Page 1

I Installation Instructions Fan Coils I

INSTALLATION

INSTRUCTIONS

Models

EBV

2-5 Ton

General Information / Installation ....... 2

Upflow Installations ................... 3

Downflow Installations ................ 3

Horizontal Installations ................ 3

Ductwork Connections ................ 4

Electrical Connections ................. 5

Diagrams ............................. 6

Transformer Information ............... 7

Refrigerant Tubing .................... 8

Refrigerant Flow Control ............... 8

Condensate Drains .................... 9

Condensate Drain Diagrams ........... 10

Start-Up Procedures .................. 11

Sequence of Operation ................ 13

Airflow Curve Charts .................. 14

Use ONLY factory listed electric heaters.

Variable Speed Fan Coils

Safety Labeling and Signal Words

Danger, Warning and Caution

The signal words DANGER, WARNING and CAU-

TION are used to identify levels of hazard seriousness.

The signal word DANGER is only used on product la-

bels to signify an immediate hazard. The signal words

WARNING and CAUTION will be used on product la-

bels and throughout this manual and other manuals that

may apply to the product.

DANGER - Immediate hazards which WILL result in

severe personal injury or death.

WARNING - Hazards or unsafe practices which

COULD result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which

COULD result in minor personal injury or product or

property damage.

Signal Words in Manuals

The signal word WARNING is used throughout this

manual in the following manner:

The signal word CAUTION is used throughout this

manual in the following manner:

Product Labeling

Signal words are used in combination with colors and/or

pictures on product labels.

CAUTION

496 01 4113 00

September 2002

Page 2

I Installation Instructions Fan Coils I

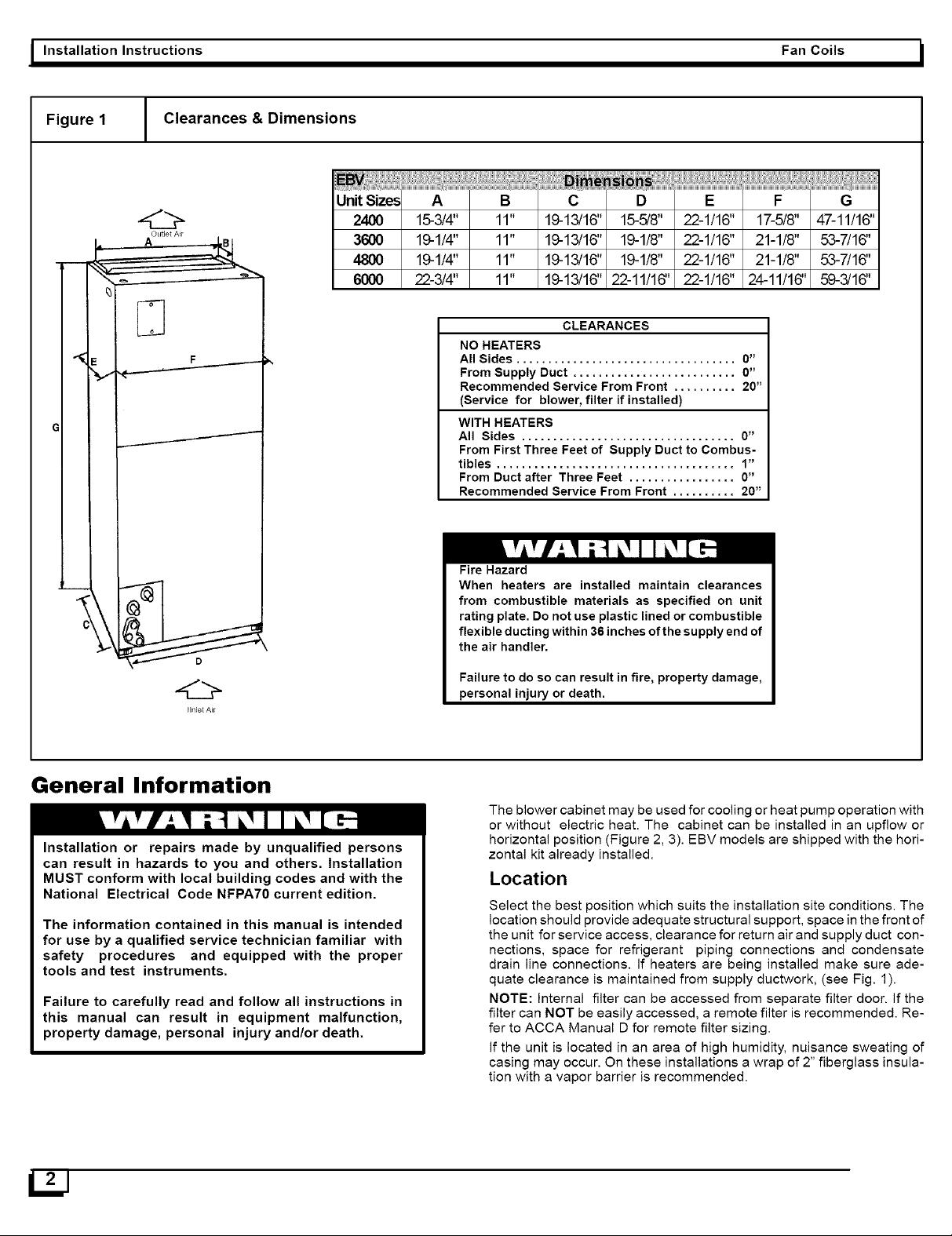

Figure 1

I Clearances & Dimensions

I

J

FI

J

Unit Size-,

2400

3600

4800

6000

A

15-3/4"

19-1/4"

19-1/4"

22-3/4"

B

11"

11"

11"

11"

NO HEATERS

All Sides ................................... 0"

From Supply Duct .......................... 0"

Recommended Service From Front .......... 20"

(Service for blower, filter if installed)

WITH HEATERS

All Sides .................................. 0"

From First Three Feet of Supply Duct to Combus-

tibles ...................................... 1"

From Duct after Three Feet ................. 0"

Recommended Service From Front .......... 20"

Fire Hazard

When heaters are installed maintain clearances

from combustible materials as specified on unit

rating plate. Do not use plastic lined or combustible

flexible ducting within 36 inches of the supply end of

the air handler.

C

1_1_1_'

1_1_1_'

1_1_1_'

1_1_1_'

CLEARANCES

D

15-5/8"

19-1/8"

19-1/8"

22-11/16"

E

22-1/16"

22-1/16"

22-1/16"

22-1/16"

F

17-5/8"

21-1/8"

21-1/8"

24-11/16"

G

47-11/16"

53-7/16"

53-7/16"

59-3/16"

J_nlet AEr

General Information

Installation or repairs made by unqualified persons

can result in hazards to you and others. Installation

MUST conform with local building codes and with the

National Electrical Code NFPA70 current edition.

The information contained in this manual is intended

for use by a qualified service technician familiar with

safety procedures and equipped with the proper

tools and test instruments.

Failure to carefully read and follow all instructions in

this manual can result in equipment malfunction,

property damage, personal injury and/or death.

Failure to do so can result in fire, property damage,

personal injury or death.

The blower cabinet may be used for cooling or heat pump operation with

or without electric heat. The cabinet can be installed in an upflow or

horizontal position (Figure 2, 3). EBV models are shipped with the hori-

zontal kit already installed.

Location

Select the best position which suits the installation site conditions. The

location should provide adequate structural support, space in the front of

the unit for service access, clearance for return air and supply duct con-

nections, space for refrigerant piping connections and condensate

drain line connections. If heaters are being installed make sure ade-

quate clearance is maintained from supply ductwork, (see Fig. 1).

NOTE: Internal filter can be accessed from separate filter door. If the

filter can NOT be easily accessed, a remote filter is recommended. Re-

fer to ACCA Manual D for remote filter sizing.

If the unit is located in an area of high humidity, nuisance sweating of

casing may occur. On these installations a wrap of 2" fiberglass insula-

tion with a vapor barrier is recommended.

UJ

Page 3

I Fan Coils

INTRODUCTION

The EBV model is designed for flexibility and can be used for upflow,

horizontal, or downflow (kit required) applications. These units are avail-

able for systems of 24,000 through 60,000 Btuh nominal cooling capac-

ity. Factory authorized electric heater packages are available in sizes 5

through 30kw. See Product Specification Literature for available acces-

sory kits.

HEATER PACKAGES

A factory approved, field installed UL listed heater package is available

from your equipment supplier. See unit rating plate for a list of factory

approved heaters. Heaters that are not factory approved could cause

damage which would not be covered under the equipment warranty.

Installation Instructions

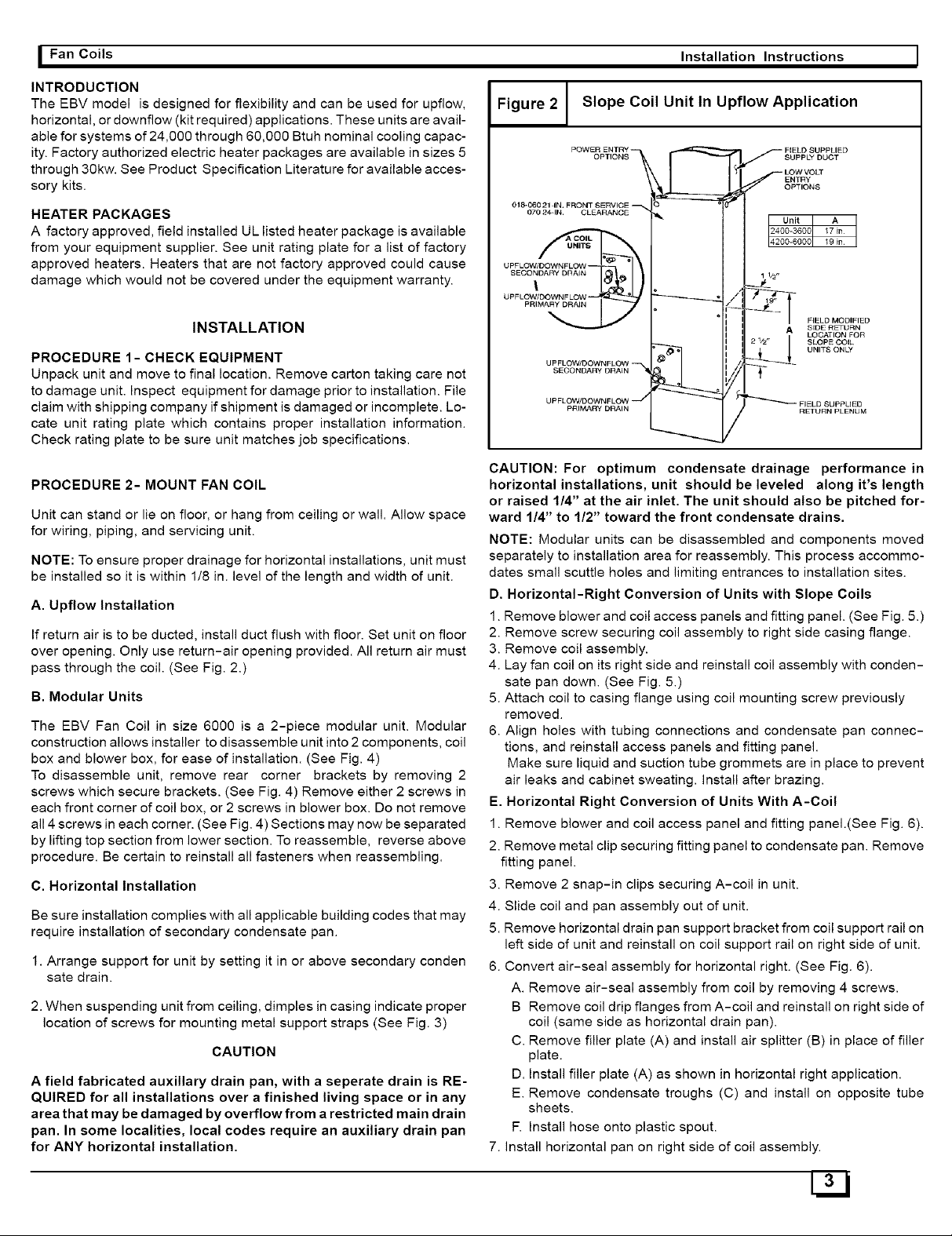

Figure 2 Slope Coil Unit In Upflow Application

SUPPLY DUCT

ENTRY

OPTIONS

018_06021 IN, FRONT SERVICE

070 24=1N CLEARANCE

UPFLOW/DOWNFLOW

Unit A

2400-3600 17 in

4200-6000 19 in

½-

INSTALLATION

PROCEDURE 1- CHECK EQUIPMENT

Unpack unit and move to final location. Remove carton taking care not

to damage unit. Inspect equipment for damage prior to installation. File

claim with shipping company if shipment is damaged or incomplete. Lo-

cate unit rating plate which contains proper installation information.

Check rating plate to be sure unit matches job specifications.

PROCEDURE 2- MOUNT FAN COIL

Unit can stand or lie on floor, or hang from ceiling or wall. Allow space

for wiring, piping, and servicing unit.

NOTE: To ensure proper drainage for horizontal installations, unit must

be installed so it is within 1/8 in. level of the length and width of unit.

A. Upflow Installation

If return air is to be ducted, install duct flush with floor. Set unit on floor

over opening. Only use return-air opening provided. All return air must

pass through the coil. (See Fig. 2.)

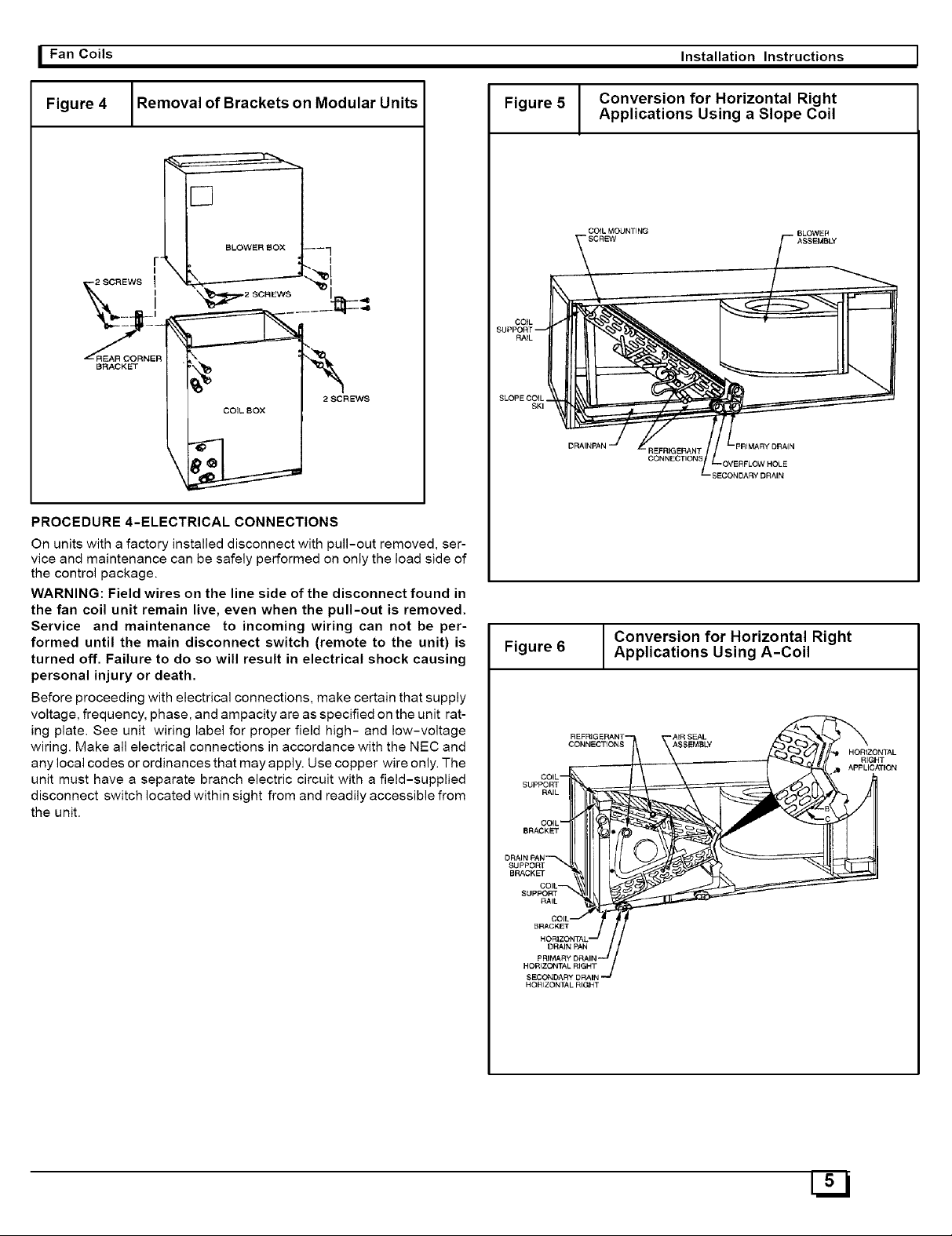

B. Modular Units

The EBV Fan Coil in size 6000 is a 2-piece modular unit. Modular

construction allows installer to disassemble unit into 2 components, coil

box and blower box, for ease of installation. (See Fig. 4)

To disassemble unit, remove rear corner brackets by removing 2

screws which secure brackets. (See Fig. 4) Remove either 2 screws in

each front corner of coil box, or 2 screws in blower box. Do not remove

all 4 screws in each corner. (See Fig. 4) Sections may now be separated

by lifting top section from lower section. To reassemble, reverse above

procedure. Be certain to reinstall all fasteners when reassembling.

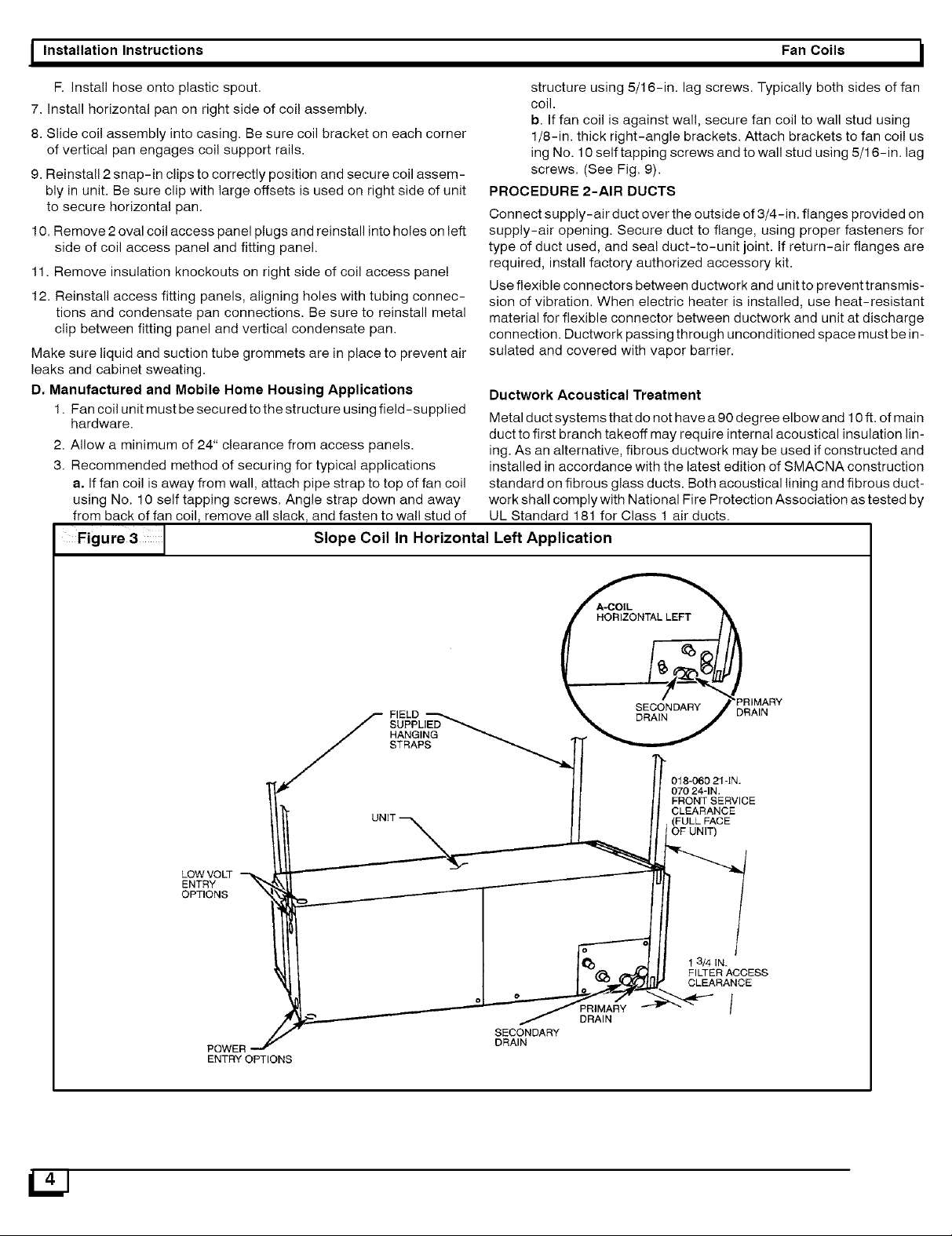

C. Horizontal Installation

Be sure installation complies with all applicable building codes that may

require installation of secondary condensate pan.

1. Arrange support for unit by setting it in or above secondary conden

sate drain.

2. When suspending unit from ceiling, dimples in casing indicate proper

location of screws for mounting metal support straps (See Fig. 3)

CAUTION

A field fabricated auxiliary drain pan, with a seperate drain is RE-

QUIRED for all installations over a finished living space or in any

area that may be damaged by overflow from a restricted main drain

pan. In some localities, local codes require an auxiliary drain pan

for ANY horizontal installation.

FIELD MODIFIED

A SIDE RETURN

LOCATION FOR

SLOPE COIL

UNITS ONLY

CAUTION: For optimum condensate drainage performance in

horizontal installations, unit should be leveled along it's length

or raised 1/4" at the air inlet. The unit should also be pitched for-

ward 1/4" to 1/2" toward the front condensate drains.

NOTE: Modular units can be disassembled and components moved

separately to installation area for reassembly. This process accommo-

dates small scuttle holes and limiting entrances to installation sites.

D. Horizontal-Right Conversion of Units with Slope Coils

1. Remove blower and coil access panels and fitting panel. (See Fig. 5.)

2. Remove screw securing coil assembly to right side casing flange.

3. Remove coil assembly.

4. Lay fan coil on its right side and reinstall coil assembly with conden-

sate pan down. (See Fig. 5.)

5. Attach coil to casing flange using coil mounting screw previously

removed.

6. Align holes with tubing connections and condensate pan connec-

tions, and reinstall access panels and fitting panel.

Make sure liquid and suction tube grommets are in place to prevent

air leaks and cabinet sweating, install after brazing.

E. Horizontal Right Conversion of Units With A-Coil

1. Remove blower and coil access panel and fitting panel.(See Fig. 6).

2. Remove metal clip securing fitting panel to condensate pan. Remove

fitting panel.

3. Remove 2 snap-in clips securing A-coil in unit.

4. Slide coil and pan assembly out of unit.

5. Remove horizontal drain pan support bracket from coil support rail on

left side of unit and reinstall on coil support rail on right side of unit.

6. Convert air-seal assembly for horizontal right. (See Fig. 6).

A. Remove air-seal assembly from coil by removing 4 screws.

B Remove coil drip flanges from A-coil and reinstall on right side of

coil (same side as horizontal drain pan).

C. Remove filler plate (A) and install air splitter (B) in place of filler

plate.

D. Install filler plate (A) as shown in horizontal right application.

E. Remove condensate troughs (C) and install on opposite tube

sheets.

F. Install hose onto plastic spout.

7. install horizontal pan on right side of coil assembly.

Page 4

I Installation Instructions Fan Coils I

F. Install hose onto plastic spout.

7. Install horizontal pan on right side of coi! assembly.

8. Slide coil assembly into casing. Be sure coil bracket on each corner

of vertical pan engages coil support rails.

9. Reinstall 2 snap-in clips to correctly position and secure coil assem-

bly in unit. Be sure clip with large offsets is used on right side of unit

to secure horizontal pan.

10. Remove 2 oval coil access panel plugs and reinstall into holes on left

side of coil access panel and fitting panel.

11. Remove insulation knockouts on right side of coil access panel

12. Reinstall access fitting panels, aligning holes with tubing connec-

tions and condensate pan connections. Be sure to reinstall metal

clip between fitting panel and vertical condensate pan.

Make sure liquid and suction tube grommets are in place to prevent air

leaks and cabinet sweating.

D. Manufactured and Mobile Home Housing Applications

1. Fan coil unit must be secured to the structure using field-supplied

hardware.

2. Allow a minimum of 24" clearance from access panels.

3. Recommended method of securing for typical applications

a. If fan coil is away from wall, attach pipe strap to top of fan coil

using No. 10 self tapping screws. Angle strap down and away

from back of fan coil, remove all slack, and fasten to wall stud of

Figure 3

Slope Coil In Horizontal Left Application

structure using 5/16-in. lag screws. Typically both sides of fan

coil.

b. If fan coil is against wall, secure fan coil to wall stud using

1/8-in. thick right-angle brackets. Attach brackets to fan coil us

ing No. 10 self tapping screws and to wall stud using 5/16-in. lag

screws. (See Fig. 9).

PROCEDURE 2-AIR DUCTS

Connect supply-air duct over the outside of 3/4-in. flanges provided on

supply-air opening. Secure duct to flange, using proper fasteners for

type of duct used, and seal duct-to-unit joint. If return-air flanges are

required, install factory authorized accessory kit.

Use flexible connectors between ductwork and unit to prevent transmis-

sion of vibration. When electric heater is installed, use heat-resistant

material for flexible connector between ductwork and unit at discharge

connection. Ductwork passing through unconditioned space must be in-

sulated and covered with vapor barrier.

Ductwork Acoustical Treatment

Metal duct systems that do not have a 90 degree elbow and 10 ft. of main

duct to first branch takeoff may require internal acoustical insulation lin-

ing. As an alternative, fibrous ductwork may be used if constructed and

installed in accordance with the latest edition of SMACNA construction

standard on fibrous glass ducts. Both acoustical lining and fibrous duct-

work shall comply with National Fire Protection Association as tested by

UL Standard 181 for Class 1 air ducts.

FIELD DRAIN

If" II .

/Ifr ...... II II CLEARANCE

11II _"- -_ I I II, (FULL FACE

LOW VOLT

ENTRY

OPTIONS

'k",,llt 1 -,"_ _.11 FILTERACOESS

POWER DRAIN

ENTRY OPTIONS

..... SEOO 2 RyDRA,. '

1_ 'PRIMARY

018-060 21 -IN.

Page 5

I Fan Coils

Installation Instructions

Figure 4 Removal of Brackets on Modular Units

_2SCREWSI_ _I

I .... ._4

_-_RE*RCORNER \ _-_

COiL BOX

PROCEDURE 4-ELECTRICAL CONNECTIONS

On units with a factory installed disconnect with pull-out removed, ser-

vice and maintenance can be safely performed on only the load side of

the control package.

WARNING: Field wires on the line side of the disconnect found in

the fan coil unit remain live, even when the pull-out is removed.

Service and maintenance to incoming wiring can not be per-

formed until the main disconnect switch (remote to the unit) is

turned off. Failure to do so will result in electrical shock causing

personal injury or death.

Before proceeding with electrical connections, make certain that supply

voltage, frequency, phase, and ampacity are as specified on the unit rat-

ing plate. See unit wiring label for proper field high- and low-voltage

wiring. Make all electrical connections in accordance with the NEC and

any local codes or ordinances that may apply. Use copper wire only. The

unit must have a separate branch electric circuit with a field-supplied

disconnect switch located within sight from and readily accessible from

the unit.

2 SCREWS

Figure 5

SLOPE COIL.

SKI

Conversion for Horizontal Right

Applications Using a Slope Coil

1

OOtL MOUNTING

- SCREW

PRIMARY DRAIN

-OVERFLOW HOLE

)RAIN

Conversion for Horizontal Right

Figure 6 Applications Using A-Coil

--AIR SEAL

SUPPORT

BRACKET

CONNECTIONS ASSEMBLY

RAIL

ASSEMBLY

HORIZONTAL

RIGHT

APPLICATION

SUPPORT

BRACKET

COIL--

SUPPORT

RAIL

HORIZONTAL RIGHT

SECONDARY DRAIN

HORIZONTAL RIGHT

Page 6

Fan Coils II Installation Instructions

Figure 7 A-Coil in Horizontal Left Application

COIL

HORIZONTAL LEFT

Figure 9 Mobile Home or Manufactured Housing

Applications

7 (EBAC)

4" MAX

SECURE FAN COILTO STRUCTUREUNIT AWAY FROM WALL

PIPE STRAP

(TYPICAL BOTH SIDES)

_. OR

UNIT AGAINST WALL

1/8-IN,THICK ANGLE

MOUNTING BRACKET

(TYPICAL BOTH SIDES)

DOWN FLOW

-- BASE KIT

SECURE UNITTO FLOOR

ANGLE BRACKET OR PIPE STRAP

4" MAX

Figure 8 Fan Coil Printed Circuit Board

-- MAX

I 5AMP L

SEC1 SEC2

SPST

NO NC

,==_C;1==,

240VAC COMMON

FAN TRAN

OOOOOOOOOOOO

HEATER/MOTOR

J2

vsD G

10-13-69

H

R

WE

W2

Y

o

c

A. Line Voltage Connections

if unit contains an electric heater, remove and discard power plug from

fan coil and connect male plug from heater to female plug from unit wir-

ing harness. (See Electric Heater Installation Instructions.)

For units without electric heat:

1. Connect 208/230v power leads from field disconnect to yellow and

black stripped leads.

2. Connect ground wire to unit ground lug.

NOTE: Units installed without electric heat should have a field-supplied

sheet metal block-off plate covering the heater opening. This will re-

duce air leakage and formation of exterior condensation.

WARNING: Before installing or servicing system, always turn off

all power to system. There may be more than I disconnect

switch. Turn off accessory heater power if applicable. Electrical

shock can cause personal injury or death.

CAUTION: If a disconnect switch is to be mounted on the unit, se-

lect a location where drill or fastener will not contact electrical or

refrigerant components. Electrical shock can cause personal

injury or death.

NOTE: Before proceeding with electrical connections, make certain that

supply voltage, frequency, and phase are as specified on unit rating

plate. Be sure that electrical service provided by the utility is sufficient

to handle the additional load imposed by this equipment. See unit wir-

ing label for proper field high- and low-voltage wiring. Make all electri-

cal connections in accordance with NEC and any local codes or

ordinances that may apply. Use copper wire only. The unit must have

a separate branch electric circuit with a field-supplied disconnect

switch located within sight from, and readily accessible from the unit.

Page 7

I Fan Coils

B. 24-v Control System

CONNECTION TO UNIT

Installation Instructions

Figure 11 Wiring Layout Air Conditioning Unit

Wire low voltage in accordance with wiring label on the blower. (See Fig.

8, 10, 11, 12, 13 and 14). Use no. 18 AWG color-coded, insulated (35

C minimum) wire to make the low-voltage connections between the

thermostat, the unit, and the outdoor equipment. If the thermostat is lo-

cated more than 100 ft. from the unit (as measured along the low-volt-

age wire), use No. 16 AWG color-coded, insulated (35 C minimum)

wire. All wiring must be NEC Class 1 and must be separated from in-

coming power leads. Refer to outdoor unit wiring instructions for any

additional wiring procedure recommendations.

TRANSFORMER INFORMATION

Transformer is factory-wired for 230v operation. For 208v applications,

disconnect the black wire from the 230v terminal on transformer and

connect it to the 208v terminal. (See Fig. 14).

HEATER STAGING

The controls are factory circuited for single-stage operation. When 2

or 3 stages are desired, remove J2 (Jumper-2) from the control board.

(See Fig. 13).

Figure 10 I Wiring Layout A/C Unit, No Heat

Thermostat Cooling Only

R

Thermostat

Air Conditioner - Adding Control for 80% Airflow

J2oo

©^_:) o o o o R

(Cooling and 1-Stage Heat)

W2 W 1 G Y O H C

Humidistat or Ourdoor Thermostat

Indoor Blower

*J2 Removed

G --

Y

W

_2

W2 W 1 G Y O H C

Indoor Blower

Outdoor Unit

R

Y

Y

Air Conditioner - Adding Control for 80% Airflow

0©0 0 O0

W2 W1 G Y O H C R

IndoorBlower

(Cooling and 2-Stage Heat)

Electric Heat Staging

Thermostat

Y

Y

* J2 Removed

Air Conditioner - Adding Control for 80% Airflow

O O O l) O O O O

W2 W 1 G Y O H C R

Indnnr Blnw_r

*J2 Removed

Humidistat or Outdoor Thermostat

Humidistat or Outdoor Thermostat

Page 8

I Installation Instructions Fan Coils I

For Electric Heating - Set switches 3, 4, and 5 on the motor control to

C. Ground Connections

WARNING: According to NEC, ANSI/NFPA 70, and local codes, the

cabinet must have an uninterrupted or unbroken ground to mini-

mize personal injury if an electrical fault should occur. The

ground may consist of electrical wire or metal conduit when

installed in accordance with existing electrical codes. If conduit

position 0 (off) or 1 (on) as specified on blower charts.

Set switches 1 and 2 to position 0 (off) or 1 (on) as specified in Figure 12

to control Fan delay ON - OFF.

NOTE: Power must be completely OFF to unit any time switch

settings are changed or settings will not take effect.

Adding Humidistator Outdoor Thermostat

connection uses reducing washers, a separate ground wire must

be used. Failure to follow this warning could result in electric

shock, fire, or death.

NOTE: Use UL-listed conduit and conduit connector for connecting

supply wire(s) to unit to obtain proper grounding. Grounding may also

be accomplished by using grounding lugs provided in control box.

D. Fan Control Board Jumper Instructions

The fan control board (see Fig. 8) has two jumpers. Jumper 1 (JP1)

jumpers two of three pins. The control unit should be factory set to the

VS (variable speed) position and should be left in this position in most

cases.

If there is a motor or control failure, and a variable speed replacement is

not readily available, it may be necessary to use a PSC motor until the

proper part can be ordered. This "limp mode" can be accessed by

moving JP 1 to the PSC pins. In this position a PSC motor can replace the

VS motor.

Jumper 2 (J2) is used to stage electric heaters. When in place, J2 ties

Wl and W2 together which should be used for single stage heat. When

J2 is removed, it allows Wl and W2 to be controlled separately and is for

applications using two stage electric heating.

MotorSpeedsand Airflow

See Figure 15

The motor speed can be set on one of eight speeds and the air flow will

adjust between 60%, 80% and 100% depending on settings. Time ON /

OFF settings can also be adjusted.

Determine coil static pressure drop, consult coil manual and measure

duct system static pressure, then determine required speed setting

from blower charts.

For Cooling/HP Heating - Set switches 6, 7, and 8 on the motor control

to position 0 (off) or 1 (on) as specified on blower charts.

Adding a humidistat or outdoor thermostat allows the airflow to be

reduced to 80% of normal allowing greater humidity control.

Humidistats are preferred but an outdoor thermostat can be used but

can only be set based on temperature. Suggested starting point is 85 F,

but this will vary depending on several factors.

The control must be wired differently on air conditioners and heat

pumps. On air conditioners connect to Y and Dehum terminals H, (see

Figure 10).

HEAT PUMPS ONLY: Heat pumps must use only the outdoor

thermostat, because it is powered instead of just performing a switching

function. This allows it to be out of the circuit when continuous

circulation is desired, which is required for the system to operate on Fan

Only for circulation, which is 60% airflow. On heat pumps connect to Y

and Dehum terminals H, and C and O to power the outdoor thermostat

(see Figure 12).

NOTE: The outdoor thermostat is not used for this application and if W

and H are energized at the same time, the unit will not run. The powered

outdoor thermostat only allows H to be energized when the system is

in the cooling mode.

PROCEDURE 5-REFRIGERANT TUBING AND FLOW CONTROL

Field-supplied tubing must be of refrigerant grade. Suction tube must

be insulated. Do not use damaged, dirty, or contaminated tubing be-

cause it may plug refrigerant flow-control device. ALWAYS evacuate

the coil and field-supplied tubing to 500 microns before opening out-

door unit service valves.

CAUTION: Braze with SiI-Fos or Phos-copper on copper to cop-

per joints and wrap a wet cloth around rear of fitting to prevent

damage to TXV.

CAUTION: If using an EBV model with a TXV in conjunction with

a single-phase reciprocating compressor, a compressor hard

start kit is required.

Page 9

I Fan Coils Installation Instructions J

Figure 12 Wiring Layout Heat Pump, No Heat

Heat Pump

Staging Heat Pump Only

Thermostat

R

G

C

O

Y

W

J2 i

Outdoor Unit

60 O,

W 2 W1 G Y 0 H

Heat Pump - Adding Control for 80% Airflow

Indoor Blower

J2

R

BL

W

Y

O

Outdoor Thermostat

W 2 W 1 G

©0o

Page 10

I InstallationInstructions FanCoils I

Figure 13 Typical Low Voltage Control Schematic For Heat Pumps

HeatPump Heat Pump with 1 -Stage Electric Heat Heat Pump with 2-Stage Electric Heat

Staging Thermostat

R

G

C

O

Y

W

-- R

/ BL

Outdoor Unit

W

Y

0

)1 O(

W 2 W 1 G Y O H

Indoor Blower

C R

Electric Heat

Heat Pump Staging Thermostat

R

G

O

Y

W 1

W2 W1 G Y O H C

Outdoor Unit

* J2 Removed

\

( (

Indoor Blower

Heat Pump - Adding Control for 80% Airflow

Heat Pump - Adding Control for 80% Airflow

R

BL

W

Y

O

Outdoor Thermostat

J2

^

0©000000

W 2 W 1 G Y O H C R

Indoor Blower

Outdoor Thermostat

() 0

W 2 W 1 G Y O H C

Indoor Blower

* J2 Removed

R

Page 11

I Fan Coils

Installation Instructions

Figure 14 Transformer Connections

___ _ _BRN

"__----_ LPRIMARY

Figure 151 Motor

Speeds

1

Motor Controller mounted to blower housing

PROCEDURE 6-CONDENSATE DRAINS

Units are equipped with primary and secondary 3/4-in. FPT drain con-

nections. For proper condensate line installations see Fig. 2, 3, 5, 6 and

7. To prevent property damage and achieve optimum drainage perfor-

mance, BOTH primary and secondary drain lines should be installed

and include properly-sized condensate traps. (See Fig. 17). Factory-

approved condensate traps are available (Kit No. EBAC01CTK1). Be

sure to install plastic push-in plugs in unused condensate drain fittings.

It is recommended that PVC fittings be used on the plastic condensate

pan. Finger-tighten plus 1-1/2 turns. Do not over-tighten. Use pipe

dope.

CAUTION: Shallow, running traps are inadequate and DO NOT al-

low proper condensate drainage. (See Fig. 18).

NOTE: When connecting condensate drain lines, avoid blocking filter

access panel, thus preventing filter removal. After connection, prime

both primary and secondary condensate traps.

NOTE: If unit is located in or above a living space where damage may

result from condensate overflow, a field-supplied, external condensate

pan should be installed underneath the entire unit, and a secondary

condensate line (with appropriate trap) should be run from the unit into

the pan. Any condensate in this external condensate pan should be

drained to a noticeable place. As an alternative to using an external con-

densate pan, some localities may allow the use of a separate 3/4-in.

condensate line (with appropriate trap) to a place where the condensate

will be noticeable. The owner of the structure must be informed that

when condensate flows from the secondary drain or external conden-

sate pan, the unit requires servicing or water damage will occur.

Heat Cool

Time CFM CFM

Delay Select Select Select

F---q l I II i

1 2 3 4 5 6 7

Time Delays:

00 0 sec. on/60 sec. off (default)

01 0 sec. on/90 sec. off

10 0 sec. on/30 sec. off

11 0 sec. on/0 sec. off

I

1 Positions (on)

8 0 Switch (off)

Page 12

I Installation Instructions Fan Coils I

Figure 16 Refrigerant Flow-Control Device

Figure 18 Insufficient Condensate Trap

DO NOT USE SHALLOW RUNNING TRAPS!

Figure 17 Recommended Condensate Trap

Figure 19 Condensate Drain

13

UNIT

o

/ ACCESS

SECONDARYDRAINREQUIRED

(USE FACTORYKIT OR

FIELD-SUPPLIEDTRAP)

PRIMARYTRAPREQUIRED_

(USE FACTORYKITOR

FIELD-SUPPMEDTRAP OF

SUFFICIENTDEPTH.

STANDARDPRIMARYTRAPS

ARE NOTSUFFICIENT.SEE

RGUREOFRECOMMENEDE)

CONDENSATETRAP)

Install traps in the condensate lines as close to the coil as possible. (See Fig. 19). Make sure that the outlet of each trap is below it connection to

the condensate pan to prevent condensate from overflowing the drain pan. Prime all traps, test for leaks, and insulate traps if located above a living

area. Condensate drain lines should be pitched downward at a minimum slope of 1 in. for every 10 ft of length. Consult local codes for additional

restrictions or precautions.

LTER

PANEL

Page 13

I Fan Coils Installation Instructions J

PROCEDURE 7-SEQUENCE OF OPERATION

A. Continuous Fan

Thermostat closes R to G. G energizes fan relay on electronic fan board

which completes circuit to indoor blower motor. When G is de-ener-

gized, there is a 90 sec delay before relay opens.

B. Cooling Mode

Thermostat energizes R to G, R to Y, and R to O (heat pump only). G

energizes fan relay on electronic fan board which completes circuit to

indoor blower motor. When G is de-energized, there is a 90 sec delay

before fan relay opens.

C. Heat Pump Heating Mode

Thermostat energizes R to G and R to Y. G energizes fan relay on elec-

tronic fan board which completes circuit to indoor blower motor. When

G is de-energized, there is a 90 sec delay before fan relay opens.

D. Heat Pump Heating with Auxiliary Electric Heat

Thermostat energizes R to G, R to Y, and R to W. G energizes fan relay

on electronic fan board which completes circuit to indoor blower motor.

W energizes electric heat relay(s) which completes circuit to heater ele-

ment(s). When W is de-energized, electric heat relay(s) open, turning

off heater elements. When G is de-energized there is a 90 sec delay be-

fore fan relay opens.

E. Electric Heat or Emergency Heat Mode

Thermostat closes R to W. W energizes electric heat relay(s) which

completes circuit to heater element(s). Blower motor is energized

through normally closed contacts on fan relay. When W is de-ener-

gized, electric heat relay(s) opens.

START-UP PROCEDURES

Refer to outdoor unit installation instructions for system start-up in-

structions and refrigerant charging method details.

CAUTION: Never operate unit without a filter. Damage to blower

motor or coil may result. Factory authorized filter kits must be

used when locating the filter inside the unit. For those applica-

tions where access to an internal filter is impractical, a field-sup-

plied filter must be installed in the return duct system.

CARE AND MAINTENANCE

To continue high performance and minimize possible equipment failure,

it is essential that periodic maintenance be performed on this equip-

ment. Consult your local dealer as to the proper frequency of mainte-

nance contract. The ability to properly perform maintenance on this

equipment requires certain mechanical skills and tools, if you do not

possess these, contact your dealer for maintenance. The only con-

sumer service recommended or required if filter replacement or clean-

ing on a monthly basis.

Page 14

I Installation Instructions Fan Coils I

Airflow Curves

EBV2400A

---_ ---_ .__- "-"_ -----_olo

00 0 I 02 03 04 05 06 07 08 09 10

External Static Pressure

EBV4800A

_ 001

_ _-_ _------_ otl

01 02 03 04 05 06 07 08 09 10

External Static Pressure

EBV3600A

1600

1200 _ "_ "-'_-_ "_-_ "_-_-_

1400 "_ "_ _ "_"-_ ooo ......................

1000 _ _.._ _ _

600 _,._ ,_,,,.,,___ __,,_

400

0/ 02 03 04 05 06 07 08 09 /0

External S_atic Pressure

EBV6000A

2200

2000

_ _ _ ,.____._... ooo

1800

1600

1400

1200

1000

80O

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

External Static Pressure

1Ol

Page 15

INTERNATIONAL COMFORT PRODUCTS

LIMITED WARRANTY CERTIFICATE

For Cooling & Heating Products

SAVE THIS CERTIFICATE. It gives you specific legal rights, and you may also have other rights which may vary from state to state and

province to province.

If your unit needs servicing, contact a qualified dealer or qualified service technician of your choice. When requesting service, please have the model

and serial number from each unit in your heating and/or cooling system readily available. Ifyour dealer needs assistance, the distributor is available to

provide support and we, in turn, support its efforts.

Fill in the installation date and model and serial numbers of the unit inthe space provided below and retain this Limited Warranty for your files.

GENERAL TERMS

Subject to the conditions and limitations stated herein, during the term of this Limited Warranty, we will provide a replacement for any functional

component part (as defined below) of your unit found to be defective in materials or workmanship. The term d this Limited Warranty isfive years from

installation on Residential Products and one year from installation on Commercial Products. Except as otherwise stated in the "Additional Terms"

section, this Limited Warranty covers only the original purchaser and subsequent transferees, and only while the unit remains at the site of the original

installation (except for mobile home installations), and only if the unit is installed inside the continental United States, Puerto Rico, Alaska, Hawaii or

Canada. Inaddition, the Limited Warranty applies only if the unit is installed and operated inaccordance with the printed instructions accompanying the

unit, and in compliance with atl applicable installation and building codes and good trade practices. As used in this Limited Warranty, "installation"

means the original installation of the unit.

THERE ARE EXCEPTIONS to this Limited Warranty as described on the reverse side of this page. All replacement parts will be warranted for the

unused portion d the warranty coverage period on the unit. The part to be replaced must be returned bythe dealer to a distributor that sells products for

International Comfort Products, in exchange for the replacement part. In lieu of providing a replacement part, we may, at our sole option, refund to you

an amount equal tothe distributor's component purchase price from us,or provide to you acredit equal to that amount to beapplied toward the purchase

of any new unit that we distribute. Ifa credit for a new unit is given in lieu of a replacement part, the rating plate from the unit being replaced must be

submitted on a warranty claim, and your dealer must make the unit being replaced available to our distributor for disposition. As acondition to warranty

coverage, the unit must receive yearly maintenance, as described in the owner's manual, by a dealer. Satisfactory proof of yearly service by a dealer

may be required.

"Functional component parts" include only the following: blower motor, unit-mounted sensors & timers, condenser motor, evaporator coil, condenser

coil, condenser fan, capacitor, transformer, single-phase strip heat elements, expansion device, reversing valve, solenoid valve, service valve,

electronic and electro-mechanicaI control board, ignitor, ignition module, draft inducer assembly, burner pilot, gas valve, limit control, pressure switch,

relays and contactors, btower wheeI, interlock switch, crosslighter, pilot shield, gas &oil burners, oil pump assembly, accumulators and factory installed

driers and strainers.

This Limited Warranty DOES NOT COVER any labor, material, refractory chambers, oiI nozzles, refrigerant, refrigerant inspection and refrigerant

reclaiming, freight and/or handling charges associated with any repair or replacement and such charges wili be your responsibility.

Toestablish the installation date for any purpose under this Limited Warranty, you must retain the original records that can establish the installation date

ofyour unit. Ifyou do not provide such documents the startdate oftheterm ofthis Limited Warranty wilI be based upon the date of unit manufacture, plus

thirty (30)days. In establishing that the required yearly service has occurred, you must furnish proof dyearly service by a qualified service technician.

This Limited Warranty does not cover: (a) failure or damages caused by accident, abuse, negligence, misuse, riot, fire, flood, or Acts of God (b)

damages caused by operating the unit where there is a corrosive atmosphere containing chlorine, fluorine, or any other damaging chemicals (other

than those found in a normal residential environment) (c) damages caused by an unauthorized alteration or repair d the unit affecting its stability or

performance (d) damages caused by improper matching or application of the unit or the unit's components (e) damages caused by failing to provide

proper maintenance and service to the unit in accordance with this Limited Warranty Certificate and the printed instructions originally provided with the

unit (f) any expenses incurred for erecting, disconnecting, or dismantling the unit (g) parts or supplies used in connection with service or maintenance,

such as refrigerant, refractory chambers, oil nozzles, filters, or belts (h) damage, repairs, inoperation or inefficiency resulting from faulty installation or

application (i) electricity or fuel costs or any increase inelectricity or fuel cost whatsoever including additional or unusual use of supplemental electric

heat (j) units which have not had the required yearly maintenance described elsewhere in this limited warranty.

In no event shall we be liable for any incidental, consequential, or special damages or expenses in connection with any use or failure of this unit.

We have not made. do not make. and hereby disclaim any implied condition or implied warrantv offitness for aparticular use or PurPose. and

anv implied condition or implied warrantv of merchantabilitv, to the fullest extent allowed bv law. We make no express or implied warranties

exceDt as stated in this Limited Warrantv certificate,

No one is authorized to change this Limited Warranty or to create for us any other obligation or liability in connection with this unit. Any implied

warranties shall last for the term of the expressed warranty contained herein. Some states and provinces do not allow the exclusion or limitation of

incidental orconsequential damages ordo not allow limitations on how long an implied warranty or condition lasts, so the above limitations or exclusions

may not apply toyou. The provisions d this Limited Warranty are inaddition to and not amodification of or subtraction from any statutory warranties and

other rights and remedies provided by law.

Please refer to reverse side of this page for additional terms.

Model No.

Serial No. Date Installed

Effective on units installed After July 1, 2002.

USA: International Comfort Products Corporation (USA) • 650 He!I-Quaker Avenue • P.O. Box 128 ° Lewisburg, Tennessee 37091 • (931-270-4100)

CANADA: international Comfort Products division of UTC Canada Corporation • 6060 Burnside Court, Unit 1, Mississauga, Ontario L5T 2T5

(905-795-8113).

Manufacturers of Airquest, Arcoaire, Clare, Comfortmaker, Dettson, He!l, Keeprite, Lincoln, Tempstar and other quality brand name private label

products.

Part No. 401 06 1010 18 (Orig. 8/9/2002)

Page 16

ADDITIONAL TERMS FOR RESIDENTIAL APPLICATIONS ONLY

The Additional Terms for the components listed below are in addition to, and subject to, the General Terms on the reverse side of this page.

VVarranty coverage is limited to parts that fail due to defect in materials or workmanship during the specified term.

CENTRAL GAS & OIL FURNACE HEAT EXCHANGERS*

Gas Model Series: C9MPV. H9MPV. T9MPV. CgMPT. H9MPT. T9MPT. C9MPD. H9MPD. T9MPD: Limited Lifetime Warranty on heat exchangers. If

a heat exchanger on one ofthese furnaces fails due to defect inthe part, we wilt provide a replacement part or, at our option, credit toward the purchase

of a new furnace manufactured by us. This additional Limited Warranty runs only to the original purchaser, and lasts only for as long as the original

purchaserlivesinthehomewherethefurnaceis initially installed.** Itisnottransferabletoanysubsequentowner. Ifthefurnacewas notinstalledinthe

home owned by the original purchaser, if the original purchaser sells the home to a subsequent owner, or if proof of original purchase cannot be

provided, then the limited warranty is only for 20 years from the date of original installation.

Gas Model Series: GDL. GNL. TNE. TDE. NTC7. NDC7. NTP6. NDP6. TDE. NTV6. VNE: A replacement heat exchanger will be provided for any

heat exchanger that fails in one of these furnaces due to defect for 25 years from the original date of installation.

Gas Model Series: NTC6. GNE. GDE. NDN6. NTG3. NDN3. FBF. NBF. NDF. NTN3. NTN6. NNE. N9MP1. N9MP2. FUH: A replacement heat

exchanger will be provided for any heat exchanger that fails in one of these furnaces due to defect for 20 years from original date of installation.

Oil Model Series: OLR(105, 160, 182), OCF, OLF, our, NOLF, NOUF, OLB, OHB, ODH, FLO, MBO, LBO, NOMF: Limited Lifetime Warranty on

heat exchangers. Ifa heat exchanger on one of these furnaces fails due to defect inthe part, we will provide a replacement part or, at our option, credit

toward the purchase of a new furnace manufactured by us. This additional Limited Warranty runs only to the original purchaser, and lasts only for as

long as the original purchaser lives in the home where the furnace is initially installed.** It is not transferable to any subsequent owner. If the furnace

was not installed in the home of the original purchaser, ifthe original purchaser sells the home to a subsequent owner, or if proof of original purchase

cannot be provided, then the limited warranty is only for 20 years from the date of original installation.

Oil Fired Floor Furnace: NFO: A replacement heat exchanger will be provided for any heat exchanger that fails due to defect for 10 years from

installation with the following limitation: during the sixth through tenth year, any credit toward your purchase of a component or toward the purchase of

any new unit will be in an amount equal to the distributor's purchase price reduced by 20 percent for each year after the fifth year.

ADDITIONAL TERMS FOR OIL FURNACE APPLICATIONS ONLY

1) OIL BURNERS - A replacement for 5 years from date of original installation for Oil Burner Parts.

2) OPTIONAL ACCESSORIES AND FUNCTIONAL PARTS: A replacement for 5 years from date of original installation. (Refractory and

oil nozzles not included)

GAS/ELECTRIC PACKAGED UNITS HEAT EXCHANGERS

Model series: PGAD. PGAA. PGMD. PGME. PGF. GPFM. PGC. GPCM: A replacement for 10 years from original date of installation.

COMPRESSORS:*

1) Premium Model Units: HAC0. HAC2. HAC4. CAC0. CAC2. CAC4. KAC0. TCA0. TCA2. TCA4. HHP0. HHP2. HHP4. CliP0. CliP2. CliP4.

TCH0. TCH2. TCH4. PGME. PYMC. PHAD. PGAD. PA95. PAPC. PAK. APK: Tothe original purchaser areplacement for 10years from original date

of installation, only if the unit is installed with factory matched coils, except air conditioner condensing units with a nominal SEER of !0 may be matched

with evaporator coils of the same nominal tonnage regardless of manufacturer and in accordance to factory recommendations. This limited 10-year

warranty is not transferable to any subsequent owner. HOWEVER, ifthe unit was not installed in the home owned by the original purchaser, if the

purchaser sells the home to asubsequent owner, or if proof of original purchase cannot be provided, then the limited warranty is only for 5years from the

original date of installation.**

2) All Other Models: Air Conditioners. Heat PumPs. & Combination Gas/Electric Units: NAC0. NAC2. NHP0. NHP2. An. A2. HO. H2. PGF.

PGC, GPFM, GPCM, PAl=, APFM, PHI:, HPFM, PGAA, PGMD, PA55, PH55, PAPA, PYPA: A replacement for 5 years from date of original

installation, only if: (a) air conditioner condensing units with SEER rating in the range of 10 to 11SEER are matched with evaporator coils of the same

nominal tonnage regardless of manufacturer and in accordance to factory recommendations, or (b) heat pump condensing units are used with factory

matched coils, unless written approval to do otherwise is obtained from manufacturer.

ADDITIONAL TERMS FOR COMMERCIAL APPLICATIONS ONLY

For purposes of this warranty a commercial application is one inwh ich: the product has over 5tons nominal cooling capacity, or is designed

for operation with 3 phase electrical power, or is installed in a commercial establishment such as a beauty or hair salon, hospital, school,

restaurant, church, hotel etc..

3-Phase Models: PGF, GPFM, GPF, PGAD, PGME, PGB, PGMG, PGMF, PGS, PGE, APE, PAE, PAB, PAMD, PAS, PAr, APFM, APF, PHB, PHE,

PYMD, HPB, PHS, CAC, ACC, CAE, ACE, CHC, HCC, CHE, HCE:

The additional Terms of the components listed below are ill addition to and subject to the General Terms on the reverse side of this page.

1) GAS FIRED HEAT EXCHANGERS (ALL MODELS):* A replacement for 10 years from date of original installation.

2) COMPRESSORS (ALL MODELS):* A replacement for 5 years from date of original installation.

3) OPTIONAL ACCESSORIES AND FUNCTIONAL COMPONENT PARTS (ALL MODELS):*

A replacement for 1 year from date of original installation.

4) COMMERCIAL OIL MODELS: OLR210, OLR350, OTF210, AMT3, AMT4, AMP3: Ten(!0) Year Limited Warranty on heat exchangers.

*To receive advantage of your limited warranty, you must provide proof of yearly service by a qualified service technician.

**To receive advantage of your warranty, you must retain the original records that can establish the installation date and proof of purchase of the unit.

MINI SPLITS:

Summary - Mini Splits Warranted for one (1) year on all replacement parts.

Additional terms for Mini Splits:

The additional Terms of the components listed below are in addition to, and subject to, the General Terms on the reverse side of this page.

1) Compressors (All Models): A replacement compressor will be provided for all compressors that fail due to defect for 5years from date of original

installation.

2) Optional Accessories and Functional Components Parts (All Models):

A replacement part will be provided for all parts that fail due to defect for one (1) year from date of original installation.

Failure to maintain the equipment through annual maintenance by a qualified service technician shall void the warranty. Proof of servicewilI be required

with atl warranty claims. Proof of purchase and installation date must be submitted with all claims.

Loading...

Loading...