Page 1

INSTALLATION

INSTRUCTIONS

Models

FWM1800A1*

FWM2400A1*

FWM3000A1 *

Apartment Air

Handler

Use ONLY factory listed electric heaters.

FWM1805A1

FWM1807A1

FWM1811A1

General Information / Installation ............ 2

Installations ............................... 3

Ductwork Connections ..................... 3

Condensate Drain .......................... 4

Orifice Sizing & Refrigerant Lines ............ 4

Field Installation of Controls ................ 5

Electrical Connections ...................... 5

Motor Speeds .............................. 6

Wiring Diagram ............................ 7

Replacement Parts ......................... 8

FWM2405A1

FWM2407A1

FWM2411A1

*Requires

AMWK001CK1

Cooling Only Control Kit

FWM3005A1

FWM3007A1

FWM3011A1

SafetyLabelingand Signal Words

Danger,Warning and Caution

The signal words DANGER, WARNING and CAUTION

are used to identify levels of hazard seriousness. The

signal word DANGER is only used on product labels to

signify an immediate hazard. The signal words WARN-

ING and CAUTION will be used on product labels and

throughout this manual and other manuals that may ap-

ply to the product.

DANGER - immediate hazards which WILL result inse-

vere personal injury or death.

WARNING - Hazards or unsafe practices which

COULD result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which COULD

result in minor personal injury or product or property

damage.

Printed in U.S.A. 664 01 3001 00

Signal Words in Manuals

The signal word WARNING is used throughout this

manual in the following manner:

The signal word CAUTION is used throughout this

manual in the following manner:

CAUTION

Product Labeling

Signal words are used in combination with colors and/or

pictures on product labels.

Nov 2000

Page 2

I Installation Instructions Blower Cabinet I

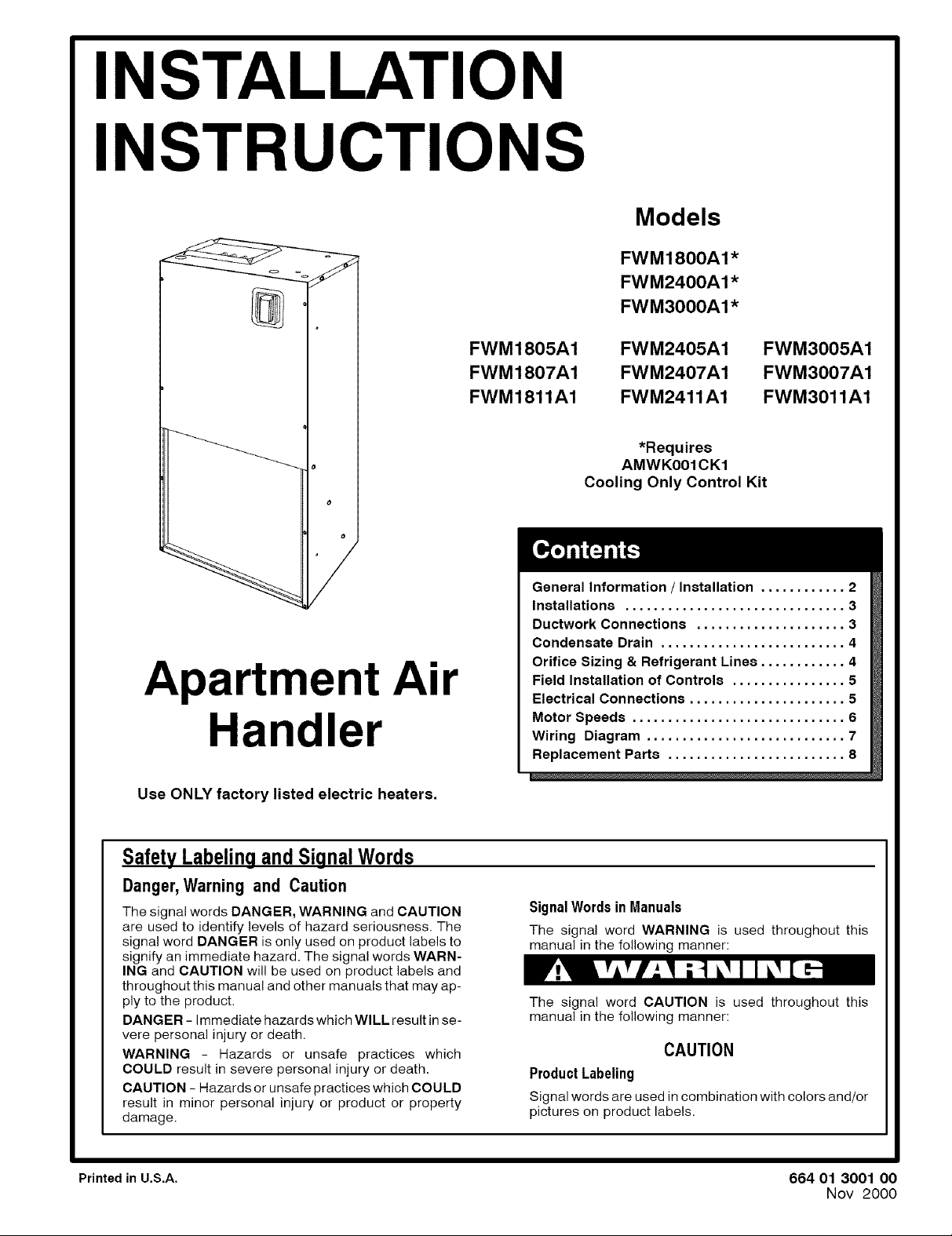

Figure 1 Nominal Installation Dimensions and Clearances

_/_ LOWVOLTAGEENTRY

(`'/8 DIA. ROLE)

POWERENTRY

:L'J/8DIA. KNOCKOUT

"/8 DIA.HOLE

2 1_16

•_,-_ 9/16

i-<--

NOTE:

1.SERIESDESIGNATIONIS

THE 14THPOSITION

OFUNITMODELNUMBER.

LINESENTRY

REFRIGERANT

@

381/'16 I

241/16

I-- PRIMARY DRAIN J -,-97/16--

PATCHPLATE ._L_ 5

FANCOILBASE #

-4-11 1/16-=-

FRONTVIEW

_-11 1/16-----1_[

BOTTOMVIEW

BLOWER,CONTROLAND

ELECTRICHEATER

ACCESSPANEL

LIQUIDTUBE

UNITCONNECTIONSIZES

SUCTION3/4I.D.SWEAT

LIQUID,3_ I.D. _WEAT

CONDENSATE,_/4 NPT

,-- FILTERMEDIA

-- SECONDARYDRAIN

1_16

CLEARANCES

All Sides .................................. 0"

From Supply Duct .......................... O"

Recommended Service From Front .......... 21"

(Service for blower, filter)

GeneralInformation

The blower cabinet may be used for cooling or heat pump

operation with or without electric heat. Installations without

Installation or repairs made by unqualified persons can

result in hazards to you and others. Installation MUST

conform with local building codes and with the

National Electrical Code NFPA70 current edition.

The information contained in this manual is intended

for use by a qualified service technician familiar with

safety procedures and equipped with the proper tools

and test instruments.

Failure to carefully read and follow all instructions in

this manual can result in equipment malfunction,

property damage, personal injury and/or death.

_J 664 01 3001 O0

electric heat, require a Cooling Control Kit. The cabinet

can be installed in an Upflow position ONLY.

Check Equipment

Unpack unit and move to final location. Remove carton,

taking care not to damage unit. Inspect equipment for

damage prior to installation. File claim with shipping

company if shipment is damaged or incomplete. Locate

rating plate on unit. It contains information needed to

properly install unit. Check rating plate to be sure unit

matches job specifications.

Page 3

I Blower Cabinet

Location

Select the best position which suits the installation site

conditions. The location should provide adequate

structural support, space inthe front of the unit for service

access, clearance for return air and supply duct

connections, space for refrigerant piping connections and

condensate drain line connections.

See Clearances in Figure 1.

A front access panel is provided, which permits access to

blower assembly and electrical controls for removal and

servicing.

NOTE: Local codes may limit application of systems

without a ducted return to single story dwellings.

Installation Instructions

NOTE: Short duct runs tend to increase noise level.

When fan coil is equipped with an electric heater, install air

ducts in accordance with standards 90A and 90B of

National Fire Protection Association (NFPA). Use of

flexible connectors between ductwork and unit will prevent

transmission of vibration.

When electric heater is installed, use heat-resistant

material for a flexible connector between ductwork and unit

air discharge connection.

Ductwork passing through unconditioned space must be

insulated and covered with a vapor barrier.

NOTE: Unit is intended for nonducted return-air

applications. Local codes may limit this unit to single-level

applications.

Installation

The unit is designed for free-air return as enclosed in a

closet with Iouvered door or for flush mounting in a wall. A

factory-authorized Iouvered grille kit is available for flush

mount application (AMWK001WG).

When unit is installed in a closet with a Iouvered door in

return-air path, the free area of Iouvered opening in the

door must be a minimum of 2.25 sq ft. Either align door

opening with unit inlet or provide a l O-in. clearance

between door and unit.

If unit is to be flush mounted in a wall, provide adequate

support underneath base of unit. To assure proper

condensate drainage, be sure unit is level.

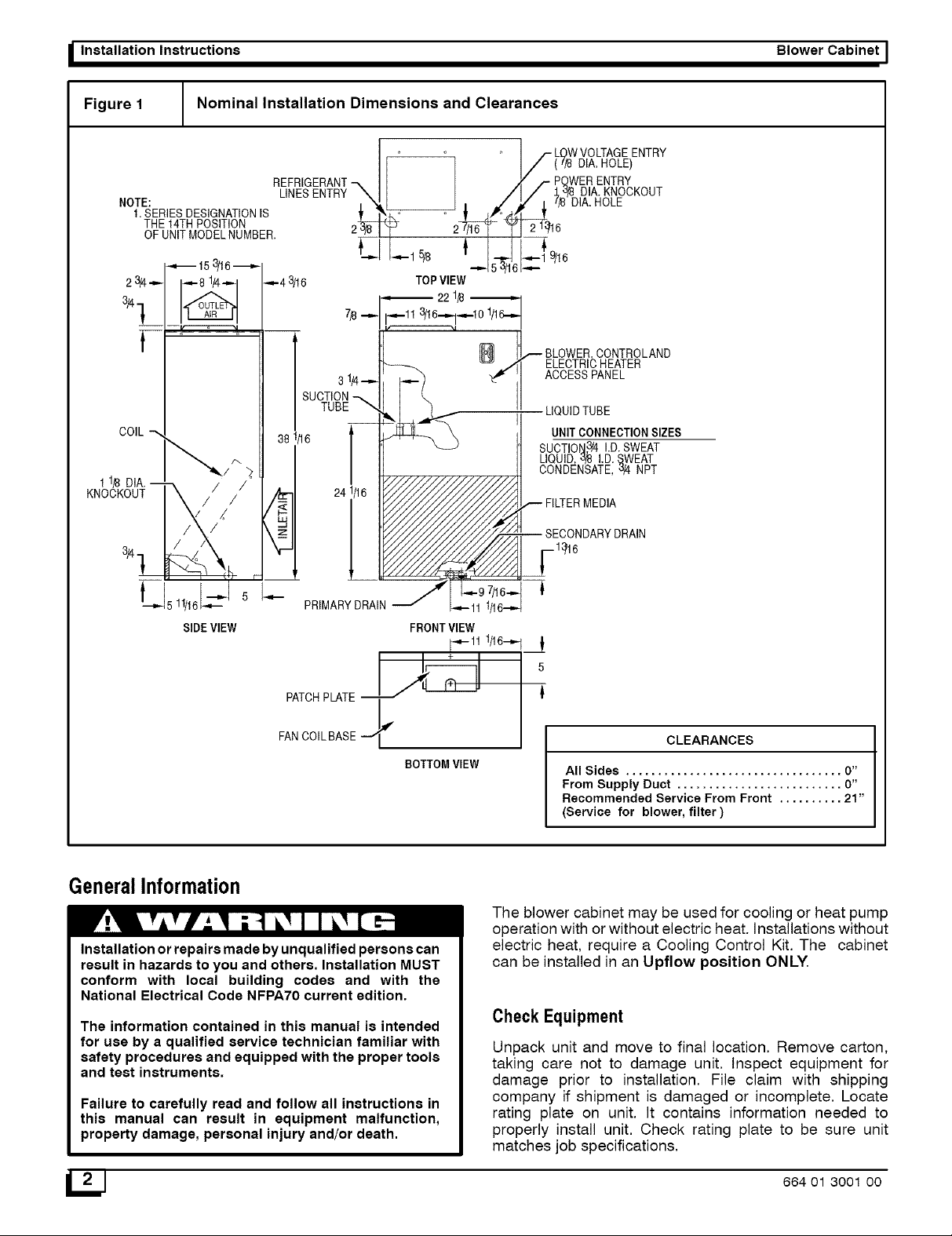

HangingCabinet

Cabinet may by hung from the wall using accessory

brackets (AMWK001MK). Use 1X 4 or2 X 4 support and a

spacer for the bottom across studs to support the unit.

Bottom spacer should be located above the bottom of the

unit so it holds the unit out from the wall in a vertical

position, See Figure 2,

CAUTION

Both wall support and spacer must be the same

thickness or the unit will not hang correctly and

Condensate Water will not drain correctly. Unit must

be vertical ortilted slightly forward which the support

bracket will do.

Figure 2 Attach Coil Cabinet to Wall

Support Brackets

DuctConnections

SupplyDuct

Connect supply-air duct over 3/4-in. flange provided on

supply-air opening. Secure duct to flange using applicable

fasteners for type of duct used, and seal duct-to-unit joint.

664 01 3001 00 3L_ J

Page 4

_ Installation Instructions Blower Cabinet I

CondensateDrain

Condensate pan has primary and secondary drain

connections to meet FHA requirements. (See Fig. 3.)

These connections have 3/4-in. female pipe threads.

Tubing for all condensate drains should be a minimum of

7/8-in. OD. Drain lines from condensate pan to exterior of

unit must be plastic pipe. Drain should be pitched

downward at a slope of 1 in. per 10 ft.

If coil is located in or above a living space where damage

may result from condensate overflow, a separate 3/4-in.

drain must be provided from secondary drain connection.

Run this drain to a place in compliance with local

installation codes where it will be noticed when unit is

operational.

Condensate flowing from secondary drain indicates a

plugged primary drain.

Install a 3-in. trap in condensate drain line as close to coil

as possible. Make sure that the top of trap is below

connection to drain pan to prevent condensate from

overflowing drain pan. Prime trap with water. Insulate drain

if located above a living area and test condensate line for

leaks.

Consult local codes for additional restrictions or

)recautions.

Figure 3 Drain Connections

Orifice Sizing & Refrigerant Lines

NOTE: Do not remove seals from coil until tubing

connections are ready to be made. See instructions

packaged with outdoor unit for connecting refrigerant

tubes.

Before connecting refrigerant tubing, be sure

factory-supplied indoor refrigerant flow-control device is

correct for outdoor unit size used. Refer to outdoor unit

installation instructions.

When changing piston, use a backup wrench and do not

over tighten. Maximum torque should not exceed 30 ft-lb.

(See Fig. 3.)

Move unit into place and install refrigerant tubing as

follows:

1. Route tubing to connection points.

2. Remove plugs from liquid and suction tubes.

3. Clean and braze tubing into place.

4. Pressurize system and leak-test. Repeat procedure

until leak-free.

CAUTION

Do not vent refrigerant to atmosphere. Recover

during system repair or final unit disposal.

/

/

/

/

DRAIN EXIT

Figure 4 Restrictor Orifice

Nut and Liquid Line

/

_-_ Rounded End

SECONDARY

DRAIN

PRIMARY

DRAIN

NOTE: Use plastic pipe from

condensate pan to

exterior of fan coil.

(TRAPEXTERNAL

TOUNIT)

__ Feeder Tubes

A86005

_J 664 01 3001 00

Page 5

I Blower Cabinet

Installation Instructions

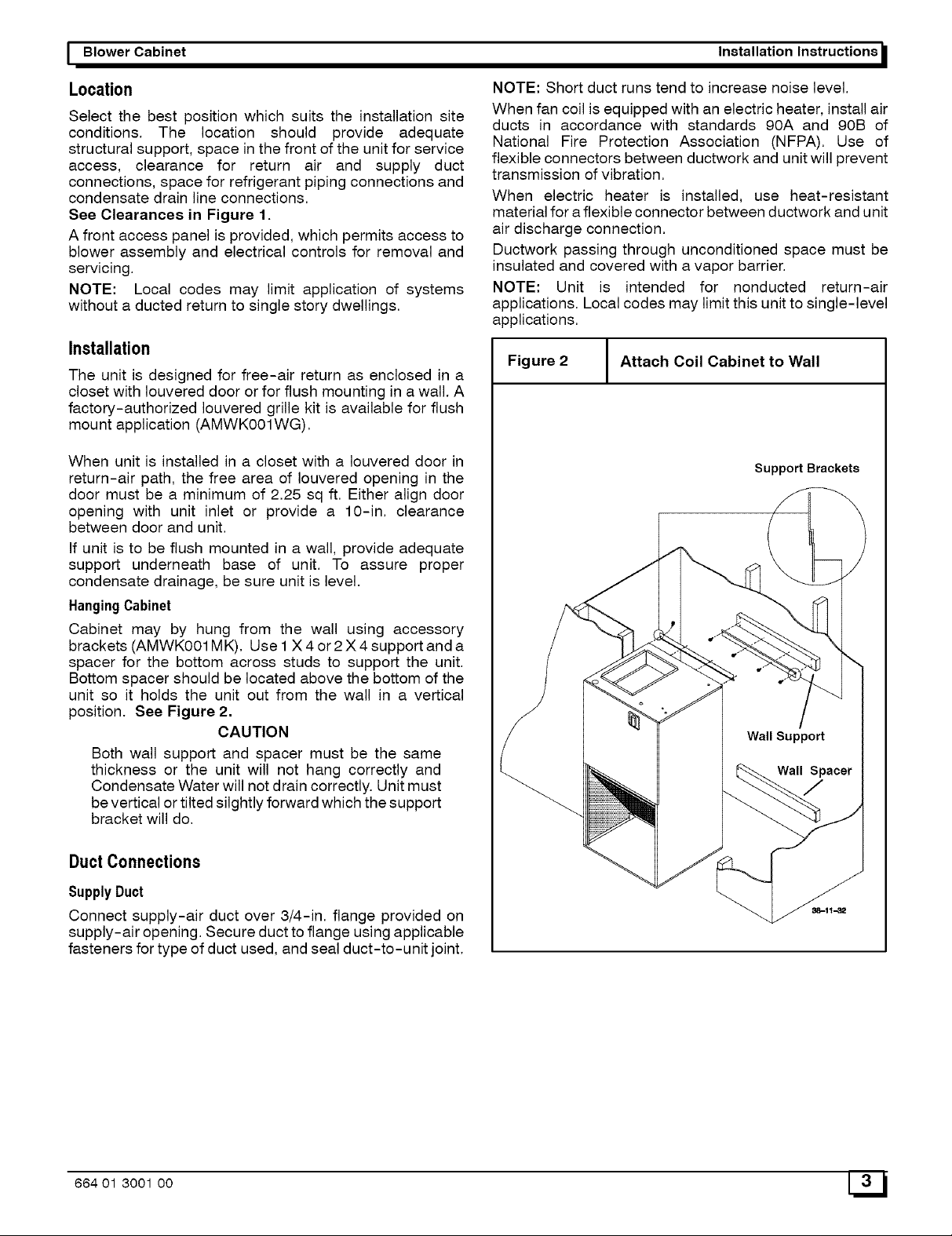

FieldInstallationof Controls

Units shipped from factory without heaters require a

field-installed cooling control kit or heater. These kits are

completely assembled and factory-wired for easy

installation.

See Installation Instructions packaged with heaters for

installation procedures. These unit Installation Instructions

are to be used in conjunction with instructions packaged

with heater. When installing accessory heat, optional

cooling control kit is not required.

INSTALLCOOLINGCONTROLPACKAGE

1. Remove blower access panel (See Fig. 5.)

2. Install cooling control panel above blower motor on

blower side plate. Attach with provided screws. (See

Fig. 5.)

3. Route thermostat leads through small knockout in top

of unit. Use grommet provided with cooling control to

protect leads where they pass through casing.

4. Make low-voltage splice connections in low-voltage

control box.

5. Route blower motor power leads up through hole in

bottom of cooling control. Connect yellow common

wire to piggyback common terminal on transformer.

Connect black (HI) or red (LOW) speed tap wire to

control board relay common terminal. See wiring

label for proper speed tap selection.

6. Route unit power supply through knockout in top of

unit and connect to line side of disconnect. Connect

ground wire to ground lug. See wiring label to make

connections.

7. Remove disconnect pullout.

8. Replace access panel.

ELECTRICALCONNECTIONS

Electrical shock hazard.

Before installing or servicing fan coil, always turn

off all power to unit. There may be more than 1dis-

connect switch. Turn off accessory heater power

if applicable.

Field wires on side of disconnect found in fan coil

remain live, even when pull-out is removed. Ser-

vice and maintenance to incoming wiring can not

be performed until main disconnect switch (re-

mote to the unit) is turned off.

Failure to do so can result in property damage,

personal injury and/or death.

NOTE: Before proceeding with electrical connections,

make certain that voltage, frequency, and phase

correspond to that specified on rating plate. Also, check to

be sure that the service provided by utility is sufficient to

handle additional load imposed by this equipment. Refer to

unit wiring label for proper field high- and low-voltage

wiring. Make all electrical connections in accordance with

9, Insert disconnect pullout through hole in access

panel,

Figure 5 Cooling Control Kit

Ag8333

NOTE: Top panel not shown for ciarity

BLOWER

ACCESS UNIT

DOOR

A98335

NEC and any local codes or ordinances that might apply.

Unit must have a separate branch electrical circuit. The

Cooling Control Kit and the heater packages provide a

disconnect switch located within sight and readily

accessible to the unit.

NOTE: All control kits are shipped from factory wired for

230-v transformer operation. For 208-v operation, move

black primary lead from 230-v terminal to 208-v terminal.

See Fig. 6 and 7 for field low-voltage wiring. See Fig. 1 for

location of the electrical inlets. For maximum ampacity and

over-current protection, see unit rating plate.

1. Provide power supply for unit being installed in

accordance with unit wiring diagram and rating plate.

2,

Connect line-voltage leads to field lugs, Use copper

wire only.

3,

Use UL listed conduit and conduit connector for

connecting line-voltage leads to unit and obtaining

proper ground. Grounding can also be accomplished

by using the ground lug provided in the control box.

4,

Install rubber grommet packed with unit in hole for

low-voltage wires.

664 01 3001 O0 5L_

Page 6

_ Installation Instructions Blower Cabinet I

5. Connect low-voltage leads to thermostat and

outdoor unit. See Fig. 5 and 6 and the outdoor unit

Figure 7 Low Voltage - Heat Pump

wiring label.

Use No. 18 AWG color-coded, insulated (35°C minimum)

wire to make low-voltage connections between thermostat

and unit. If thermostat is located more than 100 ft from unit

as measured along low-voltage wire, use No. 16 AWG

color-coded, insulated (35°C minimum) wire. All control

THERMOSTAT

FAN COIL

(CONTROL)

HEAT PUMP

(CONTROL)

4Q_ R

kits from the factory utilize a printed-circuit board (PCB)

which has a low voltage circuit protective fuse (5 amp), fan

motor speed tap selection terminal (SPT), and time delay

fi:3_c

relay (TDR) jumper. To disable the TDR feature, sever the

jumper wire JWl.

Electrical shock hazard.

Unit cabinet must have a continuous electrical

path to ground in order to minimize potential for

personal injury or death if an electrical fault

should occur. This ground may consist of electri-

cal wire or approved conduit when installed in ac-

cordance with existing codes.

Failure to do so can result in property damage,

personal injury and/or death.

See Figure 8 for Cooling Control and heater package part

numbers, wire size, overcurrent protection sizes. All

field-installed cooling control kits and heater packages are

factory wired for 230-v transformer operation. When

208-v transformer operation is desired, move the black

primary lead from the 230-v terminal to the 208-v terminal.

Figure 6 Low Voltage - Air Conditioning

THERMOSTAT

FAN COIL

(CONTROL)

R

G

_ w2

[]

[]

VlO W2

W2

4:::%0

fi: _y

A98331

SELECT PROPER BLOWER SPEED

Before operating unit, be sure that proper blower speed

has been selected. High speed tap is recommended for

most applications. For those applications requiring lower

air flows, low speed tap can be used.

ColorCodeForMotorLeadWires

MOTOR SPEED TAP WIRE COLOR

C - Common Yellow

1 - High Black

2 - Low Red

NOTE: Fan speeds are selected manually. To change the

fan speed, interchange the black and red fan motor leads

on printed circuit board terminal SPT (COM). START-UP

Refer to outdoor unit Installation Instructions for system

start-up instructions and refrigerant charging method

details.

CAREANDMAINTENANCE

For continuing high performance and to minimize possible

AIR COND.

equipment failure, it is essential that periodic maintenance

be performed on this equipment. Consult your local dealer

as to proper frequency of maintenance and availability of a

maintenance contract. The ability to properly perform

maintenance on this equipment requires certain

mechanical skills and tools. If you do not possess these,

contact your dealer for maintenance. The only consumer

service recommended or required is filter maintenance.

_J 664 01 3001 00

Page 7

I Blower Cabinet Installation Instructions

Figure 8 J Electrical Data

PART UNIT HEATER MIN WIRE MIN MAX CIRCUIT

NO. SIZE VOLTAGE KW @ AMPS SIZE* AMPACITY PROTECTION

018

AMWK001CK 024 208/230 0 0.0/0.0 0/0 75 14 2.5 15/15

O3O

018

AMWK005AH 024 208/230 5.0 18.1/20.0 12799/15700 75 10/10 25,2/27.5 30/30

O3O

018

AMWK007AH 024 208/230 7.5 27.1/30.0 19215/23515 75 8/8 36.4/40.0 40/40

O3O

018

AMWK011AH 024 208/230 11.0 39.8/44.0 25597/31331 75 6/6 52.3/57.5 60/60

O3O

NOM HEATER WIRE

CAPACITY RATING

240-V (BTUH) (°C)

( SCHEMATIC DIAGRAM ) CAUTION: "_

SEE RATING PLATE FOR MOLTS& HERTZ ATTENTION:

FIELDPOWERWIRING NECQNVJENTPA5AI_(JNSTALLATIQNSDEPLUSDE/5OVALATERRE

NOTSUITABLEFORUSEONSYSTLMSEKCEEDING/C_VTOGROUND

SEENOmE_t© ©

ii I ii ISCONNECT PER _] [_o

_I_I _i , lil lil_

_,,_ , I,O I hO I_-

O to to tO zO

z\_J\J GNO\_J

SEENOTEO

--I YEL YEL BLK I

LS2 HTR2 BLK BLK

YEL_ELAY I_BLK '

LS1 HTR1 BLK j

__ _F --RELAY 1

/ B,LKI =VDCCOlL

I I, ' I _g_

I BtUBLK.... BLK__r

SPT / ORI N VIO

GND BLK-HI BRN

__RED-LOW

Yf_YIIEL ___'F_-ORNRE_ D FJ !RY

YE£ BRN VIO

BRN BRN I

/ s_;..!RNL22 IIiI_F]P a

I-- HIL_--YBELLK_ _ '-B-,_R-RIER_-- - -S-E-E-N-OT-E#-7

.__LO__Rg..j_'RN_ELBRN_¢__

1 Use copper v4re (75°crain} only between disconnect switch and unit,

2 To bev4red inaccordance w_thnec and local codes

3 If any ofthe ori_nal wire, assupplied, must bere#aceq, use thesame or

equivalent type wire.

4 Re#ace low voltagefuse with no greater than 5AMP fuse

5 (2) Speed Motor usesHI (ELK) and LOW (RED)

6 Smaller heaters vviflhave fewer components

7 Connect R to R, Gto G, etc., see outdoor instructionsfor details

8 Cocling controls wipeg not usedwith e]ectpe heaters

GND TH ERBADSTAT UNIT

Thiscompartmentmustbe closedexcept

when servicing.

_ ROTATION 1324494-101REV,A I

SEENOTE &5

MOTOR SPEED ONE _R I LO I LO I LO

IMOTO_ SPEED TWO HTR I LO I LO I_o_

(,_ COMPONENTARRANGEMENT _)

SYSTEM TRANSFORMER: 4O.OVA

FANCOIL/HEATER: 814VA

REMAINING VAAVAILABLE: 31.GVA

RELAY 1 RED COM

•

I_ 24V 208 V

, REC i _ -c _

i i =T/; F

DISC _] PCB

FAN MOTOR THERMALLY PROTECTED

CAP CAPACITOR

COM COMMON

DISC DISCONNECT

F FUSE

FM FANMOTOR

_ FIELDPOWER WIRING

FR PCB FAN RELAY

GND EQUIPMENT GROUND

HTR HEATER

LS LIMIT SWITCH

C) MARKED ]_RMINAL

-_>- PLUG AND RECEPTACLE

PCB PRINTED CIRCUIT BOARD

REC RECTIFIER

SPT FAN SPEED TAP LOCATION

TRAN TRANSFORMER

O UNMARKED TERMINAL

FAN COIL SIZE I01S10241030

S 230 V _

GND @ @

OM

LEGEND

664 01 3001 O0 7L_ J

Page 8

_ Installation Instructions Fan Coils I

ReplacementParts

KEY DESCRIPTION PART _ _ _ _o _ _ _ _ _ _ _ _ KEY DESCRIPTION PART _ _

NO. NOMOER NO. NUM°ER

1 BtowerAs¥ 1170633 1 1 t 1 A _aneI, Top 1170627 1 1 1

1 BlowerAsy 1170634 1 1 1 1 B Bracket, Filter 1170628 1 1 1

1 BtowerAs¥ 117063_ 1 I 1 1 C Support, Coil 1170629 1 1 1

2 Motor. Blower 1170644 1 1 I 1 D Base. Fan Coil 1170630 1 1 1

2 Motor. Blower 117064_ 1 1 1 1 E 31ate 1170680 1 1 I

2 Motor. Blower 117064( 1 t 1 1 F 3anel, Blower Door 1170631 1 1 1

3 Capacitor 1170647 1 1 1 1 1 1 1 1 G =ilter 1170632 1 1 I

3 Capacitor 117064_ 1 I 1 1 H 5crew 1170636 3 3 3

4 Wheel. Blower 117065,_ 1 1 I 1 1 1 1 1 1 I 1 1 J 3anel, Blower Cutoff 1170637 1 1 1

5 Coil, Evaporator 1170681 1 1 I 1 K -lousing, Blower 1170638 1 1 1

5 Coil, Evaporator 117068,_ 1 1 1 1 L _rapper, Blower 1170639 1 1 1

5 Coil, Evaporator 117068_ 1 1 1 1

6 DistributorAsy 117065_ 1 1 I 1 M 31ate. BlowerSide 1170640 1 1 I

6 Distributor Asy 1170654 1 1 1 1 N 31ate. Blower Side (Motor Side) 1170641 1 1 1

6 DistributorAsy 117065_ 1 I 1 1 P :_ing, lntet 1170642 1 1 I

7 Restrictor, 049 108767_ 1 1 1 1 Q 5trap, Capacitor 1170643 1 1 I

7 Restrictor, O60 108767 c. 1 1 1 1 R _,rm, MotorMount 1170649 3 3 3

7 Restrictor, 066 1062387 1 t 1 1 S Band, MotorMount 1170650 1 1 1

8 Adaptor. Flow Control RH 108487_ 1 1 I 1 1 1 1 1 1 I 1 1 T 3rommet, Motor Mount 1170651 3 3 3

9 Pan, Condensate Asy 117065_ 1 1 I 1 1 1 1 1 1 I 1 1 U 3an, Condensate Shield 1170658 1 1 1

10 Pan, Condensate 1170657 1 1 I 1 1 1 1 1 1 I 1 1 V 3anel, Control 1170659 - 1

11 Element Asy 5 KW 117066_ 1 1 1 V 3anel, Control 1170660 - 1

11 E_ement Asy 75 KW 117066.c 1 1 1 W Bracket, Disc.Mtg. 1170661 1 1

11 ElementAsy 11 KW 117067C - 1 1 1 X 3anel, Protective 1170662 1 1

12 Board, Circuitw/Relay 1170671 1 I 1 1 1 1 I 1 1 Y Barrier 1170663 1 1

13 Board, Rectifier 117067_ 1 I 1 1 1 1 I 1 1 )( -larnessAsy 1170664 1 I

14 Switch. Limit 117067_ 1 2 2 1 2 2 I 2 2 )( -larnessAsy 1170665 1

15 Relay 1170674 1 1 1 1 1 1 t 1 1 )( -larnessAsy 1170666 1

16 Disconnect, Non-Fused 117067_ 1 t 1 1 1 1 1 1 1 )( -larnessAsy 1170667 I 1

17 Transformer 117067_ 1 I 1 1 1 1 I 1 1

18 Lug, Ground 1170677 1 I 1 1 1 1 I 1 1

° = °

u_ u_ u_ u_ i

Cooling Control Kit (Option)

12 Board, Circuit w/Relay 1170671 1

16 Disconnect, Non-Fused 117067[ 1

17 Transformer 117067_ 1

18 Lug, Ground 1170677 1

V Panel. Control 117067c_ 1

W Bracket, DiscMtg. 1170661 1

X Panel. Protective 117066"; 1

Y Barrier 117066." 1

)( Harness Asy 117067_ 1

M

A

o

H

E D

17

38-11-33

664 01 3001 O0

Loading...

Loading...