Page 1

These instructions must be read and understood completely before attempting installation.

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and

NOTE

The signal words DANGER, WARNING,

CAUTION, and NOTE are used to identify levels of

hazard seriousness. The signal word DANGER is

only used on product labels to signify an immediate

hazard. The signal words WARNING, CAUTION,

and NOTE will be used on product labels and

throughout this manual and other manuals that may

apply to the product.

DANGER - Immediate hazards which will result in

severe personal injury or death.

WARNING - Hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which

may result in minor personal injury or product or

property damage.

NOTE - Used to highlight suggestions which will

result in enhanced installation, reliability, or

operation.

Signal Words in Manuals

The signal word WARNING is used throughout this

manual in the following manner:

The signal word CAUTION is used throughout this

manual in the following manner:

Signal Words on Product Labeling

Signal words are used in combination with colors

and/or pictures on product labels.

TABLE OF CONTENTS

Introduction .................................... 2

Check Equipment .............................. 2

Location ....................................... 2

Installation .................................. 2 - 6

Electrical Connections ....................... 6 - 7

Controls - FSA ................................ 7

Motor Speed Selection .......................... 8

Start-up Procedures ............................ 8

Care and Maintenance .......................... 8

DEATH, PERSONAL INJURY, AND/OR PROPERTY

DAMAGE HAZARD

Failure to carefully read and follow this warning

could result in equipment malfunction, property

damage, personal injury and/or death.

Installation or repairs made by unqualified per-

sons could result in equipment malfunction, prop-

erty damage, personal injury and/or death.

The information contained in this manual is in-

tended for use by a qualified service technician fa-

miliar with safety procedures and equipped with

the proper tools and test instruments.

Installation must conform with local building

codes and with the National Electrical Code

NFPA70 current edition.

66401500200 Feb2009

Page 2

INTRODUCTION

FSA Fan Coils may be used for cooling or heat pump

operation, with or without electric heat. Models are

available with factory installed electric heaters (5 kW, 7.5

kW, or 11 kw) and with no heat. Installations without

electric heat require a Cooling Control Kit (accessory part

number AMWK001CK).

FEA and WAHA Fan Coils may be used for cooling or heat

pump operation, with or without electric heat. Models have

factory installed electric heaters (5 kW, 7.5 kW, or 11 kw).

FSA, FEA, and WAHA Fan Coils are designed to be

installed in an upflow position, free air return ONLY,

suitable for closet or flush-mount installations.

NOTE: Local codes may limit application of systems

without a ducted return to single story dwellings.

CHECK EQUIPMENT

Unpack Fan Coil and move to final location. Remove

carton, taking care not to damage Fan Coil. Inspect

equipment for damage prior to installation. File claim with

shipping company if shipment is damaged or incomplete.

LOCATION

Select the best position which suits the installation site

conditions. The location should provide adequate

structural support, space in the front of the unit for service

access, clearance for return air and supply duct

connections, space for refrigerant piping connections and

condensate drain line connections. If heaters are being

installed, make sure adequate clearance is maintained

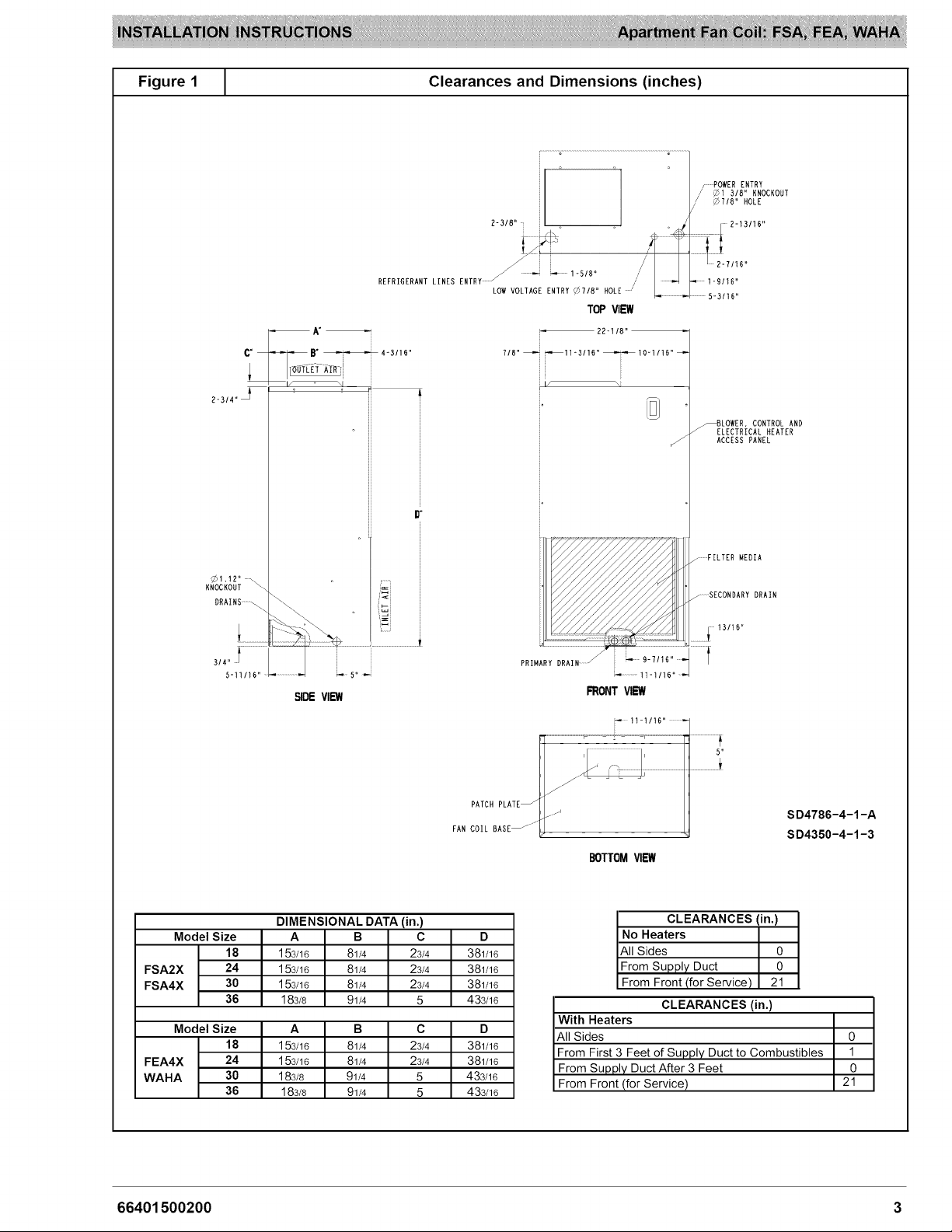

from supply duct work. See "Clearances" in Figure 1.

All models have a factory installed and appropriately

sized hard shut-off TXV metering device for use with

R-22 (FSA2X) or R410A (FSA4X, FEA4X, WAHA)

refrigerant.

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

This Fan Coil has a hard shut-off TXV metering de-

vice. A compressor Hard Start Kit is REQUIRED in

all applications where the matching outdoor unit

has a single-phase reciprocating compressor.

Locate rating plate on Fan Coil. It contains information

needed to properly install Fan Coil. Check rating plate to

be sure Fan Coil matches job specifications.

If the Fan Coil is located in an area of high humidity,

nuisance sweating of casing may occur. On these

installations, a wrap of 2" (51mm) fiberglass insulation

with a vapor barrier is recommended.

An access panel is provided on the front of the cabinet for

simple access to blower assembly and electrical controls.

Minimum clearance of 21" (533mm) in front of access

panel is required for service.

INSTALLATION

Fan coil is designed for free-air return, such as enclosed

in a closet with Iouvered door or flush mounted in a wall.

Factory-authorized Iouvered grille kits are available for

flush mount applications (accessory part numbers

AMWK001WG and AMWK002WG).

In Closet

When Fan Coil is installed in a closet with a Iouvered door

in return-air path, the free area of Iouvered opening in the

door must be a minimum of 2.25ft 2 (0.2m2)• Either align

door opening with Fan Coil inlet or provide a 10" (254mm)

clearance between door and Fan Coil.

Flush Mount

If Fan Coil is to be flush mounted in a wall, provide

adequate support underneath base of unit. Make sure

Fan Coil is level or top tilting slightly forward to assure

proper condensate drainage.

Hanging Cabinet

Cabinet may by hung from the wall using accessory

brackets (accessory part number AMWK001MK).

Use 1"x4" or 2"x4" (25x102mm or 51x102mm) wood

piece across studs for support at top of cabinet and same

size wood for spacer at bottom of cabinet. Position

bottom spacer between cabinet and wall so that it holds

the Fan Coil out from the wall in a vertical position. Refer

to Figure 2.

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in proper-

ty damage

When hanging cabinet, both wall support and

spacer must be the same thickness or the unit will

not hang correctly and Condensate Water will not

drain correctly. Fan Coil must be vertical or top

tilted slightly forward (accessory bracket creates

slight tilt).

2 66401500200

Page 3

Figure1 [ ClearancesandDimensions(inches)

// _7/8" HOLE

REFRIGERANT LINES ENTRY LOW VOLTAGE EN _ 8" OLE ' _.. .

TOP VIEW

C" B" _4-3/16" 7/8"_ _11-3/16° _t0-t/t6 °_

2"314" _ ff

D"

rPOWER ENTRY

_t 318" KNOCKOUT

LOWER, CONTROL AND

LECTRICAL HEATER

ACCESS PANEL

_1.I2"

KNOCKOUT \.

DRAINS _

3/4" l ......................

5-11/t6"

SIDEVIEW

DIMENSIONAL DATA (in.)

Model Size A B C D

18 153/16 81/4 23/4 381/16

FSA2X 24 153/16 81/4 23/4 381/16

FSA4X 30 153/16 81/4 23/4 381/16

36 183/8 91/4 5 433/16

Model Size A B C D

18 153/16 81/4 23/4 381/16

FEA4X 24 153/16 81/4 23/4 381/16

WAHA 30 183/8 91/4 5 433/16

36 183/8 91/4 5 433/16

.........FILTER MEDIA

_ SECONDARY DRAIN

13116"

PRmARY i 9-7/16......

............ ti-1/16 ....

FRONTV_

11_1/16_ .

BOTTOMVIEW

CLEARANCES (in.)

No Heaters

All Sides 0

From Supply Duct 0

From Front (for Service) 21

CLEARANCES (in.)

With Heaters

All Sides

From First 3 Feet of Supply Duct to Combustibles

From Supply Duct After 3 Feet

From Front (for Service)

SD4786-4-1-A

SD4350-4-1-3

0

1

0

21

66401500200 3

Page 4

Figure 1

(cont) Clearances and Dimensions (mm)

c B

F

69,8 _

R8.45

KNOCKOUT

DRAINS--. _\

:: _ / _34.93 KNOCKOUT

60.3 l _,/ 71,4

/ ; // /:_ 61.9

REFRIGERANT LINES ENTRY / -- _" 41.3 // / "_ ; 39,7

LOW VOLTAGE ENTRY _22,23 HOLE / L- _ t31,8

TOP VIEW

562.0

106,4

2227i _284.2_255.6_

If

_" ACCESS PANEL

/::1

; .........POWER ENTRY

/ _22.23 HOLE

/ BLOWER, CONTROL AND

ELECTRICAL HEATER

t9.1t 1!4.5

_ VIEW

PATCH PLATE _ .-_

FAN COIL BASE--''_

DIMENSIONAL DATA (ram)

Model Size A B C D

18 386 210 70 967

FSA2X 24 386 210 70 967

FSA4X 30 386 210 70 967

36 467 235 127 1097

ModelSize A B C D

18 386 210 70 967

FEA4X 24 386 210 70 967

WAHA 30 467 235 127 1097

36 467 235 127 1097

FRONTVIEW

......................._ ..............._ .........._ ..........................__

: 281.0

BOTTOM VIEW

CLEARANCES (mm)

No Heaters

All Sides 0

From Supply Duct 0

From Front (for Service) 533

CLEARANCES (ram)

With Heaters

All Sides

From First 3 Feet of Supply Duct to Combustibles

From Supply Duct After 3 Feet

From Front (for Service)

SD4786-4-1-A

SD4350-4-1-3

0

25

0

533

4 66401500200

Page 5

Figure2 L

HangingCabinetonWall

Support Brackets

Duct Connections

Connect supply-air duct over 3/4" (19mm) flange

provided on supply-air opening. Secure duct to flange

using applicable fasteners for type of duct used, and seal

duct-to-unit joint.

NOTE: Short duct runs tend to increase noise level.

When fan coil is equipped with an electric heater, install

air ducts in accordance with standards 90A and 90B of

National Fire Protection Association (NFPA). Use of

flexible connectors between ductwork and Fan Coil will

prevent transmission of vibration.

When electric heater is installed, use heat-resistant

material for a flexible connector between ductwork and

Fan Coil air discharge connection.

Ductwork passing through unconditioned space must be

insulated and covered with a vapor barrier.

NOTE: Fan Coil is intended for non-ducted return-air

applications. Local codes may limit this unit to

single-level applications.

FIRE HAZARD

Failure to maintain proper clearances could result

in personal injury, death, and/or property damage.

When heaters are installed, maintain clearances

from combustible materials as specified on unit

rating plate. Do not use plastic lined or combus-

tible flexible ducting within 36 inches (914mm) of

the supply end of the fan coil.

Condensate Drain

Condensate pan has primary and secondary drain

connections to meet FHA requirements (refer to Figure

3). These connections have 3/4" (19mm) female pipe

threads (NPT).

Tubing for all condensate drains should be a minimum of

7/8" OD (22mm). Drain lines from condensate pan to

exterior of unit must be plastic pipe. Drain should be

pitched downward at a slope of 1 inch per 10 feet (25mm

per 3m).

If coil is located in or above a living space where damage

may result from condensate overflow, a separate 3/4"

(19mm) drain must be provided from secondary drain

connection. Run this drain to a place in compliance with

local installation codes where it will be noticed when unit is

operational.

Condensate flowing from secondary drain indicates a

plugged primary drain.

Install a 3" (76mm) trap in condensate drain line as close

to coil as possible. Make sure that the top of trap is below

connection to drain pan to prevent condensate from

overflowing drain pan. Prime trap with water. Insulate

drain if located above a living area and test condensate

line for leaks.

Consult local codes for additional restrictions or

precautions.

Figure 3 _ Condensate Drain

/ /

/ /

/ /

/ /

/ /

/ /

/ _

./

'_ALTERNATE

DRAIN EXIT

/'

/

/

/

............PRIMARY

DRAIN

NOTE: Use plastic pipe from

condensate pan to

exterior of fan coil,

3-tN. MIN TRAP

(.76mm)

SECONDARY DRAIN

(TRAP EXTERNAL TO UNIT)

A86005

66401500200 5

Page 6

RefrigerantLines

NOTE:Do not remove seals from coil until tubing

connections are ready to be made. See instructions

packaged with outdoor unit for connecting refrigerant

tubes.

ELECTRICAL CONNECTIONS

ELECTRICAL SHOCK HAZARD

Failure to turn off the main (remote) disconnect

device before working on incoming (field) wiring

could result in personal injury or death.

Incoming (field) wires on the line side of the dis-

connect found in the fan coil unit remain live, even

when the pull-out is removed. Service and main-

tenance to incoming (field) wiring cannot be safely

performed until the main disconnect switch (re-

mote to the unit) is turned off.

NOTE: Before proceeding with electrical connections,

make certain that voltage, frequency, and phase

correspond to that specified on rating plate. Also, check to

be sure that the service provided by utility is sufficient to

handle additional load imposed by this equipment. Refer

to unit wiring label for proper field high-voltage and

low-voltage wiring.

Make all electrical connections in accordance with NEC

and any local codes or ordinances that might apply.

Fan Coil must have a separate branch electrical circuit.

Heater supply circuit wire size and overcurrent protection

must comply with National Electrical Code (NEC) and UL

branch circuit requirements. Wires and overcurrent

protection, integral to the heater, are not required to meet

branch circuit requirements. Internal circuit protection of

60 amps (maximum)is acceptable.

The Cooling Control Kit (FSA) and the heater packages

provide a disconnect switch located within sight and

readily accessible to the unit.

NOTE: All control kits are shipped from factory wired for

230V transformer operation. When 208V transformer

operation is required, move the black primary lead from

the 230V terminal to the 208V terminal.

Refer to Figure 1 for location of the electrical inlets. Refer

to unit rating plate for minimum circuit ampacity (MCA)

and maximum fuse or circuit breaker (maximum

over-current protection - MOCP).

1. Provide power supply for Fan Coil in accordance

with unit wiring diagram and rating plate.

2. Connect line-voltage leads to field lugs. Use

copper wire only.

Move Fan Coil into place and install refrigerant tubing as

follows:

1. Route tubing to connection points.

2. Remove plugs from liquid and suction tubes.

3. Clean tubing and braze in place.

4. Pressurize system and leak test. Repeat

procedure until leak free.

3. Use UL listed conduit and conduit connector for

connecting line-voltage leads to unit and obtaining

proper ground. Grounding can also be

accomplished by using the ground lug provided in

the control box.

4. Install rubber grommet packed with unit in hole for

low-voltage wires.

5. Connect low-voltage leads to thermostat and

outdoor unit. Refer to Figures 4 and 5 and the

outdoor unit wiring label.

Use No. 18 AWG color-coded, insulated (35 °C

minimum) wire to make low-voltage connections

between thermostat and Fan Coil. If thermostat is located

more than 100 feet (31m)from Fan Coil as measured

along low-voltage wire, use No. 16 AWG color-coded,

insulated (35 °C minimum) wire. For FSA fan coil, all

control kits from the factory utilize a printed-circuit board

(PCB) which has a low voltage circuit protective fuse (5

amp), fan motor speed tap selection terminal (SPT), and

time delay relay (TDR)jumper. To disable the TDR

feature, sever the jumper wire JW1.

ELECTRICAL SHOCK HAZARD

Failure to establish uninterrupted or unbroken

ground could result in personal injury or death.

According to NEC, NFPA 70, and local codes, the

cabinet must have an uninterrupted or unbroken

ground in order to minimize potential for personal

injury or death if an electrical fault should occur.

The ground may consist of electrical wire or metal

conduit when installed in accordance with exist-

ing electrical codes. If conduit connection uses re-

ducing washers, a separate ground wire must be

used.

6 66401500200

Page 7

Figure4 [ Low Voltage - Air Conditioner

THERMOSTAT

m

[B-

IB-

[2>

FAN COIL

(CONTROL)

RED R

GRY G

VlO W2

Figure 5 _ Low Voltage - Heat Pump

THERMOSTAT

FAN COIL

(CONTROL)

HEAT PUMP

EB-

lE-

g3_

E3-

R

C

C

AIR CONDITIONER

CONTROLS- FSA Fan Coils

Fan Coils shipped from factory without heaters require a

field-installed cooling control kit or heater, These kits are

completely assembled and factory-wired for easy

installation,

See Installation Instructions packaged with heaters for

installation procedures, When installing accessory heat,

optional cooling control kit is not required,

Install Cooling Control Kit (accessory part number

AMWK00 lCK) when heater is not present:

1. Remove blower access panel (refer to Figure 6).

2. Install cooling control panel above blower motor on

blower side plate. Attach with provided screws.

3. Route thermostat leads through small knockout in

top of unit. Use grommet provided with cooling

control to protect leads where they pass through

casing.

4. Make low-voltage splice connections in

low-voltage control box.

5. Route blower motor power leads up through hole in

bottom of cooling control. Connect yellow common

wire to piggy-back common terminal on

transformer. Connect black (HI) or red (LOW)

speed tap wire to control board relay common

terminal (SPT). Refer to wiring label for proper

speed tap selection.

6. Route unit power supply through knockout in top of

unit and connect to line side of disconnect.

Connect ground wire to ground lug. Refer to wiring

label before making connections.

7. Remove disconnect pullout.

8. Replace blower access panel.

9. Replace disconnect pullout.

D

Fq

[D-

Figure 6

COOLING

CONTROL

DISCONNECT

VlO w2

Cooling Control Kit

NOTE: Top panel not shown for clarity

BLOWER

ACCESS

PANEL

W2

O

Y

A98333

I INDOOR

UNIT

A98335

66401500200 7

Page 8

MOTOR SPEED SELECTION - FSA Fan Coils

Before operating Fan Coil, be sure that proper blower

speed has been selected. High speed tap is

recommended for most applications. For those

applications requiring lower air flows, low speed tap can

be used.

Color Code For Motor Lead Wires

MOTOR SPEED TAP WIRE COLOR

C - Common Yellow

1 - High Black

2 - Low Red

NOTE: Fan speeds are selected manually. Tochange the

fan speed, switch the black and red fan motor leads on

printed circuit board terminal SPT (COM).

MOTOR SPEED SELECTION - FEA and WAHA Fan Coils

FEA and WAHA fan speed selection is done at the fan

motor.

The Violet wire connected to motor terminal 4 is the

default Electric Heat speed (provides the minimum

airflow required for electric heat operation). Do not

remove the Violet wire from motor terminal 4.

To change the cooling (and heat pump heating) motor

speed, reposition the Gray wire at fan motor speed

terminals labeled 1, 2, 3, or 5 (refer to Figure 7). Low

speed (1) is designed for mismatch outdoor unit

applications. Medium speed (2) is designed for straight

matched operations. High speed (3) is designed for

straight matched operations that need extra airflow.

Speed (5) is designed for extra high static (0.5 inch water

column) duct situations on straight matched systems.

Figure 7 [ Motor Speed Selection

}[[])ll]l]l] Ili_ 0I (I _IE

1 i

START-UP PROCEDURE

Refer to outdoor unit Installation Instructions for system

start-up instructions and refrigerant charging method

details.

CARE AND MAINTENANCE

The system should be regularly inspected by a qualified

service technician. Consult the servicing dealer for

recommended frequency.

Between visits, the only consumer service recommended

or required is air filter maintenance and condensate drain

operation.

Air Filter

Inspect air filters at least monthly and replace or clean as

required. Disposable type filters should be replaced.

Reusable type filters may be cleaned by soaking in mild

detergent and rinsing with cold water. Install filters with

the arrows on the side pointing in the direction of air flow.

Condensate Drain

During the cooling season check at least monthly for free

flow of drainage and clean if necessary.

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in poor

unit performance and/or product damage.

Never operate Fan Coil without a filter. Damage to

blower motor or coil may result. Factory autho-

rized filter kits must be used when locating the fil-

ter inside the unit.

8 66401500200

International Comfort Products, LLC

Lewisburg, TN 37091 USA

Loading...

Loading...