ICP CHS180 Installation, Start-up And Service Instructions Manual

Installation, Start--Up, and

Service Instructions

Split System Heat Pump

Three Phase -- 208/230, 460 Volt

Save This Manual for Future Reference

Models

CHS180

506 01 2002 01

5/07/07

Split System Heat PumpsInstallation Instructions

Installation/ Startup

Information

!

FIRE, AND ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Before performing service or maintenance operations

on unit, turn off unit main power switch and install

lockout tag.

These instructions must be read and understood

completely before attempting installation.

WARNING

Installation or repairs made by unqualified

persons can result in hazards to you and others.

Installation MUST conform with local building

codes or, in the absence of local codes, with the

the National Electrical Code NFPA 70/ANSI

C1-1999 or current edition and Canadian

Electrical Code Part 1 CSA C.22.1.

The information contained in this manual is

intended for use by a qualified service technician

familiar with safety procedures and equipped

with the proper tools and test instruments.

Failure to carefully read and follow all instructions in this manual can result in equipment

malfunction, property damage, personal injury

and/or death.

After uncrating unit,inspect thoroughly for hidden damage.

If damage is found, notify the transportation company

immediately and file a concealed damage claim.

!

REDUCED EQUIPMENT LIFE AND PERSONAL INJURY

HAZARD

mproper installation, adjustment, alteration, service or

maintenance can void the warranty.

The weight of the condensing unit requires caution and

proper handling procedures when lifting or moving to

avoid personal injury. Use care to avoid contact with

sharp or pointed edges.

CAUTION

Safety Precautions

1. Always wear safety eye wear and work gloves when

installing equipment.

2. Never assume electrical power is disconnected. Check

with meter and disconnect.

3. Keep hands out of fan areas when power is connected

to equipment.

4. R--22 causes frost--bite burns.

5. R--22 is toxic when burned.

Locating The Outdoor Unit:

Check local codes covering zoning, noise, platforms.

If practical, avoid locating next to fresh air intakes, vent or

windows. Noise may carry into the openings and disturb

people inside.

Placement of the unit should be in a well drained area or

unit must be supported high enough so runoff will not enter

the unit.

Do not locate where heat, lint or exhaust fumes will be

discharged on unit (as from dryer vents).

Roof top installations are acceptable providing the roof will

support the unit and provisions are made for water

drainage and the noise or vibration through the structure.

Do not install the unit in a recessed or confined area where

recirculation of discharge air may occur.

Top skid assembly should be left in place until after the unit

is rigged into its final location.

2

Allow sufficient space for airflow clearance, wiring,

refrigerant piping, and servicing unit.

Split System Heat Pumps Installation Instructions

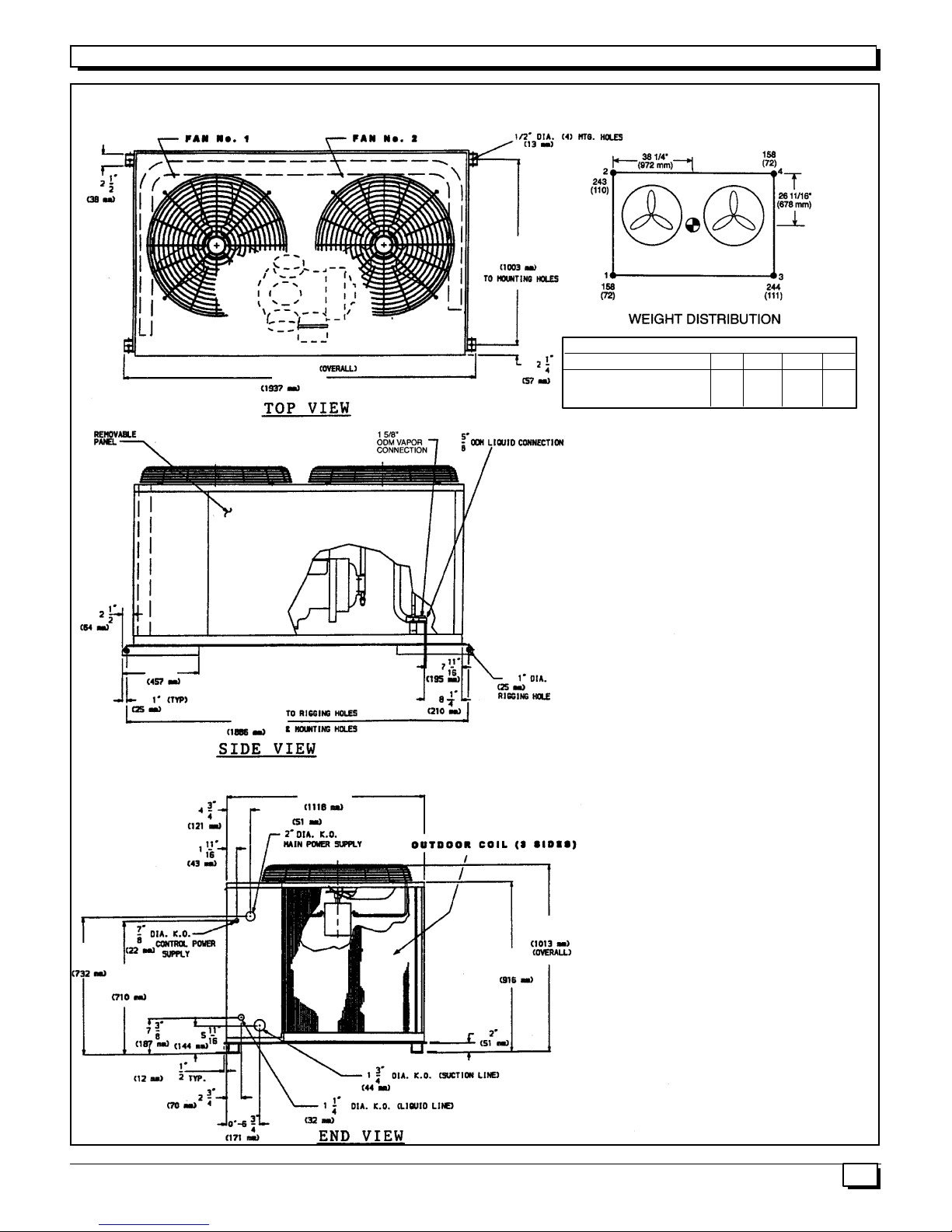

Figure 1

CHS180 UNIT DIMENSIONS and CLEARANCES

39--1/2”

76--1/2”

Unit Total Weight 1 2 3 4

CHS180 803 158 243 244 158

(365) (72) (110) (111 ) (72)

NOTE: Recommended service clearances are as follows

(local codes or jurisdictions may prevail):

Side (compressor) -- 3--1/2 ft. (1067 mm)

Side (opposidte compressor) -- 3 ft. (914 mm)

Ends -- 2 ft. (616 mm)

Top -- 5 ft. (1524 mm)

Support Point

28--13/16”

18”

74--1/4”

43”

39--7/8”

36--1/16”

27--15/16”

3

Split System Heat PumpsInstallation Instructions

Rig and Mount the Unit:

!

REDUCED EQUIPMENT LIFE HAZARD

Failure to follow these precautions could result in

damage to the unit being installed.

Be sure unit panels are securely in place prior to rigging.

RIGGING -- See Figure 2. These units are designed for

overhead rigging. Refer to rigging label for preferred

rigging method. Spreader bars are not required if top

crating is left on unit. All panels must be in place when

rigging. As further protection for coil faces, plywood sheets

may be placed against sides of unit, behind cables. Run

cables to a central suspension point so that angle from the

horizontal is not less than 45 degrees. Raise and set unit

down carefully.

If it is necessary to roll the unit into position, mount the unit

on field--supplied rails placed lengthwise under the unit

using a minimum of 3 rollers. Apply force to the rails, not the

unit. If the unit is to be skidded into position, place it on a

large pad and drag it by the pad. Do not apply any force to

the unit.

Raise from above to lift unit from the rails or pad when unit

is in final position.

After unit in position, remove all shipping materials and top

crating.

NOTE: Before mounting unit, remove holddown brackets

and release skid. If conditions or local c odes require unit to

be fastened to pad, use the mounting holes in the base

rails.

CAUTION

Clearances:

Locate unit so that outdoor coil (condenser) airflow is

unrestricted on all sides and above. See Figure 1 for unit

clearances, weight, and clearance data.

Unit Support:

The unit must be level, and supported above grade by

beams, platform or a pad. Platform or pad can be of open or

solid construction but should be of permanent materials

such as concrete, bricks, blocks, steel or pressure treated

timbers approved for ground contact. Refer to Unit

Clearances and weights to help determine size of supports

etc. Soil conditions should be considered so the platform or

pad does not shift or settle excessively and leave the unit

only partially supported.

!

REDUCED EQUIPMENT LIFE HAZARD

Failure to follow these precautions could result in

damage to the unit being installed.

Inadequate support could cause excessive vibration

and noise or binding and stress on refrigerant lines

resulting in equipment failure.

To minimize vibration or noise transmission, it is

recommended that supports not be in contact with the

building structure. However, slabs on grade constructions with an extended pad are normally acceptable.

A. Ground Level Installation:

If beams or an open platform are used for support it is

recommended that the soil be treated or area be graveled

to retard the growth of grasses and weeds.

B. Roof Top Installation:

This type of installation is not recommended on wood

frame structures where low noise levels are required.

Supporting structure or platform for the unit must be level. If

installation is on a flat roof the unit should be 4 inches

(10cm.) above roof level. Four by four posts placed over a

load bearing wall make a suitable mounting platform.

If possible, place the unit over one or more load bearing

walls. If there are several units, mount them on platforms

that are self--supporting and span load bearing walls.

These suggestions are to minimize noise and vibration

transmission through the structure.

CAUTION

4

Split System Heat Pumps Installation Instructions

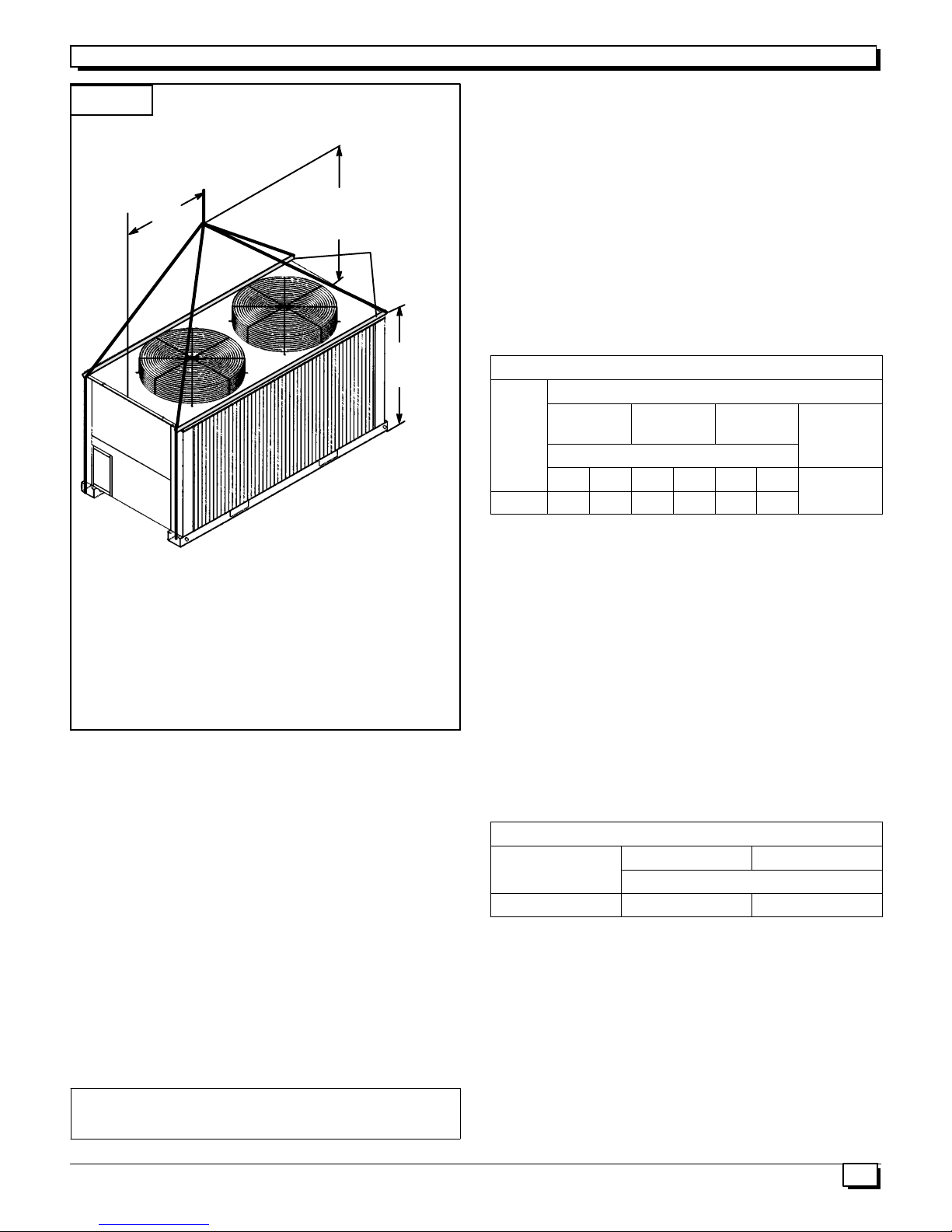

Figure 2

NOTICE TO RIGGERS

All Panels Must Be In Place When

Rigging

3’ 7”

1092mm

10’ 0”

3048mm

Spreader

Bars

10’ 0”

3048mm

NOTICE TO RIGGERS: Rig by inseting hooks into unit

base rails as shown. Maintain a distance of 120 inches (3048mm) from top of unit to eyehook. Use corner

post or top board from packaging to protect coil of unit

from damage by rigging cable. Use bumper boards for

spreader bars.

CHECK VERTICAL SEPARATION -- If there is any vertical

separation between the indoor and outdoor units, check to

ensure that the separation is within allowable limits.

Relocate equipment if necessary. See Table 2.

SIZE REFRIGERANT LINES -- Consider the length of the

piping required between the outdoor and indoor units. The

maximum allowable line length is 100 ft (30.5 m). See Table

1. Refrigerant suction piping should be insulated.

Carefully evaluate any vapor risers at minimum load

conditions to ensure proper compressor oil return. If the

indoor unit is above the outdoor unit, the riser will function

as a hot gas riser. If the outdoor unit is above the indoor

unit, the riser is a suction riser. Use a reduced diameter

riser design and construct a double riser if necessary.

Table 1 - Refrigerant Piping Sizes

Linear Length of Interconnecting Piping -- Ft. (mm)

0--25

(0 -- 7.5)

Unit

CHS180 5/8 1--5/8 3/4 1--5/8 3/4 1--5/8

L S L S L S 3/4

25 -- 60

(7.5 -- 18)

Line Size (in. OD)

61 -- 100

(18.3 -- 30 )

Maximum

Liquid Line

LEGEND

L -- Liquid Line, S -- Suction Line

*Maximum length of interconnecting pipe is 100 ft (30.5 m).

NOTES:

1. Pipe sizes are based on a 2° F(1° C) loss for liquid

and suction lines.

2. Pipe sizes are based on the maximum linear length,

shown for each column, plus a 50% allowance for

fittings.

Installing Refrigerant Lines

Complete Refrigerant Piping

Connections

Refrigerant lines must be carefully designed and

constructed to ensure equipment reliability and efficiency.

Line length, pressure drop, compressor oil return, and

vertical separation are several of the design criteria that

must be evaluated. See Table 1.

IMPORTANT: Piping must be properly sized and

installed for the system to operate efficiently.

3. Charge units with R--22 in accordance with unit

installation instructions.

4. Maximum line length must not exceed 100 ft

(30.5 m).

Table 2 - Max. Vertical Separation Between Indoor & Outdoor Units

Unit Evap. Distance ft (m)

Unit

CHS180 BHC180 80 (24.4)

Above Unit Evap.

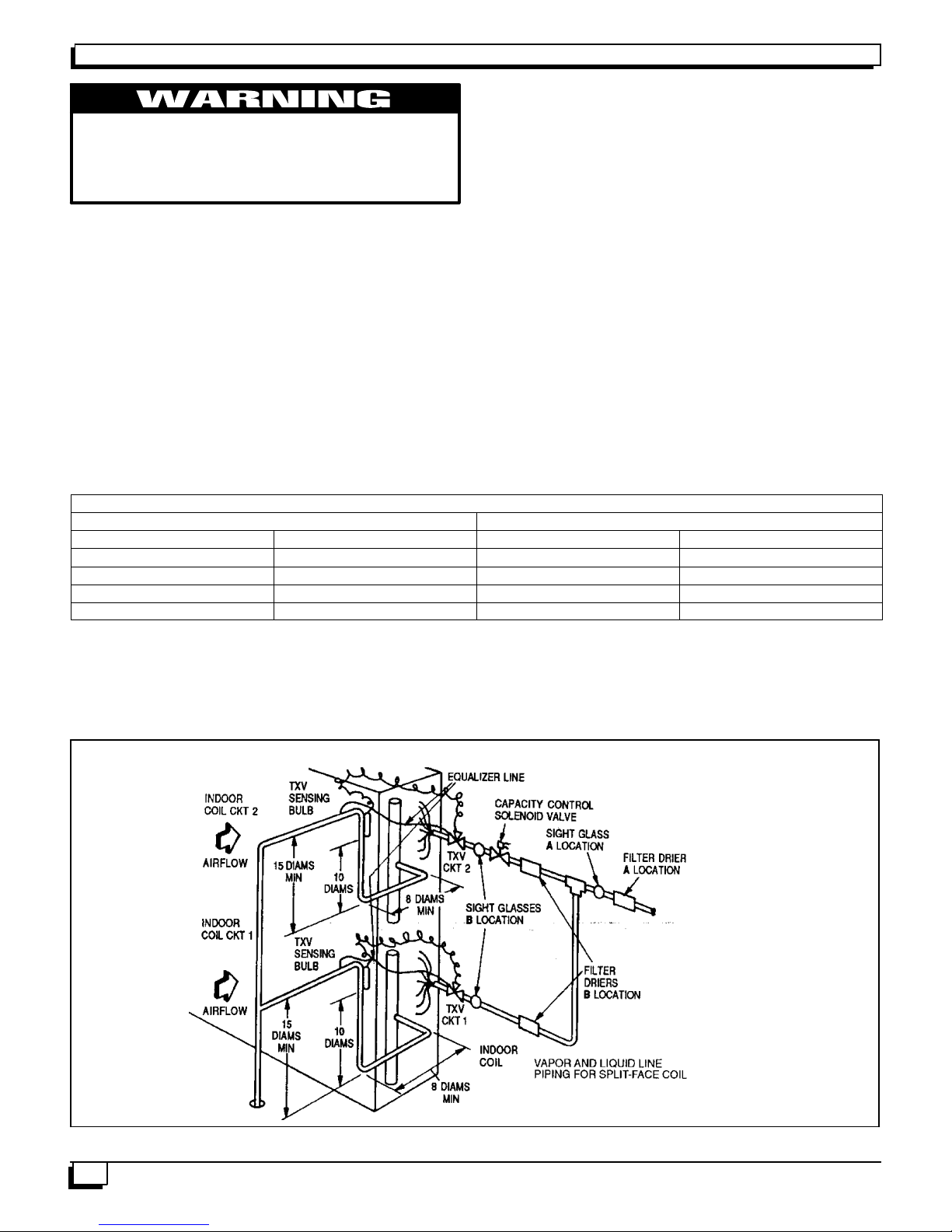

INSTALL FILTER DRIER(S) AND MOISTURE

INDICATOR(S) -- Every unit should have a filter drier and

liquid--moisture indicator (sight glass). In some

applications, depending on space and convenience

requirements, it may be desirable to install 2 filter driers

and sight glasses. One filter drier and sight glass may be

installed at A locations in Fig. 3. Or, 2 filter driers and sight

glasses may be installed at B locations.

Select the filter drier for maximum unit capacity and

minimum pressure drop. Complete the refrigerant piping

from indoor unit to outdoor unit before opening the liquid

and suction lines at the outdoor unit.

5

Split System Heat PumpsInstallation Instructions

WARNING

Recover R--22 holding charge before removing

runaround liquid piping loop. Failure to recover

holding charge before removing piping loop

could result in equipment damage and severe

injury.

MAKE PIPING CONNECTIONS

1. Open service valves in sequence:

a. Discharge service valve on compressor.

b. Suction service valve on compressor.

c. Liquid line valve.

2. Remove 1/4 --in. flare cap from liquid valve Schrader

port.

3. Attach refrigerant recovery device and recover

holding charge.

4. Remove runaround loop.

Table 3 -- Insulation for Vapor Line Exposed to Outdoor Conditions

Length of Exposed Vapor Line* Insulation Thickness

feet meter inches mm

10 3 3/8 10

25 8 1/2 13

35 11 3/4 19

50 15 3/4 19

5. Connect system liquid line from liquid connection of

outdoor unit(CHS) to indoor unit liquid line

connections. Select proper field-- supplied bi--flow

filter driers and install in the liquid line. See Fig. 2.

Install a field--supplied liquid moisture indicator

between the filter drier(s) and the liquid c onnections

on the indoor unit. Braze or silver alloy solder all

connections.

Pass nitrogen or other inert gas through piping while

making connections to prevent formation of copper oxide.

(Copper oxides are extremely active under high

temperature and pressure. Failure to prevent collection of

copper oxides may result in system component failures.)

VAPOR LINE PIPING PROCEDURE -- Connect system

vapor line to the vapor line stub on the outdoor unit and the

vapor stubs on the indoor unit. At the indoor unit, construct

vapor piping branches as shown in Fig. 3 for good mixing of

the refrigerant leaving the indoor coil during cooling. This

will ensure proper TXV (thermostatic expansion valve)

bulb sensing. Where vapor line is exposed to outdoor air,

line must be insulated. See Table 3 for insulation

requirements.

*Recommended vapor line insulation for piping exposed to outdoor conditions to prevent loss of heating during heating

cycle. When vapor line goes through interior spaces, insulation should be selected to prevent condensation on cooling

cycle. Heating capacity should be reduced 1000 Btuh (295 W) if over 35 ft (11m) of vapor line with 3/4 in. (19 mm) insulation

is exposed to outdoor conditions.

+Closed cell foam insulation with a thermal conductivity of: 0.28 Btu • in./ft 2 • h •°F (0.04W/m •°C).

Fig. 3 — Location of Sight Glass(es) and Filter Driers (Typical)

6

LEGEND

TXV -- Thermostatic Expansion Valve

Loading...

Loading...