Page 1

Electric Heat Accessory

EBP, EBX,

Installation Instructions

EBV and EBW

1800 Thru 6000

Electrical shock hazard.

Installation or repairs made by unqualified persons

can result in hazards to you and others. Installation

must conform with local building codes or, in the

absence of local codes, with National Electrical Code

ANSI/NFPA 70-1996 or current edition.

The information contained in this manual is intended

for use by a qualified service technician familiar with

safety procedures and equipped with the proper

tools and test instruments.

Shut OFF electric power at unit disconnect and/or

service panel before beginning the following proce-

dures.

Failure to carefully read and follow all instructions in

this manual can result in malfunction, property

damage, personal injury, and/or death.

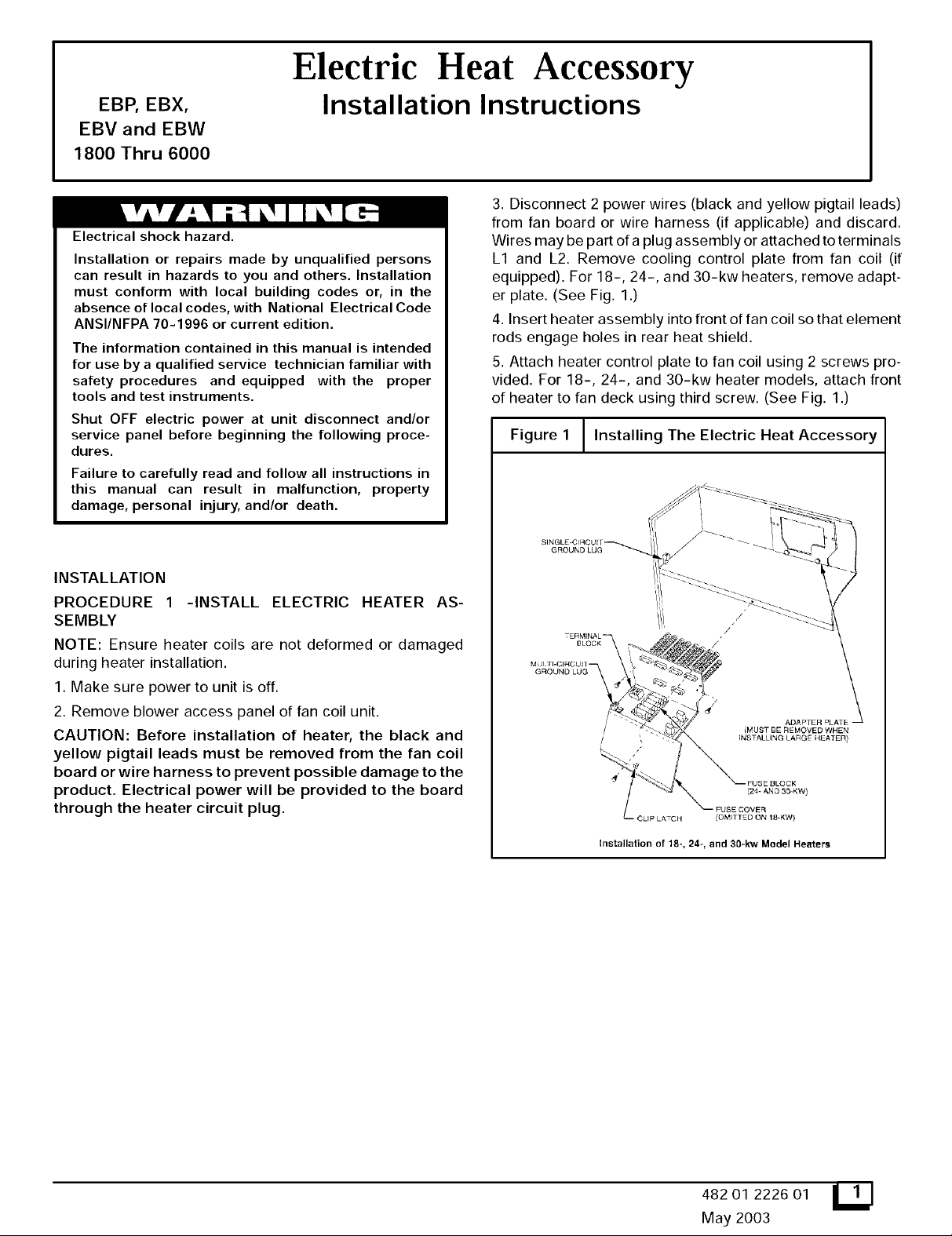

3. Disconnect 2 power wires (black and yellow pigtail leads)

from fan board or wire harness (if applicable) and discard.

Wires may be part of a plug assembly or attached to terminals

L1 and L2. Remove cooling control plate from fan coil (if

equipped). For 18-, 24-, and 30-kw heaters, remove adapt-

er plate. (See Fig. 1.)

4. Insert heater assembly into front of fan coil so that element

rods engage holes in rear heat shield.

5. Attach heater control plate to fan coil using 2 screws pro-

vided. For 18-, 24-, and 30-kw heater models, attach front

of heater to fan deck using third screw. (See Fig. 1.)

Figure 1 I Installing The Electric Heat

L

Accessory

INSTALLATION

PROCEDURE 1 -INSTALL ELECTRIC HEATER AS-

SEMBLY

NOTE: Ensure heater coils are not deformed or damaged

during heater installation.

1. Make sure power to unit is off.

2. Remove blower access panel of fan coil unit.

CAUTION: Before installation of heater, the black and

yellow pigtail leads must be removed from the fan coil

board or wire harness to prevent possible damage to the

product. Electrical power will be provided to the board

through the heater circuit plug.

GROUND LUG

/

/

ADAPTER PLA] E_

iMUST BE REMOVED WHEN

(24- AND 30-KW)

_E COVEq

- CUP LATCH

Installation of 18-, 24-, and 30-kw Model Heaters

(OMITTED ON 18-KW)

3E HEA_ER)

482 01 2226 01

May 2003

Page 2

Model Description Use With

EHKOSAKN 5 Kw Single Phase All

EHKO7AKN 8 Kw Single Phase All

EHKO7AKB 8 Kw Single Phase All

EHKO9AKCN 9 Kw / Single Phase (Field convertible to 3 phase) 2-5 Ton

EHKIOAKN 10 Kw Single Phase All

EHKIOAKB 10 Kw Single Phase All

EHK15AKF 15 Kw Single Phase 2-5 Ton

EHK15AKB 15 Kw Single Phase 2-5 Ton

EHK15AHN 15 Kw 3 Phase 3-5 Ton

EHK18AHN 18 Kw 3 Phase 3 1/2 - 5 Ton

EHK2OAKF 20 Kw Single Phase 2 1/2 - 5 Ton

EHK2OAKB 20 Kw Single Phase 2 1/2 - 5 Ton

EHK25AHCF 24 Kw / 3 Phase (Field convertible to single phase) 4 - 5 Ton

EHK3OAHCF 30 Kw / 3 Phase (Field convertible to single phase) 4 - 5 Ton

All AKB Models are Circuit Breaker Models

Fan HEATER KW

Coil

Sizes 5 8 9 10 15 18 20 24 30

1800 525 525 600* - - -

2400 700 700 700 700 775* - -

3000 875 875 875 875 1060" -

3600 1050 970 970 970 920 1040 -

4200 1225 1225 1225 1225 1225 1225 -

4800 1400 1400 1400 1400 1400 1400 1400 1400

6000 1750 1750 1750 1750 1750 1750 1750 1750

Indicates medium speed (blue). All other motor speeds at low tap.

PROCEDURE 2 -ATTACH FUSE BOX OR CIRCUIT

BREAKER BOX

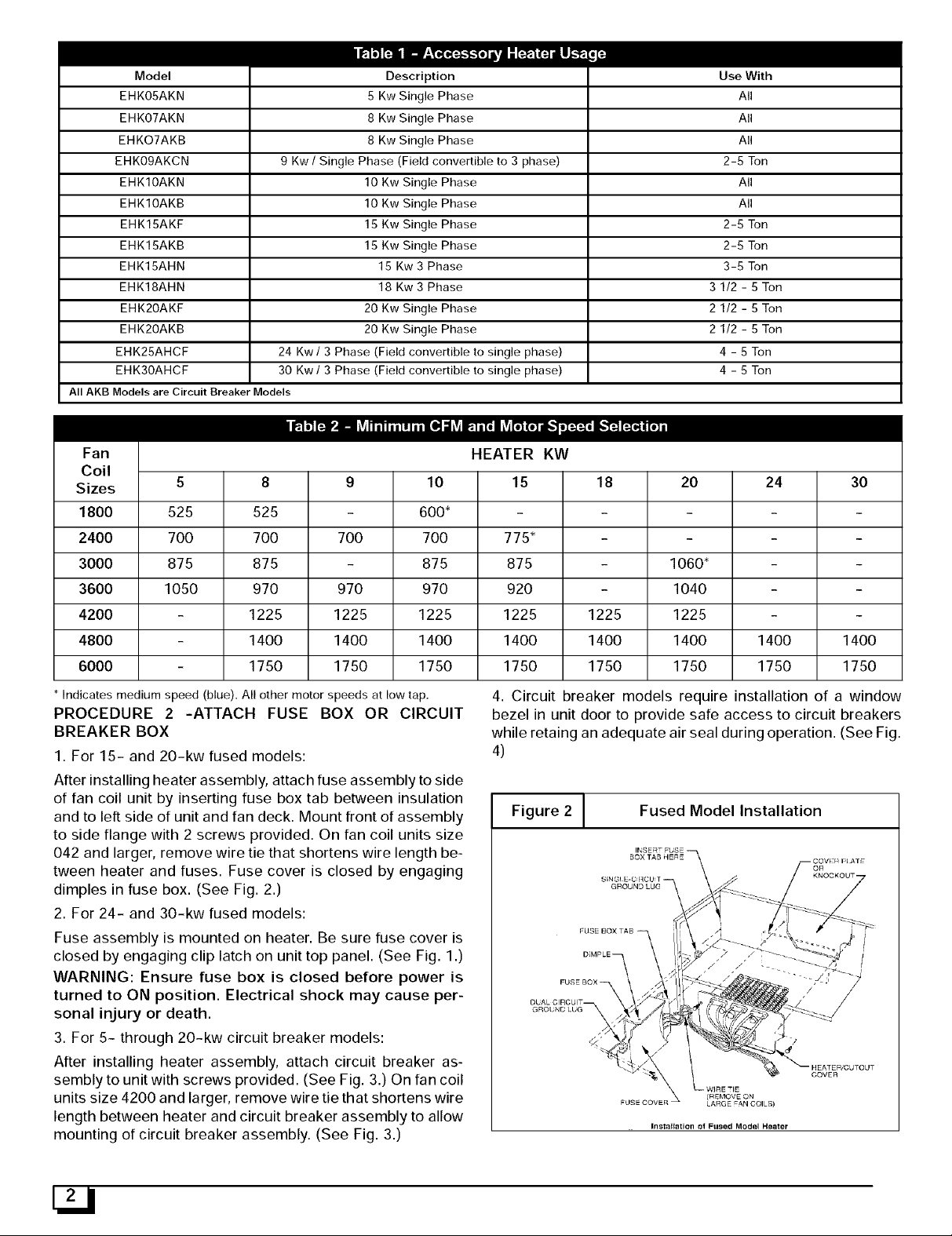

1. For 15- and 20-kw fused models:

After installing heater assembly, attach fuse assembly to side

of fan coil unit by inserting fuse box tab between insulation

and to left side of unit and fan deck. Mount front of assembly

to side flange with 2 screws provided. On fan coil units size

042 and larger, remove wire tie that shortens wire length be-

tween heater and fuses. Fuse cover is closed by engaging

dimples in fuse box. (See Fig. 2.)

2. For 24- and 30-kw fused models:

Fuse assembly is mounted on heater. Be sure fuse cover is

closed by engaging clip latch on unit top panel. (See Fig. 1.)

WARNING: Ensure fuse box is closed before power is

turned to ON position. Electrical shock may cause per-

sonal injury or death.

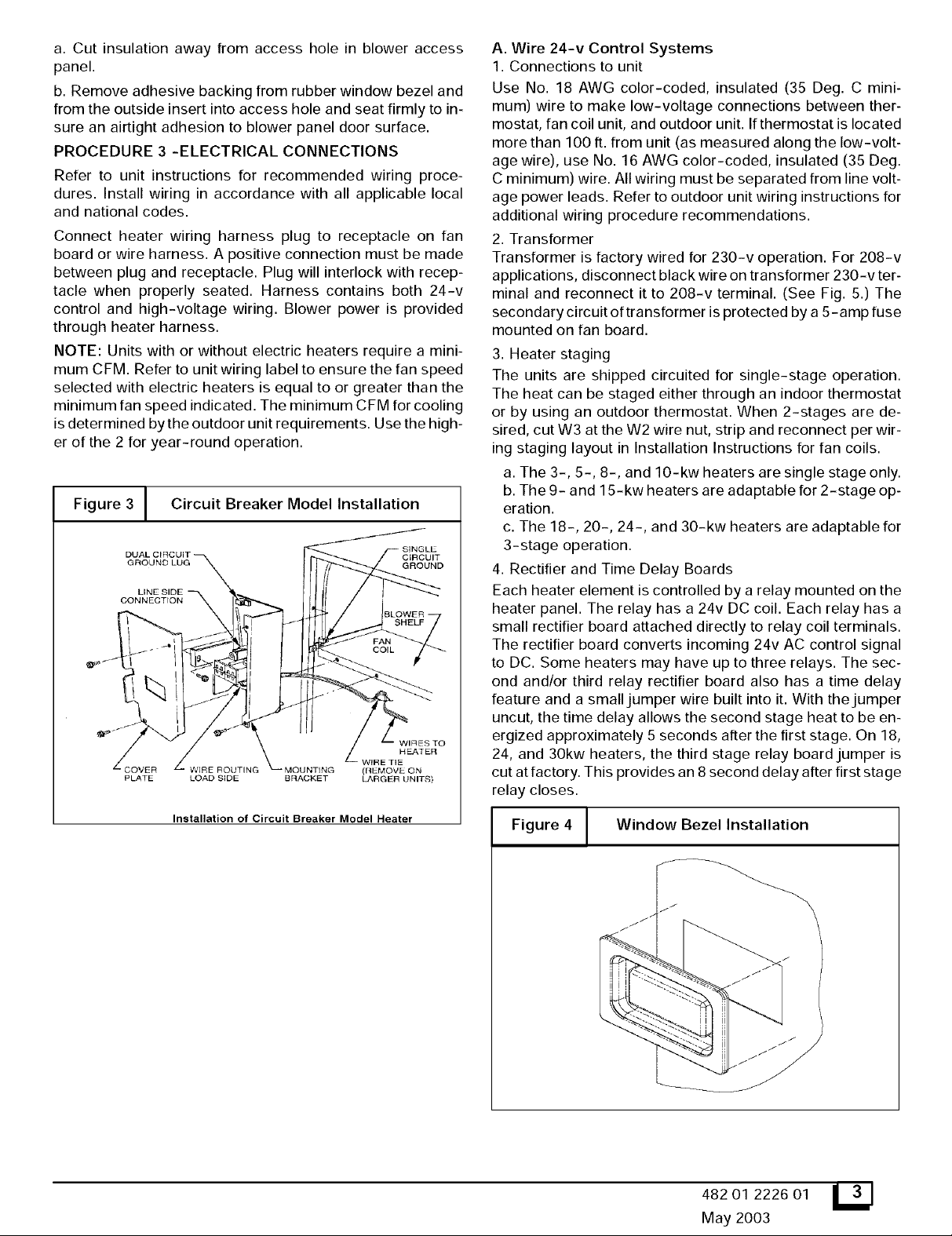

3. For 5- through 20-kw circuit breaker models:

After installing heater assembly, attach circuit breaker as-

sembly to unit with screws provided. (See Fig. 3.) On fan coil

units size 4200 and larger, remove wire tie that shortens wire

length between heater and circuit breaker assembly to allow

mounting of circuit breaker assembly. (See Fig. 3.)

4. Circuit breaker models require installation of a window

bezel in unit door to provide safe access to circuit breakers

while retaing an adequate air seal during operation. (See Fig.

4)

Figure 2 [ Fused Model Installation

DIMPLE 7

F

_ WIRE TIE

(REMOVE ON

LARGE FAN COILS)

Installation oi FIl_ed Model Heater

Page 3

a. Cut insulation away from access hole in blower access

panel.

b. Remove adhesive backing from rubber window bezel and

from the outside insert into access hole and seat firmly to in-

sure an airtight adhesion to blower panel door surface.

PROCEDURE 3 -ELECTRICAL CONNECTIONS

Refer to unit instructions for recommended wiring proce-

dures. Install wiring in accordance with all applicable local

and national codes.

Connect heater wiring harness plug to receptacle on fan

board or wire harness. A positive connection must be made

between plug and receptacle. Plug will interlock with recep-

tacle when properly seated. Harness contains both 24-v

control and high-voltage wiring. Blower power is provided

through heater harness.

NOTE: Units with or without electric heaters require a mini-

mum CFM. Refer to unit wiring label to ensure the fan speed

selected with electric heaters is equal to or greater than the

minimum fan speed indicated. The minimum CFM for cooling

is determined bythe outdoor unit requirements. Use the high-

er of the 2 for year-round operation.

Figure 3 J Circuit Breaker Model Installation

I I '_ J SHELF

Installation of Circuit Breaker Model Heater

I BLOWER

A. Wire 24-v Control Systems

1. Connections to unit

Use No. 18 AWG color-coded, insulated (35 Deg. C mini-

mum) wire to make low-voltage connections between ther-

mostat, fan coil unit, and outdoor unit. Ifthermostat is located

more than 100 ft. from unit (as measured along the low-volt-

age wire), use No. 16 AWG color-coded, insulated (35 Deg.

C minimum) wire. All wiring must be separated from line volt-

age power leads. Refer to outdoor unit wiring instructions for

additional wiring procedure recommendations.

2. Transformer

Transformer is factory wired for 230-v operation. For 208-v

applications, disconnect black wire on transformer 230-v ter-

minal and reconnect it to 208-v terminal. (See Fig. 5.) The

secondary circuit oftransformer is protected by a 5-amp fuse

mounted on fan board.

3. Heater staging

The units are shipped circuited for single-stage operation.

The heat can be staged either through an indoor thermostat

or by using an outdoor thermostat. When 2-stages are de-

sired, cut W3 at the W2 wire nut, strip and reconnect perwir-

ing staging layout in Installation Instructions for fan coils.

a. The 3-, 5-, 8-, and 10-kw heaters are single stage only.

b. The 9- and 15-kw heaters are adaptable for 2-stage op-

eration.

c. The 18-, 20-, 24-, and 30-kw heaters are adaptable for

3-stage operation.

4. Rectifier and Time Delay Boards

Each heater element is controlled by a relay mounted on the

heater panel. The relay has a 24v DC coil. Each relay has a

small rectifier board attached directly to relay coil terminals.

The rectifier board converts incoming 24v AC control signal

to DC. Some heaters may have up to three relays. The sec-

ond and/or third relay rectifier board also has a time delay

feature and a small jumper wire built into it. With the jumper

uncut, the time delay allows the second stage heat to be en-

ergized approximately 5 seconds after the first stage. On 18,

24, and 30kw heaters, the third stage relay board jumper is

cut at factory. This provides an 8 second delay after first stage

relay closes.

Figure 4 / Window Bezel Installation

i

482 01 2226 01 L_J

May 2003

Page 4

B.PowerConnections

NOTE:Heatersupplycircuitwire sizeandovercurrent

protectionmustcomplywithNationalElectricalCode(NEC)

andULbranchcircuitrequirements.(SeeTable3)Wiresand

overcurrentprotection,integraltotheheater,arenotrequired

tomeetbranchcircuitrequirements.Internalcircuitprotec-

tionof60amps(maximum)isacceptable.

1.Unprotectedheaters:(SeeFigs.6,10,and11.)

a.The5-through10-kwsingle-phaseand15-and18-kw

3-phaseheaterscanbewiredfor single-supplycircuit

only.Supplycircuitconnectstoheaterpigtailleads(termi-

nalblockon18-kwheaters).

b.The3- throughlO-kwsingle-phaseheaterscanusea

separatefield-installed,factory-authorizeddisconnectkit

whichinstallsinfancoil.

NOTE:Refertowiringlabelforcomponentlocations.

c.The9-kwheaterisfactorywiredforsinglesupplycircuit,

singlephase.Toconvertheatertosinglesupplycircuit,3

phase:

(1.)Disconnectbluewirefromlimitswitch(LS3).Cut,

strip,andconnecttofieldwireL3.

(2.)Disconnectyellow wire from LS1 and connect to LS3.

(3.) Disconnect blue wire from relay 2terminal 2 and con-

nect to LSI.

2. Circuit breaker heaters: (See Figs. 7 and 9.)

a. The 3- through lO-kw heaters can be wired for single-

supply circuit only.

b. The 15- and 20-kw heaters can be wired for dual-supply

circuits only.

3. Fused heaters: (See Figs. 8, 12, 13, and 14.)

a. The 15- and 20-kw heaters can be wired for single- or

dual-supply circuits. Single-supply circuit wiring requires a

factory-authorized, single-point adapter kit.

b. The 24- and 30-kw heaters can be wired for single- or

multiple-supply circuits. Heaters are factory wired for single

circuit 3 phase. To convert heaters to single circuit single

phase, disconnect yellow lead from L3 and connect to LI.

Disconnect black lead from L3 and connect to L2. To convert

heaters to multiple-supply circuit single phase, remove and

discard leads between single-circuit terminal block and fuse

block. Remove and discard single-circuit terminal block. At-

tach L1through L6 power leads as indicated on label next to

fuse block.

C. Ground Connections

WARNING: According to NEC, ANSI/NFPA 70, and local

codes, cabinet must have an uninterrupted or unbroken

ground to minimize personal injury if an electrical fault

should occur. The ground may consist of electrical wire

or metal conduit when installed in accordance with ex-

isting electrical codes. (See Ground/Conduit Note be-

low.) Failure to follow this warning could result in an

electric shock, fire, or death.

NOTE: Use UL-listed conduit and conduit connector for con-

necting supply wire(s) to unit to obtain proper grounding. If

conduit connection uses reducing washers, a separate

ground wire must be used. Grounding may also be accom-

plished by using grounding lugs provided in control box.

1. For unprotected or single-circuit heaters, 1 equipment

ground connection is provided on fan coil unit. (See Fig. 1

or 2.)

2. For 15- and 20-kw circuit breaker heaters, an additional

ground lug is provided on circuit breaker mounting bracket

for dual-circuit grounding. (See Fig. 3.)

3. For 15- and 20-kw fused heaters, an additional ground

lug is provided on fuse mounting bracket for dual-circuit

grounding. (See Fig. 2.)

4. For 24- and 30-kw fused heaters, 2 additional ground

lugs are provided for single-phase, multi-circuit wiring.

(See Fig. 1.)

D. Fan Speeds

1.Speed tap selection is done atfan relay. To change motor

speeds, disconnect fan lead on relay and replace with mo-

tor speed tap desired. Save insulating cap and place on

motor lead that was removed from relay. (See Fig. 15.) Re-

fer to table below for further clarification of speed tap selec-

tions.

Common Yellow

High Black

Medium Blue (Factory Selected)

Low

PROCEDURE 4 -CONVERSION OF CIRCUIT BREAKER

FOR DOWNFLOW APPLICATIONS

1. Tag and disconnect factory wiring from terminals on circuit

breaker(s).

2. Pullwhite plastic release tab on the bottom of circuit break-

er straight out to release circuit breaker from bracket. (See

Fig. 16.)

3. Remove quick connect adapters from factory side of

breaker(s). Reinstall adapters on other end of breakers(s).

Be sure adapter is located between lug screw and plate.

Torque lug screw to 30-in-.lb.

4. Rotate breaker 180 degrees from its original position and

reinstall inbracket. Slide breaker slot into sheet metal tab and

snap breaker into place. Make sure both tabs engage break-

er. Reconnect wiring on opposite end. Make sure wires are

positioned as before.

5. Remount circuit breaker bracket into unit so that the switch

will be in UP position when ON.

PROCEDURE 5 -ATTACH WIRING DIAGRAM AND RAT-

ING LABEL

Attach heater rating label included with kit over existing elec-

trical information label located on front access panel of fan

coil. (See Fig. 17.) Ifkit contains multiple rating labels, ensure

correct label is applied (check phase and supply circuits).

PROCEDURE 6 -VERIFY INSTALLATION

After completion of heater installation, check wiring to ensure

tightness and that proper connections and routings have

been made. Ensure all electrical covers are in place and

proper labels have been applied. Reinstall blower access

panel before turning unit power on.

(Blue on 2 speed models)

Red

Page 5

Heater Amps

Heater Model

EHK05AKN11

EHK05AKN12

EHK07AKN1

EHK07AKB2

EHK09AKCN1

EHK09AKCNI[

EHK10AKN1

EHK10AKB2

EHK15AKF1

EHK15AKB2

EHK15AHN1

EHK20AHN1

EHK20AKF1

EHK20AKB2

EHK25AHCF1]

EHK30AHCF1]

230v

Kw

208v

5

5

8

8

9

9

10

10

15

15

15

18

20

20

24

24

30

30

3.8

3.8

6.0

6.0

6.8

6.8

7.5

7.5

11.3

11.3

11.3

13.5

15.0

15.0

18.0

18.0

22.5

22.5

Phase

1

1

1

1

1

3

1

1

1

1

3

3

1

1

3

1

3

1

Internal

Circuit Protection

None

None

None

Ckt Bkr

None

None

None

Ckt Bkr

Fuse

Ckt Bkr

None

None

Fuse

Ckt Bkr

Fuse

Fuse

Fuse

Fuse

Single Circuit

18.1 / 20.0

18.1 / 20.0

28.9 / 32.0

28.9 / 32.0

32.8 / 36.0

18.8/20.8

36.2 / 40.0

36.2 / 40.0

54.2 / 59.9

31.3 / 34.6

37.6/41.5

72.3 / 79.9

50.1 / 55.4

86.7 / 95.5

62.6 / 69.2

109/120

808f230v

Dual Circuit

L1,L2

36.2/40.0

36.2/40.0

36.2/40,0

36.2/40.0

mnn_N_

Branch Circuit

Min. Ampacity

cuit

208 t 230v "+

Dual Circuit Single Dual Circuit Single Dual Circuit Single Dual Circuit Single Dual Circuit

L1,L2 L3,L4 Circuit L1,L2 L3,L4 Circuit L1,L2 L3,L4 Circuit L1,L2 L3,L4 Circuit L1,L2 L3,L4

Heater Model

Single Cir-

EHK05AKN11 26.0 / 28.4 10 ] 10 10 ] 10 30 / 30 66 / 66

EHK05AKN12 31.2 / 33.5 8/ 8 10 / 10 35 / 35 85 / 88

EHK05AKB21 26.0 / 28.4 10 / 10 10 / 10 30 / 30 66 / 66

EHK05AKB22 3112 / 33.5 8/ 8 10 / 10 35 / 35 85 / 88

EHK07AKN1 44.7 / 48.5 8/ 8 10 / 10 45 / 50 59 / 60

EHK07AKB2 44.7 / 48.5 8/ 8 10 / 10 45 / 50 59 / 60

EHK09AKCN1 49.5 / 53.5 8/ 6 10 / 10 50 / 60 54 / 87

EHK09AKCN1 [ 32.0 / 34.5 8/ 8 10 / 10 35 / 35 83 / 85

EHK10AKN1 53.8 / 58.5 6/ 6 10 / 10 60 / 60 78 / 80

EHK10AKB2 53.8 / 58.5 6/ 6 10 / 10 60 / 60 78 / 80

EHK15AKF1 76.3/83.4 53.8/58.5 22.7/25.0 4/4 6/6 10/10 8/8 10/10 10/10 80/90 60/60 25/25 88/89 78/80 75/76

EHK15AKB2 53.8/58.5 22.7/25.0 6/6 10/10 10/10 10/10 60/60 25/25 78/80 75/76

EHK15AHN1 47.7 / 51.8 8/ 6 10 / 10 50 / 60 56 / 90

EHK18AHN 1 55.5 / 60.4 6/ 6 10 / 8 60 / 70 76 / 77

EHK20AKF1 98.9/108.4 53.8/58.5 45.3/50.0 3/2 6/6 8/8 8/6 10/10 10/10 100/110 60/60 50/50 85/109 78/80 59/59

EHK20AKB2 53.8/58.5 45.3/50.0 6/6 8/8 10/10 10/10 60/60 50/50 78/80 59/59

EHK25AHCF1]

EHK30AHCF1] 144.8/158.5 0/ 00 6 / 6 150 / 175 117 / 150

71.2/77.8 4/4 8/8 80/80 94/95

116.9/127.9 1/1 6/6 125/150 115/116

86.8/95.0 3/3 8/8 90/100 97/98

Min. Wire Size (AWG) Min. Grnd. Wire Size Max Wire Length

208 t 230v I I 208 t 230v Max FusefCkt Bkr Amps 208 t 230v(ft.) [[

L3,L4

18.1/20.0

18.1/20.0

36.2/40.0

36.2/40.0

I

] Field convertible to 1 phase, single or multiple supply circuit,

[ Field convertible to 3 phase.

* Includes blower motor arnps o1 largest fan coil used with heater.

I I Copper wire must be used. If other than uncoated (non- plated), 75 Degrees C ambient, cop-

per wire (solid wire for 10 AWG and smaller, stranded wire for larger than 10 AWG) is used, consult

applicable tables of the National Electric Code (ANSI/NFPA 70).

[ [ Length shown is as measured 1 way along wire path between unit and service panel for a volt-

age drop not to exceed 2%.

NOTES:

1, For fan coil sizes 1800- 3600.

2. For fan coil sizes 4200- 6000.

482 01 2226 01 151

May 2003

Page 6

Figure5 J Connection of Transformer

SECOI',

RED

Figure

7 _ 5, 8 and 10 Kw Circuit Breaker

and Disconnect Heaters

I

Power I 1111 I

Wiring _ L2_ --

YEL

BLK

Figure 6 ] 5, 8, 9, and 10 Kw Non-fused Heaters

L1

Field Yellow

Power ,_

Wiring L2 Black

Field (_

Ground Ground

Wiring Lug

(9kw is field convertible to 3-phase.

See Procedure 3. B. 1. c.)

A00076

Field

Ground Ground

Wiring Lug

Figure 8 [ 15 and 20 Kw Fused Heaters

L4 .... ,__ Circuit 1 :L1-L2

L£ L3

Field Ground @ Ground lug

Wiring

Field Ground @ Ground lug

Wiring

(15 and 20kw fused heaters are factory wired for dual

supply circuits. Single supply circuit is possible

with approved single point wiring kit.)

Circuit 2 : L3-L4

A00078

Page 7

Figure 9 ] 15 and 20 Kw Circuit Breakers

Figure 11[ 18 Kw 3-Phase Heater

r

J _llll_ I Circuit 2 : L3-L4

mL2

o_

t_._

_ L3- -

L4

Fie]dGround --

Wiring

Field Ground ........ _ Ground lug

Wiring

Figure 10] 15 Kw 3-Phase Heater

L1

Field L2 z_

Power

Wiring

I Circuit 1 : L1-L2

(_) Ground lug

L3 _

Field

Ground

Wiring

Yellow

Black

Blue

_) Ground Ilug

A00080

bq

oq

oq

Figure 12[ 24 and 30 Kw Heaters

Field L1-- -- _::=::_ F

Power L2---

Wiring

L3----

Field Ground

Wiring

©

©

©

(_) Ground lug

A00081

_EF------_

-DD

oD B

_D U

-DD D

(_) Ground lug

A00082

482 01 2226 01

May 2003

Page 8

Figure13] 24and30KwHeaters

Figure 16[ Conversion of Circuit Breaker

Field

Llmm

-DE____D

Power L2---

Wiring

-DD D

Field Ground

Wiring

(Single Phase, Single Supply Circuit-Field Modified)

Figure 14] 24 and 30 Kw Heaters

L5

-- -IZ

Field

Power L1

Wiring L6 ---

L3

-- -IZ_

L4 m

L2 _

(_ Ground lug

Circuit 1 :L1-L2

Circuit 2:1_3-L4

Circuit 3:L5-L6

A00083

RELEASE TAB

@

OFF

[]

Q

Field Ground- (_ Ground lug

Wiring

Field Ground (_ Ground lug

Wiring

Field Ground (_ Ground lug

Wiring

(Single Phase, Multiple Supply Circuits-Field Modified)

Figure 15.[ Motor Speed Tap and Fan Relay

A00084

Figure 17[ Heater Rating Label Location

FROM KIT

Loading...

Loading...