Page 1

EXCEL

FACTORY BUILT CHIMNEY

INSTALLATION AND MAINTENANCE

INSTRUCTIONS

A MAJOR CAUSE OF CHIMNEY RELATED FIRES IS FAILURE TO

Maximum continuous flue gas temperature:

650°C

1200°F

Brief forced firing:

925°C

1700°F

Tested to: (3 X 30 minutes)

1150°C

2100°F

EXCEL has been tested and listed to the ULC S-629

chimney standard by Intertek Testing Services

Listing # 5965

ICC INDUSTRIAL CHIMNEY COMPANY INC.

400 J.F. Kennedy, St. Jerome

Quebec, Canada, J7Y 4B7

Tel.: (450) 565-6336

Fax: (450) 565-6519

http://www.icc-rsf.com

MAINTAIN REQUIRED CLEARANCES (AIR SPACE) TO

COMBUSTIBLE MATERIALS. IT IS OF UTMOST IMPORTANCE THAT

THIS CHIMNEY BE INSTALLED ONLY IN ACCORDANCE WITH THESE

INSTRUCTIONS.

This chimney is intended for use with solid, liquid and gas fired appliances,

including wood fired stoves, fireplaces and furnaces.

The chimney should be the size recommended by the appliance

manufacturer.

Use only ICC Model EXCEL components. Failure to do so will void the

certification and warranty of the product.

Keep these installation and operating instructions in a safe location for

future reference.

Contact local building or fire officials about restrictions and installation

inspection in your area.

FOR CANADA ONLY

XLCND-II_2010-02

Page 2

TABLE OF CONTENTS

Technical Specifications ....................................................................... 3

Creosote and Soot ............................................................................... 4

Coal ...................................................................................................... 4

Wood and Coal Stoves ......................................................................... 4

Operation and Maintenance ................................................................. 5

Chimney Fires ...................................................................................... 5

Installation Notes .................................................................................. 6

Factory built fireplaces ......................................................................... 7

Oil and gas appliances ......................................................................... 7

Chimney height..................................................................................... 7

INSTALLATION INSTRUCTIONS

Round & square support Installation .................................................... 8

Typical installations .................................................................... 8

Cathedral ceilings ..................................................................... 12

Support extensions .................................................................. 13

Universal band, roof support band ..................................................... 14

Roof support ....................................................................................... 15

Offset support ..................................................................................... 16

Offset chimney ......................................................................... 17

Offset table, without adjustable length ..................................... 18

Offset table, with adjustable length .......................................... 19

Wall support ........................................................................................ 20

Wall radiation shield ........................................................................... 21

Through the wall Installation .................................................... 22

Wall channel ....................................................................................... 24

Roof brace installation ........................................................................ 25

Adjustable length ................................................................................ 26

Anchor plate. ...................................................................................... 26

Radiation shield .................................................................................. 27

Rain cap base..................................................................................... 27

Universal storm collar ......................................................................... 28

Snow-barrier (EWS) ........................................................................... 29

Round support (ERDS) ...................................................................... 30

Extended wall support (EWSE) .......................................................... 31

Warranty ............................................................................................. 32

EXCEL Canada 2 Owner’s Manual

Page 3

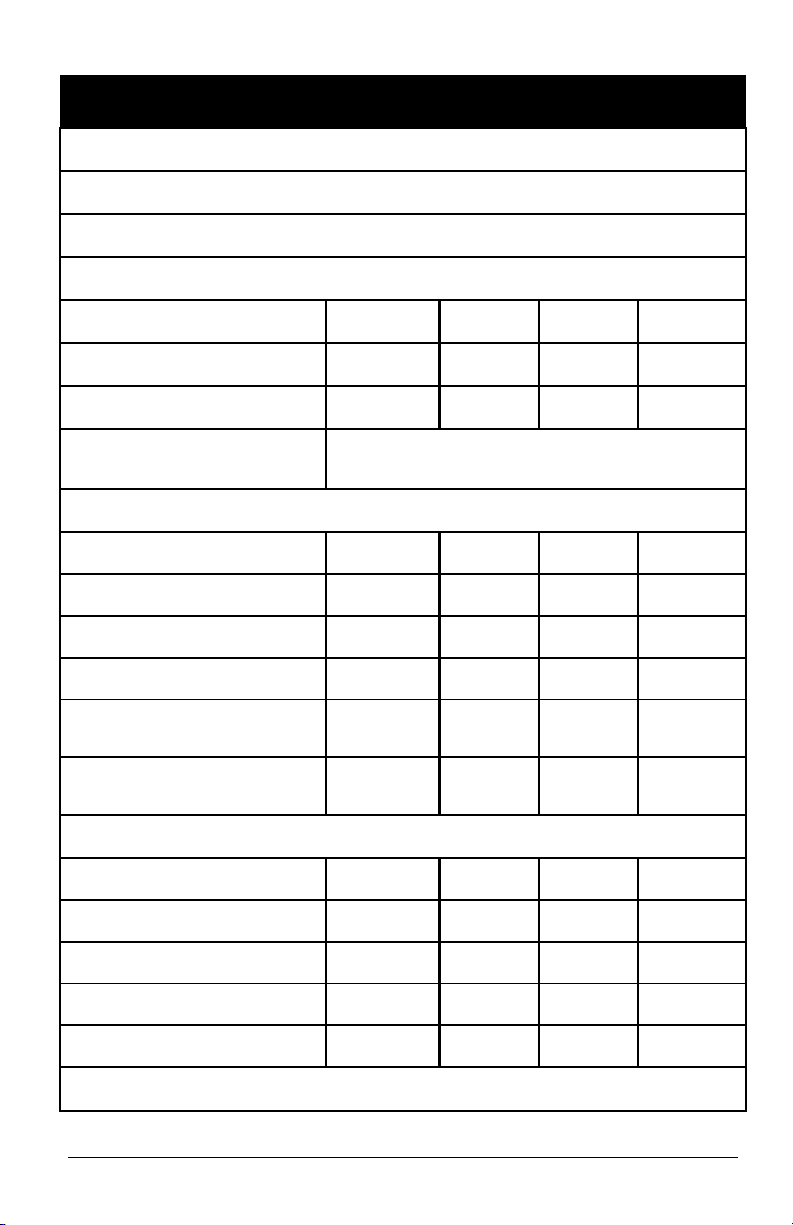

EXCEL TECHNICAL SPECIFICATIONS

Materials:

Exterior (casing): .015” Type 434 Stainless Steel

Interior (flue): .015” Type 304 Stainless Steel

Insulation: ICC “Thermoplus” Blanket

Inside Diameter

5 Inch

6 Inch

7 Inch

8 Inch

Outside diameter

7”

8”

9”

10”

Weight/Foot (lb/ft.)

3.6

4.2

4.9

5.3

Clearance to combustibles

2” or as established by factory

built supports and firestops

Rough Opening Required

Round support (ERDS & ES)

10” X 10”

10” X 10”

11” X 11”

12” X 12”

Square support (ESS)

N/A

10” X 10”

11” X 11”

12” X 12”

Roof support (ERS)

11” X 11”

12” X 12”

13” X 13”

14” X 14”

Offset support (EOS)

11” X 11”

12” X 12”

13” X 13”

14” X 14”

Radiation shields

(ERS &ERSA)

11” X 11”

12” X 12”

13” X 13”

14” X 14”

Wall radiation shield

(EWRS)

10” X 10”

10” X 10”

11” X 11”

12” X 12”

Maximum Support Capacity

Round support (ERDS & ES)

65 feet

55 feet

50 feet

45 feet

Square support (ESS)

N/A

55 feet

50 feet

45 feet

Roof support (ERS)

65 feet

55 feet

50 feet

45 feet

Wall support (EWS)

50 feet

44 feet

37 feet

35 feet

Offset support (EOS)

35 feet

30 feet

27 feet

25 feet

Radiation shields must be used at all floor joist and ceiling areas

EXCEL Canada 3 Owner’s Manual

Page 4

CREOSOTE AND SOOT - Formation and need for removal

When wood is burned slowly it produces tar and other organic vapours,

which combine with expelled moisture to form creosote. The creosote

vapours condense in the relatively cool chimney flue of a slow-burning fire.

As a result, creosote residue accumulates on the flue lining. When ignited

this creosote makes an extremely hot fire.

COAL

Some coals contain large quantities of Sulphur (up to 7%). When coal is

burned, Sulphur and coal ash are deposited in the chimney flue. This

deposit combines with moisture to form a highly corrosive acid (Sulphuric

Acid).

In order to protect your chimney, we recommend that you:

1. Burn only low Sulphur coals (less than 1% Sulphur).

2. Have your chimney cleaned within 48 hours of shutting down your stove

at the end of the heating season. Be certain that all the soot is

removed.

WOOD AND COAL STOVES

If you are planning to install a wood stove, we recommend that you:

1. Choose a stove that has a label of a recognized Testing Laboratory

(such as WH, UL, ULC, and CSA). The EPA approved, low emissions

stoves are highly recommended.

2. Connect only one solid fuel burning appliance to a chimney. Do not

connect an oil or gas burning appliance to a chimney venting a solid

fuel burning appliance.

3. Never over fire your stove. If any part of the stove or stove pipe is

glowing red, then you are over firing. Immediately close the stove’s

damper until the system cools. The high temperatures caused by over

firing can permanently damage the stove and stove pipe and may

overheat nearby combustible walls and furniture.

4. Install the stove and stove pipe as described in the Installation

Instructions accompanying the stove. BE CERTAIN TO MAINTAIN THE

REQUIRED CLEARANCES TO COMBUSTIBLE CONSTRUCTION.

5. Keep your flue gases between 300°F and 500°F. This will maximize

efficiency while minimizing condensation and creosote formation.

6. Do not burn sea driftwood. Salt is highly corrosive to all types of

stainless steel. Do not burn treated lumber.

EXCEL Canada 4 Owner’s Manual

Page 5

OPERATION AND MAINTENANCE

KEEP YOUR CHIMNEY CLEAN Wood stoves can quickly create large

deposits of creosote in the chimney. Some wood stoves can create

enough creosote in two weeks to cause a chimney fire.

When using a wood stove, we recommend that you:

1. Initially inspect the chimney system weekly. From this you will learn

how often it will be necessary to clean your chimney.

2. THE CHIMNEY SHOULD BE INSPECTED AT LEAST ONCE EVERY

TWO MONTHS DURING THE HEATING SEASON to determine if

creosote or soot has built up. When a maximum of 1/4" of creosote or

soot has accumulated, it should be removed to reduce the risk of a

chimney fire.

3. Have your chimney cleaned by a qualified chimney sweep. If you want

to clean your chimney yourself, then; clean your chimney using a

properly fitting nylon or steel brush. Do not use a brush that will scratch

the stainless steel interior of the chimney. Use of an oversize brush

may damage the chimney.

4. Do not expect chemical chimney cleaners to keep your chimney clean.

Their use does not negate the necessity of periodically inspecting and

cleaning your chimney.

CHIMNEY FIRES

If you are having a chimney fire, follow these steps:

1. Close all heater doors and combustion air controls. For fireplaces, block

the fireplace opening with a non-combustible material (such as a steel

sheet).

2. Alert your family to the possible danger.

3. If you require assistance, alert your fire department.

4. If possible, use a dry chemical fire extinguisher, baking soda or sand to

control the fire. Do not use water as it may cause a dangerous steam

explosion.

5. Watch for smouldering or fire on combustibles next to the stove, stove

pipe and chimney. Check outside to ensure that sparks and hot embers

coming out of the chimney are not igniting the roof.

6. Do not use the stove again until your chimney and stove pipe have

been inspected by a qualified chimney sweep or Fire Department

Inspector.

EXCEL Canada 5 Owner’s Manual

Page 6

INSTALLATION NOTES

1. The chimney is intended for use with cooking, heating and other

low-heat appliances.

2. A chimney venting a fireplace or an incinerator shall not vent any other

appliance.

3. The clearance between single wall stove pipe and unprotected

combustible material must not be less than 18" (reference the National

Building Code and B365).

The distance between a vertical stove pipe and the ceiling may be less

than 18" when it is installed with an EXCEL support. The reduced

clearance in this area has been confirmed as part of the chimney safety

testing.

The distance between the horizontal stove pipe and a vertical wall may

be less than 18" where the insulated chimney passes horizontally

through the wall. The distance will be determined by the Wall Radiation

Shield.

4. The maximum height of un-guyed chimney above the roof is 5 feet.

5. Portions of the chimney which may extend through accessible spaces

shall be enclosed in all cases to avoid personal contact with the

chimney and damage to the chimney.

6. Do not fill the air space around the chimney with insulation or any other

material. Do not fill the factory built supports or radiation shields with

insulation. Insulation placed in this area could cause adjacent

combustibles to overheat. Do not allow sawdust or construction debris

to accumulate around the chimney. Clean all areas surrounding the

chimney before closing up any enclosed areas.

7. The chimney shall extend at least 3 ft. above its point of penetration

with the roof and at least 2 ft. higher than any wall, roof or adjacent

building within 10 ft. of it. For chase installations, the chimney must

extend at least 8" above the top of the chase.

8. The following does not apply to installation in single and two-family

dwellings:

Factory built chimneys which extend through any story above that on

which the connected appliance is located are to be provided with

enclosures having a fire resistance rating equal to or greater than that

of the floor or roof assemblies through which they pass.

EXCEL Canada 6 Owner’s Manual

Page 7

FACTORY BUILT FIREPLACE

When Excel is approved with a factory-built fireplace, the chimney and

fireplace are tested in combination, as a complete system. It is not possible

to include specific installation instructions for each make and model of

fireplace in these instructions, you must follow the instructions included

with the fireplace you are installing.

NOTE: When EXCEL is certified for use on a factory-built fireplace it is

tested without the use of our patented radiation shield tubes (ERSF or

ERST). These radiation shields are not required for any factory-built

fireplace installations, including interior chases.

OIL AND GAZ APPLIANCES

When Excel is used to vent an oil or gas burning appliance, the ERSF or

ERST radiation shield tubes are not required, even where the chimney is

enclosed.

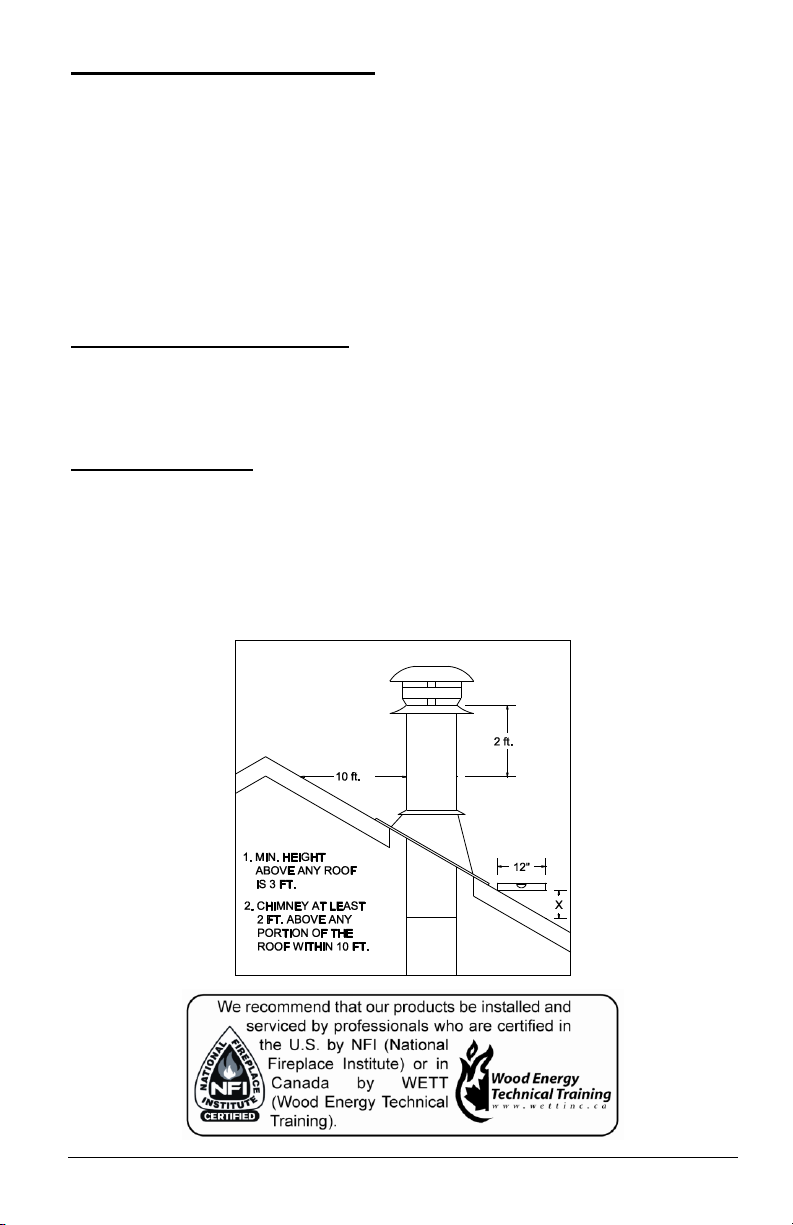

CHIMNEY HEIGHT

The minimum height of chimney required is the same for all support styles

and sizes. The diagram below shows minimum chimney height as required

by code. A quick way to calculate this dimension is to multiply the vertical

rise per 12" of horizontal distance (X in the diagram) by 10 and add 24".

When the chimney is installed within 10' of the peak it must clear the peak

by 24". The minimum chimney height is 3'.

EXCEL Canada 7 Owner’s Manual

Page 8

INSTALLATION INSTRUCTIONS

ROUND SUPPORT (ERDS) & SQUARE SUPPORT (ESS)

If you are installing your chimney in an energy efficient house which has

sealed vapour barriers (e.g.: R2000 construction) we manufacture a

special round support so that you can maintain your vapour barrier

integrity. (See part ERDSI.) The ERDSI comes with its own set of

installation instructions.

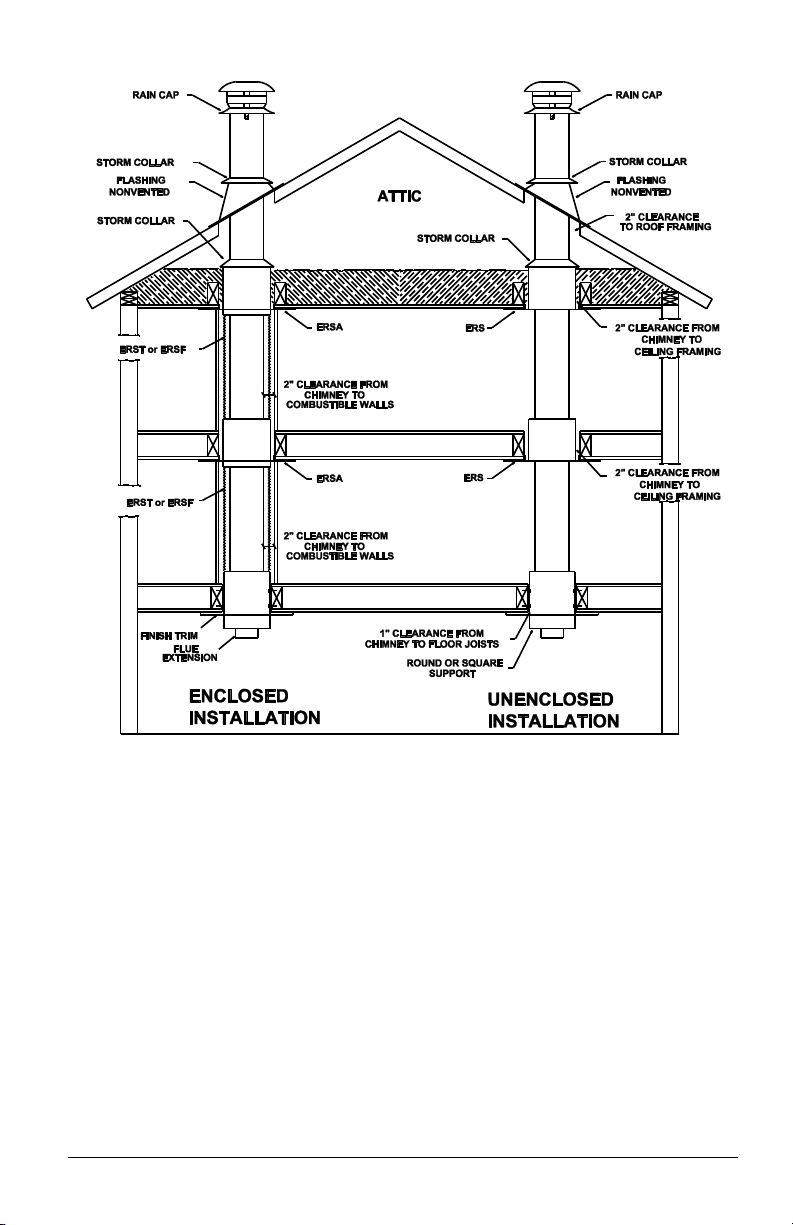

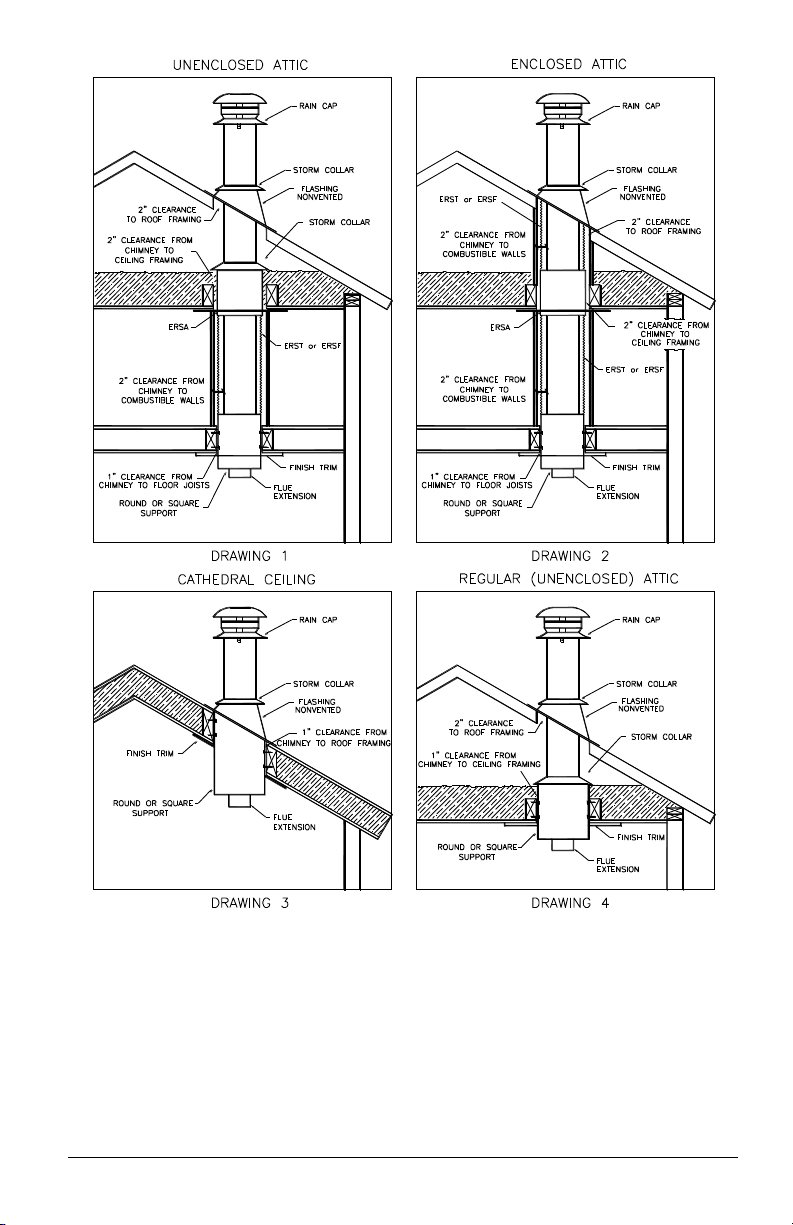

Typical round and square support installations are shown in drawings 1

thru 4 on page 10. The clearance between the chimney and combustible

material must not be less than 2" except for areas protected by the

support. Do not fill this area with insulation. If the support is installed in a

cathedral ceiling, follow the instructions for Cathedral Ceilings.

TYPICAL INSTALLATIONS

If the support is installed in a ceiling with an attic directly above, the

support also acts as the attic radiation shield when installed with a

universal storm collar (ESC).

1. Locate the chimney in a convenient place as near as possible to the

appliance outlet. Cut and frame the holes in the floor ceiling and roof

where the chimney will pass. Refer to the technical specifications on

page 3 to determine the required rough opening for the support model

and size you are installing.

NOTE: Look Up - The round and square supports are designed to protect

the surrounding combustible materials and as a result they permit 1"

clearance from the chimney to combustible framing - in the area that they

protect. When these supports are installed in a roof truss insure that the

chimney has 2" clearance at the top of the truss. This may require you to

block out the support at the bottom. Another option is to install a support

extension (see page 13). Trim the support extension flush with the roof,

this will permit the chimney to pass within 1" of the truss.

2. From below, push the support into the framed hole. The support must

protrude at least 3" below the finished ceiling. Nail the support to the

framed joist using 8 - 3" spiral nails or # 8 X 1½" wood screws. Place

the Finish Collar around the support and fasten it to the ceiling using

the two screws provided. NOTE: If you are using a 6" square support

you may find it difficult to screw it in place because there is not much

room inside it. We have provided angle brackets with this support which

can be screwed to the outside of the support box and nailed to

surrounding framing as required. Use a minimum of four # 8 X ½" metal

screws per bracket. In some cases these brackets may need to be

trimmed (e.g.: to fit under a flashing).

EXCEL Canada 8 Owner’s Manual

Page 9

NOTE: Excel is required to be enclosed (framed in) when it passes

through an occupied area in the building. In the event that Excel passes

through an unoccupied area and is not enclosed it should be installed with

ERS radiation shields instead of ERSA radiation shields. If the chimney is

not enclosed then the ERST of ERSF radiation shields are not required.

See drawing above.

Please note that Excel may be used to vent a factory built fireplace,

an oil burning appliance, or a gas burning appliance. The ERSF or

ERST radiation shield tubes are not required when venting these

appliances, even when the chimney is enclosed.

EXCEL Canada 9 Owner’s Manual

Page 10

3. Fasten the flue extension (EX) to the first length of chimney with the

three screws provided. Place the first section of chimney into the

support with the flue extension protruding through the hole in the

support. When installing additional sections of chimney line up the

vertical seams to insure that the pre-punched screw holes line up with

the slots in the outside casing. If the chimney passes through additional

floors above the support follow instruction 4. If the chimney passes

directly into the attic without going through another floor proceed to

instruction 5.

EXCEL Canada 10 Owner’s Manual

Page 11

4a. STRAIGHT CHIMNEY, NO OFFSETS: If you are venting a

factory-built fireplace or an oil or gas burning appliance see the notes

on page 7 before proceeding. From the floor above the support place

the radiation shield tube (ERST) over the first chimney length and onto

the support. Screw it to the support using the self drilling screws

provided. Install additional chimney lengths as required making sure

that you install a radiation shield (ERSA) where the chimney penetrates

the ceiling - the ERSA should be installed from the bottom, screw or nail

the ERSA solidly to the framing. The ERST is designed to slide like a

telescope. Pull the ERST up around the chimney and screw it to the

flange on the ERSA. Multiple ERST's may be screwed together if

necessary. If the chimney is enclosed through additional floors repeat

the process starting at the top of the ERSA until the chimney is installed

into the attic.

NOTE: You may use an ERSF flexible radiation shield instead of an ERST if

you prefer. Go to instruction 5.

4b. OFFSET CHIMNEY: Place the bottom half of the flexible radiation

shield (ERSF) over the first chimney length - the ERSF connector ring

will fit inside the support. Screw through the support into the ERSF

connector ring to fasten it in place. Install additional chimney lengths

and offsets as required. Place the other half of the ERSF over the first

chimney length above the offset. Install a radiation shield (ERSA) where

the chimney penetrates the ceiling. Continue installing chimney up into

the attic. Screw the top of the ERSF to the flange which projects below

the ERSA. Pull the top half of the ERSF down over the top elbow - the

flexible duct is compressed so that it can stretch up to 66% longer. Pull

the bottom half of the ERSF up over the bottom elbow in the same

manner. Screw the two halves together at a convenient location

between the elbows. If the offset is close to the top or bottom of the

enclosure you may need to shorten one half of the ERSF and attach the

extra length to the other half. An extra coupling is included with the

ERSF for this purpose. Install an offset support on one of the vertical

lengths above the offset, the offset support may be fastened to the roof

if necessary - see page 17 for offset support instructions.

5a. IF THE CHIMNEY IS NOT ENCLOSED IN THE ATTIC: Install a storm

collar (ESC) on top of the support or radiation shield. This will prevent

loose insulation from falling into the area between the chimney and the

support. Install a regular roof flashing. Go to instruction 6.

5b. IF THE CHIMNEY IS ENCLOSED IN THE ATTIC: Continue installing

chimney sections up through the roof opening. Lower a radiation shield

tube (ERST) through the roof opening and adjust it so that it sits on the

support or radiation shield below. Adjust the length of the ERST so that

it terminates just above the roof opening but under the flashing. Screw

the four sections of the ERST to each other. Install a regular roof

flashing.

EXCEL Canada 11 Owner’s Manual

Page 12

6. Install the roof flashing: Seal the joint between the roof and the

flashing with roofing tar or silicone. For sloping roofs, Place the flashing

under the upper shingles and on top of the lower shingles approximately half of the flashing should be under the shingles. Seal

the joint between the roof and the flashing with roofing tar or silicone.

Nail the flashing to the roof using roofing nails. Place the storm collar

over the chimney and the flashing. Tighten it in place. Caulk the joint

between the chimney and storm collar with silicone.

7. Continue adding chimney sections until the required chimney height is

reached. See the drawing on page 7 to determine the correct height.

8. If the chimney height above the roof exceeds 5 feet then a roof brace

must be installed.

9. Fit the rain cap to the top of the chimney. Screw the four metal screws

provided through the straps and into the top chimney length.

CATHEDRAL CEILINGS

If your home has a cathedral ceiling (no attic space between the ceiling

and the roof), install the chimney and support as follows.

1. Situate the chimney in a convenient location as near as possible to the

appliance outlet. Cut and frame a hole in the roof for the support. The

sides of this hole must be vertical. See page 3 for hole size.

2. Place the support in the opening. Lower it to the correct height as

determined by the table and diagram on page 13.

Using a level, make sure the support is vertical. If the support extends

above the roof, cut it flush with the top of the roof. Nail the support to

the frame opening using 8 - 3" spiral nails or # 8 x 1½" wood screws.

Note: If you are using a 6" square support you may find it difficult to

screw it in place because it is fairly small inside.

We have provided angle brackets with this support which can be

screwed to the outside of the support box and nailed to surrounding

framing as required. Use a minimum of four # 8 x ½" metal screws per

bracket. In some cases these brackets may need to be trimmed (e.g.: to

fit under a flashing).

EXCEL Canada 12 Owner’s Manual

Page 13

SLOPE

X

0/12 - 2/12

3”

2/12 - 7/12

51/2”

7/12 - 12/12

63/4”

12/12 - 24/12

71/2”

24/12+

121/2”

Place the Finish Collar around the support and fasten it to the ceiling

using the screws provided.

3. Attach the flue extension (found in the support box) to the bottom of the

first chimney length using the 3 metal screws provided. Put this

chimney length in the support. Push it down firmly in place.

4. Use a regular roof flashing. Put the roof flashing in place. Place the

flashing under the upper shingles and on top of the lower shingles approximately half of the flashing should be under the shingles. Seal

the joint between the roof and the flashing with roofing tar or silicone.

Nail the flashing to the roof using roofing nails. Place the storm collar

over the chimney and flashing. Caulk the joint between the chimney

and collar with silicone caulking.

5. Put the remaining required lengths of chimney in place. Fasten the

lengths together using three metal screws at each joint (provided with

the chimney). If the chimney extends more than 5 feet above the roof,

install a roof brace.

6. Fit the rain cap to the top of the chimney. Screw the four metal screws

provided through the straps and into the top chimney length.

SUPPORT EXTENSIONS - ROUND (ERDSE) OR SQUARE (ESSE)

Steep pitched cathedral ceilings, or attics with greater than average

insulation depth, may require the use of a support extension. This piece fits

down inside the support and can be adjusted to increase the support's

length by up to 22". The extension is attached to the support using the

eight metal screws provided. Be sure there is at least a 2 inch overlap

where the extension joins the support.

EXCEL Canada 13 Owner’s Manual

Page 14

UNIVERSAL BAND AND ROOF SUPPORT BAND ASSEMBLY

The universal band is a sub-component of the following parts:

- Wall Support (EWS)

- Roof Brace (ERB)

- Offset Support (EOS)

The Roof Support Band is a sub-component of the roof support and is

assembled in the same manner as the universal band.

1. The universal band and the roof support band are shipped

pre-assembled to fit 6" chimney. To install the bands on a 7" or 8"

chimney carefully remove the three 1/4" x 1" elevator bolts (five bolts for

a roof support) and replace them in the corresponding labelled holes for

7" or 8".

For 5" Ø chimney the band that come with the supports (wall, roof or

offset) and with the roof brace is made to fit the outside diameter of the

5" chimney only.

2. Bend the band around the chimney section and secure with the 1/4" x

2" bolt, lock washer and nut provided. The band will bend to conform to

the diameter of the chimney.

EXCEL Canada 14 Owner’s Manual

Page 15

ROOF SUPPORT (ESR)

The roof support may be used to support the chimney on a flat or inclined

roof.

When using a roof support the chimney must extend in to the room a

minimum of 6 inches below a finished ceiling. You must also maintain the

required horizontal clearance between the single or double wall connector

and the combustible ceiling - see diagram below.

See the table on page 3 to determine the minimum opening required in the

roof. The chimney must have 2" of clearance all around - regardless of roof

pitch.

1. Assemble the roof support band following the instructions on page 14.

2. Bolt on the two 90° roof support brackets. These brackets require two

elevator bolts per bracket - see the drawing above. Leave these bolts

loose.

EXCEL Canada 15 Owner’s Manual

Page 16

3. Slip the support down over the chimney - locate the support on the

chimney so that the required amount of chimney projects below the

finished ceiling - tighten the locking nut. Place the chimney in the

opening in the roof. Rotate the 90° brackets to adjust for the roof pitch.

Tighten the collar around the chimney, then secure it by screwing three

metal screws through the holes in the collar and into the chimney.

Tighten the four nuts which hold the brackets to the support band.

4. Center the chimney in the hole in the roof and nail or screw the support

to the roof using 6 - 2 1/2" nails or # 8 x 1 1/2" wood screws.

OFFSET SUPPORT (EOS)

This support is used for re-supporting a chimney above an offset.

Install the chimney and elbows according to the installation instructions.

Install the support as follows:

See the table on page 3 to determine the minimum opening required for

the support. The chimney must have 2" of clearance all around.

1. Assemble the band following the instructions on page 14.

2. Bolt on the offset support straps - see diagram above.

3. Slip the support down over the chimney to a convenient location.

4. Tighten the collar around the chimney, then secure it by screwing three

metal screws through the holes in the collar and into the chimney.

5. Attach the support straps to the floor or roof structure using two 3" nails

or #10 x 2" wood screws per strap.

6. Continue installing the chimney.

EXCEL Canada 16 Owner’s Manual

Page 17

OFFSET CHIMNEY

3. Use another elbow to turn the

chimney vertically. Again secure

the elbow to the chimney length

using three metal screws.

4. Install the remaining chimney as

described in the support

instructions.

5. An Offset or Roof Support must

be installed above each offset

(two elbows) to support the

chimney above the offset. This

support may be installed on any

convenient location on the

vertical run above the offset.

If it is necessary to offset the chimney in order for it to pass through an

upstairs cupboard or to clear a joist, do this by using 15°, 30° or 45°

insulated elbows.

The maximum number of elbows permitted is four (typically this would

consist of two sets of an offset and a return).

To determine the parts required for your installation refer to the drawing on

page 20 and the offset tables on page 18 and 19.

You may find it convenient to install an adjustable length between the

elbows. This will allow you to offset the exact distance you require. The

offset table on page 18 should be used when no adjustable length is

required. Use the table on page 19 when an adjustable length is required.

The maximum length of unsupported offset chimney is 8'. If the offset

chimney is longer than 8', then it must be supported at 6' intervals using an

offset support (EOS).

When you reach the height at which the elbow will be installed,

proceed as follows:

1. Install the insulated elbow on the chimney length. Turn it in the required

direction and fasten it to the chimney with the 3 metal screws provided.

Since the offset direction varies from installation to installation the

pre-punched holes will not line up.

2. Place the required length of chimney on the elbow. Fasten it to the

elbow with the three metal screws provided.

EXCEL Canada 17 Owner’s Manual

Page 18

All dimensions are in inches

EXCEL OFFSET TABLE - Use this table if you are not

installing an adjustable length between the elbows.

LENGTH BETWEEN

15° Elbows

30° Elbows

45° Elbows

OFFSETS

RISE

OFFSET

RISE

OFFSET

RISE

OFFSET

5 INCH Ø

NO LENGTH

9 1/4

1 1/4

10 1/2

2 3/4

11 1/4

4 3/4

6" Length

13 1/4

2 1/4

14 1/4

5

14 1/4

7 3/4

12" Length

19

3 3/4

19 1/4

8

18 1/2

12

18" Length

25

5 1/2

24 1/2

11

22 3/4

16 1/4

24" Length

30 3/4

7

29 3/4

14

27

20 1/2

48" Length

53 3/4

13 1/4

50 1/2

26

44

37 1/2

24" + 12"

40 1/2

9 1/2

38 3/4

19

34 1/4

27 3/4

48" + 12"

63 3/4

15 3/4

59 1/2

31

51 1/4

44 3/4

48" + 18"

69 1/2

17 1/2

64 1/2

34

55 1/2

49

48" + 24"

75 1/4

19

69 3/4

37

59 3/4

53 1/4

48" + 24" + 12"

85 1/4

21 1/2

78 3/4

42 1/4

67

60 1/2

48" + 48"

98 1/2

25 1/4

90 1/2

49

76 3/4

70

6 INCH Ø

NO LENGTH

9 1/2

1 1/4

11 3 12

5

6" Length

13 1/2

2 1/4

14 3/4

5

15

8

12" Length

19 1/4

4

19 3/4

8

19 1/4

12 1/4

18" Length

25 1/4

5 1/2

25

11

23 1/2

16 1/2

24" Length

31 7 30 1/4

14

27 3/4

20 3/4

48" Length

54

13 1/4

51

26

44 3/4

37 3/4

24" + 12"

40 3/4

9 3/4

39 1/4

19 1/4

35

28

48" + 12"

64

15 3/4

60

31 1/4

52

45

48" + 18"

69 3/4

17 1/2

65

34 1/4

56 1/4

49 1/4

48" + 24"

75 1/2

19

70 1/4

37 1/4

60 1/2

53 1/2

48" + 24" + 12"

85 1/2

21 3/4

79 1/4

42 1/4

67 3/4

60 3/4

48" + 48"

98 3/4

25 1/4

91

49 1/4

77 1/2

70 1/2

7 INCH Ø

NO LENGTH

9 3/4

1 1/4

11 1/2

3

12 3/4

5 1/4

6" Length

13 3/4

2 1/2

15 1/4

5 1/4

15 3/4

8 1/4

12" Length

19 1/2

4

20 1/4

8 1/4

20

12 1/2

18" Length

25 1/2

5 1/2

25 1/2

11 1/4

24 1/4

16 3/4

24" Length

31 1/4

7

30 3/4

14 1/4

28 1/2

21

48" Length

54 1/2

13 1/4

51 1/2

26 1/4

45 1/2

38

24" + 12"

41

9 3/4

39 3/4

19 1/4

35 3/4

28 1/4

48" + 12"

64 1/4

16

60 1/2

31 1/4

52 3/4

45 1/4

48" + 18"

70

17 1/2

65 1/2

34 1/4

57

49 1/2

48" + 24"

75 3/4

19

70 3/4

37 1/4

61 1/4

53 3/4

48" + 24" + 12"

85 3/4

21 3/4

79 3/4

42 1/2

68 1/2

61

48" + 48"

99

25 1/4

91 1/2

49 1/4

78 1/4

70 3/4

8 INCH Ø

NO LENGTH

10

1 1/4

12

3 1/4

13 1/2

5 1/2

6" Length

14

2 1/2

15 3/4

5 1/4

16 1/2

8 1/2

12" Length

19 3/4

4

20 3/4

8 1/4

20 3/4

12 3/4

18" Length

25 3/4

5 1/2

26

11 1/4

25

17

24" Length

31 1/2

7

31 1/4

14 1/4

29 1/4

21 1/4

48" Length

54 3/4

13 1/4

52

26 1/4

46 1/4

38 1/4

24" + 12"

41 1/4

9 3/4

40 1/4

19 1/2

36 1/2

28 1/2

48" + 12"

64 1/2

16

61

31 1/2

53 1/2

45 1/2

48" + 18"

70 1/4

17 1/2

66

34 1/2

57 3/4

49 3/4

48" + 24"

76 1/4

19

71 1/4

37 1/2

62

54

48" + 24" + 12"

86

21 3/4

80 1/4

42 1/2

69 1/4

61 1/4

48" + 48"

99 1/4

25 1/4

92

49 1/2

79

71

EXCEL Canada 18 Owner’s Manual

Page 19

All dimensions are in inches

Use this table when an 18 inch adjustable length is required.

LENGTH

BETWEEN

15° Elbows

30° Elbows

45° Elbows

OFFSETS

RISE

OFFSET

RISE

OFFSET

RISE

OFFSET

5 inch Ø

6" Length

23 - 28 3/4

5 - 6 1/2

22 3/4 - 28

10--13

21 1/2 - 25 3/4

14 3/4 – 19

12" Length

28 3/4 - 34 1/2

6 1/2 - 8

28 - 33 1/4

13 - 16

25 3/4 -30

19 - 23 1/4

18" Length

34 1/2 - 40 1/4

8 - 9 1/2

33 1/4 - 38 1/2

16 - 19

30 - 34 1/4

23 1/4 - 27 ½

24" Length

40 1/4 - 46 1/4

9 1/2 - 11

38 1/2 - 43 1/2

19 - 22

34 1/4 - 38 1/2

27 1/2 - 31 3/4

48" Length

63 1/2 - 69 1/4

15 3/4 - 17 1/4

59 1/4 - 64 1/2

31 - 34

51 1/4 - 55 1/4

44 1/2 - 48 3/4

24" + 12"

50 1/4 – 56

12 1/4 - 13 3/4

47 1/4 -52 1/2

24 - 27

41 1/2 - 45 3/4

34 1/4 - 39

48" + 12"

73 1/2 - 79 1/4

18 1/2 - 20

68 - 73 1/4

36 - 39

58 1/4 -62 1/2

51 3/4 - 56

48" + 18"

79 1/4 – 85

20 - 21 1/2

73 1/4 - 78 1/2

39 - 42

62 1/2 -66 3/4

56 - 60 1/4

48" + 24"

85 - 90 3/4

21 1/2 - 23

78 1/2 - 83 3/4

42 - 45

66 3/4 - 71

60 1/4 - 641/2

48" + 24" + 12"

95 -100 3/4

24 1/4 - 25 3/4

87 1/4 - 92 1/2

47 1/4 - 50 1/4

74 - 78 1/4

67 1/2 - 71 3/4

48" + 48"

108 1/4 -114

27 3/4 - 29 1/4

99 1/4 -104 1/2

54 - 57

83 3/4 - 88

77 1/4 - 81 1/2

6 inch Ø

6" Length

23 1/4 - 29

5 - 6 1/2

23 1/4 - 28 1/2

10--13

22 1/4 - 26 1/2

15 - 19 1/4

12" Length

29 - 34 3/4

6 1/2 - 8

28 1/2 - 33 3/4

13 - 16

26 1/2 - 30 1/2

19 1/4 - 23 1/2

18" Length

34 3/4 - 40 1/2

8 - 9 1/2

33 3/4 - 39

16 - 19

30 1/2 - 34 3/4

23 1/2 - 27 3/4

24" Length

40 1/2 - 46 1/2

9 1/2 - 11 1/4

39 - 44

19 - 22

34 3/4 - 39

27 3/4 - 32

48" Length

63 3/4 - 69 1/2

15 3/4 - 17 1/4

59 3/4 - 65

31 - 34

51 3/4 - 56

44 3/4 - 49

24" + 12"

50 1/2 - 56 1/4

12 1/4 - 13 3/4

47 3/4 - 53

24 1/4 - 27 1/4

42 - 46 1/4

35 - 39 1/4

48" + 12"

73 3/4 - 79 1/2

18 1/2 - 20

68 1/2 - 73 3/4

36 1/4 - 39 1/4

59 - 63 1/4

52 - 56 1/4

48" + 18"

79 1/2 - 85 1/4

20 - 21 1/2

73 3/4 - 79

39 1/4 - 42 1/4

63 1/4 - 67 1/2

56 1/4 - 60 1/2

48" + 24"

85 1/4 - 91

21 1/2 - 23

79 - 84 1/4

42 1/4 - 45 1/4

67 1/2 - 71 3/4

60 1/2 - 64 3/4

48" + 24" + 12"

95 1/4 - 101

24 1/4 - 25 3/4

87 3/4 - 93

47 1/4 - 50 1/4

74 3/4 - 79

67 3/4 - 72

48" + 48"

108 1/2 -114 1/4

27 3/4 - 29 1/4

99 3/4 – 105

54 1/4 - 57 1/4

84 1/2 - 88 3/4

77 1/2 - 81 3/4

7 inch Ø

6" Length

23 1/2 - 29 1/4

5 - 6 1/2

23 3/4 - 29

10 1/4 - 13 1/4

22 3/4 - 27

15 1/4 - 19 1/2

12" Length

29 1/4 - 35

6 1/2 - 8

29 - 34 1/4

13 1/4 - 16 1/4

27 - 31 1/4

19 1/2 - 23 3/4

18" Length

35 - 40 3/4

8 - 9 1/2

34 1/4 - 39 1/2

16 1/4 - 19 1/4

31 1/4 - 35 1/2

23 3/4 - 28

24" Length

40 3/4 - 46 3/4

9 1/2 - 11 1/4

39 1/2 - 44 1/2

19 1/4 - 22 1/4

35 1/2 - 39 3/4

28 - 32 1/4

48" Length

64 - 69 3/4

15 3/4 - 17 1/2

60 1/4 - 65 1/2

54 - 57

52 1/2 - 56 3/4

45 - 49 1/4

24" + 12"

50 3/4 - 56 1/2

12 1/4 - 13 3/4

48 1/4 - 53 1/2

1 1/2 - 4 1/2

42 3/4 - 47

35 1/4 - 39 1/2

48" + 12"

74 - 79 3/4

18 1/2 - 20

69 - 74 1/4

36 1/4 - 39 1/4

59 3/4 - 64

52 1/4 - 56 1/2

48" + 18"

79 3/4 - 85 1/2

20 - 21 1/2

74 1/4 - 79 1/2

39 1/4 - 42 1/4

64 - 68 1/4

56 1/2 - 60 3/4

48" + 24"

85 1/2 - 91 1/4

21 1/2 - 23 1/4

79 1/2 - 84 3/4

42 1/4 - 45 1/4

68 1/4 - 72 1/2

60 3/4 - 65

48" + 24" + 12"

95 1/2 -101 1/4

24 1/4 - 25 3/4

88 1/4 - 93 1/2

47 1/2 - 50 1/2

75 1/2 - 79 3/4

68 - 72 1/4

48" + 48"

108 3/4 -114 1/2

27 3/4 - 29 1/4

100 1/4 -105 1/2

54 1/4 - 57 1/4

85 1/4 - 89 1/2

77 3/4 - 82

8 inch Ø

6" Length

23 3/4 - 29 1/2

5 - 6 1/2

24 1/4 - 29 1/2

10 1/4 - 13 1/4

23 1/2 - 27 3/4

15 3/4 - 20

12" Length

29 1/2- 35 1/4

6 1/2 - 8

29 1/2 - 34 3/4

13 1/4 - 16 1/4

27 3/4 - 32

20 - 24 1/4

18" Length

35 1/4 - 41

8 - 9 3/4

34 3/4 - 40

16 1/4 - 19 1/4

32 - 36 1/4

24 1/4 - 28 1/2

24" Length

41 - 47

9 3/4 - 11 1/4

40 - 45

19 1/4 - 22 1/4

36 1/4 - 40 1/2

28 1/2 - 32 3/4

48" Length

64 1/4 - 70

15 3/4 - 17 1/2

60 3/4 - 66

31 1/4 - 34 1/4

53 1/4 - 57 1/2

45 1/4 - 49 1/2

24" + 12"

51 - 56 3/4

12 1/4 - 13 3/4

48 3/4 - 54

24 1/2 - 27 1/2

43 1/2 - 47 3/4

35 3/4 - 40

48" + 12"

74 1/4 - 80

18 1/2 - 20

69 1/2 - 74 3/4

36 1/2 - 39 1/2

60 1/2 - 64 3/4

52 1/2 - 56 3/4

48" + 18"

80 - 85 3/4

20 - 21 3/4

74 3/4 - 80

39 1/2 - 42 1/2

64 3/4 - 69

56 3/4 - 61

48" + 24"

85 3/4 - 91 1/2

21 3/4 - 23 1/4

80 - 85 1/4

42 1/2 - 45 1/2

69 - 73 1/4

61 - 65 ¼

48" + 24" + 12"

95 3/4 - 101 1/2

24 1/4 - 25 3/4

88 3/4 - 94

47 1/2 - 50 1/2

76 1/4 - 80 1/2

68 1/4 - 72 1/2

48" + 48"

109 - 114 3/4

27 3/4 - 29 1/2

100 3/4 - 106

54 1/2 - 57 1/2

86 - 90 1/4

78 - 82 1/4

The best place to install the adjustable length is immediately below the top elbow.

The adjustable length can then be adjusted to give you the offset you require.

NOTE: An adjustable length can not be used immediately above an elbow, there must be a

straight length below it.

EXCEL Canada 19 Owner’s Manual

Page 20

WALL SUPPORT (EWS)

1. Assemble the band following the instructions on page 14.

2. Fasten the wall support components to the band - see diagram above.

The components are attached to the two elevator bolts projecting from

the sides of the band.

WALL RADIATION SHIELD (EWRS)

If you are installing your chimney in an energy efficient house which has

sealed vapour barriers (e.g.: R2000 construction) we manufacture a

special wall radiation shield so that you can maintain your vapour barrier

integrity. (See part EWRSI.)

If possible install an interior chimney as it will provide better performance

than an exterior chimney. In area with continuous temperatures below

-18°C (0° F) the use of an exterior chimney may result in operating

problems such as poor draft, excessive condensation of combustion

products and rapid accumulation of creosote when connected to a wood

burning appliance. If you do install an exterior chimney, we recommend

that you enclose it using an insulated enclosure.

NOTES:

1. The chimney may be enclosed or un-enclosed. Always maintain 2"

clearance to combustible materials. Do not fill the space around the

chimney with insulation or any other material.

2. A wall support must be used to secure the chimney to the wall.

Maximum distance between wall supports is 8 feet if the chimney is not

enclosed.

3. The chimney must extend in to the room at least 4 inches.

EXCEL Canada 20 Owner’s Manual

Page 21

4. The distance between a single wall stovepipe and a parallel

combustible wall or ceiling must not be less than 18". The distance

between the horizontal stove pipe and the un-shielded vertical wall

through which the insulated chimney passes is determined by the Wall

Radiation Shield.

5. If an exterior installation is to be enclosed, allow for access to the base

of the Tee to facilitate cleaning.

6. The minimum distance between the bottom of the chimney and any

horizontal combustible is 12".

THROUGH WALL INSTALLATION

Unenclosed Exterior Installation Enclosed Exterior Installation

1. Determine where the chimney will pass through the wall.

For concrete walls cut a hole slightly larger than the chimney. If the

concrete wall has a wood wall inside it follow the instructions for a

combustible wall.

For combustible walls cut and frame a hole corresponding to the

rough opening required in the table on page 3.

2. Combustible wall:

From outside, put the exterior portion (the galvanized part with the

square plate) of the wall radiation shield in the hole. Nail the shield in

place using 4 - 2" nails or # 8 x 1 1/2" wood screws. Seal the joint

between the shield and the wall with silicone caulking.

EXCEL Canada 21 Owner’s Manual

Page 22

3. Assemble the Wall Support - follow instructions on page 20.

4. Fasten the required chimney length to the Tee side entrance. The

horizontal chimney section must extend through the finished interior

wall by at least 4 inches. In some cases you may wish to use an

adjustable length in combination with a short length for this purpose.

Attach the flue extension (EX) found in the EWRS box, to the end of

the horizontal chimney length using the 3 metal screws provided.

5. Fasten a chimney length to the top of the Tee.

6. The wall support should be installed on the first vertical chimney

section above the Tee. Tighten the universal band locking bolt just

enough to hold the wall support in place.

7. Install this assembly through the hole in the radiation shield.

8. Fasten the Wall Support brackets to the outside wall in a convenient

location directly above the hole. Use four #10 x 3" or larger screws.

Insure that the screws are fastened into a structural member and not

only to the wall sheeting. If the stud locations do not line up properly

you may wish to use a wall channel - see instructions page 24. The

Wall Support brackets are slotted to allow them to adjust in and out.

Adjust the brackets so that the chimney is a minimum of 2" from the

wall and parallel with it. Tighten the Wall Support collar around the

chimney, then secure it using 3 metal screws.

9. Stack the next chimney length in place. Align the vertical seams, this

will also align the screw holes. Fasten the lengths together using 3

metal screws. Continue installing lengths until you reach the roof or

until the required overall height is achieved. Many installers prefer to

screw two or three vertical lengths together in advance because it is

easier to screw the chimney sections together in the open than when

they are close to a wall.

10. If the chimney is installed in a combustible chase then a roof radiation

shield (ERRS) must be installed immediately below the flashing or

chase top and a ventilated flashing (EVF) must be installed. See

drawing on page 22.

11. If the chimney passes through the roof, cut a hole large enough to

provide 2" clearance between the chimney and the roof. Install a

radiation shield (ERS) from the bottom to seal the opening. Continue

installing lengths as required.

12. Install another Wall Support at 8' intervals. The Wall Support should

be adjusted to ensure the chimney is vertical and at 2" (or more)

clearance to combustibles.

EXCEL Canada 22 Owner’s Manual

Page 23

13. Put the roof flashing in place. Seal the joint between the roof and the

flashing with roofing pitch. For sloping roofs, place the flashing under

the upper shingles and on top of the lower shingles. Nail the flashing

to the roof using roofing nails. Place the storm collar over the chimney

just above the flashing. Caulk the joint between the chimney and

storm collar with silicone caulking.

14. Continue adding chimney sections until the required chimney height is

reached. See the drawing on page 7 to determine the correct height.

15. If the chimney extends more than 5' above the roof it should be

secured to the roof using a Roof Brace (ERB).

16. Fit the rain cap to the top of the chimney. Screw the four metal screws

provided through the straps and into the top chimney length. Install

the spark screen if you wish to have a spark screen.

17. FROM INSIDE. Slide the black portion of the Wall Radiation Shield

over the galvanized portion which was installed from the outside and

push it until it stops against the chimney. The black interior portion of

the Wall Radiation Shield must project into the room a minimum of 4".

Install the round finish trim with the long black screws provided.

WALL CHANNEL

The use of a wall channel will simplify the installation of a wall band or wall

support. The wall channel is 26 inches long to allow for 24 inch on centre

framing.

1. Locate the framing members you will screw the wall channel to. Do not

screw the wall channel in place yet.

2. Determine the correct location on the wall channel for the wall band or

wall support. The two short sides of the wall channel rest against the

wall. Bolt the support brackets to the wall channel with elevator bolts.

3. Screw the wall channel in place using a minimum of four #10 x 3 inch

screws.

EXCEL Canada 23 Owner’s Manual

Page 24

ROOF BRACE (ERB)

The roof brace is required to

provide extra stability for

chimneys which extend more

than 5 feet above a roof.

1. Assemble the band following

the instructions on page 14.

2. Place the band at a point at

least two thirds of the way

up the chimney. Fasten the

larger diameter section of

the braces to the collar

using the nuts provided.

Adjust the length of the

braces by telescoping one

tube inside the other until

the desired length is

reached. The angle of the

braces should not be more

than 45 degrees from

horizontal when fastened to

the roof.

3. Fasten the other end of each brace to the roof using a #10 x 4" or larger

screw and a washer. Insure that the screws are fastened into a

structural member of the roof and not only into the roof sheeting. The

two braces should be installed approximately 90° apart.

4. Tighten the bolt which locks the two tubes together very firmly. We

recommend that you screw the inside and outside tubes together using

# 8 x 1/2" screws to permanently lock them in place.

5. Tighten the locking bolt on the universal band then secure the collar by

screwing the metal screws provided through the holes in the collar and

into the chimney.

EXCEL Canada 24 Owner’s Manual

Page 25

ADJUSTABLE LENGTH (ELA18)

An adjustable chimney length is available for

chimney installations that require exact

lengths. An adjustable length can not be

installed immediately above a support,

elbow or tee. It can only be installed above a

straight length. When using the adjustable

length the flue (inside) does not adjust, only

the outside casing.

1. Determine the required length.

Once a fireplace is installed, bolt

the anchor plate to the fireplace.

Install the chimney according to

the Installation Instructions for the

Ceiling Support. Omit step 2 since

the anchor plate acts as the

chimney’s support.

2. Remove the three screws from the outside casing of the adjustable

length. Slide the two sections of the outer casing together until the

required overall length is achieved.

3. Using the stainless steel screws provided fasten the two sections of

outer casing together through the three pre-punched holes. The screws

are self drilling and will make their own holes. Cut off the exposed

insulation. The remaining insulation will compress enough to allow the

next chimney section to connect. Do not cut the inner flue, it will slide

inside the next chimney length.

4. To install the adjustable length slide the flue into the length below until

the outside casing seats firmly in place. You may need to press firmly

to compress the additional insulation. Fasten the lengths together using

the 3 metal screws provided.

ANCHOR PLATE (EAP)

This support is used on a masonry fireplace to provide a positive

connection to the chimney. It is not to be used in contact with any

combustible material, such as a wood floor.

EXCEL Canada 25 Owner’s Manual

Page 26

RADIATION SHIELD (ERS & ERSA)

The radiation shield must be

used when the chimney

passes through a floor, or

when it is installed in a attic.

See illustrations page 9. The

radiation shield is designed to

adjust for a variety of attic

heights. Always adjust the

radiation shield to be as high

as the attic will allow, even if

the additional height is not

required to provide shielding

from insulation. This will

reduce the chance that loose

fill insulation will come in

contact with the chimney

if additional insulation is added

in the future. To adjust the radiation shield simply slide the top tube up as

high as possible then screw the two sections together with the self drilling

screws provided. When the radiation shield is installed in the attic, a

universal storm collar (ESC) must be used. This will prevent the infiltration

of insulation between chimney and radiation shield.

RAIN CAP BASE (ERCB)

The rain cap base is used to seal off the end of the chimney where it is

installed without a rain cap. In some Northern areas the use of a rain cap is

either not permitted or discouraged. Excel chimneys do not have end caps

so the ends of the chimney are open to the weather unless they are

protected by a rain cap or rain cap base. Under no circumstances can

the end of an Excel chimney be left unprotected. If it is necessary for the

rain cap to be removed, a rain cap base must be installed.

EXCEL Canada 26 Owner’s Manual

Page 27

UNIVERSAL STORM COLLAR (ESC)

The universal storm collar has been

designed as a compatible fit for all

EXCEL chimneys. The universal

storm collar must be used on

regular (non-vented) flashing and

on the radiation shield when

installed in an attic. The universal

storm collar, when installed on

small diameter chimney (5” and 6”),

can be cut for ease of installation.

The cut line is shown in the

illustration of the piece.

To install the universal storm

collar:

1. Place the storm collar around the chimney.

2. Slide the tongue into the appropriate slot for the required diameter.

3. Ensure the tongue is placed into the slot correctly.

4. Use the round notch to tighten the collar around the chimney.

(When the collar is installed in an attic ensure that it's sits properly on the

radiation shield)

5. Bend the tongue back over the slot.

6. Bend the two tabs to secure the inner portion of the collar.

7. Hold the tongue in place by inserting a screw into the hole at the tip.

8. Seal the crack between chimney and collar with silicone.

9. Seal the unused slots of the universal storm collar with silicone.

EXCEL Canada 27 Owner’s Manual

Page 28

SNOW-BARRIER (ESW)

3. Position the snow wedge on the roof with

the hinge aligned with the center of the

chimney. Adjust the wedge so that the

top (hinge) is horizontal. Leave a

minimum distance of 2" between the

chimney and the top of the wedge.

4. Screw the wedge to the roof using #10 X

3" or heavier screws; be sure to install all

eight screws. Before tightening the

screws apply some silicone under each

tab to seal the screw hole in the roof.

Make sure all screws penetrate the

backing as well as the roof sheeting.

Tabs

bending

angle

Roof slope

Locking tabs’

bend

4/12

136°

7/12

130°

9/12

125°

12/12

112°

2” min

wood-

screws

Roof

slope

1. The snow wedge must be solidly fastened to the roof in order to resist

the force of a heavy snow load. Simply screwing it to typical roof

sheeting is not normally sufficient. We recommend that you install 3/4"

plywood or 2 X 6 backing large enough to accept all eight screws.

2. The tabs on the snow wedge are factory adjusted for a 4/12 roof.

These tabs must be bent in the field to adjust for the actual roof pitch

see attached table. The snow wedge is designed to be adjustable for

all pitches up to a maximum of 12/12.

EXCEL Canada 28 Owner’s Manual

Page 29

ROUND SUPPORT (ERDS)

To install the round support using the support collar follow the Excel

installation instructions for the round support replacing step #2 with the

following:

1. Slide the support collar over the support from the bottom making sure

the four tabs are pointing downwards - see drawing below. Before

screwing the collar in place you must measure to compensate for the

thickness of the framing materials and also insure that the bottom of

the support extends a minimum of 3" below the finished ceiling. Fasten

the collar to the support with the self tapping metal screws provided.

2. The tabs have been designed so that the support can be pushed up

through the square framed opening from the bottom and then rotated

1/4 turn so that the tabs sit on top of the framing - the round trim collar

is large enough to cover the square hole. Once all four tabs are sitting

on the framing it must be nailed or screwed in place. This can be

accomplished either from the top through the holes in the tabs, or

through all four sides of the support using a minimum #8 x 1 1/2"

screws.

To complete the installation follow the remaining steps in the Excel

installation instructions.

EXCEL Canada 29 Owner’s Manual

Page 30

EXTENDED WALL SUPPORT (EWSE)

the wall sheeting. If the stud locations do not

line up properly you may wish to use a wall

channel (see instructions page 24). The wall

support brackets are slotted to allow them to

adjust in and out. Adjust the brackets so that

the chimney is a minimum of 2” from

combustible material and parallel with the wall.

Tighten the Wall Support collar around the

chimney, then secure it using 3 metal screws.

Chimney

diameter

Maximum

height that

can be

supported

5” Ø

23’

6” Ø

20’

7” Ø

17’

8” Ø

16’

1. Assemble the universal support collar on the chimney section as

shown on page 14 & 15 of the Excel installation instructions.

2. Attach the horizontal braces to the universal support collar as show in

the diagram below. Place the support collar at the desired distance

from the wall using the slots on the horizontal braces. The braces are

attached to the two elevator bolts that protrude from the sides of the

support collar.

Continue the installation in accordance with the instruction manual

on page 22, wall support, and replace instructions 6 and 8 on page 23

with the following:

6. The horizontal braces and support flange should be installed on the first

vertical chimney section above the Tee. Tighten the universal band

locking bolt just enough to hold the wall support in place.

8. Install the support horizontal braces on the external wall by using four

#10 x 3" or longer screws. Attach the diagonal braces and the wall

brackets to the horizontal braces. Install the brackets on the external

wall using #10 x 3" or longer screws. As mentioned previously, ensure

that the screws are anchored in the structural member and not only to

(continue the installation in accordance with the instruction manual at the

page 22 & 23)

EXCEL Canada 30 Owner’s Manual

Page 31

LIMITED LIFETIME WARRANTY

ICC EXCEL RESIDENTIAL CHIMNEY

ICC warrants its EXCEL stainless steel chimney lengths to be free from

functional failure due to defects in material or workmanship for as long as

the original consumer owns the chimney system. This warranty provides

for replacement of any chimney lengths which fail as a result of normal use

on a residential fireplace, wood burning stove, furnace or boiler and

includes replacement of any lengths damaged as a result of a chimney fire.

(Note: Chimney fires are dangerous and preventable, we strongly

encourage you to have your chimney cleaned regularly). This warranty

does not cover damage caused to the building by chimney fires or misuse

of the product.

No claims under this warranty will be honoured unless ICC is notified of the

potential claim and is given the opportunity to have one of its agents

examine the chimney prior to replacement.

ICC will only be responsible for repair or replacement of any chimney

lengths found to be defective under this warranty. In no event shall ICC be

responsible for any incidental or consequential damage caused by defects

in the EXCEL chimney system.

During the first ten years of the warranty ICC will provide replacement

chimney lengths at no charge. During the balance of the warranty ICC will

provide replacement chimney lengths at 50% of the current retail price at

the time of the warranty claim.

ICC will not be responsible for labour of any kind required in the removal or

replacement of an EXCEL system replaced under this warranty.

This chimney is designed to vent residential heating oil, untreated wood,

low sulphur coal, and natural or LP gas. It is designed to operate at a

continuous temperature of 650°C or less. It is not designed to vent

condensing oil or gas appliances. This warranty is void if the chimney is

used in an application for which it is not designed.

The EXCEL system must be installed according to the Installation

Instructions included with every system at the time of purchase. If you do

not have a set of installation instructions they are available free upon

request. This warranty is void if the chimney is not installed according to

the installation instructions.

This warranty may not be extended or modified by our agents or

representatives. This warranty is in lieu of all other express warranties or

guarantees, of any kind.

EXCEL Canada 31 Owner’s Manual

Page 32

Notes

Loading...

Loading...