Page 1

INDUSTRIAL CONTROL COMMUNICATION

Communication Node

for EMS/BMS

Installation Instruction Manual

Models

Ethernet (ETH-1000) for BACnet IP

and Modbus TCP

Control

Serials

Mirius (Serial RS-485) for BACnet MS/TP)

and Modbus RTU

Energy Management System

Building Management System

Installation

PRINTED 0419

100318030 2000571701 (Rev. A)

Page 2

CONTENTS

INTRODUCTION ........................................................................... 3

Warnings ...................................................................................3

Parts ..........................................................................................3

Tools Required ..........................................................................3

General Guidelines ...................................................................3

FEATURES AND COMPONENTS ................................................ 5

DEVICE CONFIGURATIONS ........................................................ 6

ETH-1000 Wiring .......................................................................6

Mirius Wiring .............................................................................6

INSTALLATION CONSIDERATIONS ............................................8

Touch Screen Style Display Installation ....................................8

High Efciency Water Heater Installation – (BTH Or BTX

Models) ................................................................................. 8

Commercial Electric Water Heater (Touch Screen

Installation) ........................................................................... 8

Membrane Switch Style Display Installation ..........................10

High Efciency Water heater Installation ............................ 10

Commercial Electric Water heater Installation .................... 10

Boiler Installation .....................................................................12

XP XWH Boiler Installation ................................................. 12

ECC DEVICE VERSIONS ........................................................... 13

BACnet / Gas Water Heaters ..................................................13

Product Description ............................................................ 13

Protocol Implementation Conformance

Statement (PICS) ............................................................... 14

BACnet Standardized Device Prole (Annex L): ..................... 14

BACnet Interoperability .............................................................14

Segmentation Capability ...........................................................14

Data Link Layer Options ............................................................14

Device Address Binding ............................................................14

Character Sets ..........................................................................15

Data Types ................................................................................15

Object Types and Properties .....................................................16

Device Object Listings ........................................................ 16

Object Min/Max Values .............................................................16

BACnet/Gas Water Heaters Object List ....................................17

Central Control Board Major State Denitions ..........................20

Xi 1.0 Energy Management System (EMS) Control .................. 20

Mxi Energy Management System (EMS) Control .....................21

Fault Codes and Warnings ........................................................22

BACnet / Electric Water Heaters ............................................23

Product Description ............................................................ 23

Protocol Implementation Conformance

Statement (PICS) ............................................................... 23

BACnet Standardized Device Prole (Annex L): ....................... 23

BACnet Interoperability ............................................................23

Data Link Layer Options ............................................................24

Device Address Binding ............................................................24

Networking Options ...................................................................24

Character Sets ..........................................................................24

Data Types ................................................................................25

Object Types and Property Support ..........................................25

Device Object Listings ........................................................ 26

Device Objects Initial Values .....................................................26

Device Objects Minimum/Maximum Values ..............................26

Central Control Board Major State Denitions ..........................30

Energy Management System (EMS) Control ............................ 30

Fault Codes and Warnings ........................................................30

BACnet / Boilers ......................................................................32

Product Description ............................................................ 32

Protocol Implementation Conformance

Statement (PICS) ............................................................... 32

BACnet Standardized Device Prole (Annex L): ...................... 32

BACnet Boiler Interoperability ...................................................32

Segmentation Capability: ..........................................................32

Data Link Layer Options ............................................................33

Device Address Binding ............................................................33

Character Sets ..........................................................................33

Data Types Supported...............................................................33

Boiler Device Object Types/Property Support ..........................34

Object Listings .................................................................... 34

Boiler Device Object Initial Values ............................................34

Boiler Device Object Min/Max Values .......................................35

Boiler Slave States ....................................................................36

Boiler Modbus Register Access ................................................36

Boiler Modulating Sensor Select/DHW Demand Switch ...........37

Lock and Hold Codes ................................................................37

Modbus / Gas Water Heaters .................................................44

Product Description ............................................................ 44

Modbus Gas Water Heater Register Listings ..................... 44

Modbus Gas Water Heater Register Properties ........................44

Central Control Board Major State Denitions ..........................47

Xi 1.0 Energy Management System (EMS) Control .................. 47

Mxi Energy Management System (EMS) Control .....................47

Fault Codes and Warnings ........................................................48

Modbus / Electric Water Heaters .............................................49

Product Description ............................................................ 49

Electric Water Heater Register Listings .............................. 49

Modbus Electric Water Heaters Register Properties .................49

Central Control Board Major State Denitions ..........................52

Energy Management System (EMS) Control ............................ 52

Fault Codes and Warnings ........................................................52

ICC PROGRAM INFORMATION ................................................. 53

2

Page 3

INTRODUCTION

New building construction and energy saving techniques have

driven the need for improved communications between appliances

and building environmental systems. There are several different

protocols that have developed for accomplishing this task

including BACnet and Modbus. Since appliances come with a

variety of controls, interfacing with the various protocols presents

different challenges.

Industrial Control Communications (ICC) has developed the

devices to act as a communication gateway allowing appliances

to communicate to the different building management protocols.

The ICC module translates the appliance codes and commands

into the appropriate protocol language giving the end user the

ability to monitor and control the appliance. The end user will be

able to adjust and monitor the equipment and obtain better levels

of efciency and cost savings.

The ICC module in this kit has been designed to seamlessly

integrate with the water heater controls. Once the unit is

connected to the control and to the energy management system,

the user will be able to operate the unit with the Building

Management system interface.

WARNINGS

When installing the unit, ensure that all power is off before

opening any water heater enclosure. Failure to do so could result

in electrical shock and/or possible damage to the unit.

Do not install in areas of high temperature, in excess of 167° F.

Install in areas not subject to water or excess moisture.

PARTS

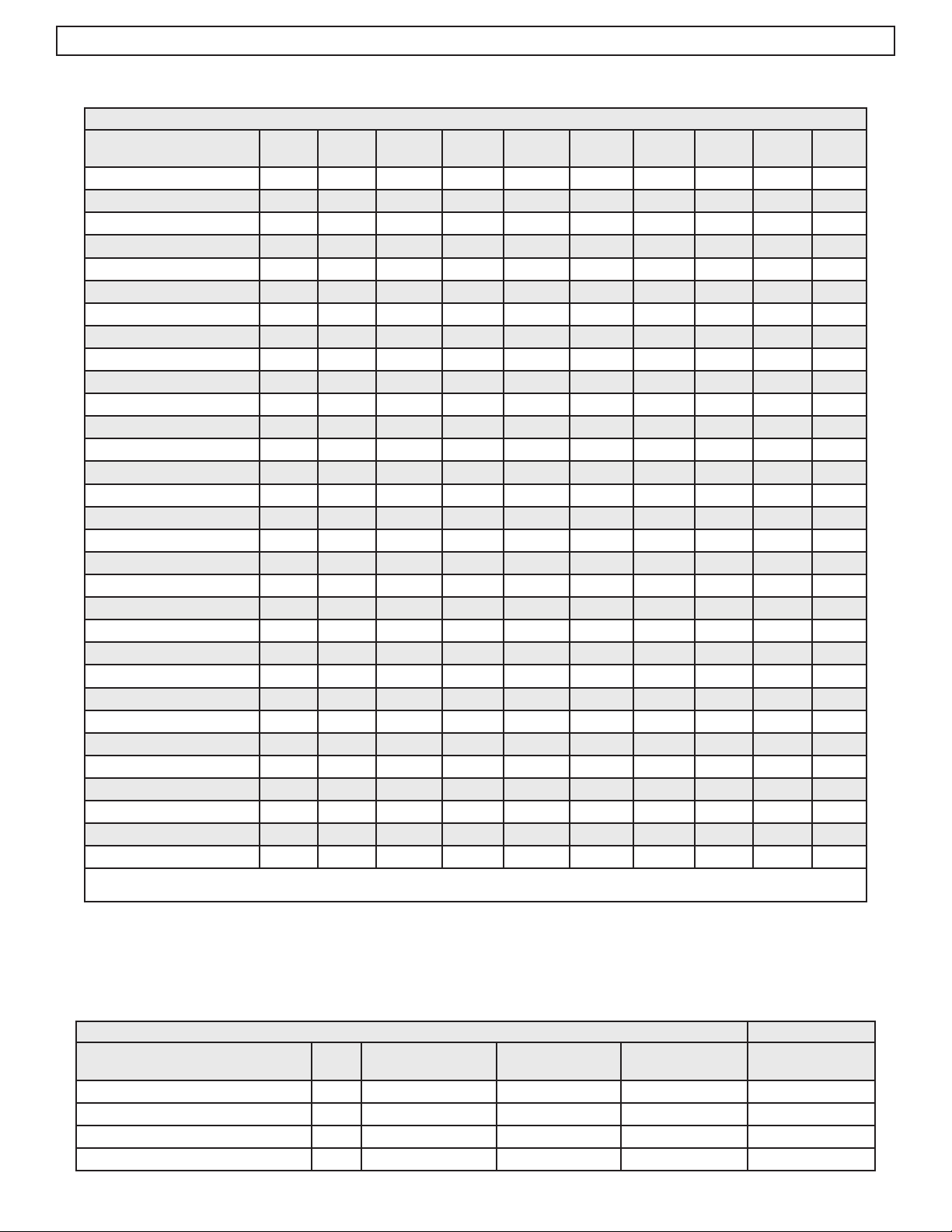

Table 1. Parts Required

Item Ethernet Serial (RS-485)

ICC Module X X

Communication Cable X X

Power Adapter X X

Jumpers 4 4

Splitter X X

USB Key X X

lists and instructions required to install and congure to your water

heater/boiler and BMS system.

Before plugging in the ICC Gateway, install the ICC Conguration

Studio from the USB key and run the program. Once running,

select File, Open Project and browse to the USB key and select

the conguration le whose name matches the gateway,

Because some USB hubs may not supply sufcient current to run

the Gateway, insure that the ICC Gateway is connected to the

power adaptor. Then connect the ICC Gateway using the USB

cable provided. Run the ICC Gateway Studio application from the

start menu.

Each conguration has default address and BACnet instance

settings that can be changed. For Mirius gateways, the default

Modbus address is 1 and the default BACnet address is 81. For

gas models the default BACnet Instance Number is 520081 and

for electric models the default instance number is 530081. For

Ethernet Gateways, the default setting is to acquire an IP address

automatically from the router (DHCP). If a static IP address is

desired this can also be set. To change these addresses and

communication settings, use the ICC Conguration Studio

application program. The latest version of this application program

can be downloaded from:

www.iccdesigns.com/icc-conguration-studio.html

Before making any changes, it is recommended to save the

installed conguration project using the disk icon or File -> Save

Project As, then give it a name and select the folder, nally press

Save.

To change the Instance number and the Device Name, scroll

down and select the Device Object and replace the text in the

boxes in the upper right corner.

TOOLS REQUIRED

Wire Cutters

24 AWG Wire Stripper

2.5 mm Flat Blade Screw Driver

GENERAL GUIDELINES

The module should be installed as close as practical to the water

heater control.

The ICC module uses a 120 Volt power adapter to supply 9 volts

DC for the unit. One 120 VAC outlet is required for each module

installed. The power adapter comes with a six foot length of wire.

If additional wire is needed, extra wire may be added, in

accordance with local ordinances for installation of low voltage

wire.

The ICC Gateway kit contains a USB key with the ICC

Conguration Studio program, all conguration les, parameter

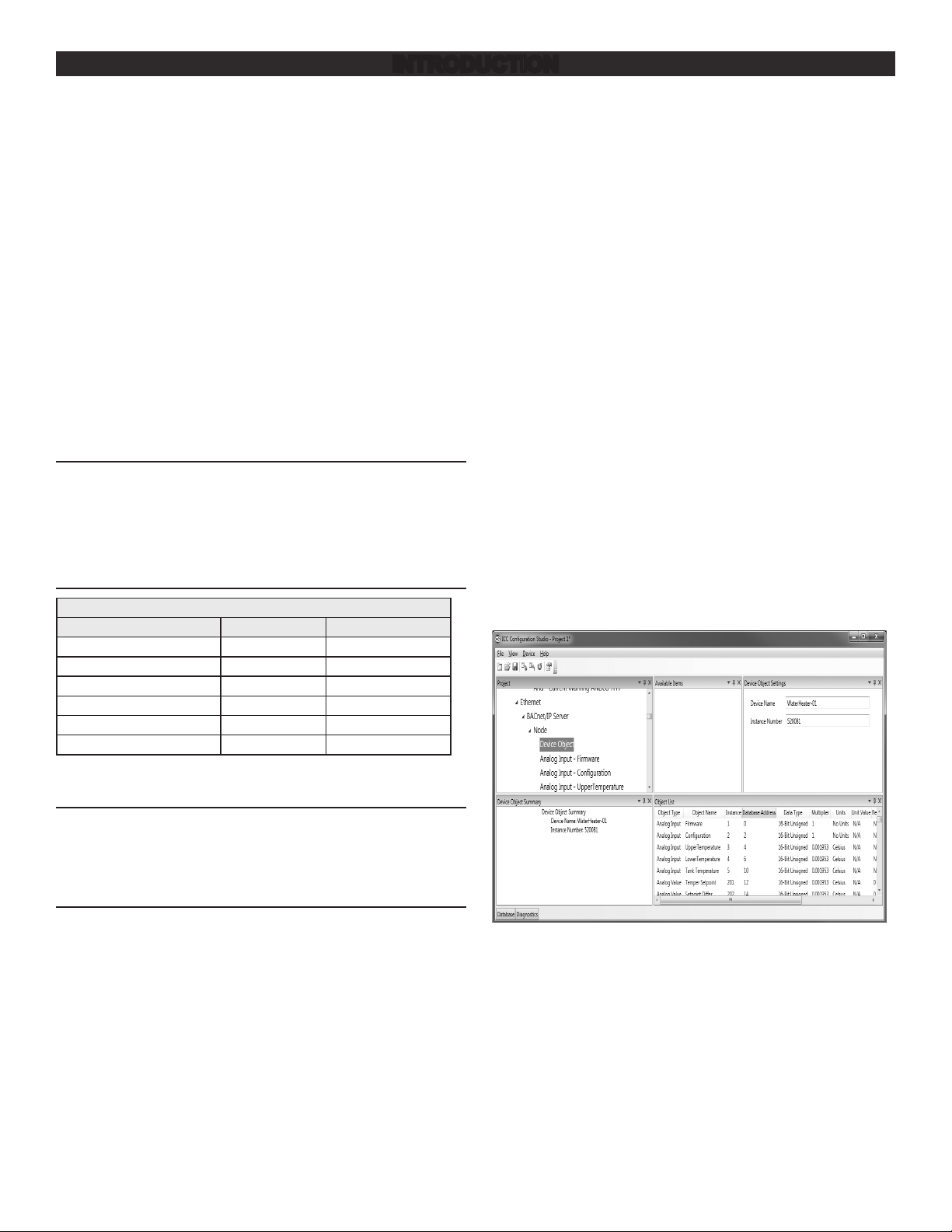

Figure 1. Changing Instance Number and Device Name

For ETH-1000 (Ethernet interface) the IP settings, including

DHCP/Static, the IP address and authentication can be changed

by selecting Ethernet from the upper left hand window and

changing the text and drop down list selection similar to changing

the Instance number above.

For Mirius (RS-485 A interface for BACnet MS/TP or ModBus

RTU), the baud rate and other serial communication parameters

can be changed by scrolling down to and selecting RS-485 A ->

ModBus RTU Slave.

3

Page 4

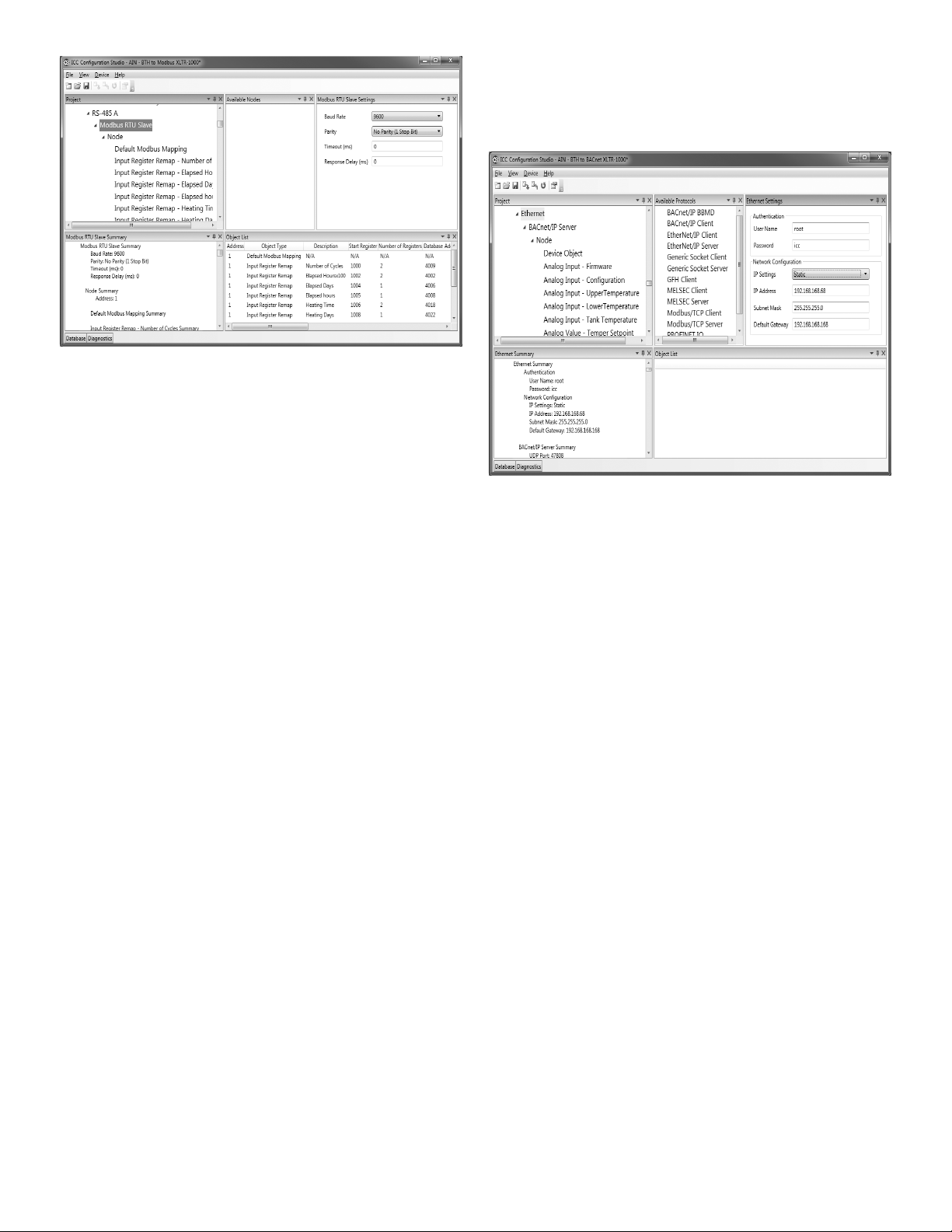

Figure 2. Changing ModBus Parameters

The ModBus address can be changed by selecting Node under

the RS-485 A -> ModBus RTU item.

Likewise for BACnet, the baud rate and other serial

communication parameters can be changed by scrolling down to

and selecting RS-485 -> BACnet MS/TP Server. The BACnet

MAC Address can be changed by selecting Node under the

RS-485 A->BACnet MS/TP Server.

Warning: Do not change any other values other than these or the

gateway conguration may not function properly. In this

case, the le saved above can be reloaded to start over.

When changes are complete press the Download Conguration icon:

Figure 3. Changing BACnet Parameters

4

Page 5

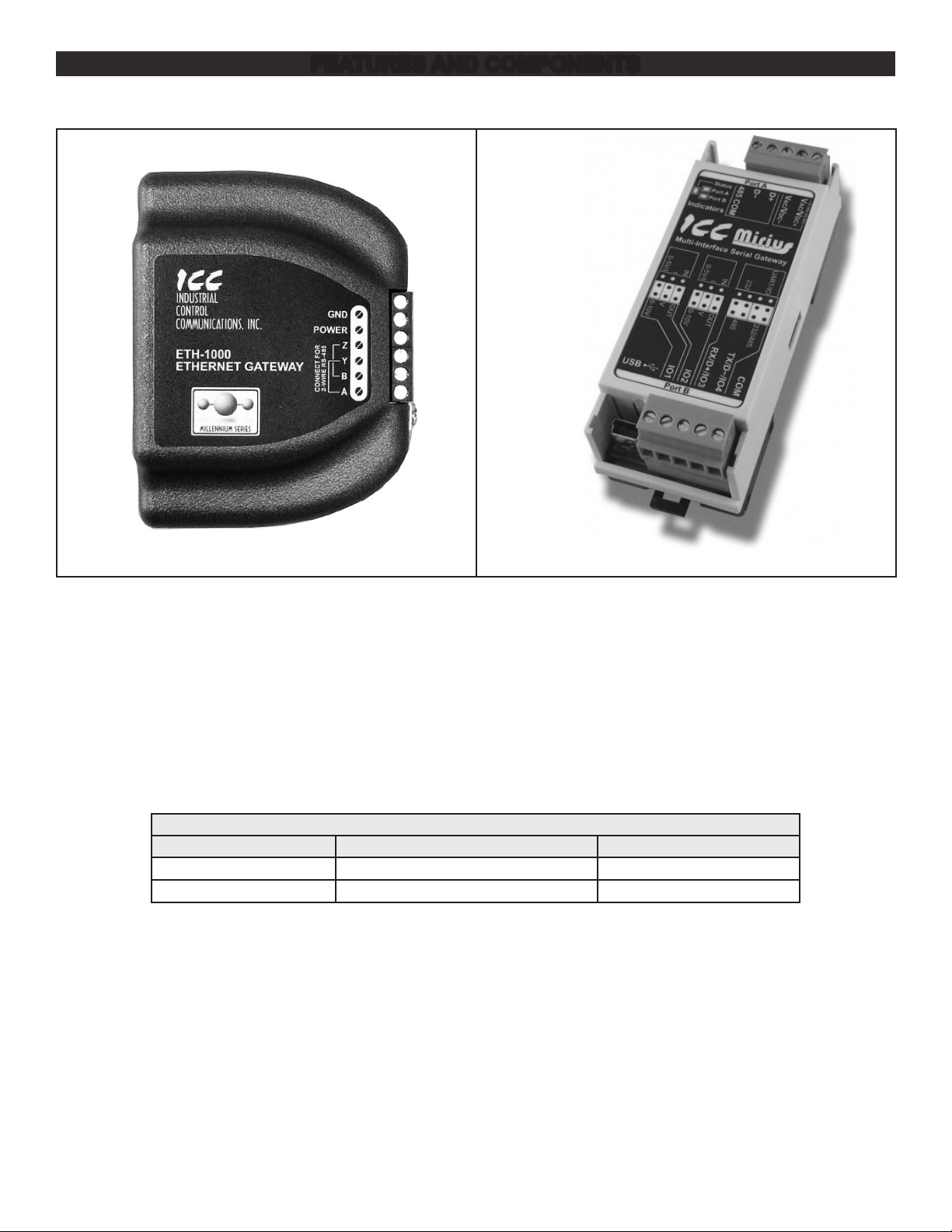

FEATURES AND COMPONENTS

Figure 4. ICC ETH-1000 (Ethernet) Version

• Works with Cyclone (BTH, BTX-100, BTXL-100, DVE, DSE/

DVE/DHE

• Use the ICC Control to enable/disable the water heater.

• Change Temperature Set points and differentials.

• Two models with four different congurations to connect to

BACnet and Modbus.

• Ethernet and Serial RS-485 versions available.

• Two-wire or four-wire RS-485 versions available.

Table 2. ICC Versions

Kit Connection Part Number

Mirius Serial - RS485 (RTU/MS/TP) 100316044

ETH-1000 Ethernet - RJ-45 100316045

Figure 5. ICC Merius Serial RS-485 Version

• Power can be supplied via the USB cable, as a 7-24 VDC

input on the main termainal block, or via IEEE 802.3af Power

over Ethernet (PoE on ETH-1000 only).

• Congure protocols, network characteristics, and client/server

object denitions.

• Graphically interact with the interal database in real-time via

the USB connection.

• Automatically discover and congure IP settings Ethernet

gateways connected to the current subnet.

• Update rmware.

5

Page 6

DEVICE CONFIGURATIONS

Brown/White Wire*

Jumper

Brown Wire*

Blue/White Wire*

From 9 VDC Power Adapter Cable

Power

Power

Jumper

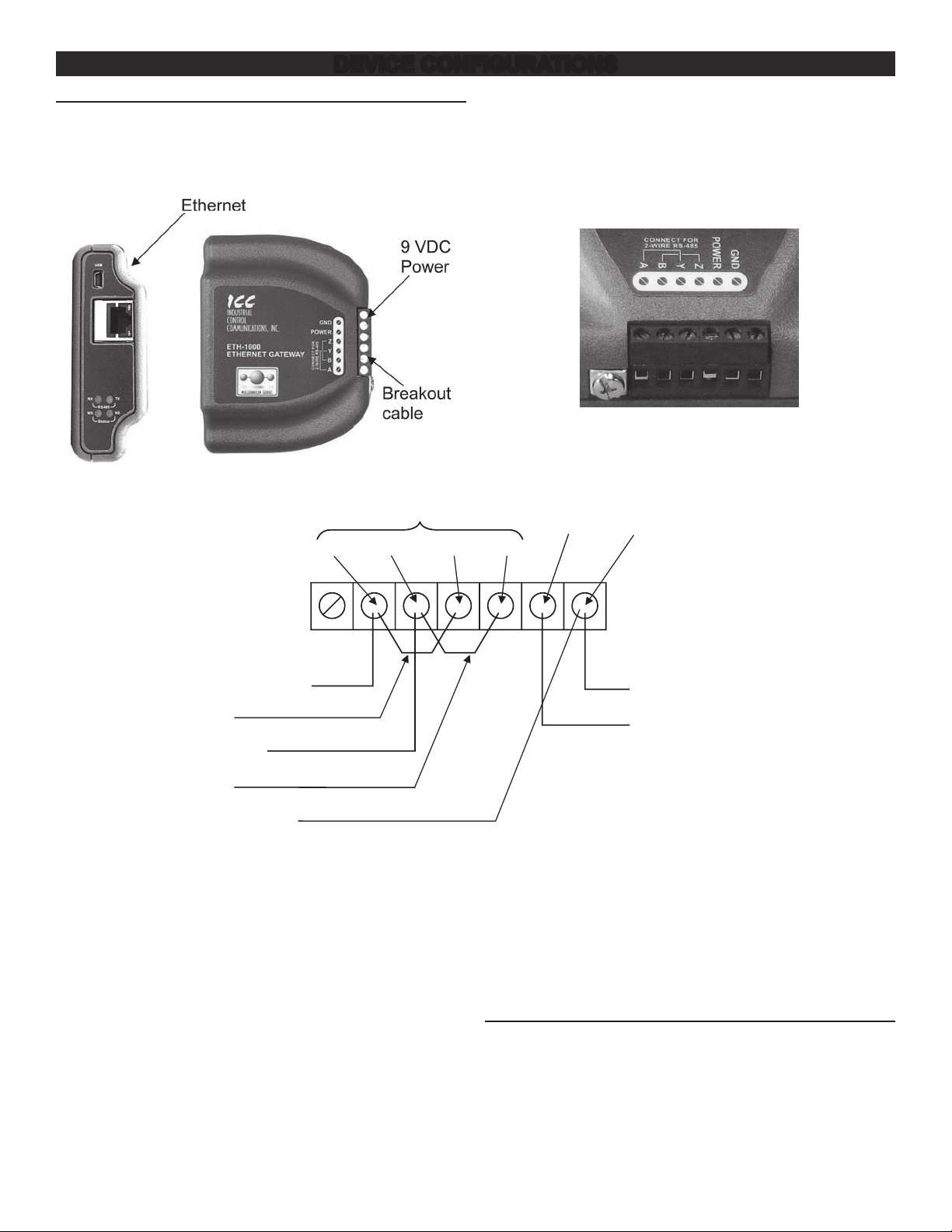

ETH-1000 WIRING

Figure 6 shows the standard conguration of the Ethernet modules.

The module has connections for 9 VDC power, three wire

connections for the communication cable, and a port for the

connection of the EMS system through Ethernet RJ-45 cable or

serial communications.

Figure 6. Standard Conguration for Ethernet Modules

Connecting of the power adapter and the boiler or water heater

communication cable to the module is accomplished on the same

end of the unit. Figure 7 is a close up of the connection terminal

and Figure 8 shows the appropriate connection to the strip using

the power adapter and communication cable.

The provided communication cable has two RJ-45 plugs.

Remove one with a wire cutter, then locate and strip the 3 wires

described below and strip 1/2 inch of insulation before connecting.

Figure 7. Connecting the Power Adapter

The connections in Figure 8 are the same regardless of the

appliance or the communication protocol.

At the opposite end of the module is the connection location for

the EMS LAN connection. The EMS uses an Ethernet connection

with an RJ-45 connector. Plug the cable into the RJ-45 receptacle.

When connecting the RS-485A connections, please note the

following:

For 2-wire systems, jumper terminal A to Y. Also jumper B to Z.

Connect the RX/TX+ (plus) wire from your Building Management

System to terminal A/Y. Connect the RX/TX– (minus) wire from

your Building Management System to terminal B/Z.

AB YZ

*From Communication Cable

†

Figure 8. Connections from the Communications and Power Adapter Cables

RS 485

Pos

GND

Black Wire

†

Black/White Wire†

For more information on connecting the ICC Gateway to your

Building Management System, please refer to the User Manual

provided on the enclosed USB key in the “Documents” folder. The

two applicable documents will be found in the Manuals.

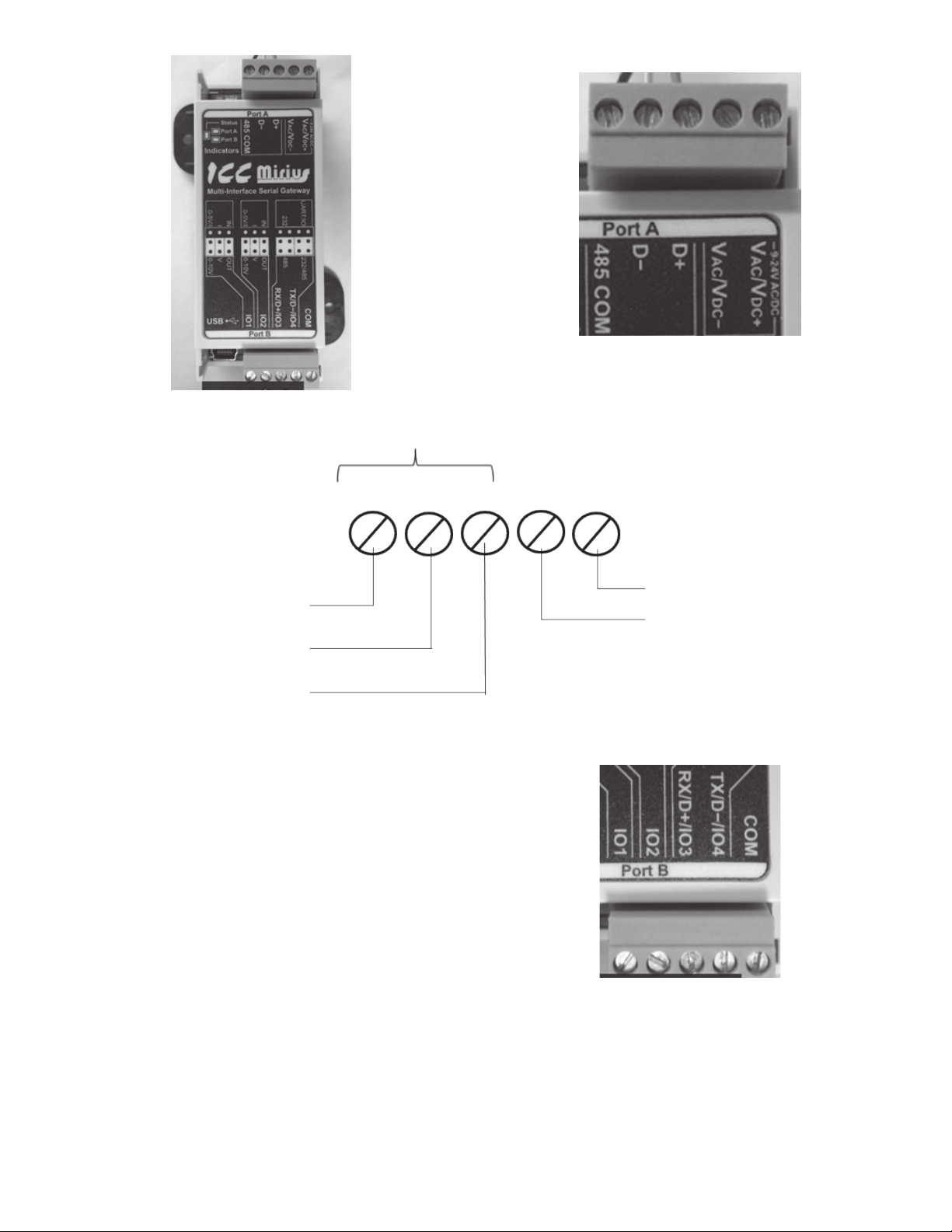

MIRIUS WIRING

Figure 9 shows the he standard conguration of the module. Port A

of the module has connections for 9 VDC power, three wire

connections for the communication (breakout) cable, for Serial

communications to the water heater/boiler.

Figure 10 is a close up of the connection terminal and Figure 11

shows the appropriate connection to the strip using the power

adapter and communication cable.

6

Page 7

Figure 9. Mirius Unit with Communications Terminal

RS485

* From Communicaon Cable

Figure 10. Close-Up View of Connection Terminal

The provided communication cable has two RJ-45 plugs.

Remove one with a wire cutter, then locate and strip the 3 wires

described below and strip 1/2 inch of insulation before connecting.

COM

Blue/White Wire*

Brown Wire*

Brown/White Wire*

†From 9VDC Power Adapter Cable

Figure 11. Mirius Wiring Schematic

The connections in Figure 11 are the same regardless of the

appliance or the communication protocol.

At the opposite end, Port B of the module is the connection

location for the EMS/BMS connection. See Figure 12. For

connections to the terminal use the labeling on the module as a

guide.

When connecting the RS-485A connections (BACnet or Modbus)

please note the following:

• Only 2-wire systems are supported

• Connect the RX/TX+ (plus) wire from your Building

Management System to terminal RX/D+. Connect the RX/

TX– (minus) wire from your Building Management System to

terminal TX/D-.

B

Power

GND

A

Power

POS

Black/White Wire†

Black Wire†

Figure 12. Mirius Port B Terminal

7

Page 8

INSTALLATION CONSIDERATIONS

There are two types of displays to consider when installing the

ICC gateway modules to the water heaters, the older type with

membrane switches and the newer style with a touch screen. The

new touch screen style display does not need the provided

RJ-485 splitter and it can be discarded.

TOUCH SCREEN STYLE DISPLAY INSTALLATION

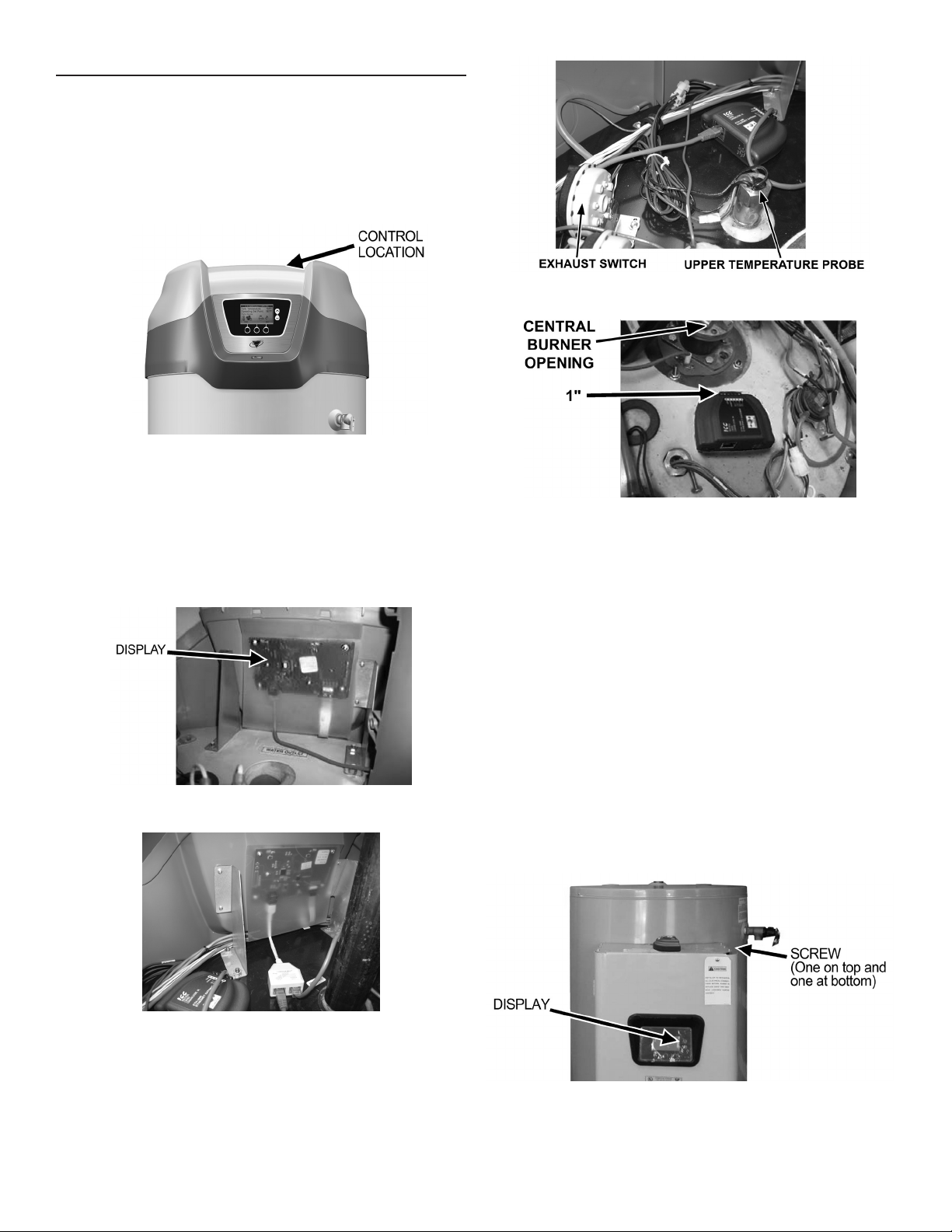

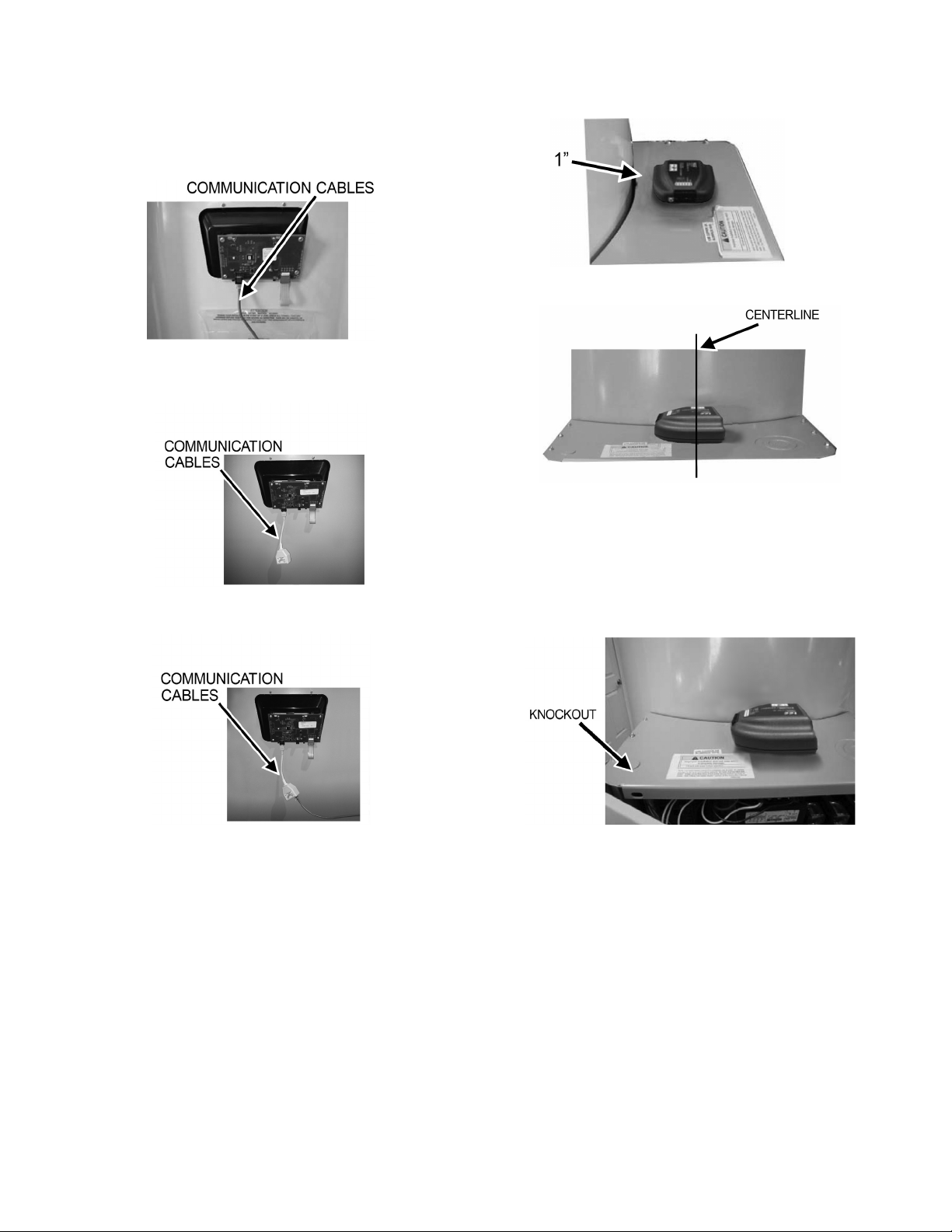

HIGH EFFICIENCY WATER HEATER INSTALLATION – (BTH OR BTX MODELS)

Follow the directions under general guidelines for connecting the

module to the Energy Management System and power. This

section will guide the installer on how to mount and connect the

module to the water heater. The control box and mounting location

on the water heater is on the top of the unit behind the display

module. See Figure 13.

Connection of the RJ-45 end of the communication cable to the

heater is required to plug into J13 of the control board inside the

“black controls box” (for newer models) requiring removal of two

screws holding the lid on. After plugging in the communications

cable, route the cable to the bottom side with the other cables and

put the lid back on with the two screws.

If the control board is in a “grey controls box” (for older model),

double check to make sure the display is not one with membrane

switches below and to the right of the display. If the display uses

membrane switches, please follow directions under the section

“MEMBRANE SWITCH STYLE DISPLAY INSTALLATION”. If it

has a grey box and is a touch screen display (replacement of

original) then the communications cable must be plug inside the

box to J9 or J10. This will require removal of the two screws

holding the lid on. After plugging in the communications cable,

route the cable to the right side with the other cables and put the

lid back on with the two screws.

Top

Control

Location

Figure 13. Controller Location (BTH or BTX models)

Removal of the top is not required, but it may be helpful to remove

the control box lid. Use a ladder to access the top of taller water

heaters.

Next locate the upper temperature probe and exhaust switch.

Position the module between the two about 1 inch from the central

burner opening. For the 500 MBTUH Model this would be next to

the upper temperature probe.

Figure 14. Location of Exhaust Switch and Upper Temperature Probe

Connect the three wires from the end of the communication cable

to the module in Accordance with page 4. Once the unit is

installed and connected, the building management system can be

connected to the appropriate connection point on the module.

Figure 15. Clearance of ICC Unit from Central Burner Opening

COMMERCIAL ELECTRIC WATER HEATER (TOUCH SCREEN INSTALLATION)

Normally the commercial electric heaters have a display with

membrane switches, but may have had a replacement touch

screen or future models may one day include touch screens. If

this heater has membrane switches on the bottom and right of the

display, then see the section below COMMERCIAL ELECTRIC

WATER HEATER INSTALLATION.

Follow directions under general guidance for connecting module

to the Energy Management System and power. This section will

guide the installer on how to mount and connect the module to the

water heater.

The module should be located where it will not interfere with the

door or in a location that is acceptable to the customer. Care

should be exercised to avoid drilling the self-tapping screws into

electrical or sensitive components. Electrical power should be

disconnected before proceeding with ICC installation.

Using a flat blade screwdriver, loosen the screws holding the door

of the unit. See Figure B1. Swing the door to the open position

and locate the control board.

Figure 16. Opening the Control Board Compartment Door

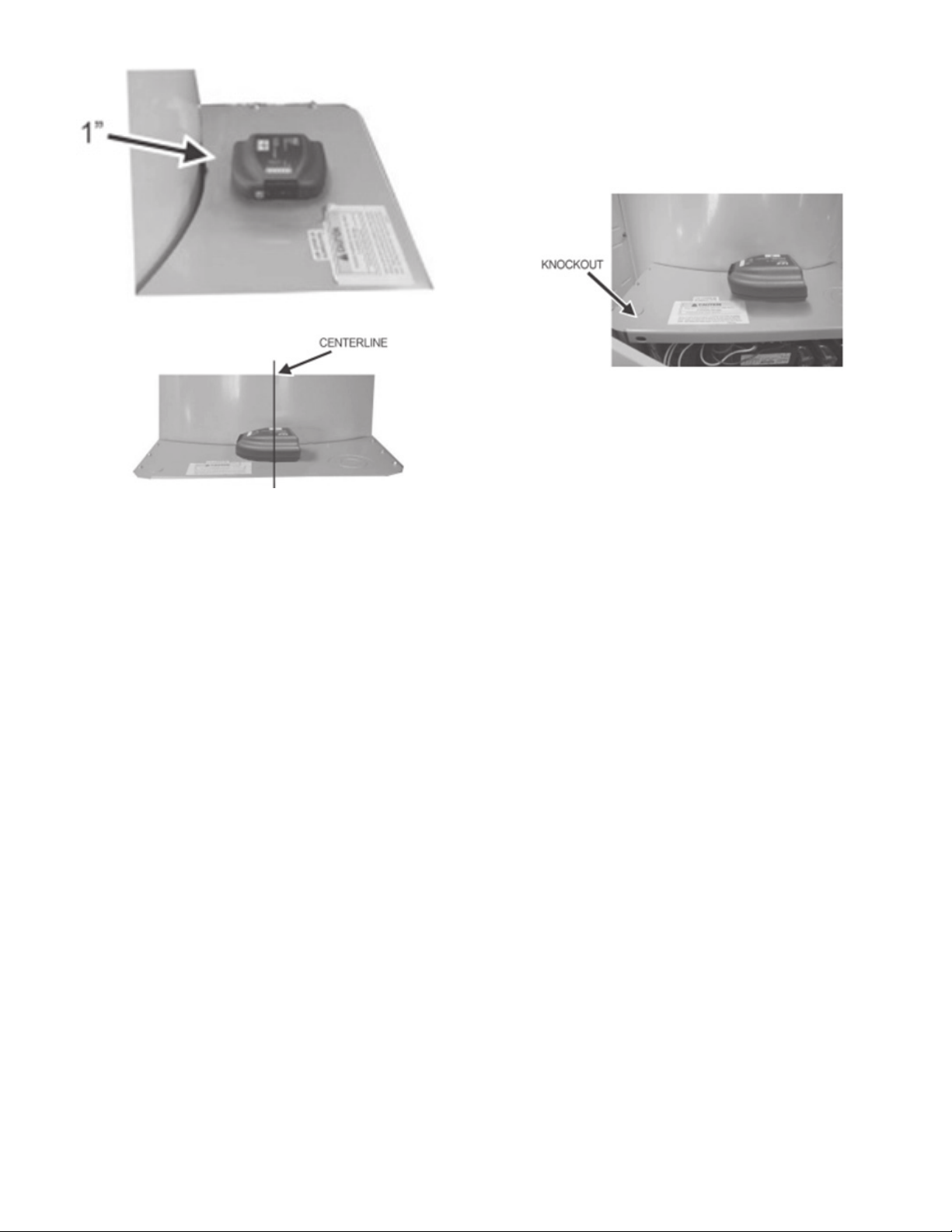

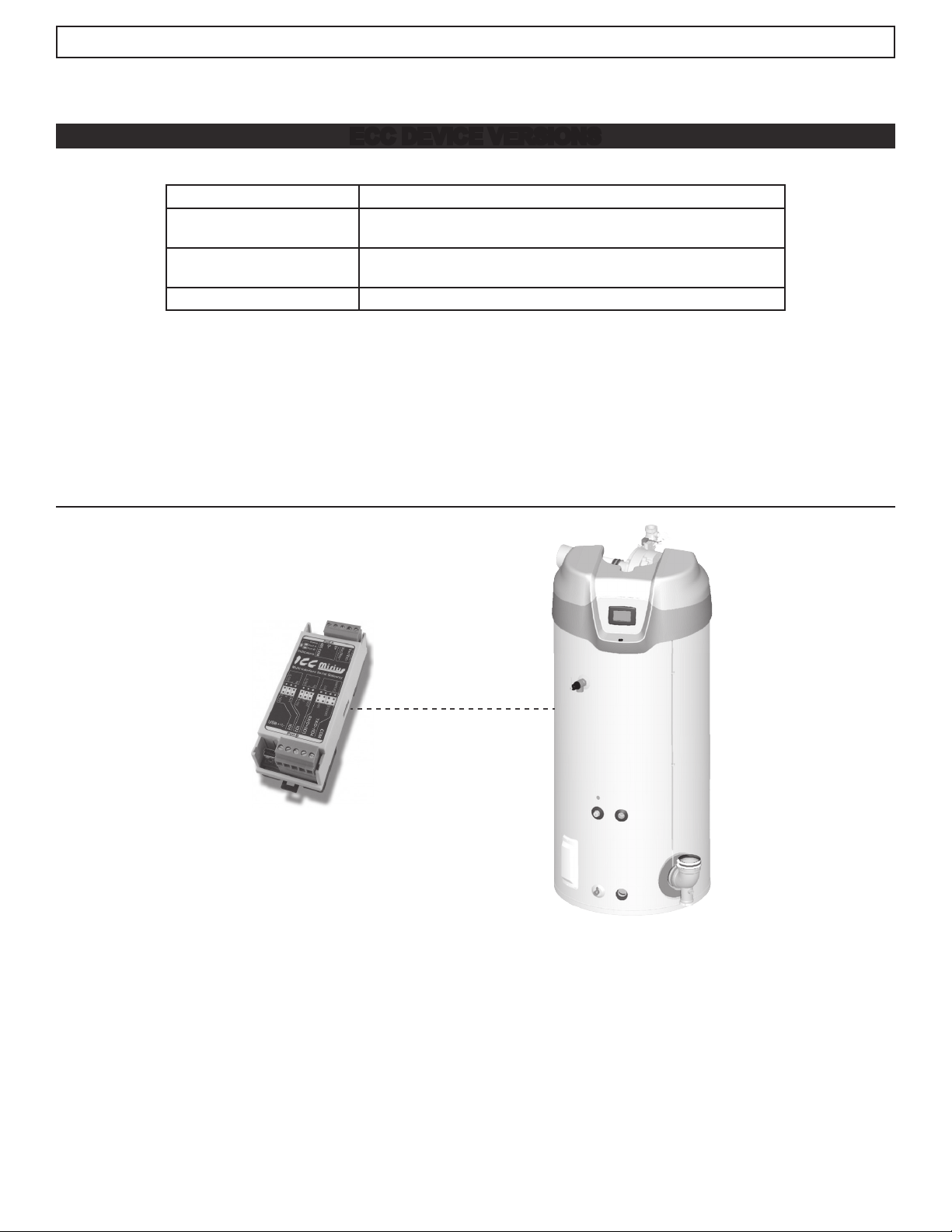

Locate the module on the top of the door cabinet approximately 1

inch from the water heater jacket and on the centerline of the unit

(See Figure 17 and Figure 18).

8

Page 9

Figure 17. ICC Location Relative to Water Heater Jacket

Figure 18. ICC Location Relative to Centerline

Remove the hole plug from the 0.875” knockout on the left corner

of the top panel. See Figure 19.

Plug the communications cable into D9 and run the three wire

connection up through the knockout and connect the three wires

to the module as shown on page 4. Once the unit is installed and

connected, the building management system can be connected to

the appropriate connection point on the module.

Figure 19. Location of Communications Wiring Knockout

9

Page 10

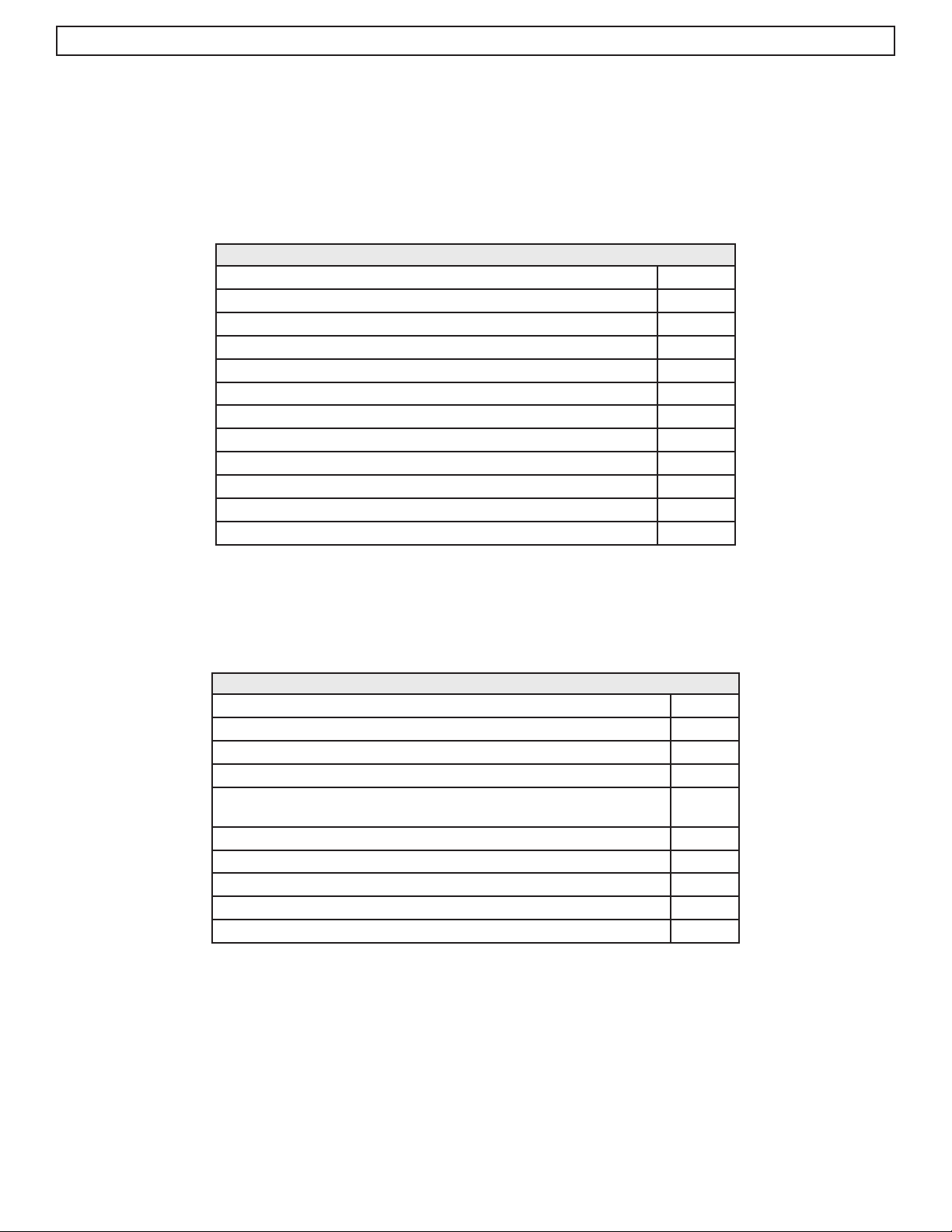

MEMBRANE SWITCH STYLE DISPLAY INSTALLATION

HIGH EFFICIENCY WATER HEATER INSTALLATION

Follow the directions under general guidelines for connecting the

module to the Energy Management System and power. This

section will guide the installer on how to mount and connect the

module to the water heater.

The control box and mounting location on the water heater is on

the top of the unit behind the display module. See Figure 20.

Figure 20. Locating the Control Box

Removal of the top is not required. Use a ladder to access the top

of taller water heaters. Locate the back of the display as shown in

Figure 21. Disconnect the RJ45 plug from the display and connect

the RJ45 plug from the split communication cord into the display

receptacle. Plug the display communication cord back into the

receptacle on the split communication cord as shown in Figure 22.

Plug the supplied wiring harness with the gateway controller into

the remaining open RJ45 port on the Split Communication cord.

Figure 21. Locating the Back of the Display

Figure 23. Locating Upper Temperature Probe and Exhaust Switch

Figure 24. Connecting the Communications Cable to the Module

Connect the three wires from the end of the communication cable

to the module in accordance with Figure 24. Once the unit is

installed and connected, the building management system can be

connected to the appropriate connection point on the module.

COMMERCIAL ELECTRIC WATER HEATER INSTALLATION

Follow directions in Device Congurations (page 6) for connecting the

module to the Energy Management System and power. This

section will guide the installer on how to mount and connect the

module to the water heater.

The module should be located where it will not interfere with the

door or in a location that is acceptable to the customer. Care

should be exercised to avoid drilling the self tapping screws into

electrical or sensitive components. Electrical power should be

disconnected before proceeding with ICC installation.

Using a flat blade screwdriver, loosen the screws holding the door

of the unit. See Figure 25.

Swing the door to the open position and locate the back of the

display module. See Figure 26.

Figure 22. Reconnecting the Communication cord to the Receptacle

Next locate the upper temperature probe and exhaust switch. See

Figure 23. Position the module between the two about 1 inch from

the central burner opening. See Figure 24. For the 500 MBTUH

model this would be next to the upper temperature probe.

Figure 25. Loosening the Screws to the Door of the Unit

10

Page 11

Unplug the display communication cable from the display. Plug

the RJ45 plug from the split communication cable into the back of

the display. See Figure 27.

Plug the display cable into the split cable receptacle as shown in

Figure 28. Plug the supplied wiring harness with the gateway

controller into the remaining open RJ45 port on the Split

Communication cable (Not shown).

Locate the module on the top of the door cabinet approximately 1

inch from the water heater jacket and on the centerline of the unit

(See Figure 29 and Figure 30).

Figure 29. Locating the Module

Figure 26. Locating the Communications Cable on Back of the

Display

Figure 27. Reconnecting RJ45 Plug from Split Communication Cable

Figure 30. Module Location Relative to Centerline

Remove the hole plug from the 0.875” knockout on the left corner

of the top panel. See Figure 31.

Run the three wire connection from the split cable up and through

the knockout and connect the three wires to the module as shown

on page 4. Once the unit is installed and connected, the building

management system can be connected to the appropriate

connection point on the module.

Figure 28. Connecting the Display Cable to Split Cable Receptacle

Figure 31. Knockout on Left Corner of Top Panel

11

Page 12

BOILER INSTALLATION

XP XWH BOILER INSTALLATION

Follow directions under general guidance for connecting module to the Energy Management System and power. This section will guide

the installer on how to mount and connect the module to the boiler.

Open the door on the low voltage wiring box on the back side of the heater to see the terminal strip where to connect the gateway to the

boiler as shown in Figure 32

Figure 32. Boiler Terminal Strip

Inside the cover of the box shows the wiring legend for the terminal strip (see Figure 33).

Figure 33. Terminal Strip Wiring Legend

Place the Gateway on top of the heater or conveniently nearby.

Locate a knock out on the right side of the low voltage box to run the communication cable through to the inside of the low voltage box.

The boiler does not have an RJ-45 connector as do the water heaters to connect Port A of the gateway, so the plug on the other end of

the communications cable must also be cut off with a wire cutter. Locate and strip the insulation ½ inch from the brown, brown/white

and blue/white wires. Connect the brown/white wire to COM2_A, the brown wire to COM2_B, and the blue/white wire to COM2_C.

12

Page 13

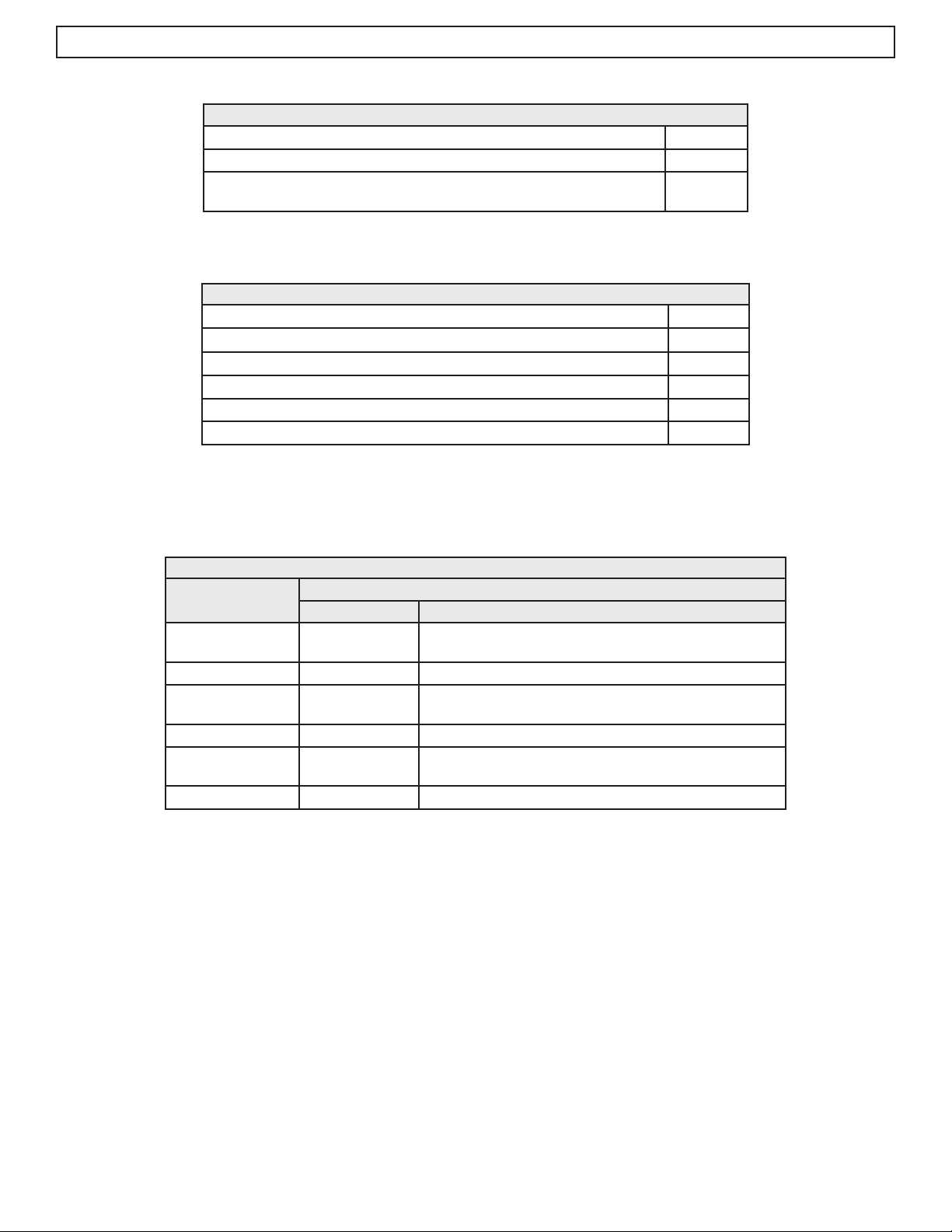

Two versions of the ECC are available as follows:

BACnet / Gas Water Heaters

ECC DEVICE VERSIONS

Product:

Product Model Number:

Product Version:

BACnet Protocol Revision:

The following sections describe the ECC communications characteristics available with each of the following types of water heaters:

• BACnet/Gas

• BACnet/Electric

• BACnet/Boilers

• ModBus/Gas

• ModBus/Electric

ICC Gateway (for use with XiTM and MXiTM Gas Water Heaters)

• 100316044 (Mirius for BACnet MT/TP)

• 100316045 (ETH-1000 for BACnet IP)

V3.000 (Mirius) or

V4.001 or greater (ETH-1000)

12 (135-2010)

BACNET / GAS WATER HEATERS

Figure 34. Cyclone Xi Gas Water Heaters (Virtual BACnet device via ICC Gateway)

PRODUCT DESCRIPTION

The Mirius is a multiprotocol RS-485 to RS-485 gateway. The ETH-1000 is an Ethernet to RS-485 multiprotocol gateway. These

products supports native BACnet, connecting directly to IP or the MS/TP LAN using baud rates of 4800, 9600, 19200, 38400, 57600,

76800, and 115200. As shipped the devices are congured as a BACnet Server.

All XI™ MXi™ controls provide communications via propriety protocol with the ICC Gateway. The Mirius supports BACnet MS/TP

communications and the ETH-1000 supports BACnet/IP to access data available at the display plus control of a limited number of

points such as Operating Setpoint.

13

Page 14

BACnet / Gas Water Heaters

PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT (PICS)

BACnet Standardized Device Prole (Annex L):

BACnet Application Specic Controller (B-ASC)

BACnet Interoperability

Table 3. BACnet Interoperability Building Blocks Supported (Annex K):

Data Sharing - ReadProperty-A (DS-RP-A)

Data Sharing - ReadProperty-B (DS-RP-B)

Data Sharing - ReadPropertyMultiple-B (DS-RPM-B)

Data Sharing - WriteProperty-A (DS-WP-A)

Data Sharing - WriteProperty-B (DS-WP-B)

Data Sharing - WritePropertyMultiple-B (DS-WPM-B)

Data Sharing – COV-B (DS-COV-B) (BACnet/IP only)

Device Management-Dynamic Device Binding-A (DM-DDB-A)

Device Management-Dynamic Device Binding-B (DM-DDB-B)

Device Management-Dynamic Object Binding-B (DM-DOB-B)

Device Management-Device Communication Control-B (DM-DCC-B)

Device Management – ReinitializeDevice-B (DM-RD-B)

Segmentation Capability

Segmentation not supported.

Data Link Layer Options

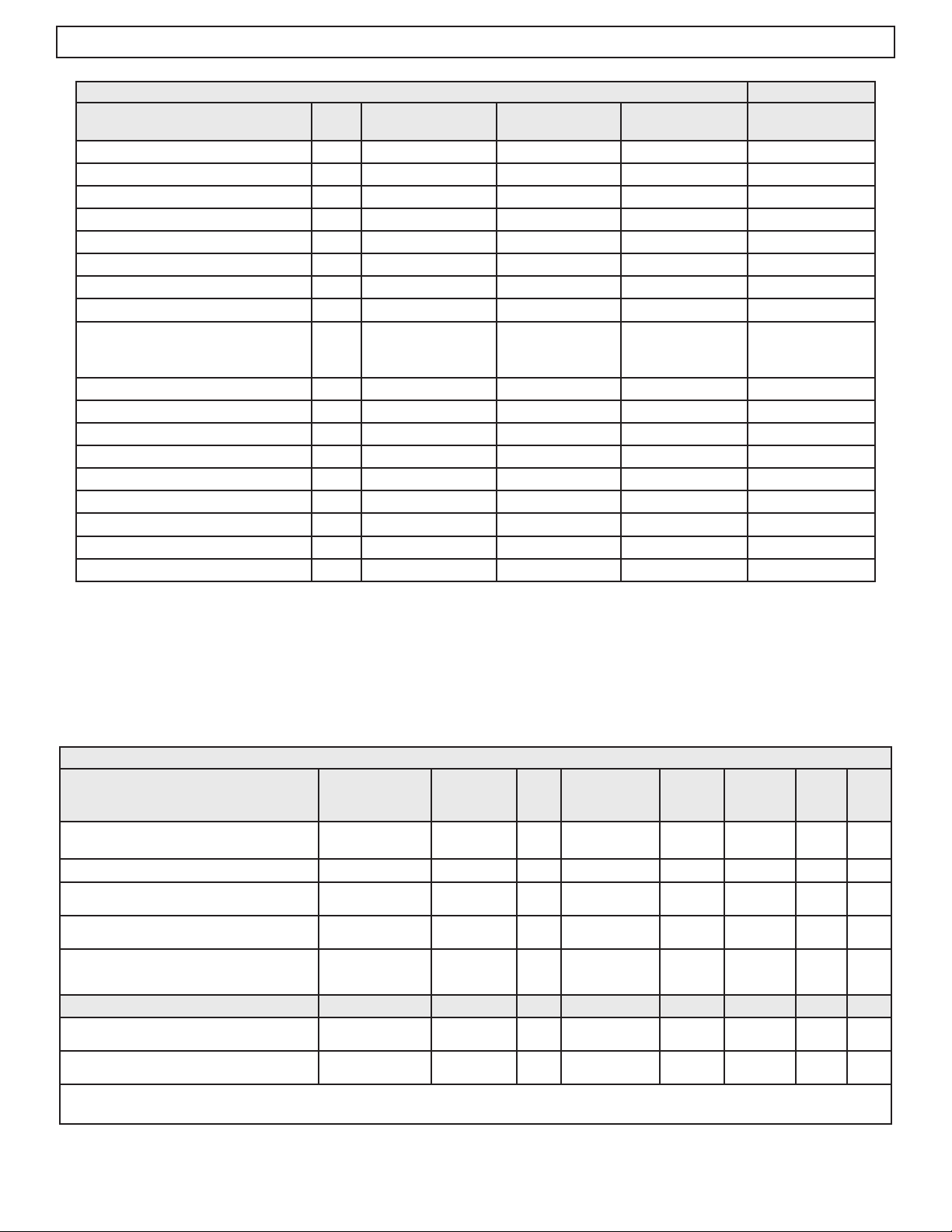

Table 4. Data Link Layer Options

BACnet IP (Annex J) (ETH-1000 only)

BACnet IP (Annex J), Foreign Device (ETH-1000 only)

ANSI/ATA 878.1, 2.5Mb. ARCNET (Clause 8)

ANSI/ATA 878.1, RS-485. ARCNET (Clause 8), baud rates() ________

MS/TP master (Clause9) baud rate(s): 4800, 19200, 38400, 57600,

76800, 115200

MS/TP slave (Clause9) baud rate(s): _________

Point-To-Point, EIA 232 (Clause 10), baud rate(s): _________

Point-To-Point, modem (Clause 10), baud rate(s): _________

LonTalk, (Clause 11), medium ________

Other: _________________

Device Address Binding

Is static device binding supported? (This is currently for two-way communications with MS/TP slaves and certain other devices.) YES

14

Page 15

Networking Options

Character Sets

BACnet / Gas Water Heaters

Table 5. Networking Options

Router, Clause 6 – List all routing congurations

Annex H, BACnet Tunneling Router over IP

BACnet/IP Broadcast Management Device (BBMD). Does the BBMD

support registrations by Foreign Devices? (ETH-1000 only)

Table 6. Character Sets Supported

ANSI X3.4

IBMTM /MicrosoftTM DBCS

ISO 8859-1

ISO 10646 (UCS-2)

ISO 10646 (UCS-4)

JIS C 6226

Data Types

The following table summarizes the data types that are accepted (in the case of a write property service) and returned (in the case of a

read property service) when targeting the present value property of each supported object type.

Table 7. Data Types Supported

Service

Object Type

Analog Output

Read Property Write Property

Real Real, Unsigned, Integer, Null

Analog Value

Analog Input Real N/A

Binary Output

Enumerated Enumerated, Boolean, Real, Unsigned, Integer, Null

Binary Value

Binary Input Enumerated N/A

Multi-state Output

Unsigned Real, Enumerated, Unsigned, Integer, Null

Multi-state Value

Multi-state Input Unsigned N/A

15

Page 16

Object Types and Properties

Property Device

Object Identier

Object Name

Object Type

System Status

Vendor Name

Vendor Identier

Model Name

Firmware Revision

App S/W Revision

Protocol Revision

Services Supported

Object Types Supported

Object List

Max APDU Length

Segmentation Support

APDU Timeout

Number APDU Retries

Max master

Max Info Frames

Device Address Binding

Database Revision

Present Value

Status Flags

Event State

Out-of Service

Units

Priority Array

Relinquish Default

Polarity

Inactive Text

Active Text

R - readable using BACnet services

W - readable and writable using BACnet services

BACnet / Gas Water Heaters

Table 8. Object Types/Property Support Table

Binary

Input

R R R R R R R R R R

R R R R R R R R R R

R R R R R R R R R R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R W W R W W R W W

R R R R R R R R R

R R R R R R R R R

R R R R R R R R R

R R R R R R

R R R R R

R R R R R

R R

R R

R R

Binary

Output

Binary

Value

Analog

Input

Analog

Output

Analog

Value

Multi

Input

Multi

Output

Multi

Value

DEVICE OBJECT LISTINGS

Object Min/Max Values

Note: Point listings have been changed completely from earlier versions of this listing.

Table 9. Device Object

Property Name ID BACnet Data Type RW Initial Value

(Mirius)

Initial Value

(ETH-1000)

Object_Identier 75 Object Identier RW Device, 520081 Device, 520081

Object_Name 77 Character String RW Water Heater-01 Water Heater-01

Object_Type 79 Enumerated R Device Device

System_Status 112 R Operational Operational

16

Page 17

BACnet / Gas Water Heaters

Table 9. Device Object

Property Name ID BACnet Data Type RW Initial Value

(Mirius)

Vendor_Name 121 R ICC, Inc. ICC, Inc.

Vendor_Identier 120 R 242 242

Model_Name 70 R Mirius ETH-1000

Firmware_Revision 44 Character String R V3.300 V4.002

Application_Software_Version 12 R V3.300 V4.002

Protocol_Version 98 R 1

Protocol_Revision 139 R 2

Protocol_Services_Supported 97 R See PICS

Protocol_Object_Types_Supported 96 R AI, AO, AV, BI,

BO, BV, MSI,

MSO, MSV

Object_List 76 R See Table See Table

Max_APDU_Length_Accepted 62 R 480 1444

Segmentation_Supported 107 R 3 3

APDU_Timeout 10 RW 1000ms 1000ms

Number_Of_APDU_Retries 73 R 3 3

Max_Master 64 RW 127 Unsupported

Device_Address_Binding 30 R {} {}

Local_Date 56 R Unsupported Unsupported

Local_Time 57 R Unsupported Unsupported

Initial Value

(ETH-1000)

AI, AO, AV, BI,

BO, BV, MSI,

MSO, MSV

BACnet/Gas Water Heaters Object List

• Not all models support all registers. Also parameter names may be different than shown here on some models.

• This table may be subject to change in the future.

• Adjustable objects are in bold and indicated by “W” (writable).

Table 10. BACnet/Gas Water Heaters Object List

BACnet

Object Name

(Description)

Firmware Ver-Rev

(Firmware Version)

Conguration Analog Input 2 Present_Value R

Upper Temperature

(Upper or Primary Temperature)

Lower Temperature

(Lower or Secondary Temperature)

Tank Temperature

(Controlling Tank Temperature algorithmically

calculated)

Temper Setpoint

(Desired Tank Temperature)

SetPoint Differ

(Setpoint Differential)

1. Data is encoded into the 16 bits as major revision (upper 8 bits) and minor revision (lower 8 bits).

2. Not recommended for use currently as UIM does not currently support and warning will come up as “Unknown.”

1

BACnet

Object

Type/Inst.

Analog Input 1 Present_Value R

Analog Input 3 Present_Value R ºC

Analog Input 4 Present_Value R ºC

Analog Input 5 Present_Value R ºC

Analog Value 201 Present_Value R/W ºC

Analog Value 202 Present_Value R/W °C

BACnet

Object

Property R/W Units

(ºF)

(°F)

Min

Value

(if W)

32.2

(90)

1.1

(2)

Max

Value

(if W) Xi 1.0 Mxi

82.2

(180)

11.1

(20)

17

Page 18

BACnet / Gas Water Heaters

Table 10. BACnet/Gas Water Heaters Object List

BACnet

Object Name

(Description)

Mxi Mod% Cmd

Commands Modulation % (0%=minimum heat,

100%=rated heat). Note: It is really an upper limit.

If heater wants to command less it will.

MxiLowTempAlrmSP2

(Low Temperature Alarm)

Number of Cycles

(Number of heating cycles)

Elapsed Time

(Time heater has been powered up in Hours with

two place beyond the decimal)

Elapsed Days

(The number of days that the heater has been

powered up)

Elapsed Hours

(The hours portion that the heater has been powered up. Use with Elapsed Days)

Heating Time

(Time heater has been actually heating water in

Hours with two place beyond the decimal)

Heating Days

(The amount of time in number of days heater has

been actually heating water)

Heating Hours

(The hours portion of the amount of time heater

has been actually heating water. Use with Heating

Days)

IgniterCurrent

(Hot Surface Igniter current in amps)

#CCB HW Faults

(CCB Hardware Fault Counter)

#Model Faults

(Model Fault Counter)

#Upper Temp Faults

(Upper Temperature Probe Fault Counter)

#Lower Temp Faults

(Lower Temperature Probe Fault Counter)

#Flame Probe Flt

(Flame Probe Fault Counter)

#Flame Status Flt

(Flame detect or not detected at proper time Fault

Counter)

#CCB Comm Faults

(Communication Fault Counter)

#ECO Faults

(High temperature Energy Cut Off switch in Upper

temperature probe Fault Counter)

#LowGasPress Flt

(Low Gas Pressure switch Fault Counter)

#Blocked In Flts

(Blocked Inlet pressure switch Fault Counter)

#Blocked Exhst Flt

(Blocked Exhaust Pressure & Condensate switch

Fault Counter)

#Ext Vent Faults

(External Vent Fault Counter)

#Blower Prv Flts

(Blower Prove Pressure Switch Fault Counter)

#Igniter Faults

(Igniter Fault Counter)

1. Data is encoded into the 16 bits as major revision (upper 8 bits) and minor revision (lower 8 bits).

2. Not recommended for use currently as UIM does not currently support and warning will come up as “Unknown.”

BACnet

Object

Type/Inst.

Analog Value 207 Present_Value R/W % 0 100

Analog Value 208 Present_Value R/W ºC

Analog Value 209 Present_Value R

Analog Value 210 Present_Value R Hours with two

Analog Value 211 Present_Value R Days

Analog Value 212 Present_Value R Hours

Analog Value 213 Present_Value R Hours with two

Analog Value 214 Present_Value R Days

Analog Value 215 Present_Value R Hours

Analog Value 216 Present_Value R Amps

Analog Value 217 Present_Value R

Analog Value 218 Present_Value R

Analog Value 219 Present_Value R

Analog Value 220 Present_Value R

Analog Value 221 Present_Value R

Analog Value 222 Present_Value R

Analog Value 223 Present_Value R

Analog Value 224 Present_Value R

Analog Value 225 Present_Value R

Analog Value 226 Present_Value R

Analog Value 227 Present_Value R

Analog Value 228 Present_Value R

Analog Value 229 Present_Value R

Analog Value 230 Present_Value R

BACnet

Object

Property R/W Units

(ºF)

places beyond

the decimal.

places beyond

the decimal.

Min

Value

(if W)

32.2

(90)

Max

Value

(if W) Xi 1.0 Mxi

82.2

(180)

18

Page 19

BACnet / Gas Water Heaters

Table 10. BACnet/Gas Water Heaters Object List

BACnet

Object Name

(Description)

#Ignition Failure

(Ignition Failure Fault Counter)

#Powr Supply Flt

(Power Supply Fault Counter)

#Powr Anode Flts

(Powered Anode Alert Counter)

EMS Mode-Status Analog Value 263 Present_Value R/W Xi 1.0 see table 3

BACnet

Object

Type/Inst.

Analog Value 231 Present_Value R

Analog Value 232 Present_Value R

Analog Value 233 Present_Value R

BACnet

Object

Property R/W Units

Min

Value

(if W)

Max

Value

(if W) Xi 1.0 Mxi

Upper Temp Open

(Upper temperature Probe open status)

Upper Temp Short

(Upper temperature Probe shorted status)

MXi Call For Heat Binary Input 303 Present_Value R 0 = No

Lower Temp Open

(Upper temperature Probe open status)

Lower Temp Short

(Upper temperature Probe shorted status)

Igntr Current OK

(Igniter Current Sensed)

Flame Sensed

(Igniter Current Sensed)

Blower Prove PS

(Blower Prove pressure switch)

Ext Vent PS

(External Vent pressure switch status if selected by

DIP switch on CCB)

Blocked Exhaust PS

(Blocked exhaust pressure switch)

Blocked Inlet PS

(Blocked air intake pressure switch)

Low Gas PS

(Low Gas supply pressure switch)

Upper Temp ECO

(Upper temperature probe high temperature Energy Cut Out Status)

External T’stat

(External Thermostat status if selected by DIP

switch on CCB)

Xi 1.0 Call For Heat

(Conditions are satised to allow heater to heat

water)

MXi LowTemp Alrm

(Tank temperature below Low Tank Temperature

Alarm setpoint)

MXi LeakDetected

(Optional Leak detector circuit detected water)

Mxi HeaterEnab’d

(Front Switch Heater Enable status)

MXi External Enab

(Optional input status)

Xi 1.0 Ign Tries

(Number of tries for ignition set by DIP switch on

CCB)

Ext Vent Relay

(External Vent Relay output commanded status)

1. Data is encoded into the 16 bits as major revision (upper 8 bits) and minor revision (lower 8 bits).

2. Not recommended for use currently as UIM does not currently support and warning will come up as “Unknown.”

Binary Input 301 Present_Value R 0 = Okay

1 = Open

Binary Input 302 Present_Value R 0 = Okay

1 = Shorted

1 = Yes

Binary Input 304 Present_Value R 0 = Okay

1 = Open

Binary Input 305 Present_Value R 0 = Okay

1 = Shorted

Binary Input 306 Present_Value R 0=No Current

1=Current

Sensed

Binary Input 307 Present_Value R 0=No Flame

1=Flame Sensed

Binary Input 308 Present_Value R 0=Open Switch

1=Closed Switch

Binary Input 309 Present_Value R 0=Open Switch

1=Closed Switch

Binary Input 310 Present_Value R 0=Open Switch

1=Closed Switch

Binary Input 311 Present_Value R 0=Open Switch

1=Closed Switch

Binary Input 312 Present_Value 0=Open Switch

1=Closed Switch

Binary Input 313 Present_Value 0=Open Switch

1=Closed Switch

Binary Input 314 Present_Value 0 = No

1 = Yes

Binary Input 315 Present_Value 0 = Okay

1 = Alarm

Binary Input 316 Present_Value 0 = Okay

1 = Alarm

Binary Input 317 Present_Value 0=No Leak

1=Leak Detected

Binary Input 318 Present_Value 0=Disabled

1 = Enabled

Binary Input 319 Present_Value 0=Disabled

1 = Enabled

Binary Input 320 Present_Value 0 = 3 tries

1 = 1 try

Binary Output 401 Present_Value 0 = Off

1 = On

19

Page 20

BACnet / Gas Water Heaters

Table 10. BACnet/Gas Water Heaters Object List

BACnet

Object Name

(Description)

Blower Relay

(Blower Relay output commanded status)

Ignition Relay

(Ignition Relay output commanded status)

Gas Valve Relay

(Gas valve Relay output commanded status)

MXi Ign Tries

(Selects 1 or 3 tries for ignition. Settable at UIM)

MXi Use Ext Enab

(Selects whether or not to use Optional External

Enable Input. Settable at UIM)

MXi Modulation

(CCB S/W version 3.15 or higher. Disables mod-

ulation on heaters that have it. May be helpful if

plumbed with Xi 1.0. Settable at UIM)

System In Fault Binary Value 504 Present_Value 0 = Okay

System State

(CCB Control State)

Fault Code Multistate Value 802 Present_Value

Alert Code Multistate Value 803 Present_Value

1. Data is encoded into the 16 bits as major revision (upper 8 bits) and minor revision (lower 8 bits).

2. Not recommended for use currently as UIM does not currently support and warning will come up as “Unknown.”

BACnet

Object

Type/Inst.

Binary Output 402 Present_Value 0 = Off

Binary Output 403 Present_Value 0 = Off

Binary Output 404 Present_Value 0 = Off

Binary Value 501 Present_Value 0 = 3 tries

Binary Value 502 Present_Value 0 = No

Binary Value 503 Present_Value 0=Disabled

Multistate Value 801 Present_Value

BACnet

Object

Property R/W Units

1 = On

1 = On

1 = On

1 = 1 try

1 = Yes

1=Enabled

1 = Alarm

See Table 10

See Table 13

See Table 13

Min

Value

(if W)

Max

Value

(if W) Xi 1.0 Mxi

Central Control Board Major State Denitions

Table 11. Gas Central Control Board (CCB) Major State Denitions

Value Xi 1.0 State MXi State

1 Off (Standby) Off (Standby)

2 Pre-Purge Pre-Purge

3 Igniter Warmup Igniting

4 Ignition Activation Gas Valve On

5 Ignition Verication Inter-Purge

6 Inter-Purge Heating

7 Heating Post-Purge

8 Post-Purge In Fault

9 Fault

Xi 1.0 Energy Management System (EMS) Control

Xi 1.0 uses a single bit setting method. Within the EMS Mode-Status point one bit command (bit 15) sets it in EMS mode, and other

ends EMS mode. Once in EMS mode, another bit command (bit 0) enables heating another disables heating.

Once in EMS mode the EMS Mode Refresh command must be periodically issued which clears a third bit (bit 14) to maintain EMS

mode, otherwise the heater will end EMS mode and resume normal operation.

20

Page 21

BACnet / Gas Water Heaters

Table 12. Xi 1.0 Energy Management System (EMS) Control

Decimal Hex Value Response

3840 0x0F00 No EMS control 0 / 0x000

3841 0x0F01 Put into EMS Mode^ 49152 / 0xC000

0000 0x0000 EMS Disable heating^ 49152 / 0xC000

0001 0x0001 EMS Enable heating^ 49153 / 0xC001

3584 0x0E00 EMS Mode Refresh^ (must write within 30 seconds

or EMS mode ends.) 15 seconds or less

recommended

Notes:

The start of a heating also depend on other factors like tank temperature dropping below Setpoint – Differential and External T’stat call for heat if that option is enabled.

Depending on when you poll the register, you may read bit 14 as 1 which is why a “C” (in hexadecimal form) might briefly reply with “8”. This is due to the control setting

this bit and if it not cleared periodically by the BACnet command, heating is disabled.

After disabling EMS mode with write of 3840, read back might have bits 14 and 1 possibly still set. To make sure these bits are clear, write a 0000 to clear bit 1 and 3584 to

clear bit 14.

Mxi Energy Management System (EMS) Control

Mxi EMS control is written as a single command to place in EMS mode and enable or disable heating.

Once in EMS mode the EMS Mode Refresh command must be periodically issued to maintain EMS mode, otherwise the heater will end

EMS mode and resume normal operation.

49152 / 0xC000 or 49153 / 0xC001 depending on

whether or not heating is enabled.

Table 13. Mxi Energy Management System (EMS) Control

Decimal Hex Value Response

0 0x0000 No EMS control~ 0 / 0x000

32768 0x8000 EMS Disable Heating^ 49152 / 0xC000

32769 0x8001 EMS Enable Heating^* 49153 / 0xC001

Notes:

~ For Versions less than 3.16, once EMS control mode is enabled it remains enabled through BACnet it will remain in EMS control mode that cannot be cleared by writing

a 0 to it. Power cycling only can clear EMS mode.

^ Depending on when you poll the register, you may read bit 14 as 1 which is why a “C” (in hexadecimal form) might briefly reply with “8”. This is due to the control setting

this bit and if it not cleared periodically by the BACnet command, heating is disabled.

* EMS command to heat must be sent every 30 maximum or heating will be disabled.

21

Page 22

BACnet / Gas Water Heaters

Fault Codes and Warnings

Note: Any Fault not listed is an internal CCB failure fault.

Table 14. Fault codes and Warnings

Index Range

(Decimal)

1 1 Okay (No Fault)

1 6 Memory

24 Incorrect Model

51 56 Power Monitor

69 72 Temperature Probe Open or Short

129 129 Leak Detected

153 154 Communications Fault

165 High temperature ECO (Energy Cut Off)

175 Safety Relay Closed fault

176 188 CCB internal errors

193 194 Processor Clock

198 201 Non-volatile Memory

204 217 Powered Anode

431 Safety Relay Opened fault

Value

22

Page 23

BACNET / ELECTRIC WATER HEATERS

BACnet / Electric Water Heaters

Figure 35. Custom and Gold Xi™ Series Electric Water Heaters (Virtual BACnet device via ICC Gateway)

PRODUCT DESCRIPTION

The Mirius is a multiprotocol RS-485 to RS-485 gateway. The ETH-1000 is an Ethernet to RS-485 multiprotocol gateway. These

products supports native BACnet, connecting directly to IP or the MS/TP LAN using baud rates of 4800, 9600, 19200, 38400, 57600,

76800, and 115200. As shipped the devices are congured as a BACnet Server.

All electronic controls provide communications via propriety protocol with the ICC Gateway. The Mirius supports BACnet MS/TP

communications and the ETH-1000 supports BACnet IP to access data available at the display plus control of a limited number of

points such as Operating Setpoint.

PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT (PICS)

BACnet Standardized Device Prole (Annex L):

BACnet Application Specic Controller (B-ASC)

BACnet Interoperability

Table 15. BACnet Interoperability Building Blocks Supported (Annex K):

Data Sharing - ReadProperty-A (DS-RP-A)

Data Sharing - ReadProperty-B (DS-RP-B)

Data Sharing - ReadPropertyMultiple-B (DS-RPM-B)

Data Sharing - WriteProperty-A (DS-WP-A)

Data Sharing - WriteProperty-B (DS-WP-B)

Data Sharing - WritePropertyMultiple-B (DS-WPM-B)

Data Sharing – COV-B (DS-COV-B) (BACnet/IP only)

Device Management-Dynamic Device Binding-A (DM-DDB-A)

Device Management-Dynamic Device Binding-B (DM-DDB-B)

Device Management-Dynamic Object Binding-B (DM-DOB-B)

23

Page 24

Device Management-Device Communication Control-B (DM-DCC-B)

Device Management – ReinitializeDevice-B (DM-RD-B)

Segmentation Capability

Segmentation not supported.

Data Link Layer Options

BACnet IP (Annex J) (ETH-1000 only)

BACnet IP (Annex J), Foreign Device (ETH-1000 only)

ANSI/ATA 878.1, 2.5Mb. ARCNET (Clause 8)

ANSI/ATA 878.1, RS-485. ARCNET (Clause 8), baud rates() ________

MS/TP master (Clause9) baud rate(s): 4800, 19200, 38400, 57600, 76800, 115200

MS/TP slave (Clause9) baud rate(s): _________

Point-To-Point, EIA 232 (Clause 10), baud rate(s): _________

Point-To-Point, modem (Clause 10), baud rate(s): _________

LonTalk, (Clause 11), medium ________

Other: _________________

BACnet / Electric Water Heaters

Table 15. BACnet Interoperability Building Blocks Supported (Annex K):

Table 16. Data Link Layer Options

Device Address Binding

Is static device binding supported? (This is currently for two-way communications with MS/TP slaves and certain other devices.) YES

Networking Options

Table 17. Networking Options

Router, Clause 6 – List all routing congurations

Annex H, BACnet Tunneling Router over IP

BACnet/IP Broadcast Management Device (BBMD). Does the BBMD support registrations by

Foreign Devices? (ETH-1000 only)

Character Sets

Table 18. Character Sets Supported

ANSI X3.4

IBMTM /MicrosoftTM DBCS

ISO 8859-1

ISO 10646 (UCS-2)

ISO 10646 (UCS-4)

JIS C 6226

24

Page 25

Data Types

Object Type

Analog Output

Analog Value

Analog Input Real N/A

Binary Output

Binary Value

Binary Input Enumerated N/A

Multi-state Output

Multi-state Value

Multi-state Input Unsigned N/A

Object Types and Property Support

Property Device

Object Identier

Object Name

Object Type

System Status

Vendor Name

Vendor Identier

Model Name

Firmware Revision

App S/W Revision

Protocol Revision

Services Supported

Object Types Supported

Object List

Max APDU Length

Segmentation Support

APDU Timeout

Number APDU Retries

Max master

Max Info Frames

Device Address Binding

Database Revision

Present Value

Status Flags

Event State

Out-of Service

Units

Priority Array

Relinquish Default

Polarity

R - readable using BACnet services

W - readable and writable using BACnet services

BACnet / Electric Water Heaters

Table 19. Data Types Supported

Service

Read Property Write Property

Real Real, Unsigned, Integer, Null

Enumerated Enumerated, Boolean, Real, Unsigned, Integer, Null

Unsigned Real, Enumerated, Unsigned, Integer, Null

Table 20. Object Types/Property Support Table

Binary

Input

R R R R R R R R R R

R R R R R R R R R R

R R R R R R R R R R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

R

Binary

Output

Binary

Value

Analog

Input

Analog

Output

Analog

Value

Multi

Input

Multi

Output

Multi

Value

R W W R W W R W W

R R R R R R R R R

R R R R R R R R R

R R R R R R R R

R R R R R R

R R R R R

R R R R R

R R

25

Page 26

BACnet / Electric Water Heaters

Table 20. Object Types/Property Support Table

Binary

Property Device

Input

Inactive Text

Active Text

R - readable using BACnet services

W - readable and writable using BACnet services

DEVICE OBJECT LISTINGS

Device Objects Initial Values

Table 21. BACnet/Electric Water Heaters Device Object

Property Name ID BACnet Data Type RW Initial Value

Object_Identier 75 Object Identier RW Device, 520081 Device, 520081

Object_Name 77 Character String RW Elec Water Heater Elec Water Heater

Object_Type 79 Enumerated R Device Device

System_Status 112 R Operational Operational

Vendor_Name 121 R ICC, Inc.

Vendor_Identier 120 R 242

Model_Name 70 R Mirius ETH-1000

Firmware_Revision 44 Character String R V3.000 V4.001

Application_Software_Version

Protocol_Version 98 R 1 1

Protocol_Revision 139 R 12 12

Protocol_Services_Supported 97 R See PICS See PICS

Protocol_Object_Types_Supported 96 R AI, AO, AV, BI, BO, BV,

Object_List 76 R See Table See Table

Max_APDU_Length_Accepted 62 R 480 1444

Segmentation_Supported 107 R 3 3

APDU_Timeout 10 RW 1000ms 1000ms

Number_Of_APDU_Retries 73 R 3 3

Max_Master 64 RW 127 Unsupported

Device_Address_Binding 30 R {} {}

Local_Date 56 R Unsupported Unsupported

Local_Time 57 R Unsupported Unsupported

12 R

Binary

Output

R R

R R

Binary

Value

Analog

Input

Analog

Output

Analog

Value

Multi

Input

Multi

Output

Initial Value

(Mirius)

V3.000 V4.001

MSI, MSO, MSV

AI, AO, AV, BI, BO, BV,

MSI, MSO, MSV

Multi

Value

(ETH-1000)

Device Objects Minimum/Maximum Values

• Not all models support all registers. Also parameter names may be different than shown here on some models.

• This table may be subject to change in the future.

• Adjustable objects are in bold and indicated by “W” (writable).

• Mirius Object names may be abbreviated to t in 16 characters.

• Where noted, some objects implemented only in ETH-1000.

Table 22. BACnet/Electric Water Heaters Object List

BACnet

Object Name

(Description)

Firmware Ver-Rev1

(Firmware Version)

Conguration Analog Input 2 Present_Value R

1. Data is encoded into the 16 bits as major revision (upper 8 bits) and minor revision (lower 8 bits).

BACnet

Object

Type/Inst.

Analog Input 1 Present_Value R

BACnet

Object

Property R/W Units

26

Min

Value

(if W)

Max

Value

(if W)

Page 27

BACnet / Electric Water Heaters

Table 22. BACnet/Electric Water Heaters Object List

BACnet

Object Name

(Description)

Tank Temperature

(Controlling (Tank) Temperature)

Lower Temperature

(Lower or Secondary Temperature)

Tank Temperature

(Controlling Tank Temperature algorithmically

calculated)

Temper Setpoint

(Desired Tank Temperature)

Differen’lBank1

(Differential Setpoint Bank 1)

Differen’lBank2

(Differential Setpoint Bank 2)

Differen’lBank3

(Differential Setpoint Bank 3)

Differen’lBank4

(Differential Setpoint Bank 4)

Differen’lBank5

(Differential Setpoint Bank 5)

Number of Cycles

(Number of heating cycles)

Elapsed Time

(Time heater has been powered up in Hours

with two place beyond the decimal)

Elapsed Days

(The number of days that the heater has been

powered up)

Elapsed Hours

(The hours portion that the heater has been

powered up. Use with Elapsed Days)

Heating Time

(Time heater has been actually heating water

in Hours with two place beyond the decimal)

Heating Days

(The amount of time in number of days heater

has been actually heating water)

Heating Hours

(The hour’s portion of the amount of time

heater has been actually heating water. Use

with Heating Days)

#CCB HW Faults

(CCB Hardware Fault Counter)

#Model Faults

ETH-1000 ONLY

(Model Fault Counter)

#Temp Probe Faults

(Temperature Probe Fault Counter)

#CCB Comm Faults

ETH-1000 only

(Communication Fault Counter)

#ECO Faults

(High temperature Energy Cut Off switch in

Upper temperature probe Fault Counter)

#Powr Anode Flts

(Powered Anode Alert Counter)

#Element Faults

(Element Fault Counter)

#LWCO Faults

(Low Water Cut Off Fault Counter)

#Element Banks Used

(Number of Element Banks in Water Heater)

1. Data is encoded into the 16 bits as major revision (upper 8 bits) and minor revision (lower 8 bits).

BACnet

Object

Type/Inst.

Analog Input 5 Present_Value R ºC

Analog Input 4 Present_Value R ºC

Analog Input 5 Present_Value R ºC

Analog Value 201 Present_Value R/W ºC

Analog Value 202 Present_Value R/W °C

Analog Value 203 Present_Value R/W °C

Analog Value 204 Present_Value R/W °C

Analog Value 205 Present_Value R/W °C

Analog Value 206 Present_Value R/W °C

Analog Value 209 Present_Value R Number

Analog Value 210 Present_Value R Hours with two

Analog Value 211 Present_Value R Days

Analog Value 212 Present_Value R Hours

Analog Value 213 Present_Value R Hours with two

Analog Value 214 Present_Value R Days

Analog Value 215 R R Hours

Analog Value 217 Present_Value R Number

Analog Value 218 Present_Value R Number

Analog Value 219 Present_Value R Number

Analog Value 223 Present_Value R Number

Analog Value 224 Present_Value R Number

Analog Value 233 Present_Value R Number

Analog Value 234 Present_Value R Number

Analog Value 235 Present_Value R Number

Analog Value 236 Present_Value R Number

BACnet

Object

Property R/W Units

places beyond the

decimal.

places beyond the

decimal.

(ºF)

(°F)

(°F)

(°F)

(°F)

(°F)

Min

Value

(if W)

32.2

(90)

.6

(1)

.6

(1)

.6

(1)

.6

(1)

.6

(1)

Max

Value

(if W)

82.2

(180)

11.1

(20)

11.1

(20)

11.1

(20)

11.1

(20)

11.1

(20)

27

Page 28

BACnet / Electric Water Heaters

Table 22. BACnet/Electric Water Heaters Object List

BACnet

Object Name

(Description)

#Elements in Bank 1

(Number elements current is check for in bank

1)

#Elements in Bank 2

(Number elements current is check for in bank

2)

#Elements in Bank 3

(Number elements current is check for in bank

3)

#Elements in Bank 4

(Number elements current is check for in bank

4)

#Elements in Bank 5

(Number elements current is check for in bank

5)

#Banks Cmd’d On

(Number of Banks currently Commanded to

be on)

Bank On Time

ETH-1000 only

(Time bank has been powered up in Hours

with two place beyond the decimal)

Bank1 On Days

(The amount of time in number of days bank

has been actually heating water)

Bank1 On Hours

(The hour’s portion of the amount of time bank

has been actually heating water. Use with

Bank1 On Days)

Bank2 On Time

ETH-1000 only

(Time bank has been powered up in Hours

with two place beyond the decimal)

Bank2 On Days

(The amount of time in number of days bank

has been actually heating water)

Bank2 On Hours

(The hour’s portion of the amount of time bank

has been actually heating water. Use with

Bank2 On Days)

Bank3 On Time

ETH-1000 only

(Time bank has been powered up in Hours

with two place beyond the decimal)

Bank3 On Days

(The amount of time in number of days bank

has been actually heating water)

Bank3 On Hours

(The hour’s portion of the amount of time bank

has been actually heating water. Use with

Bank3 On Days)

Bank4 On Time

ETH-1000 only

(Time bank has been powered up in Hours

with two place beyond the decimal)

Bank4 On Days

(The amount of time in number of days bank

has been actually heating water)

Bank4 On Hours

(The hour’s portion of the amount of time bank

has been actually heating water. Use with

Bank4 On Days)

1. Data is encoded into the 16 bits as major revision (upper 8 bits) and minor revision (lower 8 bits).

BACnet

Object

Type/Inst.

Analog Value 237 Present_Value R Number

Analog Value 238 Present_Value R Number

Analog Value 239 Present_Value R Number

Analog Value 240 Present_Value R Number

Analog Value 241 Present_Value R Number

Analog Value 242 Present_Value R Number

Analog Value 243 Present_Value R Hours with two

Analog Value 244 Present_Value R Days

Analog Value 245 Present_Value R Hours

Analog Value 246 Present_Value R Hours with two

Analog Value 247 Present_Value R Days

Analog Value 248 Present_Value R Hours

Analog Value 249 Present_Value R Hours with two

Analog Value 250 Present_Value R Days

Analog Value 251 Present_Value R Hours

Analog Value 252 Present_Value R Hours with two

Analog Value 253 Present_Value R Days

Analog Value 254 Present_Value R Hours

BACnet

Object

Property R/W Units

places beyond the

decimal.

places beyond the

decimal.

places beyond the

decimal.

places beyond the

decimal.

Min

Value

(if W)

Max

Value

(if W)

28

Page 29

BACnet / Electric Water Heaters

Table 22. BACnet/Electric Water Heaters Object List

BACnet

Object Name

(Description)

Bank5 On Time

ETH-1000 only

(Time bank has been powered up in Hours

with two place beyond the decimal)

Bank5 On Days

(The amount of time in number of days bank

has been actually heating water)

Bank5 On Hours

(The hour’s portion of the amount of time bank

has been actually heating water. Use with

Bank5 On Days)

Bank 1 Heating Cycles Analog Value 258 Present_Value R Number

Bank 2 Heating Cycles Analog Value 259 Present_Value R Number

Bank 3 Heating Cycles Analog Value 260 Present_Value R Number

Bank 4 Heating Cycles Analog Value 261 Present_Value R Number

Bank 5 Heating Cycles Analog Value 262 Present_Value R Number

EMS Mode-Status Analog Value 263 Present_Value R/W see table 3

Element Status

(Each bit is state a separate element)

BACnet

Object

Type/Inst.

Analog Value 255 Present_Value R Hours with two

Analog Value 256 Present_Value R Days

Analog Value 257 Present_Value R Hours

Analog Value 264 Present_Value R Bit 0 = Element 1

BACnet

Object

Property R/W Units

places beyond the

decimal.

Bit 1 = Element 2

.

.

.

Bit 14 = Element

15

Min

Value

(if W)

Max

Value

(if W)

Temp Probe Open

(Temperature Probe open status)

Temp Probe Short

(Temperature Probe shorted status)

Temp Probe ECO Status

(Temperature probe high temperature Energy

Cut Out Status)

Safety Relay Feedback Binary Input 321 Present_Value R 0=Open

Tank Full (LWCO) Binary Input 322 Present_Value R 0=Open Switch

AC Input1 T’stat

(External Enable 1)

AC Input2 T’stat

(External Enable 2)

Bank1 Output Status Binary Output 405 Present_Value R 0=Off

Bank2 Output Status Binary Output 406 Present_Value R 0=Off

Bank3 Output Status Binary Output 407 Present_Value R 0=Off

Bank4 Output Status Binary Output 408 Present_Value R 0=Off

Bank5 Output Status Binary Output 409 Present_Value R 0=Off

Binary Input 301 Present_Value R 0 = Okay

1 = Open

Binary Input 302 Present_Value R 0 = Okay

1 = Shorted

Binary Input 313 Present_Value R 0=Open Switch

1=Closed Switch

1=Closed

1=Closed Switch

Binary Input 323 Present_Value R 0=Open

1=Closed

Binary Input 324 Present_Value R 0=Open

1=Closed

1=On

1=On

1=On

1=On

1=On

Alarm Condition Binary Value504 Present_Value R 0=False

1=True

Output Relay Status Binary Value 505 Present_Value R 0=Relay Off

1=Relay On

System In Fault Binary Value 504 Present_Value R 0 = Okay

1 = In Fault

1. Data is encoded into the 16 bits as major revision (upper 8 bits) and minor revision (lower 8 bits).

29

0 1

Page 30

BACnet / Electric Water Heaters

Table 22. BACnet/Electric Water Heaters Object List

BACnet

Object Name

(Description)

CCB System State

(Central Control Board Control State)

Fault Code Multistate Value 802 Present_Value R See Table 25

Alert Code Multistate Value 803 Present_Value R See Table 25

1. Data is encoded into the 16 bits as major revision (upper 8 bits) and minor revision (lower 8 bits).

Central Control Board Major State Denitions

Table 23. BACnet/Electric Water Heaters Central Control Board (CCB) State

Value State

0 Off (Standby)

6 Heating

8 Fault

Energy Management System (EMS) Control

Commercial Electric water heaters with Xi controls use a single bit setting method. Within the EMS Mode-Status point one bit

command (bit 15) sets it in EMS mode, and other ends EMS mode. Once in EMS mode, another bit command (bit 0) enables heating

another disables heating.

Once in EMS mode the EMS Mode Refresh command must be periodically issued which clears a third bit (bit 14) to maintain EMS

mode, otherwise the heater will end EMS mode and resume normal operation.

Table 24. BACnet/Electric Water Heaters Energy Management System (EMS) Control

Decimal Hex Value Response

3841 0x0F01 Put into EMS Mode^ 49152 / 0xC000

0000 0x0000 EMS Disable heating^ 49152 / 0xC000

0001 0x0001 EMS Enable heating^ 49153 / 0xC001

3584 0x0E00 EMS Mode Refresh^ (must

Notes:

BACnet

Object

Type/Inst.

Multistate Value 801 Present_Value R See Table 22

BACnet

Object

Property R/W Units

49152 / 0xC000 or 49153 /

write within 30 seconds or EMS

mode ends.) 15 seconds or

0xC001 depending on whether

or not heating is enabled.

less recommended

Min

Value

(if W)

Max

Value

(if W)

The start of a heating also depend on other factors like tank temperature dropping below Setpoint – Differential and External T’stat call

for heat if that option is enabled.

^Depending on when you poll the register, you may read bit 14 as 1 which is why a “C” (in hexadecimal form) might briefly reply with

“8”. This is due to the control setting this bit and if it not cleared periodically by the BACnet command, heating is disabled.

After disabling EMS mode with write of 3840, read back might have bits 14 and 1 possibly still set. To make sure these bits are clear,

write a 0000 to clear bit 1 and 3584 to clear bit 14.

Fault Codes and Warnings

Note: Any Fault not listed is an internal CCB failure fault.

Table 25. BACnet/Electric Water Heaters Fault codes and Warnings

Index Range

(Decimal) Value

1 1 Okay (No Fault) (If System In Fault =0 )

1 6 Memory (If System In Fault = 1)

24 Incorrect Model

30

Page 31

BACnet / Electric Water Heaters

Table 25. BACnet/Electric Water Heaters Fault codes and Warnings

Index Range

(Decimal) Value

51 56 Power Monitor

69 72 Temperature Probe Open or Short

153 154 Communications Fault

165 High temperature ECO (Energy Cut Off)

171 Low Water Cut-Off

175 Safety Relay Closed fault

176 188 CCB internal errors

193 194 Processor Clock

198 201 Non-volatile Memory

205 217 Powered Anode

431 Safety Relay Opened fault

1037 1037 Element Open Warning

31

Page 32

BACnet / Boilers

BACNET / BOILERS

Figure 36. XP XWH Circulating Water Heaters (Virtual Bacnet Device Via ICC Gateway)

PRODUCT DESCRIPTION

The Mirius is a multiprotocol RS-485 to RS-485 gateway. The ETH-1000 is an Ethernet to RS-485 multiprotocol gateway. These

products supports native BACnet, connecting directly to IP or the MS/TP LAN using baud rates of 4800, 9600, 19200, 38400, 57600,

76800, and 115200. As shipped the devices are congured as a BACnet Server.

All XITM MXiTM controls provide communications via propriety protocol with the ICC Gateway. The Mirius supports BACnet MS/TP

communications and the ETH- 1000 supports BACnet/IP to access data available at the display plus control of a limited number of

points such as Operating Setpoint.

PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT (PICS)

BACnet Standardized Device Prole (Annex L):

BACnet Application Specic Controller (B-ASC)

BACnet Boiler Interoperability

Table 26. BACnet Boiler Interoperability Building Blocks Supported (Annex K):

Data Sharing - ReadProperty-A (DS-RP-A)

Data Sharing - ReadProperty-B (DS-RP-B)

Data Sharing - ReadPropertyMultiple-B (DS-RPM-B)

Data Sharing - WriteProperty-A (DS-WP-A)

Data Sharing - WriteProperty-B (DS-WP-B)

Data Sharing - WritePropertyMultiple-B (DS-WPM-B)

Data Sharing – COV-B (DS-COV-B) (BACnet/IP only)

Device Management-Dynamic Device Binding-A (DM-DDB-A)

Device Management-Dynamic Device Binding-B (DM-DDB-B)

Device Management-Dynamic Object Binding-B (DM-DOB-B)

Device Management-Device Communication Control-B (DM-DCC-B)

Device Management – ReinitializeDevice-B (DM-RD-B)

Segmentation Capability:

Segmentation not supported

32

Page 33

BACnet / Boilers

Data Link Layer Options

Table 27. BACnet Boiler Data Link Layer Options

BACnet IP (Annex J) (ETH-1000 only)

BACnet IP (Annex J), Foreign Device (ETH-1000 only)

ANSI/ATA 878.1, 2.5Mb. ARCNET (Clause 8)

ANSI/ATA 878.1, RS-485. ARCNET (Clause 8), baud rates() ________

MS/TP master (Clause9) baud rate(s): 4800, 19200, 38400, 57600,

76800, 115200

MS/TP slave (Clause9) baud rate(s): _________

Point-To-Point, EIA 232 (Clause 10), baud rate(s): _________

Point-To-Point, modem (Clause 10), baud rate(s): _________

LonTalk, (Clause 11), medium ________

Other: _________________

Device Address Binding

Is static device binding supported? (This is currently for two-way communications with MS/TP slaves and certain other devices.) YES

Table 28. BACnet Boiler Networking Options

Router, Clause 6 – List all routing congurations

Annex H, BACnet Tunneling Router over IP

BACnet/IP Broadcast Management Device (BBMD). Does the BBMD

support registrations by Foreign Devices? (ETH-1000 only)

Character Sets

Table 29. BACnet Boiler Character Sets Supported

ANSI X3.4

IBMTM /MicrosoftTM DBCS

ISO 8859-1

ISO 10646 (UCS-2)

ISO 10646 (UCS-4)

JIS C 6226

Data Types Supported

The following table summarizes the data types that are accepted (in the case of a write property service) and returned (in the case of a

read property service) when targeting the present value property of each supported object type.

Table 30. BACnet Boiler Data Types Supported

Service

Object Type

Analog Output

Read Property Write Property

Real Real, Unsigned, Integer, Null

Analog Value

Analog Input Real N/A

Binary Output

Enumerated Enumerated, Boolean, Real, Unsigned, Integer, Null

Binary Value

Binary Input Enumerated N/A

Multi-state Output

Unsigned Real, Enumerated, Unsigned, Integer, Null

Multi-state Value

Multi-state Input Unsigned N/A

33

Page 34

Boiler Device Object Types/Property Support

Table 31. BACnet Boiler Object Types/Property Support Table

Binary

Property Device

Object Identier

Object Name

Object Type

System Status

Vendor Name

Vendor Identier

Model Name

Firmware Revision

App S/W Revision

Protocol Revision

Services Supported

Object Types Supported

Object List

Max APDU Length