Page 1

www.icecompanies.com

Scrubber

Operator & Parts Manual

i36BT

Automatic

INTERNATIONAL CLEANING EQUIPMENT

8230901

REV.02(08-2016)

Page 2

2

OPERATOR MANUAL

ICE i36BT

HOW TO ORDER PARTS

Only use ICE Company supplied or equivalent parts. Parts and supplies may be ordered

online,by phone, by fax or by mail.

1. Identify the machine model.

2. Identify the machine serial number from the data label.

3. Ensure the proper serial number is used from the parts list.

4. Identify the part number and quantity.

Do not order by page or reference numbers.

5. Provide your name, company name, customer ID number,billing and shipping address,

phone number and purchase order number.

Please fill out at time of installation for future reference.

Model No.

Serial No.

Machine Options

Sales Rep.

Sales Rep. Phone No.

Customer ID Number

Installation Date

READ OPERATOR MANUAL CAREFULLY!

International Cleaning Equipment

XiangShi Road LiaoBu DongGuan GuangDong China

Tel: 0769 - 81850061

Fax:0769 - 81850001

Specifications and parts are subject to change without notice.

IMPORTANT: To ensure full warranty protection, please fill out & return

your warranty card.

PROTECT THE ENVIRONMENT

Please dispose of packaging materials,old machine components

such as batteries, hazardous fluids, including antifreeze and oil, in an

environmentally safe way according to local waste disposal regulations.

Always remember to recycle.

Page 3

3

OPERATOR MANUAL

ICE i36BT

SAFETY PROCATIONS.......................................................................................................4

MACHINE COMPONENTS...................................................................................................5

MACHINE SETUP & INSTALLATION....................................................................................6

MACHINE OPERATION.................................................................................................7

WHILE OPERATING MACHINE..........................................................................................7

TANK DRAINING..................................................................................................................8

BATTERY CHARGING.........................................................................................................9

PREVENTATIVE MAINTENANCE.......................................................................................9

BASIC TROUBLESHOOTING............................................................................................11

TECHNICAL SPECIFICATION............................................................................................12

PARTS LIST................................................................................................13-30

WEAR AND TEAR PARTS......................................................................31

WIRING DIAGRAM..........................................................................................32

TABLE OF CONTENTS

Page 4

4

OPERATOR MANUAL

ICE i36BT

SAFETY PRECAUTIONS

This machine is intended for commercial use. It

is designed exclusively to scrub hard floors in an

indoor environment and is not constructed for any

other use. Only use recommended accessories.

All operators shall read, understand and

exercise the following safety precautions:

1. Do not operate machine:

- Unless trained and authorized.

- Unless you have read and understand the

operators manual.

- In flammable or exploxive areas.

- If not in proper operating condition.

- In outdoors areas.

2. Before starting machine:

- Make sure all safety devices are in place

and operate properly.

3. When using machine:

- Go slow on inclines and slippery

surfaces.

- Follow all safety guidelines.

- Be very careful when using the machine in

reverse.

- Reduce speed when turning.

- Report and fix any damage to machine prior

to operating it.

- Never allow children to play on or

around.

- Do not operate on inclines that exceed 5%

(3°).

4. Before leaving or servicing machine:

- Stop on level surface.

- Turn off machine.

5. When servicing machine:

- Read operators manual thoroughly prior to

operating or servicing this machine.

- Use manufacturer supplied or approved

replacement parts.

- Secure machine with wheel blocks prior to

jacking the machine up.

- Use approved jack or hoist to safely elevate

the machine.

- Disconnect batteries prior to working on

machine.

- Wear gloves when handling batteries or

battery cables.

- Avoid any contact with battery acid

- Avoid moving parts. Do not wear loose fitting

clothing while servicing machine.

WARNING: Batteries emit hydrogen

gas. Explosion or fire can result from

hydrogen gas. Keep sparks and open

flames away! Keep battery compartment

open when charging.

WARNING: Flammable materials can

cause an explosion or fire. Do not use

flammable materials in tanks.

WARNING: Flammable materials or

reactive metals can cause explosion or fire.

Do not pick up.

Page 5

5

OPERATOR MANUAL

ICE i36BT

MACHINE COMPONENTS

1. Recovery Tank

2. Recovery Tank Cover

3. Brush Pressure Adjusting Buttons &

Indicator Light

Brush Pressure Increase Button

Brush Pressure Decrease Button

4. Hour Meter

5. Speed Control Knob

Slow Speed

Fast Speed

6. Battery Meter

7. Main Power Key Switch

8. 1-STEP Scrub Head Up/Down Switch &

Indicator Light

9. Solution Flow Control Buttons & Indicator

Light

Solution Flow Increase Button

Solution Flow Decrease Button

10. Vacuum Motor Switch & Indicator Light

11. Emergency Stop Button

12. Drive Motor Circuit Breaker

13. On-board Charger

14. Solution Tank Level / Drain Hose

15. Bumper Rollers

16. Ball Valve

17. Squeegee Assembly

18. Squeegee Vacuum Hose

19. Recovery Tank Drain Hose

20. Filter Assembly

21. Caster, 5 Inch

22. Squeegee Lift Lever

23. Hose Fill-port

24. Wheels,12 Inch

25. Scrub Head Skirt

26. Disk Scrub Head

27. Control Handle Start Bail

Direction Decal

28. Recovery Tank Support Stand

29. Vacuum Motor, 36VDC

30. Vacuum Motor Circuit Breaker

31. Connector,175A

32. Bucket Fill Port/ Clean-Out Port

33. Led Light

34. Brush & Pad Realease Plunger

35. Scrub Head Adjusting Bolt

36. Brush Motor,36VDC

37. Front Cover

38. Batteries

39. Solution Tank

40. Logo,ICE

41. Caster, 2 Inch, Squeegee

4

35

7

8

9

10

11

12

16

17

18

1920

22

23

25

41

+

-

2

1

15

40

38

37

36

+

-

35

27

6

13

14

21

26

24

28 29

30

31

32

33

34

39

Page 6

6

OPERATOR MANUAL

ICE i36BT

UNCRATING MACHINE

Be sure and check packing carton for any damage.

Immediately report any damage to carrier. Check

the contents of package to ensure that the

following items are included:

• Machine

• 6-6V Batteries

• Squeegee assembly

• 2-Pad Drivers

• 2-Brushes

INSTALLING BATTERIES

The batteries are already in the machine upon

delivery; However you will need to connect the

cables to the battery posts.

WARNING: Batteries emit hydrogen gas.

Explosion or fire can result from hydrogen

gas.Keep sparks and open flames away! Keep

battery compartment open when charging.

Recommended Battery spec:

6-6V, 260AH@20HR or 330AH@20HR deep cycle

batteries.

Max. batteries dimensions :

590mm (L) X 534mm (W) X 365mm (H)

1. Turn the main power key switch off.

2. Open recovery tank to gain access to battery

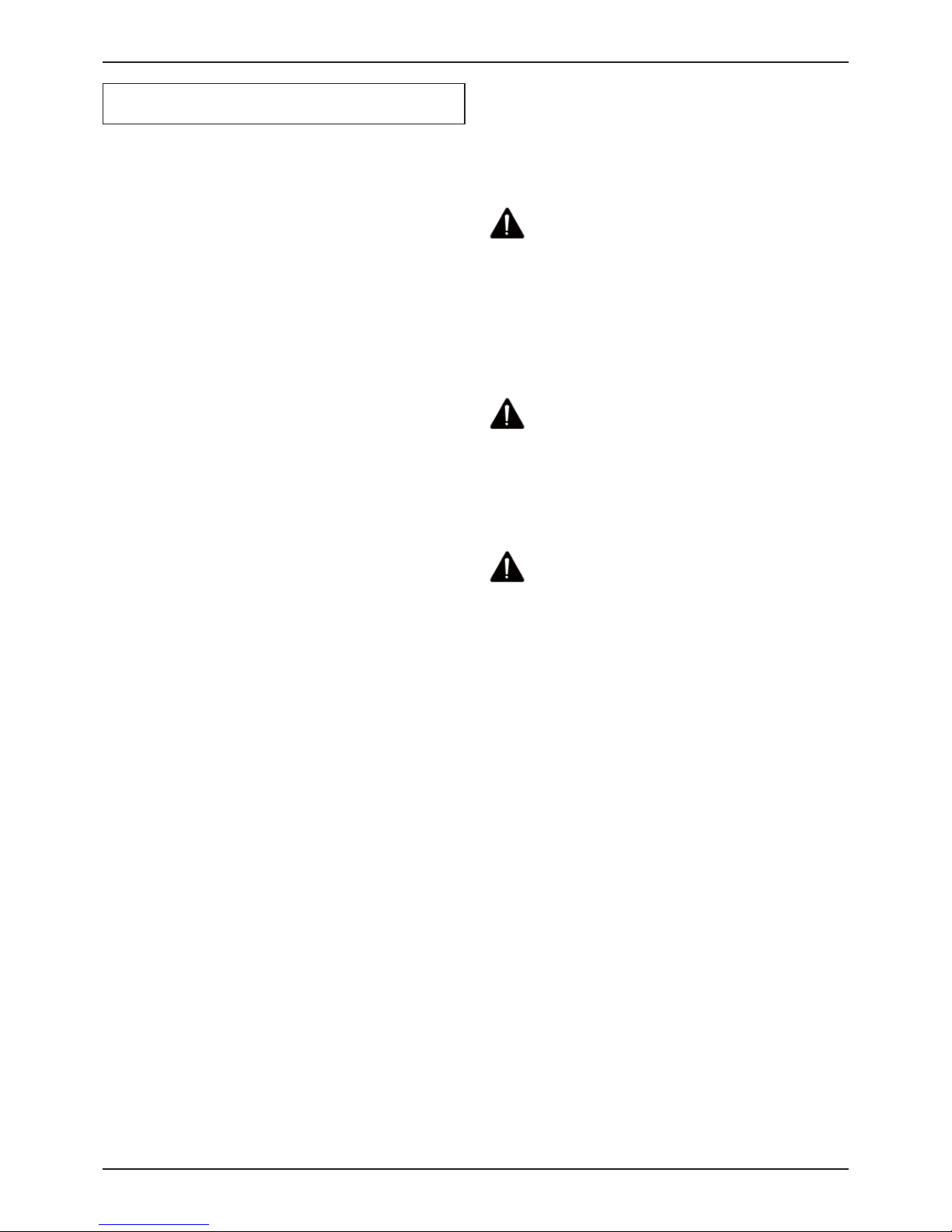

compartment.

3. Carefully place the batteries into the

compartment as shown in figure below. Place

the battery brace at the rear of the batteries.

DO NOT DROP BATTERIES INTO

COMPARTMENT!

4. Connect battery cables to posts in numbered

order as shown in drawing below.

RED to POSITIVE and BLACK to NEGATIVE.

MACHINE SET UP

PRE-OPERATION CHECKS

1. Sweep or dust mop the surface to be cleaned.

2. Check battery meter to make sure batteries are

fully charged. (See BATTERY CHARGING)

3. Check that squeegee is properly installed.

4. Check that brushes / pads is properly installed.

INSTALLING BRUSHES OR PADS

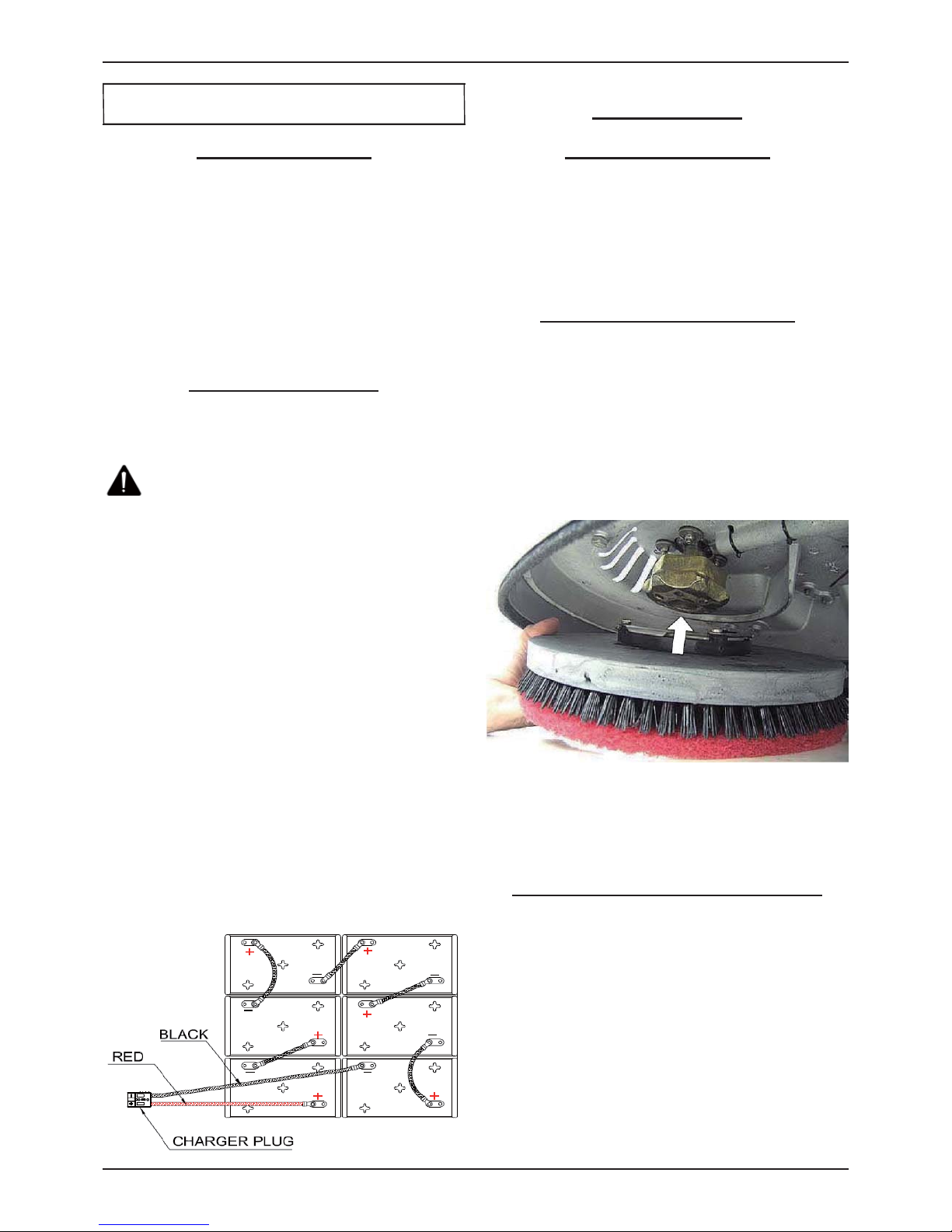

1. Turn off the 1-STEP Scrub head up/down switch

(see machine components, item #8) and Raise

the Scrub head off the floor, then stop machine

on the level surface, remove the key and ensure

the machine is turned off.

2. If using the Pad Driver, first attach the

appropriate pad to the pad driver surface.

3. Align the pad driver or brush under the motor

hub and push it upward to engage.

4. To remove the pad driver or brush, raise

the scrub head and push the pad release

plunger (see machine components, item #34)

downward.

MOUNTING THE SQUEEGEE ASSEMBLY

1. Lift the squeegee lift lever (see machine

components, item #22)to the upward position.

2. Mount the squeegee assembly to the squeegee

pivot bracket. make sure the knobs are

completely seated into the slots before securing

knobs.

3. Connect the vacuum hose to the squeegee

assembly. Loop the hose by using the hose clip

provided.

4. Check the squeegee blades for proper

adjustment.

MACHINE SET UP & INSTALLATION

Page 7

7

OPERATOR MANUAL

ICE i36BT

FILLING THE SOLUTION TANK

The machine is equipped with a hose fill-port (see

machine components, item #23) at the rear of

the machine, and a bucket fill-port (see machine

components, item #32)located under the recovery

tank. Before accessing the bucket fill-port make

sure that the recovery tank is empty.

Fill the solution tank to the "110L" level on the

solution tank sight gauge. When using the bucket

fill-port, stop filling when the level reaches the

bottom edge of the fill-port.

NOTE: When fi lling the solution tank with a

bucket, make sure that the bucket is clean. Do not

use the same bucket for fi lling and draining the

machine.

WARNING: Do not put any flammable

materials into solution tank. this can cause an

explosion or a fire. Only use recommended

cleaning chemicals. Contact your janitorial

supply distributor for recommendations on

proper chemicals.

WARNING: Do not operate machine

unless you have read and understand this

manual.

1. Turn the main power key switch(see machine

components, item #7) to the on (I) position.

2. Check the battery level meter (see machine

components, item #6), if the battery meter

is in the red, DO NOT continue to operate

the machine and recharge the batteries

immediately.

3. Turn on the 1-STEP scrub head up/dwon switch

(see machine components, #8) to lower the

scrub head to the floor, the 1-STEP switch

indicator is light.

4. Lower squeegee assembly to the floor by

lowering the squeegee lift lever(see machine

components, item #22).

5. Check the solution flow indicator (see machine

components, item #9), adjust the solution flow

control switch to a desired flow rate.

NOTE: Solution will not begin to fl ow until the

control handle bail is pulled.

6. Turn on the vacuum motor switch(see machine

components, item #10).

7. Pull the control handle bail (see machine

components, item #27) backwards to start

scrubbing .The machine will automatically

propel forward. To reverse the machine, simply

push the control handle bail forward.

NOTE:

Raise squeegee when reversing machine.

8. The scrubbing speed can be adjusted,

Adjust the speed control knob (see machine

components, item #5) to a desired speed.

NOTE: 45-60 meters (150-200 ft)per minute is

the recommended scrubbing speed.

simply press the pressure adjuting button to

increase (+) or decrease (-) the brush pressure

as needed.(see machine components, item #3)

10. To stop scrubbing, release the control handle

bail, turn off the 1-STPE switch to raise

the scrub head assembly, raise he squeegee

assembly.

WARNING: Fire Or Explosion Hazard. Do

Not Pick Up Flammable Materials Or Reactive

Metals.

1. Go slow on inclines and slippery surfaces. Do

not operate the machine on inclines that exceed

5% (3°).

2. Do not keep the machine in the same position

with pad / brush spinning, keep the machine

moving to prevent damage to floor finish.

3. If the squeegee assembly leaves streaks on the

floor, raise the squeegee off the floor and wipe

the blades down with a damp cloth. Pre-sweep

the area to prevent leaving streaks on the floor.

4. Pour a recommended defoamer into the

recovery tank if excessive foam appears.

WARNING: Do not allow foam to enter

the float shut-off screen, vacuum motor

damage will result. Foam will not activate the

float shut-off screen.

5. Occasionally check the battery level meter(see

machine components, item #6). when meter

is in the red, stop scrubbing and recharge the

batteries.

WARNING: When battery meter is in the

red, do not continue to operate the machine.

Battery damage may result.

MACHINE OPERATION

WHILE OPERATING MACHINE

Page 8

8

OPERATOR MANUAL

ICE i36BT

6. When the solution tank runs empty, press the

1-STEP switch raise the brush head. Keep the

squeegee down and continue to vacuum until all

the dirty water is picked up.

NOTE: Brush motors will not work when

the scrub head assembly raised.

NOTE: See TANK DRAINING section to learn

how to drain recovery and solution tanks.

CIRCUIT BREAKER / FUSES

The machine is equipped with 2 resettable circuit

breakers(see machine components, item #12,

item# 30) to protect the drive motor and the

vacuum motor from damage. If the circuit breakers

should trip, it can't be reset immediately. You must

first determine what caused the breaker to trip, and

allow the motor to cool down and then you can

manually reset the circuit breakers.

The machine is also equipped with a 50A current

transformer to protect the brush motors from

damage. When replacing a fuse never substitute a

higher Amps rated fuse than specified.

HOUR METER

The hour meter (see machine components, item

#4) records the number of total hours the brush

motor has been powered on. Use the hour meter

to determine when to perform recommended

maintenance procedures and to record service

history.

EMERGENCY STOP BUTTON/ BRAKE

The machine is equipped with an Electromagnetic

Brake Mechanism on the Transaxle. When in case

of Emergency, release the Control Handle bail(see

machine components, item #27) or strike the

Emergency stop button (see machine components,

item #11), the machine will be braked and then

stop. Reset the emergency stop button, turn on the

Main power key switch, and then pull the control

handle bail, the machine will be restart.

NOTE: The machine can not be moved unless the

Main Power Key Switch and the Control Handle

bail be turned on.

WARNING: Do Not Change the Default

Settings of the Electromagnetic Brake

Mechanism unless Authorized, otherwise it

may cause Machine Damage or Personal Injury.

Contact the Authorized Service center for

machine repairs.

1. Turn the machine off.

2. With the squeegee and scrub head in their "up"

position, transport machine to approved area for

draining tank(s).

DRAINING THE RECOVERY TANK

Any time scrubbing is completed, or when refilling

solution tank, the recovery tank should be drained

and cleaned.

WARNING: If the recovery tank is not

drained when the solution tank has been

refilled, foam or water may enter the filter

screen and cause damage to the vacuum

motor.

1. While holding the drain hose (see machine

components, item #19) upward, remove the cap

and lower hose to drain.

2. Open the recovery tank cover and rinse out the

tank. Use a rag to remove any excess dirt.

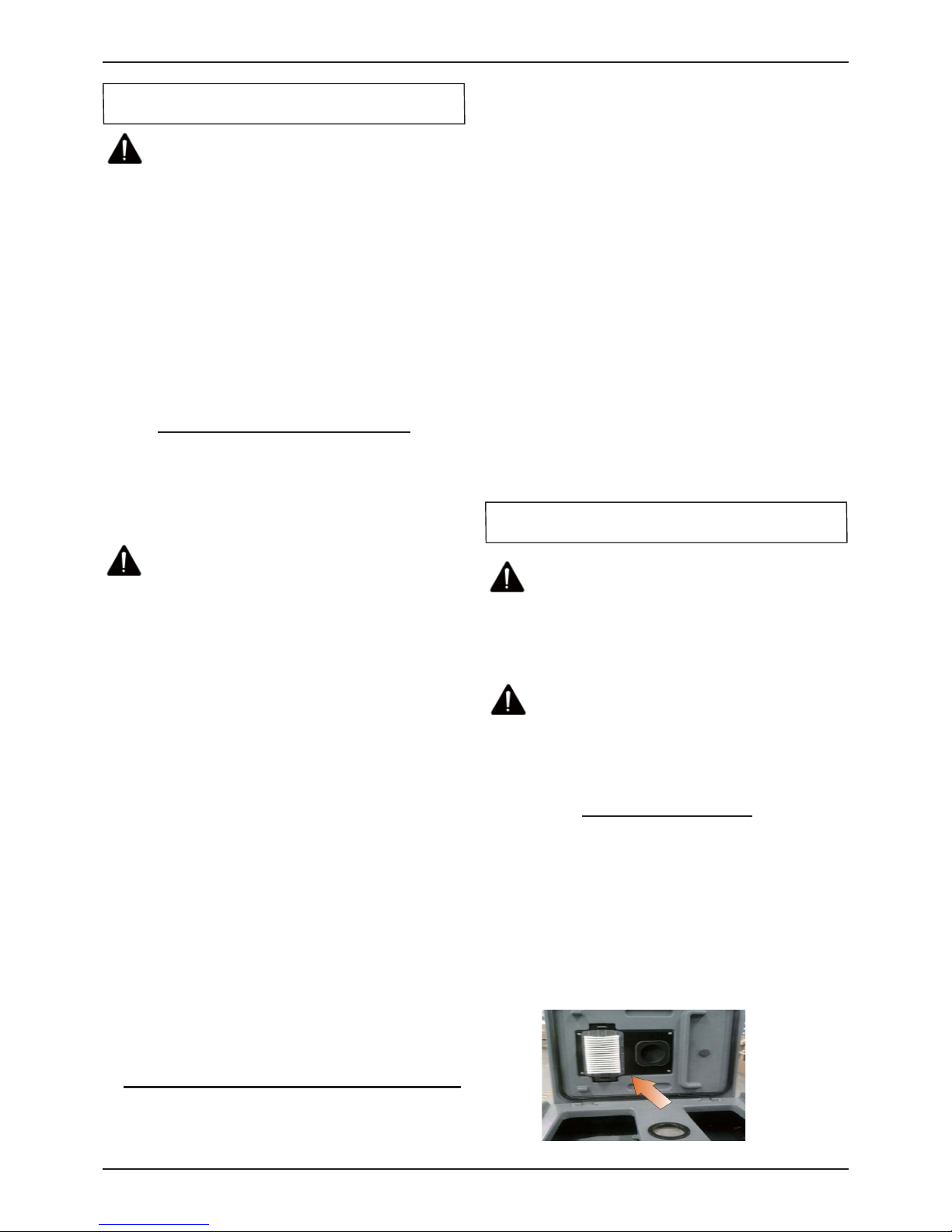

3. Clean the filter screen located in the recovery

tank .

DRAINING THE SOLUTION TANK

Any time scrubbing operation is completed, the

solution tank should be drained and cleaned.

1. Pull the solution tank level hose(see machine

components, item #14) off the hose fitting, this

will allow the solution to flow freely into a bucket

or floor drain.

2. Remove the cover of the filter assembly(see

machine components, item #20) to drain the

solution tank, check the filter screen and clean

up it if necessary.

3. Rinse the solution tank with clean water after

every use. This will help prevent chemical

buildup and clogging of the solution lines.

4. After rinsing out the tank, securely reconnect

the tank level hose to the hose fitting, replace

the filter assembly cover and be sure the

filter screen and the "O" ring is in the correct

position.

TANK DRAINING

Page 9

9

OPERATOR MANUAL

ICE i36BT

BATTERY CHARGING

WARNING: Fire Or Explosion Hazard.

Batteries Emit Hydrogen Gas. Keep Sparks and

Open Flame Away. Keep Battery Compartment

Propped Open When Charging.

NOTE: Use only apprved chargers with the

following specifi cations:

• Automatic shut off circuit

• Deep cycle charging

• Output current of 20-30 Amps

• Output voltage of 36 volts

ON-BOARD BATTERY CHARGER

As standard configuration, the machine is equiped

with the On-board battery charger (see machine

components, item #13). The settings of On-board

battery charger had been set for the recommended

batteries type.

WARNING: The On-board battery

charger setting's change are to be completed

by authorized service centers only. Failure

to properly set will result in the batteries or

charger damage.

1. Transport the machine to a well ventilated area.

2. Turn the machine off.

3. If charging wet (lead acid) batteries check the

fluid level before charging.

4. Prop up the recovery tank by the support

stand (see machine components, item #28) for

ventilation.

5. Connect the charger's AC power supply cord to

a properly grounded receptable.

6. The charger will automatically begin to charge,

once the charging cycle begins, the indicator

lights will progress from red, yellow to green.

when the green indicator light comes on, the

charging cycle is done. Unplug the charger

cord.

NOTE: The machine will can not operate when

charging.

OFF-BOARD BATTERY CHARGER (OPTION)

1. Place charger and machine in a well ventilated

area.

2. Turn the machine off.

3. If charging wet (lead acid) batteries check the

fluid level before charging.

4. Prop up the recovery tank by the support

stand (see machine components, item #28) for

ventilation.

5. Connect the charger's AC power supply cord to

a properly grounded receptable.

6. Connect the charger's DC cord into the

machine's battery receptacle at the rear of the

machine.

7. The charger will automatically begin to charge

and will autoatically shut off once the batteries

are fully charged.

8. Upon completion of charging, disconnect the

AC power supply cord first, and then disconnect

the charger from the machine.

WARNING: Before performing any

maintenance on the machine, be sure that

the power is turned off, or the batteries are

disconnected!

WARING: Repairs are to be completed

by Authorized service centers only. Any repairs

completed by unauthorized persons will avoid

the warrenty.

DAILY MAINTENANCE

1. Remove pad driver/ brush and clean with

approved cleaner.

2. Drain recovery and solution tanks completely

and rinse out with clean water. Visually check

the recovery tank for debris and clean out as

necessary.

3. Open recovery tank cover,Remove the vacuum

fan filter and rinse it out with low pressure water,

if dirty.

PREVENTATIVE MAINTENANCE

Page 10

10

OPERATOR MANUAL

ICE i36BT

4. Raise the squeegee assembly off floor and wipe

it down with a damp towel. Be sure to store the

squeegee in the up position.

5.

Clean machine with an approved cleaner and a

damp towel.

6. Recharge the batteries.

7.Check the condition of the squeegee blade

wiping edge, rotate blade if worn.

MONTHLY MAINTENANCE

1. Clean the battery tops to prevent corrosion.

2. Check for loose battery cable connections.

3. Inspect and clean the recovery tank cover seal.

Replace it if damaged.

4. Lubricate all grease points and pivot points with

silicon spray and approved grease.

5. Check the machine for loose nuts and bolts.

6. Check the machine for leaks.

MOTOR MAINTENANCE

1. Contact your local Distributor for any motor

maintenance.

2. Motor should have the brushes checked every

250 hours. Brushes should be replaced when

they are worn to a length of 10 mm or less.

BATTERY MAINTENANCE

WARNING: Batteries emit hydrogen gas

and an explosion o fire can result. Keep sparks

and fire away from batteries at all times.

WARNING: Whenever serviving batteries,

be sure to wear protective gloves. Avoid

contact with battery acid at all times.

NOTE: For the best machine performance, keep

batteries charged at all times. Do not let them sit in

a discharged condition.

1. Always follow the battery charging directions as

outlined in the BATTERY CHARGING section of

this manual.

2. Keep battery tops and terminals free from

corrosion. A strong solution of baking soda

and water is the best way to keep the batteries

corrosion free. DO NOT ALLOW THE BAKING

SODA / WATER SOLUTION TO ENTER THE

BATTERY CELLS.

3. Use a wire brush with the baking soda solution

to properly clean the battery posts and

connctions.

4. Check battery connections for wear and loose

terminals. replace if necessary.

MACHINE STORAGE

1. Always store the machine indoors.

2. Always store the machine in a dry area.

3. Always store the machine in its upright position.

4. Always store the machine with the pad driver/

brush raised off the floor.

5. Always store the machine with the squeegee

assembly raised off the floor.

6. If storing in an area which may reach freezing

temperatures, be sure to drain all fluids from the

machine prior to storage. Any damage caused

by freezing temperatures will not be covered by

the warranty.

7. Drain the recovery tank.

8. Drain the solution tank of all fluid.

PUSHING OR TOWING THE MACHINE

If the machine becomes disabled, it can be pushed

from the front or rear, but only tow it from the rear.

WARNING: When servicing machine, do

not push or tow the machine on inclines with

the brake disabled.

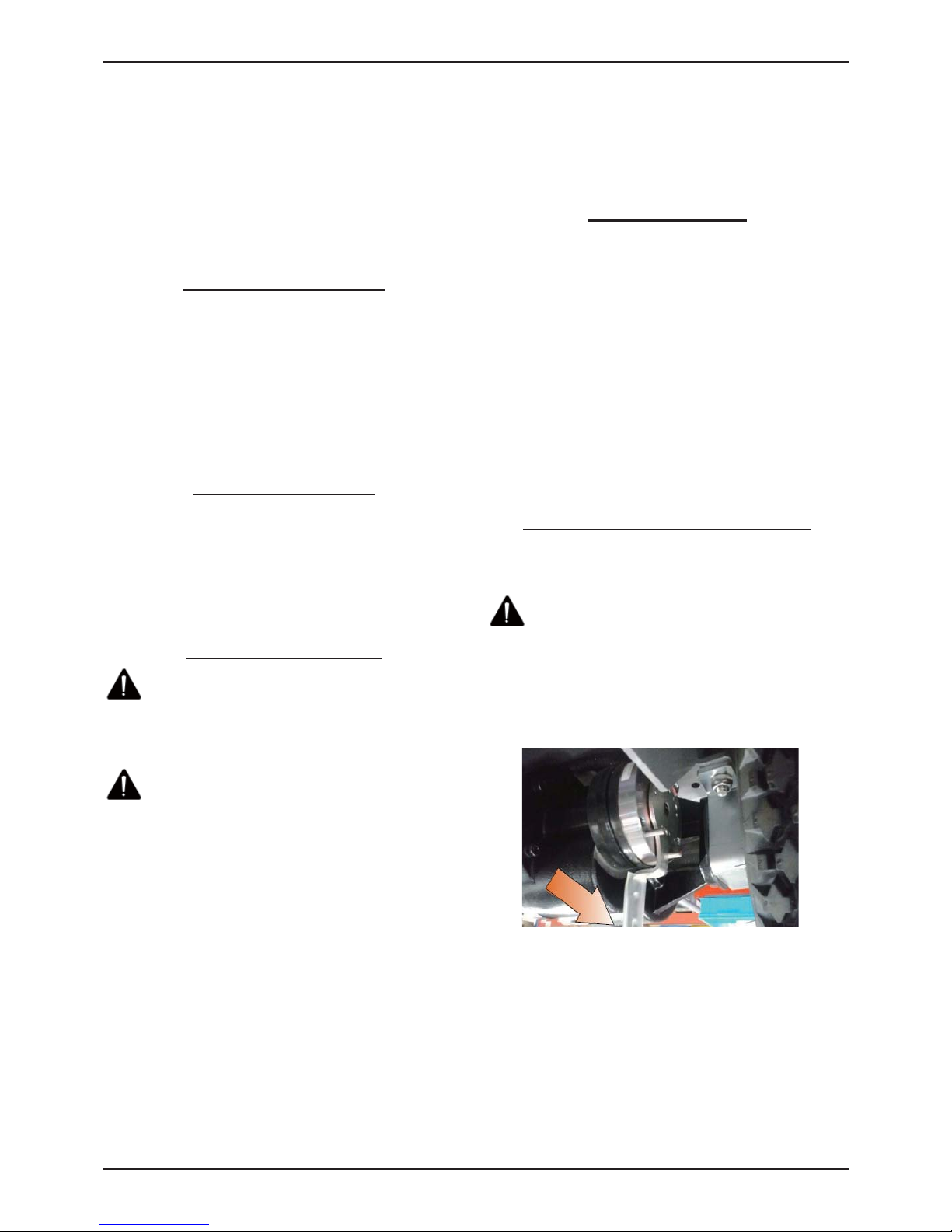

Before attempting to push or tow the

machine,disengage the brake as described

below.To disengage the brake,you can turn the

electronic brake lever to the other side.

Page 11

11

OPERATOR MANUAL

ICE i36BT

PROBLEM CAUSE SOLUTION

Machine will not

operate

Control handle bail not pulled Pull control handle bail

Batteries need to be charged Charge batteries

Bad battery(s) Replace battery(s)

Loose battery cable Tighten loose cable

Emergency stop button activated Reset Emergency stop botton

Main PCB fuse blown Contact ICE service center

Faulty key switch Contact ICE service center

Brush motor will

not operate

1-STEP scrub head up/down switch is off Turn on the 1-STEP switch

Battery meter lockout activated Recharge batteries

Brush motor fuse blown Replace 50A current transformer

Brush motors over load Turn on / off the 1-STEP switch

Faulty control handle bail switch Contact ICE service center

Faulty brush motor or wiring Contact ICE service center

Worn Motor carbon brushes Contact ICE service center

Bad solenoid Contact ICE service center

Machine does

not propel

The Main Power Key Switch be Turned off,

the Control handle bail not pulled

Turn on the Key switch, Pull the control

handle bail

Tripped drive motor circuit breaker Reset drive motor circuit breaker button

Faulty transaxle motor or wiring Contact ICE service center

Worn Motor carbon brushes Contact ICE service center

Vacuum motor

will not operate

Recovery tank is full Drain recovery tank

Tripped vacuum motor circuit breaker Reset vacuum circuit breaker button

Faulty vacuum motor or wiring Contact ICE service center

Worn Motor carbon brushes Contact ICE service center

Little or no

solution flow

Ball valve set too low or shut off Turn on the ball valve

Solution flow control knob set too low or

shut off

Adjust solution control flow knob

Clogged solution tank filter or solution

hose

Clean solution tank filter or flush out

solution hose

Clogged solution Solenoid valve Remove valve and clean

Poor water pick

up

Recovery tank is full Drain recovery tank

Loose drain hose cap Tighten cap

Clogged filter located in recovery

tank cover

Clean filter

Clogged squeegee assembly Clean squeegee assembly

Worn squeegee blades Replace or rotate squeegee blades

Incorrect squeegee blade def ection Adjust squeegee blade height

Loose vacuum hose connections Secure hose connections

Clogged vacuum hose Remove clogged debris

Damaged vacuum hose Replace vacuum hose

Recovery tank cover not in place Properly position cover

Damaged recovery tank cover seal Replace seal

Faulty vacuum motor Contact ICE service center

Low battery charge Recharge batteries

Short run time

Low battery charge Fully recharge batteries

Defective batteries Replace batteries

Batteries need maintenance See BATTERY MAINTENANCE

Faulty battery charger Repair or replace battery charger

Down pressure lever is set for extra scrub

head pressure

Lower down pressure lever

BASIC TROUBLESHOOTING

Page 12

12

OPERATOR MANUAL

ICE i36BT

TECHNICAL SPECIFICATIONS

MODEL i36BT

DIMENSIONS L X W X H 1650 X 865 X 1130 mm

WEIGHT 170 Kg

WEIGHT WITH BATTERIES 440 Kg

SOLUTION TANK CAPACITY 110 L / 29 Gal

RECOVERY TANK CAPACITY 120 L / 31.5 Gal

SQUEEGEE WIDTH 1185 mm / 46.5 in

CLEANING PATH WIDTH 800mm / 32 in

PRODUCTIVITY RATE 3250 m

2

h

DRIVE SYSTEM Transaxle, 36VDC, 350W

TRAVEL SPEED, MAXIMUM Cleaning: 65m/Min Transporting: 72 m/Min

MINIMUM ALSLE TURN 1600mm

PAD/BRUSH PRESSURE 40kg / 65kg / 90kg

SOLUTION FLOW RATE 0 ~ 3200ml/Min

BRUSH MOTOR(S) 650WX2,36VDC

VACUUM MOTOR 600W,36VDC

WATER LIFT - AIR FLOW 65 in

BATTERIES 6 - 6V, 260AH or 305AH @ 20 hr

RUN TIME PER CHARGE

4 or 4.5 Hours

VOLTAGE DC

36V

DECIBEL RATING AT

OPERATOR'S EAR, INDOORS

68 dB(A)

GRADE LEVEL, MAX 10% (6°)

Page 13

Page 14

DIA

NO

PART

NUMBER

NO

REQ'D

1 8230103

1

2 8230201

1

3 8011005

1

4 8230209

1

5 8230208

1

6 8230204

1

7 1321213

2

8 1421510

9

9 8113007

1

10 8131003

1

11 8310238

1

12 1221512

3

13 8113009

1

14 8230102

1

15 8131010

1

16 1962050

1

17 8230205

1

18 1421816

4

19 1021820

2

HEX BOLT,M8 X 20

RECOVERY TANK COVER

STRIP

CAP

RECOVERY TANK

DRAIN HOSE

CLAMP

CABLE

FLAT WASHER,M8 X 16 X 1.6

SEAL

SENSOR, LEVEL, LIQUID,

SCREW,M5X12

CLAMP

RECOVERY TANK GROUP

DESCRIPTION

CAP

GASKET

GASKET, SCREEN

SCREEN

SELF-TAPPING SCREW,ST4.2 X 13

WASHER,M5 X 10 X 1

20 8111300

2

21 1421618

8

22 1021616

8

23 8112005

1

24 1121605

3

25 8210209

3

26 8230200

1

27 1421612

5

28 1123608

3

29 1914300

1

30 8132007

1

31 8230126

1

32 4010316

1

33 8111022

1

34 8111008

1

35 8111007

1

36 8115404

1

37 1021830

1

38 8230210

1

39 8310237

1

40 8310230

1

41 8111016

2

42 1221510

7

43 8230207

1

STUD,M6 X 110

3 STAGE VACUUM MOTOR,36VDC,640W,KIT

FLAT WASHER,M6 X 12 X 1.6

LOCK NUT,M6

TIE, NYLON, 5 X 300

LABEL, BATTERY INSTALLATION

ICE LOGO

PLATE

GASKET,FILTER

PLATE

SCREW,M5 X 10

WARNING LABEL

BRACKET

RECOVERY TANK SUPPORT

SLEEVE, P/M

HEX BOLT,M8 X 30

BRACKET,FILTER

FILTER,DUST

HINGE ASSEMBLY

FLAT WASHER,M 6 X 18 X 1.6

HEX BOLT,M6 X 16

GASKET, VACUUM MOTOR

HEX NUT,M6

MUFFLER, VACUUM MOTOR

14ICE i36BT

Page 15

Page 16

DIA

NO

PART

NUMBER

NO

REQ'D

1 6210131

6

2 1421510

20

3 1221512

9

4 1123507

6

5 8230114

1

6 1421612

14

7 1021616

12

8 1221525

4

9 8230117-US

1

10 8230127

1

11 8210112

2

12 1222641

2

13 1321213

2

HOOK, CORD

SCREW,M6 X 40

SELF-TAPPING SCREW,ST4.2 X 13

CAP

,

SOLUTION FILL

PLATE

SOLUTION TANK GROUP

DESCRIPTION

NYLON, CLAMP

FLAT WASHER,M5 X 10 X 1

SCREW,M5 X 12

LOCK NUT,M5

BRACKET, ON BOARD CHARGER

FLAT WASHER,M6 X 12 X 1.6

HEX BOLT,M6 X 16

SCREW,M5 X 25

ON BOARD BATTERY CHARGER,36VDC,KIT

14

8210113

1

15 4010316

2

16 8230134

1

17 1962025

1

18 8230101

1

19 8114751

12

20 8230705

5

21 8113013

4

8210105

6

8230120

6

23 8230121

1

24 8230104

1

25 1321110

3

26 1421409

3

27 8230750

1

28 8133601

1

29 1221520

3

30 8133602

1

31 8210518

2

22

KNOB, M8

SELF-TAPPING SCREW,ST3.5 X 10

FLAT WASHER,M4 X 9 X 0.8

LED LIGHT,36V,KIT

LED LIGHT MOUNTING BASE

SCREW,M5 X 20

LED LIGHT COVER

SPACER, BATTERY

BATTERY, 260AH @ 20Hr

BATTERY, 305AH @ 20Hr (OPTIONAL)

BATTERY TRAY

COVER, FRONT

BATTERY CONNECT CABLE, BLACK

,

ICE LOGO

CLEAN TUBING

CLAMP,16 - 25mm

SOLUTION TANK

JACKET, BATTERY TERMINAL, BLACK

32 1535830

2

16ICE i36BT

SET SCREW,M8 X 30

Page 17

DIA

NO

PART

NUMBER

NO

REQ'D

SOLUTION TANK GROUP

DESCRIPTION

33 1421618

6

34 8113112

2

35 8113030

1

36 8113002

1

37 8113007

1

38 1221520

2

39 8230711

1

40 8114703

1

41 8230708

1

42 1123608

4

43 8230128

1

44 1422616

6

45 8230707

1

COVER

STRAP

BUSHING

SEAL

PLAIN WASHER ,M6 X 18 X 1.6,SS

SCREW,M5 X 20

CURRENT TRANSFORMER, 50A

CIRCUIT BREAKER, 35A

SOLENOID SWITCH,36VDC

LOCK NUT,M6

BRACKET, SOLENOID SWITCH

LOCK WASHER, M6

KIT,BATTERY CONNECT CABLE

CONNECTOR

,

SB175-GRE

Y

46

8230714

2

47 1521635

2

48 8230706

1

49 1021610

2

50 8144024

2

51 8230702

1

52 8114705

2

,

SCREW, HEX SOCKET, M6 X 35

KIT,BATTERY CONNECT CABLE

HEX BOLT,M6 X 10

LABEL,CIRCUIT BREAKER

SOLENOID SWITCH,36VDC

STAND-OFF, M6, RED

17ICE i36BT

Page 18

Page 19

DIA

NO

PART

NUMBER

NO

REQ'D

1 8211505

1

2 1421132

1

3 8210508

1

4 8135001

2

5 8211501

1

6 1123810

7

7 8211507

1

8 8211506

1

9 1123608

5

10 1421618

2

11 8211503

1

12 8114511

1

13 8211504

4

14 1121807

1

15 1421824

4

BRACKET, SQGE MNTG

BALL JOINT,M6

SHOULDER BOLT,M12 X 7 X M8

FLAT WASHER,M8 X 24 X 2

NUT,M8

FLAT WASHER,M6 X 18 X 1.6

FRAME & DRIVE GROUP

DESCRIPTION

SHOULDER BOLT,M12 X 30 X M10

FLAT WASHER,M12 X 32 X 1.5

SPIRNG

PLASTIC THRUST WASHER,M12 X 30 X 1.5

BRACKET, SQGE LIFT

LOCK NUT,M8

KNOB, M8

PIN

LOCK NUT,M6

16

8211508

1

17 8211502

1

18 1421020

13

19 1021030

8

20 1123012

13

21 1124111

6

22 1123111

6

23 1421120

6

8230129

2

8230116

2

25 8230118

2

8230810

1

8230811

1

27 8230119

2

28 1022809

1

29 1021820

5

30 1422821

5

31 1421828

5

32 8210115

2

33 8210116

2

34 1021830

5

26

24

WHEEL,12", FOAM FILL

LOCK WASHER,M8

FLAT WASHER,M8 X 28 X 2

ARM, SCRUB HEAD LIFTING

BUSHING

HEX BOLT,M8 X 30

HEX BOLT,M8 X 20

HEX BOLT,M8 X 90

TRANSAXLE, 36VDC,KIT

5",CASTER

ELECTRIC BRAKE KIT

HEX BOLT,M10 X 30

LOCK NUT,M10

FLAT WASHER,M10 X 20 X 2

BUSHING

BRACKET, SWING

NUT,CAP

LOCK NUT,7/16"- 20UNF

FLAT WASHER,M12.1 X 20 X 2

WHEEL,12", PNEUMATIC (OPTIONAL)

BRACKET, TRANSAXLE MOUNTING

35

8230105

1

36 1021025

4

19ICE i36BT

FRAME

HEX BOLT,M10 X 25

Page 20

Page 21

DIA

NO

PART

NUMBER

NO

REQ'D

1 8210830

1

2 8210807

2

3 8210309

2

4 1421816

14

5 1021825

11

6 8210806

1

7 8210820

1

8 1123810

10

9 8230300

2

10 1655025

2

11 8210808

2

12 8210809

2

13 8230301

1

14 1421612

8

15 1422616

8

16 1021620

8

17 8210805

2

18 1421828

2

SCRUB HEAD GROUP

DESCRIPTION

FLAT WASHER,M6 X 12 X 1.6

HEX BOLT,M8 X 25

BRACKET, ACTUATOR MNTG

BRACKET, SCRUB HEAD LIFT, LEFT

LOCK NUT,M8

BRUSH MOTOR, 36VDC, 630W,KIT

KEY, 5 X 5 X 25

KNOB, M10

SPRING

HOUSING, SCRUB HEAD,i36BT

LOCK WASHER, M6

HEX BOLT,M6 X 20

HUB, BRUSH DRIVE

FLAT WASHER,M8 X 28 X 3.0

BRACKET, SCRUB HEAD LIFT, RIGHT

PIN

PIN, COTTER

FLAT WASHER,M8 X 16 X 1.6

19 1422821

2

20 8218050

2

21 1221635

12

22 1221640

4

23 1421618

4

24 8210861

4

25 8210862

4

26 9000004

4

27 9050016

2

28 1321325

6

29 9000003

2

30 8116040

6

31 9040016

2

32 8210804

4

33 1022090

2

34 1111215

1

35 8210811

1

36 8210810

1

37 1421824

2

38 8115404

1

39 8116009

1

40 1021830

1

FLAT WASHER,M8 X 24 X 2

SLEEVE, P/M

PROTECTIVE WHEEL

HEX BOLT,M8 X 30

HEX NUT, M16

AJUSTMENT STUD, M16

BRACKET, ROLLER MNTG

SPRING, G-400S

CLUTCH, G-400S

LOCK WASHER,M8

BUMPER, SCRUB HEAD

HEX BOLT,M10 X 90

BRUSH ASSEMBLY, 16 INCH

SELF-TAPPING SCREW,ST5 X 25

CENTER LOCK, #3

SPACER, 6.5 X 14.5 X 7.0

PAD DRIVER, 16 INCH

SPACER

SCREW, M6 X 35

SCREW, M6 X 40

FLAT WASHER,M6 X 18 X 1.6

RETAINER BAR

21ICE i36BT

Page 22

Page 23

DIA

NO

PART

NUMBER

NO

REQ'D

1 1123810

6

2 1421824

10

3 8210306

1

4 1021825

2

5 1422821

4

6 1021820

2

7 8210311

2

8 8210312

2

9 8210314

1

10 8210310

1

11 8210313

1

12 1022800

1

13 8210316

1

14 1123008

2

15 1022811

1

GUIDE, ROLLER

SCRUB HEAD LIFT GROUP

DESCRIPTION

LOCK NUT,M8

FLAT WASHER,M8 X 24 X 2

BRACKET, GUIDE MNTG

HEX BOLT,M8 X 25

LOCK WASHER,M8

HEX BOLT,M8 X 20

SPRING

WASHER, PM

SHAFT

ROLLER

HEX BOLT,M8 X 100

BRACKET, SCRUB LIFT

LOCK NUT,3/8

HEX BOLT,M8 X 110

16 8210319

2

17 8210317

1

18 1421132

4

19 8210322

1

20 8210309

2

21 8210318

2

22 8230311

2

23 8210321

2

24 8230302

1

25 8210301

1

26 8210303

1

27 1421612

4

28 1422616

4

29 1021616

4

SLEEVE

SPRING

BRACKET, SPRING

FLAT WASHER,M 12 X 32 X 1.5

PIN

PIN, COTTER

SPRING

BOLT, SHOULDER, 3/8

ACTUATOR, 36VDC

PIN

BRACKET, ACTUATOR MNTG

FLAT WASHER,M6 X 12 X 1.6

LOCK WASHER,M6

HEX BOLT,M6 X 16

23ICE i36BT

Page 24

Page 25

DIA

NO

PART

NUMBER

NO

REQ'D

1

8118300

1

2

8118003

4

3

1021835

2

4

1421824

2

5

8116009

2

6

8115404

2

7

1421816

6

8

1021616

8

9

1421618

8

10

8210515

2

11

8230501

1

12

1123810

2

13

1221575

1

14

8210525

1

SQUEEGEE HOUSING

LOCK NUT,M8

SCREW,M5 X 75

SHORT CLAMP ASSEBLY

BRACKET, ROLLER MNTG

SQUEEGEE GROUP

DESCRIPTION

RIGHT BRACKET

STAR KNOB,M8

HEX BOLT,M8 X 35

FLAT WASHER,M8 X 24 X 2.0

PROTECTIVE W HEEL

BEARING, JOURNAL

FLAT WASHER,M8 X 16 X1 .6

HEX BOLT,M6 X 16

FLAT WASHER,M6 X 18 X 1.6

15

1123507

1

8210520

1

8211520

1

17

1022845

1

18

8210527

1

8230504

1

8230507

1

20

8230502

1

8230503

1

8230506

1

22

8118400

2

23

1121008

2

24

8118200

1

25

8230500

1

26

8118109

1

27

8118006

1

28

1962050

1

16

19

21

CLAMP ASSEMBLY, SQUEEGEE

LEFT BRACKET

SQUEEGEE ASSEMBLY

HOLDER VACUUM HOSE

VACUUM HOSE

CLAMP ASSEMBLY, SQUEEGEE WITHOUT W HEEL(OPTIONAL)

HEX BOLT,M8 X 45

WHEEL, 2 INCH

SQUEEGEE BLADE, REAR, LINATEX

SQUEEGEE BLADE, REAR, PU (OPTIONAL)

CLAMP

RETAINER,SQUEEGEE

SQUEEGEE BLADE, FRONT, LINATEX

SQUEEGEE BLADE, FRONT, PU (OPTIONAL)

CASTER, 2 INCH

HEX NUT,M10

LOCK NUT,M5

25ICE i36BT

Page 26

Page 27

DIA

NO

PART

NUMBER

NO

REQ'D

1

8119005

1

2

8119007

1

3

8119006

4

4

8230304

1

5

8119100

1

6

8119101

1

8119103

1

8119105

1

8

1622063

1

9

8119102

1

10

1421510

2

11

1221512

2

12

8230305

1

13

8230309

1

14

8230306

1

FILTER ASSEBLY

BASE, FILTER ASSEMBLY

SCREEN, FILTER, 70 MESH

SCREEN, FILTER, 40 MESH (OPTIONAL)

"O" RING

CAP, FILTER ASSEMBLY

FLAT WASHER,M5 X 10 X 1

SCREW ,M5 X 12

TUBING,ID=12 X 560MM

ELBOW, TUBING BARB

TUBING,ID=16 X 120MM

TUBING,ID=12 X 365MM

7

SOLUTION GROUP

DESCRIPTION

BALL VALVE, G1/2

ELBOW,G1/2

CLAMP

15

1962025

4

16

1221512

2

17

1422513

2

18

1421512

2

19

8230122

1

20

1914300

5

21

8230307

1

22

8310903

2

23

8230308

1

24

1962016

2

TUBING,ID=16 X 300MM

TUBING,ID=12 X 175MM

FITTING, PLASTIC, TEE

CLAMP, 10-16mm

SCREW ,M5 X 12

LOCK WASHER,M5

FLAT WASHER,M5 X 10 X 1

SOLENOID VALVE,36VDC

TIE, NYLON, 5X300

CLAMP, 16-25

mm

27

ICE i36BT

Page 28

Page 29

DIA

NO

PART

NUMBER

NO

REQ'D

1 8134001

1

2 1421307

5

3 1221306

5

4 8230709

1

5 8134015

1

6 1123305

6

7 8114710

1

8 8114709

1

9 8124717

1

10 8124718

1

11 8210410

1

12 8230701

1

13 1221512

12

14 8230713

1

15 1021616

5

LIGHT BELT,36V

HEX BOLT,M6 X 16

POTENTIOMETER

KNOB, POTENTIOMETER

CONTROL PANEL

CONTROL PANEL DECAL, i36BT

SCREW,M5 X 12

PCB ASSEMBLY,36VDC

GASLET

LOCK NUT,M3

TIMER

KEY SWITCH

CONTROL CONSOLE GROUP

DESCRIPTION

CONTROL CONSOLE HOUSING

FLAT WASHER,M3 X 7X 0.5

SCREW,M3X6

16 1421618

9

17 8124007

1

18 8210414

2

19 8124008

2

20 8144030

1

21 8114703

1

22 8124715

1

23 1421409

4

24 1221421

2

25 8114005

1

26 1421510

5

27 1021630

1

28 8014101

1

29 1021512

2

30 8134013

1

31 1421515

1

32 1021620

2

33 1121605

2

PLAIN WASHER ,M6 X18 X 1.6,SS

BUTTON,EMERGENCY STOP

CAP

SPRING

BASE, CIRCUIT BREAKERS MNTG

CIRCUIT BREAKER, 35A

EMERGENCY STOP SWITCH

CABLE, SQGE LIFT

CONNECTOR

FLAT WASHER,M5 X 10 X 1.0

HEX HEAD BOLT,M6 X 30,SS

LIFTING ROPE SPACER

FLAT WASHER,M4 X 9 X 0.8

SCREW,M4 X 20

HEX HEAD BOLT,M5 X 12,SS

FLAT WASHER,M5 X 15 X 1.0

HEX HEAD BOLT, M6 X 20

HEX NUT,M6

29ICE i36BT

Page 30

DIA

NO

PART

NUMBER

NO

REQ'D

CONTROL CONSOLE GROUP

DESCRIPTION

34 8014012

1

35 1123608

8

36 8134501

1

37 8134508

1

38 1421132

2

39 8014010

1

40 8113104

1

41 1021840

2

42 1422821

6

43 1421828

2

44 6210111

1

45 1221516

2

46 8124743

1

47 8114712

1

48 1434300

4

BAFFLE

LOCK NUT,M6

BRACKET

SLEEVE

FLAT WASHER,M12 X 32 X 1.5

SQUEEGEE LIFTING HANDLE

BALL KNOB,M8

HEX BOLT,M 8X 40

LOCK WASHER,M8

FLAT WASHER,M8 X 28 X 3

CLAMP, DRAIN HOSE

PH SCREW,M5X16,SS

MICRO SWITCH

MICRO SWITCH

LOCK WASHER, TOOTH, M3

49 1021320

4

50 8134022

1

51 8114402

1

52 1521616

2

53 8230710-US

1

54 8114300

1

55 1534608

4

56 1535630

1

57 8114306

1

58 8114101

1

59 8134300

1

60 1123507

3

61 8230704

1

62 8134021

1

63 1421824

6

64 1021820

6

65 1021535

2

66 8114707

1

RELAY

SCREW, M5 X 35

SCREW,M3 X 20

BRACKET,SWITCH

BRACKET, SPRING

REAR PLATE, CONTROL CONSOLE

FLAT WASHER,M8 X 24 X 2

HEX BOLT,M8 X 20

SPRING

SHAFT

LEVER, BAIL

LOCK NUT,M5

SPEED CONTROL BOARD,i36BT

SCREW,M6X16, HEX SCOKET

RESISTANCE,5W,300Ω,KIT

ACTUATOR

SET SCREW,M6 X 8

SET SCREW,M6 X 30

30ICE i36BT

Page 31

DIA

NO

PART

NUMBER

NO

REQ'D

1

8230129

2

2

8116009

3

3

8230119

2

4

8210513

1

5

8210514

1

6

9050016

2

7

9040016

2

16" BRUSH

16" PAD HOLDER

WAER & TEAR PARTS LIST

DESCRIPTION

WHEEL, 12 INCH

PROTECTIVE W HEEL

SQUEEGEE BLADE, FRONT, LINATEX

SQUEEGEE BLADE, REAR, LINATEX

CASTER, 5 INCH

ICE i36BT

31

Page 32

Loading...

Loading...