Page 1

ECU Installation & Operation Manual

Vertical Air Conditioners

Models ECUA90/120/150/180/240

Chapter 1 Description ........................... 5

Chapter 2 Installation ......................... 12

Chapter 3 Start-Up ............................. 21

Chapter 4 Troubleshooting ................. 22

Chapter 5 Maintenance ....................... 25

Chapter 6 Warranty ............................ 26

Chapter 7 Start-Up Checklist .............. 27

Industrial Climate Engineering™ Division of AIRXCEL®, Inc.

P.O. Box 5104 • Cordele, Georgia 31010

2002 Hoover St. • Cordele, Georgia 31015

E-mail: icesales@airxcel.com • Internet: www.acice.com

The most current version of this manual can be found at www.acice.com.

Manufactured By:

(229) 273-9558 • Fax (229) 273-5154

Part Number 02118 04/2015 rev.3

Page 2

How To Use This Manual

This manual is intended to be a guide to Industrial Climate Engineering's line of vertical air conditioners. It contains

installation, troubleshooting, maintenance, warranty, and application information. The information contained in this

manual is to be used by the installer as a guide only. This manual does not supersede or circumvent any applicable

national or local codes.

If you are installing the air conditioner rst read Chapter 1 and scan the entire manual before beginning the installation as

described in Chapter 2. Chapter 1 contains general, descriptive information and provides an overview which can speed

up the installation process and simplify troubleshooting.

If a malfunction occurs, follow this troubleshooting sequence:

1. Make sure you understand how the air conditioner works (Chapters 1 & 3).

2. Identify and correct installation errors (Chapter 2).

3. Refer to the troubleshooting information in Chapter 4.

If you are still unable to correct the problem, contact the Factory at 1-229-273-9558 for additional assistance.

Please read the following “Important Safety Precautions” before beginning any work.

Important Safety Precautions

1. USE CARE when LIFTING or TRANSPORTING equipment.

2. TRANSPORT the UNIT UPRIGHT. Laying it down on its side may cause oil to leave the compressor and breakage

or damage to other components.

3. TURN ELECTRICAL POWER OFF AT THE breaker or fuse box BEFORE installing or working on the equipment.

LINE VOLTAGES ARE HAZARDOUS or LETHAL.

4. OBSERVE and COMPLY with ALL applicable PLUMBING, ELECTRICAL, and BUILDING CODES and ordi-

nances.

5. SERVICE may be performed ONLY by QUALIFIED and EXPERIENCED PERSONS.

* Wear safety goggles when servicing the refrigeration circuit

* Beware of hot surfaces on refrigerant circuit components

* Beware of sharp edges on sheet metal components

* Use care when recovering or adding refrigerant

6. Use COMMON SENSE - BE SAFETY-CONSCIOUS

This is the safety alert symbol . When you see this symbol on the air conditioning unit and in the instruction manu-

als be alert to the potential for personal injury. Understand the signal word DANGER, WARNING and CAUTION.

These words are used to identify levels of the seriousness of the hazard.

!

DANGER

!

WARNING

!

CAUTION

Failure to comply will result in death or severe personal injury and/or property damage.

Failure to comply could result in death or severe personal injury and/or property damage.

Failure to comply could result in minor personal injury and/or property damage.

IMPORTANT is used to point out helpful suggestions that will result in improved installation, reliability or operation.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE.

© 04/2015 Industrial Climate Engineering™ Div. Airxcel™, Inc.

2

ECU 04/2015 rev.3

Page 3

WARNING

• If the information in these instructions are not followed exactly, a re may result

causing property damage, personal injury or loss of life.

• Read all instructions carefully prior to beginning the installation. Do not begin

installation if you do not understand any of the instructions.

• Improper installation, adjustment, alteration, service or maintenance can cause

property damage, personal injury or loss of life.

• Installation and service must be performed by a qualied installer or service agency in

accordance with these instructions and in compliance with all codes and requirements

of authorities having jurisdiction.

INSTALLER: Afx the instructions on the inside of the building adjacent to the

thermostat.

END USER: Retain these instructions for future reference.

Table of Contents

Chapter 1 Air Conditioner Description & Specications

1.1 General Description .................................................................................................................................5

1.2 Model Identication .................................................................................................................................5

1.3 Serial Number Date Code ........................................................................................................................5

1.4 Air Flow, Weights and Filter Sizes ...........................................................................................................6

1.5 General Operation ....................................................................................................................................6

1.6 Electronic Control Board Mode of Operation ..........................................................................................7

1.7 Optional Controls and Packages ..............................................................................................................8

1.8 Electrical Operation .................................................................................................................................9

Chapter 2 Installation

2.1 Equipment Inspection .............................................................................................................................12

2.2 Installation Requirements .......................................................................................................................12

2.3 Installation Materials ............................................................................................................................13

2.4 Porting and Duct Work ..........................................................................................................................15

2.5 Top Flange Installation ..........................................................................................................................15

2.6 Installing the Lifting Brackets ................................................................................................................16

2.7 Mounting the Unit .................................................................................................................................16

2.8 Electrical Connections ...........................................................................................................................17

Chapter 3 Start-Up

3.1 Check-Out of Cooling Cycle .................................................................................................................21

3.2 Check-Out of Heating Cycle ..................................................................................................................21

Chapter 4 Troubleshooting

4.1 Overview ................................................................................................................................................22

4.2 Failure Symptoms Guide ........................................................................................................................22

4.3 Compressor Troubleshooting .................................................................................................................23

4.4 Control Board Diagnosis ........................................................................................................................24

3

ECU 04/2015 rev.3

Page 4

Table of Contents

Chapter 5 Maintenance

5.1 Scheduled Maintenance .........................................................................................................................25

Chapter 6 Warranty

6.1 Limited Product Warranty ......................................................................................................................26

Chapter 7 Start-Up Check List

7.1 Start-Up Check List ................................................................................................................................27

Illustrations

Figure 1a. Typical Electrical Schematics for Units with One Compressor ............................................. 10

Figure 1b. Typical Electrical Schematics for Units with Two Compressors ........................................... 11

Figure 2. Top Flange and Lifting Bracket Installation .......................................................................... 16

Figure 3. Wall Mounting Detail ............................................................................................................. 17

Figure 4a. Thermostat Connection Diagram ........................................................................................... 20

Figure 4b. CommStat™ 3 Wiring Detail ................................................................................................. 20

Tables

Table 1 Cooling Performance and Air Flow ......................................................................................... 6

Table 2 Return Air Filter Sizes .............................................................................................................. 6

Table 3 Shipping Weights & Dimensions ............................................................................................. 6

Table 4 Minimum Clearances ............................................................................................................. 13

Table 5 Voltage Limitations ................................................................................................................ 13

4

ECU 04/2015 rev.3

Page 5

Chapter 1 Description & Specications

1.1 General Description

Industrial Climate Engineering's (ICE) Environmental Control Units (ECU) are a series of vertical

wall-mounted air conditioning systems that provide heating, cooling, and ventilation for electronic

equipment shelters, process control centers, E-Houses, and other applications with high internal heat

gains. The series includes multiple sizes and nominal cooling capacities from 90,000 to 240,000 BTUH.

Resistance heating elements are available in various wattages.

Industrial Climate Engineering ECU's feature an exclusive electronic control board.

The control board consolidates several of the electrical components, improves the air conditioner’s

reliability and has LED’s to indicate operating status and fault conditions to assist the service technician.

A complete description of functions of the control board is in Section 1.6

Other standard components include:

• Hot gas by-pass valve to allow operation in cold temperatures

• Thermal expansion valve to improve both efciency and capacity over a wide range of ambient

temperatures

• Phase monitor to prevent operation if the unit is not properly phased

The ECU's are designed for easy installation and service. Major components are accessible for service

beneath external panels.

All units have internal disconnects. Depending upon state and local code requirements, this feature

may eliminate the need for an external breaker or disconnect.

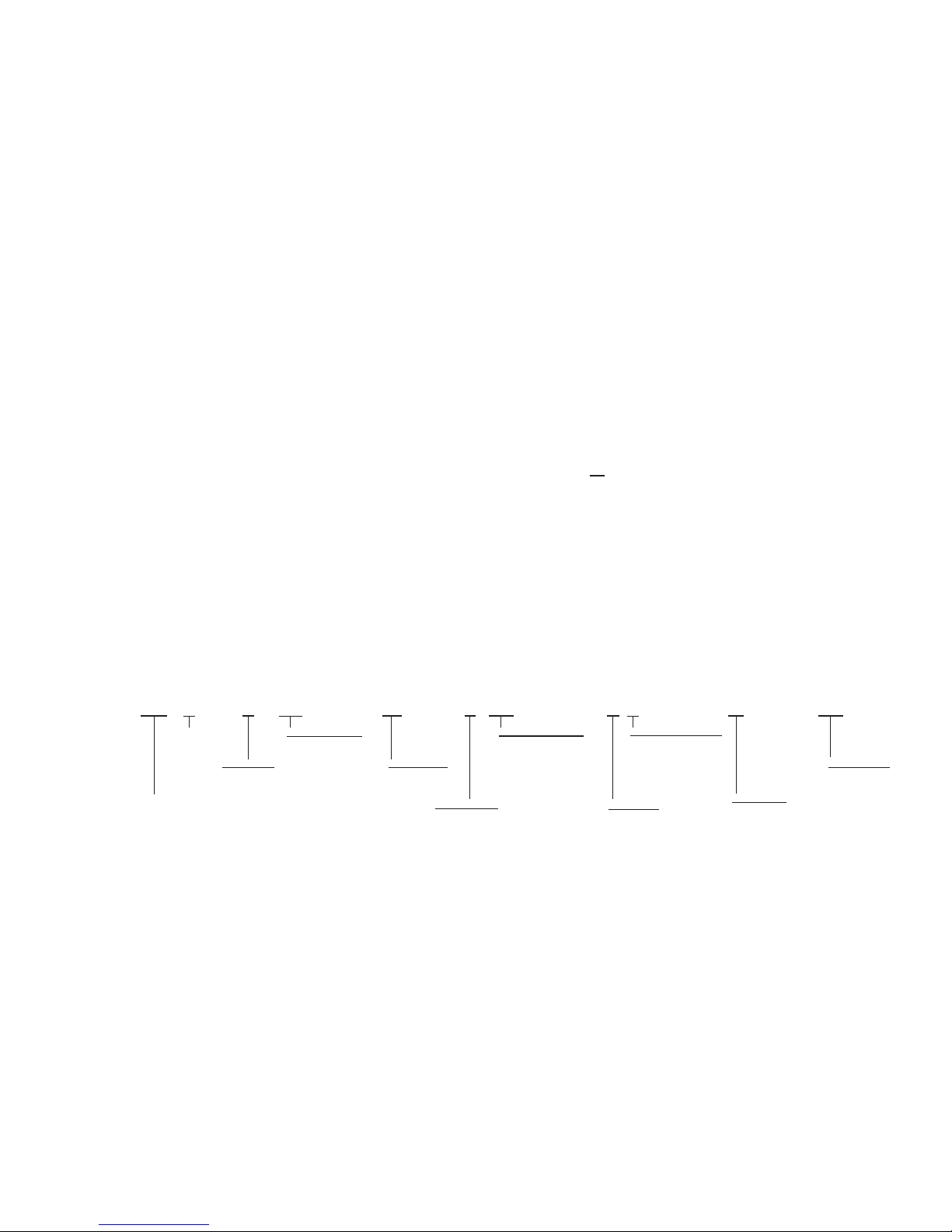

1.2 Model Identication

The model identication number is found on the data sticker. Rating plate located on side panel.

ECU D A ••• AC • ••• • • U A5 •••

D = Dual

Compressors

Environmental

Control Unit

1

The standard conguration is with one compressor. Add "D" to the model number to indicate dual compresssors.

2

The standard conguration is with the supply (conditioned) air at the top of the unit and the return air below it. In the reverse air ow conguration, the return

is at the top and the supply air below it.

3

Filter acces in the standard conguration is through the hinged, sheet metal panel on the exterior of the air conditioner. The "I" conguration allows access to

the lter from inside the building through the return air grille.

4

Three wire

5

Four wire

1

Refrigerant

A = R410A

Nominal Cooling

90 = 90,000 BTUH

120 = 120,000 BTUH

150 = 150,000 BTUH

180 = 180,000 BTUH

240 = 240,000 BTUH

System Type

Air Conditioner

Power Supply

D = 460V,3ø,60Hz

E = 380V,3ø,50Hz

C = 208/230V,3ø,60Hz

Z = 575V, 3ø,60Hz

Electric Heat – kW

000 = No Heat

090 = 9 kW

150 = 15 kW

180 = 18 kW

4

5

4

1.3 Serial Number Date Code

A = January E = May J = September D = 2014

B = February F = June K = October E = 2015

C = March G = July L = November F = 2016

D = April H = August M = December

Special Option Code

F = Reverse Air Flow

I = Factory Installed

Filter Rack Allows

Changing of Filters

from the Return Air

3

Grille

Ventilation

A = No Outside Air

(standard)

C = Economizer

2

Compressor

U = Scroll Compressor

Cabinet Color

116 = Beige

216 = Gray

(standard)

5

ECU 04/2015 rev.3

Page 6

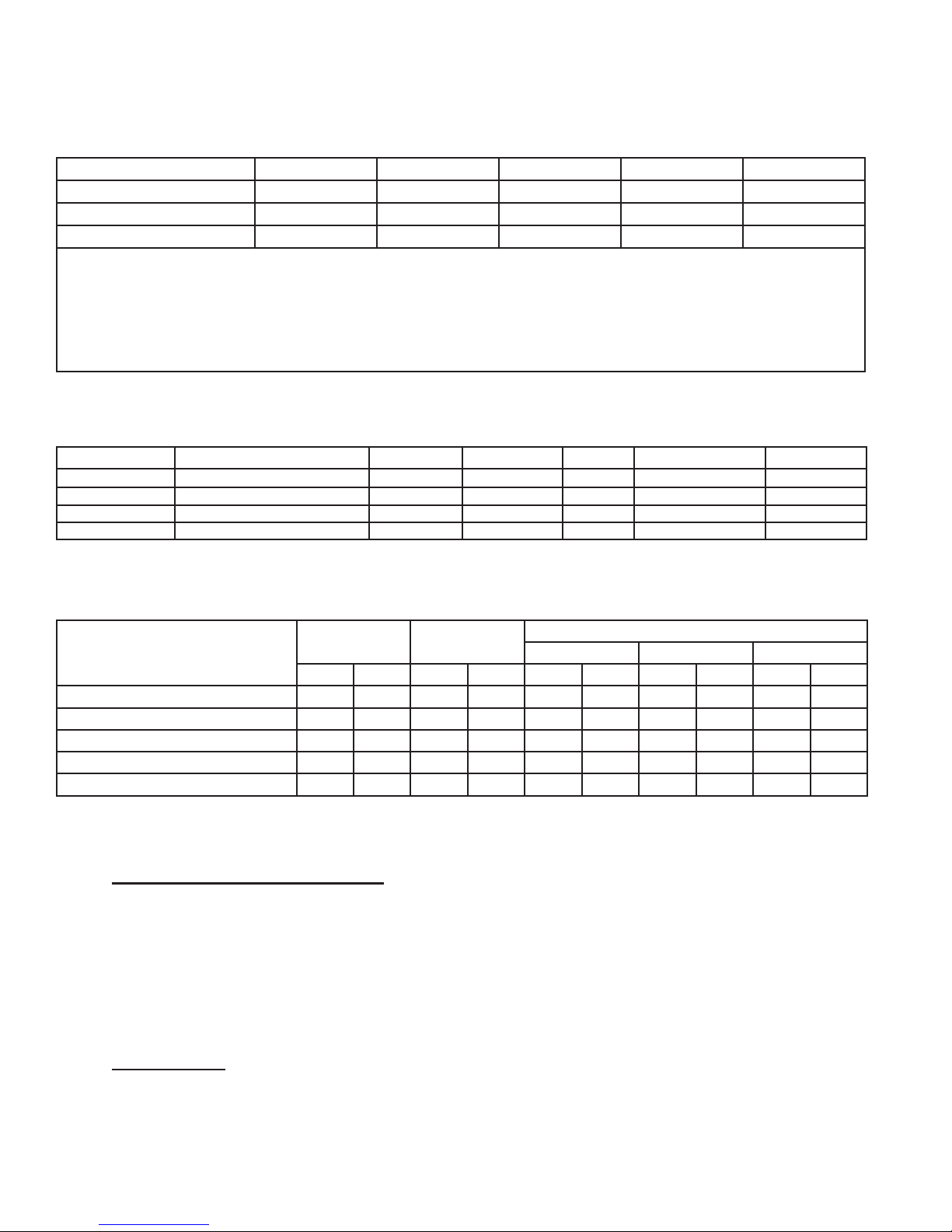

1.4 Weights and Filter Sizes

Complete electrical and performance specications and dimensional drawings are in the Product Data

Sheet.

Model Number ECUA90 ECUA120 ECUA150 ECUA180 ECUA240

Cooling BTUH

Rated Air Flow (CFM2) 3,500 4,000 5,000 6,000 8,000

ESP3 @ Rated Conditions 0.25 0.30 0.35 0.35 0.40

1

Cooling rated at 95°F (35°C) outdoor and 80°F DB/67° WB (26.5°C DB/19.5°C WB) return air

2

CFM=Cubic Feet per Minute

3

ESP=External Static Pressure

Ratings are with no outside air. Performance will be affected by altitude.

Ratings are at 230 volts for 208/230 volt units (“C” models), 460 volts for “D” models, 380 volts for “E” models, 575 volts for “Z”

models. Derate performance by 17% for ACE (380v. 3ø, 50 Hz) models

Operation of units at a different voltage from that of the rating point will affect performance and air ow.

MODEL Description INCHES MILLIMETERS PART NO. FILTERS PER UNIT MERV RATING

ECUA90/120/150 Exterior Access Return Air Filter 25" x 16" x 2" 635 x 406 x 51 80137 3 8

ECUA90/120/150 Interior Access Return Air Filter 15" x 20" x 2" 381 x 508 x 51 92365 3 8

ECUA180/240 Exterior Access Return Air Filter 25" x 16" x 2" 635 x 406 x 51 80137 4 8

ECUA180/240 Interior Access Return Air Filter 24" x 18" x 2" 610 x 457 x 51 81257 4 8

1

94,000 125,000 150,000 170,000 235,000

Table 1. Cooling Performance and Air Flow Ratings

Table 2. Return Air Filter Sizes

MODEL

ECUA90

ECUA120

ECUA150

ECUA180

ECUA240

1.5 General Operation

Refrigerant Cycle (Cooling Mode)

The air conditioners use R-410A refrigerant in a conventional vapor-compression refrigeration cycle to

transfer heat from air in an enclosed space to the outside. A motorized impeller assembly blows indoor

air across the evaporator. Cold liquid refrigerant passing through the evaporator is boiled into gas by

heat removed from the air. The warmed refrigerant gas enters the compressor where its temperature

and pressure are increased. The hot refrigerant gas condenses to liquid as heat is transferred to outdoor

air drawn across the condenser by the condenser fan. Liquid refrigerant is metered with a thermal

expansion valve (TXV) into the evaporator to repeat the cycle.

Heating Mode

Unit Weight

LBS KG LBS KG Inches MM Inches MM Inches MM

1,053 478.6 1,178 535.5 98 2,489 56 1,422 42 1,067

1,160 527.3 1,285 584.1 98 2,489 56 1,422 48 1,219

1,166 530 1,291 586.8 98 2,489 56 1,422 48 1,219

2,307 1,046 2,420 1,098 98 2,489 76 1,930 51 1,295

2,523 1,144 2,636 1,196 98 2,489 76 1,930 51 1,295

Shipping

Weight

Height Width Depth

Shipping Dimensions

Table 3. Shipping Weights & Dimensions

A wall-mounted thermostat controls the heating cycle of models which incorporate resistance heating

elements. On a call for heat, the thermostat closes the heat relay to energize the indoor fan and the

resistance elements.

6

ECU 04/2015 rev.3

Page 7

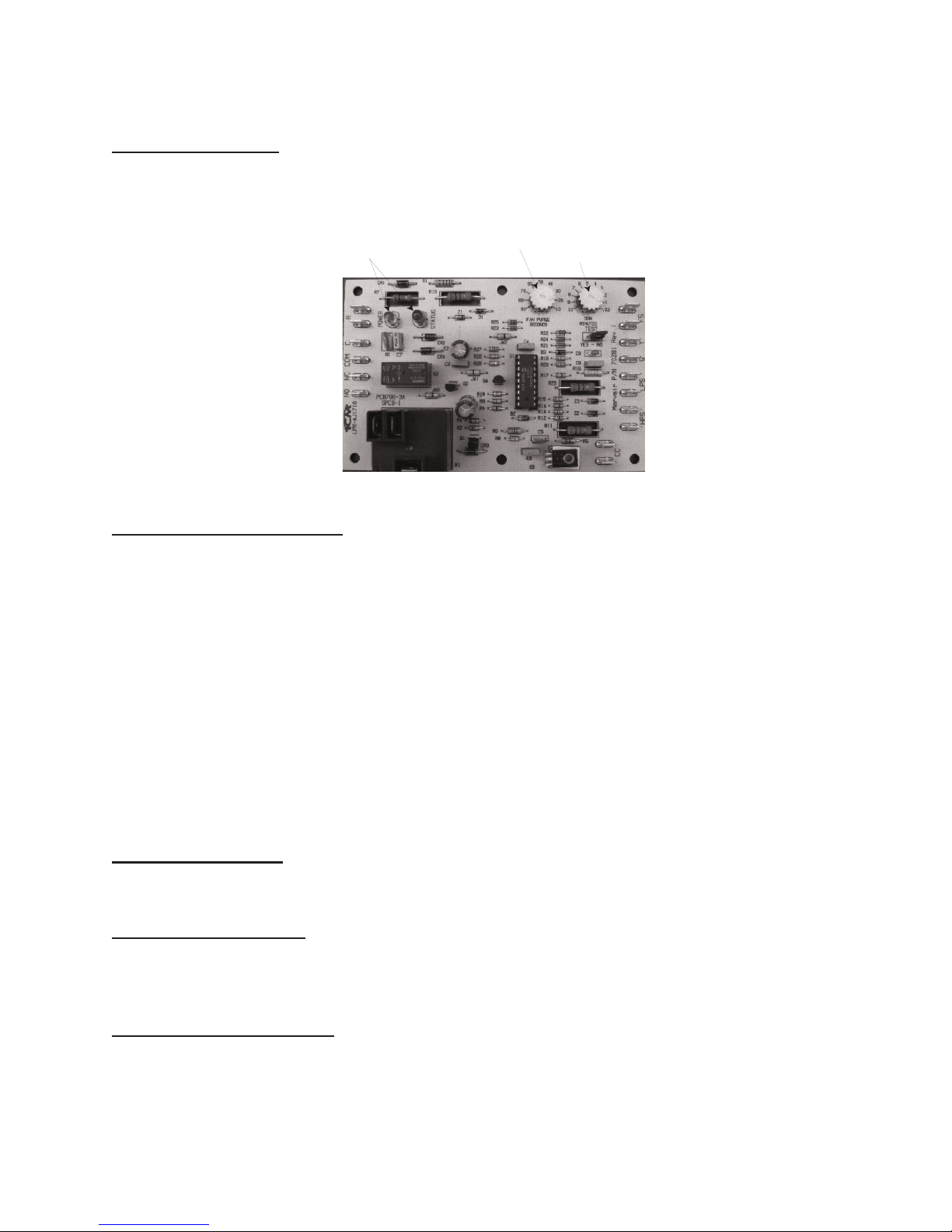

1.6 Electronic Control Board Mode of Operation

Normal

24 VAC power must be continuously applied to “R” and “C”. Upon a call for cooling “Y” and with

the high pressure switch (HPS) closed, the compressor will be energized. (Note: See the delay on

make feature.) The compressor will remain energized during the 3 minute timed low pressure by-pass

cycle. If the low pressure switch (LPS) is open after the 3 minute by-pass cycle, the compressor will

de-energize.

Lock-out

If either of the fault conditions (LPS or HPS) occurs twice during the same call for cooling, the control

board will enter into and indicate the lockout mode. In the lockout mode, the compressor is turned off.

If there is a call for indoor air ow “G”, the blower remains energized, the alarm output is energized and

the status LED will blink to indicate which fault has occurred. When the lockout condition is cleared, the

unit will reset if the demand for the thermostat is removed or when the power is reset. With the control

board, the user can now have either normally closed or normally open remote alarm dry contacts. The

air conditioners are factory wired to be normally open.

Delay on Break

If the compressor is de-energized due to a loss of a cooling “Y” call or the rst fault, the unit re-start

will be delayed 3 minutes from the time the contactor is de-energized. (Note: There is no delay on

break if the lockout condition is reset.)

Delay on Make

On initial power up only, the unit will wait 0.03 to 10 minutes from the cooling “Y” call before allowing the contactor to energize. The delay can be adjusted by the DOM wheel on the board. Factory

recommended wait is 3 minutes.

Low Pressure By-Pass Time

When starting, the low pressure switch (LPS) fault condition will be by-passed for 3 minutes before

the contactor is de-energized.

Post Purge

Upon a call for indoor airow “G” the blower will energize immediately. When in the cooling mode,

the blower will remain energized for 10 to 90 seconds (adjustable) after the compressor has been deenergized. The time period can be changed by fan purge wheel on the board. Factory setting is 90 seconds.

LED Indicator Lights

COLOR TYPE STATUS DESCRIPTION

Green Power Contstant On 24 VAC power has been applied

Red Status Contstant On Normal operation

Red Status 1 Blink High pressure switch has opened twice

Red Status 2 Blinks Low pressure switch has opened twice

High Pressure Switch

The high pressure switch is mounted on the liquid line. It is electrically connected to a lockout circuit

on the board which shuts down the system if the refrigerant pressure rises to 650 PSIG. This protects

the unit if airow through the condenser is blocked or if the outdoor fan motor fails.

Although the contacts of the high pressure switch close when the refrigerant pressure falls to approximately 450 PSIG, the system must be manually reset once the lockout circuit is activated. A manual

7

ECU 04/2015 rev.3

Page 8

reset is necessary to prevent harmful short-cycling. To reset switch, turn primary power off, then back

LEDs

POST PURGE

WHEEL

DELAY ON MAKE

(COMPRESSOR TIME DELAY)

WHEEL

on or turn thermostat system switch off, then back on.

Low Pressure Switch

The low pressure switch is mounted on the compressor suction line. It is designed to open if the refrigerant

pressure drops to 40 PSIG; it resets when the pressure rises to 60 PSIG. The switch protects the unit if

airow through the indoor blower is impeded, if the blower motor fails, or if there is a loss of refrigerant.

1.7 Optional Controls & Packages

Protective Coating Packages

Two corrosion protection packages are offered- one for the condenser section (the Coastal Environmental

package) and the other for the entire unit (the Coat-All Package).

The condenser protection package includes:

• Corrosion resistant fasteners

• Sealed or partially sealed condenser fan motor

• Two layer epoxy/urethane applied to all exposed internal copper and metal in the in the condenser

section

• An impregnated polyurethane on the condenser coil

The Coat-all package includes all of the above but also includes an impregnated polyurethane on the

evaporator coil and the two layer epoxy/urethane on all exterior and interior components and sheet metal.

(Note: the internal sheet metal which is insulated and the internal control box are not coated).

Dirty Filter Indicator

A diaphragm type of indicator measures the air pressure on either side of the lter and when the pressure

drops below the set point, a red LED is illuminated. The set point is adjustable.

Protective Coil Coatings

Either the condenser or evaporator coil can be coated. For harsh conditions, e.g., power plants, paper mills

or sites were the unit will be exposed to salt water, the condenser coil should be coated. Note: Cooling

capacity may be reduced by up to 5% on units with coated coils.

Cabinet Color and Material

The air conditioners are available in two standard cabinet colors -the standard grey with beige as an option.

The standard cabinet’s sides, top and front panels are constructed of 16 gauge painted steel. Contact your

ICE representative for color chips, custom colors and 316 stainless steel cabinets.

8

ECU 04/2015 rev.3

Page 9

Fresh Air Damper

Allows introduction of outside air into the building to provide positive pressurization. Field installed

on either the left or right hand side of the unit.

Dual Compressors With Lead/Lag Operation

Freeze Sensor On Indoor Coil

Prevents frost on the indoor coil caused by a loss of air ow or restrictive duct work. Field installed.

Filter Access From Return Air Grille

Factory or eld installed lter bracket allows changing and access to the lters from the return air grille.

See model ID, special option code “I”.

Reverse Air Flow Conguration

Location of Supply and Return Air Openings are reversed.

1.8 Electrical Operation

The compressor and condenser fan are energized with a contactor controlled by a 24 VAC pilot signal.

Some compressors incorporate an internal PTC crankcase heater that functions as long as primary power

is available. The heater drives liquid refrigerant from the crankcase and prevents loss of lubrication

caused by oil dilution. Power must be applied to the unit for 24 hours before starting the compressor.

The condenser (outside fan) motor is energized by the same contactor.

The indoor evaporator fan motor is controlled by the fan purge on the electronic control board.

9

ECU 04/2015 rev.3

Page 10

Figure 1a. Typical Electrical Schematic for Units with One Compressor

10

ECU 04/2015 rev.3

Page 11

NOTICE:

MODELS 180-240 HAVE TWO INDEPENDENT

ELECTRICAL CIRCUITS AND EACH ELECTRICAL

CIRCUIT IS WIRED THE SAME AS SHOWN.

Figure 1b. Typical Electrical Schematic for Units with Two Compressors

11

ECU 04/2015 rev.3

Page 12

Chapter 2 Installation

WARNING

Failure to observe and follow Warnings and Cautions and these Instructions could result

in death, bodily injury or property damage. Read this manual and follow its instructions

and adhere to all Cautions and Warnings in the manual and on the ICE unit.

2.1 Equipment Inspection

Concealed Damage

Inspect all cartons and packages upon receipt for damage in transit Remove cartons and check for

concealed damage. Important: keep the unit upright at all times. Remove access panels and examine

component parts. Inspect refrigerant circuit for fractures or breaks. The presence of refrigerant oil

usually indicates a rupture. If damage is apparent, immediately le a claim with the freight carrier.

Units that have been turned on their sides or tops may have concealed damage to compressor motor

mounts or to the oil system. If the unit is not upright, immediately le a claim for concealed damages

and follow these steps:

1. Set unit upright and allow to stand for 24 hours with primary power turned on.

2. Attempt to start the compressor after 24 hours.

3. If the compressor will not start, makes excessive noise, or will not pump, return the unit to the

freight carrier.

2.2 Installation Requirements

General

1. Inspect unit for completeness. Check for missing parts (e.g. hardware). Refer to the installation

kit information in section 2.3.

2. Remove access panels and check for loose wires. Tighten screw connections.

3. Complete and mail the warranty registration card.

You must consider all of the following when choosing the installation site:

1. Noise. Install the unit so that the least amount of noise will be transmitted to inhabited spaces.

2. Condensate Drainage. Condensate produced during operation must be discharged to a suitable

drain.

3. Placement.

A) Place the unit in a shaded area, if possible.

B) Install it above ground for protection against ooding.

C) The unit exhausts air. Be sure that the airow is not impeded by shrubbery or other obstruc-

tions.

D) When installing multiple units, please note the recommended clearances noted in Table 4.

4. Airow Requirements:

The maximum static pressure for the ECUA90 is 1.2 IWG (300 Pa) and 1.8 IWG (450 Pa) for the

ECUA120 and 150. Keep duct lengths as short as possible. Do not obstruct airow through the

unit.

Duct work should be designed and installed in accordance with all applicable safety codes and

standards. Industrial Climate Engineering strongly recommends referring to the current edition of

12

ECU 04/2015 rev.3

Page 13

the National Fire Protection Association Standards 90A and 90B before designing and installing duct

work. The duct system must be engineered to insure sufcient air ow through the unit to prevent

over-heating of the heater element. This includes proper supply duct sizing, sufcient quantity of

supply registers, and adequate return and lter areas. Duct work must be of correct material and must

be properly insulated. Duct work must be constructed of galvanized steel with a minimum thickness

of .019 inches. Duct work must be rmly attached, secured, and sealed to prevent air leakage. See

section 2.4 for additional duct work requirements.

5. Clearances:

Note the minimum clearances required for proper operation and service.

MODEL

ECUA90/120/150/180/240 24 inches (76 cm) 18 inches (46 cm) 24 inches (61 cm)

MIN. CLEARANCE AROUND

SIDES (SINGLE UNIT)

MIN. CLEARANCE BETWEEN

UNITS (TWO UNITS)

MIN. SPACE

ABOVE UNIT

Table 4. Minimum Clearances

6. Codes:

Make sure your installation conforms to all applicable electrical, plumbing, building, and municipal

codes. Some codes may limit installation to single story structures.

7. Electrical Supply:

The power supply must have the appropriate voltage, phase, and ampacity for the model selected.

Voltage must be maintained above minimum specied values listed below. Refer to the data sticker

on the unit for ampacity requirements.

Electrical Rating Designations* A C D Z

Nominal Voltage 208/230 208/230 460 575

Phase 1 3 3 3

Minimum Voltage 197 197 414 518

Maximum Voltage 253 253 506 600

* Letters refer to model number code designations. Refer to page 5.

Table 5. Voltage Limitations

2.3 Installation Materials

The ECU is shipped with a top bracket and lifting brackets. The top bracket provides a method of sealing

the top of the unit from water intrusion. The bracket is shipped attached to the top of the unit. Before

installing the ECU, remove the bracket and reattach as described in Section 2.5

The Lifting brackets are shipped attached to the back panel of the ECU. These brackets provide a method

for lifting the ECU. The installation of the brackets is described in Section 2.6.

13

ECU 04/2015 rev.3

Page 14

Kit Components:

Accessories:

The package may include other factory-supplied items (optional):

P/N Description

S/04581 CommStat 3 Controller, Solid State Lead/Lag Controller

S/07846 CommStat 4 Controllers, Solid State Lead/Lag Controller

50123 Digital thermostat. 1 stage heat, 1 stage cool. 7 day programmable. Fan switch: Auto &

On. Auto-change over. Keypad lockout. Non-volatile program memory.

92508 Double deection Aluminum supply grille for ECU90/120/150. 42½" x 15½"

(1,080 mm x 394 mm)

92507 Aluminum Return Grille for ECU90/120/150. 42½" x 21½" (1,080 mm x 546 mm)

Additional Items Needed:

Additional hardware and miscellaneous supplies (not furnished by ICE®) are needed for installation.

The list below contains approximate quantities of items typically needed for mounting a unit on a

wood frame wall structure. Concrete or berglass structures have different requirements. ICE cannot

recommend a specic method of attaching the air conditioner to the building due to the wide variety

of building types, code requirements, wall construction and specic installation conditions. The installation of the air conditioner to the building must take in to account all of these factors and follow best

industry practices to provide a safe and secure attachment to the building.

• (14) mounting bolts for unit mounting anges. The length needed is typically the wall thickness

plus one inch (25 mm).

• (28) washers

• (14) hex nuts

• Silicone Sealer to seal around cracks and openings

• Minimum 5 conductor low voltage multicolored wire cable (i.e. thermostat wire)

• Appropriate electrical supplies such as conduit, electrical boxes, ttings, wire connectors, etc.

• High voltage wire, sized to handle the MCA (minimum circuit ampacity) listed on the data plate.

• Over-Current Protection Device sized in accordance with the MFS (maximum fuse size) listed on

the unit data plate.

WARNING

FIRE HAZARD

Improper adjustment, alteration, service, maintenance or installation could cause serious

injury, death and/or property damage.

Installation or repairs made by unqualied persons could result in hazards to you and

others. Installation MUST conform with local codes or, in the absence of local codes, with

codes of all governmental authorities have jurisdiction.

The information contained in this manual is intended for use by a qualied service

agency that is experienced in such work, is familiar with all precautions and safety

procedures required in such work, and is equipped with the proper tools and test

instruments.

14

ECU 04/2015 rev.3

Page 15

2.4 Porting and Duct Work

General Information

Note: The following instructions are for general guidance only. Due to the wide variety of installation possibilities, specic instructions will not be given. When in doubt, follow standard and accepted

installation practices, or contact ICE™ for additional assistance.

Wall Openings

Measure the dimensions of the supply and return ports on the unit.

Cut the openings in the exterior wall for the supply and return. IMPORTANT: All units with electric

heat must have 1" (25.4mm) clearance on all four sides of the supply outlet duct ange on the

unit. The 1" (25.4mm) clearance must extend on all sides of the supply duct for the rst 3 feet

(1 meter) from the unit.

IMPORTANT: ICE™ requires a minimum of 1" (25.4mm) from the surface of any supply ducts to

combustible material for the rst 3 feet (1 meter) of the duct.

Ducting

Extensions should be cut ush with the inside wall for applications without duct work.

Applications using duct work should be designed and installed in accordance with all applicable safety

codes and standards. ICE strongly recommends referring to the current edition of the National Fire

Protection Association Standards 90A and 90B before designing and installing duct work. The duct

system must be engineered to insure sufcient air ow through the unit to prevent over-heating of the

heater element. This includes proper supply duct sizing, sufcient quantity of supply registers, adequate

return and lter area. Ductwork must be of correct material and must be properly insulated. Duct work

must be constructed of galvanized steel with a minimum thickness of .019 inches for the rst 3 feet (1

meter). Ductwork must be rmly attached, secured and sealed to prevent air leakage. Do not use duct

liner on inside of supply duct within 4 feet (122cm) of the unit.

Galvanized metal duct extensions should be used to simplify connections to duct work and grilles. Use

fabric boots to prevent the transmission of vibration through the duct system. The fabric must be U.L.

rated to a minimum of 197°F (92°C).

Minimum Airow Requirements

The duct system must be engineered to assure sufcient air ow through the unit even under adverse

conditions such as dirty lters, etc.

2.5 Top Flange Installation (See Figure 2)

1. All models have built-in side mounting anges.

2. Attach the top ange to the top of the air conditioner. The holes in the top of the air condtioner have

been predrilled. Remove the 4 screws in these holes and use these screws to attach the top ange

to the air conditioner.

3. Apply a bead of silicone sealer on the wall side of the bottom support brackets on the unit. Circle

the mounting holes with the silicone bead.

15

ECU 04/2015 rev.3

Page 16

Figure 2. Top Flange and Lifting Bracket Installation

2.6 Installing the Lifting Brackets

The ECU90/120/150 have lifting brackets that can be installed on the top of the side panels. These

brackets allow the unit to be picked up thru lifting eyes in the brackets.The lifting brackets are shipped

attached to the back panel of the ECU. Attach the brackets to the left and right side panels as shown in

Figure 2. The 4 screws for attaching the brackets are shipped in the holes at the top of the side panels.

When attaching the brackets, make sure the top of the bracket is angled towards the center of the ECU.

2.7 Mounting The Unit

1. For wiring into the back of unit, locate the lower of the two knockouts on the wall side of the unit.

Drill a one inch hole in the shelter wall to match this opening. Allow sufcient clearance to run

3/4" conduit through the hole and to the unit.

2. Lift the unit into position using an appropriate and safe lifting device.

3. Make sure that the duct anges are properly aligned with the wall opening. Adjust as necessary.

4. Note the holes in each side ange. Using the holes for guides, drill holes through the wall with a

drill bit. Insert the bolts through the anges. Install nuts and washers on the inside of the shelter.

Tighten the bolts to secure the unit.

5. Apply a bead of silicone where the side and top anges contact the exterior wall.

6. On the inside of the shelter, install the wall sleeves in the supply and return air openings. The sleeves

may be trimmed to t ush with the inside wall.

7. Check the t of each sleeve to its mating ange for possible air leaks. Apply silicone sealer to close

any gaps. Install the air return and supply grilles.

16

ECU 04/2015 rev.3

Page 17

For units with electric heat, a one inch clearance is required around the duct extensions. The duct extensions must be constructed of

galvanized steel with a minimum thickness of .019” as per the NFPA standards 90A & 90B.

Figure 3. Air Conditioner Wall Mount Detail

2.8 Electrical Connections

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow safety warnings exactly could result in serious injury, death, and/or

property damage.

Turn off electrical power at fuse box or service panel BEFORE making any electrical

connections and ensure a proper ground connection is made before connecting line

voltage.

Important

All electrical work must meet the requirements of local codes and ordinances. Work should be

done only by qualied persons.

The units may incorporate an internal crankcase heater for compressor protection. The crankcase

heater must be energized for at least 24 hours prior to starting the compressor.

Scroll compressors, like several other types of compressors, will only compress in one rotational direction.

The direction of rotation is not an issue with single-phase compressors since they will always start and

run in the proper direction. However, three phase compressors will rotate in either direction depending

upon phasing of power. Since there is a 50-50 chance of connecting power in such a way as to cause

rotation in the reverse direction, it is imperative to conrm that the compressor is rotating in the proper

direction at the initial eld start-up of the system. Verication of proper rotation is made by observing

17

ECU 04/2015 rev.3

Page 18

that the suction pressure drops and the discharge pressure rises when the compressor is energized. An

alternate method of verication for self contained system with small critical refrigerant charges, where

the installation of gauges may be objectionable, can be made by monitoring the temperature of the

refrigerant lines at the compressor. The temperature should rise on the discharge line while the suction

line temperature decreases. Reverse rotation also results in a substantially reduced current draw when

compared to tabulated values.

There is no negative impact on durability caused by operating three phase compressors in the reversed

direction for a short duration of time, usually dened as less than one hour. However, after several

minutes of operation the compressor's internal protector will trip. The compressor will then cycle on

the protector until the phasing is corrected. Reverse operation for longer than one hour may have a

negative impact on the bearings.

To change the rotation, turn off power to the unit and reverse L1 & L2 at the disconnect in the air

conditioner.

The middle front panel provides access to the electrical/control box and to the lters. This panel has hinges

on the left and right hand side. This panel should ONLY be opened by using the two hinges on the left

side OR the two hinges on the right side. NEVER OPEN ALL FOUR HINGES SIMULTANEOUSLY.

If all four hinges are opened simultaneously, the front panel will drop and may cause serious injury

and damage the panel.

DANGER

NEVER open all four hinges simultaneously. The panel should ONLY be opened by using

the two hinges on the left side OR the two hinges on the right side.

High Voltage Wiring

The power supply should have the proper voltage, phase, and ampacity for the selected model.

1. Refer to the electrical data on the data sticker on the unit for eld wiring requirements of the unit.

Size the incoming power supply lines and the fuse(s) or HACR breaker(s) according to requirements

described in the National Electric Code. Run the power conductors through the knockouts on the

side or back of the unit. Use appropriate conduit and strain reliefs.

CAUTION

Note: Power supply service must be within allowable range (+10% - 5%) of rated voltage

stamped on the unit rating plate. To operate nominal 230/208V unit at 208V, change the

transformer line tap from 240V to 208V following the instruction on wiring label in unit.

2. Connect the wires to the input side of the internal breaker or terminal block L1, L2, & L3 for three-

phase models.

3. Install the ground wire on the ground lug.

4. For units designed for operation on 208/230V, 60Hz power supply, the transformer is factory wired

for a 230V power supply. For a 208V power supply, remove the orange lead from the transformer

and connect the red lead. Insulate the orange lead.

CAUTION

The external breaker(s) that provide power to the air conditioner must be sized per the

maximum Fuse Size (MFS) shown on the Unit's data label.

18

ECU 04/2015 rev.3

Page 19

Dual Unit Phasing

For applications where one controller operates two units, e.g., the CommStat 4.

1. Wire each unit as described in steps 1 through 4 above.

2. Test for proper phasing as follows:

A. Power up the units.

B. Using an AC volt meter set to the 300 volt scale, measure voltage between terminal L1 on the

compressor contactor of unit #1 and terminal L1 on the compressor contactor of unit #2 If

voltage is present, units are wired out of phase and must be rewired.

C. If units are not in phase, turn off power and reverse the eld power leads connected to the

internal circuit breaker on one of the units only.

D. Restore power and retest the phase (step B). When the voltage reads "0", the units are in phase.

E. Turn off power and proceed.

Low Voltage Wiring

IMPORTANT. The following instructions are generic wiring instructions and may not be applicable

for air conditioners with various options. Always refer to the wiring diagram in the air conditioner for

the proper method to wire your unit.

1. On single units, pull the low voltage wiring (e.g., 18 gauge 4-conductor Class 2 thermostat wire)

from the air conditioners into the thermostat / subbase assembly. See Figure 4a for connections to

various thermostats.

2. Mount the thermostat on the wall of the shelter. The thermostat should be located so that the supply

air from the unit does NOT blow directly on to the thermostat. Connect the thermostat to the terminal

block in the air conditioner as shown in Figure 6a.

3. On dual units, refer to either the ICE CommStat 3 or CommStat 4 Controller Specication sheet.

Wire the two air conditioners to the Lead/Lag Controller, according to the wiring diagram on the

specication sheet.

Remote Signalling:

Terminals 5 & 7(N.O.) and 6 & 7 (N.C.) on the air conditioners terminal board are dry

contacts which can be used for remote signalling in the event of a/c cutoff on low or high pressure limit.

Continuous fan operation: For continuous indoor fan operation on single units, install a jumper between

terminals 8 and 3.

CommStat 3 Controller (See Figure 4b)

The CommStat 3 Controller by ICE is a solid state control package designed to operate a fully

or partially redundant air conditioning system for a telecommunication cabinet or shelter. The

CommStat 3 Controller is factory programmed with standard industry set points to facilitate installation.

If desired, each of the set points can be quickly and easily changed in the eld by the installer. See

CommStat 3 Product Data Sheet for installation and programming instructions.

CommStat 4 Lead /Lag Controller

Please refer to the Product Data sheet for the CommStat 4 controller for complete instructions

on installing and programming this controller.

19

ECU 04/2015 rev.3

Page 20

Figure 4a. Thermostat Connection Diagram

Figure 4b. CommStat 3 Wiring Diagram

20

ECU 04/2015 rev.3

Page 21

3.1 Check-Out of Cooling Cycle

Important: Be sure that the crankcase heater (if used) has been energized for at least 24 hours

before starting the unit(s). Double-check all electrical connections before applying power. All air

conditioners with scroll compressors running on 3Ø power must be checked for proper rotation

during the initial start-up. Please refer to Section 2.8 for determining if the 3Ø compressors are

rotating correctly. Incorrect rotation can damage the compressor and is not covered by the warranty

Procedure:

1. Set the cooling set point temperature on the wall thermostat to a point higher than the ambient tem-

perature. Set the heating set point temperature to a temperature that is lower than the ambient.

2. Set the thermostat system switch in the AUTO position. Nothing should operate at this time.

3. Set the time delay in the control box to three minutes. See Section 1.6.

4. Slowly lower the thermostat's cooling set point temperature until the switch closes. The indoor fan

should operate.

Once the indoor fan turns on, allow approximately three minutes for the compressor to start.

5. To stop cooling, slowly raise the thermostat cooling set point to a temperature higher than the

ambient.

Chapter 3 Start-Up

If the unit fails to operate, refer to the troubleshooting information in Chapter 4.

Follow the same procedure for additional units.

NOTE: The fan purge allows the indoor fan to run for approximately 90 seconds after the compressor

is off. This operation provides a small improvement in system rated efciency.

3.2 Check-Out of Heating Cycle

Procedure: (Applies only to units with resistance elements)

1. Raise the heating set point temperature to a setting which is higher than the ambient temperature.

The fan and electric heat should immediately cycle on.

2. Move the system switch to the "OFF" position. All functions should stop.

21

ECU 04/2015 rev.3

Page 22

4.1 Overview

The middle front panel provides access to the electrical/control box and to the lters. This panel has hinges

on the left and right hand side. This panel should ONLY be opened by using the two hinges on the left

side OR the two hinges on the right side. NEVER OPEN ALL FOUR HINGES SIMULTANEOUSLY.

If all four hinges are opened simultaneously, the front panel will drop and may cause serious injury

and damage the panel.

NEVER open all four hinges simultaneously. The panel should ONLY be opened by using

the two hinges on the left side OR the two hinges on the right side.

A comprehensive understanding of the operation of the air conditioner is a prerequisite to troubleshooting. Please read the Chapter 1 for basic information about the unit.

Our air conditioners are thoroughly tested before they are shipped from the factory. Of course, it is

possible that a defect may escape undetected, or damage may have occurred during transportation.

However, the great majority of problems result from installation errors.

If you experience difculties with the unit, please review the installation steps in Chapter 2.

Much time can be saved by taking a thoughtful and orderly approach to troubleshooting. Start with a

visual check - are there loose wires, crimped tubing, missing parts, etc? Begin deeper analysis only

after making this initial inspection.

Chapter 4 Troubleshooting

DANGER

The troubleshooting information in this manual is basic. The troubleshooting section contains problem/

solution charts for general problems, followed by a compressor section.

Not every problem can be anticipated. If you discover a problem that is not covered in this manual, we

would be very grateful if you would bring it to the attention of our service department for incorporation

in future revisions.

As always, please exercise caution and good judgement when servicing the air conditioner. Use only

safe and proven service techniques. Use refrigeration goggles when servicing the refrigeration circuit.

The refrigerant circuit has hot surfaces, and the electrical voltages inside of

the unit may be hazardous or lethal. SERVICE MAY BE PERFORMED ONLY BY

QUALIFIED AND EXPERIENCED PERSONS.

4.2 Failure Symptoms Guide

PROBLEM/SYMPTOM LIKELY CAUSE(S) CORRECTION

A. Unit does not run.

NOTE: An internal anti-short-cycle

timer will prevent the unit

from starting for .2 to 8

minutes following start-up.

1. Power supply problem.

2. Tripped internal disconnect.

3. Shut off by external thermostat or

thermostat is defective.

WARNING

1. Check power supply for adequate phase and voltage.

Check wiring to unit and external breakers or fuses.

2. Check internal circuit protection devices for continuity.

3. Check operation of wall-mounted thermostat.

4. Unit off on high or low pressure limit.

5. Internal component or connection

failure.

22

4. Reset pressure switch.

5. Check for loose wiring. Check components for failure.

ECU 04/2015 rev.3

Page 23

PROBLEM/SYMPTOM LIKELY CAUSE(S) CORRECTION

B. Unit runs for long periods or continu-

ously; cooling is insufcient.

C. Unit cycles on high/low pressure

limit.

D. Unit blows fuses or trips circuit

breaker.

1. Dirty lter or reduced airow

2. Low refrigerant.

3. Component failure.

4. Unit undersized for job.

1. Loss or restriction of airow.

2. Restriction in refrigerant circuit.

3. Refrigerant overcharge (following

eld service)

4. Defective pressure control.

1. Inadequate circuit ampacity.

1. Check air lter(s). Check blower operation. Remove

airow restriction.

2. Check for proper charge and possible refrigerant leak.

3. Check internal components, especially compressor for

proper operation.

4. Add additional units for greater capacity.

1. Check blower assembly for proper operation. Look

for airow restrictions, e.g.. the air lter. Check blower

motor and condenser fan.

2. Check for blockage or restriction, especially lter drier

and capillary tube assembly.

3. Evacuate and recharge to factory specications.

4. Check limit cutout pressures. Control is set to actuate at

approximately 60 PSIG (low pressure) and 650 PSIG (high

pressure).

1.

Note electrical requirements in Chapter 2 and correct

as necessary.

2. Short, loose, or improper connection

in eld wiring.

3. Internal short circuit. Loose or

improper connection(s) in unit.

4. Excessively high or low supply volt-

age or phase loss (3ø only).

E. Water on oor near unit. 1. Obstruction in condensate line.

2. Obstruction or leak in condensate

pan.

3. Unit is not level.

F. No space heating or reduced heating

(units equipped with resistance elements)

1. Defective heating element(s).

2. Thermal limit open.

3. Defective heater contactor.

2. Check eld wiring for errors.

3. Check wiring in unit. See wiring and schematic dia-

grams. Test components (especially the compressor)

for shorts.

4. Note voltage range limitations specic to the compressor troubleshooting section.

1. Check for clog or restriction.

2. Check pan for leak or blockage.

3. Level unit.

1. Check resistance element(s) for continuity.

2. Check continuity across thermal limit switch.

3. Check relay for proper operation. Replace if defective.

23

ECU 04/2015 rev.3

Page 24

4.3 Compressor

Troubleshooting

NOTE: It is important to rule out other component failures before condemning the compressor.

The following electrical tests will aid diagnosis:

1. Start-Up Voltage: Measure the voltage at the compressor contactor during start-up. The voltage

must exceed the minimum shown in Table 5, section 2.2, or compressor failure is likely. A low

voltage condition must be corrected.

2. Running Amperage: Connect a clip-on type ammeter to the (common) lead to the compressor.

Turn on the supply voltage and energize the unit. The compressor will initially draw high amperage;

it should soon drop to the RLA value or less. If the amperage stays high, check the motor winding

resistances.

NOTE: Feel the top of the compressor to see if it has overheated. If it is hot, the internal overload

may be open. You may have to wait several hours for it to reset.

3. Motor Winding Resistances: Using a digital volt-ohm meter (VOM), measure the resistance

across the compressor windings as shown below.

SINGLE

PHASE

R

2

S

Resistance can be measured as shown above. Any deviation from above values could indicate a

defective compressor.

4. High Voltage/Insulation Test: Test internal leakage with a megoh meter. Attach one lead to the

compressor case on a bare metal tube and to each compressor terminal to test the motor windings.

A short circuit at high voltages indicates a motor defect. Do not do this test under vacuum.

5. On single phase models, check the capacitor by substitution.

4.4 Control Board Diagnosis

The control board (see section 1.6 for a complete description of the control board) has a red diagnostic

LED which indicates the lockout fault. The control board will enter into and indicate lockout if either

of the fault conditions (LPS or HPS) occur twice.

The contactor must be closed before the rst fault condition can be recognized by the control board.

The contactor will be closed 3 minutes after the unit is energized and only if cooling is required. The

rst fault condition will open the contactor and shutdown the unit. The contactor on the unit that has

the fault condition must be closed before the second fault condition can be recognized by the control

board. The contactor on the unit with the fault condition will close after 3 minutes if the unit is still

calling for cooling and if the fault condition no longer exists. If you get a second fault condition, the

contactor will open and shutdown the unit. The “red” led will have one blink if the high pressure switch

has opened twice and will have two blinks if the low pressure switch has opened twice. The unit must

be in the cooling mode (compressor contactor Closed) before a fault condition can occur.

C

R3 > R2 > R

R

1

R3 = R2 + R

R

R

3

1

1

THREE

PHASE

T

1

3

R3 = R2 = R

R

1

T

3

R

2

T

R

2

1

24

ECU 04/2015 rev.3

Page 25

The middle front panel provides access to the electrical/control box and to the lters. This panel has hinges

on the left and right hand side. This panel should ONLY be opened by using the two hinges on the left

side OR the two hinges on the right side. NEVER OPEN ALL FOUR HINGES SIMULTANEOUSLY.

If all four hinges are opened simultaneously, the front panel will drop and may cause serious injury

and damage the panel.

NEVER open all four hinges simultaneously. The panel should ONLY be opened by using

the two hinges on the left side OR the two hinges on the right side.

5.1 Scheduled Maintenance

Industrial Climate Engineering strongly recommends that the air conditioner be serviced a minimum

of twice a year – once prior to the heating season and once prior to the cooling season. At this time

the lters, evaporator coil, condenser coil, the cabinet, and condensate drains should be serviced as

described below. Also at this time, the air conditioner should be operated in the cooling and heating

cycles as described in Chapter 3, Start-Up. In addition to this seasonal check-out, the air conditioner

should be maintained as follows:

Air Filter

Replace the air lter whenever it is visibly dirty. Never operate the unit without the lter in place. Depending upon the conguration of your unit, access to the lter can be either from the outside through

the hinged door or from the return grille on the inside of the building.

Chapter 5 Maintenance

DANGER

Evaporator

If the evaporator becomes clogged or dirty, it may be cleaned by careful vacuuming or with a commercial evaporator cleaning spray. DO NOT use a solvent containing bleach, acetone, or ammable

substances. Turn off power before cleaning. Be careful not to wet any of the electrical components.

Be sure the unit has dried before restarting.

Condenser

Periodically inspect the outdoor condenser coil and the cabinet air reliefs for dirt or obstructions.

Remove foreign objects such as leaves, paper, etc.

If the condenser coil is dirty, it may be washed off with a commercial solvent intended for this purpose.

TURN OFF POWER BEFORE CLEANING! Be sure that all electrical components are thoroughly

dry before restoring power. Use a n comb of the correct spacing to straighten mashed or bent ns.

Cabinet

The cabinet may be cleaned with a sponge and warm, soapy water or a mild detergent. Do not use

bleach, abrasive chemicals or harmful solvents.

Drains

The condensate is drained from the condensate pan through two drains – one on the left side of the

pan and the other on the right side. The condensate lines drain to the outside at the bottom of the unit

through the base pan. Each of the drain lines is looped to form a trap.

Regularly check each drain line to make sure it is not obstructed. If a commercial drain solvent is used,

ush out the drain pan and system with sufcient water to remove the solvent. Some solvents can cause

the drain pan to corrode.

Lubrication

Oiling of the condenser fan motor or the evaporator blower motor is not recommended.

25

ECU 04/2015 rev.3

Page 26

6.1 Limited Product Warranty

If any part of your Industrial Climate Engineering™ Environmental Control Unit (ECU) fails because

of a manufacturing defect within eighteen months from the date of original shipment by ICE or within

twelve months from the date of original start-up, whichever is the earlier date, ICE will furnish without

charge, EXW Cordele, Georgia, the required replacement part. Any transportation, related service labor,

diagnosis calls, lter, driers and refrigerant are not included. The owner must provide proof of the

date of the original start-up. The owner’s registration card led with ICE, the contractor’s invoice, the

certicate of occupancy or similar document are examples of proof of the date of the original start-up.

The responsibility of the Owner of the Equipment includes the following:

1. To operate the equipment according to the manufacturer’s instructions.

2. To provide easy accessibility for service.

3. To check and reset any circuit breaker(s) and/or disconnect(s) before calling for service.

4. To keep the unit clean and free of dirt.

5. To replace any lters as required.

6. To keep the outdoor coil section clean and free of leaves, paper, etc.

7. To pay the charges incurred when any of the above have not been done.

8. To pay for repair or replacement of any material or part other than those within the ICE unit

or thermostat itself.

Chapter 6 Warranty

The owner of the product may ship the allegedly defective or malfunctioning product or part to ICE, at

such owner’s expense, and ICE will diagnose the defect and, if the defect is covered under this warranty,

ICE will honor its warranty and furnish the required replacement part. All costs for shipment and risk of

loss during shipment of the product or part to ICE and back to the owner shall be the responsibility and

liability of the owner. Upon written request by an owner, ICE may arrange for remote diagnosis of the

allegedly defective or malfunctioning product or part but all costs for transportation, lodging and related

expenses with regard to such diagnostic services shall be the responsibility and liability of the owner.

An owner requesting performance under this Warranty shall provide reasonable access to the allegedly

defective or malfunctioning product to ICE and its authorized agents and employees.

This warranty only applies to products purchased and retained for use within the U.S.A, Canada and

Mexico. This warranty does not cover damage caused by improper installation, misuse of equipment

or negligent servicing.

THIS WARRANTY AND SERVICE POLICY CONSTITUTE THE EXCLUSIVE REMEDY OF ANY

PURCHASER OF A ICE ECU AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR USE, TO THE FULLEST EXTENT PERMITTED BY LAW. IN NO

EVENT SHALL ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR USE

EXCEED THE TERMS OF THE APPLICABLE WARRANTY STATED ABOVE AND ICE SHALL

HAVE NO OTHER OBLIGATION OR LIABILITY. IN NO EVENT SHALL ICE BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES OR MONETARY DAMAGES.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE

OTHER RIGHTS WHICH

VARY FROM STATE-TO-STATE. Some states do not allow limitations or exclusions, so the above

limitations and exclusions may not apply to you.

26

NEW

ECU 04/2015 rev.3

Page 27

Chapter 7 Start-Up Check List

The middle front panel provides access to the electrical/control box and to the lters. This panel has hinges

on the left and right hand side. This panel should ONLY be opened by using the two hinges on the left

side OR the two hinges on the right side. NEVER OPEN ALL FOUR HINGES SIMULTANEOUSLY.

If all four hinges are opened simultaneously, the front panel will drop and may cause serious injury

and damage the panel.

NEVER open all four hinges simultaneously. The panel should ONLY be opened by using

the two hinges on the left side OR the two hinges on the right side.

7.1 Start-Up & Commissioning Form

Please complete the information on this form and return to Marvair by mail or fax. The mailing address

and fax number can be found at the end of the form.

A. Equipment Information

Date: ________________Equipment Owner _______________________________________

Installing Company: _____________________________Installer: ____________________

Address: _______________________________________ State _______________________

City: __________________________________________

DANGER

ICE Air conditioner: Model No. _____________________________________________

Serial No. _____________________________________________

Compressor: Model No. _____________________________________________

Serial No. _____________________________________________

Compressor: Model No. _____________________________________________

Serial No. _____________________________________________

B. Pre-Start Up

Is there any shipping damage? ❒Yes ❒No

If so, where? ________________________________________________________________

Will this damage prevent starting the unit? ❒Yes ❒No

Check Power Supply, does it agree with data sticker on air conditioner? ❒Yes ❒No

Has the ground wire been connected? ❒Yes ❒No

Has the circuit protection been sized and installed properly? ❒Yes ❒No

Controls

Are the thermostat control wiring connections made and checked? ❒Yes ❒No

Are all wiring terminals (including main power supply) tight? ❒Yes ❒No

If unit has a crankcase heater, has it been energized for 24 hours? ❒Yes ❒No

On a 208/230 v. units is control transformer (24 AC) wired for correct voltage? ❒Yes ❒No

27

ECU 04/2015 rev.3

Page 28

Condensate Section

Has water been placed in drain pan to conrm proper drainage? ❒Yes ❒No

Are correct lters in place? ❒Yes ❒No

Refrigerant Piping

If leaks are found, report any leaks to ICE Warranty Service Dept.

C. Check Rated Voltage at Terminal Block for Imbalance before starting of Unit.

❒208/230V 1 Phase ❒208/230V 3 Phase ❒460V 3 Phase

❒380V 3 Phase 50Hz. ❒575 3 Phase 60 Hz.

Measured Line to Line Volts L1&L2_______V. L1&L3 ________V. L2&L3______V.

(L1&L2 + L1&L3 + L2&L3)/3 = Avg. Voltage = _______________

Max. Deviation from avg. voltage = ______________volts

Voltage imbalance = (100 x Max. Deviation)/avg. Voltage = ___________%

A voltage deviation greater than 2% with the unit running should be addressed and corrected. Excess

voltage deviation can cause the compressor to overheat and to operate inefciently.

Example: Maximum Deviation from Average Voltage X 100 (for Percent)

Average voltage

Measured Voltages:

L1 & L2 = 241 Volts

L1 & L3 = 243 Volts = 717 / 3 = 239 Average Voltage

L2 & L3 = 233 Volts

239 - 233 = 6

239 X 100=2.5% Voltage Unbalance

Three phase units only check fan & compressor rotation.

28

ECU 04/2015 rev.3

Page 29

D. Heating Mode Check & Record Readings

Room Temperature ________ ________

Outside Temperature ________ ________

Evap. Entering Air DB Temp ________ ________

Evap. Entering Air WB Temp ________ ________

Evap. Leaving Air DB Temp ________ ________

Evap. Leaving Air WB Temp ________ ________

Heater Contactor Amps (L1) ________ ________

Heater Contactor Amps (L2) ________ ________

Heater Contactor Amps (L3) ________ ________

E. Cooling Mode Check & Record Refrigerant Pressures

Recheck voltage imbalance in cooling mode:

Circuit 1 Circuit 2

(if applicable)

Measured Line to Line Volts L1&L2_______V. L1&L3 ________V. L2&L3______V.

(L1&L2 + L1&L3 + L2&L3)/3 = Avg. Voltage = _______________

Max. Deviation from avg. voltage = ______________volts

Voltage imbalance = (100 x Max. Deviation)/avg. Voltage = ___________%

29

ECU 04/2015 rev.3

Page 30

After 10 minutes of compressor operation, record the following:

Circuit 1 Circuit 2

(if applicable)

Room Temperature ________ ________

Outside Temperature ________ ________

Suction Pressure ________ ________

Suction Line Temperature ________ ________

Discharge Pressure ________ ________

Discharge Line Temperature ________ ________

Entering Condenser Air ________ ________

Leaving Condenser Air ________ ________

Evap. Entering Air DB Temp ________ ________

Evap. Entering Air WB Temp ________ ________

Evap. Leaving Air DB Temp ________ ________

Evap. Leaving Air WB Temp ________ ________

Compressor Amps (L1) ________ ________

Compressor Amps (L2) ________ ________

Compressor Amps (L3) ________ ________

Notes:

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

30

ECU 04/2015 rev.3

Loading...

Loading...