Page 1

Construction Analysis

Analog Devices

ADSP-21062-KS-160

Report Number: SCA 9704-537

®

S

e

r

v

i

n

g

t

h

e

G

l

o

b

a

l

S

e

m

i

c

o

n

d

u

c

t

o

r

I

n

d

u

s

t

r

y

S

i

n

c

e

1

9

6

4

15022 N. 75th Street

Scottsdale, AZ 85260-2476

Phone: 602-998-9780

Fax: 602-948-1925

e-mail: ice@primenet.com

Internet: http://www.ice-corp.com/ice

Page 2

INDEX TO TEXT

TITLE PAGE

INTRODUCTION 1

MAJOR FINDINGS 1

TECHNOLOGY DESCRIPTION

Assembly 2

Die Process 2 - 3

ANALYSIS RESULTS I

Assembly 4

ANALYSIS RESULTS II

Die Process and Design 5 - 7

ANALYSIS PROCEDURE 8

TABLES

Overall Evaluation 9

Package Markings 10

Wirebond Strength 10

Die Material Analysis 10

Horizontal Dimensions 11

Vertical Dimensions 12

- i -

Page 3

INTRODUCTION

This report describes a construction analysis of the Analog Devices ADSP-21062-KS-160

SHARC Digital Signal Processor. One device which was packaged in a 240-pin Plastic

Quad Flat Package (PQFP) was received for the analysis. The device was date coded 9630.

MAJOR FINDINGS

Questionable Items:

1

• Metal 2 aluminum thinned up to 90 percent2 at vias (Figure 16).

Special Features:

• Sub-micron gate lengths (0.55 micron).

1

These items present possible quality or reliability concerns. They should be discussed

with the manufacturer to determine their possible impact on the intended application.

2

Seriousness depends on design margins.

- 1 -

Page 4

TECHNOLOGY DESCRIPTION

Assembly:

• The device was packaged in a 240-pin Plastic Quad Flat Package (PQFP). A copper

heat slug (heatsink) was employed on the top of the package (cavity down

orientation). It was internally connected to ground to bias the substrate.

• Wirebonding method: A thermosonic ball bond technique employing 1.2 mil O.D.

gold wire was used.

• Dicing: Sawn (full depth) dicing.

• Die attach: A silver epoxy compound.

Die Process

• Fabrication process: Selective oxidation CMOS process employing a twin-well

process in a P substrate.

• Die coat: No die coat was used on the device.

• Final passivation: A layer of nitride over a layer of silicon-dioxide.

• Metallization: Two levels of metal defined by standard dry-etch techniques. Metal 2

consisted of aluminum with a titanium-nitride cap and a titanium barrier. Metal 1

consisted of aluminum, a titanium nitride cap and barrier, and a titanium adhesion

layer. Standard vias were used between metal 2 and metal 1. Tungsten plugs were

used as the vertical interconnect under metal 1.

• Interlevel dielectric: Interlevel dielectric consisted of two layers of silicon-dioxide

with a planarizing spin-on-glass (SOG) between them.

- 2 -

Page 5

TECHNOLOGY DESCRIPTION (continued)

• Pre-metal dielectric: This dielectric consisted of a layer of reflow glass over

densified oxide.

• Polysilicon: Two layers of polysilicon were used on the die. Poly 1 (polysilicon

and tungsten silicide) was used to form redundancy fuses, all gates on the die, and

word lines in the array. Poly 2 was used to form “pull-up” resistors in the cell

array, and formed resistors in fuse blocks which were connected to one end of the

poly 1 fuses. Both poly layers were defined by a dry-etch of good quality.

• Diffusions: Implanted N+ and P+ diffusions formed the sources/drains of

transistors. No silicide was present on diffusions. An LDD process was used with

the oxide sidewall spacers left in place. N+ diffusions were “pushed down” at

tungsten contacts.

• Wells: Planar (no step in LOCOS) twin-well process in a P substrate. No epi layer.

• Redundancy: Fuses consisting of poly 1 were present on the die. Passivation and

interlevel dielectric cutouts were made over the fuses. One end of the fuse structure

was connected to metal 1, while the other end was connected to a poly 2 resistor.

Some laser blown fuses were noted.

• Memory cells: The die employed a 2 Mbit SRAM array. The memory cells used a

4T CMOS SRAM cell design. Metal 2 distributed GND and Vcc (via Metal 1), and

formed the bit lines using metal 1 links. Metal 1 was used as the “piggy-back”

word lines. Poly 1 formed the word lines, select, and storage gates. Poly 2 formed

“pull-up” resistors and distributed Vcc.

• Design features: Slotted and beveled Metal 2 bus lines were employed for stress

relief. Both metals 1 and 2 were used in the bond pads.

- 3 -

Page 6

ANALYSIS RESULTS I

Assembly: Figures 1 - 3

Questionable Items:

1

None.

Special Features: None.

General Items:

• Overall package: The device was packaged in a 240-pin PQFP. A large copper heat

slug (heatsink) was employed on the top of the package (cavity down orientation). It

was internally connected to GND and the substrate.

• Wirebonding method: A thermosonic ball bond technique employing 1.2 mil gold

wire was used. All bonds were well formed and placed. Bond strengths were

normal as determined by wire pull tests.

• Dicing: Sawn (full depth). No large chips or cracks were noted.

• Die attach: A silver epoxy compound of normal quality.

1

These items present possible quality or reliability concerns. They should be discussed

with the manufacturer to determine their possible impact on the intended application.

- 4 -

Page 7

ANALYSIS RESULTS II

Die Process and Design: Figures 4 - 45

Questionable Items:

1

• Metal 2 aluminum thinned up to 90 percent2 at vias (Figure 16).

Special Features:

• Sub-micron gate lengths (0.55 micron).

General Items:

• Fabrication process: Selective oxidation CMOS process employing twin-wells in a

P substrate.

• Process implementation: Die layout was clean efficient. Alignment was good at all

levels.

• Die surface defects: None. No contamination, toolmarks or processing defects

were noted.

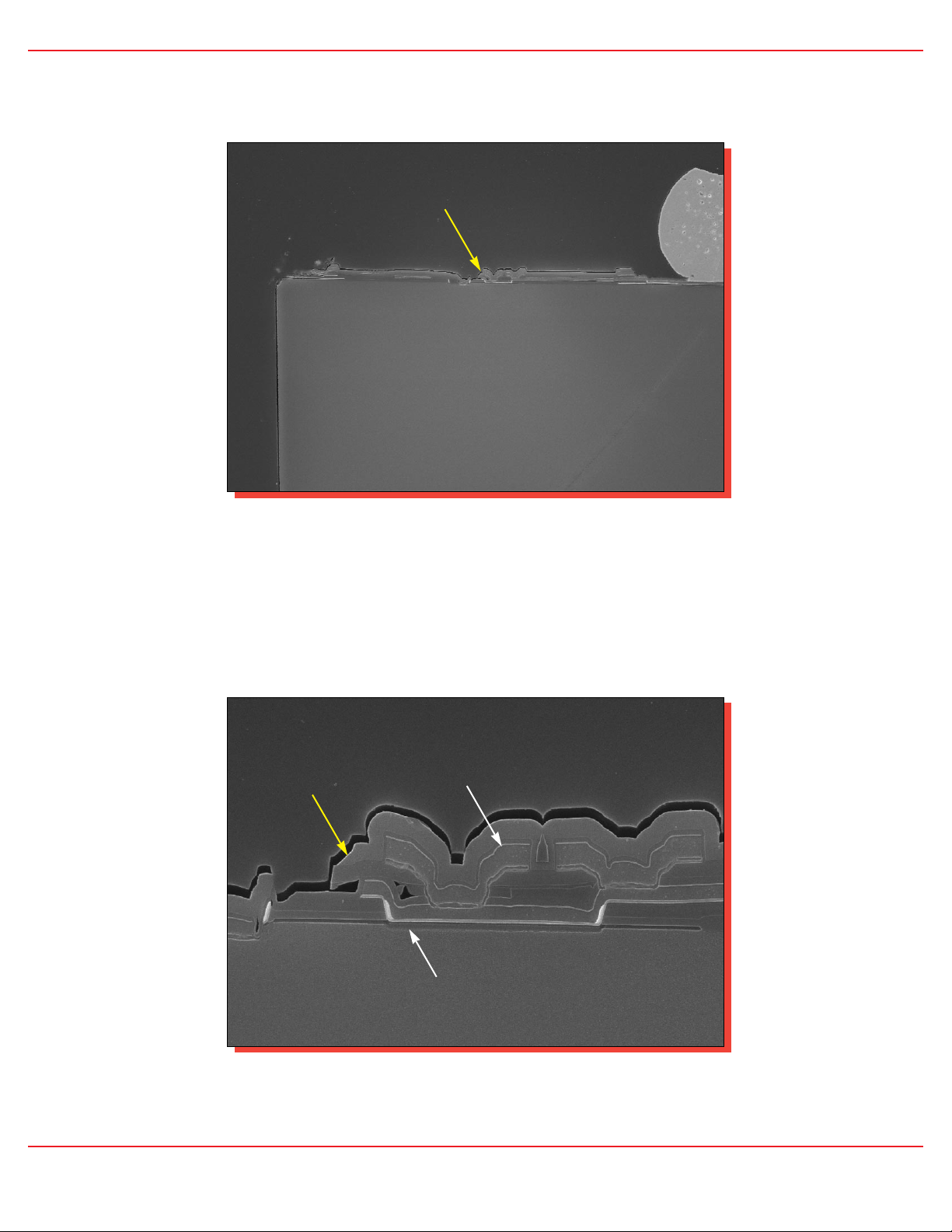

• Passivation: A layer of nitride over a layer of silicon-dioxide. Passivation coverage

and edge seal were good.

• Metallization: Two levels of metallization. Metal 2 consisted of aluminum with

titanium-nitride cap and titanium barrier. Metal 1 consisted of aluminum, titaniumnitride cap and barrier, and a titanium adhesion layer. Standard vias were used

between metal 2 and 1. Tungsten plugs were employed under metal 1.

1

These items present possible quality concerns. They should be discussed with the

manufacturer to determine their possible impact on the intended application.

2

Seriousness depends on design margins.

- 5 -

Page 8

ANALYSIS RESULTS II (continued)

• Metal patterning: All metal layers were defined by a dry etch of good quality.

• Metal defects: None. No voiding, notching or cracking of the metal layers was

found. No silicon nodules were found following removal of the aluminum.

• Metal step coverage: Metal 2 aluminum thinned up to 90 percent at most vias. The

barrier aided in retaining the connections. Virtually no metal thinning was noted in

metal 1. The tungsten plugs were nearly level with the oxide surface, so no large

steps were present for the metal to cover.

• Vias and contacts: Vias were defined by a two step process while contacts were

defined by a dry-etch. No significant over-etching was noted.

• Interlevel dielectric: Interlevel dielectric consisted of two layers of silicon-dioxide

with a spin-on-glass (SOG) to aid in planarization.

• Pre-metal dielectric: This dielectric consisted of a layer of reflow glass over

densified oxide. No problems were found.

.• Polysilicon: Two layers of polysilicon were employed. Poly 1 (polysilicon and

tungsten silicide) formed the redundancy fuses, all gates on the die, and word lines

in the array. Poly 2 was used to form resistors in the cell array and outside the fuse

blocks. Definition was by a dry etch of good quality. No problems were found.

• Isolation: LOCOS (local oxide isolation). No problems were noted and no step was

present at the well boundaries.

• Diffusions: Implanted N+ and P+ diffusions were used for sources and drains.

Deep (pushed down) N+ diffusions were noted under contacts in N regions.

Diffusions were not silicided. No problems were found.

- 6 -

Page 9

ANALYSIS RESULTS II (continued)

• Wells: Twin-wells were employed in a P substrate. No step was present at the well

boundaries, but both wells were delineated by a silicon etch. No problems were

noted.

• Buried contacts: Direct poly-to-diffusion (buried) contacts were only used in the

SRAM array. No problems were found in these areas.

• Redundancy: Poly 1 fuses were present along the row and column decode logic

outside the array. Passivation and interlevel dielectric cutouts were made over the

fuses. Laser blown fuses were noted.

• Memory cells: The die employed a 2 Mbit SRAM array. The memory cells used a

4T CMOS SRAM cell design. Metal 2 distributed GND and Vcc, and formed the

bit lines using metal 1 links. Metal 1 was used as the “piggy-back” word lines.

Poly 1 formed the word lines, select, and storage gates. Poly 2 formed “pull-up”

2

resistors and distributed Vcc. Cell size was 3.3 x 5.7 microns (19 microns

).

- 7 -

Page 10

PROCEDURE

The devices were subjected to the following analysis procedures:

External inspection

X-ray

Delid

SEM of passivation

Passivation integrity test (chemical)

Wirepull test

Passivation removal

SEM inspection of metal 2

Aluminum 2 removal

Delayer to metal 1 and inspect

Aluminum 1 removal and inspect barrier

Delayer to polycide/substrate and inspect

Die sectioning (90° for SEM)

Measure horizontal dimensions

Measure vertical dimensions

Die material analysis

*

*

Delineation of cross-sections is by silicon etch unless otherwise indicated.

- 8 -

Page 11

OVERALL QUALITY EVALUATION: Overall Rating: Normal

DETAIL OF EVALUATION

Package integrity: G

Die placement: G

Die attach quality: G

Wire spacing: N

Wirebond placement: N

Wirebond quality: G

Dicing quality: G

Wirebond method Thermosonic ball bonds using 1.2 mil

gold wire.

Die attach method Silver-epoxy

Dicing Sawn (full depth)

Die surface integrity:

Toolmarks (absence) G

Particles (absence) G

Contamination (absence) G

Process defects (absence) G

General workmanship N

Passivation integrity G

Metal definition G

Metal integrity NP

Metal registration G

Contact coverage G

Contact registration G

*

*

Metal 2 aluminum thinning up to 90 percent.

G = Good, P = Poor, N = Normal, NP = Normal/Poor

- 9 -

Page 12

PACKAGE MARKINGS

TOP

(LOGO) ANALOG DEVICES

ADSP-21062

9630 KS-160

HD/BA5454.1-1.2 (SHARC LOGO)

BOTTOM

S6 2A2

HONG KONG

WIREPULL TEST

Sample 1

# of wires tested: 22

Bond lifts: 0

Force to break - high: 12g

- low: 8g

- avg.: 9.1g

- std. dev.: 0.5

DIE MATERIAL IDENTIFICATION

Overlay passivation: Nitride over silicon-dioxide.

Metallization 2: Aluminum with a titanium-nitride cap and a

titanium barrier.

Interlevel dielectric: Multiple layers of silicon-dioxide.

Metallization 1: Aluminum with a titanium-nitride cap and

barrier, and a titanium adhesion layer.

Plugs: Tungsten.

Pre-metal glass: Silicon-dioxide.

Silicide (Poly 1): Tungsten.

- 10 -

Page 13

HORIZONTAL DIMENSIONS

Die size: 11.9 x 14.9 mm (468 x 586 mils)

Die area: 177 mm

2

(274,248 mils2)

Min pad size: 0.11 x 0.11 mm (4.4 x 4.4 mils)

Min pad window: 0.09 x 0.09 mm (3.7 x 3.7 mils)

Min pad space: 40 microns

Min metal 2 width: 0.7 micron

Min metal 2 space: 1.0 micron

Min metal 2 pitch: 1.7 micron

Min metal 1 width: 0.6 micron

Min metal 1 space: 0.7 micron

Min metal 1 pitch: 1.3 micron

Min via: 0.65 micron (round)

Min contact: 0.5 micron (round)

Min polycide width: 0.55 micron

Min polycide space: 0.8 micron

Min gate length* - (N-channel): 0.55 micron

- (P-channel): 0.55 micron

Min LOCOS: 0.8 micron

SRAM cell size: 19.0 microns

2

SRAM cell pitch: 3.3 x 5.7 microns

*

Physical gate length.

- 11 -

Page 14

VERTICAL DIMENSIONS

Die thickness: 0.5 mm (21 mils)

Layers

Passivation 2: 0.6 micron

Passivation 1: 0.15 micron

Metal 2 - cap: 0.05 micron (approx.)

- aluminum: 0.75 micron

- barrier: 0.17 micron

Interlevel dielectric - glass 2: 0.5 micron (average)

- glass 1: 0.15 micron (average)

Metal 1 - cap: 0.05 micron (approx.)

- aluminum: 0.5 micron

- barrier: 0.1 micron

- plugs: 0.6 - 1.0 micron

Pre-metal glass: 0.6 micron (average)

Polycide - silicide: 0.1 micron

- poly: 0.13 micron

Local oxide: 0.4 micron

N+ S/D diffusion: 0.2 micron

Deep N+ S/D diffusion: 0.4 micron

P+ S/D diffusion: 0.2 micron

N-well: 2.0 microns (approx.)

P-well: 2.5 microns (approx.)

- 12 -

Page 15

INDEX TO FIGURES

ASSEMBLY Figures 1 - 3

DIE LAYOUT AND IDENTIFICATION Figures 4 - 9

PHYSICAL DIE STRUCTURES Figures 10 - 46

COLOR DRAWING OF DIE STRUCTURE Figure 31

EEPROM MEMORY CELL STRUCTURES Figures 32 - 40

CIRCUIT LAYOUT AND I/O Figures 41 - 46

- ii -

Page 16

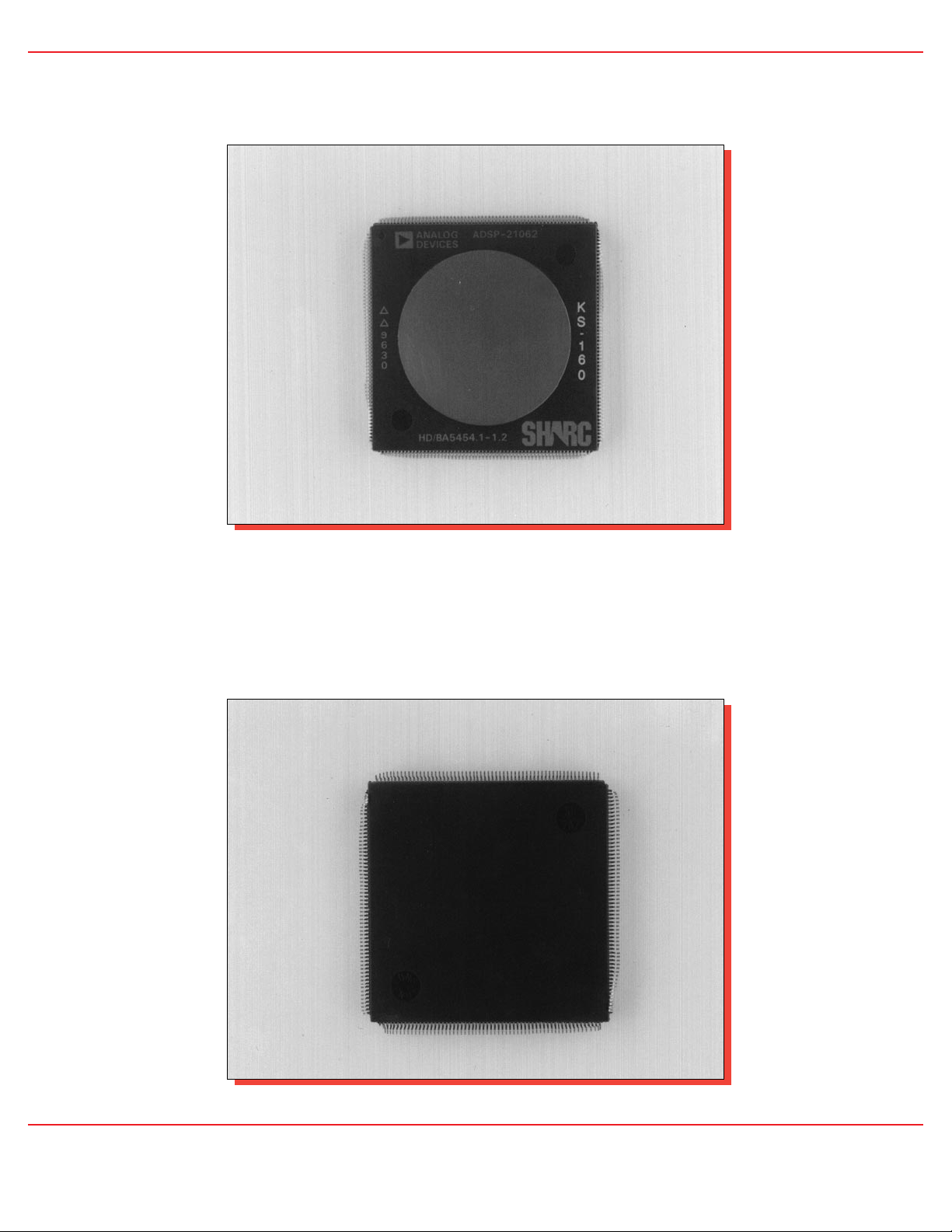

Figure 1. Package photographs of the Analog Devices ADSP-21062-KS-160

SHARC Digital Signal Processor. Mag. 1.5x.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Page 17

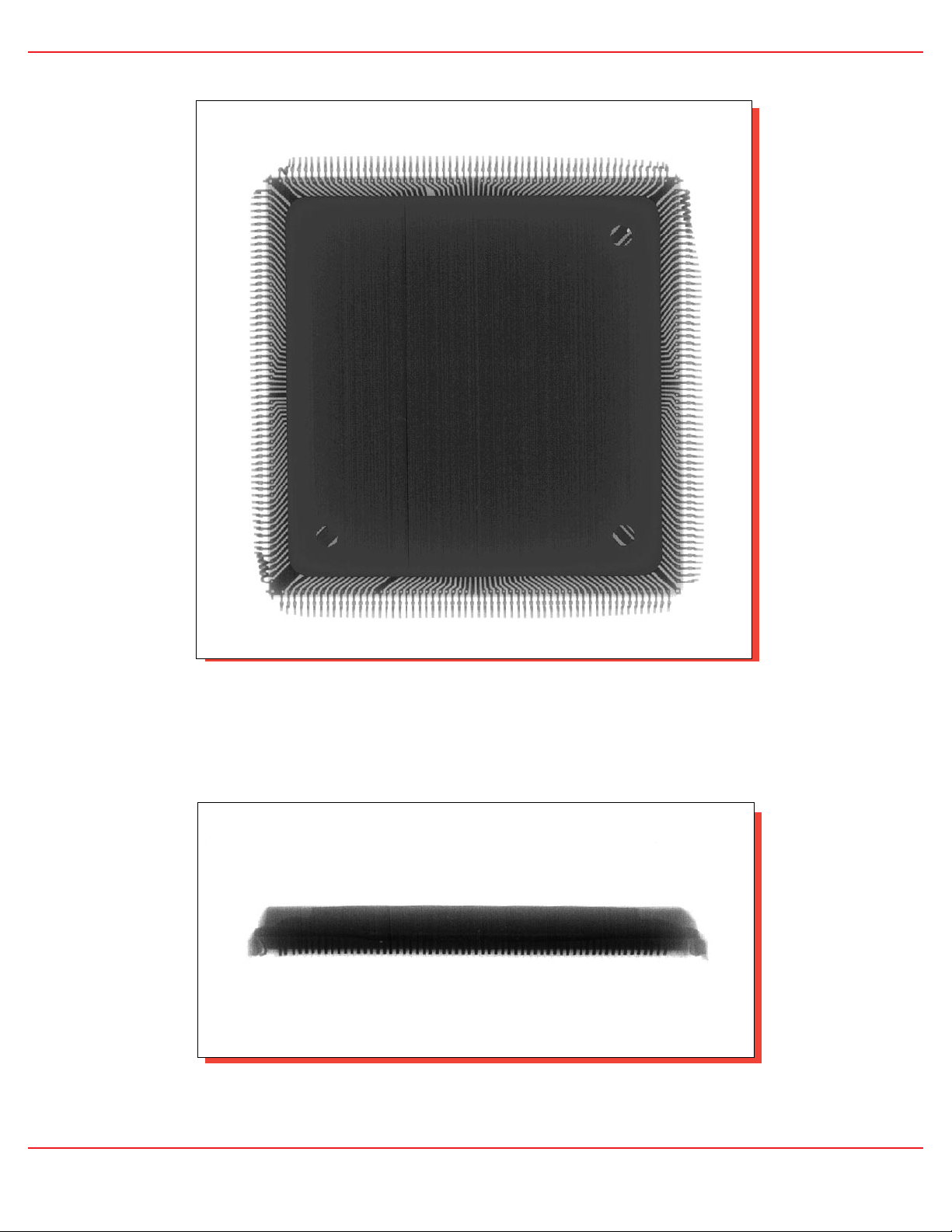

side

top

Figure 2. X-ray views of the package. Mag. 3x.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Page 18

Mag. 6500x

Mag. 800x

Figure 3. SEM section views of the edge seal.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

EDGE OF

PASSIVATION

EDGE OF

PASSIVATION

DIE

N+

METAL 1

METAL 2

Page 19

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 4. Portion of the Analog Devices ADSP-21062-KS-160 whole die. Mag. 26x.

Page 20

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 5. Portion of the Analog Devices ADSP-21062-KS-160 whole die. Mag. 26x.

Page 21

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 6. Portion of the Analog Devices ADSP-21062-KS-160 whole die. Mag. 26x.

Page 22

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 7. Remaining portion of the Analog Devices ADSP-21062-KS-160 whole die. Mag. 26x.

PIN 1

Page 23

Figure 8. Optical views of die markings. Mag. 750x.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Page 24

Figure 9. Optical views of die corners. Mag. 80x.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Page 25

Figure 10. Optical views illustrating a slotted bus line and resolution patterns.

Mag. 410x.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

SLOT

Page 26

glass etch

Figure 11. SEM section views illustrating general structure. Mag. 13,000x.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

PASSIVATION 1

PASSIVATION 2

PASSIVATION 2

METAL 2

METAL 2

METAL 1

METAL 1

W PLUG

W PLUG

N+ S/D

POLY 1 GATE

POLY 1 GATE

LOCOS

LOCOS

Page 27

Mag. 15,000x

Mag. 4600x

Figure 12. SEM views illustrating final passivation. 60°.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Page 28

Mag. 52,000x

Mag. 26,000x

Figure 13. SEM section views illustrating metal 2 line profiles.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

PASSIVATION 2

PASSIVATION 1

INTERLEVEL DIELECTRIC

METAL 2

ALUMINUM 2

TIN CAP

TiN BARRIER

Page 29

Mag. 3200x

Mag. 6500x

Mag. 6500x

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 14. Topological SEM views of metal 2 patterning. 0°.

MASK

CHANGES

METAL 2

VIAS

Page 30

Mag. 10,000x

Mag. 10,000x

Mag. 20,000x

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 15. Perspective SEM views of metal 2 step coverage. 60°.

ALUMINUM 2

TiN CAP

Ti BARRIER

Page 31

Mag. 13,000x

Mag. 26,000x

Mag. 52,000x

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 16. SEM section views of typical vias.

PASSIVATION 2

METAL 2

METAL 2

METAL 2

INTERLEVEL

DIELECTRIC

METAL 1

METAL 1

METAL 1

90% THINNING

POLY 1

LOCOS

SOG

Page 32

Mag. 52,000x

Mag. 26,000x

Figure 17. SEM section views of metal 1 line profiles.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

PASSIVATION

INTERLEVEL

DIELECTRIC

METAL 1

SOG

ALUMINUM 1

TiN CAP

TiN

BARRIER

Ti ADHESION LAYER

Page 33

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 18. Topological SEM views of metal 1 patterning. Mag. 6500x, 0°.

METAL 1

POLY 1

VIA

Page 34

Mag. 5000x

Mag. 10,000x

Mag. 20,000x

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 19. Perspective SEM views of metal 1 step coverage. 60°.

ALUMINUM 1

TiN CAP

TiN

BARRIER

Page 35

Mag. 32,000x

Mag. 16,000x

Figure 20. Perspective SEM views of metal 1 barrier and plug. 60°.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

TiN

BARRIER

W PLUG

Page 36

Figure 21. SEM section views illustrating typical metal 1 contacts. Mag. 26,000x.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

METAL 1

METAL 1

METAL 1

W PLUG

W PLUG

W PLUG

DEEP N+

N+

P+

POLY 1

LOCOS

LOCOS

Page 37

Mag. 3200x

Mag. 3200x

Mag. 5000x

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 22. Topological SEM views of poly 1 patterning. 0°.

P+

N+

POLY 1

Page 38

Mag. 8000x

Mag. 12,000x

Mag. 32,000x

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 23. Perspective SEM views of poly 1 coverage. 60°.

DIFFUSION

LOCOS

POLY 1 GATE

Page 39

N-channel

P-channel

glass etch

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 24. SEM section views of typical transistors. Mag. 52,000x.

W SILICIDE

POLY 1

POLY 1

GATE

POLY 1

GATE

GATE OXIDE

GATE OXIDE

P+ S/D

N+ S/D

DEEP N+ S/D

REFLOW GLASS

REFLOW GLASS

SIDEWALL

SPACER

Page 40

Figure 25. SEM section view of a typical birdsbeak. Mag. 52,000x.

Figure 26. Section views illustrating well structure.

Mag. 1200x

Mag. 6500x

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

DENSIFIED OXIDE

POLY 1

P-SUBSTRATE

P-WELL

P-WELL

N-WELL

LOCOS

LOCOS

METAL 2

P+

N+

GATE

OXIDE

Page 41

Mag. 1000x

Mag. 750x

Figure 27. Optical views of typical fuses.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

BLOWN FUSE

Page 42

Mag. 3200x

Mag. 1600x

Figure 28. Topological SEM views of typical fuses. 0°.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

INTACT

FUSE

LASER

BLOWN

FUSE

PASSIVATION

CUTOUT

Page 43

Mag. 4800x

Mag. 2400x

Figure 29. Perspective SEM views of typical fuses. 60°.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

BLOWN FUSE

CUTOUT

PASSIVATION

Page 44

Mag. 6500x

Mag. 13,000x

Mag. 13,000x

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 30. SEM section views of a poly 1 fuse.

CUTOUT

CUTOUT

POLY 2

METAL 2

METAL 1

PASSIVATION 2

REFLOW GLASS

LOCOS

LOCOS

POLY 1

FUSE

POLY 1

FUSE

POLY 1 FUSE

Page 45

Figure 31. Color cross section drawing illustrating device structure.

Orange = Nitride, Blue = Metal, Yellow = Oxide, Green = Poly,

Red = Diffusion, and Gray = Substrate

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

,

,

,,

,,

POLY 1

W SILICIDE

INTERLEVEL DIELECTRIC

PRE-METAL GLASS

SOG

W PLUG

TiN CAP 1

TiN CAP 2

ALUMINUM 1

Ti BARRIER

TiN BARRIER 1

ALUMINUM 2

NITRIDE PASSIVATION

GLASS

PASSIVATION

GATE OXIDE

P SUBSTRATE

LOCAL OXIDE

DEEP N+

N+ S/D

P+ S/D

P-WELL

N-WELL

Ti ADHESION LAYER

,,,,,,,,,

,,,,,,,,,

Page 46

metal 2

metal 1

unlayered

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 32. Perspective SEM views of the SRAM cell array. Mag. 10,000x, 60°.

GND

GND

GND

BIT

BIT

BIT

BIT

WORD

“PIGGY BACK”

WORD LINE

Page 47

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

POLY 2

POLY 2

POLY 1

POLY 1

POLY 1

WORD LINE

Figure 33. Detailed SEM views of the SRAM cell structures (unlayered).

Mag. 42,000x, 60°.

Page 48

metal 2

metal 1

unlayered

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 34. Topological SEM views of the SRAM cell array. Mag. 3200x, 0°.

WORD LINE

“PIGGYBACK”

WORD LINE

GND

V

CC

GND

BIT

BIT

Page 49

metal 1

metal 2

Figure 35. Detailed topological SEM views of an SRAM cell. Mag. 13,000x, 0°.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

GND

GND

BIT

BIT

BIT

BIT

“PIGGYBACK”

WORD LINE

V

CC

Page 50

unlayered

Figure 36. Detailed topological SEM view and schematic of an SRAM cell.

Mag. 13,000x, 0°.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

BIT

R1

1

4

3

R2

2

BIT

GND

GND

V

CC

WORD

R2R1

BIT

1 2

3 4

BIT

Page 51

Mag. 13,000x

Mag. 20,000x

Mag. 26,000x

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 37. SEM section views of an SRAM cell (parallel to bit line).

METAL 2 BIT LINE

METAL 2 BIT LINE

METAL 1 LINK

METAL 1 LINK

SOG

POLY 2

W

PLUG

N+ S/D

N+ S/D

DEEP

N+ S/D

POLY 1

STORAGE

GATE

POLY 1

SELECT GATE

Page 52

Mag. 35,000x

Mag. 52,000x

Mag. 52,000x

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Figure 38. SEM section views of SRAM cell details (parallel to bit line).

LOCOS

LOCOS

POLY 2

POLY 1

N+ S/D

N+ S/D

DEEP

N+ S/D

GATE OXIDE

GATE OXIDE

POLY 2 “PULL-UP”

RESISTOR

POLY 1 STORAGE

GATE

POLY 1 SELECT

GATE

Page 53

Mag. 26,000x

Mag. 13,000x

Figure 39. SEM section views of the SRAM cell array (perpendicular to bit lines).

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

LOCOS

GATE OXIDE

METAL 2

BIT LINE

BIT LINE

CONTACT

POLY 1

WORD/SELECT

LINE

POLY 1

WORD/SELECT

LINE

Page 54

Mag. 26,000x

Mag. 13,000x

Figure 40. SEM section views of the SRAM cell array (perpendicular to bit lines).

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

METAL

2

METAL 1 GND

N+ S/D

SOG

N+ S/D

POLY 1 STORAGE GATES

POLY 1 STORAGE GATE

POLY 2

LOCOS

Page 55

unlayered

intact

Figure 41. Optical views of typical device circuit layout. Mag. 820x.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Page 56

unlayered

intact

Figure 42. Optical views of typical I/O circuitry. Mag. 400x.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Page 57

Mag. 13,000x

Mag. 3200x

Figure 43. SEM section views illustrating wirebond interface.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

Au

Au

EDGE OF PASSIVATION

METAL 1

METAL 2

POLY 1

LOCOS

METAL 1

Page 58

Mag. 26,000x

Mag. 13,000x

Figure 44. SEM section views of P-channel I/O circuitry.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

METAL 2

METAL 1

METAL 1

P+ S/D

P+ S/D

POLY 1 GATE

POLY 1 GATE

SOG

SOG

Page 59

Mag. 26,000x

Mag. 13,000x

Figure 45. Additional SEM section views of N-channel I/O circuitry.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

METAL 1

METAL 1

REFLOW GLASS

METAL 2

N+ S/D

N+ S/D

POLY 1 GATE

POLY 1 GATE

SOG

Page 60

P-channel

N-channel

Figure 46. SEM section views illustrating guardbands at the edge of the I/O circuitry.

Mag. 6500x.

Integrated Circuit Engineering CorporationAnalog Devices ADSP-21062-KS-160

METAL 2

N+ GUARDBAND

P+ GUARDBAND

P-WELL

N+ S/D

POLY 1 GATE

METAL 2

N+ GUARDBAND

P+ S/D

LOCOS

POLY 1 GATE

Loading...

Loading...