Page 1

SERVICE AND INSTALLATION MANUAL

THE ICE SERIES CUBERS

ICE0250 through ICE2100 SERIES*

*Includes Undercounter and 22 Inch Series

Ice-O-Matic

11100 East 45th Ave

Denver, Colorado 80239

Part Number 9081270-01 Date 1/14

Page 2

ICE Series Notes

Ice-O-Matic has partnered with ENERGY STAR since 2004 to ensure our customers receive the

most efficient ice machines for your investment dollar. Ice-O-Matic is committed to the continuous

improvement in both energy efficiency and productivity thereby delivering the best value in energy

efficient ice machines money can buy.

For a detailed list of ENERGY STAR qualified Ice-O-Matic ice machines, go to:

http://www.iceomatic.com/Products/Sales-Literature/#

Plant-a-Tree Program

As part of our commitment to the global environment, Ice-O-Matic is devoted to sustainability

in every aspect of our business. To offset the carbon footprint of our factory in Denver, we

not only recycle materials in our packaging and manufacturing but also recycle our industrial

and office waste products.

More important, we partner with AMERICAN FORESTS and plant a tree for every ice

machine we sell, thereby supporting reforestation of key regions throughout the world. Our

goal is to plant 150,000 trees through our Global Sustainability program. Trees reduce

topsoil erosion, prevent harmful land pollutants from getting into our waterways and replace

air pollutants with fresh, clean oxygen.

Ice-O-Matic Warranty

Every Ice-O-Matic ice maker is backed by a warranty that provides both parts and labor coverage. To view the

warranty details, register products, or check your warranty status visit the “Warranty and Water Filter

Registration” page on www.iceomatic.com

This manual belongs to:_______________________________________

Always feel free to contact the Ice-O-Matic Service Department with any questions or

comments.

Ice-O-Matic

11100 East 45

Denver, Colorado 80239

Telephone: (303) 371-3737

Toll Free: (800) 423-3367

FAX: (303) 576-2944

After Hours Emergency Technical Support

(888) FIX-4-ICE (888 349-4423)

Additional Telephone Numbers

Contact: ( Area Code) Phone Number

________________________________________________________________

th

Avenue

Page 3

ICE Series Notes

Table of Contents

Table of Contents Page A1

General Information

How To Use This Manual Page A2

Model And Serial Number Format Page A3

Electrical And Mechanical Specifications Page A5-A8

Installation Guidelines Page A9

Electrical And Plumbing Requirements Page A10-A17

Remote Condenser Installation Page A18-A19

How The Machine Works Page A20

Undercounter Model Bin Removal Page A21-A22

Warranty Information Page A23-A24

Scheduled Maintenance

Maintenance Procedure Page B1

Cleaning and Sanitizing Instructions Page B1-B2

Winterizing Procedure Page B3

Cabinet Care Page B4

Troubleshooting Trees

How to Use The Troubleshooting Trees Page C1

Troubleshooting Trees Table Of Contents Page C2

Troubleshooting Trees Page C3-C18

Water System

Water Distribution And Components Page D1-D5

Refrigeration System

Refrigeration Cycle And Components Page E1

Harvest Cycle Page E5

Remote System Page E5-E6

Pump Down System Page E7

Refrigerant Specifications Page E8-E20

Electrical System

Control Circuit Page F1

Compressor And Start Components Page F1-F2

Untimed Freeze Cycle Page F3

Timed Freeze Cycle Page F4

Harvest Cycle Page F5-F9

Pump Down System Page F9

Wiring Diagrams Page G1

Page 4

ICE Series Table Of Contents

Table of Contents

Table of Contents Page A1

General Information

How To Use This Manual Page A2

Model And Serial Number Format Page A3

Installation Guidelines Page A5

Electrical And Plumbing Requirements Page A6-A13

Remote Condenser Installation Page A14-A15

How The Machine Works Page A16

Undercounter Model Bin Removal Page A17-A18

Warranty Information Page A20

Scheduled Maintenance

Maintenance Procedure Page B1

Cleaning and Sanitizing Instructions Page B1-B2

Winterizing Procedure Page B3

Cabinet Care Page B4

Troubleshooting Trees

How to Use The Troubleshooting Trees Page C1

Troubleshooting Trees Table Of Contents Page C2

Troubleshooting Trees Page C3-C18

Water System

Water Distribution And Components Page D1-D5

Refrigeration System

Refrigeration Cycle And Components Page E1

Harvest Cycle Page E5

Remote System Page E5-E6

Pump Down System Page E7

Electrical System

Control Circuit Page F1

Compressor And Start Components Page F1-F2

Untimed Freeze Cycle Page F3

Timed Freeze Cycle Page F4

Harvest Cycle Page F5-F9

Pump Down System Page F9

Electrical Sequence ICE1400-2100 Version 3 Page F10

Wiring Diagrams Page G1

Cuber Performance Data Page H1

Specifications Page I1

Page A1

Page 5

ICE Series General Information

How To Use This Manual

Ice-O-Matic provides this manual as an aid to the service technician in installation, operation,

and maintenance of the ICE Series (electro-mechanical) cube ice machines. If used properly

this manual can also assist the service technician to troubleshoot and diagnose most of the

problems that may occur with the machine.

The first two sections of this manual provide general information and maintenance information.

The remainder of the manual beginning with Section C provides troubleshooting and service

information. Section C contains flow charts called troubleshooting trees. Page C-1 provides

instructions on using the troubleshooting trees. Each troubleshooting tree is named to describe

a particular problem with the operation of the machine.

When following the troubleshooting trees, the service technician will be led through questions

and checks and end up with a probable solution. When using the troubleshooting trees, it is

important that the service technician understand the operation and adjustments of the

components being checked and the component suspected of malfunctioning. A detailed

description of the operation and adjustments of the components as well as other service

information is available in the pages that follow Section C.

Sections D, E, and F focus on a particular system in the ice machine: water distribution system,

refrigeration system, and it is important that these sections be used together with the

Troubleshooting Trees in Section C.

Most aspects of the ICE Series machines are covered in this manual, however, should you

encounter any conditions not addressed herein, please contact the Ice-O-Matic Technical

Service Department for assistance. You may also fax, e-mail or write the Ice-O-Matic Technical

Service Department:

Ice-O-Matic

11100 E. 45th Ave.

Denver, Co. 80239

Attn: Technical Service Department

E-Mail: Tech.service@iceomatic.com

Telephone Numbers Any Service communication must include:

800-423-3367 All Department • Model Number

888-349-4423 Technical Assistance Only • Serial number

303-371-3737 • A detailed explanation of the problem

Note the warning symbol where it appears in this manual.

It is an alert for important safety information on a hazard

that might cause serious injury.

Keep this manual for future reference.

The ICE Series Service Parts Manuals are available separately.

Ice-O-Matic products are not designed for outdoor installation.

Page A2

Page 6

ICE Series General Information

Model and Serial Number Format

Model Numbers

040 0 H A

ICE

Cube Size: H=Half (3/8 X 7/8 X7/8) F=Full (7/8 X 7/8 X7/8)

Voltage: 0=115V 5=240/50/1 6=208-230/60/1 7=208-230/60/3

Approximate 24 hour ice production: (x 10 @ 70°F/21°C Air and 50°F/10°C Water)

Series: Slab ice cuber, Stainless Steel Cabinet

Serial Number Date Code

The first letter in the serial number indicates the month and decade of manufacture.

The first digit in the serial number indicates the year of manufacture.

Example: A0XX-XXXXX-Z is manufactured January 2000

A1XX-XXXXX-Z is manufactured January 2001

1990-1999 MONTH 2000-2004

M JANUARY A

N FEBRUARY B

P MARCH C

Q APRIL D

R MAY E

S JUNE F

T JULY G

U AUGUST H

V SEPTEMBER I

W OCTOBER J

Y NOVEMBER K

Z DECEMBER L

Note: The letter O and letter X are not used.

Reference new serial number format on next page.

Condenser Type: A=Air W=Water R=Remote T=Top Discharge Air Cooled

Page A3

Page 7

ICE Series General Information

Model and Serial Number Format

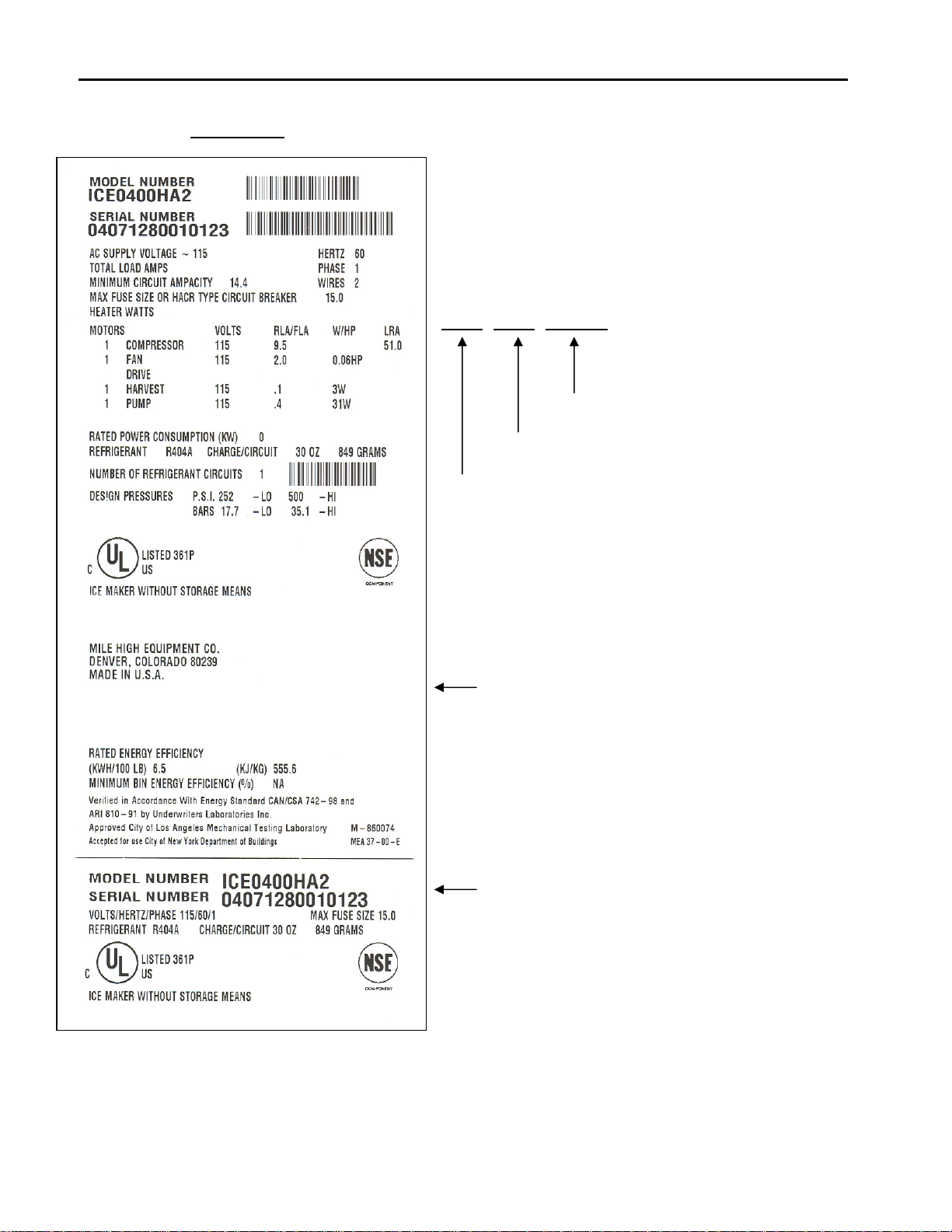

Sample Only

This format is 14 characters long and begins with a

date code followed by the Ice-O-Matic identifier, and

then a sequential number. This is an entirely

numerical serial number.

The new serial number will look like the example.

0407 1280 010123

010123 is the serial identifier.

1280 is the identifier. (Ice-O-Matic)

0407 is the date code, in YYMM format. (2004 July)

The date code will change monthly and yearly to

reflect the date of manufacture.

Large data plate will be placed on the back of

the unit.

Small data plate will be placed by the service

valves.

Page A4

Page 8

ICE Series General Information

Installation Guidelines

Note: Installation should be performed by an Ice-O-Matic trained Service Technician.

For proper operation of the Ice-O-Matic ice machine, the following installation guidelines must be

followed. Failure to do so may result in loss of production capacity, premature part failures, and

may void all warranties.

Ambient Operating Temperatures

Minimum Operating Temperature: 50°F (10°C)

Maximum Operating Temperature 100°F (38°C), 110°F (43°C) on 50 Hz. Models.

Note: Ice-O-Matic products are not designed for outdoor installation.

Incoming Water Supply (See Plumbing Diagram for line sizing Page A6-A13)

Minimum incoming water temperature: 40°F (4.5°C)

Maximum incoming water temperature: 100°F (38°C)

Minimum incoming water pressure: 20 psi (1.4 bar)

Maximum incoming water pressure: 60 psi (4.1 bar)

Note: If water pressure exceeds 60 psi (4.1 bar), a water pressure regulator must be

installed.

Drains: All drain lines must be installed per local codes. Flexible tubing is not recommended.

Route bin drain, purge drain and water condenser drain individually to a floor drain. The use of

condensate pumps for draining water is not recommended by Ice-O-Matic. Ice-O-Matic assumes

no responsibility for improperly installed equipment.

Water Filtration: A water filter system should be installed with the ice machine.

Clearance Requirements: Self contained air cooled ice machines must have a minimum of 6

inches (15cm) of clearance at the rear, top, and sides of the ice machine for proper air circulation.

Stacking: Ice-O-Matic does not endorse stacking ice machines.

Dispenser Application: A thermostatic bin control kit must be installed if the ICE Series ice

machine is placed on a dispenser. A bin top may or may not be required. (Exception is the

CD400 Dispenser)

Electrical Specifications: Refer to the serial plate at the rear of the ice machine or the charts

starting on page H1.

Adjustments

Level the machine within 1/8 inch in all directions.

Check the bin control for proper adjustment, Page F9

Check the water in the water trough for proper level, Page D1

Check the ice bridge for proper thickness, Page F4

Check the cam switch adjustment. Page F8

Check the water regulating valve adjustment if water cooled, Page E2

Page A5

Page 9

ICE Series General Information

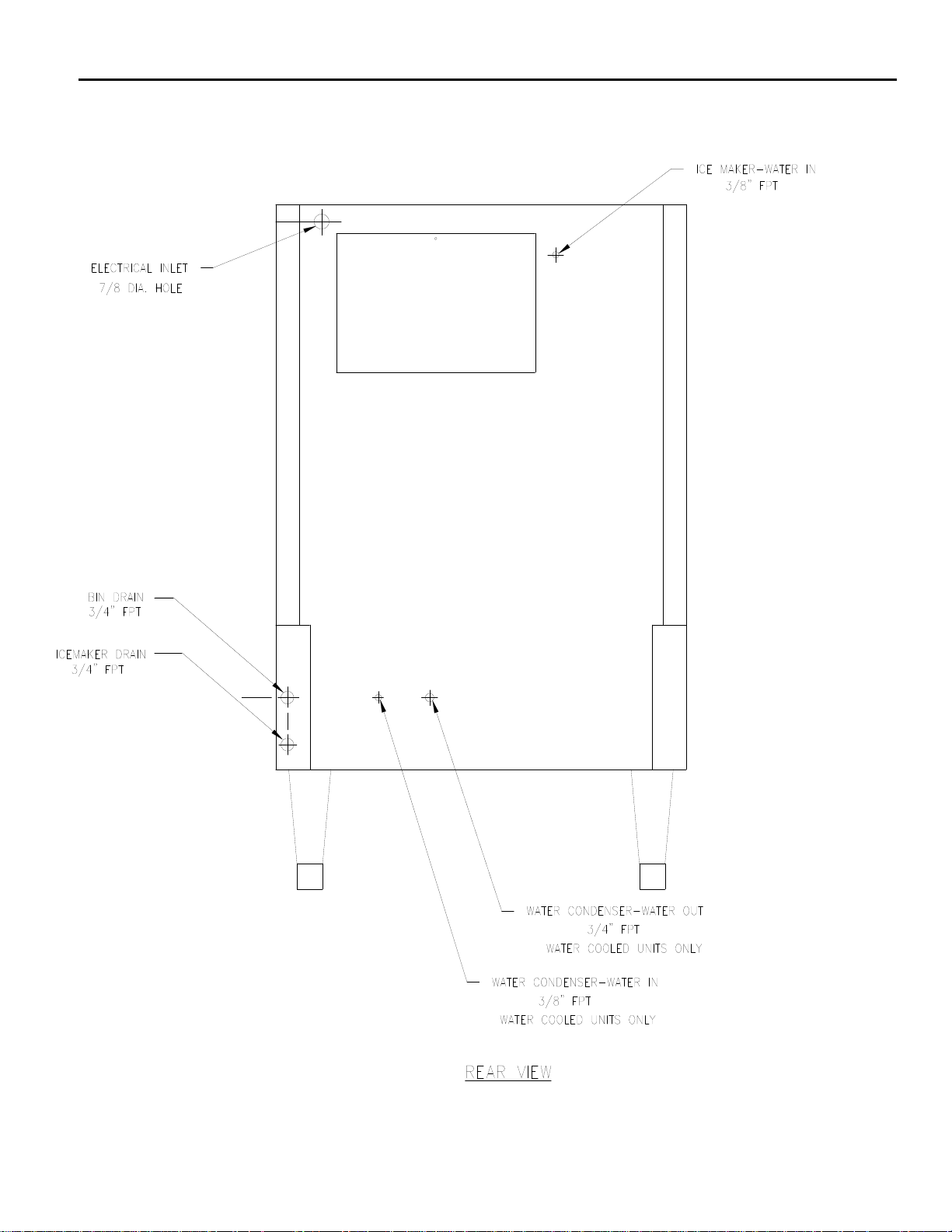

Electrical and Plumbing Requirements: ICEU150, ICEU200, ICEU205 and ICEU206

Page A6

Page 10

ICE Series General Information

Electrical and Plumbing Requirements: ICEU150, 220, 225 and 226

ICE MAKER WATER-IN

3/8 FPT OR 1/4 Male Flare

Note: The ICEU150, ICEU220, ICEU225

and ICEU226 do not have a splash

curtain.

These models utilize a thermostatic

bin control in place of a mechanical

bin switch.

Page A7

Page 11

ICE Series General Information

Electrical and Plumbing Requirements: ICEU300 and 305

ICE MAKER WATER-IN

3/8 FPT OR 1/4 Male Flare

Note: The ICEU300 does not have a

splash curtain.

This model utilize a thermostatic bin

control in place of a mechanical bin

switch.

Page A8

Page 12

ICE Series General Information

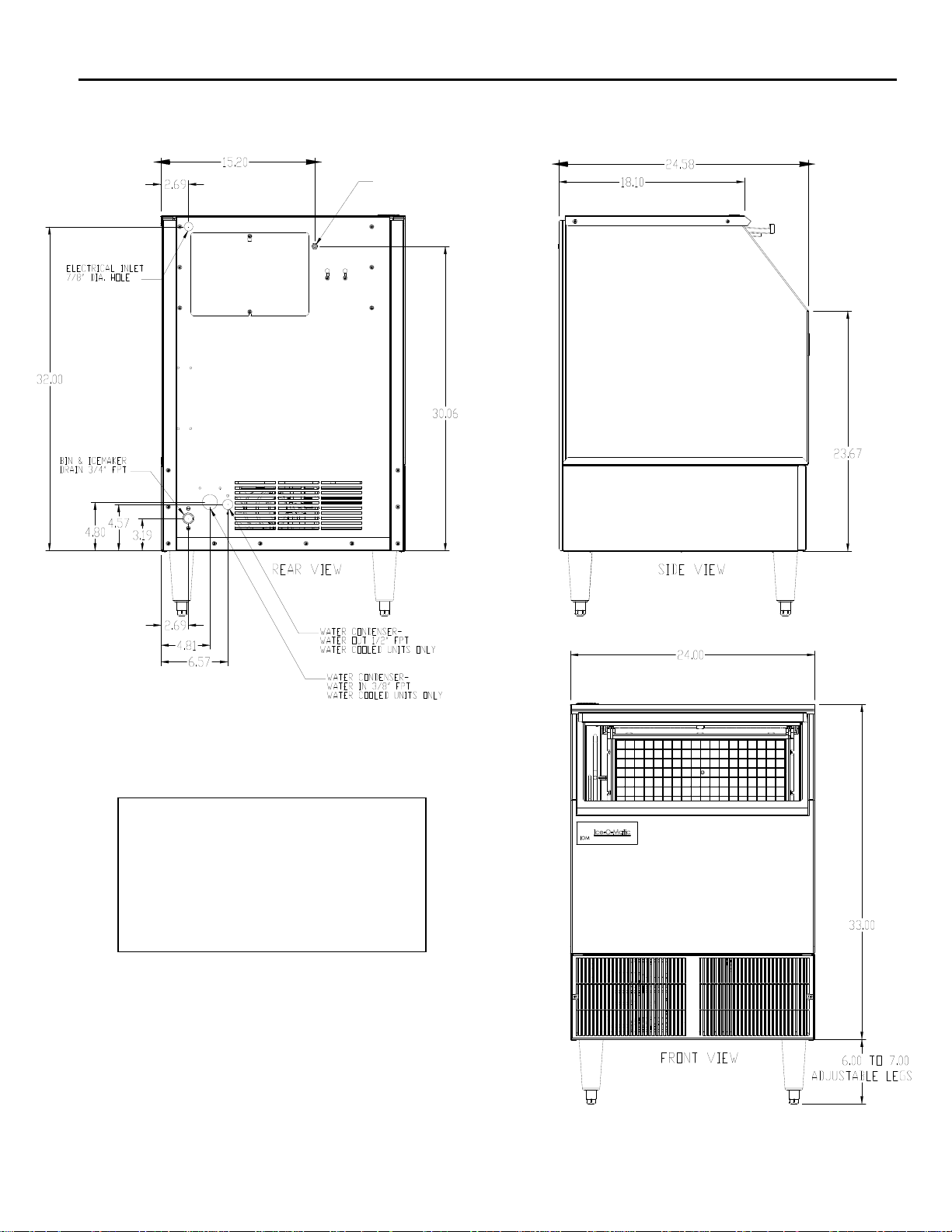

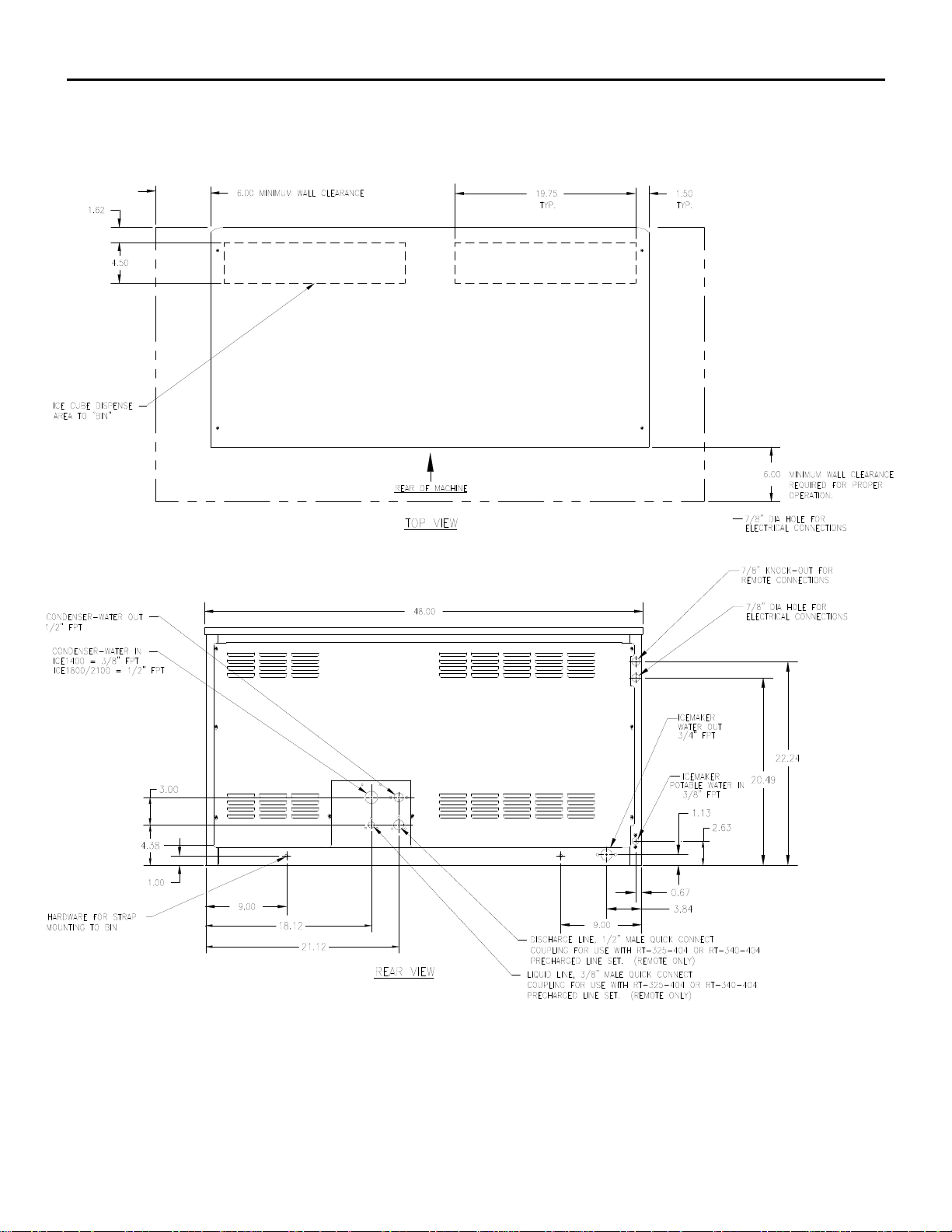

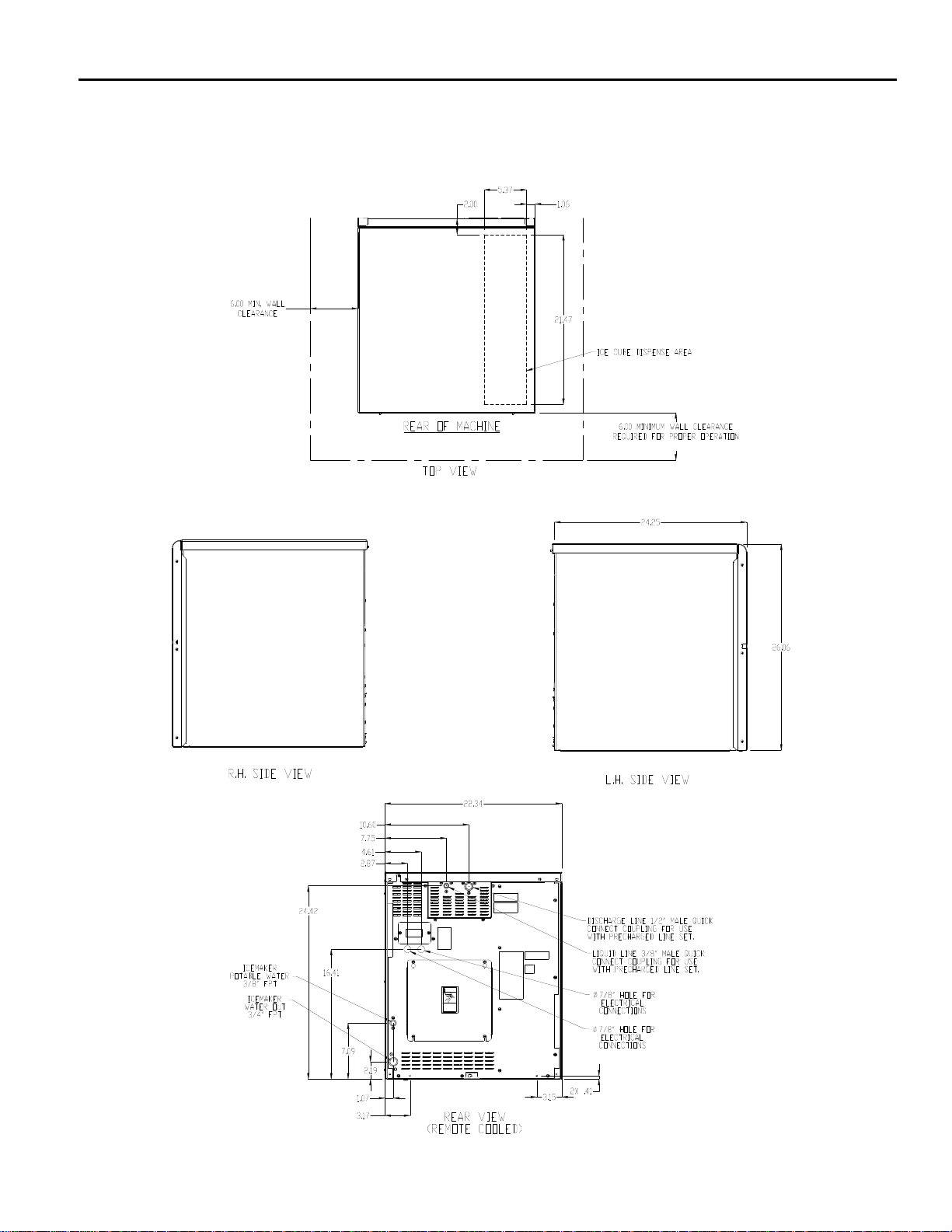

Electrical and Plumbing Requirements: ICE0250, ICE0400, ICE0500, ICE0606, ICE0806

and ICE1006 (30 Inch Wide Cubers)

Page A9

Page 13

ICE Series General Information

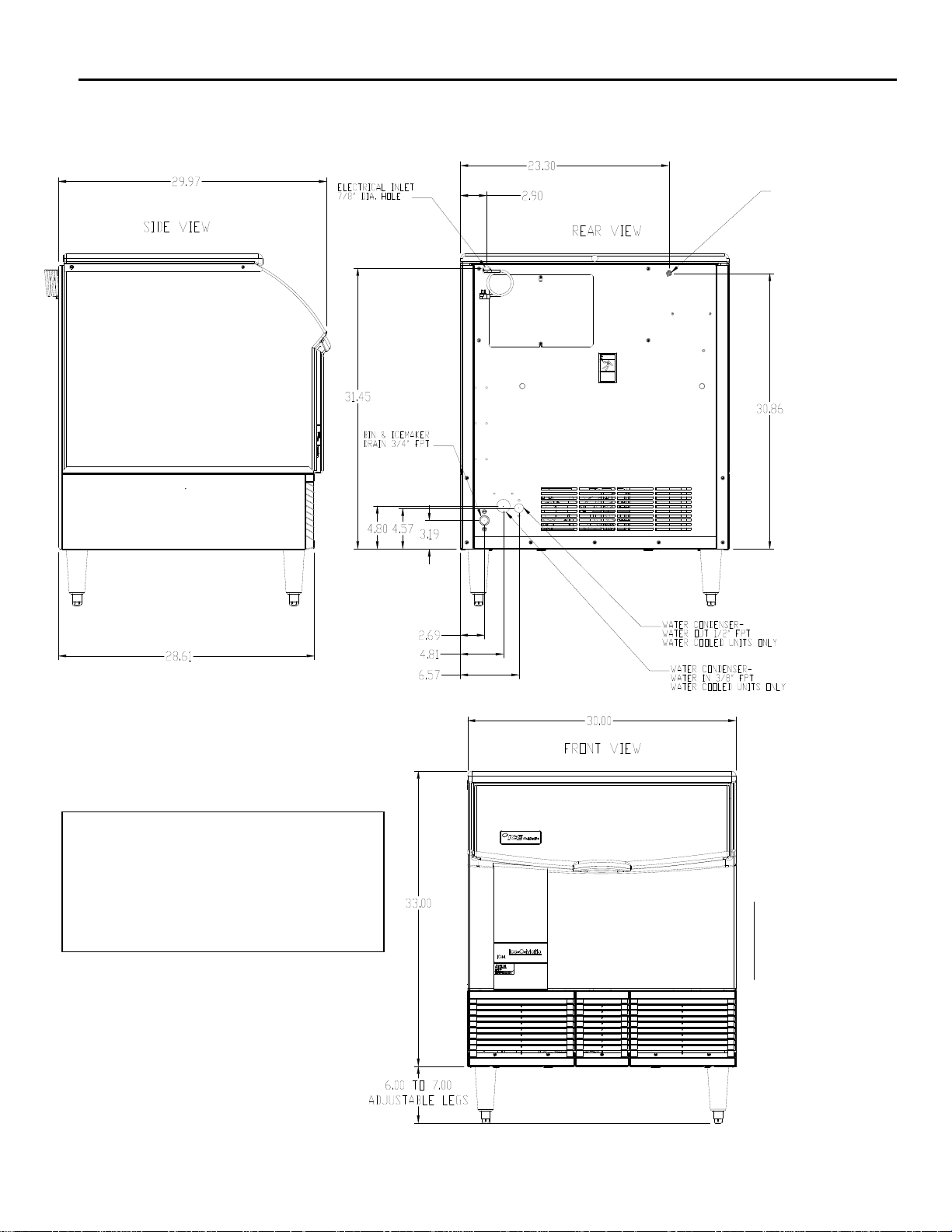

Electrical and Plumbing Requirements: ICE1406, ICE1806, ICE2106 (48 Inch Wide Cubers)

Prior to January 2008

Page A10

Page 14

ICE Series General Information

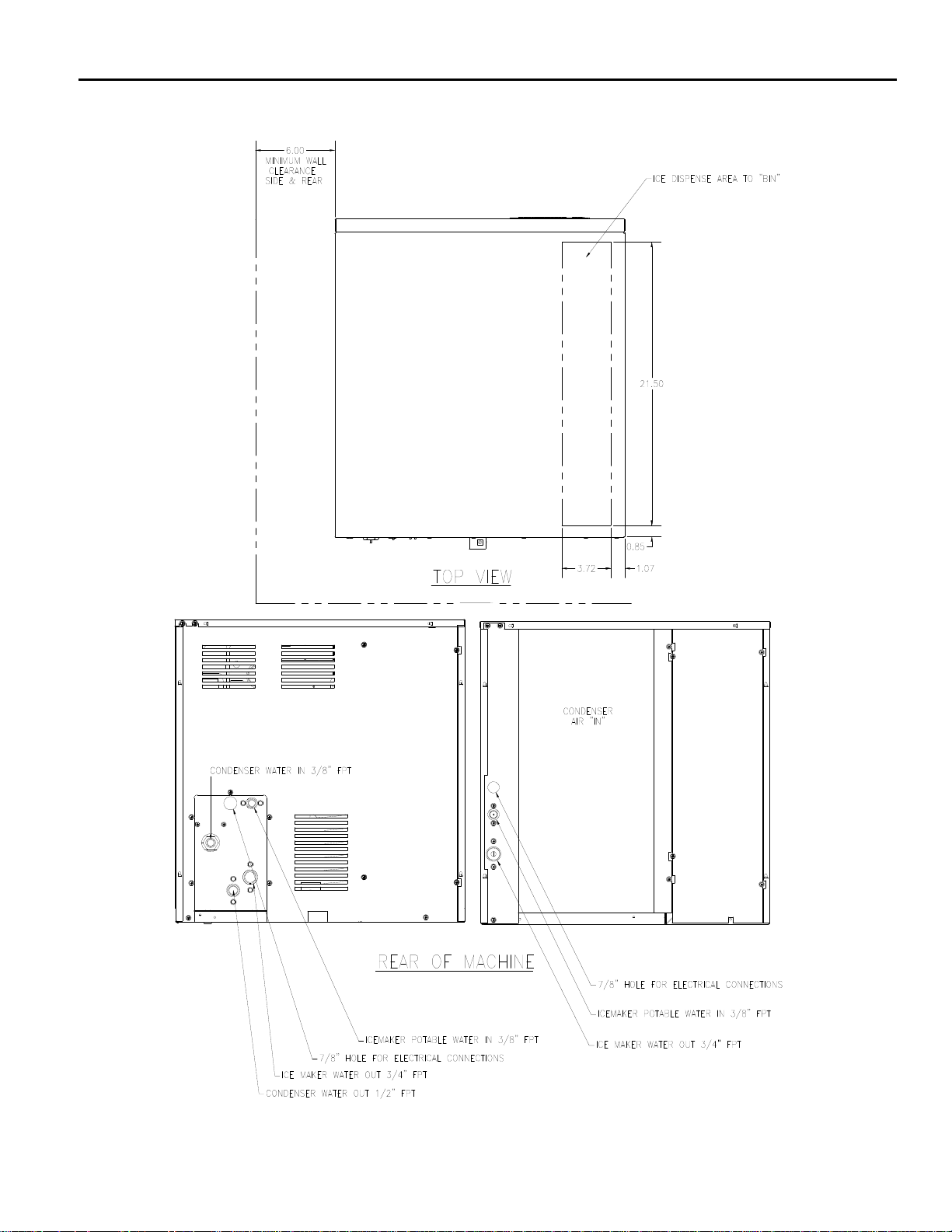

Electrical and Plumbing Requirements: ICE0320 and ICE0520 (22 Inch Wide Cubers)

Page A11

Page 15

ICE Series General Information

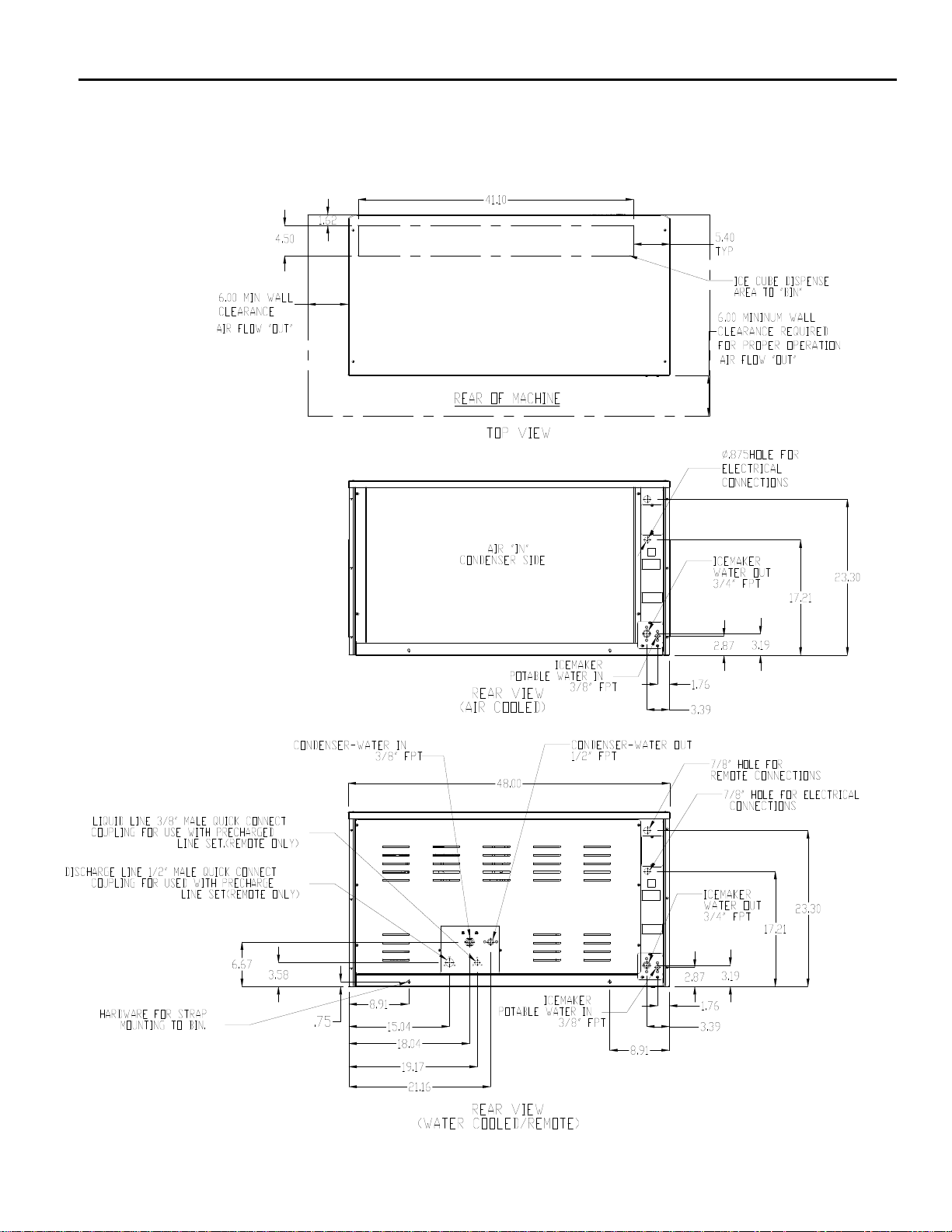

Electrical and Plumbing Requirements: ICE1400, ICE1800 and ICE2100 Revision 3

(From January 2008)

Page A12

Page 16

ICE Series General Information

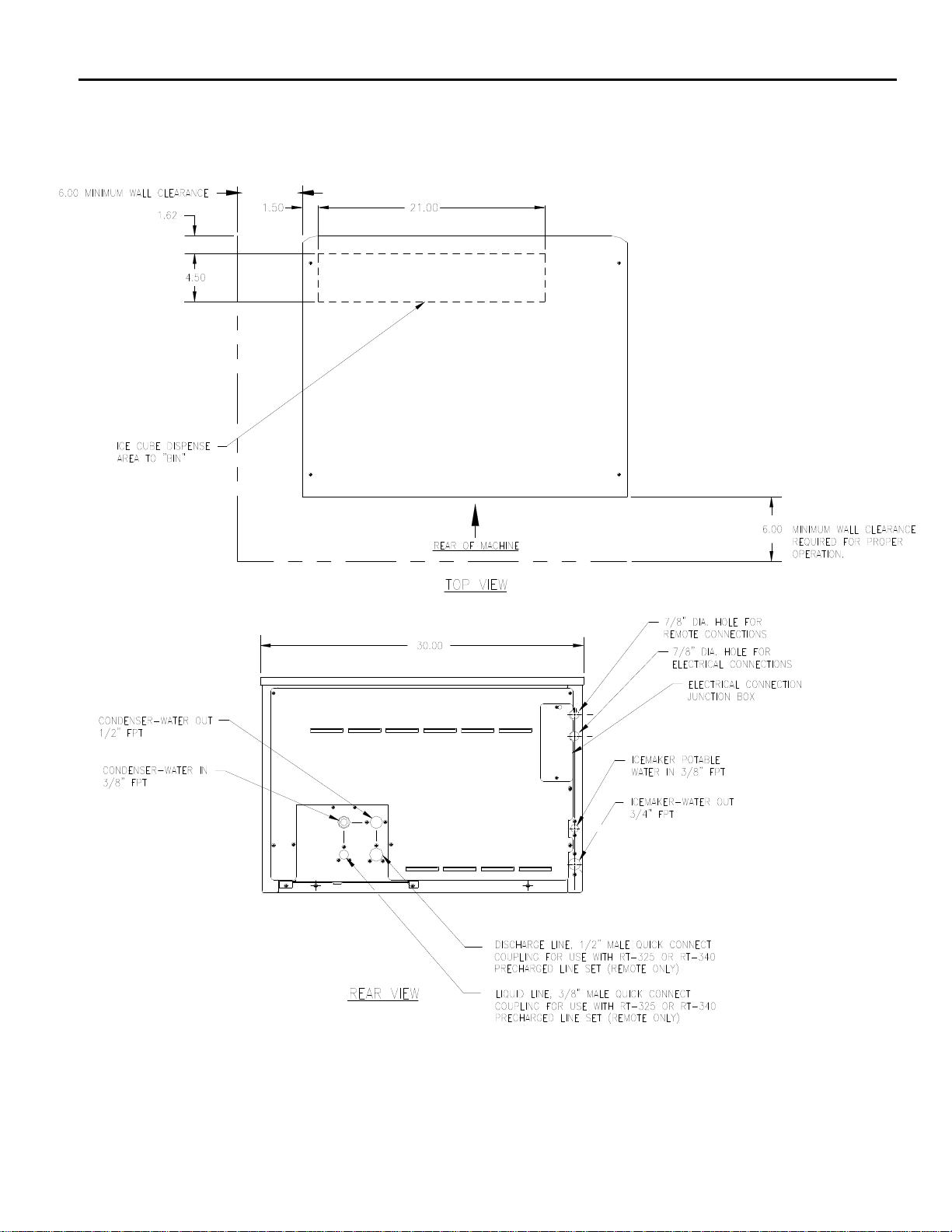

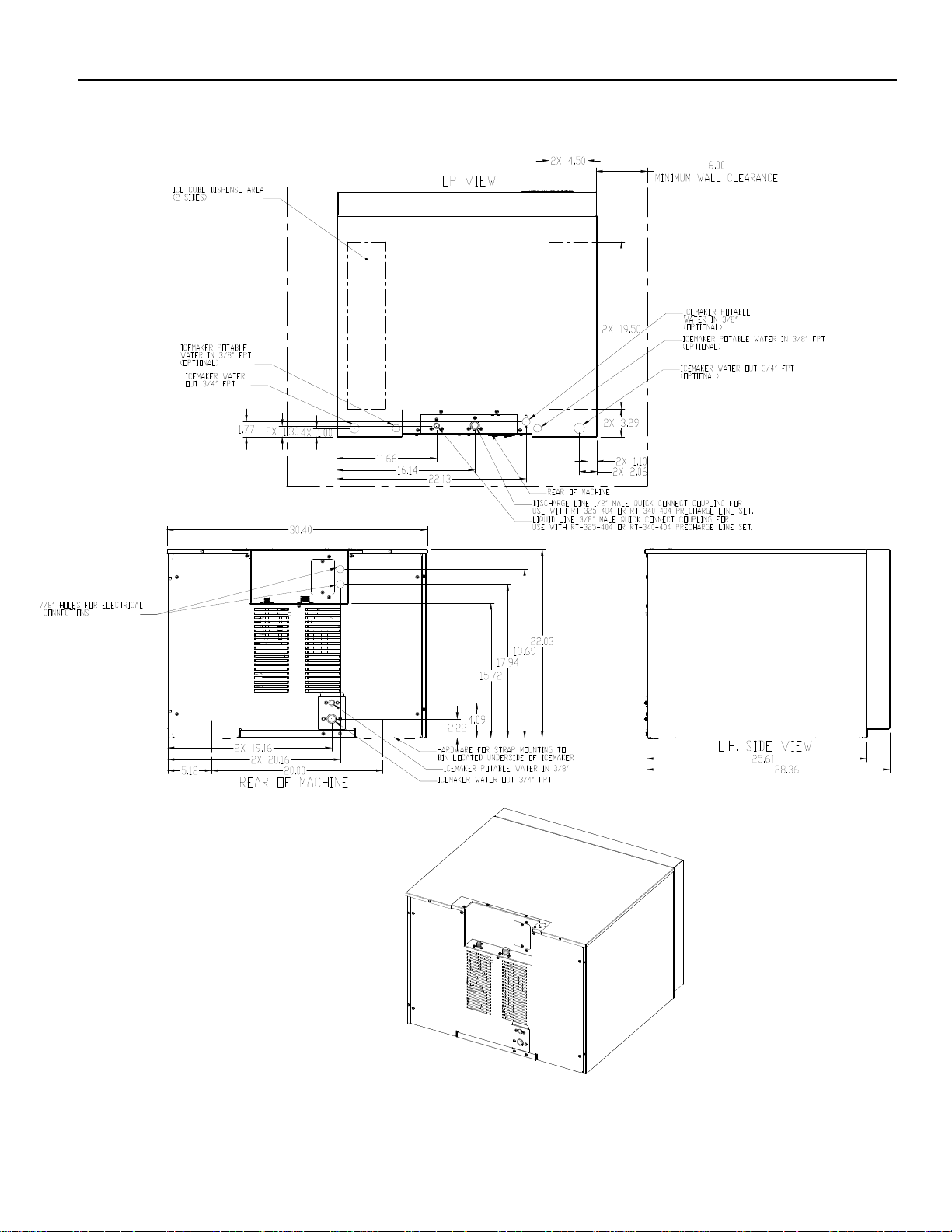

Electrical and Plumbing Requirements: ICE1506 Remote

Page A13

Page 17

ICE Series General Information

Electrical and Plumbing Requirements: ICE0726 and ICE0926 Remote

Page A14

Page 18

ICE Series General Information

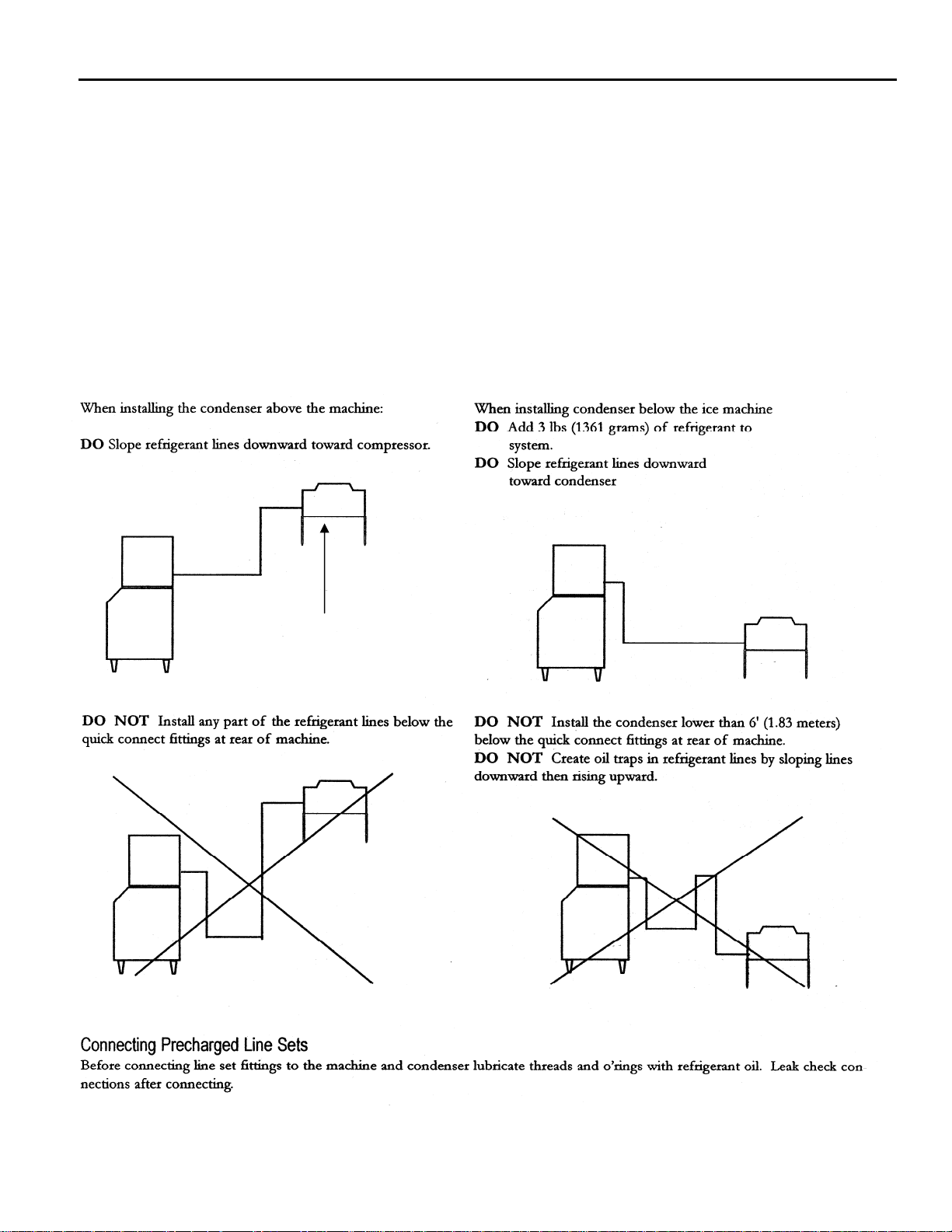

Remote Condenser Installation

For proper operation of the Ice-O-Matic ice machine, the following installation guidelines must be

followed. Failure to do so may result in loss of production capacity, premature part failure, and

may void all warranties.

Installation Guidelines

Ambient operating temperatures: -20°F (-28.9°C) to 120°F (48.9°C)

Maximum refrigerant line length: 60 ft. (18.29 Meters)

Maximum vertical rise: 16 ft. (4.88 Meters)

Minimum condenser height: ICE Series ice machine remote condensers must not be

installed more than 6 feet (1.3 meters) below the refrigerant line quick connects at the rear of the

ice machine. No part of the refrigerant lines, between the ice machine and the remote

condenser, should fall below this point. Condensers must have a vertical airflow.

Air Flow

Page A15

Page 19

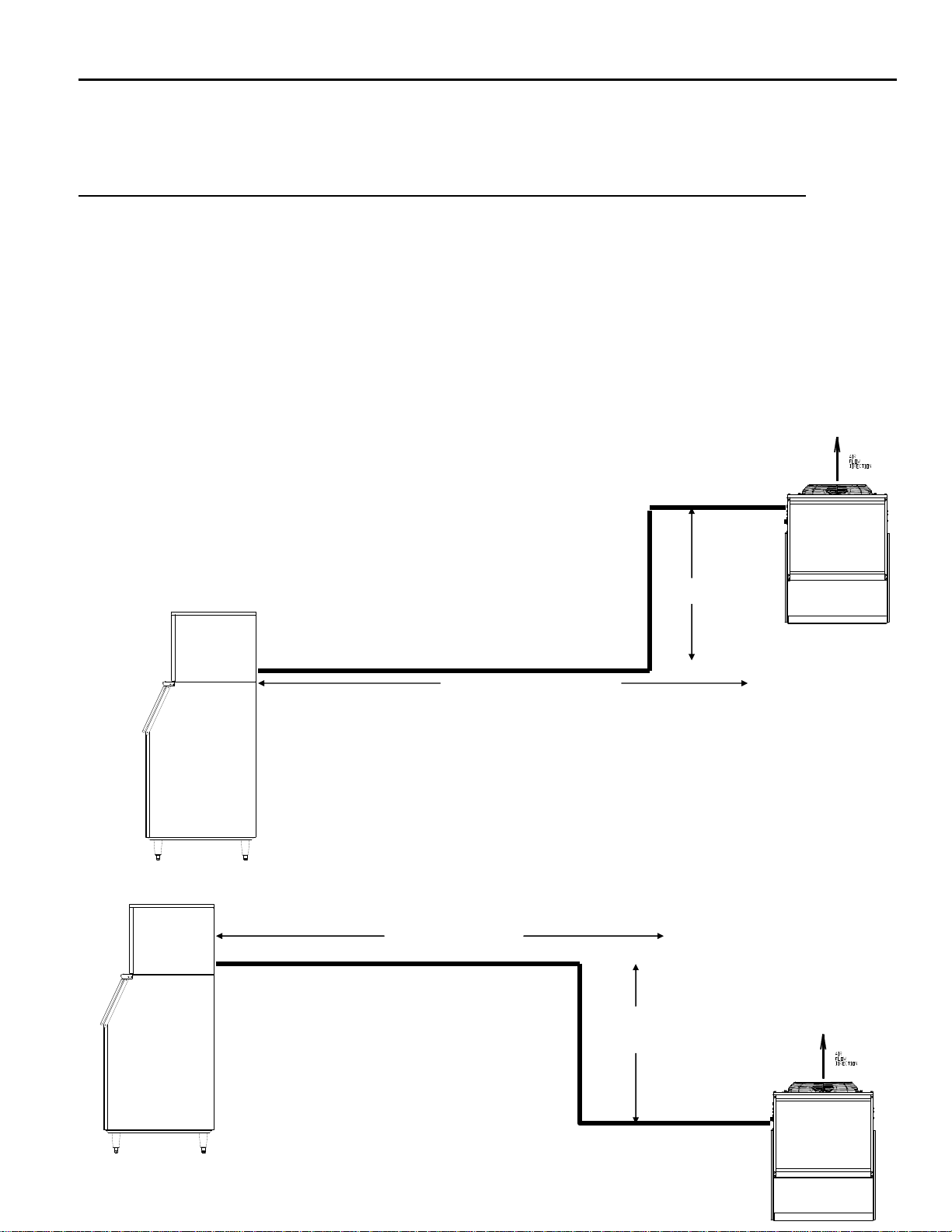

ICE Series General Information

The following remote ice makers incorporate the mixing valve in the condenser. This configuration allows

up to a 100 foot calculated remote line set run. Reference the diagram below to calculate the maximum 100

foot line set run.

ICE Machine Model Number Remote Condenser Model Number

ICE2100R3&4 &5 VRC5061B

ICE1800R3&4 &5 VRC5061B

ICE1400R3&4 &5 VRC2661B

ICE1506HR2&3&4 VRC2661B

ICE1006R3&4&5 VRC2061B

ICE0926 VRC2061B

ICE0806R3&4 &5 VRC2061B

ICE0726 VRC2061B

ICE0606R3&4&5&6 VRC1061B

ICE0500R3&4 &5 VRC1001B

Limitations for new remote machines that have the mixing valve mounted in the condenser.

Maximum Rise is 35 feet.

Maximum Drop is 15 feet.

Maximum equivalent run is 100 feet.

Formula for figuring maximum equivalent run is as follows:

Rise x 1.7 + Drop x 6.6 + horizontal run = equivalent run.

Examples: 35 ft. rise x 1.7 + 40 ft. horizontal = 99.5 equivalent feet line run

40 ft. horizontal

Verify the ICE machine is compatible with the remote

condenser. Some ice machines and some remote

condensers may or may not have a Mixing Valve (Head

Master). Only one valve is required per system. Kits are

available to modify the condenser for compatibility. For

more information contact your Ice-O-Matic Distributor.

35 ft. rise

34 ft. horizontal

10 ft. drop x 6.6 + 34 ft horizontal = 100

equivalent feet line run

Page A16

10 ft. drop

Page 20

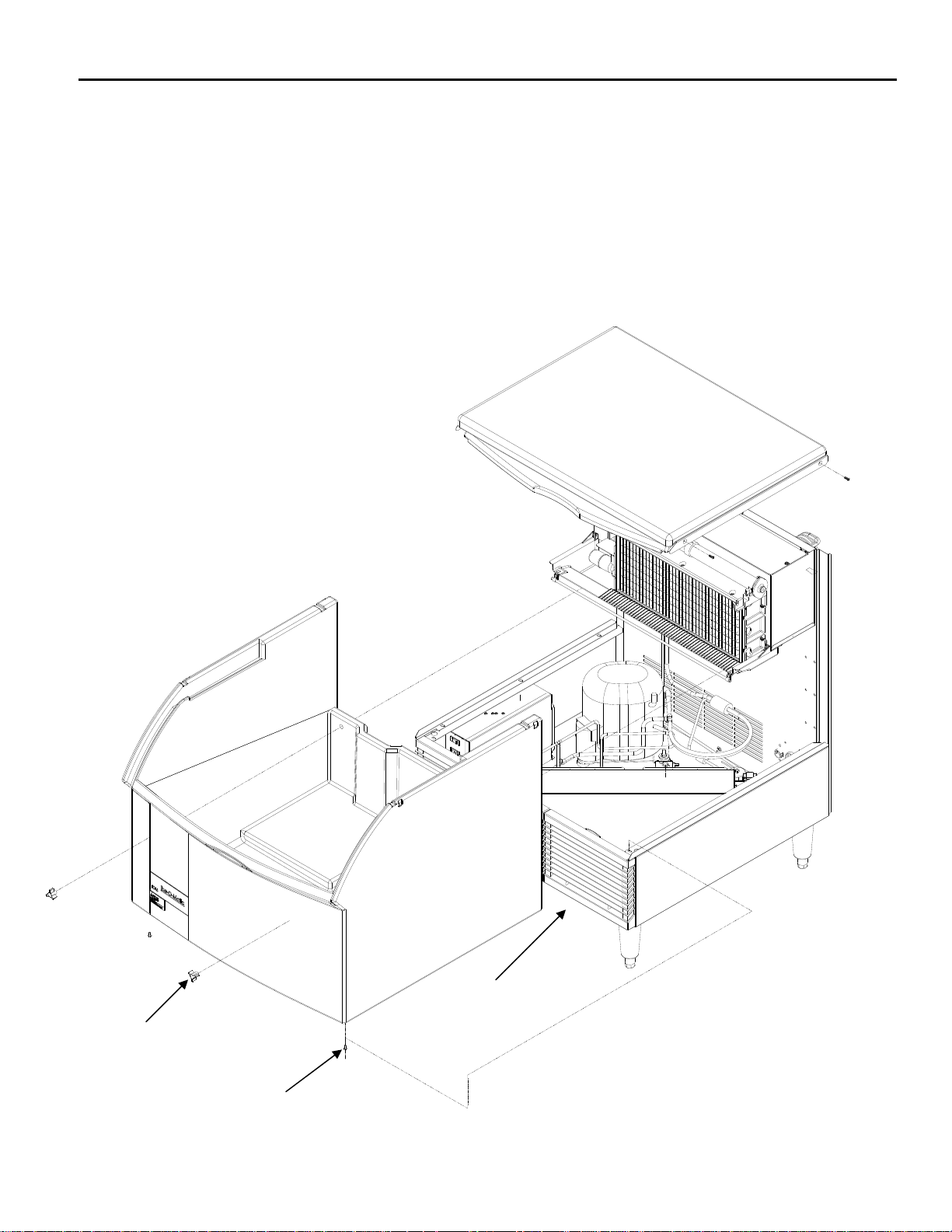

ICE Series General Information

How the ICE Machine Works

A general description of how the ICE Series cubers work is given below. The remainder of the

manual provides more detail about the components and systems.

With the ICE/OFF/WASH switch in the ICE position, the compressor, water pump and condenser

fan motor (when applicable) will energize starting the freeze cycle.

During the freeze cycle, water is circulated over the evaporator(s) where the ice cubes are formed.

When the suction pressure has pulled down to the proper cut-in pressure of the timer initiate

(pressure control), the contacts will close and energize the time delay module (timer). See Page

F3 for proper cut-in pressures. At this time the cubes will close to completion.

The remaining portion of the freeze cycle is determined by the timer setting. The timer is pre-set at

the factory to achieve the proper ice bridge thickness but may need to be adjusted upon initial

start-up, see Page F4 for initial timer settings.

Once the amount of time on the timer has passed, the control relay will be energized and the

machine will enter harvest. Power is now supplied to the water purge valve, hot gas valve, and the

harvest motor. The water purge valve opens, and allows the water pump to purge the water

remaining in the water, removing impurities and sediment. This allows the machine to produce

clear ice cubes and keep mineral build up at a minimum. The hot gas solenoid opens allowing hot

gas to go directly to the evaporator, heating the evaporator and breaking the bond between the

evaporator and the ice slab.

The harvest assist motor, which is also energized during harvest, turns a slip clutch, which pushes

a probe against the back of the ice slab. Once the evaporator has reached approximately 40F

(4.5F) in temperature, the slip clutch overcomes the bonding of the ice to the evaporator and

pushes the slab of ice off of the evaporator and into the storage bin. The clutch also actuates a

switch that rides on the outer edge of the clutch. When the clutch completes one revolution, the

switch is tripped and the machine enters the next freeze cycle.

When ice drops into a full bin during harvest, the splash curtain is held open which activates a bin

switch shutting the machine off. When ice is removed from the bin, the splash curtain will close

and the machine will come back on.

Page A17

Page 21

ICE Series General Information

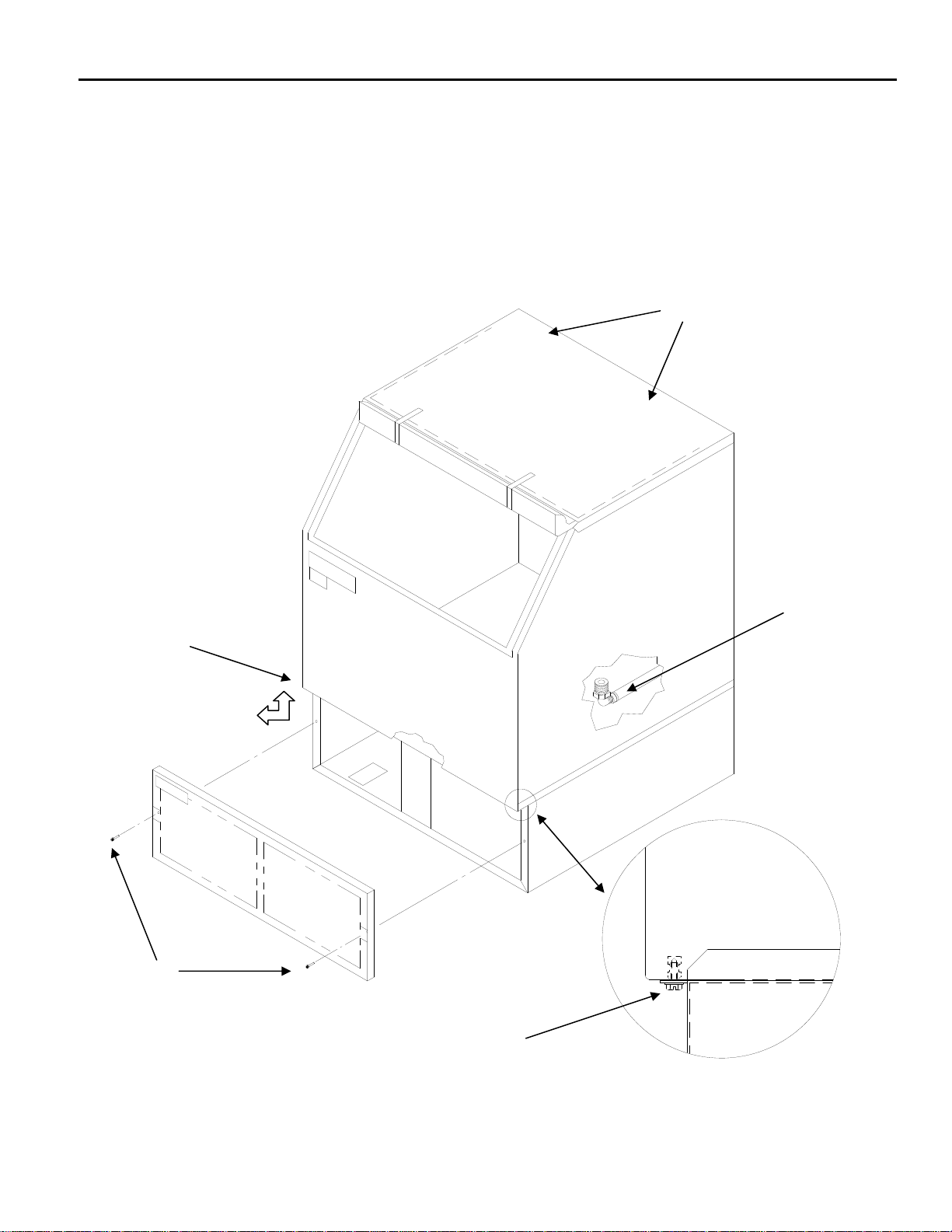

Undercounter Bin Removal-ICEU300 and ICEU150-220 (From 6/08) Series

The storage bin can be removed by:

1 Remove the lower grill.

2. Remove two screws securing bin to cabinet base.

3. Remove the thumbscrews from the back wall of the bin.

4. Disconnect bin drain.

5. Lift front of bin slightly and pull bin forward to remove.

3

2

Page A18

Page 22

ICE Series General Information

Undercounter Bin Removal-ICEU150/200 Series (Prior to 6/08)

The storage bin can be removed by:

1. Remove the two screws at the rear of the top panel.

2. Remove the two screws from the front panel.

3. Remove two screws securing bin to cabinet base.

4. Disconnect bin drain.

5. Lift front of bin slightly and pull bin forward to remove.

1

2

4

5

3

Page A19

Page 23

ICE Series General Information

Warranty Information

Every Ice-O-Matic machine is backed by a warranty that provides both parts and labor coverage.

PARTS LABOR

Two years on all parts* Two years on all components*

Three years on all ICE Maker parts* Three years on all cube ICE Maker components*

Five years on compressors*

Five years on cuber evaporators*

Water Filtration System Extended Warranty Program

Purchase a new Ice-O-Matic IFQ or IFI Series Water Filtration System with a new ICE Series ICE

Machine, replace the filter cartridge every 6 month and Ice-O-Matic will extend the limited cuber

evaporator warranty to 7 years parts and labor.

New machine and filter must be installed at same time.

Must send in both the machine and water filter registration cards within 10 days of

installation.

Must send in additional registration card for each new filter installed. This must be done

every 180 days (6 months) or less.

Program is available with all IFQ and IFI filter systems.

Replacement filter must be model number IOMQ or IOMWFRC.

Available in the USA and Canada only.

Warranty If, during the warranty period, customer uses a part for this Ice-O-Matic equipment other

than an unmodified new part purchased directly from Ice-O-Matic, Ice-O-Matic Distributors, or any

of its authorized service agents and/or the part being used is modified from its original

configuration, this warranty will be void. Further, Ice-O-Matic and its affiliates will not be liable for

any claims, damages or expenses incurred by customer which arises directly or indirectly, in whole

or in part, due to the installation of any modified part and/or part received from an unauthorized

service center. Adjustments are not covered under warranty.

Warranty Procedure If the customer is using a part that results in a voided warranty and an Ice-OMatic authorized representative travels to the installation address to perform warranty service, the

service representative will advise customer the warranty is void. Such service call will be billed to

the customer at the authorized service center’s then-applicable time and material rates.

Ice-O-Matic Warranty

Every Ice-O-Matic ice maker is backed by a warranty that provides both parts and labor coverage. To view the

warranty details, register products, or check your warranty status visit the “Warranty and Water Filter Registration”

page on www.iceomatic.com

Page A20

Page 24

ICE Series Scheduled Maintenance

Maintenance

Note: Maintenance should be performed by an Ice-O-Matic trained Service Technician.

Electrical shock and/or injury from moving parts inside this

machine can cause serious injury. Disconnect electrical

supply to machine prior to performing any adjustments or

repairs.

Failure to perform the required maintenance at the frequency specified will void warranty coverage

in the event of a related failure. To insure economical, trouble free operation of the machine, the

following maintenance is required every 6 months.

Maintenance Procedure

1. Clean the ice-making section per the instructions below. Cleaning should be performed a

minimum of every 6 months. Local water conditions may require that cleaning be performed more

often.

2. Check ice bridge thickness. See page F4 for proper thickness and adjustment procedure.

3. Check water level in trough. See page D1 for proper water level and adjustment.

4. Clean the condenser (air-cooled machines) to insure unobstructed air flow.

5. Check for leaks of any kind: Water, Refrigerant, Oil, Etc.

6. Check the bin switch for proper adjustment. See page F9 for bin switch adjustment.

7. Check the cam switch adjustment. See page F8 for cam switch adjustment.

8. Check the water valve (water-cooled machines) for proper adjustment. See page E2.

9. Check all electrical connection.

10. Oil the fan motor if the motor has an oil fitting. (Self contained air-cooled models only)

Cleaning and Sanitizing

1. Harvest problems may occur if the following procedures are not performed every 6 months.

2. Remove the ice machine front panel.

3. Make sure that all the ice is off of the evaporator. If ice is being made, wait for cycle

completion, then turn the machine “OFF” at the ICE/OFF/WASH selector switch.

4. Remove or melt all ice in the storage bin.

Page B1

Page 25

ICE Series Scheduled Maintenance

Cleaning and Sanitizing (continued)

5. Add recommended amount of approved Nickel Safe ice machine cleaner to the water trough

according to label instructions on the container.

6. Initiate the wash cycle at the ICE/OFF/WASH switch by placing the switch in the “WASH”

position. Allow the cleaner to circulate for approximately 15 minutes to remove mineral

deposits.

7. Depress the purge switch and hold until the ice machine cleaner has been flushed down the

drain and diluted by fresh incoming water.

8. Terminate the wash cycle at the ICE/OFF/WASH switch by placing the switch in the “OFF”

position. Remove the splash curtain and inspect the evaporator and water spillway to assure all

mineral residue has been removed.

9. If necessary, wipe the evaporator, spillway and other water transport surfaces with a clean soft

cloth to remove any remaining residue. If necessary, remove the water distribution tube,

disassemble and clean with a bottlebrush, see page D2. Reassemble all components and

repeat steps 4 through 7 as required to remove residue.

10. Turn OFF ice machine water supply and clean the water trough thoroughly to remove all scale

or slime build-up. If necessary, remove the water trough to reach all splash areas and float.

11. Prepare 1½ to 2 gallons (5.7 to 7.5 liters) of approved (EPA/FDA) sodium hypochloride food

equipment sanitizer to form a solution with 100 to 200 ppm free chlorine yield.

12. Add enough sanitizing solution to fill the water trough to overflowing and place the

ICE/OFF/WASH switch to the “WASH” position and allow circulation to occur for 10 minutes

and inspect all disassembled fittings for leaks. During this time, wipe down all other ice

machine splash areas, plus the interior surfaces of the bin, deflector and door with the

remaining sanitizing solution. Inspect to insure that all functional parts, fasteners, thermostat

bulbs (if used), etc. are in place.

13. Depress the purge switch and hold until sanitizer has been flushed down the drain. Turn ON

the ice machine water supply and continue to purge to the diluted sanitizing solution for another

1 to 2 minutes.

14. Place the ICE/OFF/WASH switch to the “ICE” position and replace the front panel.

15. Discard the first two ice harvests.

Page B2

Page 26

ICE Series Winterizing Procedures

Winterizing Procedures

Important!

Whenever the ice machine is taken out of operation during the winter months, the procedure below

must be performed. Failure to do so may cause serious damage and will void all warranties.

1. Turn off water to machine.

2. Make sure all ice is off of the evaporator(s). If ice is being made, initiate harvest or wait for

cycle completion.

3. Place the ICE/OFF/WASH switch to the “OFF” position.

4. Disconnect the tubing between the water pump discharge and water distribution tube.

5. Drain the water system completely.

6. On water cooled machines, hold the water regulating valve

open by prying upward on the water valve spring with a

screwdriver while using compressed air to blow all the water out

of the condenser.

7. Remove all of the ice in the storage bin and discard.

Page B3

Page 27

ICE Series Cabinet Care

Cleaning stainless steel

Commercial grades of stainless steel are susceptible to rusting. It is important that you properly

care for the stainless steel surfaces of your ice machine and bin to avoid the possibility of rust or

corrosion. Use the following recommended guidelines for keeping your stainless steel looking like

new:

1. Clean the stainless steel thoroughly once a week. Clean frequently to avoid build-up of

hard, stubborn stains. Also, hard water stains left to sit can weaken the steel's corrosion

resistance and lead to rust. Use a nonabrasive cloth or sponge, working with, not across, the

grain.

2. Don't use abrasive tools to clean the steel surface. Do not use steel wool, abrasive sponge

pads, wire brushes or scrapers to clean the steel. Such tools can break through the "passivation"

layer - the thin layer on the surface of stainless steel that protects it from corrosion.

3. Don't use cleaners that use chlorine or chlorides. Don't use chlorine bleach or products like

Comet to clean the steel. Chlorides break down the passivation layer and can cause rusting.

4. Rinse with clean water. If chlorinated cleansers are used, you must thoroughly rinse the

surface with clean water and wipe dry immediately.

5. Use the right cleaning agent. The table below lists the recommended cleaning agents for

common stainless steel cleaning problems:

Cleaning Activity Cleaning Agent Method of Application

Routine cleaning Soap, Ammonia, Windex, or Apply with a clean cloth

detergent with water. or sponge. Rinse with

Fantastik, 409 Spic’nSpan clean water and wipe dry.

Liquid are also approve for

Stainless Steel.

Removing grease or Easy-Off or similar oven Apply generously, allow

fatty acids cleaners. to stand for 15-20 minutes.

Rinse with clean water.

Repeat as required.

Removing hard water spots Vinegar Swab or wipe with clean cloth.

and scale. Rinse with clean water and

dry.

Page B4

Page 28

ICE Series Troubleshooting Trees

How To Use The Troubleshooting Trees

The troubleshooting trees were developed to be used in conjunction with the service information in

the sections that follow. If used together as intended, these two parts of the manual will allow the

ice machine service technician to quickly diagnose many of the problems encountered with the ice

machines. When used as designed, the troubleshooting trees can lead you from a general

symptom to the most likely component to suspect as the cause of the problem. The trees are not

designed to be “parts changer guides”: please do not use them as such.

Components returned to the factory for warranty are tested by the factory and will not be covered

under the warranty policy if they are not defective.

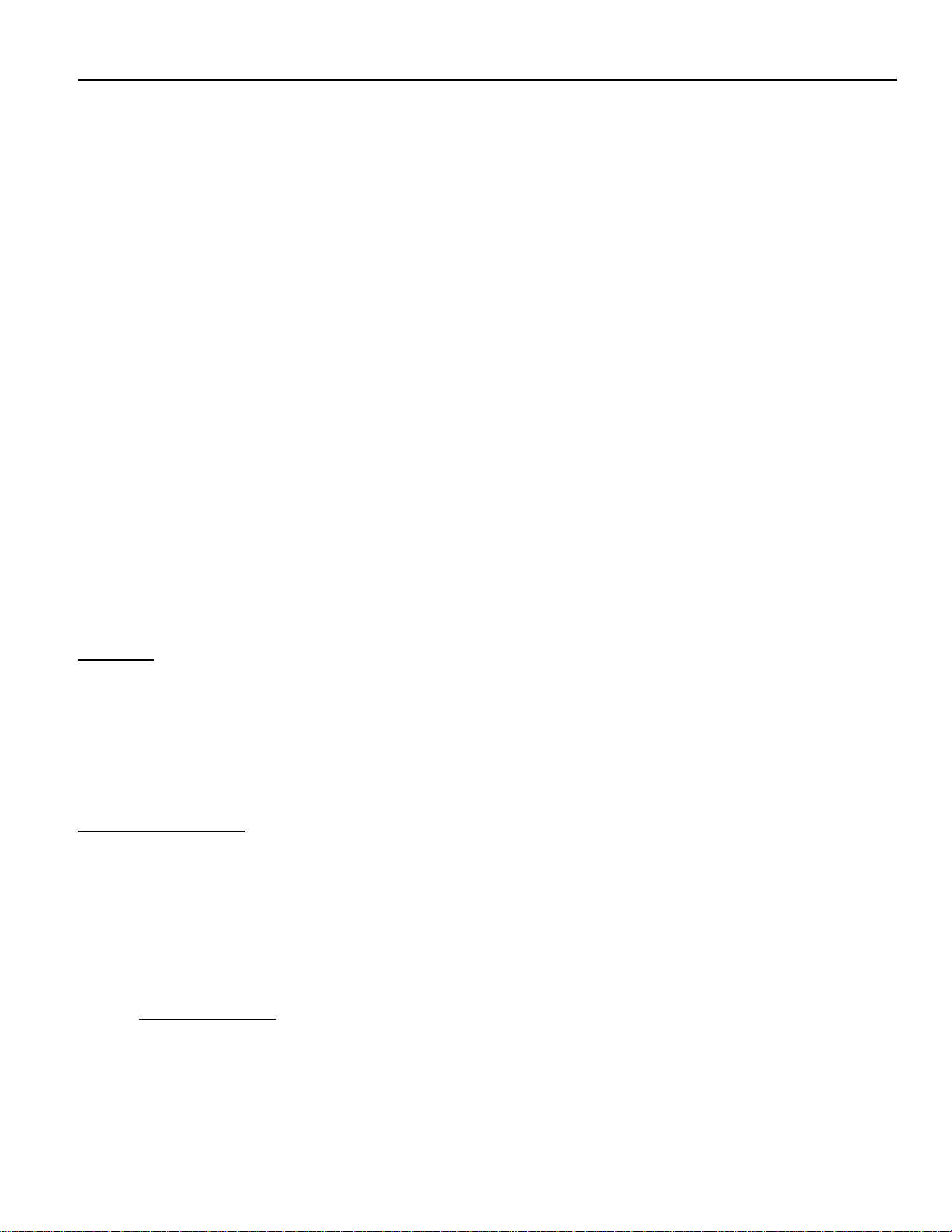

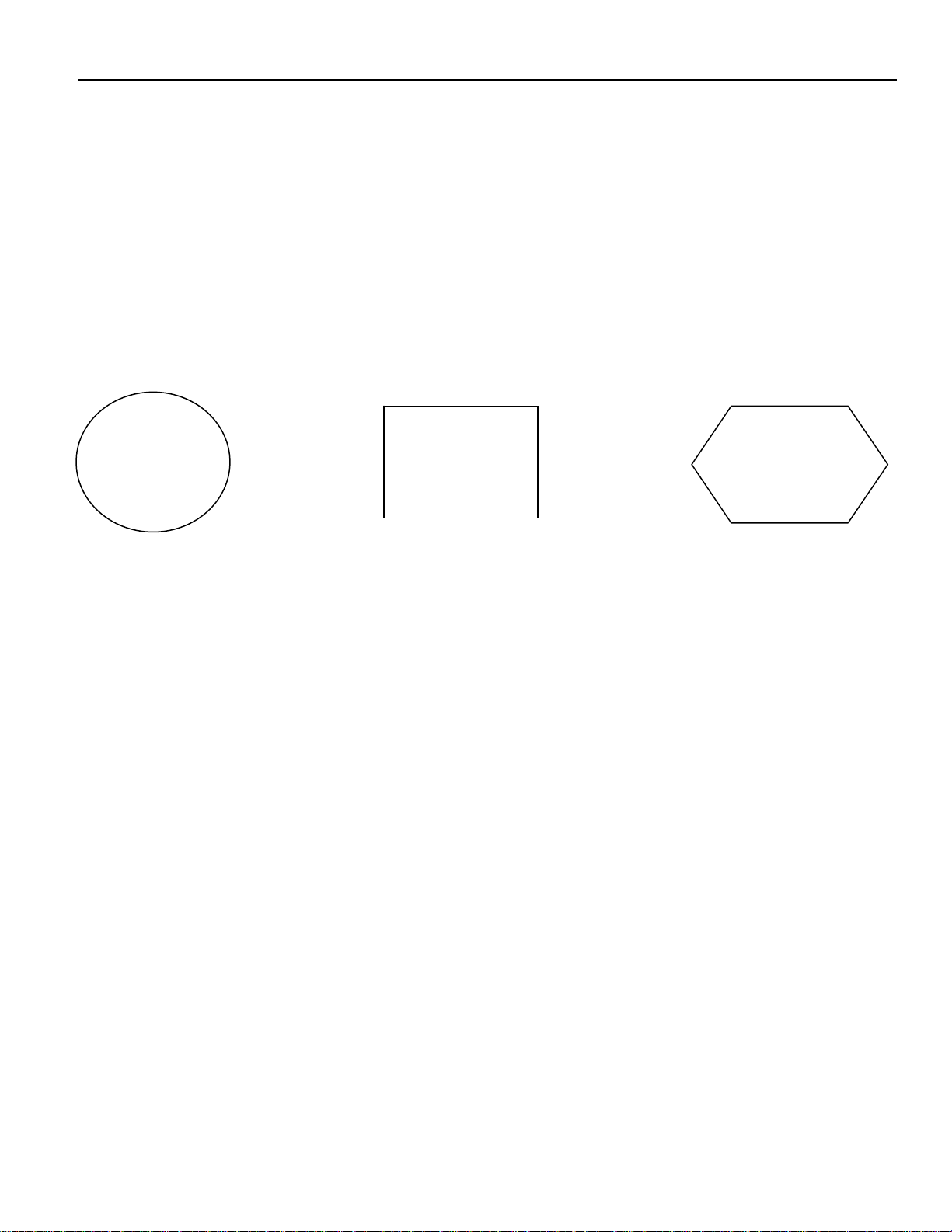

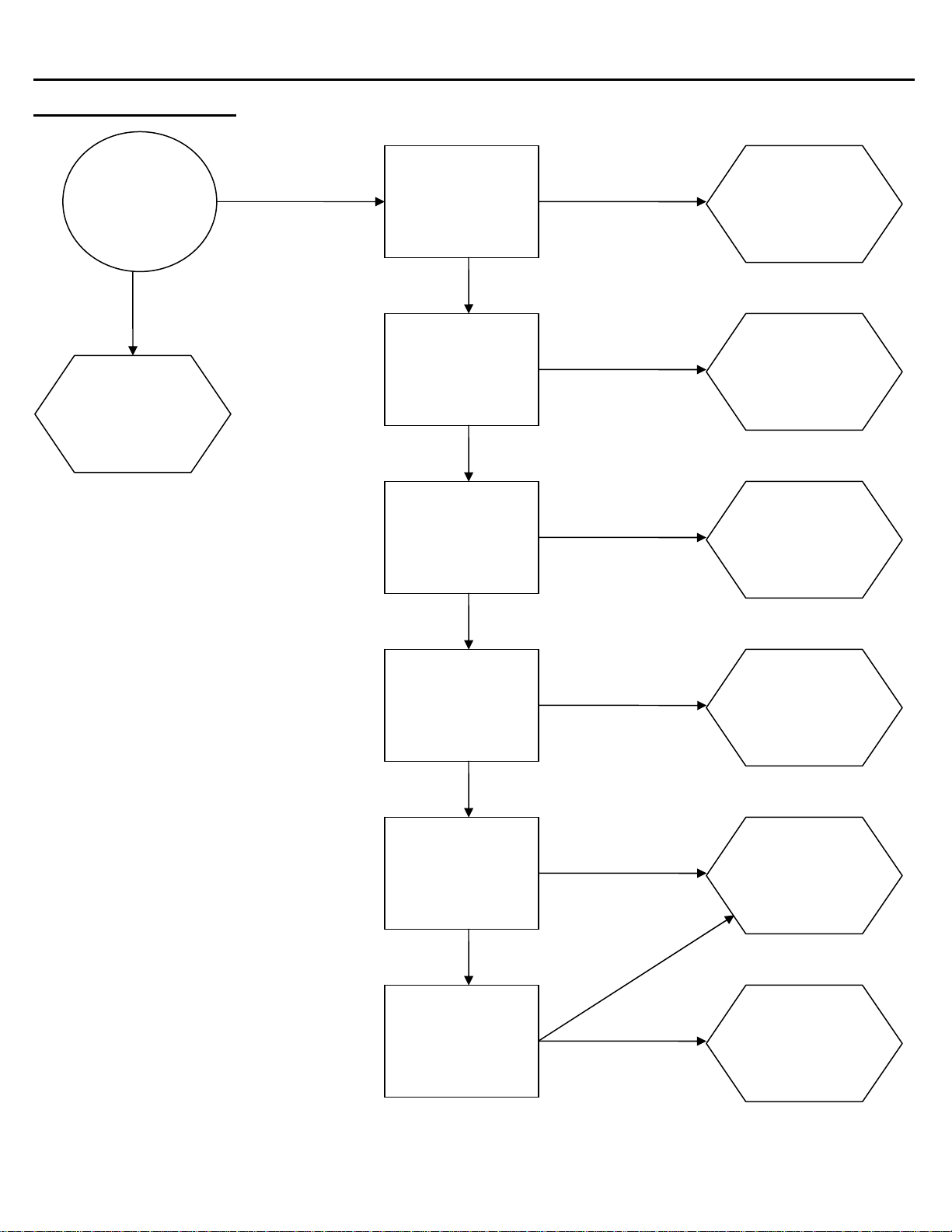

The troubleshooting trees are made of three types of boxes:

QUESTION boxes (Circle) ask a yes/no question and the answer will lead to either another

question box, a check box or a solution box.

CHECK boxes (Rectangle) will suggest a point to check for proper operation, and will often refer

you to a page in the service information sections of this manual. The result of the check may lead

to another box, or a solution box.

SOLUTION boxes (Hexagon) suggest the most likely component to cause the malfunction

described in the heading of the tree. When reaching a solution box, DO NOT immediately assume

the component is defective. The final step is to verify that the component is indeed defective, by

using the service information in the sections that follow.

To use the troubleshooting trees, first find the page with the heading describing the type of

problem occurring. Begin at the top of the page and follow the tree, step-by-step. When a check

box is reached, it may be necessary to refer to another section in the manual.

Once a solution box is reached, refer to the appropriate section to verify that the component in the

solution box is, indeed, the problem. Adjust, repair or replace the component as necessary.

?

9

!

Page C1

Page 29

ICE Series Troubleshooting Trees

Troubleshooting Trees Table Of Contents

Machine Does Not Run C3

Machine Runs, Does Not Make Ice C4 – C5

Slow Production (Cube Formation Good) C6

Low Suction Pressure C7

High Suction Pressure C8

Cubes Are Hollow C9

Uneven Bridge Thickness C10

Ice Bridge Thickness Varies Cycle To Cycle C11

Machine Produces Cloudy Ice C12

Poor Water Distribution Over Evaporator C13

Machine Does Not Enter Harvest C14

Machine Enters Harvest, Then Returns To Freeze Prematurely C15

Length Of Harvest Excessive C16

Ice Does Not Release From Evaporator C17

Hot Evaporator, Low Suction Pressure (Remote Only) C18

Page C2

Page 30

ICE Series Troubleshooting Trees

K

K

Machine Does Not Run

Is the selector

switch set to

ICE?

NO

Set selector

Switch to the

ICE position

YES NOT OK

Check for correct

power supply to the

Pressure Safety

Temperature Safety

machine

Check High

Control

Check High

Control

OK

TRIPPED

OK

OPEN

Correct field

wiring deficiency

Reset and

identify reason

for high head

pressure

Replace or

identify reason

for being open.

OK

Check Bin Control

for proper

adjustment, see

page F9

GOOD

Is this a Remote

unit?

OK

Is the Liquid line

Solenoid energized

and open?

BAD

NO

O

NOT O

Adjust as

required or

replace if

defective

Selector Switch

could be

defective, see

page F1

Find reason for

non-activity or

replace if

defective

Page C3

Page 31

ICE Series Troubleshooting Trees

Machine Runs, Does Not Make Ice

Is water

running over

the

evaporator?

NO

Go to the

Troubleshooting

Tree on page

C12

Check High

Pressure reset if

necessary

YES GO TO PAGE C5

Check for power to

the compressor

YES

Is the

compressor

running?

NO

GOOD

bad contactor or coil.

contactor coil

OK

Does the unit

have a remote

condenser?

Check contactor for

Replace if defective

Compressor or

Start

Components

could be

defective, see

page F2

OK

Continue if the

machine has a

remote

condenser

OK

Check the suction

pressure, is it low or

high?

LOW

Check refrigerant

charge

HIGH

OK

OK

NO

Check Selector

Switch,

Replace if defective

Pumpdown

Control possibly

bad

Liquid Line

Solenoid not

opening

Page C4

Page 32

ICE Series Troubleshooting Trees

Machine Runs, Does Not Make Ice (continued)

Is water

leaking out of

the Purge

Drain or Water

Trough?

YES

Repair water

leakage defect

NO

Check refrigerant

pressures, see page

E1

LOW SUCTION OK

Recover and weigh

in refrigerant charge

OK

Low side

restriction or

defective TXV

HIGH OR NORMAL

SUCTION

If head pressure is

also high, make sure

Condenser is clean

and machine has

good air flow

Check Hot Gas

Valve for leakage

during freeze, see

page E5

OK

Check for inefficient

Compressor

Page C5

Page 33

ICE Series Troubleshooting Trees

K

Slow Production (Cube Formation Good)

Does

installation

meet

guidelines?

Correct any

installation

defects

NO

YES

Check for excessive

head pressure

TOO HIGH

Is this unit air

cooled or

water cooled?

AIR

Condenser

OK

Is the Air

clean?

Check refrigeration

system, Section E

YES

Check refrigeration

system, Section E

NO

WATER

Check Water

Regulating Valve,

See page E2

O

See Condenser

service information

page E2

NOT OK

Clean

Condenser and

Condenser Fan

Blade

Adjust or

replace Water

Regulating

Valve

Page C6

Page 34

ICE Series Troubleshooting Trees

Low Suction Pressure

Does

installation

meet

guidelines?

YES

Is the water

flow over the

Evaporator

correct?

YES

Check for correct

head pressure, see

page E10

NOT OK

NO

NO

Is the

machine a

remote unit?

YES

NO

Correct

deficiency in

installation

Go to

Troubleshooting

Tree on page

C12

Low charge,

locate and

repair leak,

evacuate and

recharge

system

OK

Check TXV for

moisture based

restriction

WET SYSTEM

Replace drier,

evacuate and

recharge

system

See

Troubleshooting

Tree page C18

DRY SYSTEM NOT OK

Check for refrigerant

tubing restriction,

Check Evaporator

coil separation, see

crimps, etc.

OK

NOT OK

page E4

OK

TXV possibly

defective, see

page E3 and

page E4

Correct

restricted tubing

Replace

defective

Evaporator

Page C7

Page 35

ICE Series Troubleshooting Trees

K

High Suction Pressure

Have you

checked the

“Slow

Production”

Tree?

Is the head

pressure also

high?

Is the machine

installed to

specifications?

YES

YES

NO

NO

NO

Correct

installation

defects

Go to “Slow

Production”

Troubleshooting

Tree

Check Hot Gas

Valve, see page E5

NOT OK

Hot Gas Valve

is possibility

defective

OK

Replace

Compressor

NOT O

Check Compressor,

see page E1

OK

TXV could be

defective, see

Expansion

Valve, see page

E3 and E4

YES

Is the

Condenser

dirty?

Check for leaking

Purge valve

NO

YES

Repair or

replace

defective part

Clean the

Condenser

OK OK

Check Condenser

Fan Motor and

Blade for proper

operation, and/or

Water Valve or

Mixing Valve

NOT OK

TVX Thermal

bulb loose or

TXV could be

defective

STILL TOO

HIGH

Evacuate and

recharge system

Page C8

Page 36

ICE Series Troubleshooting Trees

K

Cubes Are Hollow

Is the water

temperature

above 100°F

(38°C)?

YES

Water

temperature too

high, correct

water

temperature

NO

Is there good

water flo w

over the

Evaporator?

NO

Go to the “Poor

Water Distribution

Over Evaporator”

Troubleshooting

Tree, page C13

YES

Is water

leaking from

the Purge

Drain?

NO

Check Timer for

proper setting, see

page F4

NOT O

Timer Initiate

Control out of

adjustment of

defective

YES

OK

Purge Valve has

an obstruction

or could be

defective

Timer Module

requires

adjustment or

could be

defective

Page C9

Page 37

ICE Series Troubleshooting Trees

Uneven Bridge Thickness

Make sure

supply water

temperature is

below 100°F

(38°C)

Check for water

leaking out of Purge

Drain

Dirty or

defective Purge

Valve

OK

NO

NO

Is water

running into

the bin?

Are the

Evaporator(s)

flooded? See

page E4 and

E5

NO

Check the suction

pressure, is it high or

low? See pageE1

YES

YES

HIGH

Problem in

water syst em,

see pages D1

and D2.

Serpentine coil

on back of

evaporator

could be

separated, see

page E4

Hot Gas Valve

could be

leaking, see

page E5

LOW

Make sure the

system is charged

properly, recover the

charge and weigh in

the correct amount

OK

Refer to page

E3 and E4 for

TXV diagnosis.

Page C10

Page 38

ICE Series Troubleshooting Trees

Ice bridge Thickness Varies Cycle To Cycle

Is air and

water temps

consistent and

within

guidelines?

YES

Check the Purge

Valve for water leaks

OK

Check Hot Gas

valve for proper

operation

NO

NOT OK

NOT OK

Correct

installation

deficiency

Clean Purge

Valve or replace

if defective

Replace Hot

Gas Valve

OK

Check Timer Initiate

Control for proper

operation

OK

Check Solid State

Timer for proper

operation

OK

TXV(s) could be

defective, see

page E3 and E4

NOT OK

NOT OK

Replace Timer

Initiate

Adjust Timer or

replace if

defective

Page C11

Page 39

ICE Series Troubleshooting Trees

Machine Produces Cloudy Ice

Is water

running evenly

across the

evaporator?

YES

Doe machine

meet

installation

guidelines?

See Section A

YES

Cloudiness is a

result of properties

in the incoming

supply water

NO

NO

See “Poor

Water Running

Over Evaporator

Troubleshooting

Tree page C13

Correct

installation

deficiency

Page C12

Page 40

ICE Series Troubleshooting Trees

Poor Water Distribution Over The Evaporator

Is the machine

level?

NO

Level the

machine

YES

OBSTRUCTED CLEAR

Is the water

level in the

Water Trough

correct? See

Section D

YES

Check Water

Distribution Tube for

obstructions or

improper assembly

See Section D

NO

Is the supply

water

pressure

correct?

Is water

leaking from

the Purge

Drain?

YES

NO

NO

YES

Correct

deficiency in

supply water

pressure

Purge valve

stuck open,

clean or replace

if defective

Float Valve not

adjusted

properly or

could be

defective

Clean Water

Distribution

Tube; insure

that it is

assembled

correctly

Check Water Pump

for proper operation

BAD

Water Pump

obstructed or

may be

defective

GOOD

Clean

Evaporator and

Spillway. See

Section B for

cleaning

instructions

Page C13

Page 41

ICE Series Troubleshooting Trees

K

KOK

K

Machine Does Not Enter Harvest

Will suction

pressure drop

below cut-in of

Timer Initiate?

YES

Does the

manual Purge

Switch

energize the

Purge Valve?

NO

Is the freeze

pattern on the

Evaporator

even?

Check for signs of a

weak Compressor,

see page E1

YES

NO

YES

Check Timer Initiate

Control for correct

cut-in pressure

Check Purge Valve

to make sure it is not

leaking, if it is

replace valve or

remove obstruction

Make sure system is

not overcharged

OK

OK

could be leaking

TXV(s) may be

stuck open, see

page E3 and E4

Hot Gas Valve

NOT OK

adjustment or

Timer Initiate

Control out of

may be

defective

High

Temperature

Safety Control

may be open,

see page F8

NO

O

Check Timer

Number 1 for proper

setting and

operation

O

Check Timer

Number 2

O

Relay Number 1

or Relay Base

may be

defective

Page C14

NOT OK

Timer may be

defective

Page 42

ICE Series Troubleshooting Trees

Machine Enters Harvest, Then Returns To Freeze Prematurely

Is the Harvest

Assist working

properly? See

page F6

NO

Adjust as

required or

replace

defective part

YES

Check the Manual

Purge Switch

Normally Closed

contacts. See page

F1

CLOSED

Check High

Temperature Safety

Control. See page

F8

CLOSED

Relay 1 or relay

Base may be

defective

OPEN

OPEN

Purge Switch is

defective

High

Temperature

Safety Control is

defective

Page C15

Page 43

ICE Series Troubleshooting Trees

Length Of Harvest Excessive

Does the

machine meet

installation

guidelines?

YES

Check Harvest

Assist Assembly for

proper operation,

see page F6

NOT OK

Adjust or

replace

defective part

NO

Correct

installation

deficiency

OK NO

Is the ice

formation

even on the

Evaporator?

YES

Does the

machine have

a remote

condenser?

YES

Low refrigerant

charge, repair

leak and weigh

in proper charge

Remote: Check

Mixing Valve

operation, page E6

Water Cooled: check

Water Valve for

proper adjustment

NO

Check suction

pressure during

harvest. See page

E5

OK

Clean Evaporator

per instructions in

Section B

OK

TOO LOW

STILL TOO LONG

Hot Gas Valve

may be

defective

Go to “Ice Does

Not Release”

Troubleshooting

Tree, page C17

Page C16

Page 44

ICE Series Troubleshooting Trees

Ice Does Not Release From Evaporator

Is the ice

bridge

correct? See

page F4

NO

Set proper

bridge

thickness, see

page F4

Check Purge valve

and Tubing for

obstructions and

proper operation,

see page D2

YES

YES

NOT OK

Is the machine

level?

YES

Does water

run over the

Evaporator

during

harvest?

Replace Purge

Valve or repair

tubing

obstruction

NO

NO

Clean the

Evaporator, see

page B2

OK

OK

Level the

machine

Check Harvest

Assist for proper

operation, see page

F6

NOT OK

Repair Harvest

Assist as

required

OK

Check Relay 1 and

Relay Base for

proper operation,

see page F5

OK

Selector

Switch may be

defective,

WASH contacts

closed in ICE

mode

Relay or Relay

Base defective

Check suction

pressure during

harvest, see page

E5

TOO LOW

Check discharge

pressure during

freeze, see page E2

TOO LOW

Low ambient or

Water regulating

Valve set too

low

GOOD

GOOD

Evaporator may

be defective,

see page E4

and E5

Hot Gas valve

may be

restricted or

defective, see

page E5

Page C17

Page 45

ICE Series Troubleshooting Trees

Hot Evaporator, Low Suction And Discharge Pressure (Remote Only)

Does the

machine meet

the installation

guidelines?

YES

Does the

machine have

the proper

refrigeration

charge?

NO

NO

YES

Correct

installation

deficiency

Mixing Valve

may be

defective, see

page E6

Repair leak,

evacuate and

weigh in

refrigerant

charge per

nameplate

Page C18

Page 46

ICE Series Water System

Water Distribution and Components

Water enters the machine through the float valve located in the water trough. The water trough

holds water used for ice making. The float valve is used to maintain the proper water level in the

water trough. During the freeze cycle water is continuously circulated over the evaporator by the

water pump. When the machine enters harvest, the purge valve (not shown) opens and mineral

laden water is pumped out of the water trough to the drain. After water is purged from the trough,

the water pump and purge valve are de-energized and the trough refills.

Float Valve

The water level can be adjusted by carefully bending the arm of the float. The water level should

be ½ inch (13mm) above the top of the water pump impeller housing during the freeze cycle.

If the float valve does not allow water into the trough or water flow is slow, the float valve may be

restricted. Remove and disassemble the float valve and clean the orifice. If the water flow is still

slow, check the water pressure to be sure it is at least 20 PSI (1.4 bar).

If the float valve does not stop the water flow, make sure the water pressure to the machine does

not exceed 60 PSI (4.1 Bar). Install a water pressure regulator if the pressure is too high. If the

water pressure is not the problem, the float plunger or the entire float valve assembly may need to

be cleaned or replaced.

Page D1

Page 47

ICE Series Water System

Water Distribution Tube

Water is pumped to a distribution tube located at the top of the evaporator and is used to distribute

water evenly over the evaporator. The distribution tube can be removed and dissembled for

cleaning if the hole becomes plugged or if there is excessive mineral build-up in the water system.

The water distribution tube is a tube within a tube. Water enters and fills the inner tube and exits

through a series of holes along the top of the inner tube. Water then fills the outer tube and exits

through a series of holes along the bottom of the outer tube. For proper water flow over the

evaporator, it is important that the tube be assembled correctly after cleaning. The tube can be

checked for proper assembly by checking the “bump” on the flanges at the tube ends, the “bump”

should be at the top.

Water Distribution Disassembly

Remove 2 screws holding the distribution tube to the evaporator spillway. Remove the clamp

holding the water tube to the distribution tube. Twist the end caps of the distribution tube

counterclockwise and pull to remove the inner tube halves from the outer tube. To reassemble,

push the inner tube halves into the outer tube with the holes facing the same direction. Make sure

the inner tube halves seat together completely. Twist the end caps clockwise ½ turn to lock the

inner tubes in place. The holes in the tubes will now be facing in the opposite directions. e directions.

Important! For proper water flow over the evaporator, the inner tube holes must face up. Important! For proper water flow over the evaporator, the inner tube holes must face up.

Turn counterclockwise to remove

Page D2

Page 48

ICE Series Water System

Water Splash Curtain

The water splash curtain covers the evaporator to prevent water from splashing into the bin and is

also used to actuate the bin switch. When the bin becomes full of ice, the splash curtain is held

open when the ice drops off of the evaporator. The actuator tab or wire bale on the splash curtain

will release pressure on the bin switch and the machine shuts off. See bin control on page F9.

On single evaporator units, the splash curtain can be opened or removed during the freeze cycle

and the machine will continue to run until the ice drops from the evaporator. On dual evaporator

units, if the curtain is opened or removed during the untimed freeze cycle, or during defrost, the

machine will shut down. If the curtain is opened or removed during the timed freeze cycle, the unit

will continue to operate.

The splash curtain can be removed by swinging the bottom of the curtain away from the

evaporator and lifting the right side of the curtain up and out of the hinge pin slot. To reinstall the

curtain, position the left side pin into the slot first, then insert the right hand side with the actuator

tab of the curtain behind the bin switch.

Note: The ICE0250 and ICE0305 utilize a curtain-retaining clip. The ICE Undercounter Series

ice machines do not

utilize a splash curtain.

Proper position of wire bale switch actuator

Water splash curtain actuator tab

positioned behind bin switch

Page D3

Page 49

ICE Series Water System

Water Purge Valve

When the machine enters the harvest cycle, the water pump continues to run and the purge valve

opens. This allows mineral laden water to be pumped from the water trough to the drain. This

helps keep the water system clean. The water pump and purge valve de-energizes once the water

is flushed from the water trough. The cam switch controls the length of time that the water pump

and purge valve remains energized see page F7. The purge valve can also be energized

manually by pushing the purge switch. The purge switch is used when cleaning the water system

to flush cleaning solution down the drain. See page B1 for cleaning instructions.

The purge valve must be completely closed during the freeze cycle. If water leaks through the

purge valve during the freeze cycle, the freeze cycle will be extended due to the float allowing

warm water into the trough and poor ice formation will result. The purge valve may be defective or

need cleaning.

The purge valve can be disassembled for cleaning by:

1. Disconnect electrical power form the ice machine.

2. Locate the Purge valve in the machine.

3. Leave the coil wires attached to the coil and lift coil from the valve body. (Note coil orientation)

4. Rotate the enclosing tube ¼ turn counterclockwise to remove.

5. Remove the enclosing tube, plunger and diaphragm from the valve body

6. Reverse procedure to reassemble.

The purge valve can be easily cleaned without removing the

entire valve body. Dirty or clogged purge valves are not

considered a warranty repair.

Page D4

Page 50

ICE Series Water System

Water Trough

The water trough can be easily removed by the following procedures:

1. Disconnect power to the ice machine.

2. Shut the water supply off to the ice machine.

3. Remove water splash curtains when

applicable.

4. Remove water trough mounting screws.

5. Carefully remove water trough from the ice

machine.

6. Reverse procedure to reassemble.

Mounting Screws

ICE 30 Inch Wide Models

ICE 22 Inch Wide Models

ICEU150/200 Models

Mounting Screws

Mounting Screws

ICE 48 Inch Wide Models

Version 3 Water

Trough

Mounting Screws

Mounting Screws

Mounting Screws

ICEU300

ICE1506 Model

Page D5

Page 51

ICE Series Refrigeration System

Refrigerant Cycle and Components

Before diagnosing the refrigeration

system, it is very important that the

refrigerant charge be correct.

Whenever the refrigeration system

has been opened, the filter-drier

must be replaced and the proper

refrigerant charge must be weighed

in. See refrigerant charge data on

page A5–A8.

Refrigerant Pressures

The suction pressure at the

beginning of the freeze cycle can vary +/- 10 psi

(.7 bar) depending on operating conditions. Reference Chart on page I1-I6. Pressures less than

this may indicate an undercharge. The discharge pressure on water-cooled units should be 250

psi (17.01 bar) for R404a units and 150 psi (10.21 bar) for R134a units. The discharge pressure

on air cooled units will vary with ambient conditions but will typically run higher than water cooled

units. Remote condensers located in ambient temperatures below 70°F (21°C) will typically run a

lower discharge pressure. See Mixing Valve later in this section.

Refrigerant in a gas state is pumped throughout the refrigeration system by a hermetic

compressor to the condenser. Heat is removed from the refrigerant either by forced air

movement through an air-cooled condenser or transferring heat from the refrigerant to water

through a water-cooled condenser. The refrigerant changes to a liquid when cooled.

The refrigerant in a liquid state passes through a filter drier. The filter drier traps

small amounts of moisture and foreign particles from the system. The filter drier must

be replaced whenever the refrigeration system is opened or if the refrigerant charge

has been completely lost.

Compressor

The compressor runs during the entire cycle. If the valves in the

compressor are damaged, the compressor will be unable to pump

refrigerant efficiently. Damaged valves are usually the result of another

problem in the refrigeration system such as liquid refrigerant returning to

the compressor, oil slugging or high head pressure. When a compressor

is replaced it is important that the refrigerant charge be weighed in and

the system checked for proper operation to prevent a repeat failure.

An inefficient compressor will usually have a higher than normal suction

pressure at the end of the cycle. The freeze cycle will be longer than normal and/or the harvest

cycle may be excessively long. Check the compressor amperage draw 5 minutes into the freeze

cycle. If the compressor amp draw (Reference data plate on ice machine back panel) is less than

70% of rated full load amps, the compressor may be inefficient. These symptoms may also be

caused by other problems, therefore it is important to use the troubleshooting trees when

diagnosing a problem. See Electrical System for more information on the compressor and

compressor start components.

Page E1

Page 52

ICE Series Refrigeration System

Air Cooled Condenser (Self Contained)

The air condenser is located in the back of the cabinet. Air is pulled

through the condenser by a fan motor and discharged through the right

hand side panel. The ICE1400 has 2 fan motors and discharges through

the right side and left side panels. The ICE Undercounter air intake

and discharge is through the front panel. A top air discharge is available

on the ICE250-ICE0606.

Do not block airflow as it will cause premature failure of the

machine and will void the warranty.

Water Cooled Condenser

If the machine has been properly installed, the water flow through the

condenser will be in a direction opposite the refrigerant flow. The water

condenser supply pressure must be between 20 psi (1.4 bar) and 60 psi

(4.1 bar). A water-regulating valve is used to control the flow of water

into the condenser. In areas that have poor water quality, the

condenser may eventually become coated with mineral deposits. This

will decrease the efficiency of the condenser resulting in high head

pressure. Water cooled condensers replaced due to excessive mineral

build up or freezing will not be covered under warranty.

Water Regulating Valve

The water-regulating valve controls the head pressure by regulating the amount of

water flow through the condenser. The bellows of the regulating valve are

connected to the high-pressure side of the refrigeration system. As the head

pressure rises, the bellows expand increasing the water flow through the water

condenser. Adjusting the spring pressure screw on top of the water valve can vary

the rate of water flow. The valve should be adjusted to maintain a discharge

pressure of 250 psi (17.01 bar) on R404a units and 150 psi (10.21 bar) on R134a

units. Water exiting the condenser should be between 100°F (38°C) and 110°F

(43°C). When the machine is off, the water valve will close completely, stopping the

flow of water through the condenser. If the water flow does not stop when the

machine is off, the valve may need cleaning or replaced.

Air Cooled Condenser (Remote)

See Pages E5 and E7

High Pressure Safety Control (Manual Reset)

If the discharge pressure becomes excessive, the high-pressure safety

control will open and shut the machine off. The high-pressure safety control

opens at 450 psi (30.62 bar) on R404a units and 250 psi (17.01 bar) on

R134a units. The high-pressure safety control is used on all water-cooled and remote

units and select air-cooled units.

High Pressure Safety Control (Automatic Reset)

The automatic reset high pressure control opens at 450 psi (30.62 bar) and closes at

338 psi (23.00 bar). The high-pressure safety control is used on all water-cooled and

remote units and select air-cooled units.

Page E2

Page 53

ICE Series Refrigeration System

Thermostatic Expansion Valve (TXV)

The thermostatic expansion valve meters the flow of refrigerant into the

evaporator changing its state from a high-pressure liquid to a low-pressure

liquid. This drop in pressure causes the refrigerant to cool. The cooled

refrigerant absorbs heat from the water circulating over the evaporator. As

the evaporator fills with liquid refrigerant, the evaporator becomes colder.

The flow of refrigerant into the evaporator is controlled by the temperature at the outlet of the

evaporator. The expansion valve bulb, mounted to the top of the suction line, senses the

evaporator outlet temperature causing the expansion valve to open or close. As ice forms on the

evaporator, the temperature drops and the flow of refrigerant into the evaporator decreases,

resulting in a drop in suction pressure.

The evaporator should become completely flooded (filled with liquid refrigerant) during the freeze

cycle. A completely flooded evaporator will have a uniform freeze pattern (ice formation across the

evaporator). A starved evaporator (not enough liquid refrigerant) will have poor or no ice formation

at the top of the evaporator, and the tube(s) exiting the evaporator will not frost. All tubes should

be within 10 degrees of each other and frosted approximately 5 minutes from the start of the freeze

cycle.

An expansion valve that is restricted or not opening properly will starve the evaporator resulting in

lower than normal suction pressure. A low refrigerant charge will also starve the evaporator and

cause low suction and discharge pressures. If not sure of the amount of charge in the system, the

refrigerant should be recovered and the correct charge be weighed in before a defective valve can

be diagnosed.

If the evaporator is starved but the suction pressure is higher than normal, the TXV is not the

problem; refer to the troubleshooting tree in section C. If the TXV sticks open or if the thermal bulb

is not making good contact with the suction line, the flow of refrigerant into the evaporator will be

too great and liquid refrigerant will flood the compressor. The suction pressure will remain higher

than normal and the machine will remain in an extended freeze cycle. Ice will build evenly but will

be very thick.

Symptom Problem Possible Remedy

Evaporator flooded but suction 1 TXV thermal bulb not making 1 Tighten bulb clamp and

pressure not dropping. good contact with suction insulate bulb.

Compressor has been checked line or uninsulated

and appears to be good. 2 TXV bulb installed incorrect 2 Locate bulb on top of

Suction line at compressor may suction line

be colder than normal 3 System overcharged 3 Recharge system

4 TXV stuck open 4 Replace TXV

Evaporator starved, no frost 1 Machine low on charge 1 Recover refrigerant

on line(s) exiting evaporator. and weigh in proper

Suction pressure is low. charge

See Evap. Diagram Pg.E4 2 TXV restricted or stuck 2 Replac e TXV and

closed drier

Continued Page E4

Page E3

Page 54

ICE Series Refrigeration System

Thermostatic Expansion Valve (Continued)

A dual evaporator machine will have one TXV for each evaporator. If one TXV sticks open and the

other is operating normally, the suction pressure will be higher than normal and both evaporators

will build thick ice. It is recommended that both valves be replace if one sticks open.

If one TXV sticks closed and one is operating normally, the suction pressure will be normal or low

but the evaporator with the defective valve will be starved (thick ice at the bottom and thin ice at

the top).

Evaporator

As water is circulated over the front of the evaporator, liquid refrigerant is circulated through the

tubing attached to the back of the evaporator. As the liquid refrigerant in the tubing vaporizes, it

absorbs heat from the water causing the water to freeze. The evaporator should be completely

flooded throughout most of the freeze cycle. A flooded evaporator will build ice evenly across the

evaporator. A starved evaporator will have uneven ice formation. Most problems with ice

formation or harvesting are not related to a defective evaporator, use the Troubleshooting Trees in

section C for additional help.

Refrigerant enters the evaporator through the bottom tube and exits through the top tube. On

(Prior to 0801) models ICE800, 1000, 1800 and 2100 the refrigerant line at the TXV outlet splits

into two feeder tubes. This split occurs at the distributor, which is a fitting that is soldered to the

TXV. One feeder tube from the distributor feeds the top of the evaporator; the other tube feeds the

bottom of the evaporator. The evaporator tubes run parallel, in opposite directions, along the back

of the evaporator creating a dual pass.

If the evaporator is flooded but not building ice evenly, it is possible the evaporator has coil

separation. Evaporator coil separation is the separation of the refrigerant tubing from the back of

the evaporator plate. This is very rare but occasionally occurs.

To confirm coil separation, remove and check the back of the evaporator. If the coil is separated,

the evaporator must be replaced. If the outlet(s) of the evaporator is not frosted, the problem is not

with coil separation (Refer to the troubleshooting trees, section C).

ICE800, 1000, 1800 and 2100 Prior to Jan, 2008

In

Out

In

Out

Out

In

Page E4

Page 55

ICE Series Refrigeration System

Note: Permanent discoloration of the evaporator plating is normal and will cause no problems with

harvesting the ice or sanitary conditions. Before condemning the evaporator for plating problems,

be certain it is not just discoloration. Good evaporators will not be covered under warranty. If the

spillway (plastic evaporator top) becomes damaged, it can be replaced. It is not necessary to

replace the entire evaporator.

As liquid refrigerant leaves the evaporator, it changes to a low-pressure gas before returning to the

compressor. Liquid refrigerant must not return to the compressor or damage will result. Frost on

the suction line at the inlet of the compressor indicates liquid returning to the compressor. Check

for frost at the end of the freeze cycle. If liquid is returning to the compressor, the problem must be

located and corrected. See Refrigerant Charge, Thermostatic Valve and Evaporator.

Harvest Cycle

Once the freeze cycle is complete, the machine enters the harvest cycle. The hot gas valve

opens to allow hot discharge gas to enter the evaporator.

Hot Gas Valve

When the machine enters harvest the hot gas valve coil is energized opening

the hot gas valve. Discharge gas is pumped through the hot gas valve directly

into the evaporator. The evaporator temperature will reach approximately 40°F

(4.5°C). The suction pressure during harvest should be a minimum of 70 psi

(4.8 bar) for R404a units or 50psi (3.4 bar) for R134a units. The discharge

pressure will drop during harvest.

If the hot gas valve does not completely open during harvest, there will not be enough hot gas in

the evaporator to defrost the ice. If there is not enough hot gas entering the evaporator, the

suction pressure will be lower than the above stated pressures. It is important when making this

check that the machine has the proper refrigerant charge, normal head pressure and the

compressor is functioning properly. If the hot gas valve leaks during the freeze cycle, ice will not

form on the top of the evaporator and suction pressure will be higher than normal. To check if the

hot gas valve is leaking, let the machine run in the freeze cycle for approximately 5 minutes. Now

feel the temperature between the inlet and outlet of the valve. A definite temperature difference

should be felt. If the lines are the same temperature and the suction pressure is higher than

normal; the valve is leaking and should be replaced. Use Troubleshooting Trees in section C.

Remote System

Machines that use remote condensers have several components that are not used in self

contained machines. A mixing valve controls the head pressure when the ambient temperature at

the condenser drops below 70°F (21°C). When the bin fills with ice or is turned off at the selector

switch, the machine will pump all the refrigerant into the receiver before shutting off.

Remote Condenser

For proper operation, the remote condenser must be installed properly.

Improper installation will void the warranty. See remote guidelines on page

A14. The location of the remote condenser should be such that the ambient

air temperature does not exceed 120°F (48.9°C). If ambient temperature

exceeds 120°F (48.9°C) ice production will decrease until the ambient

temperature decreases.

Air

Flow

Page E5

Page 56

ICE Series Refrigeration System

Remote Condenser (Continued)

If the airflow is restricted or the condenser is dirty, the head pressure will be excessively high, slow

production will result and the compressor may overheat and eventually become damaged. The

condenser coil and fan blades must be kept clean. The condenser can be cleaned with

compressed air or by using a brush. If a brush is used, brush in the direction of the fins taking care

not to bend the fins. If the condenser fins are bent, this will restrict the airflow through the

condenser and the fins will need to be straightened with a fin comb. Problems related to a dirty

condenser or poor airflow will not be covered under warranty. Note: The condenser fan motor runs

continually, it will shut off when the icemaker shuts off.

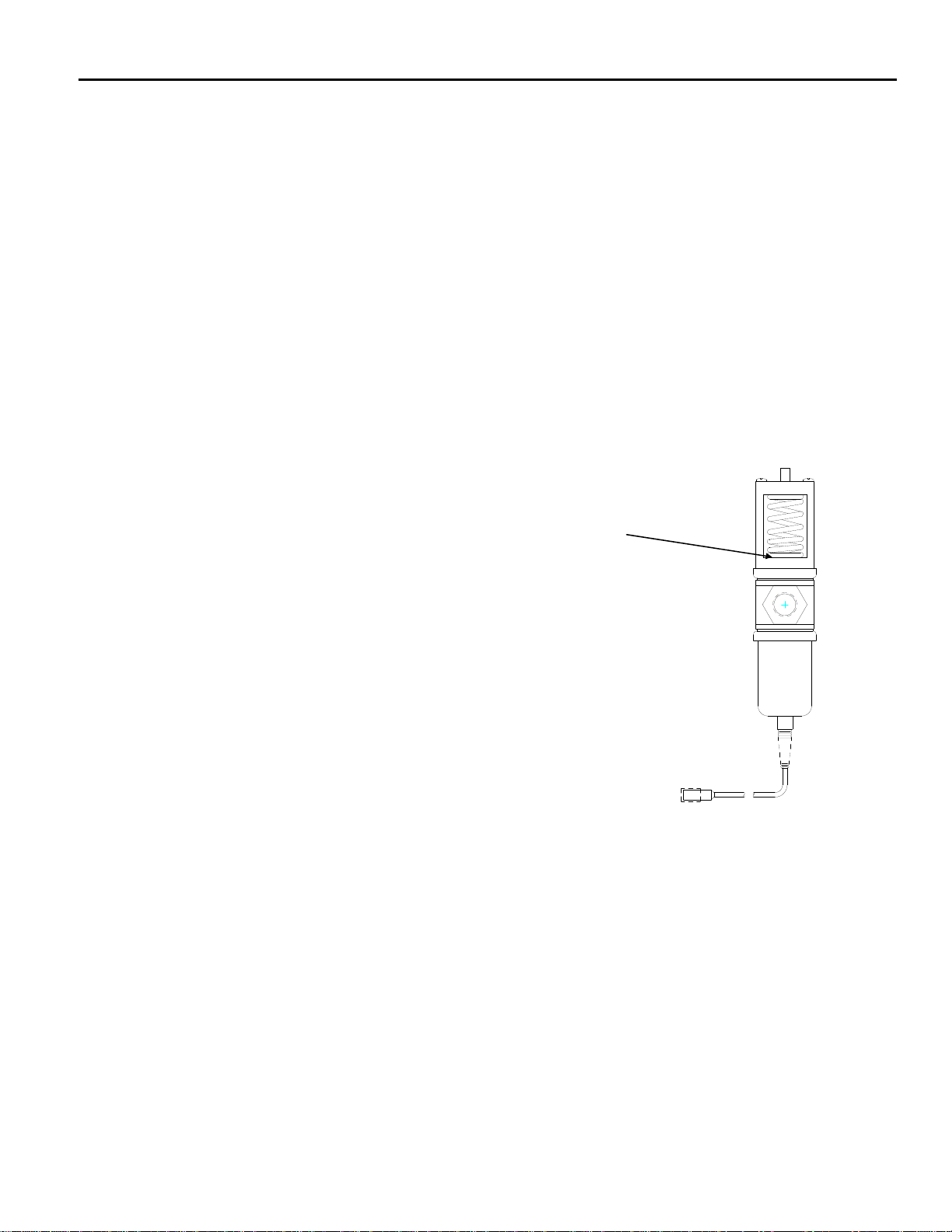

Mixing Valve

When the temperature at the condenser is above 70°F (21°C), the refrigerant flow from the

compressor is directed by the mixing valve through the condenser and into the receiver. When the

temperature at the condenser drops below 70°F (21°C), the pressure in the bellows of the mixing

valve becomes greater than the pressure of the liquid refrigerant coming from the condenser. This

change allows the valve to partially restrict the flow of

refrigerant leaving the condenser and allows discharge

gas to by-pass the condenser and flow directly into the

receiver, mixing with the liquid refrigerant from the

condenser. The amount of discharge gas that

bypasses the condenser increases as the ambient

temperature decreases. This action of the mixing

valve allows the discharge pressure to be maintained

at approximately 240 psi (16.5 bar) during low ambient

conditions. If the refrigerant system is undercharged

and the ambient temperature is below 70°F (21°C), the

mixing valve will not work properly. The mixing valve

will allow too much refrigerant to bypass the

condenser.

Problem Possible Cause Remedy

1 Head pressure low, Line between A. Valve Defective, not allowing A. Replace valve

valve and receiver cold. Ambient discharge gas into receiver

condenser temp. below 70°F (21°C)

2 Head pressure low, Line between A. System low on charge. A. Leak check. Recover

valve and receiver hot. B. Valve defective, not refrigerant and weigh

allowing liquid in proper charge.

into receiver. B. Replace valve

3. Head pressure low, Line A. Valve defective not A. Replace valve.

returning from condenser allowing refrigerant

is cool. Ambient condenser to circulate through

temperature is above 70°F (21°C) condenser.

Page E6

Page 57

ICE Series Refrigeration System

Pump Down System (Remote Only)

The pump down system prevents liquid refrigerant from migrating to the evaporator and compressor during the off cycle and prevents the compressor from slugging or starting under an excessive load.

Liquid Line Solenoid

When a machine with a remote condenser shuts off, the liquid line solenoid valve,

located at the outlet of the receiver, is de-energized causing the valve to close

completely restricting the flow of refrigerant. The compressor will pump all of the

refrigerant into the condenser and receiver.

As the system pumps down, the pressure on the low side of the system drops. When the suction

pressure drops to 10 psi (.68 bar), the pump down control opens and shuts the machine off. See

page F9 for pump down control operation. Liquid refrigerant is stored in the condenser and

receiver while the machine is off. It is normal for the machine to pump down once or twice an hour

as the pressures equalize.

When the machine comes back on (the bin switch closes or the selector switch placed to the ICE

position), the liquid line solenoid valve opens and the refrigerant is released from the receiver.

When the suction pressure rises to 35 psi (2.38 bar) the pump down control closes and the

machine comes back on. If the machine will not pump down, the valve may not be closing all the

way. A weak compressor will also prevent the machine from pumping down. Check for signs of a

weak compressor before replacing the liquid line solenoid. Prior to replacing the valve,

disassemble and check for obstructions that may not allow the valve to seat.

Receiver

If the system has a remote condenser, the refrigerant will enter a receiver before

passing through the filter drier. The receiver holds reserve liquid refrigerant during

the freeze cycle. The receiver also stores liquid refrigerant during the off cycle.

Page E7

Page 58

ICE Series Refrigeration System

Refrigerant

Refrigerant in a high-pressure liquid form is fed to an expansion valve where the refrigerant is

reduced to a low-pressure liquid. Under this low pressure, the liquid will absorb heat from the

evaporator causing the liquid to change to a vapor. This vapor is the drawn into the compressor

where the temperature and pressure of the vapor are increased. The high temperature, high

pressure vapor flows to the condenser where the heat is removed, causing the vapor to return to

the liquid form, making the refrigerant ready to flow back to the evaporator to pick up more heat.

Most Ice-O-Matic ice machine use R134a or R404a refrigerant. Always check the serial number

data plate for the proper type of refrigerant and the amount used in the machine you are servicing.

R404a and R134a are both HFC refrigerants, which result in no ozone depletion factor. R404a

cylinders are orange in color, R134a cylinders are light blue in color.

Important: When discharging refrigerant from an icemaker, recover as much of the

refrigerant as possible with a recovery device or some other means to prevent the

refrigerant from entering the atmosphere.

Method of Charging Refrigerant

In order to achieve a properly charged refrigeration system, the system must be completely

evacuated.

To achieve a complete evacuation you will need a service gauge manifold with properly maintained

hoses, and a vacuum pump capable of pulling a 50-micron vacuum. This will require a two-stage

pump.

Connect the service gauge manifold to the high and low side service ports and vacuum pump.