Page 1

INSTALLATION AND PARTS MANUAL

e

REMOTE CONDENSERS

MODELS: VRC

Ice-O-Matic

11100 East 45th Av

Denver, Colorado 80239

Part Number 9081245-01 Date 3/08

Page 2

*

Page 3

Remote Condenser Introduction

How To Use This Manual

Ice-O-Matic provides this manual as an aid to the service technician in installation and maintenance of

remote condensers. Do not attempt to perform installation, start-up or maintenance unless you have

read and fully understand this manual.

If, at any time, you encounter conditions that are not addressed in this manual, call, E-mail or write the

Ice-O-Matic Service Department:

Ice-O-Matic

11100 E. 45

Denver, Co. 80239

Attn: Technical Service Department

E-Mail: Tech.service@iceomatic.com

Telephone Numbers

800-423-3367 All Departments

888-349-4423 Technical Assistance Only (After Hours Only)

Any Service communication must include:

• Model Number

• Serial Number

• A detailed explanation of the problem

Keep this manual for future reference.

Ice-O-Matic icemakers and dispensers are not approved for outdoor installation.

WARNING

or repairs are performed on the ice machine and related equipment.

CAUTION:

the ice machine and related equipment.

th

Ave.

: Always disconnect electrical power and shut off water supply whenever maintenance

Always wear protective eyewear whenever maintenance or repairs are performed on

Page i

Page 4

Remote Condenser Table of Contents

Introduction Page i

Table of Contents Page ii

Freight Claim Procedure Page iii

Warranty Page iv

General Information Page 1

Installation Guidelines Page 2

Remote Refrigeration System Page 4

Component Description Page 5

Installation Page 6

Service Parts VRC

Page 10

Page ii

Page 5

Remote Condenser Freight Claim Procedure

Freight Claims Important!

Inspect Promptly

This merchandise has been carefully inspected and packed in accordance with the carrier’s packing

specifications. Responsibility for safe delivery has been assumed by the carrier. If loss or damage occurs,

you as the consignee must file a claim with the carrier and hold the container for carrier’s inspection.

Visible Loss or Damage

Any external evidence of loss or damage must be fully described and noted on your freight bill or express

receipt and signed by the carrier’s agent. The claim should be filed on a form available from the carrier.

Concealed Loss or Damage

If loss or damage does not appear until merchandise has been unpacked, make a written request for

inspection by the carrier within 15 days of the delivery date. Then file a claim on a form from the carrier.

File Claim Without Delay

Do Not Return Damaged Merchandise to Ice-O-Matic

Page iii

Page 6

Remote Condenser Warranty

Ice-O-Matic

Domestic & International Limited Warranty

Mile High Equipment LLC (the “Company”) warrants Ice-O-Matic brand ice machines, ice dispensers, remote condensers, water filters, and ice

storage bins to the end customer against defects in material and factory workmanship for the following:

• Cube ice machines,”GEM” model compressed ice

machines ,” MFI” model flake ice machines and remote

condensers. - Thirty-six (36) months parts and labor

• “EF” and “EMF” model flake ice machines - Twenty-four

(24) months parts and labor

• CD model dispensers - Thirty-six (36) months parts and

labor

An additional twenty-four (24) month warranty on parts (excluding labor) will be extended to all cube ice machine evaporator plates and

compressors, “GEM” model compressed ice machine compressors, and “MFI” model flake ice machine compressors from the date of original

installation. An additional thirty-six (36) month warranty on parts (excluding labor) will be extended to all “EF” and “EMF” model flake ice machine

compressors from the date of original installation. The company will replace EXW (Incoterms 2000) the Company plant or, EXW (Incoterms 2000)

the Company-authorized distributor, without cost to the Customer, that part of any such machine that becomes defective. In the event that the

Warranty Registration Card indicating the installation date has not been returned to Ice-O-Matic, the warranty period will begin on the date of

shipment from the Company. Irrespective of the actual installation date, the product will be warranted for a maximum of seventy-two (72) months

from date of shipment from the Company.

ICE-model cube ice machines which are registered in the Water Filter Extended Warranty Program will receive a total of eighty-four (84) months

parts and labor coverage on the evaporator plate from the date of original installation. Water filters must be installed at the time of installation and

registered with the Company at that time. Water filter cartridges must be changed every six (6) months and that change reported to the Company to

maintain the extended evaporator warranty.

No replacement will be made for any part or assembly which (I) has been subject to an alteration or accident; (II) was used in any way which, in the

Company’s opinion, adversely affects the machine’s performance; (III) is from a machine on which the serial number has been altered or removed;

or, (IV) uses any replacement part not authorized by the Company. This warranty does not apply to destruction or d amage caused by unauthori zed

service, using other than Ice-O-Matic authorized replacements, risks of transportation, damage resulting from adverse environmental or water

conditions, accidents, misuse, abuse, improper drainage, interruption in the electrical or water supply, charges related to the replacement of nondefective parts or components, damage by fire, flood, or acts of God.

This warranty is valid only when installation, service, and preventive maintenance are performed by a Company-authorized distributor, a Companyauthorized service agency, or a Company Regional Manager. The Company reserves the right to refuse claims made for ice machines or bins used

in more than one location. This Limited Warranty does not cover ice bills, normal maintenance, after-install adjustments, and cleaning.

Limitation of Warranty

This warranty is valid only for products produced and sh ipped from the Company after January, 2007. A product produced or installed

before that date shall be covered by the Limited Warranty in effect at the date of its shipment . The liability of the Company for breach of

this warranty shall, in any case, be limited to the cost of a new part to replace any part, which proves to be defective. The Company

makes no representations or warranties of any character as to accessories or auxiliary equipment n ot manufactured by the Company.

REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE CUSTOMER. MILE HIGH

EQUIPMENT SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH OF ANY EXPRESS OR

IMPLIED WARRANTY ON THIS PRODUCT. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, ANY IMPLIED WARRANTY OR

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ON THIS PRODUCT IS LIMITED IN DURATI ON TO THE LENGTH OF THIS

WARRANTY.

Filing a Claim

All claims for reimbursement must be received at the factory within 90 days from date of ser vice

this time period will be void. The model, the serial number and, if necessary, proof of installation, must be included in the claim. Claims for labor

to replace defective parts must be included with the part claim to receive consideration. Payment on claims for labor will be limited to the published

labor time allowance hours in effect at the time of repair. The Company may elec t to require the return of components to validate a claim. Any

defective part returned must be shipped to the Company or the Company-authorized distributor, transportation charges pre-paid, and properly

sealed and tagged. The Company does not assume any responsibility for any expenses incurred in the field incidental to the repair of equipment

covered by this warranty. The decision of the Company with respect to repair or replacement of a part shall be final. No person is authorized to give

any other warranties or to assume any other liability on the Company’s behalf unless done in writing by an officer of the Company.

GOVERNING LAW

This Limited Warranty shall be governed by the laws of the state of Delaware, U.S.A., excluding their conflicts of law principles. The United Nations

Convention on Contracts for the International Sale of Goods is hereby excluded in its entirety from application to this Limited Warranty.

Mile High Equipment LLC, 11100 East 45

Parts and Labor

• Ice storage bins -Twenty-four (24) month parts and labor

• IOD model dispensers - Twenty-four (24) months parts, Twelve (12) months

labor

• Water filter systems - Twelve (12) months parts and labor (not including filter

cartridges)

to be eligible for credit. All claims outside

th

Avenue, Denver, Colorado 80239 (303) 371-3737

January 2007

Page iv

Page 7

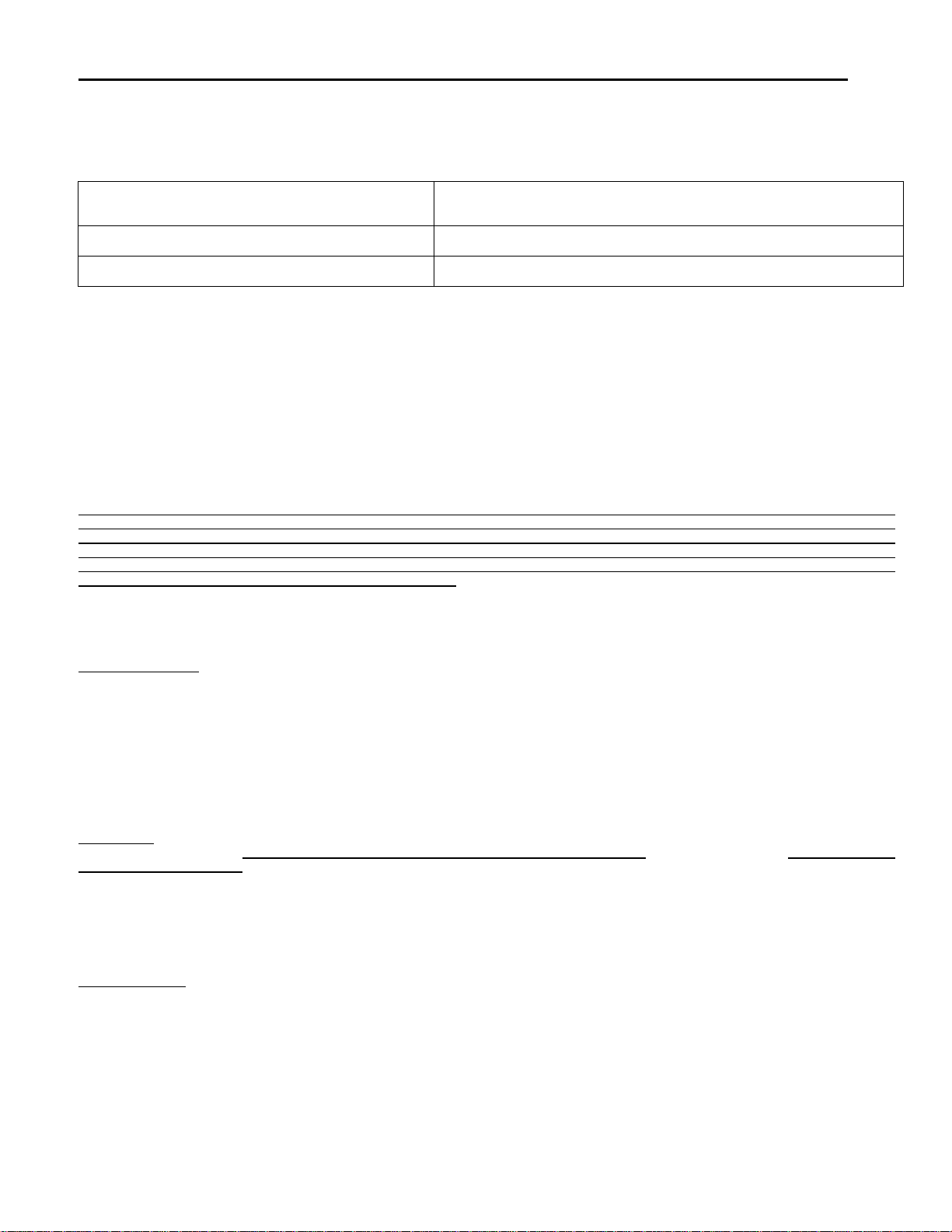

Remote Condenser General Information

Condenser Dimensions (Inches)

Model Length Width Height Compatible With:

VRC1001 29.18 29.50 38.90 ICE0500R4

VRC1061 29.18 29.50 38.90 ICE0605/6R4, EMF1106R2

VRC2061 29.18 29.50 38.90 ICE0805/6/R3, ICE1005/6/7R3,

EMF2306R2

VRC2661 29.18 29.50 38.90 ICE1405/6/7R3, ICE1506R3

VRC5061 37.78 29.50 38.76 ICE1806/7R3, ICE2106/7R3

Note the warning symbol where it appears in this manual.

It is an alert for important safety information on a hazard that might cause serious injury.

Keep this manual for future reference.

Verify the ICE machine is compatible with the remote condenser. Some ice machines and some

remote condensers may or may not have a Mixing Valve (Head Master). Only one valve is required

per system. Kits are available to modify the remote condenser for compatibility. For more

information contact your Ice-O-Matic Distributor.

VRC Condenser

Page 1

Page 8

Remote Condenser General Information

V

r

A

Introduction

Ice-O-Matic Remote Condenser Systems are comprised of three components. The pre-charged remote

condenser, the pre-charged ice maker and the pre-charged line set. The pre-charged line sets are available

in 25, 40, 45, 60 or 75 foot line set lengths. The 60 foot line set will require adding an additional 16 ounces

of refrigerant to the system. The 75 foot line set will require adding an additional 28 ounces of refrigerant to

the system.

Normal installation of the ice maker should be followed. Reference the installation instructions included with

the ice maker.

In any installation, the pre-charged line sets, consisting of a liquid line (3/8” dia.) and a discharge line

(1/2” dia.) are used as a one time initial charge type installation.

Once the sealed couplings are connected and the internal seal is broken, the lines cannot be disconnected

without losing the refrigerant charge. They are, however, reusable and when the couplers are removed and

reconnected, the complete refrigeration system must be evacuated and re-charged with the proper amount

of refrigerant. Reference the ice maker data plate or ice maker service manual for proper refrigerant

charge.

General Description

The remote condenser should not be used in areas where sufficient airflow is not available in the area the

ice maker is being installed or the heat being rejected by the condenser coil will be undesirable.

The condenser coil should not be exposed to temperatures below -20°F (-29°C) or above 120°F (49°C).

The remote condenser functions as a normal refrigeration system until the temperature at the condenser

coil drops below 70°F. At this time the mixing valve will begin to bypass enough hot gas from the discharge

line directly into the receiver to keep the liquid line feeding the expansion valve at a steady pressure. The

amount of gas bypassed will depend on the temperature at the condenser coil (the colder the temperature

at the condenser coil, the more gas will bypass and the tubing between the mixing valve and receiver will

become warmer). For the complete explanation of this valve, refer to the schematic on page 6 of this

manual.

Condenser Location

When choosing a location for the remote condenser,

reference the following guidelines:

1. Choose a location that is protected from extremes of

dirt, dust, rain, sun and prevailing winds.

2. Vertical air discharge mounting of the condenser is

required.

3. Condenser should be mounted higher than the ice

machine.

4. Condenser must be level.

5. Condenser should not be exposed to temperatures

below -20°F or above 120°F.

6. Installation must meet all local and national building,

plumbing and electrical codes.

RC Condense

irflow

Page 2

Page 9

Remote Condenser General Information

p

The VRC

a 100 foot calculated remote line set run. Reference the diagram below to calculate the maximum 100 foot

line set run.

Limitations for new remote machines that have the mixing valve mounted in the condenser.

Maximum Rise is 35 feet.

Maximum Drop is 15 feet.

Maximum equivalent run is 100 feet.

Formula for figuring maximum equivalent run is as follows:

Rise x 1.7 + Drop x 6.6 + horizontal run = equivalent run.

Examples: 35 ft. rise x 1.7 + 40 ft. horizontal = 99.5 equivalent feet line run

remote condensers incorporate the mixing valve in the condenser. This configuration allows up to

35 ft. rise

40 ft. horizontal

Verify the ICE machine is compatible with the remote

condenser. Some ice machines and some remote condensers

may or may not have a Mixing Valve (Head Master). Only one

valve is required per system. Kits are available to modify the

remote condenser for compatibility. For more information

contact your Ice-O-Matic Distributor.

34 ft. horizontal

10 ft. dro

10 ft. drop x 6.6 + 34 ft horizontal = 100 equivalent feet line run

Page 3

Page 10

Remote Condenser Remote Refrigeration System

The Remote Refrigeration System is shown in the above diagram. During the freezing cycle, high

temperature and high pressure liquid refrigerant is directed from the condenser through a mixing valve,

receiver, liquid line solenoid heat exchanger and a filter drier. The expansion valve meters refrigerant to the

coils on the back of the evaporator.

In low ambient conditions (below 70°F air temperature at the condenser) the mixing valve opens to mix

discharge gas with liquid returning from the condenser, in the receiver, to maintain discharge and liquid line

pressures.

The low temperature and pressure refrigerant leaving the evaporator is directed through the suction line

heat exchanger and is returned to the compressor. There it is compressed to a high temperature and high

pressure gas. It is then directed to a condenser to be converted again to a high pressure and high

pressure liquid.

During the harvest cycle, the hot gas solenoid valve (normally closed during the freeze cycle), opens and

directs the high temperature gas leaving the compressor into the evaporator. Once the evaporator has

reached approximately 40°F, the harvest motor overcomes the capillary attraction of the ice and the

evaporator releases the ice. At the end of the harvest cycle, the hot gas solenoid valve closes and another

freeze cycle begins.

During the off cycle, the liquid line solenoid valve closes and the system will pump down to 10-20 psi to

prevent refrigerant migration to the low side of the system.

Page 4

Page 11

Remote Condenser Component Description

Mixing Valve (Headmaster, Low Ambient Control Valve)

This valve serves as the head pressure regulating valve. It contains a pre-determined charge of nitrogen in

the valve bellows. When the temperature at the condenser is above 70°F (21°C), the refrigerant flow from

the compressor is directed by the mixing valve through the condenser and into the receiver. When the

temperature at the condenser drops below 70°F (21°C), the pressure in the bellows of the mixing valve

becomes greater than the pressure of the liquid refrigerant

coming from the condenser.

This change allows the valve to partially restrict the flow of

refrigerant leaving the condenser and allows discharge gas

to by-pass the condenser and flow directly into the receiver,

mixing with the liquid refrigerant from the condenser. The

amount of discharge gas that bypasses the condenser

increases as the ambient temperature decreases.

This action of the mixing valve allows the discharge

pressure to be maintained at approximately 217 psi during

low ambient conditions. If the refrigerant system is

undercharged and the ambient temperature is below 70°F

(21°C), the mixing valve will not work properly. The mixing

valve will allow too much refrigerant to bypass the

condenser.

Receiver

The quantity of liquid refrigerant in the receiver will vary with the temperature at the condenser

coil.

Liquid Line Solenoid and Pump Down Low Pressure Control

When the bin is full or the ON-OFF switch is turned to the OFF position, the liquid line

solenoid valve closes and the system begins to pump down. When the low pressure

reaches 10-20 psi, the pump down low pressure control opens and the contactor shuts

the machine off.

As the ice is removed from the bin or the ON-OFF switch is turned to the ON position, the

liquid line solenoid valve opens and the high side and low side pressures begin to equalize.

When the low side pressure reaches 50-75 psi, the pump down low pressure control closes and

the machine begins a freeze cycle.

When the machine is off for extended periods of time (either a full bin or the ON-OFF switch in

the OFF position), it will pump down approximately once every hour. This is due to the

equalization of pressures during the off cycle resetting the pump down low pressure control. It is

a normal function of the refrigeration system.

Condenser Fan Motor

The condenser fan motor is a single speed, permanent split capacitor motor and should be wired

according to the wiring diagram. The motor is permanently lubricated for long service life.

Page 5

Page 12

Remote Condenser Installation

Electrical Connections

1. The icemaker and the remote condenser both require a solid earth ground that meets National,

State and Local Codes.

2. Reference the ice machine and condenser date plate for current requirements to determine wire size

for electrical hook up.

3. Make sure the supply voltage is the same as the rated voltage shown on the nameplate.

4. Reference wiring diagram below for proper connections.

INSTALLATION NOTICE:

THE “VRC” SERIES REMOTE CONDENSER MAY ONLY BE USED

WITH COMPATIBLE ICE-O-MATIC ICE MAKERS

Electrical shock and/or injury from moving parts inside this machine can cause serious injury.

Disconnect electrical supply voltage to the machine and condenser prior to performing any

adjustments or repairs.

Page 6

Page 13

Remote Condenser Installation

Support Leg Installation-VRC

1. After removal of the packaging and fasteners, lift the condenser assembly off of the skid.

2. Locate the legs and leg braces attached to the condenser assembly. Cut the wire ties and separate

the legs from the condenser.

3. Locate the fasteners that are in a bag attached to the condenser top panel.

4. Assemble the legs and braces to the condenser as shown below.

Page 7

Page 14

Remote Condenser Installation

Vertical Air Flow

Page 8

Page 15

Remote Condenser Installation

Proper Tubing Routing

When installing the discharge and liquid lines from the remote condenser to the icemaker, please use the

following guidelines:

1. The remote condenser (#2) should always be installed above the icemaker (#4) as shown with a

vertical air flow on page 8.

2. All excess tubing (#1) should be routed inside the building and coiled in a vertical spiral as shown

(3#) on page 8, to prevent oil trapping in the lines. Any tubing run outside should be insulated to

protect it from surrounding ambient conditions. Tubing should follow straight line routing whenever

possible. The lowest spot in the tubing run should be the connection at the rear of the icemaker.

Both the discharge line and liquid line quick connect couplers are supplied with a Schrader Valve on one

end of the line set. The Schrader Valve end should be connected to the remote condenser on both the

discharge and liquid line for access to pressure readings at the condenser as shown (#5) above.

When attaching the quick connect couplers (#6), always lubricate the couplers with refrigerant oil. The

couplers should be tightened until snug, then tightened another quarter (1/4) of a turn.

Always leak check the quick connect couplers after installation has been made.

Page 9

Page 16

Remote Condenser Service Parts

Item Description VRC1001 VRC1061 VRC2061 VRC2661 VRC5061

1 Fan Guard 9131452-01 9131452-01 9131452-01 9131452-01 9131460-01

2 Top Panel 3013222-01 3013222-01 3013222-01 3013222-01 3013303-01

3 ¼-20 x 1/2 Screw 9031019-04 9031019-04 9031019-04 9031019-04 9031019-04

4 Fan Blade 9131451-01 9131451-01 9131451-01 9131451-01 9131461-01

5 Fan Motor 9161117-02 9161117-01 9161117-01 9161117-01 9161118-01

6 ¼-20 x ¾ Cap Screw 9031001-02 9031001-02 9031001-02 9031001-02 9031001-02

7 Flat Washer 9031003-01 9031003-01 9031003-01 9031003-01 9031003-01

8 Flanged Lock Nut 9031118-02 9031118-02 9031118-02 9031118-02 9031118-02

9 ¼-20 x 1/2 Screw 9031019-04 9031019-04 9031019-04 9031019-04 9031019-04

10 Rear Panel 3013224-01 3013224-01 3013224-01 3013224-01 3013224-01

11 Brace 3013226-01 3013226-01 3013226-01 3013226-01 3013305-01

12 Leg 3013227-01 3013227-01 3013227-01 3013227-01 3013227-01

13 Leg Brace 3013228-01 3013228-01 3013228-01 3013228-01 3013306-01

14 T-Nut-Shipping Only N/A N/A N/A N/A N/A

15 Brace 3013226-01 3013226-01 3013226-01 3013226-01 3013305-01

16 Cover Panel 3013232-01 3013232-01 N/A N/A N/A

17 Center Panel 3013225-01 3013225-01 3013225-01 3013225-01 3013304-01

18 Front Panel 3013223-01 3013223-01 3013223-01 3013223-01 3013223-01

19 Motor Brace 3013234-01 3013234-01 3013234-01 3013234-01 3013307-01

20 Motor Brace Support 3013233-01 3013233-01 3013233-01 3013233-01 3013233-01

21 Junction Box Cover 3013229-01 3013229-01 3013229-01 3013229-01 3013229-01

22 Mixing Valve 9151142-02 9151142-02 9151142-02 9151142-02 9151142-02

23 Condenser 9141130-01 9141130-01 9141130-01 9141131-01 9141133-01

24 Filter 9151143-01 9151143-01 9151143-01 9151143-01 9151143-01

25 1/2 Coupling 9091001-12 9091001-12 9091001-12 9091001-12 9091001-12

26 3/8 Coupling 9091001-11 9091001-11 9091001-11 9091001-11 9091001-11

27 Filter 9151143-02 9151143-02 9151143-02 9151143-02 9151143-02

Page 10

Page 17

Remote Condenser Service Parts

Page 11

Loading...

Loading...