ICP ENH4X24C17A1, ENH4X24T17A1, ENH4X30C17A1, ENH4X30T17A1, ENH4X31C17A1 Installation Guide

...Page 1

NOTE: Read the entire instruction manual before starting

the installation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS ........................ 1

INTRODUCTION ................................... 2

INSTALLATION .................................... 2

Horizontal Right and Left with Pan Extension ...... 3

Furnace Attachment ............................ 3

Horizontal Attic ................................ 4

Horizontal Crawl Space ......................... 4

Refrigerant Lines .............................. 4

Connect Refrigerant Liquid and Suction Lines ...... 4

Connect Condensate Drain Line ................. 5

Waste Line Connection ......................... 5

Model Number Identification ..................... 6

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

shock or other conditions which may cause death, personal

injury or property damage. Consult a qualified installer,

service agency, or your distributor or branch for information

or assistance. The qualified installer or agency must use

factory-authorized kits or accessories when modifying this

product. Refer to the individual instructions packaged with

the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective

clothing and work gloves. Use quenching cloths for brazing

operations. Have fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions

attached to the unit. Consult local building codes and the

current editions of the National Electrical Codes (NEC)

NFPA 7O.

In Canada, refer to the current editions of the Canadian

Electrical Code CSA 022.1.

Recognize safety information. This is the safety-alert

symbol /b,. When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for personal

injury.

Understand the signal words DANGER, WARNING and

CAUTION. These words are used with the safety-alert

symbol. DANGER identifies the most serious hazards which

will result in severe personal injury or death. WARNING

signifies hazards which could result in personal injury or

death. CAUTION is used to identify unsafe practices, which

may result in minor personal injury or product and property

damage. NOTE is used to highlight suggestions which will

result in enhanced installation, reliability, or operation.

NOTE: Nitrogen can leak out through the needle pierce

hole in the plugs. This does not indicate a leaking coil nor

warrant return of the coil.

ELECTRICALSHOCKHAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying or servicing system, always

turn off main power to system. There may be more than

one disconnect switch. Lock out and tag switch with a

suitable warning label.

PERSONALINJURY HAZARD

Failure to follow this caution may result in personal

injury.

This coil contains Nitrogen precharge of 15 PSIG.

Release of this pressure through the center of the

rubber plugs is required before removing the plugs.

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing and

gloves when handling parts.

484 01 3700 01 December 2011

Page 2

INTRODUCTION

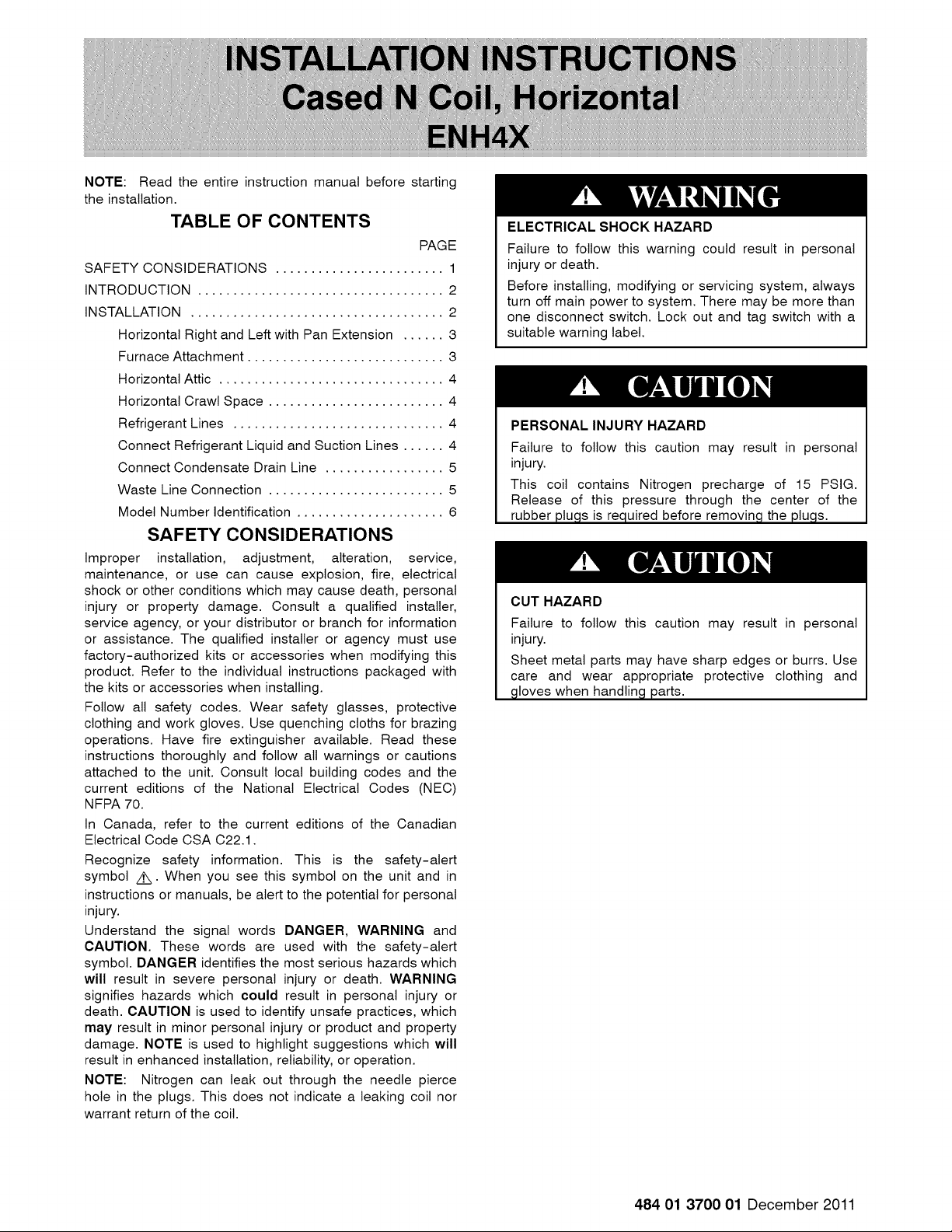

The ENH4X is a horizontal, multi-use furnace coil (see

Figure 1). With the use of field-supplied transition duct,

these furnace coils can also be applied to other similar

horizontal furnaces on the market. The ENH4X is available

in sizes 24 through 60. All models are equipped with a

factory-installed TXV and are used with R-410A refrigerant

systems.

NOTE: Models with tin-plated copper coils, "T" in the 8th

position of the model number, are installed the same as

standard copper coils.

INSTALLATION

This coil is not designed to be installed with furnaces that

measure wider than the coil itself.

These units can be installed in multiple configurations.

Before installation, there are several performance

requirements that must be considered because poor

installation can negatively alter performance. This section

will briefly discuss those factors.

Furnace

ctworCo.Ib

Airflow

Airflow

Shipping Brace

Pan Extension

Figure 1 - Model ENH4X Furnace Coil

Furnace

Coil I

o T r)O

Furnace Coil

Airflow

Firer Fra'e _1

Filler Plate -_/! _, o co

Remove

2 Screws

Ductwork

Ductwork

A06031

Ductwork Coil

o o O0

Ductwork Coil

o o ©O

Furnace

i[ ,_ Filler Plate

Filler Plate

Airflow

Airflow

A08065

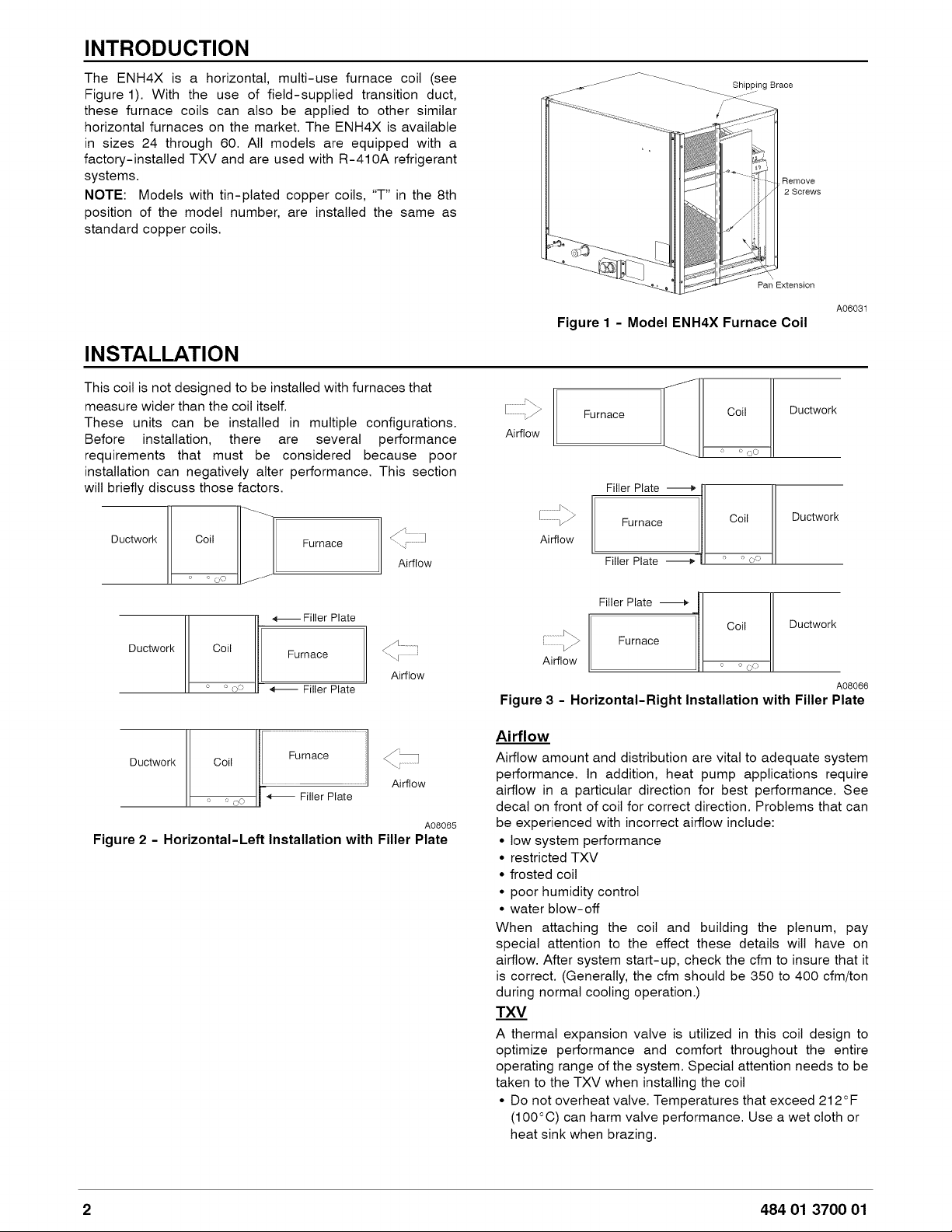

Figure 2 - Horizontal-Left Installation with Filler Plate

Filler Plate -_

Coil Ductwork

Furnace

Airflow o o co

A08066

Figure 3 - Horizontal-Right Installation with Filler Plate

Airflow

Airflow amount and distribution are vital to adequate system

performance. In addition, heat pump applications require

airflow in a particular direction for best performance. See

decal on front of coil for correct direction. Problems that can

be experienced with incorrect airflow include:

• low system performance

• restricted TXV

• frosted coil

• poor humidity control

• water blow-off

When attaching the coil and building the plenum, pay

special attention to the effect these details wilt have on

airflow. After system start-up, check the cfm to insure that it

is correct. (Generally, the cfm should be 350 to 400 cfm/ton

during normal cooling operation.)

TXV

A thermal expansion valve is utilized in this coil design to

optimize performance and comfort throughout the entire

operating range of the system. Special attention needs to be

taken to the TXV when installing the coil

• Do not overheat valve. Temperatures that exceed 212°F

(100°C) can harm valve performance. Use a wet cloth or

heat sink when brazing.

2 484 01 3700 01

Page 3

• Place liquid filter dryer near ID unit to reduce the risk of

debris clogging the valve.

• Make sure TXV bulb is securely fastened and wrapped in

the indentation on vapor line tube.

ENH4X Models:

These coils have a factory-installed hard-shutoff TXV

designed only for use with R-410A refrigerant. Use only

with outdoor units designed for R-410A.

NOTE: All TXV'S have preset superheat settings and are

not field-adjustable.

Cabinet Sweatinq

If this unit is installed in a garage, attic, or other

unconditioned space, special attention needs to be given to

the potential of cabinet sweating. A 6 inch (152 mm) wide

piece of insulation should be wrapped around the coil

casing and supply duct connection point.

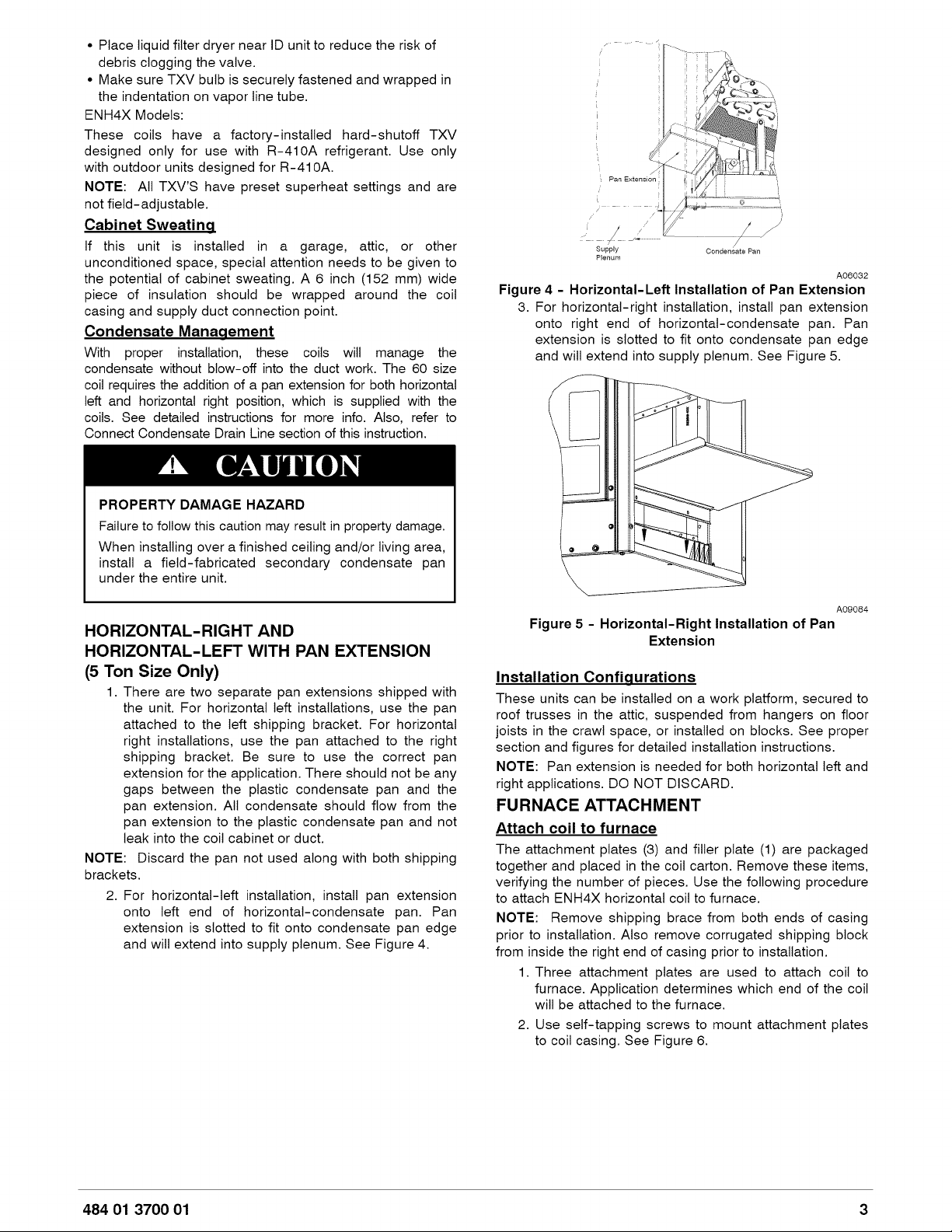

Condensate Manaqement

With proper installation, these coils wilt manage the

condensate without blow-off into the duct work. The 60 size

coil requires the addition of a pan extension for both horizontal

left and horizontal right position, which is supplied with the

coils. See detailed instructions for more info. Also, refer to

Connect Condensate Drain Line section of this instruction.

/

Pan Extension

/

Supply Condensate Pan

Plenum

A06032

Figure 4 - Horizontal-Left Installation of Pan Extension

3. For horizontal-right installation, install pan extension

onto right end of horizontal-condensate pan. Pan

extension is slotted to fit onto condensate pan edge

and will extend into supply plenum. See Figure 5.

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property damage.

When installing over a finished ceiling and/or living area,

install a field-fabricated secondary condensate pan

under the entire unit.

HORIZONTAL-RIGHT AND

HORIZONTAL-LEFT WITH PAN EXTENSION

(5 Ton Size Only)

1. There are two separate pan extensions shipped with

the unit. For horizontal left installations, use the pan

attached to the left shipping bracket. For horizontal

right installations, use the pan attached to the right

shipping bracket. Be sure to use the correct pan

extension for the application. There should not be any

gaps between the plastic condensate pan and the

pan extension. All condensate should flow from the

pan extension to the plastic condensate pan and not

leak into the coil cabinet or duct.

NOTE: Discard the pan not used along with both shipping

brackets.

2. For horizontal-left installation, install pan extension

onto left end of horizontal-condensate pan. Pan

extension is slotted to fit onto condensate pan edge

and will extend into supply plenum. See Figure 4.

A09084

Figure 5 - Horizontal-Right Installation of Pan

Extension

Installation Confiqurations

These units can be installed on a work platform, secured to

roof trusses in the attic, suspended from hangers on floor

joists in the crawl space, or installed on blocks. See proper

section and figures for detailed installation instructions.

NOTE: Pan extension is needed for both horizontal left and

right applications. DO NOT DISCARD.

FURNACE ATTACHMENT

Attach coil to furnace

The attachment plates (3) and filler plate (1) are packaged

together and placed in the coil carton. Remove these items,

verifying the number of pieces. Use the following procedure

to attach ENH4X horizontal coil to furnace.

NOTE: Remove shipping brace from both ends of casing

prior to installation. Also remove corrugated shipping block

from inside the right end of casing prior to installation.

1. Three attachment plates are used to attach coil to

furnace. Application determines which end of the coil

will be attached to the furnace.

2. Use self-tapping screws to mount attachment plates

to coil casing. See Figure 6.

484 01 3700 01 3

Page 4

i

A05419

Figure 6 - Mount Attachment Plates

3. Connect furnace snugly against coil casing.

4. Use self-tapping screws to attach furnace. See

Figure 7.

Drill After Coil _ Self-Tapping Screws

Is Installed\

\b4 _ ,

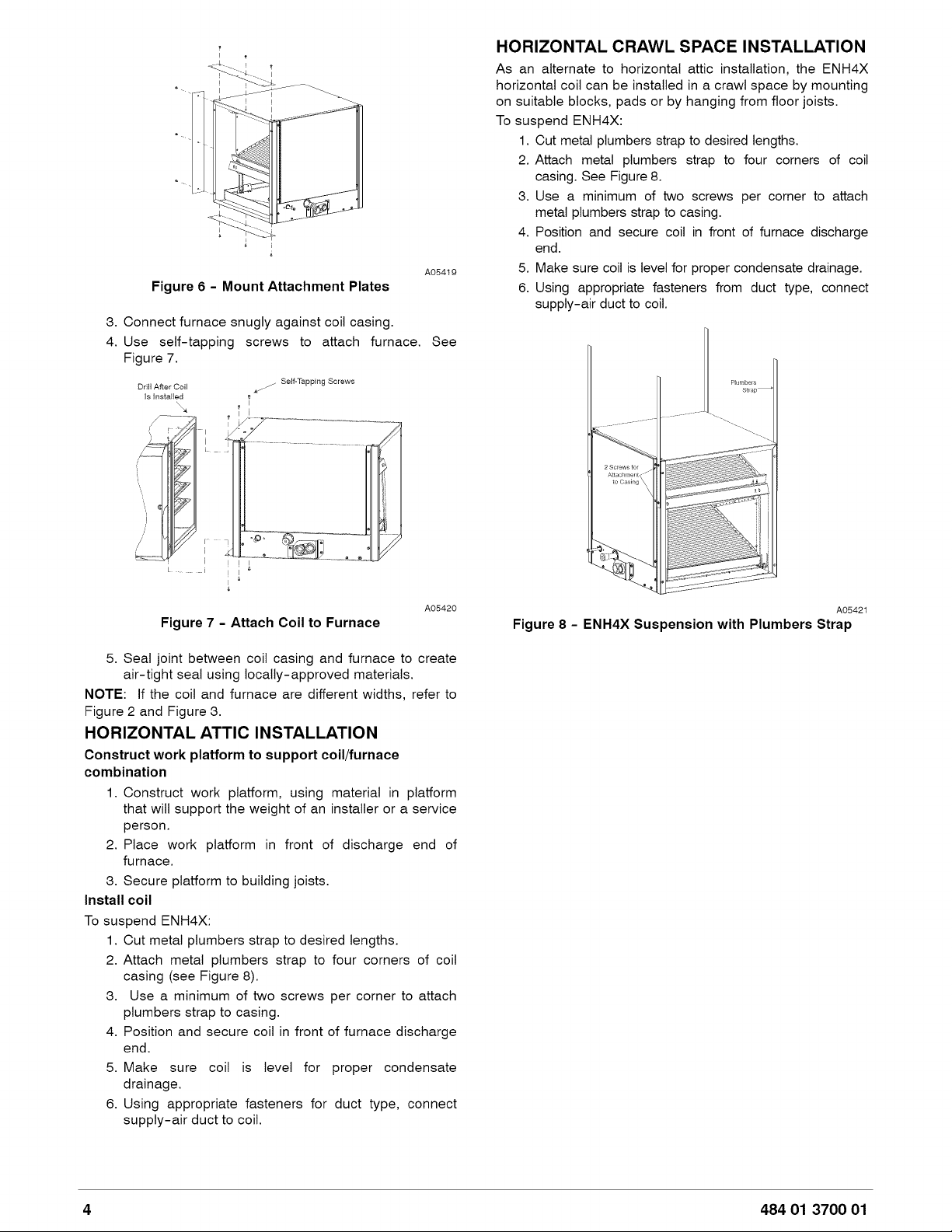

HORIZONTAL CRAWL SPACE INSTALLATION

As an alternate to horizontal attic installation, the ENH4X

horizontal coil can be installed in a crawl space by mounting

on suitable blocks, pads or by hanging from floor joists.

To suspend ENH4X:

1. Cut metal plumbers strap to desired lengths.

2. Attach metal plumbers strap to four corners of coil

casing. See Figure 8.

3. Use a minimum of two screws per corner to attach

metal plumbers strap to casing.

4. Position and secure coil in front of furnace discharge

end.

5. Make sure coil is level for proper condensate drainage.

6. Using appropriate fasteners from duct type, connect

supply-air duct to coil.

I.... i

A05420

Figure 7 - Attach Coil to Furnace

5. Seat joint between coil casing and furnace to create

air-tight seat using locally-approved materials.

NOTE: If the coil and furnace are different widths, refer to

Figure 2 and Figure 3.

HORIZONTAL ATTIC INSTALLATION

Construct work platform to support coil/furnace

combination

1. Construct work platform, using material in platform

that wilt support the weight of an installer or a service

person.

2. Place work platform in front of discharge end of

furnace.

3. Secure platform to building joists.

Install coil

To suspend ENH4X:

1. Cut metal plumbers strap to desired lengths.

2. Attach metal plumbers strap to four corners of coil

casing (see Figure 8).

3. Use a minimum of two screws per corner to attach

plumbers strap to casing.

4. Position and secure coil in front of furnace discharge

end.

5. Make sure coil is level for proper condensate

drainage.

6. Using appropriate fasteners for duct type, connect

supply-air duct to coil.

A05421

Figure 8 - ENH4X Suspension with Plumbers Strap

4 484 01 3700 01

Page 5

REFRIGERANT LINES

Refrigerant lines must be configured per local building

codes and the guidelines outlined in the OD units

installation instructions.

NOTE: The filter dryer should be placed just before the

indoor unit.

Connect Refriqerant Liquid and Suction Lines

For matched and mismatched systems, use line sizes

recommended in outdoor unit Installation Instructions.

The coil can be connected to outdoor units using accessory

refrigerant line sets or field-supplied lines of refrigerant

grade.

See Table 1 for coil connection tube size.

Table 1

MODEL NUMBER Liquid Suction

ENH4X24(C,T)17A 3/8 (1 O) 5/8 (16)

EN H4X30(C,T)I 7A 3/8 (10) 3/4 (19)

ENH4X31 (C,T)I 7A 3/8 (10) 3/4 (19)

ENH4X36(C,T)17A 3/8 (1 O) 3/4 (19)

ENH4X42(C,T)21A 3/8 (1 O) 7/8 (22)

ENH4X43(C,T)21A 3/8 (1 O) 7/8 (22)

ENH4X48(C,T)21A 3/8 (1 O) 7/8 (22)

ENH4X60(C,T)24A 3/8 (10) 7/8 (22)

ENH4X61 (C,T)24A 3/8 (1 O) 7/8 (22)

UNIT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

To avoid valve damage to the refrigerant control device

while brazing, valves must be wrapped with a

heat-sinking material such as a wet cloth.

1. Remove cabinet access door.

2. Remove rubber plugs from coil stubs using a pulling

and twisting motion. Hold coil stubs steady to avoid

bending or distorting.

3. Wrap TXV and nearby tubing with a heat-sinking

material such as a wet cloth.

4. Fit refrigerant lines into coil stubs. Wrap a heat sinking

material such as a wet cloth behind braze joints.

5. Use 1/2 psig Nitrogen purge in the suction and out the

liquid line.

6. Braze using a Sil-Fos or Phos-copper alloy. Do not use

soft solder.

7. After brazing, allow joints to coot. Slide rubber grommets

over joints. Position tubing at center of each grommet to

ensure an air seal around the tube.

8. Always evacuate lines and reclaim refrigerant when

making connections or flaring refrigerant lines. Leak

check connections before insulating entire suction line.

9. If outdoor equipment will not be installed until a later

date, braze liquid and suction lines closed outside. Add

a Schraeder port test fitting to the suction line outside.

COIL CONNECTION TUBE SIZE

inches (mm)

CONDENSATE DRAIN LINE CONNECTION

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property

damage.

When installing over a finished ceiling and/or living area,

install a field-fabricated secondary condensate pan

under the entire unit.

The coil is designed to dispose of accumulated water

through built-in condensate drain fittings. It is recommended

that PVC fittings be used on the condensate pan. Do not

over-tighten. Finger tighten plus 1-1/2 turns. Be sure to

install plastic plug in unused condensate drain fitting. Two

3/4 inch female threaded pipe connections are provided in

each coil condensate pan.

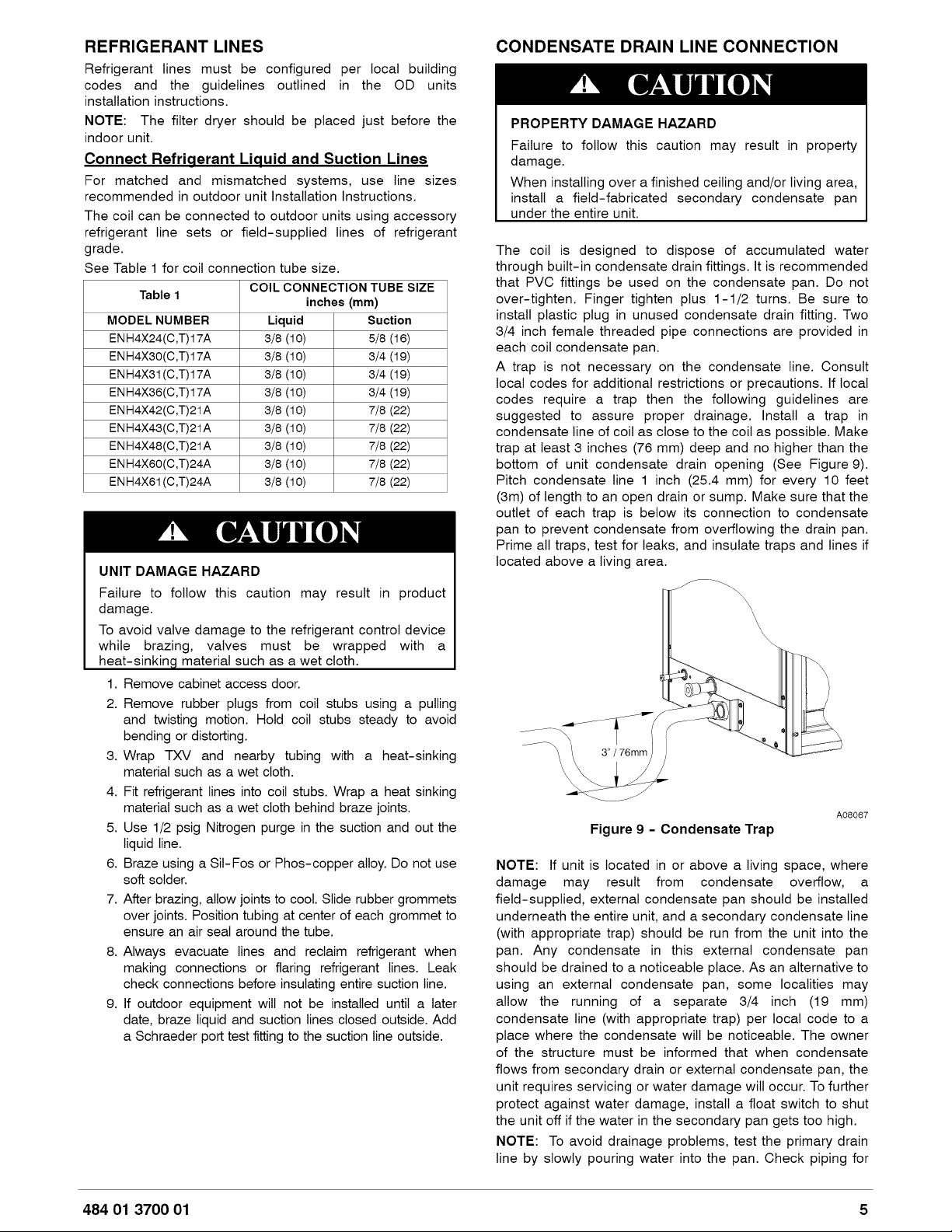

A trap is not necessary on the condensate line. Consult

local codes for additional restrictions or precautions. If local

codes require a trap then the following guidelines are

suggested to assure proper drainage. Install a trap in

condensate line of coil as close to the coil as possible. Make

trap at least 3 inches (76 mm) deep and no higher than the

bottom of unit condensate drain opening (See Figure 9).

Pitch condensate line 1 inch (25.4 mm) for every 10 feet

(3m) of length to an open drain or sump. Make sure that the

outlet of each trap is below its connection to condensate

pan to prevent condensate from overflowing the drain pan.

Prime all traps, test for leaks, and insulate traps and lines if

located above a living area.

\

\\

\

\

\

\ 3" / 76mm

\

\

A08067

Figure 9 - Condensate Trap

NOTE: If unit is located in or above a living space, where

damage may result from condensate overflow, a

field-supplied, external condensate pan should be installed

underneath the entire unit, and a secondary condensate line

(with appropriate trap) should be run from the unit into the

pan. Any condensate in this external condensate pan

should be drained to a noticeable place. As an alternative to

using an external condensate pan, some localities may

allow the running of a separate 3/4 inch (19 mm)

condensate line (with appropriate trap) per local code to a

place where the condensate will be noticeable. The owner

of the structure must be informed that when condensate

flows from secondary drain or external condensate pan, the

unit requires servicing or water damage wilt occur. To further

protect against water damage, install a float switch to shut

the unit off if the water in the secondary pan gets too high.

NOTE: To avoid drainage problems, test the primary drain

line by slowly pouring water into the pan. Check piping for

484 01 3700 01 5

Page 6

leaks and proper condensate drainage. Using the

secondary drain as explained in the previous note provides

further protection against overflow due to a clogged primary

drain.

NOTE: In applications where return air humidity levels stay

at 70% or above for a prolonged period of time,

condensation can form on the bottom of pan and drip.

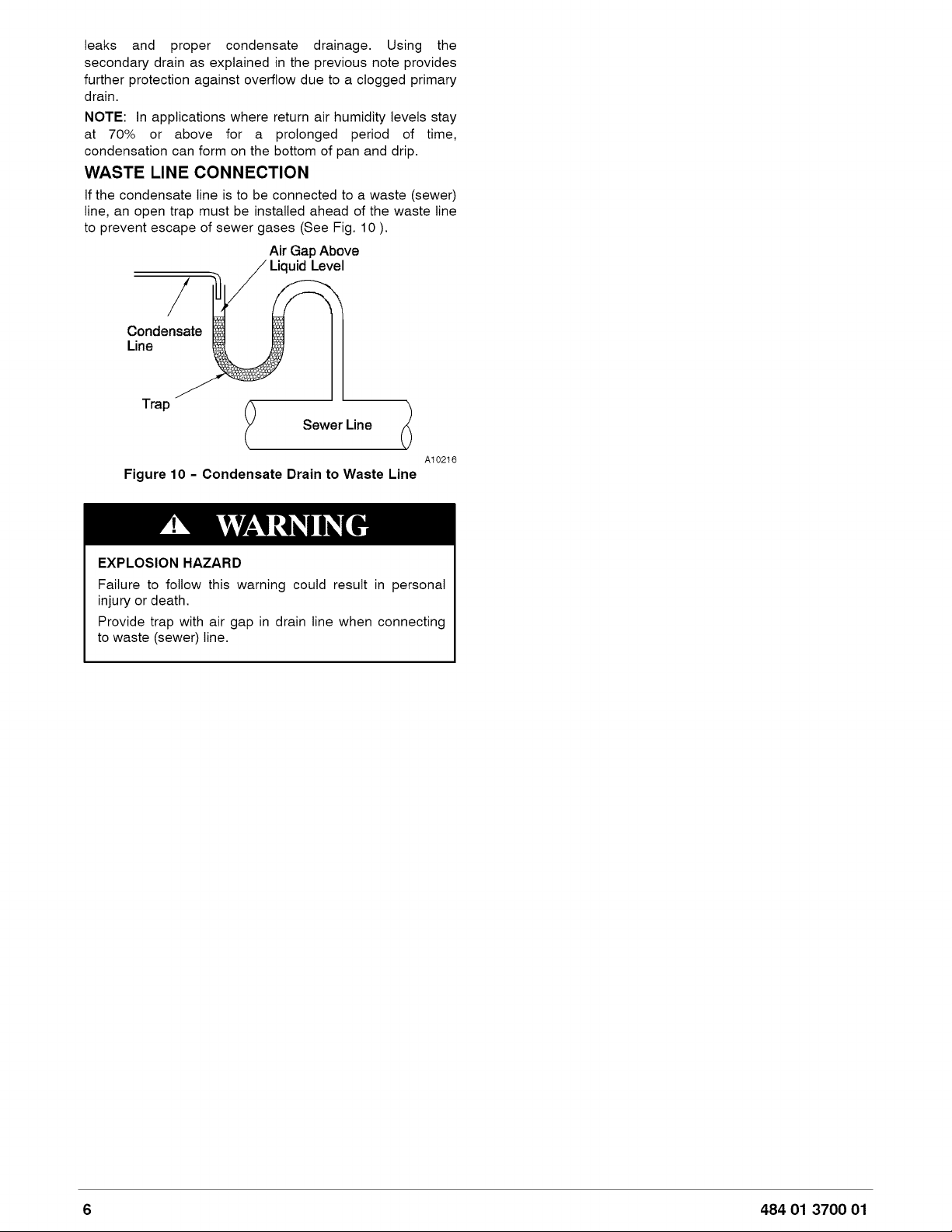

WASTE LINE CONNECTION

If the condensate line is to be connected to a waste (sewer)

line, an open trap must be installed ahead of the waste line

to prevent escape of sewer gases (See Fig. 10 ).

Air Gap Above

uid Level

Condensate

Line

• l ,.w.r.,n°t

A10216

Figure 10 - Condensate Drain to Waste Line

EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury or death.

Provide trap with air gap in drain line when connecting

to waste (sewer) line.

6 484 01 3700 01

Page 7

iiii !iiiiii!! J iiii I!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!i ii ii i Ji! iij i jiid i! ii i !iiii i J iiii I!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI i

Digit Position 1 2 3 4 5 6,7 8 9,1 0 11 12

E N H 4 X 18 C 14 A 1

E = Evaporator

B = Builder

D = Standard

N = N Coil TYPE

A = Uncased

D = Cased Upflow/Downflow

M = Cased Multiposition (Upflow/Downflow/Horizontal)

W = Cased Upflow/Downflow for narrower furnaces

H = Cased Horizontal

INSTALLATION

4 = Environmentally Sound R-410A

P = Piston

X = TXV

18 = 18,000 BTUH = 11/2tons

19 = 18,000 BTUH = 11/2tons

24 = 24,000 BTUH = 2 tons

30 = 30,000 BTUH = 21/2tons

31 = 30,000 BTUH = 21/2tons

36 = 36,000 BTUH = 3 tons

37 = 36,000 BTUH = 3 tons

42 = 42,000 BTUH = 31/2tons

43 = 42,000 BTUH = 31/2tons

48 = 48,000 BTUH = 4 tons

60 = 60,000 BTUH = 5 tons

61 = 60,000 BTUH = 5 tons

C = Plain Copper

L = Aluminum

T = Tin Coated Copper

14 = 14-3/16"

17 = 17-1/2"

21 = 21"

24 = 24-1/2"

BB = 15-1/2"

FF = 19.1"

JJ = 22.8"

LL = 24-1/2"

Sales Digit (Major Revision)

Engineering Digit (Minor Revision)

REFRIGERANT

METERING DEVICE

NOMINAL CAPACITY

HAIRPIN MATERIAL

WIDTH

International Comfort Products, LLC

484 01 3700 01 7

Lewisburg, TN 37091 USA

Page 8

NOTE: Read the entire instruction manual before starting

the installation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS ........................ 1

INTRODUCTION ................................... 2

INSTALLATION .................................... 2

Horizontal Right and Left with Pan Extension ...... 3

Furnace Attachment ............................ 3

Horizontal Attic ................................ 4

Horizontal Crawl Space ......................... 4

Refrigerant Lines .............................. 4

Connect Refrigerant Liquid and Suction Lines ...... 4

Connect Condensate Drain Line ................. 5

Waste Line Connection ......................... 5

Model Number Identification ..................... 6

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

shock or other conditions which may cause death, personal

injury or property damage. Consult a qualified installer,

service agency, or your distributor or branch for information

or assistance. The qualified installer or agency must use

factory-authorized kits or accessories when modifying this

product. Refer to the individual instructions packaged with

the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective

clothing and work gloves. Use quenching cloths for brazing

operations. Have fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions

attached to the unit. Consult local building codes and the

current editions of the National Electrical Codes (NEC)

NFPA 7O.

In Canada, refer to the current editions of the Canadian

Electrical Code CSA 022.1.

Recognize safety information. This is the safety-alert

symbol /b,. When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for personal

injury.

Understand the signal words DANGER, WARNING and

CAUTION. These words are used with the safety-alert

symbol. DANGER identifies the most serious hazards which

will result in severe personal injury or death. WARNING

signifies hazards which could result in personal injury or

death. CAUTION is used to identify unsafe practices, which

may result in minor personal injury or product and property

damage. NOTE is used to highlight suggestions which will

result in enhanced installation, reliability, or operation.

NOTE: Nitrogen can leak out through the needle pierce

hole in the plugs. This does not indicate a leaking coil nor

warrant return of the coil.

ELECTRICALSHOCKHAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying or servicing system, always

turn off main power to system. There may be more than

one disconnect switch. Lock out and tag switch with a

suitable warning label.

PERSONALINJURY HAZARD

Failure to follow this caution may result in personal

injury.

This coil contains Nitrogen precharge of 15 PSIG.

Release of this pressure through the center of the

rubber plugs is required before removing the plugs.

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing and

gloves when handling parts.

484 01 3700 01 December 2011

Page 9

INTRODUCTION

The ENH4X is a horizontal, multi-use furnace coil (see

Figure 1). With the use of field-supplied transition duct,

these furnace coils can also be applied to other similar

horizontal furnaces on the market. The ENH4X is available

in sizes 24 through 60. All models are equipped with a

factory-installed TXV and are used with R-410A refrigerant

systems.

NOTE: Models with tin-plated copper coils, "T" in the 8th

position of the model number, are installed the same as

standard copper coils.

INSTALLATION

This coil is not designed to be installed with furnaces that

measure wider than the coil itself.

These units can be installed in multiple configurations.

Before installation, there are several performance

requirements that must be considered because poor

installation can negatively alter performance. This section

will briefly discuss those factors.

Furnace

ctworCo.Ib

Airflow

Airflow

Shipping Brace

Pan Extension

Figure 1 - Model ENH4X Furnace Coil

Furnace

Coil I

o T r)O

Furnace Coil

Airflow

Firer Fra'e _1

Filler Plate -_/! _, o co

Remove

2 Screws

Ductwork

Ductwork

A06031

Ductwork Coil

o o O0

Ductwork Coil

o o ©O

Furnace

i[ ,_ Filler Plate

Filler Plate

Airflow

Airflow

A08065

Figure 2 - Horizontal-Left Installation with Filler Plate

Filler Plate -_

Coil Ductwork

Furnace

Airflow o o co

A08066

Figure 3 - Horizontal-Right Installation with Filler Plate

Airflow

Airflow amount and distribution are vital to adequate system

performance. In addition, heat pump applications require

airflow in a particular direction for best performance. See

decal on front of coil for correct direction. Problems that can

be experienced with incorrect airflow include:

• low system performance

• restricted TXV

• frosted coil

• poor humidity control

• water blow-off

When attaching the coil and building the plenum, pay

special attention to the effect these details wilt have on

airflow. After system start-up, check the cfm to insure that it

is correct. (Generally, the cfm should be 350 to 400 cfm/ton

during normal cooling operation.)

TXV

A thermal expansion valve is utilized in this coil design to

optimize performance and comfort throughout the entire

operating range of the system. Special attention needs to be

taken to the TXV when installing the coil

• Do not overheat valve. Temperatures that exceed 212°F

(100°C) can harm valve performance. Use a wet cloth or

heat sink when brazing.

2 484 01 3700 01

Page 10

• Place liquid filter dryer near ID unit to reduce the risk of

debris clogging the valve.

• Make sure TXV bulb is securely fastened and wrapped in

the indentation on vapor line tube.

ENH4X Models:

These coils have a factory-installed hard-shutoff TXV

designed only for use with R-410A refrigerant. Use only

with outdoor units designed for R-410A.

NOTE: All TXV'S have preset superheat settings and are

not field-adjustable.

Cabinet Sweatinq

If this unit is installed in a garage, attic, or other

unconditioned space, special attention needs to be given to

the potential of cabinet sweating. A 6 inch (152 mm) wide

piece of insulation should be wrapped around the coil

casing and supply duct connection point.

Condensate Manaqement

With proper installation, these coils wilt manage the

condensate without blow-off into the duct work. The 60 size

coil requires the addition of a pan extension for both horizontal

left and horizontal right position, which is supplied with the

coils. See detailed instructions for more info. Also, refer to

Connect Condensate Drain Line section of this instruction.

/

Pan Extension

/

Supply Condensate Pan

Plenum

A06032

Figure 4 - Horizontal-Left Installation of Pan Extension

3. For horizontal-right installation, install pan extension

onto right end of horizontal-condensate pan. Pan

extension is slotted to fit onto condensate pan edge

and will extend into supply plenum. See Figure 5.

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property damage.

When installing over a finished ceiling and/or living area,

install a field-fabricated secondary condensate pan

under the entire unit.

HORIZONTAL-RIGHT AND

HORIZONTAL-LEFT WITH PAN EXTENSION

(5 Ton Size Only)

1. There are two separate pan extensions shipped with

the unit. For horizontal left installations, use the pan

attached to the left shipping bracket. For horizontal

right installations, use the pan attached to the right

shipping bracket. Be sure to use the correct pan

extension for the application. There should not be any

gaps between the plastic condensate pan and the

pan extension. All condensate should flow from the

pan extension to the plastic condensate pan and not

leak into the coil cabinet or duct.

NOTE: Discard the pan not used along with both shipping

brackets.

2. For horizontal-left installation, install pan extension

onto left end of horizontal-condensate pan. Pan

extension is slotted to fit onto condensate pan edge

and will extend into supply plenum. See Figure 4.

A09084

Figure 5 - Horizontal-Right Installation of Pan

Extension

Installation Confiqurations

These units can be installed on a work platform, secured to

roof trusses in the attic, suspended from hangers on floor

joists in the crawl space, or installed on blocks. See proper

section and figures for detailed installation instructions.

NOTE: Pan extension is needed for both horizontal left and

right applications. DO NOT DISCARD.

FURNACE ATTACHMENT

Attach coil to furnace

The attachment plates (3) and filler plate (1) are packaged

together and placed in the coil carton. Remove these items,

verifying the number of pieces. Use the following procedure

to attach ENH4X horizontal coil to furnace.

NOTE: Remove shipping brace from both ends of casing

prior to installation. Also remove corrugated shipping block

from inside the right end of casing prior to installation.

1. Three attachment plates are used to attach coil to

furnace. Application determines which end of the coil

will be attached to the furnace.

2. Use self-tapping screws to mount attachment plates

to coil casing. See Figure 6.

484 01 3700 01 3

Page 11

i

A05419

Figure 6 - Mount Attachment Plates

3. Connect furnace snugly against coil casing.

4. Use self-tapping screws to attach furnace. See

Figure 7.

Drill After Coil _ Self-Tapping Screws

Is Installed\

\b4 _ ,

HORIZONTAL CRAWL SPACE INSTALLATION

As an alternate to horizontal attic installation, the ENH4X

horizontal coil can be installed in a crawl space by mounting

on suitable blocks, pads or by hanging from floor joists.

To suspend ENH4X:

1. Cut metal plumbers strap to desired lengths.

2. Attach metal plumbers strap to four corners of coil

casing. See Figure 8.

3. Use a minimum of two screws per corner to attach

metal plumbers strap to casing.

4. Position and secure coil in front of furnace discharge

end.

5. Make sure coil is level for proper condensate drainage.

6. Using appropriate fasteners from duct type, connect

supply-air duct to coil.

I.... i

A05420

Figure 7 - Attach Coil to Furnace

5. Seat joint between coil casing and furnace to create

air-tight seat using locally-approved materials.

NOTE: If the coil and furnace are different widths, refer to

Figure 2 and Figure 3.

HORIZONTAL ATTIC INSTALLATION

Construct work platform to support coil/furnace

combination

1. Construct work platform, using material in platform

that wilt support the weight of an installer or a service

person.

2. Place work platform in front of discharge end of

furnace.

3. Secure platform to building joists.

Install coil

To suspend ENH4X:

1. Cut metal plumbers strap to desired lengths.

2. Attach metal plumbers strap to four corners of coil

casing (see Figure 8).

3. Use a minimum of two screws per corner to attach

plumbers strap to casing.

4. Position and secure coil in front of furnace discharge

end.

5. Make sure coil is level for proper condensate

drainage.

6. Using appropriate fasteners for duct type, connect

supply-air duct to coil.

A05421

Figure 8 - ENH4X Suspension with Plumbers Strap

4 484 01 3700 01

Page 12

REFRIGERANT LINES

Refrigerant lines must be configured per local building

codes and the guidelines outlined in the OD units

installation instructions.

NOTE: The filter dryer should be placed just before the

indoor unit.

Connect Refriqerant Liquid and Suction Lines

For matched and mismatched systems, use line sizes

recommended in outdoor unit Installation Instructions.

The coil can be connected to outdoor units using accessory

refrigerant line sets or field-supplied lines of refrigerant

grade.

See Table 1 for coil connection tube size.

Table 1

MODEL NUMBER Liquid Suction

ENH4X24(C,T)17A 3/8 (1 O) 5/8 (16)

EN H4X30(C,T)I 7A 3/8 (10) 3/4 (19)

ENH4X31 (C,T)I 7A 3/8 (10) 3/4 (19)

ENH4X36(C,T)17A 3/8 (1 O) 3/4 (19)

ENH4X42(C,T)21A 3/8 (1 O) 7/8 (22)

ENH4X43(C,T)21A 3/8 (1 O) 7/8 (22)

ENH4X48(C,T)21A 3/8 (1 O) 7/8 (22)

ENH4X60(C,T)24A 3/8 (10) 7/8 (22)

ENH4X61 (C,T)24A 3/8 (1 O) 7/8 (22)

UNIT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

To avoid valve damage to the refrigerant control device

while brazing, valves must be wrapped with a

heat-sinking material such as a wet cloth.

1. Remove cabinet access door.

2. Remove rubber plugs from coil stubs using a pulling

and twisting motion. Hold coil stubs steady to avoid

bending or distorting.

3. Wrap TXV and nearby tubing with a heat-sinking

material such as a wet cloth.

4. Fit refrigerant lines into coil stubs. Wrap a heat sinking

material such as a wet cloth behind braze joints.

5. Use 1/2 psig Nitrogen purge in the suction and out the

liquid line.

6. Braze using a Sil-Fos or Phos-copper alloy. Do not use

soft solder.

7. After brazing, allow joints to coot. Slide rubber grommets

over joints. Position tubing at center of each grommet to

ensure an air seal around the tube.

8. Always evacuate lines and reclaim refrigerant when

making connections or flaring refrigerant lines. Leak

check connections before insulating entire suction line.

9. If outdoor equipment will not be installed until a later

date, braze liquid and suction lines closed outside. Add

a Schraeder port test fitting to the suction line outside.

COIL CONNECTION TUBE SIZE

inches (mm)

CONDENSATE DRAIN LINE CONNECTION

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property

damage.

When installing over a finished ceiling and/or living area,

install a field-fabricated secondary condensate pan

under the entire unit.

The coil is designed to dispose of accumulated water

through built-in condensate drain fittings. It is recommended

that PVC fittings be used on the condensate pan. Do not

over-tighten. Finger tighten plus 1-1/2 turns. Be sure to

install plastic plug in unused condensate drain fitting. Two

3/4 inch female threaded pipe connections are provided in

each coil condensate pan.

A trap is not necessary on the condensate line. Consult

local codes for additional restrictions or precautions. If local

codes require a trap then the following guidelines are

suggested to assure proper drainage. Install a trap in

condensate line of coil as close to the coil as possible. Make

trap at least 3 inches (76 mm) deep and no higher than the

bottom of unit condensate drain opening (See Figure 9).

Pitch condensate line 1 inch (25.4 mm) for every 10 feet

(3m) of length to an open drain or sump. Make sure that the

outlet of each trap is below its connection to condensate

pan to prevent condensate from overflowing the drain pan.

Prime all traps, test for leaks, and insulate traps and lines if

located above a living area.

\

\\

\

\

\

\ 3" / 76mm

\

\

A08067

Figure 9 - Condensate Trap

NOTE: If unit is located in or above a living space, where

damage may result from condensate overflow, a

field-supplied, external condensate pan should be installed

underneath the entire unit, and a secondary condensate line

(with appropriate trap) should be run from the unit into the

pan. Any condensate in this external condensate pan

should be drained to a noticeable place. As an alternative to

using an external condensate pan, some localities may

allow the running of a separate 3/4 inch (19 mm)

condensate line (with appropriate trap) per local code to a

place where the condensate will be noticeable. The owner

of the structure must be informed that when condensate

flows from secondary drain or external condensate pan, the

unit requires servicing or water damage wilt occur. To further

protect against water damage, install a float switch to shut

the unit off if the water in the secondary pan gets too high.

NOTE: To avoid drainage problems, test the primary drain

line by slowly pouring water into the pan. Check piping for

484 01 3700 01 5

Page 13

leaks and proper condensate drainage. Using the

secondary drain as explained in the previous note provides

further protection against overflow due to a clogged primary

drain.

NOTE: In applications where return air humidity levels stay

at 70% or above for a prolonged period of time,

condensation can form on the bottom of pan and drip.

WASTE LINE CONNECTION

If the condensate line is to be connected to a waste (sewer)

line, an open trap must be installed ahead of the waste line

to prevent escape of sewer gases (See Fig. 10 ).

Air Gap Above

uid Level

Condensate

Line

• l ,.w.r.,n°t

A10216

Figure 10 - Condensate Drain to Waste Line

EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury or death.

Provide trap with air gap in drain line when connecting

to waste (sewer) line.

6 484 01 3700 01

Page 14

iiii !iiiiii!! J iiii I!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!i ii ii i Ji! iij i jiid i! ii i !iiii i J iiii I!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI!iI i

Digit Position 1 2 3 4 5 6,7 8 9,1 0 11 12

E N H 4 X 18 C 14 A 1

E = Evaporator

B = Builder

D = Standard

N = N Coil TYPE

A = Uncased

D = Cased Upflow/Downflow

M = Cased Multiposition (Upflow/Downflow/Horizontal)

W = Cased Upflow/Downflow for narrower furnaces

H = Cased Horizontal

INSTALLATION

4 = Environmentally Sound R-410A

P = Piston

X = TXV

18 = 18,000 BTUH = 11/2tons

19 = 18,000 BTUH = 11/2tons

24 = 24,000 BTUH = 2 tons

30 = 30,000 BTUH = 21/2tons

31 = 30,000 BTUH = 21/2tons

36 = 36,000 BTUH = 3 tons

37 = 36,000 BTUH = 3 tons

42 = 42,000 BTUH = 31/2tons

43 = 42,000 BTUH = 31/2tons

48 = 48,000 BTUH = 4 tons

60 = 60,000 BTUH = 5 tons

61 = 60,000 BTUH = 5 tons

C = Plain Copper

L = Aluminum

T = Tin Coated Copper

14 = 14-3/16"

17 = 17-1/2"

21 = 21"

24 = 24-1/2"

BB = 15-1/2"

FF = 19.1"

JJ = 22.8"

LL = 24-1/2"

Sales Digit (Major Revision)

Engineering Digit (Minor Revision)

REFRIGERANT

METERING DEVICE

NOMINAL CAPACITY

HAIRPIN MATERIAL

WIDTH

International Comfort Products, LLC

484 01 3700 01 7

Lewisburg, TN 37091 USA

Loading...

Loading...