Page 1

IBM

IBM xSeries 360 Type 8686

Installation Guide

Page 2

Note::

Before using this information and the product it supports, read the general information in Appendix A, “Warranty

information” on page 47 and Appendix B, “Notices” on page 57.

Second Edition (March 2002)

© Copyright International Business Machines Corporation 2001. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract with

IBM Corp.

Page 3

© Copyright IBM Corp. 2001 iii

Contents

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Chapter 1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications and features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Notices and statements used in this book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before you begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Handling static-sensitive devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Major components of the xSeries 360 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2. Installing options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Working inside a server with power on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Removing the server top cover and bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

System board component locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Adapter considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing a hot-plug PCI or PCI-X adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing a hot-swap hard disk drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing memory modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing a microprocessor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installing a hot-swap power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Completing the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installing the server top cover and bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installing the server in the rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cabling the server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 3. Server power, controls, and indicators . . . . . . . . . . . . . . . . . . . . . . . 23

Turning on the server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Turning off the server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Standby mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Server controls and indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operator information panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 4. Configuring the server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Using the Configuration/Setup Utility program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Using the SCSISelect utility program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Using the PXE Boot Agent Utility program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Using the ServerGuide CDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Using the Remote Supervisor Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Using the ServeRAID configuration programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Chapter 5. Solving problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Diagnostic tools overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

POST beep code descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

POST error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

ServerGuide problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Light Path Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Troubleshooting charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Getting information, help, and service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Getting information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Getting help and service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Using the documentation and diagnostic programs: . . . . . . . . . . . . . . . . . . . . 43

Calling for service: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Telephone numbers:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

International Warranty Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Purchasing additional services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Page 4

iv IBM xSeries 360 Type 8686:Installation Guide

Appendix A. Warranty information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Warranty period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Warranty service and support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Before you call for service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Calling for service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

IBM Statement of Limited Warranty Z125-4753-06 8/2000 . . . . . . . . . . . . . . . . . 48

Part 1 - General Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Part 2 - Country-unique Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Appendix B. Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Edition notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Important notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Electronic emission notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Federal Communications Commission (FCC) statement. . . . . . . . . . . . . . . . . . . 59

Industry Canada Class A emission compliance statement . . . . . . . . . . . . . . . . . 59

Australia and New Zealand Class A statement . . . . . . . . . . . . . . . . . . . . . . . . . . 60

United Kingdom telecommunications safety requirement . . . . . . . . . . . . . . . . . . 60

European Union EMC Directive conformance statement. . . . . . . . . . . . . . . . . . . 60

Taiwan electrical emission statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Japanese Voluntary Control Council for Interference (VCCI) statement . . . . . . . 60

Power cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Page 5

© Copyright IBM Corp. 2001 v

Safety

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue tu rvaohjeet kohdasta Saf ety Information.

Avant d'installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí.

Page 6

vi IBM xSeries 360 Type 8686:Installation Guide

Antes de instalar este producto lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

Statement 1:

DANGER

To Connect: To Disconnect:

1. Turn everything OFF.

2. First, attach all cables to devices.

3. Attach signal cables to connectors.

4. Attach power cords to outlet.

5. Turn device ON.

1. Turn everything OFF.

2. First, remove power cords from outlet.

3. Remove signal cables from connectors.

4. Remove all cables from devices.

Electrical current from power, telephone, and communication cables is

hazardous.

To avoid a shock hazard:

• Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an electrical

storm.

• Connect all power cords to a properly wired and grounded electrical

outlet.

• Connect to properly wired outlets any equipment that will be attached

to this product.

• When possible, use one hand only to connect or disconnect signal

cables.

• Never turn on any equipment when there is evidence of fire, water, or

structural damage.

• Disconnect the attached power cords, telecommunications systems,

networks, and modems before you open the device covers, unless

instructed otherwise in the installation and configuration procedures.

• Connect and disconnect cables as described in the follow ing table

when installing, moving, or opening covers on this product or

attached devices.

Page 7

Safety vii

Statement 2:

CAUTION:

When replacing the lithium battery, use only IBM

®

Part Number 33F8354 or an

equivalent type battery recommen d ed by the manufacturer. If your system has

a module containing a lithium battery, replace it only with the same module type

made by the same manufacturer. The battery contains lithium and can explode

if not properly used, handled, or disposed of.

Do not:

• Throw or immerse into water

• Heat to more than 100°C (212°F)

• Repair or disassemble

Dispose of the battery as required by local ordinances or regulations.

Statement 3:

CAUTION:

When laser products (such as CD-ROMs, DVD drives, fiber optic devices, or

transmitters) are installed, note the following:

• Do not remove the covers. Removing the covers of the laser product could

result in exposure to hazar dous laser radiation. There are no serviceable

parts inside the device.

• Use of controls or adjustments or performance of procedures other than

those specified herein might result in hazardous radiation exposure.

DANGER

Some laser products contain an embedded Class 3A or Class 3B laser

diode. Note the following.

Laser radiation when open. Do not stare into the beam, do not view

directly with optical instruments, and avoid direct exposure to the beam.

Class 1 Laser Product

Laser Klasse 1

Laser Klass 1

Luokan 1 Laserlaite

Appareil A Laser de Classe 1

`

Page 8

viii IBM xSeries 360 Type 8686:Installation Guide

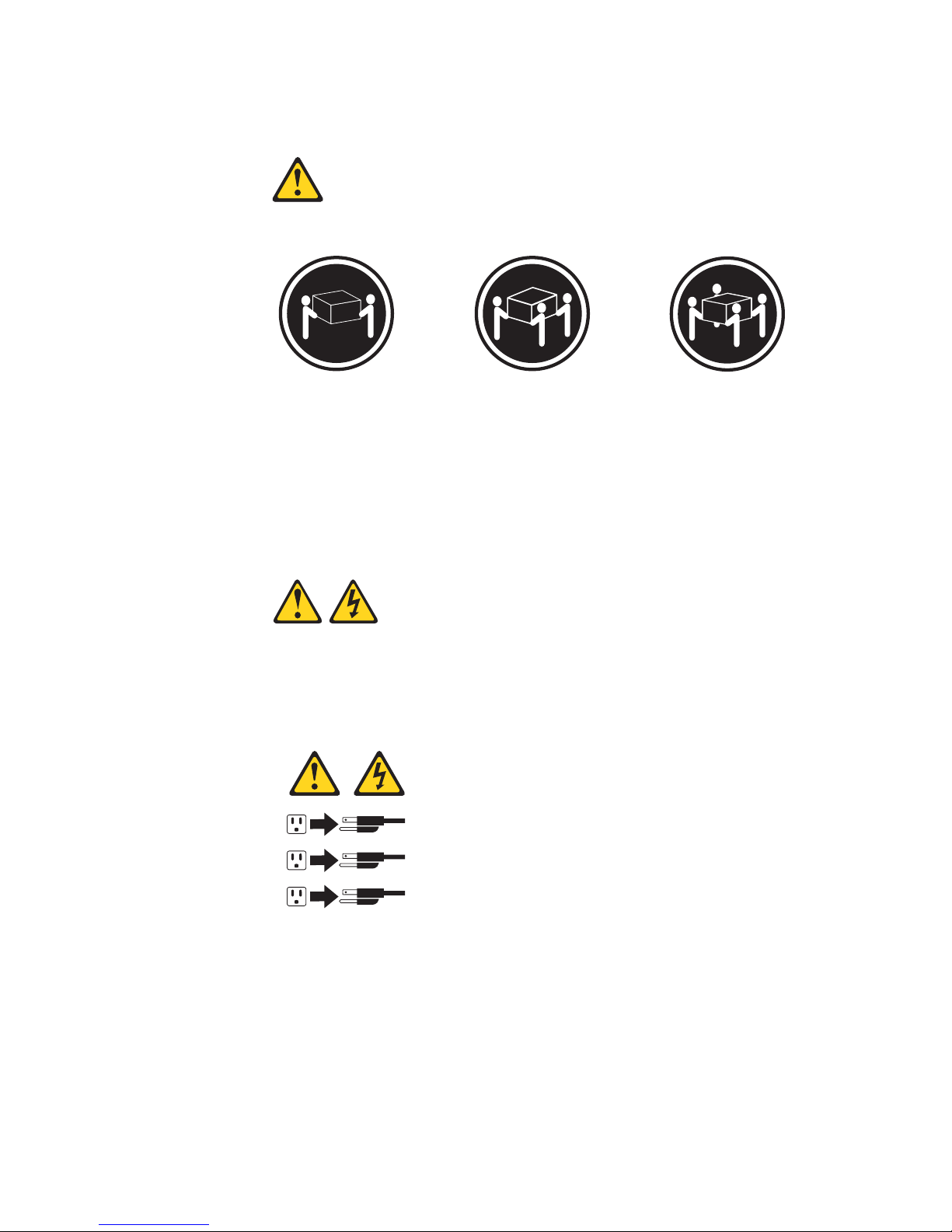

Statement 4:

CAUTION:

Use safe practices when lifting.

Statement 5:

CAUTION:

The power control button on the device and the power switch on the po wer supply do not turn off th e e lect ri cal curre nt su ppl ied t o the device. The device also

might have more than one power cor d. To remove all electrical current from the

device, ensure that all power cords are disconnected from the power source.

≥ 18 kg (39.7 lb) ≥ 32 kg (70.5 lb) ≥ 55 kg (121.2 lb)

1

2

3

Page 9

Safety ix

Statement 8:

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any component that has this label attached. There are no serviceable parts inside these

components. If you suspect a pr oblem with one of these parts, contact a service technician.

Statement 10:

CAUTION:

Do not place any object weighing more than 82 kg (180 lb) on top of rackmounted devices.

>82 kg (180 lb)

Page 10

x IBM xSeries 360 Type 8686:Installation Guide

Page 11

© Copyright IBM Corp. 2001 1

Chapter 1. Introduction

Thank you for pur chasing an IBM Eserver xSeries 360™. This Installation Guide provides the information needed to:

• Set up and cable the server

• Start and configure the server

• Install the network operating system (NOS)

The xSeries 360 server features X-Architecture

™

technology. This technology is an

IBM design blueprint that takes full advantage of existing IBM technologies to build

powerful, scalable, and reliable Intel processor-based servers. For more information

about X-Architecture technology , go to http://www.pc.ibm.com/us/eserver/xseries/xarchitecture/index.html on th e World Wide Web.

Packaged with this Installation Guide are software CDs that help you configure hardware, install device drivers, and install the network operating system (NOS). Also

included is an IBM xSeries 360 Documentation CD, which provides detailed information about this server . F or complete r ac k installation an d remov a l instructions, see t he

Rack Installation Instructions provided with your server.

If you have access to the World Wide Web, you can obtain up-to-date information

about your xSeries 360 server and other IBM server products at

http://www.ibm.com/eserver/xseries/.

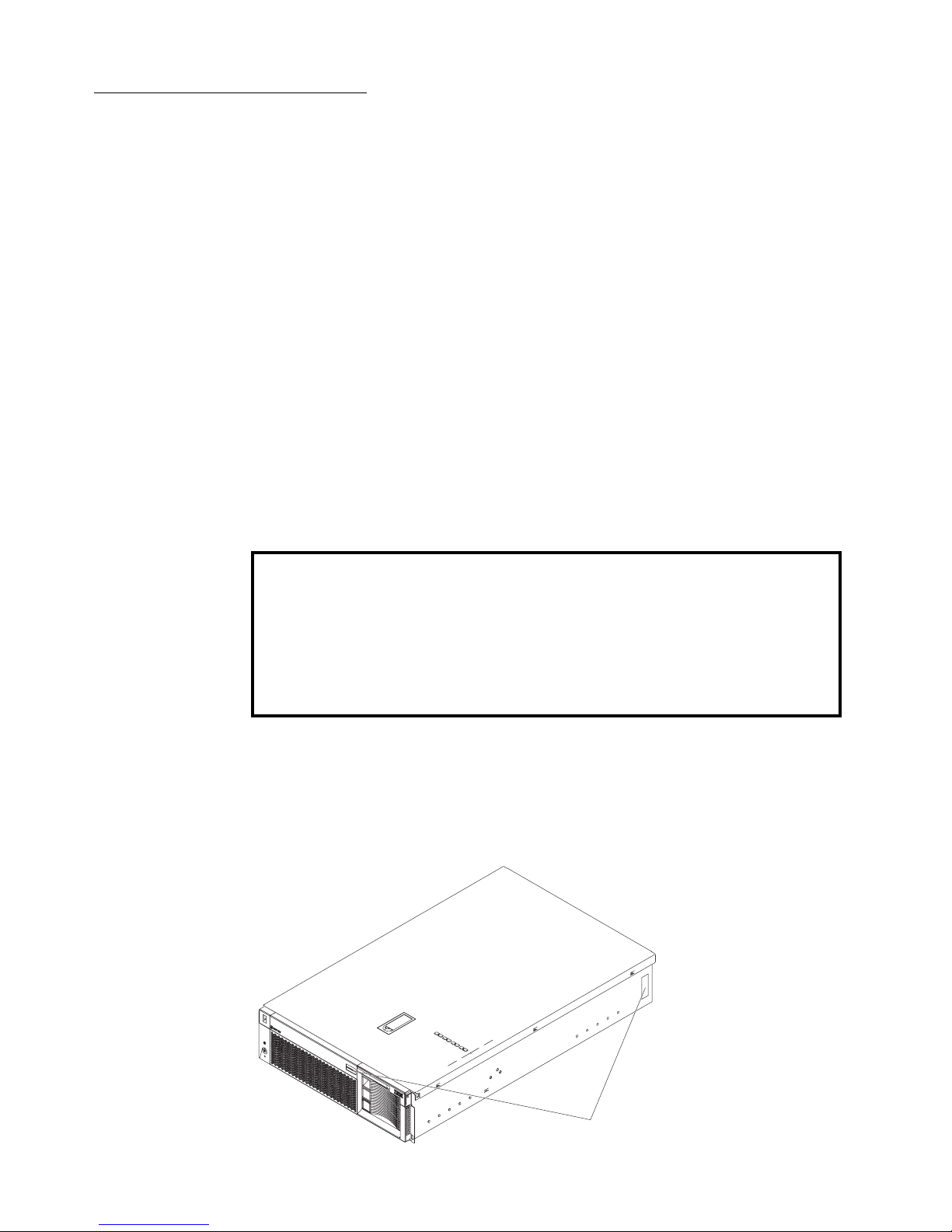

The machine type, model nu mber , and serial number ar e on the ID lab els, one located

on the bezel to the left of the CD- R OM d riv e an d the oth er at th e rear of th e right side ,

as shown in the following illustration. You will need these numbers when you register

your server with IBM.

Note: The illustrations in this document migh t differ slightly from your hardware.

Record your product information in this table.

Product name _________________________________________

Machine type _________________________________________

Model number _________________________________________

Serial number _________________________________________

ID labels

Page 12

2 IBM xSeries 360 Type 8686:Installation Guide

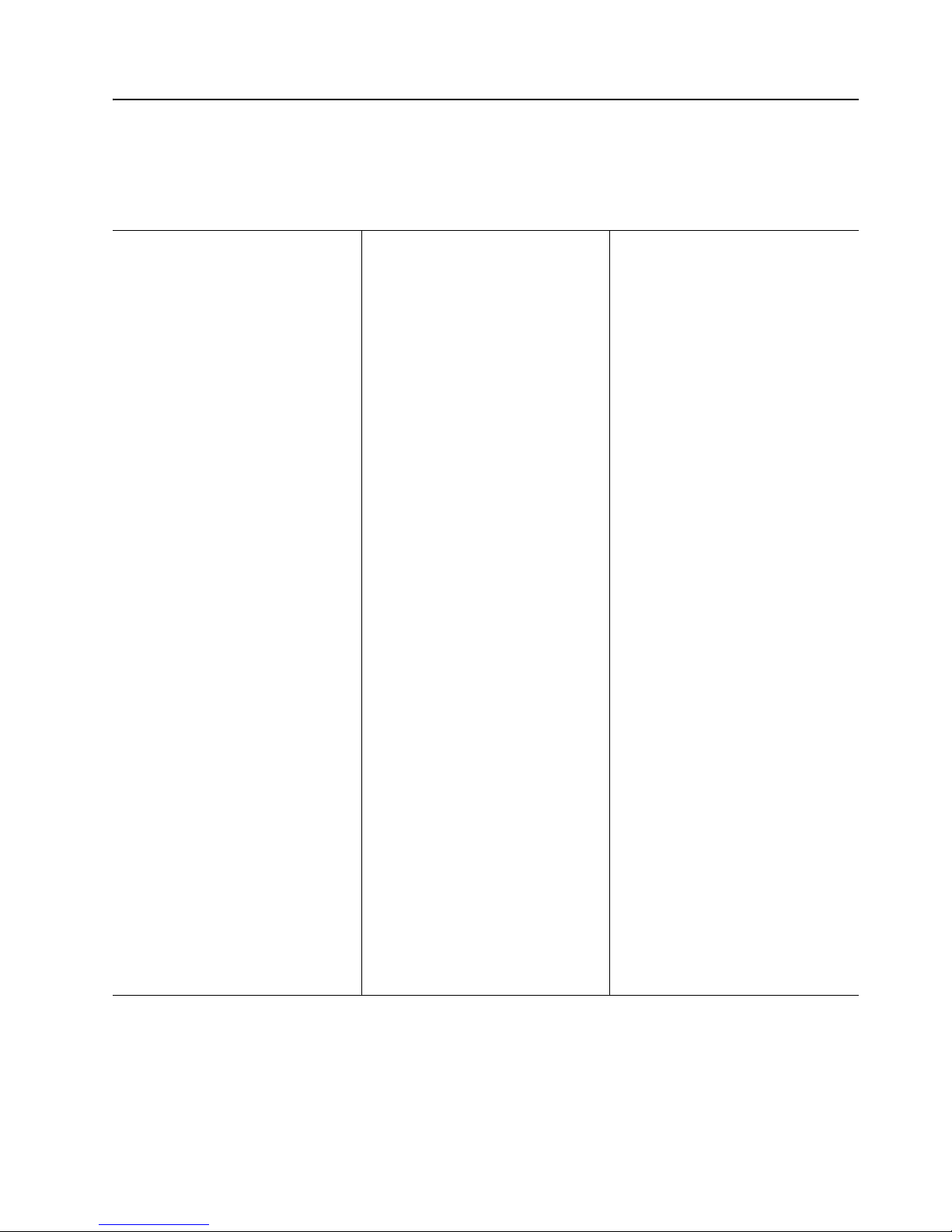

Specifications and features

The following table provides a summary of the specifications and features for the

xSeries 360 server.

Microprocessor:

• Intel Xeon

™

Processor MP

(frequency varies with server

model, each MP processor

functions as two logical

processors)

— Minimum: One

— Maximum: Four

• Level-3 cache size varies with

model

• 100 MHz front-side bus (FSB)

Chipset:

IBM XA-32

™

Chipset with integrated

memory, I/O controller, and remote I/O

controller.

Memory:

• DDR registered SDRAM DIMMs

with ECC and Chipkill

™

memory

— Minimum: 512 MB

— Maximum: 8 GB

• Slots: Interleaved, 8 slots

Drives standard:

• Slim diskette: 1.44 MB

• Slim CD-ROM: 24X-10X IDE

Hard disk drives:

• Slim-high hot-sw ap drives (n umber

of drives and drive capacity vary

with model)

•Maximum: Three

Active™ PCI-X expansion sl o t s:

• Two 100 MHz/64-bit PCI-X

• Four 66 MHz/64-bit PCI-X

Hot-swap power supplies:

370 W (115-230 V ac)

• Minimum: One

•Maximum: Three

Hot-swap cooling:

Six hot-swap fans

Video:

• S3 video controller

• Compatible with SVGA 4

• 8 MB SDRAM video memory

Size (3 U)

• Height: 134 mm (5.28 in.)

• Depth: 720 mm (28.35 in.)

• Width: 440 mm (17.32 in.)

• Weight: 25 kg (55.1 lb) to 31.7 kg

(70 lb) depending upon

configuration

Integrated functions:

• Light Path Diagnosti c s

™

• Ultra160 SCSI controller

• One 10BASE-T/100BASE-TX Intel

Ethernet controller

• Remote Supervisor Adap ter

(service processor)

— ASM in terconnect (peer-to-

peer) port

— RXE expansion port

— RXE management port

— Ethernet port

— Serial por t

• Three universal serial bus ports

• Keyboard port

•Mouse port

•Video port

Acoustical noise emissions:

• Sound power, idling: 6.3 bel

maximum

• Sound power, operating: 6.3 bel

maximum

• Sound pressure, operating: 47 dBa

maximum

Environment:

• Air temperature:

— Server on: 10° to 35°C (50° to

95°F). Altitude: 0 to 914 m

(3000 ft)

— Server on: 10° to 32°C (50° to

89.6°F). Altitude: 914 m (3000

ft) to 2133 m (7000 ft)

— Server off: 10° to 43°C (50° to

110°F). Maximum altitude:

2133 m (7000 ft)

• Humidity:

— Server on: 8% to 80%

— Server off: 8% to 80%

Heat output:

Approximate heat outp ut in British

thermal units (Btu) per hour

• Minimum configuration: 1232 Btu

(0.36 kilowatts)

• Maximum configuration: 3566 Btu

(1.045 kilowatts)

Electrical input:

• Sine-wave input (50-60 Hz)

required

• Input voltage low range:

— Minimum: 100 V ac

— Maximum: 127 V ac

• Input voltage high range:

— Minimum: 200 V ac

— Maximum: 240 V ac

• Input kilovolt-amperes (kVA)

approximately:

— Minimum: 0.08 kVA (ac power

connected, server off)

— Minimum: 0.38 kVA (dc power

on, server idle)

— Maximum: 1.1 kVA

Page 13

Chapter 1. Introduction 3

Notices and statements used in this book

The caution and danger statements used in this book also appear in the multilingual

Safety Information book, provided on the Documentation CD. Each caution and danger statement is numbered for easy reference to the corresponding statements in the

safety book.

The following types of noti ces and statements are used in this book:

• Note: These notices provide important tips, guidance, or advice.

• Important: These notices provide information or advice that might help you avoid

inconvenient or problem situations.

• Attention: These notices indicate possible damage to prog rams, de vices, or data.

An attention notice is placed just before the instruction or situation in which damage could occur.

• Caution: These statements indicate situations that ca n be potentially hazardous

to you. A caution statement is placed just before the description of a potentially

hazardous procedure step or situation.

• Danger: These statements indicate situations that can be potentially lethal or

extremely hazardous to you. A danger statement is placed just before the

description of a potentially lethal or extremely hazardous procedure step or situation.

Before you begin

Before you begin to install options in the server, read the following information:

• Become familiar with the information provided in “Safety” beginning on page v,

and “Handling static-sensitive devices”. These guidelines will help you work

safely while working with your server or options.

• Make sure that you have an adequate number of properly grounded electrical outlets for the server, monitor, and any other options that you intend to install.

• Back up all important data before you make changes to hard disk drives.

• For a list of supported options for the xSeries 360 server, refer to

http://www.ibm.com/pc/us/compat on the World Wide Web.

Handling static-sensitive devices

Attention: Static electricity can damage electronic devices and the system. To avoid

damage, keep static-sensitive devices in their static-protective packages until you are

ready to install them.

To reduce the possibility of electrostatic discharge, observe the following precautions:

• Limit your movement. Movement can cause static electricity to build up around

you.

• Handle the device carefully, holding it by its edges or its frame.

• Do not touch solder joints, pins, or exposed printed circuitry.

• Do not leave the de vice wh ere others can handle and possib ly damage the device.

• While the device is still in its static-protective package, touch it to an unpainted

metal part of the system unit for at least 2 seconds. (This drains static electricity

from the package and fro m your body.)

Page 14

4 IBM xSeries 360 Type 8686:Installation Guide

• Remove the device from its package and install it directly into the server without

setting it down. If it is necessary to set the device down, put it back in its staticprotective pac kage first. Do not pla ce the de vice on the server co ve r or on a metal

table.

• Take additional care when handling devices during cold weather as heating

reduces indoor humidity and increases static electricity.

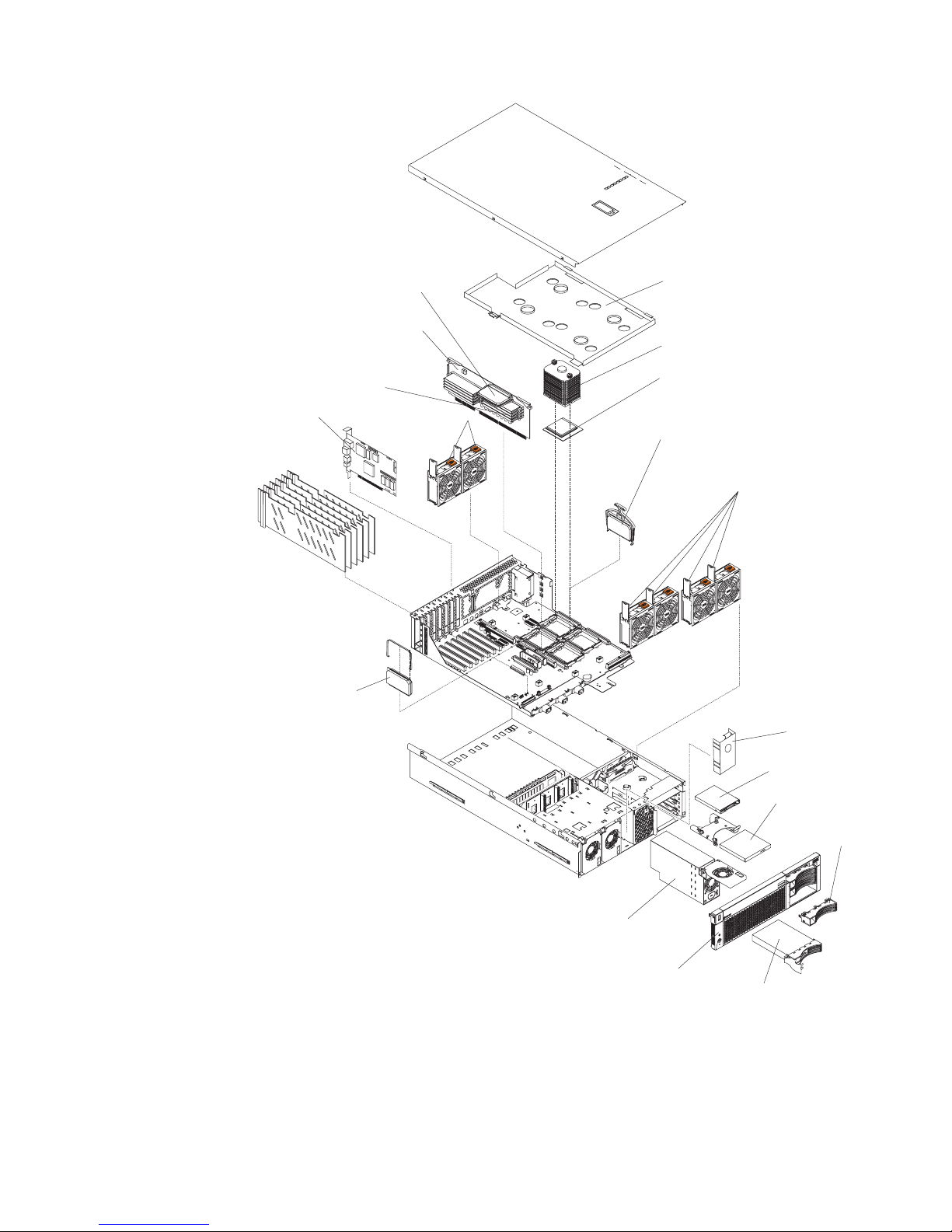

Major components of the xSeries 360

The orange color on components and labels in the server identifies hot-swap or hotplug components. You can install or remove these components while the system is

running, provided that the system is configured to support this function.

The blue color on components and labels indicates touch points where a component

can be gripped, a latch moved, and so on.

The following illustration shows the major components of the xSeries 360.

Note: The illustrations in this document migh t differ slightly from your hardware.

Page 15

Chapter 1. Introduction 5

Microprocessor heat sink

Heat sink stabilizer

Microprocessor

Microprocessor VRM

Hot-swap fans

Hot-swap fans

Hot-swap power supply

Power supply

filler panel

Bezel

Hot-swap hard drive

Hot-swap drive

filler panel

Memory board

Memory board

VRM

Dual inline

memory module

(DIMM)

Remote

Supervisor

Adapter

XA-32

chipset VRM

Diskette drive

CD-ROM drive

Page 16

6 IBM xSeries 360 Type 8686:Installation Guide

Page 17

© Copyright IBM Corp. 2001 7

Chapter 2. Installing options

This chapter provides the basic inf ormation needed to install options in the server . It is

for all users, but is written with the experienced user in mind. If you need more

detailed installation information, see the User’s Reference on the xSeries 360 Docu-

mentation CD.

Attention: When you handle Electrostatic Discharge-Sensitive devices (ESD), take

precautions to avoid damage from static electricity. For details on handling these

devices, see “Handling static-sensitive devices” on page 3.

Working inside a server with power on

The server supports hot-plug, hot-add, and hot-swap de vices an d is de signe d to ope rate safely while turned on with the cover removed. Follow these guidelines when you

work inside a server that is turned on:

Note: Operating the server for more than 30 minutes with the top cover removed

might damage server components.

• Avoid loose-fitting clothing on your forearms. Button long-sleeved shirts before

working inside the server; do not wear cufflinks while you are working inside the

server.

• Do not allow your necktie or scarf to hang inside the server.

• Remove jewelry, such as bracelets, necklaces, rings, and loose-fitting wrist

watches.

• Remove items from your shirt pocket (such as pens or pencils) that could fall into

the server as you lean over it.

• Take care to avoid dropping any metallic objects, such as paper clips, hair pins , or

screws, into the server.

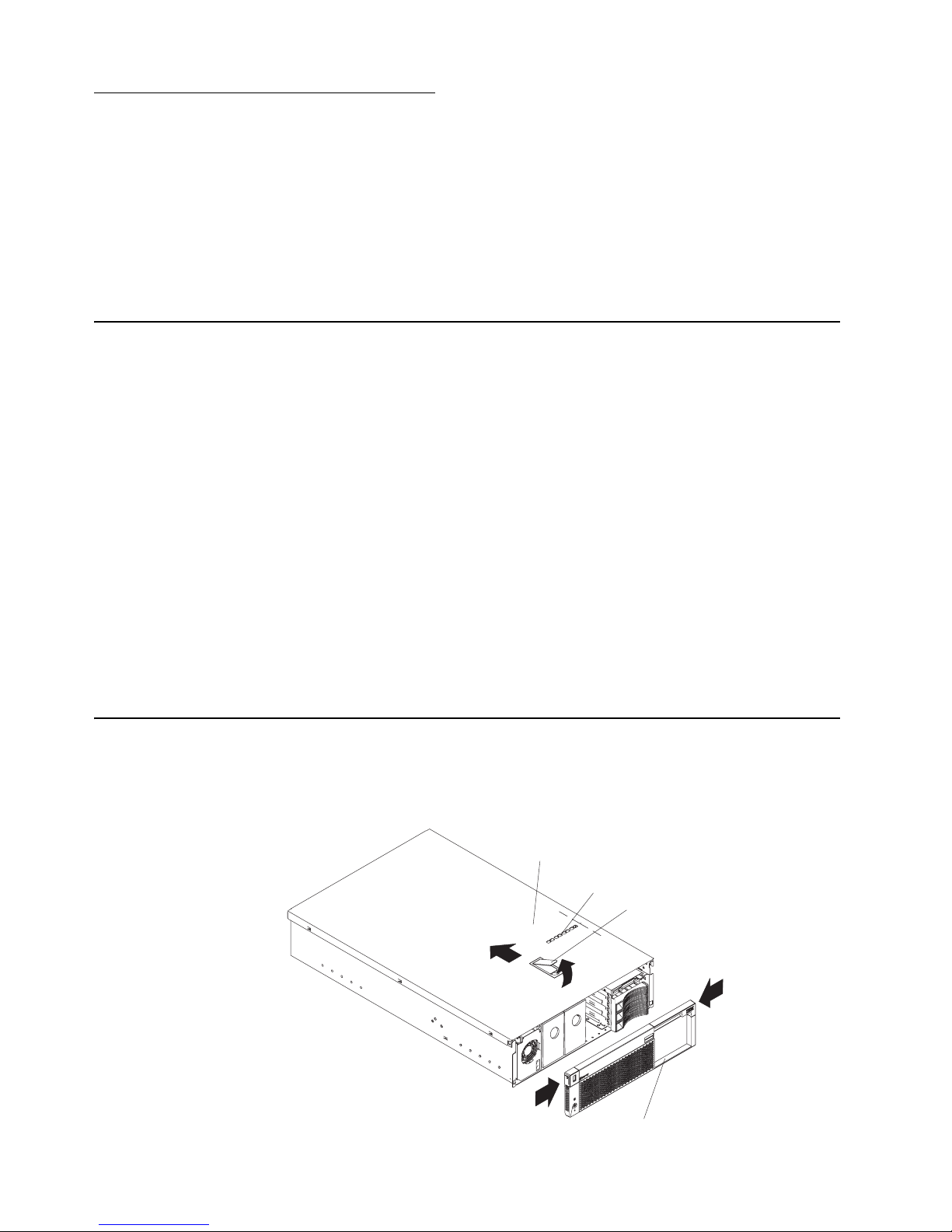

Removing the server top cover and bezel

Complete the following steps to remove the server top cover and bezel:

1. Review the safety precautions beginning on page v.

Top cover

Cover release latch

Bezel

Level 2 diagnostic panel

Page 18

8 IBM xSeries 360 Type 8686:Installation Guide

2. Lift the plastic cover-release latch on the top cover, as shown in the illustration.

Slide the top cover toward the rear of the server approximately one inch, lift it off

the server, and set it aside.

Attention: For proper cooling and airflow, replace the top cover before turning

on the server . Operating the server f or e xtended periods of t ime (ov er 30 minutes)

with the top cover removed might damage server components.

3. Press the bezel release latches and pull the top of the be zel slightly a w a y from the

server.

4. Pull the bezel up to release the two tabs at the bottom edg e of the bezel. Store

the bezel in a safe place.

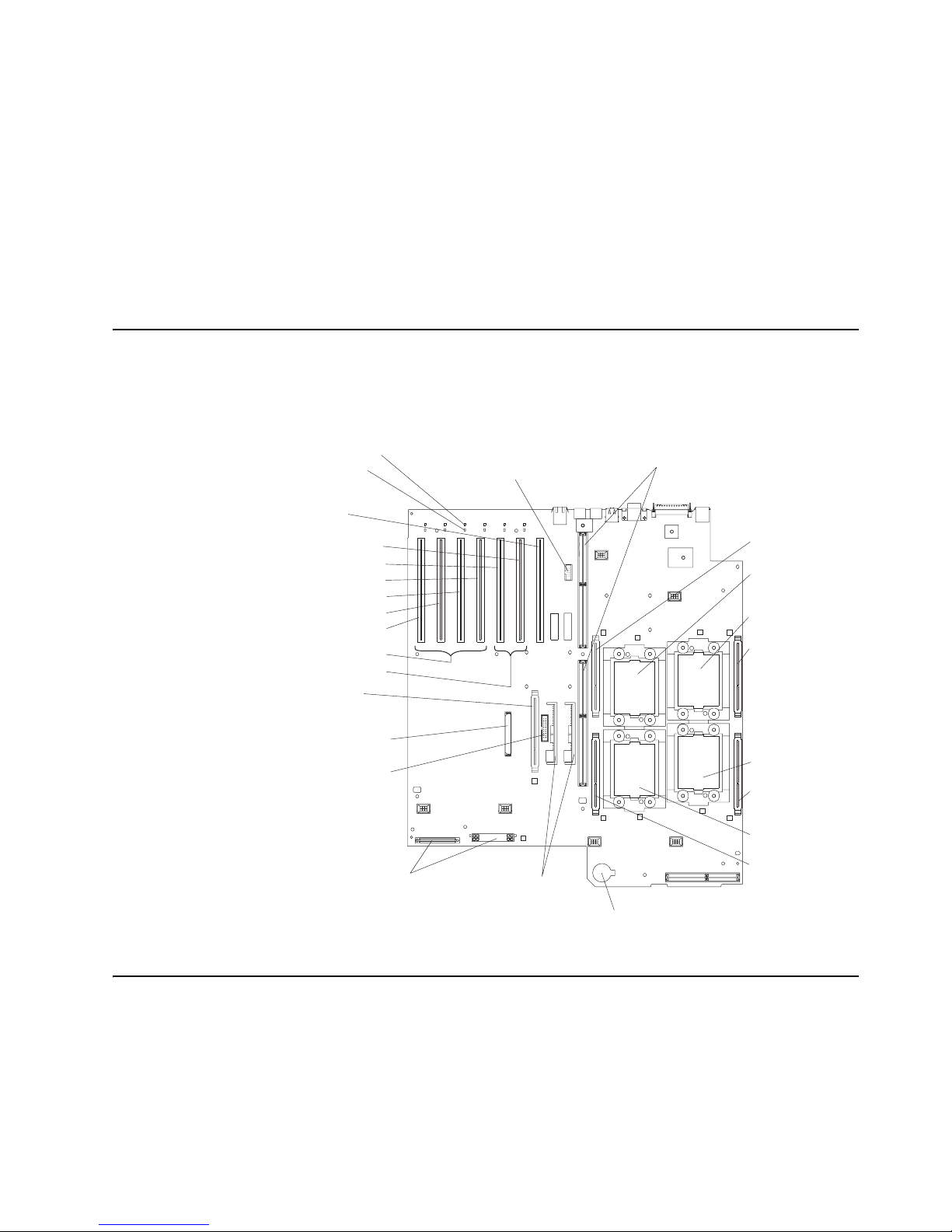

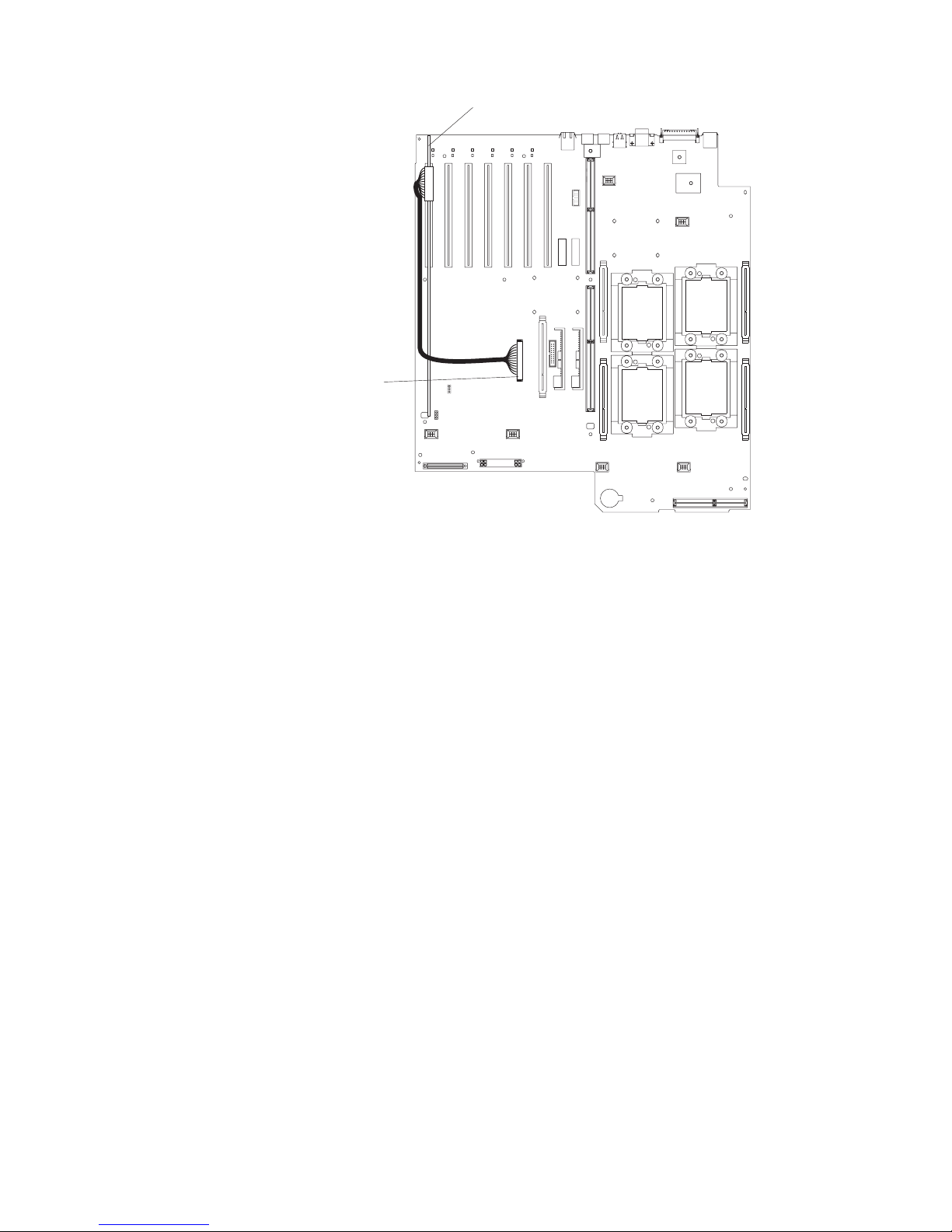

System board component locations

The following illustration sho ws the location of the connectors on the system board f or

pluggable components, and the location of the two nonpluggable VRMs used for the

PCI-X slots.

Adapter considerations

This server supports the following adapter configurations:

• Bus A (hot-plug)

— Four 66 MHz 64-bit PCI-X adapters (slots 3 through 6)

— Two 66 MHz 64-bit PCI adapters (slots 3 and 4)

— Four 33 MHz 64-bit PCI adapters (slots 3 through 6)

Microprocessor 4

VRM slot (J29)

Microprocessor 1

VRM slot (J2)

Microprocessor 3

VRM slot (J3)

Microprocessor 2

VRM slot (J30)

Microprocessor 4

socket (U22)

Microprocessor 1

socket (U11)

Microprocessor 3

socket (U12)

Microprocessor 2

socket (U23)

PCI-X slot 1

PCI-X slot 2

PCI-X slot 3

PCI-X slot 4

PCI-X slot 5

PCI-X slot 6

Remote

Supervisor

Adapter slot

(J40)

Remote Supervisor

Adapter cable

connector (J39)

XA-32 chipset

VRM slot (J41)

SCSI RAID cable

connector (J43)

Battery

Power distribution

connectors (J55, J49)

NonpluggableVRMs

PCI switch card cable

connector (J36)

Memory board connectors (J-32, J-33)

Bus A

Bus B

PCI power LED

PCI attention LED

Page 19

Chapter 2. Installing options 9

• Bus B (hot-plug)

— One 133 MHz 64-bit PCI-X adapter (slot 1)

— Two 100 MHz 64-bit PCI-X adapters (slots 1 and 2)

— Two 66 MHz 64-bit PCI-X adapters (slots 1 and 2)

— Two 66 MHz 64-bit PCI adapters (slots 1 and 2)

— Two 33 MHz 64-bit PCI adapters (slots 1 and 2)

To the right of PCI-X slot number 1 (as viewed from the front), th ere is a 33 MHz 64-bit

slot dedicated to the Remote Supervisor Adapter.

Before you install adapters, review the following:

• Locate the documentation that comes with the adapter and follow those instructions in addition to the instructions in this chapter. If you need to change switch

settings or jumper settings on the adapter, follow the instructions that come with

the adapter.

• Locate the documentation that comes with y our operati ng system. If the oper ating

system provides a way to disable or enable a hot-plug PCI/PCI-X slot, you will

need this documentation.

• If you install a ServeRAID

™

™ adapter for use with the in ternal hot-swap hard disk

drives, you must connect the internal channel cable between the adapter and the

SCSI RAID cable connector (J43) on the syste m board. However, if you do this,

you cannot install a full-length, wide adapter in PCI-X slot 1.

• The server supports only 3.3 V PCI or PCI-X adapters.

• The server uses a rotational interrupt tech nique to configu re PCI/PCI-X adap ters .

You can use this technique to install PCI/PCI-X adapter s that current ly do not support sharing of PCI interrupts.

• PCI-X slots 3 through 6 are on PCI bus A; PCI-X slots 1 and 2 are on PCI bus B.

• By default, the server st arts (boots) devices in the f ollowing or der: system IDE and

SCSI devices, then PCI/PCI-X devices.

Note: To change the startup order, start the Configuration/Setup Utility program

and select Start Options from the main menu. Then, select the Startup

Sequence Options.

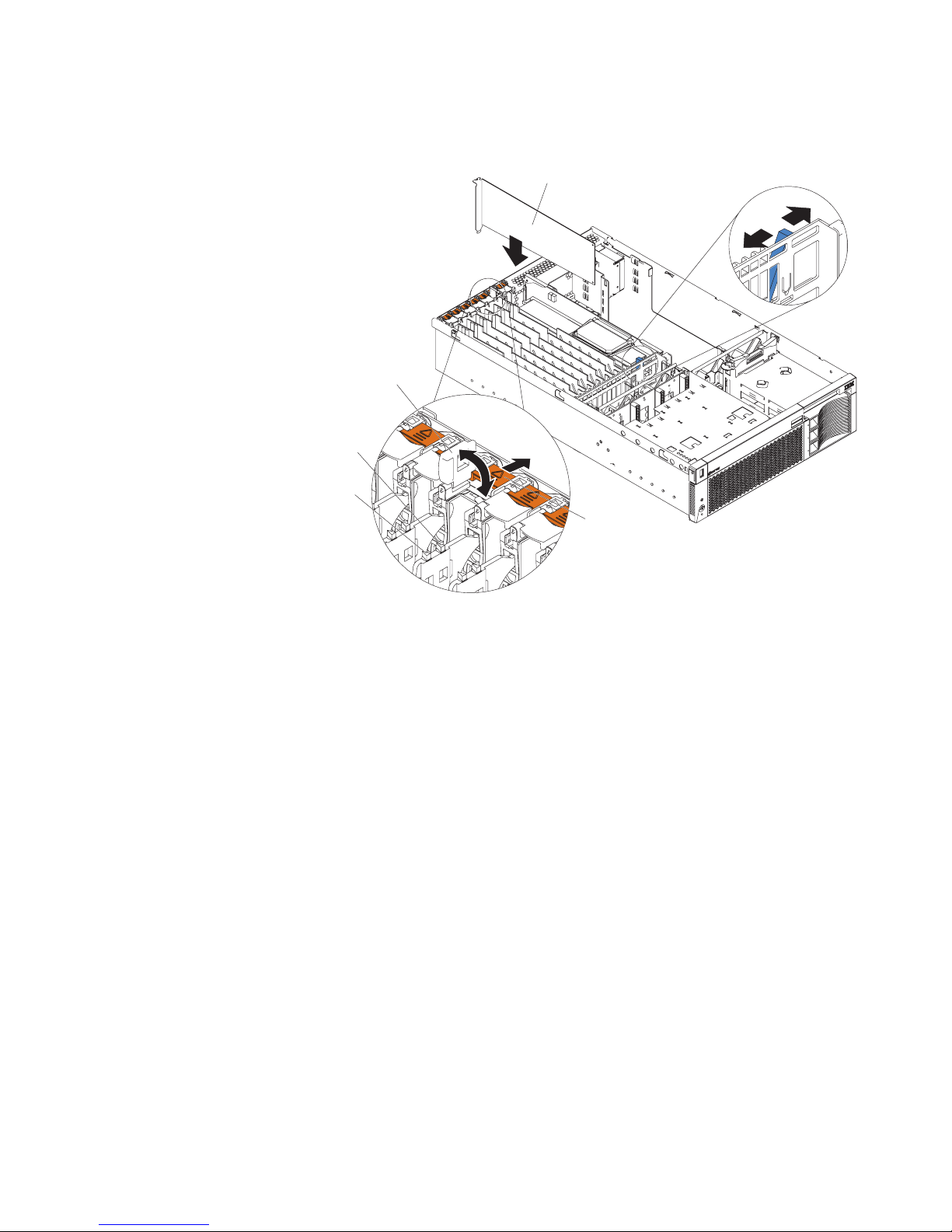

Installing a hot-plug PCI or PCI-X adapter

This section describes how to install a hot-plug PCI/PCI-X adapter. Before you continue with the adapter-installation procedure, note that all six PCI-X slots support hotplug, 64-bit, PCI/PCI-X adapters. If PCI/PCI-X adapter s are installed in both slots 1

and 2, they operate at 100 MHz or less, depending on the capacity of the adapter. If

one adapter is installed in slot 1 and slot 2 is empty, the adapter in slot 1 can operate

at 133 MHz.

Note: Ensure that the PCI hot-plug de vice driv er is installed. For details, see the doc-

umentation that came with the adapter. For more detailed instructions and

information about installing PCI/PCI-X adapters, see the section on installing

options in the User’s Reference on the xSeries 360 Documentation CD.

Complete the following steps to install a hot-plug PCI/PCI-X adapter:

1. Review the safe ty precautio ns beginning o n page v a nd “Ha ndlin g st at ic-sensitive

devices” on page 3.

Page 20

10 IBM xSeries 360 Type 8686:Installation Guide

2. Remove the top cov er (see “Rem oving th e server top co v er and bez el” on page 7)

and determine which PCI-X expansion slot you will use for the adapter.

Note: All six PCI-X slots support hot-plug PCI/PCI-X adapters.

3. Slide the orange adapter-retention tab toward the rear of the server. Lift the

adapter-retention latch. The power LED turns off for the appropriate slot.

4. Slide the expansion-slot cover up and out of the server; then, move the blue PCIadapter locking lever to the right (as viewed from the front) to enable insertion of

the new adapter.

Attention: Avoid touching the components and gold-edge connectors on the

adapter. Ensure that the adapter is completely and correctly seated in the slot.

Incomplete insertion might cause damage to the system board or to the adapter.

Attention: When you handle Electrostatic Discharge-Sensitive devices (ESD),

take precautions to avoid damage from static electricity. For details on handling

these devices, see “Handling static-sensitive devices” on page 3.

5. Remove the adapter from the static-protective package and install the adapter,

pressing it firmly into the slot.

6. Move the blue PCI-adapter locking lever to the left (as viewed from the front) to

secure the adapter; then, lower the adapter-retention latch over the top corner of

the adapter. The orange adapter-retention tab snaps into place and the power

LED turns on for the slot.

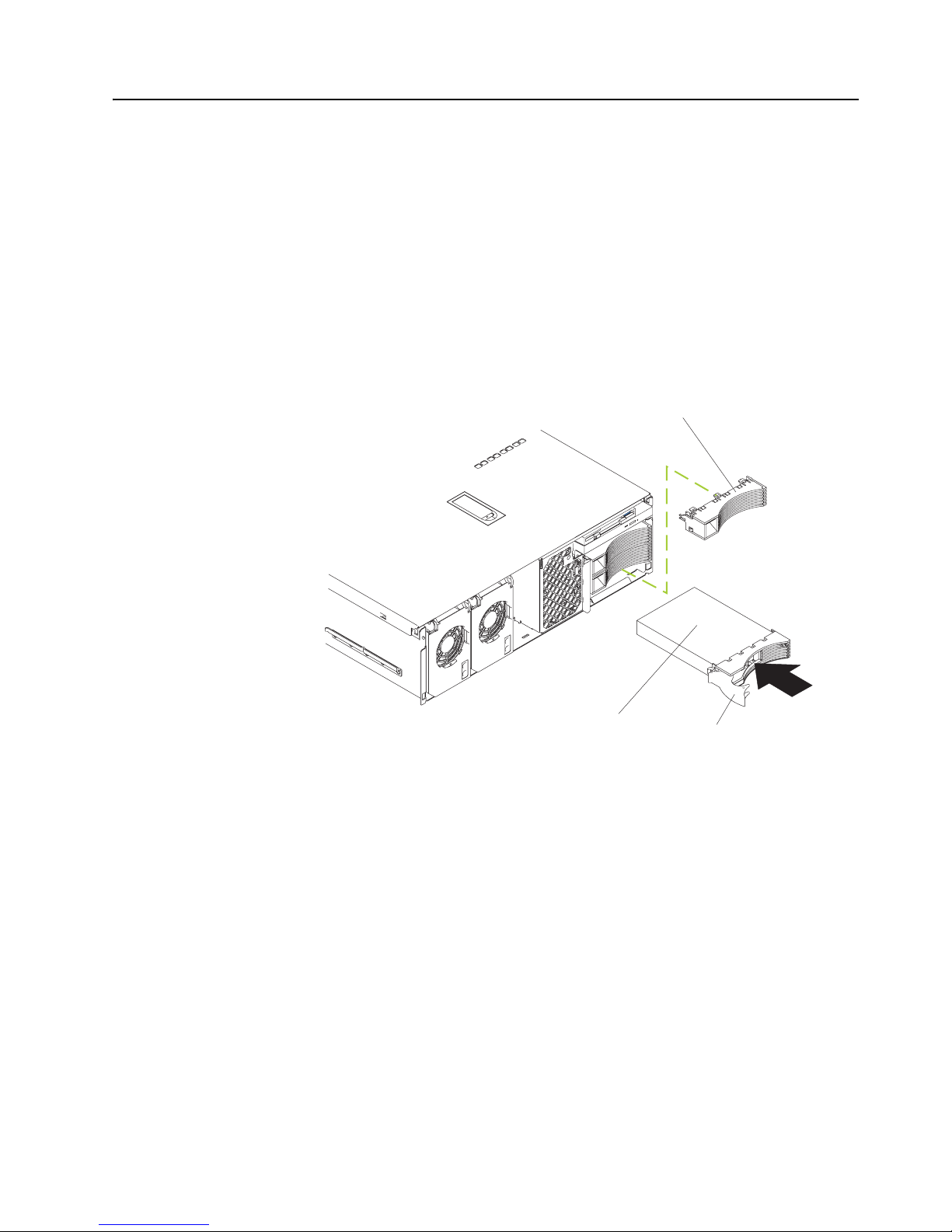

7. Connect any needed cables to the adapter. If you are installing a ServeRAID

adapter, continue with step 8. Otherwise, go t o step 12.

8. If you are installing a ServeRAID adapter and plan to use internal hard disk drives:

a. Plug in one end of the ServeRAID internal channel cable (shipped with the

server) to an internal ServeRAID channel connector on the top edge of the

ServeRAID adapter, as shown in the following illustration. You can install the

adapter in any PCI-X slot. It is shown in slot 6 here only as an example.

Unlock

Lock

Adapter locking lever

Adapter

retention

latch

Adapter

retention

tab

Adapter

Attention

LED

Power

LED

Page 21

Chapter 2. Installing options 11

b. Route the cable along the surface of the system board toward the front of the

server, then to the right under the adapters and dividers; then plug it into the

SCSI RAID cable connector (J43) on the system board.

Notes:

1) You cannot install a full-length, wide adapter in PCI-X slot 1 if the SCSI

RAID adapter cable connector is in use.

2) You might need to remo v e adapters o r plastic dividers to access the SCSI

RAID adapter cable connector.

3) The first time that you restart the server after connecting the cable, the

server issues POST error message 00180700 with modifier 9005008F;

this message is normal. It indicates that the onboard SCSI controller has

been disabled and that the RAID adapter is controlling the internal hard

disk drives.

9. If you are installing a ServeRAID adapter and plan to use external hard disk

drives:

a. Plug in one end of the ServeRAID external channel cable (separately ord er-

able) to an ex ternal channel connector on the edge of t he ServeRAID adapter

that is accessible from the rear of the server.

b. Route the cable to the external SCSI device and plug it into the appropriate

connector.

10. Install the latest ServeRAID drivers, using the ServerGuide

™

™ CDs.

11. Configure ServeRAID, using the ServeRAID adapter documentation on the

xSeries 360 Documentation CD.

12. If you have other options to install or remove, do so now; otherwise, go to “Completing the installation” on page 19.

ServeRAID adapter

SCSI RAID

cable connector

Page 22

12 IBM xSeries 360 Type 8686:Installation Guide

Installing a hot-swap hard disk drive

The server supports up to three 26 mm (1-inch), 3.5-inch, hot-sw ap hard disk driv es in

the hot-swa p ba ys . The ba ys are locate d at the right front of the server. The hot-swap

bays are connected to a hot- swap drive backplane. The backplan e i s a printed circuit

board behind the bays.

Complete the following steps to install a drive in a hot-swap bay:

1. Review the safety precautions beginning on page v.

2. Remove the filler panel from one of the empty hot-swap bays by inserting your finger into the depression at the left side of the filler panel and pulling the panel out

of the server, as shown in the following illustration.

Attention: To maintain proper system cooling, do not operate the server for

more than 10 minutes without either a drive or filler panel installed in each bay.

3. Install the hard disk drive in the hot-swap bay:

a. Ensure that the tray handle is open (that is, perpendicular to the drive).

b. Align the drive assembly with the guide rails in the bay.

c. Gently push the drive assembly into the bay until the drive stops.

d. Push the tray handle to the closed (locked) position.

e. Check the hard disk drive status LED to verify that the hard disk drive is oper-

ating properly. If the amber hard disk drive status LED for a drive is lit continuously, that individual drive is faulty and needs to be replaced. If the green

hard disk drive activity LED is flashing, the drive is being accessed.

4. If you have other options to install or remove, do so now; otherwise, go to “Completing the installation” on page 19.

Note: If the server has a ServeRAID controller or adapter installed, you might

need to reconfigure the disk arrays after installing hard disk drives. See

the ServeRAID documentation on the xSeries 360 Documentation CD for

more information.

Filler panel

Drive tray handle

(in open position)

Drive tray

assembly

Page 23

Chapter 2. Installing options 13

Installing memory modules

The server supports up to four pairs of DIMMs and supports memory interleaving.

Adding memory to the server is an easy way to ma ke programs run faster.

Notes:

1. The server supports a minimum of 512 MB of system memory and a maximum of

8 GB of system memory. The DIMM slots are arranged in two columns of four

rows each. The server supports DIMMs of 256 MB , 512 MB, and 1 GB capacities.

2. Each pair of DIMMs must be the same type, capacity, and speed. However, you

can install DIMM pairs of different capacities as long as both DIMMs in each pair

are the same.

3. Installing or removing DIMMs changes the configuration information in the server.

Therefore, after installing or removing DIMMs, you must save the ne w configuration information using the Configuration/Setup Utility program. When you restart

the server, the system displays a message indicating that the memory configuration has changed. Start the Configuration/Setup Utility program and select Save

Settings. See Chapter 4, “Configuring th e server” on page 29 for more information.

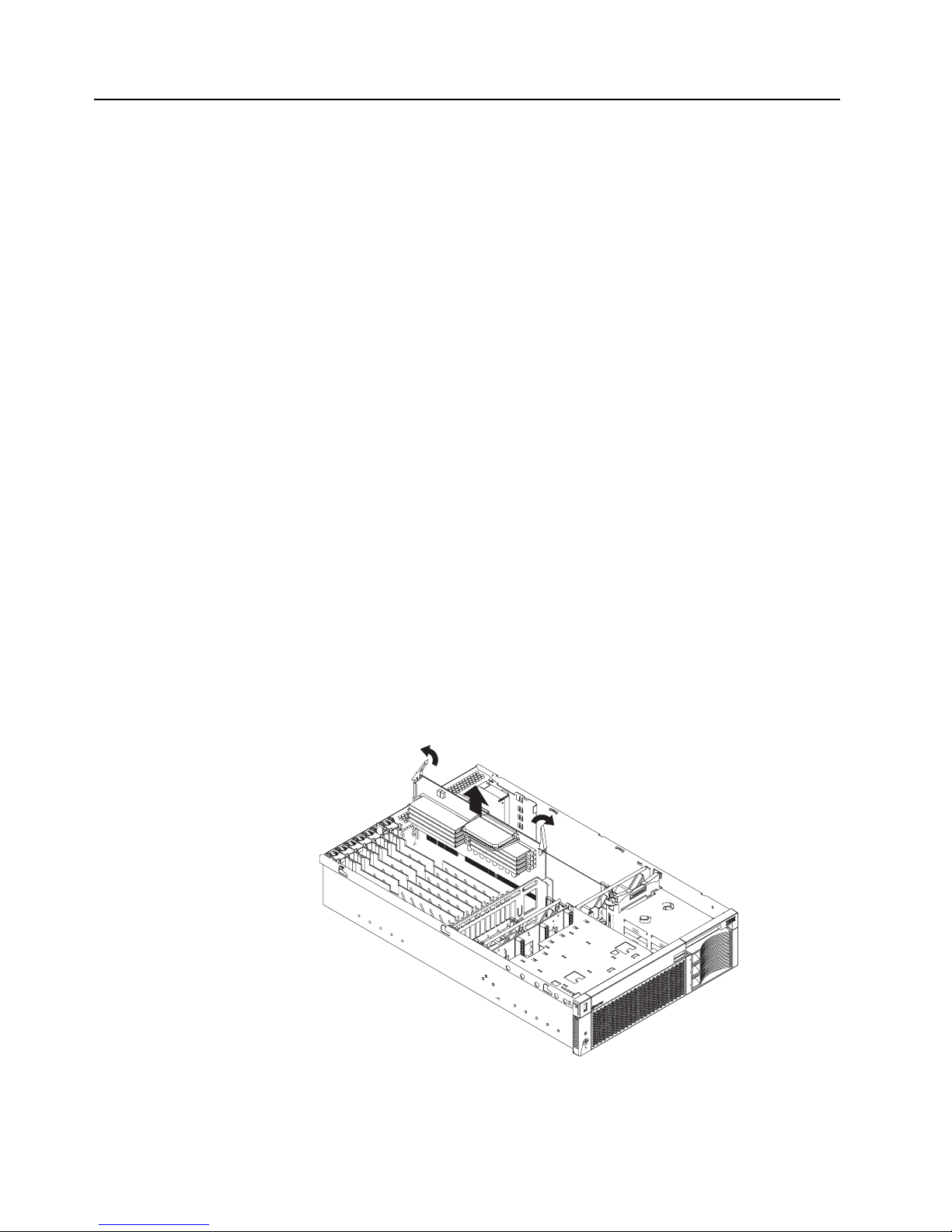

Complete the following steps to install DIMMs:

1. Review the safety precautions beginning on page v, “Handling static-sensitive

devices” on page 3, and the documentation that comes with the DIMMs.

2. Turn off the server, disconnect all power cords and external cables, and remove

the top cover (see “Removing the server top cover and bezel” on page 7).

3. Remove the memory board, as shown in the following illustration:

Attention: When you handle Electrostatic Discharge-Sensitive devices (ESD),

take precautions to avoid damage from static electricity. For details on handling

these devices, see “Handling static-sensitive devices” on page 3.

a. Lift up the two memory-board locking latches to release the board.

b. Lift the memory board out of the server.

4. When installing additional DIMMs, determine the DIMM slots into which you will

install them. You must populate the slots in pairs, one DIMM in each column, proceeding from top to bottom. Use only 2.5 V, 184-pin, PC1600, DDR registered

Page 24

14 IBM xSeries 360 Type 8686:Installation Guide

synchronous dynamic random-access memory (SDRAM) with error correcting

code (ECC).

5. Touch the static-protective package that contains the DIMM option to any

unpainted metal surface on the server. Then, remove the DIMM from the package.

6. Turn the DIMM so that the DIMM keys align correctly with the slot.

Attention: To avoid breaking the DIMM locking latches or damaging the DIMM

slots, handle the latches gently.

7. Ensure that the DIMM locking latches are in the open position. Insert the DIMM

by pressing it straight into the slot. Make sure that the locking latches snap into

the closed position. If a gap exists between the DIMM and the latches, the DIMM

has not been properly installed. In this case, open the latches , remo v e the DIMM,

and reinsert it.

First pair DIMMs 1 and 2

Second pair DIMMs 3 and 4

Third pair DIMMs 5 and 6

Fourth pair DIMMs 7 and 8

DIMM 1

DIMM 3

DIMM 4

DIMM 2

DIMM slot 3

DIMM slot 4

Memory VRM

Test button

Test LED to show

capacitor is charged

Memory board VRM slot (J11)

DIMM 1 (J14)

DIMM 3 (J13)

DIMM 5 (J12)

DIMM 7 (J4)

DIMM 2 (J15)

DIMM 4 (J9)

DIMM 6 (J7)

DIMM 8 (J5)

Test buttonTest LED to show

capacitor is charged

Page 25

Chapter 2. Installing options 15

8. Repeat steps 3 through 7 for each additional DIMM that you install.

9. Install the memory board:

a. Align the board in the guides over the memory connector.

b. Open the memory-board locking latches and insert the memory board into the

connector. Be sure that the locking latches snap into the closed position.

10. If you have other options to install or remove, do so now; otherwise, go to “Completing the installation” on page 19.

Attention: When you restart the server, the system displays a message indicating

that the memory configuration has changed.

• If you installed additional memory, start the Configuration/Setup Utility program

and select Save Settings.

• If the 3-3-3 beep code sounds during POST, the memory board may not be fully

seated. In some memory configurations, if the 3-3-3 beep code is followed by a

blank display screen and the Boot Fail Count feature in the Start Options of the

Configuration/Setup Utility is set to Enabled (its default setting), you must restart

the server three times to f orc e the syste m BIOS to reset t he memory connector or

bank of connectors from Disabled to Enabled.

Installing a microprocessor

The server comes with a minimum of one microprocessor installed on the system

board and supports up to four microprocessors. With mor e tha n one micropro ce sso r,

the server can operate as a symmetric multiprocessing (SMP) server. With SMP, certain operating systems and application programs can distribute the processing load

among the microprocessors.

Before you begin:

• Read the documentation that comes with the microprocessor to determine if you

need to update the server basic input/output system (BIOS) code. The most current level of BIOS code for the server is available through the World Wide Web at

http://www.ibm.com/pc/support.

• Obtain an SMP-capable operating system (optional). For a list of supported operating systems, go to http://www.ibm.com/pc/us/compat/ on the World Wide Web.

Attention: To avoid damage and ensure proper server operation when you install a

microprocessor, use a microprocessor that has the same cache size and type, clock

speed, and internal and external clock frequencies as the microprocessor already

installed.

Notes:

1. To order additional microprocessor options, contact your IBM reseller or IBM marketing representative.

2. The microprocessor in socket 1 is the startup (boot) microprocessor.

If you want to install addit ional micro processors , populate the micr oprocessor sockets

in numeric order, starting with socket 2. The following illustration shows the locations

of the microprocessor sockets and VRMs on the system board.

Note: If you install the microprocessors in the wrong order, the server will not power

on.

Page 26

16 IBM xSeries 360 Type 8686:Installation Guide

Complete the following steps to install a microprocessor:

1. Review the safe ty precautio ns beginning o n page v and “Ha ndling st atic-sen sit ive

devices” on page 3.

2. Turn off the server, disconnect all power cords and external cables, and remove

the top cover (see “Removing the server top cover and bezel” on page 7).

Attention: When you handle Electrostatic Discharge-Sensitive devices (ESD), take

precautions to avoid damage from static electricity. For details on handling these

devices, see “Handling static-sensitive devices” on page 3.

3. Lift off the microprocessor heat sink stabilizer as shown in the following illustration

and determine the socket where the microprocessor is to be installed.

Microprocessor

connector 1 (U11)

Microprocessor

connector 2 (U23)

Microprocessor

connector 3 (U12)

Microprocessor

connector 4 (U22)

Microprocessor 4

VRM connector

(J29)

Microprocessor 2

VRM connector

(J30)

Microprocessor 1

VRM connector

(J2)

Microprocessor 3

VRM connector

(J3)

Page 27

Chapter 2. Installing options 17

Notes:

a. The new microprocessor comes in a kit with a VRM and a heat sink.

b. If you are replacing a failed micropr ocessor, verify that you have selected the

correct microprocessor to be replaced. The LED next to the failing microprocessor will be on. Remove the microprocessor heat sink (two thumbscrews).

c. If you are installing an additional microprocessor, first install a VRM in the slot

adjacent to the microprocessor socket you have selected and r emove the protective tape from the microprocessor socket.

4. Install the microprocessor:

a. T o uch the static-protectiv e pac kage contain ing the ne w microprocessor to an y

unpainted metal surf ace on the server; then, remove the microprocessor from

the package.

b. Lift the locking lever on the socket to permit plugging in the microprocessor.

c. Align the triangle icon on the microproces so r wi th the triangle icon on the

socket and press the mi croprocessor gently into the socket.

Attention: Make sure that the microp rocessor is aligned correct ly befor e you

proceed. To avoid bending the pins on the microprocessor, do not use exces-

sive force when pressing it into the socket.

d. Close the locking lever to secure the microprocessor.

5. Install the microprocessor heat sink.

Attention: Do not disturb or contaminate th e h eat- co nductin g grease on the bot-

tom of the new heat sink. Doing so damages its heat-conducting capability and

exposes the new micr oprocessor to overheating.

Microprocessor

Microprocessor

VRM

XA-32

chipset VRM

Heat sink

Heat sink stabilizer

Page 28

18 IBM xSeries 360 Type 8686:Installation Guide

6. Remove the heat sink from its package and secure it to the top of the micropr ocessor (two thumbscrews). Press firmly on the thumbscrews and tighten them,

alternating between screws until finger tight. Do not overtighten the screws.

7. Install the heat-sink stabilizer.

8. If you have other options to install or remove, do so now; otherwise, go to “Completing the installation” on page 19.

Installing a hot-swap power supply

The server comes with a minimum of one power supply and supports up to three

power supplies. If you install or remove a power supply, observe the following precautions.

Statement 8:

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any component that has this label attached. There are no serviceable parts inside these

components. If you suspect a problem with one of these parts, contact a service technician.

Complete the following steps to install a hot-swap power supply:

1. Review the safety precautions beginning on page v.

2. Remove the bezel. See “Removing the server top cover and bezel” on page 7.

3. Remove the appropriate power-supply filler panel by inserting a finger into the

hole and pulling the panel forward. The panel pivots at the top.

Page 29

Chapter 2. Installing options 19

Note: The power supplies are numbered from left to right (1 to 3) as viewed from

the front of the server. Power supplies do not have to be installed in a particular sequence.

Attention: To ensure proper system cooling, do not leave the filler panel off the

server for more than 30 minutes.

4. Press down on the locking latch and mov e the loc king handle to the open po sition,

as shown in the illustration.

5. Slide the power supply into the chassis and fully close the locking handle.

6. Plug one end of the power cord for the new power supply into the corresponding

connector on the back of the server (connectors are numbered 1 through 3 from

top to bottom, as illustrated at “Cabling the server” on page 21). Plug the other

end of the power cord into a prop erly grounded electrical outlet.

7. Ve rify that the dc power and ac power LEDs on the front of the power supply are

lit, indicating that the power supply is operating properly.

8. Continue with “Completing the installation”.

Completing the installation

This section provides the information needed to complete the installation.

Installing the server top cover and bezel

Complete the following steps to install the server top cover and bezel:

1. Before installing the cover, check that all internal cables, ada pters , and othe r components are installed and seated corr ectly and that y ou h av e not left loose tools or

parts inside the server.

2. Move the cover-release latch to the open (up) position.

Power supply 3

Power supply 2

Locking latch

Locking handle

AC power LED

DC power LED

Power supply 1

Page 30

20 IBM xSeries 360 Type 8686:Installation Guide

3. Insert the tabs on the top cover into the matching slots in the server chassis.

4. Close the cover-release latch to pull the top cover forward and lock the to p cover

in place.

5. Insert the tabs on the bottom of the bezel into the matching holes on the server

chassis.

6. Push the top of the bezel toward the server until the two tabs at the top of the

bezel snap into place.

7. Continue with “Installing the ser ver in the rack”.

Installing the server in the rack

Install the server in the rack cabinet. For complete rack installation and removal

instructions, see the Rack Installation Instructions provided with your server.

After you have installed the server in the rack, see “Cabling t he server” o n pag e 21 for

details about connecting external cables and power cords to the server and routing

the cables through the cable management arm.

Top cover

Cover release latch

Bezel

Level 2 diagnostic panel

Page 31

Chapter 2. Installing options 21

Cabling the server

The following illustration shows the I/O ports on the rear of the server. Use this illustration to connect the external cables to the rear of the server.

The following illustration shows the cable routing for a typical server configuration.

Detailed cabling instructions, including the use of the cable management arm

(shipped with the server) are in the Rack Installation Instructions provided with the

server.

Notes:

1. The illustrations in this document might differ slightly from your hardware.

2. See the documentation that comes with the options for additional cabling instructions. It might be easier for you to route any cables before you install certain

options.

3. If you have just plugged the power cords of the server into an electrical outlet, you

must wait 30 seconds before pressing the power-control button.

For inf ormation about configuring and cab ling the Remote Supervisor Adapter to manage the server remotely or to interconnect to another device, see the xSeries 360

User’s Referenc e. For information about using the Remote Supervisor Adapter, see

the Remote Supervisor Adapter User’s Guide. Both documents are on the xSeries

360 Documentation CD.

RXE management

port

ASM interconnect

port

RXE expansion

port

Video port

USB 1

USB 2

Mouse port

Keyboard port

Ethernet port

Remote Supervisor

Adapter fault LED

(amber)

Remote Supervisor

Adapter power LED

(green)

Remote Supervisor

Adapter serial port

Remote Supervisor

Adapter Ethernet port

AC power connector 1

AC power connector 2

AC power connector 3

Page 32

22 IBM xSeries 360 Type 8686:Installation Guide

After you ha ve i nstalled the server in the r ack and connected all the needed cables , go

to “Turning on the server” on page 23.

Page 33

© Copyright IBM Corp. 2001 23

Chapter 3. Server power, controls, and indicators

This chapter explains ho w to turn on and turn off the server and describes the controls

and indicators.

Turning on the server

Turning on the server refers to the act of plugging the server power cords into the

power source and pressing the power-control button. After you install the network

operating system in the server, this typically causes the operating system to start. For

more details, see the introduction in the User’s Reference on the xSeries 360 Docu-

mentation CD.

Complete the following steps to turn on the server.

1. Turn on all external devices, such as the monitor.

Note: After you plug the power cords into the pow er source, wait 30 seconds

before pressing the power-control button on the operator information

panel. During this time, the Remote Supervisor Adapter is initializing and

the power-control button does not respond. The power LED on the information panel blinks, indicating that ac power is present in the server.

2. Press the power control button on the operator information panel. The power LED

comes on and the power-on self-test (POST) begins.

If the server is turned on and a power failure occurs, it restarts automatically when

power is restored. You can turn on the server remotely by means of the Remote

Supervisor Adapter.

When you start the server for the first time after you add or remove an internal option

or an external SCSI device, y ou might see a message telling you that the configuration

has changed. The Configuration/Setup Utility prog ram automatically starts so that you

can save the new configuration information. See Chapter 4, “Configuring the server”

on page 29 for details.

Some options have device drivers that you need to install. See the documentation

that comes with the option for information about installing any required device drivers.

The server comes with at least one microprocessor installed on the system board . If

you have installed one or more additional microprocessors, the server can now operate as an SMP server. Therefor e, you might need to upgra de th e oper a ting syst em to

support SMP. See “Using the ServerGuide CDs” on page 31 and the operatin g-system documentation for additional information.

If the server has a ServeRAID adapter installed and you have installed or removed a

hard disk drive, see the do cumentation that comes with the ServeRAID adapter for

information about reconfiguring the disk arrays.

Turning off the server

Turning off the server refers to the act of stopping the operating system, pressing the

power-control button, and disconnecting the server power cords from the power

source.

Note: Each operating system is different. Some allow an immediate shutdown; oth-

ers require an orderly shutdown procedure.

Page 34

24 IBM xSeries 360 Type 8686:Installation Guide

See the operating system documentation for the proper procedure to shut down the

operating system.

Statement 5:

CAUTION:

The power control button on the device and the power switch on the po wer supply do not turn off th e e lect ri cal curre nt su ppl ied t o the device. The device also

might have more than one power cor d. To remove all electrical current from the

device, ensure that all power cords are disconnected from the power source.

You can turn off the server in any of the following ways:

• Press the power-control b utton on the oper ator inf ormation panel. This places the

server in standby mode. The po wer LED on the oper ator information panel b links.

This does not remove all power from the server.

Note: After doing this, w ait at least 30 seconds bef ore pressing the power- control

button to turn on the server again.

• You can disconnect the server power cords from the power source to shut off all

power immediately without damaging the server.

Note: Wa it appro ximately 15 se conds after discon necting the po wer cords f or th e

server to stop running. W a tch for the power LED on the operator information panel to stop blinking.

Standby mode

Standby mode refers to the condition in which the server operating system is not running and all core logic is shut down except for the Remote Supervisor Adapter.

Complete the following steps to put the server into standby mode:

1. See the operating system documentation for the proper procedure to shut down

the operating system.

Note: Each operating system is different. Read all the documentation about

shutting down the operating system before continuing.

2. Press the power-control button on the front of the server.

You can put the server into standby mode remotely by means of the Remote Supervisor Adapter.

1

2

3

Page 35

Chapter 3. Server power, controls, and indicators 25

Server controls and indicators

The following illustration shows the controls and indicators on the front of the server.

Operator information panel: This panel, also kno wn as the front LED panel, contains

controls, indicators, and one of the t hree USB ports. See “Operator inf ormation panel”

on page 27 for details.

AC LED: Each hot-swap pow er supply has an ac po we r LED to indicate that ac po we r

is available to the power supply.

DC LED: Each hot-swap po w er su pply has a dc power LED to indicate that the power

supply is active.

Diskette drive: The server contains one standard 3.5-inch diskette drive with an LED

to indicate when it is active.

CD-ROM drive: The server contains one standard I DE CD-ROM with an LED to indicate when it is active.

Hard disk drive filler panels: A filler panel is used to cover empty hard disk drive

bays. A filler panel must be installed in each empty bay to ensure proper system cooling.

Activity LED: Each hot-swap hard disk drive has an activity LED, which flashes if the

drive is being accessed.

Status LED: Each hot-swap hard disk driv e has a status LED. If this amber LED is on

continuously , the drive has fa iled. If an optional IBM ServeRAID adapter is installed in

the server and the LED flashes slowly (one flash per second), the drive is being

rebuilt. If the LED flashes rapidly (three flashes per second), the contro ller is identi fying the drive.

Hard disk drive: The server supports a maximum of three hot-swap hard disk drives.

Power supplies 1, 2, and 3: The server supports a maximum of three hot-swap

power supplies.

Power

supply 1

Power

supply 2

Power

supply 3

AC LED

DC LED

Hard disk drive

Diskette drive

CD-ROM drive

Hard disk drive

filler panels

Activity

(green)

LED

Status

(amber)

LED

Operator information

panel

Page 36

26 IBM xSeries 360 Type 8686:Installation Guide

The following illustration shows the indicators on the rear of the server.

Ethernet link LEDs: These LEDs (one for the Remote Supervisor Adapter, one for

the network) indicate that the related Ethernet link is operational.

Ethernet TX/RX LEDs: These LEDs (one for the Remote Supervisor Adapter, one for

the network) indicate that activity is taking place on the related network.

Remote Supervisor Adapter Ethernet port: This port enables you to manage the

server from a remote location.

Remote Supervisor Adapter fault LED: This LED indicates that the Remote Supervisor Adapter has failed.

Remote Supervisor Adapter power LED: This LED indicates that power is being

supplied to the Remote Supervisor Adapter.

Ethernet port: This port enables you to connect the server to a network.

Ethernet port

Remote Supervisor

Adapter fault

(amber)

LED

Remote Supervisor

Adapter power LED

(green)

Remote Supervisor

Adapter Ethernet port

Ethernet TX/RX LEDs

Ethernet link LEDs

Page 37

Chapter 3. Server power, controls, and indicators 27

Operator information panel

The following illustration shows the controls, indicators, and USB port on the operator

information panel (also known as the front LED panel).

USB port: This port enables you to attach a USB device to the front of the server.

SCSI bus activity LED: This green LED is on when there is activity on the SCSI bus.

Information LED: This amber LED is on if the server power supplies are nonredun-

dant or some other noncritical event has occurred. See the LEDs on the Level 2 diagnostic LED panel or on the system board for specific error information. For details,

see the User’s Reference on the xSeries 360 Documentation CD.

Fault LED: This amber LED is on if a system error has occurred. See the LEDs on

the Leve l 2 diagnostic LED panel or on the system board f or specific error inf ormation.

For details, see the User’s Reference on the xSeries 360 Documentation CD.

Reset button: Press this button to reset the server and run the power-on self-test

(POST).

Power-control button: If the server is in operational mode, press this button to put it

into standby mode. If the server is in standby mode, press this button to restore it to

operational mode. See Turning on the server and “Turning off the server” on page 23

for more information about applying and removing external power to the server.

Power LED: This green LED is on if ac and dc power are present in the server. If this

LED is flashing, the server is in standby mode (ac power is present, but the power

supplies are turned off). If this LED is off, either ac power, all power supplies, or the

LED has failed.

Note: If this LED is off, it does not mean there is no electrical current present in the

server. The LED might be b urned out. To remove all electrical current from the

server, you must unplug the server power cords from the electrical outlets.

USB port

SCSI bus activity LED

Fault LED

Information LED

Reset button

Power-control button

PowerLED

Page 38

28 IBM xSeries 360 Type 8686:Installation Guide

Page 39

© Copyright IBM Corp. 2001 29

Chapter 4. Configuring the server

This chapter provides the instructions for using the utility programs. F or more detailed

information about these utility programs, see the User’s Reference on the xSeries 360

Documentation CD.

You can use the following configuration programs to customize the server hardware:

• Configuration/Setup Utility program

This program is part of the basic input/output system (BIOS) code that comes with

the server. You can use this program to change interrupt request (IRQ) settings,

change the drive startup sequence, set the date and t ime, and set pass word s. F or

information about using this utility, see “Using the Configuration/Setup Utility program” on page 30.

• SCSISelect utility program

This program is part of the basic input/output system (BIOS) code that comes with

the server . You can use this prog ram t o configur e the de vice s that ar e attach ed to

the integrated SCSI controller. Use this program to change def ault v alues, resolv e

configuration conflicts, and perform a low-level format on a SCSI hard disk drive.

For information about using this utility, see “Using the SCSISelect utility program”

on page 30.

• PXE Boot Agent Utility program

The Preboot eXecution Environment (PXE) Boot Agent Utility program is part of

the BIOS code that comes with the server. Y ou can use this progr am to select th e

boot protocol and other boot options, to display the PXE setup prompt or to disable it, to set the prompt display duration, and to select a power management

option. For information about using this utility, see “Using the PXE Boot Agent

Utility program” on page 31.

Note: The RPL selection for the Boot Protocol option is not supported for this

server.

• ServerGuide CDs

The ServerGuide CDs provide software setup and installation tools that are spe-

cifically designed for your IBM server . Use these CDs during the initial installation

of your server to configure basic hardware features and to simplify your network

operating system (NOS) installation. The ServerGuide CDs also contain a collection of application programs, which you can install after the server is up and running. See “Using the ServerGuide CDs” on page 31 for more information.

• Remote Supervisor Adapter configuration process

Configuration activities are also required f or the Remo te Supervisor Adapter. See

“Using the Remote Supervisor Adapter” on page 32 for a description of Remote

Supervisor Adapter features. For information about cabling, configuring, and

using the Remote Supervisor Adapter to manage the server remo tely, see “Using

the Remote Supervisor Adapter” on page 32 and the Remote Supervisor Adapter

User’s Guide on the xSeries 360 Documentation CD.

• ServeRAID configuration program

This program comes with the optional ServeRAID ad apters and with server mod-

els that hav e a ServeRAID adapter preinstalled. If the server has a ServeRAID

adapter installed, you must use the ServeRAID config uration program to define

and configure the disk-array subsystem before you install the operating system.

For inf ormation about using th e ServeRAID configur ation pr ogr am, see “Usin g the

ServeRAID configuration programs” on page 32 and also the ServeRAID documentation that comes on the xSeries 360 Documentation CD.

Page 40

30 IBM xSeries 360 Type 8686:Installation Guide

Using the Configuration/Setup Utility program

Configuration/Setup is a menu-driven utility that is part of the BIOS code that comes

with the server. You can use it to:

• Change the drive startup sequence

• Enable USB keyboard and mouse support

• Resolve configuration conflicts

• Set the date and time

• Set passwo rds

Complete the following steps to start the Configuration/Setup Utility program:

1. Turn on the server and watch the monitor screen.

2. When the message Press F1 for Configuration/Setup appears, press F1.

3. Follow the instructions that appear on the screen.

For more information about using the Configuration/Setup Utility program, see the

section on the Configuration/Setup Utility program in the User’s Reference on the

xSeries 360 Documentation CD.

Using the SCSISelect utility program

SCSISelect is a built-in, menu-driven configuration utility program that y ou can use to:

• View the default SCSI IDs

• Locate and correct configuration conflicts

Note: If the server has a redundant arrays of independent disks (RAID) adapter

installed, use the configuration method that is supplied with the RAID adapter

to view or change SCSI settings for devices attached to the adapter.

Complete the following steps to start the SCSISelect utility program:

1. Turn on the server.

2. When the <<< Press <CTRL><A> for SCSISelect™ Utility! >>> prompt appears,

press Ctrl+A.

Note: If an administrat or pass word ha s been set, a pr ompt appears as king you t o

type the password to start the SCSISelect utility program.

3. When the Would you like to configure the host adapter or run the SCSI

disk utility? question appears, make a selection and press Enter.

4. Use the arrow keys to select a choice from the menu.

• Press Esc to exit from the SCSISelect utility program.

• Press the F5 key to switch between color and monochrome modes (if the

monitor permits).

5. Follow the instructions on the screen to change the settings of the selecte d items;

then, press Enter.

For more information about using the SCSISelect utility program, see the section on

the SCSISelect utility program in the User’s Reference on the xSeries 360 Documen-

tation CD.

Page 41

Chapter 4. Configuring the server 31

Using the PXE Boot Agent Utility program

This program is a built-in, menu-driven configuration utility program that you can use

to:

• Select the boot protocol and other boot op tions

• Select whether to display the PXE setup prompt and the display duration

• Select a power management option

Note: The RPL selection f or the Boot Protocol option is not supported for this server.

Complete the following steps to start the PXE Boot Agent Utility program:

1. Turn on the server.

2. When the Initializing Intel Boot Agent Version X.X (Dev Build XXX)

prompt appears, press Ctrl+S.

Notes:

a. If the PXE setup prompt does not display, use the Configuration/Setup Utility

program to set the Enable Ethernet PXE/DHCP option.

b. By default, you have 2 seconds after the prompt appears on the screen to

press Ctrl+S.

3. Use the arrow keys or press Enter to select a choice from the menu.

• Press Esc to return to the previous menu.

• Press the F4 key to exit.

4. Follow the instructions on the screen to change the settings of the selecte d items;

then, press Enter.

Using the ServerGuide CDs

The ServerGuide CDs provide state-of-the-art programs to detect the server model

and hardware options that are inst alled, configure th e server hardwar e, pro vide de vice

drivers, and install your network operating system (NOS).

Note: If the ServerGuide CD doe s not start, see “ServerGuide pro b lems” on page 36.

1. Insert the Setup and Installation CD, and restart the server.

2. Follow the instructions on the screen to:

a. Select your language.

b. Select your country an d keyboard layout.

c. View the Overview to learn about ServerGuide features.

d. View the ServerGuide README file to review installation tips about your

NOS.

e. Start the setup and hardware configuration programs.

f. Start the NOS installation. You will need your copy of the NOS CD.

Note: For information on the supported NOS versions, refer to the Setup and Installa-

tion CD label.

Page 42

32 IBM xSeries 360 Type 8686:Installation Guide

Using the Remote Supervisor Adapter

The Remote Supervisor Adapter is one of the products in the Advanced System Management (ASM) family. It provides around-the-clock remote access and system management of your server and supports the following:

• Remote management regardless of the status of the server

• Remote control of hardware and operating systems

• Web-based management wit h standard Web browsers (no other software is

required)

• Text-based user interface terminal access

The Remote Supervisor Adapter provides the following specific features:

• Continuous health monitoring and control

• Advanced Predictive Failure Analysis

®

(PFA)

• Configurable automatic notification and alerts

• Remote access through Ethernet, point-to-point protocol (PPP) connection, serial

port, and ASM interconnect peer-to-peer network

• Simple Network management Protocol (SNMP)

• Domain Name system (DNS) and Dynamic Host Configuration Protocol (DHCP)

support

• Remote power control

• Remote firmware update and access to critical server settings

•Microsoft

®

Windows NT® and Windows® 2000 blue screen capture

• Independent power, which enables around-the-clock access to the server even

when the server power is off

• E-mail alerts

• Event logs that are timestamped, saved by a battery power unit, and can be

attached to e-mail alerts

• Redirection of the server graphical or text console

• Access to Vital Product Data (VPD)

• Alphameric or numeric pag er alerts

For information about cabling, configuring, and using the Remote Supervisor Adapter

to manage the server remotely, see the xSeries 360 User’s Reference and the

Remote Supervisor Adapter User’s Guide on the xSeries 360 Documentation CD.

Using the ServeRAID configuration programs

A ServeRAID adapter enables you to use multiple physical SCSI hard-disk drives as

logical drives, operating as a disk array. To enable you to configure the ServeRAID

controller, the adapter comes with a CD containing the ServeRAID Manager program

and the ServeRAID Mini-Configuration program. For details about using these programs, see the documentation that comes with the ServeRAID adapter.

Page 43

© Copyright IBM Corp. 2001 33

Chapter 5. Solving problems

This chapter provides basic troubleshooting information to help you resolve some

common problems that might occur while sett ing up the server.

If you cannot locate and correct the problem using the information in this chapter, see

the section on solving problems in the User’s Ref erence on the xSeries 360 Documen-

tation CD and the “Server Support” flowchart in the front of this booklet.

Diagnostic tools overview

The following tools are available to help you identify and resolve hardware-related

problems:

• POST beep codes and error messages

The power-on self-test (POST) ge nerates beep codes and messages to indicate

successful test completion or the detection of a problem. See “POST beep code

descriptions” on page 34 and “POST error messages” on page 35 for more information.

• Diagnostic programs and err or messages

The server diagnostic programs are stored in upgradable read-only memory

(ROM) on the system board. These programs are the primary method of testing

the major components of the server. See the solving problems section in the

User’s Referenc e on the xSeries 360 Documentation CD for more information.

• Light Path Diagnostics feature

The server has light-emitting diodes (LEDs) to help you identify problems with

server components. By f ollowing the light path, you can quickly identif y the type of

problem that occurred. The light path begins with the LEDs on the operator information panel. See “Light Path Diagnostics” on page 37 for further information.

• Troubleshooting charts

These charts list problem symptoms and suggested steps to correct th e problems.

See “Troubleshooting charts” on page 37 for an abbr eviated chart. See the solving problems section in the User’s Reference on the xSeries 360 Documentation

CD for a complete chart.

• Customized support page

You can create a customized support page that is specific to your hardware, com-

plete with frequently asked questi ons, parts information, technical hints and tips,

and downloadable files. In addition, you can choose to receive electronic mail (email) notifications whenever new information becomes available about your registered products.

After you register and create a profile for your IBM products, you can diagnose

problems using the IBM Online Assistant and you can participate in the IBM discussion forum. For m ore detailed information about registering and creating a customized profile f or your IBM products, visit the following addresses on the World

Wide Web:

http://www.ibm.com/pc/register

http://www.ibm.com/pc/support

Page 44

34 IBM xSeries 360 Type 8686:Installation Guide

POST beep code descriptions

POST emits one beep to signal successful completion. If POST detects a problem

during startup, other beep codes might occur. You can use the following abbreviated

list of beep code descriptions to help identify and resolve problems that are detected

during startup.

Note: See the solving problems section in the User’s Reference on the xSeries 360

Documentation CD for a complete list of POST beep codes.

No beep

If no beep occurs after the server completes POST, call for service.

Continuous beep

The startup (boot) microprocessor has failed, or the system board or speaker

subsystem might contain a failing component. If the system continues

through POST with no errors, call f or service. If no video appears , the startup

microprocessor has failed; have the system serviced.

One short beep

One beep indicates that the server successfully completed POST and that

POST did not detect any configuration or functional errors. One beep also

occurs after the server completes POST if you type an incorrect power-on