®

Ice Bear

30 Unit

Application Guide

for models:

IB30A-521

IB30A-523

IB30A-543

F004_C © Ice Energy, Inc., 2009. All Rights Reserved. 4May09

Phone: (877) 542-3232

Fax: (970) 545-3634

Email: productservices@ice-energy.com

www.ice-energy.com

Industry Recognition

A

Consortium of US Federal Labs

WORLD’S BEST TECHNOLOGIES,

Gold Award, 2004

ENERGY VENTURE FAIR

Most Promising Company Award,

2003, 2004, 2005

Copyright, Notices, and Trademarks

No reproduction/distribution without permission.

While this information is presented in good faith and believed to be accurate, Ice Energy disclaims the implied

warranties of merchantability and fitness for a particular purpose and makes no express warranties except as may be

stated in its written agreement with and for its customers.

In no event is Ice Energy liable to anyone for any indirect, special or consequential damages. The information and

specifications in this document are subject to change without notice. The information and specifications in this

document are subject to change without notice. Visit www.ice-energy.com

Ice Energy, Ice Bear, and CoolData are registered trademarks and Ice-Ready, Ice-Coil, and Hybrid Cooling are

trademarks of Ice Energy, Inc. Other brand or product names are trademarks of their respective owners.

CALIFORNIA TITLE 24 – 2005

Optional Compliance Measure

Energy Efficiency Standards, 2006

FLEX YOUR POWER AWARD

for Permanent Peak Power Shifting, 2007

ASHRAE / ARI

AHR Expo

Product of the Year, 2004

Energy Management

Green Building Innovation

ward 2009

© Ice Energy, Inc., 2009. All Rights Reserved.

to ensure that you have the latest version.

TOP-10 GREEN BUILDING

Product of 2005

BuildingGreen Magazine

NORTHERN COLORADO

BUSINESS REPORT

Innovative Business Award, 2005

ii Ice Bear® 30 Unit Application Guide

Table of Contents

Introduction ................................................................................................................................................... 1

Ice Bear

A Few of the Unique Installation & Startup Considerations ........................................................................ 3

Ice Bear

Applications .................................................................................................................................................. 9

Controls and Sequence of Operation .......................................................................................................... 12

Product Data and Specifications ................................................................................................................. 17

Engineering Data ........................................................................................................................................ 21

Applying an Ice Bear

Equipment Selection ................................................................................................................................... 24

Installation Considerations .......................................................................................................................... 25

Appendix A – Cooling Load Profiles ......................................................................................................... 33

Appendix B – Guide Specifications ............................................................................................................ 35

Appendix C – Ice Bear 30 Unit Equipment Schedule ................................................................................. 37

Appendix D – Title 24 Building Energy Standards Models ....................................................................... 38

Appendix E – Ice-Ready RTU & Ice-Coil Performance Data .................................................................... 39

®

30 Unit Overview ......................................................................................................................... 2

Definitions of Terms ................................................................................................................................. 2

®

30 Unit Ratings by Ton-hour ........................................................................................................ 3

Ice Bear

Approvals and Code Compliance ............................................................................................................. 4

Ice Bear

®

30 Unit Features ....................................................................................................................... 4

®

30 Unit Components ................................................................................................................. 5

Modes of Operation .................................................................................................................................. 6

Application Parameters ............................................................................................................................. 9

Typical Applications ............................................................................................................................... 10

Sample Ice Bear

Control Schematic .................................................................................................................................. 12

CoolData

®

®

Unit Configurations ................................................................................................... 10

Controller.............................................................................................................................. 14

Sequence of Operation ............................................................................................................................ 15

Ice Bear

Ice Bear

®

30 Unit Ambient Temperature Operating Ranges .................................................................. 21

®

30 Unit ETL Certified Performance Data .............................................................................. 21

®

30 Unit ................................................................................................................... 22

Airside Options ....................................................................................................................................... 22

Ice-Ready™ Rooftop Units .................................................................................................................... 24

Minimum Clearances .............................................................................................................................. 25

Lifting ..................................................................................................................................................... 26

Mounting ................................................................................................................................................ 28

Minimum Requirements for Connection of CoolData

®

Controller Wiring ............................................ 32

Sample Load Profile Spreadsheet ........................................................................................................... 34

Ice Bear® 30 Unit Application Guide iii

List of Figures

Figure 1 – Ice Bear® 30 Unit External View ........................................................................................................ 5

Figure 2 – Ice Bear® 30 Unit Internal View.......................................................................................................... 5

Figure 3 – Refrigerant Flow Schematic – Ice Make Mode ................................................................................... 7

Figure 4 – Refrigerant Flow Schematic – Ice Cooling Mode ............................................................................... 8

Figure 5 – Ice Bear®` 30 Unit (Parallel) with Ice-Ready™ Rooftop Unit .......................................................... 10

Figure 6 – Redundant (Parallel) Split System ..................................................................................................... 11

Figure 7 – Control Schematic ............................................................................................................................. 12

Figure 8 – Single Zone, Single-stage Thermostat with Economizer and Backup Condensing Unit ................... 13

Figure 9 – Single Zone, Two-stage Thermostat with Economizer and Backup Condensing Unit ..................... 13

Figure 10 – CoolData® Controller ...................................................................................................................... 14

Figure 11 – Ice Bear® 30 Unit Dimensions Rear & Side Views ......................................................................... 18

Figure 12 – Ice Bear® 30 Unit Dimensions Top View ....................................................................................... 18

Figure 13 – Ice Bear® 30 Unit Dry Center of Gravity (Left) .............................................................................. 19

Figure 14 – Ice Bear® 30 Unit Dry Center of Gravity (Top) .............................................................................. 19

Figure 15 – Ice Bear® 30 Unit Wet Center of Gravity (Left) .............................................................................. 20

Figure 16 – Ice Bear® 30 Unit Wet Center of Gravity (Top) .............................................................................. 20

Figure 17 – Ice Bear® 30 Unit with an Ice-Ready™ Rooftop Unit .................................................................... 22

Figure 18 – Ice Bear® 30 Unit with an Additional (Slab) Ice-Coil™ ................................................................. 23

Figure 19 – Ice Bear® 30 Unit with an Additional (“N”) Ice-Coil™ .................................................................. 23

Figure 20 – Ice Bear® 30 Unit with a Ductless Liquid Overfeed Coil ................................................................ 24

Figure 21 – Minimum Clearances for Unit-mounted Service Disconnect .......................................................... 25

Figure 22 – Minimum Clearances for Remotely Mounted Service Disconnect ................................................. 26

Figure 23 – Ice Bear® 30 Unit Lifting Points ..................................................................................................... 27

Figure 24 – Recommended Spreader Bar Configuration .................................................................................... 27

Figure 25 – Minimum Recommended Concrete Pad Dimensions ...................................................................... 28

Figure 26 –Sample Precast Concrete Pad ........................................................................................................... 29

Figure 27 – Ice Bear® 30 Unit on Structural Curb with Cap .............................................................................. 30

Figure 28 – Ice Bear® 30 Unit Base Dimensions ................................................................................................ 31

Figure 29 – Ice Bear® 30 Unit Base Cross Section ............................................................................................. 31

Figure 30 – Design-Day Cooling Load Profile (Example) ................................................................................. 33

Figure 31 – Sample Load Profile ........................................................................................................................ 34

iv Ice Bear® 30 Unit Application Guide

Introduction

Introduction

Thermal Energy Storage (TES) is a well-recognized energy management tool that transfers a large portion

of the electricity required for air conditioning from high-price, on-peak hours to low-price, off-peak

hours. TES systems using ice storage allow an air conditioning system to operate during off-peak hours,

transferring clean and less expensive electrical energy into stored energy. The stored cooling energy in

the ice is later delivered to provide air conditioned comfort during on-peak hours when electricity prices

are higher and electrical power is limited, less reliable, and more polluting.

Traditionally, TES systems have benefited only large energy users, such as hospitals, large office

buildings, college campuses, and schools. The ICE BEAR

®

30 unit was developed specifically so that

buildings with small air conditioning and power requirements can receive comparable energy and

environmental benefits using a variety of packaged rooftop and split system air conditioners.

Thermal Energy Storage systems address the electrical system problems that other energy efficiency

measures do not address, in particular, resource allocation to meet the supply and demand of electricity.

Peak energy costs and emission concerns will continue to be a problem for the foreseeable future. Many

utilities offer rate structures that encourage energy management systems such as TES. Time-of-Use

(TOU) rates have become standard tariffs offered by many utilities. The substantial energy price

difference between on-peak and off-peak periods provide a significant financial incentive for using some

form of thermal energy storage. The higher costs of peak electricity reflect the pollution mitigation costs

associated with the higher emissions rates of peak energy generation.

A growing number of states are adopting energy efficiency standards above and beyond the federal

appliance standards. For example, the California Building Energy Efficiency Standards “performance

approach” uses a modified ASHRAE 90.1 methodology to establish the allowable energy consumption of

a proposed building project as compared the energy consumption of a minimally-compliant of a similar

building of similar occupancy, construction type and location. California’s Title 24 Standards estimate a

proposed building’s energy budget using an hourly time-of-use methodology and assigns a unique source

energy multiplier for each hour of the year to arrive at an estimate of the amount of source energy

required to provide the energy needs of the proposed building. The utility’s complete electricity network

costs, such as generation, transmission and distribution, and environmental mitigation are estimated for

each hour of the year establishing a Time Dependent Valuation (TDV) of energy. The resulting

calculation estimates a more accurate hourly cost and environmental impact of building energy

consumption. An hourly TDV multiplier for each of the state’s 16 climate zones translates site energy use

into a more accurate approximation of total source energy costs. When this TDV multiplier is applied to

an Ice Bear unit and conventional air conditioning systems of the equal capacity, the ice storage system

has as much as 22 times more TDV energy savings potential during peak periods.

Utility cost savings are clearly just one of the benefits provided by the Ice Bear unit. Ice storage plays a

significant role in obtaining certification points for the United States Green Building Council’s LEED

program. The Ice Bear unit’s superior cooling comfort, reliability, and reductions in the energy budget

can earn one to five Energy and Atmosphere Credits and up to 6 credits in other categories.

Ice Bear® 30 Unit Application Guide 1

®

Ice Bear® 30 Unit Overview

Ice Bear® 30 Unit Overview

The Ice Bear® 30 unit is an off-the-shelf hybrid condensing unit for use with direct expansion air

conditioning systems. The Ice Bear unit is designed to store energy at night and then shift the on-peak

electrical energy of a condensing unit common to packaged rooftop, split, and mini-split systems. A

typical application will shift the electrical energy consumed by a 5-ton scroll compressor and its

associated condensing unit fans operating under full load conditions for 6 hours continuously.

Electrically, the Ice Bear unit shifts approximately 30 kW-hours of energy to the off-peak, thus reducing

the on-peak demand by about 6 kW for six hours.

The Ice Bear unit runs its integral condensing unit for about 10 hours continuously, during the coolest

part of the night, to store energy in the form of ice (30 latent ton-hours). The control signal from the

thermostat or building management system is received by the Ice Bear unit’s CoolData

Based on the time-of-day, or upon a command to shed electrical demand initiated by the utility, the

controller determines if the Ice Bear hybrid condensing unit or the electrically operated condensing unit

will operate. In the case of the Ice Bear unit, it pumps enough oil free R-410A refrigerant to an Ice-Coil

evaporator to provide effective cooling for up to 5 tons of continuous load for six hours, using less than

300 watts of power. A unique and important design feature is the Ice Bear unit’s cooling performance

independent

of outdoor ambient or rooftop temperature; in other words, it can be 75 °F or 140 °F and the

Ice Bear unit and its associated Ice-Coil’s cooling performance (5-ton rating) is unchanged.

®

controller.

Definitions of Terms

Base System: A refrigerant based, direct expansion (DX) air conditioning system, commonly referred to

as a packaged rooftop unit, split system, or mini-split system. A typical base system includes a

condensing unit, an evaporator, a blower, and controls.

Ice-Coil™ Kit: An Ice-Coil and ancillary equipment needed to convert a packaged rooftop unit into an

Ice-Ready Rooftop Unit.

Ice-Coil™: A flooded evaporator coil provided by Ice Energy, or modified to Ice Energy’s

specifications. The Ice-Coil is dedicated to the Ice Bear unit and is sometimes referred to as a liquid

overfeed evaporator coil.

Ice-Cooling: The process whereby the Ice Bear unit’s stored ice cools the refrigerant used to provide

cooling to a building space during peak energy hours (typically noon to 6pm).

Ice-Make: The nighttime process by which the Ice Bear unit converts its tank of water into a tank of ice

to be used for cooling the next day during the peak energy hours (typically noon to 6pm).

Ice-Ready™ Rooftop Unit: A packaged rooftop unit modified to include an Ice-Coil.

Multi-Stage System: A packaged rooftop unit, typically greater than 5 tons, that includes multiple

independent refrigeration circuits, for example a 10-ton unit with two 5-ton circuits.

Peak Shifting: Shifting electric load from the utility defined on-peak period to the off-peak period. OnPeak hours are typically noon through 6 pm.

Redundant Coil: The addition of an Ice-Coil to a packaged rooftop unit or split system.

®

Summer Mode: The CoolData

available during peak energy hours.

controller’s programming is optimized to ensure that stored cooling is

Standard Circuit: A common DX refrigeration circuit that includes an evaporator coil, expansion

device, and condensing unit.

2 Ice Bear® 30 Unit Application Guide

A Few of the Unique Installation & Startup Considerations

Ton-hours: Capacity in tons times the number of hours (e.g., 5 tons for 6 hours = 30 ton-hours); an

important design consideration for fixed capacity storage units such as the Ice Bear unit.

Winter Mode: The CoolData controller is programmed to extend the Ice Cooling hours to more fully

utilize the stored cooling capacity of the unit.

A Few of the Unique Installation & Startup Considerations

• In addition to the Base System, an Ice-Coil must be used, which is typically a Redundant Coil.

o A flooded evaporator coil is provided by Ice Energy, or modified to Ice Energy’s

specifications, or included as part of an Ice-Ready Rooftop Unit, whose sole purpose is to

connect to the Ice Bear unit. Uniquely, an Ice-Coil does not use any type of expansion

device (orifice, TXV, or EEV); hence the term liquid overfeed or flooded coil. A mixed

phase of liquid and vaporized refrigerant may return to the Ice Bear unit.

• Length, Sizing, and Insulation of the refrigerant supply and return line sets.

o The Ice Bear unit may be located on the ground or on the roof in close proximity to the

Ice-Coil; there are distance and elevation limitations to consider. A unique feature of the

Ice-Coil circuit is that it is charged with oil free

R-410A refrigerant.

o The liquid supply line from the Ice Bear unit to the Ice-Coil and the vapor return line

from the Ice-Coil to the Ice Bear unit are uniquely sized to Ice Energy’s design

specifications. Both the liquid supply and the vapor return line sets must be insulated.

• When to fill with water and its associated weight

o One of the last steps

in the startup sequence is to fill the Ice Bear unit with about 450

gallons of tap water. When to fill the Ice Bear unit is important; filling too soon could

cause significant and costly damage to the unit.

o The filled weight of the Ice Bear unit is an important consideration for both ground

mount and roof mount applications.

• Remote Monitoring and Control

o The Ice Bear unit is centrally monitored and may be controlled remotely. To enable this

feature, the unit must be connected to the Ice Energy Network Operations Center by a

wired or by wireless data service (such as the Internet). Typically, a wireless (3G) data

connection is installed and configured by Ice Energy. Provision may be required for an

external antenna and/or an alternate service (Internet) connection in areas where coverage

is inadequate.

• Heat Pumps

o When applying an Ice Bear 30 unit to a heat pump, the Ice Bear unit must have a

dedicated (redundant) Ice-Coil.

Ice Bear® 30 Unit Ratings by Ton-hour

Importantly, the Ice Bear unit has a limited amount of cooling capacity and therefore proper consideration

of the building’s cooling load profile is a critical step and must not be overlooked. The Ice Bear unit

should not be used as the only source of cooling for typical office building, restaurant, and retail designs.

• Storage capacity: 30 ton-hours at a peak load of 5 tons

o 5 tons for 6 hours, or 4 tons for 7.5 hours, or 3 tons for 10 hours

• Instantaneous output capacity is unaffected by ambient temperature

Ice Bear® 30 Unit Application Guide 3

Ice Bear® 30 Unit Ratings by Ton-hour

Ice Bear® 30 Unit Features

The Ice Bear 30 unit is a highly flexible TES system which can be installed “out-of-the box” in a wide

variety of configurations and environmental settings.

• Storage capacity: 30 ton-hours at a peak capacity of 5 tons

• Remotely programmable Ice Make/Ice Cooling schedules

• Remote monitoring of operation and equipment performance

• Instantaneous output capacity unaffected by ambient temperature

• Versatile staging

o Offloading a single stage of a two-stage Ice-Ready™ rooftop unit

• Rooftop or ground mounting options

• Maximum refrigerant line length: up to 150 feet between Ice Bear 30 and rooftop unit

• Maximum vertical lift: up to 35 feet above the Ice Bear 30 unit.

• Electrical consumption:

o On-peak Ice Cooling: 300 watts (nominal)

o Off-peak Ice Make: 3,470 watts (typical at 75 °F)

• Three models:

o IB30A-521—208/230V, 1 phase

o IB30A-523—208/230V, 3 phase

o IB30A-543—460V, 3 phase

Approvals and Code Compliance

Ice Energy has contracted with Intertek’s ETL SEMKO division to provide independent

confirmation of the capabilities of the Ice Bear 30 Unit. See Ice Bear® 30 Unit ETL Certified

Performance Data later in this manual.

The Ice Bear 30 unit has been approved for use as a Title 24 Compliance Option in the state of California.

Refer to Appendix D – Title 24 Building Energy Standards Models for more information.

4 Ice Bear® 30 Unit Application Guide

Ice Bear® 30 Unit Ratings by Ton-hour

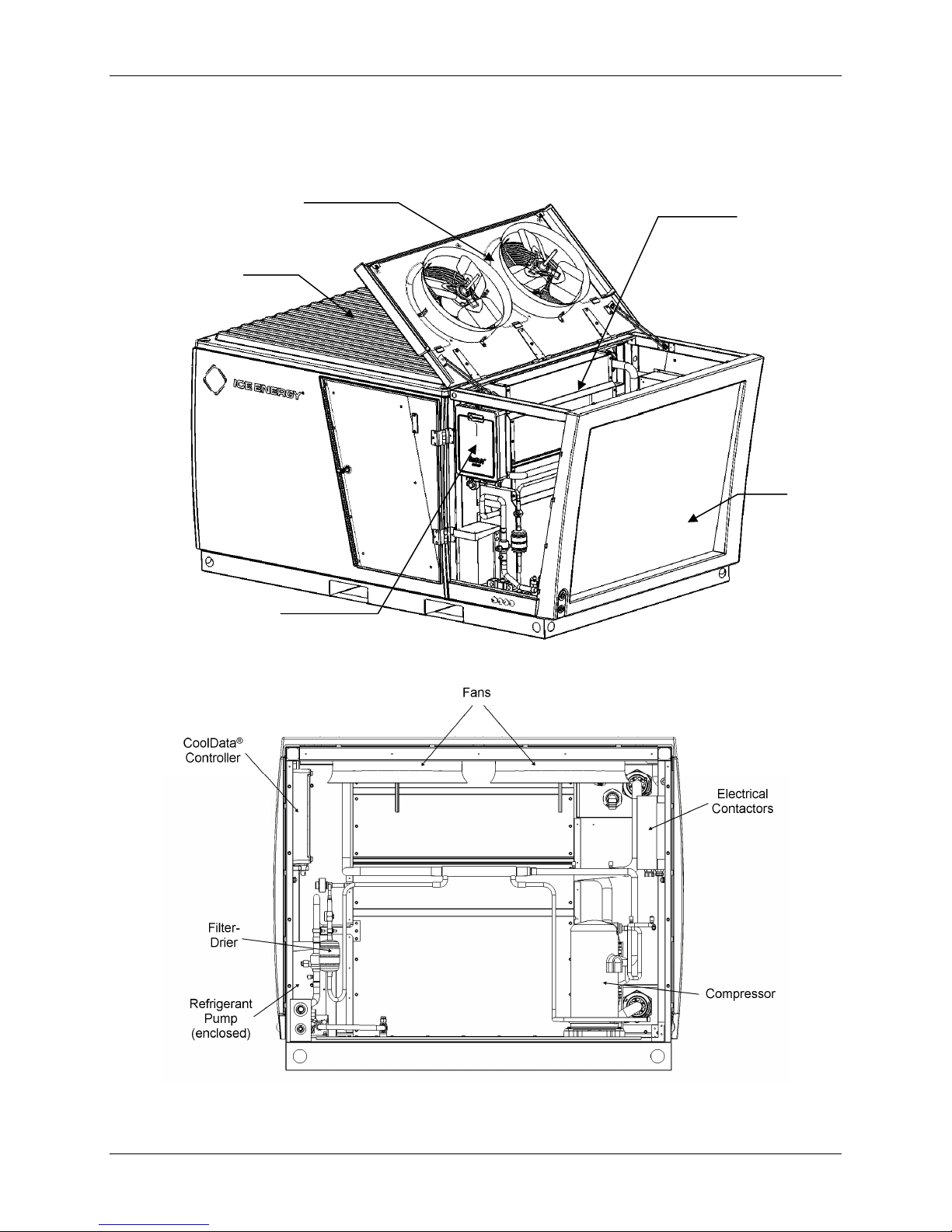

Ice Bear® 30 Unit Components

Fans

Ice Storage

Tank

CoolData®

Controller

Figure 1 – Ice Bear

®

30 Unit External View

Refrigerant

Management

System (RMS)

Ice-Make

Condensing

Coil

Figure 2 – Ice Bear

Ice Bear® 30 Unit Application Guide 5

®

30 Unit Internal View

Ice Bear® 30 Unit Ratings by Ton-hour

Modes of Operation

The Ice Bear unit is capable of operating in the following modes:

• Ice Make mode

o Night (off-peak) operation

o Storing energy, charging, making ice

• Ice Cooling mode

o Peak period operation (call for cooling)

o Discharging the stored energy, melting the ice

Note that Ice Make mode may also be referred to as “Ice Charge” or “Ice Build”. Ice Cooling mode may

also be known as “Ice Discharge” or “Ice Melt”.

Ice Make Mode

During Ice Make mode, the integral and factory pre-charged Ice Bear condensing unit (R-410A

refrigerant and miscible oil) provides low temperature refrigerant to the Ice Bear unit’s Refrigeration

Management System (RMS). On the secondary side of the RMS, a separate, oil-free R-410A charge

automatically circulates through a heat exchanger until the tap water freezes into a solid block of ice.

Ice make is typically 10 hours for a full 30 ton-hour charge and is made during the coolest time of night

or when electrical utility rates are at their lowest, or off-peak times.

Why Make Ice?

It takes 1 BTU of energy to lower the temperature of one pound of water 1 °F.

For example, it takes 1 BTU of energy to lower the temperature of one pound of water from 38 °F to

37 °F.

However, it takes 144 BTU’s of energy to change the state of one pound of water from a liquid to a solid

(ice). Therefore, it takes 144 BTU’s of energy to change the state of one pound of 32 °F water from a

liquid into ice.

The Ice Bear unit’s block of ice is sized to store 30 ton-hours of energy. There are 12,000 BTU’s per ton,

so the 30 ton-hours of stored energy are equivalent to 360,000 BTU’s. A 60,000 BTU/hour cooling load

or exactly the cooling load of one 5-ton Ice Coil (12,000 BTU’s / ton x 5 tons) running for six hours

would consume the entire Ice Make or 360,000 BTU’s of stored energy.

6 Ice Bear® 30 Unit Application Guide

Ice Bear® 30 Unit Ratings by Ton-hour

Figure 3 – Refrigerant Flow Schematic – Ice Make Mode

Ice Bear® 30 Unit Application Guide 7

Ice Bear® 30 Unit Ratings by Ton-hour

Ice Cooling Mode

During Ice Cooling mode, the integral Ice Bear condensing unit is switched off and typically one 5-ton

condensing coil on the Base System is locked out. The Ice Cooling circuit, which includes an ice-on-coil

heat exchanger, a refrigerant pump, and Ice-Coil™ are physically isolated from the Ice-Make circuit and

its refrigerant charge by a unique receiver/separator. When there is a request for cooling, a refrigerant

pump circulates the oil-free liquid R-410-A refrigerant through the liquid supply line to an Ice-Coil

located in the air stream. Typically this is a Redundant Ice-Coil installed into a packaged rooftop unit or a

slab coil mounted in the air supply duct. The vapor return line returns vaporized or mixed phase

refrigerant to the Ice Bear unit’s ice-on-coil heat exchanger where it melts ice and is condensed back into

its liquid state.

Figure 4 – Refrigerant Flow Schematic – Ice Cooling Mode

8 Ice Bear® 30 Unit Application Guide

Applications

Applications

Application Parameters

There are parameters that apply to every Ice Bear unit installation. Below is a list of installation

constraints that need to be strictly followed to ensure proper operation and reliability of the Ice Bear unit.

Installation constraints for the Ice Bear unit:

Item Specification

Line Set Sizing Ice-Coil™ supply line = 1/2”

Ice-Coil return line = 7/8”

(Both lines must be insulated.)

Maximum overall

length (to Ice-Coil)

Maximum vertical head

Ice-Coil supply line

Maximum vertical head

Ice-Coil below Ice Bear

unit

Maximum fittings per

line (supply & return)

Minimum insulation

wall thickness

Isolation valves with

service ports

Sight Glasses Install sight glasses in the Ice-Coil supply and return lines, as close

150 ft including vertical head (maximum 20 fittings)

35 ft

20 ft

20

1/2” or minimum required by local code, whichever is greater.

Isolation valves with service ports must be field installed in the Ice-

Coil supply and return lines, as close as possible to the coil.

to the Ice Bear unit as possible.

Any deviations from the above parameters require review by Ice Energy’s Technology department.

NOTE: When applying an Ice Bear 30 unit to a heat pump, the Ice Bear unit must have a dedicated

(redundant) Ice-Coil.

Ice Bear® 30 Unit Application Guide 9

Applications

Typical Applications

• Single zone

• Single Ice Bear unit or multiple Ice Bear units

• Partial storage system in a multi-stage configuration (displacing one or two stages of a multi-stage

system)

NOTE: When applying an Ice Bear 30 unit to a heat pump, the Ice Bear unit must have a dedicated

(redundant) Ice-Coil.

Sample Ice Bear® Unit Configurations

• Ice Bear unit (parallel) with Ice-Ready™ rooftop unit

• Redundant (parallel) split system

Ice Bear® 30 Unit (Parallel) with an Ice-Ready™ Rooftop Unit

The Ice Bear unit integrates with a modified packaged rooftop unit called an Ice-Ready rooftop unit. The

Ice-Ready rooftop unit, illustrated in the figure below, is a standard rooftop unit modified to include an

additional liquid overfeed coil (Ice-Coil™) that is dedicated to the Ice Bear unit. Specific systems are

available from name brand unit manufacturers as Ice-Ready rooftop units. For a list of currently

approved Ice-Ready rooftop units, and Ice-Coil kits, refer to the Ice-Ready™ Products Selection Guide

(Ice Energy form F091) or visit www.ice-energy.com

Product Services (email productservices@ice-energy.com

. For other airside options, contact Ice Energy

or call (877) 542-3232).

Figure 5 – Ice Bear

10 Ice Bear® 30 Unit Application Guide

®

` 30 Unit (Parallel) with Ice-Ready™ Rooftop Unit

Applications

Redundant (Parallel) Split System

In a redundant split system, the Ice Bear unit provides cooling as part of a separate and parallel redundant

refrigerant loop. It is only designed to take on a load for a designated period of time. The liquid overfeed

Ice-Coil is located downstream of the existing or “regular” standard DX coil.

The Ice Bear unit handles the designated load during peak load conditions, while the remainder of the

system handles the cooling load during the remainder of the day.

Figure 6 – Redundant (Parallel) Split System

Ice Bear® 30 Unit Application Guide 11

Controls and Sequence of Operation

Controls and Sequence of Operation

Control Schematic

Figure 7 – Control Schematic

12 Ice Bear® 30 Unit Application Guide

Controls and Sequence of Operation

Control Configuration Example 1

Figure 8 – Single Zone, Single-stage Thermostat with Economizer and Backup Condensing Unit

Control Configuration Example 2

Figure 9 – Single Zone, Two-stage Thermostat with Economizer and Backup Condensing Unit

Ice Bear® 30 Unit Application Guide 13

Controls and Sequence of Operation

CoolData® Controller

Features

The CoolData controller is an advanced control system that provides both controlling and monitoring

functions for the Ice Bear unit. Also, CoolData has bidirectional control and communication capabilities

for Smart Grid integration, including:

• configuration management

• real-time control

• advanced and optimal control

• real-time status, submetering, and monitoring

• performance analysis and automated diagnostics

• equipment health management

• event capture and analysis

• push and polling communications

• physical & cyber security

• data integrity readied for transactions with enterprise-level communication

Ethernet Cable

Connector

LED Indicators

Figure 10 – CoolData

®

Controller

14 Ice Bear® 30 Unit Application Guide

Controls and Sequence of Operation

Sequence of Operation

The Ice Bear unit is thermostatically controlled in the same manner as a conventional DX system. The

controller for the Ice Bear unit regulates the refrigerant and the unit’s internal components similarly to a

conventional DX air conditioning system. When a packaged unit is equipped with an economizer, the

economizer and the HVAC system will operate normally in collaboration with the Ice Bear unit.

The Ice Bear unit’s programmable controller responds to a single- or two-stage thermostat input. Either

configuration allows the Ice Bear unit to control the base system (allowing DX cooling during Ice Make,

for example). With a two-stage input, the Ice Bear unit and the additional system may be set up to

provide cooling simultaneously; whereas, with a single-stage input, only one system will provide cooling

at any given time. A single stage DX system connected to an Ice Bear unit is referred to as the backup

system. In a two-stage DX system with matching thermostat, the second DX system is referred to as a

parallel system. The programming for the Ice Bear unit’s internal controller is based on the desired Ice

Make and Ice Cooling operations. The Ice Bear unit can be configured to provide Ice Cooling for any

period of time consistent with the maximum cooling capacity, tank charge capacity, and tank recharge

requirements. The desired operating schedules are set prior to shipment or by a certified installer in the

field and can, if required, be reprogrammed remotely for optimization purposes.

The Ice Bear unit integrates with facility control systems and simple thermostats through traditional

24VAC signals, both for control and status feedback. No other communications to a facility management

system are required. The Ice Bear unit is unique as an energy storage device in that it is a fully packaged,

self-contained system. As such, it optimizes its performance independently of a facility management

system. Integration for Supervisory Control and Data Access (SCADA), additional monitoring, and other

advanced features are viable, but are not part of the standard offering.

For California Title 24 compliance applications, the programming is unalterable and operates within the

parameters of the specified product model. Control parameters are given at the factory.

Charging (Ice Make Mode)

Startup Sequence

1. Fan #1 starts and the Electronic Expansion Valve (EEV) is reset. (Charging LED blinks once.)

2. There is a 4 second delay.

3. Fan #2 starts.

4. Initial EEV position is set.

5. There is a 26 second delay.

6. Superheat set point is derived from the Condenser liquid temperature.

7. Compressor starts. (Charging LED blinks 3 times).

8. There is a 10 second delay.

9. EEV will start to control the system. (Charging LED is on solid.)

Full Charge Cutoff Sequence

1. Upon reaching charge cutoff pressure (typically 98.5 psia), the charging operation shuts down after

5 minutes.

2. The EEV is set to the closed position.

Ice Bear® 30 Unit Application Guide 15

Controls and Sequence of Operation

Cooling (Ice Cooling Mode)

Startup Sequence (call for cooling)

1. Refrigerant Pump and Solenoid Valve are energized and Water Pump starts.

2. Refrigerant Pump is initially set to minimum speed. (Cooling LED repeatedly blinks twice.)

3. There is a 10 second delay.

4. Refrigerant Pump is set to its final speed. (Cooling LED on solid until call for cooling ends, ice is

exhausted, or system transitions out of the configured ice cooling time window, as determined by

unit’s specific configuration.)

Shutdown Sequence (no call for cooling)

1. Water and Refrigerant Pumps shut down.

2. There is a 15 second delay.

3. Individual zone relay is closed.

Full Discharge Cutoff Sequence

1. Discharge cutoff condition is achieved; i.e., cutoff pressure is reached (typically 165 psia) or the

Tank water reaches a temperature of 48 °F (typical).

2. There is a 5 minute delay.

3. Refrigerant and Water Pumps are shut down.

4. There is a 15 second delay.

5. Individual zone relays are closed, if defined.

16 Ice Bear® 30 Unit Application Guide

Product Data and Specifications

Product Data and Specifications

Table 1. Ice Bear 30 Unit Cooling Performance

Maximum instantaneous cooling capacity 5 tons

Total storage module capacity 30 ton-hours

Maximum on-peak electrical demand (at maximum

application parameters, excluding crankcase heater)

Nominal on-peak electrical demand (typical installation) 300 watts

Ice Make/recharge time

(from fully melted tank of ice)

Table 2. Ice Bear 30 Unit Physical Properties

Dimensions (W x D x H) 100-1/2” x 61” x 49”

Weight (without water) 1,550 lb.

Weight (filled) 5,550 lb.

Load distribution (filled) 204 lb/linear ft

(156 lb. per ft

Water volume 475 gallons

Refrigerant charge, tank (Ice Cooling) 35 lb R-410A (factory)

Refrigerant charge, compressor (Ice Make) 11 lb 8 oz R-410A (factory)

Table 3. Ice Bear 30 Unit Electrical Properties

350 watts

11.5 hours at 75 °F

outdoor ambient temp.

2

)

Model System Type

IB30A-521

IB30A-523

IB30A-543

208/230V, 1φ

208/230V, 3φ

460V, 3φ

Minimum

Circuit

Ampacity

Maximum

Fuse

(MCA)

41.7 50

27.2 30

13.3 20

Table 4. Ice Bear 30 Unit Sound Ratings

-12

Outdoor Sound Power Level dB – (ref. 10

Overall

dBA

Octave Center Frequency

63 125 250 500 1000 2000 4000 8000

W)

IB30A 80 79.8 84.4 83.3 74.3 72.7 71.3 64.9 56.7

Notes:

1. Above ratings are values derived during Ice Making mode.

2. Compressor/condenser vibration isolation provided by OEM per equipment manufacturers’ standard specifications.

3. Outdoor sound data measured by Intertek in accordance with ARI Standard 370.

4. Ice Make ambient conditions for this test were 69 °F and 55% RH.

5. This test is not part of the ARI Certification.

6. Uncertified sound testing during Ice Cooling mode resulted in a level of 68 dBA.

Ice Bear® 30 Unit Application Guide 17

Product Data and Specifications

Figure 11 – Ice Bear

®

30 Unit Dimensions Rear & Side Views

Figure 12 – Ice Bear

®

30 Unit Dimensions Top View

18 Ice Bear® 30 Unit Application Guide

Product Data and Specifications

See the below figures for dry center of gravity.

Figure 13 – Ice Bear

®

30 Unit Dry Center of Gravity (Left)

Figure 14 – Ice Bear

®

30 Unit Dry Center of Gravity (Top)

Ice Bear® 30 Unit Application Guide 19

Product Data and Specifications

See the below figures for wet (water-filled) center of gravity.

Figure 15 – Ice Bear

®

30 Unit Wet Center of Gravity (Left)

®

Figure 16 – Ice Bear

30 Unit Wet Center of Gravity (Top)

20 Ice Bear® 30 Unit Application Guide

Engineering Data

Engineering Data

Ice Bear® 30 Unit Ambient Temperature Operating Ranges

Ice Make

• Performance tested Ice Make temperature range: 55 °F to 95 °F

• Enabled Ice Make temperature range: 15 °F to 115 °F

• Ice Make is automatically disabled below 15 °F or higher than 115 °F.

Ice Cooling

• Cooling performance is independent of ambient conditions above 15 °F.

• Ice Cooling is automatically disabled when ambient is below 15 °F.

Ice Bear® 30 Unit ETL Certified Performance Data

Table 5. Ice Make Capacity & Power at Ambient Temperature

Outdoor Temperature (°F)

Capacity Energy Capacity Energy Capacity Energy Capacity Energy Capacity Energy

Stored Consumed Stored Consumed Stored Consumed Stored Consumed Stored Consumed

(T-hrs) (kW-hr) (T-hrs) (kW-hr) (T-hrs) (kW-hr) (T-hrs) (kW-hr) (T-hrs) (kW-hr)

1 3.61 2.88 3.49 3.19 3.33 3.53 3.08 3.96 2.80 4.40

2 7.15 5.72 6.76 6.33 6.47 7.00 6.00 7.84 5.46 8.70

3 10.61 8.54 10.01 9.46 9.56 10.47 8.88 11.70 8.07 12.99

4 14.03 11.35 13.22 12.59 12.62 13.94 11.71 15.55 10.66 17.27

5 17.4 14.16 16.41 15.71 15.64 17.41 14.52 19.40 13.23 21.55

6 20.77 16.97 19.59 18.83 18.66 20.87 17.32 23.24 15.79 25.83

Time (hrs)

7 24.12 19.77 22.74 21.94 21.66 24.32 20.10 27.08 18.35 30.10

8 27.46 22.57 25.89 25.04 24.64 27.78 22.88 30.92 20.89 34.37

9 30.75 25.36 29.01 28.13 27.60 31.24 25.63 34.76 23.43 38.63

10 31.57 26.06 31.57 30.71 30.52 34.70 28.38 38.59 25.95 42.89

11 31.57 35.95 31.09 42.42 28.46 47.15

12 31.57 43.11 30.94 51.40

13 31.57 52.50

Actual Make Time (hrs) 9.24 9.84 10.36 11.17 12.25

Typical Demand (kW) 2.82 3.12 3.47 3.86 4.28

55° 65° 75° 85° 95°

Ice Bear® 30 Unit Application Guide 21

Applying an Ice Bear® 30 Unit

Applying an Ice Bear® 30 Unit

The Ice Bear 30 unit minimizes application considerations in that several airside solutions are available

that make it simple to take advantage of hybrid cooling technology. Each of the airside options shown

below involve adding a liquid overfeed coil that is dedicated to the Ice Bear unit, making the overall

solution redundant, capable of delivering 24 hours of cooling, if necessary. When load profiles permit

(i.e., when the Ice Bear unit can meet the entire cooling demand), one may apply the Ice Bear unit in a

standalone configuration.

You may apply the Ice Bear 30 unit with any of the following airside solutions. If the desired airside

solution is not listed below, contact Ice Energy Product Services (call 877-542-3232 or email

productservices@ice-energy.com

NOTE: When applying an Ice Bear 30 unit to a heat pump, the Ice Bear unit must have a dedicated

(redundant) Ice-Coil.

Airside Options

• Ice-Ready™ Rooftop Unit

• Dedicated Slab Liquid Overfeed Coil

• Dedicated “N” Liquid Overfeed Coil

• Dedicated Ductless Liquid Overfeed Coil

).

Ice-Ready™ Rooftop Unit

Figure 17 – Ice Bear

®

30 Unit with an Ice-Ready™ Rooftop Unit

22 Ice Bear® 30 Unit Application Guide

Applying an Ice Bear® 30 Unit

Slab Liquid Overfeed Coil

Figure 18 – Ice Bear

“N” Liquid Overfeed Coil

®

30 Unit with an Additional (Slab) Ice-Coil™

Figure 19 – Ice Bear

Ice Bear® 30 Unit Application Guide 23

®

30 Unit with an Additional (“N”) Ice-Coil™

Equipment Selection

Ductless Liquid Overfeed Coil

®

Figure 20 – Ice Bear

30 Unit with a Ductless Liquid Overfeed Coil

Equipment Selection

As described in the previous section, the Ice Bear unit may be paired with any of the following airside

options:

• Ice-Ready™ Rooftop Unit

• Slab Liquid Overfeed Coil

• “N” Liquid Overfeed Coil

• Ductless Liquid Overfeed Coil

Each of these airside options listed above includes an Ice-Coil™, which is a liquid overfeed coil designed

and tested to Ice Energy specifications.

Ice-Ready™ Rooftop Units

For a list of currently approved Ice-Ready rooftop units, and Ice-Coil kits, refer to the Ice-Ready™

Products Selection Guide (Ice Energy form F091) or visit www.ice-energy.com

options, contact Ice Energy Product Services (email productservices@ice-energy.com

877-542-3232).

For Ice-Ready rooftop unit performance data (including static pressure values), see Appendix E – Ice-

Ready RTU & Ice-Coil Performance Data at the end of this manual.

. For other airside

or call

24 Ice Bear® 30 Unit Application Guide

Installation Considerations

Installation Considerations

Minimum Clearances

In addition to the minimum clearances depicted in the figures that follow, ensure that a 60” vertical

clearance exists to provide for proper condenser fan operation.

NOTE: Local codes/regulations may prevail.

Figure 21 – Minimum Clearances for Unit-mounted Service Disconnect

Ice Bear® 30 Unit Application Guide 25

Installation Considerations

Figure 22 – Minimum Clearances for Remotely Mounted Service Disconnect

CAUTION

If a concrete pad is installed directly against building’s foundation, an approved expansion joint must be

installed to prevent possible noise transfer.

Lifting

Ice Energy recommends a 10’ spreader bar in an “H” configuration with two 6’- 8’ bars running

perpendicular for lifting. Any lifting method other than this one may cause damage to the exterior

components of the unit. Ice Energy is not responsible for any damage caused by alternative lifting

techniques (i.e., damage is not covered by the product warranty). Refer to the Ice Bear

Installation & Maintenance Guide for details.

26 Ice Bear® 30 Unit Application Guide

®

30 Unit

Installation Considerations

The Ice Bear unit’s lifting points are indicated in the figure below.

Lifting Points

Figure 23 – Ice Bear

®

30 Unit Lifting Points

Figure 24 – Recommended Spreader Bar Configuration

See Product Data and Specifications earlier in this manual for dry and wet (water-filled) center of gravity

dimensions.

Ice Bear® 30 Unit Application Guide 27

Installation Considerations

Mounting

The Ice Bear® 30 unit weights are as follows:

Ground Mounting

Provide leveling in compliance with local codes for clearance, easements, and soil compaction

restrictions. The Ice Bear unit must be level to within 1/8" in all directions.

Concrete Pad

• A concrete pad or other approved surface may be used, as designed and reviewed by a licensed

structural engineer.

• Refer back to Minimum Clearances.

• See Figure 25 for minimum recommended pad dimensions.

• Figure 26 provides a sample drawing of a precast concrete pad.

NOTE: Local codes/regulations may prevail.

Weight (without water) 1,550 lb

Weight (filled) 5,550 lb

Load distribution (filled) 156 lb per ft2

204 lb per linear ft

Figure 25 – Minimum Recommended Concrete Pad Dimensions

28 Ice Bear® 30 Unit Application Guide

Concrete

Pad

Ice Bear

Unit Base

Installation Considerations

CAUTION

If concrete pad is installed directly against building’s foundation, an approved expansion joint must be

installed to prevent possible noise transfer.

Ensure that roof drainage system does not undermine the Ice Bear unit’s foundation and that ALL gutters

and downspouts are properly placed and secured.

Ice Bear® 30 Unit Application Guide 29

Figure 26 –Sample Precast Concrete Pad

Installation Considerations

Rooftop Mounting

Follow structural drawings for proper location of the Ice Bear unit. Provide leveling and securing in

compliance with local codes. Level the Ice Bear unit to within 1/8" in all directions. Consult a Structural

Engineer.

Although the Ice Bear unit weighs approximately 5,500 lb, Ice Energy has successfully placed the

equipment on all standard engineered flat roofs with no modifications to the structural frame. Similar to

any piece of equipment to be placed on the roof, a structural analysis by a licensed structural engineer is

required by the permitting agency having jurisdiction over an installation.

Figure 27 illustrates an Ice Bear unit mounted on a curb with cap. Contact Ice Energy for details.

Figure 27 – Ice Bear

®

30 Unit on Structural Curb with Cap

30 Ice Bear® 30 Unit Application Guide

Installation Considerations

Figure 28 illustrates the base dimensions of the Ice Bear 30 unit to assist in designing a structural curb.

Figure 28 – Ice Bear

®

30 Unit Base Dimensions

14 ga (.075”)

Galvanized Steel

SECTION B

Figure 29 – Ice Bear

®

30 Unit Base Cross Section

Ice Bear® 30 Unit Application Guide 31

Installation Considerations

Minimum Requirements for Connection of CoolData® Controller

Wiring

The below items are the minimum requirements for basic common installations. Depending on the scope

of a given installation, additional wiring may be required. Consult plans and engineering drawings to

determine actual requirements. Contact Ice Energy Product Services (call (877) 542-3232) or email

productservices@ice-energy.com

• Conform to engineering layout drawings showing locations of wiring and thermostat.

• Document deviations in the Startup & Verification Report (F018).

• Use one #18AWG insulated 8 conductor cable between Ice Bear unit and each base unit (e.g., air

handler, packaged unit, ductless Ice-Coil) for control only.

• Use one #18AWG insulated (minimum 4 conductor) cable per Current Transducer and one

unshielded (UTP) CAT5e cable between each monitored base unit and the Ice Bear unit for

monitoring only.

• If an alternate data service connection is required, use one CAT5e cable between the Ice Bear unit

and the alternate data service (Internet) location.

) if you have questions.

32 Ice Bear® 30 Unit Application Guide

Appendix A – Cooling Load Profiles

Appendix A – Cooling Load Profiles

A design-day cooling load profile is an hour-by-hour listing of the loads for a 24-hour day. Conventional

air conditioning system sizing is based on the peak design cooling load for the year. Ice storage system

sizing is based on the maximum daily total cooling load (total ton-hours over a 24 hour period) as well as

the peak hourly load (tons). An understanding of the cooling load profile for each cooling circuit is

valuable when designing an Ice Bear unit.

6

5

4

Tons

3

2

1

0

1 2 3 4 5 6 7 8 9 101112131415161718192021222324

Time of Day

Figure 30 – Design-Day Cooling Load Profile (Example)

When designing a building cooling solution using an Ice Bear unit, you will need an hourly load profile

worksheet to determine the design-day cooling solution. You should consider two design days: the day

that requires the maximum total cooling over a 24 hour period and the day with the peak hourly load for

the year.

A load profile worksheet template is provided on the next page.

Oftentimes the Ice Bear unit is used to shift the maximum connected load, 5 tons for six consecutive

hours, coincident with the utilities’ most costly on-peak billing period, typically Noon – 6 pm. This is

especially true when displacing one stage of a multi-stage system in a location that has a high demand

(kW) charge.

Ice Bear® 30 Unit Application Guide 33

Appendix A – Cooling Load Profiles

y

d

g

A

Sample Load Profile Spreadsheet

The following blank spreadsheet is in the form recommended in Air-Conditioning and Refrigeration

Institute (ARI) Guideline T for design of Thermal Energy Storage (TES) systems. The designer should

use this type of spreadsheet and change the column headings to match the specific project. You may

expand the spreadsheet to include the hour-by-hour values for items such as: liquid flow, fluid

temperature, pressure drop, and condensing unit performance.

Time of Cooling Second Ice Ice Ambient Electric Electric

Da

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Total

Loa

Profile Unit Ice Bear Ice Bear Periods

(Tons) (Tons) (Tons) (Tons) (db F) (kW)

Condensin

Melt Make

Unit Unit

ir Demand Data

34 Ice Bear® 30 Unit Application Guide

Figure 31 – Sample Load Profile

Appendix B – Guide Specifications

Appendix B – Guide Specifications

Ice Storage Air Conditioning (ISAC) System

Cooling Capacity: Nominal 30 ton-hrs, 5 ton capacity

Duty: exterior installation

Part 1 – General

1.01 SYSTEM DESCRIPTION

A. Outdoor rated ISAC system suitable for pad mounted on-the-ground or rooftop installation. The

ISAC replaces a standard compressor / condenser in order to disassociate system power

consumption from the cooling load profile. The unit will provide cooling to building(s) by

melting stored ice. Ice is made during off-peak periods by an integrated condensing unit, as

determined by an internal controller. Unit shall consist of an ice storage tank with means of heat

extraction and rejection (heat exchanger), R-410A refrigerant, refrigerant management system,

refrigerant pump, and a standard condensing unit.

1.02 QUALITY ASSURANCE

A. ISAC system shall be rated in accordance with established procedures for testing the Ice Make

and Ice Cooling performance accepted and approved by the California Energy Commission

B. ISAC system constructed shall comply with ANSI/ASHRAE 15 safety code latest revision and

comply with NEC

C. ISAC system shall be constructed in accordance with UL 1995 standard

D. ISAC system storage tank shall be capable of withstanding 500-hour salt spray exposure per

ASTM B117

E. Ice storage heat exchange coils shall be leak tested at 150 psig and pressure tested at 275 psig.

1.03 DELIVERY STORAGE AND HANDLING

ISAC system shall be stored and handled according to the manufacturers’ recommendation.

1.04 WARRANTY

Limited warranty for parts and labor per manufacturers’ policy with the following period

limitations:

A. Compressor: 5 years from warranty commencement date

B. Condensing Unit Heat Exchanger: 5 years from warranty commencement date

C. Ice Storage Tank & Unit Heat Exchanger : 5 years from warranty commencement date

Part 2 – Products

2.01 EQUIPMENT

A. General:

Factory-assembled ISAC. Contained within the unit enclosure shall be all factory wiring, piping,

controls, and features required prior to field startup.

B. Ice Storage Tank

1. Storage tank shall be constructed of durable rotomolded polyethylene with a 3/8 inch

wall thickness.

2. Ice Storage Tank shall not require water service after initial install.

C. Integrated Ice Making Unit

The ISAC shall include an integrated Ice Making unit.

D. Refrigerant Management System

Ice Bear® 30 Unit Application Guide 35

Appendix B – Guide Specifications

The refrigerant management system will be responsible for transferring fluid medium (R-410A)

for making ice and for providing building cooling. The refrigerant management system will need

to consist of:

1. A means to convert high pressure refrigerant from condensing unit to low pressure

refrigerant cold enough to make ice

2. A means to circulate the refrigerant to the heat exchanger for making and melting ice

3. A means to circulate liquid refrigerant to an evaporator coil to cool air

4. A means to accumulate cold liquid after the warm return fluid has been cooled by the ice

E. Heat Exchanger

The heat exchanger will be composed of multiple tubes with the inside of the tube rated for

withstanding high refrigerant pressures (up to 500 PSI), providing internal ice-on-coil energy

storage, and external / internal Ice Cooling.

F. Refrigeration Components

Refrigeration circuit shall include a liquid line service valve and suction line service valve

G. Controls and Safeties

1. Minimum control functions shall operate using standard thermostat and air conditioner

24VAC control signals

2. Minimum safety devices shall include:

i. A pressure cut-off to terminate both Ice Make and Ice Cooling processes

ii. Appropriate fuses/ breakers on the electrical connections on the main panel boxes

H. Operating Characteristics of Ice Cooling mode:

The cooling capacity of the unit during Ice Cooling mode shall meet or exceed 60,000 Btu/h

at a suction temperature of 50 F. The power consumption at full load, excluding any fans

used for indoor air circulation, shall not exceed 350 watts.

I. Operating Characteristics of Ice Make:

The capacity of the ice-making condensing unit shall meet or exceed 40,000 Btu/h at 35 F

suction temperature.

J. Electrical Requirements

208/230V, 1φ: minimum circuit ampacity 42, maximum fuse 50 amps

208/230V, 3φ: minimum circuit ampacity 28, maximum fuse 30 amps

460V, 3φ: minimum circuit ampacity 13, maximum fuse 20 amps

Part 3 – Installation

3.01 INSTALLATION OF ISAC SYSTEM GENERAL

Install ISAC system in accordance with manufacturer’s installation instructions. Install units

plumb and level, firmly anchored in locations indicated, and maintain manufacturer’s

recommended clearances.

A. Electrical Wiring

Install and connect electrical devices furnished by the manufacturer but not specified to be factory

mounted. Furnish copy of manufacturer’s electrical connection diagram submittal to electrical

contractor.

B. Piping Connections

Install and connect devices furnished by manufacturer but not specified to be factory mounted.

Furnish copy of manufacturer’s piping connection diagram submittal to piping contractor.

3.02 FIELD QUALITY CONTROL

Start up ISAC unit in accordance with manufacturer’s start up instructions. Test controls and

demonstrate compliance with requirements.

36 Ice Bear® 30 Unit Application Guide

Appendix C – Ice Bear 30 Unit Equipment Schedule

Appendix C – Ice Bear 30 Unit Equipment Schedule

Table 6 illustrates a typical equipment schedule used in plan documents.

Table 6. Sample Thermal Storage Schedule for Mechanical Drawings

Thermal Storage Unit Schedule

Max.

Equipment

ID No.

IB

30 (N)

Make/

Model #

Ice Energy/

IB30A-523

Cooling

Capacity

(tons)

5 30 11.5 at 75°F

(continued)

Electrical Overall

Ph Hz Amps Typ.

Volts

208/230 3 60 30 4.0 101 x 60 x 49 5,550 lb Ice Bear unit to be connected to evaporator

Demand

(kW)

Total

Storage

Capacity

(ton-hrs)

Thermal Storage Unit Schedule

Dimensions

LxWxH

(inches)

Recharge

Time (Hrs)

R-410A 46.5 0.3 475

ambient

Operating

Weight (lb)

Refrig.

Refrig.

coil(s) in new (N) air conditioning units.

Charge

(lb)

Peak Power

Demand (kW)

Remarks

Water

Volume

(gal)

Ice Bear® 30 Unit Application Guide 37

Appendix D – Title 24 Building Energy Standards Models

Appendix D – Title 24 Building Energy Standards Models

For use as a Title 24 Compliance Option in California, the controls for Ice Cooling and Ice Make modes

are predetermined and are factory set. The model numbers listed below are defined by the corresponding

control parameters. For each model, the hours of cooling are indicated. Any cooling load outside of these

hours requires a parallel or backup DX cooling coil circuit.

When using the Ice Bear unit in dual stage cooling, both thermostat signals pass through the Ice Bear unit,

which, in turn, controls the operation of both the Ice Bear unit itself, and the second DX system. This

method assures optimal performance, and Title 24 compliance.

Table 7. Ice Bear Models (Available for Title 24 Compliance)

Parameter IB30 Model

IB30A 060-1218-4

Melt Hours

(peak)

Make Hours 21-11 21-11 19-9

Operating Months Jan-Dec Jan-Dec Jan-Dec

12-20

Jun-Sep

IB30 Model

IB30A 060-1218-6

12-20

May-Oct

IB30 Model

IB30A 060-1319-6

13-19

May-Oct

The appropriate model is determined by the designer and typically involves meeting the cooling load,

optimizing the number of TDV credits, and returning the greatest energy bill savings as determined by the

energy modeling software, such as EnergyPro.

38 Ice Bear® 30 Unit Application Guide

Appendix E – Ice-Ready RTU & Ice-Coil Performance Data

Appendix E – Ice-Ready RTU & Ice-Coil Performance Data

NOTE: The addition of an Ice Energy coil to the Original Equipment Manufacturer’s (OEM) packaged

system does not alter the ability for that equipment to meet the OEM’s published load capacity

specifications (within the ARI established parameters of ±5%). To verify this claim, Ice Energy tests the

OEM equipment before and after the modification for heat transfer capacity, and also blower power

consumption and condensate carryover, in line with the test procedure detailed in ASHRAE Standard 37.

The table below provides a summary of performance data for various Ice-Ready rooftop units.

Table 8. Performance Summary for Ice-Ready Rooftop Units

Ice-Coil

P/N

1861

(CA)

1861

(CA)

2203

(CJ)

2501

(CK)

2364

(TA)

2364

(TE)

2205

(CE)

2527

(LA)

2578

(YA)

2463

(CF)

Unit

RTU Model Description

48TFF006

48TCEA06

48PGDC06

50HJQ006

WSC060E

YSC092A

48PGD012

LGA120H4B

ZH120N15N2

48TMF012

5-ton SE Carrier R22 Gas Pack

5-ton HE Carrier R410A Gas Pack

5-ton UHE Carrier

R-410A Gas Pack

5-ton HE Carrier R22 Heat Pump

5-ton SE Trane R410A Heat Pump

7.5-ton SE Trane

R-22 Gas Pack

10-ton UHE Carrier

R-410A Gas Pack

10-ton HE Lennox

R-410A Gas Pack

10-ton SE York R410A Gas Pack

10-ton SE Carrier

R-22 Gas Pack

Tested

Configuration with

Ice Bear 30 Unit

Displaced 5T with ice

storage

Displaced 5T with ice

storage

Displaced 5T with ice

storage

Displaced 5T with ice

storage

Displaced 5T with ice

storage

Displaced 4.5T with ice

storage & DX

Displaced 5T with ice

storage & DX

Displaced 10T with

dual Ice Bear 30 units

Displaced 5T with ice

storage & DX

Displaced 10T with

dual Ice Bear 30 units

Displaced 5T with ice

storage & DX

Displaced 10T with

dual Ice Bear 30 units

Displaced 5T with ice

storage & DX

Heat Transfer

Capacity

at 75° F

Ice-Coil

(Btu/hr)

71,500 N/A 0.28

60,800 N/A 0.3

59,900 N/A 0.28

61,000 N/A 0.15

63,500 N/A 0.1

N/A 100,200 0.15

67,500 126,100 0.1

120,400 N/A 0.1

58,600 127,200 0.1

120,300 N/A 0.15

N/A 139,400 0.15

129,600 N/A 0.26

70,000 135,100 0.26

Ice + DX

(Btu/hr)

Additional

Static Pressure

Required at

400 scfm/ton

(in. H

O)

2

For a list of currently approved Ice-Ready rooftop units, and Ice-Coil kits, refer to the Ice-Ready™

Products Selection Guide (Ice Energy form F091) or visit the “resources” page at www.ice-energy.com

For other airside options, contact Ice Energy Product Services (email productservices@ice-energy.com

call (877) 542-3232).

.

or

Ice Bear® 30 Unit Application Guide 39

Appendix E – Ice-Ready RTU & Ice-Coil Performance Data

The table below provides a summary of performance data for various ducted Ice-Coils.

Table 9. Performance Summary for Ice-Coils Tested with the Ice Bear 30 Unit

Heat Transfer

Capacity at 75° F

(Btu/hr)

Coil Type Ice-Coil PN

1820 CN-42 Carrier 3.5-ton N-Coil 45,600

N-Coil

Slab

1823 CN-48 Carrier 4-ton N-Coil 50,600

1822 CN-60 Carrier 5-ton N-Coil 61,600

2584 CS-48 Carrier 4-ton Slab 49,200

2600 CS-60 Carrier 5-ton Slab 59,300

2513 LS-60 Lennox 5-ton Slab 69,000

2603 TS-60 Trane 5-ton Slab 61,000

Ice-Coil

Model No.

Description

For a list of currently approved Ice-Coils, refer to the Ice-Ready™ Products Selection Guide (Ice Energy

form F091) or visit the “resources” page at www.ice-energy.com

Energy Product Services (email productservices@ice-energy.com

. For other airside options, contact Ice

or call (877) 542-3232).

40 Ice Bear® 30 Unit Application Guide

Ice Energy, Inc.

9351 Eastman Park Dr., Suite B

Windsor, CO 80550

Phone: (877) 542-3232

(970) 545-3630

Fax: (970) 545-3634

Email: productservices@ice-energy.com

www.ice-energy.com

For parts or service, contact your Ice Energy representative.

Loading...

Loading...