Page 1

These instructions must be read and understood completely before attempting installation.

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and

NOTE

The signal words DANGER, WARNING, CAU-

TION, and NOTE are used to identify levels of haz-

ard seriousness. The signal word DANGER is only

used on product labels to signify an immediate haz-

ard. The signal words WARNING, CAUTION, and

NOTE will be used on product labels and through-

out this manual and other manuals that may apply

to the product.

DANGER - Immediate hazards which will result in

severe personal injury or death.

WARNING - Hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which

may result in minor personal injury or product or

property damage.

NOTE - Used to highlight suggestions which will

result in enhanced installation, reliability, or opera-

tion.

Signal Words in Manuals

The signal word WARNING is used throughout this

manual in the following manner:

The signal word CAUTION is used throughout this

manual in the following manner:

Signal Words on Product Labeling

Signal words are used in combination with colors

and/or pictures on product labels.

TABLE OF CONTENTS

Introduction .................................... 2

Location ....................................... 2

Position Unit ................................... 4

Air Ducts ...................................... 5

Electrical Connections .......................... 5

Refrigerant Tubing .............................. 6

Refrigerant Metering Device ..................... 6

Condensate Drains ............................. 6

Schematic ..................................... 8

Sequence of Operation ......................... 10

Care and Maintenance ......................... 10

Parts ........................................ 11

DEATH, PERSONAL INJURY, AND/OR PROPERTY

DAMAGE HAZARD

Failure to carefully read and follow this warning

could result in equipment malfunction, property

damage, personal injury and/or death.

Installation or repairs made by unqualified per-

sons could result in equipment malfunction, prop-

erty damage, personal injury and/or death.

The information contained in this manual is in-

tended for use by a qualified service technician fa-

miliar with safety procedures and equipped with

the proper tools and test instruments.

Installation must conform with local building

codes and with the National Electrical Code

NFPA70 current edition.

Specifications are subject to change without notice 496 01 2100 02 June 2006

Page 2

I _:o_: .......l_I',l_ _!I_ .......

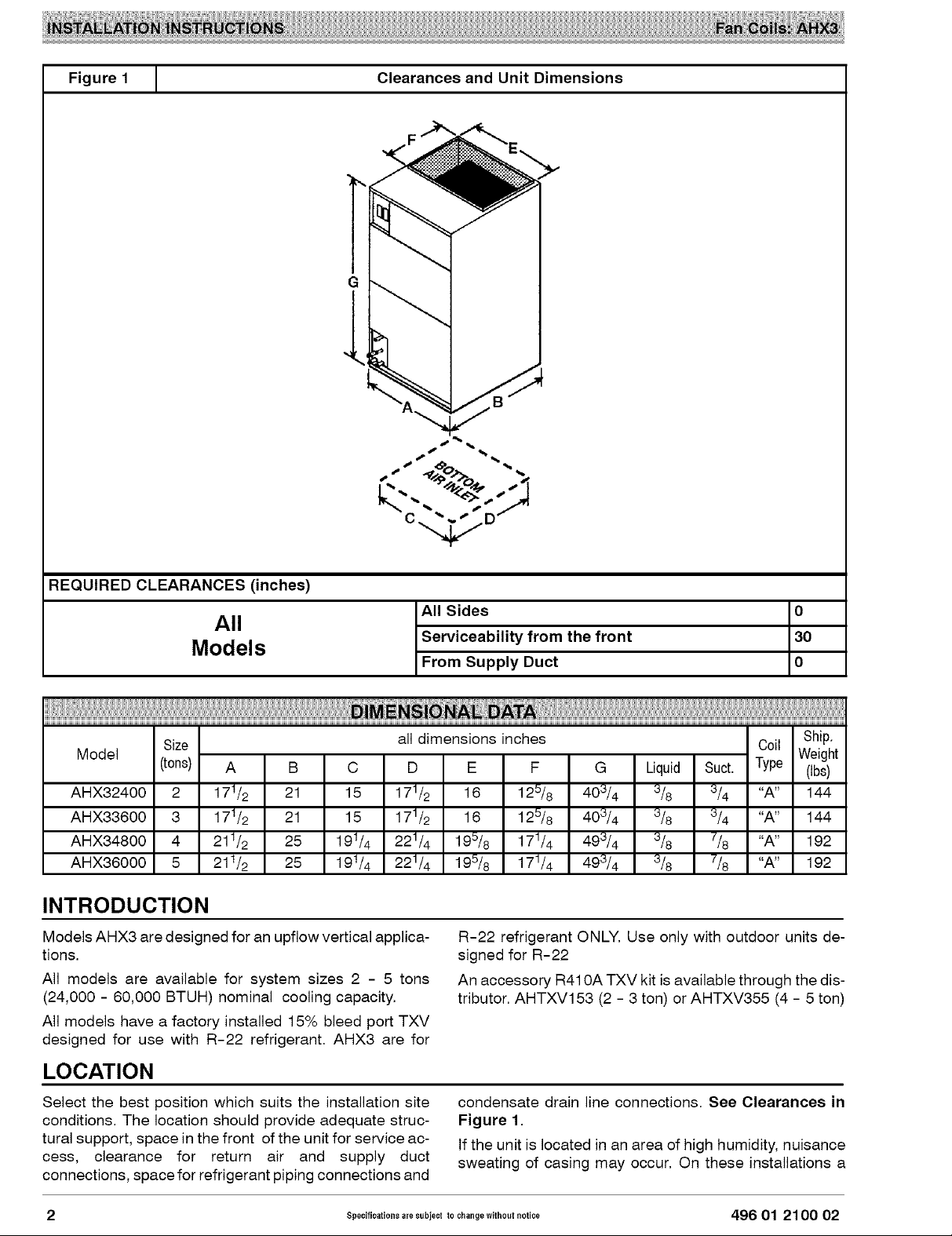

Figure 1 Clearances and Unit Dimensions

" X _ _w" / "

REQUIRED CLEARANCES (inches)

All Sides 0

All

Models Serviceability from the front 30

From Supply Duct 0

Size all dimensions inches Coil Ship.

Model (tons) A B C D E F G Liquid Suct. Type (tbs)

AHX32400 2 171/2 21 15 171/2 16 125/8 403/4 3/8 3/4 "A" 144

AHX33600 3 171/2 21 15 171/2 16 125/8 403/4 3/8 3/4 "A" 144

AHX34800 4 211/2 25 191/4 221/4 195/8 171/4 493/4 3/8 7/8 "A" 192

AHX36000 5 211/2 25 191/4 221/4 195/8 171/4 493/4 3/8 7/8 "A" 192

INTRODUCTION

Models AHX3 are designed for an upfiow vertical applica-

tions.

All models are available for system sizes 2 - 5 tons

(24,000 - 60,000 BTUH) nominal cooling capacity.

All models have a factory installed 15% bleed port TXV

designed for use with R-22 refrigerant. AHX3 are for

R-22 refrigerant ONLY. Use only with outdoor units de-

signed for R-22

An accessory R410A TXV kit is available through the dis-

tributor. AHTXV153 (2 - 3 ton) or AHTXV355 (4 - 5 ton)

Weight

LOCATION

Select the best position which suits the installation site

conditions. The location should provide adequate struc-

tural support, space in the front of the unit for service ac-

cess, clearance for return air and supply duct

connections, space for refrigerant piping connections and

2 Specifications are subject to changewithout notice 496 01 2100 02

condensate drain line connections. See Clearances in

Figure 1.

If the unit is located in an area of high humidity, nuisance

sweating of casing may occur. On these installations a

Page 3

wrap of 2" fiberglass insulation with a vapor barrier is rec-

ommended.

NOTE: Internal filter can be accessed from separate filter

door. If the filter can NOT be easily accessed, a remote

filter is recommended. Refer to ACCA Manual D for re-

mote filter sizing.

FIRE HAZARD

Failure to maintain proper clearances could result

in personal injury, death, and/or property damage.

When heaters are installed, maintain clearances

from combustible materials as specified on unit

rating plate. Do not use plastic lined or combus-

tible flexible ducting within 36 inches of the supply

end of the fan coil.

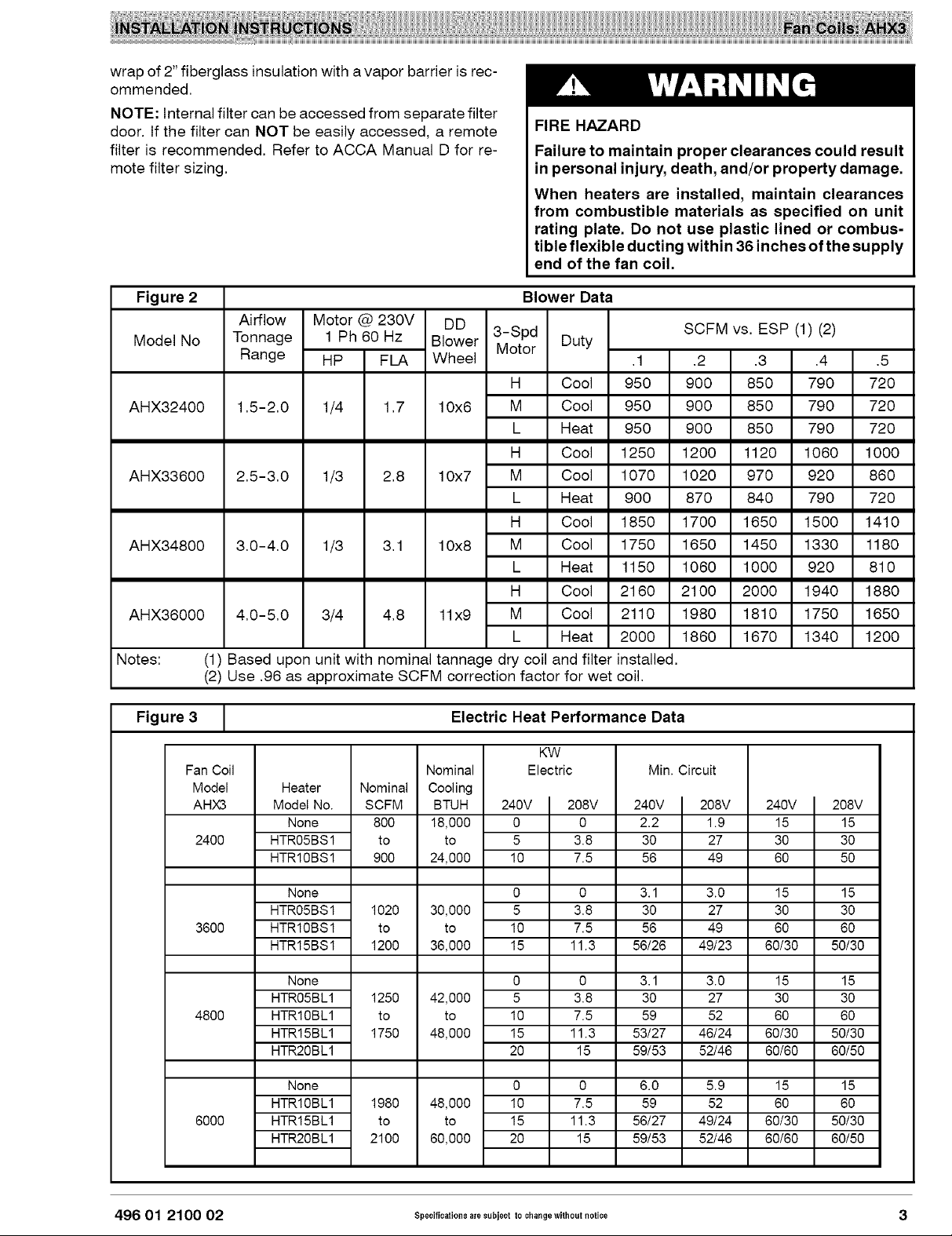

Figure 2

Airflow Motor @ 230V DD

Model No

Tonnage 1 Ph 60 Hz Blower 3-Spd

Range HP FLA Wheel

AHX32400 1.5-2.0 1/4 1.7 10x6

AHX33600 2.5-3.0 1/3 2.8 10x7

AHX34800 3.0-4.0 1/3 3.1 10x8

AHX36000

Notes:

4.0-5.0 3/4 4.8 11x9

(1) Based upon unit with nominal tannage dry coil and filter installed,

(2) Use ,96 as approximate SCFM correction factor for wet coil,

Figure 3 1

Fan Coil

Model

AHX3

2400

Heater

Model No.

None

HTR05BS 1

HTR10BS 1

Nominal

SCFM

800

900

Nominal

Cooling

18,000

to

24,000

Blower Data

Motor

H

M

L

H

M

L

H

M

L

H

M

L

Duty

,1 ,2 ,3 ,4 ,5

Cool 950 900 850 790 720

Cool 950 900 850 790 720

Heat 950 900 850 790 720

Cool 1250 1200 1120 1060 1000

Cool 1070 1020 970 920 860

Heat 900 870 840 790 720

Cool 1850 1700 1650 1500 1410

Cool 1750 1650 1450 1330 1180

Heat 1150 1060 1000 920 810

Cool 2160 2100 2000 1940 1880

Cool 2110 1980 1810 1750 1650

Heat 2000 1860 1670 1340 1200

Electric Heat Performance Data

KW

Electric

BTUH

to

240V 208V

0 0

5 3.8

10 7.5

240V 208V

SCFM vs, ESP (1) (2)

Min. Circuit

2.2 1.9

30 27

56 49

240V I

15

30

60

208V

15

30

50

3600

48OO

6000

None

HTR05BS1

HTR10BS1

HTR15BS1

None

HTR05BL1

HTR10BL1

HTR15BL1

HTR20BL1

None

HTR10BL1

HTR15BL1

HTR20BL1

1020

to

1200

1250

to

1750

1980

to

2100

30,000

to

36,000

42,000

to

48,000

48,000

to

60,000

0 0

5 3.8

10 7.5

15 11.3

0 0

5 3.8

10 7.5

15 11.3

20 15

0 0

10 7.5

15 11.3

20 15

3.1 3.0

30 27

56 49

56/26 49/23

3.1 3.0

30 27

59 52

53/27 46/24

59/53 52/46

6.0 5.9

59 52

56/27 49/24

59/53 52/46

15

30

60

60/30

15

30

60

60/30

60/60

15

60

60/30

60/60

15

30

60

50/30

15

30

60

50/30

60/50

15

60

50/30

60/50

496 01 2100 02 Specifications are subject to changewithout notice 3

Page 4

POSITION UNIT

Unit is designed to be installed in a closet or flush

mounted. Can be serviced entirely from the front, includ-

ing replacing the filter. Allow space for wiring, piping, and

servicing unit.

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in proper-

ty damage

A field fabricated auxiliary drain pan, with a sepa-

rate drain is REQUIRED for all installations over a

finished living space or in any area that may be

damaged by overflow from a restricted main drain

pan. In some localities, local codes require an aux-

iliary drain pan for ANY horizontal installation.

A. UPFLOW INSTALLATION

If return air isto be ducted through a floor, set unit on floor

over opening and use 1/8 to i/4 inch thick fireproof resil-

ient gasket between duct, unit, and floor.

Exterior surface may sweat when unit is installed in non-

conditioned space. Installer must provide protection such

as full size auxiliary drain pan on all units installed in non-

conditioned space to prevent damage from condensation

runoff. It is recommended that units be insulated with 1"

thick fiberglass with the vapor barrier on the outside.

B. HORIZONTAL APPLICATION

Units are shipped in right to left configuration. Horizontal

applications require a return air duct be attached to the

furnace inlet. The opposite end of the return air duct is at-

tached to a return air filter grill through the ceiling or wall.

For left to right applications:

1. Remove and set aside front panels.

2. Remove the coil support bracket (4 screws).

3. Remove horizontal drain pan retaining clip (1

screw).

4. Carefully remove coil assembly and bottom drain

pan.

5. Move Horizontal drain pan from left hand side of

coil to right.

6. Install modified coil assembly back into unit.

7. Reinstall coil support bracket and horizontal drain

pan retaining clip.

8. Determine drain holes being used and reposition

knockout caps.

9. Reinstall doors.

AIR DUCTS

Connect supply-air duct over the outside of %" flanges

provided on supply-air opening. Secure duct to flange us-

ing proper fasteners for type of duct used, and seal duct-

to-unit joint. If return-air flanges are required, install

factory authorized accessory kit.

Use flexible connectors between duct work and unit to

prevent transmission of vibration. Duct work passing

through unconditioned space must be insulated and cov-

ered with vapor barrier to prevent formation of conden-

sate to prevent formation of condensate.

ELECTRICAL CONNECTIONS

Refer to the unit's nameplate for specific electrical data.

Before proceeding with electrical connections, make cer-

tain that supply voltage, frequency, phase, and circuit am-

pacity are as specified on the unit rating plate. Make all

electrical connections in accordance with the NEC and

any local codes or ordinances that may apply. Use cop-

per wire rated for 75 degrees C minimum wire in the unit

wiring compartment only. A single power supply may be

connected directly to terminal block provided in the unit.

Duct work Acoustical Treatment

Metal duct systems that do not have a 90 degree elbow

and 10 feet of main duct before first branch takeoff may

require internal acoustical insulation lining. As an alterna-

tive, fibrous duct work may be used if constructed and

installed in accordance with the latest edition of SMACNA

construction standard on fibrous glass ducts. Both acous-

tical lining and fibrous duct work shall comply with Nation-

al Fire Protection Association as tested by UL Standard

181 for Class 1 air ducts.

ELECTRICAL SHOCK or UNIT DAMAGE HAZARD

Failure to follow this warning could result in per-

sonal injury, death, and/or unit damage.

Ifa disconnect switch is to be mounted on unit, se-

lect a location where drill and fasteners will not

contact electrical or refrigeration components.

4 Spe¢ificationsaresubiect to changewithout notice 496 01 2100 02

Page 5

Figure 4 L Transformer Connections

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in per-

sonal injury or death.

Turn off the main (remote) disconnect device be-

fore working on incoming (field) wiring.

Incoming (field) wires on the line side of the dis-

connect found in the fan coil unit remain live, even

when the pull-out is removed. Service and main-

tenance to incoming (field) wiring cannot be per-

formed until the main disconnect switch (remote

to the unit) is turned off.

A. LINE VOLTAGE CONNECTIONS

This Fan Coil is not electric heat compatable.

1. Connect 208/240V power leads from field discon-

nect to units high voltage terminal block.

2. Connect ground wire to unit ground lug.

B. 24V CONTROL SYSTEM

Connection to Unit

Wire low voltage in accordance with wiring label on the

unit. Use 18 AWG color-coded, insulated (35 degrees C

minimum) wire to make the low-voltage connections be-

tween the thermostat, the unit, and the outdoor equip-

ment. If the thermostat is located more than 100feet from

the unit (as measured along the low voltage wire), use 16

AWG color-coded, insulated (35 degrees C minimum)

wire. All wiring must be NEC Class 2 and must be sepa-

rated from incoming power leads. Refer to outdoor unit

wiring instructions for additional wiring recommenda-

tions.

NOTE: Before proceeding with electrical connections,

make certain that supply voltage, frequency, phase, and

circuit ampacity are as specified on the unit rating plate.

See unit wiring label for proper field high and low voltage

wiring. Make all electrical connections in accordance with

the NEC and any local codes or ordinances that may ap-

ply. Use copper wire only. The unit must have a separate

branch electric circuit with a field-supplied disconnect

switch located within sight from, and readily accessible

from the unit.

Transformer Information

Transformer is factory wired for 208/240V operation.

ll_m ==== m RED

_L_% 24VAC

BLA:CK

C. GROUND CONNECTIONS

ELECTRICALSHOCKHAZARD

Failure to establish uninterrupted or unbroken

ground could result in personal injury and/or

death.

According to NEC, ANSI/NFPA 70, and local

codes, the cabinet must have an uninterrupted or

unbroken ground in order to minimize potential

for personal injury or death if an electrical fault

should occur. The ground may consist of electri-

cal wire or metal conduit when installed in accor-

dance with existing electrical codes. If conduit

connection uses reducing washers, a separate

ground wire must be used.

NOTE: Use UL listed conduit and conduit connectors for

connecting supply wire(s) to unit to obtain proper ground-

ing. Grounding may also be accomplished by using

grounding lugs provided in control box.

D. MINIMUM CFM AND MOTOR SPEED SELECTION

Units require a minimum CFM. Refer to the unit wiring la-

bel to ensure that the fan speed selected is not lower than

the minimum fan speed indicated.

Fan speed selection is done at the fan relay. To change

motor speeds, disconnect fan lead used on relay terminal

(FR) and replace with motor speed lead desired (refer to

Figure 8). Save insulating cap and place on motor lead

removed from relay.

1

1_ANSFORME8

496 01 2100 02 Specifications are subiect to changewithout notice 5

Page 6

NOTE: In low static applications, lower motor speed tap

should be used to reduce possibility of water being blown

off coil.

All units have three (3) motor speed taps. Low speed (red

or 4) is designed for mismatch outdoor unit applications.

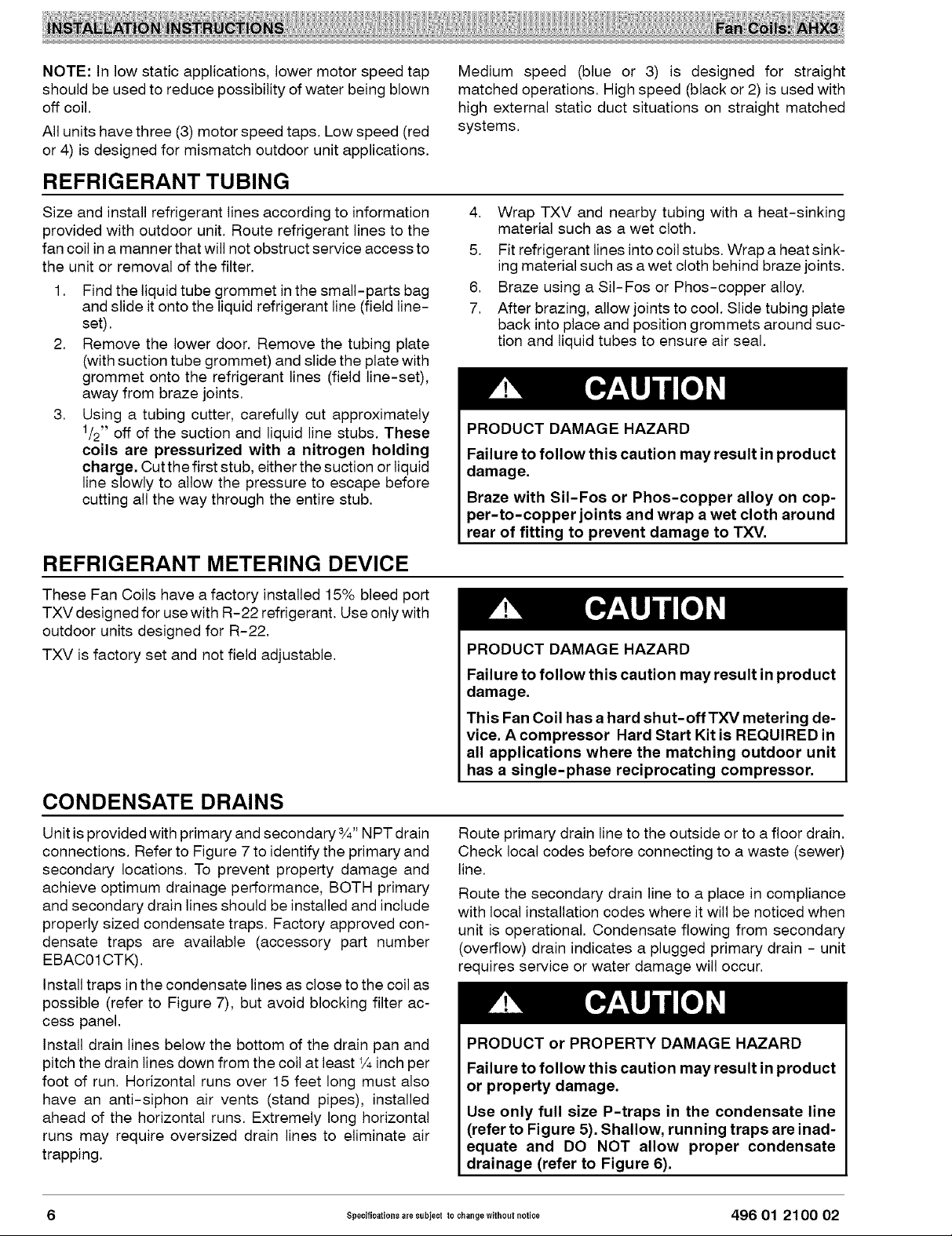

REFRIGERANT TUBING

Medium speed (blue or 3) is designed for straight

matched operations. High speed (black or 2) is used with

high external static duct situations on straight matched

systems.

Size and install refrigerant lines according to information

provided with outdoor unit. Route refrigerant lines to the

fan coil in a manner that will not obstruct service access to

the unit or removal of the filter.

1. Find the liquid tube grommet in the small-parts bag

and slide it onto the liquid refrigerant line (field line-

set).

2. Remove the lower door. Remove the tubing plate

(with suction tube grommet) and slide the plate with

grommet onto the refrigerant lines (field line-set),

away from braze joints.

3. Using a tubing cutter, carefully cut approximately

1/2" off of the suction and liquid line stubs. These

coils are pressurized with a nitrogen holding

charge, Cut the first stub, either the suction or liquid

line slowly to allow the pressure to escape before

cutting all the way through the entire stub.

REFRIGERANT METERING DEVICE

These Fan Coils have a factory installed 15% bleed port

TXV designed for use with R-22 refrigerant. Use only with

outdoor units designed for R-22.

TXV is factory set and not field adjustable.

4. Wrap TXV and nearby tubing with a heat-sinking

material such as a wet cloth.

5. Fit refrigerant lines into coil stubs. Wrap a heat sink-

ing material such as a wet cloth behind braze joints.

6. Braze using a SiI-Fos or Phos-copper alloy.

7. After brazing, allow joints to cool. Slide tubing plate

back into place and position grommets around suc-

tion and liquid tubes to ensure air seal.

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

Braze with SiI-Fos or Phos-copper alloy on cop-

per-to-copper joints and wrap a wet cloth around

rear of fitting to prevent damage to TXV.

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

This Fan Coil has a hard shut-off TXV metering de-

vice. A compressor Hard Start Kit is REQUIRED in

all applications where the matching outdoor unit

has a single-phase reciprocating compressor.

CONDENSATE DRAINS

Unit is provided with primary and secondary 3/4"NPT drain

connections. Refer to Figure 7 to identify the primary and

secondary locations. To prevent property damage and

achieve optimum drainage performance, BOTH primary

and secondary drain lines should be installed and include

properly sized condensate traps. Factory approved con-

densate traps are available (accessory part number

EBAC01 CTK).

Install traps in the condensate lines as close to the coil as

possible (refer to Figure 7), but avoid blocking filter ac-

cess panel.

Install drain lines below the bottom of the drain pan and

pitch the drain lines down from the coil at least ¼ inch per

foot of run. Horizontal runs over 15 feet long must also

have an anti-siphon air vents (stand pipes), installed

ahead of the horizontal runs. Extremely long horizontal

runs may require oversized drain lines to eliminate air

trapping.

6 Specificatio._a,esubiect to change without notice 496 01 2100 02

Route primary drain line to the outside or to a floor drain.

Check local codes before connecting to a waste (sewer)

line.

Route the secondary drain line to a place in compliance

with local installation codes where it will be noticed when

unit is operational. Condensate flowing from secondary

(overflow) drain indicates a plugged primary drain - unit

requires service or water damage will occur.

PRODUCT or PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in product

or property damage.

Use only full size P-traps in the condensate line

(refer to Figure 5). Shallow, running traps are inad-

equate and DO NOT allow proper condensate

drainage (refer to Figure 6).

Page 7

Prime all traps, test for leaks, and insulate drain lines

where sweating could cause water damage. Consult local

codes for additional requirements or precautions.

If a gravity drain cannot be used, install a condensate

pump. Install the pump as close to the indoor section as

possible.

Be sure to install plastic push-in plugs in unused conden-

sate drain holes.

PRODUCT DAMAGE HAZARD

Figure 6 [ Insufficient Condensate Trap

Failure to follow this caution may result in poor

unit performance and/or product damage.

Never operate unit without a filter. Factory autho-

rized filter kits must be used when locating the fil-

ter inside the unit. For those applications where

access to an internal filter is impractical, a field-

supplied filter must be installed in the return duct

system.

Figure 5

I Recommended Condensate Trap

2" MIN

DO NOT USE SHALLOW RUNNING TRAPS!

Figure 7

[

Condensate Drain

0

0

SECONDARY DRAIN WITH

APPROPIATE TRAP REQUIRED

(USE FACTORY KIT OR

FIELD - SUPPLIED TRAP)

PRIMARY TRAP REQUIRED (USE FACTORY KIT OR

FIELD - SUPPLIED TRAP OF PROPER DEPTH.

STANDARD P - TRAPS ARE NOT SUFFICENT. SEE

FIGURE OF RECOMMENDED CONDENSATE TRAP)

-FILTER

ACCESS

PANEL

496 01 21 O0 02 Specifications aresubject to change without notice 7

Page 8

I _:o_: .......I_NS _!I_ .......

Figure 8 1

Ii

o o

Wiring Layout - Cooling

i i

m

I

I

iiii|

I I

I I o

I

l|

I _ II' :o

8 Specificatiolls aresubiect to change without notice 496 01 21 O0 02

r

Page 9

Figure 9 1 Wiring Layout - Electric Heating

ii I__

I _ _

I I I --"_

I I I I

I

496 01 21 O0 02 S_ec]fic.tio._aresubiect to changewithoutnotice 9

........_L..!q_-_ -.io

_&__

Page 10

SEQUENCE OF OPERATION

A. CONTINUOUS FAN

Thermostat closes R to G.

G energizes Time Delay Relay (TDR).

Time Delay Relay (TDR) energizes Fan Relay (FR)

within 30 seconds.

When Fan Relay (FR) is energized, circuit is com-

plete to Indoor Blower Motor.

When G is de-energized, there is a 3 second delay

before Fan Relay (FR) opens.

B. COOLING MODE

Thermostat closes R to G, R to Y, and R to O (heat

pump only).

G energizes Time Delay Relay (TDR). Y energizes

Condense contactor, and O energizes the reversing

valve (heat pump only)

Time Delay Relay (TDR) energizes Fan Relay (FR)

within 30 seconds.

When Fan Relay (FR) is energized, circuit is com-

plete to Indoor Blower Motor.

When G is de-energized, there is a 3 second delay

before Fan Relay (FR) opens.

CARE AND MAINTENANCE

SAFETY SWITCHES

Unit is equipped with a limit switch for each sepa-

rate heating element.

These switches are normally closed and are set to

open at170 ° E

Blower continues running until unit has cooled

enough (below set point) for switches to automati-

cally reset.

C. HEATING MODE

Thermostat closes R to W and R to G.

W closes the Heat Sequencer(s) to switch line volt-

age from Terminals 1 and 4 to Terminals 3 and 5,

which energizes the Heating Elements.

G energizes the Time Delay Relay (TDR).

Time Delay Relay (TDR) energizes Fan Relay (FR)

within 30 seconds.

When Fan Relay (FR) is energized, circuit is com-

plete to Indoor Blower motor.

When G is de-energized there is a 3 second delay.

The system should be regularly inspected by a qualified

service technician. Consult the servicing dealer for rec-

ommended frequency.

Between visits, the only consumer service recommended

or required is air filter maintenance and condensate drain

operation.

Air Filter

Air handlers are factory equipped with an air filter. If the

return grille has its own filter, it is not recommended to

install a filter in the Air handler.

Inspect air filters at least monthly and replace or clean as

required. Disposable type filters should be replaced. Re-

usable type filters may be cleaned by soaking in mild de-

tergent and rinsing with cold water. Install filters with the

arrows on the side pointing in the direction of air flow.

Condensate Drain

During the cooling season check at least monthly for free

flow of drainage and clean if necessary.

10 Specification_a,esubiect to changewithout notice 496 01 2100 02

Page 11

AHX3 Series

NOTE: This illustration is for

reference only. Your unit may

differ in appearance or may not

include all components shown.

@

38- 11- 87a

496 01 21O0 02 Speciticatio_ls aresubject to change withoutnotice 11

Page 12

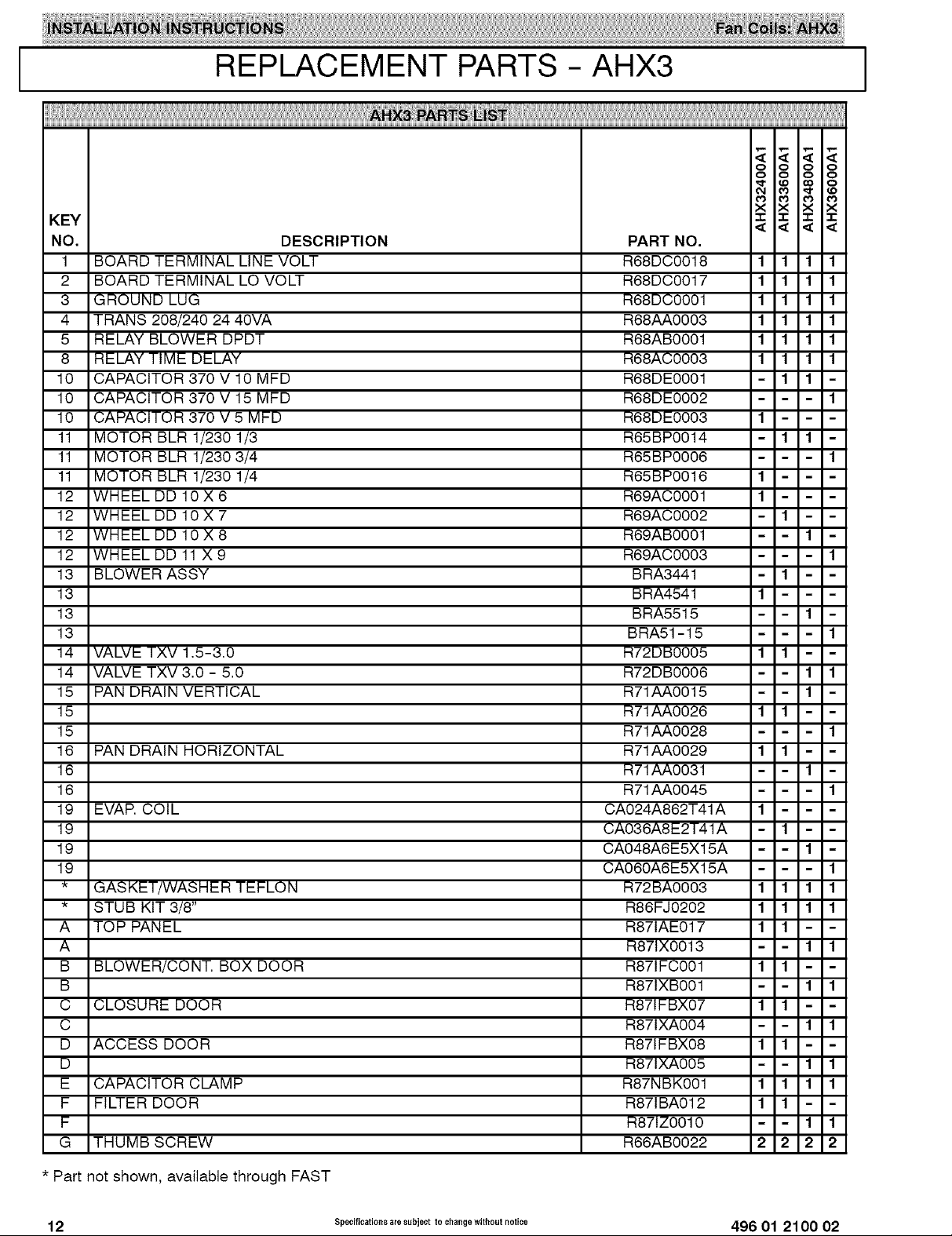

KEY

NO.

1

BOARD TERMINAL LINE VOLT

2

BOARD TERMINAL LO VOLT

3

GROUND LUG

4

TRANS 208/240 24 40VA

5

RELAY BLOWER DPDT

8

RELAY TIME DELAY

10

CAPACITOR 370 V 10 MFD

10

CAPACITOR 370 V 15 MFD

10

CAPACITOR 370 V 5 MFD

11

MOTOR BLR 1/230 1/3

11

MOTOR BLR 1/230 3/4

11

MOTOR BLR 1/230 1/4

12

WHEEL DD 10X6

12

WHEEL DD 10X7

12

WHEELDD10X8

12

WHEEL DD 11 X 9

13

BLOWER ASSY

13

13

13

14

VALVE TXV 1,5-3,0

14

VALVE TXV 3,0 - 5,0

15

PAN DRAIN VERTICAL

15

15

16

PAN DRAIN HORIZONTAL

16

16

19

EVAR COIL

19

19

19

GASKET/WASHER TEFLON

STUB KIT 3/8"

A

TOP PANEL

A

B

BLOWER/CONT, BOX DOOR

B

C

CLOSURE DOOR

C

D

ACCESS DOOR

D

E

CAPACITOR CLAMP

F

FILTER DOOR

F

G

THUMB SCREW

REPLACEMENT PARTS - AHX3

DESCRIPTION

PART NO,

R88DC0018 I I I I

R88DC0017 I I I I

R88DC0001 I I I I

R88_J_,0003 I I I I

R68AB0001 1 1 1 1

R68AC0003 1 1 1 1

R68DE0001 - 1 1

R68DE0002 - - 1

R68DE0003 1 -

R65BP0014 - 1 1

R65BP0006 - - 1

R65BP0016 1 -

R69AC0001 1 -

R69AC0002 - 1 -

R69AB0001 - 1

R69AC0003 - - 1

BRA3441 - 1 -

BRA4541 1 -

BRA5515 - 1

BRA51-15 - - 1

R72DB0005 1 1 -

R72DB0006 - 1 1

R71AA0015 - 1

R71AA0026 1 1 -

R71AA0028 - - 1

R71AA0029 1 1 -

R71AA0031 - 1

R71AA0045 - - 1

CA024A862T41A 1 -

CA036A8E2T41A - 1 -

CA048A6E5X15A - 1

CA060A6E5X15A - - 1

R72BA0003 1 1 1 1

R86FJ0202 1 1 1 1

R871AE017 1 1 -

R871X0013 - 1 1

R871FC001 1 1 -

R871XB001 - 1 1

R871FBX07 1 1 -

R871XA004 - 1 1

R871FBX08 1 1 -

R871XA005 - 1 1

R87NBK001 1 1 1 1

R871BA012 1 1 -

R871Z0010 - 1 1

R66AB0022 2 2 2 2

O O O O

O O O O

X X X X

"r "r "r -r

I

* Part not shown, available through FAST

12 Specifications aresubject tochaagewithout notice 496 01 2100 02

Loading...

Loading...