Page 1

xSeries 440

Type 8687

Option Installation Guide

Page 2

Page 3

xSeries 440

Option Installation Guide

IBM

SC59-P651-40

Page 4

Note: Before using this information and the product it supports, be sure to read the general information in Appendix A,

“Notices” on page 57.

Third Edition (July 2002)

© Copyright International Business Machines Corporation 2002. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract with

IBM Corp.

Page 5

Contents

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Chapter 1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Major components of the xSeries 440 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Center plane connectors and LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SMP Expansion Module connectors and lights . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PCI-X planar internal connectors and LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

I/O board internal connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Remote Supervisor Adapter component locations. . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 2. Installing options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Before you begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Working inside a server with power on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Handling static-sensitive devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

System reliability considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Opening the cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Removing and replacing the bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Removing and replacing a hot-swap power supply. . . . . . . . . . . . . . . . . . . . . . . . . . 17

PCI and PCI-X adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

PCI and PCI-X adapter considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installing adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cabling a ServeRAID adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installing or replacing a drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Hot-swap hard disk drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Diskette drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

CD-ROM or DVD-ROM drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

SMP Expansion Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Removing an SMP Expansion Module and cover . . . . . . . . . . . . . . . . . . . . . . . . 28

DIMMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Installing and replacing a microprocessor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Reinstalling an SMP Expansion Module and cover . . . . . . . . . . . . . . . . . . . . . . . 41

Replacing and troubleshooting fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Replacing fans 1 and 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Replacing fans 3 and 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Replacing the battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Closing the cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Cabling the server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Chapter 3. I/O connectors and indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

I/O connectors and indicators on your server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Universal Serial Bus ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Keyboard connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Video connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Auxiliary-device (pointing device) connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

RXE Expansion Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

SMP Expansion Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Remote Supervisor Adapter communication ports. . . . . . . . . . . . . . . . . . . . . . . . 53

Gigabit Ethernet port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Configuring the Gigabit Ethernet controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Ethernet port connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Appendix A. Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Edition notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

© Copyright IBM Corp. 2002 iii

Page 6

Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Important notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Electronic emission notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Federal Communications Commission (FCC) statement. . . . . . . . . . . . . . . . . . . 59

Industry Canada Class A emission compliance statement . . . . . . . . . . . . . . . . . 60

Australia and New Zealand Class A statement . . . . . . . . . . . . . . . . . . . . . . . . . . 60

United Kingdom telecommunications safety requirement . . . . . . . . . . . . . . . . . . 60

European Union EMC Directive conformance statement. . . . . . . . . . . . . . . . . . . 60

Taiwanese Class A warning statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Japanese Voluntary Control Council for Interference (VCCI) statement . . . . . . . 61

Power cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

iv xSeries 440:Option Installation Guide

Page 7

Safety

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue tu rvaohjeet kohdasta Safety Information.

Avant d'installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

© Copyright IBM Corp. 2002 v

Page 8

Antes de instalar este producto, lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

Statement 1:

DANGER

Electrical current from power, telephone, and communication cables is

hazardous.

To avoid a shock hazard:

• Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an electrical

storm.

• Connect all power cords to a properly wired and grounded electrical

outlet.

• Connect to properly wired outlets any equipment that will be attached

to this product.

• When possible, use one hand only to connect or disconnect signal

cables.

• Never turn on any equipment when there is evidence of fire, water, or

structural damage.

• Disconnect the attached power cords, telecommunications systems,

networks, and modems before you open the device covers, unless

instructed otherwise in the installation and configuration procedures.

• Connect and disconnect cables as described in the following table

when installing, moving, or opening covers on this product or

attached devices.

To Connect: To Disconnect:

1. Turn everything OFF.

2. First, attach all cables to devices.

3. Attach signal cables to connectors.

4. Attach power cords to outlet.

5. Turn device ON.

1. Turn everything OFF.

2. First, remove power cords from outlet.

3. Remove signal cables from connectors.

4. Remove all cables from de vices.

vi xSeries 440:Option Installation Guide

Page 9

Statement 2:

CAUTION:

When replacing the lithium battery, use only IBM Part Number 33F8354 or an

equivalent type battery recommen d ed by the manufacturer. If your system has

a module containing a lithium battery, replace it only with the same module type

made by the same manufacturer. The battery contains lithium and can explode

if not properly used, handled, or disposed of.

Do not:

• Throw or immerse into water

• Heat to more than 100°C (212°F)

• Repair or disassemble

Dispose of the battery as required by local ordinances or regulations.

Statement 3:

CAUTION:

When laser products (such as CD-ROMs, DVD drives, fiber optic devices, or

transmitters) are installed, note the following:

• Do not remove the covers. Removing the covers of the laser product could

result in exposure to hazar dous laser radiation. There are no serviceable

parts inside the device.

• Use of controls or adjustments or performance of procedures other than

those specified herein might result in hazardous radiation exposure.

DANGER

Some laser products contain an embedded Class 3A or Class 3B laser

diode. Note the following.

Laser radiation when open. Do not stare into the beam, do not view

directly with optical instruments, and avoid direct exposure to the beam.

Safety vii

Page 10

Statement 4:

≥ 18 kg (39.7 lb) ≥ 32 kg (70.5 lb) ≥ 55 kg (121.2 lb)

CAUTION:

Use safe practices when lifting.

Statement 5:

CAUTION:

The power control button on the device and the power switch on the power supply do not turn off th e e lect ri cal curre nt su ppl ied t o the device. The device also

might have more than one power cor d. To remove all electrical current from the

device, ensure that all power cords are disconnected from the power source.

2

1

viii xSeries 440:Option Installation Guide

Page 11

Statement 8:

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any component that has this label attached. There are no serviceable parts inside these

components. If you suspect a pr oblem with one of these parts, contact a service technician.

Safety ix

Page 12

x xSeries 440:Option Installation Guide

Page 13

Chapter 1. Introduction

There are many optional devices supported by your server. This Option Installation

Guide provides the information needed to install, remove, and connect optional

devices supported by your server.

In addition to this Option Installation Guid e , the following xSeries 440 documentation

is provided with your server:

• Installation Guide

This printed publication contains setup and installation instructions. This publica-

tion is also provided in Portable Document Format (PDF) format on the IBM

xSeries

• Rack Installation Instructions

This printed publication contains the instructions needed to in stall y our server in a

rack cabinet. This publication is also provided in PDF format on the IBM xSeries

Documentation CD.

• Safety Book

This multilingual publication is provided in PDF format on the IBM xSeries Docu-

mentation CD. It contains translated versions of the caution and danger statements that appear in the documentation for your server. Each caution and danger

statement has an assigned number, which you can use to locate the corresponding statement in your native language.

• User’s Guide

This publication is provided in PDF format on the IBM xSeries Documentation CD.

It contains general information about your server.

• Troubleshooting Guide

This publication is provided in PDF format on the IBM xSeries Documentation CD.

It contains the info rmation needed to he lp you solve problems yourself, or provide

helpful information to a service technician.

™

Documentation CD.

®

Depending on your server model, additional pub lications might be included on the IBM

xSeries Documentation CD.

© Copyright IBM Corp. 2002 1

Page 14

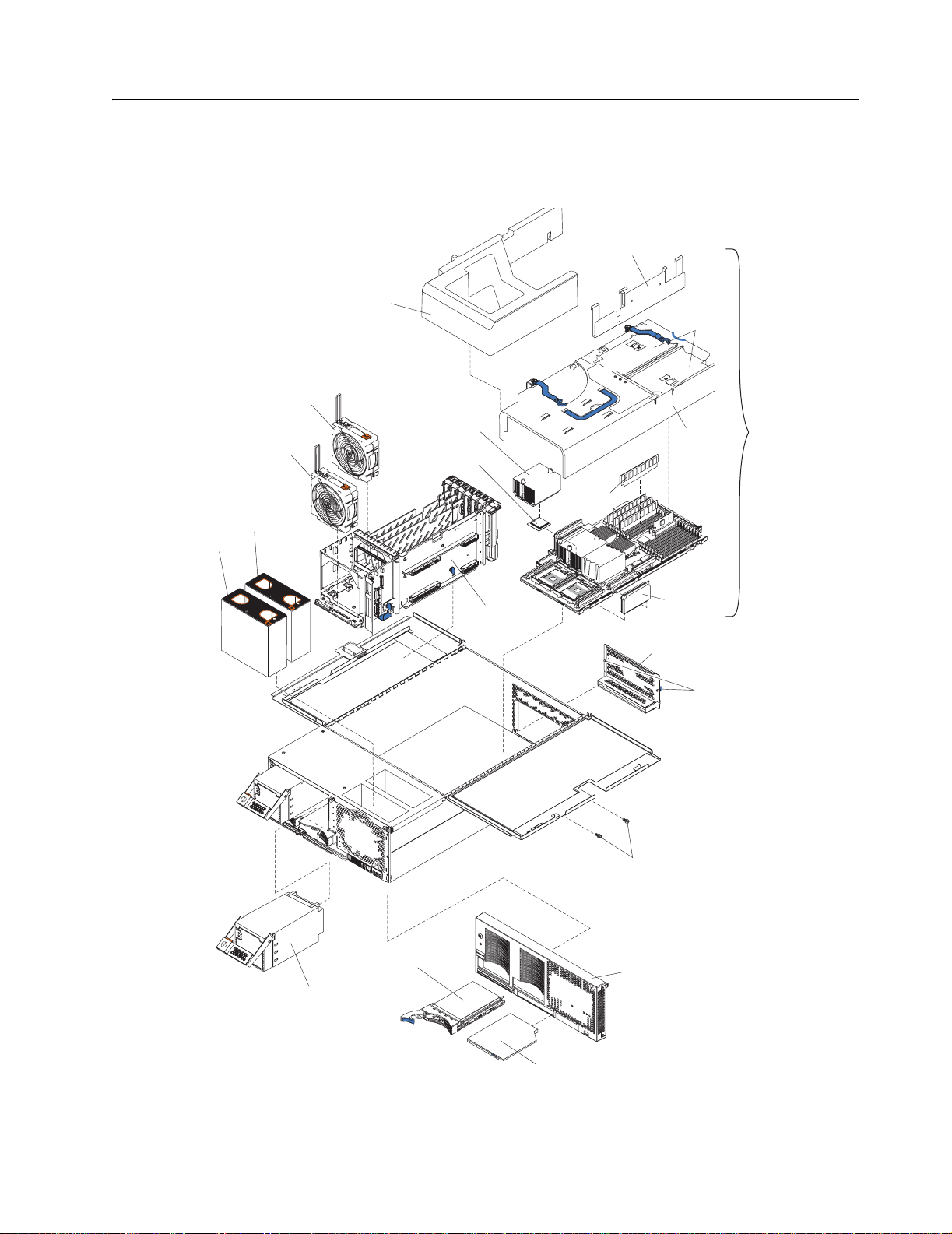

Major components of the xSeries 440

The following illustration sho ws the locations of major components in your server.

Note: The illustrations in this document might differ slightly from your hardware.

Retention bracket

Fan 1

N

O

T

E

:

F

O

F

R

O

Fan 2

R

P

R

O

P

E

R

A

I

R

F

L

O

W, R

N

T

O

F

B

O

X

Fan 4

Fan 3

N

O

T

E

:

F

O

R

P

R

O

P

E

R

A

IR

F

R

O

N

T

O

F

B

O

X

E

P

L

A

C

E

F

A

N

W

I

T

H

IN

2

M

I

N

SMP baffle

DIMM

access

doors

Heat-sink

Cover

SMP

Expansion

Module

Microprocessor

DIMM

F

L

O

W, R

E

P

L

A

C

E

F

A

N

W

I

T

H

IN

2

M

I

N

U

T

E

S

U

T

E

S

Center

plane

VRM

EMC Shield

(For single SMP Module)

Thumbscrews

Shipping thumbscrews

Hard disk

drive

Bezel

Hot-swap

power supply

CD-ROM

drive

2 xSeries 440:Option Installation Guide

Page 15

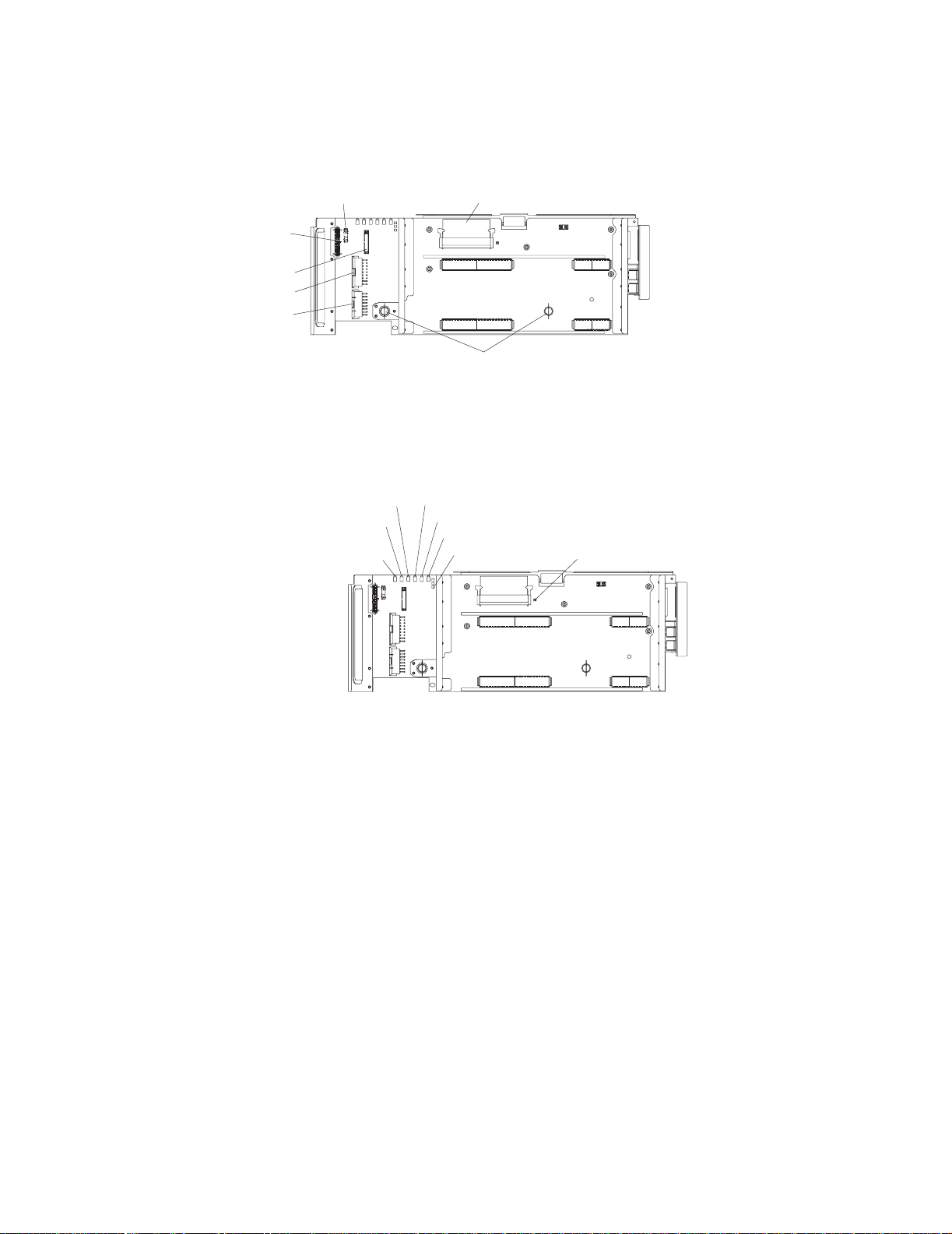

Center plane connectors and LEDs

The following illustrations identify the connectors and LEDs on the center plane. This

center plane is used to connect the power and signal paths for the SMP Expansion

Module, I/O board, and the Remote Supervisor Adapter.

Lightpath

SCSI

power

Power

Power

Power

PCI error LED

System management

error LED

I/O error LED

VRM

Thumbscrews

Center plane error LED

Lower SMP error LED

Upper SMP error LED

Power good LED

VRM error LED

Chapter 1. Introduction 3

Page 16

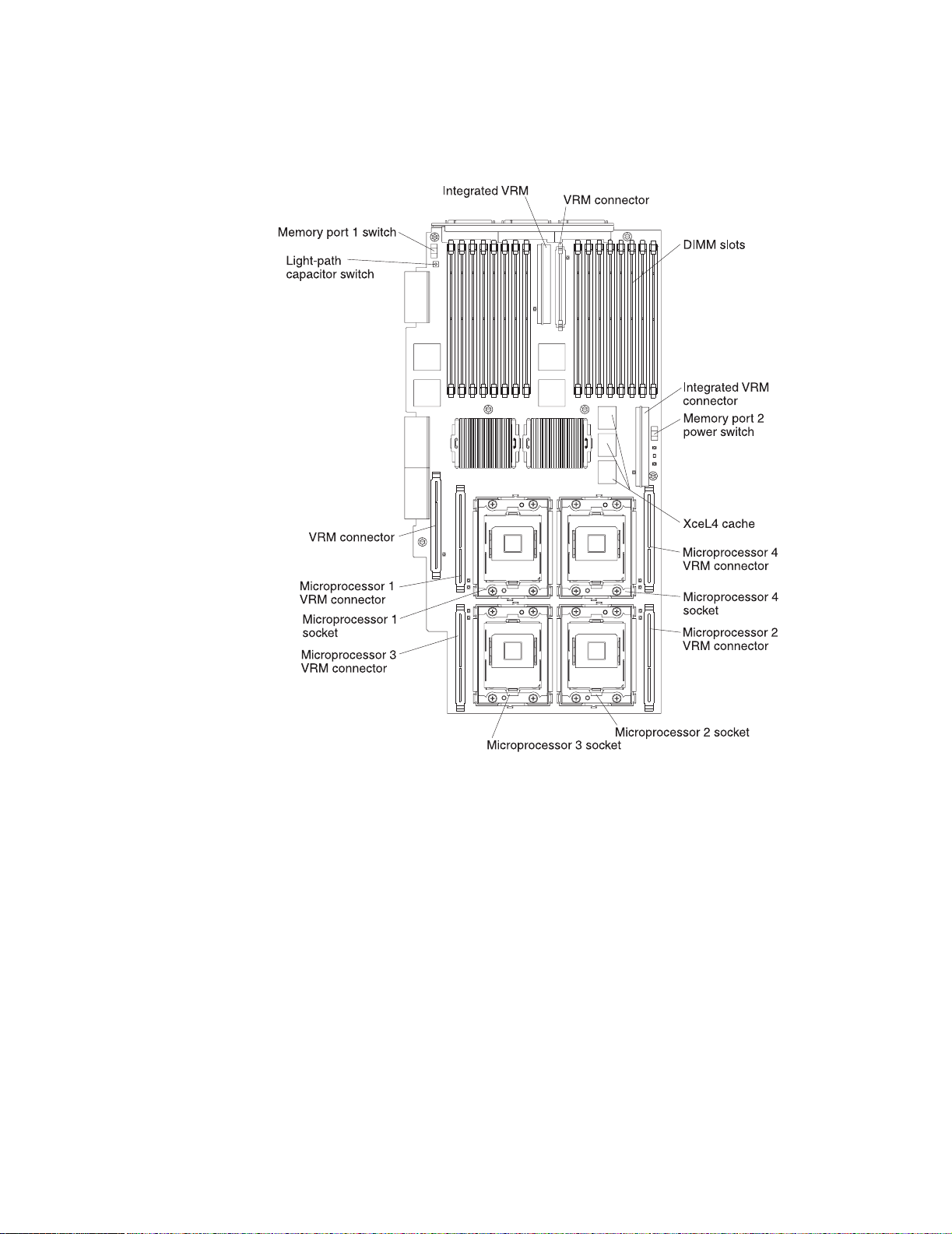

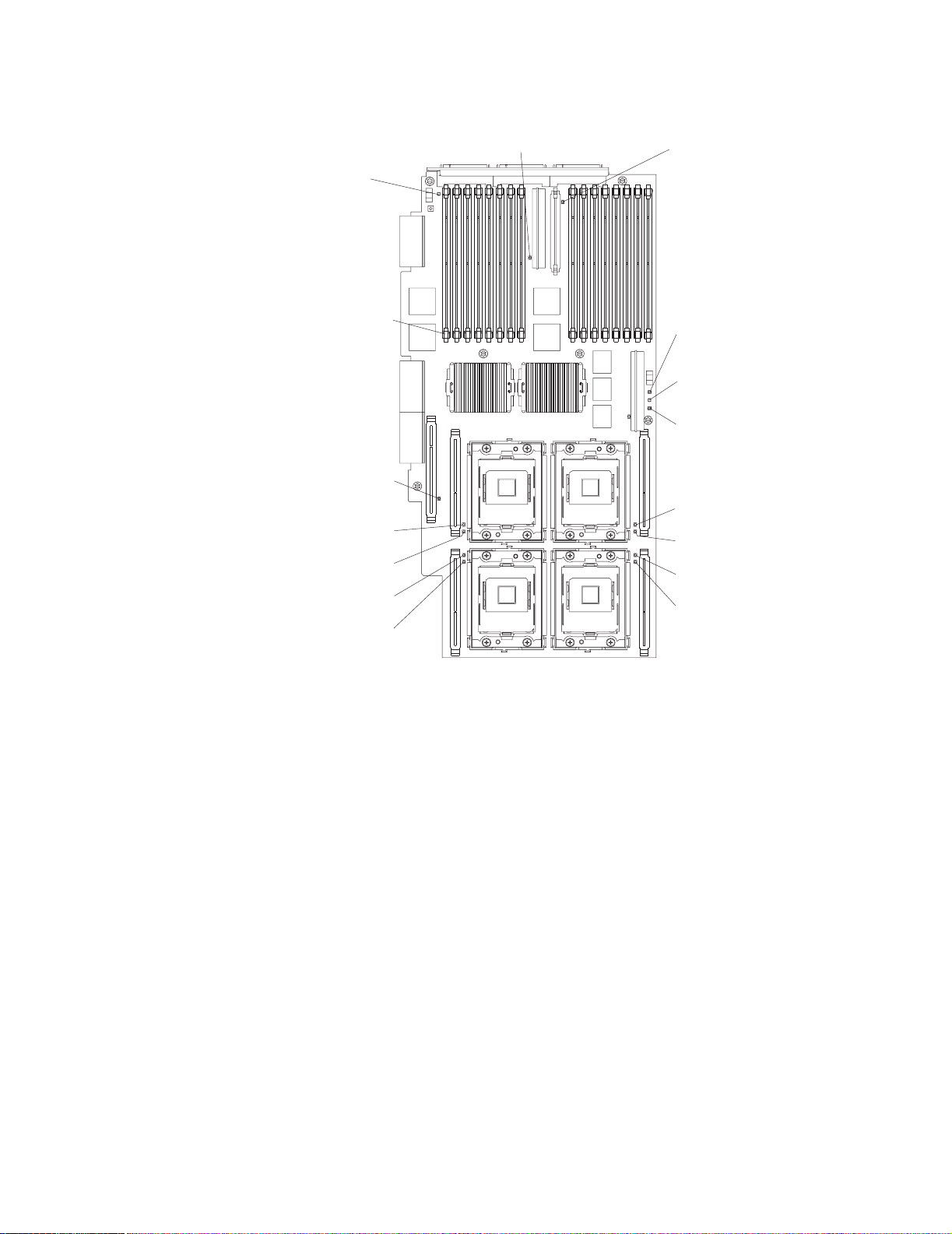

SMP Expansion Module connectors and lights

The following illustrations identify the connectors, switches, and lights on the SMP

Expansion Module.

4 xSeries 440:Option Installation Guide

Page 17

Light path capacitor

switch LED

DIMM error

LED (16X)

VRM error LED

Microprocessor 1

VRM error LED

Microprocessor 1

error LED

Microprocessor 3

error LED

Microprocessor 3

VRM error LED

SMP Expansion Module

board error LED

VRM error LED

Memory port 2

power LED

Hot-plug enabled

memory LED

Memory port 1

power LED

Microprocessor 4

VRM error LED

Microprocessor 4

error LED

Microprocessor 2

error LED

Microprocessor 2

VRM error LED

Chapter 1. Introduction 5

Page 18

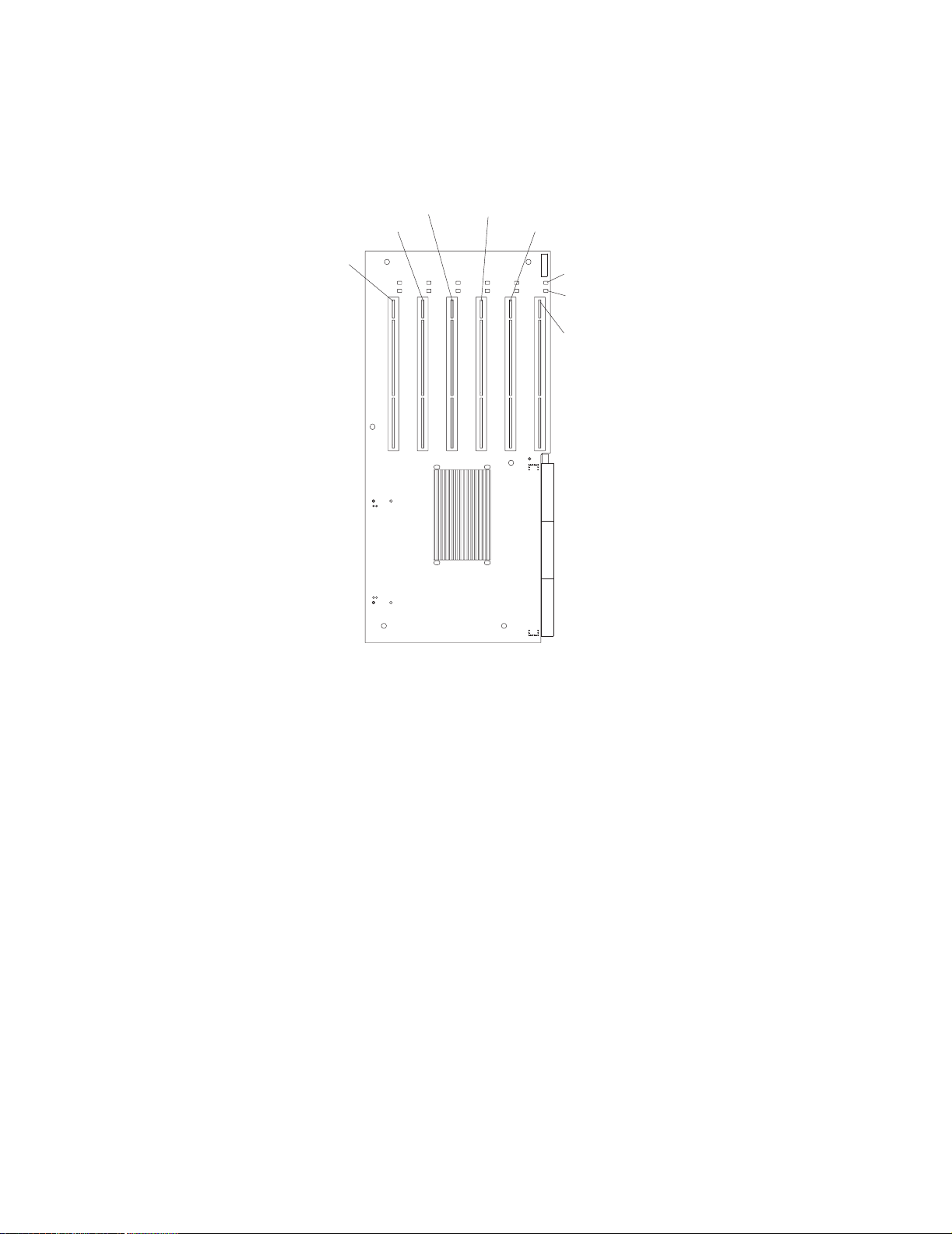

PCI-X planar internal connectors and LEDs

The following illustration identifies the internal connectors and LEDs on the PCI-X planar. This planar enables you to install adapters in the server.

PCI-X slot 6

(133 MHz)

PCI-X slot 5

(133 )MHz

PCI-X slot 4

(100 )MHz

PCI-X slot 3

(100 )MHz

PCI-X slot 2

(66 )MHz

Attention LED

Power LED

PCI-X slot 1

(66 )MHz

6 xSeries 440:Option Installation Guide

Page 19

I/O board internal connectors

The following illustration identifies the internal connectors on the I/O board. This board

supports the input and output ports located on the server.

SCSI B

connector

I/O VRM

Fan 4

connector

Fan 3

connector

Power/Reset

connector

SCSI A

connector

Riser card

connector

Fans 1 and 2

connectors

USB cable

connector

Media bays

connector

Remote Supervisor Adapter component locations

The following illustration identifies the connectors and lights on the Remote Supervisor Adapter.

Lithium

battery

Ethernet speed

External power

supply connector

Power LED

(green)

ASM Interconnect port

LED (green)

Error LED

(amber)

P

P

(RJ-14)

Serial port

(COM)

Ethernet link

LED (green)

Ethernet port

(RJ-45)

Chapter 1. Introduction 7

Page 20

8 xSeries 440:Option Installation Guide

Page 21

Chapter 2. Installing options

This chapter provides instructions to help you install options in your server. Some

option-removal inst ructions are provided in case you need to remove one option to

install another. For a list of supported options for your server, see the ServerProven

list at http://www.ibm.com/pc/compat/.

Before you begin

Before you begin to install options in your server, read the following information:

• Become familiar with the information provided in “Handling static-sensitive

devices” on page 10, and “Safety Information” on page 11. These guidelines will

help you work safely while working with your server or options.

• Make sure that you have an adequate number of properly grounded electrical outlets for your server, monitor, and any other options that you intend to install.

• Back up all important data before you make changes to disk drives.

• For a list of supported options for the xSeries 440, refer to

http://www.ibm.com/pc/us/compat/ on the World Wide Web.

Note: Some preconfigured servers have a unique list of supported op tio n s. See the

software documentation provided with those servers for more information.

®

Working inside a server with power on

Your server supports hot-swap de vice s and i s designed t o oper at e safely while turned

on with the cover removed. Follow these guidelines when you work inside a ser ver

that is turned on:

• Avoid loose-fitting clothing on your forearms. Button long-sleeved shirts before

working inside the server; do not wear cuff links while you are working inside the

server.

• Do not allow your necktie or scarf to hang inside the server.

• Remove jewelry, such as bracelets, rings, necklaces, and loose-fitting wrist

watches.

• Remove items from your shirt pocket (such as pens or pencils) that could fall into

the server as you lean over it.

• Take care to avoid dropping any metallic objects, such as paper clips, hair pins , or

screws, into the server.

© Copyright IBM Corp. 2002 9

Page 22

Handling static-sensitive devices

Attention: Static electricity can damage electronic devices an d y our system. To avoid

damage, keep static-sensiti ve devices in their static-protective package until you are

ready to install them.

To reduce the possibility of electrostatic discharge, observe the following precautions:

• Limit your movement. Movement can cause static electricity to build up around

you.

• Handle the device carefully, holding it by its edges or its frame.

• Do not touch solder joints, pins, or exposed printed circuitry.

• Do not leave the de vice wh ere others can handle and possib ly damage the de vice .

• While the device is still in its anti-static package, touch it to an unpainted metal

part of the system unit for at least 2 seconds. (This drains static electricity from the

package and from your body.)

• Remove the device from its package and install it directly into your system unit

without setting it down. If it is necessary to set the device down, place it in its

static-protective package. Do not place the device on your system unit cover or on

a metal table.

• Take additional care when handling devices during cold weather because heating

reduces indoor humidity and increases static electricity.

System reliability considerations

To help ensure proper cooling and system reliability, make sure that:

• Each of the drive bays has either a drive or a filler panel installed.

• There is space around the server to allow the cooling system to work properly.

• Cables for optional adapters are routed according to the instructions that are provided with the adapters.

• All microprocessors are the same size and clock speed.

• When two SMP Expansion modules are installed, they are connected together

through the SMP Expansion Ports.

• An SMP baffle is installed on top of the lower SMP Expansion module when only

one module is installed.

• For proper cooling, do not leave the cover open for more than 30 minutes.

• A failed fan is replaced within 48 hours.

• The top cover is closed during normal operation.

• Do not remove a defective power supply until a replacement is available.

10 xSeries 440:Option Installation Guide

Page 23

Safety Information

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue tu rvaohjeet kohdasta Safety Information.

Avant d'installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

Chapter 2. Installing options 11

Page 24

Antes de instalar este producto, lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

Statement 1:

DANGER

Electrical current from power, telephone, and communication cables is

hazardous.

To avoid a shock hazard:

• Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an electrical

storm.

• Connect all power cords to a properly wired and grounded electrical

outlet.

• Connect to properly wired outlets any equipment that will be attached

to this product.

• When possible, use one hand only to connect or disconnect signal

cables.

• Never turn on any equipment when there is evidence of fire, water, or

structural damage.

• Disconnect the attached power cords, telecommunications systems,

networks, and modems before you open the device covers, unless

instructed otherwise in the installation and configuration procedures.

• Connect and disconnect cables as described in the following table

when installing, moving, or opening covers on this product or

attached devices.

To Connect: To Disconnect:

1. Turn everything OFF.

2. First, attach all cables to devices.

3. Attach signal cables to connectors.

4. Attach power cords to outlet.

5. Turn device ON.

1. Turn everything OFF.

2. First, remove power cords from outlet.

3. Remove signal cables from connectors.

4. Remove all cables from de vices.

12 xSeries 440:Option Installation Guide

Page 25

Statement 2:

CAUTION:

When replacing the lithium battery, use only IBM Part Number 33F8354 or an

equivalent type battery recommen d ed by the manufacturer. If your system has

a module containing a lithium battery, replace it only with the same module type

made by the same manufacturer. The battery contains lithium and can explode

if not properly used, handled, or disposed of.

Do not:

• Throw or immerse into water

• Heat to more than 100°C (212°F)

• Repair or disassemble

Dispose of the battery as required by local ordinances or regulations.

Statement 3:

CAUTION:

When laser products (such as CD-ROMs, DVD drives, fiber optic devices, or

transmitters) are installed, note the following:

• Do not remove the covers. Removing the covers of the laser product could

result in exposure to hazar dous laser radiation. There are no serviceable

parts inside the device.

• Use of controls or adjustments or performance of procedures other than

those specified herein might result in hazardous radiation exposure.

DANGER

Some laser products contain an embedded Class 3A or Class 3B laser

diode. Note the following.

Laser radiation when open. Do not stare into the beam, do not view

directly with optical instruments, and avoid direct exposure to the beam.

Chapter 2. Installing options 13

Page 26

Statement 4:

≥ 18 kg (39.7 lb) ≥ 32 kg (70.5 lb) ≥ 55 kg (121.2 lb)

CAUTION:

Use safe practices when lifting.

Statement 5:

CAUTION:

The power control button on the device and the power switch on the power supply do not turn off th e e lect ri cal curre nt su ppl ied t o the device. The device also

might have more than one power cor d. To remove all electrical current from the

device, ensure that all power cords are disconnected from the power source.

2

1

14 xSeries 440:Option Installation Guide

Page 27

Statement 8:

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any component that has this label attached. There are no serviceable parts inside these

components. If you suspect a pr oblem with one of these parts, contact a service technician.

Chapter 2. Installing options 15

Page 28

Opening the cover

Complete the following steps to open the server cover:

1. Review th e information in "W orking inside a server with powe r on" and “Bef ore you

2. Slide the server out from the rack.

begin” on page 9.

Latch

N

O

T

E:

F

O

R

P

R

O

P

E

R

AI

R

F

L

O

W, R

E

P

N

O

T

E

:

FO

F

R

O

L

A

C

E

F

A

F

NW

R

O

R P

R

O

P

E

R

A

N

T O

F

B

O

X

ITH

N

T

O

IN

F

2

B

M

O

IN

X

IR

F

L

O

W,

U

T

E

R

E

P

L

A

S

C

E

F

A

N

W

IT

H

IN

2

M

IN

U

T

E

S

3. Pull the release latch on the left half of the to p cover to the right.

4. Using the finger hole in the release latch, open the left half of the cover; then,

open the right half of the cover.

Attention: For proper cooling and airflow, close the cover before turning on the

server. Operating the server for extended periods of time (over 30 minutes) with

the cover open might damage server components.

Removing and replacing the bezel

Complete the following steps to remove and replace the server bezel:

1. Remove the bezel.

a. Press on the two tabs at the top edge of the bezel, and pull the top of the

bezel slightly away from the server.

b. Press on the two tabs at the bottom edge of the bezel, and pull the bezel off

the server. Store the bezel in a safe place.

2. Replace the bezel.

a. Align the four tabs with the slots in the server chassis.

b. Press firmly against the front of the bezel until it snaps into place.

16 xSeries 440:Option Installation Guide

Page 29

Removing and replacing a hot-swap power supply

Your server comes with two hot-swap power supplies, which can be removed and

replaced without turning off the server. This section provides the information to properly remove and replace these power supplies.

Power light Power supply 1

Power supply 2

Power-on light

Power button

Reset button

Power supply

latch

Handle

Before you contin ue with the po w er supply-inst allation procedu re , re vie w th e f ollo wing.

Note: During normal operation, both power supplies must be installed for proper

operation and cooling.

If you install or remove a power supply, observe the following precautions.

Statement 8:

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any component that has this label attached. There are no serviceable parts inside these

components. If you suspect a pr oblem with one of these parts, contact a service technician.

Complete the following steps to remove and replace a power supply.

Chapter 2. Installing options 17

Page 30

H

1. Review the information in “Before you begin” on page 9 through

“Safety Information” on page 11.

2. Remove the front bezel (see “Removing and replacing the bezel” on page 16 for

instructions on removing the front bezel).

3. To remove the power supply from the server, press the release latch; then, lift the

handle on the power supply to the open position and pull the power supply out

from the server.

ot-swap

power supply

elease latch

Power supply handle

(in open position)

AC LED

DC LED

4. To install the new power supply:

a. Place the handle on the powe r supply in the open position.

b. Slide the power supply into the chassis and press the handle to the closed

position.

5. Verify that the dc power light and the ac power light on the power supply are lit,

indicating that the power supply is operating properly.

6. Replace the front bezel o n the server ( see “Remo ving and replacing t he bez el” on

page 16 for instructions).

18 xSeries 440:Option Installation Guide

Page 31

PCI and PCI-X adapters

This section provides information about the expansion slots on the system board and

peripheral component interconnect (PCI or PCI-X) adapters.

The following illustration sho ws the location of the PCI-X expansion slots on the PCI-X

board.

Note: The illustrations in this document might differ slightly from your hardware.

PCI-X slot 6

(133 MHz)

PCI-X slot 5

(133 )MHz

PCI-X slot 4

(100 )MHz

PCI-X slot 3

(100 )MHz

PCI-X slot 2

(66 )MHz

Attention LED

Power LED

PCI-X slot 1

(66 )MHz

PCI and PCI-X adapter considerations

Before you install adapters, review the following:

• Locate the documentation that comes with the adapter and follow those instructions in addition to the instructions in this chapter.

• If you need to change the switch settings or jumper settings on your adapter, follow the instructions that come with the adapter.

• Video adapters are not supported.

• Some long adapters have extension handles or brackets installed. Before installing the adapter, you must remove the extension handle or bracket.

• You can install both PCI and PCI-X adapters in the same bus. However, if you

install a PCI adapter and a PCI-X adapter in the same bus, the PCI-X feat ures of

the PCI-X adapter will be disabled and the adapter will function as a PCI adapter.

• You can install PCI or PCI-X adapters of speeds faster than what is labeled for a

particular PCI-X bus. For example, if you install two 133 MHz adapters into slots

that are labeled as 100 MHz slots, the adapters will operate at 100MHz.

• If you install a 33 MHz and a 66 MHz adapter in the same bus, the bus speed will

match that of the slowest adapter.

Chapter 2. Installing options 19

Page 32

• If a single 133 MHz adapter is installed in PCI-X Bus B (slot 3 and 4), and the

other slot in PCI-X Bus B is empty, the adapter will operate at 133 MHz.

• Your server supports six hot-plug 64-bit adapters in the expansion slots locat ed on

the PCI-X board.

Note: You can add up to 12 additional PCI-X slots to your server by connecting

your server to a remote expansion enclosure. For more information about

the expansion enclosure and how to connect your server to it, refer to the

documentation that comes with your expansion enclosure.

Bus Slot Supported adapter speed (MHz)

A166

A266

B 3 100 (133 if slot 4 is empty)

B 4 100 (133 if slot 3 is empty)

C5133

D6133

• Your server supports 3.3 V adapters; it does not support 5.0 V adapters.

• Your server uses a rotational interrupt techn ique to configure PCI-X ad apters . You

can use this technique to install PCI-X adapters that currently d o not support sharing of PCI-X interrupts.

• The system scans PCI-X slots to assign system resources. The system attempts

to start the first device found. The search order is: CD-ROM, disk drives, integrated SCSI devices, PCI-X slots (1, 2, 6, 5, 3, 4), and the integrated Ethernet

controller.

Note: You can use the Configuration/Setup Utility program to change the boot prece-

dence for your server. Select Start Options from the Configuration/Setup Utility program main menu.

Installing adapters

Complete the following steps to install an adapte r:

Attention: When you handle static-sensitive devices, take precautions to avoid

damage from static electricity. For details on handling these devices, see “Handling

static-sensitive devices” on page 10.

1. Review the information in “Working inside a server with power on” on page 9,

“Before you begin” on page 9, and “Safety Information” on page 11.

2. You must disable the Active PCI-X slots in your server using the operating system

before you insert or remove a hot-plug PCI or PCI-X adapter.

Note: Some operating systems do not support the enabling and disabling of a

PCI-X slot. If your operating system does not support this function, then

turn off your server, and disconnect all external cables and power cords

before proceeding.

3. Pull out on the quick release latches on each side of the server; then, pull the

server out of its rack enclosure until it stops.

4. Open the top cover.

20 xSeries 440:Option Installation Guide

Page 33

Note: Inside your server there are six PCI-X slots: two 66 MHz, two 100 MHz,

and two 133 MHz. Before attempting to install a new adapter, be sure

there is an available slot for it. If you need additional PCI-X slots, y ou can

purchase a Remote Expansion Enclosure either from y our IBM marketing

representative or authorized reseller.

Adapter

Adapter guide

PCI-X

divider

Tab

Attention

LED

Power

LED

retention

latch

NOTE:FO

R PR

OP

ER A

IRFLO

W, R

EP

NOTE:FOR PROPER AIRFLOW, REPLACE FANWITHIN 2 MINUTES

FRONT OF BOX

LA

CE

F

ANW

FRONT OF BOX

ITH

IN 2 MINU

TE

S

5. Set any jumpers or switches as described by the adapter manufacturer.

6. Install the adapter:

a. Open the blue adapter guide by lifting the front edge, as shown in the illustra-

tion.

b. Remove the PCI-X divider from the PCI-X slot by grasping the divider along

the top edge and lifting it from the ser ver.

c. Push the orange adapter retention latch toward the rear of the server and

open the tab.

d. Remove the expansion-slot cover.

e. Carefully grasp the adapter by its top edge or upper corners and align it with

the connector on the PCI-X board.

Note: Some long adapters have extension handles or brackets installed.

Before installing a long adapter, you must remove the extension handle or bracket.

f. Press the adapter firmly into the adapter connector.

Chapter 2. Installing options 21

Page 34

Attention: When you install an I/O adapter, be sure the adapter is correctly

seated in the connector slot. Improperly seated adapters might cause dam-

age to the board, the riser card, or the adapt er.

g. Reinstall the PCI-X dividers between the Active PCI adapter slots.

h. Push down on the b lue adapter guide to keep the adapter steady.

i. Close the tab. The orange adapter retention latch will clic k into place, securing

the adapter.

7. Connect the internal cables to the adapter. If you are installing a ServeRAID

adapter, refer to “Cabling a ServeRAID adapter” for instructions.

8. If you have other options to install or remove, do so now.

9. Close the cover on the server.

10. Enable the slot or turn on the server, depending on your operat ing system.

Cabling a ServeRAID adapter

Some xSeries 440 models come with an optional IBM ServeRAID adapter installed to

control the internal hot-swap hard disk drives and external hard disk drives. If your

server did not come with an optional IBM ServeRAID adapter installed; then, refer to

your ServeRAID adapter option documentation for complete instructions on installing

a ServeRAID adapter in your server and for additional information on ServeRAID

adapters.

™

Servers without an optional IBM ServeRAID adapter installed come with two SCSI

cables:

• One end of the first SCSI cable is attached to the connector on the SCSI backplane, and the other end is attached to the connector for the integ rated SCSI controller behind fans 3 and 4.

• The second SCSI cable is preinstalled along the inside of the server chassis and

both ends are loose inside the server . Whe n yo u install a ServeRAID adapter, you

will connect this cable to the adapter and the SCSI backplane.

The following procedure describes the internal cabling needed to install a ServeRAID

adapter.

Complete the following steps to cable the ServeRAID adapter.

1. Review the information in “Before you begin” on page 9 through “Safety Information” on page 11.

2. Turn off the server and disconnect all power cords and ex ternal cables; then, open

the server cover (see “ Opening the cover” on page 16).

3. Remove fans 3 and 4, which are located just behind the PCI-X slots.

4. Disconnect the short SCSI cable from the SCSI backplane and the integrated

SCSI controller; then, store this short cable in a safe place for future use.

5. Install the ServeRAID adapter in the PCI-X slot (see“Installing adapters” on page

20).

22 xSeries 440:Option Installation Guide

Page 35

6. Locate one end of the preinstalled SCSI cable and connect it to the

ServeRAID adapter.

Preinstalled

SCSI cable

Connect to

SCSI backplane

Connect to

ServeRAID adapter

7. Locate the other end of the preinstalle d SCSI cable and connect it to the SCSI

backplane.

Front of server

SCSI backplane

connector

8. Reinstall fans 3 and 4.

9. If you have other options to install or remove, do so now.

10. Close the cov e r on the server; then, reinstall the server in the r ac k and connect all

external cables.

11. Turn on the server.

Chapter 2. Installing options 23

Page 36

Installing or replacing a drive

In this section, you will find the instructions needed to install or replace a hot-swap

hard disk drive, diskette drive, CD-ROM drive, and DVD-ROM drive.

Hot-swap hard disk drive

Complete the following steps to install or replace a hot-swap hard disk drive:

Attention: When you handle static-sensitive devices, take precautions to avoid

damage from static electricity. For details on handling these devices, see “Handling

static-sensitive devices” on page 10.

1. Inspect the drive for any signs of damage.

2. Review the information in “Before you begin” on page 9 and “Safety Information”

on page 11.

3. Check the instructions that come with the drive for more information about installing your drive.

4. Remove the filler panel or defective hard disk drive from the hard disk drive bay.

5. Install the new hard disk drive in the drive bay:

a. Ensure that the handle on the hard disk drive tray is in the open positio n.

b. Slide the drive into the bay until it stops.

c. Push the handle on the front of the hard disk drive closed.

Filler panel

6. If you have other options to install or remove, do so now.

Flashing green

light indicates

drive activity

Solid amber

light indicates

failed drive

Flashing amber

light indicates

drive rebuild.

24 xSeries 440:Option Installation Guide

Page 37

Diskette drive

Drive considerations:

• Your xSeries 440 server supports the installation of up to two diskette drives.

• If only one diskette drive is installed, it must be installed in the left drive bay.

Complete the following steps to remove and install a diskette drive in your server:

1. Review the information in “Before you begin” on page 9 and “Safety Information”

on page 11.

Attention: The IDE drives installed in your server are not hot-swappable.

2. Turn off the server and disconnect the power cord from the back of the server.

3. Push the diskette drive eject button to the right.

4. Using the tab, pull the diskette drive partially out of the server; then, grasp the

drive and remove it from the server.

5. Install the new diskette drive:

a. Inspect the drive for any signs of damage.

b. Slide the drive into the left drive bay until it stops.

Note: In the unlikel y event that no other IDE drives are installed, the diskette

drive must be installed in the right external removable media bay.

External removable

media bays

NOTE: FOR PROPER AIRFLOW, REPLACE FANWITHIN 2 MINUTES

NOTE: FOR PROPER AIRFLOW, REPLACE FANWITHIN 2 MINUTES

FRONT OF BOX

FRONT OF BOX

Diskette

drive

Tab

Diskette drive

eject button

6. If you have other options to install or remove, do so now. Ot herwise, connect the

power cords and turn on the server.

Chapter 2. Installing options 25

Page 38

CD-ROM or DVD-ROM drive

Drive considerations:

• Your xSeries 440 server supports the installation of up to two CD-ROM drives, or

two DVD-ROM drives.

• If no other IDE drives are installed, the disk ett e drive must be installed in the right

external remov able media bay. CD-ROM or DVD-ROM drives can be installed in

either external removable media bay.

Complete the following steps to remove and install a CD-ROM or DVD-ROM drive in

your server:

1. Review the information in “Before you begin” on page 9 and “Safety Information”

on page 11.

Attention: The IDE drives installed in your server are not hot-swappable.

2. Turn off the server and disconnect the power cords from the back of the server.

3. Push the CD-ROM or DVD-ROM eject button to the right.

4. Using the tab, pull the CD-ROM or DVD-ROM drive partially out of the server;

then, grasp the drive and remove it from the server.

5. Install the new CD-ROM or DVD-ROM drive:

a. Inspect the drive for any signs of damage.

b. Slide the CD-ROM or DVD-ROM drive into the drive bay until it stops.

External removable

media bays

CD-ROM

or DVD drive

Tab

NOTE: FOR PROPER AIRFLOW, REPLACE FANWITHIN 2 MINUTES

NOTE: FOR PROPER AIRFLOW, REPLACE FANWITHIN 2 MINUTES

FRONT OF BOX

FRONT OF BOX

CD-ROM drive

eject button

6. If you have other options to install or remove, do so now. Ot herwise, connect the

power cords and turn on the server.

26 xSeries 440:Option Installation Guide

Page 39

SMP Expansion Module

The SMP Expansion Module contains the XceL4™ system cache, DIMMs, microprocessors, and voltage regulator modules (VRMs) needed to run your server. This section contains the information needed to install and remove the SMP Expansion

Module, microprocessors, VRMs, and DIMMs.

SMP Expansion Module considerations:

• For your server to operate properly, there must be a minimum of one SMP Expansion Module and one SMP baffle installed.

• An SMP Expansion Module must contain at least one microprocessor and four

DIMMs.

• If it becomes necessary to remove or install DIMMs, do so through the DIMM

access doors on the SMP Expansion Module. Refer to the “Removing and replacing DIMMs:” on page 34 for the location of the DIMM access doors.

• Before removing or installing SMP Expansion Modules, you must remove the

electromagnetic compatibility (EMC) shield and SMP Expansion cables from the

rear of the server.

• You must run the Configuration/Setup Utility whenever you remove or replace an

SMP Expansion Module or one of its associated options.

Note: The illustrations in this document might differ slightly from your hardware.

Locking levers

CAM opening

Chapter 2. Installing options 27

Page 40

Removing an SMP Expansion Module and cover

While installing options, you might nee d to remove one or both of the SMP Expansion

Modules. This section provides instructions on removing an SMP Expansion Module

from the server and removing the cover from the module.

Complete the following steps to remove an SMP Expansion Module from the server:

1. Review the information in “Before you begin” on page 9, “Handling static-sensitive

devices” on page 10, and “Safety Information” on page 11.

2. Turn off the server and peripheral devices, disconnect the power cords and all

external cables from the SMP Expansion Module; then, open the cover (see

“Opening the cover” on page 16 for details).

3. If necessary, remove the SMP baffle and retention bracket from the server.

a. Remove the shipping thumbscrews from the right side of the server.

Retention bracket

removal handles

Retention bracket

SMP Expansion

Module

N

O

T

E

:

F

O

R

P

R

O

P

E

R

A

IR

FL

O

W, R

E

P

N

O

T

E

:

F

O

F

R

O

L

A

C

E

F

A

F

N

R

W

O

R

P

R

O

P

E

R

N

T

O

F

B

O

X

IT

N

T

H

IN

O

F

2

B

M

O

A

IR

F

L

O

W, R

IN

X

U

T

E

E

P

S

LA

C

E

F

A

N

W

IT

H

IN

2

M

IN

U

T

E

S

Shipping

thumbscrews

b. Open the cover.

c. Grasp the retention bracket b y the remov al handl es and lift it up and out of the

server.

Note: If there is one SMP Module installed, you will need to remov e the SMP

baffle from the server; then, remove the retention bracket from the

lower SMP Module as described in steps 3a through 3c.

4. To remove the EMC shield from the rear of the server:

a. If there are two SMP Expansion Modules installed in the server, you must dis-

connect the SMP Expansion Cables that are connected to the SMP Expansion Modules.

b. Remove the blue thumbscrews holding the EMC shield to the server.

28 xSeries 440:Option Installation Guide

Page 41

EMC shields

Thumbscrews

For use with one

SMP Module

For use with two

SMP Modules

c. Remove the EMC shield from the rear of the server.

SMP Expansion

Cables

EMC Shield

N

O

T

E

:

F

O

R

P

R

O

P

E

R

A

IR

F

L

O

W, R

E

P

N

O

T

E

:

F

O

R

P

R

O

P

E

R

F

R

O

N

T

O

F

B

O

X

L

A

C

E

F

A

F

N

R

W

O

IT

N

T

H

O

IN

F

2

B

M

O

A

I

R

F

L

O

W,

R

E

P

L

A

C

E

F

A

IN

X

U

T

E

N

W

S

I

T

H

I

N

2

M

IN

U

T

E

S

SMP baffle

5. Grasp each of the locking levers and lift them up slightly.

6. Working from the right side of the server, rotate the two locking levers toward you

until they are fully extended, as shown.

Latch

Locking

levers

Finger relief

N

O

TE

:

F

O

R

P

R

O

P

E

R

A

IR

F

LO

W, R

E

P

N

O

T

E

:

F

F

R

LA

C

E

F

A

F

O

R

P

R

O

O

N

T

O

F B

N

R

W

O

IT

N

T

H

O

IN

F

P

E

R

A

IR

F

L

O

X

2

B

M

O

IN

X

U

T

E

O

W, R

E

P

LA

S

C

E

F

A

N

W

IT

H

IN

2

M

IN

U

T

E

S

Handle

Attention: When removing the SMP Module from the server, lift it out carefully,

taking care not to damage the components on the center plane.

Chapter 2. Installing options 29

Page 42

7. Use the handle and the finger relief on the SMP Expansion Modu le cover to carefully lift the SMP Expansion Module out of the server.

Note: The illustrations in this document might differ slightly from your hardware.

8. Remove the SMP Expansion Module cover:

a. Place the SMP Expansion Module on a flat, level surface.

b. Rotate the two locking levers just beyond the edge of the SMP Expansion

Module cover until they stop; then, using the locking levers, lift the cover off

the circuit board.

30 xSeries 440:Option Installation Guide

Page 43

DIMMs

This section contains instructions on how to install, add, and remove DIMMS. It

includes information about Active Memory and Memory Mirroring. Before preforming

any of the procedures in this section, read the “Safety Information” on page 11, “Handling static-sensitive devices” on page 10, and the DIMM considerations 32.

Your xSeries 440 server supports up to sixteen 3.3 V, 168 pin, 133 MHZ ECC SDRAM

DIMMs in each SMP Expansion Module. With both SMP Expansion Modu les installed,

the server can support a maximum of 32 SDRAM DIMMS for a total of 32 GB of memory in your server.

Notes:

1. DIMMs can be removed and replaced through the access doors on the top of the

SMP Expansion Module.

2. The illustrations in this document might differ slightly from your hardware.

DIMM

bank 2

Chapter 2. Installing options 31

Page 44

DIMM considerations:

• Your xSeries 440 server supports 512 MB and 1 GB DIMMs, for a maximum of 32

GB of system memory depending on your configuration. See the ServerPro ven list

at http://www.ibm.com/pc/compat/ for a list of memory modules you can use with

your server.

• Your server comes with four 512 MB DIMMs installed in slots 1, 3, 5, and 7 in the

SMP Expansion Module. When installing additional memory modules, you must

install four DIMMS a t a time and in the order described to maintain performance.

(See the following figure for memory connector locations.)

• When installing or removing DIMMs, it must be done in banks of four and in the

following order:

1. Bank 1 = DIMM connectors 1, 3, 5, 7

2. Bank 2 = DIMM connectors 9, 11, 13, 15

3. Bank 3 = DIMM connectors 2, 4, 6, 8

4. Bank 4 = DIMM connectors 10, 12, 14, 16

Bank 1 (standard) Bank 2

DIMM error

indicators are

built into

Bank 3

Bank 4

each handle.

• Each DIMM in an individual bank must be of the same size and clock speed to

ensure the server will operate properly. For example, in bank 1 your server came

with four 512 MB DIMMs installed. In bank 2, y ou can inst all f our 512 MB or four 1

GB DIMMs.

• When using Memory Mirroring, all of the DIMMs in each memory port must be the

same size and clock speed.

• Memory ports:

— Memory Port one

– Bank 1 = DIMM connectors 1, 3, 5, 7

– Bank 3 = DIMM connectors 2, 4, 6, 8

— Memory Port two

– Bank 2 = DIMM connectors 9, 11, 13, 15

– Bank 4 = DIMM connectors 10, 12, 14, 16

32 xSeries 440:Option Installation Guide

Page 45

• When you install or remove DIMMs, the server configuration information changes.

Therefore, you must change and save the new configuration information by using

the Configuration/Setup Utility program. When you restart the server, the system

displays a message indicati ng that the memory configuration has changed. Start

the Configuration/Setup Utility program and select Save Settings. If you need

instructions, see Chapter 2. Configuring your server in the User’s Guide on the

IBM Documentation CD.

Active Memory: Active Memory is an IBM feature that improves the reliability of

the DIMMs through Memory Mirroring, Memory Scrubbing and Memory ProteXion

• Memory Mirroring allows you to improve the memory reliability of your server by

creating a mirror of the data in memory port one and storing it in memory port two.

Note: For Memory Mirroring to work, you must have the same amount of memory

in both memory ports. For more inf ormation about the memory ports, ref er

to the DIMM considerations 32.

Complete the following steps to enable Memory Mirroring.

1. Check your operating system documentation to be sure that it supports Mem-

ory Mirroring.

2. Install DIMMs of the same size and clock speed in the two memory ports.

3. Enable Memory Mirroring in the Configuration/Setup Utility:

a. Turn on the server and watch the monitor screen.

b. When the message Press F1 for Configuration/Setup appears, press

F1.

c. From the Configuration/Setup Utility main menu, select Advance Fea-

tures.

d. Select and enable Memory Mirroring.

e. Save and exit the Configuration/Setup Utility program.

How does Memory Mirroring work?

When Memory Mirroring is enabled, the data that is written to memo ry is stored in

two locations. One copy is kept in the memory port one DIMMs, while a second

copy is kept in t he memory port two DIMMs. During the e x ecution of t he read command, the data is read from the DIMM with the least amount of reported memory

errors through Memory Scrubbing, which is enabled with Memory Mirroring.

If Memory Scrubbing determines the DIMM is damaged beyond use, read and

write operations are redirected to the remaining good DIMM. Memory Scrubbing

then reports the damaged DIMM and the Light Path Diagnostics display the error.

After the damaged DIMM is replaced, Memory Mirroring then copies the mirrored

data back into the new DIMM.

• Memory Scrubbing is an automatic daily test of all the system memory that

detects and reports memory errors that might be developing before they cause a

server outage.

Note: Memory Scrubbing and Memory ProteXion work in conjunction with each

other and do not require Memory Mirroring to be enabled to work properly.

™

.

How does Memory Scrubbing work?

When an error is detected, Memory Scrubbing determines if the error is recoverable or not. If it is recoverable, Memory ProteXion is enabled and the data that

was stored in the damaged locations is rewritten to a new location. The error is

then reported so that preventative maintenance can be performed. As long as

Chapter 2. Installing options 33

Page 46

there are enough good locations to allow the proper operation of the server, no

further action is taken other than recording the error in the error logs.

If the error is not recov erab le , the n Memory Scrubbing sends an error message to

the Light Path Diagnostics, which then turns on the proper lights and LEDs to

guide you to the damaged DIMM. If Memory Mirroring is enabled, then the mirrored copy of the data in the damaged DIMM is used to refresh the ne w DIMM

once it is installed.

• Memory ProteXion reassigns memory bits to new locations within memory when

recoverable errors have been detected.

How does Memory ProteXion work?

Once a recoverable error is found by Memory Scrubbing, Memory ProteXion

writes the data that was to be stored in the damaged memory locations to spare

memory locations within the same DIMM.

Removing and replacing DIMMs: If you need to replace or upgrade the

DIMMs in your server, you must remove the old DIMMs before you insert new ones.

This section includes the instructions needed to properly remove and replace DIMMs

from the SMP Expansion Module in your server.

Attention: When working with DIMMs or other options, you might need to remove

one or both of the SMP Expansion Modules. Before removing an SMP Expansion

Module, be sure to turn off the server and peripheral devices; then, disconnect all

external cables and power cords.

Complete the following steps to remove a DIMM from your server SMP Expansion

Module:

1. Review the information in “Before you begin” on page 9, “Handling static-sensitive

devices” on page 10, and “Safety Information” on page 11.

2. Turn off the server and peripheral devices, disconnect the power cords, and all

external cables from the SMP Expansion Module; then, open the server cover

(see “Opening the cover” on page 16 for details).

3. If necessary, remove the top SMP Expansion Module from the server. Refer to

“Removing an SMP Expansion Module and cover” on page 28 for instructions.

4. Open the DIMM access door that covers the DIMM you will be removing.

DIMM access

door

5. Open the retaining clip on each end of the DIMM connector.

6. Lift the DIMM straight up and out of the SMP Expansion Module.

7. Install a new DIMM:

34 xSeries 440:Option Installation Guide

Page 47

a. Touch the static-protective package containing the DIMM to any unpainted

metal surface on the server. Then, remove the DIMM f rom the package.

Attention: To avoid breaking the retaining clips or damaging the DIMM con-

nectors, open and close the clips gently.

b. Insert the DIMM into the connector b y a ligning the DIMM edges with the slots

at each end of the DIMM connector . Firmly press the DIMM straigh t down int o

the connector by applying pressure on both ends of the DIMM sim ultaneously.

Be sure that the retaining clips snap into the locked position when the DIMM is

firmly seated in the connector.

DIMM

Retaining

clip

c. If a gap exists between the DIMM and the retaining clips, the DIMM has not

been properly installed. In this case, open the retaining clips and remove the

DIMM; then, reinsert the DIMM.

8. Close the DIMM access door or reinstall the SMP Expansion Module cover ( se e

“Reinstalling an SMP Expansion Module and cover” on page 41).

9. If you have other options to install or remove, do so now.

10. Close the server cover. See “Closing the cover” on page 49.

Note: When you install or remove DIMMs, the server configuration information

changes. Theref ore, you must change and save the new configur ati on information by using the Configuration/Setup Utility program. Ref er to the User’ s Guide

on the Documentation CD.

Chapter 2. Installing options 35

Page 48

Installing and replacing a microprocessor

This section describes how to install and remove microprocessors and VRMs. Before

performing any of the procedures in this section, read “Safety” on page v, “Handling

static-sensitive devices” on page 10, and Before you begin.

Your xSeries 440 Server supports up to two Intel Xeon DP or four Intel Xeon MP

microprocessors in each SMP Expansion Module. With both SMP Expansio n Modules

installed, the server can support a maximum of four Intel Xeon DP or eight Intel Xeon

MP microprocessors of the same type and speed.

Note: Do not install both Intel Xeon MP and Intel Xeon DP microprocessors in the

same server or SMP Expansion Module.

Before you begin:

• Read the documentation that comes with the microprocessor to determine if you

need to update the server basic input/output system (BIOS) code. For the most

current leve l of BIOS code f or the server, go to http://www.ibm.com/pc/su pport/ on

the World Wide Web.

• Obtain an SMP-capable operating system (optional). For a list of supported operating systems, go to http://www.ibm.com/pc/us/compat/ on the World Wide Web.

Attention: To avoid damage and ensure proper server operation after you install a

replacement or an additional microproce ssor , use a micro processor that has the same

cache size and type, clock speed, and internal and external clock frequencies as the

microprocessors already installed in the individual SMP Expansion Module. For a list

of microprocessors supported by your server, see the ServerProven list at

http://www.ibm.com/pc/us/compat/ on the World Wide Web.

Notes:

1. To order additional microprocessor options, contact y our IBM mark e ting re presentative or authorized reseller.

2. The microprocessor in socket 1 of the bottom SMP Expansion Module is the startup (boot) microprocessor.

3. If you are adding additional I ntel Xeon MP microprocessors to an SMP Expansion

Module, populate the empty microprocessor sockets in numeric order, starting

with socket 1. If y ou install the microprocessors in the wrong order, the server will

not power on.

4. If you are adding additional Intel Xeon DP microprocessors to your server, you

must have a second unpopulated SMP Expansion Module. Server models tha t

come with Intel Xeon DP microprocessors support a maximum of two microprocessors per SMP Expansion Module, and are installed in microp ro ce ssor sockets

1 and 4.

The following illustration sho ws the locations of the startup microprocessor and its

VRM on the system board. It also shows the microprocessor baffles and the VRM

slots for the other microprocessor sockets.

36 xSeries 440:Option Installation Guide

Page 49

Notes:

1. The illustrations in this document might differ slightly from your hardware.

2. Remember, Intel Xeon DP microprocessors are supported in microprocessor

sockets 1 and 4 only. Intel Xeon MP microprocessor are supported in microprocessor sockets 1,2,3, and 4.

Microprocessor 4

VRM connector

Microprocessor 1 VRM

Microprocessor 1

Microprocessor 3

VRM connector

Microprocessor 4

baffle

Microprocessor 2

VRM

Microprocessor 3 socket

Microprocessor 2

Complete the following steps to install a microprocessor:

1. Read the “Handling static-sensitive devices” on page 10 and “Safety Information”

on page 11.

2. Turn off the server and peripheral devices, disconnect the power cords, and disconnect all external cables from the SMP Expansion Module; then, open the cov er

(see “Opening the cover” on page 16 for details).

3. Remove the SMP Expa nsion Module in which you plan to install the microprocessor; then, remove the module co v er and determine the soc k et where the micr oprocessor is to be installed. For details, see “Removing an SMP Expansion Module

and cover” on page 28.

Important: Before continuing, you should determine which type of microprocessors are installed in your server. The easiest way to do this is by the locations of

the installed microprocessors in the SMP module. If the microprocessors are

installed only in socke ts 1 and 4, your server came with Intel Xeon DP microprocessors. If the microprocessors are installed in any other soc k ets, such as 1 and 2

or 1,2, and 3, then your server came with Intel Xeon MP microprocessors.

Note: If your server contain s only one SMP Expansi on Module , remo ve the SMP

baffle above it t o gain access to the module. If your server contains two

SMP Expansion Modules, remove the top module to gain access to the

bottom or lower SMP module.

Chapter 2. Installing options 37

Page 50

Attention: When you handle static-sensitive devices, take precautions to avoid damage from static electricity. For details on handling these devices, see “Handling staticsensitive devices” on page 10.

4. If you are installing a new microprocessor, go to step 5; otherwise, continue:

a. Verify that you have selected the correct microprocessor to be replaced. The

LED next to the failing microprocessor will be on.

Attention: Before attempting to remove the heat sink from the microproces-

sor, note t hat the heat-conducting grease between the heat sink and the

microprocessor might have formed a strong bond. Do not force the components apart; doing so can damage the microprocessor pins. If the heat sink

does not separate from the microprocessor ea sily, loosen one heat sink captive mounting scre w first. This a llows one corner of the hea t sink to be lifted of f

of the microprocessor; then, you can loo sen the other ca ptiv e mounting scre w

and remove the heat sink.

Captive screws

VRM 3

Microprocessor

locking lever

Heat sink 3

Microprocessor 3

b. Using a screwdriver , loosen the two captiv e mounting scre ws on the heat sink,

alternating between screws until they release from the SMP board; then,

remove the heat sink.

c. Lift the microprocessor locking lev er to the open position and remove the

microprocessor.

5. Install the VRM in the slot adjacent to the microprocessor socket.

Attention: If you are installing an additional microprocessor, note that the new

microprocessor comes in a kit with a VRM. Some microprocessor options contain

a VRM with a clip to secure the VRM in the slot. This clip is not needed for installations in your server and can be discarded. When installing a new microprocessor you must install the VRM that came in the kit.

a. If you are replacing a failed VRM:

1) Verify that you have selected the correct VRM to be replaced. The LED

next to the failing VRM will be on.

2) Grasp the VRM at both upper corners and lift it out of the slot.

38 xSeries 440:Option Installation Guide

Page 51

b. Holding the new VRM by the upper corners, plug it firmly into the slot.

6. If necessary, remove the microprocessor baffle from the microprocessor socket.

Keep the microprocessor baffle for possible future use.

7. Touch the static-protective package containing the new microprocessor to any

unpainted metal surfac e on th e se rver; then, remove the microprocessor from t he

package.

8. Install the microprocessor:

Important: When installing Intel Xeon DP microprocessors, you must install them

in the following order: socket 1 then socket 4. When installing Intel Xeon MP

microprocessors, you must in stall them in the following order: sockets 1,2,3, and

then 4.

a. Ensure that the microprocessor locking lever is in the open position to permit

plugging in the microprocessor.

b. Re m ove the protective tape from the microprocessor socket.

c. Align the triangle icon on the microprocessor with the triangle icon on the

socket and press the mi croprocessor gently into the soc ket.

Attention: Make sure that the microp rocessor is aligned correct ly befor e you

proceed. To avoid bending the pins on the microprocessor, do not use exces-

sive force when pressing it into the socket.

d. Close the locking lever to secure the microprocessor.

9. If you have installed an additional microprocessor:

a. Remove the heat sink from its package and detach the pr otective cover from

the bottom of the heat sink

Attention: Do not disturb or contaminate the heat-con ducting grease on the

bottom of the new heat sink. Doing so damages its heat-conducting capability

and exposes the new microprocessor to overheating.

Chapter 2. Installing options 39

Page 52

Captive screws

Protective cover

Heat sink

b. Align the heat sink over the microprocessor; then, carefully set it down on top

of the microprocessor.

c. Using a screwdriver, secu re the heat sink t o the microproce ssor soc ke t on the

SMP board using the two captive mounting screws. Press firmly on the

screws and tighten them, alternating between them. Do not overtighten the

screws.

10. Close the SMP Expansion Module top cover; then, install th e mo d ule in the

server. For details, see “Reinstalling an SMP Expansion Module and cover” on

page 41.

11. If you have other options to install or remove, do so now.

12. Close the cov e r on the server; then, reinstall the server in the rac k and connect all

external cables. For details, see “Closing the cover” on page 49.

13. Turn on the server.

Important: If your server will not start after replacing or installing a microproces-

sor, you might have inst alled a microprocessor of a different type or the VRM is

not installed properly. Verify that yo u hav e installed the proper microprocessor and

that the VRM is properly installed.

Note: When you install or remove microprocessors, the server configuration

information changes. Therefore, you must change and save the new configuration information by using the Configuration/Setup Utility program.

Refer to the User’s Guide on the Documentation CD.

40 xSeries 440:Option Installation Guide

Page 53

Reinstalling an SMP Expansion Module and cover

After installing options in the SMP Expansion Module, you will need to reinstall the

SMP Expansion Module cover and reinstall the SMP Expansion Module in the server.

Complete the following steps to reinstall the SMP Expansion Module cover:

1. Install the cover on the SMP Expansion Module:

a. Set the cover on top of the expansion module.

b. Extend the locking levers as shown in the illustration; then, let the cam on the

front of the cover fall into the cam opening on the SMP Expansion Module circuit board.

Locking levers

CAM opening

c. Release the locking levers and align the re ar of the cov er with the rear edge of

the circuit board.

d. Press down on the cover until it snaps into place.

Chapter 2. Installing options 41

Page 54

e. Lift slightly on the locking levers and rotate them back until they stop.

Note: The illustrations in this document might differ slightly from your hard-

ware.

Locking

levers

Handle

2. Install the SMP Expansion Module into the server.

Locking

levers

Center plane

N

O

T

E

:

F

O

R

P

R

O

P

E

R

A

IR

F

LO

W, R

E

P

N

O

TE

:

F

F

R

O

L

A

C

E

F

A

F

O

R

P

R

O

P

E

N

T

O

F

B

O

N

R

W

O

ITH

N

T

O

IN

F

2

B

R

A

IR

F

LO

X

M

O

IN

X

U

TE

W, R

E

P

L

S

A

C

E

F

A

N

W

IT

H

IN

2

M

IN

U

T

E

S

Handle

a. Lift the SMP Expansion Module by its handle and use the finger relief to hold

the SMP module steady.

b. Being careful not to damage the components on the center plane, place the

SMP Expansion Module into the server.

c. Release the handle and slide the SMP Expansion Module toward the center

plane until it stops.

42 xSeries 440:Option Installation Guide

Page 55

d. Ro ta te the SM P Expans ion Mo du le locking levers forward until the SMP

Expansion Module is securely fastened in place. Refer to the following illustration.

Note: The illustrations in this document might differ slightly from your hard-

ware.

Center plane

Locking

levers

Cover

Handle

3. If you have other options to install or remove, do so now.

4. Close the cover on the server; then, reinstall the server in the rack and conn ect all

external cables. For details, see “Closing the cover” on page 49.

5. Turn on the server.

Note: When you install or remove SMP Expansion Modules, the server configu-

ration information changes . Therefore, you must change and sav e the ne w

configuration information by using the Configuration/Setup Utility progr am.

Refer to the User’s Guide on the Documentation CD.

Chapter 2. Installing options 43

Page 56

Replacing and troubleshooting fans

Your xSeries 440 server has four hot-s w ap f an assemb lies, t wo 150 mm x 3 8 mm, and