Page 1

Theseinstructionsmustbereadandunderstoodcompletelybeforeattemptinginstallation.

It is important that the Blower and Duct System be properly sized to allow the system to operate at full capacity. Poorly

designed systems will not give satisfactory cooling or economy. They may even shorten the service life of the

compressor in the outdoor unit.

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and

NOTE

The signal words DANGER, WARNING, CAU-

TION, and NOTE are used to identify levels of haz-

ard seriousness. The signal word DANGER is only

used on product labels to signify an immediate haz-

ard. The signal words WARNING, CAUTION, and

NOTE will be used on product labels and through-

out this manual and other manuals that may apply

to the product.

DANGER - Immediate hazards which will result in

severe personal injury or death.

WARNING - Hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which

may result in minor personal injury or product or

property damage.

NOTE - Used to highlight suggestions which will

result in enhanced installation, reliability, or opera-

tion.

Signal Words in Manuals

The signal word WARNING isused throughout this

manual in the following manner:

The signal word CAUTION is used throughout this

manual in the following manner:

Signal Words on Product Labeling

Signal words are used in combination with colors

and/or pictures on product labels.

TABLE OF CONTENTS

Installation .................................. 2 - 4

Condensate Drain ........................... 4 - 5

Waste Line Connection .......................... 5

Refrigerant Line Connections .................... 6

Refrigerant Metering Device ..................... 7

Check and Adjust Airflow ..................... 7 - 8

Start-Up Procedure ............................ 9

R-410A Quick Reference Guide .................. 9

ELECTRICAL SHOCK HAZARD

Failure to turn off electric power could result in

personal injury or death.

Before installing or servicing system, turn off

main power to the system. There may be more than

one disconnect switch, including accessory heat-

er(s).

484 01 3001 03 Nov 2007

Page 2

INSTALLATION

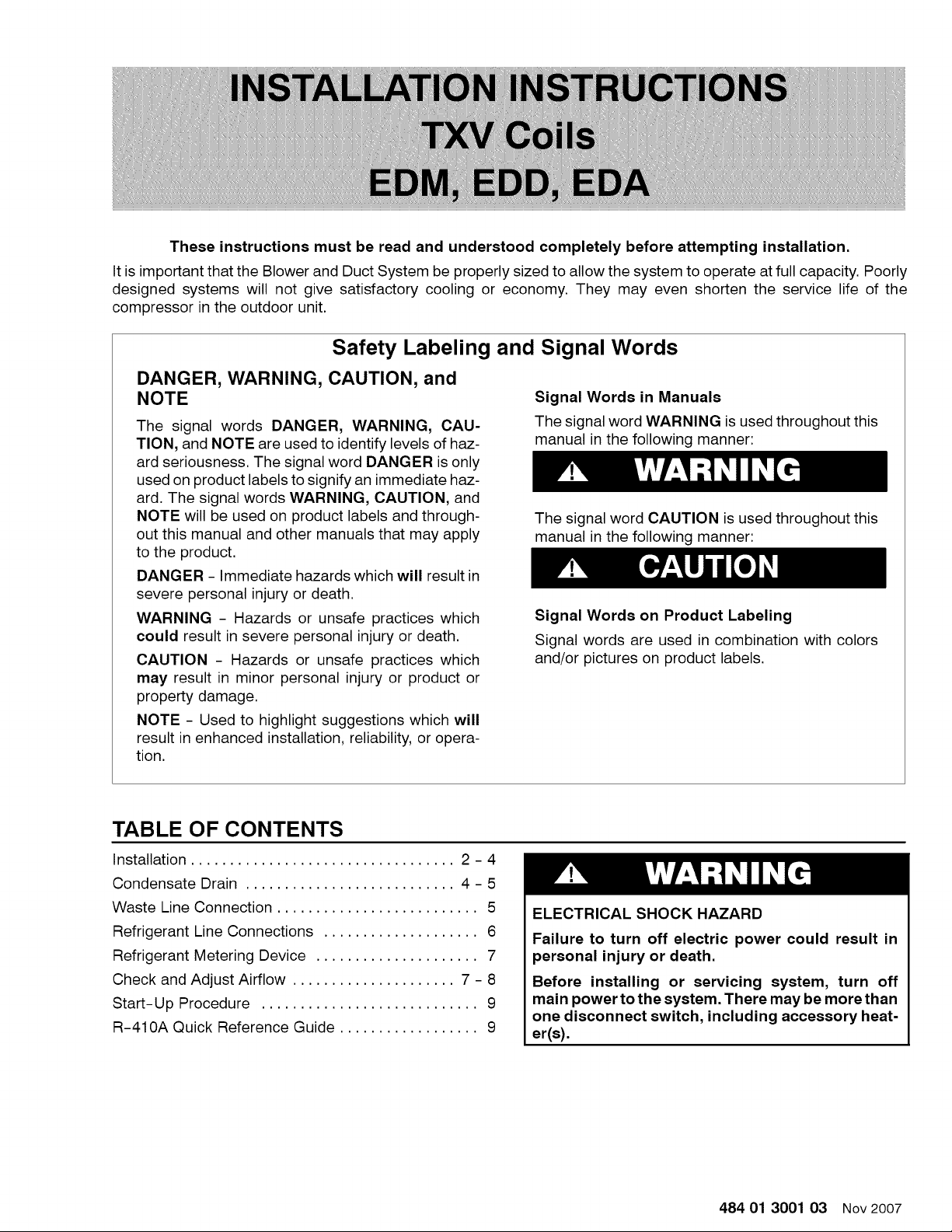

EDA Loose Coils are shipped with a metal collar plate

approximately the same size as the drain pan. The collar

plate must be installed between the drain pan and the

furnace or air handler cabinet to prevent condensation

inside the cabinet. Position the collar plate as shown in

Figure 1, with the flanges pointing down, towards the

furnace or air handler cabinet. Size the plenum or

fabricate spacers to seal against the outside of the collar

and prevent air bypass.

Figure 1 [ EDA Collar Plate

Collar Plate

under drain pan

Flanges down

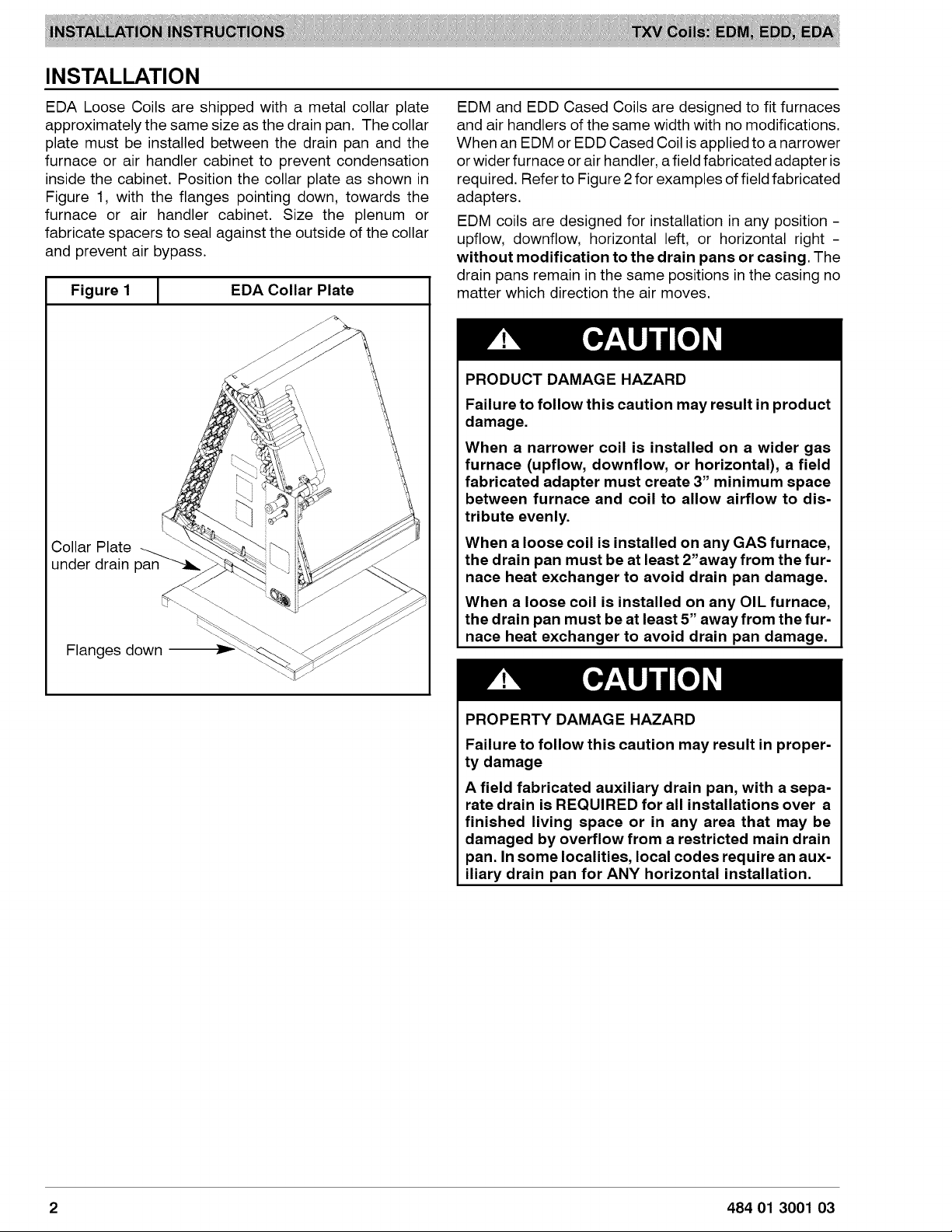

EDM and EDD Cased Coils are designed to fit furnaces

and air handlers of the same width with no modifications.

When an EDM or EDD Cased Coil is applied to a narrower

or wider furnace or air handler, a field fabricated adapter is

required. Refer to Figure 2 for examples of field fabricated

adapters.

EDM coils are designed for installation in any position -

upflow, downflow, horizontal left, or horizontal right -

without modification to the drain pans or casing. The

drain pans remain in the same positions in the casing no

matter which direction the air moves.

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

When a narrower coil is installed on a wider gas

furnace (upflow, downflow, or horizontal), a field

fabricated adapter must create 3" minimum space

between furnace and coil to allow airflow to dis-

tribute evenly.

When a loose coil is installed on any GAS furnace,

the drain pan must be at least 2"away from the fur-

nace heat exchanger to avoid drain pan damage.

When a loose coil is installed on any OIL furnace,

the drain pan must be at least 5" away from the fur-

nace heat exchanger to avoid drain pan damage.

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in proper-

ty damage

A field fabricated auxiliary drain pan, with a sepa-

rate drain is REQUIRED for all installations over a

finished living space or in any area that may be

damaged by overflow from a restricted main drain

pan. In some localities, local codes require an aux-

iliary drain pan for ANY horizontal installation.

2 484 01 3001 03

Page 3

Figure2 1 Adapters for Coils Wider or Narrower than Furnace or Air Handler

0 0

NARROWER'

COIL

ADAPTER

(FIELD SUPPLIED)

(FIELD SUPPLIED)

WIDER FURNACE

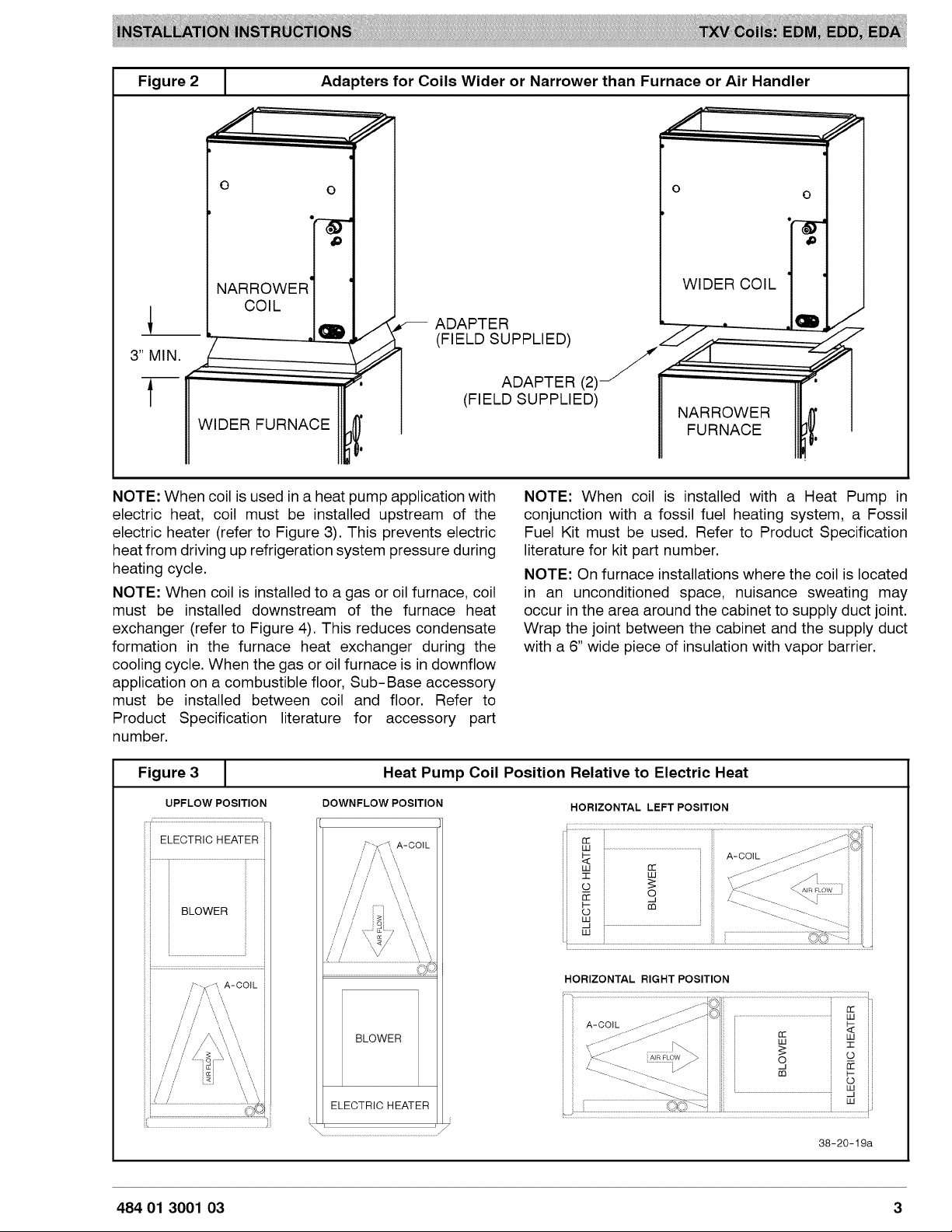

NOTE: When coil is used in a heat pump application with

electric heat, coil must be installed upstream of the

electric heater (refer to Figure 3). This prevents electric

heat from driving up refrigeration system pressure during

heating cycle.

NOTE: When coil is installed to a gas or oil furnace, coil

must be installed downstream of the furnace heat

exchanger (refer to Figure 4). This reduces condensate

formation in the furnace heat exchanger during the

cooling cycle. When the gas or oil furnace is in downflow

application on a combustible floor, Sub-Base accessory

must be installed between coil and floor. Refer to

Product Specification literature for accessory part

number.

O

O

WIDER COIL

ADAPTER

NARROWER

FURNACE

NOTE: When coil is installed with a Heat Pump in

conjunction with a fossil fuel heating system, a Fossil

Fuel Kit must be used. Refer to Product Specification

literature for kit part number.

NOTE: On furnace installations where the coil is located

in an unconditioned space, nuisance sweating may

occur in the area around the cabinet to supply duct joint.

Wrap the joint between the cabinet and the supply duct

with a 6" wide piece of insulation with vapor barrier.

Figure 3 1

UPFLOW POSITION

DOWNFLOW POSITION HORIZONTAL LEFT POSITION

ELECTRIC HEATER

Heat Pump Coil Position Relative to Electric Heat

HORIZONTAL RIGHT POSITION

BLOWER

38- 20-19a

484 01 3001 03 3

Page 4

Figure4 [

UPFLOW POSITION

/ /

// //

FURNACE

HEAT EXCHANGER

BLOWER

Coil Position Relative to Gas or Oil Furnace Heat Exchanger

HORIZONTAL LEFT POSITION

:: BLOWER

FURNACE

ii HEATEXCHANGER

HORIZONTAL RIGHT POSITION

i _ A-CO L ......... ........ i

++ +-++",, i+

i _ mz :: ..........................::+

:2:2:2:2:2:2:2:2:2:2:2:2 i

.....................SUB:B)SE)??ESS?a .................

CONDENSATE DRAIN

Coil is provided with two 3A" NPT condensate drain

connections. (EDM models have two connections for

upflow/downflow, and two more connections for

horizontal.) The connection with the larger internal

opening is the primary drain, and the connection with

the smaller internal opening is the secondary

(overflow) drain. Condensate drain lines should be

installed in a manner that does not obstruct access to the

filter. Use PVC fittings on the plastic condensate pan.

Finger tighten plus 11/2turns. Do not over-tighten. Use

pipe dope.

If coil is located in or above a living space where damage

may result from condensate overflow, a separate 3A"drain

must be provided from secondary (overflow) drain

connection. Run this drain to a place in compliance with

local installation codes where it will be noticed when unit is

operational. Condensate flowing from secondary

(overflow) drain indicates a plugged primary drain - unit

requires service or water damage will occur.

NOTE: For downflow electric furnace, the secondary

(overflow) drain connection must be installed to prevent

possibility of water dripping onto live electrical

components.

1. Connect drain lines to the appropriate drain

connections. Drain lines should not be smaller than

the drain connections (3A").

2. NOTE: Traps must be used when the coil is

installed on the return air side of the system. When

coil is installed on the supply side (outlet air) it is not

necessary to install traps and better drainage is

usually achieved without traps.

Install properly sized condensate traps in the drain

line as close to the coil as possible. Install drain lines

belowthe bottom of the drain pan and pitch the drain

lines down from the coil at least ¼ inch per foot of

run. Horizontal runs over 15 feet long must also

........... + T ++ ......................................................>:-<,+%y:::: 1 ++

have an anti-siphon air vent (stand pipe), installed

ahead of the horizontal run. An extremely long

horizontal run may require an oversized drain line to

eliminate air trapping.

Refer to Figure 5 for minimum trap dimensions.

.

Route to the outside or to a floor drain. Check local

codes before connecting to a waste (sewer) line.

4.

Prime all traps, test for leaks, and insulate drain

lines where sweating could cause water damage.

5.

If a gravity drain cannot be used, install a

condensate pump. Install the pump as close to the

indoor section as possible.

Figure 5 I Recommended Condensate Trap

2" MIN

4 484 01 3001 03

Page 5

NOTE: EDM coils 3 tons and larger feature two wires significance whatsoever. They are only for channeling

fastened between the horizontal drain pan and splash condensate from the splash guards to the drain pan in

guards, at the top of the A-coil. These are for water horizontal applications. Refer to Figure 6.

management only. These wires have NO electrical

Figure 6 I Condensate Wires

Condensate Management Wire

1

(both sides)

WASTE LINE CONNECTION

If the condensate line is to be connected to a waste

(sewer) line, an open trap must be installed ahead of the

waste line to prevent escape of sewer gases

(refer to Figure 7).

EXPLOSION HAZARD

Failure to provide trap could result in personal in-

jury, death, or property damage.

Provide trap with air gap in drain line when con-

necting to waste (sewer) line. Refer to Figure 6.

Figure 7

Condensate

Line

Trap

Condensate Drain to Waste Line

J

Air Gap Above

Liquid Level

l Sewer Line t

484 01 3001 03 5

Page 6

REFRIGERANT LINE CONNECTIONS

PERSONAL INJURY HAZARD

Failure to relieve pressure in the coil could result

in personal injury.

Wear eye protection.

Coil is factory charged with 15 psi nitrogen. Pierce

the centers of both rubber tubing plugs to relieve

pressure before removing plugs.

NOTE: Factory nitrogen charge may escape past rubber

plugs during storage. This does not indicate a leaking coil

nor warrant return of the coil.

Size and install refrigerant lines according to information

provided with outdoor unit. Coil connection tube sizes are

shown in Figure 8. Route refrigerant lines to the coil in a

manner that will not obstruct service access to the unit or

removal of the filter.

1. Remove cabinet door. Remove tubing plate with

rubber grommets and slide plate with grommets

onto the refrigerant lines (field line-set), away from

braze joints.

2. Remove rubber plugs from coil stubs using a pulling

and twisting motion. Hold coil stubs steady to avoid

bending or distorting.

.

Wrap TXV and nearby tubing with a heat-sinking

material such as a wet cloth.

4.

Fit refrigerant lines into coil stubs. Wrap a heat

sinking material such as a wet cloth behind braze

joints.

NOTE: See outdoor unit Installation Instructions

regarding requirements for installation of a

filter-drier in the liquid line close to the indoor coil.

,

Braze using a SiI-Fos or Phos-copper alloy.

6.

After brazing, allow joints to cool. Slide tubing plate

with rubber grommets over joints. Position tubing at

center of each grommet to ensure an air seal

around the tube (refer to Figure 9).

Figure 9 J Refrigerant Lines

RUBBER

GROMMETS

TUBING PLATE

Strainer screen is factory installed inside the liquid tube

stub (TXV tube). Leave the strainer screen in place during

installation (refer to Figure 10).

Figure 10 J Strainer Screen

r-q

ainer Screen (_

TXV

Figure 8 Coil Connection Tube Size (inch)

Model Size Liquid Suction

18 (1½ ton) 3/8 5/8

24 (2 ton) 3/8 5/8

30 (2½ ton) 3/8 3A

36 (3 ton) 3/8 3A

42 (4½ ton) 3/8 7/8

48 (4 ton) 3/8 7/8

60 (5 ton) 3/8 7/8

6 484 01 3001 03

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

Braze with SiI-Fos or Phos-copper alloy on cop-

per-to-copper joints and wrap a wet cloth around

rear of fitting to prevent damage to TXV.

[1

Page 7

REFRIGERANT METERING DEVICE

EDM2, EDD2, EDA2 Models:

These Coils have a factory installed hard shut-off TXV

designed only for use with R-22 refrigerant. Use only with

outdoor units designed for R-22.

EDM4, EDD4, EDA4 Models:

These Coils have a factory installed hard shut-off TXV

designed only for use with R-410A refrigerant. Use only

with outdoor units designed for R-410A.

TXV is factory set and not field adjustable.

CHECK AND ADJUST AIR FLOW

ELECTRICAL SHOCK HAZARD

Failure to shut of electric power could result in

personal injury or death.

Before adjusting blower speed, shut off electric

power to the furnace or blower module.

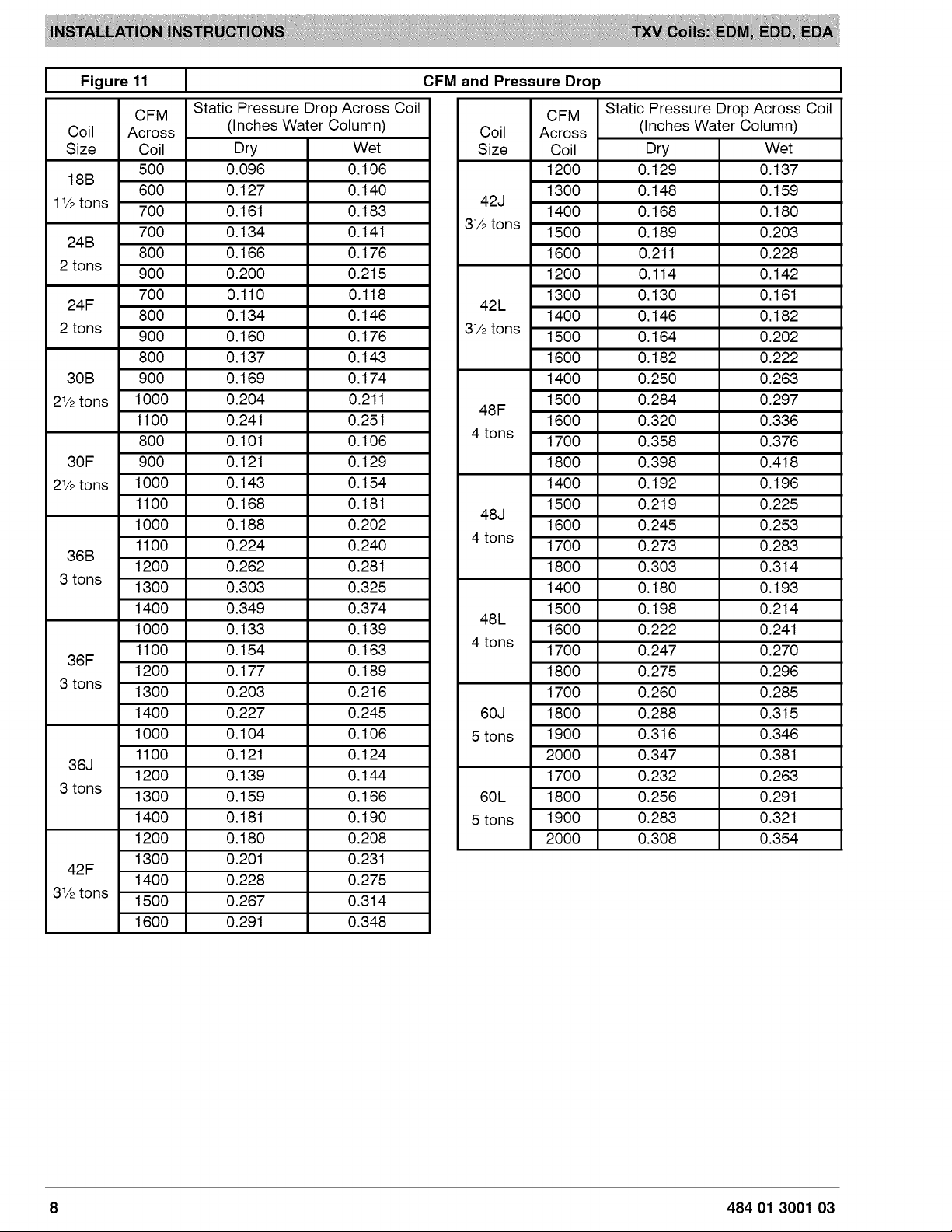

It is important that the correct amount of air (CFM) flows

through the coil. The installer must determine the

required CFM based on the characteristics of the specific

system (such as system size, ducting, components, and

accessories). In general, 400 CFM per ton is the nominal

required value, with a range of 350 - 450 CFM per ton.

Check Static Pressure Drop and CFM Across Coil

The amount of air (CFM) is related to a pressure drop. To

determine the CFM, measure the pressure drop using an

inclined manometer (sometimes called draft gauge or air

flow gauge).

1. The coil should be dry and clean. The air filter must

be clean and in place. All registers open. DO NOT

run the outdoor unit when checking air flow.

2. Run the blower on cooling speed.

3. Using the manometer (draft gauge or flow gauge),

measure the static pressure drop across the dry coil

and compare it to the numbers in Figure 11.

4. Find the corresponding CFM in Figure 11.

Adjusting Air Flow

If CFM istoo low, increase the blower speed and measure

the static pressure drop again. Determine CFM from

Figure 11.

If CFM istoo high, reduce the blower speed and measure

the static pressure drop again. Determine CFM from

Figure 11.

NOTE: Change blower speed as shown in the

instructions for the furnace or air handler.

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

This Coil has a hard shut-off TXV metering device.

A compressor Hard Start Kit is required in all ap-

plications where the matching outdoor unit has a

single-phase reciprocating compressor.

NOTE: It may not be possible to obtain a gauge reading

exactly the same as shown in Figure 11. This is due to

variations in duct systems and blower speeds.

If the motor is at the highest speed and the CFM isstill not

high enough, replace the blower and/or motor with a

larger size.

If the unit has an adjustable belt driven blower, use an

ammeter to check the motor current draw. If the current

draw is higher than the motor name plate amps, replace

the motor with one of greater horsepower.

484 01 3001 03 7

Page 8

I Figure 11 I CFM and Pressure Drop

Wet

0.106

0.140

0.183

0.141

0.176

0.215

0.118

0.146

0.176

0.143

0.174

0.211

0.251

0.106

0.129

0.154

0.181

0.202

0.240

0.281

0.325

0.374

0.139

0.163

0.189

0.216

0.245

0.106

0.124

0.144

0.166

0.190

0.208

0.231

0.275

0.314

0.348

Coil

Coil

Size

42J

31/2tons

42L

31/2tons

48F

4 tons

48J

4 tons

48L

4 tons

60J

5 tons

60L

5 tons

CFM

Across

Coil

1200

1300

1400

1500

1600

1200

1300

1400

1500

1600

1400

1500

1600

1700

1800

1400

1500

1600

1700

1800

1400

1500

1600

1700

1800

1700

1800

1900

2000

1700

1800

1900

2000

Coil

Size

18B

11/2tons

24B

2 tons

24F

2 tons

30B

21/2tons

30F

21/2tons

36B

3 tons

36F

3 tons

36J

3 tons

42F

31/2tons

CFM

Across

Coil

5OO

6OO

7OO

7OO

8OO

9OO

7OO

8OO

9OO

800

900

1000

1100

800

900

1000

1100

1000

1100

1200

1300

1400

1000

1100

1200

1300

1400

1000

1100

1200

1300

1400

1200

1300

1400

1500

1600

Static Pressure Drop Across

(Inches Water Column)

Dry

0.096

0.127

0.161

0.134

0.166

0.200

0.110

0.134

0.160

0.137

0.169

0.204

0.241

0.101

0.121

0.143

0.168

0.188

0.224

0.262

0.303

0.349

0.133

0.154

0.177

0.203

0.227

0.104

0.121

0.139

0.159

0.181

0.180

0.201

0.228

0.267

0.291

Static Pressure Drop Across Coil

(Inches Water Column)

Dry

0.129

0.148

0.168

0.189

0.211

0.114

0.130

0.146

0.164

0.182

0.250

0.284

0.320

0.358

0.398

0.192

0.219

0.245

0.273

0.303

0.180

0.198

0.222

0.247

0.275

0.260

0.288

0.316

0.347

0.232

0.256

0.283

0.308

Wet

0.137

0.159

0.180

0.203

0.228

0.142

0.161

0.182

0.202

0.222

0.263

0.297

0.336

0.376

0.418

0.196

0.225

0.253

0.283

0.314

0.193

0.214

0.241

0.270

0.296

0.285

0.315

0.346

0.381

0.263

0.291

0.321

0.354

8 484 01 3001 03

Page 9

START-UP PROCEDURE

Refer to outdoor unit Installation Instructions for

refrigeration system start-up instructions and refrigerant

charging method details.

R-410A QUICK REFERENCE GUIDE

• R-410A refrigerant operates at 50% - 70% higher pressures than R-22. Be sure that servicing equipment and

replacement components are designed to operate with R-410A.

• R-410A refrigerant cylinders are rose colored.

• Recovery cylinder service pressure rating must be 400 psig, DOT 4BA400 or DOT BW400.

• R-410A systems should be charged with liquid refrigerant. Use a commercial type metering device in the

manifold hose.

• Manifold sets should be 750 psig high-side and 200 psig low-side with 520 psig low-side retard.

• Use hoses with 750 psig service pressure rating.

• Leak detectors should be designed to detect HFC refrigerant.

• R-410A, as with other HFC refrigerants, is only compatible with POE oils.

• POE oils absorb moisture rapidly. Do not expose oil to atmosphere.

• POE oils may cause damage to certain plastics and roofing materials.

• Vacuum pumps will not remove moisture from oil.

• A liquid line filter-drier is required on every unit.

• Do not use liquid line filter-driers with rated working pressures less than 600 psig.

• Do not install a suction line filter-drier in liquid line.

• Wrap all filter-driers and service valves with wet cloth when brazing.

• Do not use with an R-22 TXV.

• If indoor unit is equipped with an R-22 TXV, it must be changed to an R-410A TXV.

• Do not use capillary tube indoor coils.

• Never open system to atmosphere while it is under a vacuum.

• When system must be opened for service, break vacuum with dry nitrogen and replace all filter-driers.

• Do not vent R-410A into the atmosphere.

• Observe all WARNINGS, CAUTIONS, NOTES, and bold text.

484 01 3001 03 9

Loading...

Loading...