ICP PAF060K000A, PAF048K000A, PAF042K000A, PAF036K000A, PAF030K000A Owner’s Manual

...

Installation

Instructions

• Safety Labeling and Rules

• Installation Requirements

• Location/Clearances

• Air Distribution

• Wiring

• Ductwork Connections

• Start-Up

• Operation

• Maintenance

• Inspection

• Hoisting/Rigging

3 thru 7-1/2 Ton

Belt Drive Models

Electric Cool & Heat

Printed in U.S.A. 513 01 1302 00 10/23/01

I Installation Instructions Combination Units I

1. Safety Labeling And Signal Words

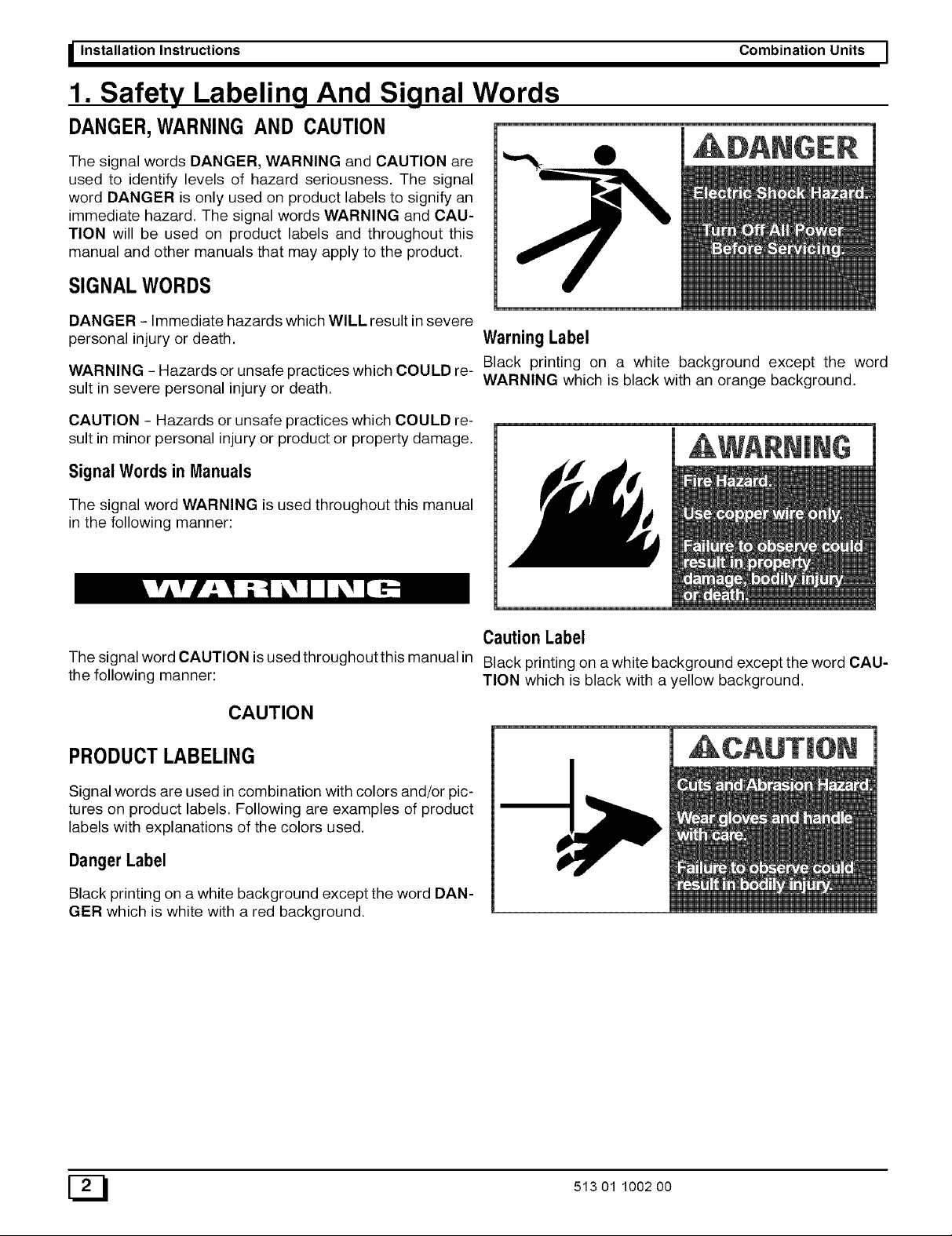

DANGER,WARNING AND CAUTION

The signal words DANGER, WARNING and CAUTION are

used to identify levels of hazard seriousness. The signal

word DANGER is only used on product labels to signify an

immediate hazard. The signal words WARNING and CAU-

TION will be used on product labels and throughout this

manual and other manuals that may apply to the product.

SIGNALWORDS

DANGER - Immediate hazards which WILL result in severe

personal injury or death.

WARNING - Hazards or unsafe practices which COULD re-

sult in severe personal injury or death.

CAUTION - Hazards or unsafe practices which COULD re-

sult in minor personal injury or product or property damage.

Signal Wordsin Manuals

The signal word WARNING is used throughout this manual

in the following manner:

Warning Label

Black printing on a white background except the word

WARNING which is black with an orange background.

Caution Label

The signal word CAUTION is used throughoutthis manual in Black printing on awhite background except the word CAU-

the following manner: TION which is black with a yellow background.

CAUTION

PRODUCTLABELING

Signal words are used incombination with colors and/or pic-

tures on product labels. Following are examples of product

labels with explanations of the colors used.

DangerLabel

Black printing on a white background except the word DAN-

GER which is white with a red background.

E_ 513 01 1002 O0

I Combination Units Installation Instructions I

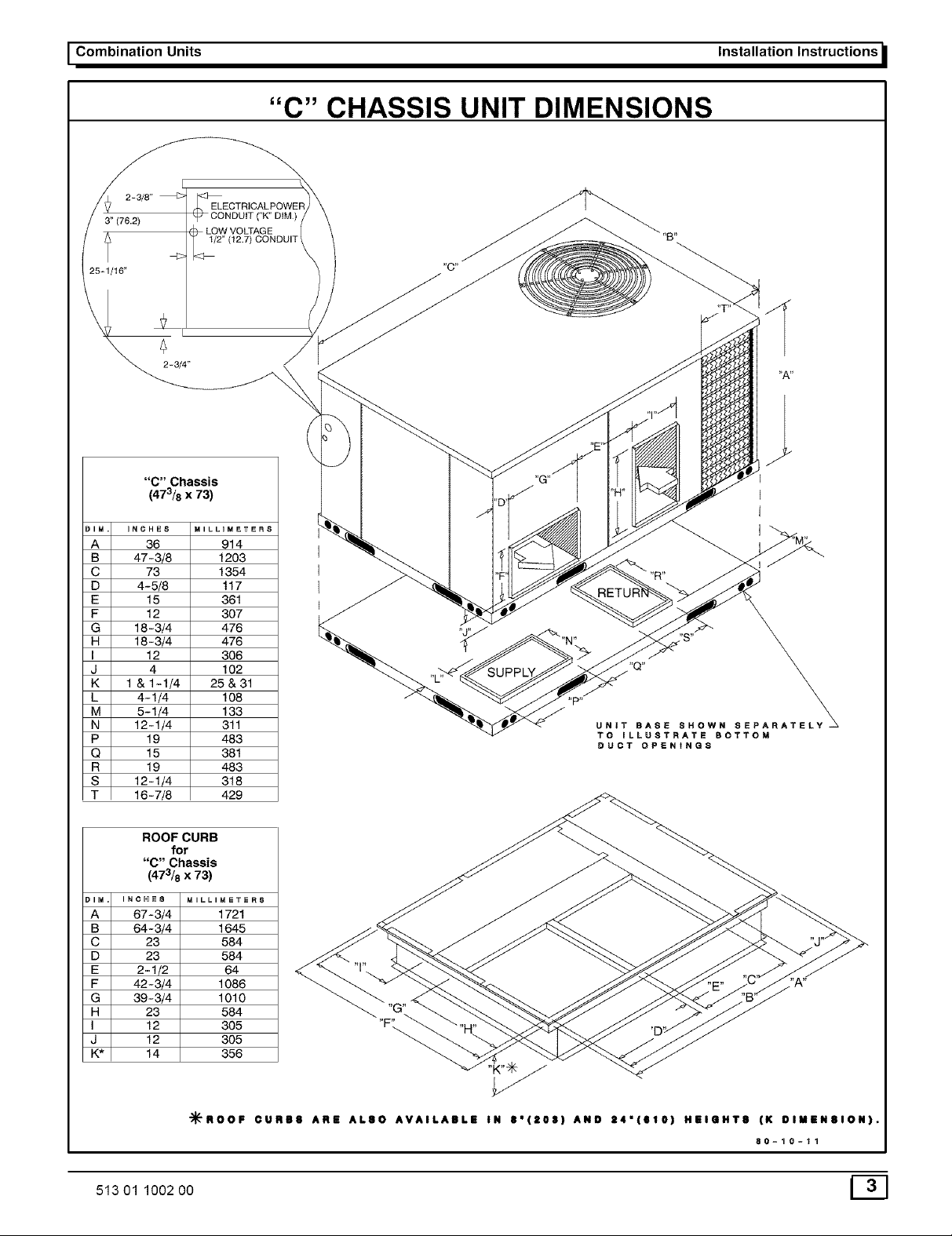

"C" CHASSIS UNIT DIMENSIONS

2-3/8"

3" (76.2)

"C" Chassis

) LOW VOLTAGE

(473/8 x 73)

1/2" (12.7) CONDUIT

"C"

DIM= ONCH_8 MILLOMETERS

A 36 914

B 47-3/8 1203

C 73 1354

D 4-5/8 t17

E 15 36t

F 12 307

G 18- 3/4 476

H 18- 3/4 476

I 12 306

J 4 102

K 1&1-1/4 25&31

L 4-1/4 108

M 5-1/4 133

N 12-1/4 311

P 19 483

Q 15 38t

R 19 483

S 12-1/4 318

T 16 - 7/8 429

ROOF CURB

for

"C" Chassis

(473/8 x 73)

DIM. INCH'8 MILLIMETER8

A 67-3/4 172t

B 64-3/4 1645

C 23 584

D 23 584

E 2-t/2 64

F 42-3/4 1086

G 39-3/4 1010

H 23 584

I 12 305

J 12 305

K* 14 356

UNIT BASE SHOWN SEPARAT

TO ILLUSTRATE BOTTOM

DUCT OPENINGS

513 01 1002 00

_)_ROOF OURB8 ARE AL80 AVAILABLE IN I'(105) AND E4"(elo) HEIGHT8 (K DIMEN81ON).

80-10-11

_ Installation Instructions

Combination Units I

2. Safe Installation Requirements

Installation or repairs made by unqualified per-

sons can result in hazards to you and others.

Installation MUST conform with local building

codes or, in the absence of local codes, with the

National Electrical Code NFPA70-1990 or in Can-

ada the CSA C.22.1 - Canadian Electrical Code

Part 1.

The information contained in this manual is in-

tended for use by a qualified service technician

familiar with safety procedures and equipped

with the proper tools and test instruments.

Failure to carefully read and follow all instruc-

tions inthis manual can result in furnace malfunc-

tion, property damage, personal injury and/or

death.

NOTE: It is the personal responsibility and obligation of the

customer to contact a qualified installer to ensure that the

installation is adequate and conforms to governing codes

and ordinances.

3. Locating the Unit

The unit is designed for outdoor installation only. The unit

may be installed on a concrete mounting base at ground lev-

el, or on a rooftop with an adequate platform or if using as a

downflow model, with a roof curb.

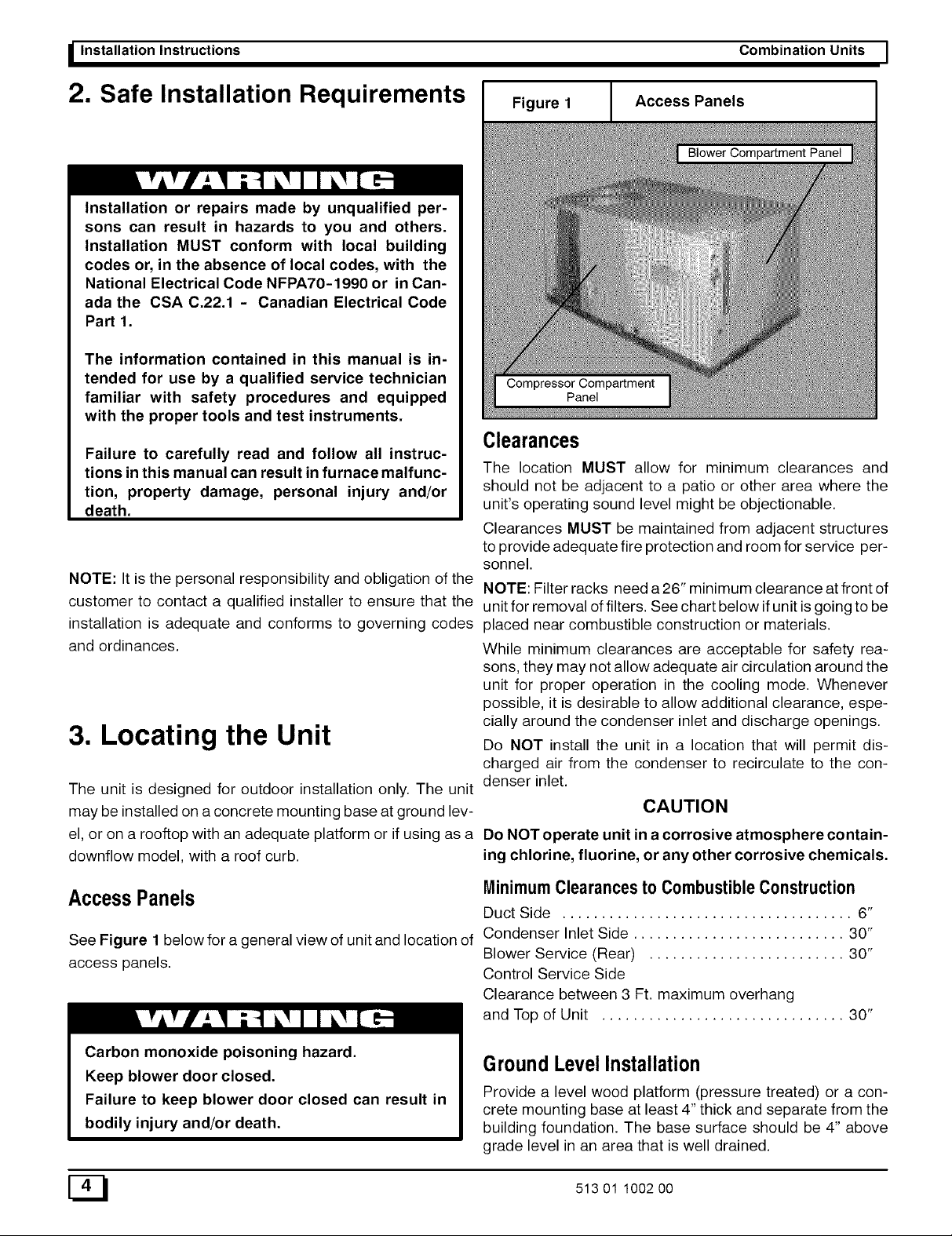

Figure 1

Access Panels

Clearances

The location MUST allow for minimum clearances and

should not be adjacent to a patio or other area where the

unit's operating sound level might be objectionable.

Clearances MUST be maintained from adjacent structures

to provide adequate fire protection and room for service per-

sonnel.

NOTE: Filter racks need a 26" minimum clearance at front of

unit for removal offilters. See chart below if unit isgoing to be

placed near combustible construction or materials.

While minimum clearances are acceptable for safety rea-

sons, they may not allow adequate air circulation around the

unit for proper operation in the cooling mode. Whenever

possible, it is desirable to allow additional clearance, espe-

cially around the condenser inlet and discharge openings.

Do NOT install the unit in a location that will permit dis-

charged air from the condenser to recirculate to the con-

denser inlet.

CAUTION

Do NOT operate unit in a corrosive atmosphere contain-

ing chlorine, fluorine, or any other corrosive chemicals.

AccessPanels

See Figure 1 below for a general view of unit and location of

access panels.

Carbon monoxide poisoning hazard.

Keep blower door closed.

Failure to keep blower door closed can result in

bodily injury and/or death.

E_ 513 01 1002 O0

MinimumClearances to CombustibleConstruction

Duct Side ..................................... 6"

Condenser Inlet Side ........................... 30"

Blower Service (Rear) ......................... 30"

Control Service Side

Clearance between 3 Ft. maximum overhang

and Top of Unit ............................... 30"

Ground LevelInstallation

Provide a level wood platform (pressure treated) or a con-

crete mounting base at least 4" thick and separate from the

building foundation. The base surface should be 4" above

grade level in an area that is well drained.

I Combination Units

Installation Instructions

CAUTION

Unit will NOT operate properly unless it is installed level

front to rear and side to side.

RooftopInstallation

The existing roof structure MUST be adequate to support the

weight of the unit or the roof MUST be reinforced. Check the

weight of the unit in relation to the roof structure and local

building codes or ordinances and reinforce if necessary.

The unit MUST besituated to provide safe access for servic-

ing. Support for the unit MUST be level and may consist of a

platform or a combination of platform and roof beams or

curb. The platform may be constructed of combustible mate-

rial (wood only), or covered with Class A, B or C roof cover-

ing.

Hoisting

The unit should be hoisted with two lifting slings. Attach the

slings to rigging shackles that have been hooked through

holes in the base rail.

Place a short piece of 2x4 between unit and sling near the

top edge to protect unit from damage. Two spreader bars

MUST be used to keep slings from possibly crushing the

sheet metal or damaging the unit. Make sure equipment is

adequate for weight of unit, and that slings will not allow unit

to shift. Refer to Figure 18, last page of these instructions for

illustrated rigging instructions.

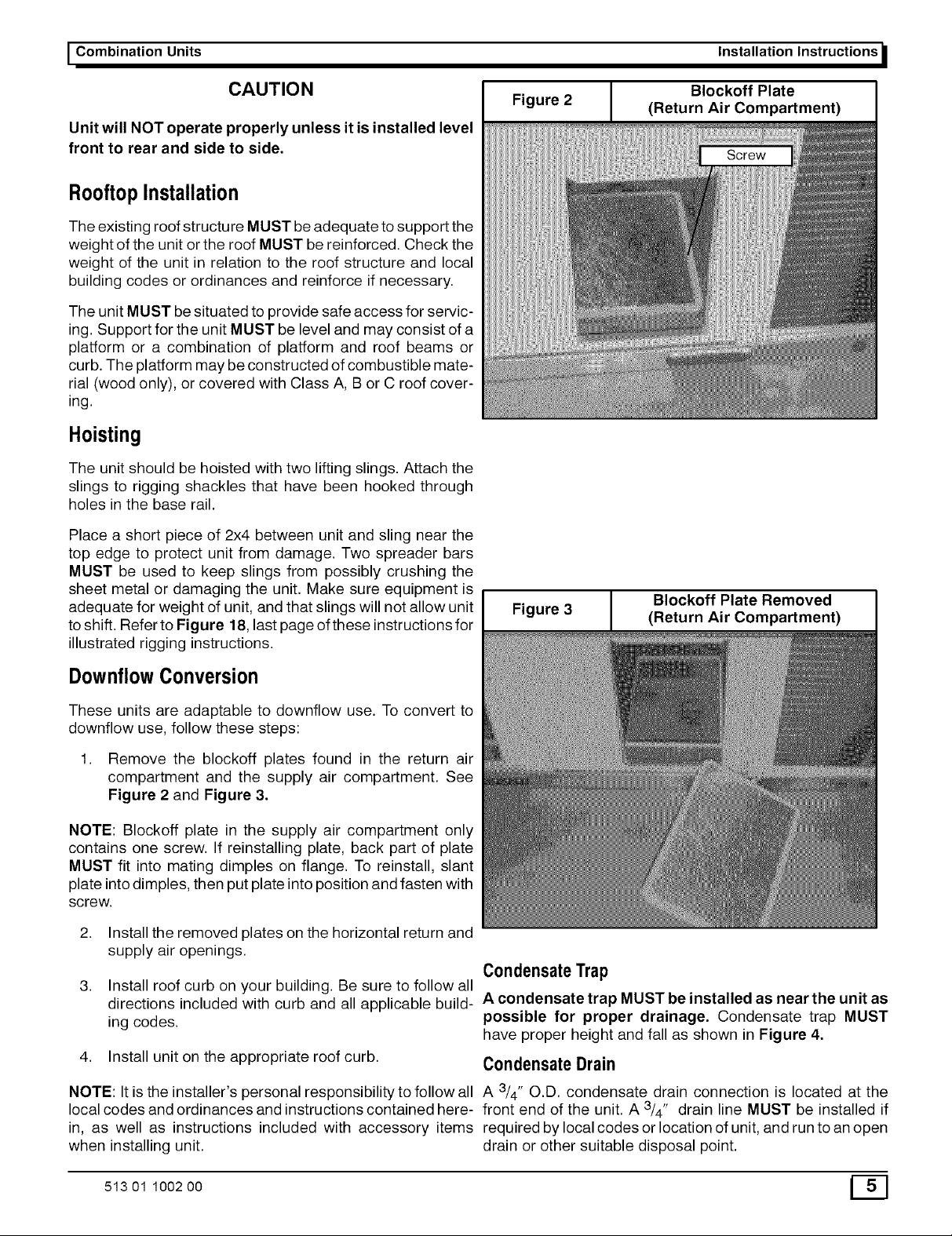

Figure 2

I Figure 3

Blockoff Plate

(Return Air Compartment)

Screw

Blockoff Plate Removed

(Return Air Compartment)

DownflowConversion

These units are adaptable to downflow use. To convert to

downflow use, follow these steps:

1. Remove the blockoff plates found in the return air

compartment and the supply air compartment. See

Figure 2 and Figure 3.

NOTE: Blockoff plate in the supply air compartment only

contains one screw. If reinstalling plate, back part of plate

MUST fit into mating dimples on flange. To reinstall, slant

plate into dimples, then put plate into position and fasten with

screw.

2. Install the removed plates on the horizontal return and

supply air openings.

3. Install roof curb on your building. Be sure to follow all

directions included with curb and all applicable build- A condensate trap MUST be installed as near the unit as

ing codes, possible for proper drainage. Condensate trap MUST

4. Install unit on the appropriate roof curb. Condensate Drain

NOTE: It is the installer's personal responsibility to follow all A 3/4" O.D. condensate drain connection is located at the

local codes and ordinances and instructions contained here- front end of the unit. A 3/4" drain line MUST be installed if

in, as well as instructions included with accessory items required by local codes or location of unit, and run to an open

when installing unit. drain or other suitable disposal point.

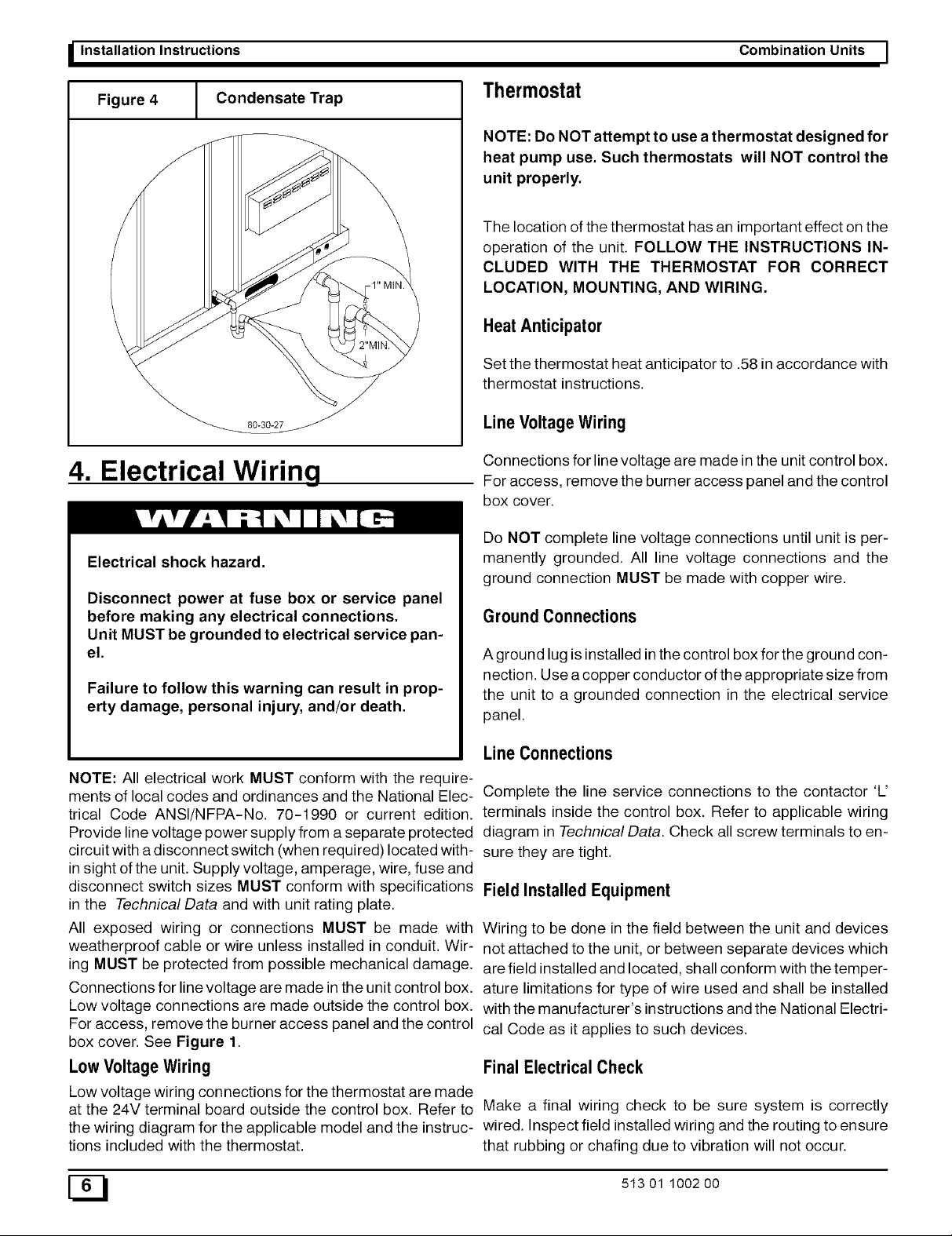

CondensateTrap

have proper height and fall as shown in Figure 4.

513 01 1002 00 E_]

I Installation Instructions

Combination Units I

Figure 4 Condensate Trap

80-30-27

4. Electrical Wiring

Electrical shock hazard.

Disconnect power at fuse box or service panel

before making any electrical connections.

Unit MUST be grounded to electrical service pan-

el.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

Thermostat

NOTE: Do NOT attempt to use a thermostat designed for

heat pump use. Such thermostats will NOT control the

unit properly.

The location of the thermostat has an important effect on the

operation of the unit. FOLLOW THE INSTRUCTIONS IN-

CLUDED WITH THE THERMOSTAT FOR CORRECT

LOCATION, MOUNTING, AND WIRING.

HeatAnticipator

Set the thermostat heat anticipator to .58 in accordance with

thermostat instructions.

LineVoltageWiring

Connections for line voltage are made in the unit control box.

For access, remove the burner access panel and the control

box cover.

Do NOT complete line voltage connections until unit is per-

manently grounded. All line voltage connections and the

ground connection MUST be made with copper wire.

GroundConnections

A ground lug is installed in the control box for the ground con-

nection. Use a copper conductor of the appropriate size from

the unit to a grounded connection in the electrical service

panel.

Line Connections

NOTE: All electrical work MUST conform with the require-

ments of local codes and ordinances and the National Elec-

trical Code ANSI/NFPA-No. 70-1990 or current edition.

Provide line voltage power supply from a separate protected

circuit with a disconnect switch (when required) located with-

in sight of the unit. Supply voltage, amperage, wire, fuse and

disconnect switch sizes MUST conform with specifications

in the Technical Data and with unit rating plate.

All exposed wiring or connections MUST be made with

weatherproof cable or wire unless installed in conduit. Wir-

ing MUST be protected from possible mechanical damage.

Connections for line voltage are made inthe unit control box.

Low voltage connections are made outside the control box.

For access, remove the burner access panel and the control

box cover. See Figure 1.

LowVoltage Wiring

Low voltage wiring connections for the thermostat are made

at the 24V terminal board outside the control box. Refer to

the wiring diagram for the applicable model and the instruc-

tions included with the thermostat.

E_ 513 01 1002 00

Complete the line service connections to the contactor 'L'

terminals inside the control box. Refer to applicable wiring

diagram in Technical Data. Check all screw terminals to en-

sure they are tight.

FieldInstalled Equipment

Wiring to be done in the field between the unit and devices

not attached to the unit, or between separate devices which

are field installed and located, shall conform with the temper-

ature limitations for type of wire used and shall be installed

with the manufacturer's instructions and the National Electri-

cal Code as it applies to such devices.

FinalElectrical Check

Make a final wiring check to be sure system is correctly

wired. Inspect field installed wiring and the routing to ensure

that rubbing or chafing due to vibration will not occur.

I Combination Units Installation Instructions

5. Air Distribution System

Ductwork

NOTE: The total heat loss from the structure as expressed in

total Btu/hr(Kw) MUST be calculated by manufacturer's

method or in accordance with "A.S.H.R.A.E. Guide" or

"Manual N - Load Calculations" published by the Air Condi-

tioning Contractors ofAmerica or in Canada H.R.A.I. "Manu-

al N". The total heat loss calculated should be equal to or

less than the unit heating capacity, output based on D.O.E.

test procedures, steady state efficiency times input.

Ductwork, supply registers, and return air grilles MUST be

designed and sized to handle the greater of the units heating

or cooling airvolume requirements. If the unit isconnected to

an existing system, the ductwork MUST be checked to make

sure it is adequate. Extra runs or larger duct sizes may have

to be installed. Use only non-combustible type insula-

tion on supply plenum or supply ductwork within 6

feet(2m) of unit,

Maximum recommended velocity in supply trunk ducts is

1000 feet (305m) per minute and 800 feet (244m) per minute

in return trunk ducts. Velocity in branches should not exceed

800 feet (244m) per minute supply and 600 feet (183m) per

minute in the return.

Ductwork installed outdoors should have a minimum of 2"

(50.8mm) of fiberglass insulation and a weatherproof vapor

barrier. It should also be protected against damage. Caulk

and flashing, or other means adequate to provide a perma-

nent weather seal should be used.

Ductwork installed in attics or other areas exposed to out-

side temperatures should be installed with a minimum of 2"

(50.8mm) fiberglass insulation and have an indoor type va-

por barrier.

The use of flexible, non-combustible connectors between

main trunk ducts and supply and return air plenums is rec-

ommended to minimize vibration transmission.

NOTE: Connect supply and return air plenums to unit in a

manner that will allow the top of the unit to be removed with-

out removing plenums. Plenums MUST be individually

sealed to unit casing.

Filters

Circulating Blower

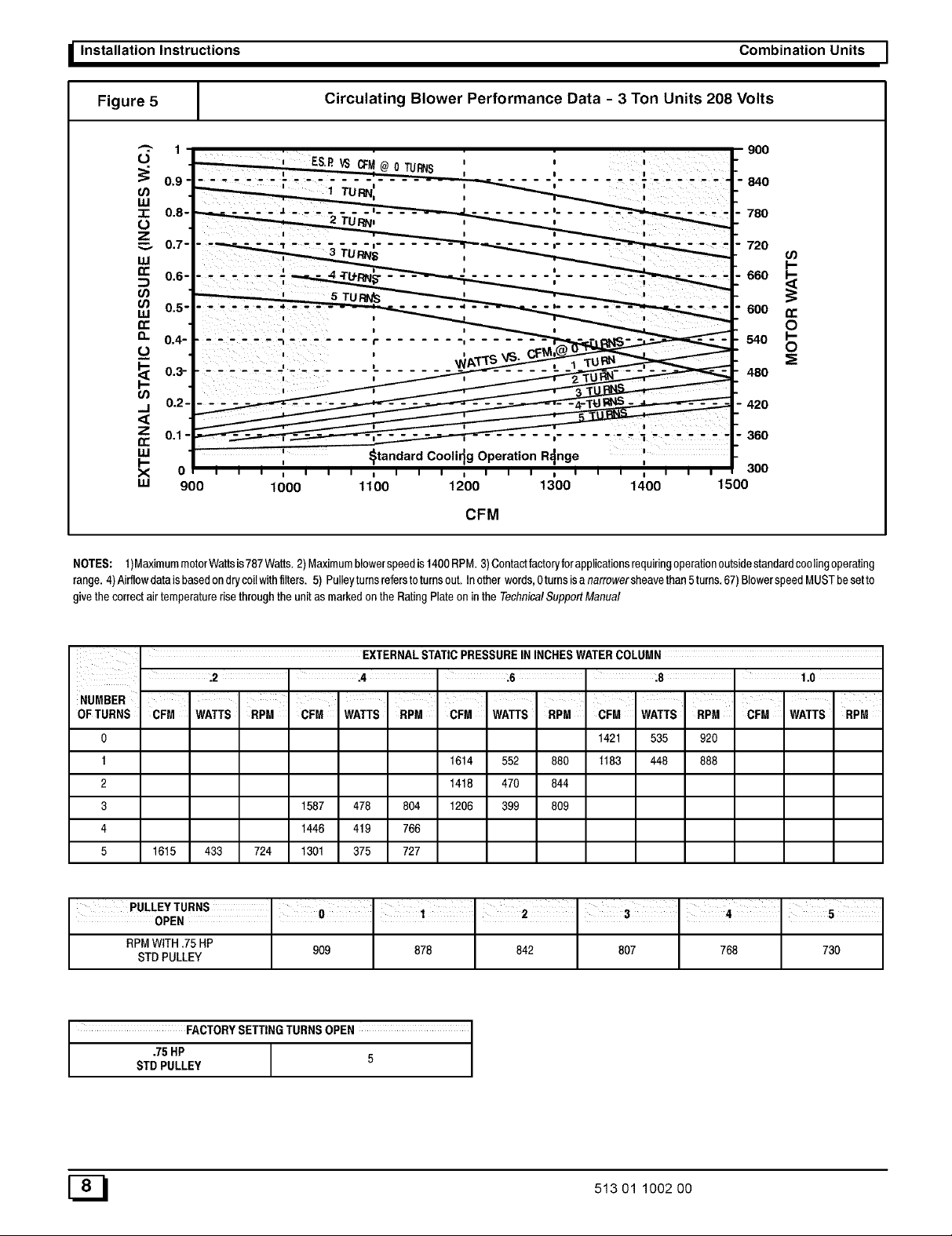

DeterminingPulleyTurns

1. From the system design, determine the external static

pressure (ESP) for the supply ducts, return ducts and

registers, diffusers, grilles, dampers, heaters and spe-

cial filters (if any).

2. If unit isto be set up in cooling mode, add .08" W.C. (20

Pa) for wet coil operation to the total ESP determined

in Step 1.

3. From the system design, determine the desired airflow

in CFM (L/s).

4. To determine the pulley turns necessary to obtain the

desired CFM (L/s), go to the Circulating Blower Perfor-

mance Data graph for the unit.

CAUTION

Do NOT operate the unit without all filters in place.

All air MUST pass through a filter before entering the unit.

Electronic air cleaner, optional filter racks, or other accessi-

ble filter arrangements MUST be installed in the return air

ductwork.

NOTE: Ifthe unit has an economizer or any other type of out-

door air damper, disposable filters MUST be used in the in-

ternal filter racks.

For replacement filter sizes and instructions, see Air Filters.

513 01 1002 00 [_]

_ Installation Instructions Combination Units I

Figure 5 Circulating Blower Performance Data - 3 Ton Units 208 Volts

780

720

U)

1--

660

600 rr"

0

540 I--

0

=E

48O

420

360

300

1100 1200 1300 1400

CFM

1500

NOTES: 1)MaximummotorWattsis787Watts.2)Maximumblowerspeedist400RPM. 3)__ntactfact_ryf_rapp_icati_nsrequiring_perati_n_utsidesta_dardco__ing_perating

range.4)Airflowdata isbasedondrycoilwithfilters. 5) Puneyturnsreferstoturnsout.Inother words,0turnsisa narrowersheavethan5turns.67)BlowerspeedMUSTbesetto

givethe correctairtemperaturerise throughtheunit as markedonthe RatingPlateon inthe TechnicalSupportManual

EXTERNALSTATICPRESSUREIN INCHESWATERCOLUMN

. :2 -:4 -:6 -:8 - 1.0

NUMBER = I I , I _ I I I , I I

OFTURNS CFM WATTS RPM CFM WATTS RPM CFM WATTS RPM CFM WATTS RPM CFM WATTS RPM

0

t

2

3

4

5 1615 433 724

RPMWtTH.75 HP 909 878

STD PULLEY

1587 478 804

1446 419 766

1301 375 727

1614 552 880

1418 470 844

1206 399 809

842 807 768 730

1421 535 920

t183 448 888

I FACTORYSETTINGTURNSOPEN

.75HP

STD PULLEY 5

E_ 513 01 1002 O0

Loading...

Loading...