Page 1

P/N 361715-21

Revision: AB, November 2007

TORUS

126/380/500

Operator Manual

Page 2

Copyright November 2007, Interactive Coding Equipment(herein referred to asICE). All rights

reserved.

This document is the property of Interactive Coding Equipment and contains confidential and

proprietary information owned by ICE. Any unauthorized copying, use or disclosure of it without the

prior written permission of ICE is strictly prohibited.

Page 3

Rev AB i

Compliance Information

For Customers in the U.S.A.

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions:

1) This device may not cause harmful interference, and

2) This device must accept any interference received, including

interference that may cause undesired operation.

Warning

PERSONAL INJURY. Changes or modifications to this unit not

expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide responsible protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference. In such cases, the users will be required to

correct the interference at their own expense.

Shielded cables must be used with this unit to ensure compliance with

Class A FCC limits.

The user may find the following booklet prepared by the Federal

Communications Commission helpful: How to Identify and Resolve

Radio-TV Interference Problems. This booklet is available from the U.S.

Government Printing Office, Washington, DC 20402, Stock No. 004-0000345-4.

This equipment has been tested and certified for compliance with U.S.

regulations regarding safety by TUV Rheinland of North America, Inc.

For Customers in Canada

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications.

Page 4

Torus 126, 380 and 500 Operator Manual

ii

Rev AB

This equipment has been tested and certified for compliance with

Canadian regulations regarding safety by TUV Rheinland of North

America, Inc.

Pour la Clientèle du Canada

Le present appareil numerique n’emet pas de bruits radioelectriques

depassant les limites applicales aux appareils numerique de las class A

prescrites dans le Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.

Cet équipment est certifié CSA.

For Customers in the European Union

This equipment displays the CE mark to indicate conformance to the

following legislation:

• EN60950-1:2001, A11:2004 Safety Requirements for Information

Technology Equipment

• EN 55022:1998, A1:2000, A2:2003 Class B Radiated and Conducted

Emissions

• EN61000-3-2: 2000, A2:2005 Harmonics

• EN61000-3-3: 1995, A1:2001 Voltage Fluctuations

• EN55024:1998, A1:2001, A2:2003

ITE immunity using:

IEC 61000-4-2 Electrostatic Discharge

IEC 61000-4-3 Radiated Electromagnetic Field

IEC 61000-4-4 Electrical Fast Transient

IEC 61000-4-5 Surge

IEC 61000-4-6 Conducted RF

IEC 61000-4-8 50 Hz Radiated Susc.

IEC 61000-4-11 Voltage Dips, Interrupts

Page 5

Rev AB iii

Support and Training

Contact Information

If you have any questions or need assistance, contact Interactive Coding

Equipment at 1-800-843-3610 (for all customers within the United States).

Outside the U.S., the customers must contact their Interactive Coding

Equipment distributor or subsidiary for assistance.

Service Program

About Total Source Commitment

Total Source® TOTAL SERVICE PLUS RELIABILITY, is the Interactive

Coding Equipment commitment to provide you - our customer - the

complete service you deserve.

The Total Source Commitment

The ICE Total Source® Service Program is an integral part of our business

in providing marks, codes, and images where, when, and how often

customers specify for packages, products, or printed materials. Our

commitment includes:

• Applications support

• Installation services

• Maintenance training

• Customer response center

• Technical support

• Field service

• Extended hours phone assistance

• Parts and supplies

•Repair service

Customer Training

If you wish to perform your own service and maintenance on the printer,

Interactive Coding Equipment highly recommends you, to complete a

Customer Training Course on the printer.

Note: The manuals are intended to be supplements to (and not replacements for)

Interactive Coding Equipment Customer Training.

Page 6

Torus 126, 380 and 500 Operator Manual

iv

Rev AB

For more information on Interactive Coding Equipment Customer

Training Courses, call 1-800-843-3610 (within the United States only).

Outside the U.S., customer should contact a ICE subsidiary office or their

local ICE distributor for more information.

Page 7

Rev AB 1

Table of Contents

Compliance Information

For Customers in the U.S.A.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

For Customers in Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Pour la Clientèle du Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

For Customers in the European Union. . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Support and Training

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Service Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Customer Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Chapter 1 — Introduction

About Torus 126, 380 and 500. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Print Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Main Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Chapter 2 — Safety

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Safety Conventions Used in the Manual. . . . . . . . . . . . . . . . . . . . . . . . 2–2

Warning Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Caution Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Equipment Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Comply with Electrical Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Avoid Breathing Exhaust Vapors . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Do Not Remove Warning Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Placement of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Ink Safety Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Safety Warnings for 126, 380 and 500 Printers . . . . . . . . . . . . . . . . . . 2–7

Medical Emergencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

Emergencies Involving Printer Fluids . . . . . . . . . . . . . . . . . . . . . . 2–9

Rocky Mountain Poison Control Center . . . . . . . . . . . . . . . . . . . 2–10

Chapter 3 — CLARiTY™ Operator Interface

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Home Page of CLARiTY™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Screen Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Data Entry Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Page 8

Torus 126, 380 and 500 Operator Manual

2

Rev AB

Chapter 4 — Equipment Operation

Turn on the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–1

Set the Air Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–3

Start the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–5

Printer LED Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–6

Add Ink. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–6

Review the Ink Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–6

Insert a New Ink Canister . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–7

Capacity of the Ink Canisters . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–12

How to Get High Quality Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–14

Clean the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–15

Button 'A' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–16

Button 'B' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–17

Chapter 5 — Software Operations

Select a Job for Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–1

Variable Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–5

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–5

How to Change Variable Information. . . . . . . . . . . . . . . . . . . . . . .5–6

Information about Current Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–9

Enable or Disable the Print (On-Line/Off-Line) . . . . . . . . . . . . . . . .5–10

Print Position Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–11

Self Cleaning Frequency of Operation. . . . . . . . . . . . . . . . . . . . . . . . .5–13

Warnings and Fault Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–14

Set the Correct Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–18

Select the Correct Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–20

Page 9

Rev AB About Torus 126, 380 and 500 1-1

1

Introduction

About Torus 126, 380 and 500

The Torus 126, 380 and 500 printers are self-maintaining ink jet printers.

The design of the printer enables the printer to print high resolution text,

barcodes and graphics. These printers are easy to use and cost effective.

The126, 380 and 500 printers use the CLARiTY™ operator interface as a

standard. The interface is a part of the printer (that is you do not require to

connect the printers to an external Personal Computer (PC) for normal

operation). The icons in the interface provide easy navigation to the

operator. The Slave units do not have the interface.

An external PC is required only to configure the printer and download the

messages into the printer.

The auto-purging printhead makes sure that there is a consistent and high

quality code during the production period. This printhead does not use

more than the required amount of ink. The ink is supplied through non

pressurised, ink canisters that are installed in the canister chute which

make the printers easy to use and clean.

Print Area

The print area for the 126, 380 and 500 printers is shown in Table 1-1.

Note: The Torus 126, 380 and 500 printers are referred to as ‘printer’ in this

document.

Printer Type Print Area

Torus 126 17mm X 2000mm

Torus 380 50mm X 2000mm

Torus 500 70mm X 2000mm

Table 1-1: Print Area

Page 10

Torus 126, 380 and 500 Operator Manual

1-2 Main Parts

Rev AB

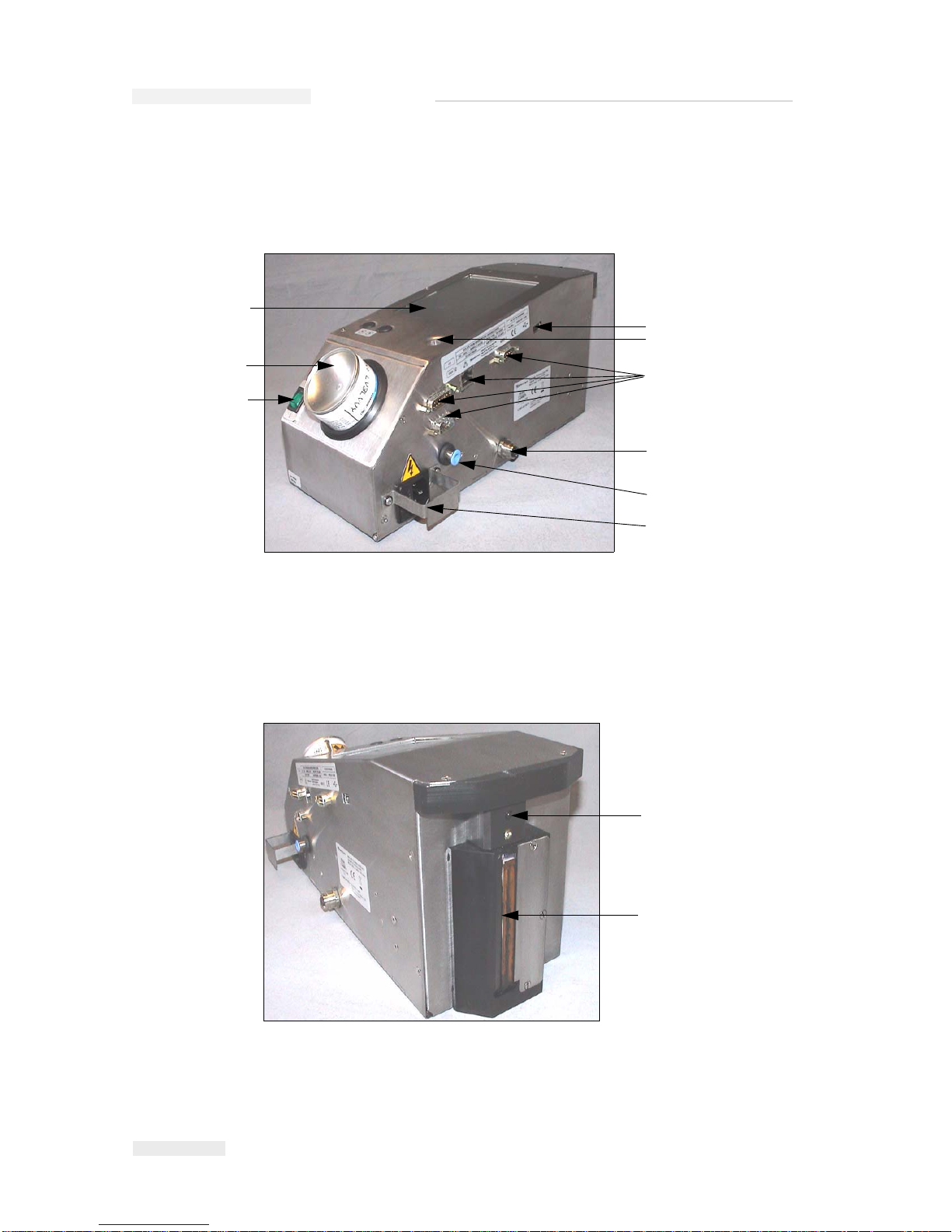

Main Parts

Figure 1-1 and Figure 1-2 show the printer with the main components and

connections highlighted.

Figure 1-1: Printer Parts

1. USB Port

2. Printer Status LED

3. I/O, Ethernet and Communications

Connectors

4. Remote Product Sensor Connector

5. Air Pipe Connector

6. Main Power Inlet

7. Power Switch

8. Ink Canister

9. CLARiTY Operator Interface

1

3

4

5

6

7

8

9

2

1

Figure 1-2: Printhead

1. Internal Product Sensor

2. Printhead

2

Page 11

Rev AB Introduction 2-1

2

Safety

This chapter contains the following topics:

•Introduction

• Safety conventions used in this manual

• Equipment safety guidelines

• Placement of the printer

• Ink safety guidelines

• Safety Warnings for126/380/500 printers

• Medical emergencies

Caution

Read this chapter thoroughly before attempting to install, operate,

service, or maintain this equipment.

Warning

The intended use of this printer is to print information directly onto

a product. Use of this equipment in any other purpose may lead to

serious personal injury.

Introduction

The policy of Interactive Coding Equipment is to manufacture non-contact

printing/coding systems and ink supplies that meet high standards of

performance and reliability. Therefore, we employ strict quality control

techniques to eliminate the potential for defects and hazards in our

products.

Page 12

Torus 126, 380 and 500 Operator Manual

2-2 Safety Conventions Used in the Manual

Rev AB

The safety guidelines provided in this chapter are intended to educate the

operator on all safety issues so that the operator can operate the printer

safely.

Safety Conventions Used in the Manual

Specific safety information is listed throughout this manual in the form of

Warning and Caution statements. Pay close attention to these statements

as they contain important information that help in avoiding potential

hazards to yourself or to the equipment.

Warning Statements

• Warning statements are used to indicate hazards or unsafe practices

that may result in personal injury or death

• They have a triangular symbol with an exclamation mark to the

immediate left of the text

• They are always preceded by the word “Warning”

• They are always found before the step or information referring to the

hazard

For example:

Warning

The next step, “Cleaning the Printhead,” must be performed by

service or maintenance personnel. Qualified personnel have

successfully completed the training courses, have sufficient

experience with the printer, and are aware of the potential hazards

to which they are exposed.

Caution Statements

• Caution statements are used to indicate hazards or unsafe practices

that can result in equipment or property damage

• They have a triangular symbol with an exclamation mark to the

immediate left of the text

• They are always preceded by the word “Caution”

• They are always found before the step or information referring to the

hazard

Page 13

Torus 126, 380 and 500 Operator Manual

Rev AB Equipment Safety Guidelines 2-3

Example:

Caution

Never turn off the printer by switching the AC power switch to the

Off (O) position. Before pressing the Off key, allow the printer to

complete the three and a half minute shutdown sequence. Failure in

following this procedure prevents the printer from drawing the ink

in the ink return line, back into the reservoir. This may cause the ink

to dry in the ink return line, resulting in problems when you turn the

printer on again.

Equipment Safety Guidelines

This section contains important safety guidelines pertaining to the

operation and handling of the printer and associated equipment.

Warning

Always observe the following safety guidelines when operating and

handling the printer and associated equipment.

Comply with Electrical Codes

All electrical wiring and connections must comply with

applicable local codes. Consult the appropriate

regulatory agency for further information.

Avoid Breathing Exhaust Vapors

During this operation, the printer releases fumes from

the printer exhaust tube. These fumes may be flammable

and cause a health hazard. Therefore, do not allow the

exhaust to be confined to an area that does not have

proper ventilation, or be located near a source of

ignition. Printer exhaust fumes are generally heavier

than air, so keep all sources of ignition away from low

Page 14

Torus 126, 380 and 500 Operator Manual

2-4 Placement of the Printer

Rev AB

areas where fumes may travel or accumulate.

If, under any circumstances, the printer is to be kept in a place that lacks

proper ventilation, it is necessary to expel the printer exhaust to outside

air. Consult the appropriate regulatory agency concerned with the

emission permit and venting system requirements, before giving vent to

the printer exhaust into the outside air.

Note: A Vapor Exhaust Ducting Kit is available at Interactive Coding

Equipment.

Do Not Remove Warning Labels

Do not, under any circumstances, remove or obstruct

any warning, caution, or instruction labels present on

the printer.

Placement of the Printer

Warning

Do not place the printer in a hazardous location. Hazardous

locations might create an explosion, leading to personal injury.

Hazardous locations, as defined in the United States, are those areas that

may contain hazardous materials in a quantity sufficient to create an

explosion. These are defined in Article 500 of the National Electrical Code

ANSI/NFPA 70–1993.

Outside the United States, you must ensure compliance with all local

regulations regarding equipment placement in potentially hazardous

locations.

Ink Safety Guidelines

This section provides important safety guidelines pertaining to the use

and handling of printer supplies (inks, make-up fluids, and cleaning

solutions).

Page 15

Torus 126, 380 and 500 Operator Manual

Rev AB Ink Safety Guidelines 2-5

Warning

Always observe the following safety guidelines when using or

handling inks, make-up fluids, and cleaning solutions.

For continued protection against possible fire hazard, use only ICE

supplies with a flash point no lower than -22 °C (-8 °F) and boiling

point no lower than 56 °C (133 °F).

No Smoking

Do not smoke when you are near the printer or

printhead. If the printer exhaust fumes are subjected to

an ignition source, it may result in an explosion or fire.

Wear Safety Glasses

Wear safety glasses with side shields (or equivalent eye

protection) when handling any ink, make-up fluid, or

cleaning solution. If it splashes on your eyes, flush your

eyes with water for 15 minutes and consult a physician

immediately.

Avoid Skin Contact

Wear butyl rubber gloves when handling any ink,

make-up fluid, or cleaning solution. Avoid contact with

skin and mucous membranes (nasal passage, throat).

Upon contact with skin, remove any contaminated

clothing and wash the area with soap and water.

Consult a physician if irritation persists.

Avoid Breathing in the Vapors

Avoid prolonged exposure to print exhaust vapors. If

respiratory protection is needed, a cartridge organic

respirator can be used.

Page 16

Torus 126, 380 and 500 Operator Manual

2-6 Ink Safety Guidelines

Rev AB

Dispose Ink Properly

Do not pour any ink, make-up fluid, or cleaning solution

into sinks, sewers, or drains. Waste disposal must

comply with local regulations. Contact the appropriate

regulatory agency for further information.

Read the Material Safety Data Sheets

Read and understand the Material Safety Data Sheet

(MSDS) before using any ink, make-up fluid, or cleaning

solution. An MSDS exists for each type of ink, make-up

fluid, and cleaning solution. The appropriate sheet or

sheets are supplied along with the shipped product.

Ensure that you retain all MSDSs for future reference in

case you need to consult a physician regarding an ink-related accident.

Additional copies of MSDSs are available upon request, and can be

obtained by contacting the ICE Customer Service Department at 800–

843–3610. Outside the U.S., customers should contact a subsidiary ICE

office or their local ICE distributor.

Store Inks Properly

Certain inks, make-up fluids, and cleaning solutions are

flammable and must be stored appropriately. Storage

must comply with local regulations. Contact the

appropriate regulatory agency for further information.

The label on the bottle or the MSDS indicates if a

particular fluid is flammable or not.

Caution

The waste container or service tray ground to the printhead must be

made of metal. Use of a non-metallic waste container/service tray

may result in the possibility of electrostatic discharge.

Page 17

Torus 126, 380 and 500 Operator Manual

Rev AB Safety Warnings for 126, 380 and 500 Printers 2-7

Safety Warnings for 126, 380 and 500 Printers

Some additional warnings that are specific to the 126, 380 and 500 printers

are described in this section.

Warning

Before opening or removing any printer covers, ensure that the

mains power is disconnected and compressed air supplies are

switched off.

Warning

This equipment must be installed with a locally positioned mains

supply isolation device. This can be either a plug and socket or a

switch disconnector or circuit breaker in accordance with IEC 609473 or IEC 60947-2.

Warning

Always isolate equipment from the mains and remove mains power

connector to the printer before attempting any maintenance or repair

on any part of the product.

Warning

Before connecting compressed air supply to Torus 126, 380 and 500,

ensure the air regulator adjustment knob has been turned fully anticlockwise.

Warning

Ensure that any cables from the printer are secured to avoid chance

of movement into walkways and becoming a trip hazard.

Page 18

Torus 126, 380 and 500 Operator Manual

2-8 Safety Warnings for 126, 380 and 500 Printers

Rev AB

Warning

Do not point the printhead directly and in close proximity to the

eyes, unless the printer is switched off and isolated from the mains

and compressed air supplies.

Warning

The printer uses an operator control console mounted on the top of

the unit. Ensure that this panel is at a height where access and use is

least restricted.

Warning

Regard any warning or hazard information supplied with any

cleaning fluid or consumable products. When using any chemicals,

always wear protective gloves and only use in well-ventilated areas.

Warning

There will be sections of the 602004 Torus 126, 380 and 500 control

board that will be permanently powered via the on-board lithium

battery - therefore it is essential that the board should never be

placed onto nor stored in or on any conductive surface (including

conductive, plastic bags etc.) as this would flatten the battery and/or

potentially result in battery overheating.

Warning

The Torus 126, 380 and 500 printer is supplied with warning

symbols for power supply and compressed air. If any part of these

symbols become damaged, worn or removed they must be

immediately replaced.

Page 19

Torus 126, 380 and 500 Operator Manual

Rev AB Medical Emergencies 2-9

Warning

Ensure that all external energy sources are isolated from the printer

before opening the outer casing. This includes the mains power

cable and I/O cable assembly (if used).

Warning

When you replace an old battery with a new battery, make sure to

use the correct type of battery. The failure to follow this warning can

cause injury or explosion.

Warning

Dispose the used batteries according to the local regulations. Replace

with the correct type of battery. The failure to follow this warning

can cause injury or explosion.

Medical Emergencies

This section provides important medical information in case of an

accident.

Warning

In the event of a medical emergency, contact a physician

immediately.

Emergencies Involving Printer Fluids

If the incident involves an ink, make-up fluid, or cleaning solution, carry

the bottle and/or MSDS with you to the physician’s office. These items

contain important information that the physician may require, to provide

the precise medical treatment.

Page 20

Torus 126, 380 and 500 Operator Manual

2-10 Medical Emergencies

Rev AB

Rocky Mountain Poison Control Center

All of ICE inks, make-up fluids, and cleaning solutions are also registered

with the Rocky Mountain Poison Control Center, located in the United

States. If the bottle or MSDS cannot be located, the physician can contact

the Rocky Mountain Poison Control Center to obtain the information

required.

Rocky Mountain Poison Control Center

(303) 623-5716

Note: Persons outside the United States requiring medical attention can have a

physician contact the Rocky Mountain Poison Control Center in the United

States or a poison control center or hospital in their own area.

Page 21

Rev AB Introduction 3-1

3

CLARiTY™ Operator

Interface

This chapter contains the following topics:

• Home Page of CLARiTY™

• Screen Description

• Data Entry Pad

Introduction

The CLARiTY™ operator interface is a touch screen system. The icons in

the interface help the operator to navigate through the software easily.

Normally most areas of the interface are active. The operator can touch the

active areas to select the required feature. The interface also contains the

icons that are like buttons on the normal control panel (for example,

).

Page 22

Torus 126, 380 and 500 Operator Manual

3-2 Home Page of CLARiTY™

Rev AB

Home Page of CLARiTY™

The Home Page of the CLARITY™ is shown in Figure 3-1.

Screen Description

Icons

The screen has icons that help you navigate to the key pages of the

interface. You can reach any key page from the current page with these

icons (Refer to Figure 3-2 and Table 3-1).

Figure 3-1: Home Page of CLARiTY™

Page 23

Torus 126, 380 and 500 Operator Manual

Rev AB Screen Description 3-3

Control Icons

You can use the control icons to get control on the printer immediately

(refer to Figure 3-3).

Icon Description

Home Takes you to the Home page

Status

Window

Takes you to the Fault and Warning pages

Tools Takes you to the Setup an d Diag n os tics Tools page

Scroll Bar Allows to navigate up and down the screen selected. This icon

is useful to find a Job in the Torus 126, 380 and 500 database.

Control

icons

Refer to “Control Icons” on page 3-3.

Job Use to load the next image (job) for printing and to enter any

variable data

Navigation

Bar

Indicates the location of your current screen in the menu tree

The current screen allows you to do the following tasks:

• Touch the Back icon to return one level up

• Touch any level displayed on the Navigation Bar to take

you to that level

Table 3-1: Shortcut Icons

Figure 3-2: Shortcut Icons

Status Window

Tools Icon

Back Icon

Scroll Bar

Down Icon

Navigation Bar

Home Icon

Control

Icons

Up Icon

Print Icon

Page 24

Torus 126, 380 and 500 Operator Manual

3-4 Screen Description

Rev AB

Active Areas

The Production Performance and Consumables areas in Figure 3-4 take you to

the screens that have more information and statistics.

Figure 3-3: Control Frame Icons

Stop

Run

Start-up/Shut Down

Figure 3-4: Performance and Consumables Status

Consumables

Production Performance

Active Area

Page 25

Torus 126, 380 and 500 Operator Manual

Rev AB Data Entry Pad 3-5

Data Entry Pad

An alphanumeric, mobile phone style data entry pad is provided to the

operator to enter the data in the CLARiTY™ interface.

The different keys in the data entry pad are shown in Table 3-2.

Key Characters (in turn)

1.,?/:!-&;+#()'"_@$¢£€¥%<>¿¡§=¤

ABC2abcДАБВГЕЖЗдабвгежз¢

DEF3defИЙЛКийлк€

GHI4ghiОМНомн

JKL5jkl£

MNO6mnoЦФТУШСцфтушс

Table 3-2: Data Entry Pad Map - English (Default)

Figure 3-5: Data Entry Pad

Page 26

Torus 126, 380 and 500 Operator Manual

3-6 Data Entry Pad

Rev AB

PQRS7pqrs$ß\

TUV8tuvЬЩЫЪьщыъ

WXYZ9wxyz

Cursor left

0*

Cursor right

Backspace/Clear

Space

Key Characters (in turn)

Table 3-2: Data Entry Pad Map - English (Default) (Continued)

Page 27

Rev AB Turn on the Printer 4-1

4

Equipment Operation

This chapter describes the procedures to do the following tasks:

• Turn on the printer

• Set the air pressure

• Start the printer

• Printer LED Functions

• Add the ink

• Get High quality print

• Clean the printhead

Turn on the Printer

Press the power switch on the rear of the unit to turn on the printer (refer

to Figure 4-1).

Figure 4-1: Power Switch

Power Switch

Page 28

Torus 126, 380 and 500 Operator Manual

4-2 Turn on the Printer

Rev AB

The sequence of steps that occur after you turn on the printer are as

follows:

1 During the startup sequence, the printer performs a number of self-

diagnostic checks. These checks take approximately 90 seconds to

complete.

2 During the self-diagnostic checks, the CLARiTY™ interface screen

shows the first set of diagnostic data. Ignore this data.

3 When the self-diagnostic checks are complete, the CLARiTY™ Home

Page appears (refer to

Figure 4-2).

4 The status window of the Home Page shows the SHUTDOWN status.

5 During the SHUTDOWN status, the Stop (red) and Run (green)

buttons (

Figure 4-2) are disabled (in grey color).

Note: If the print sensor is activated accidentally, the printer will not operate

because all the sensor and encoder input are ignored during the shutdown

status.

Note: During the shutdown status, make sure that the production line and

printer are prepared and ready for the shutdown.

Figure 4-2: Home Page

Stop(red)

Run(green)

Shutdown

Shutdown Status

Page 29

Torus 126, 380 and 500 Operator Manual

Rev AB Set the Air Pressure 4-3

Set the Air Pressure

The printer comes with an air regulator. During the installation of the

printer, the air regulator must be installed near the printer.

To increase the pressure, turn the air regulator control knob to the right

side. To decrease the pressure, turn the knob to the left side (Figure 4-3 on

page 4-4).

Caution

The air pressure must be set according to the printer type. Follow the

recommended values. The failure to follow this caution can decrease

the efficiency of the printer.

The air pressure requirement for the Torus 126/380/500 is shown in the

Table 4-1.

Printer Type Air Pressure

Torus 126 2.5 Bar

Torus 380 3.5 Bar

Torus 500 4.5 Bar

Table 4-1: Air Pressures

Page 30

Torus 126, 380 and 500 Operator Manual

4-4 Set the Air Pressure

Rev AB

Figure 4-3: Air Regulator

Control Knob

Page 31

Torus 126, 380 and 500 Operator Manual

Rev AB Start the Printer 4-5

Start the Printer

Touch the Start-Up/Shutdown icon to start the printer.

The events that occur after you touch the Start-Up/Shutdown icon are as

follows:

•The Offline status appears in the status window of the CLARiTY™

Home Page (refer to

Figure 4-4).

•The Stop and Run buttons become active (Figure 4-4).

• If a fault or a warning condition exists, a fault or warning message

appears in the status window instead of the Offline status. You must

clear the fault or warning message before you continue the process of

printing.

Refer to “Warnings and Fault Messages” on page 5-14 for more

information on Fault and Warning messages.

Figure 4-4: Home Page - Offline

Startup/Shutdown

Offline Status

Page 32

Torus 126, 380 and 500 Operator Manual

4-6 Printer LED Functions

Rev AB

Printer LED Functions

The printer has a dual colored LED below the CLARiTY™ interface that

indicates the status of the printer (Figure 4-5).

The LED states and their functions are shown in Table 4-2.

Add Ink

This section describes the following topics:

• How to review the status of the ink

• Correct time to insert a new ink canister

• The number of prints possible with the available ink

Review the Ink Status

The Consumables area of the Home Page screen displays a percentage

value of ink that is left in the ink canister of the printer. For example refer

to Figure 4-6 on page 4-7.

LED States Function

Green (constant) On-line, ready to print

Green (flashing) On-line and printing (LED flashes

for every print)

Orange (Flashing) CLARiTY update in progress

Red (constant) Off-line

Red (flashing) Fault condition

Table 4-2: LED Status and their Functions

Figure 4-5: Printer LED

Printer Status LED

Page 33

Torus 126, 380 and 500 Operator Manual

Rev AB Add Ink 4-7

A description of the colors that appear in the status bar is as follows:

Insert a New Ink Canister

The ink must be added when the ink low level warning appears on the

CLARiTY™ screen. The ink status bar must show less than 5% (Figure 4-

6). The ink status shown on the status bar makes sure that the present ink

canister is replaced after the present canister becomes empty.

When the consumables meter status is red before a new canister is fitted,

the printer will go through a longer filling cycle before the printing

continues.

Color Description

Blue The reservoir is full and replacement ink canister is not required

Yellow Enough ink is available for printing but you can add a new ink

canister. If a new ink canister is not added, the printer operates

until the printhead ink reservoir reaches a critically low level.

Red The ink canister is empty. A new ink canister must be added

and the ink empty fault must be cleared.

Table 4-3: Colors in the Consumables Status Area

Figure 4-6: Consumables Area

Consumables Area

Ink Status

Page 34

Torus 126, 380 and 500 Operator Manual

4-8 Add Ink

Rev AB

The ink type required for the type of printer is shown in the Table 4-4.

Do the following tasks to replace an empty ink canister with a new

canister:

1 Touch the Consumables area on the Home Page (Figure 4-6 on page 4-7).

The Consumables page appears (Figure 4-7).

2 Touch the Add Ink icon (Figure 4-7). The Add Ink screen appears

(Figure 4-8 on page 4-9).

Printer Ink Type (for a

175ml Ink Can)

Ink Type (for a

365ml Ink Can)

Torus 126 M512 NA

Torus 380 M512 M512-K

Torus 500 M512 M512-K

Table 4-4: Ink Types

Figure 4-7: Consumables Screen

Add Ink Icon

Page 35

Torus 126, 380 and 500 Operator Manual

Rev AB Add Ink 4-9

3 Enter the unique ink canister code found on the label of the every ink

canister (

Figure 4-9 on page 4-9) and touch the OK icon.

If you enter a wrong ink canister code, an error message appears (4-

10). Enter the correct ink canister code.

Figure 4-8: Add Ink Screen

Figure 4-9: Canister Code

Ink Canister Code

Page 36

Torus 126, 380 and 500 Operator Manual

4-10 Add Ink

Rev AB

Warning

EQUIPMENT DAMAGE. The use of incompatible ink can seriously

damage the printer and such damage will not be covered under

warranty.

4 After the CLARiTY™ validates the new ink canister code, you can

replace the empty canister with a new canister. To fit the new canister

do the following tasks:

a. Turn the empty canister to the left side and remove the canister

from the canister chute (

Figure 4-11 on page 4-11).

Figure 4-10: Invalid Ink Code Messages

Page 37

Torus 126, 380 and 500 Operator Manual

Rev AB Add Ink 4-11

5 Remove the protective cover from the new ink canister.

6 Align the new canister into the canister chute and turn to your right

(

Figure 4-12).

7 Insert and set the new canister inside the chute carefully. Do not

overtighten.

Note: When you must refit a half full ink canister, the ink canister code must

be entered again.

Figure 4-11: Removal of Empty Ink Canister

Canister Chute

Figure 4-12: Direction of Insertion

Page 38

Torus 126, 380 and 500 Operator Manual

4-12 Add Ink

Rev AB

Capacity of the Ink Canisters

Do the following tasks to check the amount of ink that is available in the

current ink canister:

1 Touch the Consumables area on the Home Page screen during the

printer Running status (

Figure 4-13). The Consumables screen that

displays the number of prints (Figure 4-14 on page 4-13) appears.

This screen displays Prints Per Ink Canister and Prints Left in Canister.

The Prints Per Ink Canister gives the number of prints from a full ink

canister and Prints Left in Canister gives the number of prints left from

the current canister.

2 When a new job is selected, the number of prints is calculated again

and displayed on the screen. This number of prints depends on the

amount of ink the new image requires.

Figure 4-13: Consumables Area - Running

Consumables Area

Running Status

Page 39

Torus 126, 380 and 500 Operator Manual

Rev AB Add Ink 4-13

3 Use the Up and Down buttons to see the Estimated Empty Time and

Estimated Time Remaining for the current ink canister (

Figure 4-15 on

page 4-13).

Figure 4-14: Number of Prints

Prints from a full

Prints Left from the

Current Canister

Ink Canister

Figure 4-15: Estimated Time Display

Estimated Canister

Estimated Time Left

for Present Ink Canister.

Empty Time

Up Icon

Down Icon

Page 40

Torus 126, 380 and 500 Operator Manual

4-14 How to Get High Quality Print

Rev AB

How to Get High Quality Print

To get high quality print, make sure to move the products past the

printhead in a consistent method. For correct conveyor movement, refer to

the following guidelines:

• A high grip and flat belt conveyor with pack guidance is

recommended.

• Make sure that there is enough space between the products to get

correct print signals. This action prevents the products from not being

printed.

• Gravity roller conveyors are not recommended. The box speed and

spacing can change according to the product speed and weight.

• Powered roller conveyors can decrease the print quality. This type of

roller is not recommended for barcodes or high resolution graphic

applications.

• If the barcodes are required in the image, then an encoder must

measure accurately the speed of the product. This accuracy in the

speed measurement leads to best print performance.

The maximum and minimum conveyor speeds for Torus 126/380/500 are

shown in Table 4-5.

The most common causes for low quality of print are described below:

• Incorrect movement of the product past the printhead (for example

the use of gravity conveyors, roller conveyors)

• Dust or dirt blocking or deflecting jets

• Slippage of the product on the conveyor

• The distance between the face of the printhead and the printed surface

is not consistent. This difference is caused normally because of the

following reasons:

- The product guidance (product handling) is not enough.

- The product is distorted (for example, bent cardboard box).

Printer Type Minimu m Speed Maximum Speed

Torus 126 10 mm/second

(0.6 m/min)

550 mm/second

(33 m/min)

Torus 380 10 mm/second

(0.6 m/min)

550 mm/second

(33 m/min)

Torus 500 10 mm/second

(0.6 m/min)

550 mm/second

(33 m/min)

Table 4-5: Conveyor Speeds

Page 41

Torus 126, 380 and 500 Operator Manual

Rev AB Clean the Printhead 4-15

Note: To get high quality prints, the distance between the printhead and the

product must not be greater than 2mm (

Figure 4-16 on page 4-15). Use the

pack guidance on the conveying equipment to maintain this distance.

Note: The Delrin guide on the front side of the printer helps to protect the

printhead from any potential damage and to maintain the jetting distance to

the product.

Clean the Printhead

The 126/380/500 printhead does not require the operator to clean or

prime at normal intervals because this printer is an auto-purging printer.

If the print quality decreases, the A and B buttons on the printer provide

additional functions to clean the printer further (refer to Figure 4-17 on

page 4-16).

Box Distance < 2mm

Figure 4-16: Box Distance

Page 42

Torus 126, 380 and 500 Operator Manual

4-16 Clean the Printhead

Rev AB

Button 'A'

Caution

Do not touch or remove the nozzle plate or the jetting face of the

printhead under any condition while you perform the procedures in

this section (refer to

Figure 4-18 on page 4-17 and Figure 4-19 on

page 4-18).

When you can see bands of missing print across the print, the quality of

the print has decreased and not acceptable standard. You must press

button A in this condition.

You can use the button for the following two purposes:

• Press the button for one second, then release to start the sequence of

controlled purge.

A small quantity of ink that removes the dirt from the jetting orifices is

purged through the printhead.

• Press and hold the button to activate a longer cleaning cycle. When

the cycle begins, release the button A.

Note: This cycle must be used when shorter operation to clean the printer

does not remove the blocks in the jets.

Figure 4-17: A and B Buttons

Page 43

Torus 126, 380 and 500 Operator Manual

Rev AB Clean the Printhead 4-17

A larger quantity of ink that washes the printhead face is purged

through the printhead jets. Then an air blast is used to removes excess

ink.

Button 'B'

When you press the button 'B', the system uses the air to clear away any

contamination on the printhead faceplate.

Press and hold the button B for some seconds to clean the printhead

faceplate completely of any ink and dirt.

This method is best to remove any dirt following a visual inspection of the

printhead.

Basic Maintenance

When the printer is operated in dirty environments, the operator must

clean around the jetting face of the printer (refer to the Figure 4-19 on

page 4-18). This process maintains the efficiency of the ink return system.

The failure to perform this basic maintenance can cause the loss of ink.

Basic maintenance includes the removal of dirt that closes the clearance

between the nozzle plate and the front plate. This process must be

performed as necessary.

Figure 4-18: Printhead Nozzle Plate

Printhead

Nozzle Plate

Page 44

Torus 126, 380 and 500 Operator Manual

4-18 Clean the Printhead

Rev AB

Figure 4-19: Printhead Jetting Face

1. Printhead Nozzle Plate

2. Blow Nozzle Plate

3. Ink Collector

4. Knife Edge

5. Ink Drain Channel

6. Printhead Front Plate

1

2

3

4

5

6

Page 45

Rev AB Select a Job for Printing 5-1

5

Software Operations

This chapter contains the following topics:

• Select a Job for Printing

• Variable Information

• Information about Current Job

• Enable or Disable the Print (On-Line/Off-Line)

• Print Position Adjustment

• Self Cleaning Frequency of Operation

• Warnings and Fault Messages

• Set the Correct Time and Date

• Select the Correct Language

Select a Job for Printing

Introduction

When the printer is in Running, Offline or in the Shutdown status, you can

select a new print image or job. You can select, edit and see the image on

the WYSIWYG display before printing the image.

Touch the OK icon to replace the current image with the new job.

If you must cancel the process of job selection, touch the Cancel button or

the Home button (refer to Figure 5-6 on page 5-5).

Procedure

To select a job for printing, do the following tasks:

1 Touch the Job icon (Figure 5-1 on page 5-2).

A Job List screen with the different jobs stored in the local memory is

displayed (

Figure 5-2 on page 5-2).

Page 46

Torus 126, 380 and 500 Operator Manual

5-2 Select a Job for Printing

Rev AB

Figure 5-1: Job Icon

Job

Home

Figure 5-2: List of Jobs

List of Jobs

Page 47

Torus 126, 380 and 500 Operator Manual

Rev AB Select a Job for Printing 5-3

2 If the job list is short, then Touch the job name and the name of the job

is highlighted (

Figure 5-3).

3 If the job database is large to fit into the screen, you can select the job

in two methods:

• A scroll bar appears (Figure 5-4 on page 5-4). The scroll bar helps you

move up and down the database to see all the jobs and select the

required job.

•Touch the Data Entry Pad icon (Figure 5-4 on page 5-4). The Job Select

screen appears with a data entry keypad (like a mobile phone). The

job name is completed automatically as you begin to enter the

characters in the job name until you select the required job (

Figure 5-3

on page 5-3).

Job Highlighted

Figure 5-3: Job Selection

Page 48

Torus 126, 380 and 500 Operator Manual

5-4 Select a Job for Printing

Rev AB

Figure 5-4: Scroll Bar

Scroll Bar

Data Entry Pad

Figure 5-5: Job Selection Screens

Page 49

Torus 126, 380 and 500 Operator Manual

Rev AB Variable Information 5-5

4 When you select the required job, the CLARiTY™ displays a print

preview of the selected job (

Figure 5-6).

5 Touch the OK icon after the information displayed is correct (Figure 5-

6). The printer starts printing the job.

6 If your job contains variable information, refer to “How to Change

Variable Information” on page 5-6 for more information.

Variable Information

Introduction

If there are Job Variables (variable information fields) like a Batch Code on

the selected Job, CLARiTY™ prompts to edit or enter these fields.

If there are any variable TEXT fields, CLARiTY™ displays them first.

The check box at the side of variable fields indicates the fields that are

entered and fields that are not entered (Figure 5-7 on page 5-6).

A checkmark is added to the check box as you edit or enter the data in the

CLARiTY™. When all the boxes have a checkmark, you can continue to

the next step.

To select the Job variable you require to change, touch the related prompt.

This variable gets highlighted and display the default data in the data

window (Figure 5-7 on page 5-6).

Figure 5-6: Job Preview

Cancel

OK

Page 50

Torus 126, 380 and 500 Operator Manual

5-6 Variable Information

Rev AB

To change the variable text, touch the data window and use the data entry

keypad.

The Figure 5-7 shows the Job Variables for the job BBE1 and there is a

DATE field variable only (for use as a Best Before End Date).

How to Change Variable Information

Do the following tasks to change the default data for the DATE field

variable in the Job BBE1:

1 If the default date displayed in the data window (11 March 2004) is

correct, touch the OK icon and this date is printed (

Figure 5-7).

Figure 5-7: Job Variables

Data Window

Prompt

Checkbox

OK

Page 51

Torus 126, 380 and 500 Operator Manual

Rev AB Variable Information 5-7

2 Touch the data window or the data entry pad to move to the calendar

screen if you want to change the date information (

Figure 5-8).

• To change the month and the year, touch the and icons until

the correct month, and year is reached.

• To select a day of the month, touch the date.

Note: The red box in Figure 5-8 displays the current date and the blue

background displays the date selected for printing. The dates that are not

available for selection are in grey box.

3 Touch the OK icon and the data information is changed. If you have

many dates in your Job, repeat the steps one and two for each date.

4 The CLARiTY™ automatically returns to the Job variables list where

the check box for the date field is checked (

Figure 5-9 on page 5-8).

Figure 5-8: Calendar Screen

Page 52

Torus 126, 380 and 500 Operator Manual

5-8 Variable Information

Rev AB

5 Touch the OK icon and continue to the WYSIWYG Preview screen

(

Figure 5-10). Use the Zoom icon to see a bigger image.

6 Check the Job for correct data and touch the OK icon.

The printer prints all the products with the new job information.

You can touch the OK icon else, you can touch the Cancel icon or the

Home icon to return to the start.

Figure 5-9: Checked Box

Figure 5-10: Preview

Page 53

Torus 126, 380 and 500 Operator Manual

Rev AB Information about Current Job 5-9

Information about Current Job

The Home Page displays the name of the current job (Figure 5-11). Touch

the job name on the screen and the WYSIWYG information of the job is

displayed.

The example below displays the job that the 126, 380 and 500 printer is

printing. The job is shown in the WYSIWYG display (Figure 5-12). Use the

Zoom icon to see a bigger image.

Touch the Back or Home icon to return to the Home Page (Figure 5-12).

Figure 5-11: Job Name

Figure 5-12: Zoom Button

Zoom

Back

Home

Job

Page 54

Torus 126, 380 and 500 Operator Manual

5-10 Enable or Disable the Print (On-Line/Off-Line)

Rev AB

Enable or Disable the Print (On-Line/Off-Line)

To enable the printer, touch the Run (green) icon and the printer status bar

changes to Running status (Figure 5-13).

To disable the printer, touch the Stop (red) button (Figure 5-13) and the

printer status bar returns to Offline status.

Note: If the print sensor is activated when the printer is in Offline status, the

printer will not operate.

Note: If the print sensor is activated when the printer is in Online status, the

printer starts the print and performs all activities normally.

When the printer is in Online or Offline status, you can perform the

following activities:

• Select a new job

• You can add the ink

• Examine the printer parameters

• Clean the printhead with the buttons A and B (“Clean the Printhead”

on page 4-15).

Figure 5-13: Enable and Disable Printing

Run

Stop

Page 55

Torus 126, 380 and 500 Operator Manual

Rev AB Print Position Adjustment 5-11

Print Position Adjustment

To adjust the position of the print with reference to the front edge of the

box, do the following tasks:

1 Navigate to Tools > Setup > Printhead in the Home Page. The Printhead

setup page appears (

Figure 5-14).

2 Touch the Registration Delay icon. Enter the new print position (in

millimeters) with the keypad (

Figure 5-15).

Follow any of the below methods to make the adjustments:

•Touch the and icons to make small adjustments in the

position.

• Touch the data entry pad icon and use the pad to enter a new number

(

Figure 5-16 on page 5-12).

• Enter the Min, Max or Default values (Figure 5-17 on page 5-13).

Figure 5-14: Printhead Setup Screen

Tools

Page 56

Torus 126, 380 and 500 Operator Manual

5-12 Print Position Adjustment

Rev AB

Figure 5-15: Registration Delay

Registration Delay

Data Entry Pad

Figure 5-16: Registration Delay - Keypad

Page 57

Torus 126, 380 and 500 Operator Manual

Rev AB Self Cleaning Frequency of Operation 5-13

3 Touch the OK icon to set the new position.

Note: Smaller values move the print closer to the front edge of the product.

Larger values move the print away from the front edge.

Self Cleaning Frequency of Operation

If a remote print sensor is used, the 126, 380 and 500 printer has the ability

to clean the printhead by itself before every box. The filter life is increased

to the maximum if the printer is set to clean the printhead every tenth box.

Note: During the cleaning operations, the ink is returned to the ink reservoir and

used again.

If the printer operates in a very dirty environment, the self cleaning cycle

must be performed more number of times. This process maintains good

print quality and the long life of the printhead.

The printer includes a parameter with the name Prints per Cleaning Cycle

that you can configure. The parameter helps to set the self cleaning cycle

according to the factory environment. The default value is set at 10.

Do the following tasks to enter the Prints per Cleaning Cycle value:

1 Navigate to Tools > Setup > Printhead and scroll below to reach the

Prints per Cleaning Cycle. Enter the required value (

Figure 5-18 on

page 5-14).

2 Touch the OK icon followed by the Home icon.

Figure 5-17: Min, Max and Default Values

Page 58

Torus 126, 380 and 500 Operator Manual

5-14 Warnings and Fault Messages

Rev AB

Warnings and Fault Messages

When a Warning or a Fault condition occurs, the CLARiTY™ displays the

related message at the top of the screen (Figure 5-19).

Figure 5-18: Prints per Cleaning Cycle

Figure 5-19: Warning Message

Page 59

Torus 126, 380 and 500 Operator Manual

Rev AB Warnings and Fault Messages 5-15

Warnings

The CLARiTY™ displays all the Warning messages with an amber color in

the background (Figure 5-19 on page 5-14). When in a Warning condition,

the printer continues to operates.

When you touch the Warning message area on CLARiTY™, instructions

to clear the message are displayed.

The Figure 5-20 shows the ink low warning and gives the instructions to

clear the Warning sign by replacement of the empty ink canister with a

new canister. Follow the instructions displayed on the screen to clear the

Warning.

Figure 5-20: Ink Low Warning

Page 60

Torus 126, 380 and 500 Operator Manual

5-16 Warnings and Fault Messages

Rev AB

Faults

The CLARiTY™ displays all the Fault messages with a red color in the

background (Figure 5-21 on page 5-16). During a Fault condition, the

printer does not operate until the Fault is cleared. You can see in Figure 521 that the ink canister is empty.

The printer Fault output changes the status of the printer. If you can link

the fault status to the production line then, the printer can stop the line.

The above interlock helps the customer to make sure that the printing is

done on all the products.

Note: The LED below the CLARiTY™ Operator screen flashes (red) until the

fault is cleared and the printer starts printing.

Touch the Fault message area and the CLARiTY™ screen displays some

instructions.

The example in Figure 5-22 on page 5-17 shows that there is no ink in the

printer. The instructions on the screen tells you how you can add a new

ink canister and clear the Fault on the CLARiTY™ screen (Figure 5-22 on

page 5-17).

Figure 5-21: Fault

Page 61

Torus 126, 380 and 500 Operator Manual

Rev AB Warnings and Fault Messages 5-17

When the Fault message is cleared, then the printer begins to print again.

Figure 5-22: Out of Ink Fault

Page 62

Torus 126, 380 and 500 Operator Manual

5-18 Set the Correct Time and Date

Rev AB

Set the Correct Time and Date

Do the following tasks to set the correct time and date at the CLARiTY™

screen:

1 Navigate to Tools > Setup > Control from the Home Page. The Control

Screen appears (

Figure 5-23).

2 Select the Date and Time from the list displayed (Figure 5-23).

3 Touch Date and the calendar page appears (Figure 5-24 on page 5-19).

4 Use the and icons to select the current month and year.

5 Touch and select the current date from the calendar.

6 Touch the OK button.

Figure 5-23: Control Screen

Date And Time

Page 63

Torus 126, 380 and 500 Operator Manual

Rev AB Set the Correct Time and Date 5-19

7 Touch the Time icon and the time page appears (Figure 5-25).

8 Use the and keys to set the Hours, Minutes and Seconds.

9 Touch the OK button.

10 Touch the Home icon to return to the Home Page.

Figure 5-24: Calendar Screen

Figure 5-25: Time

Page 64

Torus 126, 380 and 500 Operator Manual

5-20 Select the Correct Language

Rev AB

Select the Correct Language

The CLARiTY™ has the ability to display all pages in different languages

and date codes in the format for that country.

For example: Month Day Year for USA and Day Month Year for UK.

Do the following tasks to select the language:

1 Navigate to Tools > Setup > Control > Internationalisation and the

Internationalisation screen appears (

Figure 5-26).

The current language is displayed.

2 Touch the Language icon and select the language you require from the

list. The selected language is highlighted (

Figure 5-27).

Figure 5-26: Internationalisation Screen

Page 65

Torus 126, 380 and 500 Operator Manual

Rev AB Select the Correct Language 5-21

3 Touch the OK icon.

4 Select the Region/Country icon to select the region or the country

(

Figure 5-26 on page 5-20).

5 Select the region required (Figure 5-28) and touch the OK icon.

6 Touch the OK icon.

7 Touch the Home icon to return to the Home Page.

Figure 5-27: Language Selection

Figure 5-28: Region/Country

Loading...

Loading...