Page 1

IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive

Installation and User's Guide

Page 2

Page 3

IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive

Installation and User's Guide

Page 4

Note: Before using this information and the product it supports, read the general information in

“Notices” on page 77 and the IBM Safety Information, and IBM Environmental Notices and User's

Guide on the IBM Documentation CD, and the IBM Warranty Information document that comes with

the system.

Second Edition (June 2013)

© Copyright IBM Corporation 2013.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Figures ...............v

Tables ...............vii

Safety ...............ix

Guidelines for trained service technicians.....x

Inspecting for unsafe conditions .......x

Guidelines for servicing electrical equipment . . xi

Safety statements ............xii

Chapter 1. Introduction ........1

Drive features ..............1

Front panel of the drive ..........2

Rear panel of the drive ...........2

Drive performance ............3

Cartridge compatibility ...........3

Speed matching .............4

Channel calibration ............5

Data cartridge capacity scaling ........5

Encryption ...............5

Inhibit firmware down-leveling ........5

SAS interface ..............5

Supported Servers and Operating Systems ....6

Supported device drivers ..........6

Ethernet port ..............6

Linear Tape File System (LTFS) ........6

Chapter 2. Tape drive installation ....9

Installation guidelines ...........9

Handling static-sensitive devices........9

Inventory checklist ............10

Installing a tape drive ...........10

Unpacking the drive ..........10

Acclimating the drive and media ......11

Turning off the enclosure or server .....11

Setting the feature switches ........11

Mounting the drive in an enclosure or server . . 12

Connecting and testing power to the drive . . . 12

Connecting the cable ..........13

Running drive diagnostics ........13

Installing device drivers .........13

Connecting the external interface cable (enclosure

or server installations only) ........14

Configuring the drive to the server, switch, or

hub................14

Updating firmware ............14

Registering for My Support .........15

Chapter 3. Operating the drive ....17

Operating modes ............17

Power button ..............17

Single-character display (SCD) ........17

Status lights ..............18

Unload button .............21

Inserting a tape cartridge ..........22

Removing a tape cartridge .........23

Mid-tape recovery ............23

Cleaning the drive head ..........23

Cleaning the tape drive ..........24

Tape drive status web page .........24

Diagnostic and maintenance functions .....25

Entering Maintenance mode ........27

Exiting Maintenance mode ........27

Function code 0: Maintenance mode .....28

Function code 1: Run drive diagnostics ....28

Function code 2: Update drive firmware from

FMR tape ..............29

Function code 3: Create FMR tape ......30

Function code 4: Force a drive dump .....30

Function code 5: Copy drive dump .....31

Function code 6: Run host interface wrap test . . 32

Function code 7: Run RS-422 wrap test ....33

Function code 8: Unmake FMR tape .....33

Function code 9: Display error code log ....34

Function code A: Clear error code log ....34

Function code C: Insert cartridge into tape drive 35

Function code E: Test cartridge and media . . . 35

Function code F: Write performance test ....36

Function code H: Test head ........37

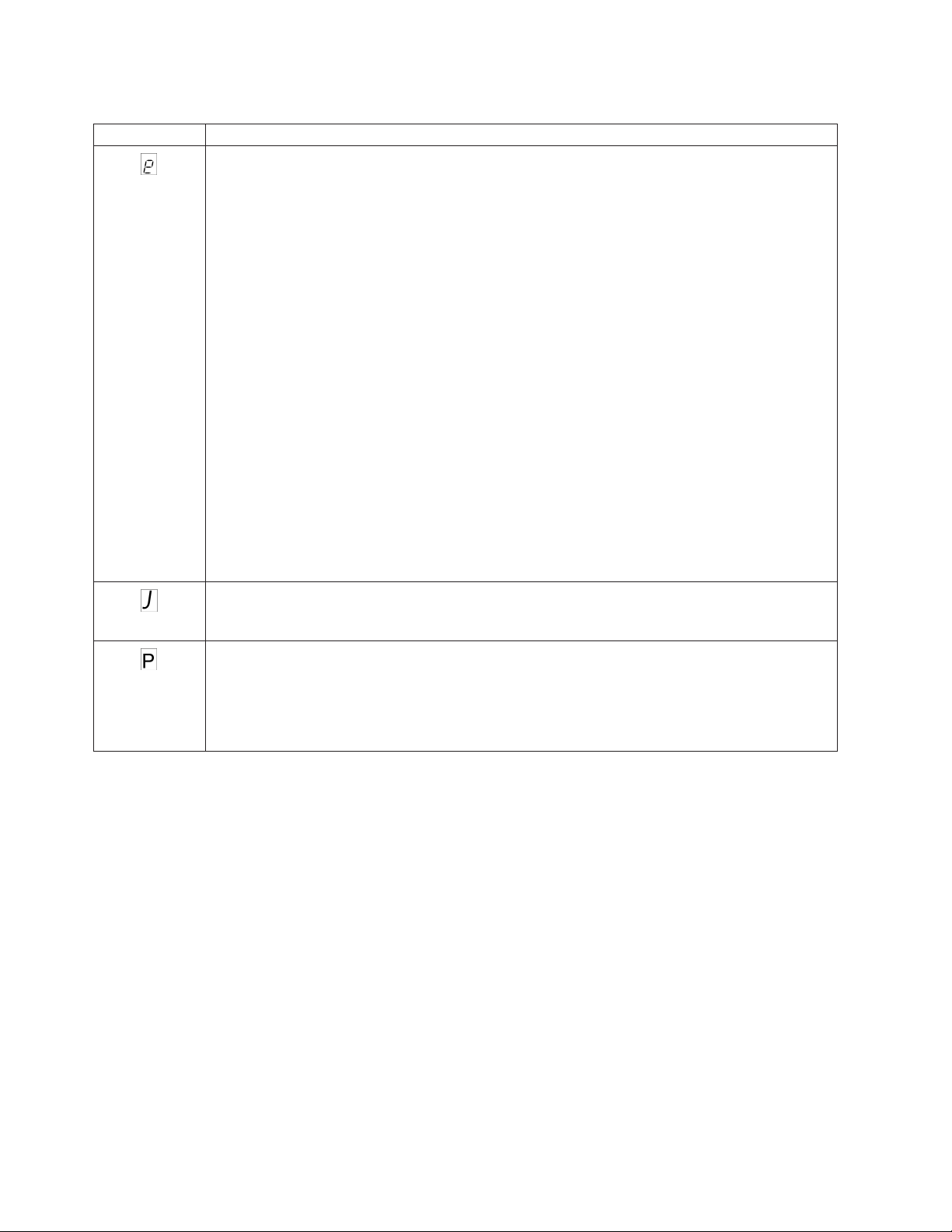

Function code J: Fast read/write test .....38

Function code L: Load/unload test .....39

Function code P: Enable post error reporting . . 39

Function code U: Disable post error reporting . . 40

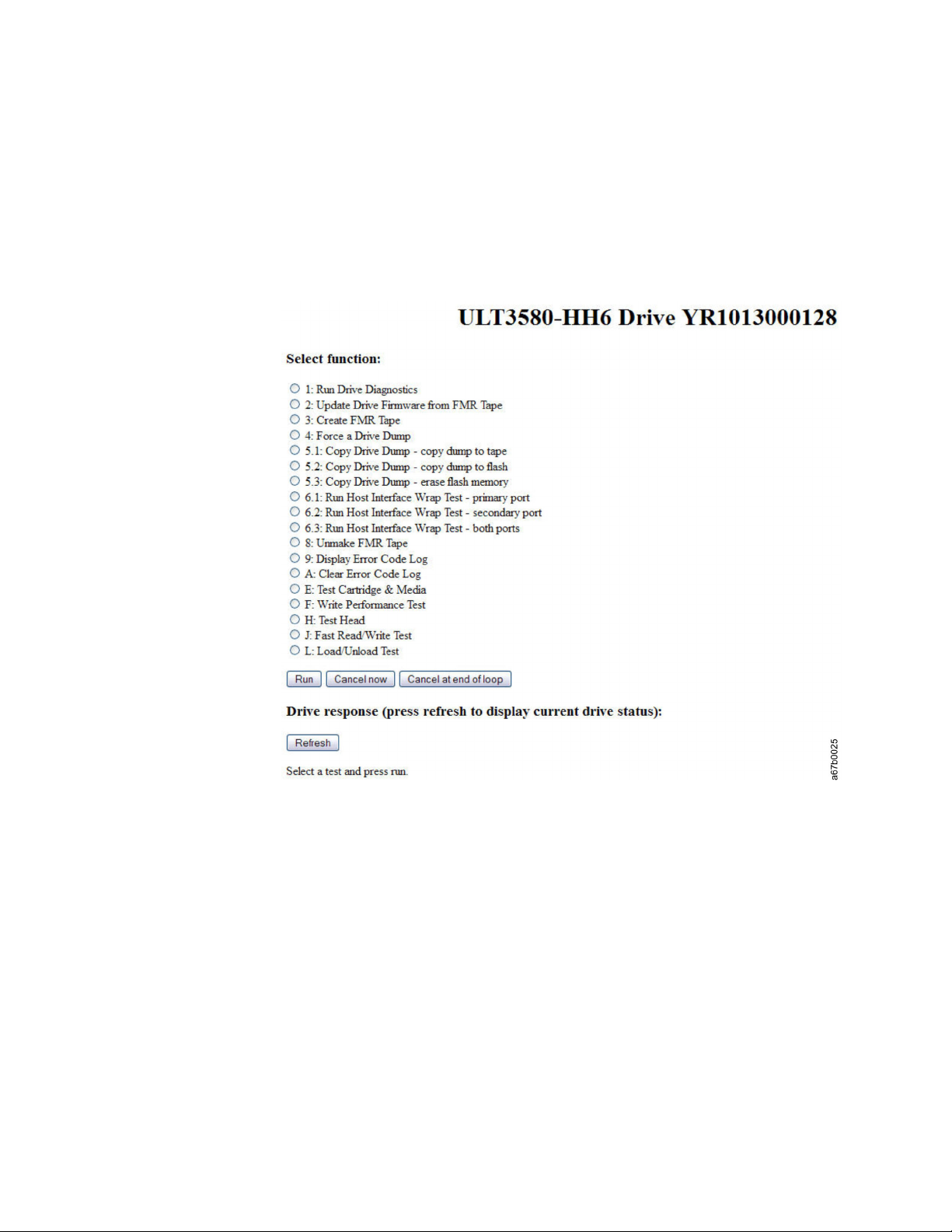

Tape drive diagnostic and maintenance web page 40

Chapter 4. Using Ultrium media ....43

Types of cartridges ............44

Data cartridge ............44

WORM (Write Once, Read Many) cartridge. . . 45

Cleaning cartridge ...........47

Cartridge compatibility ..........47

Handling cartridges ...........47

Provide training ............48

Provide proper acclimation and environmental

conditions ..............48

Inspect the cartridge ..........48

Handle the cartridge carefully .......48

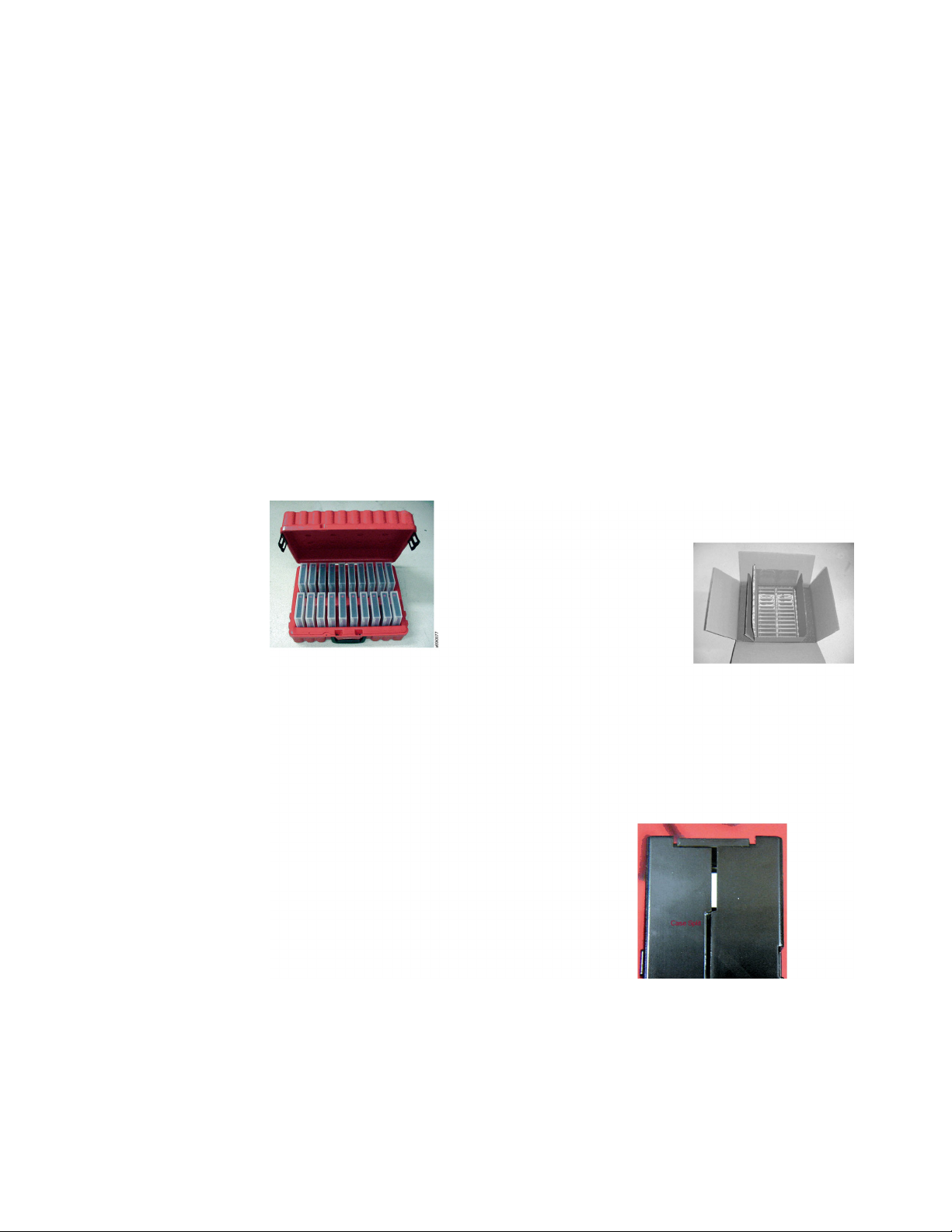

Tape cartridge packaging .........49

Environmental and shipping specifications for tape

cartridges ...............50

Disposing of tape cartridges .........51

Chapter 5. Resolving problems ....53

Procedure 1: Inspecting a cartridge for damage . . 53

Procedure 2: Checking SAS host connections . . . 54

Procedure 3: Verifying host interface communication 54

Resolving problems reported by the server ....55

Resolving problems with the tape media ....55

Replacing the tape drive ..........56

© Copyright IBM Corp. 2013 iii

Page 6

Appendix A. Getting help and technical

assistance .............57

Before you call .............57

Using the documentation ..........58

Getting help and information from the World Wide

Web.................58

How to send DSA data to IBM ........58

Creating a personalized support web page ....58

Software service and support ........58

Hardware service and support ........59

IBM Taiwan product service .........59

Appendix B. TapeAlert flags .....61

Appendix C. Error codes and

messages .............63

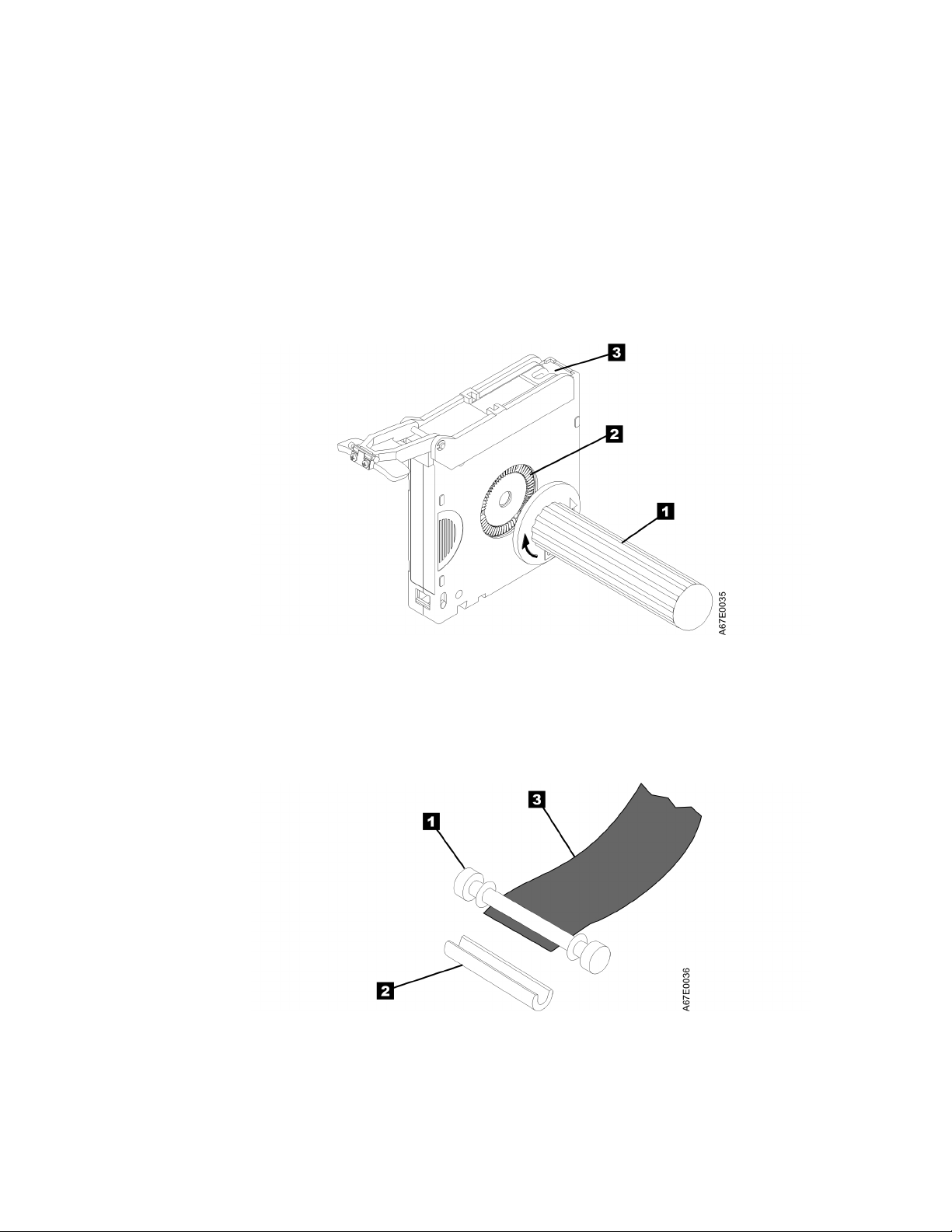

Appendix D. Repairing a cartridge . . . 69

Examples of cartridge problems .......69

Repositioning a leader pin .........69

Reattaching a leader pin ..........71

Documentation format...........80

Telecommunication regulatory statement ....80

Electronic emission notices .........80

Federal Communications Commission (FCC)

statement ..............80

Industry Canada Class A emission compliance

statement ..............81

Avis de conformité à la réglementation

d'Industrie Canada ...........81

Australia and New Zealand Class A statement . 81

European Union EMC Directive conformance

statement ..............81

Germany Class A statement ........82

Japan VCCI Class A statement .......83

Japan Electronics and Information Technology

Industries Association (JEITA) statement....83

Korea Communications Commission (KCC)

statement ..............83

Russia Electromagnetic Interference (EMI) Class

A statement .............83

People's Republic of China Class A electronic

emission statement ...........84

Taiwan Class A compliance statement ....84

Notices ..............77

Trademarks ..............77

Important notes .............78

Particulate contamination..........79

Glossary ..............85

Index ...............95

iv

IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 7

Figures

1. View of a tape drive ..........1

2. Tape drive front panel element descriptions 2

3. Tape drive rear panel element descriptions 2

4. Inserting a cartridge into the drive .....22

5. Drive status web page .........24

6. Drive status web page - Topic details ....25

7. Tape drive diagnostic page .......41

8. The IBM LTO Ultrium Data Cartridge....43

9. Ultrium data cartridge on the left; WORM

cartridge on the right .........46

10. Tape cartridges in a Turtlecase ......49

11. Double-boxing tape cartridges for shipping 50

12. Flowchart for analyzing maintenance problems 53

13. Leader pin in the incorrect and correct

positions .............70

14. Placing the dislodged leader pin into the

correct position ...........70

15. Rewinding the tape into the cartridge ....71

16. Leader Pin Reattachment Kit .......72

17. Attaching the leader pin attach tool to the

cartridge .............73

18. Winding the tape out of the cartridge ....74

19. Removing the C-clip from the leader pin 74

20. Attaching the leader pin to the tape ....75

© Copyright IBM Corp. 2013 v

Page 8

vi IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 9

Tables

1. CRU and Option part numbers ......1

2. Performance rates and times .......3

3. Ultrium cartridge compatibility with Ultrium

tape drives .............3

4. Performance parameters.........4

5. Feature switch definitions ........11

6. Meaning of status lights and single-character

display (SCD) ............19

7. Functions that the Unload button performs 21

8. Diagnostic and maintenance functions . . . 26

9. Ultrium cartridge compatibility with Ultrium

tape drives .............47

10. Environment for operating, storing, and

shipping LTO media .........50

11. CRU and Option part numbers ......56

12. Error codes on the SCD ........63

13. Limits for particulates and gases .....79

© Copyright IBM Corp. 2013 vii

Page 10

viii IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 11

Safety

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d'installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

© Copyright IBM Corp. 2013 ix

Page 12

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

Antes de instalar este producto, lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

Guidelines for trained service technicians

This section contains information for trained service technicians.

Inspecting for unsafe conditions

Use this information to help you identify potential unsafe conditions in an IBM

product that you are working on.

Each IBM product, as it was designed and manufactured, has required safety items

to protect users and service technicians from injury. The information in this section

addresses only those items. Use good judgment to identify potential unsafe

conditions that might be caused by non-IBM alterations or attachment of non-IBM

features or optional devices that are not addressed in this section. If you identify

x IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

®

Page 13

an unsafe condition, you must determine how serious the hazard is and whether

you must correct the problem before you work on the product.

Consider the following conditions and the safety hazards that they present:

v Electrical hazards, especially primary power. Primary voltage on the frame can

cause serious or fatal electrical shock.

v Explosive hazards, such as a damaged CRT face or a bulging capacitor.

v Mechanical hazards, such as loose or missing hardware.

To inspect the product for potential unsafe conditions, complete the following

steps:

1. Make sure that the power is off and the power cords are disconnected.

2. Make sure that the exterior cover is not damaged, loose, or broken, and observe

any sharp edges.

3. Check the power cords:

v Make sure that the third-wire ground connector is in good condition. Use a

meter to measure third-wire ground continuity for 0.1 ohm or less between

the external ground pin and the frame ground.

v Make sure that the power cords are the correct type.

v Make sure that the insulation is not frayed or worn.

4. Remove the cover.

5. Check for any obvious non-IBM alterations. Use good judgment as to the safety

of any non-IBM alterations.

6. Check inside the system for any obvious unsafe conditions, such as metal

filings, contamination, water or other liquid, or signs of fire or smoke damage.

7. Check for worn, frayed, or pinched cables.

8. Make sure that the power-supply cover fasteners (screws or rivets) have not

been removed or tampered with.

Guidelines for servicing electrical equipment

Observe these guidelines when you service electrical equipment.

v Check the area for electrical hazards such as moist floors, nongrounded power

extension cords, and missing safety grounds.

v Use only approved tools and test equipment. Some hand tools have handles that

are covered with a soft material that does not provide insulation from live

electrical current.

v Regularly inspect and maintain your electrical hand tools for safe operational

condition. Do not use worn or broken tools or testers.

v Do not touch the reflective surface of a dental mirror to a live electrical circuit.

The surface is conductive and can cause personal injury or equipment damage if

it touches a live electrical circuit.

v Some rubber floor mats contain small conductive fibers to decrease electrostatic

discharge. Do not use this type of mat to protect yourself from electrical shock.

v Do not work alone under hazardous conditions or near equipment that has

hazardous voltages.

v Locate the emergency power-off (EPO) switch, disconnecting switch, or electrical

outlet so that you can turn off the power quickly in the event of an electrical

accident.

v Disconnect all power before you perform a mechanical inspection, work near

power supplies, or remove or install main units.

Safety xi

Page 14

v Before you work on the equipment, disconnect the power cord. If you cannot

disconnect the power cord, have the customer power-off the wall box that

supplies power to the equipment and lock the wall box in the off position.

v Never assume that power has been disconnected from a circuit. Check it to

make sure that it has been disconnected.

v If you have to work on equipment that has exposed electrical circuits, observe

the following precautions:

– Make sure that another person who is familiar with the power-off controls is

near you and is available to turn off the power if necessary.

– When you work with powered-on electrical equipment, use only one hand.

Keep the other hand in your pocket or behind your back to avoid creating a

complete circuit that could cause an electrical shock.

– When you use a tester, set the controls correctly and use the approved probe

leads and accessories for that tester.

– Stand on a suitable rubber mat to insulate you from grounds such as metal

floor strips and equipment frames.

v Use extreme care when you measure high voltages.

v To ensure proper grounding of components such as power supplies, pumps,

blowers, fans, and motor generators, do not service these components outside of

their normal operating locations.

v If an electrical accident occurs, use caution, turn off the power, and send another

person to get medical aid.

Safety statements

These statements provide the caution and danger information that is used in this

documentation.

Important:

Each caution and danger statement in this documentation is labeled with a

number. This number is used to cross reference an English-language caution or

danger statement with translated versions of the caution or danger statement in

the Safety Information document.

For example, if a caution statement is labeled “Statement 1,” translations for that

caution statement are in the Safety Information document under “Statement 1.”

Be sure to read all caution and danger statements in this documentation before you

perform the procedures. Read any additional safety information that comes with

your system or optional device before you install the device.

Statement 1

xii IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 15

DANGER

Electrical current from power, telephone, and communication cables is

hazardous.

To avoid a shock hazard:

v Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an electrical storm.

v Connect all power cords to a properly wired and grounded electrical outlet.

v Connect to properly wired outlets any equipment that will be attached to

this product.

v When possible, use one hand only to connect or disconnect signal cables.

v Never turn on any equipment when there is evidence of fire, water, or

structural damage.

v Disconnect the attached power cords, telecommunications systems,

networks, and modems before you open the device covers, unless

instructed otherwise in the installation and configuration procedures.

v Connect and disconnect cables as described in the following table when

installing, moving, or opening covers on this product or attached devices.

To Connect: To Disconnect:

1. Turn everything OFF.

2. First, attach all cables to devices.

3. Attach signal cables to connectors.

4. Attach power cords to outlet.

5. Turn device ON.

1. Turn everything OFF.

2. First, remove power cords from outlet.

3. Remove signal cables from connectors.

4. Remove all cables from devices.

Statement 3

CAUTION:

When laser products (such as CD-ROMs, DVD drives, fiber optic devices, or

transmitters) are installed, note the following:

v Do not remove the covers. Removing the covers of the laser product could

result in exposure to hazardous laser radiation. There are no serviceable parts

inside the device.

v Use of controls or adjustments or performance of procedures other than those

specified herein might result in hazardous radiation exposure.

Safety xiii

Page 16

DANGER

Some laser products contain an embedded Class 3A or Class 3B laser diode.

Note the following.

Laser radiation when open. Do not stare into the beam, do not view directly

with optical instruments, and avoid direct exposure to the beam.

Statement 5

CAUTION:

The power control button on the device and the power switch on the power

supply do not turn off the electrical current supplied to the device. The device

also might have more than one power cord. To remove all electrical current from

the device, ensure that all power cords are disconnected from the power source.

Statement 8

xiv IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 17

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any component

that has this label attached. There are no serviceable parts inside these

components. If you suspect a problem with one of these parts, contact a service

technician.

Safety xv

Page 18

xvi IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 19

Chapter 1. Introduction

The product description of the IBM Half High LTO Ultrium Gen 6 Internal SAS

Tape Drive.

The IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive is a

high-performance, high-capacity data-storage device that is designed to back up

and restore open systems applications. The drive can be integrated into an

enclosure, such as a desktop unit, server, tape autoloader, or tape library. It is the

sixth generation in the Ultrium series of products, and is available with a Serial

Attached SCSI interface (SAS). This model incorporates the Linear Tape-Open

(LTO) IBM Ultrium 6 Half High Tape Drive.

Read this entire document and the IBM Safety Information, Safety Information Labels,

Warranty, and Environmental Notices and User Guide documents that come with the

drive before you install or use the drive.

Figure 1. View of a tape drive

The Customer Replaceable Unit (CRU) part numbers and the Option part numbers

for the IBM LTO 6 Half High Tape Drive are shown in the following list:

Table 1. CRU and Option part numbers

Description CRU part number Option part number

IBM Internal Half High LTO

Gen 6 SAS Tape Drive

SAS cable (internal) 49Y9901

Tape Mount Kit 41Y7711

35P1049 00D8924

Drive features

The tape drive offers the following features.

v Dual port 6 Gbps Serial Attached Small Computer Systems Interface (SAS)

Note: Although the tape drive has two SAS ports, the drive supports only one

host connection.

v Half height form factor

© Copyright IBM Corp. 2013 1

Page 20

v Native storage capacity of 2500 GB (2.5 TB) per cartridge (6250 GB at 2.5:1

compression)

v Maximum native data transfer rate of up to 160 MB per second

v Burst data transfer rate of 600 MB per second

v 512 MB read-and-write cache

v Support for encryption on Ultrium 5 and Ultrium 6 tape cartridges

v Single Character Display (SCD) operator panel

v Ready, Fault, and Encryption status lights

v Maintenance Mode functions

v Support for WORM (Write Once Read Many) on WORM cartridge types

Front panel of the drive

The tape drive front panel's elements descriptions.

Figure 2. Tape drive front panel element descriptions

Rear panel of the drive

The tape drive rear panel's elements descriptions.

Figure 3. Tape drive rear panel element descriptions

Fan

SAS and power

cable connector

2 IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 21

Drive performance

Details about the tape drive processing speed are shown in the following table.

Table 2. Performance rates and times

Native data rate 160 MB/second (with Ultrium 6 media)

Maximum sustained data rate (at maximum compression) 550 MB/second

Burst data rate 600 MB/second

Nominal load-to-ready time 12 seconds

Nominal unload time 17 seconds

Average rewind time 62 seconds

Note: All sustained data rates are dependent on the capabilities of the interconnect, and application software

performance might be slower than the published performance ratings.

By using the built-in data-compression capability of the tape drive, a faster data

rate than the native data transfer rate can be achieved. However, the actual

performance of the drive is a function of many components, such as the host

system processor, disk data rate, block size, data compression ratio, SAS bus

capabilities, and system or application software.

Cartridge compatibility

The tape drive uses the IBM LTO Ultrium 2500 GB Data Cartridge and is

compatible with the cartridges of its predecessor, the IBM Half High LTO Ultrium

5 Tape Drive.

The drive has the following capabilities and limitations:

Note: To improve system performance, the drive uses a feature called speed

matching to dynamically adjust its native (uncompressed) data rate to the slower

data rate of a server. For more information about speed matching, see “Speed

matching” on page 4.

Table 3. Ultrium cartridge compatibility with Ultrium tape drives

IBM LTO Ultrium Data Cartridges

IBM Ultrium

Tape Drive

Ultrium 6 Read/Write Read/Write Read only

Ultrium 5 Read/Write Read/Write Read only

Ultrium 4 Read/Write Read/Write Read only

Ultrium 3 Read/Write Read/Write Read only

Ultrium 2 Read/Write Read/Write

Ultrium 1 Read/Write

2500 GB

(Ultrium 6)

1500 GB

(Ultrium 5)

800 GB

(Ultrium 4)

400 GB

(Ultrium 3)

200 GB

(Ultrium 2)

100 GB

(Ultrium 1)

Note: The IBM Half High LTO Ultrium 6 Tape Drive reads and writes Ultrium 6

cartridges to Ultrium 6 format and also reads and writes Ultrium 5 cartridges to

Ultrium 5 format, including WORM and Data Encryption.

Chapter 1. Product description 3

Page 22

Speed matching

The drive reads tapes that have been written by other licensed Ultrium 6 drives,

and writes to tapes that can be read by other licensed Ultrium 6 drives.

In addition to using the IBM LTO Ultrium Data Cartridge with up to 2500 GB

capacity, the drive also offers read/write capability for certified LTO Ultrium tape

cartridges.

Important: The IBM Half High LTO Ultrium 6 Tape Drive cartridge has a limited

one year warranty provided by IBM Storage Media. If any defect in material or

manufacture appears within one year of the date of original purchase of this

product, it will be replaced or the purchase price refunded. Please contact the seller

of the of IBM Data Storage products or visit us on the web at http://www-

03.ibm.com/systems/storage/media/. Within the US and Canada, call toll free

(888)426-6334 or (888)IBM-MEDIA) to receive warranty service or product

information.

To improve system performance, the drive uses a technique called speed matching to

dynamically adjust its native (uncompressed) data rate to the slower data rate of a

server.

With speed matching, the drive operates at different speeds when reading or

writing the Ultrium 5 or Ultrium 6 cartridge format. Native data rates are as

follows in the table below.

Table 4. Performance parameters

Generation 6 media Generation 5 media Generation 4 media

Speed matching data

rates (MB/second)

Ultrium generation media

160.0 140.0 120.0

150.77 130.0 113.1

141.54 120.0 106.0

132.31 112.7 99.2

123.08 105.5 92.3

113.85 98.2 85.3

104.62 90.9 78.5

95.38 83.6 71.4

86.15 76.4 64.6

76.92 69.1 57.6

67.69 61.8 50.7

58.46 53.5 43.8

49.23 46.3 36.9

40.00 40.0 30.5

If the server net (compressed) data rate is between two of the preceding native

data rates, the drive calculates the appropriate data rate at which to operate. Speed

matching dramatically reduces backhitch, the condition that occurs when a tape

stops, reverses, and restarts motion. A backhitch is usually the result of a mismatch

between the data rates of the server and the drive.

4 IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 23

Channel calibration

System performance is further optimized by a feature called Channel calibration,in

which the drive automatically customizes each read/write data channel to

compensate for variations in such things as the recording channel's transfer

function, the media, and characteristics of the drive head.

Data cartridge capacity scaling

The SET CAPACITY SCSI command enables a customer to capacity scale a data

cartridge to enable faster random access. For example, a user can capacity scale a

data cartridge to 20% of its normal length which improves the average access time

by almost a factor of 5; however, it also reduces the native capacity of the tape to

500 GB.

Encryption

The IBM LTO 6 Half High Tape Drive supports host Application Managed

Encryption (AME), using T10 encryption methods.

However, encryption must be enabled through the software application that you

use to manage the tape drive. For more information about enabling encryption, see

the independent software vendor documentation that came with your software.

Data encryption is supported only with LTO Ultrium 4, LTO Ultrium 5, and LTO

Ultrium 6 data cartridges. The encryption-enabled drive contains the necessary

hardware and firmware to encrypt and decrypt host tape application data.

Encryption policy and encryption keys are provided by the host application; there

is no encryption setup required for this drive. A drive digital certificate is installed

at manufacturing time. Each drive has a unique serial number and certificate. The

T10 application might validate each drive instance by checking the drive's digital

certificate.

Application-managed encryption is supported on AIX

and Solaris. Encryption requires the latest device drivers available on the IBM

website: http://www.ibm.com/support/fixcentral.

For more information, see the IBM Tape Device Drivers Encryption Support and IBM

LTO Ultrium Tape Drive SCSI Reference documentation.

Inhibit firmware down-leveling

The drive provides the capability to prevent loading and installing drive microcode

via a Field Microcode Replace (FMR tape) if the firmware level contained in the

FMR tape is older than the code level already installed. This option is controlled

by the host application. No checking is performed if the firmware level is loaded

via the host interface or the library interface.

SAS interface

The drive has a dual-port 6 Gbps SAS (Serial Attached SCSI) host interface, but

only one of the SAS ports is used for a host connection.

Important: The tape drive supports only one host connection.

®

, Windows Server, Linux®,

Chapter 1. Product description 5

Page 24

A drive with a SAS interface can be linked directly to controllers. SAS is a

performance improvement over traditional SCSI because SAS enables multiple

devices (up to 128) of different sizes and types to be connected simultaneously

with thinner and longer cables; its full-duplex signal transmission supports 6.0 Gb

per second. SAS drives can be hot-plugged.

SAS drives will auto-negotiate speed. There are no configurable topologies, and

therefore no feature switches associated with SAS.

Supported Servers and Operating Systems

The latest supported attachments.

To determine the latest supported attachments, visit the IBM ServerProven website

for System x Tape Backup Units: http://www-03.ibm.com/servers/eserver/

serverproven/compat/us/xseries/storage/tmatrix.html.

For specific instructions about attaching the drive, see Chapter 2, “Tape drive

installation,” on page 9.

Supported device drivers

Getting the supported device drivers for the tape drive.

To download the latest device drivers, go to http://www-947.ibm.com/support/

entry/portal/, and complete the following steps.

Note: Changes are made periodically to the IBM website. The actual procedure

might vary slightly from what is described in this document.

1. Go to http://www-947.ibm.com/support/entry/portal/.

2. In the Search support & downloads text field at the top right hand corner of

the screen, type tape files and press Enter.

3. In the list of search results, click the link Tape Files (index) - Software for tape

drives and libraries.

Ethernet port

The IBM LTO 6 Half High Tape Drive has a single 1 Gbps Ethernet port on the

rear panel, with a RJ45 connector.

The default IP address is 169.254.0.3, but the drive’s IP address can be changed as

needed. Refer to the IBM Tape Diagnostic Tool from the http://www-947.ibm.com/

support/entry/portal/ website on how to make this change.

The Ethernet port is used only for monitoring drive status and servicing the drive,

not for data transmission.

Linear Tape File System (LTFS)

The Linear Tape File System (LTFS) is a file system that works in conjunction with

LTO Generation tape technology to access data stored on an IBM tape cartridge.

LTFS uses the file system’s format and resources of the operating system (OS) on

which it is running to graphically display the contents of a tape cartridge in the

OS’s graphical user interface (GUI) format; typically a folder/tree structure. Using

6 IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 25

the host operating system’s graphical file manager, reading data on a LTO tape

cartridge is as easy as dragging and dropping. Users can run any application

designed for disk files against tape data without concern for the fact that the data

is physically stored on tape.

Chapter 1. Product description 7

Page 26

8 IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 27

Chapter 2. Tape drive installation

This chapter describes the installation procedures for the tape drive. It is the

customer's responsibility to install this product.

This is a customer setup unit. It is the customer's responsibility to install this

product.

Depending on the type of enclosure or server, installation procedures might vary.

Refer to the enclosure or server documentation for drive installation. The following

generic procedures can be used if the enclosure or server documentation is not

available:

v “Installing a tape drive” on page 10

Note: Before you install the tape drive, read the information in the following

sections:

v “Installation guidelines”

v “Handling static-sensitive devices”

v “Inventory checklist” on page 10

Installation guidelines

Before you remove or replace a device, read the following safety information.

v Read the safety information in “Safety” on page ix. This information will help

you work safely. Take standard electrostatic discharge precautions when you

work inside the server.

v Observe good housekeeping in the area where you are working. Place removed

covers and other parts in a safe place.

v Do not attempt to lift an object that you think is too heavy for you. If you have

to lift a heavy object, observe the following precautions:

– Make sure that you can stand safely without slipping.

– Distribute the weight of the object equally between your feet.

– Use a slow lifting force. Never move suddenly or twist when you lift a heavy

object.

– To avoid straining the muscles in your back, lift by standing or by pushing

up with your leg muscles.

v Make sure that you have an adequate number of properly grounded electrical

outlets for the server and all attached devices.

v Back up all important data before you make changes to disk drives.

Handling static-sensitive devices

To avoid static electricity damage when handling the drive, use the following

precautions.

v Limit your movement. Movement can cause static electricity to build around

you.

v Always handle the drive carefully. Never touch exposed circuitry.

v Prevent others from touching the drive.

© Copyright IBM Corp. 2013 9

Page 28

v Before unpacking and installing the drive into an enclosure or server, touch its

static-protective packaging to an unpainted metal surface on the enclosure or

server for at least two seconds. This reduces static electricity in the packaging

and your body.

v When possible, remove the drive from its static-protective packaging and install

it directly into an enclosure or server without setting it down. When this is not

possible, place the drive's packaging on a smooth, level surface and place the

drive on the packaging.

v Do not place the drive on the cover of the enclosure or server, or on any other

metal surface.

Inventory checklist

Make sure that the following items are included in the shipment.

v Power cord (You must order the applicable cord for your country or region

separately.)

v IBM LTO Ultrium Cleaning Cartridge

v Single-connector SAS wrap tool

v Optional Rack Mount Kit

v Documentation CD, that includes the IBM Half High LTO Ultrium Gen 6 Internal

SAS Tape Drive Installation and User's Guide (this document), the multilingual

Safety Information, Safety Information Labels, Environmental Notices and User's Guide,

and the Warranty.

v SAS cables are not part of the ship group. They must be ordered separately.

Installing a tape drive

Use the information in this section to install a tape drive. The following list of

steps provides a brief overview of the installation process.

1. “Unpacking the drive”

2. “Acclimating the drive and media” on page 11

3. “Turning off the enclosure or server” on page 11

4. “Setting the feature switches” on page 11

5. “Mounting the drive in an enclosure or server” on page 12

6. “Connecting and testing power to the drive” on page 12

7. “Connecting the cable” on page 13

8. “Running drive diagnostics” on page 13

9. “Installing device drivers” on page 13

10. “Connecting the external interface cable (enclosure or server installations

only)” on page 14

11. “Configuring the drive to the server, switch, or hub” on page 14

Unpacking the drive

Use this information to unpack the drive.

Unpack the drive and store the packaging for future moves or shipping.

Attention: If you return the unit for service, ship it in its original or equivalent

packing material, or the warranty may be invalidated.

10 IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 29

Acclimating the drive and media

Acclimation time is required if the temperature of the drive and media when

unpacked is different than the temperature of its operating environment (measured

at the front of the bezel near the air intake area). The recommended acclimation

time is four hours after the drive has been unpacked or one hour after any

condensation that you can see has evaporated, whichever is greater.

When acclimating the drive, apply the following measures:

v If the drive is colder than its operating environment and the air contains

sufficient humidity, condensation might occur in the drive and damage it. When

the drive has warmed to the operating temperature range (greater than 10°C or

50°F) and no danger of condensation is present (the air is dry), warm the drive

more quickly by powering it on for 30 minutes. Use a diagnostic tape to test the

drive before inserting a tape that contains data.

v If the drive is hotter than its operating environment, the tape can stick to the

drive head. When the drive has cooled to the operating temperature range (less

than 40°C or 104°F), cool the drive more quickly by applying airflow for 30

minutes. Power-on the drive and use a diagnostic tape to test it before inserting

a tape that contains data.

If you are uncertain about whether the temperature of the drive is within the

recommended operating range or the humidity is sufficient to cause condensation,

acclimate the drive for the full four hours.

Turning off the enclosure or server

Use this information to turn off the enclosure or server.

1. Turn off the enclosure (or the unit that provides power to the drive).

2. Disconnect the power cord from both the electrical outlet and the enclosure (or

the unit that provides power to the drive).

Setting the feature switches

The tape drive has eight factory-set feature switches by which the drive is

configured for various functions. The feature switches are preset to the off position

at the factory but are described here in case you must change the feature-switch

settings for your application.

The feature switches are on the rear panel of the tape drive. The switches are

labeled 1 through 8 and the on and off positions are marked. The feature switches

are defined in the following table.

Table 5. Feature switch definitions

Switch On function Off function

1 Library interface at 9,600 baud /

polled

2 Library interface uses two stop bits Library interface uses one stop bit

3 Reserved Reserved

4 Library interface at 115,000 baud rate Switch 1 active

5 Enable ADI Enable LDI

6 Reserved Reserved

7 Disable head brush ERP

8 Reserved Reserved

1

Library interface at 38,400 baud /

non-polled

Enable head brush ERP

1

Chapter 2. Installation 11

Page 30

Table 5. Feature switch definitions (continued)

Switch On function Off function

Note: The default settings for the feature switches are all switches placed in the off

position.

*The head brush error recovery procedure (ERP) is intended to prevent a permanent read

or write error by removing debris that might have accumulated on the read or write head.

In order to brush the head, the tape must be unthreaded to expose the head. This forces

the loader to be cycled to enable re-thread. During the loader cycling, the back of the

cartridge will temporarily extend beyond the front of the bezel. Extension of the cartridge

is problematic in some automation environments, so you have the ability to disable this

function. If the head brush ERP is disabled, the drive will immediately report the

permanent error instead of activating the head brush ERP.

Mounting the drive in an enclosure or server

Use this information to mount the drive in an enclosure or server.

When mounting the drive:

v Use an appropriate screw length.

v Make sure that no objects such as screw heads, cables, or adjacent devices, are

pressing against the frame.

v Do not obstruct the ventilation slots at the rear of the drive.

v Allow sufficient space for accessing the drive's front panel controls.

To mount the drive into an enclosure or server:

1. Remove the cover of your enclosure or server (refer to the instructions in the

documentation provided with your enclosure or server).

2. Place the drive into your enclosure or server so that the tape load compartment

of the drive faces the tape load compartment of the enclosure or server.

3. Insert two M3 screws into the mounting holes of the two side brackets located

on the left and right sides of the chassis.

Attention: When the mounting screws or drive rail prongs are inserted into the

drive, they must not extend farther than 2.5 mm (0.098 in.) inside the chassis.

Otherwise, they might damage the drive.

Connecting and testing power to the drive

The drive does not contain its own power source; it must be powered externally.

To connect and test power to the drive, complete the following steps:

1. Ensure that the enclosure (or unit that supplies power to the drive) is powered

off.

2. Ensure that the power cord is disconnected from both the enclosure (or unit

that supplies power to the drive) and the power outlet.

3. Connect the enclosure (or unit that supplies power to the drive) internal power

cable to the power connector on the drive.

4. Connect the power cord to the enclosure (or unit that supplies power to the

drive) and to the electrical outlet.

12 IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 31

5. Review the location of the single-character display (SCD) and the status LED in

“Front panel of the drive” on page 2. To make sure that the drive is receiving

power, watch for the following while turning on the power to the enclosure or

server:

v During the power-on/initialization and POST (Power-On Self Test), the SCD

briefly displays

there are no POST errors. If a POST error has been detected, an error code

will be displayed in the SCD and the status LED will flash amber.

Attention: If the SCD does not come on, the drive might not be getting

power.

v The status LED will be off during the initial power-on and initialization. The

status LED briefly becomes green and then becomes amber during the

remainder of the power-on and initialization phase. The status LED becomes

solid green after the power-on/initialization and POST are complete.

6. Turn off the enclosure or server.

7. Disconnect the power cord from both the enclosure or server and the electrical

outlet.

, then becomes blank (not lit) when POST is complete and

Connecting the cable

Connect the enclosure or server's internal SAS cable to the SAS connector on the

drive. Attach the host side (data and power) of the SAS cable included with your

tape drive to the SAS and power connectors on your server. Then, attach the drive

side to the drive connector (for the drive connector location, see “Rear panel of the

drive” on page 2.

Running drive diagnostics

Use this information to run the drive diagnostics tool.

1. Replace the cover on the enclosure or server.

2. If you are not already connected to a power source, connect the power cord to

both the enclosure or server and the electrical outlet.

3. Turn on the enclosure or server.

4. Run one or more of the following drive diagnostics:

v “Function code 1: Run drive diagnostics” on page 28

v “Function code 6: Run host interface wrap test” on page 32

v “Function code 7: Run RS-422 wrap test” on page 33

If an error code appears on the single-character display (SCD), go to

Appendix C, “Error codes and messages,” on page 63. If no error appears,

continue to the next step.

5. Turn off the enclosure or server.

6. Disconnect the power cord from both the enclosure or server and the electrical

outlet.

Installing device drivers

Use this information to install device drivers.

A device driver is firmware that enables the tape drive to interact with a variety of

servers. Refer to “Supported device drivers” on page 6 for instructions on

downloading the latest device drivers.

Chapter 2. Installation 13

Page 32

If you intend to use the tape drive with a commercial software application, refer to

that application's installation instructions to install the device driver and configure

the tape drive.

If you do not intend to use the tape drive with a commercial software application,

refer to the IBM Tape Device Drivers Installation and User’s Guide.

Connecting the external interface cable (enclosure or server installations only)

For information about connecting the enclosure or server, see the documentation

for your enclosure or server.

Connecting the external SAS interface to the server

Use this information to connect the external SAS interface to the server.

To connect the enclosure or server to the SAS interface, complete the following

steps:

1. Connect the external SAS cable that ships with the drive to both the enclosure

or server (for the location of the connectors, refer to the documentation for

your enclosure or server).

2. Run the applicable SAS attachment verification procedure for your server.

If you want to power a device on or off while it is connected to the same bus as a

drive, you can do so if, during the power-on cycle, you quiesce all devices

(including the drive) on the bus.

Configuring the drive to the server, switch, or hub

To configure the drive to work with the server, see the documentation for that

server, switch, or hub.

The drive is now ready for use.

Updating firmware

Use this information to update firmware.

Attention: When updating firmware, do not turn off power to the drive until the

update is complete, or the firmware update might not take effect.

It is your responsibility to make sure that the drive has the latest firmware.

Periodically check for updated levels of drive firmware by visiting the IBM

website.

To download the latest firmware, go to http://www-947.ibm.com/support/entry/

portal/, or complete the following steps.

Note: Changes are made periodically to the IBM website. The actual procedure

might vary slightly from what is described in this document.

1. Go to http://www-947.ibm.com/support/entry/portal/.

2. In the Search support and downloads text field at the bottom of the screen,

3. In the list of search results, click the link Tape Files (index) - Software for tape

type tape files and press Enter.

drives and libraries.

14 IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 33

Registering for My Support

Use this information to register for My Support.

My Support registration provides e-mail notification when new firmware levels

have been updated and are available for download and installation. To register for

My Support, visit the web at http://www.ibm.com/support/mySupport.

Chapter 2. Installation 15

Page 34

16 IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 35

Chapter 3. Operating the drive

Operating the drive involves using the following front panel items.

v Power button

v Single-character display (SCD)

v SCD dot

v Ready and Fault status lights

v Unload button

v Encryption status light

Operating modes

The drive functions in the following modes.

Operation mode

Operation mode functions include reading and writing data, cartridge

manipulation, error reporting, and firmware updating using an FMR

cartridge. For more information, see “Status lights” on page 18.

Maintenance mode

Maintenance mode functions include drive diagnostic, creating or

unmaking FMR cartridge, and drive dump manipulation (force to RAM,

copy to tape, copy to flash memory, and erase flash). For more information,

see “Diagnostic and maintenance functions” on page 25.

The Unload button is used to switch between modes. For more information, see

“Unload button” on page 21.

Power button

The Power button is a push button that turns the tape drive on or off.

The button is located on the front panel (see “Front panel of the drive” on page 2).

When the Power button is in the off position, the primary electrical power within

the enclosure or server is still active. To remove all electrical power to the

enclosure or server, unplug the power cord from the receptacle at the rear of the

drive.

When the unit is powered-on but idle, the Ready light (see “Front panel of the

drive” on page 2) is solid green; when it is performing a function, the Ready light

is flashing green.

Single-character display (SCD)

This section describes the SCD in the front panel of the drive.

The SCD (see “Front panel of the drive” on page 2) presents a single-character

code for:

v Error conditions and informational messages

v Diagnostic or maintenance functions (while in Maintenance mode only)

© Copyright IBM Corp. 2013 17

Page 36

Appendix C, “Error codes and messages,” on page 63 lists the codes for error

conditions and informational messages. If multiple errors occur, the code with the

highest priority (represented by the lowest number) displays first. When the error

is corrected, the code with the next highest priority displays, and so on until no

errors remain.

“Diagnostic and maintenance functions” on page 25 lists the single-character codes

that represent diagnostic or maintenance functions. To initiate a function the unit

must be in Maintenance mode.

The SCD is blank during normal operation.

SCD dot

If a drive dump is present while the drive is in Maintenance mode, a single dot

8

illuminates in the lower right corner of the SCD (see

“Function code 5: Copy drive dump” on page 31.

The SCD dot is on solid if the dump is in RAM memory. The SCD dot flashes if

the dump is in FLASH memory.

The SCD dot turns off when you obtain a dump with IBM TotalStorage Tape

Diagnostic Tool (ITDT) or SCSI command, or update the drive firmware.

). To copy the dump, see

Note: If the drive dump is stored in RAM memory (SCD dot on solid), the dump

will be lost when you turn OFF the power or reset the drive.

Status lights

Use this information for the status lights on the front panel of the drive.

The status lights (see “Front panel of the drive” on page 2) are LEDs that provide

information about the state of the drive. The Ready status light is green and the

Fault status light is amber, and solid or flashing when lit. The Encryption status

light is white.

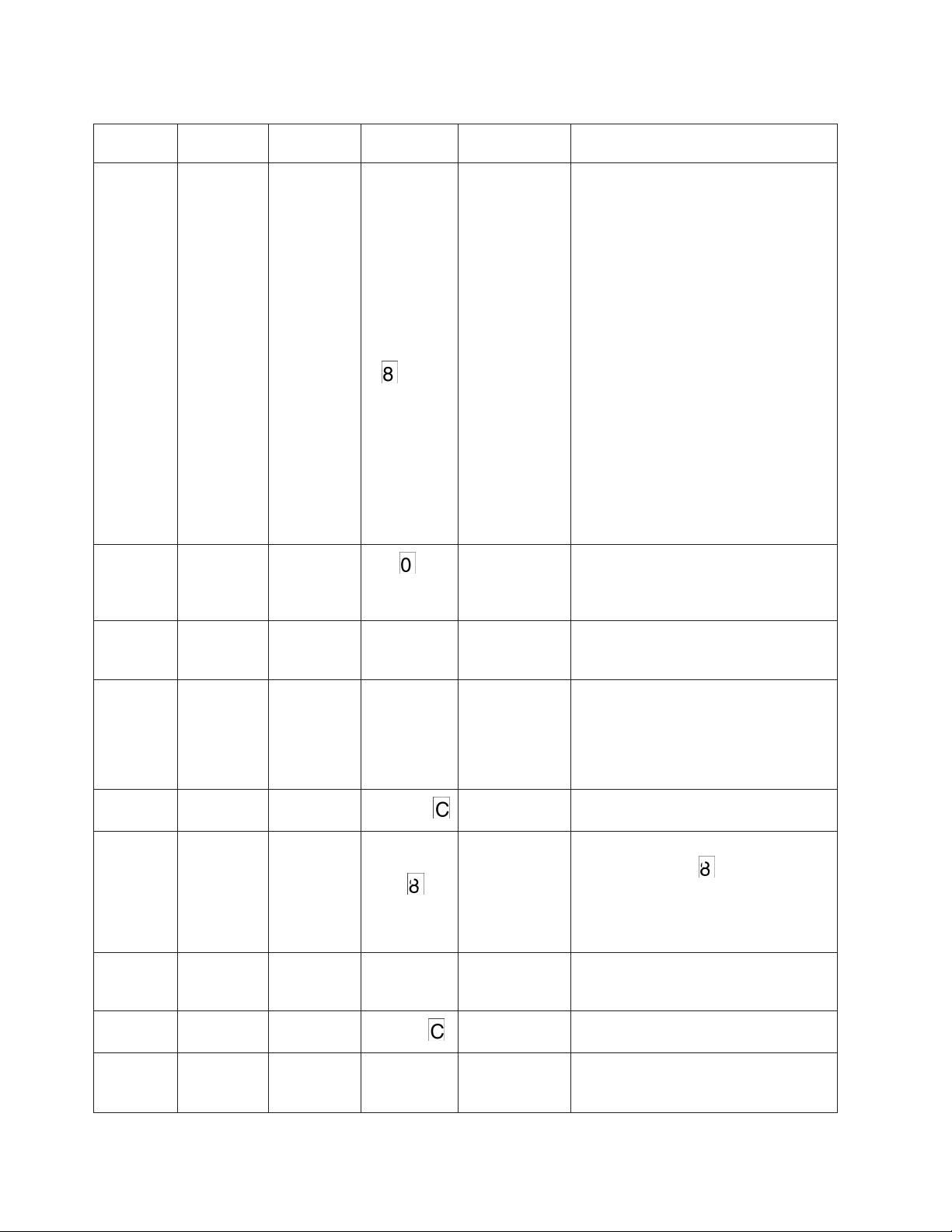

Mode SCD Ready LED (green) Fault LED (amber)

Operational Blank On Off

Activity (tape movement)

in Operational mode

Maintenance Solid character Flashing On

Executing maintenance

selection

Error condition Solid character Off Flashing

Power is turned on or a

reset is initiated

Blank Flashing Off

Flashing character Off On

Random segments Off On

Note: The white Encryption status light will be on when the tape drive has a

cartridge loaded and all data on this cartridge is encrypted (excluding the label).

This applies to LTO Ultrium 6 and Ultrium 5 cartridges only.

Table 6 on page 19 lists the conditions of the status lights and Single-character

display (SCD) and provides an explanation of what each condition means.

18 IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 37

Table 6. Meaning of status lights and single-character display (SCD)

Ready

status light

Fault status

light

Encryption

status light

SCD SCD dot Meaning

Off Off Off Off Off The drive has no power or is powered

off.

Green and

solid

Off On or off Off Off The drive is powered on and in an idle

state.

Note: If a cartridge is loaded, the white

Encryption status light will be on when

all the data on the cartridge is encrypted

(excluding the label). This applies to

LTO Ultrium 6 and Ultrium 5 cartridges

only.

Flashing

green (once

per second)

Off On or off Off Off The drive is reading from the tape,

writing to the tape, rewinding the tape,

locating data on the tape, loading the

tape, or unloading the tape.

Note: The white Encryption status light

will be on when all the data on the

cartridge is encrypted (excluding the

label). This applies to LTO Ultrium 6

and Ultrium 5 cartridges only.

Flashing

green (once

per second)

Off Off Off Off If the drive contains a cartridge when

the drive is turned on, the drive

completes POST and slowly rewinds the

tape (the process may take up to 10

minutes). The light stops blinking and

becomes solid when the drive completes

the recovery and is ready for a read or

write operation. To eject the cartridge,

press the Unload button.

Off Amber and

solid

Off Displaying an

error code or

Maintenance

mode

function

On or off The drive is displaying error codes from

the error code log on the SCD. For more

information, see “Function code 9:

Display error code log” on page 34 and

Appendix C, “Error codes and

messages,” on page 63.

Chapter 3. Operations 19

Page 38

Table 6. Meaning of status lights and single-character display (SCD) (continued)

Ready

status light

On or off On or off On or Off Displaying

Fault status

light

Encryption

status light

SCD SCD dot Meaning

On or off During power on, or a drive reset, the

random

segments,

then blank,

then

displaying

random

drive front panel will display drive

progress as follows:

1. SCD will display random segments

2. SCD will display random segments

segments,

then

3. SCD will display random segments

displaying

4. SCD will display [8] (LEDs - green

blank

, then

5. SCD will go blank (LEDs - green on,

If an error is detected when the drive

power is turned on or during a reset,

the tape drive posts an error code to the

SCD. To determine the error, locate the

code in Appendix C, “Error codes and

messages,” on page 63.

Off Amber and

solid

Off

On or off The drive is entering or exiting from

Maintenance mode. For more

information, see “Function code 0:

Maintenance mode” on page 28.

Off Amber and

solid

Off Flashing

selected

On or off The drive is executing the selected

function while in Maintenance mode.

function

Off Flashing

amber (once

per second)

Off Displaying

error code

Off An error occurred and the drive or

media may require service, or it may

require cleaning. Note the code on the

SCD, then go to Appendix C, “Error

codes and messages,” on page 63 to

determine the action that is required.

Off Flashing

amber

Off Flashing

amber

Off

Displaying

Off Displaying

Function

code

flashing

or

Off The drive needs to be cleaned.

Off The drive is updating firmware.

SCD will display a if an FMR

cartridge is in use. The SCD will be off

if the SAS interface is in use. For more

information, see “Updating firmware”

on page 14.

Off Flashing

amber (twice

per second)

Off Amber and

solid

Off Flashing

Off Off Off The drive detected an error and is

performing a firmware recovery. It will

reset automatically.

Off

Flashing

Off The drive is ready for a cartridge to be

loaded.

Off Off On There is a drive dump in flash memory.

amber (twice

per second)

(no LEDs on).

(LEDs - green on, amber off)

(LEDs - green off, amber on)

off, amber on)

amber off) after the power is turned

on or after the drive is reset.

1

The

20 IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 39

Table 6. Meaning of status lights and single-character display (SCD) (continued)

Ready

status light

1

Power should not be disconnected from the drive until the microcode update is complete. The drive indicates that

the update is complete by resetting and performing POST.

Fault status

light

Encryption

status light

SCD SCD dot Meaning

Unload button

This section describes the functions of the Unload button.

The Unload button (see “Front panel of the drive” on page 2) performs the

following functions:

Table 7. Functions that the Unload button performs

Unload button Function How to initiate the function

Rewind the tape into the

cartridge and eject the

cartridge from the drive

Place the drive in

Maintenance mode

Press the Unload button once. The status light flashes green while the drive is

rewinding and unloading.

Note: During a rewind and eject operation, the drive does not accept SCSI commands

from the server.

Ensure that the drive is unloaded. Then, within 2 seconds, press the Unload button

three times. The drive is in Maintenance mode when the status light becomes solid

Scroll through the

maintenance functions

Exit Maintenance mode

Force a drive dump (part

of the Maintenance mode)

amber and

Note: While in Maintenance mode, the drive does not accept SCSI interface

commands.

Note: If you attempt to enter Maintenance mode with a cartridge in the drive, the

drive will rewind and eject the cartridge. Remove the cartridge and repeat the steps

for entering Maintenance mode.

While in Maintenance mode, press the Unload button once per second to increase the

display character by one. When you reach the character of the diagnostic or

maintenance function that you want (see “Diagnostic and maintenance functions” on

page 25), press and hold the Unload button for 3 seconds.

Press the Unload button once per second to increment the display character until

displays. Then press and hold the Unload button for three seconds. Maintenance mode

is exited when the status light becomes solid green and the SCD becomes blank.

Attention: If the drive detects a permanent error and displays an error code, it

automatically forces a drive dump (also known as a save of the firmware trace). If you

force a drive dump, the existing dump will be overwritten and data will be lost. After

you force a drive dump, do not turn off the power to the drive or you might lose the

dump data.

Choose one of the following procedures:

v If the drive is in Maintenance mode (status light is flashing and fault light is solid),

see “Function code 4: Force a drive dump” on page 30.

v If the drive is in Operating mode (status light is solid or flashing green), press and

hold the Unload button for ten seconds.

If captured dump data exists, the drive places it into a dump area. For information

about retrieving the data, see “Procedure 1: Inspecting a cartridge for damage” on

page 53.

appears in the SCD.

Chapter 3. Operations 21

Page 40

Table 7. Functions that the Unload button performs (continued)

Unload button Function How to initiate the function

Reset the drive Press and hold the Unload button until the drive begins the reset procedure (status

light will be amber).

Note: If a tape cartridge is loaded in the drive the drive will unload the tape. Repeat

the procedure to reset the drive after the tape is unloaded. The drive saves a dump of

the current drive state, then reboots to allow communication. Do not reset the drive

power; this will erase the contents of the dump.

Inserting a tape cartridge

Use this information to insert a tape cartridge.

To insert a tape cartridge, complete the following steps:

1. Make sure that the drive power is turned on.

2. Make sure that the write-protect switch on the tape cartridge is properly set

(see “Write-protect switch” on page 45).

3. Grasp the cartridge so that the write-protect switch faces you (see Figure 4).

4. Slide the cartridge into the tape load compartment.

Note:

a. If the cartridge is already in an ejected position and you want to reinsert it,

remove the cartridge then insert it again.

b. If the cartridge is already loaded and you reset the drive power, the tape

will reload.

c. Do not attempt to load a cartridge when the drive is in Maintenance mode

until the drive requests it.

Figure 4. Inserting a cartridge into the drive

22 IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 41

Removing a tape cartridge

Use this information to remove a tape cartridge.

Attention: To clean the tape drive, use only an IBM LTO Ultrium Cleaning

Cartridge. The use of cleaning methods other than an LTO cleaning cartridge

might cause damage to the drive.

To remove a tape cartridge, complete the following steps:

1. Make sure that the drive power is turned on.

2. Press the Unload button. The drive rewinds the tape and partially ejects the

cartridge. The Ready light flashes green while the tape rewinds, then becomes

blank before the cartridge partially ejects.

3. After the cartridge partially ejects, grasp the cartridge and remove it.

Important: Always remove an ejected cartridge before reinserting it.

Whenever you unload a tape cartridge, the drive writes any pertinent information

to the cartridge memory.

Mid-tape recovery

If the tape drive is reset while a cartridge is loaded, the drive will slowly rewind

the tape and eject the cartridge. If the drive power is turned off and then on again

while a cartridge is loaded, the drive will slowly rewind the tape. The drive will

not automatically eject the cartridge.

The Ready light flashes and the SCD will be counting down from 9 to 0, indicating

the approximate cartridge rewinding status. Between the counts, the SCD displays

random segments while the tape is rewinding into the cartridge. Push the Unload

button to eject the cartridge when the Ready light stops flashing.

Cleaning the drive head

Use this information to clean the drive head.

Attention: When cleaning the drive head, use the IBM LTO Ultrium Cleaning

Cartridge. You can use another LTO cleaning cartridge, but it might not meet the

standards of reliability established by IBM.

Clean the drive head whenever

the status light is flashing amber once per second. You do not need to clean the

drive head on a periodic basis.

Note: In Maintenance mode, a flashing

means to insert a cartridge, not clean the drive head.

To clean the head, insert the cleaning cartridge into the tape load compartment (see

“Front panel of the drive” on page 2). The drive performs the cleaning

automatically in less than 2 minutes and then ejects the cartridge. The drive will

perform a short load and unload test while ejecting the drive. Wait for the drive to

finish before removing the cartridge.

is displayed on the single-character display and

with the solid amber status light,

Note: The drive will automatically eject an expired cleaning cartridge.

Chapter 3. Operations 23

Page 42

The IBM LTO Ultrium Cleaning Cartridge is valid for 50 uses, and then must be

replaced.

Cleaning the tape drive

Clean the exterior surface of the tape drive with a damp towel. If you use a liquid

all-purpose cleaner, apply it to the towel. Do not spray cleaner directly on the tape

drive.

Do not clean the interior of the tape drive; damage may result.

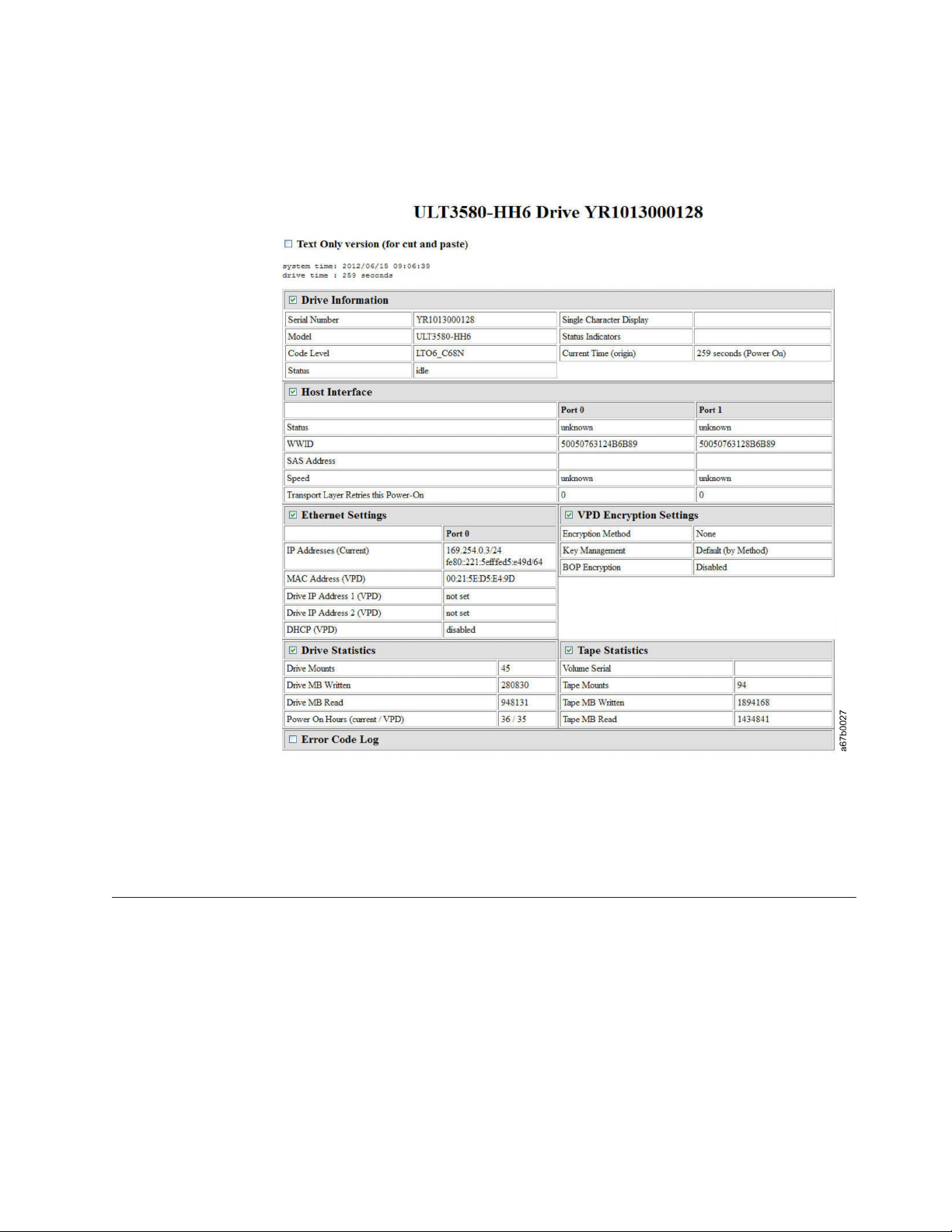

Tape drive status web page

The status of the tape drive is accessible from the tape drive’s Ethernet port.

The drive status can be viewed from the web page. The drive status cannot be

changed from the web page. The tape drive status is available when the drive is

operating or idle.

Note: The drive must be powered on.

1. Connect the host computer or a laptop to the tape drive’s Ethernet port (RJ45

connector) using an Ethernet patch cable.

2. Use a web browser to connect to http://169.254.0.3 to view the current tape

drive status on an HTML web page.

Note:

a. If the drive’s IP address has been changed, use that address instead.

b. The web page is static, so it must be refreshed frequently to show the latest

drive status.

Figure 5. Drive status web page

The tape drive model and serial number are shown at the top of the page.

The web page is divided into sections by topic. The topics are:

v Drive Information

v Host Information

v Ethernet Settings

v VPD Encryption Settings

v Drive Statistics

24 IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 43

v Tape Statistics (if a cartridge is loaded in the tape drive)

v Engineering Error Log

Click in the box by the title of the section to see the topic details.

Figure 6. Drive status web page - Topic details

The web page format can be changed to text mode by selecting the “Text Only

version” box near the top of the web page. In text mode, the tape drive status

information can be copied and pasted easily if it needs to be sent to support

personnel.

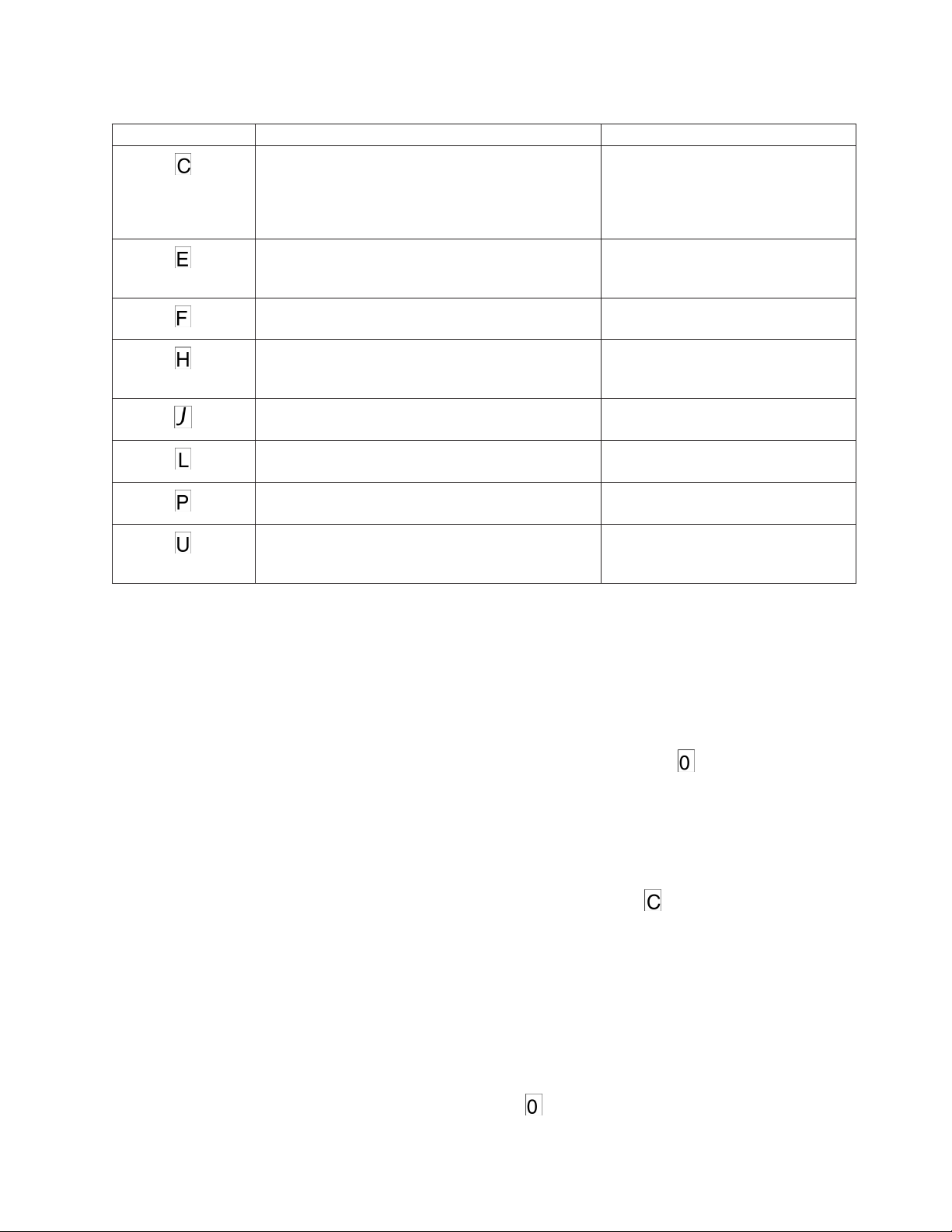

Diagnostic and maintenance functions

The diagnostic and maintenance functions of the tape drive.

The drive is capable of the following:

v Run diagnostics

v Test write and read functions

v Test a suspect tape cartridge

v Update firmware

v Perform other diagnostic and maintenance functions

The drive must be in maintenance mode to perform these functions.

Chapter 3. Operations 25

Page 44

Attention: Maintenance functions cannot be performed concurrently with read or

write operations. While in maintenance mode, the tape drive does not accept SCSI

commands from the server. The tape drive accepts LDI or RS-422 commands.

Table 8 describes each diagnostic and maintenance function that the drive can

perform, gives the function code which appears on the Single-character display

(SCD), and directs you to the instructions for performing the function. Use a

customer-supplied scratch (blank) data cartridge for diagnostic testing. The

diagnostic and maintenance functions are not supported on the WORM and

partitioned data tape cartridges.

Note: During normal operation the fan runs only when cooling is required. The

fan will be turned on and off during the POST and Run Drive Diagnostics to

demonstrate that the fan is operational.

Table 8. Diagnostic and maintenance functions

Function code Diagnostic or maintenance function Instructions location

Exit Maintenance Mode: Causes the drive to become

available for reading and writing data.

Run Drive Diagnostics: Runs tests to determine

whether the drive can properly load and unload

cartridges, and read and write data.

Update Tape Drive Firmware from FMR Tape:

Loads updated firmware from a field microcode

replacement (FMR) tape.

Create FMR Tape: Copies its field microcode

replacement (FMR) data to a customer-supplied

scratch (blank) data cartridge.

Force a Drive Dump: Performs a dump of data (also

known as saving a microcode trace).

Copy Drive Dump: Copies data from a drive dump

(captured by using Function code 4) to the beginning

of a customer-supplied scratch (blank) data

cartridge, copies a drive dump to flash memory, or

erases a dump from flash memory.

Run Host Interface Wrap Test: Performs a check of

the circuitry from and to the connector.

Run RS-422 Wrap Test: This test causes the drive to

perform a check of the circuitry and connector for

the RS-422 interface.

Unmake FMR Tape: Erases the FMR data on a

customer-supplied scratch (blank) data cartridge and

rewrite the cartridge memory on the tape. This turns

the cartridge into a valid customer-supplied scratch

data cartridge.

Display Error Code Log: Displays the last 10 error

codes, one at a time. The codes are ordered; the most

recent is presented first and the oldest is presented

last.

Clear Error Code Log: Erases the contents of the

error code log.

“Function code 0: Maintenance mode”

on page 28

“Function code 1: Run drive

diagnostics” on page 28

“Function code 2: Update drive

firmware from FMR tape” on page 29

“Function code 3: Create FMR tape”

on page 30

“Function code 4: Force a drive

dump” on page 30

“Function code 5: Copy drive dump”

on page 31

“Function code 6: Run host interface

wrap test” on page 32

“Function code 7: Run RS-422 wrap

test” on page 33

“Function code 8: Unmake FMR tape”

on page 33

“Function code 9: Display error code

log” on page 34

“Function code A: Clear error code

log” on page 34

26 IBM Half High LTO Ultrium Gen 6 Internal SAS Tape Drive: Installation and User's Guide

Page 45

Table 8. Diagnostic and maintenance functions (continued)

Function code Diagnostic or maintenance function Instructions location

Insert Cartridge into Tape Drive: This function

cannot be selected by itself, but is a part of other

maintenance functions (such as Run Tape Drive

Diagnostics and Create FMR Tape) that require a

tape cartridge to be loaded.

Test Cartridge & Media: Performs tests to make sure

that a suspect cartridge and its magnetic tape are

acceptable.

Write Performance Test: Performs tests to make sure

that the drive can read from and write to tape.

Test Head: Performs tests to make sure that the tape

drive head and tape-carriage mechanics are working

correctly.

Fast Read/Write Test: Performs tests to make sure

that the drive can read from and write to tape.

Load/Unload Test: Tests the ability of the drive to

load and unload a tape cartridge.

Enable Post Error Reporting: When selected,

deferred-check conditions are reported to the host.

Disable Post Error Reporting: When selected,

deferred-check conditions are NOT reported to the

host.

“Function code C: Insert cartridge into

tape drive” on page 35

“Function code E: Test cartridge and

media” on page 35

“Function code F: Write performance

test” on page 36

“Function code H: Test head” on page

37

“Function code J: Fast read/write test”

on page 38

“Function code L: Load/unload test”

on page 39

“Function code P: Enable post error

reporting” on page 39

“Function code U: Disable post error

reporting” on page 40

Entering Maintenance mode

The drive must be in Maintenance mode to run drive diagnostics or maintenance

functions.

To put the unit in Maintenance mode, complete the following steps:

1. Make sure that no cartridge is in the drive.

2. Press the Unload button three times within 2 seconds.

and the Fault light turns amber.

Note: If a cartridge is in the tape drive, it will eject the first time that you press

the Unload button and the drive will not be placed in Maintenance mode. To

continue placing the drive in Maintenance mode, perform the preceding step.

While in Maintenance mode, the drive will not accept a cartridge unless the

drive requests it. The SCD will display a flashing

needs to be inserted.

Maintenance functions cannot be performed concurrently with read or write

operations. While in Maintenance mode, the drive does not acknowledge SCSI

commands from the server.

Exiting Maintenance mode

Use this information to exit Maintenance mode.

appears in the SCD,

to indicate a cartridge

The drive must be in Function code

in order to exit Maintenance mode.

Chapter 3. Operations 27

Page 46

To exit Maintenance mode:

1. Press the Unload button once per second until

the Unload button for 3 or more seconds then release the button to take the

drive out of Maintenance mode. If no error is detected,

in the SCD, and it goes blank. The drive then exits Maintenance mode and the

Ready light turns on.

2. If an error is detected, the SCD shows an error code but still exits Maintenance

mode. To determine the error, locate the code in Appendix C, “Error codes and

messages,” on page 63. To clear the error, turn the power off, then on again.

Note: The drive also exits Maintenance mode automatically after it completes a

maintenance function or after 10 minutes if no action has occurred.

Function code 0: Maintenance mode

Function code makes the drive available for running drive diagnostics or

maintenance functions, or exiting from Maintenance mode.

1. Put the drive in Maintenance mode. For instructions, see “Entering

Maintenance mode” on page 27.

2. To exit Maintenance mode, see “Exiting Maintenance mode” on page 27.

The drive exits Maintenance mode automatically after it completes a maintenance

function or after 10 minutes if no action has occurred.

is displayed. Press and hold

temporarily appears

Function code 1: Run drive diagnostics

Approximate Run Time = 5 minutes per loop

Total Number of Loops = 1

Function code

and unload cartridges and read and write data.

Once you begin this test, the diagnostic begins the loop sequence. Time the first

loop by pressing the Unload button once to stop the diagnostic after the

completion of the first loop, then record the time it takes for the test to complete.

Compare the recorded time with the "Approximate Run Time" above. If the test

runs successfully but the execution time is significantly longer than the

"Approximate Run Time", run “Function code F: Write performance test” on page