ICP *9MPT050F12, *9MPT100J16, *9MPT075F14, *9MPT125L20, *9MPV050F12 Installation Instruction

...Page 1

*9MPT & *9MPV

FAN ASSISTED,

DIRECT OR NON--DIRECT VENT

GAS FURNACE

* Denotes Brands (C, H, T)

SAFETY REQUIREMENTS

Recognize safety information. This is the safety-- alert symbol!. When you see this symbol on the furnace and in instructions manuals be alert to

the potential for personal injury.

Understand the signal words DANGER,WARNING,or CAUTION. These words are used with the safety--alertsymbol. DANGER identifies the most

serious hazards, those that willresult in severe personal injury or death. WARNING signifies a hazard that could result in personal injury or death.

CAUTION is used to identify unsafe practices that may result in minor personal injury or product and property damage. NOTE is used to highlight

suggestions that will result in enhanced installation, reliability, or operation.

Installing and servicing heating equipment can be hazardous due to gas and electrical components. Only trained and qualified personnel should

install, repair, or service heating equipment.

Untrained service personnel can perform basic maintenance functions such as cleaning and replacing air filters. All other operations must be

performed by trained service personnel. When working on heating equipment, observe precautions in the literature, on tags, and on labels attached

to or shipped with the unit and other safety precautions that may apply.

Follow all safety codes. In the United States, follow all safety codes including the current edition National Fuel Gas Code (NFGC) ANSI

Z223.1--2002/NFPA No. 54--2002. In Canada, refer to the current edition of the National Standard of Canada Natural Gas and Propane Installation

Code (NSCNGPIC) CSA B149.1--05. Wear safety glasses and work gloves. Have fire extinguisher available during start --up and adjustment

procedures and service calls.

These instructions cover minimum requirements and conform to existing national standards and safety codes. In some instances, these instructions

exceed certain local codes and ordinances, especially those that may not have kept up with changing residential construction practices. We require

these instructions as a minimum for a safe installation.

Ò

International Comfort Products, LLC

Lewisburg, TN 37091

1. Safe Installation Requirements 3...................

2. Installation 4..................................

3. Combustion & VentilationAir 8....................

4. Vent & Combustion Air Piping 11...................

5. Concentric VentTermination 29....................

6. Gas Supply and Piping 32........................

!

WARNING

ELECTRIC SHOCK HAZARD

Failure to follow safety

warnings exactly could result

in serious injury and/or death.

Turn Off All Power Before

Servicing.

Ò

Table of Contents

INSTALLER: Affix these instructions

on or adjacent to the furnace.

CONSUMER: Retain these

instructions for future reference.

7. ElectricalWiring 35............................

8. Ductworkand Filter 37.........................

9. Checksand Adjustments 40.....................

10. Furnace Maintenance 43........................

11. Sequenceof Operation & Diagnostics *9MPV 44......

12. Sequence of Operation & Diagnostics *9MPT 46......

TechSupport and Parts 49.........................

!

CARBON MONOXIDE POISONING AND FIRE

HAZARD.

Failuretofollowsafetywarnings exactly could

result in serious injury,death,and/or property

damage.

This furnace is not designed for use in mobile

homes, trailers or recreational vehicles.

WARNING

PrintedinU.S.A. 07/18/2005 440 01 2021 (01)

Page 2

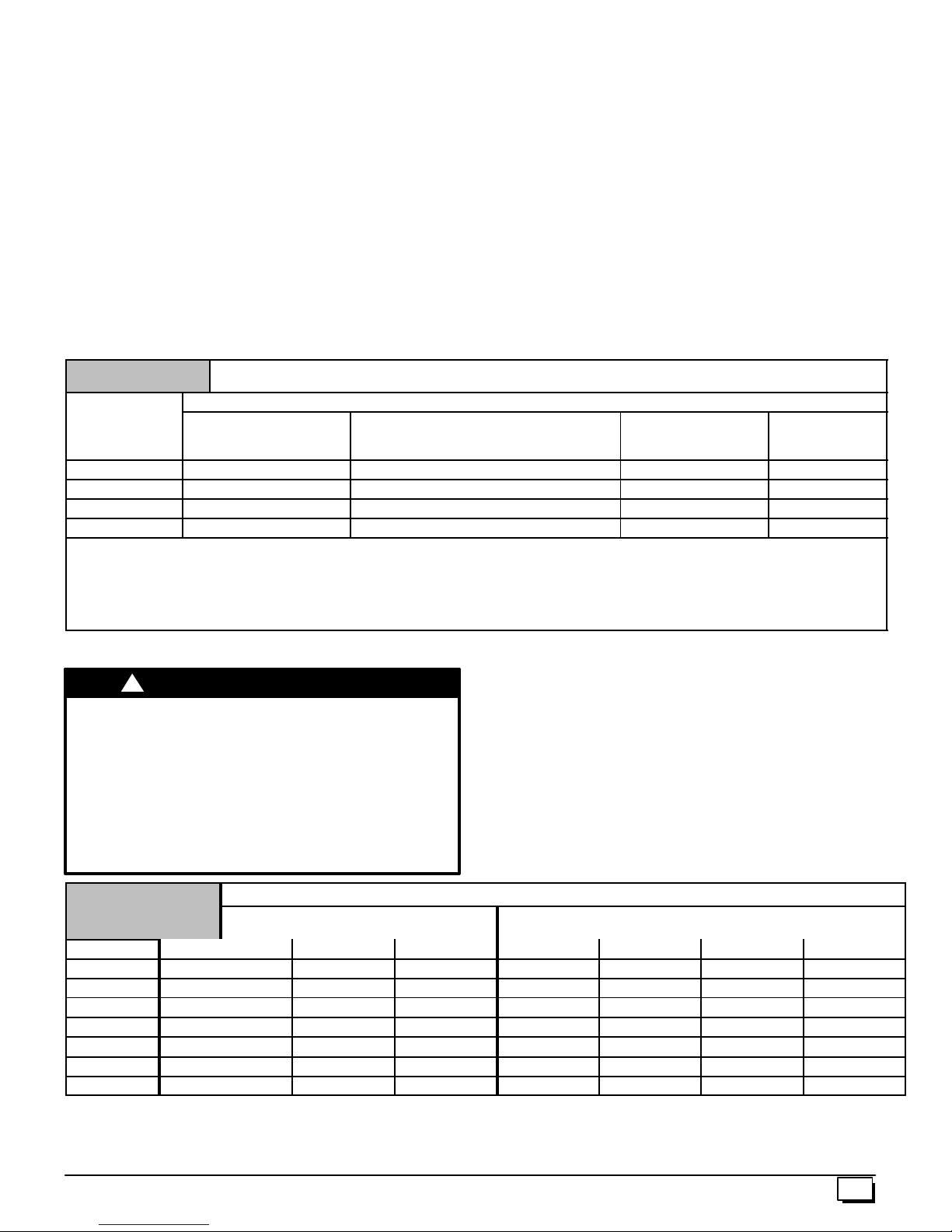

START--UP CHECK SHEET

For 90+ Furnace

(Keep this page for future reference)

Dealer Name:

Address: Business Card Here

City, State(Province), Zip or Postal Code:

Phone:

Owner Name:

Address:

City, State(Province), Zip or Postal Code:

Model Number:

Serial Number:

Type of Gas: Natural: LP:

Which blower speed tap is used?

High Fire

For variable speed models (*9MPV), What dip switches are

selected?

High Fire

Temperature of Supply Air: High Fire (°F) or (°C)

Temperature of Return Air: (°F) or (°C)

Temp. Rise Hi Fire (Supply -- Return ): (°F) or (°C)

Lo Fire (Supply -- Return ): (°F) or (°C)

Low Fire or (Cooling)

Low Fire or (Cooling)

Low Fire (°F) or (°C)

Manual Gas Shut--Off Upstream

of Furnace/Drip--Leg? YES

Condensate Drain Connected? YES NO

Condensate Drain Trapped? YES NO

Transition Pressure switch hose relocated for U/D/H

Application? YES

Blower Speed Checked? YES NO

All Electrical Connections Tight? YES NO

Gas Valve turned ON? YES NO

Measured Line Pressure When Firing Unit:

Calculated Firing Rate:(See Checks and Adjustments Sec-

tion). (Lo)

Temperature Rise (supply--return temperature):(°F)

Measured Manifold Gas Pressure: (Lo) &(Hi)

Static Pressure (Ducts): Supply Air Return

NO

&(Hi)

NO

Filter Type and Size:

Fan “Time ON” Setting:

Fan “Time OFF” Setting:

Dealer Comments:

2

Date of Start--Up:

CO ?

CO2 ?

440 01 2021 01

Page 3

1. Safe Installation Requirements

!

WARNING

FIRE, EXPLOSION, AND ASPHIXIATION HAZARD

Improper adjustment, alteration, service,

maintanence or installation could cause death,

personal injury and/or property damage.

Installation or repairs made by unqualified persons

could result in hazards to you and others.

Installation MUST conform with local codes or, in

the absence of local codes, with codes of all

governmental authorities having jurisdiction.

The information contained in this manual is

intended for use by a qualified service agency that

is experienced in such work, is familiar with all

precautions and safety procedures required in

such work, and is equipped with the proper tools

and test instruments.

NOTE: This furnace is design--certified by the CSA International

(formerly AGA and CGA) for installation in the United States and

Canada. Refer to the appropriate codes, along with this manual,

for proper installation.

· Use only the Type of gas approved for this furnace (see

RatingPla te on unit). Overfiring will result in failure of heat

exchanger and cause dangerous operation. (Furnaces

can be converted to L.P. gas with approved kit.)

· Install this furnace only in a location and position as speci-

fied in “2. Installation” of these instructions.

· Provide adequate combustion and ventilation air to the fur-

nace as specified in “4. Combustionand VentilationAir” of

these instructions.

· Combustion products must be discharged outdoors. Con-

nect this furnace to an approved vent system only, as spe-

cified in “5. Combustion and Ventilation Air, 6. Horizontal

Venting and 7. Masonry Chimney Venting” of these in-

structions.

· Never test for gas leaks with an open flame. Use a com-

mercially available soap solution made specifically for the

detection of leaks to check all connections, as specified in

“8. Gas Supply and Piping, Final Check” of these instruc-

tions.

· Always install furnace to operate within the furnace’s in-

tended temperature--rise range with a duct system which

has an external static pressure within the allowable range,

as specified in “Technical Support Manual” of these in-

structions. See furnace rating plate.

· When a furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space containing the furnace, the return air shall also be handled by a

duct(s) sealed to the furnace casing and terminating outside the space containing the furnace.

· A gas--fired furnace for installation in a residential garage

must be installed as specified in “2. Installation Requirements” of these instructions.

· This furnace is not to be used for temporary heating of

buildings or structures under construction.

· This furnace is NOT approved for installation in mo-

bile homes, trailers or recreation vehicles.

· Seal around supply and return air ducts.

· Install correct filter type and size.

· Unit MUST be installed so electrical components are pro-

tected from direct contact with water.

Safety Rules

Your unit is built to provide many years of safe and dependable

service providing it is properly installed and maintained. However,

abuse and/or improper use can shorten the life of the unit and

create hazards for you, the owner.

A. The U.S. Consumer Product Safety Commission encourages

installation of carbon monoxide alarms. There can be various

sources of carbon monoxide in a building or dwelling. The

sources could be gas--fired clothes dryers, gas cooking

stoves, water heaters, furnaces, gas--fired fireplaces, wood

fireplaces.

Carbon monoxide can cause serious bodily injury and/or

death. Carbon monoxide or “CO” is a colorless and odorless

gas produced when fuel is not burned completely or when the

flame does not receive sufficient oxygen.

Therefore, to helpalert people of potentially dangerous carbon

monoxide levels, you should have a commercially available

carbon monoxide alarm that is listed by a nationally recognized testing agency in accordance with UnderwritersLaboratories Inc. Standard for Single and Multiple Station Carbon

Monoxide Alarms, ANSI/UL 2034 or the CSA 6.19--01 Residential Carbon Alarming Devices installed and maintained in

the building ordwelling concurrently with the gas--firedfurnace

installation (see Note below). The alarm should be installed as

recommended by the alarm manufacturer’s installation instructions.

B. There can be numerous sources of fire or smoke in a building

or dwelling. Fire or smoke can cause serious bodily injury,

death, and/or property damage. Therefore, in order to alert

people of potentiallydangerous fire orsmoke, you should have

fire extinguisher andsmoke alarms listedby Underwriters Laboratories installed and maintained in the building or dwelling

(see Note below).

Note: The manufacturer of your furnace does not test any alarms

and makes no representations regarding any brand or type

of alarms.

C. To ensure safe and efficient operation of your unit, you should

do the following:

1. Thoroughly read this manual and labels on the unit. This

will help you understand how your unit operates and the hazards involved with gas and electricity.

2. Do not use this unit if any part has been under water. Im-

mediately call a qualified service technician to inspect the unit

and to replace anypart of the control system and any gas control which has been under water.

3. Never obstruct the vent grilles,or any ducts that provide

air to the unit. Air must be provided for proper combustion

and ventilation of flue gases.

440 01 2021 01

3

Page 4

Frozen Water Pipe Hazard

!

WATER DAMAGE TO PROPERTY HAZARD

FaiIure to protect against the risk of freezing may

result in property damage.

Do not leave your home unattended for long periods

during freezing weather without turning off water

supply and draining water pipes or otherwise

protecting against the risk of frozen pipes and

resultant damage.

Your furnace is designed solely to provide a safe and comfortable

living environment. The furnace is NOT designed to ensure that

water pipes will not freeze. It is equipped with several safety devices that are designed to turn the furnace off and prevent it from

restarting in the event of various potentially unsafe conditions.

If your furnace remains off for an extended time, the pipes in your

home could freeze and burst, resulting in serious water damage.

If the structure will be unattended during cold weather you should

take these precautions.

1. Turn off the water supply to the structure and drain the water

lines if possible and add an antifreeze for potable water to

drain traps and toilet tanks. Open faucets in appropriate

areas.

CAUTION

-- o r --

2. Have someone check the structure frequently during cold

weather to make sure it is warm enough to prevent pipes

from freezing. Instruct them on a service agency to call to

provide service, if required.

-- o r --

3. Install a reliable remote sensing device that will notify somebody of freezing conditions within the home.

Winter Shutdown

If you go away during the winter months and do not leave the heat

on in your home,the plastic transition box and the condensatetrap

on the furnace must be protected from freeze damage.(See

Figure 9 trough Figure 18)

1. Disconnect the5/8² OD rubber hose from the vent drain fitting that is located downstream of the combustion blower.

Insert a funnel into the hose and pour four(4) ounces of sanitary type (RV) antifreeze into the condensate trap. Reconnect the

fitting. Secure with the hose clamp.

2. Disconnect the3/4² OD rubber hose from the condensate

trap. Insert a funnel into the hose and and pour four(4)

ounces of sanitary type (RV) antifreeze into the plastic Transition box. Squeeze the hose together near the end and

quickly reconnect the

condensate trap. Secure with the hose c lamp.

When you return home, your furnace will be ready to start, as it is

not necessary to drain the antifreeze from the furnace.

5

/8² OD rubber hose to the stub on the vent drain

3

/4² ODrubber hose to the stub on the

2. Installation

!

CARBON MONOXIDE POISONING HAZARD

Failure to properly vent this furnace or other

appliances could result in death or personal injury.

This furnace can NOT be common vented or

connected to any type B, BW or L vent or vent

connector, nor to any portion of a factory--built or

masonry chimney. If this furnace is replacing a

previously common-vented furnace, it may be

necessary to resize the existing vent and chimney

to prevent oversizing problems for the other

remaining appliance(s). See Venting and Combus-

tionAirCheckin the 5.Combusion&VentilationAir

section. This furnace MUST be vented to the

outside.

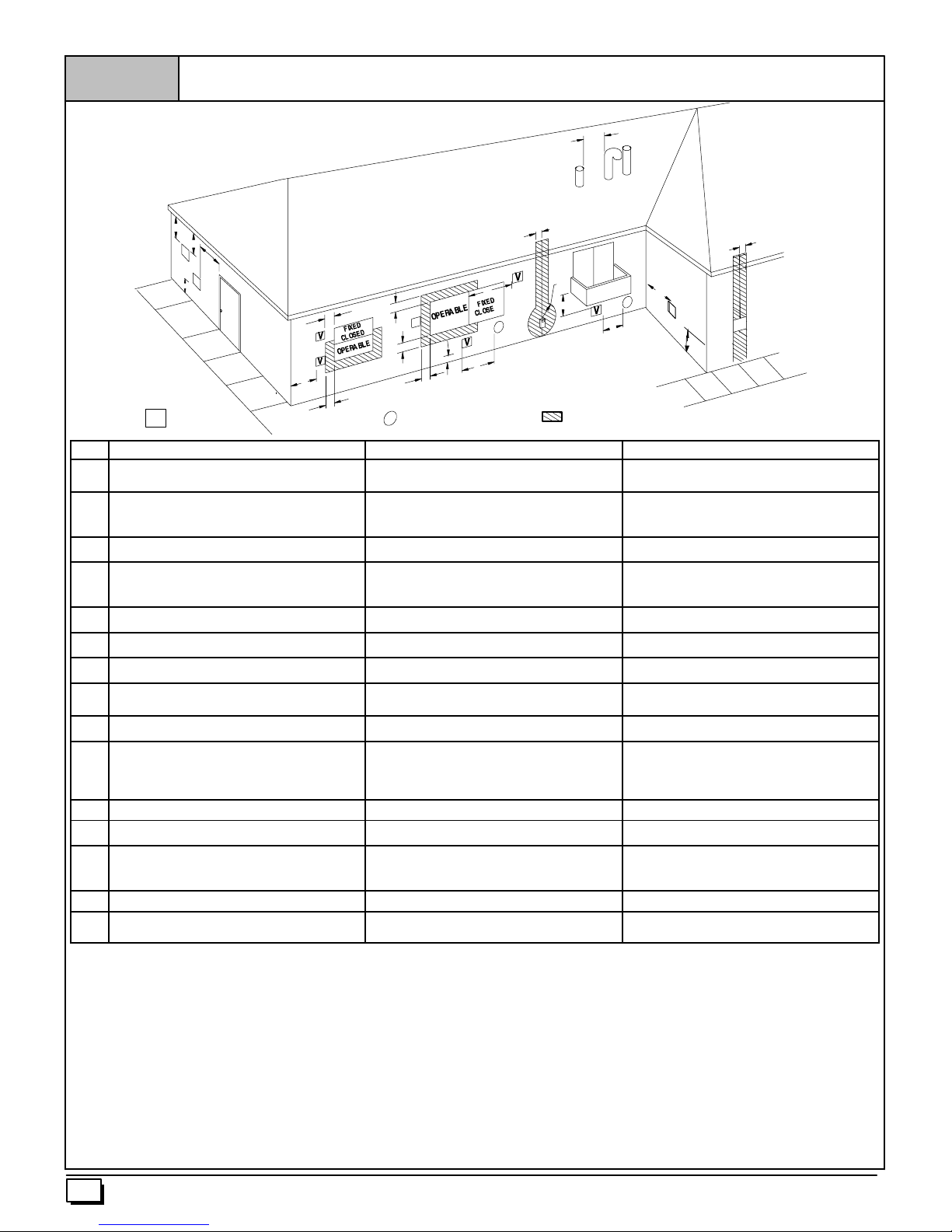

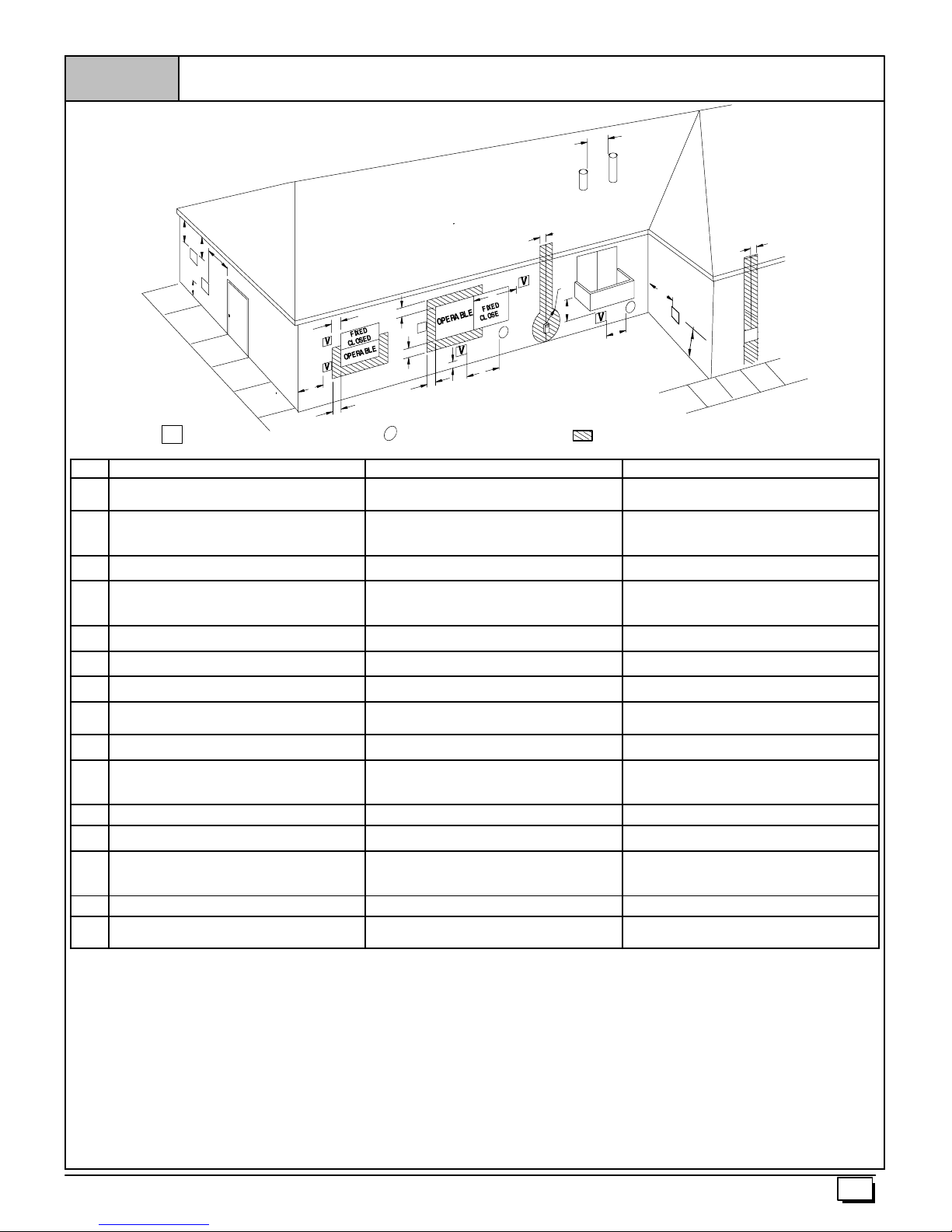

Installation Positions

This furnace can be installed in an upflow, horizontal (either left or

right) or downflow airflow position. DO NOT install this furnace on

its back. For the upflow position, the return air ductwork can be attached to either the left or right side panel and/or the bottom. For

horizontal and downflow positions, the return air ductwork must be

attached to the bottom. The return air ductwork must never be attached to the back of the furnace.

WARNING

Location and Clearances

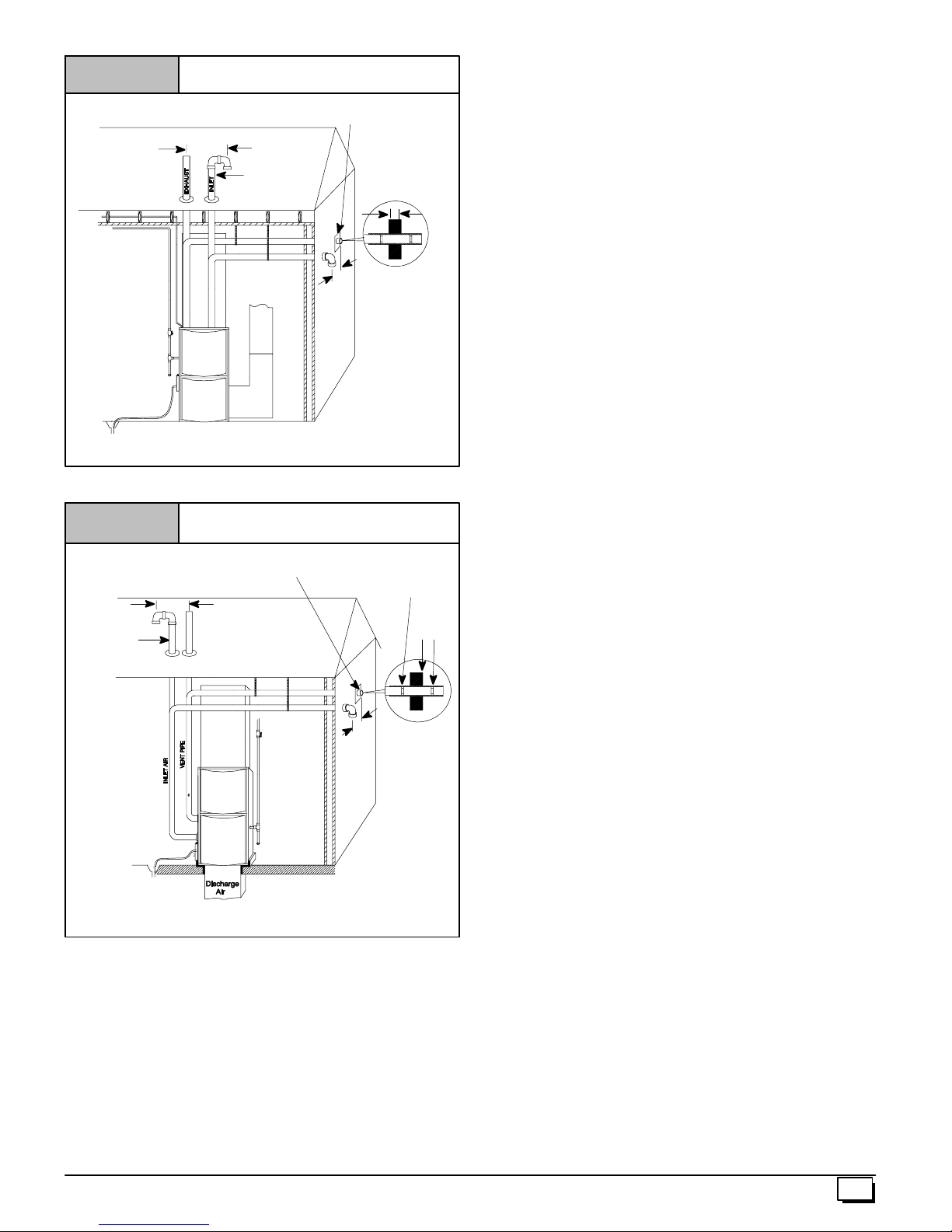

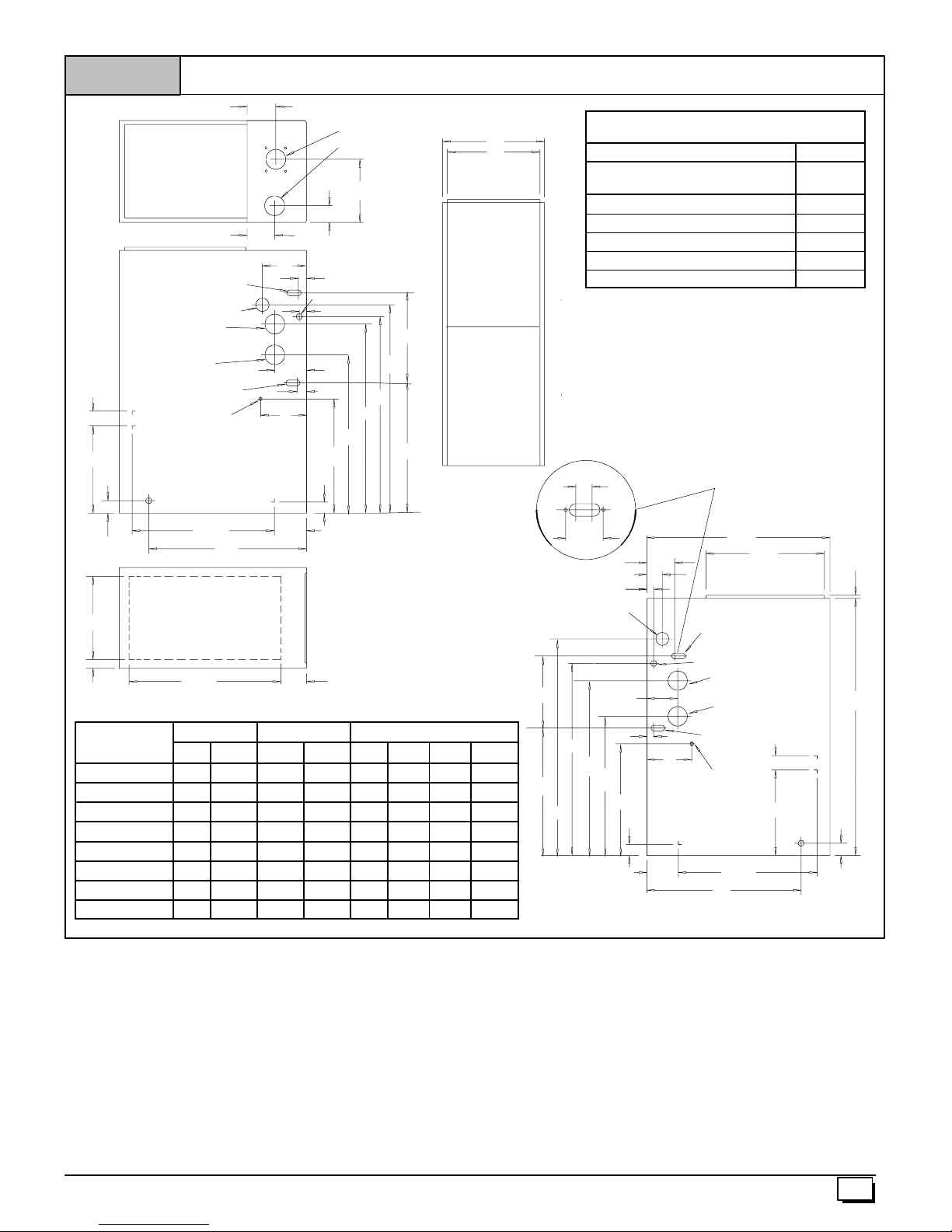

1. Refer to Figure 1 or Figure 2 for typical installation and

basic connecting parts required. Refer to Figure 3 for typical horizontal direct vent installation and basic connecting

parts required. Supply and return air plenums and duct are

also required.

2. If furnace is a replacement, it is usually best to install the furnace where the old one was. Choose the location or evaluate the existinglocation based uponthe minimum clearance

and furnace dimensions (Figure 4 ).

!

FROZEN AND BURST WATER PIPE HAZARD

FaiIure to protect against the risk of freezing may

result in property damage.

Special precautions MUST be made if installing

furnace in an area which may drop below freezing.

This can cause improper operation or damage to

equipment. If furnace environment hasthe potential

of freezing, the drain trap and drainline must be

protected. The use of electric heat tape or RV

antifreeze is recommended for these installations.

(See“Condensate Trap Freeze Protection Section”)

CAUTION

4

440 01 2021 01

Page 5

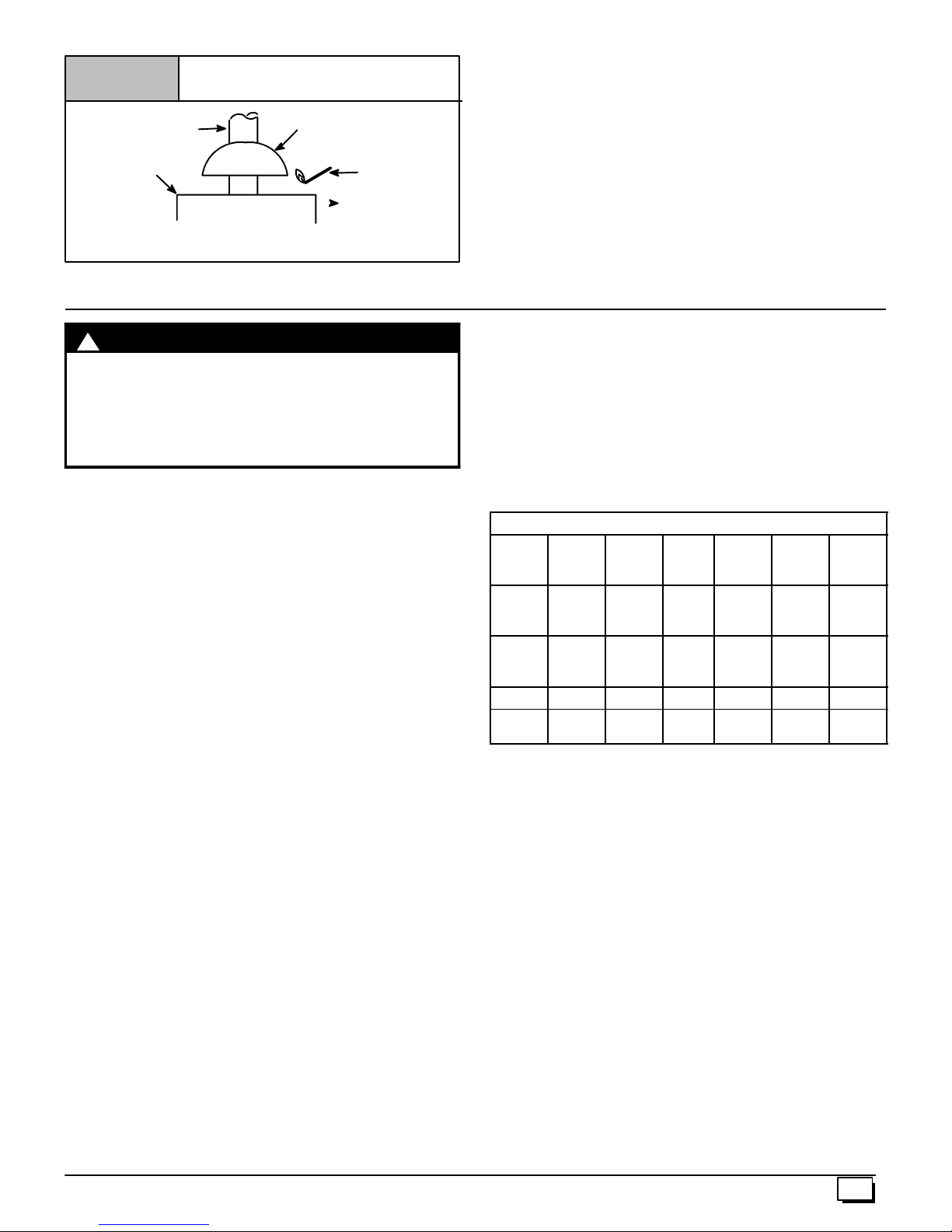

Figure 1

*8² Min.

20¢ Max.

in same

atmospheric

zone

VentPipes MUST be

supported

Horizontallyand

Vertically

*Increaseminimumfrom8²

below 0 °°°° F).

T y pical Upflow Installation

Aluminumornon--rustingshield recommended.

(SeeVentTermination Shielding fordimensions).

InletPipe

(notusedon

SinglePipe

model)

DISCHARGEAIR

² to18²²²² forcoldclimates(sustainedtemperatures

²²

Couplingon endsof

exhaust pipe. Total

pipe & coupling outside structure = 8²

*8² Min.

20¢ Max.

insameatmosphericzone

25--23--33

Figure 2 Typical Downflow Installation

InletPipe

(notusedon

SinglePipe

model)

VentPipes MUST

besupportedHorizontally and Vertically

* Increaseminimum from8 ²

below 0°°°°F).

See VentTermination

Shielding in VentSection.

*8² Min.

20¢ Max.insame

atmosphericzone

² to18²²²² forcold climates(sustained temperatures

²²

Coupling on inside

andoutsideofwallto

restrainvent pipe

8² Min.

*8² Min.

20¢ Max.

in same

atmosphericzone

25--23--33a

Installation Requirements

1. Install furnace level.

2. This furnace is NOT to be used for temporary heat of build-

ings or structures under construction.

3. Install furnace as centralized as practical with respect to the

heat distribution system.

4. Install the vent pipes as short as practical, and in accor-

dance to these instructions. (See Vent and Combustion

Air Piping section).

5. Maintain clearance for fire safety and servicing. A front

clearance of 24² is required for access to the burner, controls and filter. See clearance requirements in Figure 4.

6. Use a raised base for upflow furnace if the floor is damp or

wetattimes.

7. For downflow installations, non combustible subbase must

be used under the furnace unless installation is on a non

combustible floor surface. This requirement applies even

when a coil box or cabinet is used.

8. For horizontal installations, line contact is permissible only

between lines formed by intersection of back and two sides

of furnace jacket, and building joists, studs or framing.

9. Residential garage installations require:

· Burners and ignition sources installed at least 18² above

the floor.

· Located or physically protected from possible damage by

a vehicle.

10. Local codes may require a drain pan under the entire furnace and condensate trap when the furnace is installed in

attic application.

This furnace may be used for construction heat provided that all

the following conditions are met:

· The furnace is permanently installed with all electrical wir-

ing, piping, venting and ducting installed according to these

installation instructions. A return air duct is provided,sealed

to the furnace casing, and terminated outside the space

containing the furnace. This prevents a negative pressure

condition as created by the circulating air blower, causing a

flame rollout and/or drawing combustion products into the

structure.

· The furnace is controlled by a thermostat. It may not be “hot

wired” to provide heat continuously to the structure without

thermostatic control.

· Clean outside air is provided for combustion. This is to mini-

mize the corrosive effects of adhesives, sealers and other

construction materials. It also prevents the entrainment of

drywall dust into combustion air, which can cause fouling

and plugging of furnace components.

· The temperature of the return air to the furnace is main-

tained between 55° F(13° C) and 80° F(27° C) , with no eve-

ning setback or shutdown. The use of the furnace while the

structure is under construction is deemed to be intermittent

operation per our installation instructions.

· The air temperature rise is within the rated rise range on the

furnace rating plate, and the firing rate has been set to the

rating plate value.

· The filters used to clean the circulating air during the

construction process must be either changed or thoroughly

cleaned prior to occupancy.

· The furnace, ductwork and filters are cleaned as necessary

to remove drywall dust and construction debris from all

HVAC system components after construction is completed.

· Afterconstruction is complete, verify furnace operating con-

ditions including ignition, input rate, temperature rise and

venting according to these instructions.

440 01 2021 01

5

Page 6

!

WARNING

CARBON MONOXIDE POISONING HAZARD.

FaiIuretofollow this warning could resultindeathor

personal injury.

Do NOT operate furnace in a corrosive atmosphere

containing chlorine, f luorine or any other damaging

chemicals, which could shorten furnace life.

Refer to 3. Combustion & Ventilation Air section,

Contaminated Combustion Air for combustion air

evaluation and remedy.

Furnace Installation Considerations

The installation ofthe furnace for a given application will dictate the

position of thefurnace, the airflow, ductwork connections, vent and

combustion air piping. Consideration must be given to the follow ing:

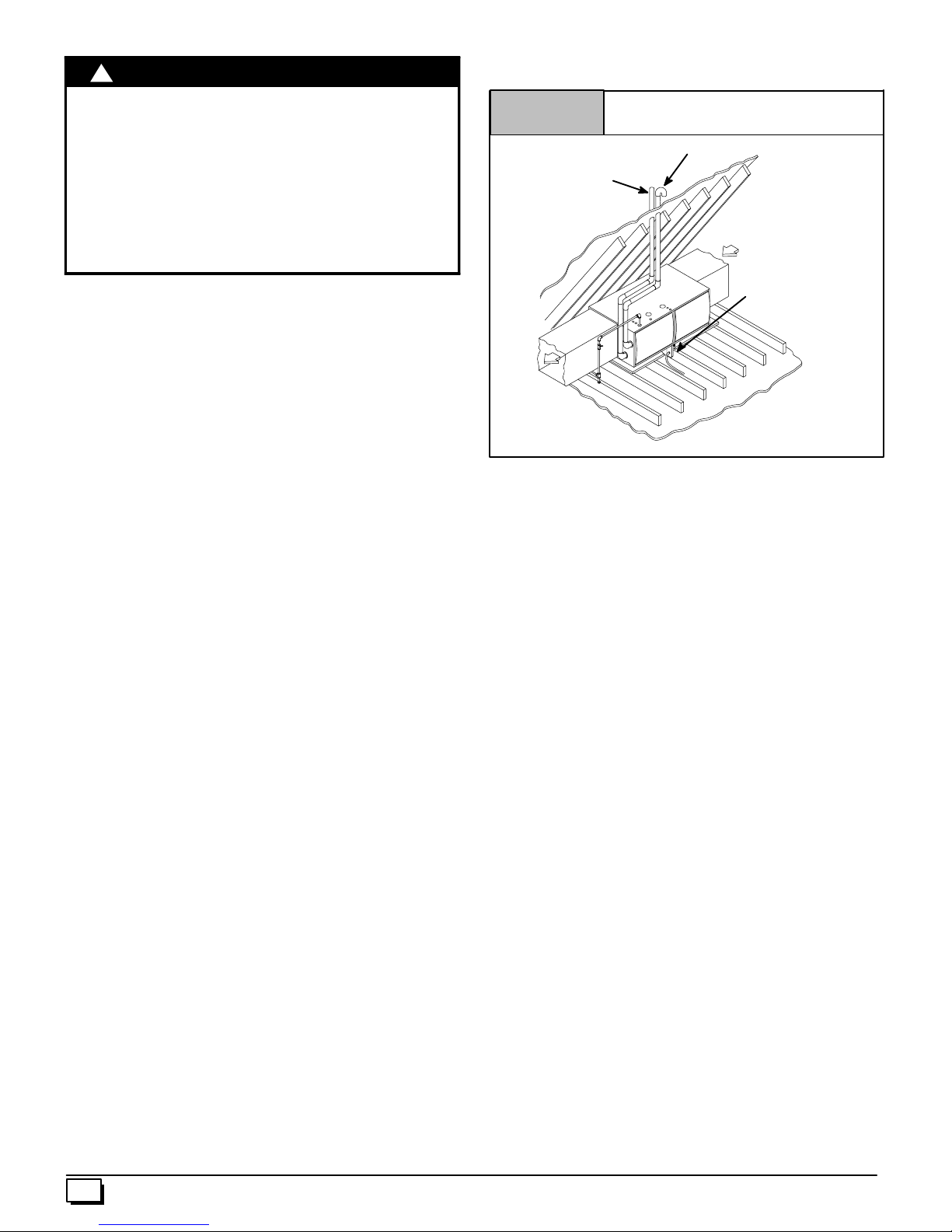

Horizontal Furnace Installation

Figure 3

Vent

Pipe

T ypical Horizontal Installation

Inlet Pipe (not used on SinglePipe model)

Condensate

Trap

Condensate Trap and Drain Lines

The supplied condensate trap must be attached to the furnace

side panel on either the left or right side. For horizontal installations, the drain trap is vertically attached to the side panel below

the furnace. A minimum clearance of 6² below the furnace is required for the condensate trap. Downward slope of the condensate drain line from the condensate trap to the drain location must

be provided. Adequate freeze protection of the drain trap and the

drain line must be provided. See “CondensateDrainTrap”section

for further details.

Leveling

Proper leveling of the furnace must be provided to insure proper

drainage of the condensate from the furnace. The furnace must be

level to within

and downflow installations or top to bottom for horizontal installations.

1

/4² from front to back and fromside to side for upflow

Ventand Combustion Air Connections

On the Dual Certified furnace, the vent and combustion air pipes

attach to the furnace through the top panel for the upflow and horizontal installations. For the downflow installation, the vent and

combustion air pipes attach to the furnace through the alternate

locations on the furnace side panels.

Note: On the Direct Vent furnace, the vent pipe attaches to the furnace through the side panels. The combustion air pipe attaches to

the top panel or to the alternate location on the side panel.

On the Single Pipe furnace, the vent pipe attaches to the furnace

through the furnace side panels.

Note: Repositioning of the combustion blower is required for the

vent pipe connection to the furnace through the “right side” panel.

See “Vent and Combustion Air Piping” section for further details.

25--23--34

NOTE: 5² bottom clearance required for condensate trap.

This furnace can be installed horizontally in an attic, basement,

crawl s pace, alcove, or suspended from a ceiling in a basement or

utility room (See Figure 3). Do notinstall furnace on its back or in

the reverse airflow positions as safety control operation will be adversely affected.

If the furnace is to be suspended from the floor joists in a crawl

space or the rafters in an attic, it is necessary to use steel pipe

straps or an angle iron frame to rigidly attachthe furnace to prevent

movement. These straps should be attached to the furnace with

sheet metal screws and to the rafters or joists with bolts. The preferred method is to use an angle iron frame bolted to the rafters or

joists. (Takecaution to allowdoor panels to be removedfor maintenance)

If the furnace is to be installed in a crawl s pace, consult local

codes. A suitable concrete pad or blocks are recommended for

crawl space installation on the ground.

NOTE: 6² bottom clearance required for condensate trap.

Twenty four (24) inches between the front of the furnace and adja cent construction orother appliances MUSTbe maintainedfor ser vice clearance. (Thirty (30) inches is required to remove furnace).

Keep all insulating materials clear from louvered door. Insulating

materials may be combustible.

The horizontal furnaces may be installed directly on combustible

wood flooring or supports as long as all required furnace clearances are met. See Figure 3 .

This furnace MUST NOTbe installed directly on carpeting or tile or

other combustible material other than wood flooring or supports.

For horizontal installation over a finished living space. A field fabricated auxiliary drain pan with drain pipe is required to prevent

damage by overflow due to blocked condensate drain.

6

440 01 2021 01

Page 7

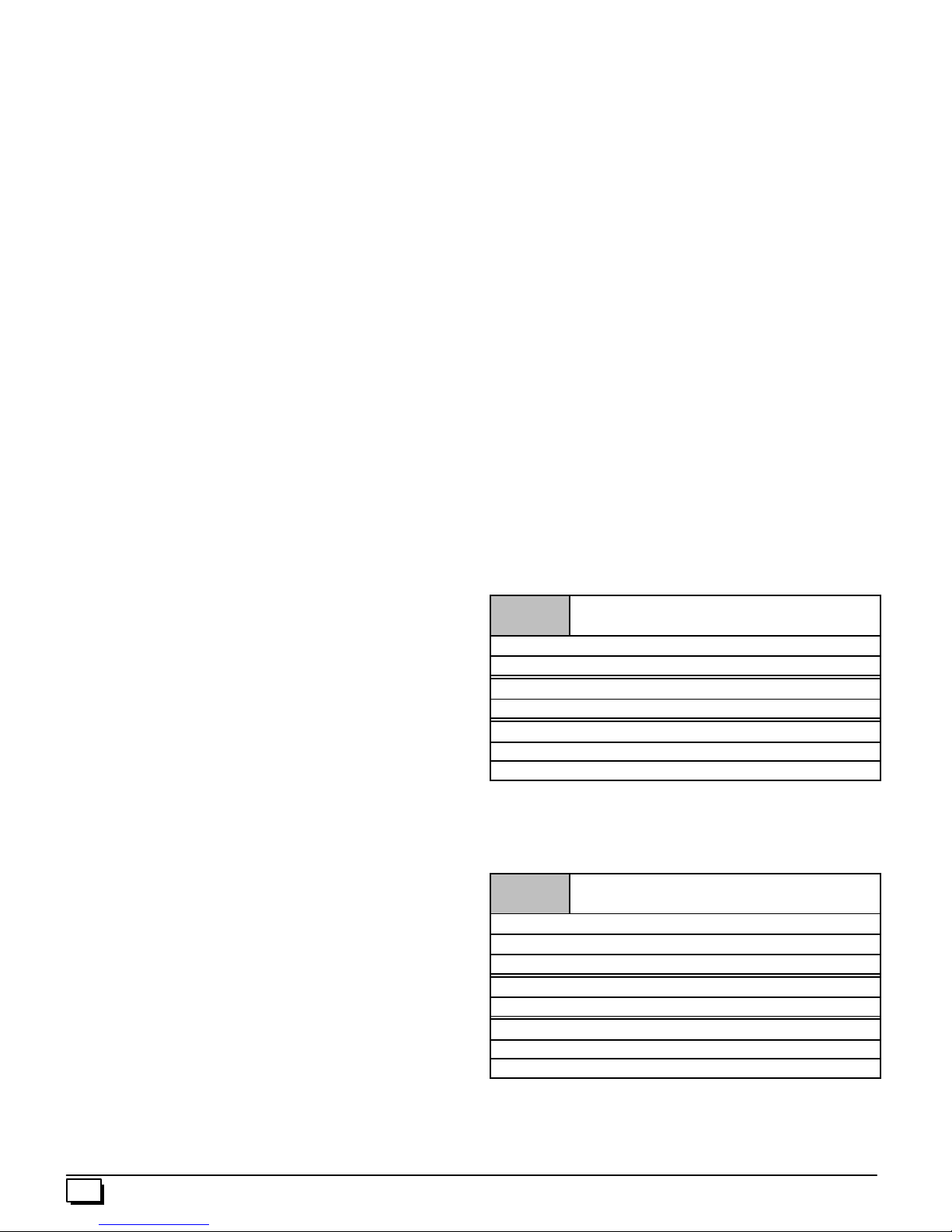

Figure 4

Uni

t

Dimensions and Clearances

F

AIR INTAKE

VENT

TOP

H

G

E

LEFT SIDE

TRAP (COUNTERFLOW)

GAS

VENT

AIR INTAKE

(ALTERNATE)

TRAP

UPFLOW/HORIZONTAL

1

2

/

4

1

/

13

4

7

1

/

8

THERMOSTAT

215/

8

24

413/

611/

16

ELECTRICAL

11/

4

11/

16

11

13

/

16

3111/

283/

16

297/

16

8

4

1913/

16

16

13/

8

7

241/

175/

16

111/

16

47/

8

Drawing is representative,

but some models may vary

D

C

BOTTOM

1

23

/

8

37/

8

ALL DIMENSIONS IN INCHES

Unit

Capacity

Cabinet Bottom Top

A B C D E F G H

*9MPT050F12 191/8175/821/8143/443/841/221/291/

*9MPT075F14 191/8175/821/8143/443/841/221/291/

*9MPT100J16 223/4211/4115/16183/443/841/225/8113/

*9MPT125L20 241/223

7

/

23 43/841/221/4121/

16

*9MPV050F12 191/8175/821/8143/443/841/221/291/

*9MPV075F12 191/8175/821/8143/443/841/221/291/

*9MPV100J20 223/4211/4115/16183/443/841/225/8113/

*9MPV125L20 241/223

7

/

23 43/841/221/4121/

16

* Dentoes Brand

A

B

FRONT

2

2

8

4

2

2

8

4

COMBUSTIBLE MATERIALS FOR ALL UNITS

MINIMUM CLEARANCES TO

REAR 0

FRONT (combustion air openings in

furnace and in structure)

Required For Service

ALL SIDES Of SUPPLY PLENUM 1²

SIDES 0

VENT 0

TOP OF FURNACE 1²

*30² clearance recommended forfurnaceremoval.

Horizontalposition: Line contactis permissibleonlybetween

linesformedby intersectionsof top and two sides of furnace

jacket,and building joists,studsor framing.

NOTE: Evaporator “A” coil drain pan dimensions may

vary from furnace duct opening size. Always consult

evaporator specifications for duct size requirements.

Furnace is designed for bottom return or side return.

Return air through back of furnace is NOT allowed.

1

1

/

4

7

2

913/

/

8

45/

16

3

/

2

8

11/

16

GAS

3

/

1

16

16

3311/

16

297/

273/

413/

16

11/

16

8

16

215/

8

175/

111/

7

16

16

7

4

/

8

281/

2

1

18

/

RIGHT SIDE

TRAP

(COUNTERFLOW)

ELECTRICAL

AIR INTAKE(ALTERNATE)

VENT

TRAP

UPFLOW/HORIZONTAL

215/

21/

131/

8

THERMOSTAT

24

2

3²

*24²

3

/

4

TYPE

40

4

4

17/

8

25--23--36b

440 01 2021 01

7

Page 8

3. Combustion & Ventilation Air

For Single Pipe Installation

(Non--Direct Vent)

!

CARBON MONOXIDE POISONING HAZARD

Failure to provide adequate combustion and

ventilation air could result in death or personal

injury.

Use methods described here to provide

combustion and ventilation air.

Furnaces require ventilation openings to provide sufficient air for

proper combustion and ventilation of flue gases. All duct or openings for supplying combustion and ventilation air must comply with

National Fuel Gas Code, NFPA54/ANSI Z223.1, 2002 (or current

edition) and applicable provisions of local building codes.

1. Section 8.3, Air for Combustion and Ventilation, of the Nation al Fuel Gas Code, National Fuel Gas Code (NFGC), ANSI

Z223.1--2002/NFPA 54--2002 in the U.S.,

2. Sections 7.2, 7.3, 7.5, 7.6, 7.7, and 7.8 of National Standard of

Canada, Natural Gas and Propane Installation Code

(NSCNGPIC), CSA B149.1--05 in Canada,

3. Applicable provisions of the local building code.

This furnace can NOT be c ommon vented or connected to any

type B, BW or L vent or vent connector,nor to any portion ofa factory--built or masonry chimney. Multistory venting i s NOT permitted.

If this furnace is replacing a previously common-vented furnace, it

may be necessary to resize the existing v ent and chimney to prevent oversizing problems for the other remaining appliance(s).

See “VentingandCombustionAir Check” in this section. This fur-

nace MUST be vented to the outside.

When the installation is complete, check that all appliances have

adequate combustion air and are v enting properly. See Venting

AndCombustionAirCheckin “5. GasVentInstallation” Section in

this manual.

WARNING

Outdoor Combustion Air Method

A space having less than 50 cubic feet per1,000 BTUH input rating

for all gas appliances installed in the space requires outdoor air for

combustion and ventilation.

Air Openings and Connecting Ducts

1. Total input rating for all non direct vent gas appliances

MUST be considered when determining free area of openings.

2. Connect ducts or openings directly to outside.

3. When screens are used to cover openings, they MUST be

no less than1/4² mesh.

4. The minimum dimension of rectangular air ducts MUST

NOT be less than 3².

5. When sizing grille or louver, use the free area of opening. If

free area is NOT stamped or marked on grill or louver, assume a 20% free area for wood and 60% for metal.

Confined Space Installation

NOTE: A confined space is defined as an area with less than 50

cubic feet per 1,000 BTUH input rating for all gas appliances

installed in the area.

Requirements

1. Provide confined space with sufficient air for proper combustion and ventilation of flue gases using horizontal or vertical ducts or openings.

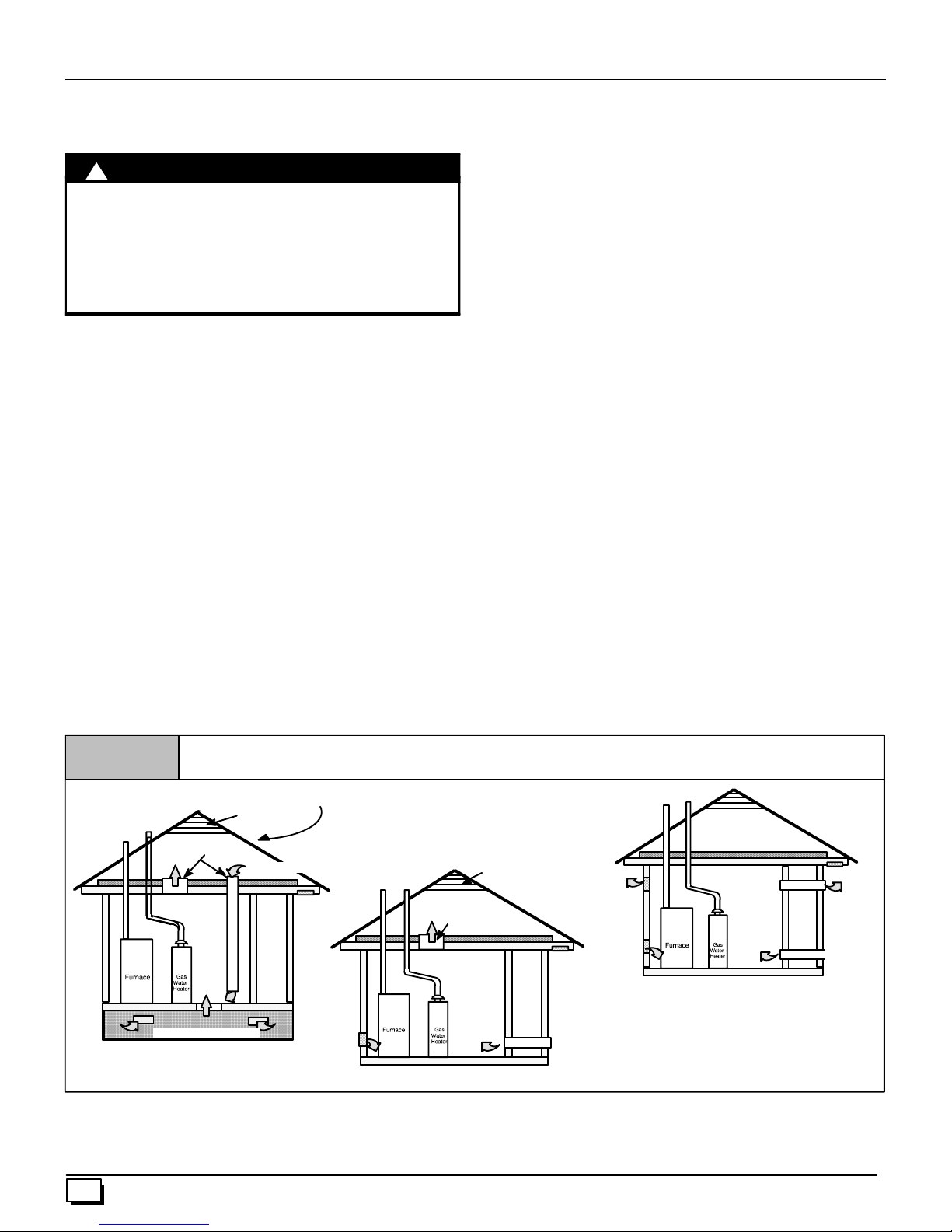

2. Figure 5 illustrate how to provide combustion and ventilation air. A minimum of two permanent openings, one inlet

and one outlet, are required.

a. One opening MUST commencewithin12² of the floor

and the second opening MUST commence within 12² of

the ceiling.

b. Size openings and ducts per Table 1.

Figure 5

Outside Air (This is O NLY a guide. Subject to codes of country having jurisdiction.)

This installation NOT approved in Canada

Gable Vent

Gas Vent

VentilatedAttic

TopAbove Insulation

Outlet Air (1)

VentilatedCrawl Space

Alternate Inlet Air (1)

Alternate Inlet Air (1)

Soffit Vent

Inlet

Air (1)

Gas Vent

c. Horizontal duct openings require 1 square inch of free

area per 2,000 BTUH (1,100 mm2/kW) of combined input

for all gas appliances in the space (see Table 1).

8

Gable Vent

VentilatedAttic

TopAbove Insulation

OutletAir (1)

Gas Vent

Outlet

Soffit Vent

Inlet

Air (2)

Outlet

Air (1)

Inlet

Air (1)

Minimum OneInlet and One OutletAir Supply is Required

May bein any Combination Shown

Inlet Air Opening Must be Within12² of floor

Outlet Air Opening Must be Within12² of ceiling

(1) 1 Square Inch per 4000 BTUH

(2) 1 Square Inch per 2000 BTUH

Inlet

Air (2)

Air (2)

d. Vertical duct openings or openings directly communicat-

ing with the outdoors require 1 square inch of free area

per 4,000 BTUH (550 mm

2

/kW) for combined input of all

gas appliances in the space (see Table 1).

440 01 2021 01

Page 9

3. One opening MUST be within 12² of the floor and the sec-

BTU

H

ond opening within 12² of the ceiling.

a. 1 sq. in of free area per 3,000 BTUH (700 mm

2

/kW) for

combined input of all gas appliances in the space (see

Table 1) and

b. not less than the sum of the areas of allvent connectors in

the space.

The opening shall commence within 12² of the top of the enclosure. Appliances shallhave clearances ofat least 1² from the sides

and back and 6² from the front. The opening shall directly communicate with the outdoors or shall communicate through a vertical or

horizontal duct to the outdoors or spaces (crawl or attic) that freely

communicate with the outdoors.

4. Size openings and ducts per Table 1.

a. Indoor openings that comply with the Indoor Combus-

tion Air Method below and

b. Outdoor openings located as required in the Outdoor

Combustion Air Method above and

c. Outdoor openings sized as follows.

1) Calculate the Ratio of all Indoor Space volume

divided by required volume for IndoorCombustion

Air Method.

2) Outdoor opening size reduction Factor is 1 minus

the Ratio in 1) above.

3) Minimum size of Outdoor openings shall be the size

required in Outdoor Combustion Air Method

above multiplied by reduction Factor.

5. Horizontal duct openings require 1 square inch of free area

per 2,000 BTUH of combined input for all gas appliances in

area (see Table 1).

6. Vertical duct openings or openings directly to outside require 1 square inch of free area per 4,000 BTUH for combined input of all gas appliances in area (see Table 1).

Table 1

Input

Rating

50,000 25sq.in. 16.7 sq. in. 12.5 sq. in. 4²

75,000 37.5 sq. in. 25sq. in. 18.75 sq. in. 5²

100,000 50sq.in. 33.3 sq. in. 25 sq. in. 6²

125,000 62.50 sq. in. 41.7 sq. in. 31.25 sq. in. 7²

EXAMPLE: Determining Free Area

Furnace

100,000

Furnace

100,000

Unconfined Space Installation

!

Free Area

TwoHorizontal Ducts

(sq. in./2,000 BTUH)

Water Heater

+

+

30,000

Water Heater

30,000

=

=

WARNING

Minimum FreeAreaRequired for Each Opening or Duct to Outdoors

TwoVerticalDuctsor

(sq. in./4,000BTUH)

(sq. in./3,000 BTUH)

Total Input

(130,000 ¸ 4,000)

Total Input

(130,000 ¸ 2,000)

Single Opening

==32.5 Sq. In. Vertical

65 Sq. In. Horizontal

An unconfined space is defined as an area having a minimum volume of 50 cubic feet per 1,000 Btuh total input rating for all gas appliances in area. Refer to Table 2 for minimum area required.

Openings

CARBON MONOXIDE POISONING HAZARD

Failure to supply additional air by means of

ventilation grilles or ducts could result in death or

personal injury.

An unconfined space or homes with tight

construction may not have adequate air infiltration

for proper combustion and ventilationofflue gases.

Most homes will require additional air.

Rd Duct

(sq. in./4,000 BTUH)

MINIMUM SPACE VOLUME FOR 100% COMBUSTION AND VENTILATIONAIR FROM INDOORS (ft3)

Table 2

ACH

0.60 1,050 1,400 1,750 1,250 1,875 2,500 3,125

0.50 1,260 1,680 2,100 1,500 2,250 3,000 3,750

0.40 1,575 2,100 2,625 1,875 2,813 3,750 4,688

0.30 2,100 2,800 3,500 2,500 3,750 5,000 6,250

0.20 3,150 4,200 5,250 3,750 5,625 7,500 9,375

0.10 6,300 8,400 10,500 7,500 11,250 15,000 18,750

0.00 NP NP NP NP NP NP NP

NP = Not Permitted

Table 2 Minimum Space Volumes were determined by using the

following equations from the National Fuel Gas Code ANSI

Z223.1/NFPA 54--2002, 8.3.3.2:

440 01 2021 01

30 40 50 50 75 100 125

Other Than Fan-Assisted Total

(1,000’sBtuh)

Fan-assisted Total

(1,000’sBtuh)

1. For other than fan--assisted appliances such as a draft

hood--equipped water heater,

9

Page 10

(

1000 Btu / hr

(

1000 Btu / hr

I

I

other

fan

)

)

3

Volume

2. For fan--assisted appliances such as this furnace,

Volume

If:

The following requirements apply to the Standard Method and to

the Known Air Infiltration Rate Method.

other

fan

= combined input of all other than fan--assisted

I

other

appliances in Btu/hr

I

= combined input of all fan--assisted appliancesin Btu/hr

fan

ACH = air changes per hour (ACH shall not exceed 0.60.)

21 ft

=

ACH

3

15 ft

=

ACH

· Adjoining rooms can be considered part of a space, if there

are no closable doors between rooms.

· An attic or crawl space may be considered a space that freely

communicateswith the outdoors provided there are adequate

ventilation openings directly to outdoors. Openings MUSTremain open and NOT have any means of being closed off. Ventilation openings to outdoors MUST be at least 1 square inch

of free area per 4,000 BTUH of total input rating for all gas appliances in the space.

· Combining s paces on the same floor level. Each opening

shall have a free area of at least 1² 2/1,000 BTUH (2,000

mm2/kW) of the total input rating of all gas appliances in the

space, but not less than 100 in2 (0.06 m2). Once opening

shall commence within 12² (300 mm) of the ceiling and the

second opening shall commence within 12² (300 mm) of the

floor. The minimumdimension of air openings shall be atleast

3² (80 mm).

· Combining spaces on different floor levels. The volumes of

spaces on different floor levels shall be considered communicating spaces if connected by one or more permanent openings in doors or floors having a free area of at least 2² 2/1,000

Btuh (4,400 mm2/kW) of total input rating of all gas appliances.

· In spaces that use the Indoor Combustion Air Method, in-

filtration should be adequate to provide air for combustion,

ventilation and dilution of flue gases. However, in buildings

with unusually tight construction, additional air MUST be provided using the methods described in section titled Outdoor

Combustion Air Method:

· Unusually tight construction is defined as Construction with

1. Walls and ceilings exposed to the outdoors have a continuous, sealed vapor barrier. Openings are gasketed or

sealed and

2. Doors and openable windows are weather stripped and

3. Other openings are caulked or sealed. These include

joints around window and door frames, between sole

plates and floors, between wall--ceiling joints, between

wall panels, at penetrations for plumbing, electrical and

gas lines, etc.

Ventilation Air

Some provincial codes and local municipalities require ventilation

or make--up air be brought into the conditioned space as replacement air. Whichever method is used, the mixed return air temperature across the heat exchanger MUST not fall below 60° so that

flue gases will not condense excessively in the heat exchanger.

Excessive condensation will shorten the life of the heat exchanger

and possibly void your warranty.

Venting and Combustion Air Check

The following information is s upplied to allow the installer to make

adjustments to the setup of existing appliances, IF REQUIRED,

based on good trade practices, local codes, and good judgement

of the installer. Manufacturer does NOT take responsibility for

modifications made to existing equipment.

NOTE: If this installation replaces an existing furnace from a

commonly vented system, the original venting system may no longer be sized to properly vent the attached appliances. An improperly sized venting system may cause the formation of condensate

in the vent and the leakage or spillage of vent gases. To make sure

there is adequate combustion air for all appliances, MAKE THE

FOLLOWING CHECK.

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

applianceconnected totheventing systembeingplaced

into operation, could result in carbon monoxide

poisoning or death:

Thefollowingstepsshall be followed for each appliance

connected to the venting system being placed into

operation, while all other appliances connected to the

venting system are not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 or CSA B149.1, Natural Gas and PropaneInstallationCodeand these instructions. Determine

that there is no blockage or restriction, leakage, corrosion

and other deficiencies which could cause an unsafe condition.

3. As far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other

spaces of the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected

to the venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they are operating at maximum speed. Do not operate a summerexhaust

fan.

6. Follow the lighting instructions. Place the appliance being

inspected into operation. Adjust the thermostat so appliance is operating continuously.

7. Test for spillage from draft hood equipped appliances at

the draft hoodrelief opening after5 minutesof main burner

operation. Use the flame of a match or candle. (Figure 6)

8. If improper venting is observed, during any of the above

tests, the venting system must be corrected in accor-

dance with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and/or CSA B149.1, Natural Gas and

Propane Installation Code.

9. After it has been determined that each appliance connected to the venting system properly vents when tested

as outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas--fired burning appliance to their previous conditions of use.

WARNING

10

440 01 2021 01

Page 11

Figure 6

Vent Check

For Two Pipe Installation

(Direct Vent)

Vent Pipe

Typical Gas

Water Heater

If flame pulls towards draft hood, this indicates

sufficient venting.

Draft Hood

Match

This furnace can NOT be c ommon vented or connected to any

type B, BW or L vent or vent connector,nor to any portion ofa facto ry--built or masonry chimney. If this furnace is replacing apreviously common-vented furnace, it may be necessary to resize the

existing vent and chimney to prevent oversizing problems for the

other remaining appliance(s). See “Venting and Combustion Air

Check” in this section. This furnace MUST be v ented to the out-

side.

4. Vent and Combustion Air Piping

!

WARNING

CARBON MONOXIDE POISONING HAZARD.

Failure to properly vent this furnace could result in

death or personal injury.

Use methods described here to provide combustion

and ventilation air.

Dual Certified (*9MPT & *9MPV Models)

Direct or Non-Direct Vent

This furnace is certified as a CategoryIVfurnace. This furnace can

be installed as a direct vent furnace using outside air for combustion or the furnace can use air from inside the s tructure for combustion. The INLET air pipe is optional. If combustion air comes from

inside the structure, adequate make up air MUST be provided to

compensate for oxygen burned. See Confined Space Installa-

tion in the Combustion and Ventilation Air chapter. If c ombus tion air is drawn from outside the structure, it MUST be taken from

the same atmospheric pressure zone as the vent pipe.

Contaminated Combustion Air

Installations in certain areas or types of structures will increase the

exposure to chemicals or halogens that may harm the furnace.

The following areas or types of structures may contain or have exposure to the substances listed below. The installation must be

evaluated carefully as it may be necessary to provide outside air

for combustion.

· Commercial buildings.

· Buildings with indoor pools.

· Furnaces installed in laundry rooms.

· Furnaces installed i n hobby or craft rooms.

· Furnaces installed near chemical storage areas.

· Permanent wave solutions for hair.

· Chlorinated waxes and cleaners.

· Chlorine based swimming pool chemicals.

· Water softening chemicals.

· De--icing salts or chemicals.

· Carbon tetrachloride.

· Halogen type refrigerants.

· Cleaning solvents (such as perchloroethylene).

· Printing inks, paint removers, varnishes, etc.

· Hydrochloric acid.

· Sulfuric Acid.

· Solvent cements and glues.

·

· Masonry acid washing materials.

Vent and Combustion Air Piping Guidelines

This furnace is approved for venting with Schedule 40 PVC,

CPVC, ABS, Cellular Core pipe fittings and SDR--26 PVC.

Materials

ABS D1527 __ F628

PVC D1785 D2241 F891

CPVC F441 F442 -- -- F438 -- -- F493

ABS to

PVC

NOTE: 1) In Canada, all pipe, fittings & cements must conform to

applicable CSA standards or to local codes having jurisdiction.

the specific venting material.

vent cement that meets the requirements of ASTM D3138.

cementing plastic pipe and fittings.

NOTE: In order to create a seal that allows future removal of pipe,

RTVsealant MUSTbe usedonthe inletpipewhere it joins to the

furnace.

NOTE: All vent piping MUSTbeinstalledincompliancewithlocal

codes or ordinances, these instructions, good trade practices, and

codes of country having jurisdiction.

1. Determine the best routing and termination for the vent pipe

2. Determine the size required for the vent pipe and air inlet

3. Loosely assemble all venting parts without adhesive (pipe

4. Furnace shall be installed so as to prevent the accumulation

Antistatic fabric softeners for clothes dryers.

Applicable ASTM Standards for Vent Materials

Sch. 40

Pipe

-- -- -- -- -- -- -- -- -- -- D3138

2) Only use solvent cements that are marked for use with

3) ABS to PVC transition joints REQUIRE a special sol-

4) Refer to ASTM D2855 for general procedure to use for

and air inlet pipe by referring to all of the instructions and

guidelines in this Section.

pipe.

joint cement) for correct fit before final assembly.

of condensate.

SDR

Pipe

Cell

Core

Pipe

Fittings Primer

D2468

&

D2661

D2466

&

D2665

-- -- D2235

F656 D2564

Solv.

Cement

440 01 2021 01

11

Page 12

5. Use of vertical piping is preferred because there will be

some moisture in the flue gases that may condense as it

leaves the vent pipe.

6. The vertical vent pipe MUSTbe supported so that no weight

is allowed to rest on the combustion blower.

7. Exhaust vent piping or air inlet piping diameter MUST NOT

be reduced.

8. All exhaust vent piping from the furnace to termination

MUST slope upwards. A minimum of

required to properly return condensate to the furnace drain

system.

9. Use DWV type long radius elbows whenever possible, as

they provide for the minimum slope on horizontal runs and

they provide less resistance in the vent system. If DWV elbows cannot be used, use two, 45° elbows when possible.

On horizontal runs the elbows can be slightly misaligned to

provide the correct slope.

10. All horizontal pipe runs MUST be supported at least every

five feet with galvanized strap or other rust resistant material. NO sags or dips are permitted.

11. All vertical pipe runs MUST be supported every six feet

where accessible.

12. The maximum pipe length is 40¢ total in the inlet or outlet

side of the system. Up to five,90° elbows can be used on the

inlet or the outlet. With the Concentric Vent TerminationKits

(NAHA001CV or NAHA002CV), the maximum pipe length

is 35¢ with490° elbows. If more elbows are required, reduce

the length of both the inlet and exhaust pipes 5¢ for each

additional elbow used. (See Table 3 or Table 4).

13. The minimum pipe run length is 2¢.

14. The piping can be run in the same chase or adjacent to supply or vent pipe for water supply or waste plumbing. It can

also be run in the same chase with a vent from another 90+

furnace.

NOTE:InNO case can the piping be run in a chase where

temperatures can exceed 140° F. or where radiated heat

from adjacent surfaces would exceed 140° F.

15. The vent outlet MUST be installed to terminate in the same

atmospheric pressure zone as the combustion air inlet.

16. The vent system can be installed in an existing unused

chimney provided that:

1

/4² per foot of run is

· Both the exhaust vent and air intake run the length of the

chimney.

· No other gas fired appliance or fireplace (solid fuel) is

vented into the chimney.

· The top of the chimney MUST be sealed flush or crowned

up to seal against rain or melting snow so ONLYthe piping

protrudes.

· The termination clearances shown in Figure 7 are main-

tained.

17. Furnace applications with vertical vents requiring vent diameter increaser fittings must have increaser fittings

installed in vertical portion of the vent. Condensate will be

trapped in the vent if the vent diameter is increased prior to

having an elbow turned upward. This could cause nuisance

tripping of the pressure switch.

Combustion Air and VentPiping Insulation

Guidelines

NOTE: Use closed cell, neoprene insulation or equivalent. If Fiberglass or equivalent insulation is used it must have a vapor barrier.

UseRvaluesof7upto10¢, R--11if exposure exceeds 10¢. If Fiber-

glass insulation is used, exterior to the structure, the pipe MUST

be boxed in and sealed against moisture.

1. When the vent or combustion air pipe height above the roof

exceeds 30², or if an exterior vertical riser is used on a horizontal vent to get above snow levels, the exterior portion

MUST be insulated.

2. When combustion air inlet piping is installed above a suspended ceiling, the pipe MUST be insulated with moisture

resistant insulation such as Armaflex or other equivalent

type of insulation.

3. Insulate combustion air inlet piping when run in warm, humid spaces.

Sizing Combustion Air and Vent Pipe

Consult Table 3 or Table 4 to select the proper diameter exhaust

and combustion air piping. Exhaust and combustion air piping is

sized for each furnace Btuh size based on total lineal vent length

(on inlet or outlet side), and number of 90° elbows required.

1. Double Pipe Installation--If installing as a direct--vent ap-

pliance, consult Table 4 to select the proper diameter exhaust and combustion air piping. Exhaust and combustion

air piping is sized for each furnace Btuh size based on total

lineal vent length (on inlet oroutlet side), and number of 90°

elbows required.

2. Single Pipe Installation--If installing as a non--direct vent

appliance, (single outlet pipe and no inlet pipe) refer to

Table 3. The table shows the maximum number of elbows

allowed with any given pipe diameter and length of run.

3. Use of Elbows--Two 45° elbows can be substituted for one

90° elbow. The elbow or elbows used for vent termination

outside the structure AREcounted, including elbows needed to bring termination above expected snow levels.

Table 3

50,000 & 75,000 Btuh Furnaces

40¢¢¢¢ & (5) 90° elbows with 2² PVC pipe

40¢¢¢¢ & (5) 90° elbows with 3² PVC pipe

40¢¢¢¢ & (5) 90° elbows with 3² PVC pipe

Elbows are DWV Long Radius Type for 2² and 3² vents.

If more than five elbows are required, reduce the length of

both the inlet and exhaust pipes 5¢ foreach additional elbow

used.

NOTE: It is allowable to use larger diameter pipe and fitting than

shown in the tables but not smaller diameters than shown.

Table 4

50,000 & 75,000 Btuh Furnaces

40¢¢¢¢ & (5) 90° elbows with 2² PVC pipe

40¢ & (5) 90° elbows with 3² PVC pipe

40¢ & (5) 90° elbows with 3² PVC pipe

Elbows are DWV Long Radius Type for 2² and 3² vents.

If more than five elbows are required, reduce the length of

both the inlet and exhaust pipes 5¢ for each additional elbow

used.

*Feetof pipe is whichever pipe run is the longest, either inlet

or outlet side.

Pipe Diameter Table

Single Piping ONLY

100,000 Btuh Furnace

125,000 Btuh Furnace

Pipe Diameter Table

Dual Piping ONLY

75,000 Btuh Furnaces

100,000 Btuh Furnace

125,000 Btuh Furnace

12

440 01 2021 01

Page 13

For “Concentric Termination Kit” Venting table, see

“Section 11” in this manual.

VentTerminationClearances

!

CARBON MONOXIDE POISONING AND FIRE

HAZARD.

Failure to properly vent this furnace could result in

death, personal injury and/or property damage.

Inlet and outlet pipes may NOT be vented directly

above each other.

WARNING

1. Determine termination locations based on clearances specified in following steps andas shownin Figure 7, Figure 8,

Figure 20, through Figure 27.

For “Concentric Termination Kit” clearances, see Figure 30,

Figure 31, Figure 32, Figure 33 and Figure 3 4 in “Section 10”

in this manual.

2. This furnace is Dual Certified and can be installed as a

single pipe appliance (all combustion from inside the structure) or asa directvent appliance where all combustionair is

taken from outside the s tructure.

3. For Single Pipe installation refer to Figure 8 for vent termination c learances.

4. For Direct Vent installation, refer to Figure 7 for vent termination.

440 01 2021 01

13

Page 14

Figure 7

Direct Vent Te rmination Clearance

X

N

Y

Y

D

E

V

B

V

O

C

F

V

VENT TERMINAL

Item Clearance Description Canadian Installation (1)

A Clearance abovegrade, veranda, porch, deck, balcony, or

anticipated snow level

B Clearance toa window or door that may be opened 6² (15cm) forappliances £ 10,000 BTUH (3kW), 12² (30

C Clearance to a permanently closed window

D Vertical clearance to a ventilated soffit locatedabovethe

terminal within a horizontal distance of 2¢ (61cm) from the

centerline of the terminal

E Clearance to an unventilated soffit

F Clearance toan outside corner

G Clearance to an inside corner

H Clearance to each side of thecenterline extendedabove

electrical meter or gas service regulator assembly

I Clearance to service regulator vent outlet 3¢ (91 cm)

J Clearance to non--mechanical air supply inlet tobuilding or

the combustion air inlet toany other appliance

K Clearance toa mechanical air supply inlet 6¢ (1.83 m) 3¢ (91cm) aboveifwithin 10¢ (3m horizontally)

L Clearance under a veranda, porch,deck, orbalcony 12² (30cm) +

M Clearance to each sideof the centerline extended above or

below vent terminal of the furnace to a dryer or water heater

vent, or other appliance’s direct ventintake or exhaust.

N Clearance from a plumbing vent stack 3¢ (91 cm) 3¢ (91 cm)

O Clearance above a pavedsidewalk or paveddriveway located

on public property.

(1.) In accordance with thecurrentCSA B149.1, Natural Gas and Propane Installation Code

(2.) In accordance with thecurrent ANSI Z223.1/NFPA 54, National Fuel GasCode

#18² (46cm) aboveroof surface

+ Permittedonly if veranda, porch, deck, or balcony is fully open ona minimum oftwo sides beneath the floor.

B

B

V

B

B

X

AIR SUPPLYINLET

12² (30cm) # 12² (30 cm)

cm) for appliances > 10,000Btuh(3 kW) and £ 100,000 Btuh

(30kW), 36² (91 cm) forappliances > 100,000Btuh (30 kW)

* *

* *

* *

* *

* *

3¢ (91 cm) within15¢ (4.5 m) abovethe meter/regulator

assembly

6² (15 cm) for appliances £ 10,000 BTUH (3kW), 9² (23 cm)

for appliances > 10,000Btuh (3 kW) and £ 100,000 Btuh (30

kW) and £ 50,000 Btuh (15 kW), 12² (30 cm) forappliances

> 50,000Btuh(15 kW)

12² (30cm) 12² (30cm)

7¢ (2.13 m) 7¢ (2.13 m)

B

X

J

A

H

I

L

AREA WHERE TERMINAL IS NOT PERMITED

X

G

V

K

6² (15cm) forappliances £ 10,000 BTUH (3kW), 9² (23cm)

for appliances > 10,000Btuh (3 kW) and £ 50,000Btuh (15

kW), 12² (30 cm) for appliances > 50,000 Btuh(15 kW)

3¢ (91 cm) within15¢ (4.5 m) above themeter/regulator

assembly

A

U.S. Installation (2)

*

6² (15 cm) for appliances £ 10,000 BTUH (3kW), 9² (23 cm)

for appliances > 10,000Btuh (3 kW) and £ 50,000 Btuh (15

kW), 12² (30 cm) for appliances > 50,000Btuh(15 kW)

*

M

V

25--24--65--2

* Forclearancesnot specifiedin ANSIZ223.1/NFPA 54orCSAB149.1, clearancesshallbe inaccordance withlocal installation codesand therequirements ofthe gassupplier andthemanufacture’sinstallation

instructions.

** A vent shall not terminate directly above a sidewalk or paved driveway thatislocated between two single family dwellingsand serves both dwellings.

Notes:

1. The vent forthis appliance shall notterminate

a. Over public walkways; or

b. Nearsoffitvents or crawl space vents or other areas where condensate or vapor could create a nusiance or hazard orproperty damage;or

c. Where condensate vapor could cause damageor could be detrimental to the operation ofregulators, relief valves, or otherequipment.

2. Whenlocatingvent terminations,considerationmustbe given to prevailingwinds, location,andother conditions which may cause recirculation of the combustion products ofadjacent vents.

Recirculation can cause poor combustion, inlet condensate problems, and accelerated corrosion of the heat exchangers.

14

440 01 2021 01

Page 15

Figure 8

Other than Direct Vent Termination Clearance

N

Y

Y

D

E

V

B

O

V

C

F

B

V

VENT TERMINAL

Item Clearance Descriptions Canadian Installation (1)

A Clearance abovegrade, veranda, porch, deck, balcony, or

anticipated snow level

B Clearance toa window or door that may be opened 6² (15cm) forappliances £ 10,000 BTUH (3kW), 12² (30

C Clearance to a permanently closed window

D Vertical clearance to a ventilated soffit locatedabovethe

terminal within a horizontal distance of 2¢ (61cm) from the

centerline of the terminal

E Clearance to an unventilated soffit

F Clearance toan outside corner

G Clearance to an inside corner

H Clearance to each side of thecenterline extendedabove

electrical meter or gas service regulator assembly

I Clearance to service regulator vent outlet 3¢ (91 cm)

J Clearance to non--mechanical air supply inlet tobuilding or

the combustion air inlet toany other appliance

K Clearance toa mechanical air supply inlet 6¢ (1.83 m) 3¢ (91cm) aboveifwithin 10¢ (3m horizontally)

L Clearance under a veranda, porch,deck, orbalcony 12² (30cm) +

M Clearance to each sideof the centerline extended above or

below vent terminal of the furnace to a dryer or water heater

vent, or other appliance’s direct ventintake or exhaust.

N Clearance from a plumbing vent stack 3¢ (91 cm) 3¢ (91 cm)

O Clearance above a pavedsidewalk or paveddriveway located

on public property.

(1.) In accordance with thecurrentCSA B149.1, Natural Gas and Propane Installation Code

(2.) In accordance with thecurrent ANSI Z223.1/NFPA 54, National Fuel GasCode

#18² (46cm) aboveroof surface

+ Permittedonly if veranda, porch, deck, or balcony is fully open ona minimum oftwo sides beneath the floor.

B

V

B

B

X

AIR SUPPLYINLET

12² (30cm) # 12² (30 cm)

cm) for appliances > 10,000Btuh(3 kW) and £ 100,000 Btuh

(30kW), 36² (91 cm) forappliances > 100,000Btuh (30 kW)

* *

* *

* *

* *

* *

3¢ (91 cm) within15¢ (4.5 m) abovethe meter/regulator

assembly

6² (15 cm) for appliances £ 10,000 BTUH (3kW), 12² (30

cm) for appliances > 10,000Btuh(3 kW) and £ 100,000 Btuh

(30kW), 36² (91 cm) forappliances > 100,000Btuh (30 kW)

* *

7¢ (2.13 m) 7¢ (2.13 m)

B

X

J

A

H

I

L

X

G

V

K

AREA WHERE TERMINAL IS NOT PERMITED

4¢ (1.2m)belowor to the side of the opening. 1¢ (30 cm)

above theopening.

3¢ (91 cm) within15¢ (4.5 m) above themeter/regulator

assembly

A

*

4¢ (1.2m)belowor to the side ofopening:1¢ (30 cm) above

opening.

*

M

V

25--24--65--2

U.S. Installation (2)

* For clearances not specifiedin ANSI Z223.1/NFPA 54 orCSA B149.1, clearances shall be inaccordance with local installation codes and therequirements ofthe gas supplier and the manufacture’s

installation instructions.

** A vent shall not terminate directly above a sidewalk or paved driveway thatislocated between two single family dwellingsand serves both dwellings.

Notes:

1. The vent forthis appliance shall notterminate

a. Over public walkways; or

b. Nearsoffitvents or crawl space vents or other areas where condensate or vapor could create a nusiance or hazard orproperty damage;or

c. Where condensate vapor could cause damageor could be detrimental to the operation ofregulators, relief valves, or otherequipment.

2. Whenlocatingvent terminations,considerationmustbe given to prevailingwinds, location,andother conditions which may cause recirculation of the combustion products ofadjacent vents.

Recirculation can cause poor combustion, inlet condensate problems, and accelerated corrosion of the heat exchangers.

440 01 2021 01

15

Page 16

CondensateDrain Trap

This furnace removes both sensible and latent heat from the products of combustion. Removal of the latent heat results in condensation of the water vapor. The condensate is removed from the

furnace through the drains in the plastic transition and the vent fitting. The drains connect to the factory installed internally mounted

condensate drain trap on the left or right side of the furnace.

The startup of a new furnace will involve a cycle or two of the furnace to properly prime the condensate trap with water. Until the

trap is fully primed, some condensate will be pulled into the combustion blower. The furnace may cycleon the pressure switch connected to the plastic transition box due to condensate buildup.

After the trap is primed, the condensate will start draining from the

furnace. The combustion blower will clear out any remaining condensate in the blower housing through the vent fitting downstream

of the blower. Note that the condensate trap can also be primed by

pouring water into the

hose from either the gutter or the white PVC Tee Trap.Using a fun nel pour eight (8) ounces of water into

flow through the drain hose and into the condensate drain trap.

This will prime both the vent and the transition sides of the trap.Reconnect the

gutter or the PVC Tee Trap.

The condensate drain trap supplied with the furnace MUST be

used. The drain connection on the condensate drain trap is sized

3

/4² PVC or CPVC pipe, however alternate1/2² CPVC (nominal

for

5

/8² O.D.) or vinyl tubing with a minimum inner diameter (I.D.) of

5

/8² may also be used, as allowed by local codes. Alternate drain

pipes and hoses may be used as allowed by local codes.

The drain line must maintain a

the drain.1/4² per foot is recommended. Installation of an overflow

line is recommended when the1/4² per foot slope to the condensate drain cannot be maintained. See Figure 18 for proper routing

and installation of the overflow.

DO NOT trap the drain line in any other location than at the condensate drain trap supplied with the furnace.

If possible, DO NOT route the drain line where it may freeze. The

drain line must terminate at an inside drain to prevent freezing of

the condensate and possible property damage.

1

/2² ID drain hose to the original component, either the

1

/2² drain hose. Remove the1/2² ID drain

1

/2² ID drain hose.Water will

1

/4² per footdownward slope toward

1. A condensate sump pump MUST be used if required by lo-

cal codes, or if no indoor floor drain is available. The condensate pump must be approved for use with acidic

condensate.

2. A plugged condensate drain line or a failed condensate

pump will allow condensate to spill. If thefurnace is installed

where a condensate spill could cause damage, it is recommended that an auxiliary safety switch be installed to prevent operation of the equipment in the event of pump failure

or plugged drain line. If used, an auxiliary safety switch

should be installed in the R c ircuit (low voltage) ONLY.

3. If the auxiliary switch in the condensate pump is used, the

furnace may shut down due to a blocked condensate line or

failed pump. To prevent frozen water pipes see the “Frozen

Water Pipe Hazard” section on Page 4 of this manual.

!

CAUTION

FROZEN AND BURST WATER PIPE HAZARD

Failure to do so may result in burst water pipes,

serious property damage.

If a condensate pump is installed, a plugged

condensate drain or a failed pump may cause the

furnace to shut down. Do not leave the home

unattended during freezing weather without turning

off water supply and draining water pipes or

otherwiseprotectingagainsttheriskof frozenpipes.

Condensate Drain Trap Freeze Protection

Special precautions MUST be made if installing furnace in an area

which may drop below freezing. This can cause improper operation or damage to the equipment. If the the furnace environment

has the potential of freezing, the drain trap and drain line must be

protected. Use 3 to 6 watt per foot at 115volt, 40° F self--regulating

shielded and waterproof heat tape. Wrap the drain trap and drain

line with the heat tape and secure with the ties. Follow the heat

tape manufacturer’s recommendations. Prime the trap before furnace operation.

16

440 01 2021 01

Page 17

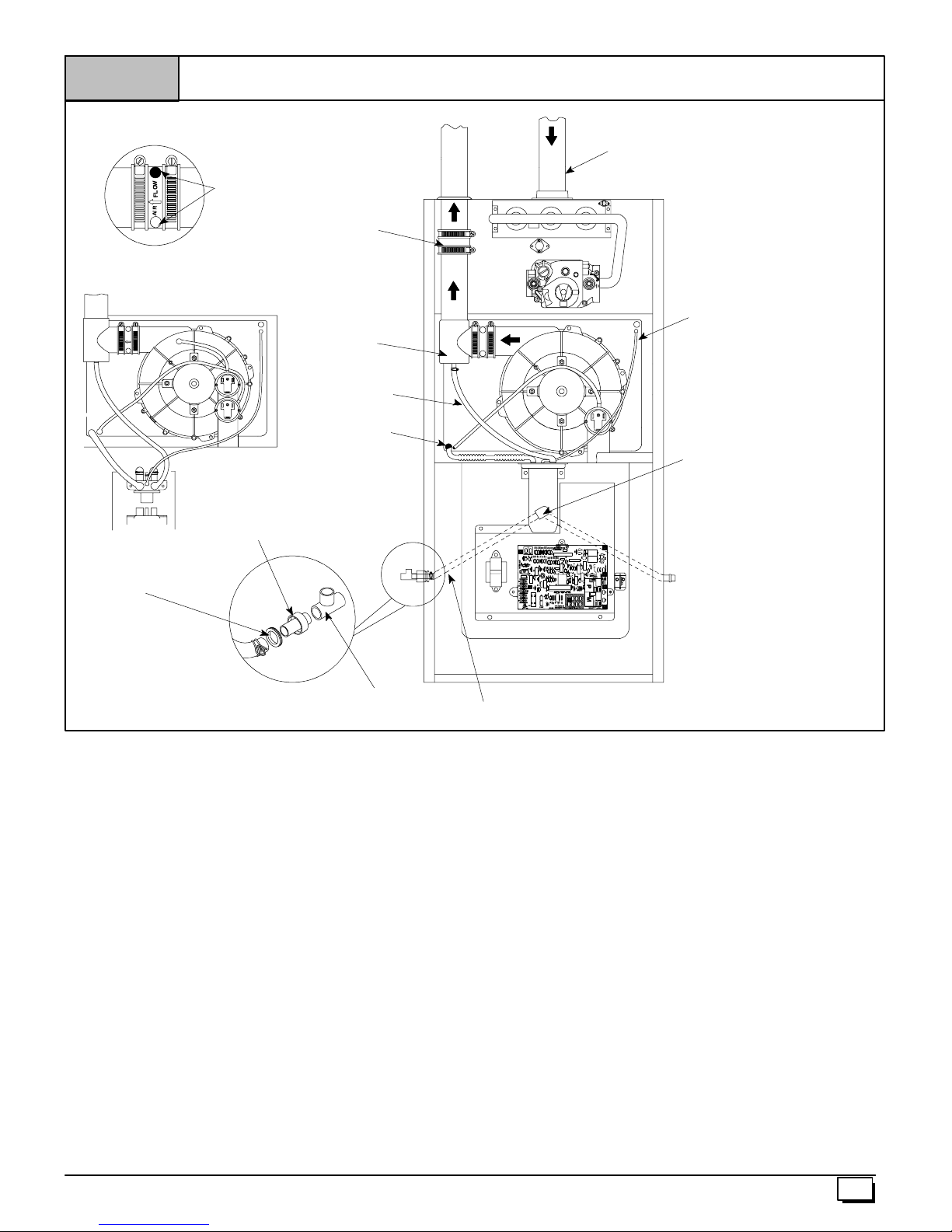

Figure 9

Upflow Installations Top Vent

Vent Drain

&Clamps

Dual Pressure Switch Detail

FLOW

AIR

Casing Grommet

Black Rubber

5

/

²

² ID

²²

8

(Loose partsbag)

Plastic Caps (2)

Yellowor black

Coupling & Clamps

(Optional)

DrainTee

Drain Tube

Black Rubber

1

/

²

² ID&Clamps

²²

2

Drain Tube

Corrugated

5

Drain ConnectorBlack PVC

3

/

²

² PVC X1/

²²

4

(Loose partsbag)

²

² CPVC

²²

2

/

²

² ID&Clamps

²²

8

EXHAUST

ON

On Some Models

ONLY

Single Pressure Switch

ReliefTube

Black Rubber

StreetElbow

1

/

²

² CPVC

²²

2

(Loose partsbag)

3

/

²

² ID

²²

16

INLET

V

E

N

T

IN

OFF

Drain LineVent Tee

1

/

²

² CPVC (Field supplied)

²²

2

3

/

²

² PVC or

²²

4

Drain TubeBlack Rubber5/

Cut lengthtofit (Loose parts bag)

²

² ID & Clamps,

²²

8

25--24--67

Upflow Installations Top Vent (See Figure 9)

Remove plug from the sideof the furnace casing where Drain Tube

will exit.

5

Install casing grommet (black rubber

/8² ID grommet -- in loose

parts bag)

1

Install the

Install the black PVC tube connector (

/2² CPVC street elbow on discharge of Trap

3

/4² PVC x1/2² CPVC from

loose parts bag) as shown in the illustration above.

5

Cut the black Drain Tube (

/8² ID -- in loose parts bag) to length to

fit between Trap and tube connector through grommet.

Clamp both ends of the Drain Tube using clamps provided.

NOTE: “PVC” is used as a generic term. Pipe and fitting materials used must be acceptable to the local code officials having

jurisdiction.

Glue the CPVC street elbow to the Trap using appropriate cleaner

and solvent cement.

Connect the Tee trap and the main drain line exiting the casing as

shown Figure 18.

Note: It is recommended that all PVC piping and fitting connections be fit up and inspected before final cementing. Trapmustbe

primed before operation. Verify all condensate drain connections are securely clamped. A coupling and clamps (in loose part

bag) may be installed as shown for future servicing of the vent system.

440 01 2021 01

17

Page 18

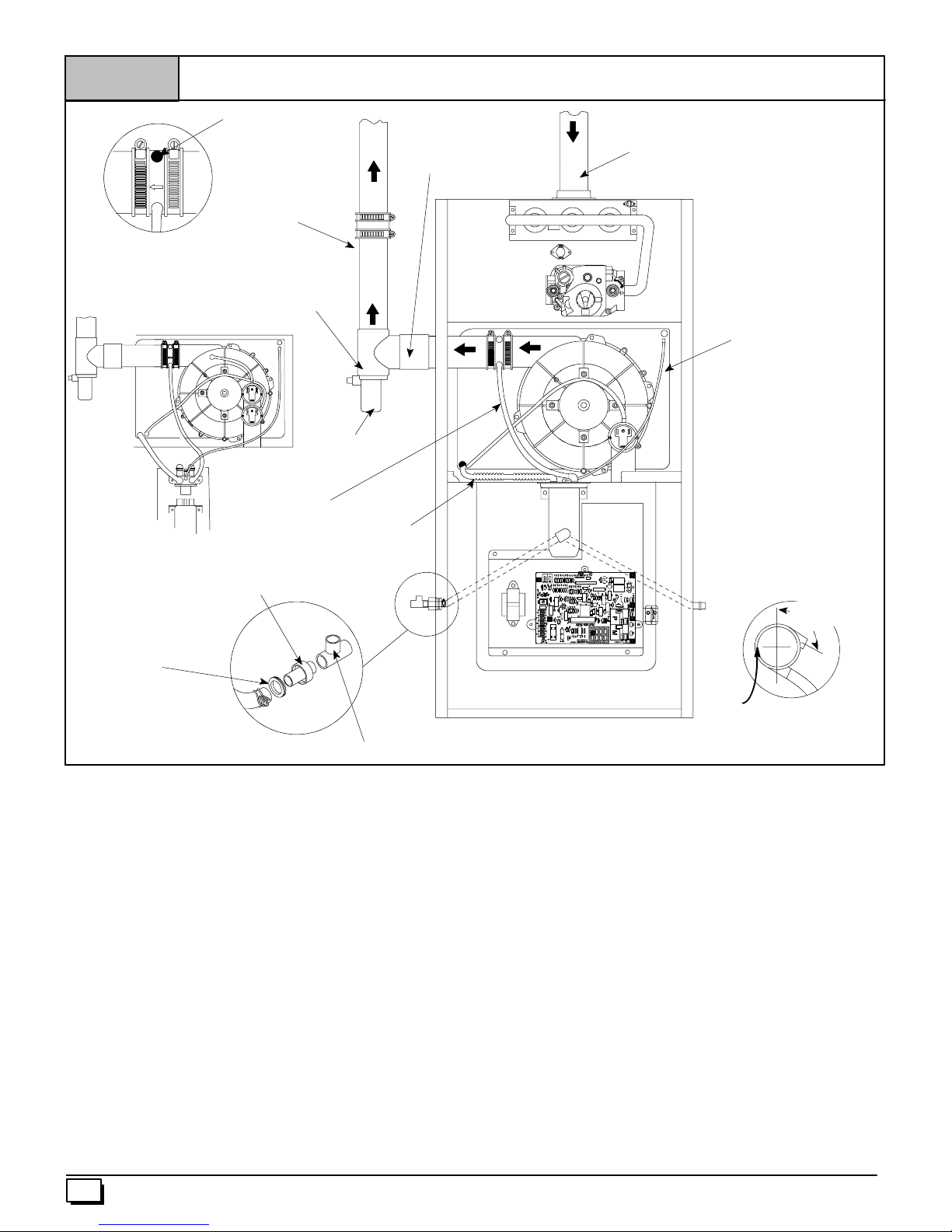

Figure 10

Vent Drain

&Clamps

Upflow Installations Vent thru Left Side

Dual Pressure Switch Detail

AIR FLOWAIR FLOW

Drain ConnectorBlack PVC

3

/

²

² PVC X1/

²²

4

(Loose partsbag)

Plastic Cap

Yellowor black

Coupling & Clamps

(Optional)

Either:The PVC

Drain Teeor a field

supplied 2²²²² PVC Tee

Drain Tube

Black Rubber

1

/

²

² ID&Clamps

²²

2

²

² CPVC

²²

2

EXHAUST

TeeTrap White PVC

(loose partsbag)

Drain Tube

Corrugated

5

/

²

² ID&Clamps

²²

8

2²²²² PVC Coupling

INLET

On Some Models

ONLY

V

E

N

T

IN

ON

OFF

Single Pressure Switch

ReliefTube

Black Rubber

3

/

²

² ID

²²

16

SIDE VIEW

Rotate downward

5°°°° to 10°

°

°°

Casing Grommet

Black Rubber

5

/

²

² ID

²²

8

(Loose partsbag)

Drain LineVentTee

3

/

²

² PVC or1/

²²

4

²

² CPVC (Fieldsupplied)

²²

2

Upflow Installations Vent thru Left Side (See Figure 10)

Remove Drain Tee from inducer discharge and remove black

Drain Tube (1/2² ID) from bottom of Drain Tee. (*9MPT or V models

only)

Install Vent Pipe grommet in side of casing.

Cut an appropriate length of 2² PVC pipe long enough to exit the

cabinet and connect the vent drain to either:

· A2² PVC coupling fastened onto the Drain Tee (*9MPT or V

models)

Install Tee trap into bottom of tee.

Install the

Install the black PVC drain connector (

1

/2² CPVC street elbow on discharge of Trap

3

/4² PVC x1/2² CPVC from

loose parts bag) as shown in the illustration above.

Cut the black Drain Tube (5/8² ID -- in loose parts bag) to length to

fit between Trap and tube connector through grommet.

Clamp both ends of the Drain Tube using clamps provided.

Glue the CPVC street elbow to the Trap using appropriate cleaner

and solvent cement.

Connect the Tee trap and the main drain line exiting the casing as

shown in Figure 18.

Note: It is recommended that all PVC piping and fitting connections be fit up and inspected before final cementing. Both the in-

ternal Trap and the external Tee Trap must be primed before

operation. Verify all condensate drain connections are securely

clamped. A c oupling and clamps (in loose part bag) may be

installed as shown for future servicing of the vent system.

NOTE: Built- -inchannel will

be angled5° to 10° also.

25--24--67a

18

440 01 2021 01

Page 19

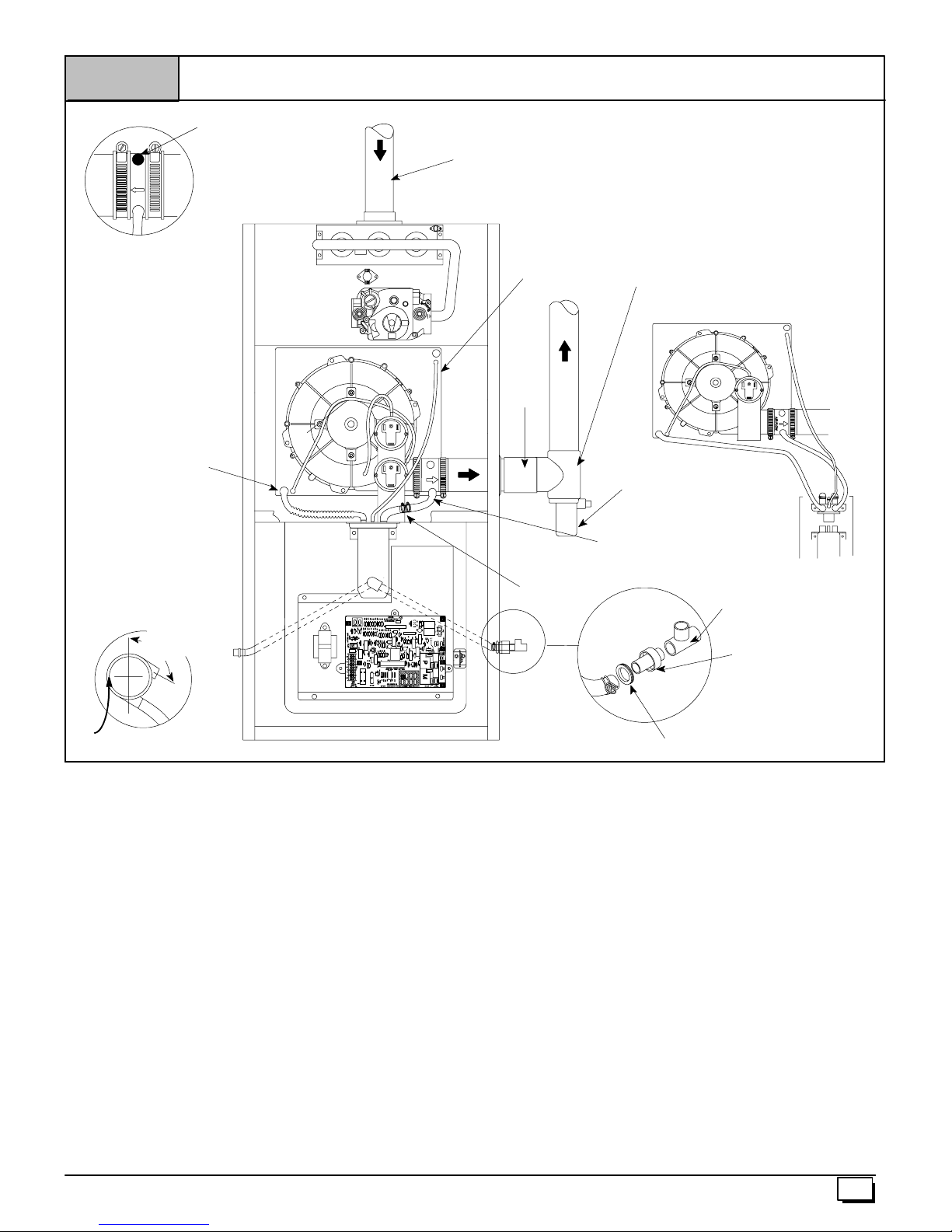

Figure 11

All Models Vent thru Right Side

Plastic Cap

Yellowor black

INLET

Dual Pressure Switch

On Some Models

ONLY

Vent Drain

&Clamps

Drain Tube

Corrugated

5

/

²

² ID&Clamps

²²

8

SIDE VIEW

Rotate

downward

5°°°° to 10°

Relief Tube

Black Rubber

3

/

²

² ID

²²

V

E

N

T

IN

ON

OFF

16

Either:The PVC

Drain Teeor a field

supplied 2²²²² PVC Tee

Single Pressure Switch Details

2²²²² PVC

Coupling

EXHAUST

AIR FLOW

TeeTrap White PVC

(loose partsbag)

Elbow Tubes(2) Black Rubber

1

/

²

² ID&Clamps

²²

2

(loose partsbag)

Barbed Coupling,1/

(loose partsbag)

°

°°

²

² OD

²²

2

²

² CPVC

²²

2

3

/

4

Drain LineVentTee

1

/

²

² CPVC (Field supplied)

or

²²

2

Drain ConnectorBlack PVC

3

/

²

² PVC X1/

²²

4

(Loose partsbag)

²

² PVC

²²

NOTE: Built- -inchannel will

be angled5° to 10° also.

All Models Vent thru Right Side (See Figure 11)

Disconnect the black Drain Tube between the drain vent and the

Trap.

Rotate the inducer 180° for a right side vent after loosening the 4

inducer attachment screws. Reinstall and retighten the inducer

screws to 20² pounds torque.

Using the1/2² OD barbed coupling in the loose parts bag connect

together with the 2 short1/2² ID elbow tubes and connect the lower

discharge port of the vent drain to the Trap. Secure allconnections

with clamps.

Install the vent pipe grommet into the casing

Cut an appropriate length of 2² PVC pipe long enough to exit the

cabinet and connect the vent drain to either:

· A2² PVC coupling fastened onto the Drain Tee

Install Tee Trap into bottom section of Tee.

Remove plug from the sideof the furnace casing where Drain Tube

will exit.

Casing Grommet

Black Rubber

(Loose partsbag)

Install casing grommet (black rubber

5

/

²

² CPVC

²²

8

5

/8² ID grommet -- in loose

25--24--68

parts bag)

1

Install the

Install the black PVC tube connector (

/2² CPVC street elbow on discharge of Trap

3

/4² PVC x1/2² CPVC from

loose parts bag) as shown in the illustration above

5

Cut the black Drain Tube (