ICP F9MXT1002120A, F9MXT0601714A, F9MXT0801716A, F9MXT0802120A, F9MXT1202422A Service And Technical Support Manual

...Page 1

Printed in U.S.A. 440 04 4321 04 July 2012

SERVICE AND TECHNICAL

SUPPORT MANUAL

Two−Stage, ECM Blower Motor

35” Tall, High Efficiency Condensing Gas Furnace

(F/G)9MXT

Save this manual for future reference.

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and NOTE

The signal words DANGER, WARNING,

CAUTION, and NOTE are used to identify levels of

hazard seriousness. The signal word DANGER is

only used on product labels to signify an immediate

hazard. The signal words WARNING, CAUTION,

and NOTE will be used on product labels and

throughout this manual and other manual that may

apply to the product.

DANGER − Immediate hazards which will result in

severe personal injury or death.

WARNING − Hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION − Hazards or unsafe practices which

may result in minor personal injury or product or

property damage.

NOTE − Used to highlight suggestions which will

result in enhanced installation, reliability, or

operation.

!

WARNING

Signal Words in Manuals

The signal word CAUTION is used throughout

this manual in the following manner:

!

CAUTION

Signal Words on Product Labeling

Signal words are used in combination with

colors and/or pictures or product labels.

The signal word WARNING is used throughout

this manual in the following manner:

Safety−alert symbol

When you see this symbol on the unit and in

instructions or manuals, be alert to the

potential for personal injury.

TABLE OF CONTENTS

START−UP, ADJUSTMENT, AND SAFETY CHECK 4...........

THERMOSTAT SETUP SWITCH 4...........................

PRIME CONDENSATE TRAP WITH WATER 4.................

PURGE GAS LINES 4......................................

ADJUSTMENTS 5.........................................

ADJUST TEMPERATURE RISE 10............................

ADJUST BLOWER OFF DELAY (HEAT MODE) 11..............

ADJUST COOLING AIRFLOW 11.............................

ADJUST CONTINUOUS FAN AIRFLOW 11....................

ADJUST THERMOSTAT HEAT ANTICIPATOR 11...............

CHECK SAFETY CONTROLS 12.............................

CHECKLIST 12.............................................

SERVICE AND MAINTENANCE PROCEDURES 13.............

ELECTRICAL CONTROLS AND WIRING 13...................

TROUBLESHOOTING 13....................................

CLEANING AND/OR REPLACING AIR FILTER 15..............

BLOWER MOTOR AND WHEEL MAINTENANCE 15............

CLEANING BURNERS AND FLAME SENSOR 17...............

SERVICING HOT SURFACE IGNITER 18......................

FLUSHING COLLECTOR BOX AND DRAINAGE SYSTEM 18....

CLEANING CONDENSATE DRAIN AND TRAP 19..............

CLEANING HEAT EXCHANGERS 19..........................

SERVICE LABEL 21.........................................

WIRING DIAGRAM 22.......................................

SEQUENCE OF OPERATION 25.............................

PARTS REPLACEMENT INFORMATION GUIDE 29.............

PRODUCT NOMENCLATURE 30.............................

MODELS

(F/G)9MXT0401410A

(F/G)9MXT0601714A

(F/G)9MXT0801716A

(F/G)9MXT0802120A

(F/G)9MXT1002120A

(F/G)9MXT1202422A

Use of the AHRI Certified TM Mark indicates a

manufacturer’s participation in the program.

For verification of certification for individual

products, go to www.ahridirectory.org .

Page 2

440 04 4321 04

Specifications are subject to change without notice.

2

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock,

or other conditions which may cause death, personal injury, or

property damage. Consult a qualified installer, service agency,

or your distributor or branch for information or assistance. The

qualified installer or agency must use factory−authorized kits or

accessories when modifying this product. Refer to the individual

instructions packaged with the kits or accessories when

installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit. Consult local building codes,

the current editions of the National Fuel Gas Code (NFCG)

NFPA 54/ANSI Z223.1, and the National Electrical Code (NEC)

NFPA 70.

In Canada refer to the current editions of the National standards

of Canada CAN/CSA−B149.1 and .2 Natural Gas and Propane

Installation Codes, and Canadian Electrical Code CSA C22.1.

Recognize safety information. This is the safety−alert symbol

. When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand these signal words; DANGER, WARNING, and

CAUTION. These words are used with the safety−alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced installation,

reliability, or operation.

!

WARNING

PERSONAL INJURY, AND/OR PROPERTY

DAMAGE HAZARD

Failure to carefully read and follow this warning could

result in equipment malfunction, property damage,

personal injury and/or death.

Installation or repairs made by unqualified persons could

result in equipment malfunction, property damage,

personal injury and/or death.

The information contained in this manual is intended for

use by a qualified service technician familiar with safety

procedures and equipped with proper tools and test

instruments.

Installation must conform with local building codes and

with the Natural Fuel Gas Code (NFCG) NFPA 54/ANSI

Z223.1, and National standards of Canada

CAN/CSA−B149.1 and .2 Natural Gas and Propane

Installation Codes.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal

injury or death.

Before performing service or maintenance operations

on unit, always turn off main power switch to unit and

install lockout tag. Unit may have more than one power

switch.

!

WARNING

CARBON MONOXIDE POISONING AND FIRE

HAZARD

Failure to follow safety warnings could result in personal

injury, death, and/or property damage.

This furnace is not designed for use in mobile homes,

trailers or recreational vehicles.

!

CAUTION

CUT HAZARD

Failure to follow this caution may result in damage

personal injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing, safety

glasses and gloves when handling parts and servicing

furnaces.

Page 3

SERVICE AND TECHNICAL MANUAL Gas Furnace: (F/G)9MXT

440 04 4321 04 3

Specifications subject to change without notice.

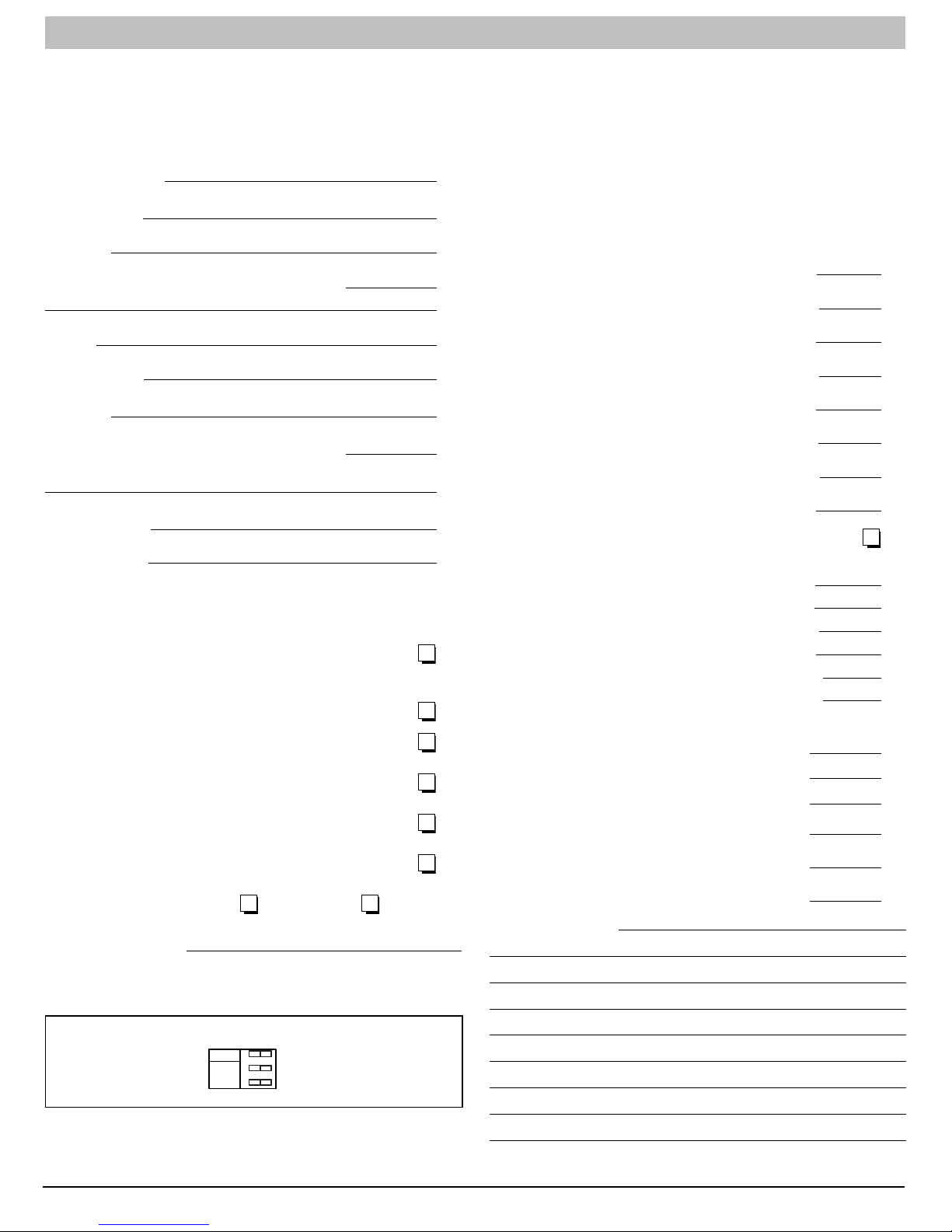

START−UP CHECK SHEET

For PSC Models (F/G)9MXT

(This sheet is optional. Keep for future reference.)

Date of Start−Up:

Dealer Name:

Address:

City, State(Province), Zip or Postal Code:

Phone:

Owner Name:

Address:

City, State(Province), Zip or Postal Code:

Model Number:

Serial Number:

Setup Checks

Check the box when task is complete.

All Electrical Connections Tight?

Have hoses been relocated for furnace U/D/H application?

Condensate Drain Connected?

Condensate Drain Trapped?

Manual Gas Shut−off Upstream of Furnace/Drip Leg

Gas Valve turned ON?

Type of Gas: Natural: Propane:

Filter Type and Size:

Shade in Heating Fan “Time OFF” Setting and Thermostat

Type setting:

ON

OFF

1 2 3

TT

OFF

DLY

Calculated Input (BTU) Rate: (See Checks and Adjustments

Section).

Heating Check

Measured Line Pressure During High Heat:

Measured Manifold Pressure: High Heat

Low Heat

Temperature of Supply Air: High Heat

Low Heat

Temperature of Return Air:

Temperature Rise (Supply − Return): High Heat

Low Heat

In Rise Range (see furnace rating plate)?

Static Pressure (Ducts) High Heat: Supply

Return

The Blower Speed Tap used for: High Heat

Low Heat

Optional Check: CO?

CO2?

Cooling Check

Temperature of Supply Air:

Temperature of Return Air:

Temperature Difference:

Static Pressure (Ducts) Cooling: Supply

Return

The Blower Speed Tap used for: Cooling

Dealer Comments:

Page 4

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

START−UP, ADJUSTMENT, AND SAFETY

CHECK

General

1. Furnace must have a 115-v power supply properly

connected and grounded.

NOTE: Proper polarity must be maintained for 115-v wiring.

Control status indicator light flashes code 10 and furnace does

not operate if polarity is incorrect or if the furnace is not

grounded.

Thermostat wire connections at terminals R, W/W1, G,

2.

and Y/Y2 must be made at 24-v terminal block on

furnace control.

3. Natural gas service pressure must not exceed 0.5 psig

(14-in. w.c., 350 Pa), but must be no less than 0.16 psig

(4.5-in. w.c., 1125 Pa).

4. Blower door must be in place to complete 115-v electrical

circuit and supply power to the furnace components.

!

CAUTION

UNIT OPERATION HAZARD

Failure to follow this caution may result in intermittent unit

operation or performance dissatisfaction.

These furnaces are equipped with a manual reset limit

switch in burner assembly. This switch opens and shuts off

power to the gas valve if an overheat condition (flame

rollout) occurs in the burner assembly/enclosure. Correct

inadequate combustion-air supply, improper gas pressure

setting, improper burner or gas orifice positioning, or

improper venting condition before resetting switch. DO

NOT jumper this switch.

Before operating furnace, check flame rollout manual reset

switch for continuity. If necessary, press button to reset switch.

EAC-1 terminal is energized whenever blower operates. HUM

terminal is only energized when the the gas valve is energized

in heating.

Thermostat Setup Switch

This furnace can be installed with either a single−stage heating

or a two−stage heating thermostat. Setup switch SW−1 (TT) is

used to configure the furnace for single or two stage thermostat

operation. (See Figure 4)

For single−stage thermostats, connect thermostat W to W/W1

at furnace control terminal block. (See Figure 7) For

single−stage thermostats, the control will operate for 12

minutes on low heat, then switch to high heat if heat call

remains. Setup switch SW−1 (TT) must be in the

factory−shipped OFF position. See Figure 7 and Figure 15 for

setup switch information.

If a two−stage heating thermostat is to be used, move setup

switch SW−1 (TT) to ON position before starting furnace. This

overrides built−in control process for selecting high and low

heat and allows the two−stage thermostat to select gas heating

modes. The W2 from thermostat must be connected to W2 on

control terminal block.

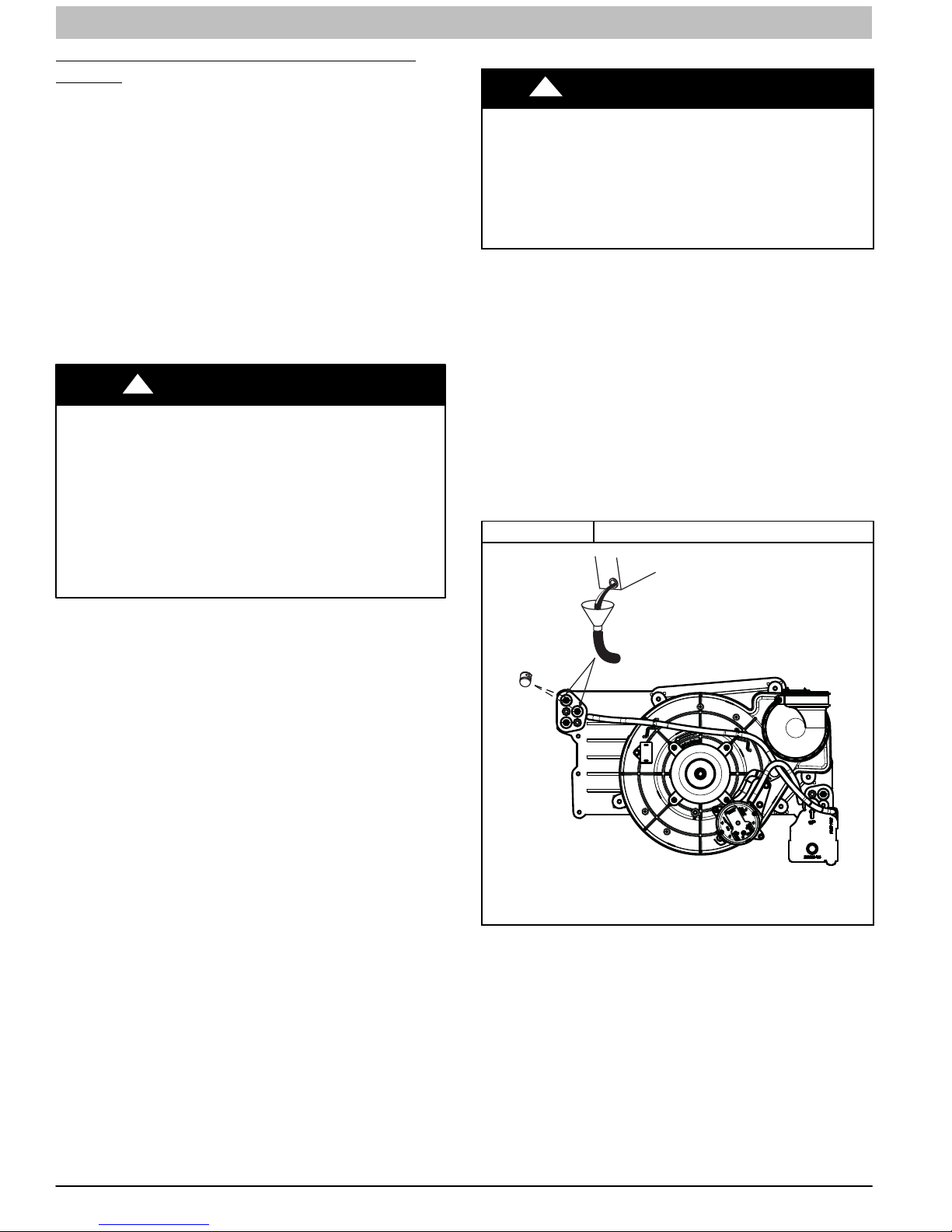

Prime Condensate Trap with Water

! WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow these warnings could result in personal injury

or death.

Failure to use a properly configured trap or NOT

water-priming trap before operating furnace may allow

positive pressure vent gases to enter the structure through

drain tube. Vent gases contain carbon monoxide which is

tasteless and odorless.

1. Remove upper and middle collector box drain plugs

opposite of the condensate trap. (See Figure 1)

2. Connect field-supplied 5/8-in. (16 mm) ID tube with

attached funnel (see Figure 1) to upper collector box

drain connection.

3. Pour one quart (liter) of water into funnel/tube. Water

should run through collector box, overfill condensate

trap, and flow into open field drain.

4. Remove funnel; replace collector box drain plug.

5. Connect field-supplied 5/8-in. (16 mm) ID tube to middle

collector box drain port.

6. Pour one quart (liter) of water into funnel/tube. Water

should run through collector box, overfill condensate

trap, and flow into open field drain.

7. Remove funnel and tube from collector box and replace

collector box drain plug.

Figure 1 Priming Condensate Drain

Representative drawing only, some models may vary in appearance.

L11F065

Purge Gas Lines

If not previously done, purge the lines after all connections

have been made and check for leaks.

4 440 04 4321 04

Specifications subject to change without notice.

Page 5

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

! WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Never purge a gas line into a combustion chamber. Never

test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection of

leaks to check all connections. A fire or explosion may result

causing property damage, personal injury or loss of life.

Adjustments

!

FIRE HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

DO NOT bottom out gas valve regulator adjusting screw.

This can result in unregulated manifold pressure and

result in excess overfire and heat exchanger failures.

FURNACE DAMAGE HAZARD

Failure to follow this caution may result in reduced furnace

life.

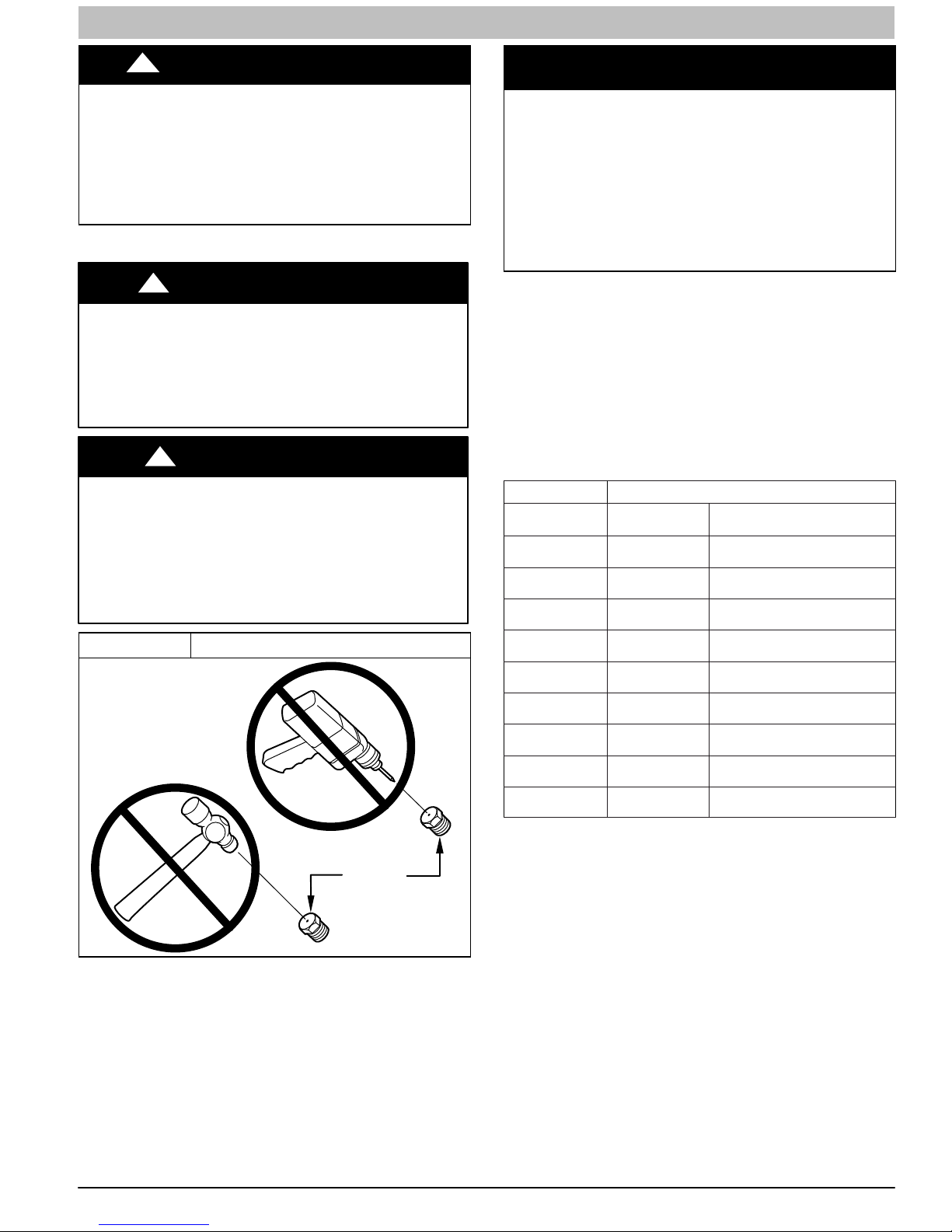

DO NOT redrill orifices. Improper drilling (burrs,

out−of−round holes, etc.) can cause excessive burner

noise and misdirection of burner flames. This can result in

flame impingement of heat exchangers, causing failures.

(See Figure 2)

Figure 2 Orifice Hole

For proper operation and long term reliability the furnace input

rate must be within +/−2 percent of input rate on furnace rating

plate, or as adjusted for altitude.

The gas input rate on rating plate is for installation at altitudes

up to 2000 ft. (610 M).

WARNING

!

CAUTION

BURNER

ORIFICE

A93059

NOTICE

The NATURAL GAS manifold pressure adjustments in Table 3

compensate for BOTH altitude AND gas heating value. DO

NOT apply an additional de−rate factor to the pressures shown

in Table 3.

The heating content of natural gas at altitude may already

provide for a reduction in capacity or altitude. Refer to Table 3.

No adjustments to the furnace may be necessary at altitude for

certain gas heating values.

Refer to the instructions provided in the factory-specified

LP/Propane conversion kit for instructions for setting gas

manifold pressures for LP/Propane applications.

In the USA, the input rating for altitudes above 2000 ft. (610 M)

must be reduced by 2 percent for each 1000 ft. (305 M) above

sea level refer to Table 1. The natural gas manifold pressures

in Table 3 adjust for BOTH altitude and natural gas heating

value.

In Canada, the input rating must be reduced by 5 percent for

altitudes of 2000 ft. to 4500 ft. (610 to 1372 M) above sea level.

The natural gas manifold pressures in Table 3 adjust for BOTH

altitude and natural gas heating value.

NOTE: For Canadian altitudes of 2000 to 4500 ft. (610 to 1372

M), use USA altitudes of 2001 to 3000 ft. (611 to 914 M) in

Table 3.

Table 1 Altitude Derate Multiplier for USA

ALTITUDE

FT. (M)

0–2000

(0−610)

2001–3000

(610−914)

3001–4000

(914−1219)

4001–5000

(1219−1524)

5001–6000

(1524−1829)

6001–7000

(1829−2134)

7001–8000

(2134−2438)

8001–9000

(2438−2743)

9001–10,000

(2743−3048)

* Derate multiplier factors are based on midpoint altitude for altitude range.

NOTE: For Canadian altitudes of 2000 to 4500 ft. (610 to

1372 M), use USA altitudes of 2001 to 3000 ft. (610 to 914

M)

To adjust manifold pressure to obtain the proper input rate, first,

determine if the furnace has the correct orifice installed. At

higher altitudes or different gas heat contents, it may be

necessary to change the factory orifice to a different orifice.

Tables have been provided in the furnace Service and

Technical Manual to match the required orifice to the manifold

pressure to the heat content and specific gravity of the gas. to

do this:

1. Obtain average yearly gas heat value (at installed

altitude) from local gas supplier.

PERCENT

OF DERATE

0 1.00

4−6 0.95

6−8 0.93

8−10 0.91

10−12 0.89

12−14 0.87

14−16 0.85

16−18 0.83

18−20 0.81

DERATE MULTIPLIER

FACTOR*

440 04 4321 04 5

Specifications subject to change without notice.

Page 6

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

2. Obtain average yearly gas specific gravity from local gas

supplier.

3. Find installation altitude in Table 3.

4. Find closest natural gas heat value and specific gravity in

Table 3. Follow heat value and specific gravity lines to

point of intersection to find orifice size and low-and

high-heat manifold pressure settings for proper

operation.

5. Check and verify burner orifice size in furnace. NEVER

ASSUME ORIFICE SIZE. ALWAYS CHECK AND

VERIFY.

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Re−install manifold pressure tap plug in gas valve to

prevent gas leak.

14. Apply pipe dope sparingly to end of inlet gas pipe plug

!

WARNING

and re−install in the gas valve.

Adjust Manifold Pressure

NOTICE

If orifice hole appears damaged or it is suspected to have been

redrilled, check orifice hole with a numbered drill bit of correct

size. Never redrill an orifice. A burr−free and squarely aligned

orifice hole is essential for proper flame characteristics.

6. Replace orifice with correct size, if required by Table 3.

Use only factory−supplied orifices. See EXAMPLE 1.

EXAMPLE 1:

0 - 2000 ft. (0 - 609.6M) altitude

Heating value = 1050 Btu/cu ft.

Specific gravity = 0.62

Therefore: Orifice No. 44

(Furnace is shipped with No. 44 orifices. In this example, all

main burner orifices are the correct size and do not need to be

changed to obtain proper input rate.)

Manifold pressure: 3.4-in. w.c. (847 Pa) for high heat, 1.4-in.

w.c. (349 Pa) for low heat

NOTE: To convert gas manifold Table pressures to Pascals,

multiply the in.w.c. value by 249.1 Pa/in. w.c. (1 in. wc. = 249.1

Pa).

Check Inlet Gas Pressure

The inlet gas pressure must be checked with the furnace

operating in maximum heat. This is necessary to make sure the

inlet gas pressure does not fall below the minimum pressure of

4.5 in. w.c.

1. Make sure the gas supply is turned off to the furnace and

at the electric switch on the gas valve.

2. Remove the 1/8 in. NPT plug from the inlet pressure tap

on the gas valve.

3. Connect a manometer to the inlet pressure tap on gas

valve.

4. Turn on furnace power supply.

5. Turn gas supply manual shutoff valve to ON position.

6. Turn furnace gas valve switch to ON position.

7. Jumper the R to W/W1 and W2 thermostat connections

at the furnace control board.

8. When main burners ignite, confirm inlet gas pressure is

between 4.5 in. w.c. (1125 Pa) and 13.6 in. w.c. (3388

Pa).

9. Remove jumper across thermostat connections to

terminate call for heat. Wait until the blower off delay is

completed.

10. Turn furnace gas valve electric switch to OFF position.

11. Turn gas supply manual shutoff valve to OFF position.

12. Turn off furnace power supply.

13. Remove manometer from the inlet pressure tap of the

gas valve.

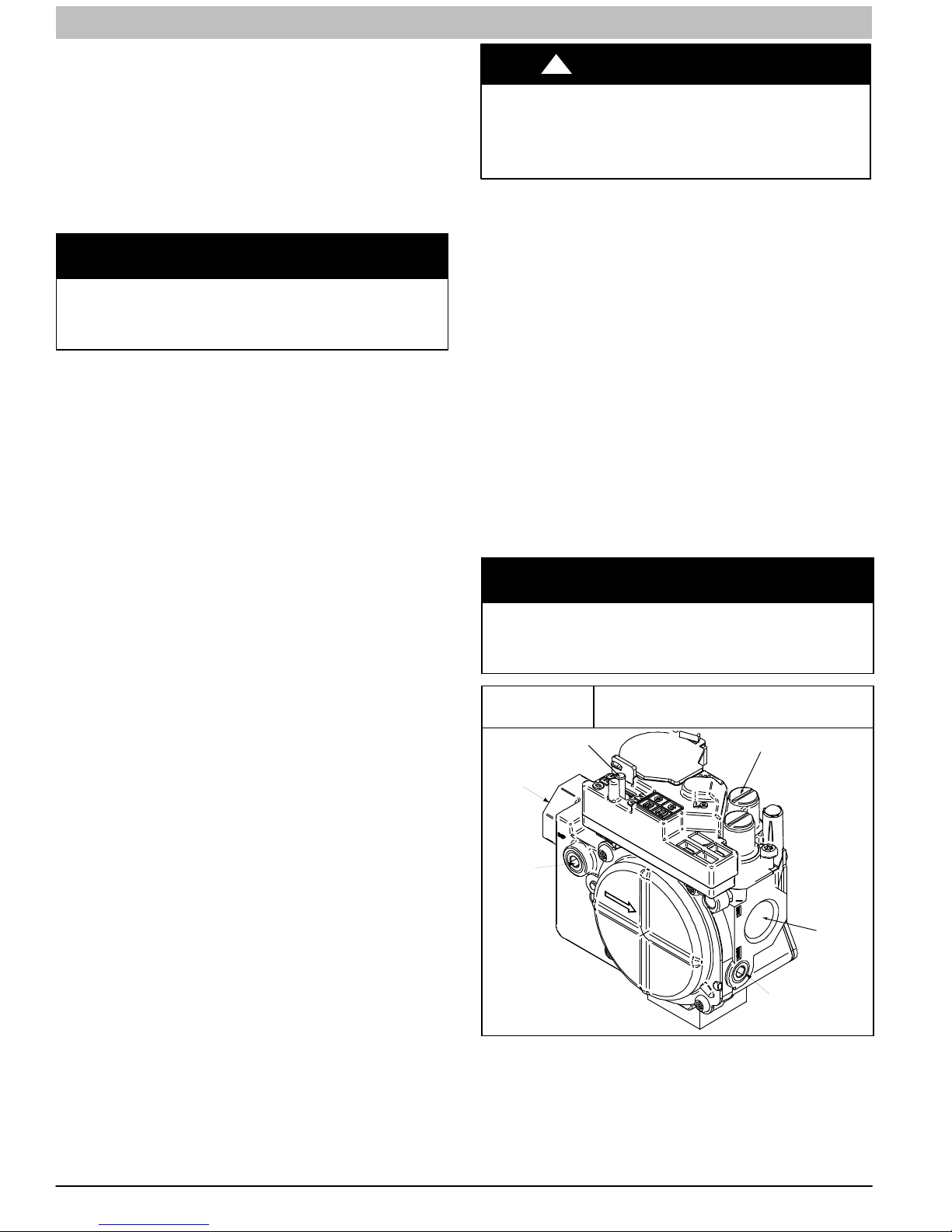

1. Adjust manifold pressure to obtain low fire input rate.

(See Figure 3)

a. Turn gas valve ON/OFF switch to OFF.

b. Remove manifold pressure tap plug from gas valve.

c. Connect a water column manometer or similar device

to manifold pressure tap.

d. Turn gas valve ON/OFF switch to ON.

e. Move setup switch SW−1 (TT) on furnace control to

ON position to lock furnace in low−heat operation.

(See Figure 4 and Figure 15)

f. Manually close blower door switch.

g. Jumper R and W/W1 thermostat connections on

control to start furnace. (See Figure 4)

h. Remove regulator adjustment cap from low heat gas

valve pressure regulator (See Figure 3) and turn

low−heat adjusting screw (3/16 or smaller flat−tipped

screwdriver) counterclockwise (out) to decrease input

rate or clockwise (in) to increase input rate.

NOTICE

DO NOT set low−heat manifold pressure less than 1.3−in. w.c.

(324 Pa) or more than 1.7−in. w.c. (423 Pa) for natural gas. If

required manifold pressure is outside this range, change main

burner orifices.

Figure 3

1/2” NPT Inlet

1/8” NPT Inlet

Pressure Tap

i. Install low−heat regulator adjustment cap.

j. Move setup switch SW−1 (TT) to off position after

completing low−heat adjustment.

Redundant Automatic Gas Control

Valve (2−Stage)

ON/OFF Switch

Regulator Seal Cap

Regulator Adjustment

Regulator Seal Cap under Cap

1/8” NPT Manifold

Pressure Tap

1/2” NPT Outlet

A11152

6 440 04 4321 04

Specifications subject to change without notice.

Page 7

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

k. Leave manometer or similar device connected and

proceed to Step 2.

2. Adjust manifold pressure to obtain high fire input rate.

(See Figure 3)

a. Jumper R to W/W1 and W2 thermostat connections

on furnace control. This keeps furnace locked in

high−heat operation.

b. Remove regulator adjustment cap from high−heat

gas valve pressure regulator (See Figure 3) and turn

high heat adjusting screw (3/16−in. or smaller

flat−tipped screwdriver) counterclockwise (out) to

decrease input rate or clockwise (in) to increase input

rate.

NOTICE

DO NOT set high−heat manifold pressure less than 3.2−in. w.c.

(797 Pa) or more than 3.8 in. w.c. (947 Pa) for natural gas. If

required manifold pressure is outside this range, change main

burner orifices to obtain manifold pressure in this range.

c. When correct input is obtained, replace caps that

conceal gas valve regulator adjustment screws. Main

burner flame should be clear blue, almost

transparent. (See Figure 13)

d. Reinstall manifold pressure tap plug to gas valve.

e. Remove jumpers R to W/W1 and R to W2.

3. Verify natural gas input rate by clocking meter.

NOTE: Contact your HVAC distributor or gas supplier for metric

gas meter Tables, if required.

a. Turn off all other gas appliances and pilots served by

the meter.

b. Move setup switch SW−1 (TT) to ON position. This

keeps furnace locked in low−heat operation when

only W/W1 is energized.

c. Jumper R to W/W1.

d. Run furnace for 3 minutes in low−heat operation.

e. Measure time (in sec) for gas meter to complete one

revolution and note reading. The 2 or 5 cubic feet dial

provides a more accurate measurement of gas flow.

f. Refer to Table 2 for cubic ft. of gas per hr.

g. Multiply gas rate cu ft./hr by heating value (Btuh/cu

ft.) to obtain input rate.

h. If clocked rate does not match required input from

Step 1, increase manifold pressure to increase input

or decrease manifold pressure to decrease input.

Repeat steps b through e of Step 1 until correct

low−heat input is achieved. Re−install low heat

regulator seal cap on gas valve.

i. Jumper R to W/W1, and W2. This keeps furnace

locked in high--heat operation when both W/W1 and

W2 are energized.

j. Repeat items (d) through (h) for high-heat operation,

repeating Step 2 and adjusting the high-heat

regulator screw, as required.

4. Restore furnace to normal operating condition.

a. Turn gas valve ON/OFF switch to OFF.

b. Remove water column manometer or similar device

from manifold pressure tap.

c. Replace manifold pressure tap plug to gas valve.

d. Turn gas valve ON/OFF switch to ON.

e. Move setup SW-1 switch (TT) on furnace control to

position required for attached thermostat (OFF for

single-stage thermostats, ON for two-stage

thermostats).

f. Check for gas leaks and verify furnace operation.

!

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Re−install manifold pressure tap plug in gas valve to

prevent gas leak.

WARNING

440 04 4321 04 7

Specifications subject to change without notice.

Page 8

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

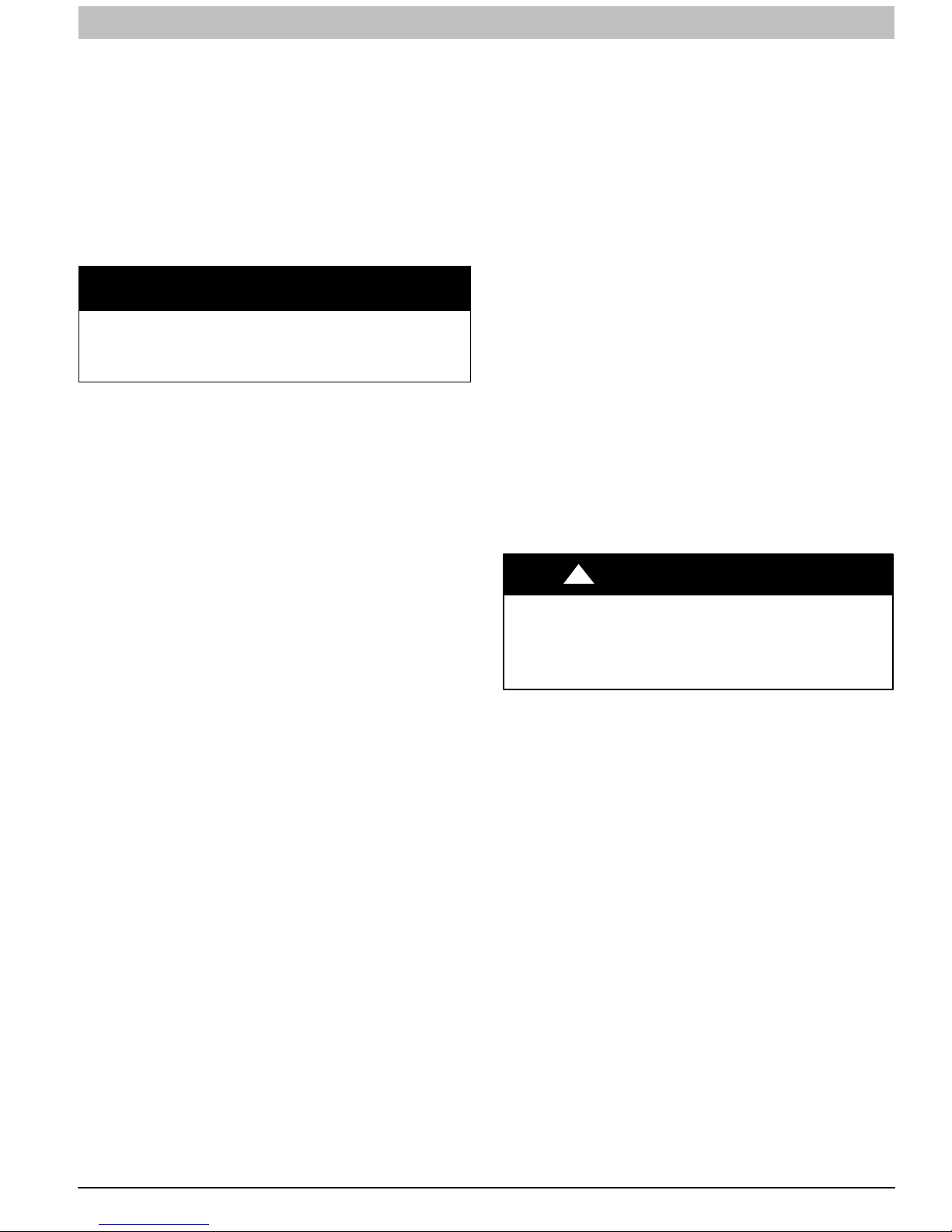

Figure 4 Example of Two−Stage Furnace Control Board

SET UP SWITCHES

THERMOSTAT TYPE (TT)

AND HEAT OFF−DELAY

SW1

ON

OFF

COM

24V

Table 2

SECONDS G

FOR 1 REVOLUTION

Gas Rate (CU ft./hr)

SIZE OF TEST DIAL SECONDS

1 Cu Ft. 2 Cu Ft. 5 Cu Ft. 1 Cu Ft. 2 Cu Ft. 5 Cu Ft.

10 360 720 1800 50 72 144 360

11 327 655 1636 51 71 141 355

12 300 600 1500 52 69 138 346

13 277 555 1385 53 68 136 340

14 257 514 1286 54 67 133 333

15 240 480 1200 55 65 131 327

16 225 450 1125 56 64 129 321

17 212 424 1059 57 63 126 316

18 200 400 1000 58 62 124 310

19 189 379 947 59 61 122 305

20 180 360 900 60 60 120 300

21 171 343 857 62 58 116 290

22 164 327 818 64 56 112 281

23 157 313 783 66 54 109 273

24 150 300 750 68 53 106 265

25 144 288 720 70 51 103 257

26 138 277 692 72 50 100 250

27 133 267 667 74 48 97 243

28 129 257 643 76 47 95 237

29 124 248 621 78 46 92 231

30 120 240 600 80 45 90 225

31 11 6 232 581 82 44 88 220

32 11 3 225 563 84 43 86 214

33 109 218 545 86 42 84 209

34 106 212 529 88 41 82 205

35 103 206 514 90 40 80 200

36 100 200 500 92 39 78 196

37 97 195 486 94 38 76 192

38 95 189 474 96 38 75 188

39 92 185 462 98 37 74 184

40 90 180 450 100 36 72 180

41 88 176 439 102 35 71 178

42 86 172 429 104 35 69 173

43 84 167 419 106 34 68 170

44 82 164 409 108 33 67 167

45 80 160 400 11 0 33 65 164

46 78 157 391 11 2 32 64 161

47 76 153 383 11 6 31 62 155

48 75 150 375 120 30 60 150

49 73 147 367

8 440 04 4321 04

W2 Y1 DHUM G COM W/W1 Y/Y2 R

24−V THERMOS TAT

TERMINALS

3−AMP FUSE

LED OPERATION

& DIAGNOSTIC LIGHT

BLOWER SPEED

TERMINALS

115−VAC (L2)

NEUTRAL

CONNECTIONS

24V

FUSE 3−AMP

COM

HI HT

COOL

LO H T

SPARE 2

SPARE 1

L2

TEST / TWIN

COM/BLUE 24VAC/RED

24V MTR TAPS

EAC−2

FOR 1 REVOLUTION

Specifications subject to change without notice.

SW1

ON

OFF

1 2 3

TT

OFF

DLY

PLT

HUM

24VAC

PL1

1

EAC TERMINAL

115 VAC 1.0 AMP

MAX

115 VAC LINE (L1)

INPUT

TWINNING AND/OR

COMPONENT TEST

TERMINAL

11 5 VA C

BLOWER POWER (BL1)

CONNECTION

EAC−1

L1 BL−1 XFMR

HUMIDIFIER TERMINAL

(24 VAC 0.5 AMPS MAX)

TRANSFORMER

24 VAC CONNECTIONS

P−1 LOW VOLTAGE

11 5 VA C

TRANSFORMER

PRIMARY

P2 − HOT SURFACE

IGNITER/INDUCE R

MOTOR CONNECTION

IDR

HSIR

1

PL2

HUM

115 VAC HUM

HSI HI LO

SIZE OF TEST DIAL

IHI/LOR

IDM

L12F037

Page 9

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

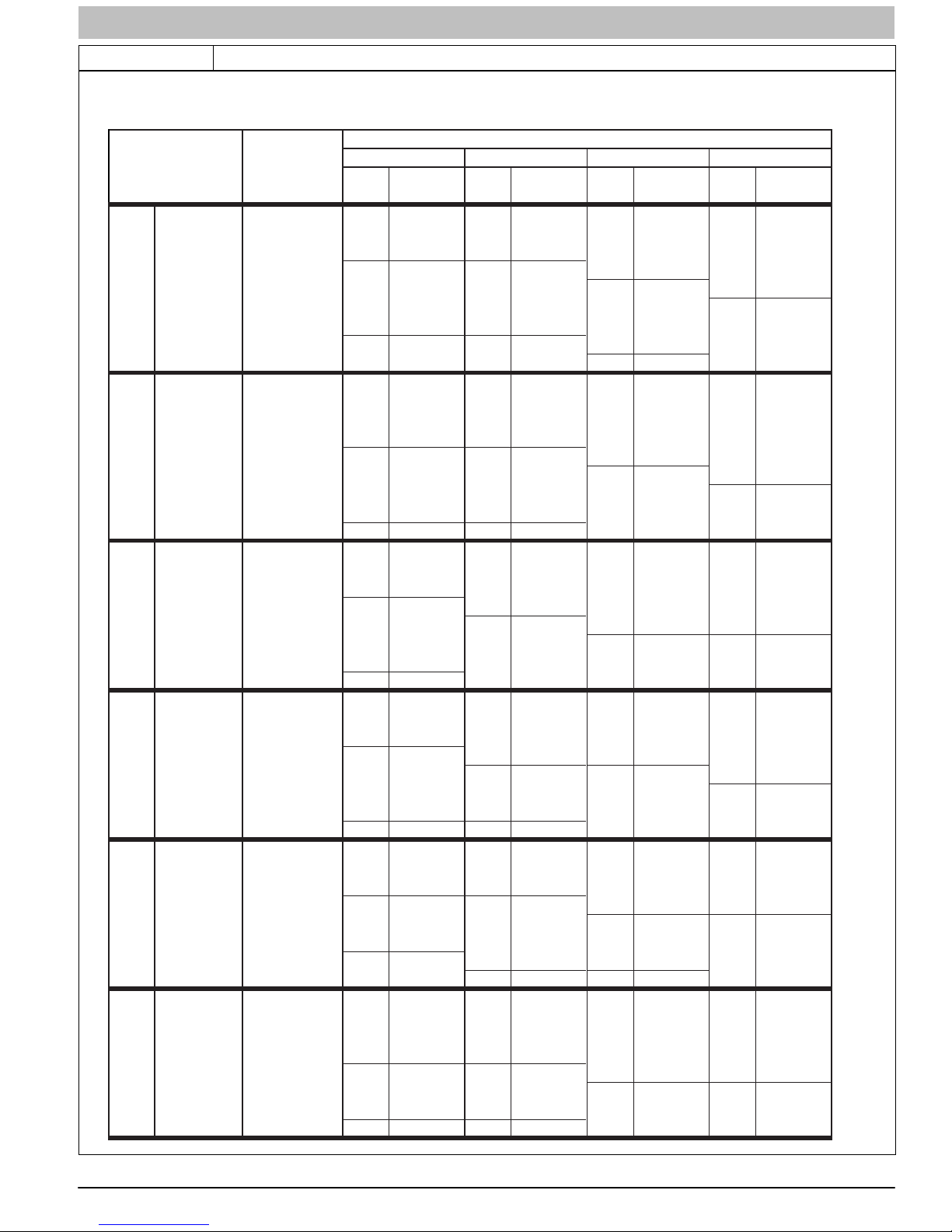

Table 3 Orifice Size and Manifold Pressure (in. w.c.) for Gas Input Rate

TWO-STAGE FURNACE

(TABULATED DATA BASED ON 20,000 BTUH HIGH-HEAT / 13,000 BTUH LOW-HEAT PER BURNER,

DERATED 2%/1000 FT (305M) ABOVE SEA LEVEL)

ALTITUDE

RANGE

ft (m)

092543 3.6 / 1.5 43 3.7 / 1.6 43 3.8 / 1.6 42 3.2 / 1.4

(0) 950 43 3.4 / 1.4 43 3.5 / 1.5 43 3.6 / 1.5 43 3.7 / 1.6

to 1000 44 3.5 / 1.5 44 3.6 / 1.5 44 3.8 / 1.6 43 3.4 / 1.4

U.S.A. and CanadaU.S.A. On

y U.S.A. Only U.S.A. and Canada

l

U.S.A. On

ly

ly

U.S.A. On

2000 1050 44 3.2 / 1.3 44 3.3 / 1.4 44 3.4 / 1.4 44 3.5 / 1.5

(610) 1075 45 3.7 / 1.6 45 3.8 / 1.6 44 3.3 / 1.4 44 3.4 / 1.4

U.S.A. 800 42 3.4 / 1.4 42 3.5 / 1.5 42 3.6 / 1.5 42 3.7 / 1.6

2001 (611) 825 43 3.8 / 1.6 42 3.3 / 1.4 42 3.4 / 1.4 42 3.5 / 1.5

to 850 43 3.6 / 1.5 43 3.7 / 1.6 42 3.2 / 1.3 42 3.3 / 1.4

3000 (914) 875 43 3.4 / 1.4 43 3.5 / 1.5 43 3.7 / 1.5 43 3.8 / 1.6

Canada 925 44 3.5 / 1.5 44 3.6 / 1.5 44 3.8 / 1.6 43 3.4 / 1.4

2001 (611) 950 44 3.3 / 1.4 44 3.4 / 1.5 44 3.6 / 1.5 44 3.7 / 1.6

to 975 44 3.2 / 1.3 44 3.3 / 1.4 44 3.4 / 1.4 44 3.5 / 1.5

4500 (1372) 1000 46 3.8 / 1.6 45 3.8 / 1.6 44 3.2 / 1.4 44 3.3 / 1.4

3001 800 43 3.8 / 1.6 42 3.2 / 1.4 42 3.3 / 1.4 42 3.4 / 1.4

(915) 825 43 3.6 / 1.5 43 3.7 / 1.6 43 3.8 / 1.6 42 3.2 / 1.4

to

4000 900 44 3.4 / 1.4 44 3.5 / 1.5 44 3.7 / 1.5 44 3.8 / 1.6

(1219) 925 44 3.2 / 1.4 44 3.4 / 1.4 44 3.5 / 1.5 44 3.6 / 1.5

4001 775 43 3.7 / 1.6 43 3.8 / 1.6 42 3.3 / 1.4 42 3.4 / 1.4

(1220) 800 43 3.5 / 1.5 43 3.6 / 1.5 43 3.7 / 1.6 43 3.8 / 1.6

to

5000 875 44 3.3 / 1.4 44 3.5 / 1.5 44 3.6 / 1.5 44 3.7 / 1.6

(1524) 900 44 3.2 / 1.3 44 3.3 / 1.4 44 3.4 / 1.4 44 3.5 / 1.5

5001 750 43 3.7 / 1.5 43 3.8 / 1.6 42 3.2 / 1.4 42 3.3 / 1.4

(1525) 775 43 3.4 / 1.4 43 3.5 / 1.5 43 3.7 / 1.5 43 3.8 / 1.6

to

6000 850 44 3.3 / 1.4 44 3.4 / 1.4 44 3.5 / 1.5 44 3.6 / 1.5

(1829) 875 45 3.7 / 1.6 44 3.2 / 1.3 44 3.3 / 1.4 44 3.4 / 1.4

6001 700 42 3.2 / 1.3 42 3.3 / 1.4 42 3.4 / 1.4 42 3.5 / 1.5

(1830) 725 43 3.6 / 1.5 43 3.7 / 1.6 43 3.8 / 1.6 42 3.3 / 1.4

to

7000 800 44 3.4 / 1.4 44 3.5 / 1.5 44 3.6 / 1.5 44 3.7 / 1.6

(2133) 825 44 3.2 / 1.3 44 3.3 / 1.4 44 3.4 / 1.4 44 3.5 / 1.5

HEATVALUE0.580.600.620.64

AT ALTITUDE Orifice Mnfld Press Orifice Mnfld Press Orifice Mnfld Press Orifice Mnfld Press

(Btu/cu ft) No. High/Low No. High/Low No. High/Low No. High/Low

900 43 3.8 / 1.6 42 3.2 / 1.4 42 3.3 / 1.4 42 3.4 / 1.4

975 44 3.7 / 1.6 44 3.8 / 1.6 43 3.4 / 1.5 43 3.6 / 1.5

1025 44 3.3 / 1.4 44 3.5 / 1.5 44 3.6 / 1.5 44 3.7 / 1.6

1100 46 3.7 / 1.6 46 3.8 / 1.6 45 3.8 / 1.6 44 3.2 / 1.4

900 44 3.7 / 1.6 44 3.8 / 1.6 43 3.5 / 1.5 43 3.6 / 1.5

775 42 3.3 / 1.4 42 3.4 / 1.4 42 3.5 / 1.5 42 3.6 / 1.5

850 44 3.8 / 1.6 43 3.5 / 1.5 43 3.6 / 1.5 43 3.7 / 1.6

875 44 3.6 / 1.5 44 3.7 / 1.6 43 3.4 / 1.4 43 3.5 / 1.5

950 45 3.7 / 1.6 44 3.2 / 1.3 44 3.3 / 1.4 44 3.4 / 1.4

750 42 3.3 / 1.4 42 3.4 / 1.4 42 3.5 / 1.5 42 3.6 / 1.5

825 44 3.8 / 1.6 43 3.4 / 1.4 43 3.5 / 1.5 43 3.6 / 1.5

850 44 3.5 / 1.5 44 3.7 / 1.5 44 3.8 / 1.6 43 3.4 / 1.4

925 46 3.8 / 1.6 45 3.7 / 1.6 44 3.2 / 1.4 44 3.3 / 1.4

725 42 3.2 / 1.4 42 3.3 / 1.4 42 3.4 / 1.5 42 3.5 / 1.5

800 44 3.7 / 1.6 44 3.8 / 1.6 43 3.4 / 1.5 43 3.5 / 1.5

825 44 3.5 / 1.5 44 3.6 / 1.5 44 3.7 / 1.6 44 3.8 / 1.6

900 46 3.7 / 1.6 46 3.8 / 1.6 45 3.8 / 1.6 44 3.2 / 1.4

675 42 3.4 / 1.4 42 3.5 / 1.5 42 3.6 / 1.5 42 3.8 / 1.6

750 43 3.4 / 1.4 43 3.5 / 1.5 43 3.6 / 1.5 43 3.7 / 1.6

775 44 3.6 / 1.5 44 3.7 / 1.6 43 3.4 / 1.4 43 3.5 / 1.5

850 46 3.8 / 1.6 45 3.8 / 1.6 44 3.2 / 1.4 44 3.3 / 1.4

SAGLARUTANFOYTIVARGCIFICEPSSAG.GVA

A11252A

440 04 4321 04 9

Specifications subject to change without notice.

Page 10

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

Table 3 (Cont.) Orifice Size and Manifold Pressure (in. w.c.) for Gas Input Rate

TWO-STAGE FURNACE

(TABULATED DATA BASED ON 20,000 BTUH HIGH-HEAT / 13,000 BTUH LOW-HEAT PER BURNER,

DERATED 2%/1000 FT (305M) ABOVE SEA LEVEL)

ALTITUDE

RANGE

ft (m)

7001 675 43 3.8 / 1.6 42 3.2 / 1.4 42 3.3 / 1.4 42 3.4 / 1.5

(2134) 700 43 3.5 / 1.5 43 3.7 / 1.5 43 3.8 / 1.6 42 3.2 / 1.4

to

8000 775 44 3.3 / 1.4 44 3.4 / 1.4 44 3.5 / 1.5 44 3.7 / 1.5

(2438) 800 45 3.8 / 1.6 44 3.2 / 1.4 44 3.3 / 1.4 44 3.4 / 1.4

8001 650 43 3.8 / 1.6 42 3.2 / 1.4 42 3.3 / 1.4 42 3.4 / 1.4

(2439) 675 43 3.5 / 1.5 43 3.6 / 1.5 43 3.7 / 1.6 42 3.2 / 1.3

to

U.S.A. OnlyU.S.A. Only U.S.A. Only

* Orifice numbers shown in BOLD are f actory-installed.

9000 750 44 3.3 / 1.4 44 3.4 / 1.4 44 3.5 / 1.5 44 3.6 / 1.5

(2743) 775 45 3.7 / 1.6 44 3.2 / 1.3 44 3.3 / 1.4 44 3.4 / 1.4

9001 600 42 3.3 / 1.4 42 3.4 / 1.5 42 3.6 / 1.5 42 3.7 / 1.6

(2744) 625 43 3.7 / 1.6 42 3.2 / 1.3 42 3.3 / 1.4 42 3.4 / 1.4

to

10000 700 44 3.4 / 1.4 44 3.5 / 1.5 44 3.7 / 1.5 44 3.8 / 1.6

(3048) 725 44 3.2 / 1.3 44 3.3 / 1.4 44 3.4 / 1.4 44 3.5 / 1.5

HEATVALUE0.580.600.620.64

AT ALTITUDE Orifice Mnfld Press Orifice Mnfld Press Orifice Mnfld Press Orifice Mnfld Press

(Btu/cu ft) No. High/Low No. High/Low No. High/Low No. High/Low

650 42 3.4 / 1.4 42 3.5 / 1.5 42 3.6 / 1.5 42 3.7 / 1.6

725 44 3.8 / 1.6 43 3.4 / 1.4 43 3.5 / 1.5 43 3.6 / 1.5

750 44 3.5 / 1.5 44 3.7 / 1.5 44 3.8 / 1.6 43 3.4 / 1.4

825 46 3.7 / 1.6 46 3.8 / 1.6 45 3.8 / 1.6 44 3.2 / 1.4

625 42 3.4 / 1.4 42 3.5 / 1.5 42 3.6 / 1.5 42 3.7 / 1.6

700 44 3.7 / 1.6 43 3.4 / 1.4 43 3.5 / 1.5 43 3.6 / 1.5

725 44 3.5 / 1.5 44 3.6 / 1.5 44 3.7 / 1.6 44 3.8 / 1.6

650 43 3.5 / 1.5 43 3.6 / 1.5 43 3.7 / 1.6 43 3.8 / 1.6

675 44 3.7 / 1.6 44 3.8 / 1.6 43 3.4 / 1.4 43 3.5 / 1.5

SAGLARUTANFOYTIVARGCIFICEPSSAG.GVA

A11252B

Adjust Temperature Rise

NOTE: Blower door must be installed when taking temperature

rise reading. Leaving blower door off will result in incorrect

temperature measurements, due to possible changes in duct

static pressure and airflow.

!

CAUTION

FURNACE DAMAGE HAZARD

Failure to follow this caution may result in:

S Overheating the heat exchangers or condensing

flue gases in heat exchanger areas not designed

for condensate

S Shortened furnace life

S Component damage

Temperature rise must be within limits specified on furnace

rating plate. Recommended operation is at midpoint of rise

range or slightly above.

Place SW−1 (TT) in ON position. Jumper R to W/W1 and W2 to

check high−heat temperature rise. To check low−heat

temperature rise, remove jumper to W2. Determine air

temperature rise for both high and low−heat. Do not exceed

temperature rise ranges specified on unit rating plate for high

and low−heat.

This furnace must operate within the temperature rise ranges

specified on the furnace rating plate. Determine the air

temperature as follows:

1. Place duct thermometers in return and supply ducts as

close to furnace as possible. Be sure thermometers do

not “see” heat exchangers so that radiant heat does not

affect thermometer readings. This is particularly

important with straight run ducts.

2. When thermometer readings stabilize, subtract return−air

temperature from supply−air temperature to determine

temperature rise.

If the temperature rise is outside this range, check the

following:

1. Gas input for low and high heat operation.

2. Derate for altitude if applicable.

3. Return and supply ducts for excessive restrictions

causing static pressures greater than 0.50−in. w.c. (125

Pa)

4. Adjust temperature rise by adjusting blower speed.

S Increase blower speed to reduce temperature rise.

S Decrease blower speed to increase temperature rise.

!

WARNING

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal injury

or death.

Disconnect 115vac electrical power before changing speed

tap.

10 440 04 4321 04

Specifications subject to change without notice.

Page 11

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

Table 4 Blower Speed Taps

COLOR SPEED

Gray 5 Cool

Yellow 4 Spare

Blue 3 HI HT

Orange 2 Spare

Red 1 LO HT/Cont Fan

For low−heat, the following connections can be made at LO HT

on control:

FACTORY

ATTACHED TO:

S Orange blower motor lead

S Red blower motor lead − Factory Setting

(Read following caution before changing taps.)

!

CAUTION

UNIT DAMAGE HAZARD

To avoid operating outside the rise range and avoid

component damage:

Refer to the Air Delivery Tables to determine which airflows

and settings are allowed for proper heating airflow. DO NOT

use the highlighted settings for High−Stage Heating airflow.

The highlighted settings are to be used for Low−Stage

Heating and Cooling ONLY.

Change the blower speed taps as required to maintain proper

temperature rise for Heating and Cooling as described above.

To change blower motor speed selections for heating mode,

remove blower motor lead from control HEAT terminal(s). (See

Figure 4) Select desired blower motor speed lead(s) from the

other motor leads and relocate it/them to LOW or HIGH HEAT

terminal(s). Reconnect original lead on SPARE terminal

Adjust Blower Off Delay (Heat Mode)

If desired, the main blower off time delay period may be

lengthened or shortened when operating in the heating mode

to provide greater comfort. For position and location of switches

on control center. (See Figure 4 and Figure 15)

a. Remove blower door if installed.

b. Turn setup switches SW−2 and SW−3 ON or OFF for

desired blower off delay. See Table 5, Figure 4 and

Figure 15.

c. Proceed to “Set Blower Off Delay” before installing

blower door.

Table 5 Blower Speed Taps

DESIRED HEATING MODE

BLOWER OFF DELAY

(SEC.)

90 OFF OFF

120 OFF ON

150 ON OFF

180 ON ON

SETUP SWITCH

(SW-2 & SW-3)

POSITION

SW-2 SW-3

Adjust Continuous Fan Airflow

The Continuous Fan airflow can be set from the remaining

blower speed taps. Refer to the Air Delivery Tables in these

instructions.

The Continuous Fan speed can be changed to any other

speed tap by toggling th Fan switch at the thermostat. See the

Sequence of Operation for details.

!

CAUTION

FURNACE OVERHEATING HAZARD

Failure to follow this caution may result in reduced furnace

life.

Recheck temperature rise. It must be within limits specified

on the rating plate. Recommended operation is at the

mid−point of rise range or slightly above.

Adjust Thermostat Heat Anticipator

Mechanical thermostat: Set thermostat heat anticipator to

match the amp. draw of the electrical components in the

R-W/W1 circuit. Accurate amp. draw readings can be obtained

at the wires normally connected to thermostat sub-base

terminals, R and W. The thermostat anticipator should NOT be

in the circuit while measuring current. (See Figure 5)

1. Set SW-1 (TT) switch on furnace control board to ON.

(See Figure 4)

2. Remove thermostat from sub-base or from wall.

3. Connect an amp. meter across the R and W sub-base

terminals or R and W wires at wall.

4. Record amp. draw across terminals when furnace is in

low heat and after blower starts.

5. Set heat anticipator on thermostat per thermostat

instructions and install on sub-base or wall.

6. Turn SW-1 (TT) switch OFF.

7. Install blower access door.

Electronic thermostat: Set cycle rate for 3 cycles per hr.

Figure 5 Amp. Draw Check with Ammeter

THERMOSTAT SUBBASE

TERMINALS WITH

THERMOSTAT REMOVED

(ANITICIPATOR, CLOCK, ETC.,

MUST BE OUT OF CIRCUIT.)

HOOK-AROUND

AMMETER

R Y W G

Adjust Cooling Airflow

The cooling airflow can be set from the remaining blower speed

taps. Refer to the Air Delivery Tables in these instructions.

If a two−stage air conditioning or heat pump is installed, the

Low Cooling Speed is the same speed tap as the Low Heat

(LO HT), as well as Continuous Fan.

440 04 4321 04 11

EXAMPLE:

Specifications subject to change without notice.

10 TURNS

FROM UNIT 24-V

CONTROL TERMINALS

5.0 AMPS ON AMMETER

10 TURNS AROUND JAWS

0.5 AMPS FOR THERMOSTAT

=

ANTICIPATOR SETTING

A96316

Page 12

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

Table 6 AIR DELIVERY - CFM (with filter1)

UNIT

SIZE

0401410 SIDE/BOTTOM

0601714 SIDE/BOTTOM

0801716 SIDE/BOTTOM

0802120

1002120

1202422

RETURN-AIR

CONNECTION

BOTTOM or

TWO-SIDES

BOTTOM or

TWO-SIDES

BOTTOM or

TWO-SIDES

SPEED

2

TAPS

Gray 1120 1080 1030 980 925 875 820 760 690 630

Yellow 880 845 810 780 740 710 680 640 615 570

Blue 695 665 620 575 535 495 455 420 370 280

Orange 640 595 540 495 460 420 370 310 260 230

Red 570 525 475 425 385 330 255 220 -

Gray 1720 1670 1620 1565 1505 1440 1375 1295 1220 1135

Yellow 1325 1285 1255 1220 1185 1145 1115 1075 1040 1000

Blue 1010 970 925 875 835 785 745 690 660 620

Orange 1160 1115 1080 1045 1000 960 920 875 840 785

Red 785 715 655 595 530 490 435 385 340 285

Gray 1810 1770 1720 1665 1610 1540 1475 1400 1315 1235

Yellow 1535 1500 1475 1435 1405 1370 1340 1310 1245 1160

Blue 1380 1340 1305 1270 1240 1200 1165 1130 1090 1050

Orange 1180 1130 1095 1060 1015 975 935 895 850 800

Red 1100 1045 1010 970 920 885 845 790 745 690

Gray 2290 2225 2155 2090 2015 1930 1845 1750 1640 1515

Yellow 1810 1760 1725 1685 1640 1600 1555 1520 1480 1415

Blue 1385 1340 1285 1240 1200 1140 1090 1050 995 950

4, 5

Orange 1560 1520 1475 1430 1385 1335 1295 1240 1200 1150

Red 1055 985 910 860 795 750 680 615 565 495

Gray 2340 2295 2250 2195 2110 2030 1935 1835 1725 1605

Yellow 1950 1900 1855 1800 1755 1705 1655 1605 1560 1485

Blue 1750 1700 1650 1605 1555 1500 1455 1395 1350 1300

4, 5

Orange 1570 1520 1460 1410 1350 1300 1240 1195 1140 1095

Red 1350 1280 1225 1155 1105 1045 1000 950 895 830

Gray 2275 2230 2185 2130 2055 1950 1825 1710 1610 1500

Yellow 1875 1820 1770 1720 1660 1600 1550 1505 1450 1390

Blue 2170 2125 2075 2025 1975 1900 1790 1695 1590 1470

4, 5

Orange 31475 1420 1350 1280 1215 1165 1105 1050 995 930

Red

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

3

1625 1565 1505 1445 1385 1325 1275 1225 1170 1130

NOTE:

1. A filter is required for each return−air inlet. Airflow performance includes a 3/4 in. (19 mm) washable filter media such as contained in factory−authorized accessory

filter rack. See accessory list. To determine airflow performance without this filter, assume an additional 0.1 in. W.C. available external static pressure.

2. ADJUST THE BLOWER SPEED TAPS AS NECESSARY FOR THE PROPER AIR TEMPERATURE RISE FOR EACH INSTALLATION.

3. Shaded areas indicate that this airflow range is BELOW THE RANGE ALLOWED FOR HIGH−STAGE HEATING OPERATION. THESE AIRFLOW RANGES MAY

ONLY BE USED FOR LOW−STAGE HEAT OR COOLING.

4. Airflows over 1800 CFM require bottom return, two−side return, or bottom and side return. A minimum filter size of 20” x 25” is required.

5. For upflow applications, air entering from one side into both the side of the furnace and a return air base counts as a side and bottom return.

6. The ”−” entry indicates an unstable operating condition.

Check Safety Controls

The flame sensor, gas valve, and pressure switch were all

checked in the Start−up procedure section as part of normal

operation.

1. Check Main Limit Switch

This control shuts off combustion system and energizes

air−circulating blower motor, if furnace overheats. By

using this method to check the temperature limit control,

it can be established that the limit is functioning properly

and that the limit will operate if there is a restricted

return−air supply or motor failure. If the limit control does

not function during this test, the cause must be

determined and corrected.

a. Run furnace for at least 5 minutes.

b. Gradually block off return air with a piece of

cardboard or sheet metal until the limit trips.

c. Unblock return air to permit normal circulation.

d. Burners will re−light when furnace cools down.

2. Check Pressure Switch(es)

This control proves operation of the draft inducer blower.

a. Turn off 115−V power to furnace.

b. Disconnect inducer motor lead wires from wire

harness.

c. Turn on 115−V power to furnace.

d. Set thermostat to “call for heat” and wait 1 minute.

When pressure switch is functioning properly, hot

surface igniter should NOT glow and control

diagnostic light flashes a status code 3. If hot surface

igniter glows when inducer motor is disconnected,

shut down furnace immediately.

e. Determine reason pressure switch did not function

properly and correct condition.

EXTERNAL STATIC PRESSURE (IN.W.C.)

6

f. Turn off 115−V power to furnace.

g. Reconnect inducer motor wires, replace outer door,

and turn on 115−V power.

h. Blower will run for 90 seconds before beginning the

call for heat again.

i. Furnace should ignite normally.

Checklist

1. Put away tools and instruments. Clean up debris.

2. Verify that the jumper is removed from the TEST/TWIN

terminal. Verify that there is nothing plugged into the PLT

connector.

NOTE: Note: If there is a jumper connector plugged into PLT,

remove it and discard. (See Figure 14)

3. Verify that Heating Operating Mode switch SW−1 is set

properly.. (See Figure 14)

4. Verify that the Blower/Heat Off−Delay SW−2 and SW−3

switches are set as desired. (See Figure 14)

5. Verify that the blower (lower door in upflow position) and

control (“Main” or upper door in upflow position) doors

are properly installed.

6. Verify that the Status LED glows. If not, check that the

power supply is energized and that the blower door is

secure. (See Figure 14) to interpret diagnostic codes.

7. Cycle test furnace with room thermostat to be sure that it

operates properly with the room thermostat. Check all

modes including Heat, Cool and Fan.

8. Check operation of accessories per manufacturer’s

instructions.

9. Review Home Owner’s Information with owner.

10. Attach entire literature packet to furnace.

6

-

12 440 04 4321 04

Specifications subject to change without notice.

Page 13

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

SERVICE AND MAINTENANCE

PROCEDURES

!

FIRE, INJURY OR DEATH HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

The ability to properly perform maintenance on this

equipment requires certain knowledge, mechanical

skills, tools, and equipment. If you do not possess

these, do not attempt to perform any service and

maintenance on this equipment other than those

procedures recommended in the Owner’s Manual.

ENVIRONMENTAL HAZARD

Failure to follow this caution may result in

environmental pollution.

Remove and recycle all components or materials (i.e.

oil, refrigerant, control board, etc.) before unit final

disposal.

WARNING

!

CAUTION

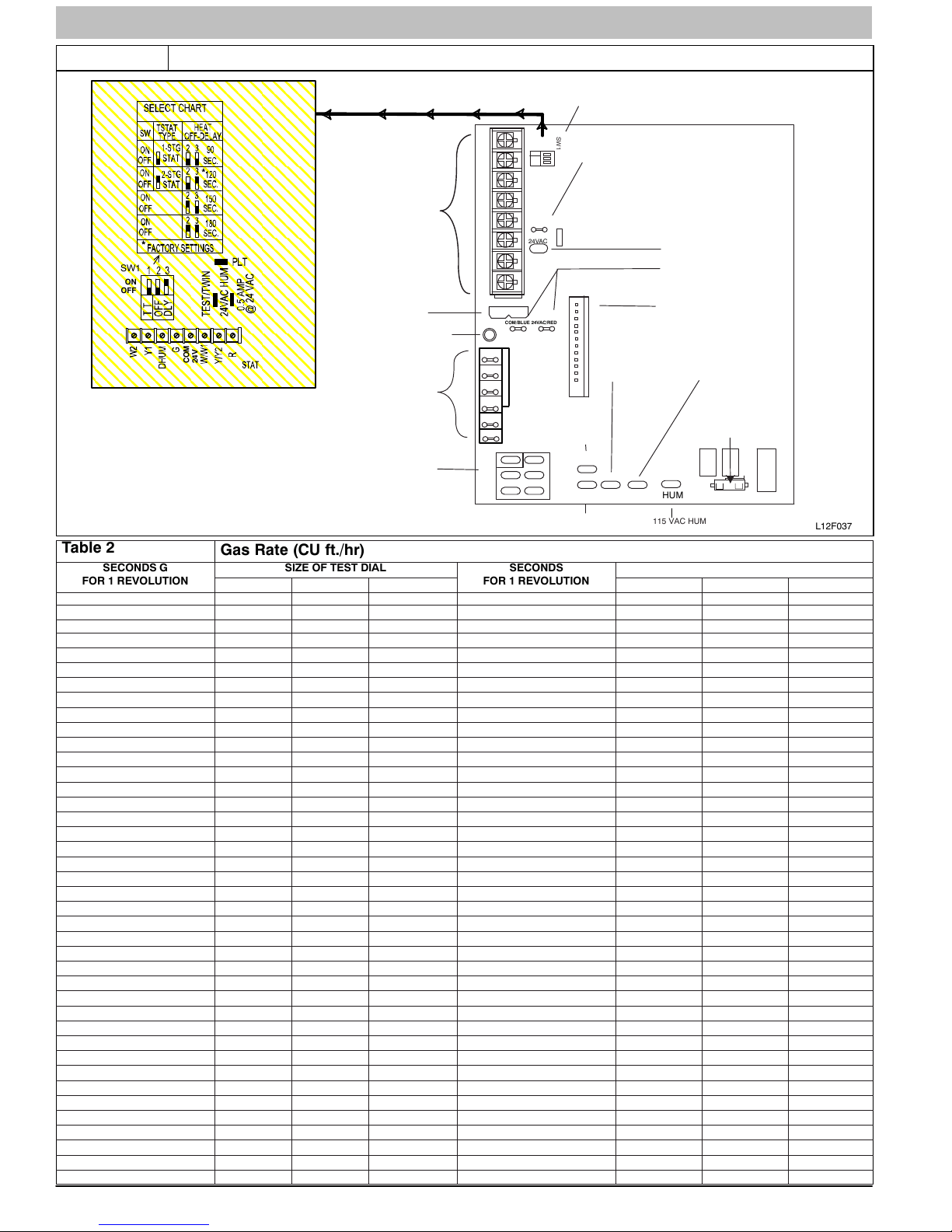

Figure 6 Multipoise Orientations

Electrical Controls and Wiring

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

There may be more than one electrical supply to the

furnace. Check accessories and cooling unit for

additional electrical supplies that must be shut off

during furnace servicing. Lock out and tag switch with

a suitable warning label.

WARNING

A93041

!

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow this warning could result in personal

injury or death, or property damage.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF

position and install a lockout tag. There may be more

than one disconnect switch. Lock out and tag switch

with a suitable warning label. Verify proper operation

after servicing.

ELECTRICAL OPERATION HAZARD

Failure to follow this caution may result in improper

furnace operation or failure of furnace.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation.

WARNING

!

CAUTION

General

These instructions are written as if the furnace is installed in an

upflow application. An upflow furnace application is where the

blower is located below the combustion and controls section of

the furnace, and conditioned air is discharged upward. Since

this furnace can be installed in any of the 4 positions shown in

Figure 6, you must revise your orientation to component

location accordingly.

The electrical ground and polarity for 115−V wiring must be

properly maintained. Refer to Figure 7 for field wiring

information and to Figure 15 for furnace wiring information.

NOTE: If the polarity is not correct, the STATUS LED on the

control will flash code 10 and prevent the furnace from heating.

The control system also requires an earth ground for proper

operation of the control and flame−sensing electrode.

The 24−V circuit contains an automotive−type, 3−amp. fuse

located on the control. (See Figure 4) Any shorts of the 24−V

wiring during installation, service, or maintenance will cause

this fuse to blow. If fuse replacement is required, use ONLY a

3−amp. fuse. The control LED display will be off when fuse

needs to be replaced.

Troubleshooting

Refer to the service label. (See Figure 14—Service Label)

The Troubleshooting Guide − Flow Chart (See Figure 16) can

be a useful tool in isolating furnace operation problems.

Beginning with the word “Start,” answer each question and

follow the appropriate arrow to the next item.

The Guide − Flow Chart will help to identify the problem or

failed component. After replacing any component, verify correct

operation sequence.

Proper instrumentation is required to service electrical controls.

The control in this furnace is equipped with a Status Code LED

(Light−Emitting Diode) to aid in installation, servicing, and

troubleshooting. Status codes can be viewed at the indicator in

blower door. The green furnace control LED is either be a

heartbeat, off, or a code composed of 1 or 2 digits. The first

digit is the number of short flashes, the second digit is the

number of long flashes.

440 04 4321 04 13

Specifications subject to change without notice.

Page 14

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

Figure 7 Heating and Cooling Application Wiring Diagram with Single−Stage Thermostat

FIELD 24-VOLT WIRING

FIELD 115-, 208/230-, 460-VOLT WIRING

FACTORY 24-VOLT WIRING

FACTORY 115-VOLT WIRING

BLK

WHT

GND

115-VOLT FIELD-

SUPPLIED

FUSED

DISCONNECT

BLK

WHT

JUNCTION

BOX

FIVE

WIRE

THREE-WIRE

HEATING-

ONLY

CONTROL

BOX

FURNACE

W2

COM

W/W1

Y/Y2

R

G

24-VOLT

TERMINAL

BLOCK

NOTE 2

WC Y RG

NOTE 1

NOTES: 1.

Connect Y/Y2-terminal as shown for proper operation.

2.

Some thermostats require a "C" terminal connection as shown.

3.

If any of the original wire, as supplied, must be replaced, use

same type or equivalent wire.

1-STAGE

THERMOSTAT

TERMINALS

CONDENSING

UNIT

FIELD-SUPPLIED

FUSED DISCONNECT

GND

208/230- OR

460-VOLT

THREE

PHASE

208/230VOLT

SINGLE

PHASE

A95236

For an explanation of status codes, refer to service label

located on control door or Figure 14, and the troubleshooting

guide which can be obtained from your distributor.

Retrieving Stored Fault Codes

NOTE: Fault codes cannot be retrieved if a thermostat signal

(24-V on W, Y, G, etc.) is present, or if any delays such as

blower off-delays are active.

The stored status codes will NOT be erased from the control

memory when 115- or 24-V power is interrupted. See the

Service Label (See Figure 14) for more information. The most

recent fault code may be retrieved as follows:

1. Leave 115-V power connected to furnace.

2. Observe the status LED through the blower door (the

lower door on upflow applications) indicator. Refer to the

Service Label (See Figure 14) to interpret the LED.

3. Remove the Main/Control door (the upper door on upflow

installations).

4. BRIEFLY (2−3 seconds) disconnect and reconnect ONE

of the main limit wires.

5. The LED will flash the last stored fault code. Refer to the

Service Label (See Figure 14) to interpret the LED.

6. A component test sequence will follow.

7. Reinstall the Main/Control door.

Component Self−Test

NOTE: The furnace control component test allows all

components to run for a short time; except the gas valve and

humidifier terminal HUM 24 VAC are not energized. The EAC-1

terminal is energized when the blower is energized. The HUM

terminal is energized when the inducer is energized. This

feature helps diagnose a system problem in case of a

component failure. The component test feature will not operate

if any thermostat signal is present at the control and not until all

time delays are completed.

To begin Component Self−Test:

1. Remove blower access door.

2. Disconnect the thermostat R lead from furnace control.

3. Manually close blower door switch.

Caution must be taken when manually closing this switch for

service purposes.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury, or death.

Blower access door switch opens 115−V power to

control. No component operation can occur unless

switch is closed. Caution must be taken when

manually closing this switch for service purposes.

4. For approximately 2 sec, short (jumper) the C terminal on

control to the TEST/TWIN 3/16—in. (5 mm)

quick-connect terminal on control until the LED goes off.

Remove jumper from terminals. (See Figure 4)

NOTE: If TEST/TWIN and C terminals are jumpered longer

than 2 sec., LED will flash code 10 and ignore component test

request.

Component test sequence is as follows:

a. LED will display previous status code 4 times.

b. Inducer motor starts and continues to run until Step g

of component test sequence.

c. After 7 seconds the hot surface igniter is energized for

15 sec., then off.

d. Blower motor operates on LO−HT speed for 10 sec.

e. Blower motor operates on HI−HT speed for 10 sec.

f. Blower motor operates on COOL speed for 10 sec.

g. Inducer motor goes to low speed for 10 sec., then stops.

5. Reconnect R lead to furnace control, remove tape from

blower door switch, and re-install blower door.

6. Verify furnace shut down by lowering thermostat setting

below room temperature.

7. Verify that furnace restarts by raising thermostat setting

above room temperature.

14 440 04 4321 04

Specifications subject to change without notice.

Page 15

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

8. Release blower door switch, reattach wire to “R” terminal

on furnace control board and replace blower door.

Care and Maintenance

!

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Never store flammable or combustible materials on,

near, or in contact with the furnace, such as:

1. Spray or aerosol cans, rags, brooms, dust

mops, vacuum cleaners, or other cleaning

tools.

2. Soap powders, bleaches, waxes or other

cleaning compounds, plastic or plastic

containers, gasoline, kerosene, cigarette lighter

fluid, dry cleaning fluids, or other volatile fluids.

3. Paint thinners and other painting compounds,

paper bags, or other paper products. Exposure

to these materials could lead to corrosion of the

heat exchangers.

For continuing high performance and to minimize possible

furnace failure, periodic maintenance must be performed on

this furnace. Consult your local dealer about proper frequency

of maintenance and the availability of a maintenance contract.

!

ELECTRICAL SHOCK AND FIRE HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Turn off the gas and electrical supplies to the furnace

and install lockout tag before performing any

maintenance or service. Follow the operating

instructions on the label attached to the furnace.

!

CARBON MONOXIDE POISONING AND FIRE

HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Never operate furnace without a filter or filtration

device installed. Never operate a furnace with filter or

filtration device access doors removed.

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs.

Use care and wear appropriate protective clothing,

safety glasses and gloves when handling parts, and

servicing furnaces.

The minimum maintenance on this furnace is as follows:

1. Check and clean air filter each month or more frequently

if required. Replace if torn.

2. Check blower motor and wheel for cleanliness each

heating and cooling season. Clean as necessary.

WARNING

WARNING

WARNING

!

CAUTION

3. Check electrical connections for tightness and controls

for proper operation each heating season. Service as

necessary.

4. Inspect burner compartment before each heating season

for rust, corrosion, soot or excessive dust. If necessary,

have furnace and burner serviced by a qualified service

agency.

5. Inspect the vent pipe/vent system before each heating

season for water leakage, sagging pipes or broken

fittings. Have vent pipes/vent system serviced by a

qualified service agency.

6. Inspect any accessories attached to the furnace such as

a humidifier or electronic air cleaner. Perform any service

or maintenance to the accessories as recommended in

the accessory instructions.

Cleaning and/or Replacing Air Filter

The air filter type may vary depending on the application or

orientation. The filter is external to the furnace casing. There

are no provisions for an internal filter with this furnace. See

“Filter Arrangement” under the “Installation” section of this

manual.

NOTE: If the filter has an airflow direction arrow, the arrow

must point toward the blower.

To clean or replace filters, proceed as follows:

!

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow this warning could result in personal

injury or death, or property damage.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF

position and install a lockout tag. There may be more

than one disconnect switch. Lock out and tag switch

with a suitable warning label. Verify proper operation

after servicing.

1. Turn off electrical supply to furnace.

2. Remove filter cabinet door.

3. Slide filter out of cabinet.

4. If equipped with permanent, washable filter, clean filter by

spraying cold tap water through filter in opposite direction

of airflow. Rinse filter and let dry. Oiling or coating of the

filter is not recommended.

5. If equipped with factory specified disposable media filter,

replace only with a factory specified media filter of the

same size.

6. Slide filter into cabinet.

7. Replace filter cabinet door.

8. Turn on electrical supply to furnace.

WARNING

Blower Motor and Wheel Maintenance

To ensure long life, economy, and high efficiency, clean

accumulated dirt and grease from blower wheel and motor

annually.

The inducer and blower motors are pre−lubricated and require

no additional lubrication. These motors can be identified by the

absence of oil ports on each end of the motor.

The following items should be performed by a qualified service

technician. Clean blower motor and wheel as follows:

1. Turn off electrical supply to furnace.

2. Remove blower door.

3. All factory wires can be left connected, but field

thermostat and accessory wiring may need to be

disconnected depending on their length and routing.

440 04 4321 04 15

Specifications subject to change without notice.

Page 16

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

4. If the vent and combustion air pipe passes through the

blower compartment, it will be necessary to remove the

pipes from the blower compartment.

Disconnect the vent and combustion air pipe by:

a. Loosen the clamps on the vent couplings and

combustion air pipe external to the furnace.

b. Separate the pipes from the couplings and move

them aside.

c. Loosen the clamps on the vent couplings and

combustion air pipe located on the blower shelf.

d. Separate the pipes from the blower compartment and

set aside.

e. Remove the couplings from the pipe adapters and set

aside.

f. After servicing the blower, reverse steps a through e.

g. Tighten all clamps 15 lb−in.

See Figure 8 for steps 5 through 14.

5. Remove screws securing blower assembly to blower

shelf and slide blower assembly out of furnace. Detach

ground wire and disconnect blower motor harness plugs

from blower motor.

NOTE: Blower wheel is fragile. Use care.

6. Clean blower wheel and motor by using a vacuum with

soft brush attachment. Be careful not to disturb balance

weights (clips) on blower wheel vanes. Do not bend

wheel or blades as balance will be affected.

7. If greasy residue is present on blower wheel, remove

wheel from the blower housing and wash it with an

appropriate degreaser. To remove wheel:

a. Mark blower wheel location on shaft before

disassembly to ensure proper reassembly.

b. Loosen setscrew holding blower wheel on motor

shaft.

NOTE: Mark blower mounting arms and blower housing so

each arm is positioned at the same hole location during

reassembly.

c. Mark blower wheel orientation and cutoff plate

location to ensure proper reassembly.

d. Remove screws securing cutoff plate and remove

cutoff plate from housing.

e. Remove bolts holding motor mounts to blower

housing and slide motor and mounts out of housing.

f. Remove blower wheel from housing.

g. Clean wheel per instructions on degreaser cleaner.

Do not get degreaser in motor.

8. Reassemble motor and blower wheel by reversing items

7b through 7f. Ensure wheel is positioned for proper

rotation.

9. Torque motor mounting bolts to 40 +/− 10 lb−in. when

reassembling.

10. Torque blower wheel set screw to 160 +/− 20 lb−in. when

reassembling.

11. Verify that blower wheel is centered in blower housing

and set screw contacts the flat portion of the motor shaft.

Loosen set screw on blower wheel and reposition if

necessary.

12. Spin the blower wheel by hand to verify that the wheel

does not rub on the housing.

13. Reinstall blower assembly in furnace.

14. Reinstall 2 screws securing blower assembly to blower

deck.

15. Reconnect blower leads to furnace control. Refer to

furnace wiring diagram, and connect thermostat leads if

previously disconnected.

NOTE: Be sure to attach ground wire and reconnect blower

harness plugs to blower motor.

Figure 8 Blower Assembly

MOTOR SHAFT FLAT

SET SCREW

GROMMET

MOTOR ARM

SCREW LOCATION

BLO HSG ASSY

BRACKET

BRACKET

ENGAGEMENT

DETAIL A

SEE DETAIL A

CUTOFF, BLOWER

WHEEL, BLOWER

BRACKET

POWER CHOKE

OR CAPACITOR

WHEN REQUIRED

SCREW

(GND)

MOTOR WHEEL HUB

A11584A

SCREW

A11584B

A11584C

A11584D

BLOWER HSG ASSY

MOTOR, BLOWER

A11584E

16 440 04 4321 04

Specifications subject to change without notice.

Page 17

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

6. Remove individual wires from terminals on gas valve.

!

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal

injury or death.

Blower door switch opens 115−V power to control. No

component operation can occur unless switch is closed.

Caution must be taken when manually closing this

switch for service purposes.

16. Downflow or horizontal furnaces with vent pipe through

furnace only:

a. Install and connect short piece of vent pipe inside

furnace to existing vent.

b. Connect vent connector to vent elbow.

17. Turn on electrical supply. Manually close blower door

switch. Use a piece of tape to hold switch closed. Check

for proper rotation and speed changes between heating

and cooling by jumpering R to G and R to Y/Y2 on

furnace control thermostat terminals. If outdoor

temperature is below 70_F (21_C), turn off circuit breaker

to outdoor unit before running furnace in the cooling

cycle. Turn outdoor circuit breaker on after completing

cooling cycle. (See Figure 4)

NOTE: If R−W/W1 thermostat terminals are jumpered at the

time blower door switch is closed, blower will run for 90 sec

before beginning a heating cycle.

a. Perform component self−test as shown at the bottom

of the SERVICE label, located on the control door.

b. Verify blower is rotating in the correct direction

18. If furnace is operating properly, RELEASE BLOWER

DOOR SWITCH. Remove any jumpers or reconnect any

disconnected thermostat leads. Replace blower door.

19. Turn on gas supply and cycle furnace through one

complete heating cycle. Verify the furnace temperature

rise as shown in Adjustments Section. Adjust

temperature rise as shown in Adjustments Section.

WARNING

Cleaning Burners and Flame Sensor

The following items must be performed by a qualified service

technician. If the burners develop an accumulation of light dirt

or dust, they may be cleaned by using the following procedure:

NOTE: Use a back-up wrench on the gas valve to prevent the

valve from rotating on the manifold or damaging the mounting

to the burner assembly.

!

ELECTRICAL SHOCK AND FIRE HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Turn off the gas and electrical supplies to the furnace

and install lockout tag before performing any

maintenance or service. Follow the operating

instructions on the label attached to the furnace.

Refer to Figure 9.

1. Disconnect power at external disconnect, fuse or circuit

breaker.

2. Turn off gas at external shut-off or gas meter.

3. Remove control door and set aside.

4. Turn electric switch on gas valve to OFF.

5. Disconnect the gas pipe from gas valve and remove pipe

from the furnace casing.

WARNING

7. Disconnect Hot Surface Igniter (HSI) wires from HSI.

8. Disconnect Flame Sensor wire from Flame Sensor.

9. Support the manifold and remove the four screws that

secure the manifold assembly to the burner assembly

and set aside. Note the location of the green/yellow wire

and ground terminal.

10. Inspect the orifices in the manifold assembly for

blockages or obstructions. Remove orifice and clean or

replace orifice.

11. Remove the four screws that attach the top plate of the

casing to the furnace.

12. Raise top plate up slightly and prop it up with a small

piece of wood or folded cardboard.

13. Support the burner assembly and remove the screws

that attach the burner assembly to the heat exchanger

cell panel.

14. Remove wires from both rollout switches.

15. Slide one−piece burner out of slots on sides of burner

assembly.

16. Remove the flame sensor from the burner assembly.

17. (Optional) Remove the Hot Surface Igniter (HSI) and

bracket from the burner assembly.

18. Check igniter resistance. Nominal resistance is 40 to 70

ohms at room temperature and is stable over the life of

the igniter.

19. Clean burner with a brush and a vacuum.

20. Clean the flame sensor with fine steel wool (0000 grade).

Do not use sand paper or emery cloth.

Figure 9 Burner Assembly

BURNER SUPT. ASSY

BURNER ASSY

FLAME ROLL−OUT SWITCH

FLAME SENSOR

(

BELOW BURNER)

Representative drawing only, some models may vary in appearance.

To reinstall burner assembly:

1. Install the Hot Surface Igniter (HSI) and bracket in burner

assembly.

2. Install flame sensor on burner.

3. Align the edges of the one-piece burner with the slots in

the burner assembly and slide the burners forward until

they are fully seated in the burner assembly.

4. Align the orifices in the manifold assembly with the

support rings on the end of the burner.

5. Insert the orifices in the support rings of the burners.

NOTE: If manifold does not fit flush against the burner, do not

force the manifold on the burner assembly. The burners are not

fully seated forward in the burner assembly. Remove the

manifold and check burner positioning in the burner assembly

assembly before re-installing the manifold.

L11F064

440 04 4321 04 17

Specifications subject to change without notice.

Page 18

SERVICE AND TECHNICAL SUPPORT MANUAL Gas Furnace: (F/G)9MXT

6. Attach the green/yellow wire and ground terminal to one

of the manifold mounting screws.

7. Install the remaining manifold mounting screws.

8. Check the igniter alignment. See Figure 9, Figure 10

and Figure 11.

Figure 10 Igniter Position − Top View

1-1/4-in.

(31.8)

2-1/2-in.

(64.4)

A11405

Figure 11 Igniter Position − Side View

2ïin.

50 mm

3/8ïin.

9.6 mm

3/16ïin.

4.6 mm

+ 1/32

1/10ïin.

ï 1/16ïin.

+0.8

2.5 mm

ï1.5 mm

L12F041

9. Attach the wires to the roll-out switches.

10. Align the burner assembly with the openings in the

primary cell inlet panel and attach the burner assembly to

the cell panel.

11. Connect the wire for the flame sensor.

12. Connect the wire for the Hot Surface Igniter.

NOTE: Use propane-resistant pipe dope to prevent leaks. Do

not use Teflon tape.

13. Install the gas pipe to the gas valve.

!

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Never purge a gas line into a combustion chamber.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made

specifically for the detection of leaks to check all

connections. A fire or explosion may result causing

property damage, personal injury or loss of life.

14. Check for gas leaks with a commercially available soap

solution made specifically for the detection of leaks.

WARNING

15. Turn gas on at electric switch on gas valve and at

external shut-off or meter

16. Turn power on at external disconnect, fuse or circuit

breaker.

17. Run the furnace through two complete heating cycles to

check for proper operation

18. Install control door when complete.

Servicing Hot Surface Igniter

The igniter does NOT require annual inspection. Check igniter

resistance before removal. Refer to Figure 9, Figure 10 and

Figure 11.

1. Turn off gas and electrical supplies to furnace.

2. Remove control door.

3. Disconnect igniter wire connection.

4. Check igniter resistance. Igniter resistance is affected by

temperature. Only check resistance when the igniter is at

room temperature.

a. Using an ohm meter, check resistance across both

igniter leads in connector.

b. Cold reading should be between 40 ohms and 70

ohms.

5. Remove igniter assembly.

a. Using a 1/4−in. driver, remove the two screws

securing the igniter mounting bracket to the burner

assembly (See Figure 9)

b. Carefully withdraw the igniter and bracket assembly

through the front of the burner assembly without

striking the igniter on surrounding parts.

c. Inspect igniter for signs of damage or failure.

d. If replacement is required, remove the screw that

secures the igniter on igniter bracket and remove the

igniter.

6. To replace igniter and bracket assembly, reverse items

5a through 5d.

7. Reconnect igniter harness to the igniter, dressing the

igniter wires to ensure there is no tension on the igniter

itself. (See Figure 9)

8. Turn on gas and electrical supplies to furnace.

9. Verify igniter operation by initiating control board self−test

feature or by cycling thermostat.

10. Replace control door.

Flushing Collector Box and Drainage System

!

ELECTRICAL SHOCK AND FIRE HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Turn off the gas and electrical supplies to the furnace

and install lockout tag before performing any

maintenance or service. Follow the operating

instructions on the label attached to the furnace.

1. Turn off gas and electrical supplies to furnace.

2. Remove control door.

3. Disconnect pressure switch tube from pressure switch

port.

NOTE: Ensure the pressure switch tube disconnected from the