ICP F9MXE0801716A1, F9MXE0401410A1, F9MXE0601714A1, (F/G)9MVT, (F/G)9MXT Installation Instructions Manual

...Page 1

HJJ(J|)i(i)))_J))1))

These instructions must be read and understood completely before attempting installation.

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and NOTE

The signal words DANGER, WARNING,

CAUTION, and NOTE are used to identify levels of

hazard seriousness. The signal word DANGER is

only used on product labels to signify an immediate

hazard. The signal words WARNING, CAUTION,

and NOTE will be used on product labels and

throughout this manual and other manual that may

apply to the product.

DANGER - Immediate hazards which will result in

severe personal injury or death.

WARNING - Hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which

may result in minor personal injury or product or

property damage.

NOTE - Used to highlight suggestions which will

result in enhanced installation, reliability, or

operation.

TABLE OF CONTENTS

SAFETY CONSiDERATiONS ....................................... 3

iNTRODUCTiON ............................................... 4

CODES AND STANDARDS ........................................ 4

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS PROCEDURE ........... 5

DIMENSIONS ................................................. 6

LOCATION ................................................... 7

LOCATION RELATIVE TO COOLING EQUIPMENT ........................ 9

AiR FOR COMBUSTION AND VENTiLATiON ............................ 9

CONDENSATE TRAP ............................................ 12

iNSTALLATION ................................................ 18

UPFLOW INSTALLATION ......................................... 18

DOWNFLOW INSTALLATION ....................................... 19

HORIZONTAL INSTALLATION ...................................... 22

FILTER ARRANGEMENT ......................................... 24

AiR DUCTS ................................................... 26

GAS PiPiNG .................................................. 26

ELECTRICAL CONNECTIONS ...................................... 28

J-BOX iNSTALLATION ........................................... 29

VENTING .................................................... 35

SPECIAL VENTING REQUIREMENTS FOR INSTALLATIONS iN CANADA ........ 35

DIRECT VENT / 2-PIPE SYSTEM ................................... 41

VENTILATED COMBUSTION AiR .................................... 41

TERMINATION REQUIREMENTS FOR THE

PROVINCES OF ALBERTA AND SASKATCHEWAN ....................... 41

iNSTALLING THE VENT TERMINATION ............................... 46

MAXIMUM EQUIVALENT VENT LENTH ............................... 50

Signal Words in Manuals

The signal word WARNING is used throughout

this manual in the following manner:

The signal word CAUTION is used throughout

this manual in the following manner:

Signal Words on Product Labeling

Signal words are used in combination with

colors and/or pictures or product labels.

Z_ Safety-alert symbol

When you see this symbol on the unit and in

instructions or manuals, be alert to the

potential for personal injury.

MAXIMUM ALLOWABLE EXPOSED VENT LENGTHS iN

UNCONDITIONED SPACE - SINGLE STAGE .......................... 51

MAXIMUM ALLOWABLE EXPOSED VENT LENGTHS iN

UNCONDITIONED SPACE - TWO-STAGE ............................ 52

IS09001)

Use of the AHRI Certified TM Mark indicates a

manufacturer's participation in the program,

For verification of certification for individual

products, go to www,ahridirectory.org .

INSTALLER: Affix these instructions on or adjacent to the

furnace,

CONSUMER: Retain these instructions for future

reference.

Portions of the text and tables are reprinted from NFPA 54/ANSI Z223.1-2009_;P, with permission of National Fire Protection Association, Quincy, MA 02269 and American Gas Association, Washington, DC

20001. This reprinted material is not the complete and official position of the NFPA or ANSI, on the referenced subject, which is represented only by the standard in its entirety,

PrintedinU.S.A. 440 01 4001 02 Sept.2011

Page 2

Required Notice for Massachusetts Installations

Important

The Commonwealth of Massachusetts requires compliance with regulation 248 CMR as follows:

5.08: Modifications to NFPA-54, Chapter 10

2) Revise 10.8.3 by adding the following additional requirements:

(a)

For all side wall horizontally vented gas fueled equipment installed in every dwelling, building or structure used in whole or in part for residential

purposes, including those owned or operated by the Commonwealth and where the side wall exhaust vent termination is less than seven (7) feet

above finished grade in the area of the venting, including but not limited to decks and porches, the following requirements shall be satisfied:

1,

INSTALLATION OF CARBON MONOXIDE DETECTORS. At the time of installation of the side wall horizontal vented gas fueled equipment, the

installing plumber or gasfitter shall observe that a hard wired carbon monoxide detector with an alarm and battery back-up is installed on the floor

level where the gas equipment is to be installed, in addition, the installing plumber or gasfitter shall observe that a battery operated or hard wired

carbon monoxide detector with an alarm is installed on each additional level of the dwelling, building or structure served by the side wall

horizontal vented gas fueled equipment. It shall be the responsibility of the property owner to secure the services of qualified license professionals

for the installation of hard wired carbon monoxide detectors.

a. In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic, the hard wired carbon

monoxide detector with alarm and battery back-up may be installed on the next adjacent floor level.

b. In the event that the requirements of this subdivision can not be met at the time of completion of installation, the owner shall have a period of

thirty (30) days to comply with the above requirement; provided, however, that during said thirty (30) day period, a battery operated carbon

monoxide detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon monoxide detector as required in accordance with the above provisions shall

comply with NFPA 720 and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mounted to the exterior of the building at a minimum height of eight (8) feet

above grade directly in line with the exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment. The sign shall

read, in print size no less than one-half (1/2) inch in size, "GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS".

4. INSPECTION. The state of local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve the installation unless,

upon inspection, the inspector observes carbon monoxide detectors and signage installed in accordance with the provisions of 248 CMR

5.08(2)(a) 1 through 4.

(b) EXEMPTIONS: The following equipment is exempt from 248 CMR 5.08(2)(a) 1 through 4:

1. The equipment listed in Chapter 10 entitled "Equipment Not Required To Be Vented" in the most current edition of NFPA 54 as adopted by the

Board; and

2. Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate from the dwelling, building or

structure used in whole or in part for residential purposes.

(c)

MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM PROVIDED. When the manufacturer of Product Approved side wall

horizontally vented gas equipment provides a venting system design or venting system components with the equipment, the instructions provided by

the manufacturer for installation of the equipment and the venting system shall include:

1. Detailed instructions for the installation of the venting system design or the venting system components; and

2. A complete parts list for the venting system design or venting system.

(d)

MANUFACTURER REQUIREMENTS - GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED. When the manufacturer of a Product Approved side

wall horizontally vented gas fueled equipment does not provide the parts for venting the flue gases, but identifies "special venting systems", the

following requirements shall be satisfied by the manufacturer:

1. The referenced "special venting system" instructions shall be included with the appliance or equipment installation instructions; and

2. The "special venting systems" shall be Product Approved by the Board, and the instructions for that system shall include a parts list and detailed

installation instructions.

(e)

A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment, all venting instructions, all parts lists

for venting instructions, and/or all venting design instructions shall remain with the appliance or equipment at the completion of the installation.

For questions regarding these requirements, please contact the Commonwealth of Massachusetts Board of State Examiners of Plumbers and Gas

Fitters, 239 Causeway Street, Boston, MA 02114. 617-727-9952

2 Specifications are subject to change without notice. 440 01 4001 02

Page 3

Safety Considerations

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in dangerous

operation, personal injury, death, or property damage.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide

poisoning, explosion, fire, electrical shock, or other

conditions which may cause personal injury or property

damage. Consult a qualified service agency, local gas

supplier, or your distributor or branch for information or

assistance. The qualified service agency must use

only factory-authorized and listed kits or accessories

when modifying this product.

FURNACE RELIABILITY HAZARD

Failure to follow this caution may result in unit

component damage.

Application of this furnace should be indoors with

special attention given to vent sizing and material, gas

input rate, air temperature rise, unit leveling, and unit

sizing.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock,

or other conditions which may cause personal injury or property

damage. Consult a qualified service agency, local gas supplier,

or your distributor or branch for information or assistance. The

qualified installer or agency must use only factory-authorized

and listed kits or accessories when modifying this product.

Refer to the individual instructions packaged with the kits or

accessories when installing.

Installing and servicing heating equipment can be hazardous

due to gas and electrical components. Only trained and

qualified personnel should install, repair, or service

heating equipment. Untrained personnel can perform basic

maintenance functions such as cleaning and replacing air

filters. All other operations must be performed by trained

service personnel. When working on heating equipment,

observe precautions in literature, on tags, and on labels

attached to or shipped with furnace and other safety

precautions that may apply.

These instructions cover minimum requirements and conform

to existing national standards and safety codes. In some

instances, these instructions exceed certain local codes and

ordinances, especially those that may not have kept up with

changing residential construction practices. We require these

instructions as a minimum for a safe installation.

Follow all safety codes. Wear safety glasses, protective

clothing, and work gloves. Have a fire extinguisher available.

Read these instructions thoroughly and follow all warnings or

cautions included in literature and attached to the unit.

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing, safety

glasses and gloves when handling parts, and servicing

furnaces.

This is the safety-alert symbol /N •When you see this symbol

on the furnace and in instructions or manuals, be alert to the

potential for personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety-alert symbol.

DANGER identifies the most serious hazards which will result

in severe personal injury or death. WARNING signifies a

hazard which could result in personal injury or death.

CAUTION is used to identify hazards which may result in minor

personal injury or product and property damage. NOTE is used

to highlight suggestions which will result in enhanced

installation, reliability, or operation.

1. Use only with type of gas approved for this furnace.

Refer to the furnace rating plate.

2. Install this furnace only in a location and position as

specified in the "Location" section of these instructions.

3. Provide adequate combustion and ventilation air to the

furnace space as specified in "Air for Combustion and

Ventilation" section.

4. Combustion products must be discharged outdoors.

Connect this furnace to an approved vent system only,

as specified in the "Venting" section of these

instructions.

5. Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically

for the detection of leaks to check all connections, as

specified in the "Gas Piping" section.

6. Always install furnace to operate within the furnace's

intended temperature-rise range with a duct system

which has an external static pressure within the

allowable range, as specified in the "Start-Up,

Adjustments, and Safety Check" section. See furnace

rating plate.

7. When a furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space

containing the furnace, the return air shall also be

handled by duct(s) sealed to the furnace casing and

terminating outside the space containing the furnace.

See "Air Ducts" section.

8. A gas-fired furnace for installation in a residential

garage must be installed as specified in the warning box

in the "Location" section. (See Figure 4)

9. The furnace may be used for construction heat provided

that the furnace installation and operation complies with

the first CAUTION in the LOCATION section on page 7

of these instructions.

10. These Multipoise Gas-Fired Furnaces are CSA

design-certified for use with natural and propane gases

(see furnace rating plate) and for installation in alcoves,

attics, basements, closets, utility rooms, crawlspaces,

and garages. The furnace is factory-shipped for use

with natural gas. A CSA (A.G.A. and C.G.A.) listed

accessory gas conversion kit is required to convert

furnace for use with propane gas.

11. See Table 1 for required clearances to combustible

construction.

440 01 4001 02 Specificati ..... bject to change without notice. 3

Page 4

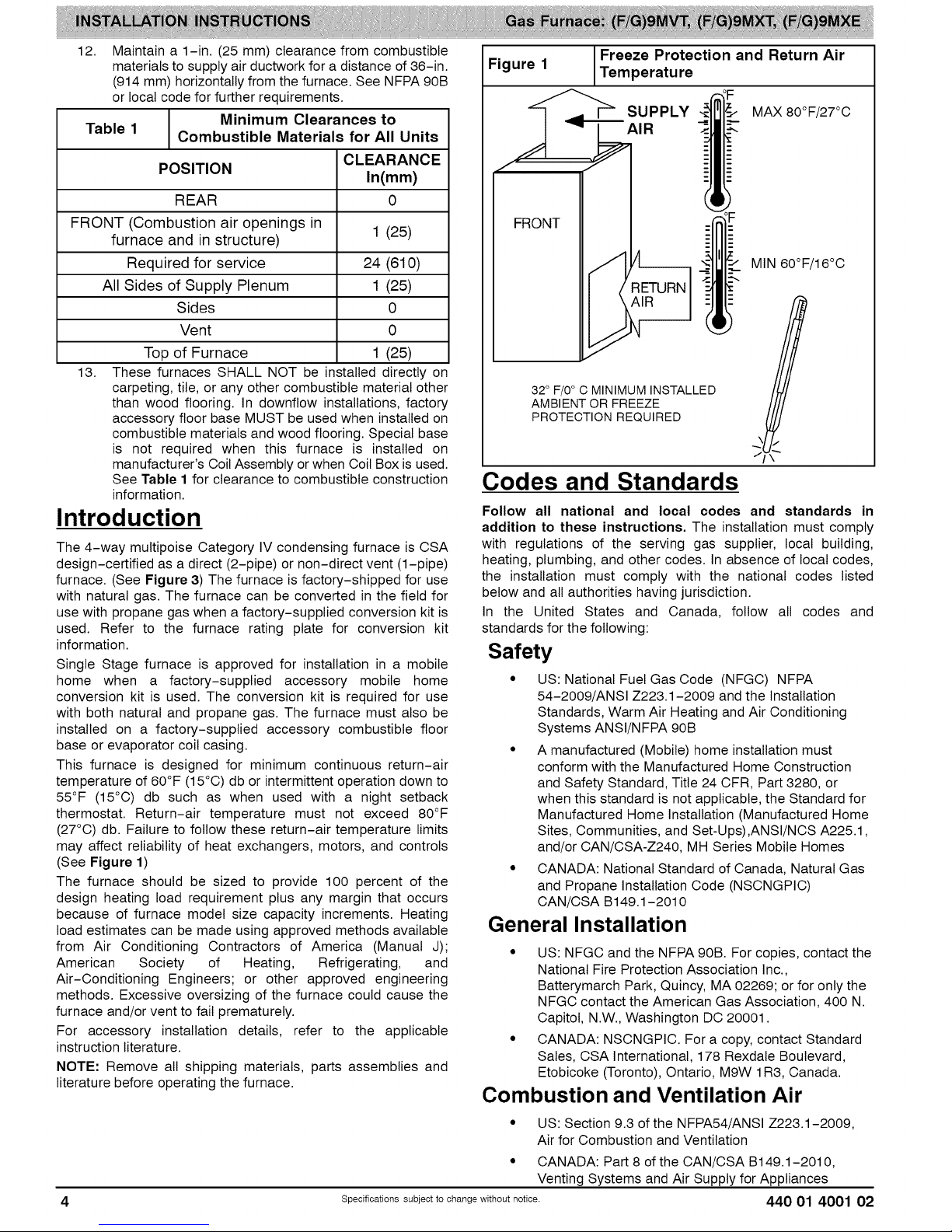

12.

Maintain a 1-in. (25 mm) clearance from combustible

materials to supply air ductwork for a distance of 36-in.

(914 mm) horizontally from the furnace. See NFPA 90B

or local code for further requirements.

Minimum Clearances to

Table 1 Combustible Materials for All Units

POSITION

CLEARANCE

In(mm)

REAR 0

FRONT (Combustion air openings in

furnace and in structure) 1 (25)

Required for service 24 (610)

All Sides of Supply Plenum 1 (25)

Sides 0

Vent 0

Top of Furnace 1 (25)

13. These furnaces SHALL NOT be installed directly on

carpeting, tile, or any other combustible material other

than wood flooring. In downflow installations, factory

accessory floor base MUST be used when installed on

combustible materials and wood flooring. Special base

is not required when this furnace is installed on

manufacturer's CoilAssemblyorwhen Coil Box is used.

See Table 1 for clearance to combustible construction

information.

Introduction

The 4-way multipoise Category IV condensing furnace is CSA

design-certified as a direct (2-pipe) or non-direct vent (1-pipe)

furnace. (See Figure 3) The furnace is factory-shipped for use

with natural gas. The furnace can be converted in the field for

use with propane gas when a factory-supplied conversion kit is

used. Refer to the furnace rating plate for conversion kit

information.

Single Stage furnace is approved for installation in a mobile

home when a factory-supplied accessory mobile home

conversion kit is used. The conversion kit is required for use

with both natural and propane gas. The furnace must also be

installed on a factory-supplied accessory combustible floor

base or evaporator coil casing.

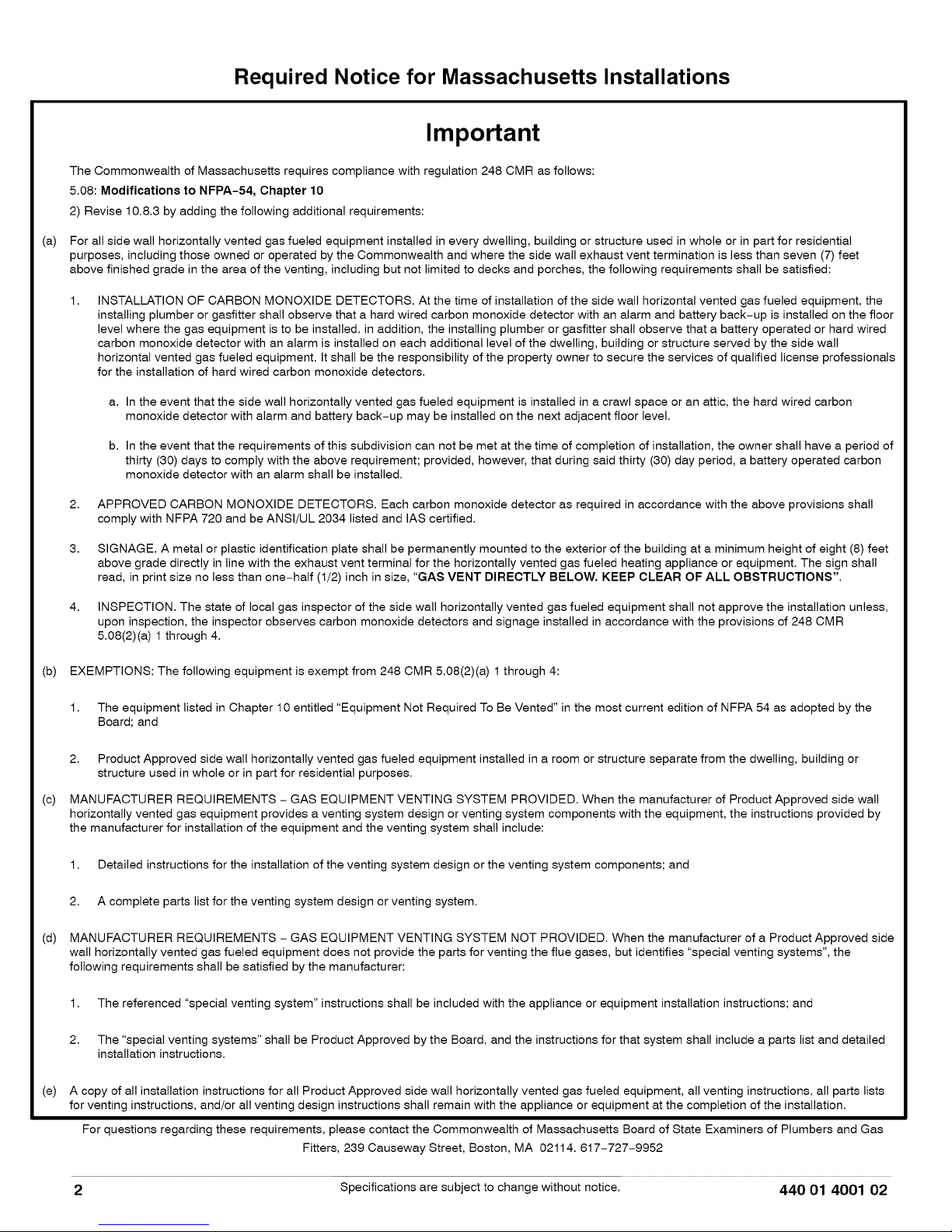

This furnace is designed for minimum continuous return-air

temperature of 60°F (15°C) db or intermittent operation down to

55°F (15°C) db such as when used with a night setback

thermostat. Return-air temperature must not exceed 80°F

(27°C) db. Failure to follow these return-air temperature limits

may affect reliability of heat exchangers, motors, and controls

(See Figure 1)

The furnace should be sized to provide 100 percent of the

design heating load requirement plus any margin that occurs

because of furnace model size capacity increments. Heating

load estimates can be made using approved methods available

from Air Conditioning Contractors of America (Manual J);

American Society of Heating, Refrigerating, and

Air-Conditioning Engineers; or other approved engineering

methods. Excessive oversizing of the furnace could cause the

furnace and/or vent to fail prematurely.

For accessory installation details, refer to the applicable

instruction literature.

NOTE: Remove all shipping materials, parts assemblies and

literature before operating the furnace.

Figure 1

I Freeze Protection and Return Air

Temperature

SUPPLY MAX80°F/27°C

_AIR

FRONT

MIN 60°F/16°C

32° F/0° C MINIMUM INSTALLED

AMBIENT OR FREEZE

PROTECTION REQUIRED

J

Codes and Standards

Follow all national and local codes and standards in

addition to these instructions. The installation must comply

with regulations of the serving gas supplier, local building,

heating, plumbing, and other codes. In absence of local codes,

the installation must comply with the national codes listed

below and all authorities having jurisdiction.

In the United States and Canada, follow all codes and

standards for the following:

Safety

• US: National Fuel Gas Code (NFGC) NFPA

54-2009/ANSI Z223.1-2009 and the Installation

Standards, Warm Air Heating and Air Conditioning

Systems ANSI/NFPA 90B

• A manufactured (Mobile) home installation must

conform with the Manufactured Home Construction

and Safety Standard, Title 24 CFR, Part 3280, or

when this standard is not applicable, the Standard for

Manufactured Home Installation (Manufactured Home

Sites, Communities, and Set-Ups),ANSI/NCS A225.1,

and/or CAN/CSA-Z240, MH Series Mobile Homes

• CANADA: National Standard of Canada, Natural Gas

and Propane Installation Code (NSCNGPIC)

CAN/CSA B149.1-2010

General Installation

• US: NFGC and the NFPA 90B. For copies, contact the

National Fire Protection Association Inc.,

Batterymarch Park, Quincy, MA 02269; or for only the

NFGC contact the American Gas Association, 400 N.

Capitol, N.W., Washington DC 20001.

• CANADA: NSCNGPIC. For a copy, contact Standard

Sales, CSA International, 178 Rexdale Boulevard,

Etobicoke (Toronto), Ontario, M9W 1R3, Canada.

Combustion and Ventilation Air

• US: Section 9.3 ofthe NFPA54/ANSI Z223.1-2009,

Air for Combustion and Ventilation

• CANADA: Part 8 of the CAN/CSA B149.1-2010,

Venting Systems and Air Supply for Appliances

Specificati ..... bject to change without notice. 440 01 4001 02

Page 5

Duct Systems

• US and CANADA: Air Conditioning Contractors

Association (ACCA) Manual D, Sheet Metal and Air

Conditioning Contractors National Association

(SMACNA), or American Society of Heating,

Refrigeration, and Air Conditioning Engineers (ASHRAE)

2005 Fundamentals Handbook Chapter 35.

Acoustical Lining and Fibrous Glass

Duct

• US and CANADA: current edition of SMACNA, NFPA

90B as tested by UL Standard 181 for Class I Rigid Air

Ducts

Gas Piping and Gas Pipe Pressure

Testing

• U.S.A.: NFPA 54/ANSI Z223.1-2009, NFGC; Chapters

5, 6, 7, and 8 and national plumbing codes.

• CANADA: CAN/CSA-B149.1-2010, Parts 4, 5, 6 and

9.

In the state of Massachusetts:

• This product must be installed by a licensed plumber or

gas fitter.

• When flexible connectors are used, the maximum

length shall not exceed 36-in. (914 mm).

• When lever type gas shutoffs are used they shall be

T-handle type.

• The use of copper tubing for gas piping is not

approved by the state of Massachusetts.

Electrical Connections

• U.S.A.: National Electrical Code (NEC) ANSI/NFPA

70-2011

• CANADA: Canadian Electrical Code CSA C22.1

Electrostatic Discharge (ESD)

Precautions Procedure

FURNACE RELIABILITY HAZARD

Failure to follow this caution may result in unit com-

3onent damage.

Electrostatic discharge can affect electronic compon-

ents. Take precautions during furnace installation and

servicing to protect the furnace electronic control. Pre-

cautions will prevent electrostatic discharges from per-

sonnel and hand tools which are held during the pro-

cedure. These precautions will help to avoid exposing

the control to electrostatic discharge by putting the

furnace, the control, and the person at the same elec-

trostatic potential.

1. Disconnect all power to the furnace. Multiple

disconnects may be required. DO NOT TOUCH THE

CONTROL OR ANY WIRE CONNECTED TO THE

CONTROL PRIOR TO DISCHARGING YOUR BODY'S

ELECTROSTATIC CHARGE TO GROUND.

2. Firmly touch the clean, unpainted, metal surface of the

furnace chassis which is close to the control. Tools held

in a person's hand during grounding will be satisfactorily

discharged.

3. After touching the chassis, you may proceed to service

the control or connecting wires as long as you do nothing

to recharge your body with static electricity (for example;

DO NOT move or shuffle your feet, do not touch

ungrounded objects, etc.).

4. If you touch ungrounded objects (and recharge your

body with static electricity), firmly touch a clean,

unpainted metal surface of the furnace again before

touching control or wires.

5. Use this procedure for installed and uninstatled

(ungrounded) furnaces.

6. Before removing a new control from its container,

discharge your body's electrostatic charge to ground to

protect the control from damage. If the control is to be

installed in a furnace, follow items 1 through 4 before

bringing the control or yourself in contact with the

furnace. Put all used and new controls into containers

before touching ungrounded objects.

7. An ESD service kit (available from commercial sources)

may also be used to prevent ESD damage.

Accessories

See Specification Sheets for a list of accessories for this

product.

Table 2

QUANTITY COMPONENT NAME

1 Air Intake Pipe Flange

1 Vent Pipe Flange

2 Coupling Flange Gaskets

10 Sharp Tip Screws (Vent and Inlet Flanges)

1 Vent Pipe Coupling

2 Vent Pipe Coupling Clamps

1 Pressure Switch Tube

1

1 Drain Tube Elbow

1 Drain Extension Tube

2 Drain Tube Clamps

1 Drain Line Grommet

1 Gas Line Grommet

1 Gas Line Knockout Plug

1 Junction Box Cover

1 Junction Box Base

1 Green Ground Screw

3 Blunt Tip Screws (Junction Box)

1 Thermostat Wire Grommet

Loose Parts Bag Contents

(shipped in blower compartment)

Outlet Choke Plate (used with 40k BTUH

furnaces, only)

440 01 4001 02 Specificati ..... bject to change without notice. 5

Page 6

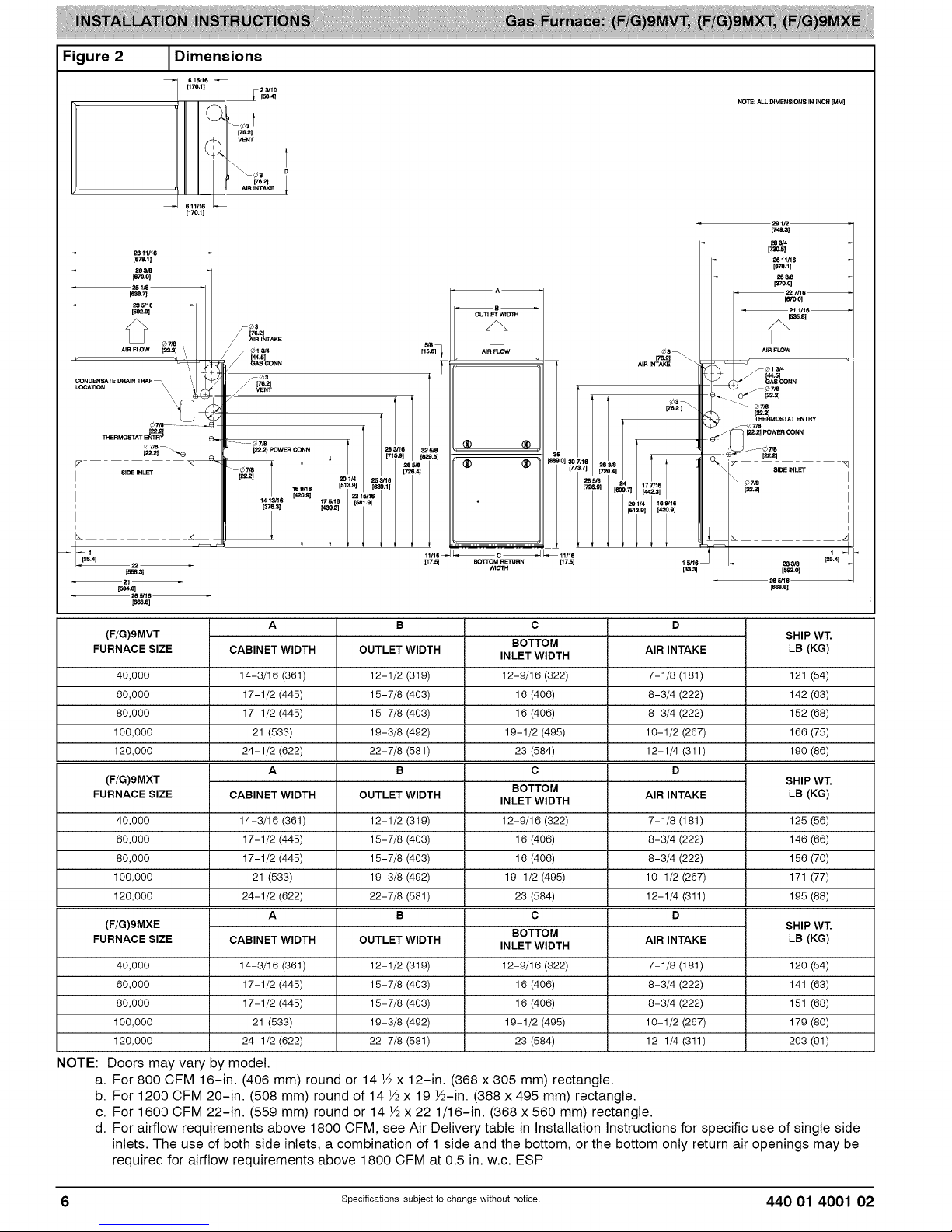

Figure 2

LOCATION

JDimensions

615/1(

[17&1] 23/10

611116

[17o41

NOlle; ALL DIMENSIONS IN INCH [MM]

OUTLET WIDTH

AIR FLOW

[22.2]POWERCONN

(F/G)9MVT

FURNACE SIZE

40,000

60,000

80,000

100,000

120,000

(F/G)9MXT

FURNACE SIZE

40,000

60,000

80,000

100,000

120,000

(F/G)9MXE

FURNACE SIZE

40,000 14-3/16 (361) 12-1/2 (319) 7-1/8 (181)

60,000 17-1/2 (445) 15-7/8 (403) 8-3/4 (222)

80,000 17-1/2 (445) 15-7/8 (403) 8-3/4 (222)

100,000 21 (533) 19-3/8 (492) 10-1/2 (267)

120,000 24-1/2 (622) 22-7/8 (581) 12-1/4 (311)

A

CABINET WIDTH

14-3/16 (361)

17-1/2 (445)

17-1/2 (445)

21 (533)

24-1/2 (622)

A

CABINET WIDTH

14-3/16 (361)

17-1/2 (445)

17-1/2 (445)

21 (533)

24-1/2 (622)

A

CABINET WIDTH

B

OUTLET WIDTH

12-1/2 (319)

15-7/8 (403)

15-7/8 (403)

19-3/8 (492)

22-7/8 (581)

B

OUTLET WIDTH

12-1/2 (319)

15-7/8 (403)

15-7/8 (403)

19-3/8 (492)

22-7/8 (581)

B

OUTLET WIDTH

C

BOTTOM

INLET WIDTH

12-9/16 (322)

16 (406)

16 (406)

19-1/2 (495)

23 (584)

C

BOTTOM

INLET WIDTH

12-9/16 (322)

16 (406)

16 (406)

19-1/2 (495)

23 (584)

C

BOTTOM

INLET WIDTH

12-9/16 (322)

16 (406)

16 (406)

19-1/2 (495)

23 (584)

D

AIR INTAKE

7-1/8 (181)

8-3/4 (222)

8-3/4 (222)

10-1/2 (267)

12-1/4 (311)

D

AIR INTAKE

7-1/8 (181)

8-3/4 (222)

8-3/4 (222)

10-1/2 (267)

12-1/4 (311)

D

AIR INTAKE

NOTE: Doors may vary by model.

a. For 800 CFM 16-in. (406 mm) round or 14 ½ x 12-in. (368 x 305 mm) rectangle.

b. For 1200 CFM 20-in. (508 mm) round of 14 ½ x 19 ½-in. (368 x 495 mm) rectangle.

c. For 1600 CFM 22-in. (559 mm) round or 14 ½ x 22 1/16-in. (368 x 560 mm) rectangle.

d. For airflow requirements above 1800 CFM, see Air Delivery table in Installation Instructions for specific use of single side

inlets. The use of both side inlets, a combination of 1 side and the bottom, or the bottom only return air openings may be

required for airflow requirements above 1800 CFM at 0.5 in. w.c. ESP

SHIP WT,

LB (KG)

121 (54)

142 (63)

152 (68)

166 (75)

190 (86)

SHIP WT,

LB (KG)

125 (56)

146 (66)

156 (70)

171 (77)

195 (88)

SHIP WT,

LB (KG)

120 (54)

141 (63)

151 (68)

179 (80)

203 (91)

6 Specificati ..... bject to change without notice. 440 01 4001 02

Page 7

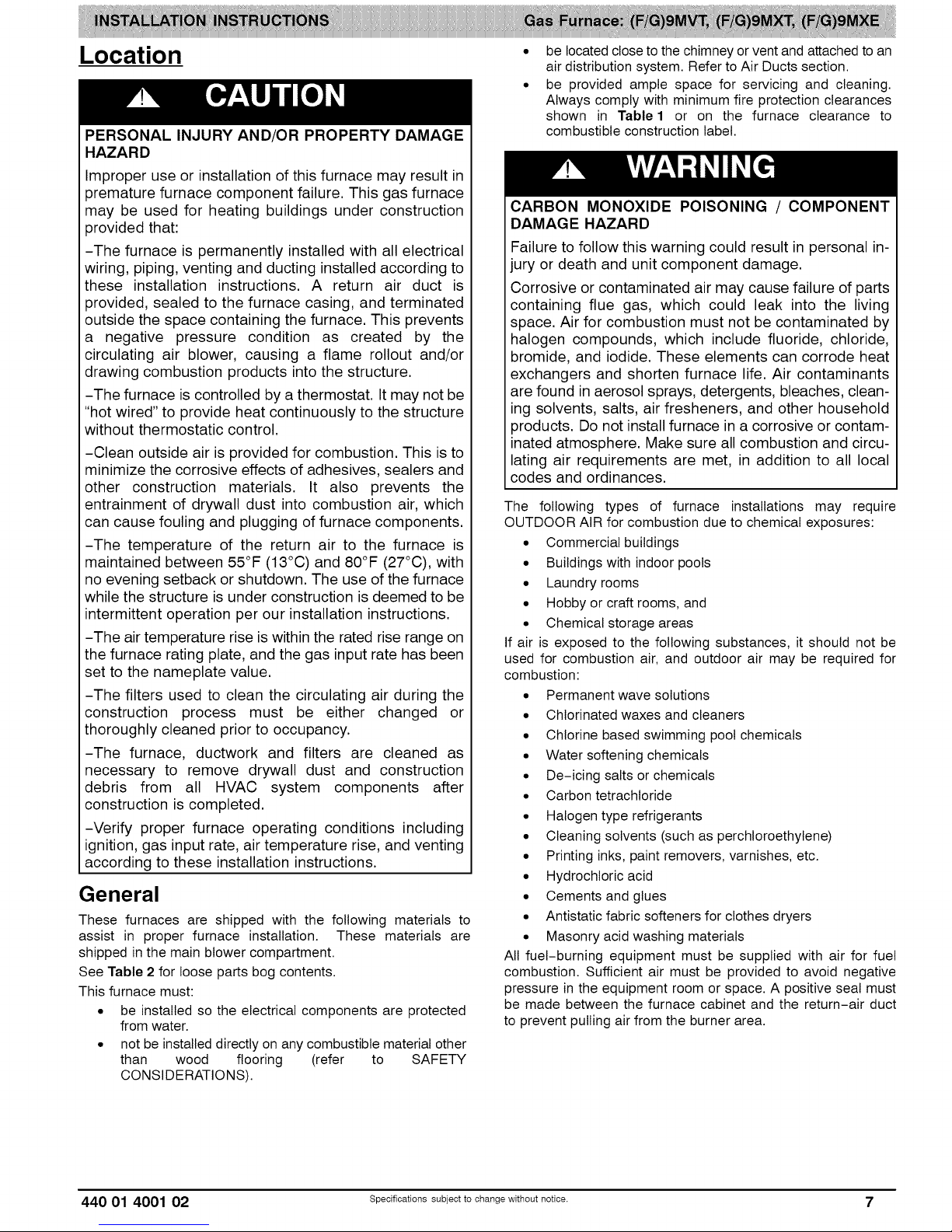

Location

PERSONAL INJURY AND/OR PROPERTY DAMAGE

HAZARD

Improper use or installation of this furnace may result in

3remature furnace component failure. This gas furnace

may be used for heating buildings under construction

3rovided that:

-The furnace is permanently installed with all electrical

wiring, piping, venting and ducting installed according to

these installation instructions. A return air duct is

3rovided, sealed to the furnace casing, and terminated

outside the space containing the furnace. This prevents

a negative pressure condition as created by the

circulating air blower, causing a flame rollout and/or

drawing combustion products into the structure.

-The furnace is controlled by a thermostat. It may not be

"hot wired" to provide heat continuously to the structure

without thermostatic control.

-Clean outside air is provided for combustion. This is to

minimize the corrosive effects of adhesives, sealers and

other construction materials. It also prevents the

entrainment of drywall dust into combustion air, which

can cause fouling and plugging of furnace components.

-The temperature of the return air to the furnace is

maintained between 55°F (13°C) and 80°F (27°C), with

no evening setback or shutdown. The use of the furnace

while the structure is under construction is deemed to be

intermittent operation per our installation instructions.

-The air temperature rise is within the rated rise range on

the furnace rating plate, and the gas input rate has been

set to the nameplate value.

-The filters used to clean the circulating air during the

construction process must be either changed or

thoroughly cleaned prior to occupancy.

-The furnace, ductwork and filters are cleaned as

necessary to remove drywall dust and construction

debris from all HVAC system components after

construction is completed.

-Verify proper furnace operating conditions including

ignition, gas input rate, air temperature rise, and venting

according to these installation instructions.

General

These furnaces are shipped with the following materials to

assist in proper furnace installation. These materials are

shipped in the main blower compartment.

See Table 2 for loose parts bog contents.

This furnace must:

• be installed so the electrical components are protected

from water.

• notbe installeddirectlyon any combustiblematerial other

than wood flooring (refer to SAFETY

CONSIDERATIONS).

be located close to the chimney or vent and attached to an

air distribution system. Refer to Air Ducts section.

be provided ample space for servicing and cleaning.

Always comply with minimum fire protection clearances

shown in Table 1 or on the furnace clearance to

combustible construction label.

CARBON MONOXIDE POISONING / COMPONENT

DAMAGE HAZARD

Failure to follow this warning could result in personal in-

jury or death and unit component damage.

Corrosive or contaminated air may cause failure of parts

containing flue gas, which could leak into the living

space. Air for combustion must not be contaminated by

halogen compounds, which include fluoride, chloride,

bromide, and iodide. These elements can corrode heat

exchangers and shorten furnace life. Air contaminants

are found in aerosol sprays, detergents, bleaches, clean-

ing solvents, salts, air fresheners, and other household

products. Do not install furnace in a corrosive or contam-

inated atmosphere. Make sure all combustion and circu-

lating air requirements are met, in addition to all local

codes and ordinances.

The following types of furnace installations may require

OUTDOOR AIR for combustion due to chemical exposures:

• Commercial buildings

• Buildings with indoor pools

• Laundry rooms

• Hobby or craft rooms, and

• Chemical storage areas

If air is exposed to the following substances, it should not be

used for combustion air, and outdoor air may be required for

combustion:

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine based swimming pool chemicals

• Water softening chemicals

• De-icing salts or chemicals

• Carbon tetrachloride

• Halogen type refrigerants

• Cleaning solvents (such as perchloroethylene)

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid

• Cements and glues

• Antistatic fabric softeners for clothes dryers

• Masonry acid washing materials

All fuel-burning equipment must be supplied with air for fuel

combustion. Sufficient air must be provided to avoid negative

pressure in the equipment room or space. A positive seal must

be made between the furnace cabinet and the return-air duct

to prevent pulling air from the burner area.

440 01 4001 02 Specificati ..... bject to change without notice. 7

Page 8

Figure 3 1Multipoise Orientations

THE BLOWER iS LOCATED

TOTHE RIGHT OFTHE

BURNER SECTION, AND

AIR CONDiTiONED AiR iS

DISCHARGED TO THE LEFT.

AIRFLOW

THE BLOWER iS

LOCATED BELOW THE

BURNER SECTION, AND

CONDiTiONED AIR iS

DISCHARGED UPWARD.

I HORIZONTAL RIGHT/AIFF_LQW

THE BLOWER iS

LOCATED ABOVE THE

BURNER SECTION, AND

CONDiTiONED AiR iS

DISCHARGED DOWNWARD AIRFLOW

FIRE, INJURY OR DEATH HAZARD

Failure to follow this warning could result in personal in-

jury, death and/or property damage.

When the furnace is installed in a residential garage, the

burners and ignition sources must be located at least

18-in. (457 mm) above the floor. The furnace must be

located or protected to avoid damage by vehicles. When

the furnace is installed in a public garage, airplane

hangar, or other building having a hazardous atmo-

sphere, the furnace must be installed in accordance with

the NFPA 54/ANSI Z223.1-2009 or CAN/CSA

B149.1-2010. (See Figure 4)

Figure 4 1Installation in a Garage

THE BLOWER iS

LOCATED TO THE LEFT

OF THE BURNER SECTION,

AND CONDiTiONED AiR iS

DISCHARGED TO THE RIGHT.

FIRE HAZARD

Failure to follow this warning could result in personal in-

jury, death and/or property damage.

Do not install the furnace on its back or hang furnace with

control compartment facing downward. Safety control

operation will be adversely affected. Never connect re-

turn-air ducts to the back of the furnace. (See Figure 5)

Figure 5 _Prohibit Installations

BACK

18-1N. (457.2 mm)

MINIMUM TO BURNERS

8 Specificati ..... bject to change without notice. 440 01 4001 02

A10494

A93044

Page 9

Location Relative to Cooling

Equipment

The cooling coil must be installed parallel with, or on the

downstream side of the unit to avoid condensation in the heat

exchangers. When installed parallel with the furnace, dampers

or other flow control must prevent chilled air from entering the

furnace. If the dampers are manually operated, they must be

equipped with means to prevent operation of either unit unless

the damper is in the full-heat or full-cool position.

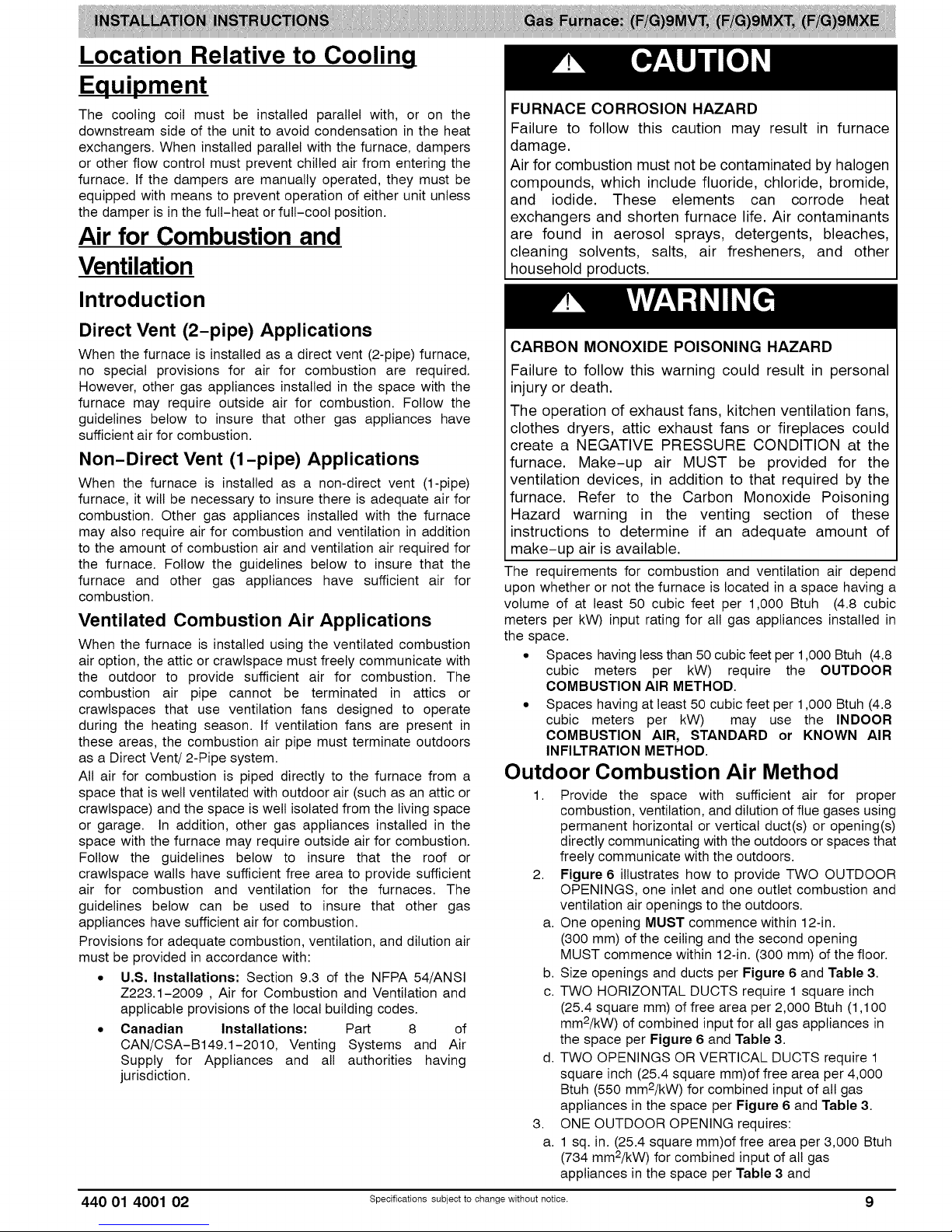

Air for Combustion and

Ventilation

Introduction

FURNACE CORROSION HAZARD

Failure to follow this caution may result in furnace

damage.

Air for combustion must not be contaminated by halogen

compounds, which include fluoride, chloride, bromide,

and iodide. These elements can corrode heat

exchangers and shorten furnace life. Air contaminants

are found in aerosol sprays, detergents, bleaches,

cleaning solvents, salts, air fresheners, and other

household products.

Direct Vent (2-pipe) Applications

When the furnace is installed as a direct vent (2-pipe) furnace,

no special provisions for air for combustion are required.

However, other gas appliances installed in the space with the

furnace may require outside air for combustion. Follow the

guidelines below to insure that other gas appliances have

sufficient air for combustion.

Non-Direct Vent (1-pipe) Applications

When the furnace is installed as a non-direct vent (1-pipe)

furnace, it wilt be necessary to insure there is adequate air for

combustion. Other gas appliances installed with the furnace

may also require air for combustion and ventilation in addition

to the amount of combustion air and ventilation air required for

the furnace. Follow the guidelines below to insure that the

furnace and other gas appliances have sufficient air for

combustion.

Ventilated Combustion Air Applications

When the furnace is installed using the ventilated combustion

air option, the attic or crawlspace must freely communicate with

the outdoor to provide sufficient air for combustion. The

combustion air pipe cannot be terminated in attics or

crawlspaces that use ventilation fans designed to operate

during the heating season. If ventilation fans are present in

these areas, the combustion air pipe must terminate outdoors

as a Direct Vent/2-Pipe system.

All air for combustion is piped directly to the furnace from a

space that is well ventilated with outdoor air (such as an attic or

crawlspace) and the space is well isolated from the living space

or garage. In addition, other gas appliances installed in the

space with the furnace may require outside air for combustion.

Follow the guidelines below to insure that the roof or

crawlspace walls have sufficient free area to provide sufficient

air for combustion and ventilation for the furnaces. The

guidelines below can be used to insure that other gas

appliances have sufficient air for combustion.

Provisions for adequate combustion, ventilation, and dilution air

must be provided in accordance with:

• U.S. Installations: Section 9.3 of the NFPA 54/ANSI

Z223.1-2009 , Air for Combustion and Ventilation and

applicable provisions of the local building codes.

• Canadian Installations: Part 8 of

CAN/CSA-B149.1-2010, Venting Systems and Air

Supply for Appliances and all authorities having

jurisdiction.

440 01 4001 02 Specificati ..... bject to change without notice. 9

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

injury or death.

The operation of exhaust fans, kitchen ventilation fans,

clothes dryers, attic exhaust fans or fireplaces could

create a NEGATIVE PRESSURE CONDITION at the

furnace. Make-up air MUST be provided for the

ventilation devices, in addition to that required by the

furnace. Refer to the Carbon Monoxide Poisoning

Hazard warning in the venting section of these

instructions to determine if an adequate amount of

make-up air is available.

The requirements for combustion and ventilation air depend

upon whether or not the furnace is located in a space having a

volume of at least 50 cubic feet per 1,000 Btuh (4.8 cubic

meters per kW) input rating for all gas appliances installed in

the space.

• Spaces having less than 50 cubic feet per 1,000 Btuh (4.8

cubic meters per kW) require the OUTDOOR

COMBUSTION AIR METHOD.

• Spaces having at least 50 cubic feet per 1,000 Btuh (4.8

cubic meters per kW) may use the INDOOR

COMBUSTION AIR, STANDARD or KNOWN AIR

INFILTRATION METHOD.

Outdoor Combustion Air Method

1. Provide the space with sufficient air for proper

combustion, ventilation, and dilution of flue gases using

permanent horizontal or vertical duct(s) or opening(s)

directly communicating with the outdoors or spaces that

freely communicate with the outdoors.

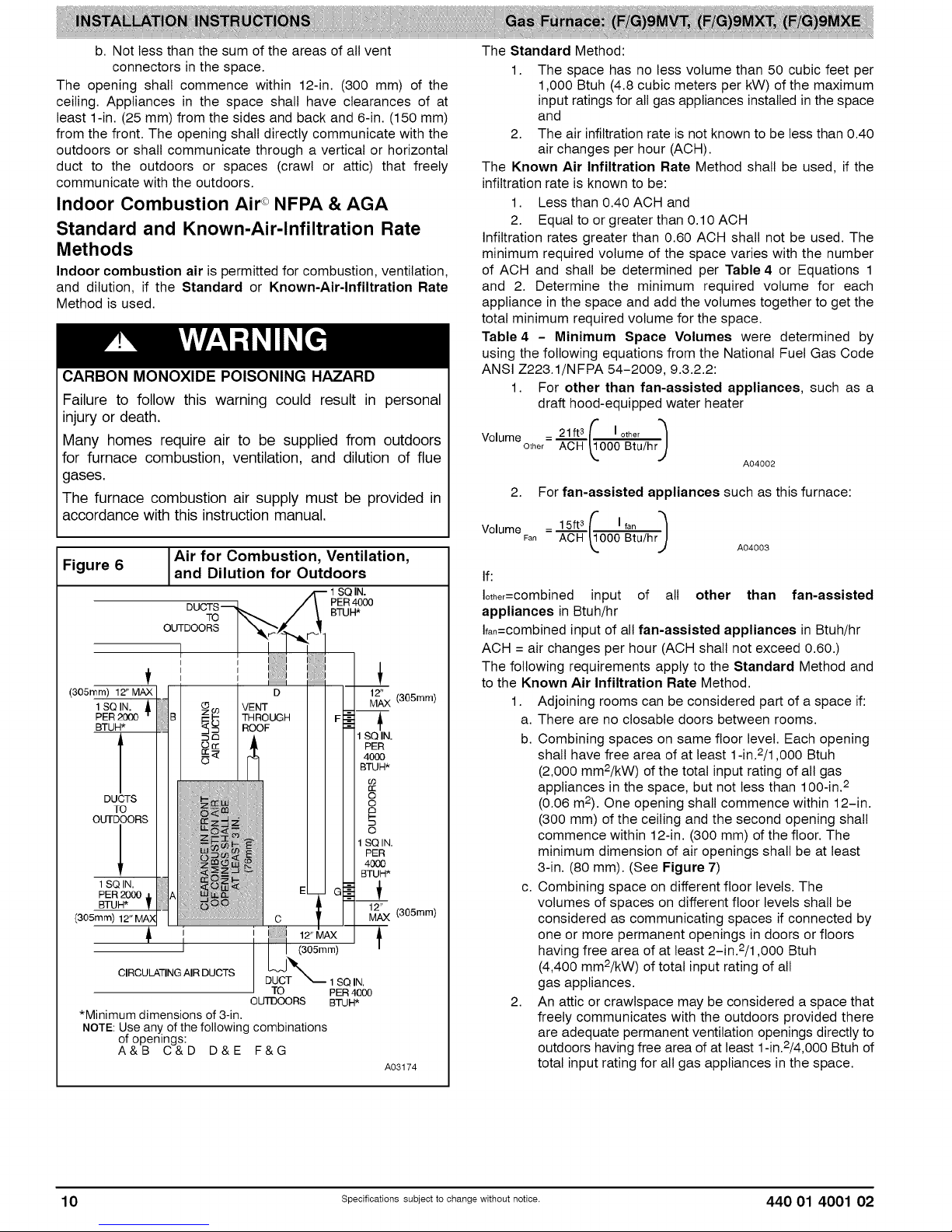

2. Figure 6 illustrates how to provide TWO OUTDOOR

OPENINGS, one inlet and one outlet combustion and

ventilation air openings to the outdoors.

a. One opening MUST commence within 12-in.

(300 mm) of the ceiling and the second opening

MUST commence within 12-in. (300 mm) of the floor.

b. Size openings and ducts per Figure 6 and Table 3.

c. TWO HORIZONTAL DUCTS require 1 square inch

(25.4 square mm) of free area per 2,000 Btuh (1,100

mm2/kW) of combined input for all gas appliances in

the space per Figure 6 and Table 3.

d. TWO OPENINGS OR VERTICAL DUCTS require 1

square inch (25.4 square mm)of free area per 4,000

Btuh (550 mm2/kW) for combined input of all gas

appliances in the space per Figure 6 and Table 3.

3. ONE OUTDOOR OPENING requires:

a. 1 sq. in. (25.4 square mm)of free area per 3,000 Btuh

(734 mm2/kW) for combined input of all gas

appliances in the space per Table 3 and

Page 10

b. Not less than the sum of the areas of all vent

connectors in the space.

The opening shall commence within 12-in. (300 mm) of the

ceiling. Appliances in the space shall have clearances of at

least 1-in. (25 mm) from the sides and back and 6-in. (150 mm)

from the front. The opening shall directly communicate with the

outdoors or shall communicate through a vertical or horizontal

duct to the outdoors or spaces (crawl or attic) that freely

communicate with the outdoors.

Indoor Combustion Air ° NFPA & AGA

Standard and Known-Air-Infiltration Rate

Methods

Indoor combustion air is permitted for combustion, ventilation,

and dilution, if the Standard or Known-Air-Infiltration Rate

Method is used.

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

injury or death.

Many homes require air to be supplied from outdoors

for furnace combustion, ventilation, and dilution of flue

gases.

The furnace combustion air supply must be provided in

accordance with this instruction manual.

Figure 6

(305_m/12"M_X]j

lseiN, ill

PER 2000 B

BTUH*

sa i .

PER 2000 A

(305mm)12"MAN | I

CIRCULATINGAIR DUCTS

*Minimum dimensions of 3-in.

NOTE: Use any of the following combinations

of openings:

A&B C&D D&E F&G

Air for Combustion, Ventilation,and Dilution for Outdoors

DUCTS ,

TO BTUH

OUiDOORS

I I Ii

D

VENT

THROUGH

ROOF

I

' 1

TO PER 4000

OUTDOORS BTUH*

12" MAX

(305mm)

1 SQ IN.

I SQ IN,

/

f

12/_X (305ram}

t

1 so IN.

PER

4000

BTUH*

09

n-

O

O

£

o

SQ IN,

PER

4000

BTUH*

_2j_X (aO5mm)

t

A03174

The Standard Method:

1. The space has no less volume than 50 cubic feet per

1,000 Btuh (4.8 cubic meters per kW) of the maximum

input ratings for all gas appliances installed inthe space

and

2. The air infiltration rate is not known to be less than 0.40

air changes per hour (ACH).

The Known Air Infiltration Rate Method shall be used, if the

infiltration rate is known to be:

1. Less than 0.40 ACH and

2. Equal to or greater than 0.10 ACH

Infiltration rates greater than 0.60 ACH shall not be used. The

minimum required volume of the space varies with the number

of ACH and shall be determined per Table 4 or Equations 1

and 2. Determine the minimum required volume for each

appliance in the space and add the volumes together to get the

total minimum required volume for the space.

Table 4 - Minimum Space Volumes were determined by

using the following equations from the National Fuel Gas Code

ANSI Z223.1/NFPA 54-2009, 9.3.2.2:

1. For other than fan-assisted appliances, such as a

draft hood-equipped water heater

Volume -21ft3 _f' I°ther

Other ACH _.000 Btu/hrJ

A04002

2. For fan-assisted appliances such as this furnace:

Volume Fan ACH 000 Btu/hr

A04003

If:

Iother=combined input of all other than fan-assisted

appliances in Btuh/hr

Itan=combined input of all fan-assisted appliances in Btuh/hr

ACH = air changes per hour (ACH shall not exceed 0.60.)

The following requirements apply to the Standard Method and

to the Known Air Infiltration Rate Method.

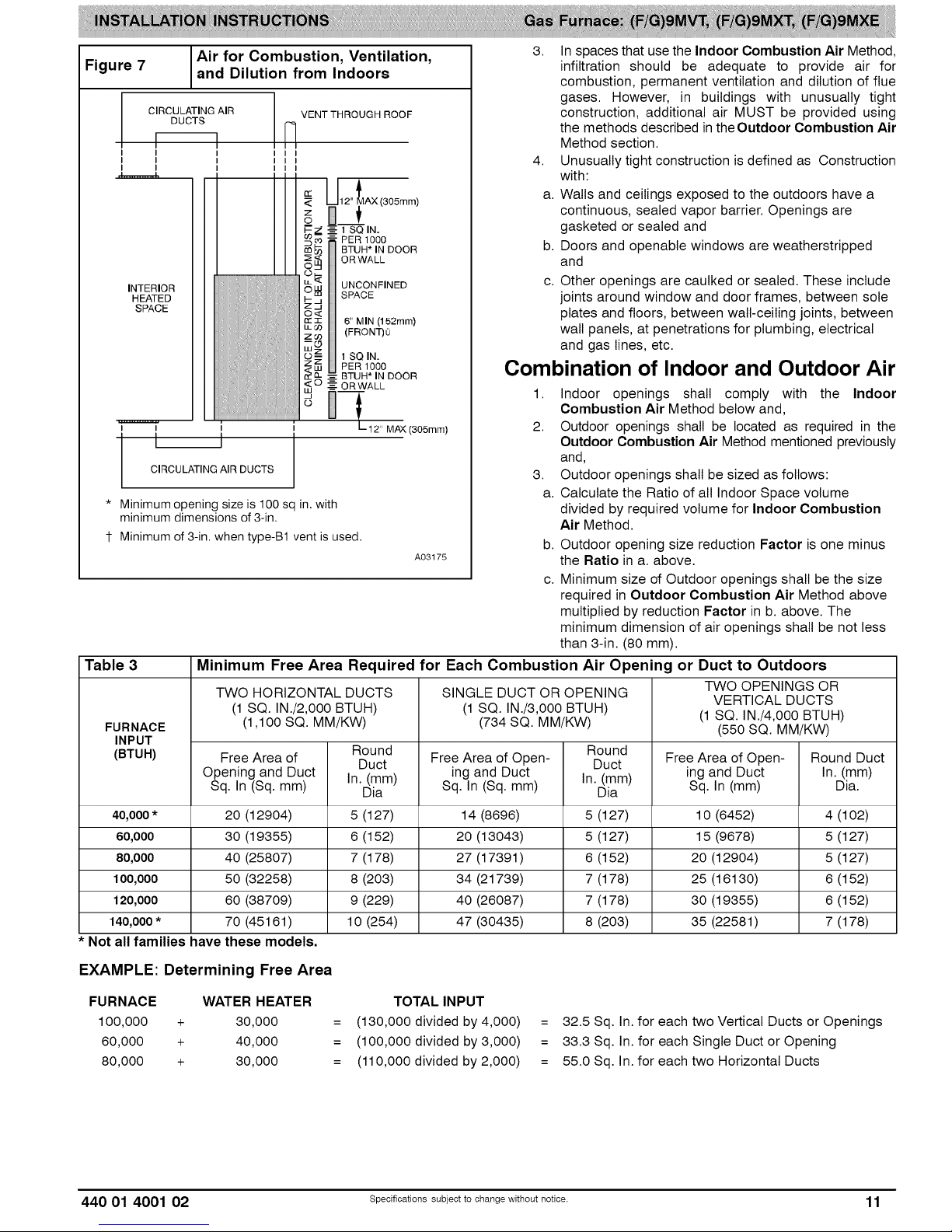

1. Adjoining rooms can be considered part of a space if:

a. There are no closable doors between rooms.

b. Combining spaces on same floor level. Each opening

shall have free area of at least 1-in.2/1,000 Btuh

(2,000 mm2/kW) of the total input rating of all gas

appliances in the space, but not less than 100-in. 2

(0.06 m2). One opening shall commence within 12-in.

(300 mm) of the ceiling and the second opening shall

commence within 12-in. (300 mm) of the floor. The

minimum dimension of air openings shall be at least

3-in. (80 mm). (See Figure 7)

c. Combining space on different floor levels. The

volumes of spaces on different floor levels shall be

considered as communicating spaces if connected by

one or more permanent openings in doors or floors

having free area of at least 2-in.2/1,000 Btuh

(4,400 mm2/kW) of total input rating of all

gas appliances.

2. An attic or crawlspace may be considered a space that

freely communicates with the outdoors provided there

are adequate permanent ventilation openings directly to

outdoors having free area of at least 1-in.2/4,000 Btuh of

total input rating for all gas appliances in the space.

10 Specificati ..... bject to change without notice. 440 01 4001 02

Page 11

Airfor Combustion,Ventilation, 3.

Figure 7 and Dilution from Indoors

In spaces that use the Indoor Combustion Air Method,

infiltration should be adequate to provide air for

combustion, permanent ventilation and dilution of flue

gases. However, in buildings with unusually tight

CIRCULATING AIR VENT THROUGH ROOF

DUCTS

I

I

I

I I I I

I I I I

I I I I

_(305mm)

construction, additional air MUST be provided using

the methods described in the Outdoor Combustion Air

Method section.

4.

Unusually tight construction is defined as Construction

with:

a.

Walls and ceilings exposed to the outdoors have a

continuous, sealed vapor barrier. Openings are

E_ ----_SQIN.

_" _ = PER 1000

_: _ BTUH* IN DOOR

_ ORWALL

INTERIOR

HEATED

SPACE

i C_ UNCONFINED

rr T 6" MIN (152ram)

u_ o0 (FRONT)0

z_

zZ PER 1000

g O___&_ALL

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

I i i - 12" MAX (305mm)

o

I I

CIRCULATING AIR DUCTS

* Minimum opening size is 100 sq in. with

minimum dimensions of 3-in.

1- Minimum of 3-in. when type-B1 vent is used.

Combination of Indoor and Outdoor Air

A03175

gasketed or sealed and

b.

Doors and openable windows are weatherstripped

and

C.

Other openings are caulked or sealed. These include

joints around window and door frames, between sole

plates and floors, between walt-ceiling joints, between

wall panels, at penetrations for plumbing, electrical

and gas lines, etc.

1.

Indoor openings shall comply with the Indoor

Combustion Air Method below and,

2.

Outdoor openings shall be located as required in the

Outdoor Combustion Air Method mentioned previously

and,

3.

Outdoor openings shall be sized as follows:

a.

Calculate the Ratio of all Indoor Space volume

divided by required volume for Indoor Combustion

Air Method.

b.

Outdoor opening size reduction Factor is one minus

the Ratio in a. above.

C.

Minimum size of Outdoor openings shall be the size

required in Outdoor Combustion Air Method above

multiplied by reduction Factor in b. above. The

minimum dimension of air openings shall be not less

than 3-in. (80 mm).

Table 3 Minimum Free Area Required for Each Combustion Air Opening or Duct to Outdoors

TWO HORIZONTAL DUCTS SINGLE DUCT OR OPENING TWO OPENINGS OR

(1 SQ. IN./2,000 BTUH) (1 SQ. IN./3,000 BTUH)

FURNACE (1,100 SQ. MM/KW) (734 SQ. MM/KW) (1 SQ. IN./4,000 BTUH)

INPUT

Round Round

VERTICAL DUCTS

(550 SQ. MM/KW)

(BTUH) Free Area of Duct Free Area of Open- Duct Free Area of Open- Round Duct

Opening and Duct In. (mm) ing and Duct In. (mm) ing and Duct In. (mm)

Sq. In (Sq. mm) Dia Sq. In (Sq. mm) Dia Sq. In (mm) Dia.

40,000* 20 (12904) 5 (127) 14 (8696) 5 (127) 10 (6452) 4 (102)

60,000 30 (19355) 6 (152) 20 (13043) 5 (127) 15 (9678) 5 (127)

80,000 40 (25807) 7 (178) 27 (17391) 6 (152) 20 (12904) 5 (127)

100,000 50 (32258) 8 (203) 34 (21739) 7 (178) 25 (16130) 6 (152)

120,000 60 (38709) 9 (229) 40 (26087) 7 (178) 30 (19355) 6 (152)

140,000" 70 (45161) 10 (254) 47 (30435) 8 (203) 35 (22581) 7 (178)

• Not all families have these models,

EXAMPLE: Determining Free Area

FURNACE WATER HEATER TOTAL INPUT

100,000 + 30,000 = (130,000 divided by 4,000)

60,000 + 40,000 = (100,000 divided by 3,000)

80,000 + 30,000 = (110,000 divided by 2,000)

440 01 4001 02 Specificati ..... bject to change without notice. 11

= 32.5 Sq. In. for each two Vertical Ducts or Openings

= 33.3 Sq. In. for each Single Duct or Opening

= 55.0 Sq. In. for each two Horizontal Ducts

Page 12

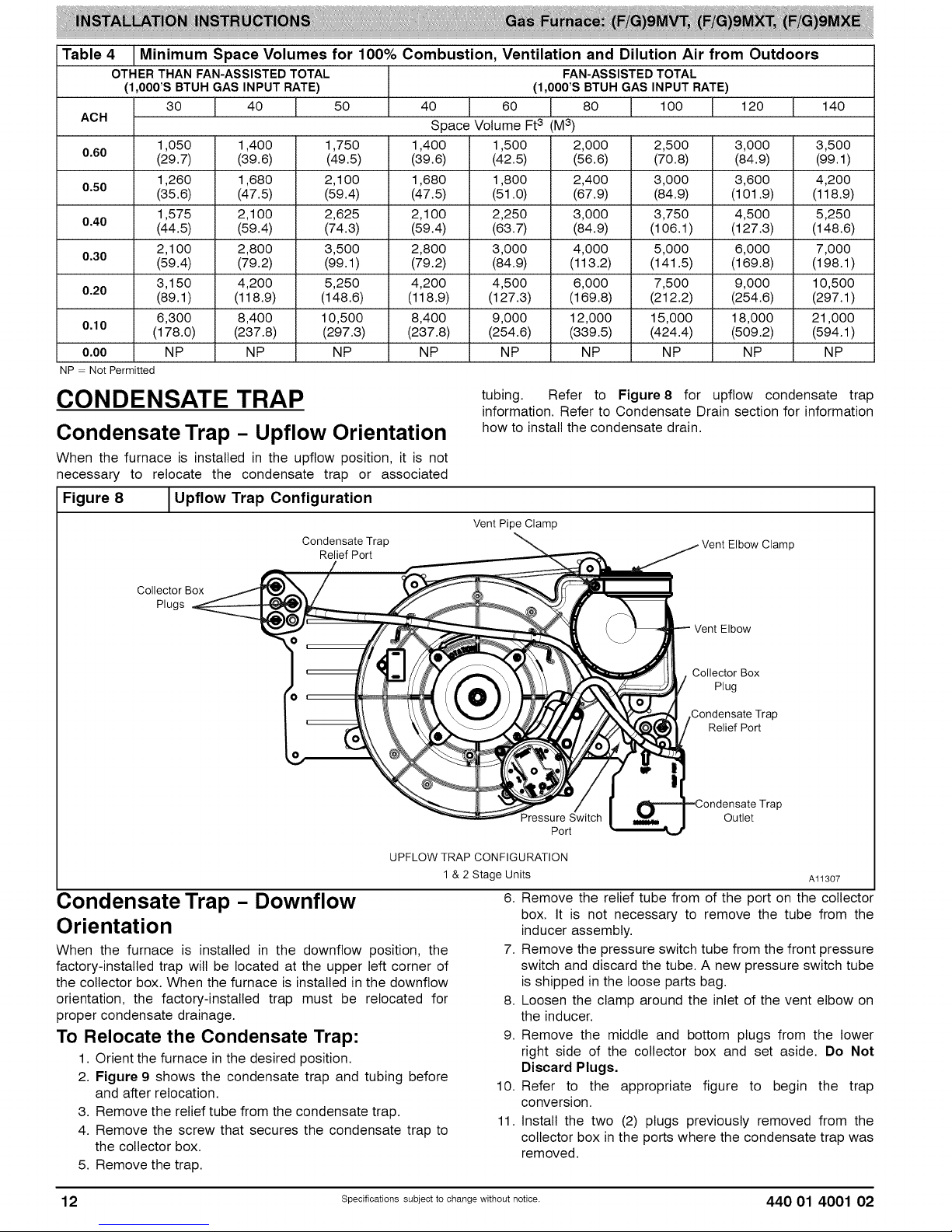

Table 4 Minimum Space Volumes for 100% Combustion, Ventilation and Dilution Air from Outdoors

OTHER THAN FAN-ASSISTEDTOTAL FAN-ASSISTEDTOTAL

(1,000'S BTUH GAS INPUT RATE) (1,000'S BTUH GAS INPUT RATE)

30 40 50 40 60 80 1O0 120 140

AOH Space Volume Ft3 (M3)

1,050 1,400 1,750 1,400 1,500 2,000 2,500 3,000 3,500

0.60 (29.7) (39.6) (49.5) (39.6) (42.5) (56.6) (70.8) (84.9) (99.1)

1,260 1,680 2,1 O0 1,680 1,800 2,400 3,000 3,600 4,200

0.50 (35.6) (47.5) (59.4) (47.5) (51.0) (67.9) (84.9) (101.9) (118.9)

1,575 2,1 O0 2,625 2,1 O0 2,250 3,000 3,750 4,500 5,250

0.40 (44.5) (59.4) (74.3) (59.4) (63.7) (84.9) (106.1 ) (127.3) (148.6)

2,1 O0 2,800 3,500 2,800 3,000 4,000 5,000 6,000 7,000

0.30 (59.4) (79.2) (99.1) (79.2) (84.9) (113.2) (141.5) (169.8) (198.1 )

3,150 4,200 5,250 4,200 4,500 6,000 7,500 9,000 10,500

0.20 (89.1) (118.9) (148.6) (118.9) (127.3) (169.8) (212.2) (254.6) (297.1)

6,300 8,400 10,500 8,400 9,000 12,000 15,000 18,000 21,000

0,10 (178.0) (237.8) (297.3) (237.8) (254.6) (339.5) (424.4) (509.2) (594.1)

0,00 NP NP NP NP NP NP NP NP NP

NP = Not Permitted

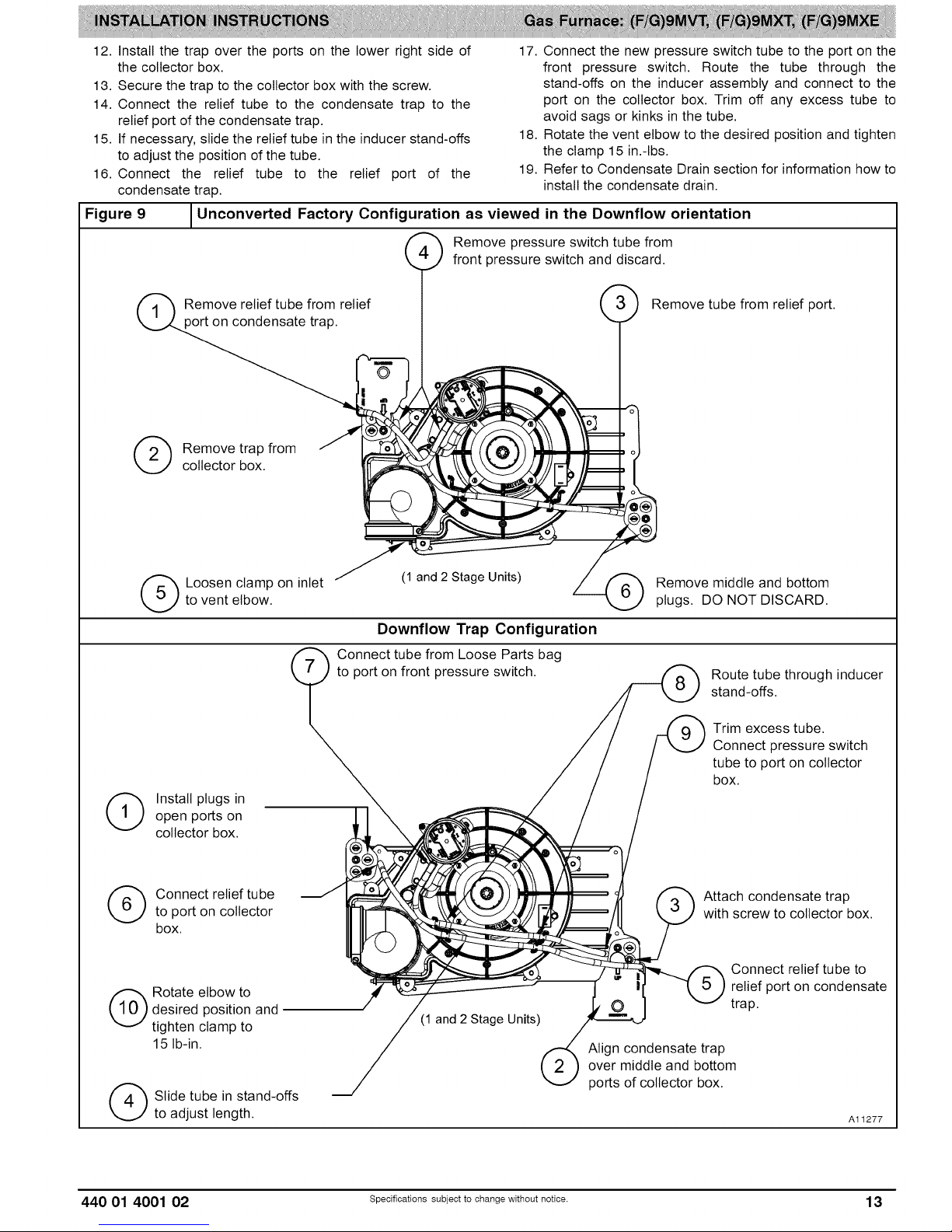

CONDENSATE TRAP

Condensate Trap - Upflow Orientation

tubing. Refer to Figure8 for upflow condensate trap

information. Refer to Condensate Drain section for information

how to install the condensate drain.

When the furnace is installed in the upflow position, it is not

necessary to relocate the condensate trap or associated

Figure 8 1Upflow Trap Configuration

Vent Pipe Clamp

Condensate Trap

Relief Port

Vent Elbow Clamp

Collector Box

Plugs

UPFLOW TRAP CONFIGURATION

Condensate Trap - Downflow

Orientation

When the furnace is installed in the downflow position, the

factory-installed trap will be located at the upper left corner of

the collector box. When the furnace is installed in the downflow

orientation, the factory-installed trap must be relocated for

proper condensate drainage.

To Relocate the Condensate Trap:

1. Orient the furnace in the desired position.

2. Figure 9 shows the condensate trap and tubing before

and after relocation.

3. Remove the relief tube from the condensate trap.

4. Remove the screw that secures the condensate trap to

the collector box.

5. Remove the trap.

1 & 2 Stage Units

6. Remove the relief tube from of the port on the collector

7. Remove the pressure switch tube from the front pressure

8. Loosen the clamp around the inlet of the vent elbow on

9. Remove the middle and bottom plugs from the lower

10. Refer to the appropriate figure to begin the trap

11. Install the two (2) plugs previously removed from the

Vent Elbow

Collector Box

Plug

Condensate Trap

Relief Port

Pressure Switch

Port

Outlet

P

Al1307

box. It is not necessary to remove the tube from the

inducer assembly.

switch and discard the tube. A new pressure switch tube

is shipped in the loose parts bag.

the inducer.

right side of the collector box and set aside. Do Not

Discard Plugs,

conversion.

collector box in the ports where the condensate trap was

removed.

12 Specificati ..... bject to change without notice. 440 01 4001 02

Page 13

12. Install the trap over the ports on the lower right side of

the collector box.

13. Secure the trap to the collector box with the screw.

14. Connect the relief tube to the condensate trap to the

relief port of the condensate trap.

15. If necessary, slide the relief tube in the inducer stand-offs

to adjust the position of the tube.

16. Connect the relief tube to the relief port of the

condensate trap.

Figure 9

Unconverted Factory Configuration as viewed in the Downflow orientation

17. Connect the new pressure switch tube to the port on the

front pressure switch. Route the tube through the

stand-offs on the inducer assembly and connect to the

port on the collector box. Trim off any excess tube to

avoid sags or kinks in the tube.

18. Rotate the vent elbow to the desired position and tighten

the clamp 15 in.-Ibs.

19. Refer to Condensate Drain section for information how to

install the condensate drain.

Remove relief tube from relief Remove tube from relief port.

on condensate trap.

(_ emove trap from

collector box.

to vent elbow.

(_ Loosen clamp on inlet

(_ _ Remove pressure switch tube from

(1 and 2 Stage Units)

front pressure switch and discard.

Downflow Trap Configuration

Connect tube from Loose Parts bag

to port on front pressure switch.

Remove middle and bottom

plugs. DO NOT DISCARD.

Route tube through inducer

stand-offs.

(_ Install plugs inopen ports on

collector box.

(_ Connect relief tube

to port on collector

box.

desired position and

(_ otate elbow to

tighten clamp to

15 Ib-in.

(_ Slide tube in stand-offs

to adjust length.

Trim excess tube.

Connect pressure switch

tube to port on collector

box.

Attach condensate trap

with screw to collector box.

Connect relief tube to

relief port on condensate

trap.

(1 and 2 Stage Units)

Align condensate trap

over middle and bottom

ports of collector box.

Al1277

440 01 4001 02 Specificati ..... bject to change without notice. 13

Page 14

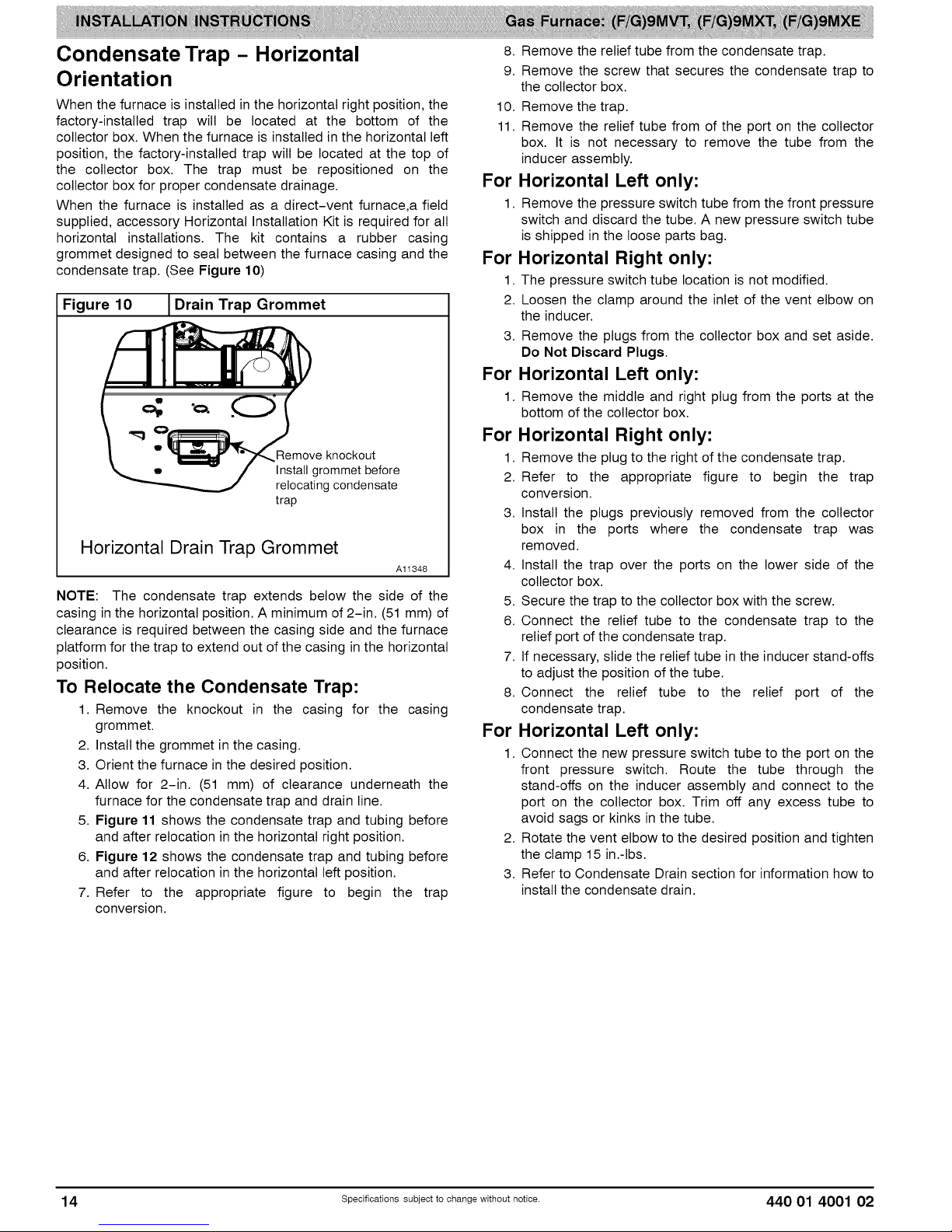

Condensate Trap - Horizontal

Orientation

When the furnace is installed in the horizontal right position, the

factory-installed trap will be located at the bottom of the

collector box. When the furnace is installed in the horizontal left

position, the factory-installed trap will be located at the top of

the collector box. The trap must be repositioned on the

collector box for proper condensate drainage.

When the furnace is installed as a direct-vent furnace,a field

supplied, accessory Horizontal Installation Kit is required for all

horizontal installations. The kit contains a rubber casing

grommet designed to seal between the furnace casing and the

condensate trap. (See Figure 10)

Figure

NOTE: The condensate trap extends below the side of the

casing inthe horizontal position. A minimum of 2-in. (51 mm) of

clearance is required between the casing side and the furnace

platform for the trap to extend out of the casing in the horizontal

position.

To Relocate the Condensate Trap:

10 I Drain Trap Grommet

Remove knockout

Install grommet before

relocating condensate

trap

Horizontal Drain Trap Grommet

Al1348

1. Remove the knockout in the casing for the casing

grommet.

2. Install the grommet in the casing.

3. Orient the furnace in the desired position.

4. Allow for 2-in. (51 mm) of clearance underneath the

furnace for the condensate trap and drain line.

5. Figure 11 shows the condensate trap and tubing before

and after relocation in the horizontal right position.

6. Figure 12 shows the condensate trap and tubing before

and after relocation in the horizontal left position.

7. Refer to the appropriate figure to begin the trap

conversion.

8. Remove the relief tube from the condensate trap.

9. Remove the screw that secures the condensate trap to

the collector box.

10. Remove the trap.

11. Remove the relief tube from of the port on the collector

box. It is not necessary to remove the tube from the

inducer assembly.

For Horizontal Left only:

1. Remove the pressure switch tube from the front pressure

switch and discard the tube. A new pressure switch tube

is shipped in the loose parts bag.

For Horizontal Right only:

1. The pressure switch tube location is not modified.

2. Loosen the clamp around the inlet of the vent elbow on

the inducer.

3. Remove the plugs from the collector box and set aside.

Do Not Discard Plugs.

For Horizontal Left only:

1. Remove the middle and right plug from the ports at the

bottom of the collector box.

For Horizontal Right only:

1. Remove the plug to the right of the condensate trap.

2. Refer to the appropriate figure to begin the trap

conversion.

3. Install the plugs previously removed from the collector

box in the ports where the condensate trap was

removed.

4. Install the trap over the ports on the lower side of the

collector box.

5. Secure the trap to the collector box with the screw.

6. Connect the relief tube to the condensate trap to the

relief port of the condensate trap.

7. If necessary, slide the relief tube in the inducer stand-offs

to adjust the position of the tube.

8. Connect the relief tube to the relief port of the

condensate trap.

For Horizontal Left only:

1. Connect the new pressure switch tube to the port on the

front pressure switch. Route the tube through the

stand-offs on the inducer assembly and connect to the

port on the collector box. Trim off any excess tube to

avoid sags or kinks in the tube.

2. Rotate the vent elbow to the desired position and tighten

the clamp 15 in.-Ibs.

3. Refer to Condensate Drain section for information how to

install the condensate drain.

14 Specificati..... bject to change withoutnotice. 440 01 4001 02

Page 15

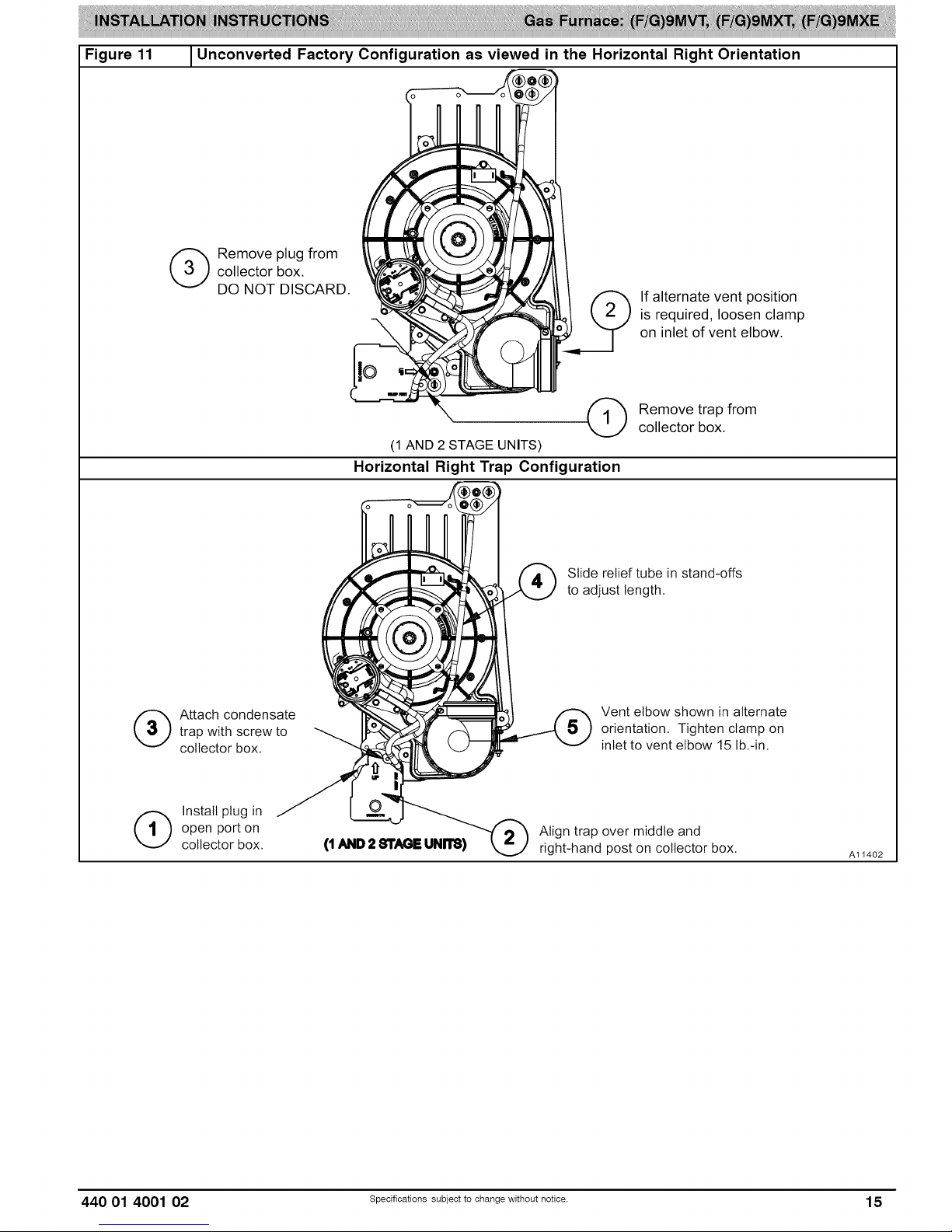

Figure 11 _Unconverted Factory Configuration as viewed in the Horizontal Right Orientation

(_ emove plug from

(_ ttach condensate

collector box.

DO NOT DISCARD.

trap with screw to

collector box.

\

(1AND 2 STAGE UNITS)

Horizontal Right Trap Configuration

Slide relief tube in stand-offs

to adjust length.

If alternate vent position

is required, loosen clamp

on inlet of vent elbow.

Remove trap from

collector box.

Vent elbow shown in alternate

orientation. Tighten clamp on

inlet to vent elbow 15 lb.-in.

open port on

(_ Install plug in

collector box.

440 01 4001 02 Specificati..... bject to change withoutnotice. 15

(1 AND 2 8"rAGEuNrm)

Align trap over middle and

right-hand post on collector box.

Al1402

Page 16

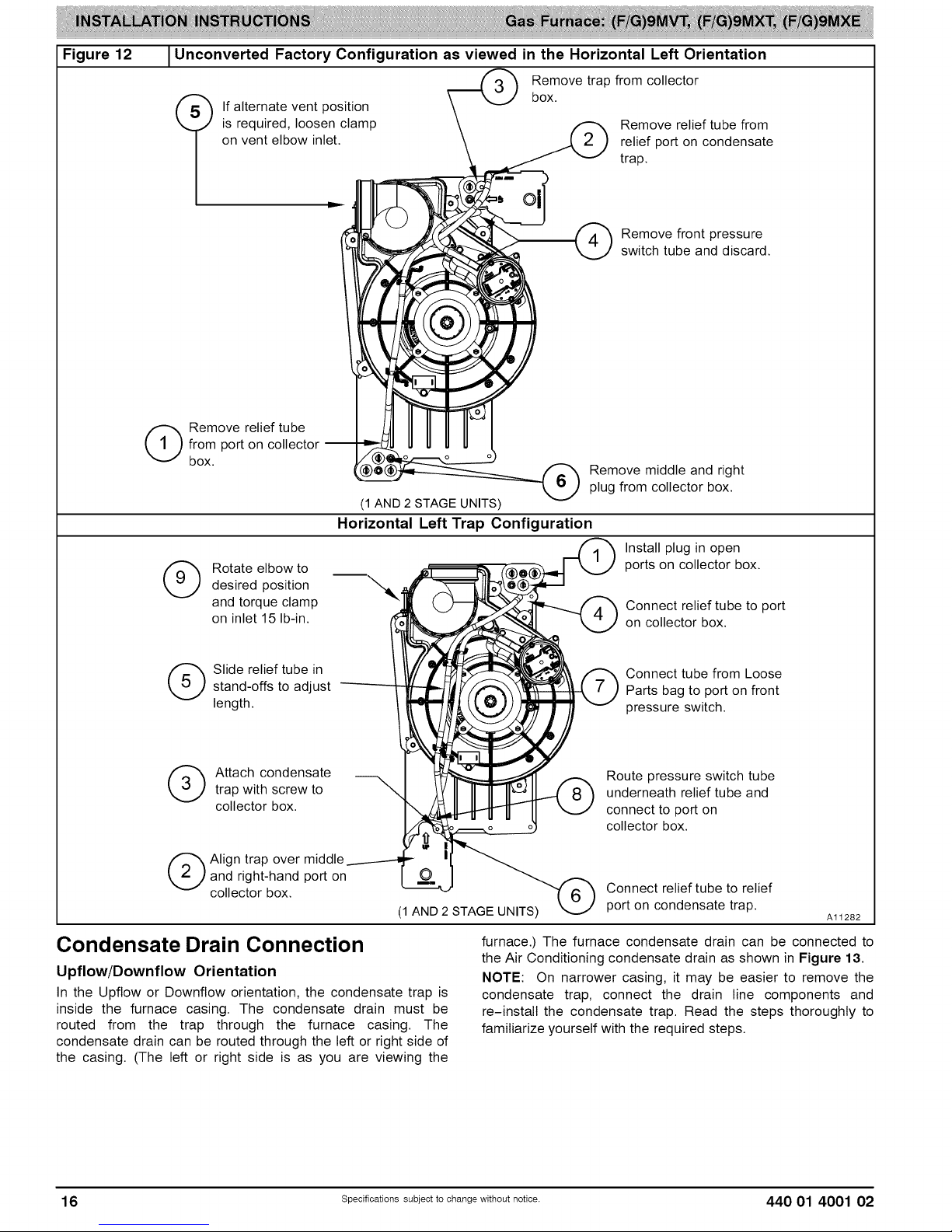

Figure 12 1Unconverted Factory Configuration as viewed in the Horizontal Left Orientation

Remove trap from collector

is required, loosen clamp

on vent elbow inlet.

t f alternate vent position box.

ID

from port on collector --

(_ emove relief tube

box.

(1 AND 2 STAGE UNITS)

Horizontal Left Trap Configuration

(_ otate elbow todesired position

and torque clamp

on inlet 15 Ib-in.

Remove relief tube from

relief port on condensate

trap.

Remove front pressure

switch tube and discard.

Remove middle and right

plug from collector box.

Install plug in open

ports on collector box.

Connect relief tube to port

on collector box.

(_ Slide relief tube instand-offs to adjust

length.

(_ ttach condensate

trap with screw to

collector box.

and right-hand port on

(_ Align trap over middle

collector box.

(1 AND 2 STAGE UNITS)

Condensate Drain Connection

Upflow/Downflow Orientation

In the Upflow or Downflow orientation, the condensate trap is

inside the furnace casing. The condensate drain must be

routed from the trap through the furnace casing. The

condensate drain can be routed through the left or right side of

the casing. (The left or right side is as you are viewing the

Connect tube from Loose

Parts bag to port on front

pressure switch.

Route pressure switch tube

underneath relief tube and

connect to port on

collector box.

Connect relief tube to relief

port on condensate trap.

Al1282

furnace.) The furnace condensate drain can be connected to

the Air Conditioning condensate drain as shown in Figure 13.

NOTE: On narrower casing, it may be easier to remove the

condensate trap, connect the drain line components and

re-install the condensate trap. Read the steps thoroughly to

familiarize yourself with the required steps.

16 specificati..... bject to change withoutnotice. 440 01 4001 02

Page 17

Figure13

Example of Field Drain Attachment

OPEN STAND

PIPE FOR

A/C OR

HUMIDIFIER

DRAIN

U

i_==-=TEE

TO OPEN

DRAIN

"-1

For Right Side Condensate Drain:

1. Remove the 7/9-in. knock-out from the right side of the

casing. (See Figure 14)

2. Remove the pre-formed drain tube and two spring

clamps from the loose parts bag.

3. Slide a spring clamp 1-in. down the plain end of the

drain tube.

4. From inside the casing, insert the formed grommet end

of the tube through the 7/8-in. knockout in the casing.

5. Pull the tube through the casing from the outside until it is

seated in the knockout

6. Attach the plain end of the drain tube to the outlet stub

on the drain trap. Secure the drain tube to the trap with

the spring clamp.

7. Slide a spring clamp over the open end of the drain tube

outside the casing.

8. Open the spring clamp and connect a field-supplied

1/2-in. CPVC street elbow to the open end of the drain

tube.

9. Connect additional 1/2-in. CPVC piping to a condensate

pump approved for use with acidic furnace condensate

or to a code-approved drain.

For Left Side Condensate Drain Connection:

1. For left side condensate drainage, the drain line is routed

from the condensate trap, behind the inducer and out

through the left side of the casing. A pre-formed "Z" pipe

is provided in the loose parts bag shipped with the

furnace. The "Z" pipe is long enough to extend out of the

casing on the 14 3/16-in. (360 mm) wide furnace. Larger

casings will require a field supplied CPVC pipe and to

extend the drain line out of the furnace.

2. The "Z" pipe is connected to the condensate trap by

modifying the formed rubber drain tube. Connect the

drain line as shown below:

3. Remove the knock-out from the left side of the casing.

(See Figure 14)

Al1276

4. Install the grommet for the 1/2-in. CPVC drain line in the

7/8-in. knockout in the casing.

5. Remove the pre-formed drain tube, the offset 1/2-in.

CPVC pipe and two spring clamps from the loose parts

bag.

6. Remove the formed grommet on the tube by cutting the

tube along the vertical line located about 1-in. away from

the formed grommet. (See Figure 15)

7. Slide a spring clamp 1-in. down the plain end of the

drain tube

8. With the bend in the tube oriented horizontally and plain

end of the tube pointing away from you, insert the 1/2-in

CPVC pipe into the other end of the drain tube. Rotate

the tube so the offset in the tube points away from you.

Slide a spring clamp over the open end of the 1/2-in.

CPVC tube and secure the cut end of drain tube to the

pipe.

9. Prime the bare end of the pipe with CPVC primer.

10. Route the offset pipe behind the inducer assembly and

through the grommet in the casing, if the "Z" pipe is long

enough. If the "Z" pipe is not long enough, continue with

installation.

11. Attach the plain end of the drain tube to the outlet stub

on the drain trap. Secure the drain tube to the trap with

the spring clamp.

12. If the "Z" pipe does not extend through the casing, slide a

piece of field supplied CPVC through the grommet in the

casing, otherwise, go to Step 17.

13. Cement a 1/2-in. CPVC coupling to the end of the CPVC

pipe.

14. Apply cement to the end of the "Z" pipe connected to the

condensate trap.

15. Connect the field-supplied CPVC pipe to the CPVC pipe

connected to the condensate trap.

16. Cut off excess CPVC pipe outside the casing.

17. Connect additional 1/2-in. CPVC piping to a condensate

pump approved for use with acidic furnace condensate

or to a code-approved drain.

18.

When a condensate pump is not used, slope the pipe

away from the furnace to allow for proper drainage.

Figure 14

JKnockout Removal

o

¢

Al1305

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing, safety

glasses and gloves when handling parts, and servicing

furnaces.

440 01 4001 02 specifioati..... bject to change withoutnotice. 17

Page 18

Figure 15

Modify Drain Tube

Cutand removeformed end of

draintube for left sideand horizontal

drainconnection

\

RIGHT SIDE DRAIN ELBOW

7. Slide the other spring clamp down the plain end of the

drain tube.

8. Connect additional 1/2-in. CPVC piping to a condensate

pump approved for use with acidic furnace condensate

or to a code-approved drain.

9. When a condensate pump is not used, slope the pipe

away from the furnace to allow for proper drainage.

Figure 17 I Formed Tube Grommet

INSTALL CLAMPS ON DRAIN TUBE

ATTACH DRAIN TUBETO CONDENSATF---- 7

DRAIN TRAP /

PULL DRAIN STUB

THROUGH CASING

Al1388

Figure 16 1Drain Trap Connection and Routing

Attach tube to condensate trap

Cut formed end off \

condensate drain tube \

Field supplied 1/2"CPVC Connect short end _ 2 _' _=l_.

_7UlPl_ng2t,,d:a in ext e nsio n. of "Z"pipe to modified\[_ \" ill

TRAP, DRAIN ELBOW WITH DISCHARGE PIPE

Modified drain tube connect to

condensate trap and "Z" pipe

Field supplied 1/2"

CPVC to drain

Casing grommet from Field-supplied 1/2"CPVC coupling & drain

loose parts bag pipe 17 1/2" 21"and 24 1/2"casings

i _ET etr_ mDAkM D_I ITem D_J_Mr_ kMml IP_D

\

Al1344

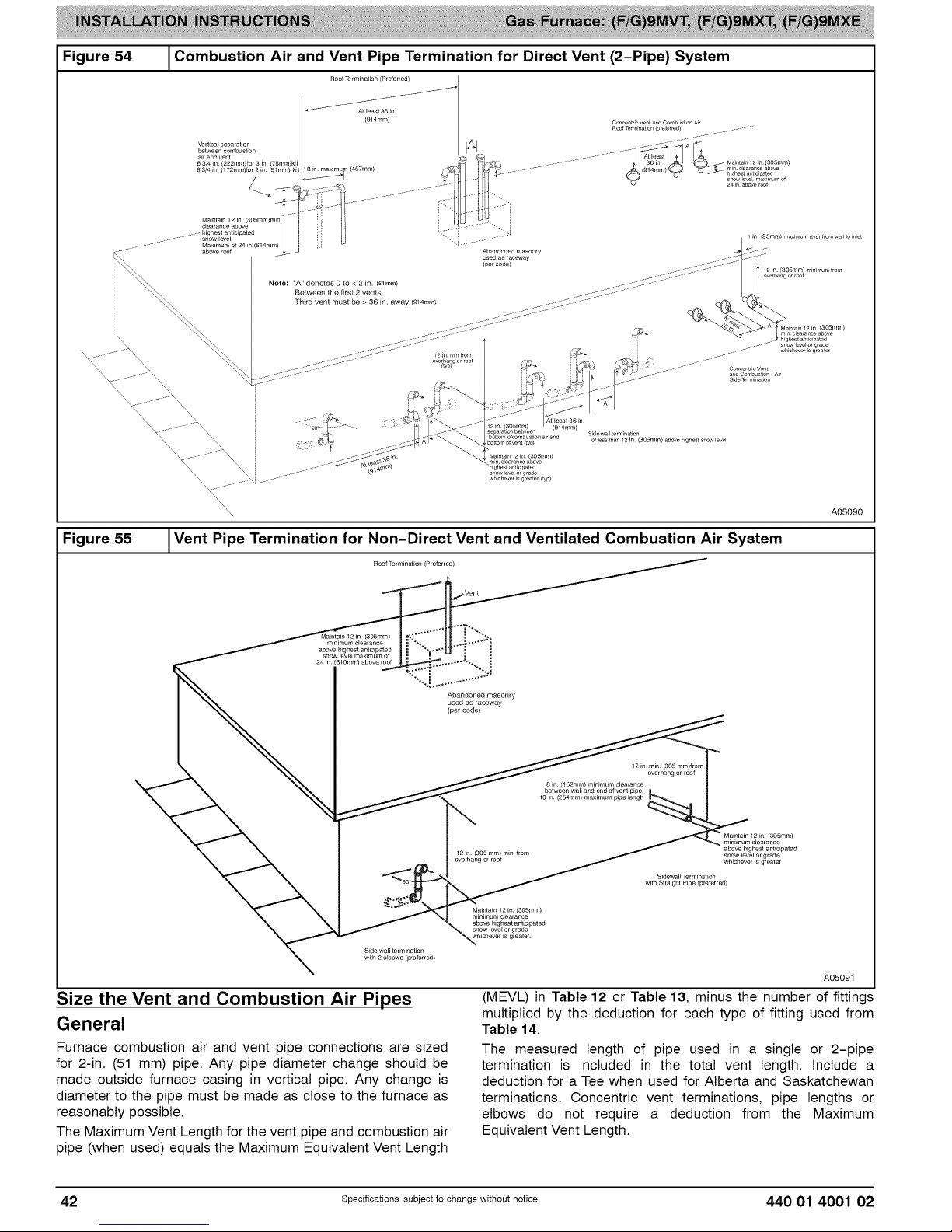

Horizontal Orientation

1. In the Horizontal orientation, a field supplied accessory

drain trap grommet is required to seal the gap between

the casing and the condensate trap. The condensate

trap outlet extends 2-in. (51 mm) below the furnace

casing. To allow for servicing the trap, the condensate

drain tube in the loose parts bag can be modified to

make a coupler to allow for future service of the

condensate trap and drain line.

2. Remove the knock-out for the condensate trap in the

side of the casing.

3. Install the drain trap grommet in the casing. If necessary,

remove the trap, install the grommet and re-install the

trap.

4. Remove the pre-formed drain tube, the offset 1/2-in.

CPVC pipe and two spring clamps from the loose parts

bag.

5. Remove the formed grommet on the tube to create an

elbow or straight connector. (See Figure 17)

6. Connect the cut tube to the outlet of the condensate trap

with 1 spring clamp.

//

//

\\\\\

OPEN SPRING CLAMP

INSERT FIELD - SUPPLIED

1/2'" CPVC DRAIN PIPE

* CLAMP MAY BE LOCATED

ON OUTSIDE OF DRAIN TUBE

RIGHT SIDE DRAIN INSTALLATION

Al1342

NSTALLATION

UPFLOW INSTALLATION

NOTE: The furnace must be pitched forward as shown in

Figure 18 for proper condensate drainage.

Figure 18 /Furnace Pitch Requirements

LEVEL0-IN. (0 MM)TO

1/2-1N.(13 MM) MAX

MIN 1/4-IN.(6 MM) TO

1/2-1N.(13 MM) MAX

FRONT

UPFLOW OR

DOWNFLOW HORIZONTAL Al1237

Supply Air Connections

For a furnace not equipped with a cooling coil, the outlet duct

shall be provided with a removable access panel. This opening

shall be accessible when the furnace is installed and shall be of

such a size that the heat exchanger can be viewed for possible

openings using light assistance or a probe can be inserted for

sampling the air stream. The cover attachment shall prevent

leaks.

18 Specificati ..... bject to change without notice. 440 01 4001 02

Page 19

Connect supply-air duct to flanges on furnace supply-air

outlet. Bend flange upward to 90 ° with wide duct pliers. (See

Figure 22) The supply-air duct must be connected to ONLY

the furnace supply-outlet-air duct flanges or air conditioning

coil casing (when used). DO NOT cut main furnace casing side

to attach supply air duct, humidifier, or other accessories. All

accessories MUST be connected to duct external to furnace

main casing.

Return Air Connections

FIRE HAZARD

A failure to follow this warning could cause personal

injury, death and/or property damage.

Never connect return-air ducts to the back of the

furnace. Follow instructions below.

The return-air duct must be connected to bottom, sides (left or

right), or a combination of bottom and side(s) of main furnace

casing as shown in Figure27, Figure28 and Figure29,

Bypass humidifier may be attached into unused return air side

of the furnace casing.

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed

in bottom return-air opening. Remove and discard this panel

when bottom return air is used. To remove bottom closure

panel, perform the following:

1. Tilt or raise furnace and remove four (4) screws holding

bottom plate. (See Figure 19)

2. Remove bottom plate.

3. Remove bottom closure panel.

4. Reinstall bottom plate and screws.

Figure 19 |Removing Bottom Closure Panel

I

.L

'>,

4 _" _ BOTTOM

c,osoRE

PANEL

openings in DOWNFLOW configuration. (See Figure27,

Figure 28 and Figure 29)

Leveling Legs (If Desired)

In upflow position with side return inlet(s), leveling legs may be

used. (See Figure 20) Install field-supplied, 5/16 x 1-1/2-in. (8

x 38 mm) (max) corrosion-resistant machine bolts, washers

and nuts.

Figure 20 1Leveling Legs

5/

(8ram)

1 3/4'

(44mrn)

1 3/4"

(44mrn)

(8mrn)

5/16"

(8mm)

(44mm) 1 3/41'

(44mm) 1

A89014

NOTE: Bottom closure must be used when leveling legs are

used. It may be necessary to remove and reinstall bottom

closure panel to install leveling legs. To remove bottom closure

panel, see Step 1 in Bottom Return Air Inlet section.

To install leveling legs:

1. Position furnace on its back. Locate and drill a hole in

each bottom corner of furnace.

2. For each leg, install nut on bolt and then install bolt with

nut in hole. (Install flat washer if desired.)

3. Install another nut on other side of furnace base. (Install

flat washer if desired.)

4. Adjust outside nut to provide desired height, and tighten

inside nut to secure arrangement.

5. Reinstall bottom closure panel if removed.

DOWN FLOW INSTALLATION

NOTE: The furnace must be pitched forward as shown in

Figure 18 for proper condensate drainage.

BOTTOM

PLATE

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed

in bottom return-air opening. This panel MUST be in place

when only side return air is used.

NOTE: Side return-air openings can be used in UPFLOW and

most HORIZONTAL configurations. Do not use side return-air

440 01 4001 02 Specificati ..... bject to change without notice. 19

Lll F004

Supply Air Connections

NOTE: For downflow applications, this furnace is approved for

use on combustible flooring when any one of the following

three accessories are used (see specification sheets for list of

approved accessories):

• Special Base - NAHA01101SB

• Cased Coil Assembly- END4X, ENW4X

1. Determine application being installed from Table 5.

2. Construct hole in floor per Table 5 and Figure 21.

3. Construct plenum to dimensions specified in Table 5

and Figure 21.

Page 20

4. InstallasshowninFigure23.IfCoilAssemblyPartis

used,installasshowninFigure24.

Figure 21

Floor and Plenum Opening

Dimensions

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing, safety

glasses and gloves when handling parts, and servicing

furnaces.

Connect supply-air duct to supply-air outlet on furnace. Bend

flange inward past 90 ° with wide duct pliers (See Table 1

Figure 22) The supply-air duct must be connected to ONLY

the furnace supply outlet or air conditioning coil casing (when

used). When installed on combustible material, supply-air duct

must be connected to ONLY the factory-approved accessory

subbase, or a factory-approved air conditioning coil casing. DO

NOT cut main furnace casing to attach supply side air duct,

humidifier, or other accessories. All accessories MUST be

connected to duct external to furnace casing.

Return Air Connections

A96283

NOTE: It is recommended that the perforated supply-air duct

flanges be completely removed from furnace when installing

the furnace on a factory-supplied cased coil or coil box. To

remove the supply-air duct flange, use wide duct pliers or hand

seamers to bend flange back and forth until it breaks off. Be

careful of sharp edges. (See Figure 22)

Figure 22 I Duct Flanges

UPFLOW DOWN FLOW HORIZONTAL

PERFORATED

DISCHARGE DUCT

NGE

L - -

i i

\

120 '_ YES 120 °'_,_

MIN MIN

FIRE HAZARD

A failure to follow this warning could cause personal

injury, death and/or property damage.

Never connect return-air ducts to the back of the

furnace. Follow instructions below.

The return-air duct must be connected to return-air opening

(bottom inlet) as shown in Figure 27. DO NOT cut into casing

sides (left or right). Bypass humidifier connections should be

made at ductwork or coil casing sides exterior to furnace. (See

Figure 27)

/

L _ _

YES

\

YES

YES

L _

120_

MIN

YES

YES

20 Specificati ..... bject to change without notice. 440 01 4001 02

NO

NO

NO

A1049[

Page 21

Table 5

FURNACE

CASING WIDTH

IN, (mm)

Opening Dimensions - in. (mm)