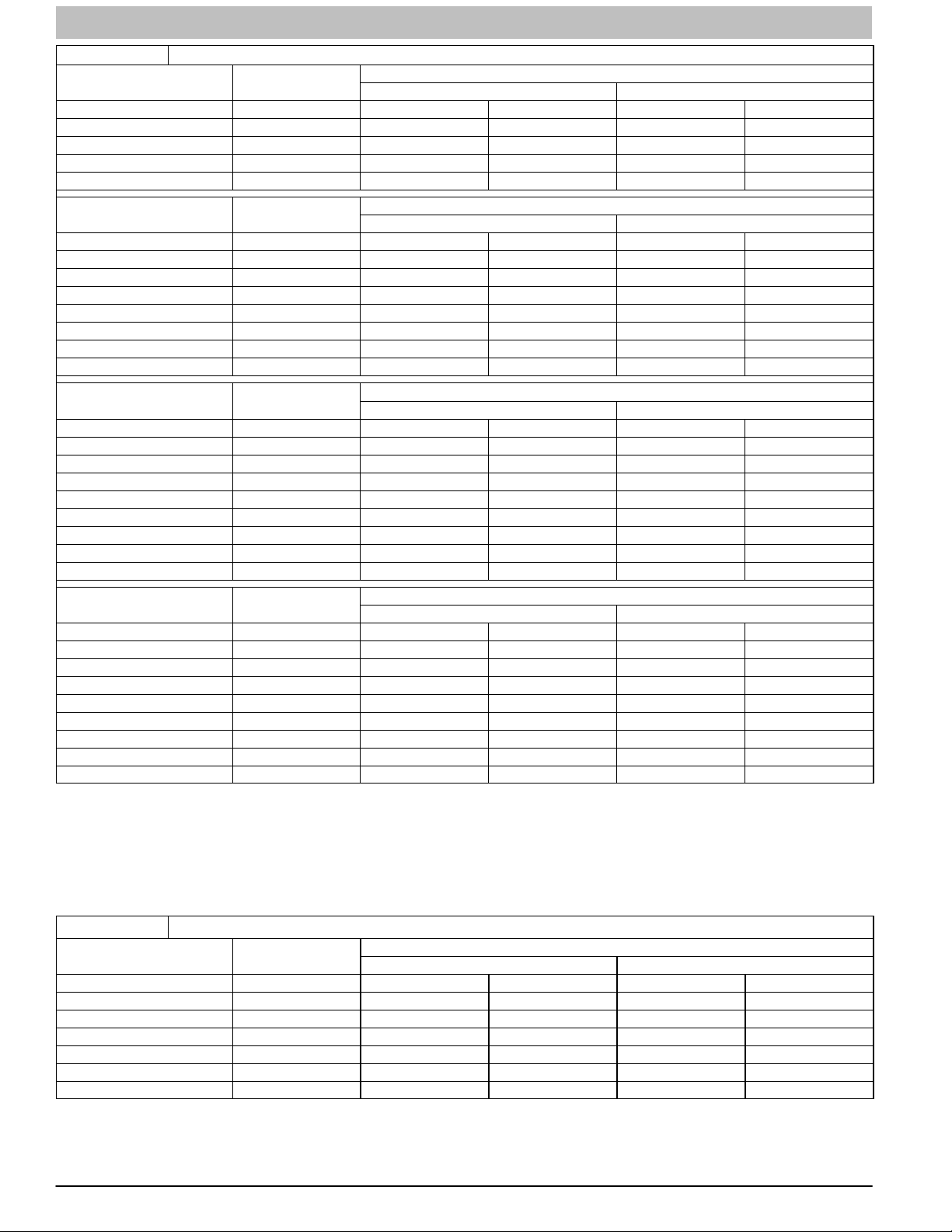

Figure 13

AIRFLOW

OF

DIRECTION

AIRFLOW

OF

DIRECTION

Example of Field Drain Attachment

(NOT ALLOWED)

Evaporator Coil

+

Condensing

Furnace

+

Blower

-

-

Evaporator Coil

+

Condensing

Furnace

+

+

+

+

+

+

+

+

+

< +

< +

< +

+

-

+

-

+

-

+

+

+

+

+

-

+

-

Blower

-

-

-

-

+ = Positive pressure

< + = Pressure lower than areas with +

− = Negative pressure

-

+ = Positive pressure

< + = Pressure lower than areas with +

− = Negative pressure

Blower creates positive pressure.

Positive pressure extends into coil

condensate drain (no trap).

Furnace condensate does not flow

consistently when drain is at positive

pressure.

+

A14532A

Open

+

+

3/4

+

3/4

+

3/4

+

+

standpipe

3/4” PVC

1/2” CPVC or larger*

3/4

A14532B

3/4

< +

< +

3/4” PVC

+

< +

+

1/2

1/2

Figure 14 Example of Field Drain Attachment

&RLORUKXPLGLILHUGUDLQ

ZKHQXVHG

Air gap here

Open standpipeLQKLJK

Evaporator Coil

+

Condensing

Furnace

+

Blower

-

+

+

+

AIRFLOW

OF

+

DIRECTION

-

-