ICP DLF4HH12J1A, DLF4AV09J1A, DLF4HV09J1A, DLF4AH12J1A, DLC4AV12J1A Service Manual

...

R−410A Ductless Split System

Air Conditioner and Heat Pump

INTRODUCTION

SERVICE MANUAL

MODELS: DLC4(A/H)−Outdoor, DLF4(A/H)−Indoor

SIZES: 9K, 12K, 18K, 24K, 30K, and 36K

This Service Manual provides the necessary information to

service, repair, and maintain the DLF4(A,H), DLC4(A/H)

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS 1........................

SPECIFICATIONS 2..................................

MODEL / SERIAL NUMBER NOMENCLATURE 16.......

STANDARD FEATURES AND ACCESSORIES 17........

DIMENSIONS 18.....................................

CLEARANCES 22....................................

SYSTEM OPERATING ENVELOPE 23..................

ELECTRICAL DATA 25...............................

CONNECTION DIAGRAMS 26.........................

WIRING DIAGRAMS 27...............................

REFRIGERATION SYSTEM DIAGRAM 36...............

REFRIGERANT LINES 38.............................

SYSTEM EVACUATION AND CHARGING 39............

CONTROL SYSTEM 40...............................

MODES OF OPERATION 44...........................

TROUBLESHOOTING 47.............................

DIAGNOSTIC CHARTS 48............................

MALFUNCTION ANALYSIS 55.........................

APPENDIX 79.......................................

SAFETY CONSIDERATIONS

Follow all safety codes. Wear safety glasses and work

gloves. Keep quenching cloth and fire extinguisher nearby

when brazing. Use care in handling, rigging, and setting

bulky equipment.

Read these instructions thoroughly and follow all warnings

or cautions included in literature and attached to the unit.

Consult local building codes and National Electrical Code

(NEC) for special requirements. In Canada, refer to current

editions of the Canadian Electrical Code, CSA 22.1.

Recognize safety information. This is the safety−alert

!

!

symbol

instructions or manuals, be alert to the potential for personal

injury.Understand these signal words: DANGER,

WARNING, and CAUTION. These words are used with the

safety−alert symbol. DANGER identifies the most serious

hazards which will result in severe personal injury or death.

WARNING signifies hazards which could result in personal

injury or death. CAUTION is used to identify unsafe

practices which may result in minor personal injury or

product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation,

reliability, or operation.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF

position. There may be more than 1 disconnect switch.

Lock out and tag switch with a suitable warning label.

. When you see this symbol on the unit and in

!

WARNING

Installing, starting up, and servicing air−conditioning

equipment can be hazardous due to system pressures,

electrical components, and equipment location (roofs,

elevated structures, etc.).

Only trained, qualified installers and service mechanics

should install, start−up, and service this equipment.

Untrained personnel can perform basic maintenance

functions such as cleaning coils. All other operations should

be performed by trained service personnel.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Do not bury more than 36 in. (914 mm) of refrigerant

pipe in the ground. If any section of pipe is buried, there

must be a 6 in. (152 mm) vertical rise to the valve

connections on the outdoor units. If more than the

recommended length is buried, refrigerant may migrate

to the cooler buried section during extended periods of

system shutdown. This causes refrigerant slugging and

could possibly damage the compressor at start−up.

CAUTION

421 01 9204 00 1/03/13

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

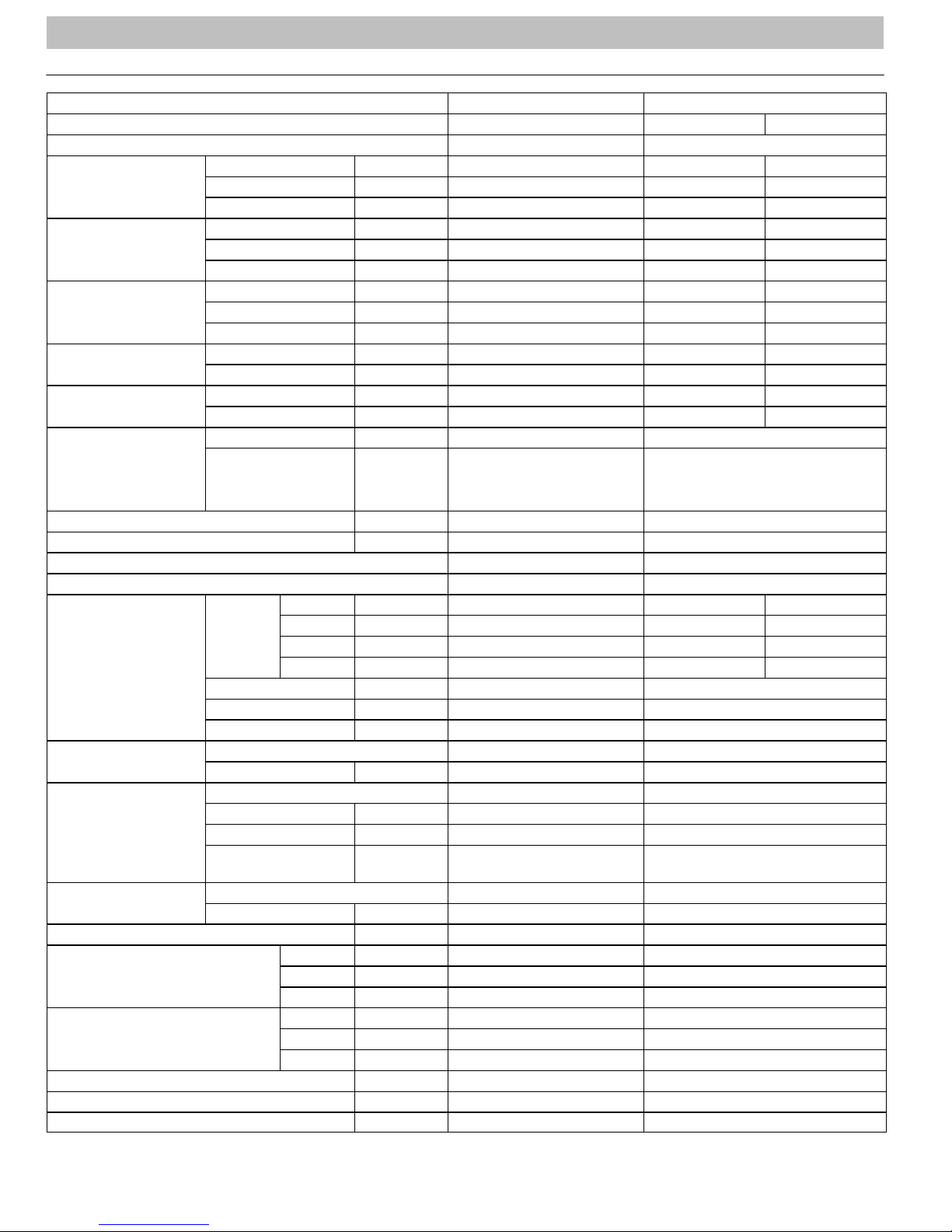

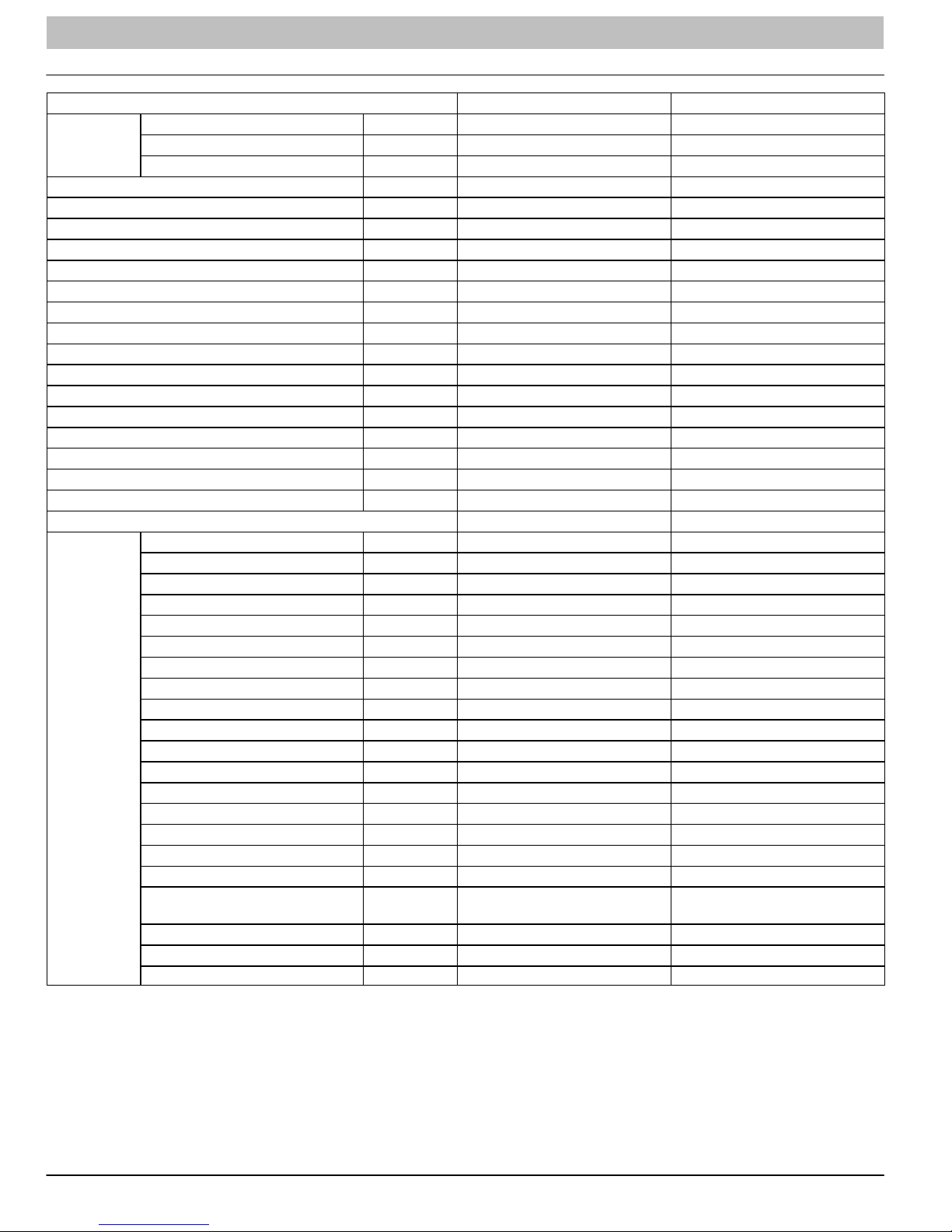

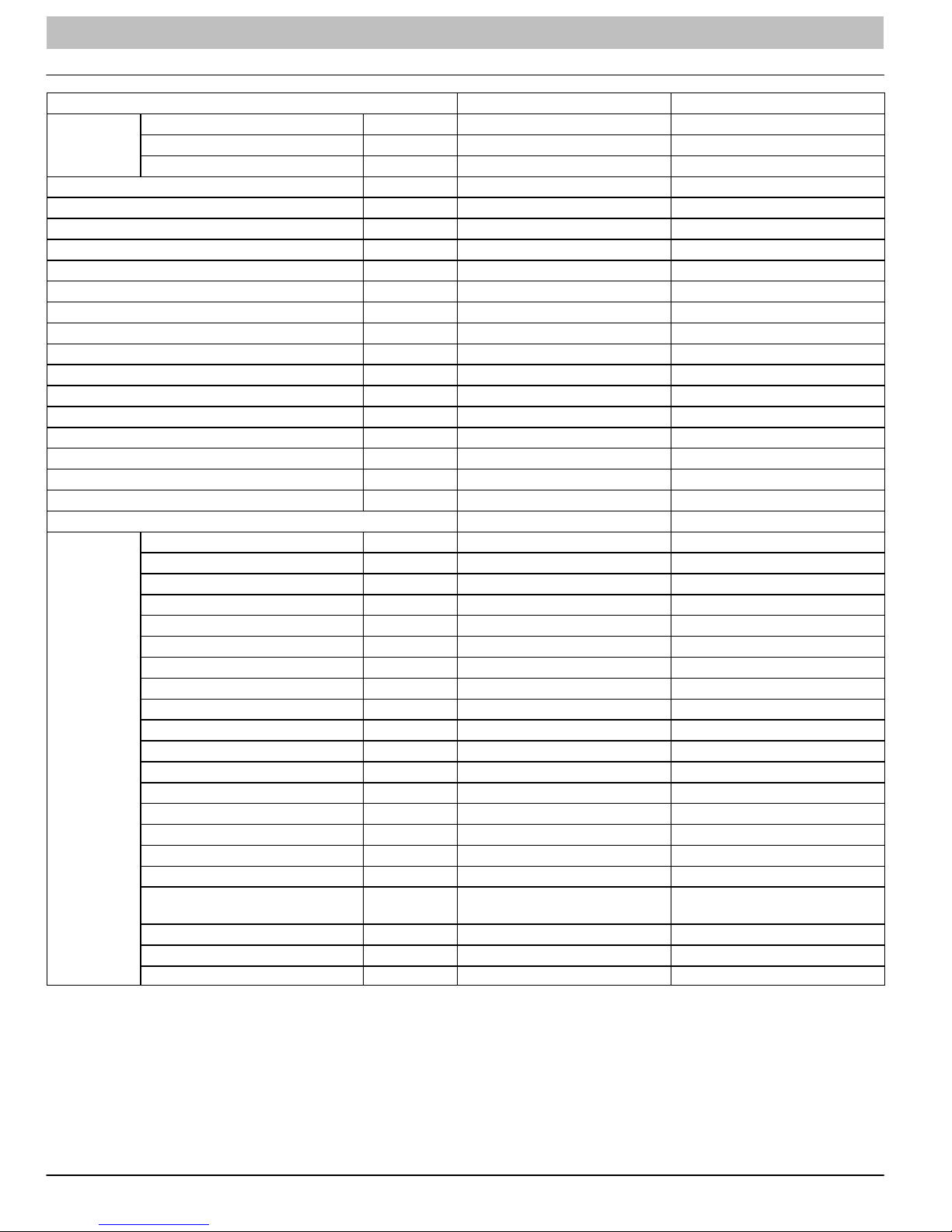

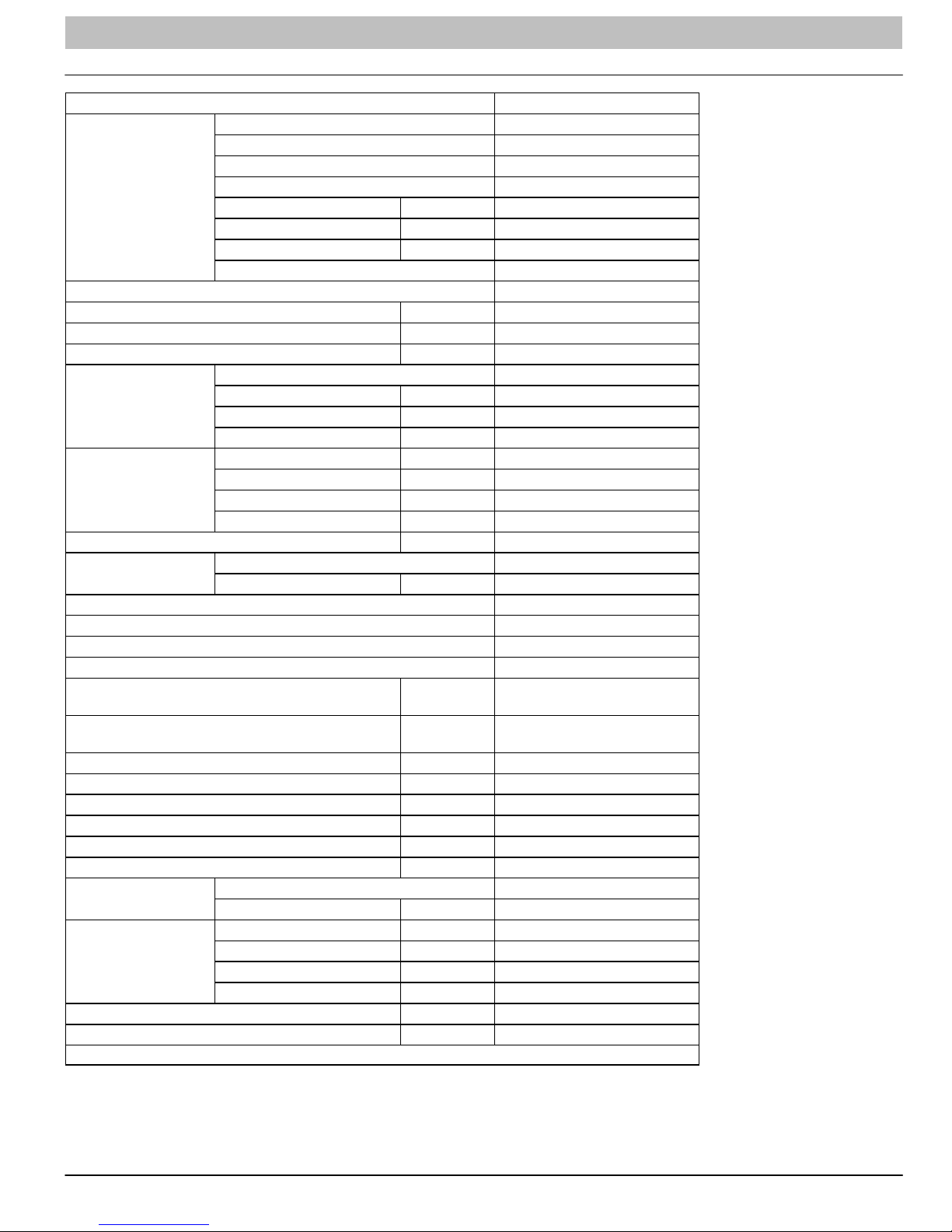

PRODUCT SPECIFICATIONS

Model − Indoor Unit DLF4AH09J1A DLF4HH09J1A

Function Cooling Cooling Heating

Rated Voltage 115V 115V

Frequency

(Inverter different

Compressor speed)

Total Capacity

(Inverter different

Compressor speed)

Power Input

(Inverter different

Compressor speed)

Rated Input

Rated Current

Air Volume

High Hz 70 70 63

Standard Hz 41 41 44

Low Hz 15 15 15

High W/Btuh 3100 / 10600 3100 / 10600 3250 / 11100

Standard W/Btuh 2650 / 9000 2650 / 9000 2820 / 9500

Low W/Btuh 1300 / 4435 1300 / 4435 930 / 3200

High W 1050 1050 1100

Standard W 634 634 700

Low W 180 180 220

High W 1050 1050 1100

Standard W 634 634 700

High A 16.8 16.8 17.0

Standard A 7.0 7.0 7.5

CFM 370 370

Dehumidifying Volume I/h 0.8 0.8

EER / C.O.P 14.2 14.2

SEER / HSPF 22 22 / 9.8

Indoor Unit DLF4AH09J1A DLF4HH09J1A

SH r/min 1260 1260 1320

Speed

Fan Motor

Output W 20 20

Capacitor mF 4.0 4.0

RLA A 0.38 0.38

Fan

Evaporator

Swing Motor

Fuse A 3.15 3.15

Sound Pressure Level

Sound Pressure Level

Dimension (WxHxD) Inch 33 x 11 x 7 33 x 11 x 7

Dimension of Package (WxHxD) Inch 36 x 14 x 10 36 x 14 x 10

Net Weight / Gross Weight Inch 29 / 38 29 / 38

Type Cross Flow Fan Cross Flow Fan

Diameter−Length Inch f3.6x25.4 f3.6x25.4

Pipe Diameter Inch f0.3 f0.3

Row−Fin Gap Inch 2−0.06 2−0.06

Coil length (I) x height

(H) x coil width (L)

Model MP24AA MP24AA

Output W 2.4 2.4

H r/min 1050 1050 1200

M r/min 920 920 1100

L r/min 730 730 950

Aluminum Fin Copper Tube Aluminum Fin Copper Tube

Inch 25.4 x 10.5 x 1 25.4 x 10.5 x 1

H dB (A) 34 34

M dB (A) 30 30

L dB (A) 26 26

H dB (A) 44 44

M dB (A) 40 40

L dB (A) 36 36

2 421 01 9204 00

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

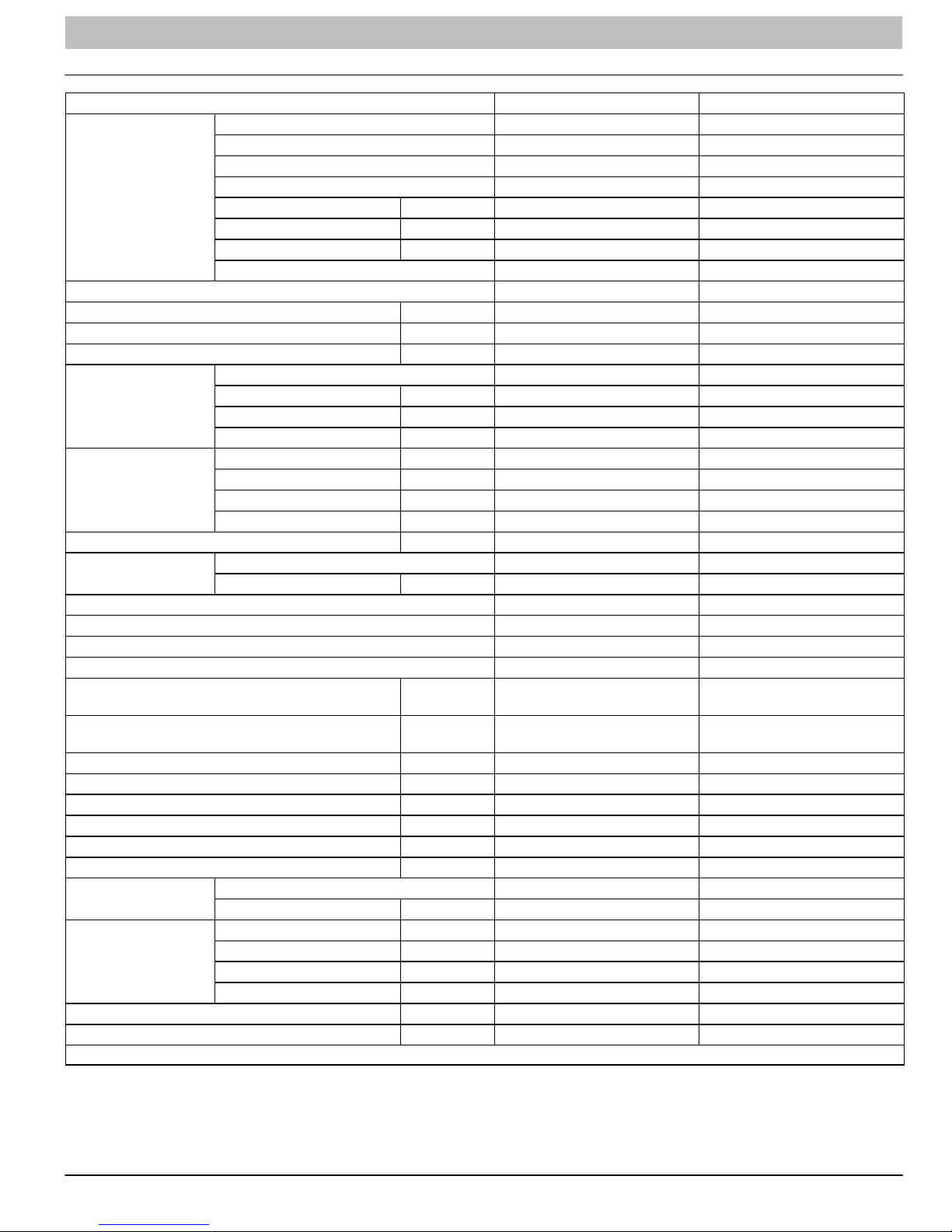

PRODUCT SPECIFICATIONS (Cont.)

Model − Outdoor Unit DLF4AV09J1A DLF4HV09J1A

Manufacturer Sanyo Sanyo

Model C−6RZ110H1A C−6RZ110H1A

Type Twin Rotary Twin Rotary

Compressor

Throttling Method

Starting Method Transducer Starting Transducer Starting

Working Temperature Range °F 55 ~ 115 55 ~ 11 5 5 ~ 24

Heat Exchanger Coil

Coil Length (I) x Height (H) x Width (L) inch 31.5 x 19.5 x.05 31.5 x 19.5 x.05

Fan Motor

Air Flow Volume of Outdoor Unit Ft3/min 1118 1118

Fan

Defrosting Method / /

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure for

the Discharge Side

Permissible Excessive Operating Pressure for

the Suction Side

Sound Pressure Level DB (A) ≤50 ≤50

Sound Power Level DB (A) ≤63 ≤63

Dimensions (WxHxD) inch 33 X 21 X 12.6 33 X 21 X 12.6

Dimensions of Package (WxHxD) inch 34.5 X 22.8 X 14.2 34.5 X 22.8 X 14.2

Net Weight / Gross Weight Lbs. 96 / 110 96 / 110

Refrigerant

Connection Pipe

Max. Interunit height Difference Ft. 33 33

Max. Interunit Piping Length Ft. 66 66

* The above data is subject to change without notice. Please refer to the nameplate of the unit.

L.R.A. A 33 33

R.L.A. A 4.59 / 2.81 4.59 / 2.81

Power Input W 775 / 735 775 / 735

Overload Protectorr Int11I−3979 Int11I−3979

Electronic Expansion Valve

Throttling

Coil

Pipe Diameter inch f0.3 f0.3

Rows−Fin Gap inch 2−0.06 2−0.06

Speed rpm 900 / 650 900 / 650 900

Output of Fan Motor W 40 40

R.L.A. A 0.17 0.17

Capacitor mF / /

Type Axial Fan Axial Fan

Diameter inch 15.7 15.7

Mpa 3.8 3.8

Mpa 1.2 1.2

Name of Refrigerant R410A R410A

Weight Oz. 42 42

Length (m) Ft. 16 16

Gas Additional

Charge

Liquid Pipe Diameter inch f1/4 f1/4

Gas Pipe Diameter inch f3/8 f3/8

Oz/ft 1.1613 1.1613

Aluminum Fin−Copper

Tube

Electronic Expansion Valve Throttling

Aluminum Fin−Copper Tube

421 08 9204 00 3

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

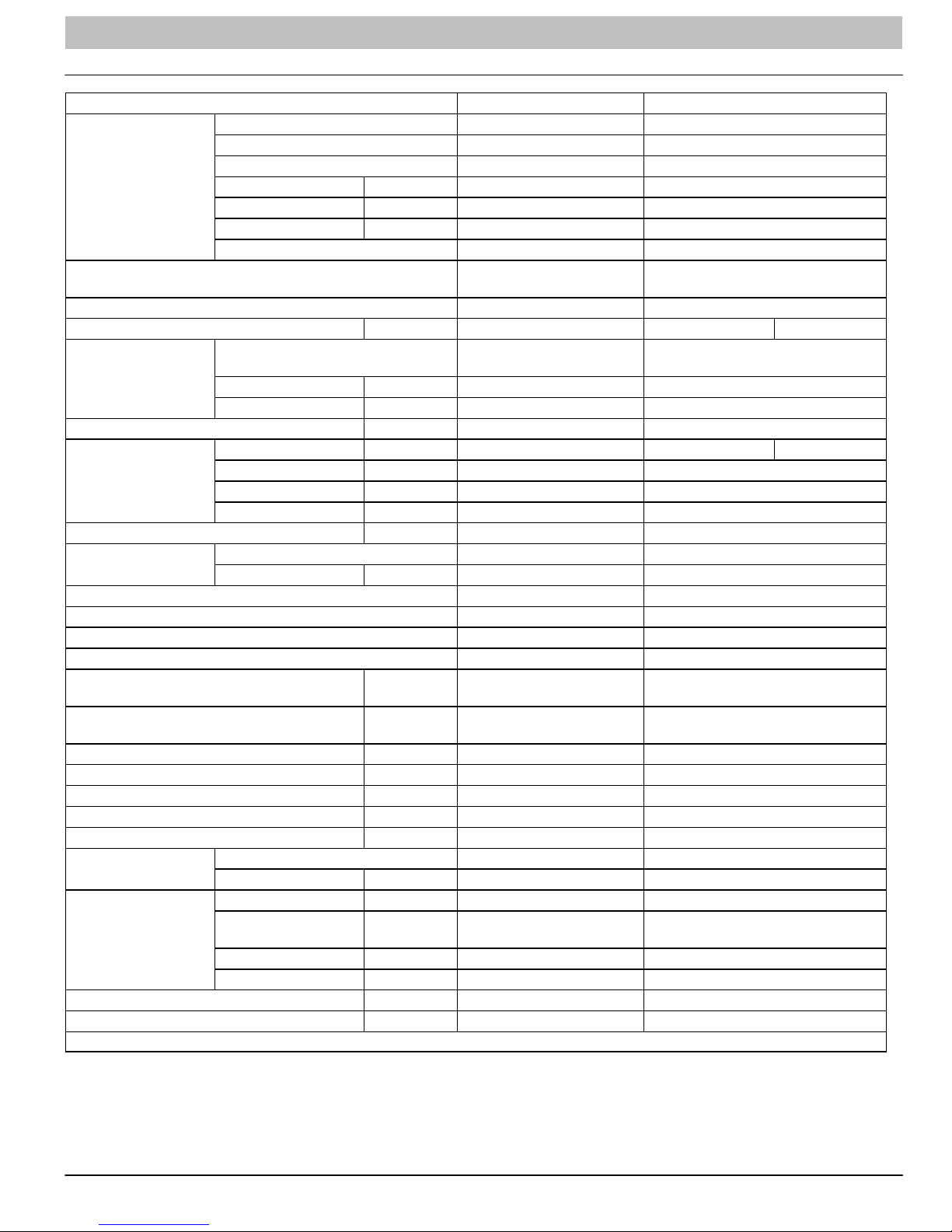

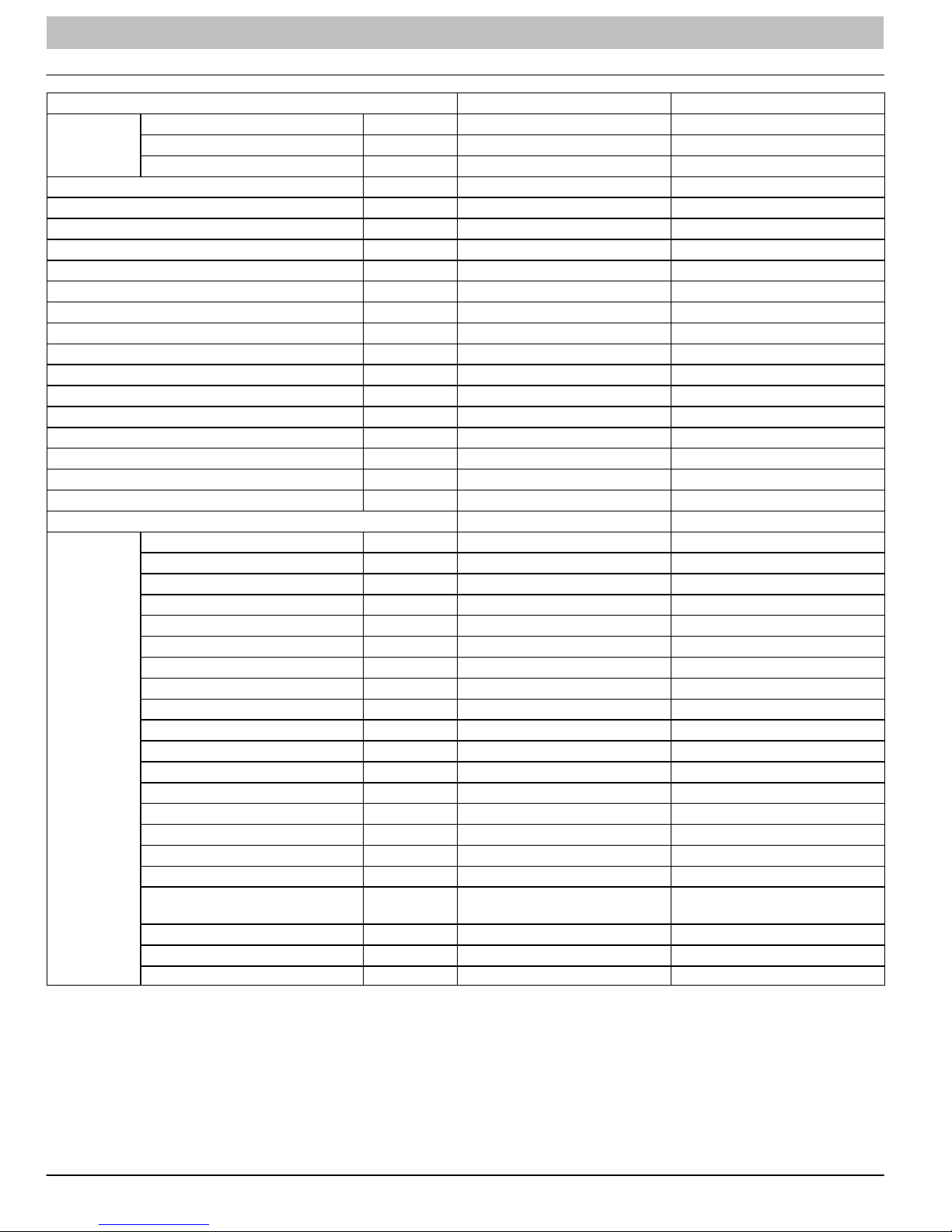

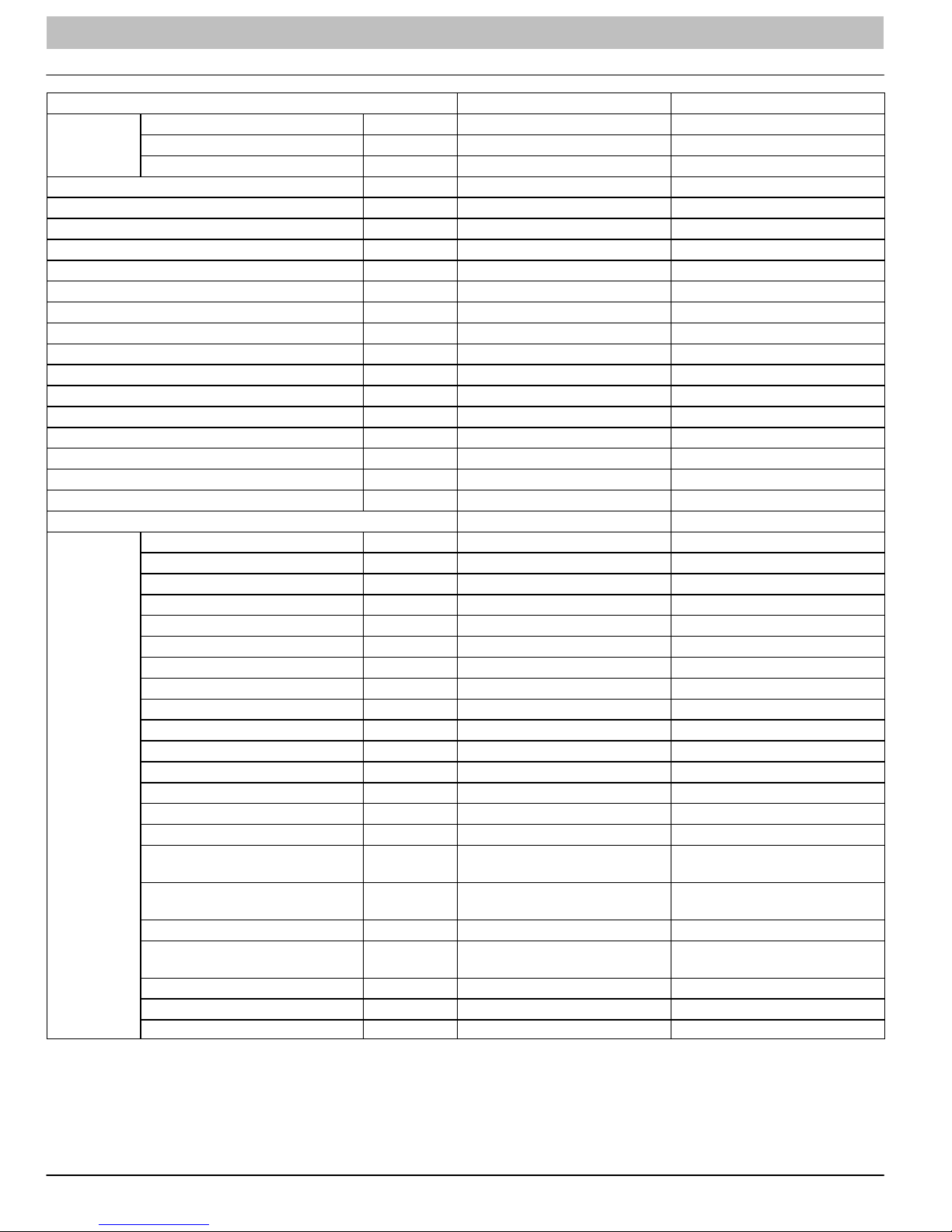

PRODUCT SPECIFICATIONS

Model − Indoor Unit DLF4AH12J1A DLF4HH12J1A

Function Cooling Cooling Heating

Rated Voltage 115V 115V

Frequency

(Inverter different

Compressor speed)

Total Capacity

(Inverter different

Compressor speed)

Power Input

(Inverter different

Compressor speed)

Rated Input

Rated Current

Air Volume

High Hz 70 70 63

Standard Hz 41 41 44

Low Hz 15 15 15

High W/Btuh 3100 / 10600 3100 / 10600 3250 / 11100

Standard W/Btuh 2650 / 9000 2650 / 9000 2820 / 9500

Low W/Btuh 1300 / 4435 1300 / 4435 930 / 3200

High W 1050 1050 1100

Standard W 634 634 700

Low W 180 180 220

High W 1050 1050 1100

Standard W 634 634 700

High A 16.8 16.8 17.0

Standard A 7.0 7.0 7.5

CFM 370 370

Dehumidifying Volume I/h 0.8 0.8

EER / C.O.P 14.2 14.2

SEER / HSPF 22 22 / 9.8

Indoor Unit DLF4AH12J1A DLF4HH12J1A

SH r/min 1260 1260 1320

Speed

Fan Motor

Output W 20 20

Capacitor mF 4.0 4.0

RLA A 0.38 0.38

Fan

Evaporator

Swing Motor

Fuse A 3.15 3.15

Sound Pressure Level

Sound Pressure Level

Dimension (WxHxD) Inch 33 x 11 x 7 33 x 11 x 7

Dimension of Package (WxHxD) Inch 36 x 14 x 10 36 x 14 x 10

Net Weight / Gross Weight Inch 29 / 38 29 / 38

Type Cross Flow Fan Cross Flow Fan

Diameter−Length Inch f3.6x25.4 f3.6x25.4

Pipe Diameter Inch f0.3 f0.3

Row−Fin Gap Inch 2−0.06 2−0.06

Coil length (I) x height

(H) x coil width (L)

Model MP24AA MP24AA

Output W 2.4 2.4

H r/min 1050 1050 1200

M r/min 920 920 1100

L r/min 730 730 950

Aluminum Fin Copper Tube Aluminum Fin Copper Tube

Inch 25.4 x 10.5 x 1 25.4 x 10.5 x 1

H dB (A) 34 34

M dB (A) 30 30

L dB (A) 26 26

H dB (A) 44 44

M dB (A) 40 40

L dB (A) 36 36

4 421 08 9204 00

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

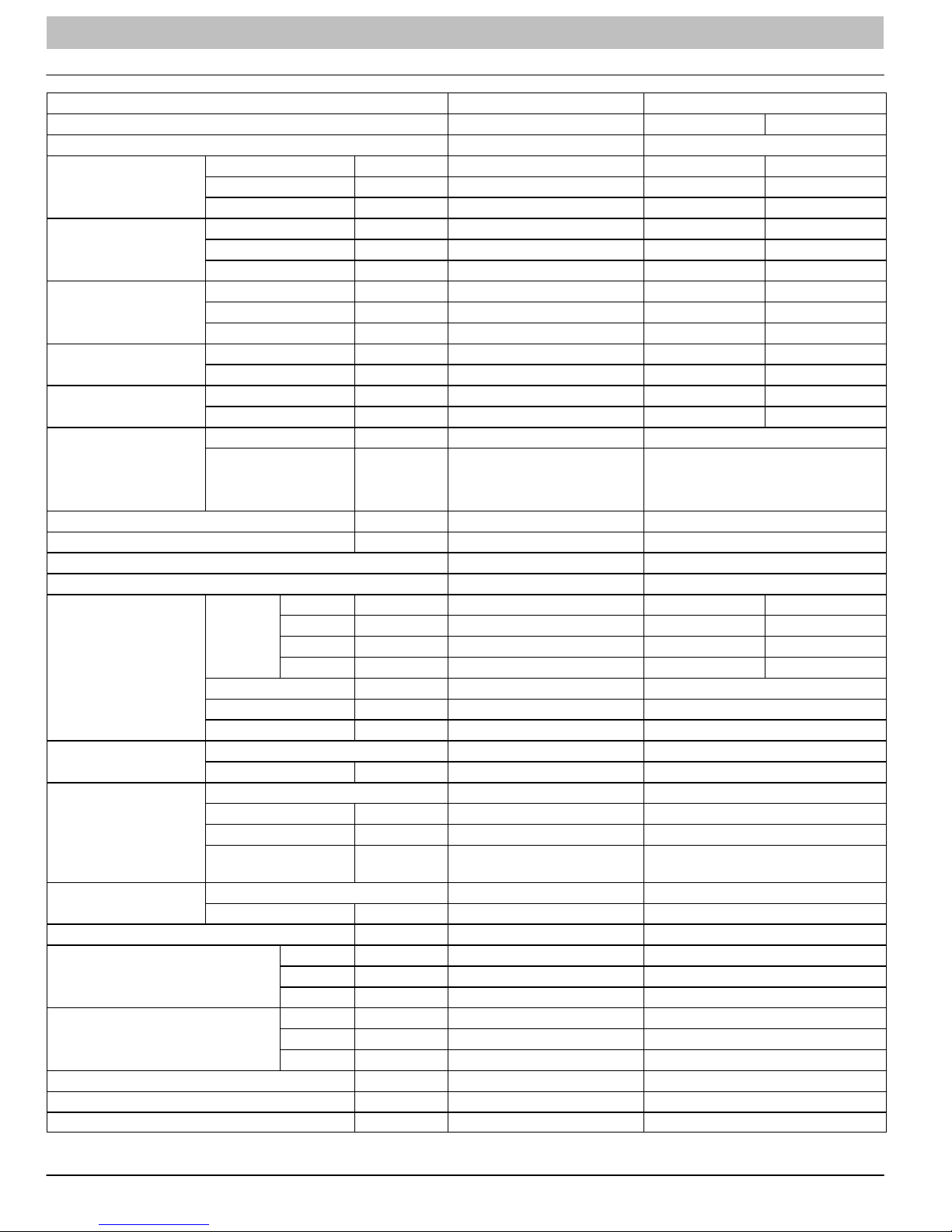

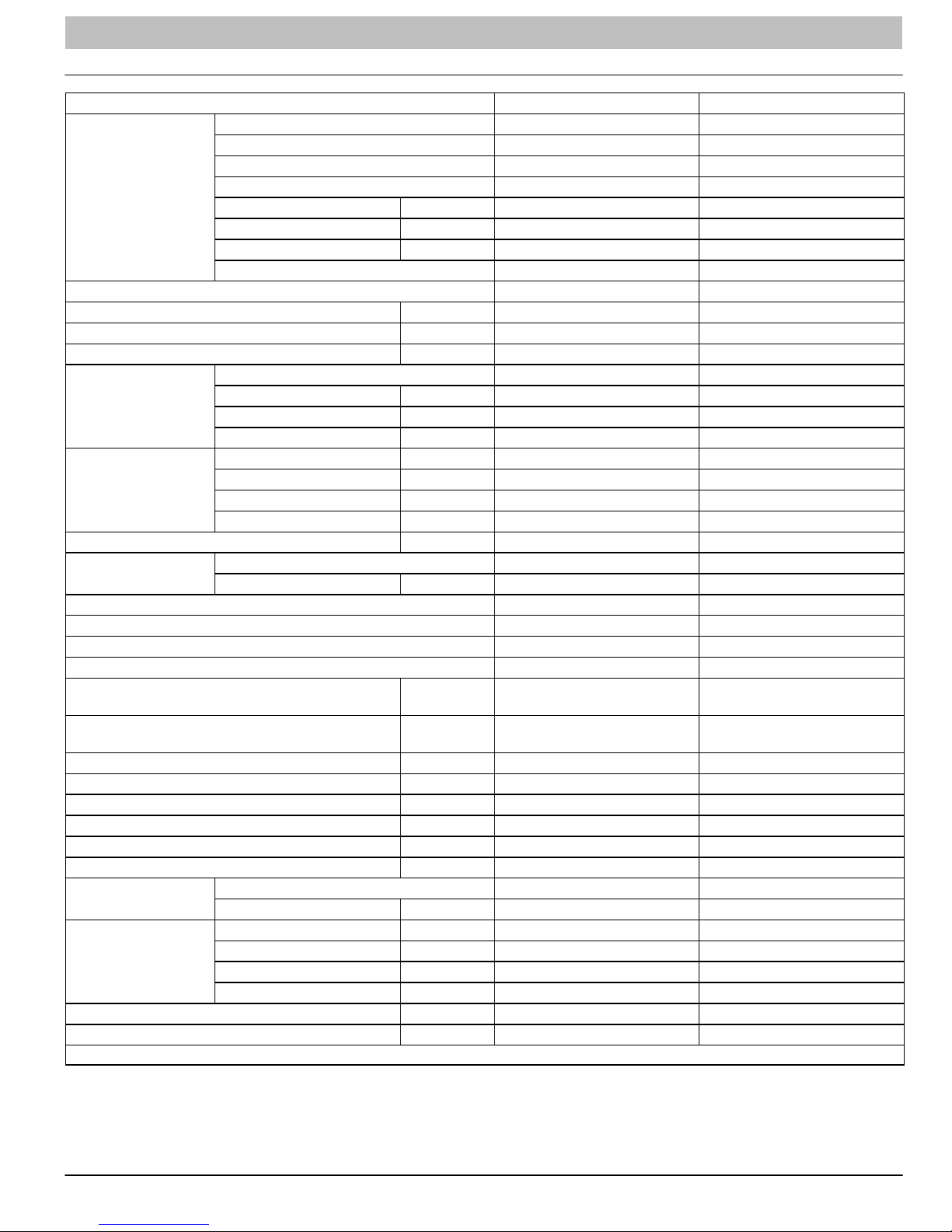

PRODUCT SPECIFICATIONS (Cont.)

Model − Outdoor Unit DLC4AV12J1A DLC4HV12J1A

Manufacturer Sanyo Sanyo

Model C−6RZ110H1A C−6RZ110H1A

Type Twin Rotary Twin Rotary

Compressor

Throttling Method

Starting Method Transducer Starting Transducer Starting

Working Temperature Range °F 55 ~ 115 55 ~ 11 5 5 ~ 75

Heat Exchanger Coil

Coil Length (I) x Height (H) x Width (L) inch 30.2 x 20 x0.9 30.2 x 20 x0.9

Fan Motor

Air Flow Volume of Outdoor Unit Ft3/min 111 8 1118

Fan

Defrosting Method / Auto Defrost

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure for

the Discharge Side

Permissible Excessive Operating Pressure for

the Suction Side

Sound Pressure Level DB (A) ≤53 ≤53

Sound Power Level DB (A) ≤65 ≤65

Dimensions (WxHxD) inch 33 X 21 X 12.6 33 X 21 X 12.6

Dimensions of Package (WxHxD) inch 34.5 X 22.8 X 14.2 34.5 X 22.8 X 14.2

Net Weight / Gross Weight Lbs. 107 / 118 107 / 118

Refrigerant

Connection Pipe

Max. Interunit height Difference Ft. 33 33

Max. Interunit Piping Length Ft. 66 66

* The above data is subject to change without notice. Please refer to the nameplate of the unit.

L.R.A. A 33 33

R.L.A. A 4.59 / 2.81 4.59 / 2.81

Power Input W 775 / 735 775 / 735

Overload Protectorr Int11I−3979 Int11I−3979

Electronic Expansion Valve

Throttling

Coil

Pipe Diameter inch f0.4 f0.4

Rows−Fin Gap inch 2−0.06 2−0.06

Speed rpm 900 / 680 900 / 680 900

Output of Fan Motor W 40 40

R.L.A. A 0.17 0.17

Capacitor mF / /

Type Axial Fan Axial Fan

Diameter inch 15.7 15.7

Mpa 3.8 3.8

Mpa 1.2 1.2

Name of Refrigerant R410A R410A

Weight Oz. 45.5 45.5

Length (m) Ft. 16 16

Gas Additional

Charge

Liquid Pipe Diameter inch f1/4 f1/4

Gas Pipe Diameter inch f3/8 f3/8

Oz/ft 1.1613 1.1613

Aluminum Fin−Copper

Tube

Electronic Expansion Valve Throttling

Aluminum Fin−Copper Tube

421 08 9204 00 5

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

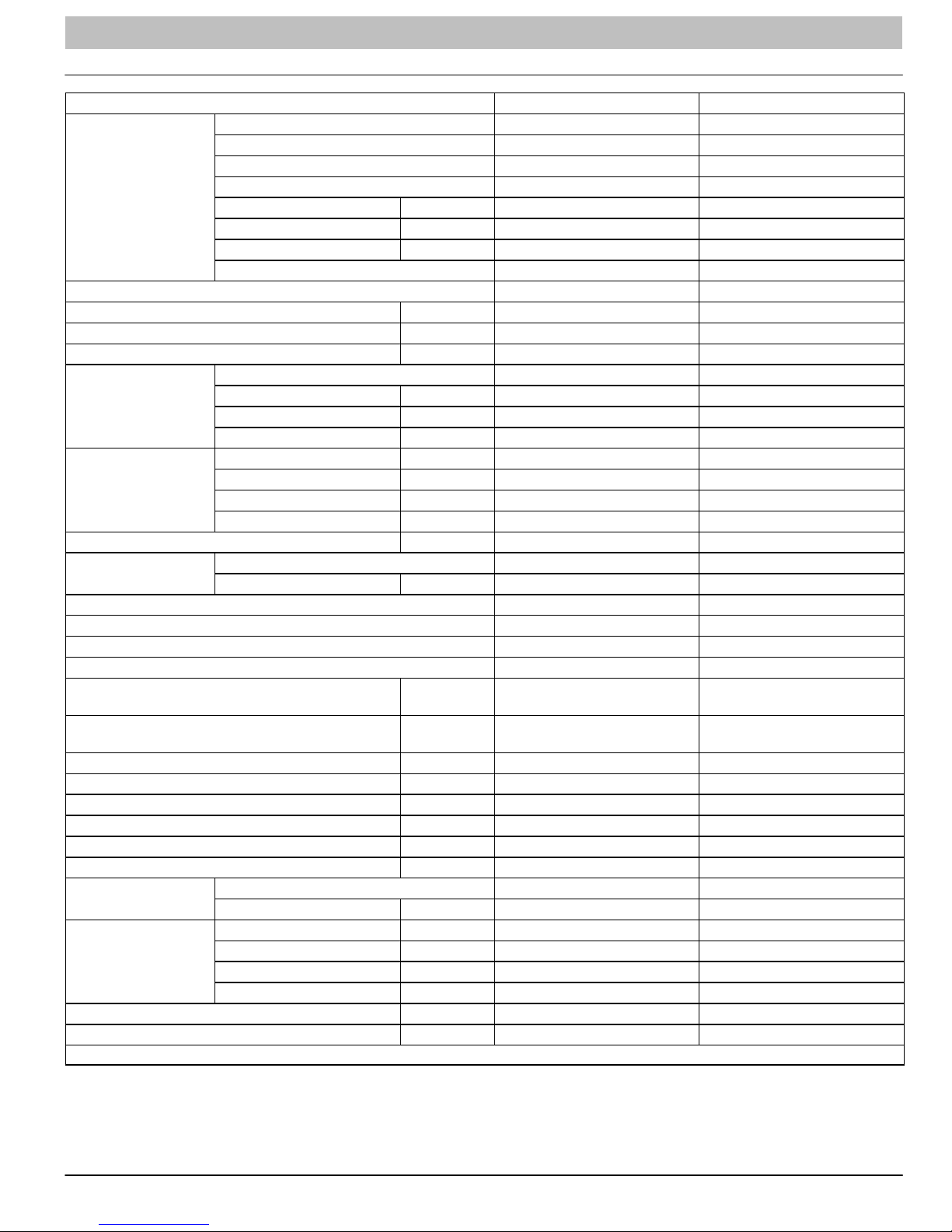

PRODUCT SPECIFICATIONS (Cont.)

Model DLC4AV12K1A DLC4HV12K1A

Power

Supply

Power Supply Mode Outdoor Outdoor

Cooling Capacity (Min − Max) Btu/h 12000 (3100−13000) 12000 (3100−13000)

Heating Capacity (Min. − Max) Btu/h N/A 13000 (2400−14000)

Cooling Power Input (Min. − Max.) W 1000 (365−1080) 1000 (365−1080)

Heating Power Input (Min. − Max.) W N/A 1000 (340−1360)

Cooling Current Input A 4.5 4.5

Heating Current Input A N/A 5.2

Rated Input W 1500 1500

Rated Current A 15 15

Air Flow Volume (S/H/M/L) CFM 335/277/253/218 335/277/253/218

Dehumidifying Volume Pint/h 2.959 2.959

EER Btu/hW 12 12

COP Btu/hW N/A 10.8

SEER 20 20

HSPF N/A 9.2

Application Area m

Model − Indoor Unit DLF4AH12K1A DLF4HH12K1A

Indoor Unit

Rated Voltage V~ 208/230 208/230

Rated Frequency Hz 60 60

Phases 1 1

2

Fan Type Cross−flow Cross−flow

Fan Diameter Length (DXL) inch f3.6x25.4 f3.6x25.4

Cooling Speed (S/H/M/L) r/min 1330/1100/950/750 1330/1100/950/750

Heating Speed (S/H/M/L) r/min N/A 1350/1170/1050/950

Fan Motor Power Output W 20 20

Fan Motor RLA A 0.2 0.2

Fan Motor Capacitor mF 1 1

Evaporator Form W Aluminum Fin−Copper Tube Aluminum Fin−Copper Tube

Evaporator Pipe Diameter inch f0.27 f0.27

Evaporator Row−fin Gap inch 2−0.05 2−0.05

Evaporator Coil Length (LxDxW) inch 22.8x1x10.4 22.8x1x10.4

Swing Motor Model MP24AA MP24AA

Swing Motor Power Output W 2.4 2.4

Fuse Current A 3.15 3.15

Sound Pressure Level (S/H/M/L) dB (A) 42/39/36/33 42/39/36/33

Sound Power Level (S/H/M/L) dB (A) 52/49/46/43 52/49/46/43

Dimension (WxHxD) inch 33.3X10.8X7 33.3X10.8X7

Dimension of Carton Box

(WxHxD)

Dimension of Package (WxHxD) inch 36X10.1X14.6 36X10.1X14.6

Net Weight lb 22 22

Gross Weight lb 28.7 28.7

inch 36X10X14 36X10X14

16−24 16−24

6 421 08 9204 00

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

PRODUCT SPECIFICATIONS (Cont.)

Model − Outdoor Unit DLC4AV12K1A DLC4HV12K1A

Manufacturer Mitsubishi Mitsubishi

Model KNB092FTAMC KNB092FTAMC

Oil FV50S FV50S

Compressor

Throttling Method Electronic Expansion Valve Electronic Expansion Valve

Set Temperature Range °F 60.8 ~ 86 60.8 ~ 86

Cooling Operation Ambient Temperature Range °F 0.4 ~ 109.4 0.4 ~ 109.4

Heating Operation Ambient Temperature Range °F N/A −5 ~ 75.0

Condenser

Fan Motor

Air Flow Volume of Outdoor Unit CFM 941.6 941.6

Fan

Defrosting Method N/A Automatic Defrosting

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure for the

Discharge Side

Permissible Excessive Operating Pressure for the

Suction Side

Sound Pressure Level (H/M/L) DB (A) 52/−/− 52/−/−

Sound Power Level (H/M/L) DB (A) 62/−/− 62/−/−

Dimensions (WxHxD) inch 33.4x23.2x12.6 33.4x23.2x12.6

Dimensions of Carton Box (WxHxD) inch 34.5x14.2x24.8 34.5x14.2x24.8

Dimensions of Package (WxHxD) inch 34.7x14.3x25.4 34.7x14.3x25.4

Net Weight / Gross Weight Lbs. 88.2 / 97.02 88.2 / 97.02

Refrigerant

Connection Pipe

Max. Interunit height Difference Ft. 33 33

Max. Interunit Piping Length Ft. 66 66

* The above data is subject to change without notice. Please refer to the nameplate of the unit.

Type Rotary Rotary

L.R.A. A 13.8 13.8

R.L.A. A 3.2 3.2

Power Input W 860 860

Overload Protector INT11L−6578 INT11L−6578

Form Aluminum Fin−copper Tube Aluminum Fin−copper Tube

Pipe Diameter inch f0.37 f0.37

Rows−Fin Gap inch 2−0.05 2−0.05

Coil Length (LxDxW) inch 29.4x1.7x22 29.4x1.7x22

Speed rpm 680 / 900 680 / 900

Output of Fan Motor W 30 30

R.L.A. A 0.13 0.13

Capacitor mF N/A N/A

Type Axial Flow Axial Flow

Diameter inch 15.748 15.748

Mpa 4.3 4.3

Mpa 2.5 2.5

Name of Refrigerant R410A R410A

Weight Oz. 45.864 45.864

Length inch 25 25

Gas Additional Charge Oz/ft 0.53 0.7

Liquid Pipe Outer Diameter inch 1/4 1/4

Gas Pipe Outer Diameter inch 3/8 3/8

421 08 9204 00 7

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

PRODUCT SPECIFICATIONS (Cont.)

Model DLC4AV18K1A DLC4HV18K1A

Power

Supply

Power Supply Mode Outdoor Outdoor

Cooling Capacity (Min − Max) Btu/h 18000 (5970−22350) 18000 (5970−22350)

Heating Capacity (Min. − Max) Btu/h N/A 19800 (4100−22000)

Cooling Power Input (Min. − Max.) W 1500 (300−2650) 1500 (300−2650)

Heating Power Input (Min. − Max.) W N/A 1650 (335−2750)

Cooling Current Input A 6.65 6.65

Heating Current Input A N/A 7.32

Rated Input W 2650 2750

Rated Current A 11.757 12.201

Air Flow Volume (S/H/M/L) CFM 500/459/383/324 500/459/383/324

Dehumidifying Volume Pint/h 0.852 0.852

EER Btu/hW 12 12

COP Btu/hW N/A 12

SEER 18 18

HSPF N/A 10

Application Area m

Model − Indoor Unit DLF4AH18K1A DLF4HH18K1A

Indoor Unit

Rated Voltage V~ 208/230 208/230

Rated Frequency Hz 60 60

Phases 1 1

2

Fan Type Cross−flow Cross−flow

Fan Diameter Length (DXL) inch f3.86x28 f3.86x28

Cooling Speed (S/H/M/L) r/min 1500/1200/1050/900 1500/1200/1050/900

Heating Speed (S/H/M/L) r/min N/A 1500/1250/1150/1050

Fan Motor Power Output W 20 20

Fan Motor RLA A 0.32 0.32

Fan Motor Capacitor mF 1.5 1.5

Evaporator Form W Aluminum Fin−Copper Tube Aluminum Fin−Copper Tube

Evaporator Pipe Diameter inch f0.27 f0.27

Evaporator Row−fin Gap inch 2−0.05 2−0.05

Evaporator Coil Length (LxDxW) inch 28x1x12 28x1x12

Swing Motor Model MP28VB MP28VB

Swing Motor Power Output W 2.5 2.5

Fuse Current A 3.15 3.15

Sound Pressure Level (S/H/M/L) dB (A) 49/44/40/35 49/44/40/35

Sound Power Level (S/H/M/L) dB (A) 59/54/50/45 59/54/50/45

Dimension (WxHxD) inch 37X11.7X7.9 37X11.7X7.9

Dimension of Carton Box

(WxHxD)

Dimension of Package (WxHxD) inch 39.7X11.2X15 39.7X11.2X15

Net Weight lb 28.665 28.665

Gross Weight lb 37.485 37.485

inch 39.6X11.1X14.4 39.6X11.1X14.4

27−42 27−42

8 421 08 9204 00

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

PRODUCT SPECIFICATIONS (Cont.)

Model − Outdoor Unit DLC4AV18K1A DLC4HV18K1A

Manufacturer Mitsubishi Mitsubishi

Model SNB130FGAMC SNB130FGAMC

Oil FV50S−PVE FV50S−PVE

Compressor

Throttling Method Electronic Expansion Valve Electronic Expansion Valve

Set Temperature Range °F 61 ~ 86 61 ~ 86

Cooling Operation Ambient Temperature Range °F 14 ~ 109.0 14 ~ 109.0

Heating Operation Ambient Temperature Range °F N/A 19.4 − 75.0

Condenser

Fan Motor

Air Flow Volume of Outdoor Unit CFM 1883.2 1883.2

Fan

Defrosting Method N/A Automatic Defrosting

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure for the

Discharge Side

Permissible Excessive Operating Pressure for the

Suction Side

Sound Pressure Level (H/M/L) DB (A) 55/−/− 55/−/−

Sound Power Level (H/M/L) DB (A) 65/−/− 65/−/−

Dimensions (WxHxD) inch 37.6x27.6x15.6 37.6x27.6x15.6

Dimensions of Carton Box (WxHxD) inch 40.4x18x29 40.4x18x29

Dimensions of Package (WxHxD) inch 40.5x18x29.5 40.5x18x29.5

Net Weight / Gross Weight Lbs. 99.225 / 110.25 99.225 / 110.25

Refrigerant

Connection Pipe

Max. Interunit height Difference Ft. 33 33

Max. Interunit Piping Length Ft. 82 82

* The above data is subject to change without notice. Please refer to the nameplate of the unit.

Type Rotary Rotary

L.R.A. A 13.8 13.8

R.L.A. A 4.1 4.1

Power Input W 1200 1200

Overload Protector INT11L−6578 INT11L−6578

Form Aluminum Fin−copper Tube Aluminum Fin−copper Tube

Pipe Diameter inch f0.37 f0.37

Rows−Fin Gap inch 2−0.05 2−0.05

Coil Length (LxDxW) inch 33x1.5x26 33x1.5x26

Speed rpm 800 800

Output of Fan Motor W 60 60

R.L.A. A 0.28 0.28

Capacitor mF N/A N/A

Type Axial Flow Axial Flow

Diameter inch 20.472 20.472

Mpa 4.3 4.3

Mpa 2.5 2.5

Name of Refrigerant R410A R410A

Weight Oz. 49.392 49.392

Length inch 25 25

Gas Additional Charge Oz/ft 0.2 0.2

Liquid Pipe Outer Diameter inch 1/4 1/4

Gas Pipe Outer Diameter inch 1/2 1/2

421 08 9204 00 9

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

PRODUCT SPECIFICATIONS (Cont.)

Model DLC4AV24K1A DLC4HV24K1A

Power

Supply

Power Supply Mode Outdoor Outdoor

Cooling Capacity (Min − Max) Btu/h 21400 (9600−25000) 21400 (9600−25000)

Heating Capacity (Min. − Max) Btu/h N/A 23000 (4300−26000)

Cooling Power Input (Min. − Max.) W 1780 (500−2650) 1780 (500−2650)

Heating Power Input (Min. − Max.) W N/A 2100 (400−2750)

Cooling Current Input A 7.941 7.941

Heating Current Input A N/A 9.317

Rated Input W 2650 2750

Rated Current A 11.757 12.201

Air Flow Volume (S/H/M/L) CFM 589/471/412/353 589/471/412/353

Dehumidifying Volume Pint/h 1.183 1.183

EER Btu/hW 12 12

COP Btu/hW N/A 10.95

SEER 18 18

HSPF N/A 10

Application Area m

Model − Indoor Unit DLF4AH24K1A DLF4HH24K1A

Indoor Unit

Rated Voltage V~ 208/230 208/230

Rated Frequency Hz 60 60

Phases 1 1

2

Fan Type Cross−flow Cross−flow

Fan Diameter Length (DXL) inch f3.86x30 f3.86x30

Cooling Speed (S/H/M/L) r/min 1500/1200/1050/900 1500/1200/1050/900

Heating Speed (S/H/M/L) r/min N/A 1450/1150/1020/950

Fan Motor Power Output W 260 260

Fan Motor RLA A 0.24 0.24

Fan Motor Capacitor mF N/A N/A

Evaporator Form W Aluminum Fin−Copper Tube Aluminum Fin−Copper Tube

Evaporator Pipe Diameter inch f0.27 f0.27

Evaporator Row−fin Gap inch 2−0.06 2−0.06

Evaporator Coil Length (LxDxW) inch 30x1x15.5 30x1x15.5

Swing Motor Model MP35XX MP35XX

Swing Motor Power Output W 3 3

Fuse Current A 3.15 3.15

Sound Pressure Level (S/H/M/L) dB (A) 53/45/41/37 53/45/41/37

Sound Power Level (S/H/M/L) dB (A) 63/55/51/47 63/55/51/47

Dimension (WxHxD) inch 39.7X12.4X8.6 39.7X12.4X8.6

Dimension of Carton Box

(WxHxD)

Dimension of Package (WxHxD) inch 42.4X15.7X12.9 42.4X15.7X12.9

Net Weight lb 35.28 35.28

Gross Weight lb 46.305 46.305

inch 42.2X15.5X12.3 42.2X15.5X12.3

27−42 27−42

10 421 08 9204 00

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

PRODUCT SPECIFICATIONS (Cont.)

Model − Outdoor Unit DLC4AV24K1A DLC4HV24K1A

Manufacturer Mitsubishi Mitsubishi

Model SNB150FGAMC SNB150FGAMC

Oil FV50S−PVE FV50S−PVE

Compressor

Throttling Method Electronic Expansion Valve Electronic Expansion Valve

Set Temperature Range °F 61 ~ 86 61 ~ 86

Cooling Operation Ambient Temperature Range °F 5 ~ 109.0 5 ~ 109.0

Heating Operation Ambient Temperature Range °F N/A 19.4 − 75.0

Condenser

Fan Motor

Air Flow Volume of Outdoor Unit CFM 2354 2354

Fan

Defrosting Method N/A N/A

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure for the

Discharge Side

Permissible Excessive Operating Pressure for the

Suction Side

Sound Pressure Level (H/M/L) DB (A) 56/−/− 56/−/−

Sound Power Level (H/M/L) DB (A) 66/−/− 66/−/−

Dimensions (WxHxD) inch 38.6x31.1x16.8 38.6x31.1x16.8

Dimensions of Carton Box (WxHxD) inch 42.5x19x33 42.5x19x33

Dimensions of Package (WxHxD) inch 42.6x19x33.7 42.6x19x33.7

Net Weight / Gross Weight Lbs. 119 / 132 119 / 132

Refrigerant

Connection Pipe

Max. Interunit height Difference Ft. 33 33

Max. Interunit Piping Length Ft. 82 82

* The above data is subject to change without notice. Please refer to the nameplate of the unit.

Type Rotary Rotary

L.R.A. A 18.5 18.5

R.L.A. A 4.9 4.9

Power Input W 1420 1420

Overload Protector INT11L−6578 INT11L−6578

Form Aluminum Fin−copper Tube Aluminum Fin−copper Tube

Pipe Diameter inch f0.27 f0.27

Rows−Fin Gap inch 2−0.05 2−0.05

Coil Length (LxDxW) inch 38x1.5x29 38x1.5x29

Speed rpm 800 800

Output of Fan Motor W 90 90

R.L.A. A 1.1 1.1

Capacitor mF 4 4

Type Axial Flow Axial Flow

Diameter inch 21.732 21.732

Mpa 4.3 4.3

Mpa 2.5 2.5

Name of Refrigerant R410A R410A

Weight Oz. 56.448 56.448

Length inch 25 25

Gas Additional Charge Oz/ft 0.2 0.2

Liquid Pipe Outer Diameter inch 1/4 1/4

Gas Pipe Outer Diameter inch 5/8 5/8

421 08 9204 00 11

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

PRODUCT SPECIFICATIONS (Cont.)

Model DLF4HH30K1A DLF4HH36K1A

Power

Supply

Power Supply Mode Outdoor Outdoor

Cooling Capacity (Min − Max) Btu/h 28000 (9500−30000) 33600 (7400−36000)

Heating Capacity (Min. − Max) Btu/h 28400 (10000−33000) 34600 (1500−36000)

Cooling Power Input (Min. − Max.) W 2780 (350−3400) 3650 (450−3800)

Heating Power Input (Min. − Max.) W 2870 (450−3300) 3560 (560−3700)

Cooling Current Input A 12.1 16.6

Heating Current Input A 12.5 9.21

Rated Input W 3475 4000

Rated Current A 16.7 18.2

Air Flow Volume (S/H/M/L) CFM −/706/677/647/− −/824/706/677/−

Dehumidifying Volume Pint/h 1.42 1.166

EER Btu/hW 10.7 9.21

COP Btu/hW 9.93 9.72

SEER 16 16

HSPF 8.2 8.2

Application Area m

Model − Indoor Unit DLC4HV30K1A DLC4HH36K1A

Indoor Unit

Rated Voltage V~ 208/230 208/230

Rated Frequency Hz 60 60

Phases 1 1

2

Fan Type Cross−flow Cross−flow

Fan Diameter Length (DXL) inch f4.25x20.58X2 f4.25x20.58X2

Cooling Speed (SH/H/ML/SL) r/min −/1410/1280/1200/− −1550/1400/1300/−

Heating Speed (SH/H/ML/SL) r/min −/1410/1280/1200/− −1550/1400/1300/−

Fan Motor Power Output W 40 60

Fan Motor RLA A 0.4 0.47

Fan Motor Capacitor mF 3.5 3.5

Input of Heater W − −

Evaporator Form W Aluminum Fin−Copper Tube Aluminum Fin−Copper Tube

Evaporator Pipe Diameter inch f11/40 f11/40

Evaporator Row−fin Gap inch 2−0.055 2−0.055

Evaporator Coil Length (LxDxW) inch 142.3x1x15 142.3x1x15

Swing Motor Model MP24BA MP24BA

Swing Motor Power Output W 2 2

Fuse Current A 3.15 3.15

Sound Pressure Level

(SH/H/M/L/SL)

Sound Power Level

(SH/H/M/L/SL)

Dimension (WxHxD) inch 53.1X12.8X10.0 53.1X12.8X10.0

Dimension of Carton Box

(WxHxD)

Dimension of Package (WxHxD) inch 56.7X16.6X14.0 56.7X16.6X14.0

Net Weight lb 44.1 44.1

Gross Weight lb 59.5 59.5

dB (A) −/57/54/46/− −57/56/53/−

dB (A) −/57/54/46/− −/69/66/63/−

inch 56.6X16.5X13.5 56.7X16.6X14.0

377−550 495−753

12 421 08 9204 00

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

PRODUCT SPECIFICATIONS (Cont.)

Model − Outdoor Unit DLC4HV30K1A DLC4HV36K1A

Manufacturer Zhuhai Landa Mitsubishi

Model QXAS−D23ZX090 TNB306FPGMCMC

Oil PVE (FV50S) FV50S

Compressor

Throttling Method Electronic Expansion Valve Electronic Expansion Valve

Set Temperature Range °F 61 ~ 86 61 ~ 86

Cooling Operation Ambient Temperature Range °F 5 ~ 109.0 5 ~ 109.0

Heating Operation Ambient Temperature Range °F 19.4−75.0 19.4 − 75.0

Condenser

Fan Motor

Air Flow Volume of Outdoor Unit CFM 2354 2589

Fan

Defrosting Method Automatic Defrosting Automatic Defrosting

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure for the

Discharge Side

Permissible Excessive Operating Pressure for the

Suction Side

Sound Pressure Level (H/M/L) DB (A) 62/−/− 65/−/−

Sound Power Level (H/M/L) DB (A) 72/−/− 75/−/−

Dimensions (WxHxD) inch 38.6x31.1x16.8 38.6x31.1x16.8

Dimensions of Carton Box (WxHxD) inch 42.5x19.1x33 42.5x19.1x33

Dimensions of Package (WxHxD) inch 42.6x19x33.7 42.6x19x33.7

Net Weight / Gross Weight Lbs. 154 / 163 161 / 170

Refrigerant

Connection Pipe

Max. Interunit height Difference Ft. 32.8 32.8

Max. Interunit Piping Length Ft. 98.4 98.4

* The above data is subject to change without notice. Please refer to the nameplate of the unit.

Type Rotary Rotary

L.R.A. A 40 67

R.L.A. A 12 13.5

Power Input W 2450 3010

Overload Protector INT11L−6233 CS01F272H01

Form Aluminum Fin−copper Tube Aluminum Fin−copper Tube

Pipe Diameter inch f01/3 f3/8

Rows−Fin Gap inch 2−0.055 2−0.055

Coil Length (LxDxW) inch 37.5x1.5x29.4 37x1.7x30

Speed rpm 830 900

Output of Fan Motor W 90 170

R.L.A. A 0.45 0.73

Capacitor mF N/A N/A

Type Axial Flow Axial Flow

Diameter inch f21.73 f21.73

PSI 551 551

PSI 174 174

Name of Refrigerant R410A R410A

Weight Oz. 84.7 91.7

Length inch 24.6 24.6

Gas Additional Charge Oz/ft 0.5 0.2

Liquid Pipe Outer Diameter inch f1/4 f1/4

Gas Pipe Outer Diameter inch f5/8 f5/8

421 08 9204 00 13

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

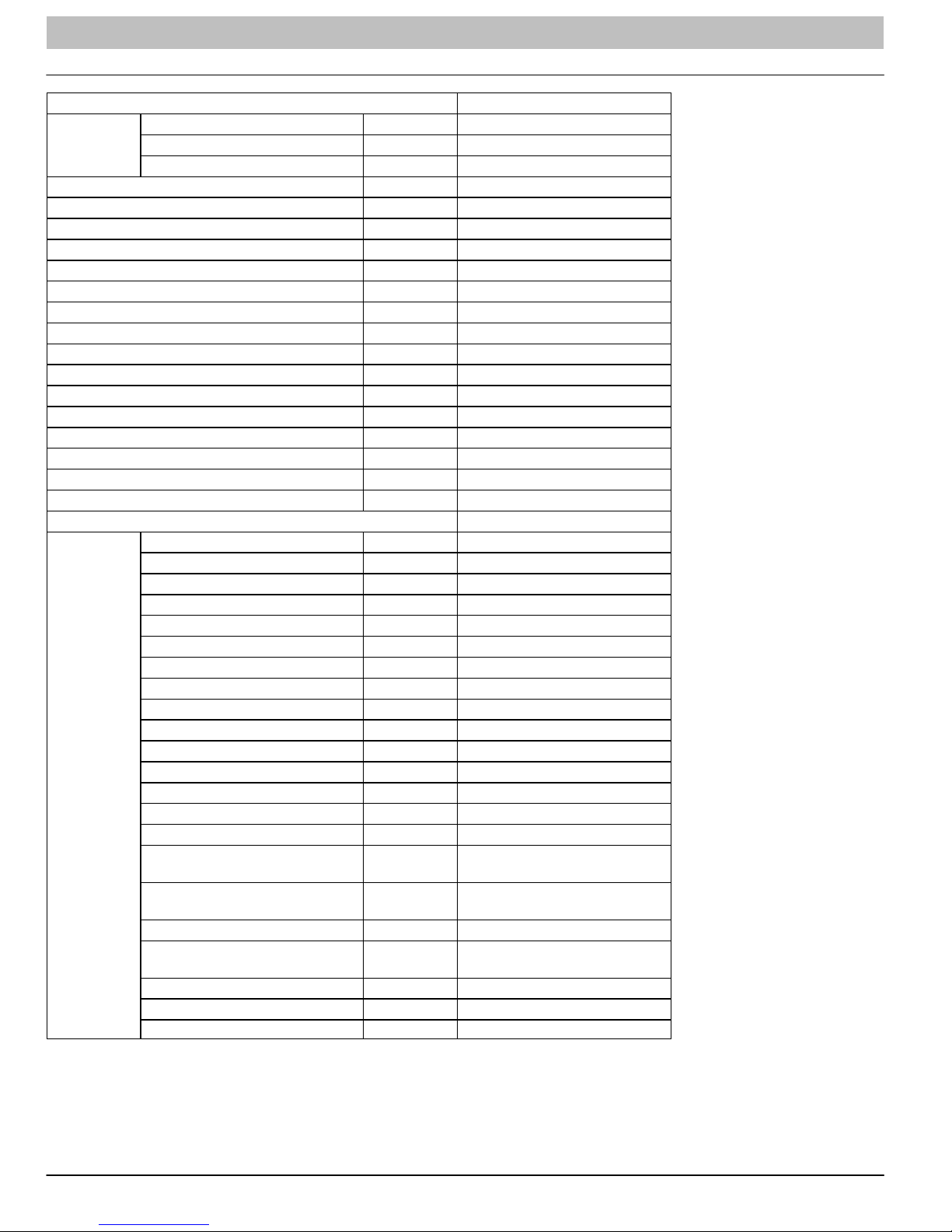

PRODUCT SPECIFICATIONS (Cont.)

Model DLF4AH36K1A

Power

Supply

Power Supply Mode Outdoor

Cooling Capacity (Min − Max) Btu/h 33600 (7400−36000)

Heating Capacity (Min. − Max) Btu/h N/A

Cooling Power Input (Min. − Max.) W 3650 (410−3800)

Heating Power Input (Min. − Max.) W N/A

Cooling Current Input A 15.9

Heating Current Input A N/A

Rated Input W 4200

Rated Current A 18.2

Air Flow Volume (S/H/M/L) CFM −/824/706/677/−

Dehumidifying Volume Pint/h 1.66

EER Btu/hW 9.21

COP Btu/hW N/A

SEER 16

HSPF N/A

Application Area m

Model − Indoor Unit DLF4AH36K1A

Indoor Unit

Rated Voltage V~ 208/230

Rated Frequency Hz 60

Phases 1

2

Fan Type Cross−flow

Fan Diameter Length (DXL) inch f4.25x20.58X2

Cooling Speed (SH/H/ML/SL) r/min −/1550/1400/12300/−

Heating Speed (SH/H/ML/SL) r/min N/A

Fan Motor Power Output W 60

Fan Motor RLA A 0.47

Fan Motor Capacitor mF 3.5

Input of Heater W N/A

Evaporator Form W Aluminum Fin−Copper Tube

Evaporator Pipe Diameter inch f11/40

Evaporator Row−fin Gap inch 2−0.055

Evaporator Coil Length (LxDxW) inch 142.3x1x15

Swing Motor Model MP24BA

Swing Motor Power Output W 2

Fuse Current A 3.15

Sound Pressure Level

(SH/H/M/L/SL)

Sound Power Level

(SH/H/M/L/SL)

Dimension (WxHxD) inch 53.1X12.8X10.0

Dimension of Carton Box

(WxHxD)

Dimension of Package (WxHxD) inch 56.7X16.6X14.0

Net Weight lb 44.1

Gross Weight lb 59.5

dB (A) −/59/56/53/−

dB (A) −/69/66/63/−

inch 56.6X16.5X13.5

495−753

14 421 08 9204 00

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

PRODUCT SPECIFICATIONS (Cont.)

Model − Outdoor Unit DLC4AV36K1A

Manufacturer Mitsubishi

Model TNB306FPGMCMC

Oil FV50S

Compressor

Throttling Method Capillary

Set Temperature Range °F 61 ~ 86

Cooling Operation Ambient Temperature Range °F 5 ~ 109.0

Heating Operation Ambient Temperature Range °F 19.4 − 75.0

Condenser

Fan Motor

Air Flow Volume of Outdoor Unit CFM 2589

Fan

Defrosting Method N/A

Climate Type T1

Isolation I

Moisture Protection IP24

Permissible Excessive Operating Pressure for the

Discharge Side

Permissible Excessive Operating Pressure for the

Suction Side

Sound Pressure Level (H/M/L) DB (A) 65/−/−

Sound Power Level (H/M/L) DB (A) 75/−/−

Dimensions (WxHxD) inch 38.6x31.1x16.7

Dimensions of Carton Box (WxHxD) inch 42.5x19.1x33.1

Dimensions of Package (WxHxD) inch 42.6x19.2x33.6

Net Weight / Gross Weight Lbs. 161 / 170

Refrigerant

Connection Pipe

Max. Interunit height Difference Ft. 32.8

Max. Interunit Piping Length Ft. 98.4

* The above data is subject to change without notice. Please refer to the nameplate of the unit.

Type Rotary

L.R.A. A 67

R.L.A. A 13.5

Power Input W 3010

Overload Protector CS01F272H01

Form Aluminum Fin−copper Tube

Pipe Diameter inch f3/8

Rows−Fin Gap inch 2−0.055

Coil Length (LxDxW) inch 37x1.7x30

Speed rpm 900

Output of Fan Motor W 170

R.L.A. A 0.73

Capacitor mF N/A

Type Axial Flow

Diameter inch f21.73

PSI 551

PSI 174

Name of Refrigerant R410A

Weight Oz. 91.7

Length inch 24.6

Gas Additional Charge Oz/ft 0.2

Liquid Pipe Outer Diameter inch f1/4

Gas Pipe Outer Diameter inch f5/8

421 08 9204 00 15

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

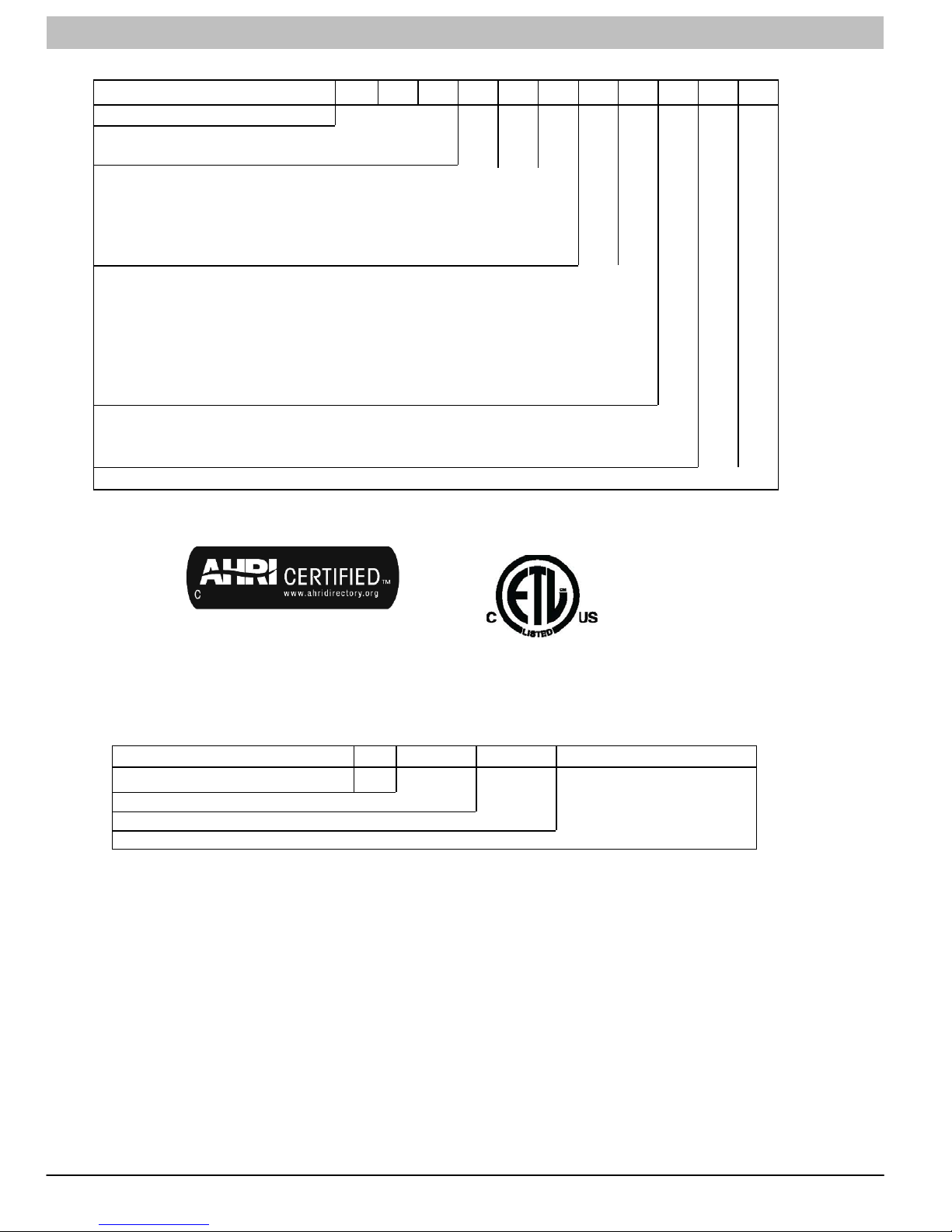

MODEL NOMENCLATURE

MODEL SERIES

Position Number 1 2 3 4 5 6 7 8 9 10 11

DLC = Outdoor

DLF = Indoor Outdoor/Indoor

4AV = AC Outdoor

4AH = AC Indoor

4HV = HP Outdoor

4HH = HP Indoor

09 = 9k BTU

12 = 12k BTU

18 = 18k BTU

24 = 24k BTU

30 = 30k BTU

36 = 36k BTU

J = 115−1−60

K = 208/230−1−60

1A Factory Designation

D L C 4 A V 0 9 J 1 A

Type

Size

Voltage

Use of the AHRI Certified TM Mark indicates a

manufacturer’s participation in the program. For

verification of certification for individual products,

go to www.ahridirectory.org .

SERIAL NUMBER NOMENCLATURE

Position Number 1 2 3 4 5 6 7 8 9 10

Serial Number

Year

Week

Sequential Digits Unique for Each Factory

V 1 0 2 2 1 2 3 4 5

16 421 08 9204 00

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

STANDARD FEATURES AND ACCESSORIES

Ease of Operation

Mounting Brackets S

Low Voltage Connections S

Comfort Features

Microprocessor Controls S

Wireless Remote Control S

Rapid Cooling/Heating S

Automatic Air Sweep S

Cold Blow Prevention S

Continuous Fan S

Auto Restart Feature S

Memory Function S

Auto Changeover S

Energy Saving Features

Inverter Driven Compressor S

Sleep Mode S

24 Hour Stop/Start Timer* S

Safety and Reliability

Indoor Unit Freeze Protection S

3 Minute Compressor Time Delay S

High Compressor Discharge Temperature S

Low Voltage Protection S

Compressor Overload Protection S

Compressor Over Current Protection S

IPM Module Protection S

Ease of Service and Maintenance

Cleanable Filters S

Diagnostic LED’s ON Outdoor Board S

Error Messages Displayed Front Panel S

Application Flexibility

Condensate Pump A

Low Ambient Heating and Cooling on most models A

Standard Warranty

7 Year Compressor Limited Warranty S

5 Year Parts Limited Warranty S

Extended Warranty

6 −10 Year Compressor Only O

2 − 6 Year Parts Only O

2 − 6 Year Parts Only; 1 − 6 Year Labor O

2 − 6 Year Parts Only; 6 − 10 Year Compressor Only;

1 − 6 Year Labor

Legend

S = Standard

A = Accessory

O = Optional

* Sizes 09, 18, & 24K have a clock.

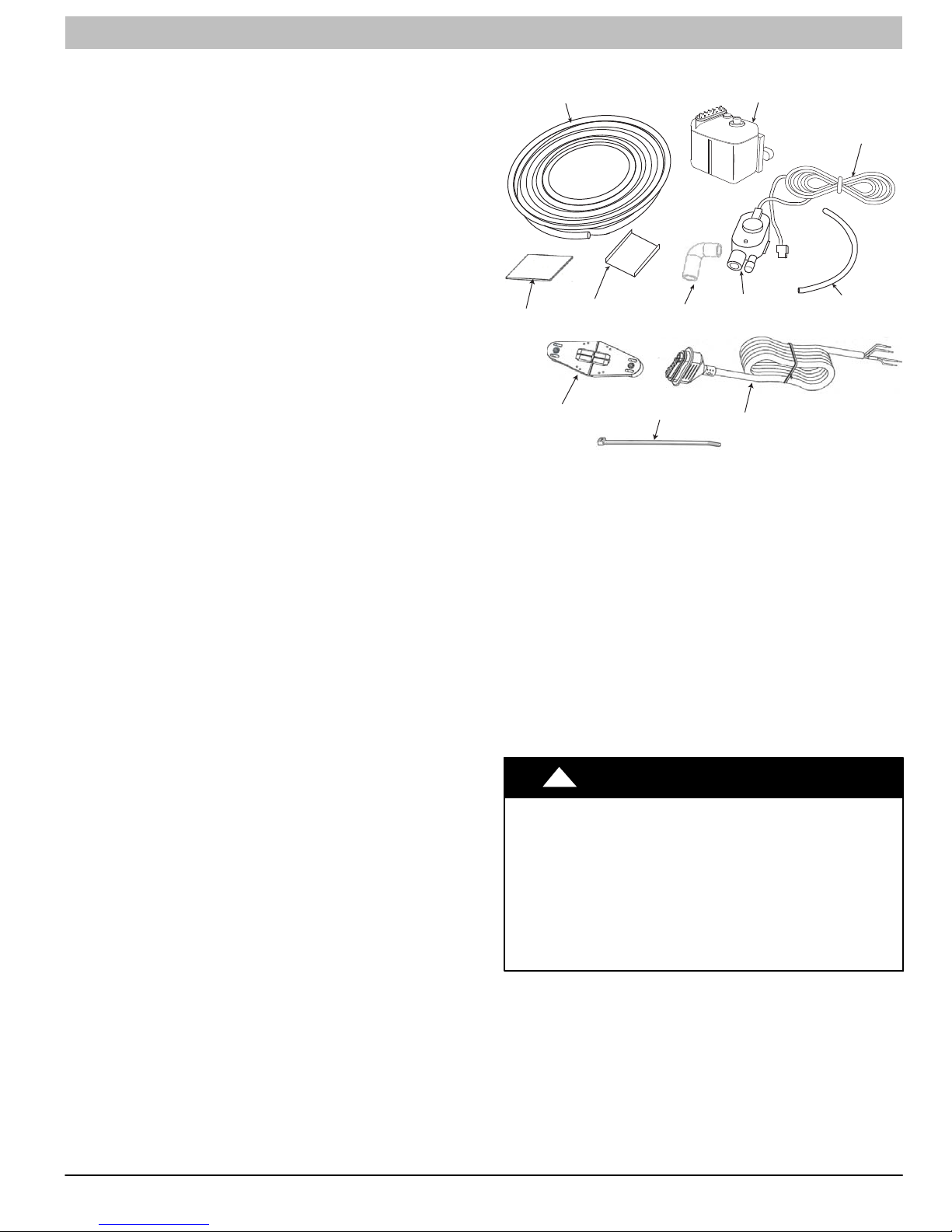

16’ Transparent

Suction Discharge Tubing

Adhesive

Mounting Bracket

Detection Unit

Mounting Bracket

5/8” Rubber Elbow

Wire Ties (6)

Figure 1 - Accessory Condensate Pump Kit

Table 1 − Accessory Condensate Pump Kit Contents

Item Qty.

16 ft Transparent Suction/Discharge Tubing 1

Condensate Pump Assembly 1

Low voltage Power Cord 1

Transparent Detection Unit Vent Tubing 1

Power Cable 1

Wire Ties 6

Wall Mount Bracket 1

Adhesive 1

Detection Unit Mounting Bracket 1

⅝−in Rubber Elbow 1

Detection Unit 1

!

ELECTRICAL SHOCK HAZARD

O

Failure to follow this warning could result in personal injury

or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

Ensure power is disconnected to the fan coil unit. On some

systems both the fan coil and the outdoor unit may be on

the same disconnect. There may be more than 1 disconnect

switch. Lock out and tag switch with a suitable warning

label.

WARNING

Condensate Pump

Assembly

Detection Unit

Power Cable

Low Voltage

Power Cord

Transparent

Detection

Unit Vent Tubing

A12227

421 08 9204 00 17

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

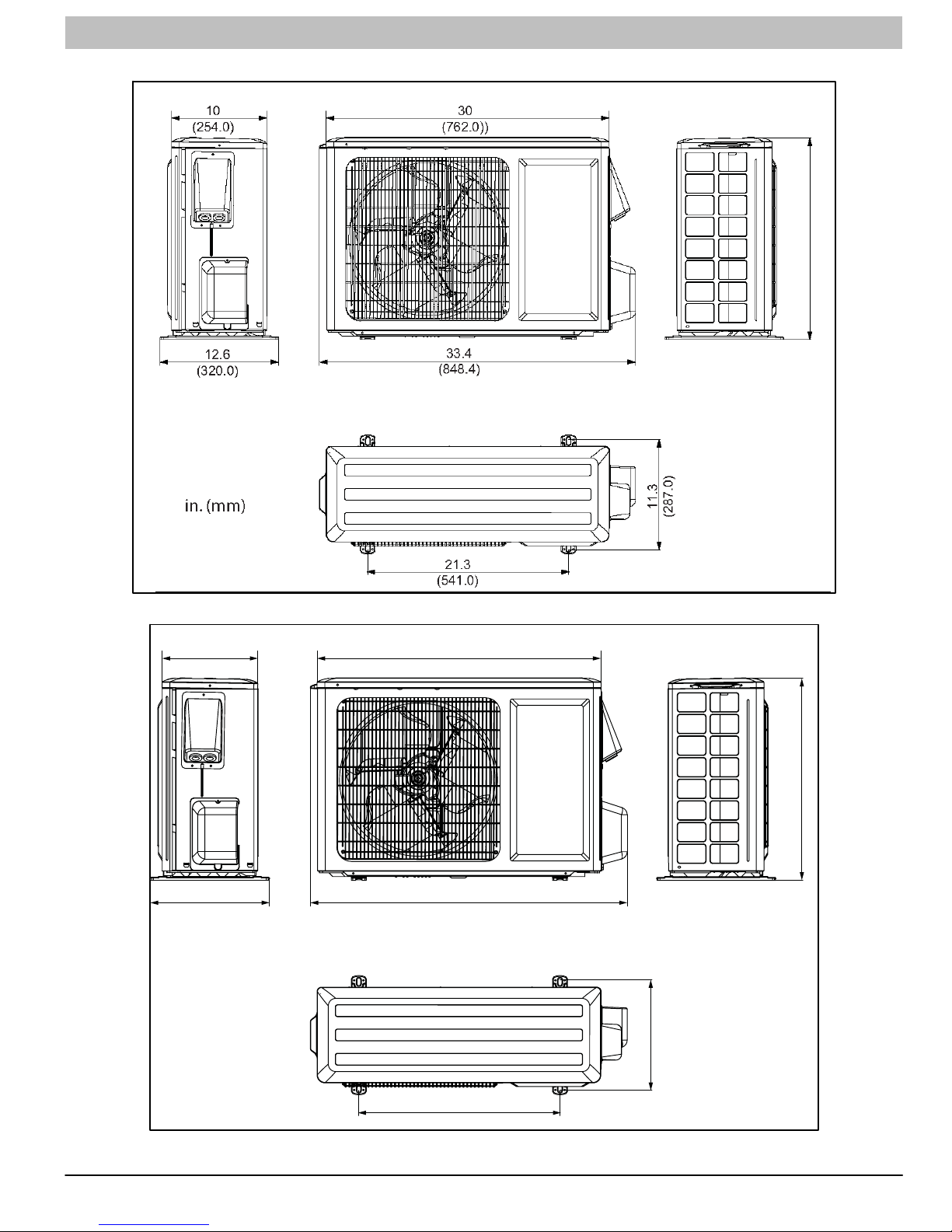

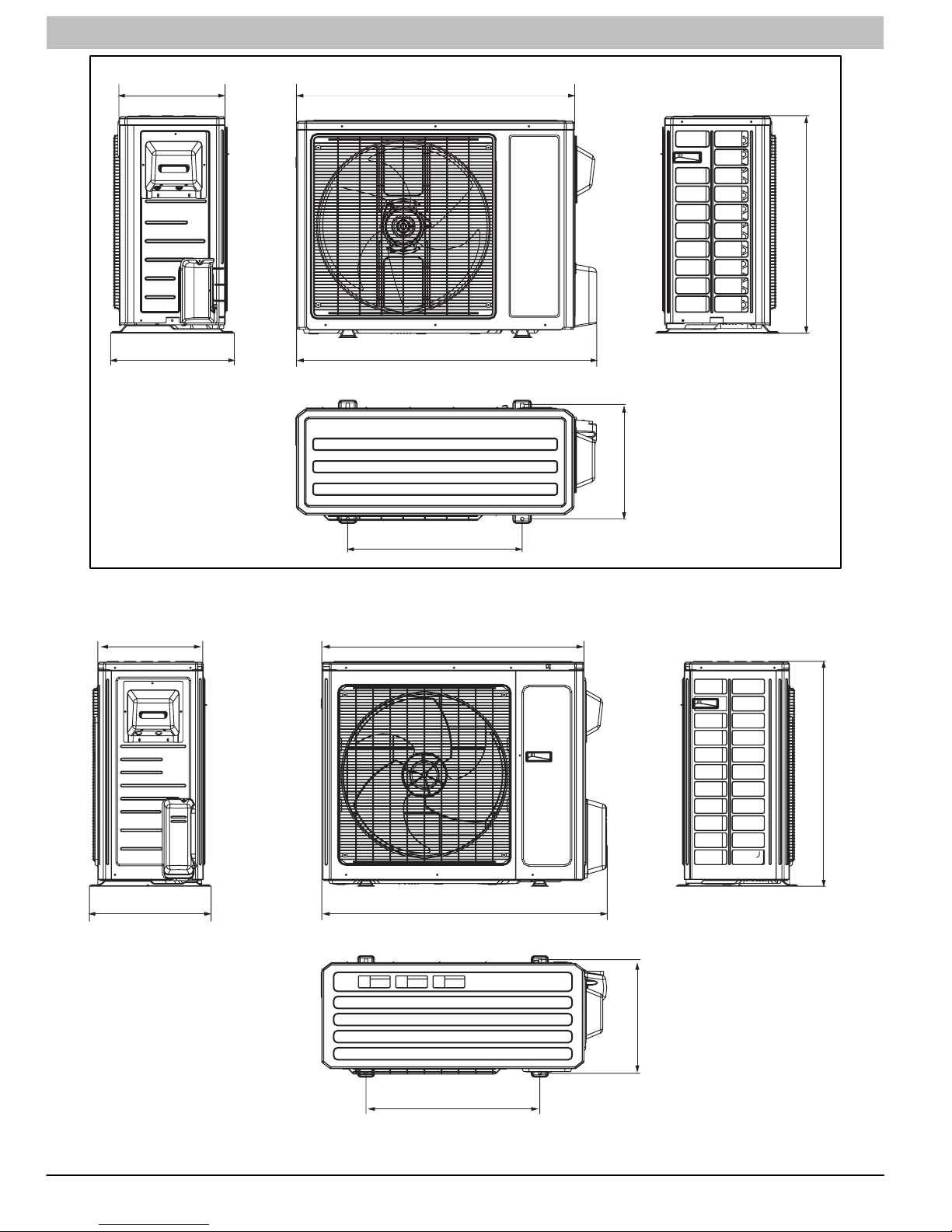

DIMENSIONS − INDOOR

WD

H

Unit Size

9k 33.3 (846) 10.7 (272) 7.1 (180) 29 (13)

12k 33.3 (846) 10.7 (272) 7.1 (180) 29 (13)

18k 37.0 (940) 11.7 (297) 7.9 (201) 29 (13)

24k 39.7 (1008) 12.4 (315) 8.6 (218) 35 (16)

30k 53.1 (1349) 12.8 (325) 10.0 (54) 44.1 (20.0)

36k 53.1 (1349) 12.8 (325) 10.0 (54) 44.1 (20.0)

W

In. (mm)

H

In. (mm)

D

In. (mm)

Net Operating Weight

Lbs. (Kg)

A12377

18 421 08 9204 00

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

DIMENSIONS − OUTDOOR

UNIT SIZE − 09

(Net Operating Weight: 96 lbs.- 44 kg.)

21.3

(541)

10

(254.0)

12.6

(320.0)

in. (mm)

UNIT SIZE − 12

(Net Operating Weight: 107 lbs.- 49 kg.)

30

(762.0))

33.4

(848.4)

11.3

(287.0)

23.2

A12380

(589.3)

421 08 9204 00 19

21.3

(541.0)

A12381

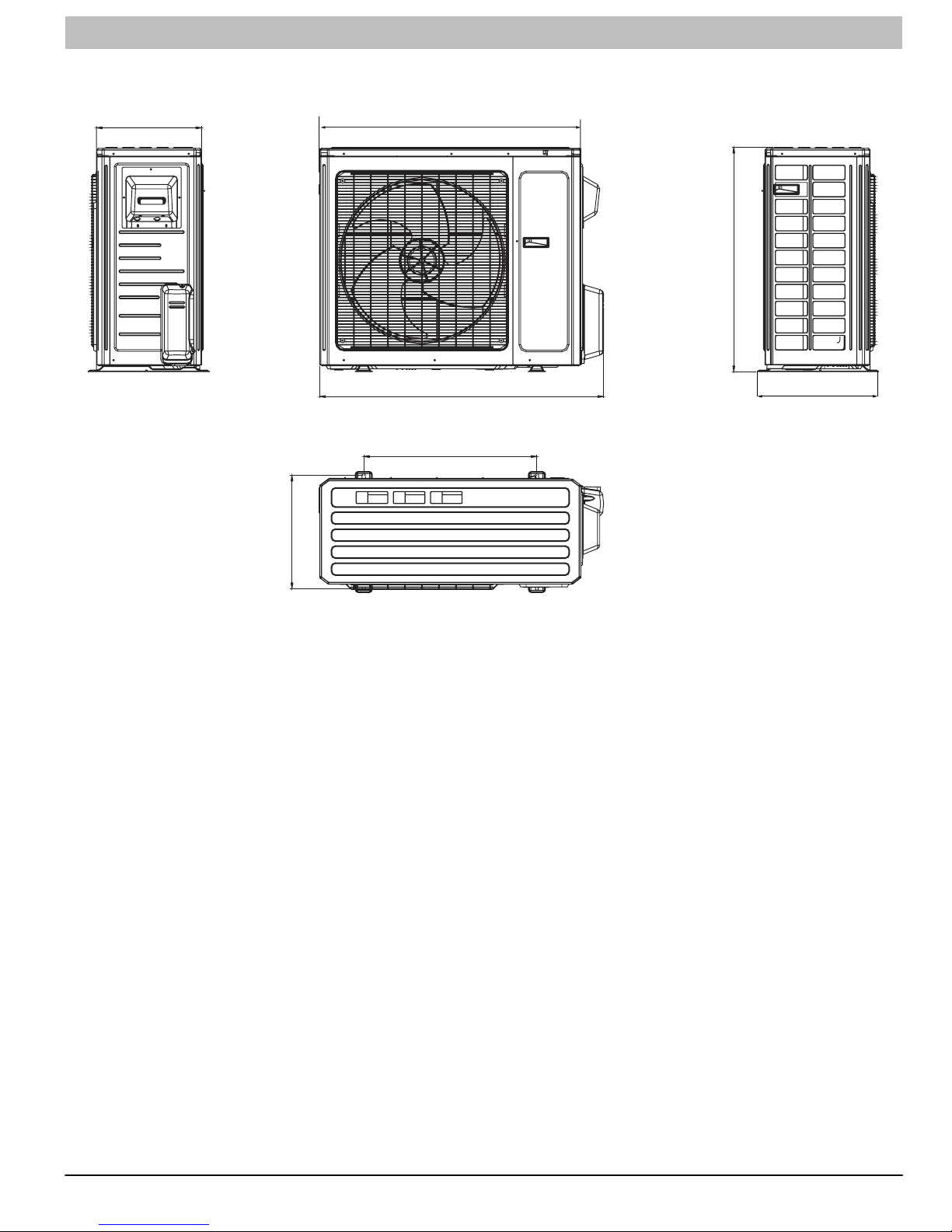

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

13.4

(340.4)

15.6

(396.2)

in. (mm)

UNIT SIZE − 18

35

(889.0)

37.6

(955.0)

(Net Operating Weight: 99 lbs.- 45 kg.)

14.5

(368.3)

27.6

(701.0)

14.6

(368.3)

16.8

(426.7)

22

(558.8)

UNIT SIZE − 24

(914.4)

(980.4)

(Net Operating Weight: 121 lbs.- 55 kg.)

36

38.6

31.1

A12382

(789.9)

in. (mm)

20 421 08 9204 00

24

(609.6)

15.7

(398.8)

A12383

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

UNIT SIZE − 30 (Net Operating Weight: 154 lbs − 70 kg.)

36 (Net Operating Weight: 161 lbs − 73 kg.)

14.6

(370.8)

36

(914.4)

(789.9)

31.1

in. (mm)

(398.8)

15.7

38.6

(980.4)

24

(609.6)

16.7

(424.2)

A12379

421 08 9204 00 21

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

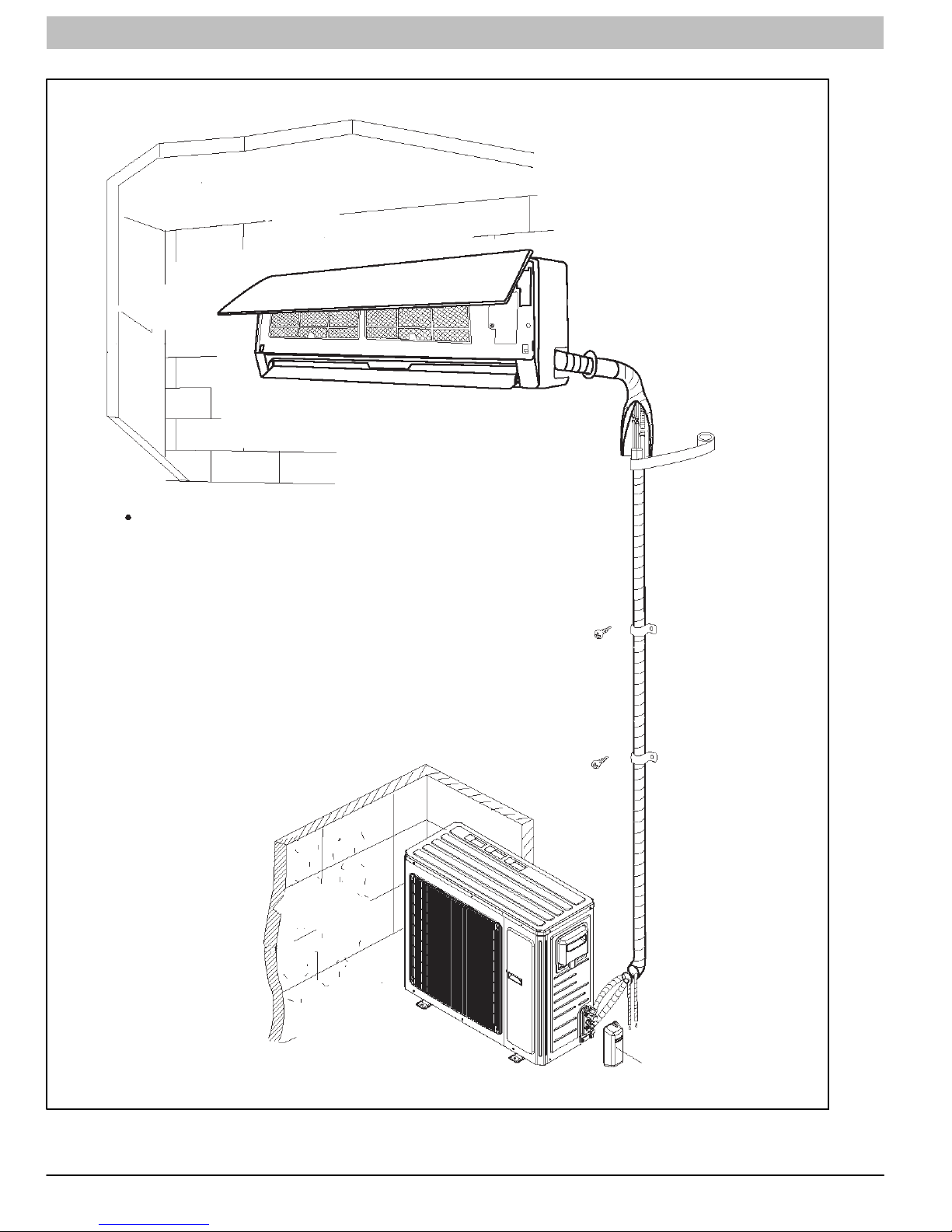

CLEARANCES

Indoor Unit

Distance to Ceiling

6” (152 mm)

Distance to Wall

6” (152 mm)

Clearance in front of unit

118” (2997 mm)

The clearance dimensions are necessary for a correct installation,

and are the minimum permissible distances to adjacent structures.

Distance to Floor

66” (1676 mm)

Distance to Wall

6” (152 mm)

NOTE: Refrigerant lines

may be routed in any of

the (4) directions, right,

right rear, left, or left rear.

See instructions for de

tails.

Outdoor Unit

Above Unit

20” (508 mm)

Distance to

Back Wall

12” (305 mm)

Air Discharge Side

79” (2007 mm)

Figure 2 - Unit clearance

Air Inlet Side

12” (305 mm)

Distance to Wall

20” (508 mm)

Valve Cover

A07891

22 421 08 9204 00

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

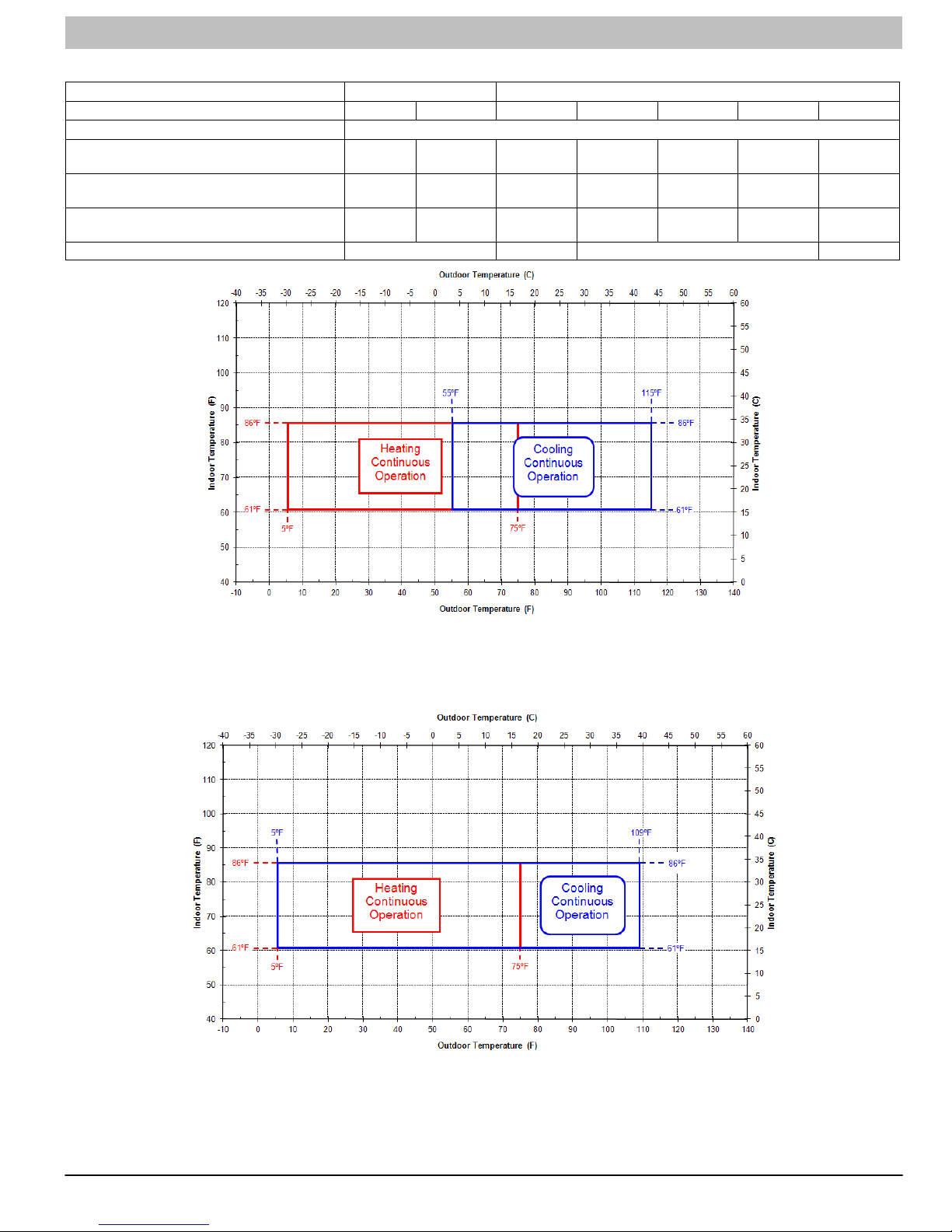

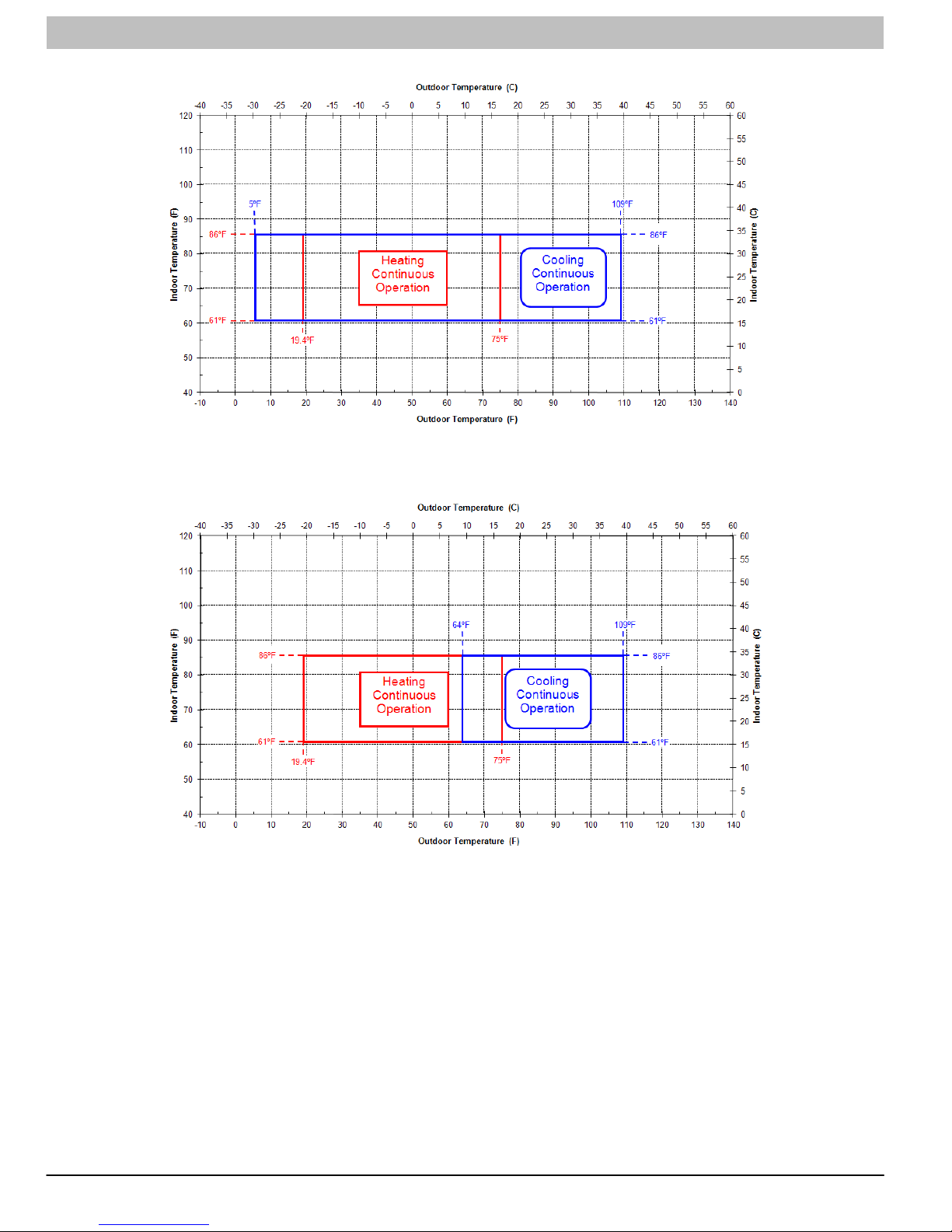

SYSTEM OPERATING ENVELOPES

Supply Voltage 115-1-60 AC 208/230-1-60 AC

Model Size 9k 12k 12k 18k 24k 30k 36k

Indoor Operating Range (A/C and HP) °F (°C) 61 - 86 (16 - 30)

Cooling Ambient Operating Range (A/C) °F (°C)

Cooling Ambient Operating Range (HP) °F (°C)

Heating Ambient Operating Range (HP) °F (°C)

Figure 3 4 5 6

55 - 115

(13 - 46)

55 - 115

(13 - 46)

5 - 75

(-15 - 24)

55 - 115

(13 - 46)

55 - 115

(13 - 46)

5 - 75

(-15 - 24)

5 - 109

(-15 - 43)

5 - 109

(-15 - 43)

5 - 75

(-15 - 24)

5 - 109

(-15 - 43)

5 - 109

(-15 - 43)

19.4 - 75

(-7 - 24)

5 - 109

(-15 - 43)

5 - 109

(-15 - 43)

19.4 - 75

(-7 - 24)

N/A 64 - 109

5 - 109

(-15 - 43)

19.4 - 75

(-7 - 24)

(18 - 43)

64 - 109

(18 - 43)

19.4 - 75

(-7 - 24)

Figure 3 - 9k / 12k 115V System Operating Envelopes

Figure 4 - 12k 230V System Operating Envelopes

421 08 9204 00 23

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

SYSTEM OPERATING ENVELOPES (CONT.)

Figure 5 - 18k, 24k, and 30k 230V System Operating Envelopes

Figure 6 - 36k 230V System Operating Envelopes

24 421 08 9204 00

SERVICE MANUAL R−410A Ductless Split System: DLF4(A/H), DLC4(A/H)

ELECTRICAL DATA

Table 2 − Accessory Condensate Pump Kit Contents

Electrical Data Table

Operating

Unit

Size

9K 115 −1−60 103/127 16.03 33 0.17 0.054 30 115 V−AC 0.38 0.056 20 22 35

12K 115−1−60 103/127 17.53 33 0.17 0.058 30 115 V−AC 0.38 0.056 20 23 40

12K 208/230−1−60 187/253 6.47 13.8 0.14 0.058 30 208/230 V−AC 0.20 0.056 20 10 15

18K 208/230−1−60 187/253 9.70 13.8 0.32 0.156 60 208/230 V−AC 0.28 0.075 20 13 20

24K 208/230−1−60 187/253 11.04 18.5 1.10 0.224 90 176−375V−DC 0.24 0.068 60 16 25

30K 208/230−1−60 187/253 13.45 40 0.45 0.228 100 208/230 V−AC 0.40 0.106 40 20 30

36K−AC 208/230−1−60 187/253 16.92 67 0.73 0.268 170 208/230 V−AC 0.47 0.114 60 24 35

36K−HP 208/230−1−60 187/253 17.50 67 0.73 0.268 170 208/230 V−AC 0.47 0.114 60 24 40

LEGEND

FLA − Full Load Amps

LRA − Locked Rotor Amps

MCA − Minimum Circuit Amps

RLA − Rated Load Amps

MOCP − Maximum Over Current Protection

WIRING

The main power is supplied to the outdoor unit. The field

supplied connecting cable from the outdoor unit to indoor unit

consists of four wires and provides the power for the indoor unit

as well as the communication signal and ground between the

outdoor and indoor unit.

Two wires are high voltage AC power, one is low voltage DC

signal and one is a ground wire.

Consult local building codes, NEC (National Electrical Code) or

CEC (Canadian Electrical Code) for special requirements.

Voltage drop on the connecting cable should be kept to a

minimum. Use cable size and max length below:

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Use copper conductors only with a minimum 300 volt

rating and 2/64 inch thick insulation.

System Voltage

Volts−Ph.−Freq.

18 AWG 50 ft. (16m)

16 AWG 100 ft. (33m)

!

CAUTION

Voltage

(Min/Max)

Compressor Outdoor Fan Indoor Fan

Output

RLA LRA FLA HP

Watts Volts FLA HP

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Be sure to comply with local codes while running wire from

indoor unit to outdoor unit.

Every wire must be connected firmly. Loose wiring may

cause terminal to overheat or result in unit malfunction. A

fire hazard may also exist. Therefore, be sure all wiring is

tightly connected.

No wire should be allowed to touch refrigerant tubing,

compressor or any moving parts.

Disconnecting means must be provided and shall be

located within sight and readily accessible from the air

conditioner.

Connecting cable with conduit shall be routed through

hole in the conduit panel.

CAUTION

Output

Watts

MCA

Fuse/CB

Amps

(MOCP)

Max

421 08 9204 00 25

Loading...

Loading...