Page 1

INSTA LATION

INSTRUCTIONS

s

.//

/

/

Models

EF08B1500A1, A2

EF12F1900A

EF16J2200A

EF20N2600A

With

AMF001NHA

Accessory No Heat Kit

Use ONLY factor'

listed electric heaters.

ECTRIC

FURNACE

SafetyLabeling and SignalWords

Danger,Warning and Caution

The signal words DANGER, WARNING and CAUTION

are used to identify levels of hazard seriousness. The

signal word DANGER is only used on product labels to

signify an immediate hazard. The signal words WARN-

ING and CAUTION will be used on product labels and

throughout this manual and other manuals that may ap-

ply to the product.

DANGER - Immediate hazards which WILL result in se-

vere personal injury or death.

WARNING - Hazards or unsafe practices which

COULD result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which COULD

result in minor personal injury or product or property

damage.

Safety Labeling and Signal Words Coy

General Information / Installation ............ 2

Vertical Installations ........................ 2

Horizontal Installations ..................... 3

Condensate Drain .......................... 5

Refrigerant Orifice and Lines ................ 5

Electrical Wiring ............................ 6

Checks and Maintenance .................... 7

Blower Performance ........................ 8

Signal Words in Manuals

The signal word WARNING is used throughout this

manual in the following manner:

The signal word CAUTION is used throughout this

manual in the following manner:

CAUTION

Product Labeling

Signal words are used incombination with colors and/or

pictures on product labels.

Printed in U.S.A. 442 01 2201 02

6-99

Page 2

_ Installation Instructions Electric Furnace I

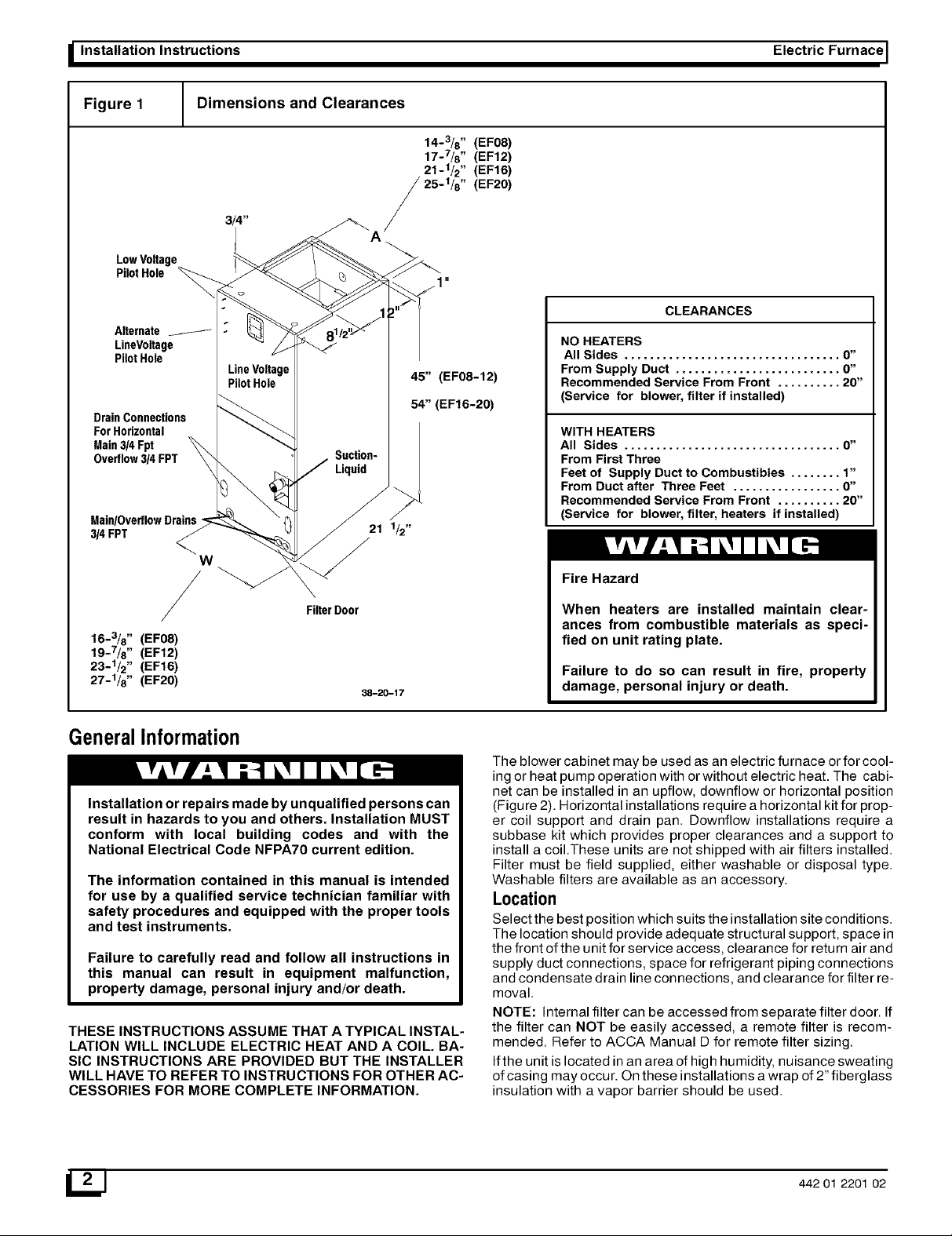

Figure 1 Dimensions and Clearances

14-3/8 " (EF08)

17-7/8 " (EF12)

21-1/2" (EF16)

25-1/8 " (EF20)

3/4"

LowVoltage

PilotH01e

CLEARANCES

Alternate

LineVoltage

PilotHole

DrainConnections

For Horizontal

Main3/4 Fpt

Overflow3/4 FPT

Main/OverflowDrains -

3/4 FPT

W

LineVoltage

PilotHole

45" (EF08-12)

54" (EF16-20)

Suction-

Liquid

NO HEATERS

All Sides .................................. O"

From Supply Duct .......................... 0"

Recommended Service From Front .......... 20"

(Service for blower, filter if installed)

WITH HEATERS

All Sides .................................. O"

From First Three

Feet of Supply Duct to Combustibles ........ 1"

From Duct after Three Feet ................. 0"

Recommended Service From Front .......... 20"

(Service for blower, filter, heaters if installed)

Fire Hazard

/

16-3/8 '' (EF08)

19-7/8 '' (EF12)

FilterDoor

23-1/2" (EF16)

27-1/8'' (EF20)

38-20-17

GeneralInformation

Installation or repairs made by unqualified persons can

result in hazards to you and others. Installation MUST

conform with local building codes and with the

National Electrical Code NFPA70 current edition.

The information contained in this manual is intended

for use by a qualified service technician familiar with

safety procedures and equipped with the proper tools

and test instruments.

Failure to carefully read and follow all instructions in

this manual can result in equipment malfunction,

property damage, personal injury and/or death.

THESE INSTRUCTIONS ASSUME THAT A TYPICAL INSTAL-

LATION WILL INCLUDE ELECTRIC HEAT AND A COIL. BA-

SIC INSTRUCTIONS ARE PROVIDED BUT THE INSTALLER

WILL HAVE TO REFER TO INSTRUCTIONS FOR OTHER AC-

CESSORIES FOR MORE COMPLETE INFORMATION.

When heaters are installed maintain clear-

ances from combustible materials as speci-

fied on unit rating plate.

Failure to do so can result in fire, property

damage, personal injury or death.

The blower cabinet may be used as an electric furnace or for cool-

ing or heat pump operation with or without electric heat. The cabi-

net can be installed in an upflow, downflow or horizontal position

(Figure 2). Horizontal installations require a horizontal kit for prop-

er coil support and drain pan. Downflow installations require a

subbase kit which provides proper clearances and a support to

install a coil.These units are not shipped with air filters installed.

Filter must be field supplied, either washable or disposal type.

Washable filters are available as an accessory.

Location

Select the best position which suits the installation site conditions.

The location should provide adequate structural support, space in

the front of the unit for service access, clearance for return air and

supply duct connections, space for refrigerant piping connections

and condensate drain line connections, and clearance for filter re-

moval.

NOTE: Internal filter can be accessed from separate filter door. If

the filter can NOT be easily accessed, a remote filter is recom-

mended. Refer to ACCA Manual D for remote filter sizing.

Ifthe unit is located in an area of high humidity, nuisance sweating

of casing may occur. On these installations a wrap of 2" fiberglass

insulation with a vapor barrier should be used.

442 01 2201 02

Page 3

I Electric Furnace Installation Instructions I

UpflowInstallations

The unit is ready to install in the upflow position without modifica-

tions.

The unit MUST be supported on the bottom ONLY and set on a

supporting frame or shelf. Use screws through the bottom to an-

chor to supporting frame.

DownflowInstallations

Refer to instructions with Subbase Kit.

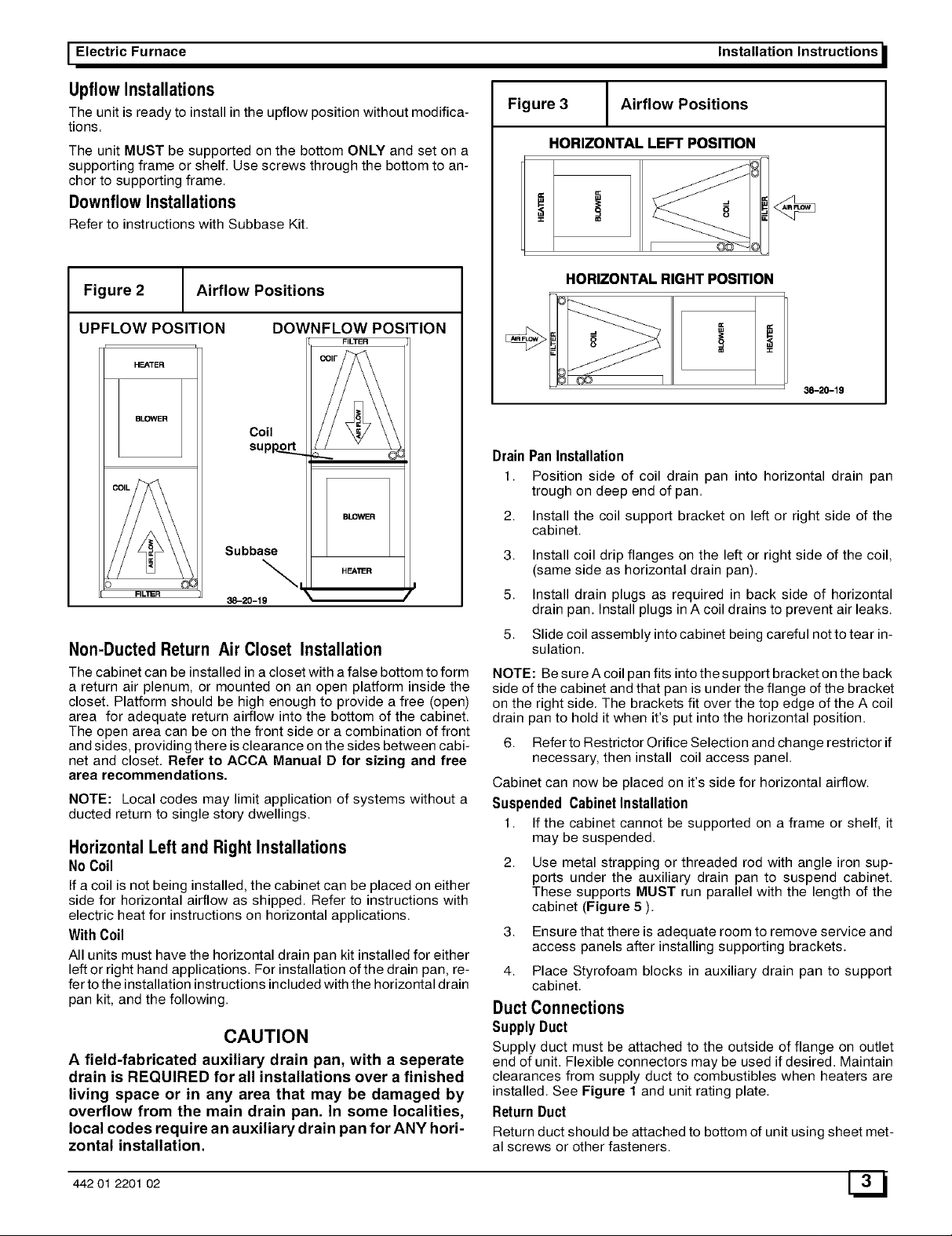

Figure 2 Airflow Positions

UPFLOW POSITION

HEATER

BLOWER

DOWNFLOW POSITION

FILTER

Coil

supop_._

Subbase

HF-_'_R

\ /

FILI_R

\,

38-20-19

Non-DuctedReturn Air Closet Installation

The cabinet can be installed in a closet with a false bottom to form

a return air plenum, or mounted on an open platform inside the

closet. Platform should be high enough to provide a free (open)

area for adequate return airflow into the bottom of the cabinet.

The open area can be on the front side or a combination of front

and sides, providing there is clearance on the sides between cabi-

net and closet. Refer to ACCA Manual D for sizing and free

area recommendations.

NOTE: Local codes may limit application of systems without a

ducted return to single story dwellings.

Horizontal Leftand Right Installations

No Coil

Ifa coil is not being installed, the cabinet can be placed on either

side for horizontal airflow as shipped. Refer to instructions with

electric heat for instructions on horizontal applications.

With Coil

All units must have the horizontal drain pan kit installed for either

left or right hand applications. For installation of the drain pan, re-

fer to the installation instructions included with the horizontal drain

pan kit, and the following.

CAUTION

A field-fabricated auxiliary drain pan, with a seperate

drain is REQUIRED for all installations over a finished

living space or in any area that may be damaged by

overflow from the main drain pan. In some localities,

local codes require an auxiliary drain pan for ANY hori-

zontal installation.

Figure 3 Airflow Positions

HORIZONTAL LEFT POSITION

HORIZONTAL RIGHT POSITION

,,=,

38-20-19

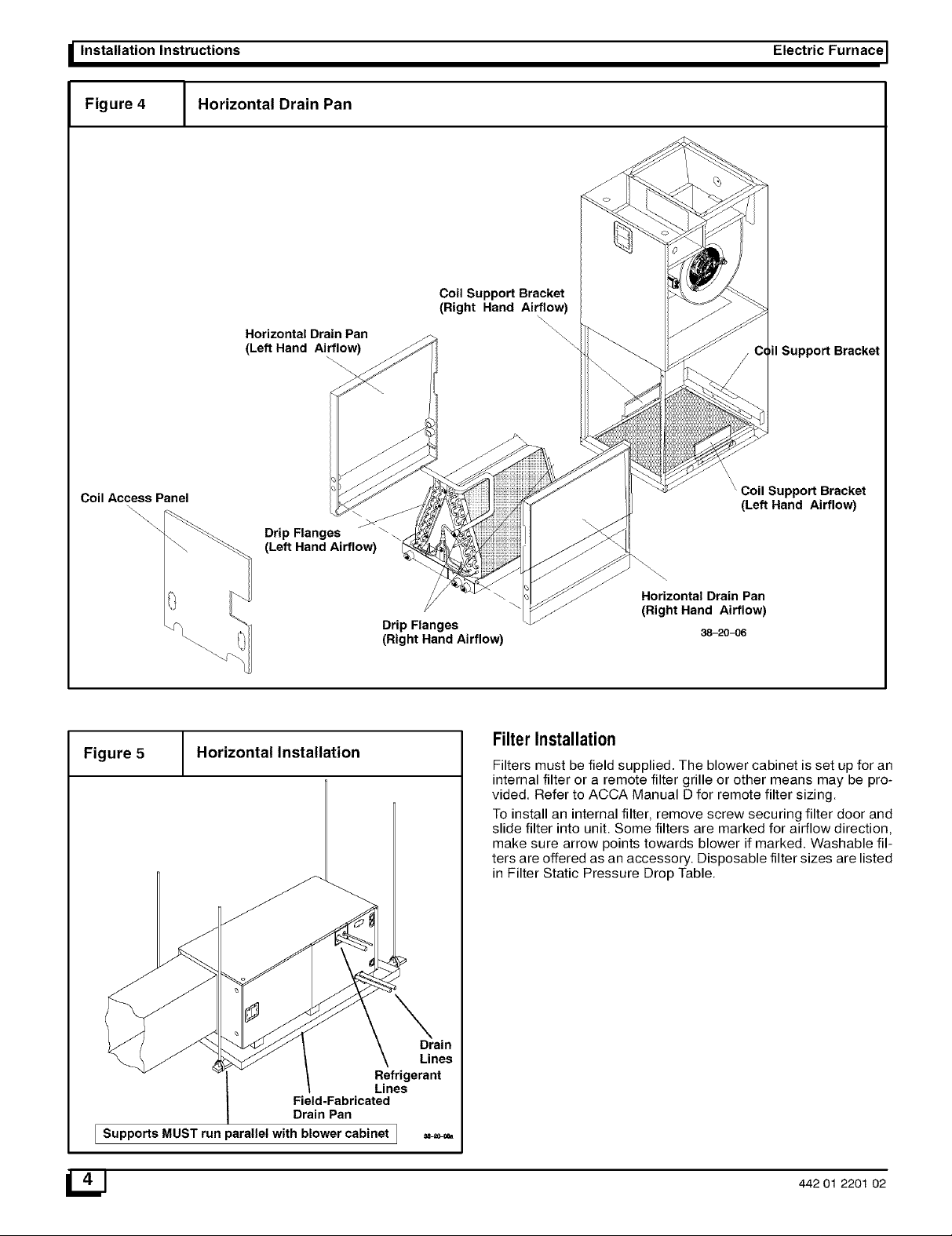

Drain Pan Installation

1. Position side of coil drain pan into horizontal drain pan

trough on deep end of pan.

2,

Install the coil support bracket on left or right side of the

cabinet.

3,

Install coil drip flanges on the left or right side of the coil,

(same side as horizontal drain pan).

5.

Install drain plugs as required in back side of horizontal

drain pan. Install plugs in A coil drains to prevent air leaks.

5.

Slide coil assembly into cabinet being careful not to tear in-

sulation.

NOTE: Be sure A coil pan fits into the support bracket on the back

side of the cabinet and that pan is under the flange of the bracket

on the right side. The brackets fit over the top edge of the A coil

drain pan to hold it when it's put into the horizontal position.

6. Refer to Restrictor Orifice Selection and change restrictor if

necessary, then install coil access panel.

Cabinet can now be placed on it's side for horizontal airflow.

Suspended Cabinet Installation

1. If the cabinet cannot be supported on a frame or shelf, it

may be suspended.

2,

Use metal strapping or threaded rod with angle iron sup-

ports under the auxiliary drain pan to suspend cabinet.

These supports MUST run parallel with the length of the

cabinet (Figure 5 ).

3,

Ensure that there is adequate room to remove service and

access panels after installing supporting brackets.

4.

Place Styrofoam blocks in auxiliary drain pan to support

cabinet.

DuctConnections

Supply Duct

Supply duct must be attached to the outside of flange on outlet

end of unit. Flexible connectors may be used if desired. Maintain

clearances from supply duct to combustibles when heaters are

installed. See Figure 1 and unit rating plate.

Return Duct

Return duct should be attached to bottom of unitusing sheet met-

al screws or other fasteners.

442 01 2201 02 W

Page 4

_ Installation Instructions

Figure 4 / Horizontal Drain Pan

1

Horizontal Drain Pan

(Left Hand Ai_ow)

Coil Support Bracket

(Right Hand Ai_w)

Electric Furnace I

\

il Support Bracket

Coil Access Panel

\

\

Drip Flanges

(Left Hand Airflow)

Figure 5 Horizontal Installation

Drip Flanges

(Right Hand Airflow)

Coil Support Bracket

(Left Hand Airflow)

Horizontal Drain Pan

(Right Hand Airflow)

38-20-06

FilterInstallation

Filters must be field supplied. The blower cabinet is set up for an

internal filter or a remote filter grille or other means may be pro-

vided. Refer to ACCA Manual D for remote filter sizing.

To install an internal filter, remove screw securing filter door and

slide filter into unit. Some filters are marked for airflow direction,

make sure arrow points towards blower if marked. Washable fil-

ters are offered as an accessory. Disposable filter sizes are listed

in Filter Static Pressure Drop Table.

Field-Fabricated

L Drain Pan

I Supports MUST run parallel with blowercabinet I =_=0_,

442 01 2201 02

Page 5

I Electric Furnace

CondensateDrain

Installation Instructions

The unit is provided with 3/4" National Pipe Thread (NPT) con-

densate drains. (Figure 1). Any drain can be used as a primary or

secondary drain. Condensate drain lines should be installed in a

manner that does not obstruct access to the filter.

There is a secondary drain fitting supplied with the unit that will

convert any of the primary condensate drain connections into a

secondary drain connection. This fitting should be installed in any

of the primary drain connections to convert itto asecondary drain.

1. Connect the drain lines to the appropriate drain fittings. 3/4"

PVC or other type of drain line may be used. The drain line

must not be smaller than the drain fitting.

2. Install a trap in the drain line below the bottom of the drain

pan and pitch the drain lines down from the coil at least I/4"

per foot of run. Horizontal runs over 15 feet long must also

have an anti-siphon air vent (stand pipe), installed ahead

of the horizontal run. An extremely long horizontal run may

require an oversized drain line to eliminate air trapping.

3. Route to the outside orto a floor drain, laundry tray or waste

line (sewer). Check local codes before connecting to a

sewer line.

4. Insulate drain lines where sweating could cause water

damage.

5. If a gravity drain cannot be used, install a condensate

pump. Install the pump as close to the indoor section as

possible.

SpecialNoteFor DownflowInstallations

For downflow installations, a secondary overflow drain

connection must be installed to prevent water from dripping onto

live electrical components. Use the secondary fitting on the

evaporator coil.

Waste Line Connection

Ifthe condensate line is to be connected to a waste line, an open

trap must be installed ahead of the waste line to prevent escape of

sewer gases. NEVER CONNECT THE DRAIN LINE DIRECTLY

TO A WASTE LINE. ALWAYS INCLUDE AN AIR GAP AND

TRAP, (Figure 6). Be sure to keep the trap filled with water during

the winter or off season.

Figure 6 J Condensate Drain to Waste Line

Air Gap Above

Condensate uid Level

Line

Sewer Line_-_

RestrictorOrificeSelection

A restrictor orifice is located in a fitting at the distributor. The facto-

ry installed restrictor orifice is identified on the unit rating plate.

The restrictor orifice may require changing to obtain best perfor-

mance. Refer to the restrictor charts furnished with the outdoor

unit.

ChangingRestrictorOrifice

1. Remove the liquid line fitting and replace restrictor orifice.

(STANDARD RIGHT HAND THREAD)

2. Make sure the restrictor is installed with the rounded end to-

ward the feeder tubes. See Figure 7.

RefrigerantLine Connections

Size refrigerant lines according to information provided with out-

door condensing unit. Route the refrigerant lines to the coil in a

manner that will not obstruct service access to the unit or removal

of the filter.

1. Remove rubber plugs from refrigerant connections using a

pulling and twisting motion. Hold refrigerant lines to avoid

bending or distorting.

2. Remove the coil door before brazing refrigerant connec-

tions to prevent damage to paint finish.

3. Fit refrigerant lines into coil connections and remove the

tubing plate and slide plate over the refrigerant lines to as-

sure sufficient room for brazing.

4. Reinstall tubing plate and door and install the gasket, pro-

vided with the unit, over the suction and liquid lines into the

tubing plate recess to ensure an air seal around the coil.

See Figure 8.

Figure 7 J Restrictor Orifice

Nut and Liquid Line

Jwith Strainer

Restrictor Orifice

_--_ Rounded End

/FeederTubes

I

Figure 8 J Refrigerant Lines

Gasket

Plate

Recessed

Area

For Gasket

442 01 2201 02 W

Page 6

_ Installation Instructions Electric Furnace I

ElectricHeat

Refer to Electric Heat Installation Manual to install heaters.

ElectricalWiring

Overcurrent Protection

The power supply wiring to the unit MUST be provided with over-

Electrical shock hazard.

Turn OFF electric power at fuse box or service

panel before making any electrical connections

and ensure a proper ground connection is made

before connecting line voltage.

Failure to do so can result in property damage,

personal injury and/or death.

All electrical work MUST conform with the requirements of local

codes and ordinances and the National Electrical Code NFPA 70

current edition.

Electrical Heaters& Operating Controls

The low voltage transformer and the fan control are standard on

all models and are prewired at the factory. To operate the blower

coil, a heater accessory or a no-heat kit must be installed. Line

voltage connections are made to the heater accessory or the no-

heat kit.

Low Voltage Control Connections

The 24 volt power supply is provided by an internally wired low

voltage transformer which is standard on all models. If power

supply is 208 volt, the low voltage transformer must be rewired to

the 208 volt tap. See the unit wiring label.

Field supplied low voltage wiring can enter the unit on the top left

hand corner or the left hand side panel. When using the left hand

side panel entrance, the low voltage wiring must be fed through

the entrance hole in the bottom of the control box.

Install the strain relief bushing (supplied with unit) in the selected

hole and a hole plug (supplied with unit) in the unused hole.

Connect the field wiring at the screw terminals of the control

board. Refer to Figure 9.

Keep the low voltage wiring as short as possible inside the control

box.

Complete connections between indoor blower, outdoor section,

indoor thermostat and electronic outdoor thermostat (accessory)

according to instruction provided with the Condenser Installation

Instructions or those provided with the accessory and refer to Fig-

ure 10.

Install No Heat Kit

If electric heat is not used, install accessory No Heat Kit.

1.. Locate adapter and filler plates, with screws inside pack-

age.

2.. Attach adapter plate and filler plate to bracket if required to

match cabinet, Refer to Figure 9.

3.. Secure the electric heat accessory with four screws.

4.. Connect the plug from No Heat Kit wiring into the recep-

tacle on the control board on the side of the cabinet.

current protection. Governing codes may require this to be fuses

ONLY or circuit breakers.

For blower cabinets without heaters, a 15 amp circuit may be

used.

Line Voltage Connections

Line voltage wiring may be brought into the unit through the top

right-hand corner or the right-hand side panel. The correct hole

size required by the conduit fitting must be punched at the pilot

hole location. Plug the unused pilot hole with a hole plug (supplied

with unit). Refer to Figure 9 for line voltage connections.

Grounding

Use a copper conductor (#14AWG) from the unit to a grounded

connection in the electric service panel or a properly driven and

electrically grounded ground rod.

Line Voltage Connection

1. A disconnect switch MUST be located within sight of the

unit.

2. Provide line voltage power supply (208V-240V) from a

separate 15 amp circuit.

3. Connect line voltage L1 and L2 to the lugs on the No Heat

Kit, Figure 9.

Figure 9 Installing No Heat Accessory

LowVoltage _ Matching Receptable

Connections J_ F For No Heat Kit

__ or Electric Heater

Filler Plate _ _'_ _

(EF16-20) _ ,J.I]J_P_K__ __

Adapter Plate _ o_.._..._"_ _

Lugs for

Line Voltage

and Ground

Connections

NoHeatKitTechnicalData

Maximum

OvercurRnt

No Heat

Model

AMF001NH

6J 442 01 2201 02

Supp_ CircuR

Volts Phase Redz

240 I 60

208 I 60

Supply

Circuit

No,

Single

Single

Maximum

Motor

AMPS.

6.0

6.0

Total

AMPS.

6.0

6.0

Branch

Circuit

Ampacity

7.5

7.5

Prote_we

Device

(AMP&)

15

15

No. Size Length (Ft)

2 14 104

2 14 90

Recommended

SupplyWire

75 oC. Copper

Max,

Ground

Wire

No. Size

1 14

1 14

Page 7

I Electric Furnace Installation Instructions

Changing Motor Speed

The blower motor comes from the factory wired for medium or

high speed. To change the blower speed, disconnect the black

wire at the blower motor terminal block and reconnect at the de-

;ired blower speed tap.

Figure 10 I Typical Low Voltage Connections

Thermostat Cooling Only

Outdoor Unit

R

G --

Y

Y

Y

w

W 2 W 1 G Y O H C R

000 000 )1

Indoor Blower

Cooling with Electric Heat

Thermostat

R

G --

Air Flow Check

For proper system operation, the air flow through the indoor coil

should be between 350 and 450 cfm per ton of cooling capacity.

The air flow through the unit can be determined by measuring the

external static pressure to the unit and selecting the motor speed

tap that will most closely provide the required air flow.

1. Set up to measure external static pressure at the supply

and return duct connections (Figure 11).

2. Drill holes in the ducts for pressure taps, pitot tubes, or oth-

er accurate pressure sensing devices.

3. Connect these taps to a level inclined manometer or draft

gauge.

4. Ensure the coil and filter are clean, and all the registers are

open.

5. Determine the external static pressure with the blower op-

erating.

6. Refer to the Air Flow Data (Figure 6) table to find the speed

tap that will most closely provide the required air flow for the

system.

7. Refer to Changing the Motor Speed in these instructions if

the speed tap is to be changed.

8. Recheck the external static pressure with the new speed

tap, and confirm speed tap selection.

Figure 11

Static Pressure Check

SupplyS

Staging

Thermostat

Outdoor Unit

o R

Heat Pump with Electric Heat

Wl °oj

-- y

Outdoor Unit

Indoor Manometer /

Section _

Return (

Maintenance

R

BL

W

O

Filters

Filters must be cleaned when they become dirty. Inspect at least

once per month. The frequency of cleaning depends upon the

hours of operation and the local atmospheric conditions. Clean fil-

ters keep unit efficiency high.

Lubrication

The bearings of the blower motor are permanently lubricated.

CondensateDrains

During the cooling season check the condensate drain lines to be

sure that condensate is flowing from the primary drain but not

from the secondary drain. If condensate ever flows from the sec-

ondary drain the unit should be promptly shut off and the conden-

sate pan and drains cleaned to insure afree flowing primary drain.

442 01 2201 02 W

Page 8

I Installation Instructions Electric Furnace I

Airflow Based on no coil, no filter, no electric heat. Deduct heater static shown in heater static table. Deduct filter

static shown in filter static table. Deduct coil static, See Coil Specification Sheet. Deduct .10 for Horizontal Drain

Pan Kit. Deduct .20 for Downflow Subbase Kit.

I= =_:I SP IN. WG, I _I_[.1 SP IN. WG.

SPEED Volts 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 SPEED Volts 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

LOW 230V 1053 1013 965 911 856 761 654 552

208V 863 827 788 725 641 568 492 381

MED 230V 1333 1281 1221 1150 1060 990 857 743

208V 1156 1115 1059 997 941 853 738 618

HIGH 230V 1553 1486 1411 1328 1227 1106 1032 865

208V 1394 1336 1272 1195 1096 1023 924 774

I _ ;lik.il SP IN. WG, I = _'_01 SP IN. WG.

SPEED Volts 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 SPEED Volts 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

LOW 230V 1103 1092 1086 1060 1024 973 906 803 LOW 230V 1673 1670 1669 1643 1587 1461 1298 1081

208V 903 893 877 858 830 781 728 642 208V 1320 1306 1289 1237 1147 1006 810 576

MED 230V 1498 1473 1451 1409 1352 1277 1173 1044 MED 230V 2060 2030 1980 1912 1835 1723 1594 1444

208V 1246 1239 1222 1202 1160 1098 1014 906 208V 1676 1656 1613 1531 1381 1201 986 683

HIGH 230V 1860 1815 1760 1685 1596 1491 1352 1178 HIGH 230V 2554 2459 2352 2242 2116 1966 1809 1606

208V 1602 1584 1553 1501 1432 1347 1241 1096 208V 2420 2334 2244 2137 2021 1875 1732 1558

LOW 230V 1103 1088 1067 1040 994 921 849 749

208V 872 847 820 788 750 696 630 530

MED 230V 1500 1493 1470 1438 1383 1303 1143 993

208V 1229 1223 1198 1169 1123 1031 926 798

HIGH 230V 1912 1879 1830 1771 1684 1577 1429 1154

208V 1629 1609 1584 1545 1478 1393 1214 1058

MODEL

EF08

EF12

EF16

EF20

II i iPr-*" 'ml

NOMINAL

FILTERSIZE

14X20

18X20

20X20

25X20

1"1'1i1=1'1i1'1"

CFM

600 800 1000 1200 1400 1600 1800 2000

0.05 0.09 0.13 0.19 ............

........ 0.09 0.12 0.17 0.22 ......

.............. 0.12 0.15 0.19 ---

.............. 0.09 0.11 0.14 0.18

L_J 442 01 2201 02

Page 9

I Blower Coils Installation Instructions

Sequence Of Operation

Mode |Thermostat to Con- | Control Control Function

trol Board 24 volt [ State

Electric Heat Only

Constant Blower

Fan Switch ON)

Thermostat calls for

Heat

Constant Blower

Fan Switch ON)

Cooling Only Unit

(Thermostat calls for

Cooling)

Cooling Only Unit

(Thermostat calls for

Heat)

Heat Pump

(Thermostat calls for

Cooling)

Heat Pump Y & G

(Thermostat calls for

Heat)

Heat Pump cannot

Y&G&Wl &W2

maintain proper temp.

Electric Heat Tempera-

ture satifised

Heat Pump

Y&G&O&W1 &W2

(Goes into Defrost

Mode)

Heat Pump

Room temp. satifised)

Heat Pump

(Emergency Heat)

G

G&W1 &W2

Cooling Only

G

Y&G

G&W1 &W2

Y&G&O

Y&G

G&W1 &W2

On

Off

On

Off

Unit With Electric Heat

On

Off

On

Off

On

Off

Heat Pump With

On

Off

On

On

Off

On

Off

Off

On

Off

Fan On.

Fan Off.

Fan On, 1st Stage Of Heat On, then 2nd Stage Of Heat On.

2nd thenlst Stage Of Heat Off. 6 sec delay, then Fan Off.

Fan On.

Fan Off.

Compressor On, Fan On.

Compressor Off, 60 Second Delay - Then Fan Off.

Fan On, 1st Stage Of Heat On, then 2nd Stage Of Heat On.

2nd thenlst Stage Of Heat Off. 6 sec delay, then Fan Off.

Electric Heat

Compressor On, Reversing Valve Energized, Fan On.

Compressor Off, 60 Second Delay And Then Fan Off.

Compressor On, Fan On

1st Stage Of Heat On, then 2nd Stage Of Heat On

2nd then 1st Stage Of Heat Off

Reversing valve switches unit to cooling, 1st Stage Of Heat

On, then 2nd Stage Of Heat On

Reversing valve switches back to heating, 2nd then 1st Stage

Of Heat Off

Compressor Off, 60 Second Delay And Then Fan Off.

Fan On, 1st Stage Of Heat On, then 2nd Stage Of Heat On.

2nd then 1st Stage Of Heat Off. 6 sec delay, then Fan Off.

NOTE: Electric Heat Elements are controlled by relays with a delay sequence from the logic board to provide sequencing between elements.

LimitOperation

The temperature limit responds to over-temperature conditions inthe air duct. Ifthe temperature limit trips, the electric heater relays will

be de-energized and the fan relay will be energized. Once the limit resets, the control will resume normal operation. If the limit trips four

times during a single call for heat, the control will go into a 1 hour soft lockout. During the soft lockout, the fan relay will respond to

thermostat inputs but the heater relays are disabled. Ifthe control detects a limit trip during the soft lockout, the control will go into a hard

lockout. Once in ahard lockout, the fan relay is locked on and the heater relays are disabled. Turning the power to the unitoff and then on

will clear this state.

442 01 2201 02 W

Page 10

I Installation Instructions Electric Furnace I

POWER SUPPLY:208/230-1-60 USE COPPER CONDUCTORS ONLY.

KEY: HIGH VOLT; LOW VOLT.

R----.>_MITi'_ - -xRI LIMIT

----_-4ZN

--BK --------_

BASE UNIT WITH NO-HEAT KIT AMFOOINH INSTALLED

•SEE INSTALLATION MANUAL FOR PROPER HEATING AND COOLING

FACTORY PRE-SET SPEED CONNECTIONS FOR YOUR UNIT.

LIMIT

m_

BK"[_ Y

I

BK _ 0

\ \ Y\

AMFK@SAH ELECTRIC HEATER

5 Kw

GRD

BK

SkI] ?fqrYl'_--_L_BLoN/To -- _-_-?

i0_os o

\ I Lo_-i lU_ lu_

_ o__ _ ,___--__-=_==_-_

,4,4,0>" I \ -4-1

AMFK20AH ELECTRIC HEATER

20 Kw

O_D

LIMIT

25 Kw

GRD

GRD

GRO

7.5 & 10 Kw

BK AMFKI4AH ELECTRIC HEATER BK

•AMFKISAH ELECTRIC HEATER (2 LIMITS)

BK

30Kw

GRD

ORO

ORO

:N

1085247-CAMFK3@AH ELECTRIC HEATER

442 01 2201 02

Page 11

I Blower Coils

ReplacemaentParts

DD,

EE,

Installation Instructions

Q

Z2

W

14

0

BB

Y

10

11

AA

442 01 2201 02 1_

/

T

38-20-21

38-20-26

Page 12

_ Installation Instructions

Models EFO8B15OOA1 / A2, EF12F19OOA1, EF16J22OOA1, EF2ON26OOA1

Electric Furnace I

Key Description

No

9 Control,FanTimer

10 Transformer

11 Motor,Blower

11

11

12 Mount,BlowerMotor

12

13 Wheel,Blower

13

13

14 Capacitor,10MFD,370V

14 15MFD,370V

F Wrapper

F

F

F

H Plate,Tubing

K Grommet,TubingPlate

K

O Panel,RearBlowerDeck

O

O

O

P Panel,FrontBlowerDeck

P

P

P

Q Panel,SideBlowerDeck

Q

Q

Q

R Bracket,ControlFan

S Bracket,DrainPan

S

S

S

T Stop,Coil

U Adapter,Filter

V Panel,Top

V

V

V

W Housing,Blower

W

W

X Panel,BlowerCutoff

X

X

Y Clamp,Capacitor

Z1 Rail,BlowerR.H.

Z2 Rail,BlowerL.H.

Part

No.

1085914

1082611

1083044

1083045

1083046

1002801

609227

600586

600587

96839

1094956

1094959

1084500

1084501

1084502

1084503

1082600

1082987

1082957

1082604

1082844

1082845

1082846

1082603

1082841

1082842

1082843

1082622

1082847

1082848

1082849

1082617

1082609

1082927

1082928

1082929

1083349

1084788

1082610

1082835

1082836

1082837

1083343

1082940

1082941

1082607

1082616

1082949

1095020

1082615

1082618

EF--00A1

08 12 16 20

1 1 1 1

1 1 1 1

1

* 1 1

* * * 1

1 1 1

* * * 1

1

* 1

* * 1 1

1 1 1

* * * 1

1

* 1

* * 1

* * * 1

1 1 1 1

1 1

* 1 1 1

1

* 1

* * 1

* * * 1

1

* 1

* * 1

* * * 1

2

* 2

* * 2

* * * 2

1 1 1 1

1

* 1

* * 1

* * * 1

2 2 2 2

* * 1

1

* 1

* * 1

* * * 1

1

* 1

* * 1 1

1

* 1

* * 1 1

1 1 1 1

1 1 1 1

1 1 1 1

Key Description

No

AA Door,CoilAccess

AA

AA

AA

AB Panel,Fill-in

AB

AB

AB

BB Door,BlowerAccess

BB

BB

BB

BB

CC Door,FilterAccess

CC

CC

CC

DD Plate,HeaterAdapter

EE Plate,HeaterFiller

)( Manual,Installation

Part EF--00A1

No. 08 12 16 20

1082606 1

1082930 * 1

1082931 * * 1

1082932 * * * 1

1084512 1

1084513 * 1

1084514 * * 1

1084515 * * * 1

1082605 1

1085301** 1

1082838 * 1

1082839 * * 1

1082840 * * * 1

1082608 1

1082832 * 1

1082833 * * 1

1082834 * * * 1

1084606 * 1 1 1

1084608 * * 1 1

44201220100 1 1 1 1

** EF08-- A1 Models with AMFK14 Electric Heat and all

EF08--A2 models

442 01 2201 02

Loading...

Loading...