Page 1

ERserver

xSeries 445 Type 8870

Option Installation Guide

Page 2

Page 3

ER s e r v e r

xSeries 445 Type 8870

Option Installation Guide

Page 4

Note: Before using this information and the product it supports, read the general information in “Getting

help and technical assistance”, on page 83.

First Edition (June 2003)

© Copyright International Business Machines Corporation 2003. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Safety ............................v

Chapter 1. Introduction......................1

Related publications .......................1

Major components of the xSeries 445 server ..............2

Center plane connectors and LEDs .................3

SMP Expansion Module connectors and LEDs.............4

PCI-X planar internal connectors and LEDs ..............6

I/O board internal connectors ...................7

Remote Supervisor Adapter component locations............7

Chapter 2. Installing options....................9

Installation guidelines .......................9

System reliability guidelines....................9

Working inside the server with power on ..............10

Handling static-sensitive devices .................10

Safety information ........................11

Opening the cover .......................16

Removing and replacing the bezel..................17

Removing and replacing a hot-swap power supply ............18

PCI and PCI-X adapters .....................20

Cabling a ServeRAID adapter ..................23

Installing the serial port .....................25

Installing or replacing a drive....................28

Hot-swap hard disk drive ....................28

Diskette drive ........................29

DVD-ROM drive .......................30

SMP Expansion Module .....................31

Removing and Installing the SMP Expansion Module and cover ......32

Memory Module .......................38

Installing and replacing a microprocessor ..............46

Replacing and troubleshooting fans .................52

Replacing fans 1 and 2 .....................52

Replacing fans 3 and 4 .....................53

Replacing the battery ......................55

Closing the cover ........................57

Connecting the cables ......................58

SMP Expansion Port cabling ...................59

RXE Expansion Port cabling ...................64

RXE Management Port cabling ..................69

Power cabling .........................72

SCSI cabling..........................72

USB cabling ..........................72

Video cabling .........................72

Mouse cabling .........................73

Keyboard cabling .......................73

Gigabit Ethernet cabling .....................73

Remote Supervisor Adapter cabling .................73

Chapter 3. I/O connectors and LEDs ................75

Universal Serial Bus connectors ..................76

USB cables and hubs .....................76

USB-port connectors......................76

© Copyright IBM Corp. 2003 iii

Page 6

Keyboard connector .......................76

Video connector ........................76

Auxiliary-device (pointing device) connector ..............77

RXE Expansion Port .......................77

SMP Expansion Port.......................77

Serial Port ..........................77

Remote Supervisor Adapter communication connectors ..........78

Gigabit Ethernet port.......................80

Configuring the Gigabit Ethernet controller..............80

Ethernet port connectors ....................81

Appendix. Getting help and technical assistance ...........83

Before you call .........................83

Using the documentation .....................83

Getting help and information from the World Wide Web ..........83

Software service and support ...................84

Hardware service and support ...................84

Index ............................85

iv xSeries 445 Type 8870: Option Installation Guide

Page 7

Safety

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d’installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

© Copyright IBM Corp. 2003 v

Page 8

Antes de instalar este producto, lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

Statement 1:

DANGER

Electrical current from power, telephone, and communication cables is

hazardous.

To avoid a shock hazard:

v Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an electrical

storm.

v Connect all power cords to a properly wired and grounded electrical

outlet.

v Connect to properly wired outlets any equipment that will be attached to

this product.

v When possible, use one hand only to connect or disconnect signal

cables.

v Never turn on any equipment when there is evidence of fire, water, or

structural damage.

v Disconnect the attached power cords, telecommunications systems,

networks, and modems before you open the device covers, unless

instructed otherwise in the installation and configuration procedures.

v Connect and disconnect cables as described in the following table when

installing, moving, or opening covers on this product or attached

devices.

To Connect: To Disconnect:

1. Turn everything OFF.

2. First, attach all cables to devices.

3. Attach signal cables to connectors.

4. Attach power cords to outlet.

5. Turn device ON.

vi xSeries 445 Type 8870: Option Installation Guide

1. Turn everything OFF.

2. First, remove power cords from outlet.

3. Remove signal cables from connectors.

4. Remove all cables from devices.

Page 9

Statement 2:

CAUTION:

When replacing the lithium battery, use only IBM Part Number 33F8354 or an

equivalent type battery recommended by the manufacturer. If your system has

a module containing a lithium battery, replace it only with the same module

type made by the same manufacturer. The battery contains lithium and can

explode if not properly used, handled, or disposed of.

Do not:

v Throw or immerse into water

v Heat to more than 100°C (212°F)

v Repair or disassemble

Dispose of the battery as required by local ordinances or regulations.

Statement 3:

CAUTION:

When laser products (such as CD-ROMs, DVD drives, fiber optic devices, or

transmitters) are installed, note the following:

v Do not remove the covers. Removing the covers of the laser product could

result in exposure to hazardous laser radiation. There are no serviceable

parts inside the device.

v Use of controls or adjustments or performance of procedures other than

those specified herein might result in hazardous radiation exposure.

DANGER

Some laser products contain an embedded Class 3A or Class 3B laser

diode. Note the following.

Laser radiation when open. Do not stare into the beam, do not view directly

with optical instruments, and avoid direct exposure to the beam.

Safety vii

Page 10

Statement 4:

≥ 18 kg (39.7 lb) ≥ 32 kg (70.5 lb) ≥ 55 kg (121.2 lb)

CAUTION:

Use safe practices when lifting.

Statement 5:

CAUTION:

The power control button on the device and the power switch on the power

supply do not turn off the electrical current supplied to the device. The device

also might have more than one power cord. To remove all electrical current

from the device, ensure that all power cords are disconnected from the power

source.

2

1

viii xSeries 445 Type 8870: Option Installation Guide

Page 11

Statement 8:

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any

component that has this label attached. There are no serviceable parts inside

these components. If you suspect a problem with one of these parts, contact

a service technician.

Statement 10:

CAUTION:

Do not place any object weighing more than 82 kg (180 lb) on top of

rack-mounted devices.

>82 kg (180 lb)

Statement 13:

DANGER

Overloading a branch circuit is potentially a fire hazard and a shock hazard

under certain conditions. To avoid these hazards, ensure that your system

electrical requirements do not exceed branch circuit protection

requirements. Refer to the information that is provided with your device for

electrical specifications.

Safety ix

Page 12

WARNING: Handling the cord on this product or cords associated with accessories

sold with this product, will expose you to lead, a chemical known to the State of

California to cause cancer, and birth defects or other reproductive harm. Wash

hands after handling.

ADVERTENCIA: El contacto con el cable de este producto o con cables de

accesorios que se venden junto con este producto, pueden exponerle al plomo, un

elemento químico que en el estado de California de los Estados Unidos está

considerado como un causante de cancer y de defectos congénitos, además de

otros riesgos reproductivos. Lávese las manos después de usar el producto.

x xSeries 445 Type 8870: Option Installation Guide

Page 13

Chapter 1. Introduction

This Option Installation Guide contains instructions for installing, removing, and

connecting optional devices.

Related publications

In addition to this Option Installation Guide, the following xSeries 445

documentation is provided with your server:

v Installation Guide

This printed publication contains instructions for setting up your server and basic

instructions for installing some options.

v Rack Installation Instructions

This printed publication contains instructions for installing your server in a rack

cabinet.

v Safety Information

This publication is in PDF on the IBM

translated caution and danger statements. Each caution and danger statement

that appears in the documentation has a number that you can use to locate the

corresponding statement in your language in the Safety Information book.

v User’s Guide

This publication is in PDF on the IBM xSeries Documentation CD. It contains

general information about your server.

v Hardware Maintenance Manual and Troubleshooting Guide

This publication is in PDF on the IBM xSeries Documentation CD. It contains

information to help you solve problems yourself, and it contains information for

service technicians.

®

xSeries™Documentation CD. It contains

Depending on your server model, additional publications might be included on the

IBM xSeries Documentation CD.

© Copyright IBM Corp. 2003 1

Page 14

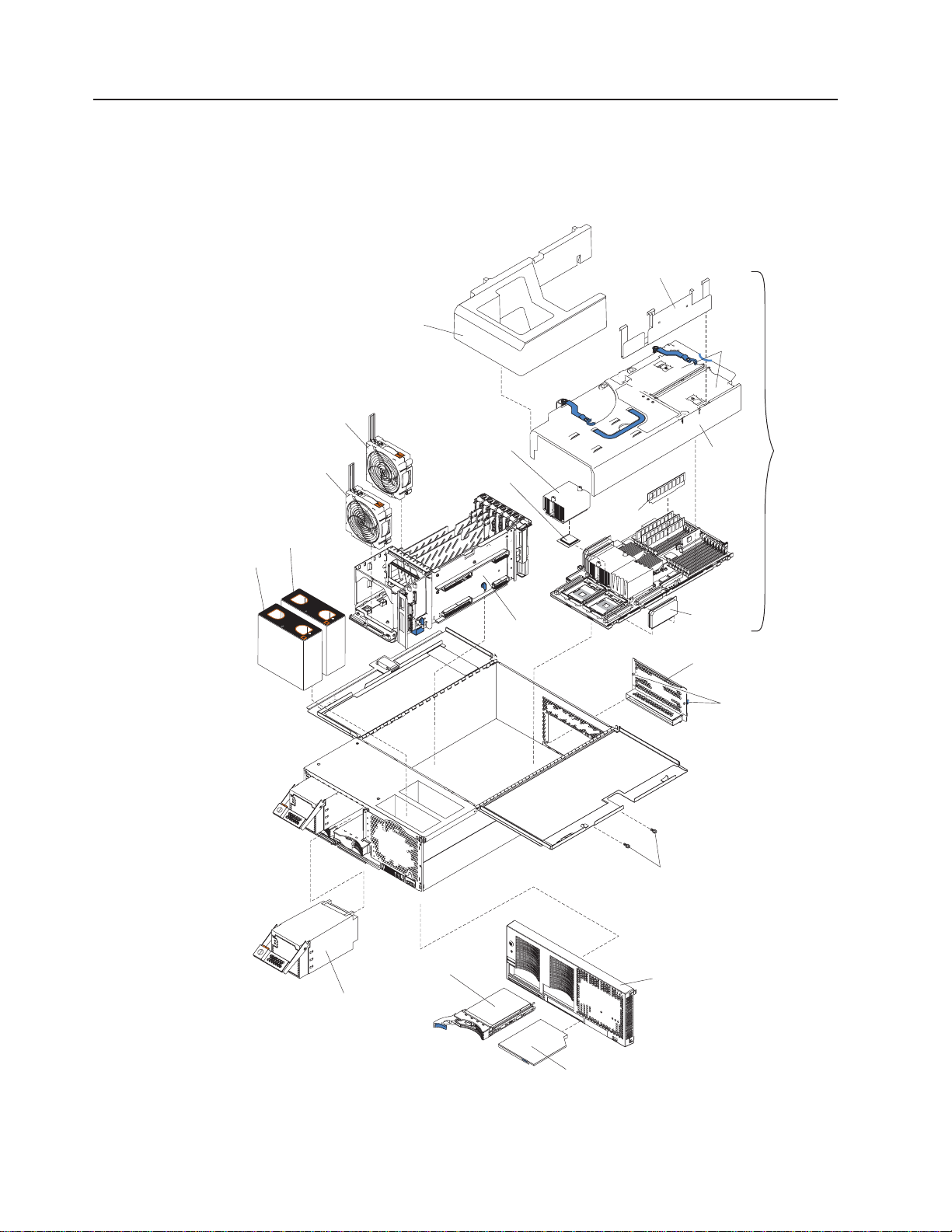

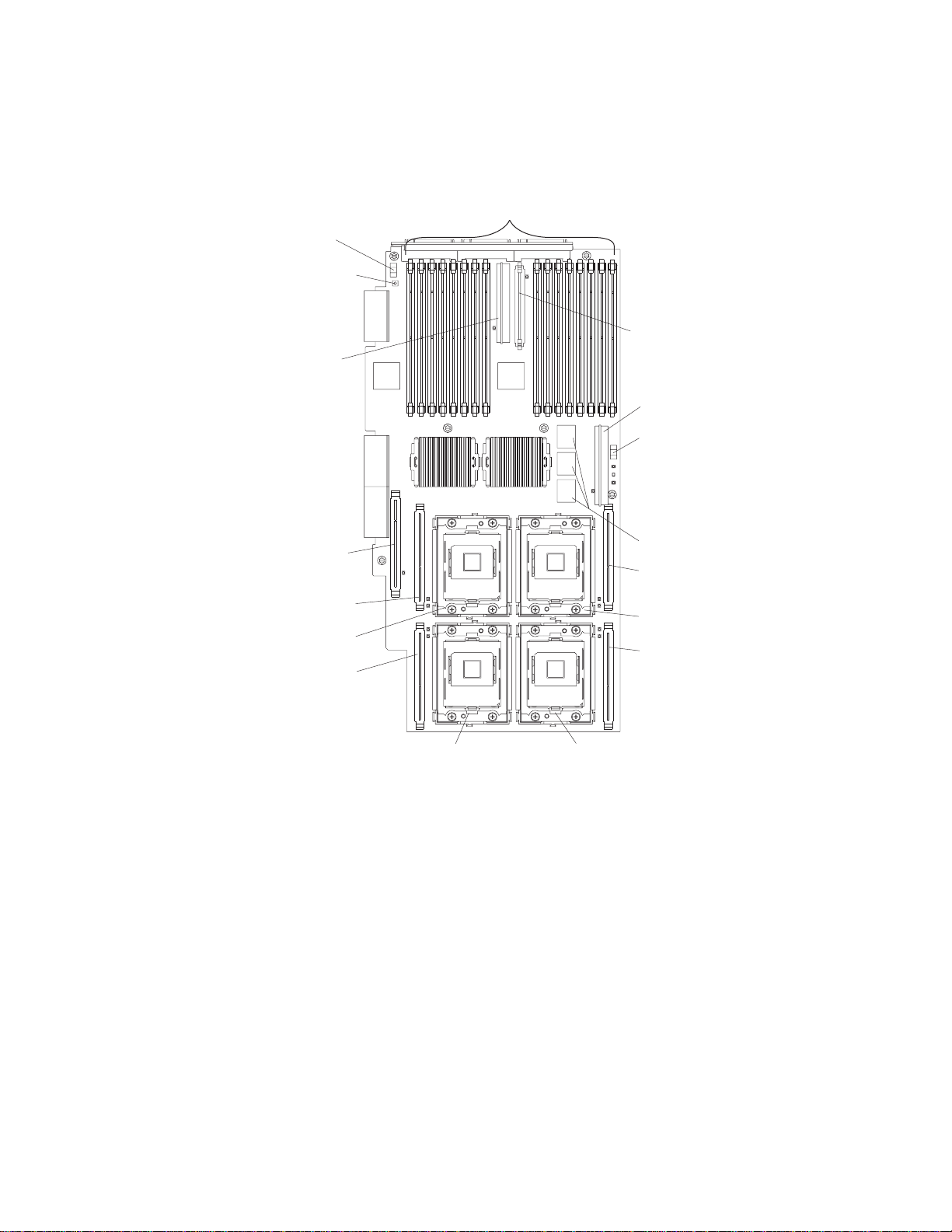

Major components of the xSeries 445 server

The following illustration shows the locations of major components in your server.

Note: The illustrations in this document might differ slightly from your hardware.

Retention bracket

Fan 1

N

O

T

E

:

F

F

R

Fan 2

O

R

P

R

O

P

E

R

A

IR

F

L

O

N

T

O

F

B

O

X

Fan 3

N

O

T

E

:

F

O

R

P

R

O

F

R

O

N

T

O

F

O

W,

R

E

P

L

A

C

E

F

A

N

W

IT

H

Fan 4

P

E

R

A

IR

F

L

O

W,

R

E

P

L

A

C

B

O

X

IN

2

M

IN

U

T

E

S

E

F

A

N

W

IT

H

IN

2

M

IN

U

T

E

S

SMP baffle

Heat-sink

Microprocessor

Center

plane

DIMM

DIMM

access

doors

SMP

Cover

Expansion

Module

VRM

EMC shield

(for single SMP

Expansion Module)

Thumbscrews

Hot-swap

power supply

Figure 1. Major components of the xSeries 445 server

2 xSeries 445 Type 8870: Option Installation Guide

Hard disk

drive

Shipping thumbscrews

Bezel

DVD-ROM

drive

Page 15

Center plane connectors and LEDs

The following illustrations identify the connectors and LEDs on the center plane.

This center plane is used to connect the power and signal paths for the SMP

Expansion Module, I/O board, and the Remote Supervisor Adapter.

Force power-on

(J37)

Light path (J8)

SMP 2 (J14)

SCSI

power (J9)

Power

(J11)

Power

(J19)

Power

(J23)

J30 J32 J31 J29 J28

Reserved

Figure 2. Center plane connectors

System management

power fault

LED (CR5)

I/O power fault

LED (CR6)

System power

present LED

(CR7)

Power present

(CR10)

PCI-X power fault LED (CR4)

Center plane power fault LED (CR3)

Lower SMP power fault LED (CR2)

Upper SMP power fault LED (CR1)

VRM (J12)

Thumbscrews

Serial port (J7)

SMP 2

(J15)

SMP 1

(J25)

SMP 1 (J24)

Lower SMP

power good LED

(CR8)

Figure 3. Center plane LEDs

Upper SMP

power good LED

(CR9)

Chapter 1. Introduction 3

Page 16

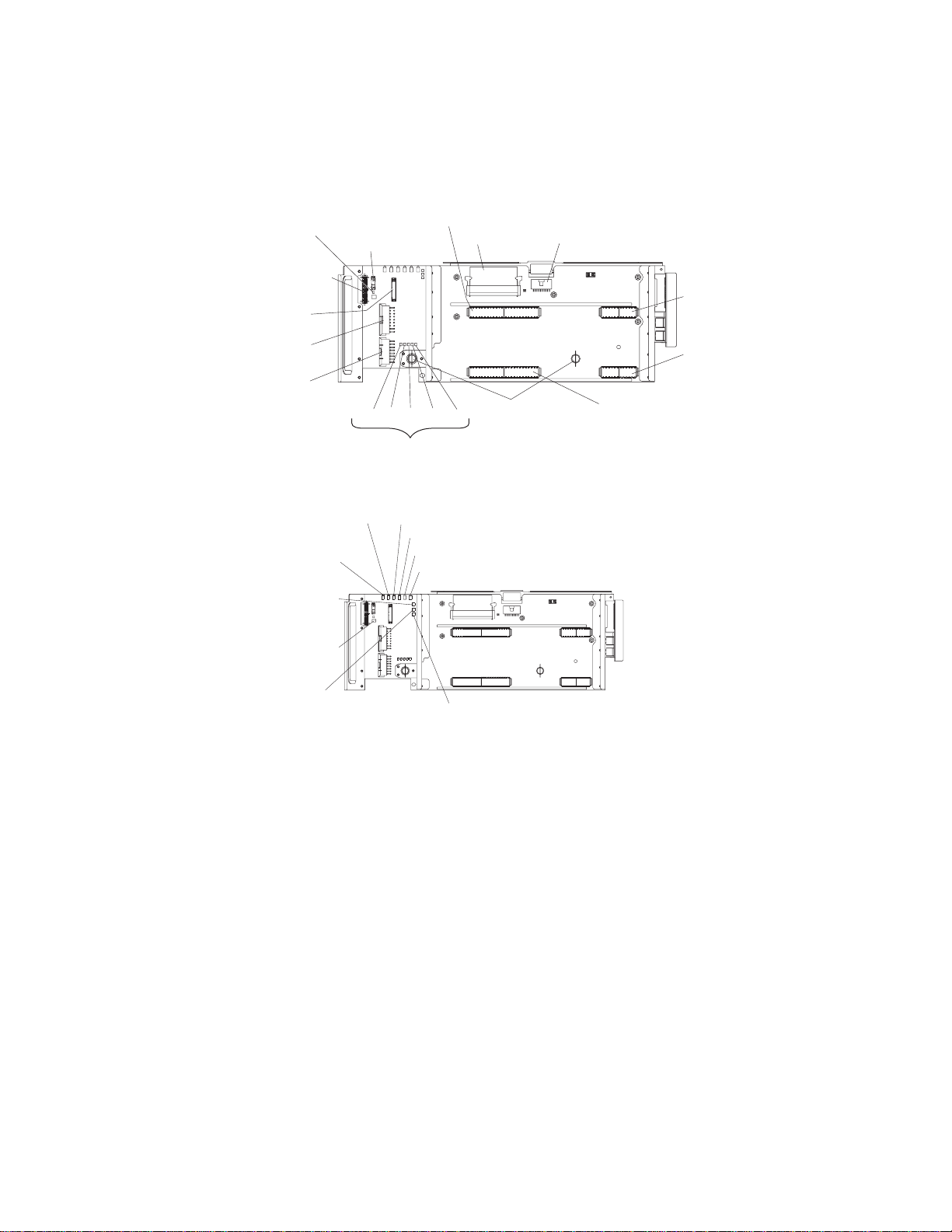

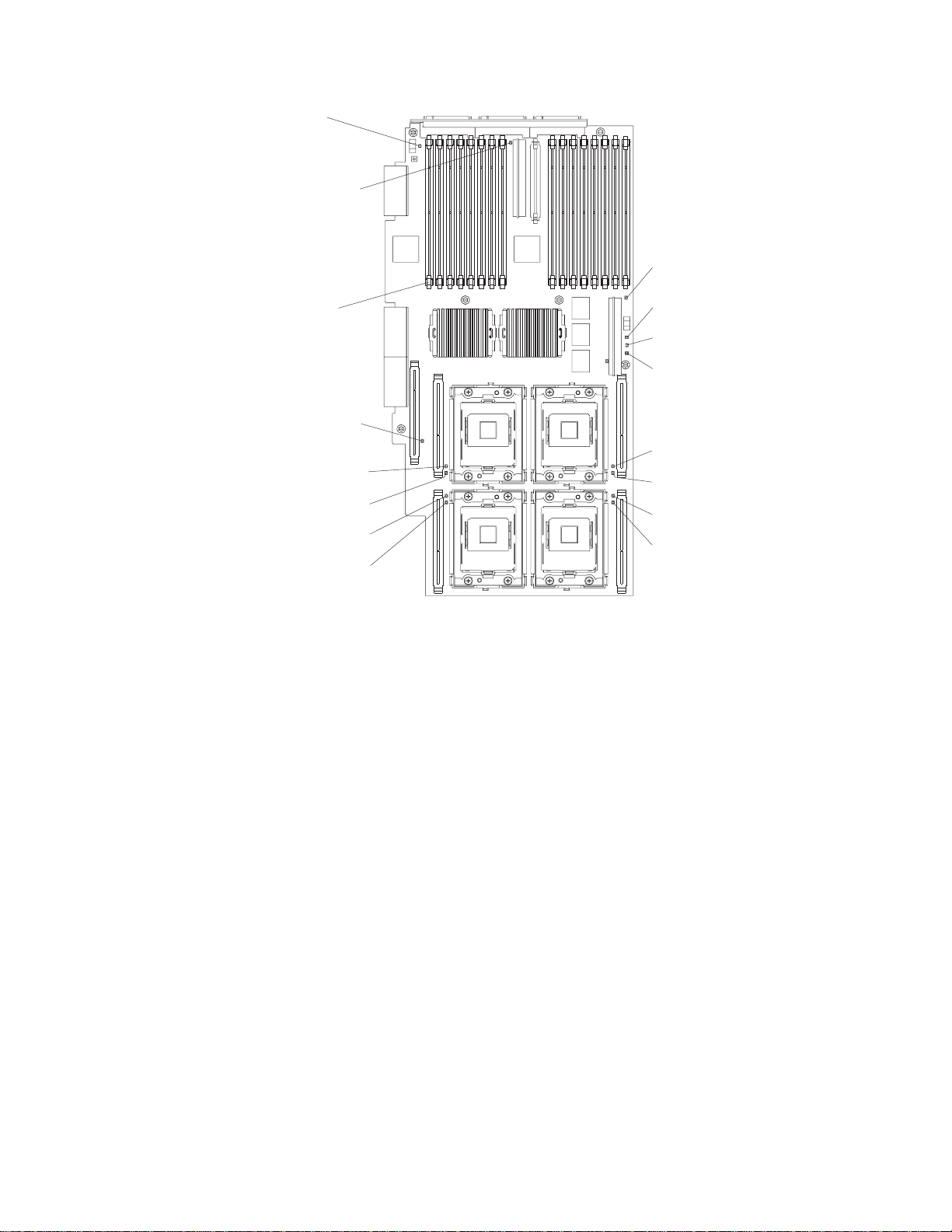

SMP Expansion Module connectors and LEDs

The following illustrations identify the connectors, switches, and LEDs on the SMP

Expansion Module.

DIMM connectors

(J1 - J16)

Memory port 1

switch (SN2)

Remind/Light Path

capacitor switch

(SW1)

Integrated

VRM connector

(U13)

VRM connector

(J44)

Microprocessor 1

VRM connector (J35)

Microprocessor 1

socket (U22)

Microprocessor 3

VRM connector (J36)

Figure 4. SMP Module connectors

IntegratedVRM

(U17)

VRM connector

(J28)

Memory port 2

power switch (SN1)

XceL4 cache

Microprocessor 4

VRM connector (J22)

Microprocessor 4

socket (U12)

Microprocessor 2

VRM connector (J23)

Microprocessor 2 socket (U13)Microprocessor 3 socket (U24)

4 xSeries 445 Type 8870: Option Installation Guide

Page 17

Light path

capacitor

LED (CR49)

SMP expansion

board bad error

LED (CR34)

VRM error LED

(CR33)

DIMM error

LED (16X)

(J1-J16)

VRM error LED

(CR47)

Microprocessor 1

VRM error LED (CR42)

Microprocessor 1

error LED (CR41)

Microprocessor 3

error LED (CR43)

Microprocessor 3

VRM error LED (CR44)

Figure 5. SMP Module LEDs

Memory port 2

power LED (CR17)

Hot-plug enabled

memory LED (CR18)

Memory port 1

power LED (CR19)

Microprocessor 4

VRM error LED (CR22)

Microprocessor 4

error LED (CR23)

Microprocessor 2

error LED (CR24)

Microprocessor 2

VRM error LED (CR25)

Chapter 1. Introduction 5

Page 18

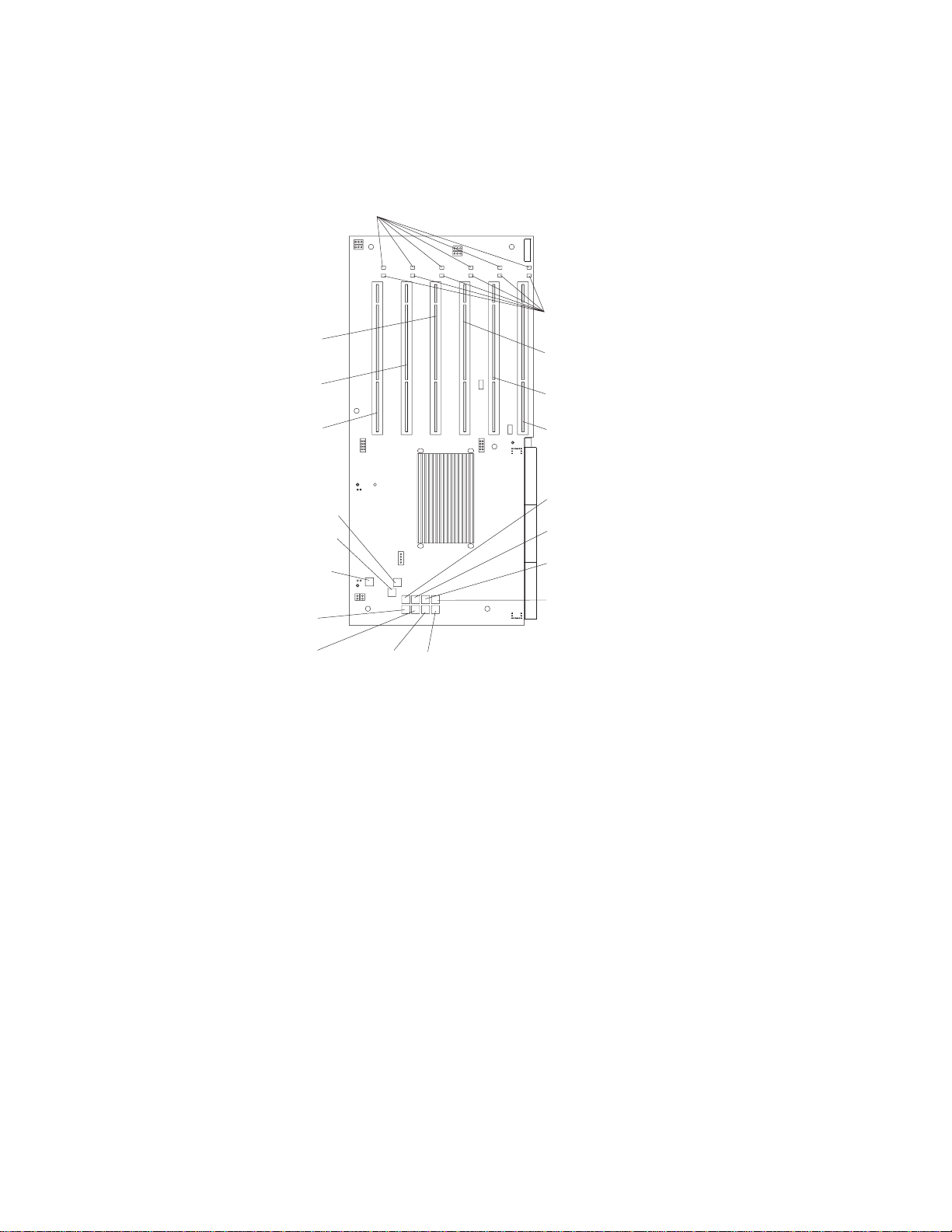

PCI-X planar internal connectors and LEDs

The following illustration identifies the internal connectors and LEDs on the PCI-X

planar. This planar enables you to install adapters in the server.

Attention LEDs

(CR20 - CR25)

PCI-X slot 4

(100 ) (J4)MHz

PCI-X slot 5

(133 ) (J5)MHz

PCI-X slot 6

(133 MHz) (J6)

Power LEDs

(CR14 - CR19)

PCI-X slot 3

(100 ) (J3)MHz

PCI-X slot 2

(66 ) (J2)MHz

PCI-X slot 1

(66 ) (J1)MHz

1.8V (CR6)

2.5V (CR1)

VRM present

(CR12)

PERR PCI

bus D (CR4)

PERR PCI

bus C (CR9)

PERR PCI

bus B (CR10)

PERR PCI

bus A (CR11)

Figure 6. PCI-X board connectors and LEDs

SERR PCI

bus D (CR2)

SERR PCI

bus C (CR7)

SERR PCI

bus B (CR3)

SERR PCI

bus A (CR8)

6 xSeries 445 Type 8870: Option Installation Guide

Page 19

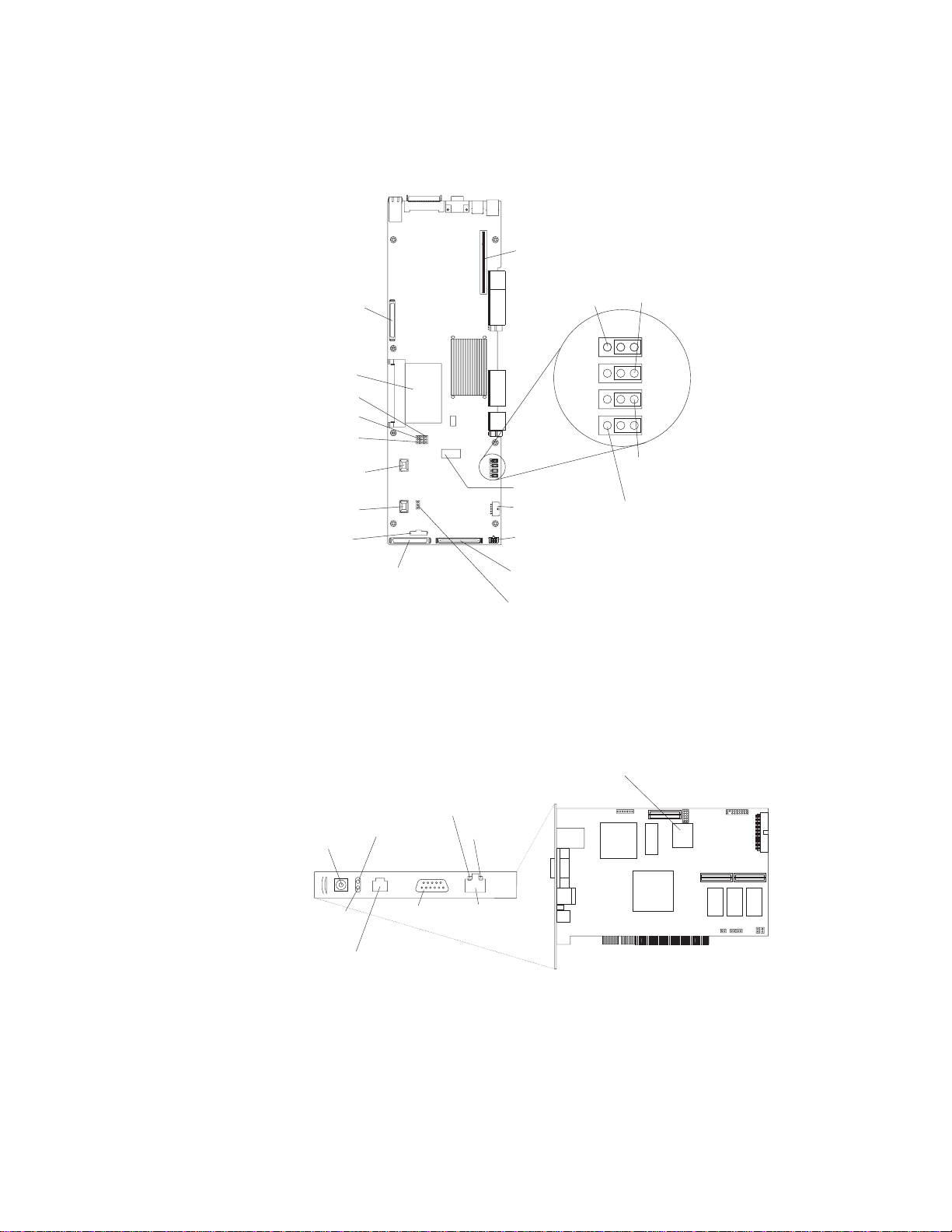

I/O board internal connectors

The following illustration identifies the internal connectors on the I/O board. This

board supports the input and output ports in the server.

SCSI B

connector (J38)

I/O VRM (J31)

Reserved (J12)

Reserved (J11)

Reserved (J10)

Fan 4

connector (J21)

Fan 3

connector (J9)

Power/Reset

connector (J5)

SCSI A

connector (J2)

Riser card

connector (J44)

Boot recovery

(BIOS) (J28)

3 2 13 2 1

Battery (BH1)

Fans 1 and 2

connectors (J8)

USB cable

connector (J1)

Media bays

connector (J3)

Reserved (J55)

Clear CMOS

(J19)

3 2 13 2 1

Power-on

password (J20)

WOL disable

(J14)

Figure 7. I/O board connectors

Remote Supervisor Adapter component locations

The following illustration identifies the connectors and LEDs on the Remote

Supervisor Adapter.

Lithium

battery

Ethernet activity

LED (green)

External power

supply connector

Power LED

(green)

ASM Interconnect port

Error LED

(amber)

P

P

Management

(RJ-14)

port

Figure 8. Remote Supervisor Adapter connectors and LEDs

Ethernet link

LED (green)

Ethernet port

(RJ-45)

Chapter 1. Introduction 7

Page 20

8 xSeries 445 Type 8870: Option Installation Guide

Page 21

Chapter 2. Installing options

This chapter provides instructions for installing hardware options in your server.

Some option-removal instructions are provided in case you need to remove one

option to install another. For a list of supported options for your server, see the

ServerProven

Installation guidelines

Before you begin to install options in your server, read the following information:

v Read the safety information beginning on page v and the guidelines in “Handling

static-sensitive devices” on page 10. This information will help you work safely

with your server and options.

v Make sure that you have an adequate number of properly grounded electrical

outlets for your server, monitor, and other devices that you will connect to the

server.

v Back up all important data before you make changes to disk drives.

v Have a small flat-blade screwdriver available.

v You do not need to turn off the server to install or replace hot-swap power

supplies, hot-swap fans, or hot-plug Universal Serial Bus (USB) devices.

v The orange color on components and labels identifies hot-swap or hot-plug

components. You can install or remove hot-swap and hot-plug components while

the server is running, provided that the server is configured to support this

capability. See the instructions in this chapter for more information about

removing and installing hot-swap and hot-plug components.

v The blue color on components and labels indicates touch points, where a

component can be gripped, a latch moved, and so on.

v For a list of supported options for your server, go to

http://www.ibm.com/pc/compat/.

®

list at http://www.ibm.com/pc/compat/.

System reliability guidelines

To help ensure proper cooling and system reliability, make sure that:

v Each of the drive bays has a drive or a filler panel and electromagnetic

compatibility (EMC) shield installed in it.

v If the server has only one SMP Expansion Module installed, the SMP baffle is

installed during normal operation.

v There is adequate space around the server to allow the server cooling system to

work properly. Leave approximately 50 mm (2.0 in.) of open space around the

front and rear of the server. Do not place objects in front of the fans.

v Do not leave open spaces above or below an installed server in a rack cabinet.

To prevent damage to server components, always install a blank filler panel to

cover the open space and to ensure proper air circulation.

v You have followed the cabling instructions that come with optional adapters.

v You have replaced a failed fan within 48 hours.

v You have replaced a hot-swap drive within 2 minutes of removal.

v Microprocessor socket 2 always contains either a microprocessor baffle or a

microprocessor and heat sink.

© Copyright IBM Corp. 2003 9

Page 22

Working inside the server with power on

Your server supports hot-swap or hot-replace devices and is designed to operate

safely while turned on with the cover removed. Follow these guidelines when you

work inside a server that is turned on:

v Avoid loose-fitting clothing on your forearms. Button long-sleeved shirts before

working inside the server; do not wear cuff links while you are working inside the

server.

v Do not allow your necktie or scarf to hang inside the server.

v Remove jewelry, such as bracelets, rings, necklaces, and loose-fitting wrist

watches.

v Remove items from your shirt pocket (such as pens or pencils) that could fall into

the server as you lean over it.

v Take care to avoid dropping any metallic objects, such as paper clips, hair pins,

or screws, into the server.

Handling static-sensitive devices

Attention: Static electricity can damage electronic devices and your system. To

avoid damage, keep static-sensitive devices in their static-protective packages until

you are ready to install them.

To reduce the possibility of electrostatic discharge, observe the following

precautions:

v Limit your movement. Movement can cause static electricity to build up around

you.

v Handle the device carefully, holding it by its edges or its frame.

v Do not touch solder joints, pins, or exposed printed circuitry.

v Do not leave the device where others can handle and possibly damage the

device.

v While the device is still in its anti-static package, touch it to an unpainted metal

part of the system unit for at least 2 seconds. (This drains static electricity from

the package and from your body.)

v Remove the device from its package and install it directly into your system unit

without setting it down. If it is necessary to set the device down, place it in its

static-protective package. Do not place the device on your system unit cover or

on a metal table.

v Take additional care when handling devices during cold weather because heating

reduces indoor humidity and increases static electricity.

10 xSeries 445 Type 8870: Option Installation Guide

Page 23

Safety information

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d’installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

Antes de instalar este producto, lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

Chapter 2. Installing options 11

Page 24

Statement 1:

DANGER

Electrical current from power, telephone, and communication cables is

hazardous.

To avoid a shock hazard:

v Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an electrical

storm.

v Connect all power cords to a properly wired and grounded electrical

outlet.

v Connect to properly wired outlets any equipment that will be attached to

this product.

v When possible, use one hand only to connect or disconnect signal

cables.

v Never turn on any equipment when there is evidence of fire, water, or

structural damage.

v Disconnect the attached power cords, telecommunications systems,

networks, and modems before you open the device covers, unless

instructed otherwise in the installation and configuration procedures.

v Connect and disconnect cables as described in the following table when

installing, moving, or opening covers on this product or attached

devices.

To Connect: To Disconnect:

1. Turn everything OFF.

2. First, attach all cables to devices.

3. Attach signal cables to connectors.

4. Attach power cords to outlet.

5. Turn device ON.

1. Turn everything OFF.

2. First, remove power cords from outlet.

3. Remove signal cables from connectors.

4. Remove all cables from devices.

12 xSeries 445 Type 8870: Option Installation Guide

Page 25

Statement 2:

CAUTION:

When replacing the lithium battery, use only IBM Part Number 33F8354 or an

equivalent type battery recommended by the manufacturer. If your system has

a module containing a lithium battery, replace it only with the same module

type made by the same manufacturer. The battery contains lithium and can

explode if not properly used, handled, or disposed of.

Do not:

v Throw or immerse into water

v Heat to more than 100°C (212°F)

v Repair or disassemble

Dispose of the battery as required by local ordinances or regulations.

Statement 3:

CAUTION:

When laser products (such as CD-ROMs, DVD drives, fiber optic devices, or

transmitters) are installed, note the following:

v Do not remove the covers. Removing the covers of the laser product could

result in exposure to hazardous laser radiation. There are no serviceable

parts inside the device.

v Use of controls or adjustments or performance of procedures other than

those specified herein might result in hazardous radiation exposure.

DANGER

Some laser products contain an embedded Class 3A or Class 3B laser

diode. Note the following.

Laser radiation when open. Do not stare into the beam, do not view directly

with optical instruments, and avoid direct exposure to the beam.

Chapter 2. Installing options 13

Page 26

Statement 4:

≥ 18 kg (39.7 lb) ≥ 32 kg (70.5 lb) ≥ 55 kg (121.2 lb)

CAUTION:

Use safe practices when lifting.

Statement 5:

CAUTION:

The power control button on the device and the power switch on the power

supply do not turn off the electrical current supplied to the device. The device

also might have more than one power cord. To remove all electrical current

from the device, ensure that all power cords are disconnected from the power

source.

2

1

Statement 8:

14 xSeries 445 Type 8870: Option Installation Guide

Page 27

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any

component that has this label attached. There are no serviceable parts inside

these components. If you suspect a problem with one of these parts, contact

a service technician.

Statement 10:

CAUTION:

Do not place any object weighing more than 82 kg (180 lb) on top of

rack-mounted devices.

>82 kg (180 lb)

Chapter 2. Installing options 15

Page 28

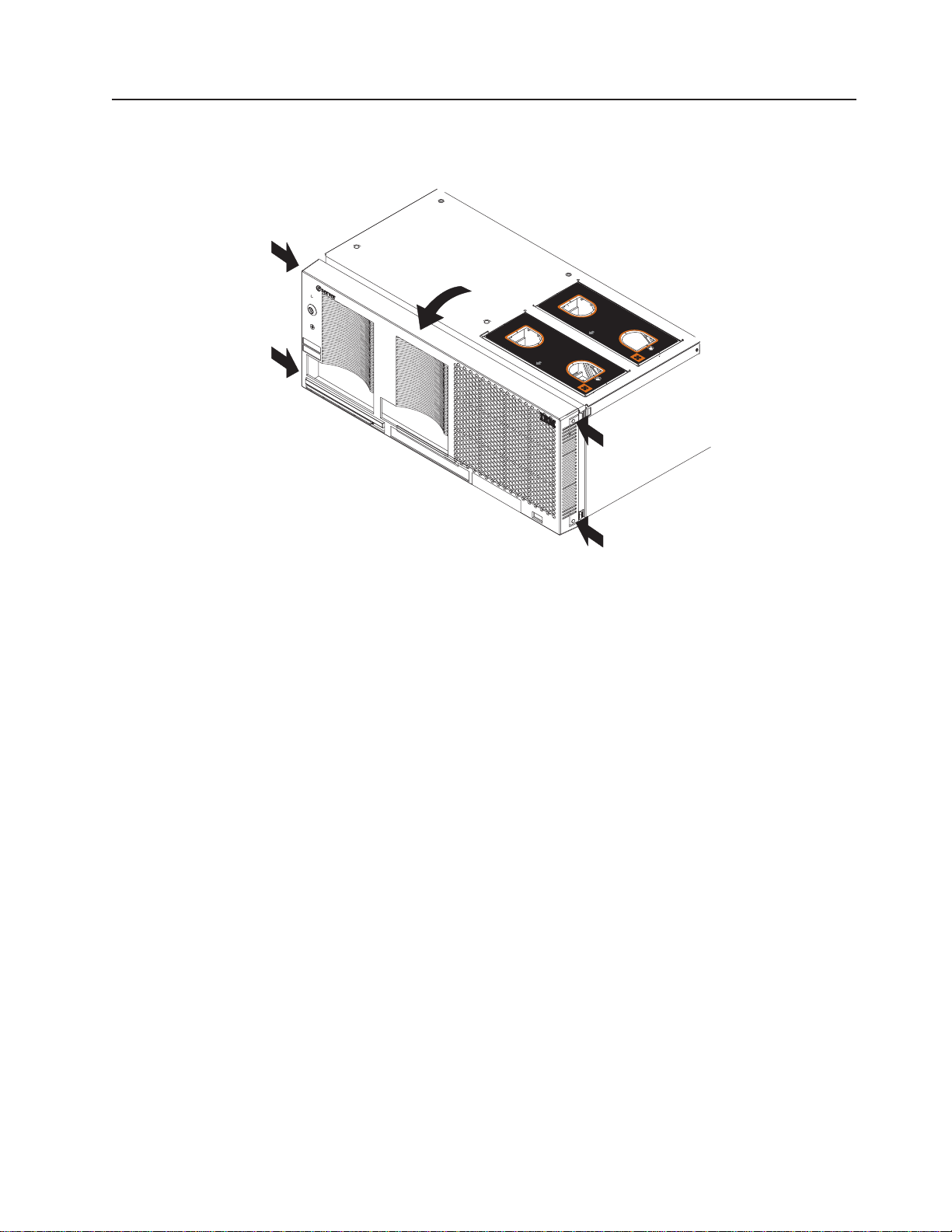

Opening the cover

Complete the following steps to open the server cover:

1. Read the safety information beginning on page v and “Installation guidelines” on

2. Pull out on the quick release latches on each side of the server; then, pull the

Latch

page 9.

server out of its rack enclosure until it stops.

N

O

T

E

:

F

O

R

P

R

O

P

E

R

A

IR

F

L

O

W,

R

E

P

N

O

T

E

:

F

R

L

A

C

E

F

F

O

R

P

O

N

T

A

F

N

R

W

O

IT

N

T

R

O

P

E

R

O

F

B

O

X

H

O

IN

F

2

B

M

O

A

I

R

F

L

I

X

N

U

T

E

O

W,

R

E

P

S

L

A

C

E

F

A

N

W

I

T

H

IN

2

M

IN

U

T

E

S

Figure 9. Opening the cover

3. Pull the release latch on the left half of the top cover to the right.

4. Using the finger hole in the release latch, open the left half of the cover; then,

open the right half of the cover.

Attention: For proper cooling and airflow, close the cover before turning on

the server. Operating the server for extended periods of time (more than 30

minutes) with the cover open might damage server components.

16 xSeries 445 Type 8870: Option Installation Guide

Page 29

Removing and replacing the bezel

Complete the following steps to remove and replace the server bezel:

N

O

T

E: FO

R

PR

O

P

ER

A

IR

FLO

W, R

E

N

OTE:

F

O

R PR

O

PE

R

A

IR

FLO

W, R

EP

LA

F

C

RON

T

O

F B

O

X

PLA

C

E F

FRO

N

E FANW

ANW

T O

F BO

ITHIN

ITH

IN

2 M

X

2 M

IN

U

TES

INU

TE

S

Figure 10. Removing the bezel

1. Removing the bezel.

a. Press on the two tabs at the top edge of the bezel, and pull the top of the

bezel slightly away from the server.

b. Press on the two tabs at the bottom edge of the bezel, and pull the bezel off

the server. Store the bezel in a safe place.

2. Replace the bezel.

a. Align the four tabs with the slots in the server chassis.

b. Press firmly against the front of the bezel until it snaps into place.

Chapter 2. Installing options 17

Page 30

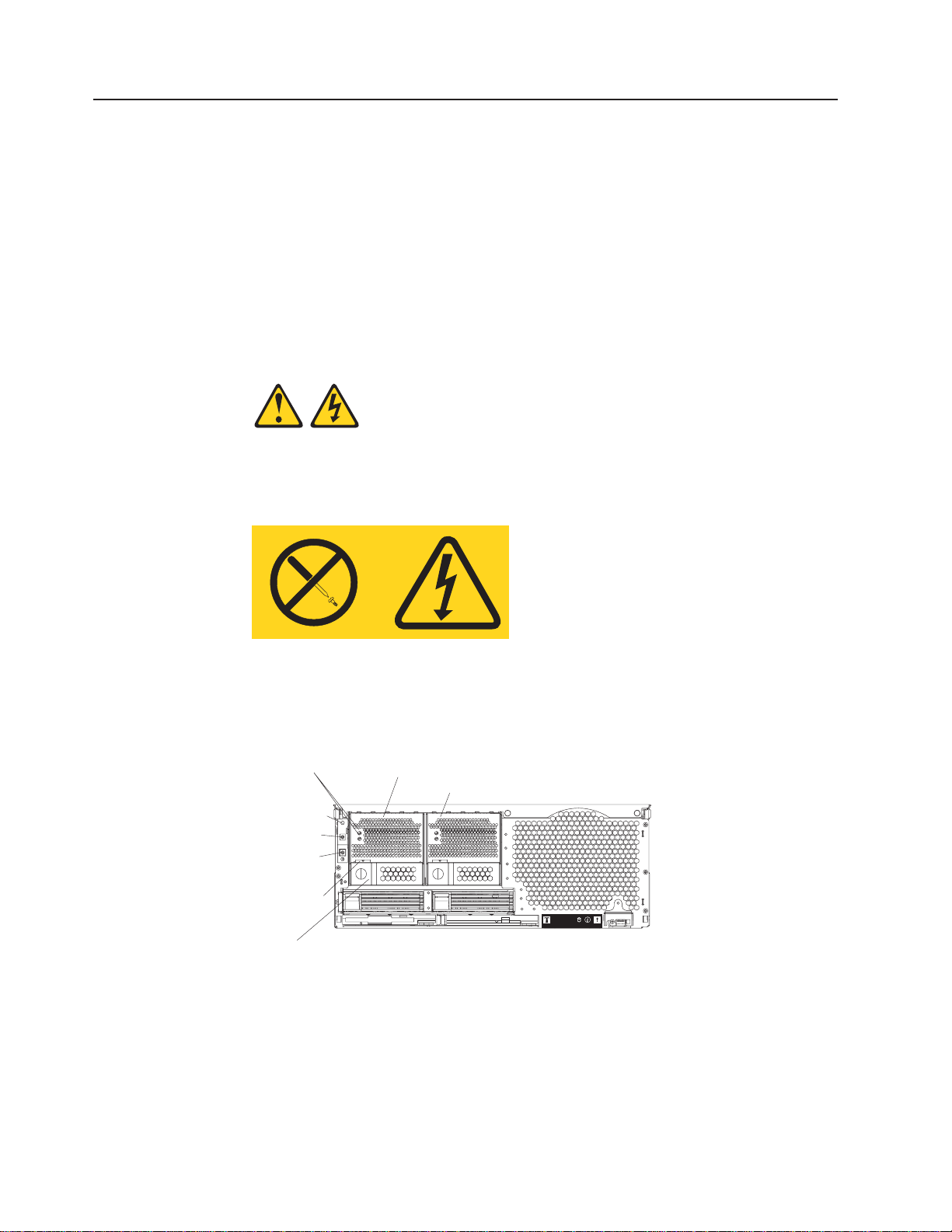

Removing and replacing a hot-swap power supply

You can remove and replace the two hot-swap power supplies in your server

without turning off the server. This section provides instructions for removing and

installing the hot-swap power supplies.The following notes and safety information

contains information you must consider when removing or installing a hot-swap

power supply:

v During normal operation, both power supplies must be installed for proper

operation and cooling.

v The xSeries 445 server requires a 220 V power connection for full power-supply

redundancy. Whenever possible, use a 220 V connection for all configurations.

However, you can use a 110 V connection, but without power-supply redundancy.

Statement 8:

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any

component that has this label attached. There are no serviceable parts inside

these components. If you suspect a problem with one of these parts, contact

a service technician.

Power light Power supply 1

Power supply 2

Power-on light

Power button

Reset button

Power supply

latch

Handle

Figure 11. Hot-swap power supply

Complete the following steps to remove and replace a power supply:

1. Read the safety information beginning on page v and “Installation guidelines” on

page 9.

2. Remove the front bezel (see “Removing and replacing the bezel” on page 17 for

instructions on removing the front bezel).

18 xSeries 445 Type 8870: Option Installation Guide

Page 31

Hot-swap

power supply

Release latch

Power supply handle

(in open position)

AC LED

DC LED

Figure 12. Removing a power supply

3. Press the release latch; then, lift the handle on the power supply to the open

position and remove the power supply.

Hot-swap

power supply

Release latch

Power supply handle

(in open position)

Figure 13. Installing a power supply

AC LED

DC LED

Chapter 2. Installing options 19

Page 32

4. Install the new power supply:

a. Place the handle on the power supply in the open position.

b. Slide the power supply into the chassis and press the handle to the closed

position.

5. Verify that the dc power LED and the ac power LED on the power supply are lit,

indicating that the power supply is operating properly.

6. Replace the front bezel on the server (see “Removing and replacing the bezel”

on page 17 for instructions).

PCI and PCI-X adapters

The following notes describe the types of adapters that your server supports and

other information that you must consider when installing an adapter:

v The following illustration shows the location of the PCI-X expansion slots on the

PCI-X board.

Note: The illustrations in this document might differ slightly from your hardware.

PCI-X slot 6

(133 MHz)

PCI-X slot 5

(133 )MHz

PCI-X slot 4

(100 )MHz

PCI-X slot 3

(100 )MHz

PCI-X slot 2

(66 )MHz

Attention LED

Power LED

PCI-X slot 1

(66 )MHz

Figure 14. PCI-X slots

v Locate the documentation that comes with the adapter and follow those

instructions in addition to the instructions in this chapter.

v If you need to change the switch settings or jumper settings on your adapter,

follow the instructions that come with the adapter.

v Video adapters are not supported.

v Some long adapters have extension handles or brackets installed. Before

installing the adapter, you must remove the extension handle or bracket.

20 xSeries 445 Type 8870: Option Installation Guide

Page 33

v Your server uses a rotational interrupt technique to configure PCI-X adapters.

You can use this technique to install PCI-X adapters that currently do not support

sharing of PCI-X interrupts.

v Your server scans devices and PCI-X slots to assign system resources in the

following order: DVD-ROM drive; disk drives; integrated SCSI devices; PCI-X

slots 1, 2, 3, 4, 5, 6; and the integrated Ethernet controller. If an RXE-100

enclosure is attached to the server, the scan continues in sequence with PCI

slots 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, and 18.

v You can use the Configuration/Setup Utility program to change the sequence and

have the server scan one of the first six PCI slots before it scans the integrated

devices. You cannot change the scan sequence of the PCI slots in an RXE-100

enclosure.

v You can install both PCI and PCI-X adapters in the same bus. However, if you

install a PCI adapter and a PCI-X adapter in the same bus, the PCI-X features of

the PCI-X adapter will be disabled, and the adapter will function as a PCI

adapter.

v You can install PCI or PCI-X adapters of speeds faster than what is labeled for a

particular PCI-X bus. For example, if you install two 133 MHz adapters into slots

that are labeled as 100 MHz slots, the adapters will operate at 100 MHz.

v If you install a 33 MHz and a 66 MHz adapter in the same bus, the bus speed

will match that of the slowest adapter.

v If a single 133 MHz adapter is installed in PCI-X Bus B (slot 3 and 4) and the

other slot in PCI-X Bus B is empty, the adapter will operate at 133 MHz.

v Your server supports six hot-plug 64-bit adapters in the expansion slots located

on the PCI-X board.

Note: You can add up to 12 PCI-X slots to your server by connecting your

server to a remote I/O expansion enclosure. For more information about

the expansion enclosure and how to connect your server to it, see the

documentation that comes with your expansion enclosure.

Bus Slot Supported adapter speed (MHz)

A166

A266

B 3 100 (133 if slot 4 is empty)

B 4 100 (133 if slot 3 is empty)

C 5 133

D 6 133

v Your server supports 3.3 V adapters; it does not support 5.0 V adapters.

v Do not install a PCI-X adapter in PCI-X slot 1 if you are going to install the serial

port that comes with your server. See “Installing the serial port” on page 25 for

instruction for installing the serial port.

Complete the following steps to install an adapter:

1. Read the safety information beginning on page v and “Installation guidelines”

on page 9.

Chapter 2. Installing options 21

Page 34

2. Use the operating system to disable the Active PCI-X slot; then, insert or

remove a hot-plug PCI or PCI-X adapter. Some operating systems do not

support the enabling and disabling of a PCI-X slot. If your operating system

does not support this function, then turn off your server, and disconnect all

power cords and external cables before proceeding.

3. Pull out on the quick release latches on each side of the server; then, pull the

server out of its rack enclosure until it stops.

4. Open the top cover.

Note: Inside your server there are six PCI-X slots: two 66 MHz, two 100 MHz,

and two 133 MHz. Before attempting to install a new adapter, be sure

there is an available slot for it. If you need additional PCI-X slots, you

can purchase a Remote Expansion Enclosure either from your IBM

marketing representative or authorized reseller.

Adapter

Adapter guide

PCI-X

divider

Tab

Attention

LED

Power

LED

retention

latch

Figure 15. PCI-X slot components

5. See the documentation that comes with your adapter for any cabling

instructions; then, set any jumpers or switches as described by the adapter

manufacturer.

Note: Route adapter cables before you install the adapter.

6. Install the adapter:

a. Open the blue adapter guide by lifting the front edge, as shown in the

illustration.

22 xSeries 445 Type 8870: Option Installation Guide

NOTE:FOR PROPER AIRFLOW, REPLACE FANWITHIN 2 MINUTES

NOTE:FOR PROPER AIRFLOW, REPLACE FANWITHIN 2 MINUTES

FRONT OF BOX

FRONT OF BOX

Page 35

b. Push the orange adapter retention latch toward the rear of the server and

open the tab.

c. Remove the expansion-slot cover and the PCI-X divider. If you are

hot-swapping a PCI or PCI-X adapter do not remove the PCI-X divider.

d. Carefully grasp the adapter by its top edge or upper corners and align it

with the connector on the PCI-X board.

e. If necessary remove the extension handles or bracket before installing a

long adapter.

Attention: When you install an PCI-X adapter, make sure that the

adapter is correctly seated in the connector slot. Improperly seated

adapters might cause damage to the board, the riser card, or the adapter.

f. Press the adapter firmly into the adapter connector.

g. If necessary reinstall the PCI-X dividers between the Active PCI-X adapter

slots.

h. Push down on the blue adapter guide to keep the adapter steady.

i. Close the tab. The orange adapter retention latch will click into place,

securing the adapter.

7. Connect the internal cables to the adapter. If you are installing a ServeRAID

adapter, see “Cabling a ServeRAID adapter” for instructions.

8. If you have other options to install or remove, do so now.

9. Close the cover on the server; then, reinstall the server in the rack and

connect all external cables.

10. Enable the slot or turn on the server, depending on your operating system.

™

Cabling a ServeRAID adapter

Some xSeries 445 models come with an optional IBM ServeRAID adapter installed

to control the internal hot-swap hard disk drives. If you are installing an optional

IBM ServeRAID adapter, see the ServeRAID documentation and the cabling

information in this section to install the ServeRAID adapter.

Servers that do not come with an IBM ServeRAID adapter installed come with two

SCSI cables:

v One end of the first SCSI cable is attached to the connector on the SCSI

backplane on the I/O board, and the other end is attached to the connector for

the integrated SCSI controller behind fans 3 and 4.

v The second SCSI cable is preinstalled along the inside of the server and both

ends are loose inside the server. When you install a ServeRAID adapter, you will

connect this cable to the adapter and to the SCSI backplane on the I/O board.

The following procedure describes the internal cabling for installing a ServeRAID

adapter.

Important: When installing multiple ServeRAID adapters in a server that has the

PCI-X slot enabled for high scan (boot) priority, make sure that the ServeRAID

adapter controlling the startup (boot) drive is installed in a PCI slot that is scanned

before the PCI slots that contain the other ServeRAID adapters. See “PCI and

PCI-X adapters” on page 20.

Complete the following steps to cable the ServeRAID adapter:

1. Read the safety information beginning on page v and “Installation guidelines”

on page 9.

Chapter 2. Installing options 23

Page 36

2. Turn off the server and disconnect all power cords and external cables; then,

open the server cover (see “Opening the cover” on page 16).

3. Remove fans 3 and 4, which are located just behind the PCI-X slots.

4. Disconnect the short SCSI cable from the SCSI backplane and the integrated

SCSI controller on the I/O board; then, store this short cable in a safe place for

future use.

5. Install the ServeRAID adapter in a PCI-X slot (see“PCI and PCI-X adapters” on

page 20).

6. Locate one end of the preinstalled SCSI cable and connect it to the

ServeRAID adapter.

Preinstalled

SCSI cable

Connect to

SCSI backplane

Figure 16. Location of preinstalled SCSI cable

Connect to

ServeRAID adapter

7. Locate the other end of the preinstalled SCSI cable and connect it to the SCSI

backplane.

24 xSeries 445 Type 8870: Option Installation Guide

Page 37

Front of server

SCSI backplane

connector

Figure 17. Connecting the SCSI cable to the SCSI backplane

8. Reinstall fans 3 and 4.

9. If you have other options to install or remove, do so now.

10. Close the cover on the server; then, reinstall the server in the rack and

connect all external cables.

11. Turn on the server.

Installing the serial port

Included with your server is a serial port that you can install at any time. This

section provides the instructions for installing the serial port.

Note: The serial port will occupy PCI-X slot one.

Complete the following steps to install the serial port:

1. Read the safety information beginning on page v and “Installation guidelines”

on page 9.

2. Pull out on the quick release latches on each side of the server; then, pull the

server out of its rack enclosure until it stops.

3. Open the top cover.

Chapter 2. Installing options 25

Page 38

Adapter guide

PCI-X

divider

N

O

T

E

:

F

O

R

P

R

O

P

E

R

A

I

N

R

O

T

E

:

F

F

O

R

O

R

N

P

T

R

O

O

F

P

E

B

R

O

X

A

I

R

F

L

O

W,

R

E

P

L

A

C

E

F

A

F

N

R

W

O

I

N

T

T

H

I

O

N

F

2

B

M

O

I

X

N

U

Attention

LED

Power

LED

F

L

O

W,

R

E

P

L

A

C

E

F

A

N

W

I

T

H

I

N

2

M

I

T

E

S

Adapter

Tab

retention

latch

N

U

T

E

S

Figure 18. PCI-X slot components

4. Open the blue adapter guide by lifting the front edge, as shown in the

illustration.

5. Remove the PCI-X slot cover and the PCI-X divider from slot one.

26 xSeries 445 Type 8870: Option Installation Guide

Page 39

Serial port

Tab

Serial connector

N

O

T

E

:

F

O

R

P

R

O

P

E

R

A

I

R

F

L

O

W,

R

E

P

N

O

T

E

:

F

O

R

P

R

O

P

E

F

R

O

N

T

O

F

B

O

L

A

C

E

F

A

F

N

R

W

O

I

N

T

T

H

I

O

N

F

2

B

R

A

I

R

F

L

O

W,

R

E

P

L

A

C

X

M

O

I

X

N

U

T

E

E

F

A

N

W

S

I

T

H

I

N

2

M

I

N

U

T

E

S

Figure 19. Insert the serial port into PCI-X slot 1

Adapter

retention

latch

6. Insert the serial port into the opening.

7. Close the tab; then, push down on the blue adapter retention latch until it

clicks into place.

Serial connector

Figure 20. Route the serial port ribbon cable through the slot

8. Route the ribbon cable through the lower slot in the center of the server.

9. Connect the serial ports ribbon to the connector on the center planar.

10. If you have other options to install or remove, do so now.

11. Close the top cover.

Chapter 2. Installing options 27

Page 40

12. Slide the server into the rack enclosure until it stops; then, secure the server in

the rack enclosure using the quick release latches.

13. Connect all external cables and turn on the server.

Note: Use the Configuration/Setup Utility program to configure the serial port.

Installing or replacing a drive

This section provides the instructions for installing and replacing a hot-swap hard

disk drive, diskette drive, and DVD-ROM drive.

Hot-swap hard disk drive

Complete the following steps to install or replace a hot-swap hard disk drive.

Attention: When you handle static-sensitive devices, take precautions to avoid

damage from static electricity. For details on handling these devices, see “Handling

static-sensitive devices” on page 10.

1. Read the safety information beginning on page v and “Installation guidelines” on

page 9.

2. Inspect the drive for any signs of damage.

3. Check the instructions that come with the drive for more information about

installing your drive.

4. Remove the filler panel or defective hard disk drive from the hard disk drive bay.

5. Install the new hard disk drive in the drive bay:

a. Ensure that the handle on the hard disk drive tray is in the open position.

b. Slide the drive into the bay until it stops.

c. Push the handle on the front of the hard disk drive closed.

Filler panel

Figure 21. Installing a hard disk drive

Note: When the hard disk drive activity LED is on, it indicates that the hard disk

drive is in use. When the drive is connected to the integrated SCSI

controller with RAID capabilities, a flashing status LED indicates that the

drive is a secondary drive in a mirrored pair and the drive is being

synchronized. When the drive is connected to an optional ServeRAID

controller, a slowly flashing (one flash per second) status LED indicates

28 xSeries 445 Type 8870: Option Installation Guide

Page 41

Diskette drive

that the drive is being rebuilt. When the LED is flashing rapidly (three

flashes per second), it indicates that the controller is identifying the drive.

6. If you have other options to install or remove, do so now.

The following notes contain information that you must consider when installing

diskette drive:

v Your xSeries 445 server supports the installation of up to two diskette drives.

v If only one diskette drive is installed, it must be installed in the right drive bay.

Complete the following steps to remove and install a diskette drive in your server:

1. Read the safety information beginning on page v and “Installation guidelines” on

page 9.

Attention: The IDE drives installed in your server are not hot-swappable.

2. Turn off the server and disconnect the power cord from the back of the server.

3. Push the diskette drive eject button to the right.

4. Using the tab, pull the diskette drive partially out of the server; then, grasp the

drive and remove it from the server.

5. Install the new diskette drive:

a. Inspect the drive for any signs of damage.

b. Slide the drive into the left drive bay until it stops.

Note: In the unlikely event that no other IDE drives are installed, the

diskette drive must be installed in the right external removable media

bay.

External removable

media bays

NOTE: FOR PROPER AIRFLOW, REPLACE FANW

NOTE: FOR PROPER AIRFLOW, REPLACE FANW

FRONT OF BOX

ITHIN 2 MINUTES

FRONT OF BOX

ITH

IN 2 MINUTES

Diskette

drive

Tab

Diskette drive

eject button

Figure 22. Installing a diskette disk drive

6. If you have other options to install or remove, do so now. Otherwise, connect

the power cords and turn on the server.

Chapter 2. Installing options 29

Page 42

DVD-ROM drive

The following notes contain information that you must consider when installing a

DVD-ROM:

v Your xSeries 445 server supports the installation of up to two DVD-ROM drives.

v If no other IDE drives are installed, the diskette drive must be installed in the

right external removable media bay. DVD-ROM drives can be installed in either

external removable media bay.

Complete the following steps to remove and install a DVD-ROM drive in your

server:

1. Read the safety information beginning on page v and “Installation guidelines” on

page 9.

Attention: The IDE drives installed in your server are not hot-swappable.

2. Turn off the server and disconnect the power cords from the back of the server.

3. Push the DVD-ROM eject button to the right.

4. Using the tab, pull the DVD-ROM drive partially out of the server; then, grasp

the drive and remove it from the server.

5. Install the new DVD-ROM drive:

a. Inspect the drive for any signs of damage.

b. Slide the DVD-ROM drive into the drive bay until it stops.

External removable

media bays

N

O

T

E

:

F

O

R

P

R

O

P

E

R

A

IR

F

L

O

W, R

E

P

L

A

C

E

F

A

F

N

R

W

O

IT

N

T

H

O

IN

F

2

B

M

O

IN

X

E

P

L

A

C

E

F

A

N

W

IT

H

IN

2

M

IN

U

T

E

S

DVD-ROM drive

U

T

E

S

DVD-ROM drive

N

O

T

E

:

F

O

R

P

R

O

P

E

R

A

IR

F

L

O

W, R

F

R

O

N

T

O

F

B

O

X

eject button

Tab

Figure 23. Installing a DVD-ROM drive

6. If you have other options to install or remove, do so now. Otherwise, connect

the power cords and turn on the server.

30 xSeries 445 Type 8870: Option Installation Guide

Page 43

SMP Expansion Module

The SMP Expansion Module contains the XceL4™system cache, DIMMs,

microprocessors, and voltage regulator modules (VRMs) needed to run your server.

This section contains the information needed to install and remove the SMP

Expansion Module, microprocessors, VRMs, and DIMMs.

The following notes describe components in the SMP Expansion Module and other

information that you must consider when installing an SMP Expansion Module:

v Use two hands to install or remove an SMP Expansion Module. Do not allow the

expansion module to come in contact with the center planar while lifting it out or

putting into the server.

v For your server to operate properly, there must be a minimum of one SMP

Expansion Module installed.

v An SMP Expansion Module must contain at least one microprocessor and two

DIMMs.

v If there is only one SMP Expansion Module installed in the server, an SMP baffle

must be installed in place of the upper SMP Expansion Module to ensure proper

cooling of the server.

v When the minimum number of microprocessors are installed in the SMP

Expansion Module, a microprocessor baffle must be installed in microprocessor

socket 4 to ensure proper cooling within the server.

v Before removing or installing SMP Expansion Modules, you must remove the

retention bracket or brackets and electromagnetic compatibility (EMC) shield from

the rear of the server.

v You must run the Configuration/Setup Utility program whenever you remove or

replace an SMP Expansion Module or one of its associated options.

Chapter 2. Installing options 31

Page 44

Removing and Installing the SMP Expansion Module and cover

This section describes how to remove and install an SMP Expansion Module and its

cover.

Removing the SMP Expansion Module and cover

Complete the following steps to remove an SMP Expansion Module from the server

and to remove the SMP Expansion Module cover:

1. Read the safety information beginning on page v and “Installation guidelines” on

page 9.

2. Turn off the server and peripheral devices, disconnect the power cords and all

external cables from the SMP Expansion Module.

3. Pull out on the quick release latches on each side of the server; then, pull the

server out of its rack enclosure until it stops.

4. Open the top cover.

5. If necessary, remove the SMP baffle.

6. Remove the retention bracket from the server:

a. Remove the shipping thumbscrews from the right side of the server.

Note: There are two shipping thumbscrews per retention bracket.

Retention bracket

removal handles

Retention bracket

SMP Expansion

Module

N

O

T

E

:

F

O

R

P

R

O

P

E

R

A

I

R

F

L

O

W,

R

E

P

N

O

T

E

:

F

F

R

L

A

C

E

F

A

F

O

R

P

R

O

O

N

T

O

F

N

R

W

O

I

N

T

T

H

I

O

N

F

P

E

R

A

I

R

B

O

X

2

B

M

O

I

X

N

U

F

L

O

W,

R

E

T

E

P

S

L

A

C

E

F

A

N

W

I

T

H

I

N

2

M

I

N

U

T

E

S

Shipping

thumbscrews

Figure 24. Removing the retention bracket and shipping thumbscrews

b. Grasp the retention bracket by the removal handles and lift it up and out of

the server. Store the retention bracket or brackets in a safe place for use

later.

Note: If there is one SMP Expansion Module installed, you will need to

remove the SMP baffle from the server; then, remove the retention

bracket from the lower SMP Expansion Module as described in steps

3a and 3b.

32 xSeries 445 Type 8870: Option Installation Guide

Page 45

7. Loosen the blue thumbscrews securing the EMC shield; then, remove the EMC

shield from the server.

EMC shields

ThumbscrewsThumbscrews

For use with one

SMP Module

For use with two

SMP Modules

Figure 25. EMC shields

8. Grasp each of the locking levers on the top of the SMP Expansion Module, and

lift them up slightly.

9. Working from the right side of the server, rotate the two locking levers toward

you until they are fully extended, as shown.

Latch

N

O

T

E

:

F

O

R

P

R

O

P

E

R

A

IR

F

L

O

W,

R

E

P

N

O

T

E

:

F

F

R

L

A

C

E

F

A

F

O

R

P

R

O

N

T

O

F

N

R

W

O

IT

N

T

H

O

O

P

E

R

A

B

O

X

IN

F

2

B

M

O

I

X

IR

F

L

O

N

U

T

E

W, R

S

E

P

L

A

C

E

F

A

N

W

IT

H

IN

2

M

IN

U

T

E

S

Locking

levers

Finger relief

Handle

Figure 26. Rotate the locking levers to remove the SMP Expansion Module

Attention: When removing the SMP Expansion Module from the server, lift it

out carefully, taking care not to damage the components on the center plane.

10. Use the handle and the finger relief on the SMP Expansion Module cover to

carefully lift the SMP Expansion Module out of the server.

11. Remove the SMP Expansion Module cover:

a. Place the SMP Expansion Module on a flat, level surface.

Chapter 2. Installing options 33

Page 46

Figure 27. Fully extending the locking levers to remove the SMP Expansion Module cover

b. Rotate the two locking levers until they are fully extended beyond the edge

of the SMP Expansion Module cover. Do not force the locking levers past

the position shown in the illustration.

c. Using the locking levers, lift the front edge of the cover off the SMP

Expansion Module.

d. Lift the cover off the SMP Expansion Module.

Figure 28. Lifting the cover off

Installing the SMP Expansion Module and cover

The following notes contain information that you must considered when installing

the SMP Expansion Module:

v If there are two SMP Expansion Modules installed in your server, you must install

the retention brackets for each of the SMP Expansion Module.

v If the server is going to shipped or moved over a long distance, you must

reinstall the retention brackets and shipping thumbscrews for each SMP

Expansion Module.

Complete the following steps to install the SMP Expansion Module cover and the

SMP Expansion Module:

1. Install the cover on the SMP Expansion Module:

a. Set the cover on top of the expansion module.

34 xSeries 445 Type 8870: Option Installation Guide

Page 47

b. Extend the locking levers as shown in the illustration; then, let the cam on

the front of the cover fall into the cam opening on the SMP Expansion

Module circuit board.

Locking levers

CAM opening

Figure 29. Installing the SMP Expansion Module cover

c. Release the locking levers and align the rear of the cover with the rear edge

of the circuit board.

d. Press down on the cover until it snaps into place.

Chapter 2. Installing options 35

Page 48

e. Lift slightly on the locking levers and rotate them back until they stop.

Locking

levers

Handle

Figure 30. Locking lever position for installing the SMP Expansion Module

2. Install the SMP Expansion Module into the server:

Locking

levers

Center plane

N

O

T

E

:

F

O

R

P

R

O

P

E

R

A

IR

F

L

O

W, R

E

P

N

O

T

E

:

F

R

L

A

C

E

F

F

O

R

P

O

N

T

A

F

N

R

W

O

IT

N

T

R

O

P

E

R

O

F

B

O

X

H

I

O

N

F

2

B

M

O

A

IR

F

IN

X

U

T

L

O

W, R

E

E

P

S

L

A

C

E

F

A

N

W

IT

H

IN

2

M

IN

U

T

E

S

Handle

Figure 31. SMP Expansion Module locking lever position

a. Lift the SMP Expansion Module by its handle and use the finger relief to

hold the SMP Expansion Module steady.

b. Being careful not to damage the components on the center planar, lower the

SMP Expansion Module into the server.

c. Release the handle and slide the SMP Expansion Module toward the center

planar until it stops.

36 xSeries 445 Type 8870: Option Installation Guide

Page 49

d. Rotate the SMP Expansion Module locking levers forward until the SMP

Expansion Module is securely fastened in place. See the following

illustration.

Center plane

Locking

levers

Cover

Handle

Figure 32. Locking lever position when the SMP Expansion Module is installed

3. Install the EMC shield on the rear of the server; then, hand tighten the blue

thumbscrews to secure the EMC shield.

EMC shields

ThumbscrewsThumbscrews

For use with one

SMP Module

For use with two

SMP Modules

Figure 33. EMC shields

4. If you have other options to install or remove, do so now.

5. Close the top cover.

6. Slide the server into the rack enclosure until it stops; then, secure the server in

the rack enclosure using the quick release latches.

7. Connect all external cables and turn on the server.

8. Turn on the server.

Chapter 2. Installing options 37

Page 50

Memory Module

This section contains instructions on installing, adding, hot-adding, removing, and

hot-replacing memory modules. It includes information about memory mirroring and

Memory ProteXion features of the Active Memory technology.

The following notes describe the types of dual inline memory modules (DIMMs) that

your server supports and other information that you must consider when installing

DIMMs:

v Your server comes with a minimum of two 512 MB DIMMs installed in slots 1,

and 3 in the SMP Expansion Module and supports 512 MB, 1 GB, and 2 GB

DIMMs, for a maximum of 64 GB of system memory depending on your

configuration.

v IBM periodically makes updates available to provide enhancements to the

standard features of your server. Currently, your xSeries 445 server supports the

memory mirroring and Memory ProteXion features of the Active Memory

technology. Check the IBM support Web site occasionally to make sure that you

have the most current levels of system software installed.

v The hot-add memory feature enables you to add DIMMs without turning off the

server. This feature is supported only in those servers using Windows Server

2003 Enterprise or Datacenter editions.

v To use the hot-add memory feature you must first disable memory mirroring in

the Configuration/Setup Utility program, and there cannot be any DIMMs present

in the port in which you want to add DIMMs.

v The hot-replace memory feature allows you to replace DIMMs of the same type,

size, and clock speed without turning off the server.

v To use the hot-replace memory feature you must enable memory mirroring in the

Configuration/Setup Utility program.

v When using memory mirroring, all of the DIMMs in each memory port must be

the same size and clock speed.

v Damaged or faulty DIMMs can be replaced without having to replace all the

DIMMs in the bank. Ensure the new DIMM is the same size and clock speed as

the other DIMMs in the bank.

v See the ServerProven list at http://www.ibm.com/pc/compat/ for a list of memory

modules for use with your server. For optimum performance, balance the amount

memory between the two ports.

v When installing or removing DIMMs, it must be done in pairs and in the following

order.

Table 1. Memory

Port Bank Slot number

1 1 1, 3

219,11

1 2 2, 4

2 2 10, 12

1 3 5, 7

2 3 13, 15

1 4 6, 8

2 4 14, 16

38 xSeries 445 Type 8870: Option Installation Guide

Page 51

Bank 1 Bank 1

Bank 3 Bank 3

DIMM error

indicators are

built into

each handle.

Bank 2 Bank 4

Port 1

Bank 2 Bank 4

Port 2

Figure 34. DIMM banks

v Each pair or bank of DIMMs must be of the same size and clock speed.

v When you install or remove a bank of DIMMs, the server configuration

information changes. Therefore, you must change and save the new

configuration information by using the Configuration/Setup Utility program. When

you restart the server, the server displays a message indicating that the memory

configuration has changed. Start the Configuration/Setup Utility program and

select Save Settings. If you need instructions, see ″Chapter 2. Configuring the

server″ in the User’s Guide on the IBM Documentation CD.

v The illustrations in this document might differ slightly from your hardware.

Chapter 2. Installing options 39

Page 52

Figure 35. DIMM installation

DIMM

Active Memory

Active Memory is an IBM technology that improves the reliability of the DIMMs

through memory mirroring, memory scrubbing, and Memory ProteXion™features.

The following notes describe the Active Memory features:

v Memory mirroring enables you to improve the reliability of the memory in your

server by creating a mirror of the data in memory port 1 and storing it in memory

port 2.

Note: For memory mirroring to work, you must have DIMMs of the same size

and clock speed in both memory ports.

Complete the following steps to enable memory mirroring:

1. Check your operating system documentation to make sure that it supports

memory mirroring.

2. Install DIMMs of the same size and clock speed in the two memory ports.

3. Enable memory mirroring in the Configuration/Setup Utility program:

a. Turn on the server and watch the monitor screen.

b. When the message Press F1 for Configuration/Setup appears, press

F1.

c. From the Configuration/Setup Utility main menu, select Advanced Setup.

d. Select Memory Settings.

e. Select Memory Mirroring Settings.

f. Enable the SMP Module memory mirroring setting from within this

window.

g. Save and exit the Configuration/Setup Utility program.

40 xSeries 445 Type 8870: Option Installation Guide

Page 53

When memory mirroring is enabled, the data that is written to memory is stored

in two locations. One copy is kept in the memory port 1 DIMMs, while a second

copy is kept in the memory port 2 DIMMs. During the execution of the read

command, the data is read from the DIMM with the least number of reported

memory errors through Memory scrubbing, which is enabled with memory

mirroring.

If memory scrubbing determines that a DIMM is damaged beyond use, read and

write operations are redirected to the remaining good DIMMs. Memory scrubbing

then reports the damaged DIMM and the Light Path Diagnostics feature displays

the error. After the damaged DIMM is replaced, memory mirroring then copies the

mirrored data back into the new DIMM.

v Memory scrubbing is an automatic daily test of all the system memory that

detects and reports memory errors that might be developing before they cause a

server outage.

Note: Memory scrubbing and Memory ProteXion technology work with each

other and do not require memory mirroring to be enabled to work.

When an error is detected, memory scrubbing determines whether the error is

recoverable. If it is recoverable, Memory ProteXion is enabled and the data that

was stored in the damaged locations is rewritten to a new location. The error is

then reported so that preventive maintenance can be performed. Provided that

there are enough good locations to enable the correct operation of the server, no

further action is taken other than recording the error in the error logs.

If the error is not recoverable, memory scrubbing sends an error message to the

Light Path Diagnostics feature, which then lights the applicable LEDs to guide

you to the damaged DIMM. If memory mirroring is enabled, the mirrored copy of

the data in the mirrored DIMM is used to refresh the new DIMM after it is

installed.

v Memory ProteXion reassigns memory bits to new locations within memory when

recoverable errors have been detected.

When a recoverable error is found by memory scrubbing, the Memory ProteXion

feature writes the data that was to be stored in the damaged memory locations to

spare memory locations within the same DIMM.

Removing and replacing DIMMs

Complete the following steps to remove and replace a DIMM in the SMP Expansion

Module with the server turned off.

Attention: When working with DIMMs or other options, you might need to remove

one or both of the SMP Expansion Modules. See “Hot-replace DIMMs” on page 43

for information on how to hot-replace DIMMs with the server turned on.

1. Read the safety information beginning on page v and “Installation guidelines”

on page 9.

2. Turn off the server and peripheral devices, disconnect the power cords, and all

external cables from the SMP Expansion Module.

3. Pull out on the quick release latches on each side of the server; then, pull the

server out of its rack enclosure until it stops.

4. Open the top cover.

5. If necessary, remove the top SMP Expansion Module or SMP baffle from the

server. See “Removing the SMP Expansion Module and cover” on page 32 for

instructions.

Chapter 2. Installing options 41

Page 54

6. Open the DIMM access door that covers the DIMM you will be removing.

DIMM access

door

Figure 36. Opening the DIMM access door

7. Open the retaining clip on each end of the DIMM connector.

8. Lift the DIMM straight up and out of the SMP Expansion Module.

9. Install a new DIMM:

a. Touch the static-protective package containing the DIMM to any unpainted

metal surface on the server. Then, remove the DIMM from the package.

Attention: To avoid breaking the retaining clips or damaging the DIMM

connectors, open and close the clips gently.

b. Insert the DIMM into the connector by aligning the DIMM edges with the

slots at each end of the DIMM connector. Firmly press the DIMM straight

down into the connector by applying pressure on both ends of the DIMM

simultaneously. Be sure that the retaining clips snap into the locked

position when the DIMM is firmly seated in the connector.

DIMM

Figure 37. Inserting a DIMM into a DIMM slot

Attention: If there is a gap between the DIMM and the retaining clips,

the DIMM has not been properly installed. In this case, open the retaining

clips and remove the DIMM; then, reinsert the DIMM.

c. Repeat steps 9a and 9b for each DIMM.

42 xSeries 445 Type 8870: Option Installation Guide

Retaining

clip

Page 55

10. Close the DIMM access door.

11. If necessary, reinstall either the top SMP Expansion Module or SMP baffle in

the server. See “Installing the SMP Expansion Module and cover” on page 34

for instructions.

12. Close the top cover.

13. Slide the server into the rack enclosure until it stops; then, secure the server in

the rack enclosure using the quick release latches.

14. Connect all external cables and turn on the server.

Note: When you install or remove banks of DIMMs, the server configuration

information changes. Therefore, you must change and save the new

configuration information by using the Configuration/Setup Utility program.

See the User’s Guide on the Documentation CD.

Hot-replace DIMMs

This section includes the instructions needed to hot-replace DIMMs in your server

SMP Expansion Module with the power on.

Note: Before you attempt to hot-replace a DIMM, make sure that the new DIMM is

the same size and clock speed and that memory mirroring is enabled.

Attention: If two SMP Expansion Modules are installed in a server, you cannot

hot-replace or hot-add the DIMMs in the lowest SMP Expansion Module. To gain

access to the DIMMs of a lower SMP Expansion Module, you must first remove the

upper SMP Expansion Module, which requires you to turn off the server. See

“Removing and replacing DIMMs” on page 41 for information about how to remove

and replace DIMMs while the server is turned off.

Complete the following steps to hot-replace a DIMM in your server SMP Expansion

Module:

1. Read the safety information beginning on page v and “Installation guidelines”

on page 9.

2. Pull out on the quick release latches on each side of the server; then, pull the

server out of its rack enclosure until it stops.

3. Open the top cover.

4. If necessary, remove the SMP baffle.