Page 1

SAFETY CONSIDERATIONS

Improper installation adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock,

or other conditions which may cause death, personal injury, or

property damage. Consult a qualified installer, service agency,

or your distributor or branch for information or assistance. The

qualified installer or agency must use factory--authorized kits or

accessories when modifying this product Refer to the individual

instructions packaged with the kits or accessories when

installing.

Follow all safety codes. Wear safety glasses, protective

clothing, and work gloves. Use quenching cloth for brazing

operations. Have a fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions

included in literature and attached to the unit. Consult local

building codes, the current editions of the National Electrical

Code (NEC) NFPA 70. In Canada refer to the current editions of

the Canadian Electrical Code CSA C22.1

Recognize safety information. This is the safety-alert symbol

/_. When you see this symbol on the furnace and in

instructions or manuals, be alert to the potential for personal

injury. Understand the signal words DANGER, WARNING,

CAUTION and NOTE. The words DANGER, WARNING, and

CAUTION are used with the safety alert symbol. DANGER

identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies a hazard which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced installation,

reliability, or operation.

Introduction

The EHIA electric heaters are designed specifically for the follow-

ing revised Modular Blower units with a sales code and series

change of B1 & Cl. The Modular units have been updated with

new electronic fan control boards.

208/230v PSC Blower 208/230v Variable-Speed Blower

MF08B1500B1 MV08B1500B1

MF12F1900B1 MV12F1900B1

MF16J2200B1 MY16J2200B1

MF20L2400B1 MV20L2400B1

208/230v PSC Blower 208/230v Variable-Speed Blower

MF08001401 MY08001401

MF12001701 MY12001701

MF160021 C1 MY160021 C1

MF20002401 MV20002401

iii

PERSONAL INJURY, AND/OR PROPERTY DAMAGE

HAZARD

Failure to carefully read and follow this warning could result in

equipment malfunction, property damage, personal injury

and/or death.

Installation or repairs made by unqualified persons could result

in equipment malfunction, property damage, personal injury

and/or death.

The information contained in this manual is intended for use by

a qualified service technician familiar with safety procedures

and equipped with proper tools and test instruments.

Follow all safety codes. Wear safety glasses, protective

clothing, and work gloves. Use quenching cloth for brazing

operations. Have a fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions

included in literature and attached to the unit. Consult local

building codes, the current editions of the National Electrical

Code (NEC) NFPA 70. In Canada refer to the current editions

of the Canadian Electrical Code CSA O22.1

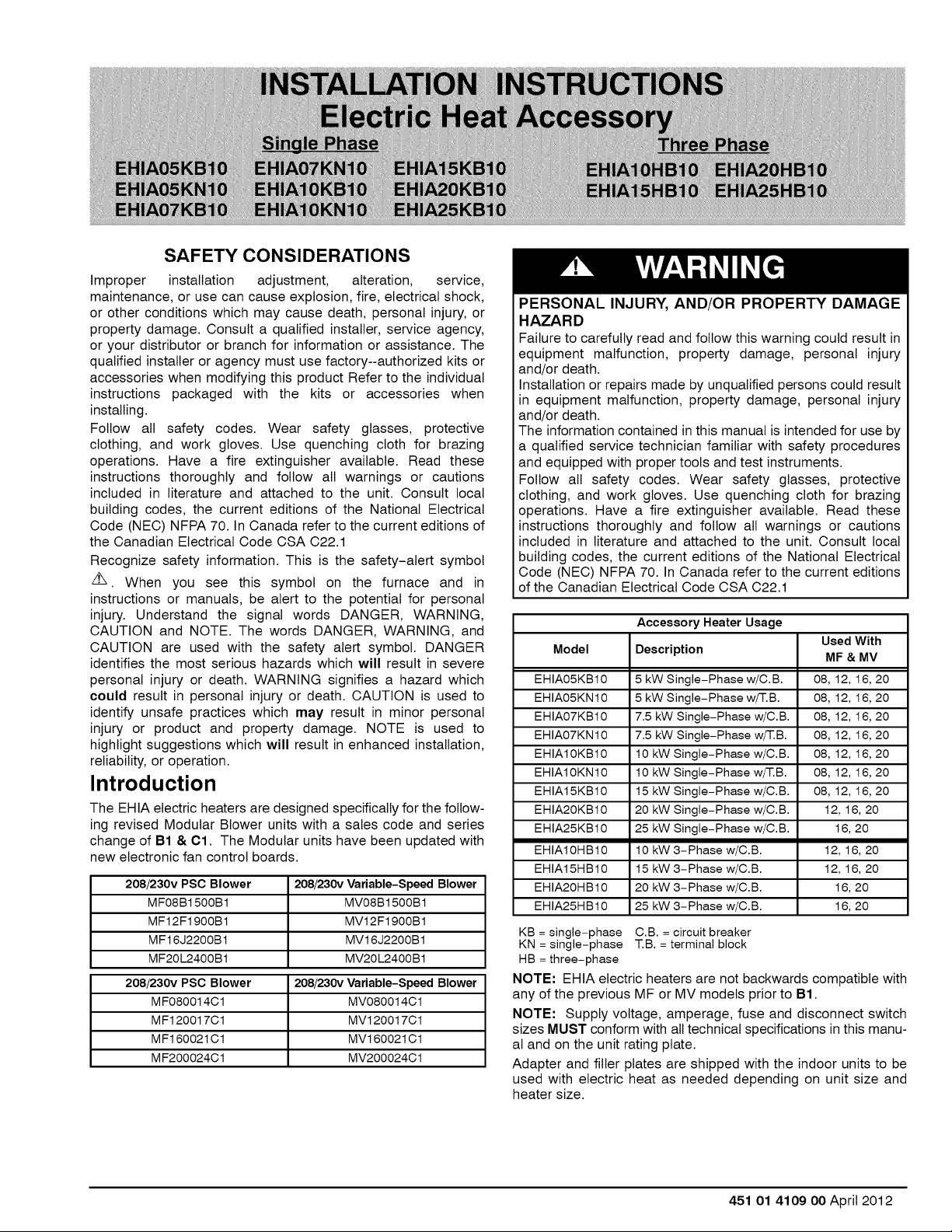

Accessory Heater Usage

Used With

Model Description MF & MV

EHIA05KB10 5 kW Single-Phase w/C.B. 08, 12, 16, 20

EHIA05KNt0 5 kW Single-Phase w/T.B. 08, 12, 16, 20

EHIA07KB10 7.5 kW Single-Phase w/C.B. 08, 12, 16, 20

EHIA07KNt0 7.5 kW Single-Phase w/T.B. 08, 12, 16, 20

EHIA10KB10 10 kW Single-Phase w/C.B. 08, 12, 16, 20

EHIA10KNt0 10 kW Single-Phase w/T.B. 08, 12, 16, 20

EHIA15KB10 15 kW Single-Phase w/C.B. 08, 12, 16, 20

EHIA20KB10 20 kW Single-Phase w/C.B. 12, 16, 20

EHIA25KB10 25 kW Single-Phase w/C.B. 16, 20

EHIA10HB10 10 kW 3-Phase w/C.B. 12, 16, 20

EHIA15HB10 15 kW 3-Phase w/C.B. 12, 16, 20

EHIA20HB10 20 kW 3-Phase w/C.B. 16, 20

EHIA25HB10 25 kW 3-Phase w/C.B. 16, 20

KB= single-phase C.B. = circuit breaker

KN =single-phase T.B.= terminal block

HB =three-phase

NOTE: EHIA electric heaters are not backwards compatible with

any of the previous MF or MV models prior to B1.

NOTE: Supply voltage, amperage, fuse and disconnect switch

sizes MUST conform with all technical specifications in this manu-

al and on the unit rating plate.

Adapter and filler plates are shipped with the indoor units to be

used with electric heat as needed depending on unit size and

heater size.

451 01 4109 O0April 2012

Page 2

ELECTRICALSHOCK HAZARD

Failure to follow this warning could result in personal injury or

death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position and

install a lockout tag. There may be more than one electrical

supply to the furnace. Check accessories and cooling unit for

additional electrical supplies that must be shut off during

furnace servicing. Lockout and tag switch with a suitable

warning label. Verify proper operation after servicing.

1. Shut OFF electric power at unit disconnect switch or ser-

vice panel.

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate clothing, safety glasses and gloves when

handling parts and servicing furnaces.

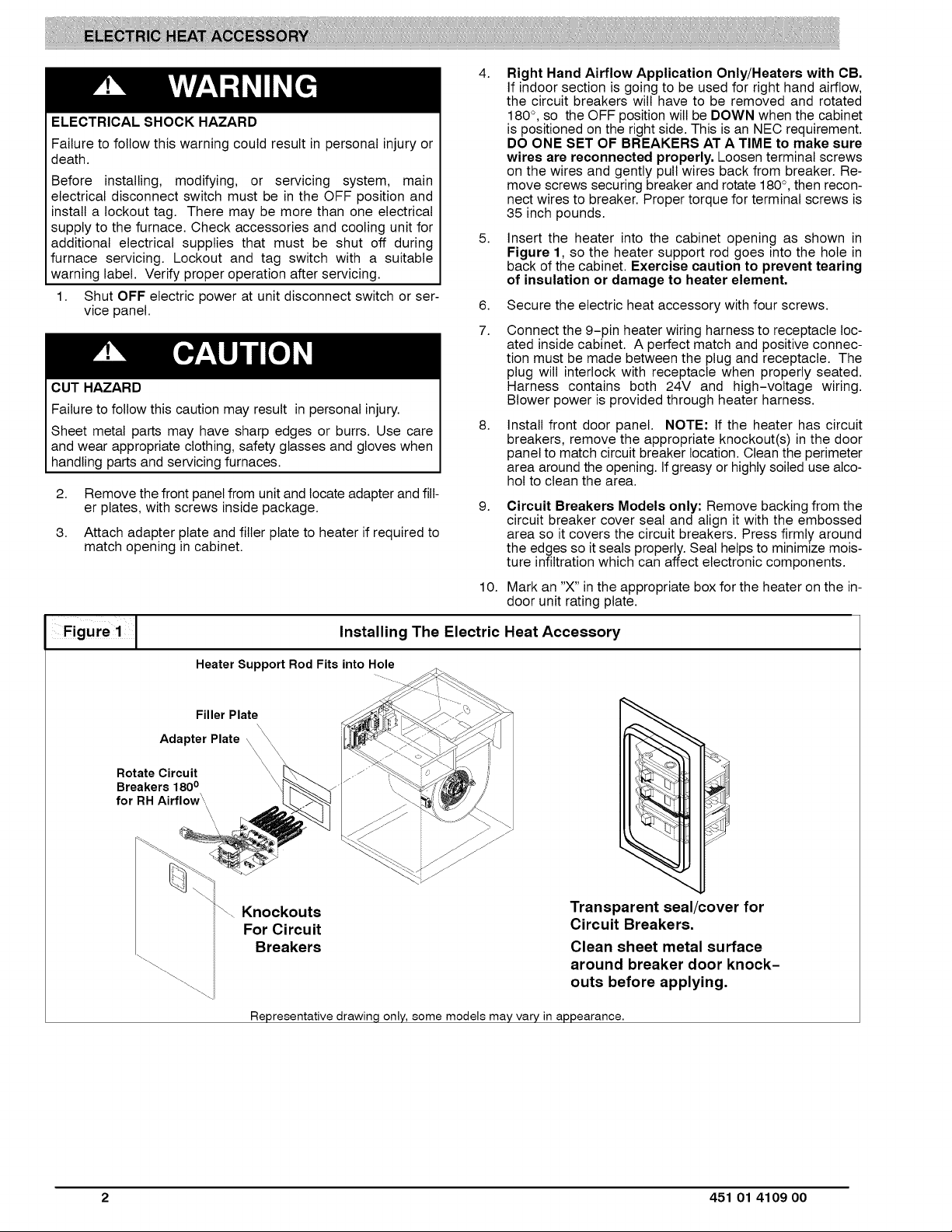

2.

Remove the front panel from unit and locate adapter and fill-

er plates, with screws inside package.

3.

Attach adapter plate and filler plate to heater if required to

match opening in cabinet.

4.

Right Hand Airflow Application Only/Heaters with CB.

If indoor section is going to be used for right hand airflow,

the circuit breakers will have to be removed and rotated

180°, so the OFF position will be DOWN when the cabinet

is positioned on the right side. This isan NEC requirement.

DO ONE SET OF BREAKERS AT A TIME to make sure

wires are reconnected properly, Loosen terminal screws

on the wires and gently pull wires back from breaker. Re-

move screws securing breaker and rotate 180°,then recon-

nect wires to breaker. Proper torque for terminal screws is

35 inch pounds.

5.

Insert the heater into the cabinet opening as shown in

Figure 1, so the heater support rod goes into the hole in

back of the cabinet. Exercise caution to prevent tearing

of insulation or damage to heater element,

8.

Secure the electric heat accessory with four screws.

7.

Connect the 9-pin heater wiring harness to receptacle loc-

ated inside cabinet. A perfect match and positive connec-

tion must be made between the plug and receptacle. The

plug will interlock with receptacle when properly seated.

Harness contains both 24V and high-voltage wiring.

Blower power is provided through heater harness.

8.

Install front door panel. NOTE: If the heater has circuit

breakers, remove the appropriate knockout(s) in the door

panel to match circuit breaker location. Clean the perimeter

area around the opening. If greasy or highly soiled use alco-

hol to clean the area.

9.

Circuit Breakers Models only: Remove backing from the

circuit breaker cover seal and align it with the embossed

area so it covers the circuit breakers. Press firmly around

the edges so itseals properly. Seal helps to minimize mois-

ture infiltration which can affect electronic components.

10. Mark an "X" in the appropriate box for the heater on the in-

door unit rating plate.

Figure 1Jl Installing The Electric Heat

Heater Support RodFits into Hole

Filler Plate

Adapter Plate \

Rotate Circuit

Breakers 1800

for RHAirflow \

• \\

\,

Knockouts

For Circuit

Breakers

Representative drawin,q only, some models may vary in appearance.

Accessory

Transparent seal/cover for

Circuit Breakers.

Clean sheet metal surface

around breaker door knock-

outs before applying.

2 451 01 4109 00

Page 3

Wiring

All line voltage connections and ground connections MUST be

made with copper wire.

The power supply wiring MUST have overcurrent protection. This

can be either fuses or circuit breakers. The maximum size for the

overcurrent protection is shown in the column labeled "Max. Fuse

or NEC HACR Breaker (Amps)" inthe Electrical Data Table or on

the unit rating plate.

Connect supply voltage wires to the Circuit Breakers on the heater

or to the terminal block on the heater. Power for the blower motor is

supplied through the connector from the heater to the control

board.

Grounding

Permanently ground the electric heat accessory in accordance

with local codes and ordinances and in the United States with Na-

tional Electrical Code ANSI/NFPA70-2011 or current edition. Use

a copper conductor of the appropriate size from the electric heat

accessory ground lug, to a grounding lug on the circuit breaker

panel. On models with more than one circuit, a separate copper

ground wire MUST be connected for each circuit.

ELECTRICAL SHOCK HAZARD

Failure follow this warning could result in personal injury

or death.

The unit cabinet must have an uninterrupted or unbroken

ground to minimize personal injury if an electrical fault

should occur. The ground may consist of electrical sire

or metal conduit when installed in accordance with

existing electrical codes.

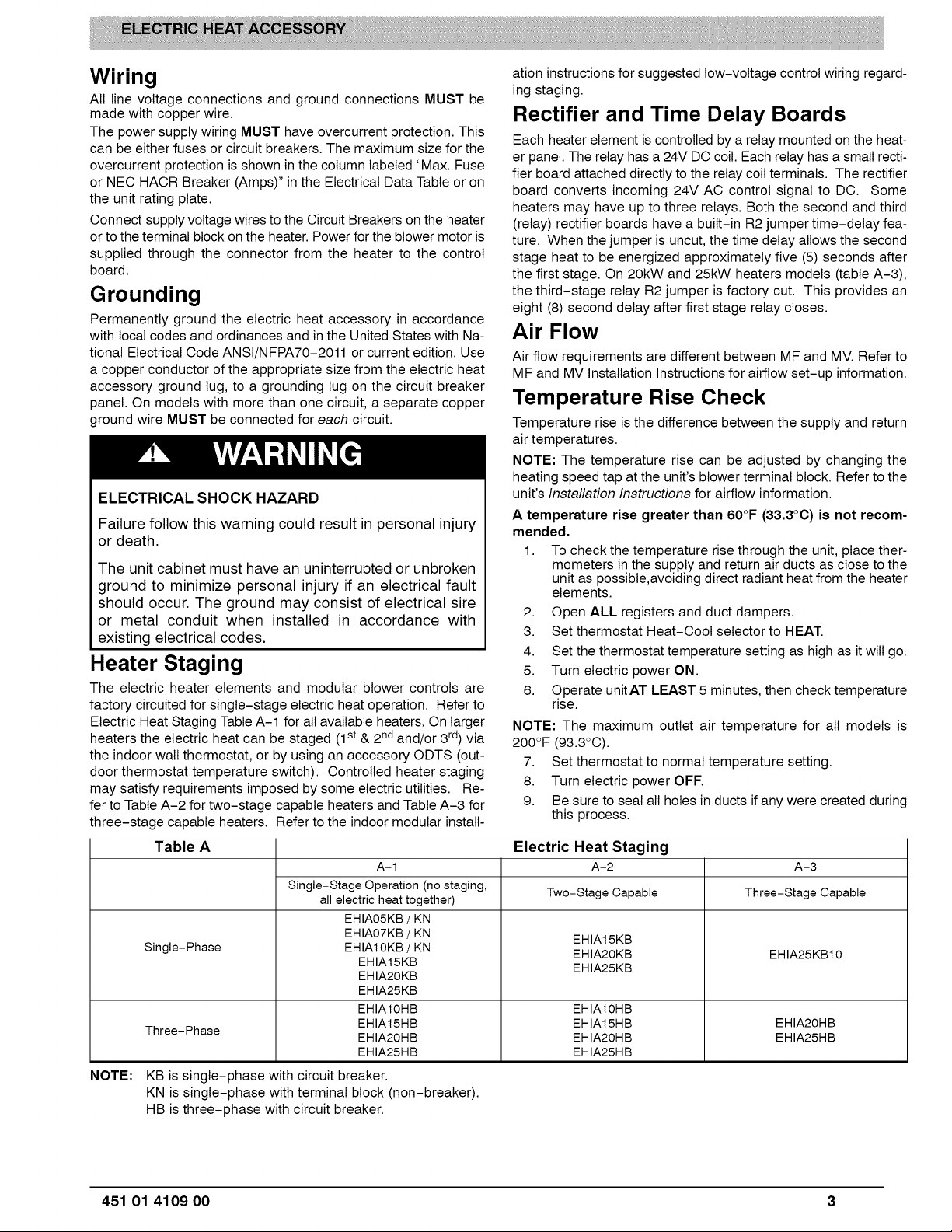

Heater Staging

The electric heater elements and modular blower controls are

factory circuited for single-stage electric heat operation. Refer to

Electric Heat Staging Table A-1 for all available heaters. On larger

heaters the electric heat can be staged (1st & 2nd and/or 3 rd) via

the indoor wall thermostat, or by using an accessory ODTS (out-

door thermostat temperature switch). Controlled heater staging

may satisfy requirements imposed by some electric utilities. Re-

fer to Table A-2 for two-stage capable heaters and Table A-3 for

three-stage capable heaters. Refer to the indoor modular install-

Table A Electric Heat Staging

A-1

Single-Stage Operation (no staging,

all electric heat together)

EHIA05KB / KN

EHIA07KB / KN

Single-Phase

Three-Phase

NOTE: KB is single-phase with circuit breaker.

KN is single-phase with terminal block (non-breaker).

HB is three-phase with circuit breaker.

EHIA10KB / KN

EHIA15KB

EHIA20KB

EHIA25KB

EHIAIOHB

EHIA15HB

EHIA20HB

EHIA25HB

ation instructions for suggested low-voltage control wiring regard-

ing staging.

Rectifier and Time Delay Boards

Each heater element is controlled by a relay mounted on the heat-

er panel. The relay has a 24V DO coil. Each relay has a small recti-

fier board attached directly to the relay coil terminals. The rectifier

board converts incoming 24V AC control signal to DC. Some

heaters may have up to three relays. Both the second and third

(relay) rectifier boards have a built-in R2 jumper time-delay fea-

ture. When the jumper is uncut, the time delay allows the second

stage heat to be energized approximately five (5) seconds after

the first stage. On 20kW and 25kW heaters models (table A-3),

the third-stage relay R2 jumper is factory cut. This provides an

eight (8) second delay after first stage relay closes.

Air Flow

Air flow requirements are different between MF and MV. Refer to

MF and MV Installation Instructions for airflow set-up information.

Temperature Rise Check

Temperature rise is the difference between the supply and return

air temperatures.

NOTE: The temperature rise can be adjusted by changing the

heating speed tap at the unit's blower terminal block. Refer to the

unit's Installation Instructions for airflow information.

A temperature rise greater than 60°F (33.300) is not recom-

mended,

1. To check the temperature rise through the unit, place ther-

mometers in the supply and return air ducts as close to the

unit as possible,avoiding direct radiant heat from the heater

elements.

2. Open ALL registers and duct dampers.

3. Set thermostat Heat-Cool selector to HEAT.

4. Set the thermostat temperature setting as high as it will go.

5. Turn electric power ON.

6. Operate unitAT LEAST 5 minutes, then check temperature

rise.

NOTE: The maximum outlet air temperature for all models is

200°F (93.3°C).

7. Set thermostat to normal temperature setting.

8. Turn electric power OFF.

9. Be sure to seat all holes in ducts if any were created during

this process.

A-2 A-3

Two-Stage Capable Three-Stage Capable

EHIA15KB

EHIA20KB

EHIA25KB

EHIA10HB

EHIA15HB

EHIA20HB

EHIA25HB

EHIA25KB10

EHIA20HB

EHIA25HB

451 01 4109 O0 3

Page 4

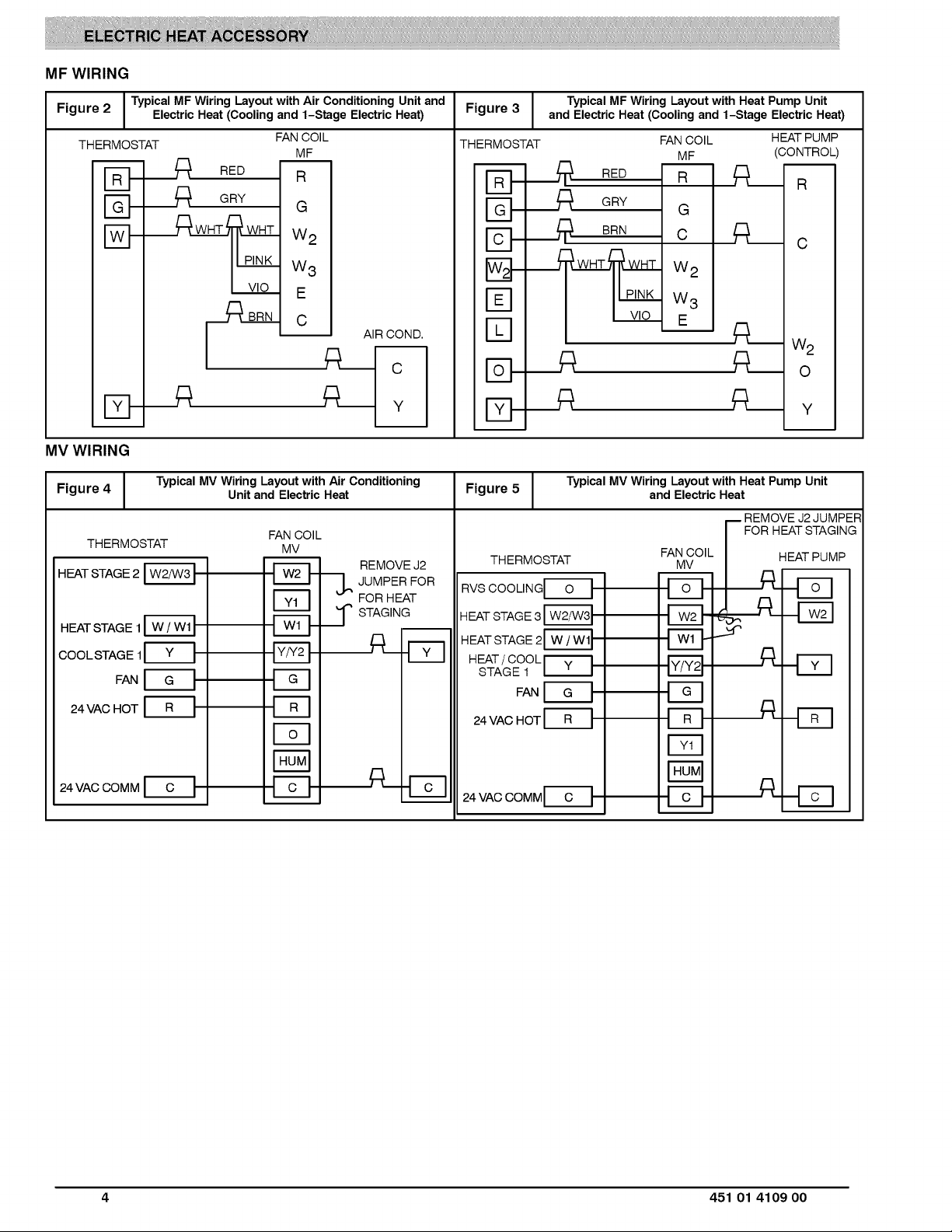

MFWIRING

Figure 2 Electric Heat (Cooling and 1-Stage Electric Heat) Figure 3 and Electric Heat (Cooling and 1-Stage Electric Heat)

MV WIRING

Figure 4 Typical MV Wiring Layout with Air Conditioning Typical MV Wiring Layout with Heat Pump Unit

HEAT STAGE 2

HEAT STAGE 1

COOL STAGE 1

24 VAC HOT

I Typical MF Wiring Layout with Air Conditioning Unit and Typical MF Wiring Layout with Heat Pump Unit

THERMOSTAT THERMOSTAT

m

D

D

RED

._ GRY

FAN COIL

MF

R

G

W2

W3

E

AIR COND.

m

N-

IN-

IN-

N-

%

K]

RED

_/_ GRY

BRN

FAN COIL

MF

R

G

C

W2

W 3

,E ,

IN-

THERMOSTAT

FAN

A__

Unit and Electric Heat Figure 5 and Electric Heat

FAN COIL

MV

REMOVE J2

F_q

"---_ JUMPER FOR

FOR HEAT

..._ STAGING

RVS COOLINGI--O_I

HEAT STAGE 3

HEAT STAGE 2_

HEAT / COOL I_v'_l

STAGE 1 I ' I

24 VAC HOT F_I

_A _q__

THERMOSTAT MV

FAN COIL

E_

FAN

,_q

,_q

HEAT PUMP

(CONTROL)

R

C

W2

O

Y

-- REMOVE J2 JUMPEF

FOR HEAT STAGING

HEAT PUMP

_-E3

_-EB

A-E_

Fq

F_

24 VAC COMM

24 VAC COMM F_I

,_q

_-E3

4 451 01 4109 O0

Page 5

TECHNICAL DATA (MF only) Single Phase with Circuit Breaker

Heater

Model

EHIA05KB10

EHIA07KB10

EHIA10KB10

EHIA15KB10

EHIA20KB10

EHIA25KB10

Supply Heat- Heat kW Per Circuit kW Per Heater Motor Total Circuit Device # of Wire Max. # of Min

Nom. Supply Heater Max FLA Min Protective 75 0C. Copper Wire

Volt- BTUH KW Element No. Circuit AMPS. AMPS. AMPS. Ampacity (AMPS.) Wires Size Length (Ft) Wires Size

240 16378 4.8 4.8

208 12283 3.6 3.6

240 24567 7.2 3.6

208 18425 5.4 2.7

240 32756 9.6 4.8

208 24567 7.2 3.6

240 49134 14.4 4.8

Single 4.8 20.0 6 26.0 32.5 35 2 8 113 1 10

Single 3.6 17.3 6 23.3 29.1 30 2 10 118 1 10

Single 7.2 30.0 6 36.0 45.0 45 2 8 81 1 10

Single 5.4 26.0 6 32.0 40.0 40 2 8 92 1 10

Single 9.6 40.0 6 46.0 57.5 60 2 6 101 1 10

Single 7.2 34.6 6 40.6 50.8 60 2 6 115 1 10

Single 14.4 60.0 6 66.0 82.5 90 2 4 113 1 8

Mult. 1 9.6 40.0 6 46.0 57.5 60 2 6 101 1 10

Mult. 2 4.8 20.0 0 20.0 25.0 25 2 10 95 1 10

208 36851 10.8 3.6

Single 10.8 51.9 6 57.9 72.4 80 2 4 128 1 8

Mult. 1 7.2 34.6 6 40.6 50.8 60 2 6 115 1 10

Mult. 2 3.6 17.3 0 17.3 21.6 25 2 10 109 1 10

240 65513 19.2 4.8

Single 19.2 80.0 6 86.0 107.5 110 2 2 137 1 6

Mult. 1 9.6 40.0 6 46.0 57.5 60 2 6 101 1 10

Mult. 2 9.6 40.0 0 40.0 50.0 50 2 8 73 1 10

208 49134 14.4 3.6

Single 14.4 69.2 6 75.2 94.0 100 2 3 124 1 10

Mult. 1 7.2 34.6 6 40.6 50.8 60 2 6 115 1 10

Mult. 2 7.2 34.6 0 34.6 43.3 45 2 8 85 1 10

240 81891 24 4.8

Single 24 100.0 6 106.0 132.5 150 2 1/0 177 1 6

Mult. 1 9.6 40.0 6 46.0 57.5 60 2 6 102 1 10

Mult. 2 9.6 40.0 0 40.0 50.0 50 2 8 74 1 10

Mult. 3 4.8 20.0 0 20.0 25.0 25 2 12 60 1 10

208 61418 18 3.6

Single 18 86.5 6 92.5 115.7 125 2 1 161 1 6

Mult. 1 7.2 34.7 6 40.7 50.8 60 2 6 104 1 10

Mult. 2 7.2 34.7 0 34.7 43.3 45 2 8 77 1 10

Mult. 3 3.6 17.3 0 17.3 21.7 25 2 12 62 1 10

Maximum Recommended**

MCA Overcur- SupplyWire Ground

TECHNICAL DATA (MF only) Single-Phase with Terminal Block

Heater

Model

EHIA05KN10

EHIA07KN10

EHIA10KN10

Supply Heat- Heat kW Per Circuit kW Per Heater M_or Total Circuit

Nom. Supply Heater Max FLA Min

Volt- BTUH KW Element

240 16378 4.8 4.8

208 12283 3.6 3.6

240 24567 7.2 3.6

208 18425 5.4 2.7

240 32756 9.6 4.8

208 24567 7.2 3.6

No. Circuit AMPS. AMPS. AMPS. Ampacity (AMPS.) Wires Size Length (Ft)

Single 4.8 20.0 6 26.0 32.5 35 2 8 113

Single 3.6 17.3 6 23.3 29.1 30 2 10 118

Single 7.2 30.0 6 36.0 45.0 45 2 8 81

Single 5.4 26.0 6 32.0 40.0 40 2 8 92

Single 9.6 40.0 6 46.0 57.5 60 2 6 101

Single 7.2 34.6 6 40.6 50.8 60 2 6 115

TECHNICAL DATA (MF only) Three Phase with Circuit Breaker

Heater

Supply Heat- Heat kW Per Circuit kW Per Heater Motor Total Circuit

Model

EHIA10HB10

EHIA15HB10

EHIA20HB10

EHIA25HB10

Conversion: 1 foot = .3048 meters

** Must conform to local building codes and national standards

USA: National Electrical Code (NEC)ANSI/NFPA 70-2011

CANADA: Canadian Electrical Code CSA C22.1

Nom. Supply Heater Max FLA Min

Volt- BTUH KW Element

240 32756 9.6 3.2

208 24567 7.2 2.4

240 49134 14.4 4.8

208 36851 10.8 3.6

240 65513 19.2 3.2

No,

Circuit AMPS. AMPS. AMPS. Ampacity (AMPS.) Wires Size Length (Ft)

Single 9.6 23.1 6

Single 7.2 20.0 6

Single 14.4 34.7 6

Single 10.8 30.0 6

Single 19.2 46.2 6

Mult. 1 6.4 15.4 6

Mult. 2 12.8 30.8 0

208 49134 14.4 2.4

Single 14.4 40.0 6

Mult. 1 4.8 13.3 6

Mult. 2 9.6 26.7 0

240 81891 24 4

Single 24 57.8 6

Mult. 1 8 19.3 6

Mult. 2 16 38.5 0

208 61418 18

Single 18 50.0 6

Mult. 1 6 16.7 6

Mult. 2 12 33.3 0

29.1 36.4 40 3 8

26.0 32.5 35 3 8

40.7 50.9 60 3 6

36.0 45.0 45 3 8

52.2 65.3 70 3 4

21.4 26.8 30 3 10

30.8 38.5 40 3 8

46.0 57.5 60 3 6

19.3 24.2 30 3 10

26.7 33.3 35 3 8

63.8 79.8 80 3 4

25.3 31.6 35 3 8

38.5 48.2 50 3 8

56.0 70.0 70 3 4

22.7 28.3 30 3 10

33.3 41.7 45 3 8

MCA

MCA

Maximum Recommended**

Overcur- SupplyWire

Protective 75 0C. Copper

Device # of Wire Max.

Maximum

Recommended**

Overcur- SupplyWire

Protective 75 0C. Copper

Device # of Wire Max.

117 1 10

131 1 10

132 1 8

94 1 10

165 1 8

102 1 10

110 1 10

117 1 8

113 1 10

127 1 10

135 1 8

134 1 10

88 1 10

153 1 8

96 1 10

102 1 10

Ground

Wire

# of Min

Wires Size

1 10

1 10

1 10

1 10

1 10

1 10

Ground

Wire

# of Min

Wires Size

451 01 4109 O0 5

Page 6

TECHNICAL DATA (MV only) Single Phase with Circuit Breaker

Nom. Supply Heater Max FLA Min Protective 75 0C. Copper Wire

Heater

Model

EHIA05KB10

EHIA07KB10

EHIA10KB10

EHIA15KB10

EHIA20KB10

EHIA25KB10

Supply Heat- Heat kW Per Circuit kW Per Heater Motor Total Circuit Device # of Wire Max. # of Min

Volt- BTuH KW Element No. Circuit AMP& AMP& AMP& Ampacity (AMP&) Wires Size Length (Ft) Wires Size

240 16378 4.8 4.8 Single 4.8 20.0 7.3 27.3 34.1 35 2 8 108 1 10

208 12283 3.6 3.6 Single 3.6 17.3 7.3 24.6 30.8 35 2 8 119 1 10

240 24567 7.2 3.6 Single 7.2 30.0 7.3 37.3 46.6 50 2 8 79 1 10

208 18425 5.4 2.7 Single 5.4 26.0 7.3 33.3 41.6 45 2 8 88 1 10

240 32756 9.6 4.8 Single 9.6 40.0 7.3 47.3 59.1 60 2 6 99 1 10

208 24567 7.2 3.6 Single 7.2 34.6 7.3 41.9 52.4 60 2 6 111 1 10

240 49134 14.4 4.8 Single 14.4 60.0 7.3 67.3 84.1 90 2 4 110 1 8

Mult. 1 9.6 40.0 7.3 47.3 59.1 60 2 6 99 1 10

Mult. 2 4.8 20.0 0 20.0 25.0 25 2 10 95 1 10

208 36851 10.8 3.6 Single 10.8 51.9 7.3 59.2 74.0 80 2 4 126 1 8

Mult. 1 7.2 34.6 7.3 41.9 52.4 60 2 6 111 1 10

Mult. 2 3.6 17.3 0 17.3 21.6 25 2 10 109 1 10

240 65513 19.2 4.8 Single 19.2 80.0 7.3 87.3 109.1 110 2 2 135 1 6

Mult. 1 9.6 40.0 7.3 47.3 59.1 60 2 6 99 1 10

Mult. 2 9.6 40.0 0 40.0 50.0 50 2 8 73 1 10

208 49134 14.4 3.6 Single 14.4 69.2 7.3 76.5 95.7 10O 2 3 122 1 6

Mult. 1 7.2 34.6 7.3 41.9 52.4 60 2 6 111 1 10

Mult. 2 7.2 34.6 0 34.6 43.3 45 2 8 85 1 10

240 81891 24 4.8 Single 24 100.0 7.3 107.3 134.1 150 2 10 175 1 6

Mult. 1 9.6 40.0 6.0 46.0 57.5 60 2 6 102 1 10

Mult. 2 9.6 40.0 0 40.0 50.0 50 2 8 74 1 10

Mult. 3 4.8 20.0 0 20.0 25.0 25 2 12 60 1 10

208 61418 18 3.6 Single 18 86.5 7.3 93.8 117.3 125 2 1 159 1 6

Mult. 1 7.2 34.7 6.0 40.7 50.8 60 2 6 104 1 10

Mult. 2 7.2 34.7 0 34.7 43.3 45 2 8 77 1 10

Mult. 3 3.6 17.3 0 17.3 21.7 25 2 12 62 1 10

Maximum Recommended*_

MCA Overcurrent SupplyWire Ground

TECHNICAL DATA (MV only) Single-Phase with Terminal Block

Heater

Model Volt- BTUH KW Element

EHIA05KN10

EHIA07KN10

EHIA10KN10

Supply Heat- Heat kWPer Circuit kWPer Heater Motor Total Circuit Device # of Wire Max.

Nom. Supply Heater Max FLA Min Protective 750 C. Copper

240 16378 4.8 4.8

208 12283 3.6 3.6

240 24567 7.2 3.6

208 18425 5.4 2.7

240 32756 9.6 4.8

208 24567 7.2 3.6

No. Circuit AMP& AMP& AMP& Ampacity (AMP&) Wire Size Length (Ft)

Single 4.8 20.0 7.3 27.3 34.1 35 2 8 108

Single 3.6 17.3 7.3 24.6 30.8 35 2 8 119

Single 7.2 30.0 7.3 37.3 46.6 50 2 8 79

Single 5.4 26.0 7.3 33.3 41.6 45 2 8 88

Single 9.6 40.0 7.3 47.3 59.1 60 2 6 99

Single 7.2 34.6 7.3 41.9 52.4 60 2 6 111

TECHNICAL DATA (MV only) Three-Phase with Circuit Breaker

Heater

Model

EHIA10HB10

EHIA15HB10

EHIA20HB10

EHIA25HB10

Supply Heat- Heat kW Per Circuit kW Per Heater Motor Total Circuit

Conversion: 1 foot = .3048 meters

** Must conform to local building codes and national standards

USA: National Electrical Code (NEC) ANSI/NFPA 70-2011

CANADA: Canadian Electrical Code CSA C22.1

Nom. Supply Heater Max FLA Min

Volt- B:rUH KW Element

240 32756 9.6 3.2

208 24567 7.2 2.4

240 49134 14.4 4.8

208 36851 10.8 3.6

240 65513 19.2 3.2

208 49134 14.4 2.4

240 81891 24 4

208 61418 18

No,

Single 9.6 23.1

Single 7.2 20.0

Single 14.4 34.7

Single 10.8 30.0

Single 19.2 46.2

Mult. 1 6.4 15.4

Mult. 2 12.8 30.8

Single 14.4 40.0

Mult. 1 4.8 13.3

Mult. 2 9.6 26.7

Single 24 57.8

Mult. 1 8 19.3

Mult. 2 16 38.5

Single 18 50.0

Mult. 1 6 16.7

Mult. 2 12 33.3

Circuit AMP& AMP& AMP& Ampacity (AMP&) Wires Size Length (Ft)

7.3 30.4 38.0 40 3 8

7.3 27.3 34.1 35 3 8

7.3 42.0 52.5 60 3 6

7.3 37.3 46.6 50 3 8

7.3 53.5 66.9 70 3 4

7.3 22.7 28.4 30 3 10

0 30.8 38.5 40 3 8

7.3 47.3 59.1 60 3 6

7.3 20.6 25.8 30 3 10

0 26.7 33.3 35 3 8

7.3 65.1 81.4 90 3 4

7.3 26.6 33.2 35 3 8

0 38.5 48.2 50 3 8

7.3 57.3 71.7 80 3 4

7.3 24.0 30.0 30 3 10

0 33.3 41.7 45 3 8

Maximum

MCA Overcurrent SupplyWire

Maximum

MCA

Overcur- SupplyWire

Protective 75 0C. Copper

Device # of Wire Max.

Recommended**

Recommended*"*

Ground

Wire

# of Min

Wires Size

1 10

1 10

1 10

1 10

1 10

1 10

Ground

Wire

# of Min

Wires Size

112 1 10

125 1 10

128 1 10

91 1 10

161 1 8

96 1 10

110 1 10

114 1 10

106 1 10

127 1 10

132 1 8

128 1 10

88 1 10

150 1 8

91 1 10

102 1 10

6 451 O14109 OO

Page 7

HEATER STAGING (MF & MV)

Single-Phase

ELECTRIC HEATER

EHIA05KB10

EHIA07KB10

EHIA10KB10

EHIA15KB10

EHIA20KB10

EHIA25KB10

VOLTAGE

208-240/1/60

208-240/1/60

208-240/1/60

208-240/1/60

208-240/1/60

208-240/1/60

TOTAL HEAT KW 18t STAGE KW (Wl)

208V 240V

3.6 4.8

5.4 7.2

7.2 9.6

10.8 14.4

14.4 19.2

18 24

208V 240V

3.6 4.8

5.4 7.2

7.2 9.6

7.2 9.6

7.2 9.6

7.2 9.6

2nd STAGE KW(W2)

240V208V

3.6

7.2

10.8

4.8

9.6

14.4

EHIA05KN10

EHIA07KN10

EHIA10KN10

208-240/1/60

208-240/1/60

208-240/1/60

3.6 4.8

5.4 7.2

7.2 9.6

3.6 4.8

5.4 7.2

7.2 9.6

Three-Phase

ELECTRIC HEATER

EHIA10HB10

EHIA15HB10

EHIA20HB10

EHIA25HB10

VOLTAGE

208-240/3/60

208-240/3/60

208-240/3/60

208-240/3/60

TOTAL HEAT KW

208v 240v

7.2 9.6

10.8 14.4

14.4 19.2

18 24

18t STAGE KW (Wl)

208v 240v

7.2 9.6

10.8 14.4

4.8 6.4

6 8

2nd STAGE KW (W2)

208v 240v

9.6

12

ELECTRIC HEATER STATIC PRESSURE DROP - ESP IN WC (MF & MV)

Single-Phase

CFM EHIA05 EHIA07 EHIA10 EHIA15 EHIA20 EHIA25

600 0.01 0.01 0.01

700 0.01 0.01 0.01

800 0.01 0.01 0.01 0.01 -

900 0.01 0.01 0.01 0.01 -

1000 0.01 0.01 0.01 0.01 0.02 -

1100 0.01 0.01 0.01 0.02 0.02 -

1200 0.01 0.01 0.01 0.02 0.02 -

1300 0.01 0.02 0.02 0.02 0.02 -

1400 0.01 0.02 0.02 0.02 0.03 0.03

1500 0.01 0.02 0.02 0.02 0.03 0.04

1600 0.01 0.02 0.02 0.03 0.03 0.04

1700 0.01 0.02 0.02 0.03 0.03 0.04

1800 0.01 0.02 0.02 0.03 0.04 0.04

1900 0.01 0.02 0.02 0.03 0.04 0.05

2000 0.01 0.02 0.02 0.03 0.04 0.05

Three-Phase

CFM - EHIA10 EHIA15 EHIA20 EHIA25

600 - 0.01 -

700 - 0.01 -

800 - 0.01 0.01 -

900 - 0.01 0.01 -

1000 - 0.01 0.01 0.02 -

1100 - 0.01 0.02 0.02 -

1200 - 0.01 0.02 0.02 -

1300 - 0.02 0.02 0.02 -

1400 - 0.02 0.02 0.03 0.03

1500 - 0.02 0.02 0.03 0.04

1600 - 0.02 0.03 0.03 0.04

1700 - 0.02 0.03 0.03 0.04

1800 - 0.02 0.03 0.04 0.04

1900 - 0.02 0.03 0.04 0.05

2000 - 0.02 0.03 0.04 0.05

12.8

16

451 01 4109 O0 7

Page 8

WIRING DIAGRAM FOR SINGLE-PHASE HEAT ACCESSORIES WITH CIRCUIT BREAKER

EHIA05KB10

r

SCHEMATIC DIAGRAM SINGLE SUPPLY CIRCUIT )

ELD OWERW,R,.G

SEE RATING PLATE

FOR VOLTS AND HERTZ

| SEE NOTE #1

_GND

HEATER VA: 1.7

DISCONNECT PER NEC

COMPONENT ARRANGEMENT )

.......

HTR1

9

_i °'

TF1 HTR1 LS1 n.- RELAY1

YE............._L

YEL BLU BLK

BLK

RELAY1

22VDC COIL

EZ3

PLUGS $ $ WH RN

7 9 6 2 3 5 1

NOTES:

1. Use Copper Wire (75 ° Min) Only Between Disconnect Switch And Unit.

2. To Be Wired In Accordance With Nec And Local Codes.

3. If Any Of The Original Wire, As Supplied, Must Be Replaced, Use The Same

Or Equivalent Type Wire.

111002195 rev.1

\

CB CIRCUIT BREAKER

GND EQUIPMENT GROUND

HTR HEATER

41 LS

REC

TDR

TF

O

---)>---

_I Y _',

LEGEND

LIMIT SWITCH

RECTIFIER

TIME DELAY RECTIFIER

THERMAL FUSE

FIELD POWER WIRING

MARKED TERMINAL

PLUG AND RECEPTACLE

EHIA05KB10

EHIA07KB10 / EHIA10KB10

f

(- SCHEMATIC DIAGRAM SINGLE SUPPLY CIRCUIT )

FIELD I_OWER WIRING

SEE RATING PLATE

FOR VOLTS AND HERTZ

I SEE NOTE #1

_GND

E9

YEL TF2 HTR2 LS2 BLU RELAY1 BL-

YI:L I_LU 2 I_)\ r.

YEL_ TI;: *1 I-ITI_ "1 I_'1 RELAY1 >BLK

_ TT_,IF HT.R1 LSl BLU _LL /

_T RELAY1

YEL BLU BLK I REC I

I I I WH_RN

17 9 6 z ._ 5

k. •

PLUG _ XL/ _

NOTES:

1,

Use Copper Wire (75 ° Min) Only Between Disconnect Switch And Unit.

2.

To Be Wired In Accordance With Nec And Local Codes.

3.

If Any Of The Original Wire, As Supplied, Must Be Replaced, Use The Same

Or Equivalent Type Wire.

HEATER VA: 1.7

DISCONNECT PER NEC

>qd

x

111002197 rev.1

( COMPONENT ARRANGEMENT .)

.......

HTR2

iii I trl

\

CB

CIRCUIT BREAKER

GND

EQUIPMENT GROUND

HTR

HEATER

4 I LS

_ FIELD POWER WIRING

-_-_ PLUG AND RECEPTACLE

LIMIT SWITCH

REC

RECTIFIER

TDR

TIME DELAY RECTIFIER

TF

THERMAL FUSE

O MARKEDTERMINAL

EHIA07KB10 / EHIA10KB10

Io I

,ITI

L____J

LEGEND

,_-_@

8 451 01 4109 00

Page 9

EHIA15KB10

( SCHEMATIC DIAGRAM SINGLE SUPPLY CIRCUIT )

ELD OWER R,NG

SEE RATING PLATE

FOR VOLTS AND HERTZ

I SEE NOTE #1

_GND

HEATER VA: 3.4

DISCOINNECT PER NEC

COMPONENT ARRANGEMENT )

I1--1 I--

__7_.._j-- __Y_, ___

i i

Ea

RELAY2 =.----_

YEL TF3 HTR3 LS3 BL" RELAY2 BLK

Y_L .... ULU 2

YEL TF2 HTR2 LS2 BLU RELAY1 BLK

YEL #LU AY1 BLK

22VDC COIL

YEL BLU BLK I REC I

I I I WH_RN

"..1/ PLUG _ _, _/ '..1/

I 7 9 6 2 3

NOTES:

1. Use Copper Wire (75 ° Min) Only Between Disconnect Switch And Unit.

2. To Be Wired In Accordance With Nec And Local Codes.

3. If Any Of The Original Wire, As Supplied, Must Be Replaced, Use The Same

Or Equivalent Type Wire.

• I 111002198 rev.1 ,

I

PNK BRN

,1, +

5 4 I

kZ__!

CB CIRCUIT BREAKER

GND EQUIPMENT GROUND

HTR HEATER

LS LIMIT SWITCH

REC RECTIFIER

TDR TIME DELAY RECTIFIER

TF THERMAL FUSE

III FIELD POWER WIRING

O MARKED TERMINAL

"_'_ PLUG AND RECEPTACLE

RELAY1 r---_

LEGEND

EHIA15KB10

I O I

EHIA2OKBIO

r

(SCHEMATIC DIAGRAM SINGLE SUPPLY CIRCUIT )

I FIELD I_OWER WIIRING SEE RATING PLATE

FOR VOLTS AND HERTZ

HEATER VA: 3.4

DISCOINNECT PER NEC

IC,a

GND SEE NOTE #1

I YEL TF4 HTR4 LS4 BLU RELAY2 BL"

_ _//"TF3 HTR3 LS3 BLU

YEL TF2 HTR2 LS2 BL- RELAY1 BL"

YLL _LU 6 I_)\ r'

' I / RELAY1

YEL BLU BLK

I I I WH_RN

I 7 9 6 2 3

PLUG _ _J/ _

NOTES:

"N

PNK BRN

5 4 I

1. Use Copper Wire (75 ° Min) Only Between Disconnect Switch And Unit. TF

2. To Be Wired In Accordance With Nec And Local Codes. 11--

3. If Any Of The Original Wire, As Supplied, Must Be Replaced, Use The Same O

Or Equivalent Type Wire. _>_

• I 111002199 rev.1

RELAY1 RELAY2

22VDC COIL

COMPONENT ARRANGEMENT )

(1 ....... ,, .......

HTR2 HTR1

HTR4 HTR3

LEGEND

CB

CIRCUIT BREAKER

GND

EQUIPMENT GROUND

HTR

HEATER

LS

LIMIT SWITCH

REC

RECTIFIER

TDR

TIME DELAY RECTIFIER

THERMAL FUSE

FIELD POWER WIRING

MARKED TERMINAL

PLUG AND RECEPTACLE

EHIA20KB10

J

451 01 4109 O0 9

Page 10

EHIA25KB10

(SCHEMATIC DIAGRAM SINGLE SUPPLY CIRCUIT ) HEATER VA: 5.1

FIELD POWER WIRING SEE RATING PLATE DISCONNECT PER NEC

I I I I FOR VOLTS AND HERTZ I I I I

/ I--;Ik--II--4TI I--A-q I SEENOTE#1 _ I--4TI I--4TI /

.... HTR RELAY IB'K/

I YEL TF4 HTR4 LS4 BLU RELAY2 BLK I

YEL TF2 HTR2 LS2 BLU RELAY1 BLK

YcL B_ 6 I_)_ PNIK _IRN

YEL R T_F1 HTR1 LSl .... F_ELAYI_ 7 BLK RELAYS I

_Lu 2 _ 22REd'IlL I 2,vF%o"l

Y!, _- B!u B!K I--_

I I I WH_RN 1 VlO BRN

xJ/ PLUG _ _ _ x_ q/xJ,," xJ/

17 9 6 2 3 5 1 4 I

NOTES:

1. Use Copper Wire (75 ° Min) Only Between Disconnect Switch And Unit.

2. To Be Wired In Accordance With Nec And Local Codes.

3. If Any Of The Original Wire, As Supplied, Must Be Replaced, Use The Same

Or Equivalent Type Wire.

/

I 111002200 rev.1

I

COMPONENT ARRANGEMENT )

(" "] (" ";

HTR2 HTR1

HTR4 HTR3

HTR5

RELAY1 RELAY2 RELAY3

[____EC__I[__P__%_IL_P__%_I

LEGEND

CB CIRCUIT BREAKER

GND EQUIPMENT GROUND

HTR HEATER

LS LIMIT SWITCH

REC RECTIFIER

TDR TIME DELAY RECTIFIER

TF THERMAL FUSE

_ FIELD POWER WIRING

O MARKED TERMINAL

"_>-- PLUG AND RECEPTACLE

EHIA25KB10

10 451 01 410900

Page 11

WIRING DIAGRAM FOR SINGLE-PHASE HEAT ACCESSORIES WITH

TERMINAL BLOCK (NON-BREAKER)

EHIAO5KNIO

:SCHEMATIC DIAGRAM SINGLE SUPPLY CIRCUIT :)

I I SEE NOTE #1

IELD POWER WIRING SEE RATING PLATE DISCONNECT PER NEC

FOR VOLTS AND HERTZ

HEATER VA: 1.7

:COMPONENT ARRANGEMENT )

(- ........... ]

:QZ.......

HTR1

'

._ GND

rI---Ii

_ I 0 I

v _ L:__J

TF1 HTR1 LS1 BL- RELAY1

YEI_ _ )_.._ _..£ _.

YEL BLU BLK I REC I

PLUGS $ $ WHTq;--7RN

7 9 6 2 3 5

NOTES:

1. Use Copper Wire (75 ° Min) Only Between Disconnect Switch And Unit.

2. To Be Wired In Accordance With Nec And Local Codes.

3. If Any Of The Original Wire, As Supplied, Must Be Replaced, Use The Same

Or Equivalent Type Wire.

• J

BLK

RELAY1

22VDC COIL

111002192 rev.1

1 41

TB

I I

LEGEND

GND EQUIPMENT GROUND

HTR HEATER

LS LIMIT SWITCH

REC RECTIFIER

TB TERMINAL BLOCK

TDR TIME DELAY RECTIFIER

TF THERMAL FUSE

_ FIELD POWER WIRING

O MARKED TERMINAL

.i>>._ PLUG AND RECEPTACLE

EHIA05KN10

EHIA07KN10 / EHIA10KN10

(, SCHEMATIC DIAGRAM SINGLE SUPPLY CIRCUIT ) HEATER VA: 117

I FIELD POWER WIRING SEE RATING PLATE DISCONNECT PER NEC

I I SEE NOTE #1

FOR VOLTS AND HERTZ

/

, i

G.D

YEL TF2 HTR2 LS2 BLU RELAY1 BL"

Y_ _Lu 2 I'_\ r"

YEL_ T_ _4TP_ I_ RELAYI >BLK

I RELAY1

YEL BLU BLK

I I / WH_RN

I 7 9 6 2 3 5

PLUG _ ",,I,," ",,I,,"

NOTES:

1. Use Copper Wire (75 ° Min) Only Between Disconnect Switch And Unit.

2. To Be Wired In Accordance With Nec And Local Codes.

3. If Any Of The Original Wire, As Supplied, Must Be Replaced, Use The Same

Or Equivalent Type Wire.

I 111002194 rev.1

i

:COMPONENT ARRANGEMENT )

(- ........... .)

._j I WI

w I rrl

\

GND EQUIPMENT GROUND

HTR HEATER

LS LIMIT SWITCH

41

REC RECTIFIER

TB TERMINAL BLOCK

TDR TIME DELAY RECTIFIER

TF THERMAL FUSE

_ FIELD POWER WIRING

0 MARKED TERMINAL

"_>'_ PLUG AND RECEPTACLE

EHIA07KN10 / EHIA10KN10

HTR1

HTR2

LEGEND

iI---Ii

i o I

L:__J

TB

i i

I I

,_-_@

451 01 4109 O0 11

Page 12

WIRING DIAGRAM FOR THREE-PHASE HEAT ACCESSORIES

EHIA10HB10 / EHIA15HB10

( SCHEMATIC DIAGRAM SINGLE SUPPLY CIRCUIT ) HEATER VA: 3.4

I FOR VOLTS AND HERTZ

ELD POWER WIRING SEE RATING PLATE

GND

_] SEE NOTE #1

BLK TF3 HTR3 LS3 BL" RELAY2 _.,

_LR .... _LU 2

RELAY1 . r. TF2 HTR2 LS2 _m.

2 Y=L OLU

• v=. TF1 HTR1 LS1 n... RELAY1 n, ..

YEL BLU BLK

DISCONNECT PER NE_._

cr E

__Go_,,

Y RELAY1

/

22VDC COIL

I I I WHTI_ IBRN PNK

17 9 6 2 3 5

PLUG ",,1/ ",,1/ ',,1/ ',,1/ ",.J/

NOTES:

1. Use Copper Wire (75 ° Min) Only Between Disconnect Switch And Unit.

2. To Be Wired In Accordance With Nec And Local Codes.

3. If Any Of The Original Wire, As Supplied, Must Be Replaced, Use The Same

Or Equivalent Type Wire.

4. 208/240V 3-Phase Heaters shown above.

I 111002202 rev.1

COMPONENT ARRANGEMENT )

1/-

I1--1 I--

I'-_ ' ' _?£-I

,._ 7_,__/,-- ,._Y,,_J __.,

RELAY2 ,-----,

i(::) I

kS__!

RELAY2

3dpLEGEND

c0

CIRCUIT BREAKER

BRN GND

4 I LS

III

"_>_ PLUG AND RECEPTACLE

EQUIPMENT GROUND

HEATER

HTR

LIMIT SWITCH

REC

RECTIFIER

TDR

TIME DELAY RECTIFIER

TF

THERMAL FUSE

FIELD POWER WIRING

0

MARKED TERMINAL

EHIA10HB10 / EHIA15HB10

RELAY1 ,-----,

ic) I

_ ¢i,,o,

%__J

3qb

J

EHIA20HB10 / EHIA25HB10

( SCHEMATIC DIAGRAM SINGLE SUPPLY CIRCUIT ) HEATER VA: 5.1 (COMPONENT ARRANGEMENT )

FIELD POWER WIRING SEE RATING PLATE DISCONNECT PER NEC fr-_--_\ t_--_\

I I I I FORVOLTSANDHERTZ | | | I '._ _fH,' '._b u £_.'

l _ _ _ | SEE NOTE#1 _ _ _ l ,----'-H-T-R'-2...... . ,-----H-T-R-1 ..... .

I_X)I I_X)I I_Y--,)l_ I_Y--,)l I_X)I I_X)I .- HTR2_ -. .- HTR3_ -.

I k IBLK_ T._F6 HTR6 LS6 _,. RELAYP'IBLU I// -- -- --

I1 IBLu_LS5_ ,HTR5 -TF5 _YELf_RE,LA, Y3 .... 1//

I I _u _ _1// RELAY1 RELAY2 RELAY3

I _ 2 _LI% AA,--O--f_ _ // RELAY2 I ..L ..L I I ..L ..L I I ..L ..L I

I "_ " "_ - _ ....... - I /I 22VDCCOIL I t T I I t t I I T t I

I k BLK LS3 HTR3 tF3 _._ RELAY2 _., J "1 I®GI I®@1 I® QI

I =_ o_ 6 F_---_I I _ rrl--_--01]rrl--_-ol]rh--_--01]

I ' BLU/ I _, .... • i_1 i_1 i_1

[ .... RELAY1 .... LS2 HTR2 TF2 _ J PNK BRN ,I REC ,I ,I TDR ,I ,I TDR ,I

I 2 _L - R_i/--_ELAY1 I 2=_,L ...... --" ..................

L v=, LS1 HTR1 TF1 _,, RELAY1 BLKI 22VDCCOIL I _ I _4. /rt_-I:Cklr_

|_ r__,/ [_-_-_ | [-[__u.._ CB CIRCUIT BREAKER

YEL BLU........... BLK \^tWT_'_'-_N I VlO. BRN. GND EQUIPMENT GROUND

"4/ PLUG -_/ x.]/ x.]/ x.]/ x_/ x_/ "..1/ HTR HEATER

I 7 9 6 2 3 5 1 4 I LS LIMIT SWITCH

NOTES: REC RECTIFIER

1. Use Copper Wire (75 ° Min) Only Between Disconnect Switch And Unit.

2. To Be Wired In Accordance With Nec And Local Codes.

3. If Any Of The Original Wire, As Supplied, Must Be Replaced, Use The Same

Or Equivalent Type Wire.

4. 208/240V 3-Phase Heaters shown above. I 111002204 rev.1

TDR TIME DELAY RECTIFIER

TF THERMAL FUSE

_ FIELD POWERWIRING

0 MARKED TERMINAL

"_'_ PLUG AND RECEPTACLE

EHIA20HB10 / EHIA25HB10

12 451 01 4109 00

Page 13

Replacement Parts

4

5

Representative drawing only, some models may vary in appearance.

KEY

NO.

1

Circuit Breaker, 25 Amp

DESCRIPTION

Circuit Breaker, 35 Amp

Circuit Breaker, 45 Amp

Circuit Breaker, 50 Amp

Circuit Breaker, 60 Amp

Circuit Breaker, 30 Amp, 3P

Circuit Breaker, 40 Amp, 3P

Circuit Breaker, 45 Amp, 3P

Circuit Breaker, 60 Amp, 3P

2 Lug, Ground

3 Rectifier Board

Rectifier Board

4 Limit, Thermal - L140-40F

Limit, Thermal - L145-40F

5 Thermal Cutoff

6 Relay

][ PARTS NOT SHOWN

][ I Circuit Breaker Seal

1-Phase 3-Phase

-r- -r- -r- -r- -r- -r- -r- -r- -r- -r- -r- -r- -r-

PART NO.

1082008

1082010

1082012

1082013

1082014

U.I U.I U.I U.I U.I U.I U.I U.I U.I U.I U.I U.I U.I

1 - 1

1

1

1 1

1 1 1 1

1083190

1084792

1 1 1

1084793

1080913

91590

1171780

1171906

1176270

1176271

1176269

1172506

11087843 I-I-I-11111111111111111111

1 1 1 1 1 1 2 2 3 1 1 2 2

1 1 1 1 1 1 1 1 1 1 1 1 1

1 1 2 1 1 2 2

4 5 6

1 22 1 223 336

1 2 2 1 2 2 3 4 5 3 3 6 6

1 1 1 1 1 1 2 2 3 2 2 3 3

1

1

1

451 01 4109 O0 13

Loading...

Loading...